Page 1

Series G Model G

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

METERING

PUMP

INSTALLATION,

OPERATION, AND

MAINTENANCE

MANUAL

Please record the following data for file reference

Tag Number(s): ________________________________

Model Number: ________________________________

Serial Number: ________________________________

Installation Date: ______________________________

Installation Location: ___________________________

201 Ivyland Road

Ivyland, PA 18974

TEL: (215) 293-0401

FAX: (215) 293-0445

www.lmipumps.com

339-0089-000

ISSUED 02/2010

Page 2

Precautions

For Pumps with PVC & 316SS Liquid Ends

WHEN USED IN SWIMMING POOLS OR SPAS/HOT TUBS

(ANSI/NSF 50)

1. Caution on Chemical Concentration:

!

There is a potential for elevated chemical concentration during periods of no flow, for example,

during backwash in the system. Steps, such as turning the pump off, should be taken during

operation or installation to prevent this. Contact your sales representative or distributor about

other external control options to help mitigate this risk.

2. Flow Indicating Device:

!

To ensure operation of the pump it is recommended that some type of Flow Indicating Device be

installed to measure water flow rates and be appropriate for the output of the pump. Contact your

distributor or sales representative for further information.

3. Head Loss / Over Pressure Protection / Back Pressure-Anti-Siphon Valve:

!

3.1 Milton Roy metering pumps are positive displacement. Head loss is not applicable to the

pump.

3.2 To ensure safe operation of the pump it is recommended that some type of safety/pressurerelief valve be installed to protect the piping and other system components from failing due to

excessive pressure.

3.3 If you are pumping downhill or into low or no system pressure, a back pressure/anti-siphon

device should be installed to prevent over pumping or siphoning. Contact your distributor or sales

representative for further information.

4. Additional Operation and Installation Instructions for 316SS or PVC Liquid Ends:

!

4.1 Application of this pump to swimming pool/spas only evaluated to NSF/ANSI 50.

4.2 There is a potential for elevated chemical concentration during periods of no flow, for

example, during backwash in the system. Steps, such as turning the pump off, should be taken

during operation or installation to prevent this. See your sales representative or distributor about

other external control options to help mitigate this risk.

4.3 Liquid Compatibility CAUTION: Determine if the materials of construction included in the liquid

handling portion of your pump are adequate for the solution (chemical) to be pumped. ALWAYS

wear protective clothing, face shield, safety glasses and gloves when working on or near your

metering pump. Additional precautions should be taken depending on the solution being pumped.

Refer to MSDS precautions from your solution supplier. Reference a Milton Roy Material

Selection Chart for aid in selecting appropriate material of construction for fluids of your specific

metering pump. Contact your sales representative or distributor for further information.

i

Page 3

General Precautions For All Pumps

The following precautions should be taken when working with all metering pumps.

Please read this section carefully prior to installation.

Protective Clothing

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working on or near your

metering pump. Additional pre

to Material Safety Data Sheets for the solution being pumped.

Hearing Protection

It is recommended that hearing protection be used if the pump is in an environment where the timeweighted average sound level (TWA) of 85 decibels is exceeded. (as measured on the A scale -- slow

!

response)

Electrical Safety

• Remove power and ensure that it remains off while maintaining pump.

• DO NOT FORGET TO

•

!

Liquid Compatibility

Verify if the materials of construction of the wetted components of your pu

solution (chemical) to be pumped.

!

Pumps Water “Primed”

All pumps are tested with water at the factory. If your process solution is n

the Pump Head Assembly with an appropriate solution before introducing the process solution

!

Plumbing and Electrical Connections

Always adhere to your local plumbing and electrical codes.

!

Line Depressurization

To reduce the risk of chemical contact during disassembly or maintenance, the suction and discharge

lines should be depressurized before servicing.

!

Over Pressure Protection

To ensure safe operation of the system it is recommended that some type of safety/pressure-relief valve

!

be installed to protect the piping and other system components from damage due to over-pressure.

Lifting

This manual should be used as a guide only - Follow your company’s recommended lifting procedures. It

!

is not intended to replace or take precedence over recommendations, policies and procedures judged as

safe due to the local environment than what is contained herein.

Use lifting equipment that is rated for the weight of the equipment to be lifted.

!

Electric protection of the motor (Thermal protection or by means of fuses) i

the rated current indicated on the motor data plate.

cautions should be taken depending on the solution being pumped. Refer

CONNECT THE PUMP TO EARTH

s to correspond to

mp are recommended for the

ot compatible with water, flush

ii

Page 4

TABLE OF CONTENTS

SECTION 1 - DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 PRINCIPLE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 GENERAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 PRODUCT CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2 - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 PIPING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.6 LEAK DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 ELECTRICAL CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION 3 - OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 INITIAL START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SECTION 4 - MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 SHIPPING PUMPS FOR REPAIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 PREVENTIVE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 CORRECTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4.1 Check Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4.1.1 Plastic Check Valves (PVC, PVDF, Polypropylene, & Sulfuric Acid

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4.1.2 Models SG6 & SG7 Liquid End - Stainless Steel Check Valves . . . . . . . . 16

4.4.1.3 Model SG5 Liquid End - Stainless Steel Check Valves . . . . . . . . . . . . . . . 17

4.4.1.4 Model SG5 Liquid End - Slurry Service Check Valves, use until

1 June 2008. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4.1.5 Models SG5, SG6, & SG7 Liquid End - Slurry Service Check Valves . . . . 18

4.4.1.6 Models SG5, SG6 & SG7 Liquid End - Polymer Service Check Valves . . 18

4.4.2 Diaphragm Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4.2.1 Diaphragm Removal (All types; Refer to Figures 6-13 ). . . . . . . . . . . . . . . 19

iii

Page 5

TABLE OF CONTENTS (CONT.)

4.4.2.2 Disassembly (Only Those Units With a “Hex Head“

Diaphragm Cap Design) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.2.3 Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4.2.4 Reinstallation of Assembly (Refer to Figure 6 Through 13) . . . . . . . . . . . 19

4.4.3 Replacing Oil Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SECTION 5 - TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SECTION 5 - PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 ILLUSTRATED PARTS LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 DRIVE, SIDE VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 DRIVE, TOP VIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 SG5 PLASTIC LIQUID END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.6 SG5 METALLIC LIQUID END - STAINLESS STEEL - NPT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.7 SG6 PLASTIC LIQUID END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8 SG6 METALLIC LIQUID END - STAINLESS STEEL - NPT. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.9 SG7 PLASTIC LIQUID END . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.10 SG7 METALLIC LIQUID END - STAINLESS STEEL - NPT. . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.11 CHECK VALVE PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

iv

Page 6

THIS PAGE INTENTIONALLY BLANK

v

Page 7

SECTION 1

DESCRIPTION

1.1 GENERAL INFORMATION

The Series G Model G is a reciprocating, chemical

dosing pump capable of producing controlled flows

up to 310 gallons per hour (1175 L/H) at pressures

up to 150 psi (10 BAR) (depending on the model).

These pumps feature a mechanically actuated diaphragm liquid end, which eliminates the need for

flow-restricting contour plates, and a stroke adjustment mechanism based on the variable eccentric

principle instead of the traditional lost-motion

design. This design substantially reduces pressure

and flow pulsations contributing to an increase in

the life of system components and more continuous chemical injection. It is designed for industrial

service and offers an accuracy of ±2% of 100%

rated flow between 10% and 100% of its flow

range.

1.2 PRINCIPLES OF OPERATION

The pump consists of two major assemblies; the

drive and the liquid end. Pump delivery is a function of the drive’s stroke rate, liquid en d size and

stroke length. Stroke length can be adjusted while

the pump is running or stopped by turning the

stroke adjusting knob.

The drive motor transmits rotary motion to a worm

gear speed reduction unit which in turn drives the

variable eccentric crank. The adjustable crank

imparts reciprocating motion to the diaphragm

through an interposing connecting rod. The stroke

length is adjusted by changing the position of the

variable eccentric crank in the connecting rod

assembly.

As the diaphragm starts back on the suction stroke,

the pressure immediately drops inside the liquid

end. When the liquid end pressure drops below the

suction line pressure, the suction ball check is

“pushed” upward and the process fluid in the suction line flows into the liquid end chamber. When

the suction stroke ends, the diaphragm movement

momentarily stops. The pressure in the liquid end

equalizes with the pressure in the suction line and

the suction ball check seats.

NOTE: It is important that the pressu re in the

liquid end remain above the vapor pressure of

the process fluid during the suction stroke. If

the fluid pressure drops below the vapor pressure, cavitation will occur, negatively impacting

the performance of the pump. If you suspect

the possibility of cavitation, contact your LMI

Distributor for assistance.

As the diaphragm starts forward on the discharge

stroke the pressure immediately rises inside the

liquid end. When the liquid end pressure rises

above the discharge line pressure, the discharge

ball check is “pushed” upward and the process fluid

in the liquid end flows into the discharge line. When

the discharge stroke ends, the diaphragm momentarily stops again. The pressure in the liquid end

equalizes with the discharge line pressure and the

discharge ball check reset. The cycle then starts

again.

1.3 GENERAL SPECIFICATIONS

FLOW RATE:

Up to 300 GPH (1175 L/H)

PRESSURE:

Up to 150 PSIG (10 BAR)

DESIGN:

Mechanically Actuated Diaphragm

DRIVE:

Variable Eccentric

ACCURACY:

±2% of 100% rated flow between 10% and 100%

of rated flow

ADJUSTMENT:

Lockable micrometer is adjustable from 0% to

100% while pump is running or stopped

LUBRICATION:

Oil bath Over 50ºF (10ºC), Zurn EP 95, 3 1/2

qt.(3.3 liter). Below 50ºF (10ºC), Zurn EP 35

WEIGHT:

90 lb (40.8kg)

1

Page 8

Figure 1. Model/Product Code.

