Page 1

Instruction Manual

®

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

Series A

Electronic Metering Pumps

For le reference, please record the following data:

Model No: _____________________________________

Serial No: _____________________________________

Installation Date: ________________________________

Installation Location: _____________________________

When ordering replacement parts for your LMI Metering Pump

or Accessory, please include complete Model Number and

Serial Number of your unit.

Carefully read and understand all precautions before

installing or servicing any metering pump.

201 Ivyland Rd.

Ivyland, PA 18974

TEL: (215) 293-0401

FAX: (215) 293-0445

www.lmipumps.com

Lit# 2002.A 2/2010

Page 2

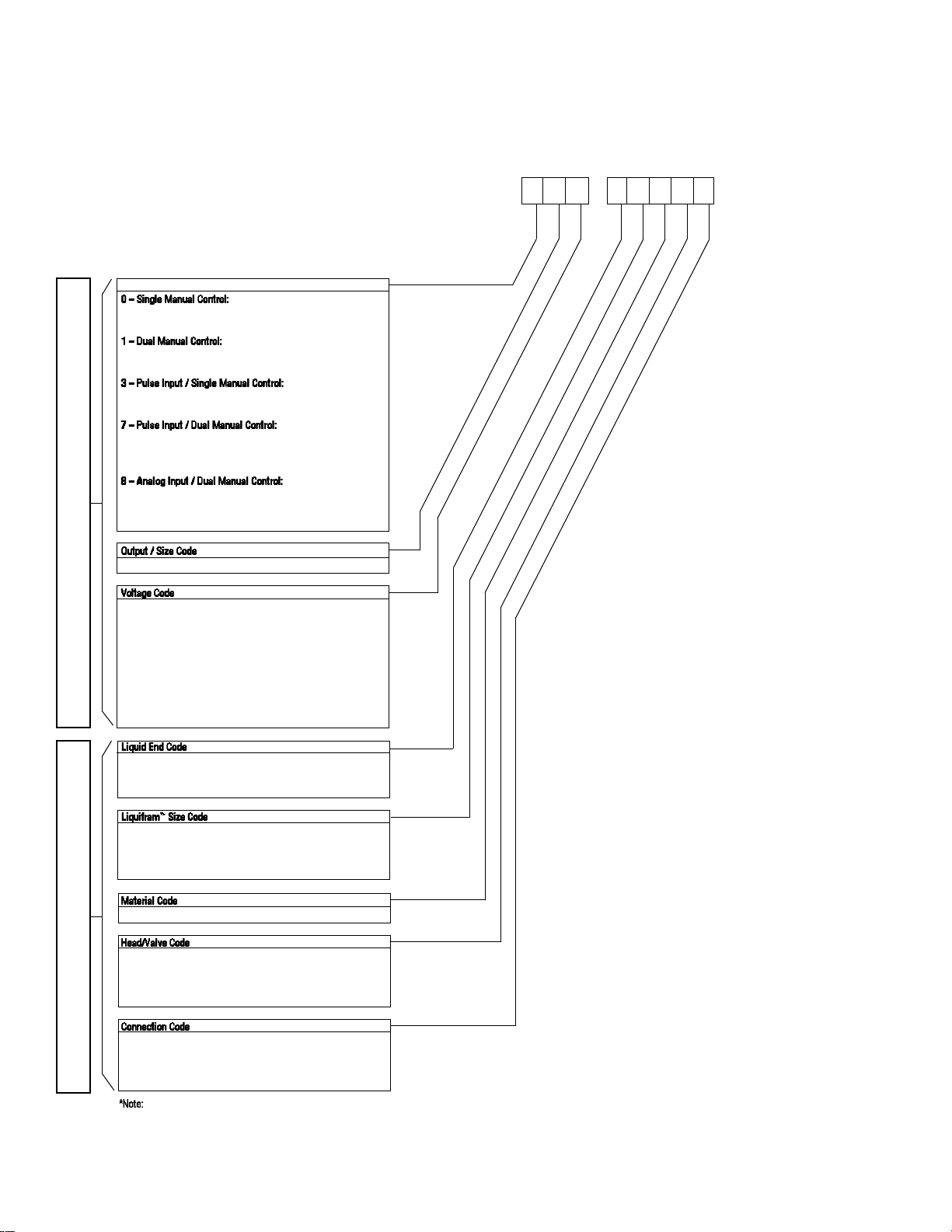

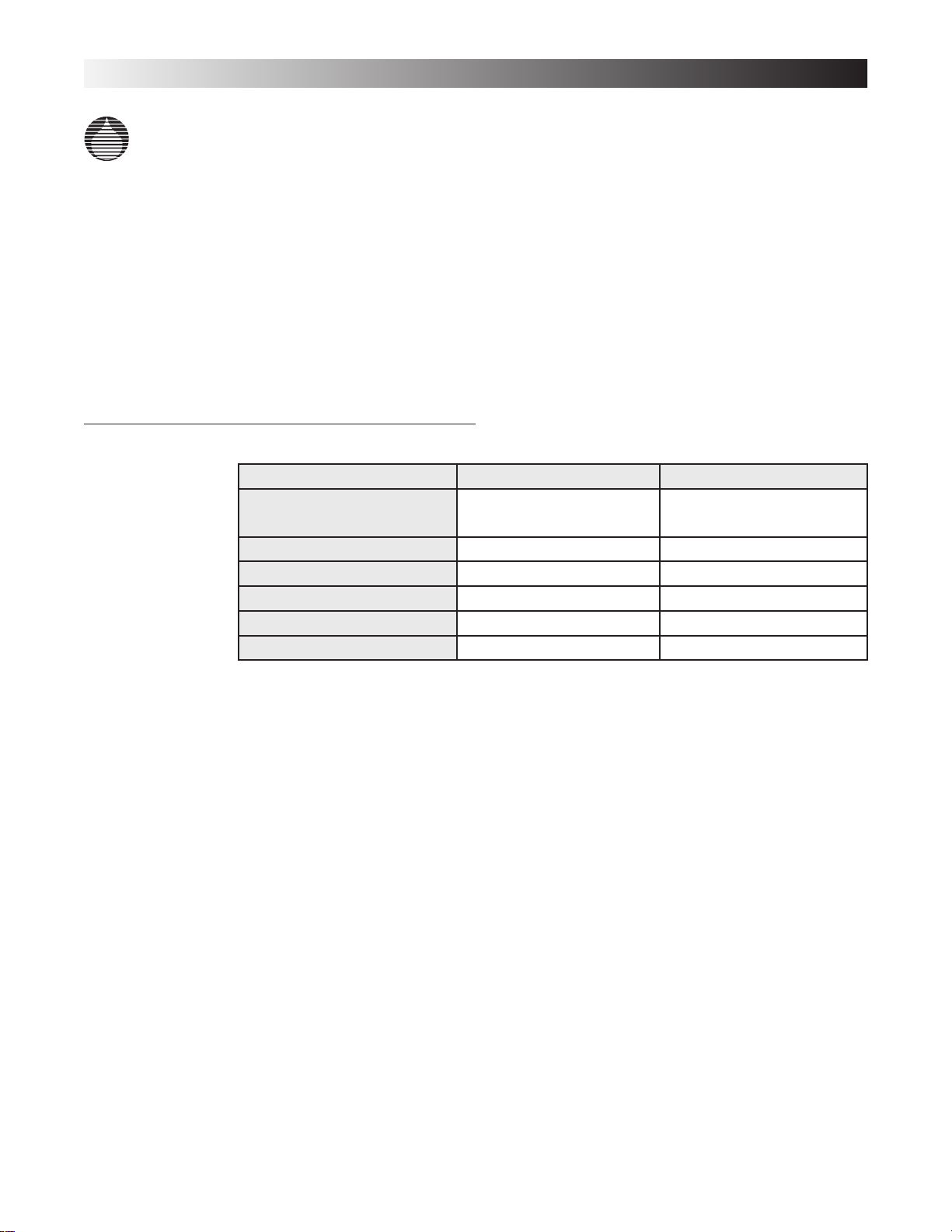

Liquid End

Control Code

Speed (stroking frequency) fixed and stroke length manually

adjustable

Speed (stroking frequency) and stroke length manually

adjustable

External control capability through pulse input and low level float

switch plus manual control adjustments of control code 0

External control capability through pulse input and low

level float switch plus manual control adjustments of control

code 1

External control capability through 4-20 mA input and

low level float switch plus manual control adjustments of

control code 1

See Most Recent Price List for Flow and Pressure Ratings

1 – 110-120V US Plug

2 – 220-240V US Plug

3 – 220-240V DIN Plug

4 – 220-240V Israel Plug

5 – 220-240V UK Plug

6 – 220-240V Aust/NZ Plug

7 – 220-240V Swiss Plug

8 – 110-120V No Plug

9 – 220-240V Indian Plug

7 – Molded Head, Single Ball Check Valves

8 – Molded Head, Double Ball Check Valves

9 – Machined Head, Double Ball Check Valves

1 – 0.2 in

2

2 – 0.4 in

2

3 – 0.8 in

2

4 – 1.6 in

2

See Most Recent Price List for Material Options

S – FastPrime™Head + 4FV

N – FastPrime

™

Head

H – AutoPrime

™

Head + 4FV

A – AutoPrime

™

Head

I – Inch Tubing

M – Metric Tubing

P – 1⁄2” NPT - 1⁄2” BSP Pipe

U – Black, UV Resistant Tubing

Model A 7 5 1 - 8 2 8 S I

Model Code Configuration

Series A

Drive

Not all configurations are available. Please see your local

distributor or price list for available options.