2

Page 9

1.3 GENERAL SPECIFICATIONS (CONT.)

SUCTION LIFT

TEMPERATURE

Ambient and Liquid:

122 ºF (50 ºC) Maximum

14 ºF (-10 ºC) Minimum

5 ft. (2.5 meters) of water column maximum. 11

psia minimum internal pressure (4 psi maximum

vacuum).

PAINT

Powder Coating

3

Page 10

1.4 PRODUCT CODE

Series G Model G pumps are available in a variety

of different configurations. For a breakdown of the

options included in a specific pump, co mpare the

pump model number and product code found on

the pump nameplate with the model/produ ct code

breakdown shown in Figure 1. A sample nameplate is shown in Figure 2.

Figure 2. Sample Nameplate

4

Page 11

SECTION 2

WARNING

INSTALLATION

2.1 UNPACKING

Pumps are shipped f.o.b. factory or representative

warehouse and the title passes to the customer

when the carrier signs for receipt of the pump. In

the event that damages occur during shipment, it is

the responsibility of the customer to notify the carrier immediately and to file a damage claim.

Carefully examine the shipping crate upon receipt

from the carrier to be sure there is no obvious damage to the contents. Open the crate carefully so

accessory items fastened to the inside of the crate

will not be damaged or lost. Examine all material

inside the crate and check against packing list to

be sure that all items are accounted for and intact.

2.2 SAFETY PRECAUTIONS

WHEN INSTALLING, OPERATING, AND

MAINTAINING THE SERIES G MODEL G

PUMP, KEEP SAFETY CONSIDERATIONS FOREMOST. USE PROPER

TOOLS, PROTECTIVE CLOTHING, AND

EYE PROTECTION WHEN WORKING

ON THE EQUIPMENT AND INSTALL

THE EQUIPMENT WITH A VIEW

TOWARD ENSURING SAFE OPERATION. FOLLOW THE INSTRUCTIONS IN

THIS MANUAL AND TAKE ADDITIONAL

SAFETY MEASURES APPROPRIATE

TO THE LIQUID BEING PUMPED. BE

EXTREMELY CAREFUL IN THE PRESENCE OF HAZARDOUS SUBSTANCES

(E.G., CORROSIVES, TOXINS, SOLVENTS, ACIDS, CAUSTICS, FLAMMABLES, ETC.).

THE PERSONNEL RESPONSIBLE FOR

INSTALLATION, OPERATION AND

MAINTENANCE OF THIS EQUIPMENT

MUST BECOME FULLY ACQUAINTED

WITH THE CONTENTS OF THIS MANUAL.

ANY SERVICING OF THIS EQUIPMENT

MUST BE CARRIED OUT WHEN THE

UNIT IS STOPPED AND ALL PRESSURE HAS BEEN BLED FROM THE LIQUID END. SHUT-OFF VALVES IN

SUCTION AND DISCHARGE SIDES OF

THE LIQUID END SHOULD BE CLOSED

WHILE THE UNIT IS BEING SERVICED.

ACTIONS SHOULD BE TAKEN TO ELIMINATE THE POSSIBILITY OF ACCIDENTAL START-UP WHILE SERVICING IS

TAKING PLACE. A NOTICE SHOULD BE

POSTED BY THE POWER SWITCH TO

WARN THAT SERVICING IS BEING

CARRIED OUT ON THE EQUIPMENT.

SWITCH OFF THE POWER SUPPLY AS

SOON AS ANY FAULT IS DETECTED

DURING OPERATION (EXAMPLES:

ABNORMALLY HIGH DRIVE TEMPERATURE, UNUSUAL NOISE, DIAPHRAGM

FAILURE).

2.3 STORAGE

Short Term Storage (Less than 6 Months)

It is preferable to store the material under a shelter

in its original package to protect it from adverse

weather conditions. In condensing atmospheres,

follow the long term storage procedure.

Long Term Storage (Longer than 6 Months)

The primary consideration in storage of pump

equipment is to prevent corrosion of external and

internal components. This corrosion is caused by

natural circulation of air as temperatur e of the surroundings change from day to night, day to day,

and from season to season. It is not practical to

prevent this circulation which carries water vapor

and other corrosive gasses, so it is necessary to

protect internal and external surfaces from their

effects to the extent possible.

When the instructions given in this section are

completed, the equipment is to be stored sheltered; protected from direct exposure to weather.

5

Page 12

The prepared equipment should be co vered with a

plastic sheet or a tarpaulin, but in a manner which

will allow air circulation and prevent capture of

moisture. Equipment should be stored 12 inches or

more above the ground.

If equipment is to be shipped directly from Milton

Roy into long term storage, contact Milton Roy to

arrange for factory preparation.

Pump Drive

1. Flood the gearbox compartment with a high

grade lubricating oil/rust preventative such as

Mobile Oil Corporation product “Mobilarma 524.”

Fill the compartment completely to minimize air

space and water vapor condensation. After storage, drain this material and refill the equipment

with the recommended lubricant for equipment

commissioning.

2. Remove drive motor and liquid end, and brush

all unpainted metal surfaces with multipurpose

grease (NLGI grade 2 or 3). Store these unattached.

Electrical Equipment

1. Motors should be prepared in the manner prescribed by their manufacturer. If information is not

available, dismount and store motors as indicated

in step 3 below.

2. Dismount electrical equipment (including

motors) from the pump.

3. For all electrical equipment, place packets of

Vapor Phase Corrosion Inhibitor (VPCI) inside of

the enclosure, then place the entire enclosure, with

additional packets, inside a plastic bag. Seal the

bag tightly closed. Contact your distributor or LMI/

Milton Roy Service Department for recommended

VPCI materials.

Support the pump firmly in a level position on a

solid, vibration-free foundation, preferably with the

base above floor level to protect the pump from

wash downs and to provide easier access for service. Be sure to allow enough space around the

pump for easy access during maintenance operations, pump adjustments, and/or oil filling or draining procedures.

Series G Model G pumps are provided with mounting holes to accommodate anchor bolts. Refer to

Figure 3 for mounting hole dimensions.

Some Series G Model G pumps are shipped with

motors dismounted. After anchoring pump in position, install motor, referring to Figure 7, Sheet 1.

Make sure spring (360) provided with pump is

installed in worm shaft prior to motor installation.

Pumps installed outdoors should be protected by a

shelter.

2.5 PIPING

NPSH Considerations

Size piping to accommodate peak instantaneous

flow. Because of the reciprocating motion of the

pump diaphragm, pump delivery follows an approximate sine curve with a peak instantaneous flow pi

(3.14) times the average flow. Therefore, piping

must be designed for a flow 3.14 times the pump

capacity; this means that a pump rated for 88 gallons per hour (333.1 L/hr.) requires piping sufficient

for 3.14 x 88 gph, or 276 gph (1044.7 L/ hr.).

2.4 MOUNTING

TO AVOID POSSIBLE DAMAGE TO

EITHER PUMP OR PERSONNEL, BOLT

PUMP DOWN AS SOON AS IT IS IN

POSITION.

Figure 3. Mounting Hole Dimensions

6

Page 13

To minimize viscous flow losses when handling viscous liquids, it may be necessary to use suction

piping up to four times larger than the size of the

suction connection on the pump. If in doubt, contact your nearest LMI Distributor to determine the

necessary pipe size.

• Use piping heavy enough to withstand

maximum pressures.

• Remove burrs, sharp edges, and debris

from inside piping. Blow out all pipe lines

before making final connections to pump.

General Piping Considerations

• Use extreme care in piping to plastic liquid

end pumps with rigid pipe such as PVC. If

excessive stresses or vibration is unavoidable, flexible connections are recommended.

• Use piping materials that will resist corrosion by the liquid being pumped. Use care

in selecting materials to avoid galvanic corrosion at pump liquid end connections.

• Because vapor in the liquid end will cause

inaccurate pump delivery, piping should be

sloped to prevent vapor pockets

• When pumping suspended solids (such as

slurries), install plugged crosses at all 90°

line turns to permit line cleaning without

dismantling piping.