(SS Head only)

®

Page 3

Contents

1.0 Precautions ................................................................ 4

2.0 Introduction ................................................................. 6

2.1 Specications ........................................................ 6

2

.2 Unpacking Check List ................................................. 7

3

.0 Installation.................................................................. 8

3

.1 Pump Location and Installation........................................... 8

3.2 Pump Mounting....................................................... 8

3

.2.1 Flooded Suction ...................................................... 8

3

.2.2 Suction Lift - Wall Bracket Mount ..........................................9

3

.2.3 Suction Lift - Tank Mount.................................................9

3

.2.4 Suction Lift - Shelf Mount ................................................9

3

.3 Tubing Connections....................................................10

3

.4 Four-Function Valves (4-FV) .............................................11

3

.5 Four-Function Valve Installation...........................................12

3

.6 FastPrime™ .........................................................12

3

.7 AutoPrime™ .........................................................13

3

.8 Foot Valve/Suction Tubing Installation......................................14

3

.9 Injection Check Valve and Discharge Tubing Installation .......................15

4

.0 Operation ..................................................................16

4.

1 Output Adjustment Controls .............................................16

4.

2 Start-up and Adjustment ................................................17

4.2.1 Start-Up/Priming for FastPrime™ Heads ....................................17

4.

2.2 Start-Up/Priming for Pump Supplied with 4-FV...............................18

4.

2.3 Start-Up/Priming Without 4-FV ...........................................18

4.

3 Output Adjustment ....................................................18

4.

3.1 Total Pump Output ....................................................19

4.

3.2 Calibration in Internal Mode .............................................19

4.

3.3 Calibration in External Mode.............................................20

4.

4 Methods of Externally Triggering or Pacing A3, A7, and A8 Pumps................21

4.4.1 Control Modes........................................................22

4.4.1.1 Local Mode ..........................................................22

4.4.1.2 Remote Mode (for A3, and A7) ...........................................22

4.4.1.3 Remote Mode (for A8)..................................................22

4.4.1.4 Calibrating the Analog Input Settings (for A8) ................................23

5.

0 Spare Parts Replacement and Routine Maintenance.................................24

5.

1 Depressurizing the Discharge Line (for Pumps Equipped with a 4-FV Only) ........24

5.

2 Depressurizing The Discharge Line (for Single Ball FastPrime™ Heads Only) .......24

5.

3 Liquifram™ (Diaphragm) Replacement .....................................25

5.

4 Cartridge Valve and O-Ring Replacement ..................................26

5.

5 Injection Check Valve Parts Replacement...................................27

5.

6 FastPrime™ Valve O-Ring Replacement ....................................28

5.7

Stroke Length Setting ..................................................30

5.8

A Drive Parts List .....................................................31

5.9

EPU Wiring Diagram ...................................................32

5.10

Liquid End Parts List ...................................................32

6

.0 Troubleshooting..............................................................37

3

Page 4

PRECAUTIONS

1.0 PRECAUTIONS

The following precautions should be taken when working with LMI metering pumps.

Please read this section carefully prior to installation.

Protective Clothing

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working

on or near your metering pump. Additional precautions should be taken depending on

the solution being pumped. Refer to MSDS precautions from your solution supplier.

Water Pre-Prime

All LMI pumps are pre-primed with water when shipped from the factory. If your solution is not compatible with water, disassemble the Pump Head Assembly. Thoroughly

dry the pump head, valves, seal rings, balls and Liquifram

head assembly tightening screws in a crisscross pattern. Rell the pump head with the

solution to be pumped before priming the pump. (This will aid in priming.)

Liquid Compatibility

CAUTION: The evaluation performed by UL was tested with water only. LMI pumps

are tested by NSF for use on muriatic acid and sodium hypochlorite. Determine if the

materials of construction included in the liquid handling portion of your pump are adequate for the solution (chemical) to be pumped. Always refer to the solution supplier

and the LMI Chemical Resistance Chart for compatibility of your specic LMI metering

pump. Contact your local LMI distributor for further information.

™

(diaphragm). Reassemble

Tubing Connections

Inlet and outlet tubing or pipe sizes must not be reduced. Outlet tubing size must not be

increased. Make certain that all tubing is SECURELY ATTACHED to ttings prior to

start-up (see Section 3.3, Tubing Connections). ALWAYS use LMI supplied tubing with

your pump, as the tubing is specically designed for use with the pump ttings. It is recommended that all tubing be shielded and secure to prevent possible injury in case of

rupture or accidental damage. If tubing is exposed to sunlight, black UV resistant tubing

should be installed. Check tubing frequently for cracks and replace as necessary.

Vinyl Tubing

Your carton may contain a roll of clear vinyl tubing; this is only for connection to the

return line of the FastPrime

Fittings and Machine Threads

All ttings should be hand-tightened. An additional 1/8 - 1/4 turn after the tting is snug

may be necessary to provide a leak-proof seal. Excessive overtightening or use of a pipe

wrench can cause damage to the ttings, seals, or pump head.

All LMI pumps have straight screw machine threads on the head and ttings and are

sealed by the O-rings. DO NOT use Teon

may only be used on the 1/2" NPT thread side of the Injection Check Valve, the stainless

steel liquid end connections, or if piping is directly connected to the pipe threads of the suction or discharge ttings.

4

™

Head and must not be used as discharge tubing.

®

tape or pipe dope to seal threads. Teon® Tape

Page 5

Plumbing

Always adhere to your local plumbing codes and requirements. Be sure installation does

not constitute a cross connection. Check local plumbing codes for guidelines. LMI is not

responsible for improper installations.

Back Pressure/Anti-Syphon Valve

If you are pumping downhill or into low or no system pressure, a back pressure/antisyphon device such as LMI’s Four-Function Valve should be installed to prevent overpumping or syphoning. Contact your LMI distributor for furthur information.

Electrical Connections

WARNING: To reduce the risk of electrical shock, the metering pump must be plugged

into a properly grounded grounding-type receptacle with ratings conforming to the data

on the pump control panel. The pump must be connected to a good ground. Do not use

adapters! All wiring must conform to local electrical codes. If the supply cord is damaged,

it must be replaced by the manufacturer, stocking distributor, or authorized repair center

in order to avoid a hazard.

PRECAUTIONS

Ground Fault Circuit Interrupter

WARNING: To reduce the risk of electric shock, install only on a circuit protected by a

Ground Fault Circuit Interrupter (GFCI).

Line Depressurization

To reduce the risk of chemical splash during disassembly or maintenance, all installations

should be equipped with line depressurization capability. Using LMI’s Four-Function

Valve (4-FV) is one way to include this feature.

Over Pressure Protection

To ensure safe operation of the pump it is recommended that some type of safety/pressurerelief valve be installed to protect the piping and other system components from failing

due to excessive pressure.

Chemical Concentration

There is a potential for elevated chemical concentration during periods of no ow, for

example, during backwash in the system. Steps, such as turning the pump off, should be

taken during operation or installation to prevent this.

See your distributor about other external control options to help mitigate this risk.

Retightening Components

Plastic materials will typically exhibit creep characteristics when under pressure over a

period of time and to insure a proper t it may be necessary to retighten the head bolts

periodically. To insure proper operation, we recommend tightening the bolts to 25 inchpounds after the rst week of operation and on a monthly basis thereafter.

5

Page 6

INTRODUCTION

2.0 Introduction

LMI is the world’s most versatile manufacturer of economical and efcient metering

pumps. This manual addresses the installation, maintenance and troubleshooting procedures for manually and externally controlled pumps. LMI has a worldwide network of

stocking representatives and authorized repair centers to give you prompt and efcient

service.

Please review this manual carefully. Pay particular attention to warnings and precautions.

Always follow good safety procedures, including the use of proper clothing, eye and face

protection.

This manual is for Roytronic

2.1 Specications

Operating

Temperature

Voltage 110 to 120 V 220 to 240 V

Frequency 50 to 60 Hz 50 to 60 Hz

Max. Current 0.66 A 0.34 A

Wattage 39 W 42 W

Fuse Specication 1.25 AHT (5 x 20 mm) 1.25 AHT (5 x 20 mm)

®

Series A pumps.

AXX1, AXX8 AXX2-AXX7, AXX9

14 to 113°F

–10 to 45°C

14 to 113°F

–10 to 45°C

6

Page 7

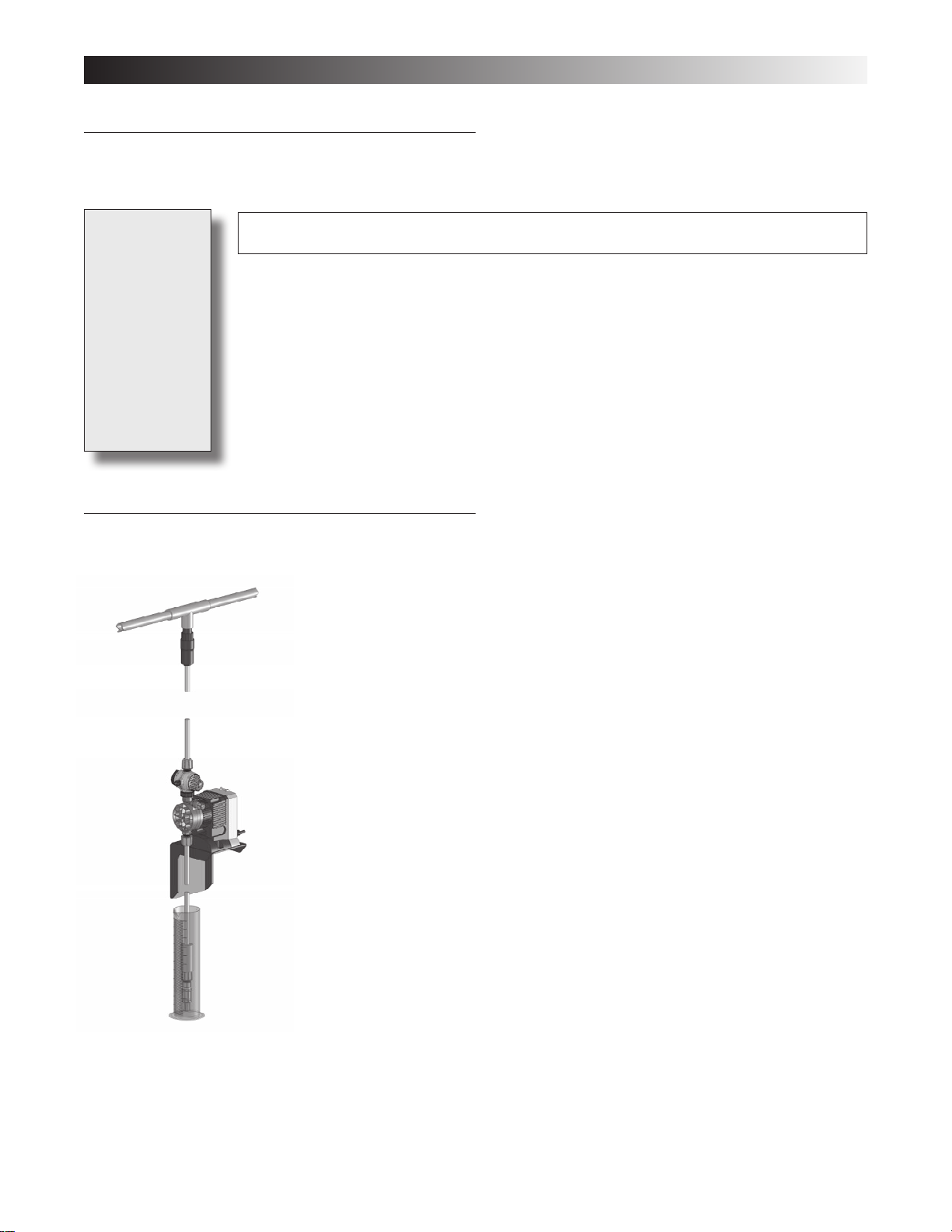

2.2 Unpacking Check List

Your carton will contain many or all of the following items. Please notify the carrier

immediately if there are any signs of damage to the pump or its parts.

UNPACKING CHECK LIST

Metering Pump

Ceramic Foot Valve

Weight

Foot Valve

Injection Check

Valve

Tubing (0 to 3 Rolls)

Four-Function Valve

(Optional)

Low-Level Sensor

(Optional)

External Control

Cable (Optional)

Tube Connection

Hardware

7

Page 8

INSTALLATION

3.0 Installation

3.1 Pump Location and Installation

Locate pump in an area convenient to solution tank and electrical supply.

The pump should be accessible for routine maintenance, and should not be operated in

ambient temperatures above 113°F (45°C). If the pump will be exposed to direct sunlight,

LMI black, UV resistant tubing should be installed.

This pump is cord connected and not intended for permanent mounting to a building.

However, temporary mounting to stabilize the pump during operation may be necessary

as long as tools are not required for the installation or removal of the pump.

3.2 Pump Mounting

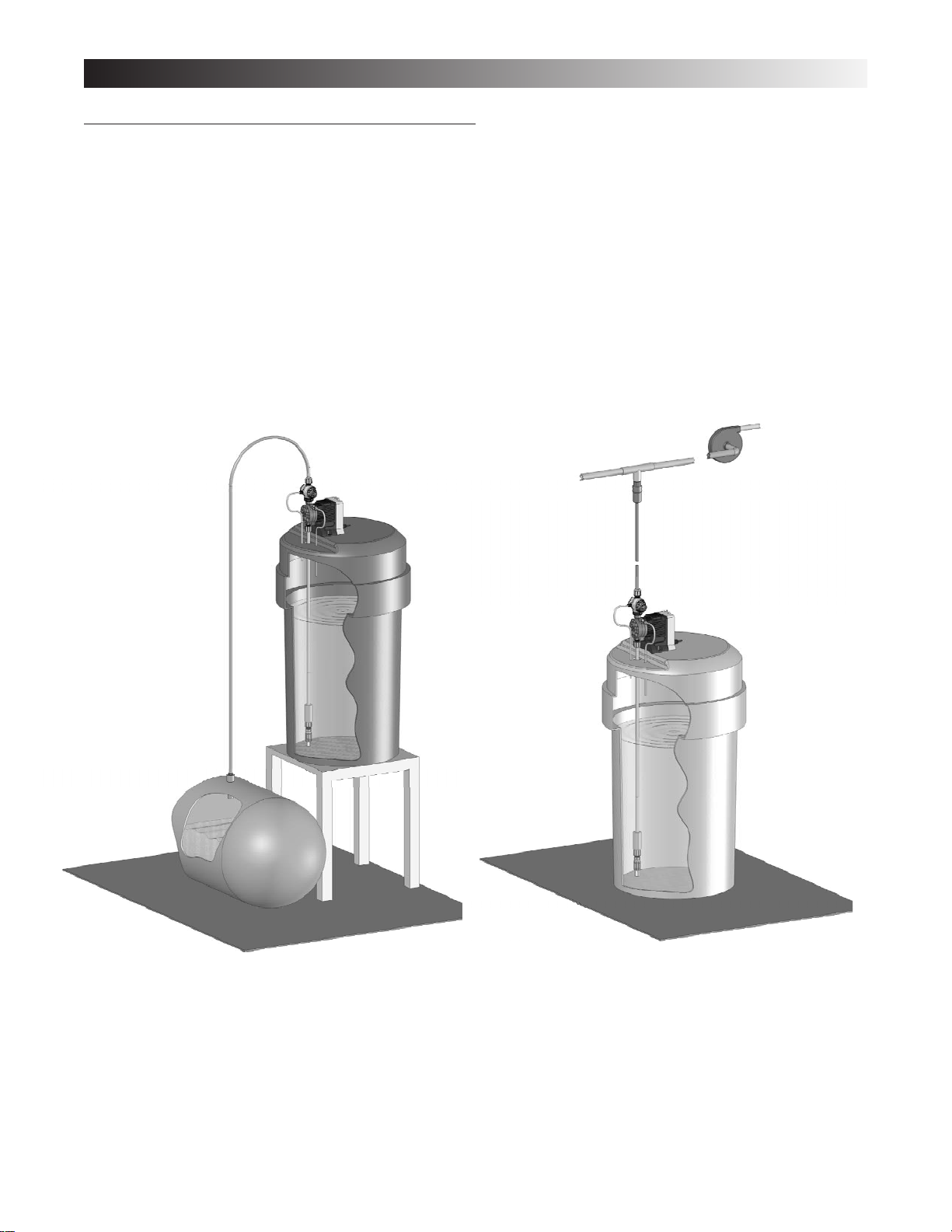

The pump can be mounted in one of two ways:

A. FLOODED SUCTION (ideal installation); or

SUCTION LIFT - when suction lift is less than 5 feet (1.5 m) for solutions having a

B.

specic gravity of water or viscosity of less than 100 cSt (centistokes). For denser or

more viscous solutions, consult distributor.

Note that suction conditions can affect the performance of the pump. This effect is

more pronounced with lower pressure pumps. Consult your distributor for additional

information.

Your LMI metering pump must be mounted so that the suction and discharge valves

are vertical. NEVER position pump head and ttings horizontally.