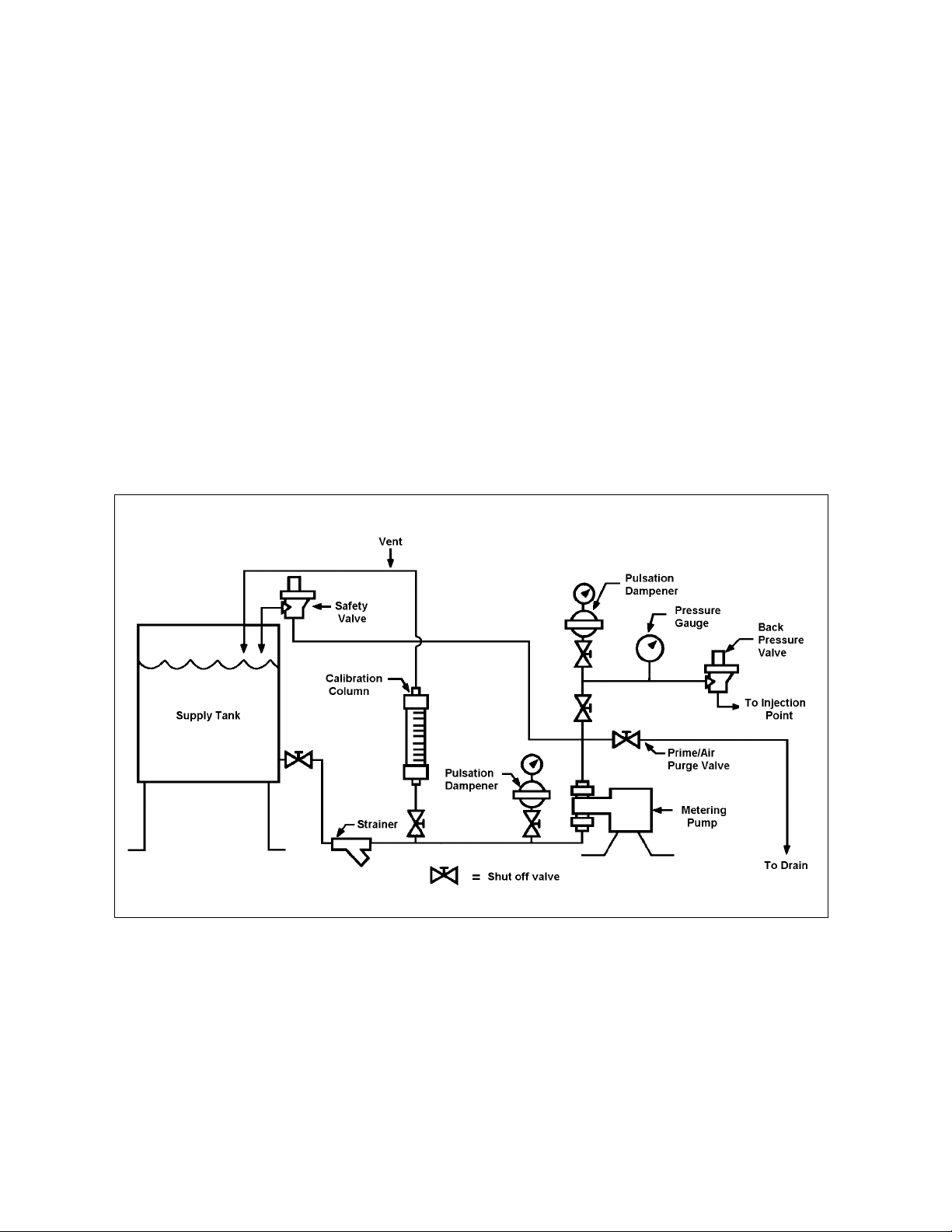

• See Figure 4 for a typical recommended

pump installation scheme.

Figure 4. Typical Recommended Pump Installation Scheme

7

Page 14

Suction Piping Considerations

• It is preferable to have the suction of the

pump flooded by locating the liquid end

below the lowest level of the liquid in the

supply tank. Installing the supply vessel on

the suction line close to the pump can help

ensure a flooded suction line. (Consult with

your LMI distributor or the LMI/Milton Roy

technical support team for assistance in

such applications.)

• Avoid negative suction pressure conditions

(suction lift), as such conditions adversely

affect metering accuracy. A lift of 8.2 feet

(2.5 meters) of water column is the maximum suction lift permissible.

• If possible use metal or plastic tubing for

the suction line because tubing has a

smooth inner surface and can be formed

into long, sweeping bends to minimize frictional flow losses.

• A strainer should be used in the suction

line to prevent foreign particles from entering the liquid end. This and any other measures which prevent debris from entering

and fouling the ball-checks will give

increased maintenance-free service.

Check strainer frequently to prevent block age which could lead to cavitation.

• Keep suction piping as short and straight

as possible.

• Series G Model G pumps are designed to

operate with process liquid supplied at or

above atmospheric pressure. Although

these pumps can move liquids supplied at

less than atmospheric pressure, in these

negative pressure applications it is important that all connections be absolutely drip

free and vacuum tight, and that a foot

valve be installed at the bottom of the suction line (see Figure 5).

• When pumping a liquid near its boiling

point (max temp is 125 degrees F), provide

enough suction head to prevent the liquid

from “flashing” into vapor when it enters

the pump liquid end on the suction stroke.

• Piping size should be larger than the liquid

end suction fitting to prevent pump s tarvation.

• If long suction lines are unavoidable, install

a stand pipe near the pump in the suction

line.

• Suction piping must be absolutely airtight

to ensure accurate pumping. After installation, test suction piping for leaks with air

and soap solution.

Discharge Piping Considerations

• Install pipe large enough to prevent excessive pressure losses on the discharge

stroke of the pump. Maximum pressure at

the discharge fitting on the liquid end must

be kept at or below the rated pressure

(Max. allowable working pressure shown

on the pump nameplate).

• The pump will not deliver a controlled flow

unless the discharge line pressure is 10 psi

greater than the suction line pressure.

There are a number of ways to create an

artificial pressure, such as by installing a

back pressure valve. (Please contact your

LMI distributor for recommendations to

increase back pressure in slurry applications.)

Figure 5. Suction Lift Installation

• When pumping water-treatment chemicals

directly into boiler drums, use one liquid

end assembly for each boiler drum. Dis-

8

Page 15

charging into a manifold having the slightest pressure difference between its several

discharge connections can diminish metering accuracy as the outlet with the lowest

pressure will receive more liquid than the

other outlets.

Back Pressure Valves

A Milton Roy Back Pressure Valve (Figure 4)

should be installed in the discharge line near the

pump to ensure sufficient discharge head pressure

for proper pump metering action. Back pressure

valves for large pumps with long and extremely

small discharge lines may have to be installed near

the point of discharge into the process (to minimize

siphoning tendencies).

Pulsation Dampeners

An accumulator, surge chamber, surge suppressor,

or pulsation dampener should be used with the

back pressure valve in the discharge line to absorb

the flow peaks between the pump and the back

pressure valve. Without the pulsation dampener

the valve mechanism will snap open and closed

with the surge from each pump stroke. The pulsation dampener will allow the back pressure valve to

oscillate about a partly-closed position, thus minimizing wear on the valve. Discharge line pulsation

dampeners offer the further advantage of limiting

the flow and pressure variations characteristic of

this kind of pump. Installing a properly sized pulsation dampener will improve pump performance and

may reduce system costs dramatically by permitting the substitution of smaller piping. Please contact your LMI distributor for further information on

pulsation dampeners.

Safety Valves

Motor-driven positive displacement pumps can

develop excessive discharge pressures long

before thermal overload devices interrupt the motor

electrical circuit. To prevent a blocked discharge

line from causing damage to the pump, piping, or

process equipment, install a Milton Roy Safety

Valve in the pump discharge line. This valve is

designed and sized to handle system flow rates

and pressures safely while resisting corrosion by

the process liquid.

Install the safety valve in the discharge line

between the pump and the nearest shut-off valve.

(This will prevent pump damage from accidental

valve closure.) Pipe the safety valve outlet back to

the suction tank or to drain, but in either case

ensure that the pipe end is continuously visible so

safety valve leakage may be detected. Milton Roy

safety valves must be installed at top of supply tank

in order to function properly (see Figure 4).

Check Valves

A check valve should be installed at the point

where the discharge line enters a boiler or other

high-pressure vessel. This will prevent back flow

through the discharge piping and will isolate the

pump discharge from system pressures (a safety

consideration).

Shut-off Valves

Provide shut-off valves in both suction and discharge lines next to the pump. Locate discharge

line shut-off valve downstream from the inlet connection of the safety valve. Figure 4 shows recommended valve locations.

2.6 LEAK DETECTION

The Series G Model G pumps are equipped with a

leak detection port. For ease of installation, each

pump has a plastic tubing connector installed in the

leak detection port (see item 448 in Figure 7, Sheet

2). In the event of a failure of the oil seal (70 in Figure 7, Sheet 1) or PTFE diaphragm assembly (260

in Figures 8 through 13), pump drive oil or process

fluid will escape from this leakage port. During

pump installation, actions should be t aken to i nsure

that this leakage is safely collected by installing

tubing between the leak detection port and an

appropriate containment vessel.

2.7 ELECTRICAL CONNECTIONS

Ensure that the electrical supply matches the pump

motor nameplate characteristics.

OPERATION WITH THE WRONG

MOTOR ROTATION WILL DAMAGE THE

PUMP AND MOTOR AND VOID THE

WARRANTY.

9

Page 16

Before operating the pump, check the direction of

rotation of the motor to be sure it matches the

direction of the arrow stamped on the motor (rotation should be clockwise when viewed from the top

of the motor). If motor rotation is incorrect, refer to

the motor data plate or motor manufacturer’s

instructions for reversing.

DO NOT FORGET TO CONNECT THE

PUMP TO AN EARTH GROUND!

Electric protection of the motor (fuses, overload

meters or relays) should correspond to the rated

current indicated on the motor data plate.

10

Page 17

SECTION 3

WARNING

OPERATION

3.1 INITIAL START-UP

FAILURE TO CHECK TORQUE ON NONMETALLIC HEAD BOLTS PRIOR TO

STARTUP AND AFTER ONE WEEK OF

OPERATION MAY EXPOSE

OPERATING PERSONNEL TO

HAZARDOUS LIQUIDS.

Check the torque on all non-metallic head bolts

prior to startup. Recheck torque on all non-metallic

head bolts after pump has been operating for one

week. Torque the head assembly screws in a

crosswise pattern as follows:

(1) Liquid End Size SG5 and SG6 non-metallic

head bolts to 90 inch pounds.

(2) Liquid End Size SG7 non-metallic head

bolts to 125 inch pounds.

Check that all mounting bolts are tight, piping is

installed properly, and the discharge line is open.

Check oil drain plug for tightness. Remove the oil

fill cap and fill the pump casing until level is

between the markings on the oil fill cap dipstick,

(approximately 3 quarts (2.8 Liters)).

NOTE: The oil furnished with the pump is

grade AGMA No. 5 EP with a viscosity of 1000

SSU at 100°F (218.4 cSt at 40°C). For operation in ambient temperatures below 50°F

(10°C), substitute AGMA No. 2 EP with a viscosity of 400 SSU at 100°F (86.4 cSt at 40°C).

Manufacturers' equivalent oils are shown

below.NOTE:

ABOVE 50°F

Chevron

Exxon

Mobil

Texaco

Shell

................. N.L. Gear Compound 220

.................... Spartan E.P. 220

...................... Mobilgear 630

................ ... Meropa 220

...................... Omaha 220

BELOW 50°F

Chevron

................. N.L. Gear Compound 68

Exxon

.....................Spartan E.P. 68

......... ... ... ... ... .Mobilgear 626

Mobil

Texaco

Shell

.................. .Meropa 68

...................... .Omaha 68

BEFORE SWITCHING ON POWER TO

THE PUMP, TURN THE CAPACITY

ADJUSTMENT KNOB TO ZERO. CHECK

THAT ALL SHUT-OFF VALVES IN THE

SUCTION AND DISCHARGE LINES ARE

OPEN BEFORE INCREASING THE

CAPACITY ADJUSTMENT FROM ZERO.

DO NOT TRY TO ADJUST PUMP

CAPACITY BELOW O% OR ABOVE

100% OR DAMAGE TO PUMP MAY

OCCUR. KEEP ADJUSTMENT KNOB

BETWEEN 0 AND 100 %.

Manual Capacity Control

To adjust pump capacity, loosen the stroke locking

knob (320, Figure 7, Sheet 2) located in the pumpside cover. Pump capacity is adjusted by turning

the micrometer type stroke adjustment knob (330)

clockwise to decrease capacity or counterclockwise to increase capacity as required. The adjustment scale is marked in percent (%) of full stroke,

with calibration lines on the knob at 1% intervals.

After adjusting the knob to the desired capacity setting, hand tighten the stroke locking screw to maintain the capacity setting.

Filling Pumping System

It is especially important that pump suction and discharge lines be free of entrained air. To ensure this

condition, operate the pump without any discharge

pressure and fill the entire pumping system with liquid before starting pressure tests. A simple method

to assure priming of the pump is to install a tee an d

a shut-off valve at the discharge connection of the

pump.

11

Page 18

If the pump is idle for long periods, temperature

changes in the process liquid may produce air in

the system. To discharge the air, install a valve in

the discharge line which will allow the process liquid to be pumped to exhaust when starting the

pump.

Capacity Calibration

After the first 12 hours of operation, the pump may

be tested and calibrated to find the exact pump

capacity under specific operating conditions.

Usually, calibrating the pump at only 100, 50, and

10 percent capacity settings is enough to indicate

pump performance throughout the adjustment

range.

The pump can be calibrated by measuring the

decrease in liquid level pumped from a calibrated

vessel. This method is recommended for hazardous liquids because it eliminates operator contact

with the liquid. Milton Roy test-tube Calibration Col-

umns are available for convenient and accurate

calibration of any pump.

THE FOLLOWING METHOD IS NOT

GENERALLY RECOMMENDED AS IT

MAY EXPOSE OPERATING PERSONNEL TO HAZARDOUS LIQUIDS. FUTHERMORE, THE PUMP MAY OVER PUMP

DRAMATICALLY AND THE POSITION

OF THE CAPACITY ADJUSTMENT

KNOB MAY HAVE LITTLE EFEECT ON

MEASURING FLOW RATE.

The pump can also be calibrated by collecting and

measuring pumped liquid at the pump discharge

port. It may be necessary to create discharge head

at the liquid takeoff point so that the pump will

operate properly. (See Section 2 for recommended

ways to do this.)

12

Page 19

SECTION 4

MAINTENANCE

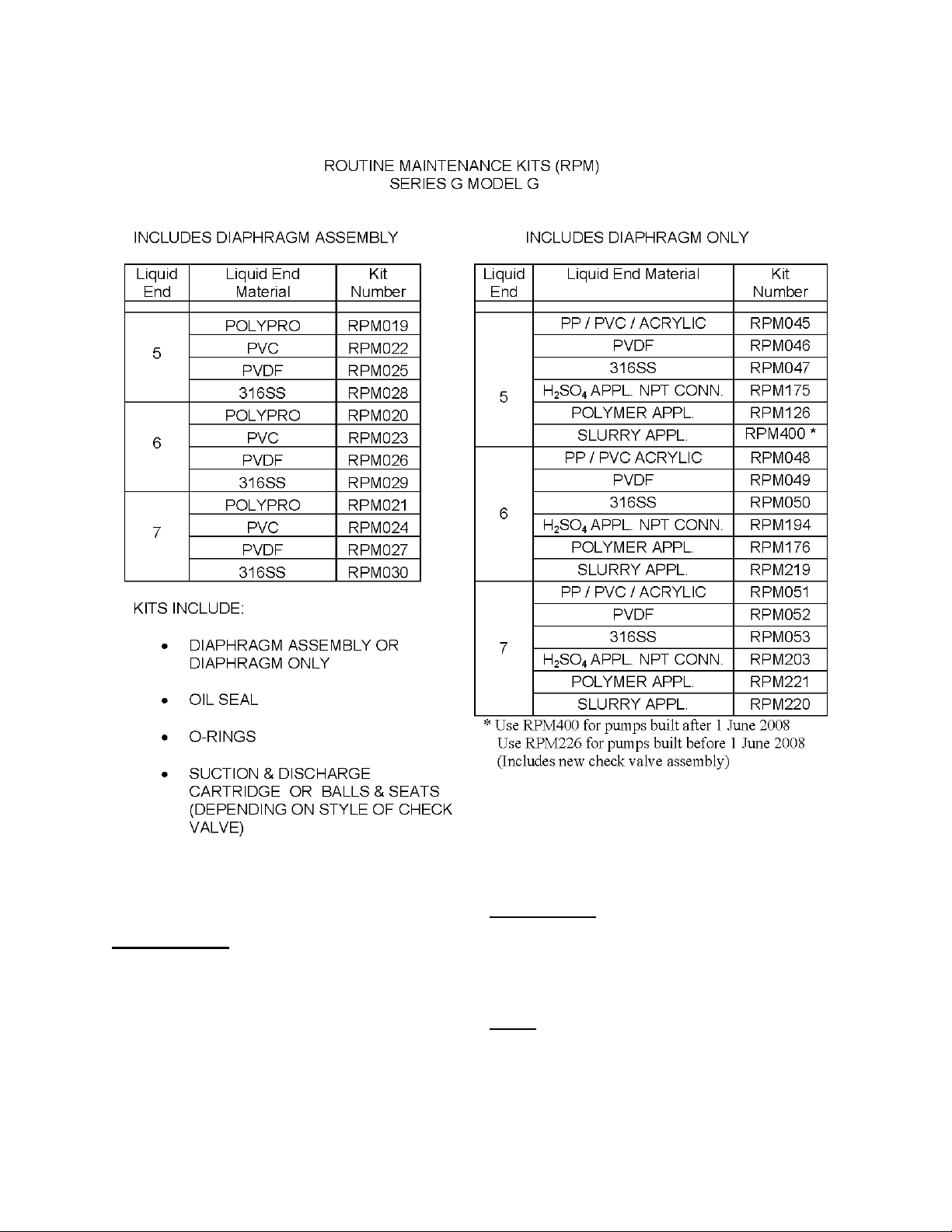

4.1 SPARE PARTS

To avoid excessive downtime in the event of a

parts malfunction, the spare parts shown below

should be stocked for each pump to pre vent serious delays in repairs. Refer to Figures 8–14 and

the accompanying parts lists. For your convenience, these parts can be purchased either separately or packaged in the form of Routine

Preventive Maintenance (RPM) Kits. RPM kit

numbers are listed in Section 1.

RPM kit numbers RPM019 through RPM030 contain pre-assembled diaphragms, oil seal and check

valve parts. Cap piece (240), set screw (250), diaphragm (260), and support nut (270) is pre-assembled in kits RPM019 through RPM030. A spanner

wrench, which may not always be available in the

field, is required to disassemble the diaphragm

assembly.

RPM Kits RPM045 through RPM053 and RPM126,

through RPM220 contain a diaphragm, oil seal,

and check valve parts. Series G Model G pumps

built with the latest design do not need a spanner

wrench to disassemble the diaphragm assembly.

The diaphragm assembly can be disassembled

with a 30mm socket (Section 4, paragraph 4.4. 2).

The diaphragm can then be replaced.

All Other Liquid Ends

(1) Diaphragm (260)

(2) Oil Seal (70)

(3) Seat, O-Ring, Ball Set (423)

(See parts list)

Parts orders must include the following:

1. Quantity required

2. Part number

3. Part description

4. Pump serial number (found on nameplate)

5. Pump model number (found on nameplate)

6. Pump product code (found on nameplate)

Always include the serial number, model number,

and product code in all correspondence regarding

the unit.

Drive Worms and Gears

Either type of kit can be used for your pump. The

user must decide which type is better for them.

When ordering RPM Kits RPM045 through

RPM053 for an old style pump, where a spanner

wrench is required to disassemble the diaphragm

assembly, order a new hex head support nut (270)

with the RPM kit. Future maintenance on the Macroy pump will not require a spanner wrench.

SG5, Metallic Liquid End

(1) Diaphragm (260)

(2) Oil Seal (70)

(3) Check Valve Assemblies (425)

(See parts list)

Worms (Fig 7, Item 342) and gears (50) must be

sold in sets to assure proper operation.

4.2 SHIPPING PUMPS FOR REPAIR

Pumps can not be accepted for repair without a

Return Material Authorization. Pumps should be

clearly labeled to indicate the liquid being pumped.