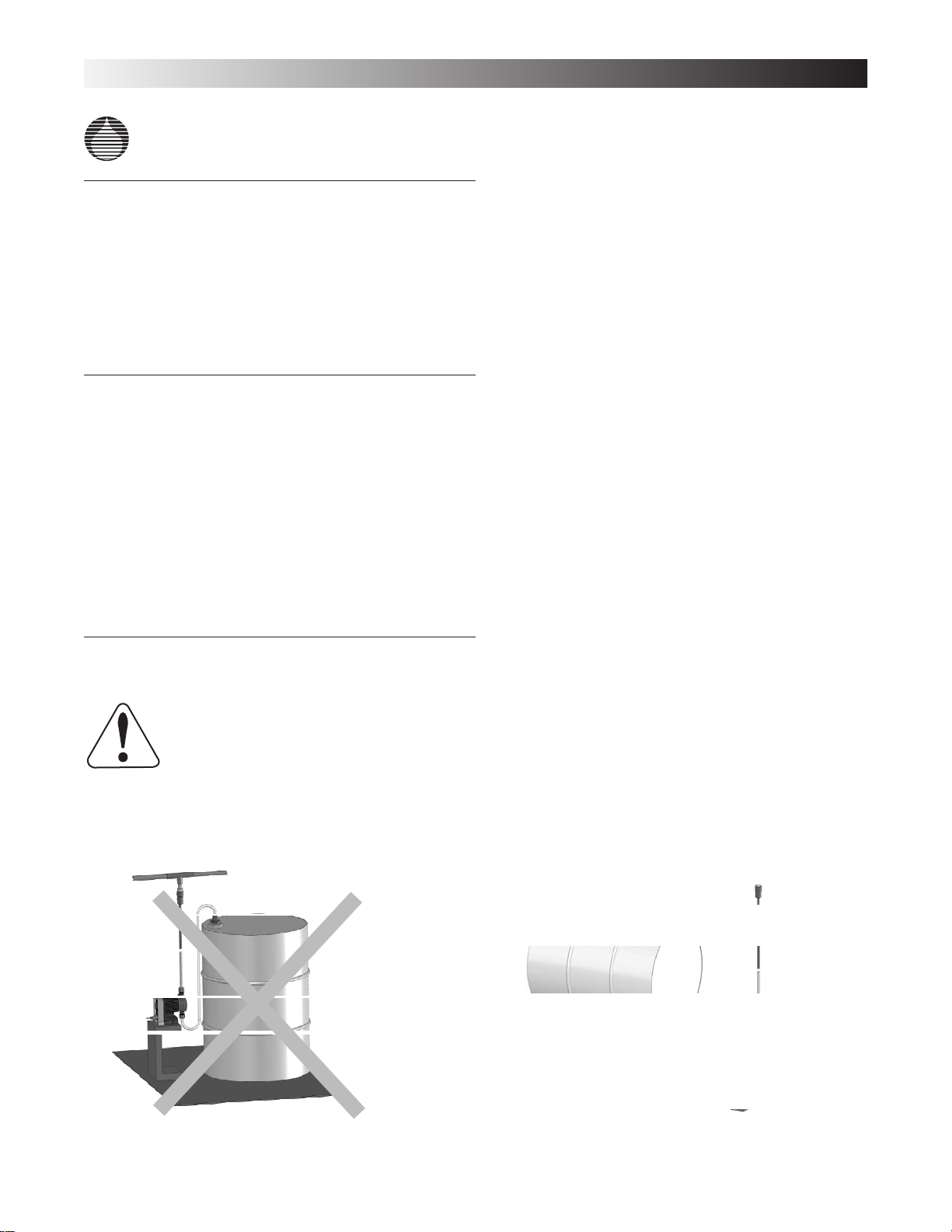

3.2.1 Flooded Suction

For ooded suction the pump is mounted at the base of the storage tank. This installation

is the most trouble-free, and is recommended for very low outputs, solutions that gasify,

and high-viscosity solutions. Since the suction tubing is lled with solution, priming is

accomplished quickly and the chance of losing prime is reduced. A foot valve is not

necessary in a ooded suction installation.

When pumping downhill or into low or no pressure system, a back pressure/anti-syphon

device should be installed to prevent overpumping or syphoning.

Although popular for all solutions, LMI recommends ooded suction installations for

all high-viscosity uid applications.

INCORRECT

Avoid this type of false ooded suction.

8

CORRECT

Page 9

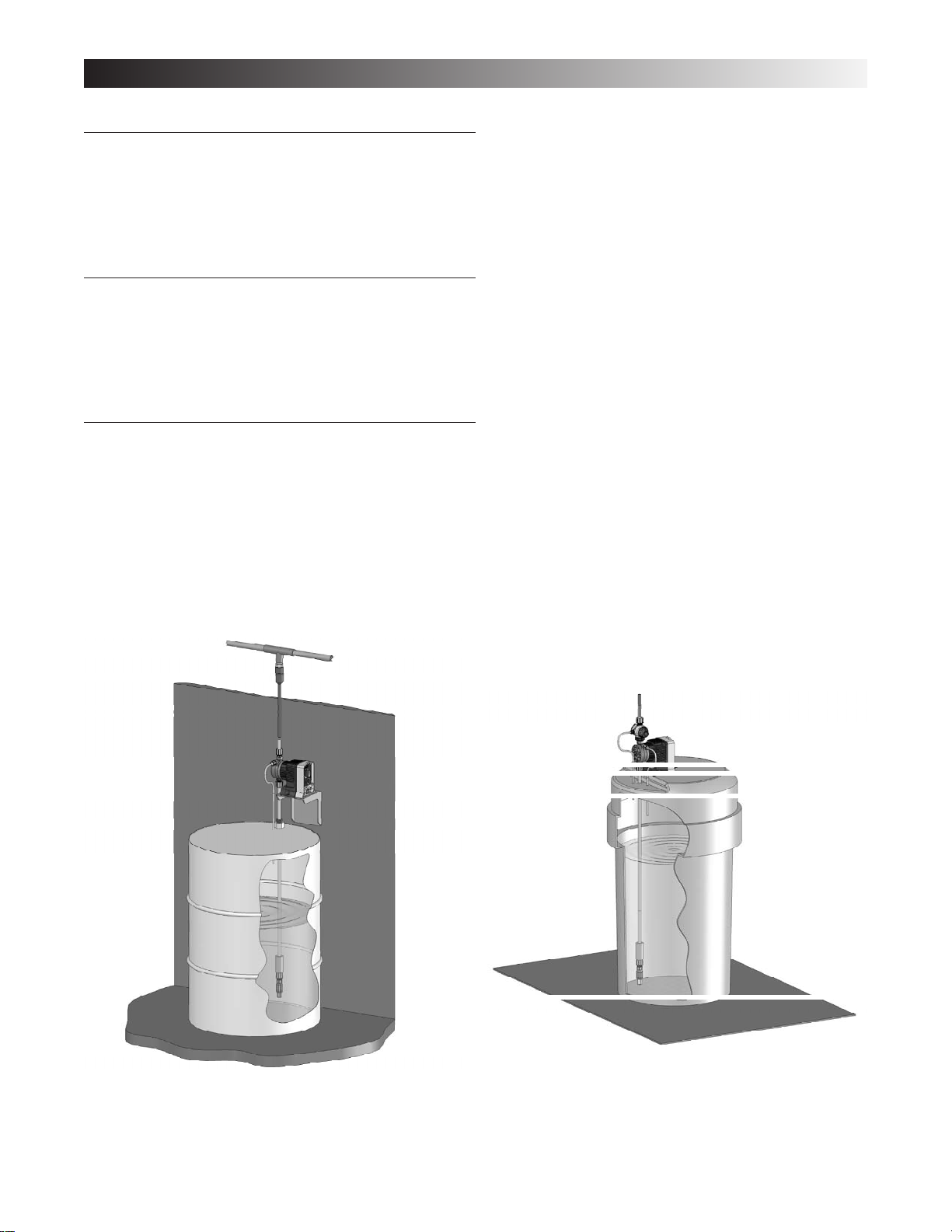

3.2.2 Suction Lift - Wall Bracket Mount

The pump may be mounted using an LMI Wall Mount Bracket Assembly (part no. 34643)

directly above the solution tank. A pump mounted in this manner allows for easy changing of solution tanks or drums.

3.2.3 Suction Lift - Tank Mount

The pump may be mounted on a molded tank provided there is a recess to keep the pump

stationary. LMI 10-gallon tank (part no. 27421), 35-gallon tank (part no. 27400), and

50-gallon tank (part no. 26350) have molded recesses for pump mounting.

3.2.4 Suction Lift - Shelf Mount

The pump may be mounted on a shelf (customer supplied) maintaining a suction lift of

less than 5 ft (1.5 m). An LMI mounting kit (part number 10461) is available for securing

the pump to a shelf.