Process liquid should be flushed from the pump liquid end and oil should be drained from the pump

housing before the pump is shipped.

NOTE: Federal law prohibits handling of

equipment that is not accompanied by an

OSHA Material Safety Data Sheet (MSDS). A

completed MSDS must be packed in the shipping crate with any pump shipped for repair.

These safety precautions will aid the troubleshooting and repair procedure and preclude

serious injury to repair personnel from hazard-

13

Page 20

ous residue in pump liquid end. A Materials

Safety Data Sheet must accompany a ll returns.

All inquiries or parts orders should be addressed to

your local LMI representative or distributor.

4.3 PREVENTIVE MAINTENANCE

LMI pumps are carefully designed, m anufactured,

assembled, and quality tested to give reliable service with minimal maintenance. However, a weekly

maintenance check is recommended to visually

confirm proper operation of the pump.

Drive

Inspect the ball check and seat for chemical or

physical damage. The ball should be perfectly

round and free of pits, mars, or scratches. The seat

should retain a sharp edge where the ball contacts

for proper sealing. If the seat edge is worn or damaged, or has any pits, mars, or scratches, it should

be replaced. If the ball and/or seat is excessively

damaged, the replacement schedule should be

shortened accordingly. If the ball and seat are both

in good condition, the replacement schedule can

be lengthened.

Complete instructions for replacing worn check

valve parts are given in the “Corrective Maintenance” section.

Initially, change gear drive oil after the first 250

hours of operation. Then change drive oil after

every 4000 hours of operation or every six months,

whichever comes first. Refer to “Initial Start-up” in

Section 3, Operation, for information on recommended oil and oil capacity.

NOTE: When adding oil, pour in a thin, slow

stream to avoid overflow.

Diaphragm Assembly

The Series G Model G diaphragm assembly should

be replaced every 4000 hours of operation to avoid

the possibility of failure. Refer to the instructions in

the “Corrective Maintenance” section.

Oil Seal

The Series G Model G oil seal should be replac ed

every 4000 hours of operation to avoid the possibility of failure. Oil seal replacement requires the

removal of the diaphragm assembly, so it is recommended that the oil seal and diaphragm be

replaced at the same time. Refer to the instructions

in the “Corrective Maintenance” section.

Check Valves

4.4 CORRECTIVE MAINTENANCE

BEFORE CARRYING OUT ANY SERVICING OPERATION ON THE METERING

UNIT OR PIPES, DISCONNECT ELECTRICAL POWER FROM THE PUMP,

AND TAKE THE NECESSARY STEPS

TO ENSURE THAT THE HARMFUL LIQUID THEY CONTAIN CANNOT ESCAPE

OR COME INTO CONTACT WITH PERSONNEL. SUITABLE PROTECTIVE

EQUIPMENT MUST BE PROVIDED.

CHECK THAT ALL PRESSURE HAS

BEEN BLED FROM THE PUMP DRIVE

AND PUMP LIQUID END BEFORE PROCEEDING WITH DISMANTLING.

Cleaning Fouled Check Valves

Check valve assemblies are designed to be self

cleaning and should seldom need servicing.

Fouled check valves can usually be cleaned by

pumping a solution of mild detergent and warm

water (if compatible with liquid being pumped) for

15 minutes, followed by flushing with water.

LMI recommends that check valve balls, seats,

gaskets, and o-rings be replaced on a annual

basis. If highly corrosive material (acids, slurries,

etc.) is being pumped, some applications may

require more frequent replacement.

To determine if check valves need maintenance,

disassemble the check valves following the instructions in the “Corrective Maintenance” section.

4.4.1 Check Valve Replacement

General

Before beginning work on the valve assemblies,

make sure the shut-off valves are closed and that

pressure has been bled from the system. When

replacing the valves, take care to systematically

change their O-rings and/or gaskets. Take care to

14

Page 21

properly assemble the valve assemblies; the ball

must be placed on the sharp edge of the seats.

Check valves are supplied in four different configurations: plastic, stainless steel, slurry, and polymer.

Be sure to refer to the appropriate instructional set

below.

BE SURE TO FOLLOW INSTRUCTIONS

CAREFULLY AND REFER TO THE

APPROPRIATE FIGURE WHEN REASSEMBLING CHECK VALVES. IF CHECK

VALVE CARTRIDGES ARE INSTALLED

INCORRECTLY, ONE OF THE FOLLOWING WILL OCCUR: (A) IMMEDIATE

SEVERE DAMAGE TO PUMP MECHANISM, (B) NO PUMPING, (C) REVERSE

PUMPING ACTION (FROM DISCHARGE

LINE INTO SUCTION LINE).

4.4.1.1 Plastic Check Valves (PVC, PVDF,

Polypropylene, and Sulfuric Acid Service, Fig.

14A or 14C):

Disassembly

Check pump data plate for model number.

1. Unscrew the union nut (435). The union end

(445) is held in place by the union nut and will separate easily from the other liquid end parts.

2. Unscrew the ball guide (424) from the liquid

end.

3. Screw the union nut part way (one or two

turns) onto the end of the ball guide that has the

seat in it. Be sure the union nut is on loosely. This

will allow a gap for the seat (420) to fall into as it is

removed from the ball guide.

4. Set the ball guide/union nut onto a flat surface

with the union nut down. Looking into the top of

the ball guide, you will see four large holes surrounding one small hole. Insert a thin, blunt instrument such as a hex head screwdriver into the small

center hole until it rests on the top of the ball (422).

IF YOU ARE DISASSEMBLING UNIT

FOR INSPECTION ONLY, BE SURE TO

USE A BLUNT INSTRUMENT AND TAP

GENTLY TO AVOID DAMAGING THE

BALL. IF THE BALL AND/OR SEAT ARE

DAMAGED DURING DISASSEMBLY,

THEY WILL HAVE TO BE REPLACED. IF

AVAILABLE, TO AVOID DAMAGE, IT IS

ADVISABLE TO USE GENTLE AIR

PRESSURE (APPLIED AT END OPPOSITE THE SEAT - 420) FOR BALL AND

SEAT REMOVAL.

5. Tap screwdriver gently with a hammer until the

ball and seat are released from the ball guide.

6. Carefully remove the two or three o-rings (depending on model number) from the ball guide and

seat.

7. Carefully clean any parts to be reused. If any

chemicals are used in the cleaning process,

ensure that they are compatible with the process

liquid.

Reassembly

1. Fit new o-rings into position on the ball guide

and seat.

NOTE: To assure a tight, leak free seal, new

o-rings should be used each time the check

valves are disassembled.

2. Drop the ball into the curved inner chamber

end of the ball guide.

IF THE SEAT IS IMPROPERLY POSITIONED, THE BALL WILL NOT CREATE

A TIGHT SEAL AND POOR PUMPING

PERFORMANCE WILL RESULT.

3. Set the ball guide on a flat surface so that the

side with the ball faces upwards. Position seat on

the ball guide, trapping the ball inside. When the

seat is pressed into the ball guide, the beveled

edge of the seat must be facing outward. The

15

Page 22

bevel should not face the inside of the check valve

(refer to Figure 14A or 14C). Use a flat surface

such as a board to press the seat into the ball

guide with firm, even pressure.

THE ORDER OF ASSEMBLY AND ORIENTATION OF THE SUCTION AND DISCHARGE CHECK VALVES IS

DIFFERENT. REFER TO FIGURE 8, 10,

12, 14A, AND 14C FOR PROPER

ASSEMBLY ORDER AND ORIENTATION. IF CHECK VALVE CARTRIDGES

ARE INSTALLED INCORRECTLY, ONE

OF THE FOLLOWING WILL OCCUR: (A)

IMMEDIATE SEVERE DAMAGE TO

PUMP MECHANISM, (B) NO PUMPING,

(C) REVERSE PUMPING ACTION

(FROM DISCHARGE LINE INTO SUCTION LINE).

4. Position the union end (445) onto the correct

end of the ball guide. Refer to Figure 14A or 14C,

as the correct end is determined by whether the

valve is intended for the suction or discharge port

of the liquid end. Slip the union nut (435) over the

union end and screw tightly (hand tight only) onto

the ball guide.

5. Screw the valve assembly into the liquid end

body (hand tight only). DO NOT OVER

TIGHTEN.

4.4.1.2 Models SG6 & SG7 Liquid Ends - Stainless Steel Check Valves (Figure 14D):

Disassembly

ensure that they are compatible with the process

liquid.

Reassembly

1. Drop the ball into the curved inner chamber

end of the ball guide.

DO NOT REUSE OLD GASKETS (419).

EVEN IF BALL AND SEAT ARE NOT

WORN AND DO NOT NEED REPLACING, NEW GASKETS MUST BE USED

ANY TIME THE CHECK VALVES ARE

DISASSEMBLED.

2. Place a new gasket on the rim of the ball guide

(424), and sit the seat on top of the ball guide, trapping the ball and gasket between the seat and ball

guide.

THE ORDER OF ASSEMBLY AND ORIENTATION OF THE SUCTION AND DISCHARGE CHECK VALVES IS

DIFFERENT. REFER TO FIGURE 11, 13,

AND 14D FOR PROPER ASSEMBLY

ORDER AND ORIENTATION. IF CHECK

VALVE CARTRIDGES ARE INSTALLED

INCORRECTLY, ONE OF THE FOLLOWING WILL OCCUR: (A) IMMEDIATE

SEVERE DAMAGE TO PUMP MECHANISM, (B) NO PUMPING, (C) REVERSE

PUMPING ACTION (FROM DISCHARGE

LINE INTO SUCTION LINE).

1. Unscrew the three screws (441 & 442) and

remove them and their three washers (439).

2. Remove the valve clamp (437).

3. The connection (435), seat (420), ball (422)

and ball guide (424) should all now slip apart easily.

4. Remove and discard the three gaskets (419).

5. Carefully clean any parts to be reused. If any

chemicals are used in the cleaning process,

3. Position the connection (435) onto the correct

end of the ball guide with a gasket trapped

between the two metal surfaces. Refer to Figure

14D, as the correct end is determined by whether

the valve is intended for the suction or discharge

port of the liquid end.

4. Position the check valve assembly onto the liquid end, trapping a gasket between the two metal

surfaces (seat and pump head).

5. Slide the valve clamp (437) over the connection (435) and screw into the liquid end using the

16

Page 23

three screws (441,442) and their split washers

(439). Since one screw (441) is shorter than the

others, be sure that it is screwed into t he appropriate hole.

4.4.1.3 Model SG5 Liquid End - Stainless Steel

Check Valve (Fig. 14B):

Disassembly

SG5 stainless steel check valves differ from the

plastic versions in that the ball seat is integral to

the ball guide. The seats cannot easily be

inspected for damage or wear. If you suspect that

the check valve may be damaged or worn, replace

the entire check valve assembly as per the instructions below .

1. Unscrew the coupling (445).

2. Unscrew the ball guide (424) from the liquid

end.

3. Remove and discard the o-rings (419).

4. Carefully clean any parts to be reused. If any

chemicals are used in the cleaning process,

ensure that they are compatible with the process

liquid.

Reassembly

NOTE: To assure a tight, leak free seal, new

o-rings should be used each time the check

valves are disassembled.

2. Screw the coupling (445) onto the check valve

assembly, trapping a new o-ring (419, 423)

between the coupling and the check valve assembly.

4.4.1.4 Model SG5 Liquid End - Slurry Service

Check Valves, use until 1 June 2008 (Fig. 14E) :

Replacement

THE ORDER OF ASSEMBLY AND ORIENTATION OF THE SUCTION AND DISCHARGE CHECK VALVES IS

DIFFERENT. REFER TO FIGURE 8 AND

14E FOR PROPER ASSEMBLY ORDER

AND ORIENTATION. IF CHECK VALVE

CARTRIDGES ARE INSTALLED INCORRECTLY, ONE OF THE FOLLOWING

WILL OCCUR: (A) IMMEDIATE SEVERE

DAMAGE TO PUMP MECHANISM, (B)

NO PUMPING, (C) REVERSE PUMPING

ACTION (FROM DISCHARGE LINE INTO

SUCTION LINE).

1. Unscrew the coupling (445).

THE ORDER OF ASSEMBLY AND ORIENTATION OF THE SUCTION AND DISCHARGE CHECK VALVES IS

DIFFERENT. REFER TO FIGURE 9 AND

14B FOR PROPER ASSEMBLY ORDER

AND ORIENTATION. IF CHECK VALVE

CARTRIDGES ARE INSTALLED INCORRECTLY, ONE OF THE FOLLOWING

WILL OCCUR: (A) IMMEDIATE SEVERE

DAMAGE TO PUMP MECHANISM, (B)

NO PUMPING, (C) REVERSE PUMPING

ACTION (FROM DISCHARGE LINE INTO

SUCTION LINE).

1. Screw the correct end of the check valve

assembly into the liquid end (refer to Figure 14B),

trapping a new o-ring between the liquid end and

the check valve assembly.

2. Unscrew the valve body (424) from the pump

head (280).

3. Remove and discard the valve assembly:

assembly includes two O-rings (419), slurry seal

ring (420), ball (422), check valve body (424), and

dowel pin.

4. Clean the new valve assembly and threaded

port in the head (280).

NOTE: To assure a tight, leak free seal, new

o-rings should be used each time the check

valves are disassembled.

5. Screw correct end of check valve assembly into

liquid end (refer to Figure 14E), trapping a new oring (419) between liquid end and check valve

assembly.

17

Page 24

6. Screw coupling (445) on to check valve asse mbly, trapping a new o-ring (419) between coupling

and check valve assembly.

4.4.1.5 Models SG5, SG6 & SG7 Liquid End Slurry Service Check Valves (Figure 14E &

14G):

Replacement

new o-ring (419) between liquid end and check

valve assembly.

8. Screw coupling (445) onto check valve assembly, trapping a new o-ring (419) between coupling

and check valve assembly.

4.4.1.6 Models SG5, SG6 & SG7 Liquid End Polymer Service Check Valves (Figure 14F):

Replacement

Suction

THE ORDER OF ASSEMBLY AND ORIENTATION OF THE SUCTION AND DISCHARGE CHECK VALVES IS

DIFFERENT. REFER TO FIGURE 14G

FOR PROPER ASSEMBLY ORDER AND

ORIENTATION. IF CHECK VALVE CARTRIDGES ARE INSTALLED INCORRECTLY, ONE OF THE FOLLOWING

WILL OCCUR: (A) IMMEDIATE SEVERE

DAMAGE TO PUMP MECHANISM, (B)

NO PUMPING, (C) REVERSE PUMPING

ACTION (FROM DISCHARGE LINE INTO

SUCTION LINE).

1. Unscrew valve body (424) from pump head

(280).

2. Remove the valve assembly (425): assembly

includes ball (421 or 422), seat (420), retain pin

(428, SG5 only), valve body (424), and two (SG5)

or three (SG6 & SG7 O-rings (419).

3. Remove and discard o-rings (419), seat (420)

and ball (421 or 422).

4. Clean valve body (424) and threaded port in

head (280).

Follow the instruction for replacement of ball, seat,

& seal: liquid end SG6 and SG7 - plastic check

valves paragraph 4.4.1.1. The procedures are the

same.

Discharge

1. Unscrew valve body (425) from pump head

(280).

2. Remove valve assembly: assembly includes

two O-rings (419), seat (420), ball (422), poppet

(426), spring (423) and check valve body (425).

3. Replace O-rings (419), seat (420), ball (422),

poppet (426), and spring (423).

4. Clean valve body (425) and threaded port in

head (280).

5. Install new check valve assembly in orientation

shown.

On discharge side, drop cartridge assembly into

threaded port in head. Screw valve body into discharge side of diaphragm head until valve is hand

tight. DO NOT OVERTIGHTEN

.

5. Place a new O-ring (419) around seat (420).

Place new seat (420) and new ball (421 or 422)

inside valve body (424).

6. Add O-ring (419) and install new check valve

assembly in orientation shown.

NOTE: To assure a tight, leak free seal, new

o-rings should be used each time the check

valves are disassembled.

7. Screw correct end of chec k v alv e ass em b ly in to

liquid end (refer to Figure 14E or 14G) , trapping a

4.4.2 Diaphragm Replacement

BEFORE BEGINNING DIAPHRAGM

REPLACEMENT, MAKE SURE THAT

ALL SHUT-OFF VALVES ARE CLOSED

AND ALL PRESSURE IS BLED FROM

THE LIQUID END. MAKE SURE POWER

TO PUMP IS TURNED OFF AND CANNOT BE ACTIVATED.

18

Page 25

It is recommended that the oil seal and diaphragm

be replaced at the same time. The instructions

given under “Replacing the Oil Seal” are com plete

instructions for replacing both th e oil seal and diaphragm. If you plan to replace both, refer to the

“Replacing the Oil Seal” instructions, and disregard

the instructions below. These instructions are

intended for use only if the diaphragm is being

replaced independent of the oil seal.

4.4.2.1 Diaphragm Removal (All types; Refer to

Figures 6-13)

1. Set the stroke adjusting knob to 100%.

2. Disconnect the suction and discharge piping.

3. Unscrew the six diaphragm head bolts (290).

4. Remove the pump head (280) from the pump

body.

5. Turn the motor fan by hand (remove the motor

shroud if necessary) until the end of the diaphragm

(240) is fully forward, and unscrew the diaphragm

assembly from the connecting rod (60).

4.4.2.2 Disassembly (Only Those Units With a

“Hex Head “ Diaphragm Cap Design, Figure 6)

1. Secure the hex cap (240) in a vise, and loosen

the support nut (270) using a 30mm hex socket.

2. After complete disassembly inspect the support nut (270). It should be free of corrosion and

clean. The angled surface must be smooth to protect the diaphragm from damage. If the support

nut does not meet these requirements, replace it.

4.4.2.3 Reassembly

1. Mount the hex cap (240) in a vise (do not overtighten), and with surfaces cleaned place a new

diaphragm (260) onto the cap as shown Figure 6

through Figure 13 (convolution pointing toward the

support nut).

2. The set screw (250) hand tight in the cap (240)

with the hex socket end visible.

3. Screw the support nut (270) onto the set screw

until hand tight

4. DO NOT OVERTIGHTEN the support nut.

Use a 30mm hex socket and torque wrench to

tighten the support nut. The torque depends on

pump model number.

Figure 6. Diaphragm Assembly

• For model numbers SG5 & SG6: Torque is

20 foot pounds.

• For model number SG7: Torque is 30 foot

pounds.

4.4.2.4 Reinstallation of Assembly (Refer to

Figures 6 Through 13)

1. With the stroke adjusting knob at 100% and

the diaphragm fully forward as in steps 1 and 5 of

paragraph 4.4.2.1, screw the diaphragm assembly

into the connecting rod until it reaches its natural

mechanical stop.

2. Turn the motor fan by hand until the diaphragm

rests properly on the diaphragm support (230).

Reinstall the motor shroud if previously removed.

3. Fit the diaphragm head back into place on the

pump body.

19

Page 26

4. Torque the six diaphragm head bolts to the following inch pounds in a crisscross pattern:

diaphragm from the connecting rod (60), using a

30mm hex socket on diaphragm cap (240).