INSTALLATION

9

Page 10

INSTALLATION

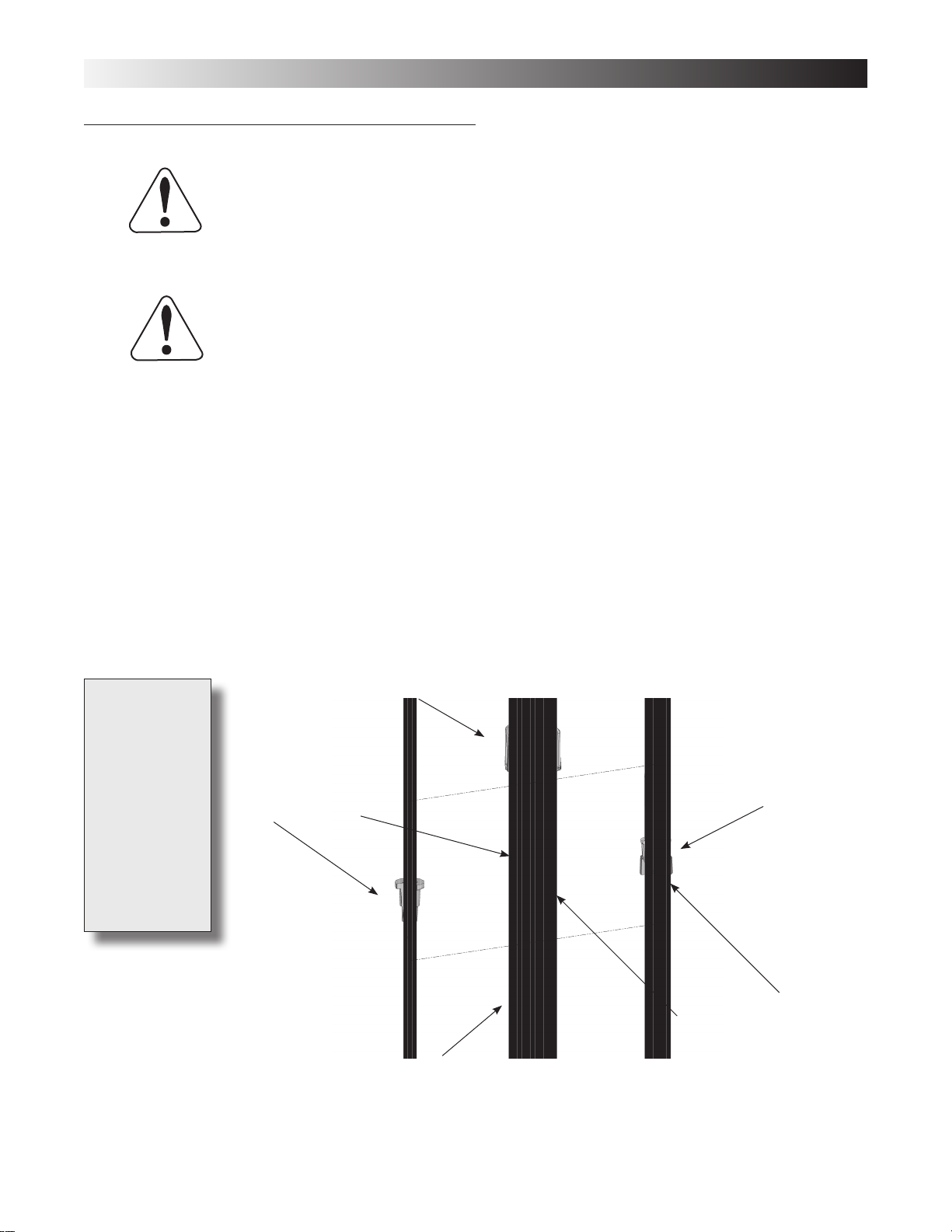

3.3 Tubing Connections

Use only LMI tubing.

DO NOT USE CLEAR VINYL TUBING ON THE DISCHARGE SIDE OF THE

PUMP. The pressure created by the pump can rupture vinyl tubing, which is only for

connection to the return line of the FastPrime

Before installation, all tubing must be cut with a clean square end.

Valve and head connections from the factory are capped or plugged to retain pre-prime

water. Remove and discard these caps or plugs before connecting tubing.

DO NOT USE PLIERS OR PIPE WRENCH ON COUPLING NUTS OR FITTINGS.

To assemble tubing into the ttings:

1. Put coupling nut over tubing.

2. Press on Ferrule – Female about one inch (25 mm).

3. For 1⁄4" or 6mm OD tubing cut tubing so that only 1⁄4" to 3⁄8" (5-10 mm) protrudes

from the Ferrule. For all other tubing push the tube to the bottom of the groove in the

Ferrule – Male.

™

tting.

Replacement

Ferrules, and

Coupling Nuts

are available as

the following kit

numbers:

¼” Tube – 77382

3

8

⁄

” Tube – 77383

½” Tube – 77384

One kit is needed

for each end of

the tube.

4. Firmly hand tighten the coupling nut onto the tting. Tightening with pliers may cause

the ferrules to break.

Coupling Nut

Ferrule - Female

Ferrule - Female

" Tubing

4

⁄

1

" Tubing

8

⁄

3

" Tubing

2

⁄

1

Ferrule - Male

10

Fitting

Page 11

3.4 Four-Function Valves (4-FV)

Your pump may be equipped with a 4-FV, or standard discharge valve. If your pump is

not equipped with a four-function valve and you feel it is needed in your application, it

can be purchased as an accessory. Contact your local LMI stocking distributor. The

features of a 4-FV are listed below.

1. Pressure Relief: If the discharge line is over pressurized, the valve opens sending solution back to the supply tank.

2. Line Depressurization: Opening the relief knob provides line drain back to the supply

tank.

3. Anti-Syphon: Prevents syphoning when pumping solution downhill or into a vacuum.

4. Back Pressure: Supplies approximately 25 psi back pressure to prevent overpumping

when little or no system back pressure is present.

INSTALLATION

4-FV prevents syphoning when

pumping downhill into

low or no pressure.

Typical Installations Requiring the Anti-Syphon

4-FV prevents syphoning when

pumping into a vacuum such as the

suction side of a recirculating pump.

Feature of a Four-Function Valve

11

Page 12

INSTALLATION

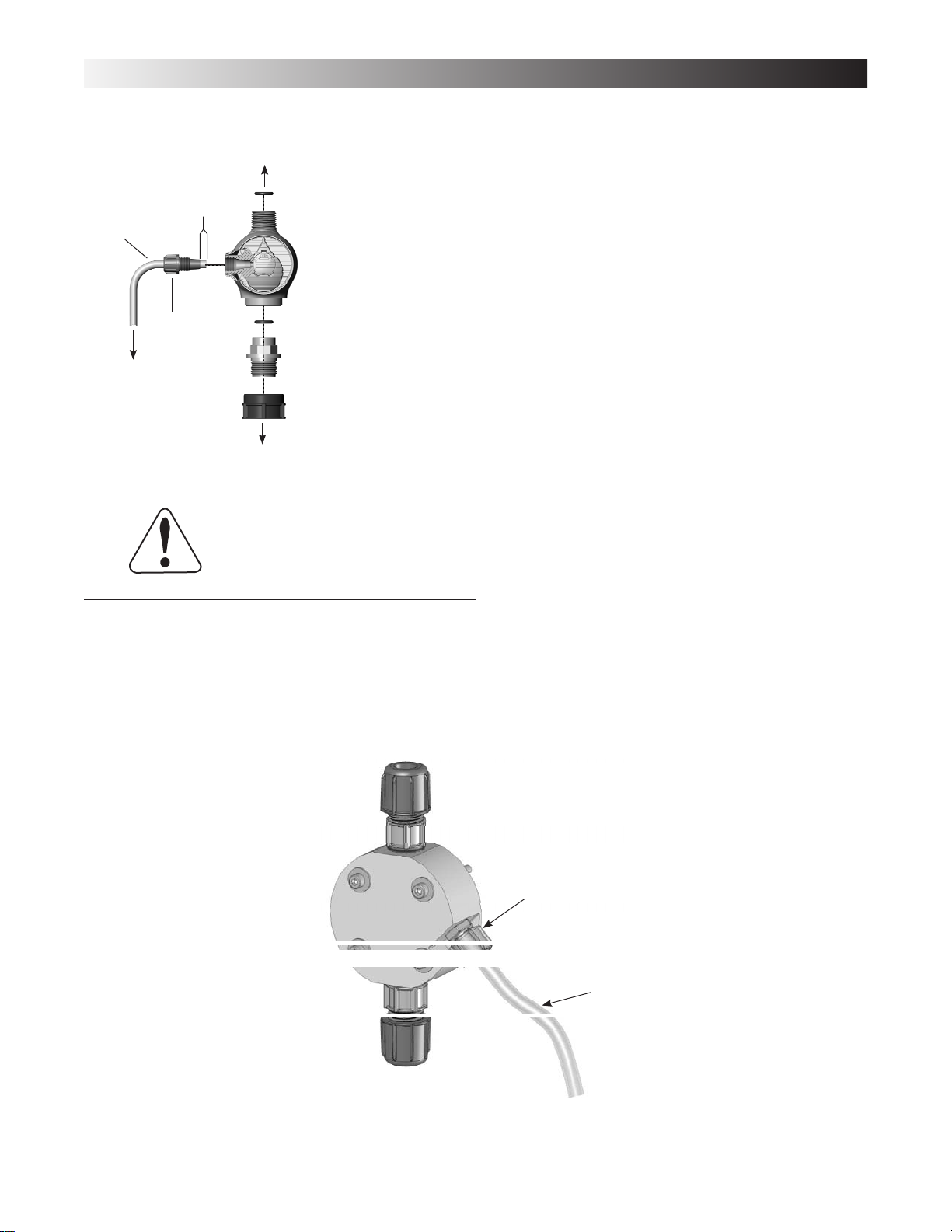

3.5 Four-Function Valve Installation

Discharge

1/4"

Through

1/4" Tubing

Four-Function

Bleed Nut

4-FV Fitting

To Solution

Tank or Drum

Coupling Nut

To Pump Head

Four-Function Valve Tubing Connection

This return line tubing must be secured to ensure pumped solution will safely return to supply

tank.