(1) Liquid End Size SG5 and SG6 metallic and

non-metallic head bolts to 90 inch pounds.

(2) Liquid End Size SG7 non-metallic head

bolts to 125 inch pounds.

(3) Liquid End Size SG7 metallic head bolts to

250 inch pounds.

4.4.3 Replacing Oil Seal

BEFORE BEGINNING OIL SEAL

REPLACEMENT, MAKE SURE THAT

ALL SHUT-OFF VALVES ARE CLOSED

AND ALL PRESSURE IS BLED FROM

THE LIQUID END. MAKE SURE POWER

TO PUMP IS TURNED OFF AND CANNOT BE ACTIVATED.

When replacing the oil seal, the diaphragm assembly must be removed first. For ease of service, it is

recommended that the oil seal be replaced in conjunction with the diaphragm assembly. Therefore,

the instructions below include the “Diaphragm

Replacement” instructions, and can be used for

both oil seal replacement and diaphragm replacement.

Disassembly (Refer to Figure 6 through 13).

1. Drain oil from the pump by unscrewing drain

plug and O-ring, located underneath capacity

adjustment knob (330).

7. Remove the diaphragm support ring (230).

8. Remove the retaining ring (220) from the connecting rod.

9. Slide the small oil seal clamp (210) off the

connecting rod.

10. Remove the large oil seal clamp (80) by

unscrewing the four slotted screws (90).

11. Pull the oil seal (70) off of the connecting rod.

Reassembly (Refer to Figure 6 through 13).

1. Install a new oil seal (70) onto the connecting

rod.

2. Slide small oil seal clamp (210) onto the end of

the connecting rod and secure in place with the

retaining ring (220). A drive socket large enough to

fit over the end of the connecting rod should be

used to push the retaining ring until it snaps into

place in the retaining ring groove in the connecting

rod.

3. Secure the large oil seal clamp (80) over the oil

seal with the four slotted screws (90).

4. Place the diaphragm support ring (230) into

position making sure beveled side (for diaphragm

support) is facing up (refer to Figure 6 through 13).

For SG7 liquid ends, the support ring (230) has

stepped diameters. Make sure that the larger

diameter is installed into the metal adapter ring

(225 Figure 12 and 13).

2. Set the capacity adjusting knob (330) to 100%.

3. Disconnect the suction and discharge piping.

4. Unscrew the six diaphragm head bolts.

5. Remove the diaphragm head assembly from

the pump body.

6. Turn the motor fan by hand (remove the

shroud if necessary) until the end of the diaphragm

assembly (240) is fully forward, and unscrew the

5. With the stroke adjusting knob at 100% and

the diaphragm fully forward as in steps 2 and 6 of

disassembly instructions, screw the diaphragm

assembly into the connecting rod until it reaches its

natural mechanical stop.

6. Turn the motor fan by hand until the diaphragm

rests properly on the diaphragm suppor t r ing ( 230 ).

Reinstall the motor shroud if previously removed.

With the stroke adjusting knob at 100% and the

diaphragm fully forward as in steps 2 an d 6 of disassembly instructions, screw the diaphragm

assembly into the connecting rod until it reaches its

natural mechanical stop.

20

Page 27

7. Fit the diaphragm head back into place on the

pump body.

8. Torque the six diaphragm head bolts to the following inch pounds in a crisscross pattern:

(1) Liquid End Size SG5 and SG6 metallic and

non-metallic head bolts to 90 inch pounds.

(2) Liquid End Size SG7 non-metallic head

bolts to 125 inch pounds.

(3) Liquid End Size SG7 metallic head bolts to

250 inch pounds.

4. Add oil to pump, following directions given in

“Initial Start-up” in Section 3.

21

Page 28

SECTION 5

TROUBLESHOOTING GUIDE

SYMPTOMS REMEDIES

Pump will not operate • Low process liquid level in the tank. Add liquid

• Worn or dirty check valves. Clean or replace.

• Blocked discharge line. Clear line.

• Frozen liquid. Thaw liquid throughout pumping system.

• Blown fuse. Replace fuse.

• Open thermal overload device in motor starter. Reset

device

• Broken wire. Locate and repair.

• Low voltage. Investigate and correct (wiring may be too

light).

• Pump not primed. Allow suction line and pump head to fill

with liquid before pumping against pressure. Refer to

“Filling Pumping System” in Section 3.

• Capacity adjustment set at zero. Readjust capacity.

Insufficient delivery • Incorrect capacity adjustment. Readjust capacity setting.

• Incorrect pump seed. Match live voltage and frequency to

pump motor data plate.

• Starved suction. Increase piping size or suction head.

• Leaky suction piping. Repair piping.

• High suction lift. Rearrange equipment to decrease lift.

• Liquid near boiling. Cool liquid or increase suction head.

• Leaky safety valve in discharge line. Repair or replace

safety valve.

• High liquid viscosity . Reduce viscosity (e.g., heat or dilute

liquid).

• Worn or dirty check valve seats. Clean or replace.

Erratic delivery • Leaky suction piping. Repair piping.

• Leaky safety valve. Repair or replace safety valve.

• Insufficient suction head. Raise suction tank level or pressurize tank.

• Liquid near boiling. Cool liquid or increase suction head.

• Worn or dirty check valves. Clean or replace.

• Clogged or dirty line strainer. Clean strainer.

Motor and pump body hot • Normal operating temperat ur e of both motor and pump

body is frequently uncomfortable to the touch. However,

neither should exceed 200°F (93°C).

• Power supply does not match electrical requirement of

motor. Insure proper matching of power supply and

motor.

• Pump is being operated at greater than rated performance. Reduce pressure or stroke speed. If this is not

practical, contact service facility.

• Pump improperly lubricated. Drain oil and refill with

proper amount of recommended lubricant.

22

Page 29

SYMPTOMS REMEDIES

Pump still pumps even at zero capacity setting

Gear noise • Excessive backlash. Consult service facility.

Loud knock with each stroke • Excessive gear set wear. Consult service facility.

Noisy operation in liquid end • Nosie in check valves. Ball chec ks mo ve up and do wn

• Improperly adjust micrometer knob. Readjust capacity

setting.

• Insufficient discharge pressure. Correct condition (e.g.,

install a back pressure valve).

• Worn bearings. Consult service facility.

• Wrong or insufficient lubricant. Replace or replenish lubricant.

• Worn bearings. Consult service facility.

with some force. A distinct “clicking” noise is normal,

especially in metal piping systems.

23

Page 30

SECTION 6

PARTS

6.1 GENERAL

This section gives information regarding replaceable components.

6.2 ILLUSTRATED PARTS LIST

1. Figure and Item Number Column

a) The item numbers shown in the detailed

parts list correspond to the item numbers

appearing on the exploded view illustration. To find an unknown part number,

locate the part on the illustration and note

the item number. Look for the item number

on the detailed parts list. The part number

is on the same line. A dash (-) precedes

non-illustrated item numbers.

2. Description Column

a) The name of the item is in the description

column.

3. Part Number Column

a) The supplier’s part number is listed in the

part number column.

4. Quantity Column

a) The numbers appearing in the quantity col-

umn are the total quantity of the listed part

required in its immediate assembly.

5. Reference Code Column

a) This column is used to denote assembly

and detail part variations among similar

components (models) covered by this publication. When the symbol “A1”, “B1”, “C1”,

etc. is entered in this column, the part is

used only in the model (liquid end and

material codes, see Figure 1 and pump

data plate) at which the symbol appears. If

the column is blank, the part is used in all

models.

24

Page 31

Figure 7 (Sheet 1 of 2). Series G Model G Drive Parts - Side View

25

Page 32

6.3 DRIVE, SIDE VIEW

FIGURE

NUMBER

7 40 Bearing Cup (Timken) 4090116050 1

ITEM

NUMBER

60 Connecting Rod S60654 1

70 Oil Seal, Buna N 60048 1

80 Oil Seal Clamp, Aluminum 60034 1

90 Slotted Pan Head Screw, M3x10,

304 SS

340 Bearing Cone (Timken) (See Note 1) 4090116040 1

342 Worm, 8:1 (See Note 1) S60198 1

342 Worm, 10:1 (See Note 1) S60195 1

342 Worm, 14:1 (See Note 1) S60828 1

342 Worm, 20:1 (See Note 1) S60196 1

342 Worm, 40:1 (See Note 1) S60197 1

- Worm Assembly (43 SPM, 56C, 40:1),

Gear S60011 (See Note 1)

- Worm Assembly (36 SPM, IEC 80

Frame, 40:1), Gear S60011 (See Note

1)

DESCRIPTION PART

NUMBER

60294 4

60397 1

60224 1

QTY REFERENCE

CODE

344 Spring Pin, 0.187 x 1-1/8 STL (See

346 Worm Shaft Coupling, 56C (See Note

346 Worm Shaft Coupling, IEC 71 (See

- Items not shown

- Worm Assembly (86 SPM, 56C, 20:1),

Gear S60009 (See Note 1)

- Worm Assembly (72 SPM, IEC 80

Frame, 20:1), Gear S60009 (See Note

1)

- Worm Assembly (173 SPM, 56C, 10:1),

Gear S60007 (See Note 1)

- Worm Assembly (144 SPM, IEC 80

Frame, 10:1), Gear S60007 (See Note

1)

- Worm Assembly (180 SPM, IEC 80

Frame, 8:1), Gear S60050 (See Note 1)

Note 1)

1)

Note 1)

60396 1

60223 1

60395 1

60222 1

60221 1

4010005101 1

60261 1

60260 1

26

Page 33

7 346 Worm Shaft Coupling, IEC 80 (See

Note 1)