3.6 FastPrime™

Valve Body

To install a 4-FV, the 4-FV Fitting and Coupling Nut should be

assembled with the appropriate cartridges into the discharge port

of the pump. Use a 13/16” or 20 mm socket to tighten tting. Tightening to 50 inch-pounds is recommended. Do not over tighten.

To assemble the Four-Function Valve Body, assemble the coupling

nut and the threads at the bottom of the body. Firmly hand tighten

the body in the desired orientation. Next, insert the ¼” tubing

through the Bleed Nut. Ensure that about ¼” (6 mm) of tubing is

protruding through the tip of the Bleed Nut. Firmly hand tighten

the Bleed Nut in the hole on the side of the 4-FV. This tubing should

be routed back to the supply tank. To ensure proper function of the

priming function, the end of this tubing should not be submerged

in the solution..

The FastPrime™ Head is equipped with a valve that allows for opening the head to at-

™

mospheric pressure. When installing a pump equipped with a FastPrime

Head connect

the 3/8" outer diameter clear vinyl tubing provided with the pump to the barbed nozzle.

Route the vinyl return line back to the solution tank. This tubing must not be submerged

in the solution.

FastPrimeTM Valve

3/8" Clear Vinyl Tubing

12

FastPrime™ Head

Page 13

3.7 AutoPrime™

INSTALLATION

The AutoPrime™ Liquid End is equipped with a valve that allows for constant removal

of vapors and gasses inherent with effervescent chemicals such as Sodium Hypochlorite

and Hydrogen Peroxide. The valve keeps the pump primed automatically. When installing a pump equipped with an AutoPrime™ Liquid End connect the 1/2" OD Polyethylene

tubing to the top vertical tting, and route this line back to the supply tank. To ensure

priming, this tubing should not be submerged in the solution. The horizontal tting is

the discharge, and the bottom vertical tting is the suction.

Return Fitting

Using 1/2" polyethylene

tubing here and

route to supply tank.

Discharge Fitting

Suction Fitting

13

Page 14

INSTALLATION

3.8 Foot Valve/Suction Tubing Installation

The Foot Valve acts as a check valve to keep the pump primed in suction lift applications.

The foot valve is designed to be submersed in the solution tank or drum and must sit in

a vertical position at the bottom. Position approximately 2 inches (50 mm) off the bottom

if the tank or drum contains sediment.

Pump models

equipped with

high-viscosity

liquid ends are

not equipped

with foot valves.

Flooded suction

is recommended.

A 1/2" NPT

connector is

included for

flooded suction

installations.

The ceramic weight, when installed, helps position the foot valve in a vertical position.

1. Attach the foot valve to one end of the suction tubing (see Tubing Connections, Section 3.3).

2. Slide the ceramic weight over the tubing end until it contacts the top of the foot valve

coupling nut.

3. Place foot valve and tubing into the solution tank. Check that the foot valve is vertical

and approximately 2 inches (50 mm) from the bottom of the tank or drum (see illustration). Connect the other end of the tubing to the suction side of the pump head

(bottom side) (see Tubing Connections, Section 3.3).

14

Tilted Sideways WILL NOT PRIME

Foot Valve

INCORRECT

Return Lines

Must Not Be

Submerged

Use Ceramic

Weight

2.0 in. (50 mm)

for Sediment Accumulation

Foot Valve Must

Remain Vertical

CORRECT

Page 15

3.9 Injection Check Valve and Discharge Tubing Installation

The Injection Check Valve prevents backow from a treated line. Install the injection

check valve at the location where chemical is being injected into the system. Any size

NPTF tting or pipe tee with a reducing bushing to 1/2" NPTF will accept the injection

check valve. Teon

When installing the Injection Check Valve, be sure to position it so that the valve enters

the bottom of your pipe in a vertical position. Variations left and right within 80° are

acceptable (see illustration).

After cutting an appropriate length of tubing, connect tubing to the injection check valve

then back to the discharge side of the pump head. Make sure it does not crimp or come

into contact with hot or sharp surfaces (see Tubing Connections, Section 3.3).

Pipe Cross

Section

®

tape should only be used on threads that are connected with pipes.

INSTALLATION

40°

Variation

Acceptable

Injection

Check Valve

Flow

40°

Variation

Acceptable

CORRECT

Use Teon

Tape here on

Pipe threads only

Do NOT use

Teon tape

On machined

Threads

Typical Injection Check Valve Installations

1" Pipe Tee

Reducing

Bushing

1" to 1/2" NPT

(Customer Supplied)

Injection

Check Valve

Flow

15

Page 16

OPERATION

4.0 Operation

4.1 Output Adjustment Controls

1. Power/Mode Selection Button: This button allows convenient starting

and stopping of the pump. For pumps with external control capability

(A3, A7, A8) this button switches pump operation between internal and

external modes. When operating in internal mode the Pulse Indicator

Light will ash green. When operating in external mode the Pulse Indicator Light will ash yellow.

➂

Speed Adjustment Knob: This knob provides adjustment of the stroking

2.

speed. For pumps with this knob (A1, A7, A8) turning this knob clockwise

➀

P increases stroke frequency (speed) from a minimum of 1 stroke per

minute.

➃

➄

➆

➂ ➀

➃

Stroke Adjustment Knob: This knob provides adjustment of the stroke

3.

➁

➅

length. Turning this knob clockwise P increases the stroke length, which

results in a higher amount of chemical displaced per stroke. It is recommended that the stroke range stay between 20% and 100%.

Pulse Indicator Light: This light will ash green when pumping in internal

4.

mode, and will ash yellow when pumping in external mode. The light is

on between strokes and off during the actual stroke.

Low-Level Indicator Light: This light will turn red when a Low-Level

5.

Sensor registers a low chemical level. This will turn off the pump. You

must have a Low-Level Sensor connected to the pump through the LowLevel Connector for this function to operate.

Low-Level Connector (3-Pin): This connector is for the connection of a

6.

Low-Level Sensor (48413). The low-level switch input connections are

always active for all models in all functional modes. If the uid level drops

below the level specied by the Low-Level Sensor, the pump will stop and

the Low-Level Indicator Light will turn on. The pump is designed to

recognize an open circuit as full, and a closed circuit as empty. The pin

functions are as follows:

1. Low Level Signal

3. No Connection

4. Ground/Return Connection

16

Page 17

OPERATION

DETAIL D

SCALE 5 : 1

➂

➄

➁

➃

7. External Control Connector (5-Pin): This connector is for the connection of various

options and accessories that can be used to externally control the pump. The pin functions (and the wire color for the standard LMI external control cable) are as follows:

1. Remote On Signal (Brown)

➀

2. Ground/Return Connection (White)

3. External Pulse Signal (Blue) (used only with A3, and A7 Series pumps)

4. 18Volt Supply Voltage (Black)

5. 4-20mA Input Signal (Green/Yellow) (used only with A8 Series pumps).

Some of the accessories available for use with A3, and A7 Series metering pumps are

listed below. Note that an Adapter Cable (48488) is needed when connecting any of the

MICROPACE(TM) units or owmeters.

A. MICROPACE™ A/D Converter (MP-100) - for translating a 4-20 milliamp signal

into an analog signal.

B. MICROPACE™ Divider (MP-400D) - for reducing the frequency of high frequency

pulses.

C. MICROPACE™ Multiplier (MP-500M) - for increasing the frequency of low

frequency pulses.

D. Pulse Transmitter (48489) - for pulsing in time with another LMI Electronic

Metering Pump.

E. RFP Flowmeter and Programmable Divider - for pacing the stroke frequency off

of the system ow.

F. FC Flowmeter/Contactor - for pacing the stroke frequency off of the system ow.

4.2 Start-up and Adjustment

• The pump is normally self-priming if suction lift is 5 ft (1.5m) or less and the steps below

are followed.

• Pumps are shipped from the factory with water in the pump head to aid in priming.

4.2.1 Start-Up/Priming for FastPrime™ Heads

Read this entire section completely before proceeding.

When all precautionary steps have been taken, the pump is mounted, and the tubing is

securely attached, you may now start priming the pump.

Plug in or switch the pump on.

1.

2. While the pump is running, set the Speed Adjustment Knob and the Stroke Adjust-

ment Knob at 100%.

3.

Turn The FastPrime™ knob 1 to 2 turns counter-clockwise Q.

The suction tubing should begin to ll with solution from the tank.

4.

5. A small amount of solution will begin to discharge out the return line of the FastPrime™

valve. Once this happens, turn the knob clockwise P until hand tight and SHUT THE

PUMP OFF.

6.

The pump is now primed.

7. Proceed to output adjustment, Section 4.3.

17

Page 18

OPERATION

4.2.2 Start-Up/Priming for Pump Supplied with 4-FV

Read this entire section completely before proceeding.

When all precautionary steps have been taken, the pump is mounted, and the tubing is

securely attached, you may now start priming the pump.

If the pump does

not self-prime,

remove the 4-FV

on the discharge

side of the pump

head. Remove

the check valve

and pour water

or solution into

the port until the

head is filled.

Replace valve,

then follow start

up/priming steps.

Plug in or switch the pump on.

1.

2. While the pump is running, set the Speed Adjustment Knob and the Stroke Adjust-

ment Knob at 100%.

3. Open the relief side (black knob) of the 4-FV by turning to the stop (about 1/8 turn).

The suction tubing should begin to ll with solution from the tank.

4.

5. A small amount of solution will begin to discharge out the return line of the 4-FV.

Once this happens, return the knob to the 12:00 position and SHUT THE PUMP OFF.

The pump is now primed.

6.

7. Proceed to output adjustment, Section 4.3.

4.2.3 Start-Up/Priming Without 4-FV

If the pump does

not self-prime,

remove the

discharge check

valve and pour

water or solution

into the port until

the head is filled.

Replace valve,

then follow start

up/priming steps.

Read this entire section completely before proceeding.

When all precautionary steps have been taken, the pump is mounted, and the tubing is

securely attached, you may prime the pump.

1. Plug in or switch on the pump.

2. While the pump is running, set the speed knob and the stroke knob at 100%.

3. The suction tubing should begin to ll with solution from the tank.

4. Once the solution begins to exit the pump head on the discharge side, SHUT THE

PUMP OFF.

The pump is now primed.

5.

6. Proceed to output adjustment, Section 4.3.

4.3 Output Adjustment

Once the pump has been primed, an appropriate output adjustment MUST be made.

Pump output should be calculated and adjustments made accordingly.

18

Page 19

4.3.1 Total Pump Output

Calculate the approximate output of the pump as follows:

OPERATION

When converting

between different

units, remember

these conversion

factors:

1 Gallon =

3.785 Liters

1 Day =

1,440 Minutes

240 SPM =

14,400 SPH

PUMP OUTPUT = MAX PUMP OUTPUT x % SPEED x % STROKE

Example: A151-928SI

Use Max Output (from dataplate on side of pump) = 1 GPH (1 gallon per hour).

If the pump is set at 60% speed and 70% stroke length, the approximate pump output is:

1.0 x 0.60 x 0.70 = 0.42 GPH.

Multiply by 24 (hours in one day) to calculate in gallons per day. If pump is not equipped

with speed adjustment, calculate by Max Pump Output x % Stroke only.

4.3.2 Calibration in Internal Mode

Once installation is complete and the approximate output has been determined,

the pump should be calibrated to adjust speed and stroke for your actual desired

output. (Calibration cylinders may be purchased from your local LMI distributor,

ref. publication 1798.)

Be sure the pump is primed, and discharge tubing and Injection Check Valve

1.

are installed as they would be in normal service (i.e., including factors such as

injection pressure, uid viscosity, and suction lift).

Place the Foot Valve in a graduated container with a volume of 1000 ml or

2.

more.

3. Plug in and switch pump to Internal Mode. Pump until all the air is exhausted

from the suction line and head.

4. Turn the pump off. Rell graduated container to a level starting point.

5. Using a stopwatch or timer, turn the pump on for a measured amount of time

(120 pump strokes minimum). The longer the time period, the more condent

you can be of the results. Be sure to count the number of strokes during the

calibration period when making comparisons.

Turn the pump off. Note the time elapsed in relation to volume displaced in

6.

the graduate. Now, calculate the output in the time unit you choose (minutes,

hours, days, etc.).

If the output is too low or too great, use the Stroke Adjustment Knob and/or

7.

the Speed Adjustment Knob to ne-tune the amount of ow, estimating required correction and repeat steps 1-7.

19

Page 20

OPERATION

4.3.3 Calibration in External Mode

1. Since pump output is governed by an external device such as Flowmeter-Pulser,

Liquitron™ Controller, or 4-20 mA DC signal from an instrument with an LMI

It may be helpful

to decrease

the speed of

the pump in

order to count

the number

of strokes. For

accuracy count at

least 120 strokes.

Analog-to-Digital Converter, only the output per stroke may be calibrated.

With pump primed and discharge tubing connected to the injection point as it would

2.

be in normal service, place Foot Valve Assembly in a graduated container with a volume of 1000 ml or more.

. Switch pump to Internal mode with Speed Adjustment Knob set at 100% until air is

3

exhausted from suction line and pump head.

. Switch pump OFF and rell graduate to a starting point.

4

5. Switch pump ON and count the number of strokes for exactly one minute, then switch

pump OFF.

. Note volume pumped during the calibration period of one minute. Divide into this

6

the number of strokes to determine the volume of solution pumped per stroke.

Example: 720 ml in 240 strokes = 3.0 ml per stroke.

Multiply this by your expected stroke rate per minute, per hour or per day and compare

with desired output requirements.

7. Turn Stroke Adjustment Knob to your best estimate of required correction and repeat

calibration procedure.

20

Page 21

4.4 Methods of Externally Triggering or Pacing A3, A7, and A8 Pumps

Full (Open)

Empty (Closed)

4-20 milliamp DC

4-20 milliamp DC

Higher Frequency Pulses

Lower Frequency Pulses

Pulse

Transmitter

MICROPACE

™

4DIGIT DIVIDER

MP-400D

MICROPACE

™

A/D CONVERTER

MP-100

MICROPACE

™

4DIGIT MULT IPLIER

MP-500M

RFP Flowmeter

Programmable

Divider

Programmable

Divider

FC Flowmeter/Contactor

A3, A7, A8

A3, A7

A8

Optional

Low Level

Sensor

Method of Triggering A3, and A7 Pumps Through External Control Connector

OPERATION

1. Switch Closure

Switch closing

triggers pump

2. NPN Transistor

Base goes high

to trigger pump

3. PNP Transistor

Base goes low

to trigger pump

4. Opto

Isolator

The default configuration

for the Remote On/Off

input is: open contacts

= pump stopped, closed

contacts = pump enabled.

Therefore pins 1 and 2

of the External Control

Connector must be shorted

together in external mode

for the pump to respond to

external signals.

Blue

PIN

White

+ Blue

− White

Switch or transistors must be capable of switching 24V DC at

3

15 milliamperes. Minimum time in low impedance state (

2

25 milliseconds. Minimum time in high impedance state (

is 50 milliseconds.

3

2

NOTE: Pins 1 (Brown wire) and 2 (White wire) must be connected/

ON) is

OFF)

shorted together in order for the pump to be ‘ON’ in external

+ Blue

− White

+ Blue

− White

3

mode.

2

3

2

These pumps have two operating modes: Local (Pulse Indicator Light ashes

green) and Remote (Pulse Indicator Light ashes yellow). Pressing the Power/

Mode Selection Button switches between Local and Remote modes. The default

conguration for operating mode is Local mode.

When the pump is in Local mode the Remote On/Off input is ignored. When the

pump is in Remote mode the Remote On/Off input is always monitored. The

pump will return to the last power mode if power is interrupted.

21

Page 22

OPERATION

4.4.1 Control Modes

4.4.1.1 Local Mode

• WheninLocalmodetheA3pumprunscontinuouslyatmaximumspeed.

• When in Local mode A7 and A8 pumps run atthe speed indicated by the speed

knob.

4.4.1.2 Remote Mode (for A3, and A7)

The default

definition of a

pulse is: close =

pulse starts, open

= pulse ends.

Pins 1 (brown wire) and 2 (white wire) must be connected/shorted together in order for

the pump to respond to pulses in external mode.

• InRemotemodepulsesoccurringfasterthanarateof1200pulsesperminute(less

than 50ms apart) and pulses with a duration of less than 25ms are ignored.

• Pulsesoccurringbetween240strokesperminute(SPM)and1200pulsesperminute

results in the pump running at 240 SPM.

• Pulsesoccurringatlessthan240SPMresultsinthepumpstrokingatthatrate.

4.4.1.3 Remote Mode (for A8)

Pins 1 (brown wire) and 2 (white wire) must be connected/shorted together in order for

the pump to respond to a milliamp signal.

In Remote mode the pump speed is controlled by a milliamp (mA) Analog Input signal.

The factory default settings for the Analog Input are: 20mA input = maximum speed,

4 mA = 0 strokes per minute. The mA input setting can be calibrated to any level between

0 – 22 mA. When recalibrating the input settings, the span between high and low input

must be greater than 6 mA. If the span is not large enough, the Pulse Indicator Light will

ash green and yellow alternately at about 10 times per second.

In the default settings, the fast level mA input is greater than the slow level mA input.