360 Spring (56C) (See Note 2) 60264 1

360 Spring (IEC 80) (See Note 2) 60225 1

370 Vent with Dip Stick 70067 1

376 IEC 80 Motor Adapter Ring 60199 1

377 Hex Head Screw, M10 x 25MM Steel

(IEC 80 motor)

60194 1

4350001732 4

390 Motor (1 hp, 1 ph, 1800 rpm, 115/230,

60 hz, 56C)

390 Motor (1 hp, 3 ph, 1500 rpm, 220/380,

50 hz, 56C)

390 Motor ( 1hp, 3 ph, 1800 rpm, 230/460,

60 hz, 56C)

390 Motor (1 hp, 1750 rpm, 90 VDC, PM-

TEFC-56C)

390 Motor (1 hp, W/VAR SPD AC Drive) 60297 1

400 Hex Head Screw (3/8-16 x 1) (56C

motor)

400 Hex Head Screw (M10 x 25 mm) (IEC

80 motor)

410 Flat Washer (3/8) (56C motor) 4040009012 4

410 Flat Washer (M10) (IEC 80 motor) 4340005152 4

417 Caution, Motor Decal G 60148 1

450 Base 61266 1

460 Hex Head Screw (M8 x 35 mm) 4350035542 4

465 Spring Lock Washer (8 mm) 4340009002 4

470 Hex Nut (M8) 4350000042 4

4112008010 1

4112008315 1

4112008310 1

4112008610 1

4050018119 4

4350001732 4

- Items not shown

Note 1: Worm-Gear-Shaft Assembly includes gear (50) worm (342), spring pin (344), spring (360),

worm shaft coupling (346), and bearing cone (340). Gear (50) and worm (342) sold only as assembly

(343)

Note 2: Part number for 56C motor spring (60264) applies to two-piece worm assembly: worm and

motor coupling piece joined together by a spring pin (344). If worm is previous one-piece design (no

spring pin), the correct 56C motor spring part number is 60059.

27

Page 34

Figure 7 (Sheet 2 of 2). Series G Model G Basic Parts - Top View

28

Page 35

6.4 DRIVE, TOP VIEW

FIGURE

NUMBER

7 10 Drive Housing Assembly (Includes

ITEM

NUMBER

Items 30, 40, and 448))

10 Housing, Stroke Counting (Includes

Items 30, 40, and 448)

30 Thrust Bearing, Bronze 60014 1

50 Gear (36/43 SPM), 50 Hz/60 Hz (See

Note 1)

50 Gear (72/86 SPM), 50 Hz/60 Hz (See

Note 1)

50 Gear (103/123 SPM), 50 Hz/60 Hz (See

Note 1)

50 Gear (144/173 SPM), 50 Hz/60 Hz (See

Note 1)

50 Gear (180 SPM), 50 Hz (See Note 1) S60050 1

100 Sliding Crank 60002 1

101 Spring Pin, 0.125 x 1/2 4010003031 1

110 Eccentric, Steel 60003 1

110 Eccentric, Stroke Counting 60875 1

DESCRIPTION PART

NUMBER

60001 1

60877 1

S60011 1

S60009 1

S60829 1

S60007 1

QTY REFERENCE

CODE

120 Shoe 60052 1

140 Single Row Bearing 4099994000 1

150 Truarc Retaining Ring 4040107231 1

160 Parker O-ring, Buna N 4080095171 1

170 Stroke Adjustment Screw Asse mbly 60950 1

171 Stroke Screw, Part of Item 170 H60768 1

172 Bearing Retainer, Part of Item 170 H60757 1

174 Socket Head Screw M4 x 8MM, part of

175 Stroke Scale 2530046062 1

185 Dowel Pin 1/8 x 1-3/8, Part of Item 170 4010021143 1

190 Parker O-ring (2-246), Buna N 4080095371 1

200 Cover H60767 1

205 Hex Head Screw (M8 x 16 mm) 4350001622 4

210 Oil Seal Clamp, Aluminum 60043 1

220 Truarc Retaining Ring 4040133060 1

- Items not shown.

41663 4

item 170

29

Page 36

7 - M12 Lockwasher, 18-8 SS 4340009095 6

- M12 Hex Nut, 304 SS 4350000085 6

310 Ball 5/16, Nylon 60152 1

320 Stroke Locking Knob 60398 1

322 O-Ring, 2-012 Bunan N 4080109091 1

330 Stroke Adjustment Knob 70066 1

331 Flat Washer 1/4”, 18.8 SS 4040005012 1

332 Pan Head Screw #8 x 1-1/2”, 18.8 SS 40722 1

335 Logo Decal (Stroke Knob) 70022 1

448 Tubing Connector (1/4” OD x 1/4” ID) 4020479028 1

- Gear Oil (AGMA 5 EP, ZURN EP95) - 1

Quart Can

- Items not shown.

Note 1: Worm-Gear-Shaft Assembly includes gear (50) worm (342), spring pin (344), spring (360),

worm shaft coupling (346), and bearing cone (340). Gear (50) and worm (342) sold only as assembly

(343)

Note 2: Part number for 56C motor spring (60264) applies to two-piece worm assembly: worm and

motor coupling piece joined together by a spring pin (344). If worm is previous one-piece design (no

spring pin), the correct 56C motor spring part number is 60059.

4070152010 3

30

Page 37

Figure 8. SG5 Plastic Liquid End

31

Page 38

6.5 SG5 PLASTIC LIQUID END

Model:

Liquid End: Material: Reference Code:

SG5_ _ _ _ _ _8_ _ _ _ _ _ A (PVC)

SG5_ _ _ _ _ _1_ _ _ _ _ _ B (POLY)

SG5_ _ _ _ _ _2_ _ _ _ _ _ C (PVDF)

Model:

Liquid End: Material: ReferenceCode:

SG5_ _ _ _ _ _ P_ _ _ _ _ E (POLYMER)

SG5_ _ _ _ _ _ L_ _ _ _ _ F (SLURRY)

SG5_ _ _ _ _ _ N_ _ _ _ _G (H

2SO4

)

FIGURE

NUMBER

ITEM

NUMBER

DESCRIPTION PART

NUMBER

8 230 Diaphragm Support Ring 60035 1

240 Diaphragm Cap, Part of Item 261 60628 1 A, E, F, G

240 Diaphragm Cap, Part of Item 261 60629 1 B

240 Diaphragm Cap, Part of Item 261 60630 1 C

250 Set Screw, Dog Pt., M10 x 45 mm, Sin-

4350071284 1 A, B, C, E

gle Diaphragm, Part of Item 261

260 Diaphragm, Part of Item 261 60618 1

261 Diaphragm Assy , (Replaceable Design ,

60150 1 A, E, F, G

Consists of Items 240, 250, 260, and

270), See Note 1

261 Diaphragm Assembly, (Replaceable

3050976110 1 B

Design, Consists of Items 240, 250,

260, and 270), See Note 1

261 Diaphragm Assy , (Replaceable Design ,

3050976130 1 C

Consists of Items 240, 250, 260, and

270), See Note 1

270 Diaphragm Support Nut, Part of Item

60632 1

261

280 Diaphragm Head, PVC 60033 1 A, E, F, G

QTY REFERENCE

CODE

280 Diaphragm Head, PP 60032 1 B

280 Diaphragm Head, PVDF 60031 1 C

290 Hex Head Screw, M8 x 90, Single Dia-

4350035655 6 A, B, C

phragm

290 Hex Head Screw, M8 x 110, Double

4350001655 6 A, B, C

Diaphragm

300 Flat Washer (M8) 4340005085 6

300 Back-up Plate SG5/SG6 60754 1 B

Note 1: Diaphragm Assembly (261) can be purchased assembled or items 240, 250, 260, and 270

can be purchased separately.

32

Page 39

Figure 9. SG5 Metallic Liquid End

33

Page 40

6.6 SG5 METALLIC LIQUID END - STAINLESS STEEL- NPT

Model:

Liquid End: Material:

SG5_ _ _ _ _ _7_ _ _ _ _ _

FIGURE

NUMBER

9 230 Diaphragm Support Ring 60035 1

ITEM

NUMBER

240 Diaphragm Cap, Part of Item 261 60631 1

250 Set Screw, Dog Pt., M10 x 45 mm, Sin-

gle Diaphragm, Part of Item 261

260 Diaphragm, Part of Item 261 60618 1

261 Diaphragm Assy , (Replaceable Design ,

Consists of Items 240, 250, 260, and

270), See Note 1

270 Diaphragm Support Nut, Part of Item

261

280 Diaphragm Head 210760016 1

290 Hex Head Screw, M8 x 90, Single Dia-

phragm

300 Flat Washer (M8) 4340005085 6

DESCRIPTION PART

NUMBER

4350071284 1

3050976120 1

60632 1

4350035655 6

QTY REFERENCE

CODE

Note 1: Diaphragm Assembly (261) can be purchased assembled or items 240, 250, 260, and 270

can be purchased separately.

34

Page 41

Figure 10. SG6 Plastic Liquid End

35

Page 42

6.7 SG6 PLASTIC LIQUID END

Model:

Liquid End: Material: ReferenceCode:

SG6_ _ _ _ _ _8_ _ _ _ _ _ A (PVC)

SG6_ _ _ _ _ _1_ _ _ _ _ _ B (POLY)

SG6_ _ _ _ _ _2_ _ _ _ _ _ C (PVDF)

Model:

Liquid End: Material: ReferenceCode:

SG6_ _ _ _ _ _ P_ _ _ _ _ E (POLYMER)

SG6_ _ _ _ _ _ L_ _ _ _ _ F (SLURRY)

SG6_ _ _ _ _ _ N_ _ _ _ _G (H

2SO4

)

FIGURE

NUMBER

ITEM