This is known as direct action. In direct action when the mA input is at or above the setting for the fast level, the pump will run at maximum speed. When the mA input is below

the setting for the slow level, the pump will stop.

22

Reverse action is when the slow level mA input is greater than the fast level mA input. In

reverse action when the mA input is at or below the setting for the fast level, the pump

will run at maximum speed. When the mA input is above the setting for the slow level,

the pump will stop.

Page 23

4.4.1.4 Calibrating the Analog Input Settings (for A8)

1. Press and hold the Power/Mode Selection Button for more than 5 seconds. This enters

the calibration mode. Pumping will stop while in calibration mode.

2. Turn the Speed Adjustment Knob completely clockwise P to enter the fast level analog

input state. The Pulse Indicator Light will ash 1 second green ¼ second yellow.

3. Apply the desired fast level analog signal and press the Power/Mode Selection Button

for less than 3 seconds. The Pulse Indicator Light will be green for 1 second before

resuming ashing to conrm storage of the setting.

4. Turn the Speed Adjustment Knob completely counter-clockwise Q to enter the slow

level analog input state. The Pulse Indicator Light will ash 1 second yellow ¼ second

green.

5. Apply the desired slow level analog signal and press the Power/Mode Selection Button

for less than 3 seconds. The Pulse Indicator Light will be yellow for 1 second before

resuming ashing to conrm storage of the setting.

6. To return the pump to the factory default settings turn the Speed Adjustment Knob

to 50%. The Pulse Indicator Light should ash 1 second green, 1 second yellow. Then

press the Power/Mode Selection Button.

OPERATION

7. To exit calibration mode press and hold the Power/Mode Selection Button for more

than 3 seconds.

23

Page 24

MAINTENANCE

5.0 Spare Parts Replacement and Routine Maintenance

LMI recommends replacing the elastomeric components of the pump on an annual basis.

Refer to the LMI Metering Pump Price List for the proper Spare Parts Kit or RPM Pro

™

kit number or contact your local LMI stocking distributor.

Pac

5.1 Depressurizing the Discharge Line

(for Pumps Equipped with a 4-FV Only)

ALWAYS wear protective clothing, face shield, safety glasses and gloves when performing

any maintenance or replacement on your pump.

To reduce the risk of chemical splash during disassembly or maintenance, all installations

should be equipped with line depressurization capability. Using LMI’s Four-Function Valve

(4-FV) is one way to include this feature.

Read steps 1 and 2 below before proceeding.

. Be sure the Injection Check Valve is properly installed and is operating. If a shut off

1

valve has been installed downstream of the Injection Valve, it should be closed.

Be sure your relief tubing is connected to your 4-FV and runs back to your solution drum

or tank.

. Turn the black knob on the 4-FV 1/8 turn to the stop. Turn and hold the yellow knob

2

for a few seconds. The discharge line is now depressurized. Keep both valve knobs

open until solution drains back down the discharge tubing into the solution tank or

drum. Then release the yellow knob, and turn the black knob to its normal position.

5.2 Depressurizing the Discharge Line

(for Single-Ball FastPrime™ Heads Only)

ALWAYS wear protective clothing, face shield, safety glasses and gloves when performing

any maintenance or replacement on your pump.

Read steps 1 and 2 below before proceeding.

1. Be sure the Injection Check Valve is properly installed and is operating. If a shut off

valve has been installed downstream of the Injection Valve, it should be closed.

Be sure your relief tubing is connected to your FastPrime

tion drum or tank.

™

2. Turn the FastPrime

line is now depressurized. Keep valve open until solution drains back down the discharge tubing into solution drum or tank. Then turn the knob clockwise P to tighten

knob to closed position.

knob one-and-a-half turns counter-clockwise Q. The discharge

™

valve and runs back to your solu-

24

Page 25

5.3 Liquifram™ (Diaphragm) Replacement

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working near

or performing any maintenance or replacement on your pump. See MSDS information from

solution supplier for additional precautions.

LMI metering pumps are designed for trouble-free operation, yet routine maintenance

of elastomeric parts is essential for optimum performance. This involves replacing the

Liquifram

spring. LMI recommends replacing these parts at least once a year; however, frequency

will depend on your particular application.

When replacing the Liquifram

spring should also be replaced (see next Section 5.4). A Spare Parts Kit or RPM Pro Pac

kit containing these parts may be obtained from your local distributor.

™

, cartridge valves, O-rings, 4-FV cap assemblies and the injection check valve

™

MAINTENANCE

, the cartridge valves, or O-rings, the injection check valve

Replacing the Liquifram

™

:

1. Carefully depressurize, drain, and disconnect the

discharge line (see previous sections in this

manual).

™

Head

Liquifram

2. Place the Foot Valve into a container of water or

other neutralizing solution. Turn the pump on to

ush the head assembly. Once the pump head has

been ushed, lift the Foot Valve out of the solution

and continue to pump air into the pump head until

the pump head is purged of water or neutralizing

solution.

™

Adapter Disk

Shaft

Seal

If the liquid cannot be pumped due to Liquifram

Drive

carefully disconnect the suction and discharge tubing

using protective clothing, gloves and face shield. Remove

the four screws and washers from the head and immerse

the head in water or other neutralizing solution.

3. Start the pump. While running, set the Stroke Adjustment Knob to 0% and turn the

pump off.

4. With the unit off, unscrew the Liquifram™ by carefully grasping the outer edge and

™

turning it counter-clockwise Q. Discard old Liquifram

™

(located behind the Liquifram

) and ensure that the diameter of the raised section is

the same as the diameter of the replacement Liquifram

. Remove the Adapter Disk

™

.

5. Remove Adapter Disk and check condition of the Shaft Seal. Replace Shaft Seal if

necessary.

6

. Replace the Adapter Disk so that the drain hole of the disk is oriented downward,

and the mounting holes line up with the mounting holes of the pump.

Be careful not to scratch the Teon

®

face of the new Liquifram™.

™

rupture,

7

. Screw on the new Liquifram™ clockwise P until turned all the way in. Start the pump

and turn the stroke knob to 100%. Stop the pump.

8. Remount the pump head using the four (4) screws and washers. Tighten in a criss-cross

pattern. After one week of operation, recheck the screws and tighten if necessary.

25

Page 26

MAINTENANCE

5.4 Cartridge Valve and O-ring Replacement

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working on

or performing any maintenance or replacement on your pump. See MSDS information from

solution supplier for additional precautions.

Refer to the LMI Metering Pump Price List for the proper Spare Parts Kit or RPM Pro

™

kit number or contact your local LMI stocking distributor.

Pac

1. Carefully depressurize and disconnect the discharge line (see Section 5.1 or 5.2 in this

manual).

2. Place the Foot Valve into a container of water or other neutralizing solution. Turn the

pump on to ush the head assembly. Once the pump has been ushed, lift the Foot

Valve out and continue to pump to let air into the pump head until pump is purged

of water or neutralizing solution.

If the liquid cannot be pumped due to Liquifram

and discharge tubing using protective clothing, gloves and face shield. Remove the four screws

and washers from the head and immerse the head in water or other neutralizing solution.

Spare part replacement kits include specic instructions for valve replacement. Please

follow the instructions included with the replacement kit.

™

rupture, carefully disconnect the suction

Carefully disconnect one tubing connection and tting at a time, then remove and

3.

replace the worn valve and O-rings. If necessary, carefully loosen stuck valves by prying side to side using a small screwdriver through the center hole of the valve.

Before disassembling the check valves, note the orientation of the valve.

Install new check valves in each location. Ensure that the cartridges are oriented

4.

correctly.

26

Page 27

5.5 Injection Check Valve Parts Replacement

Depressurize and drain pipeline (or isolate Injection Check Valve point using valves) so that

Injection Check Valve can safely be disassembled.

ALWAYS wear protective clothing, face shield, safety glasses and gloves when working near

or performing any maintenance or replacement on your pump. See MSDS information from

solution supplier for additional precautions.

Refer to the LMI Metering Pump Price List for the proper Spare Parts Kit or RPM Pro

™

kit number or contact your local LMI stocking distributor.

Pac

1. Isolate Injection Check Valve and depressurize pipe or drain pipeline.

2. Carefully depressurize and disconnect the discharge line (see Section 5.1 or 5.2 in this

manual).

Spare part replacement kits include specic instructions for valve replacement. Please

follow the instructions included with the replacement kit.

Carefully disconnect the tubing leading to the Injection Check Valve, then remove the

3.

Injection Check Valve Fitting. Remove and replace the worn spring, seat, ball, and

O-ring.

MAINTENANCE

Before disassembling the check valve, note the orientation of the parts.

Install a new spring, seat, ball, and O-ring. Ensure that the parts are oriented

4.

correctly.

O-Ring

Injection Check

Valve Fitting

Spring

Ball

Seat

O-Ring

27

Page 28

MAINTENANCE

5.6 FastPrime™ Valve O-Ring Replacement

ALWAYS wear protective clothing, face shield, safety glasses and gloves when performing

any maintenance or replacement on your pump.

Refer to the LMI Metering Pump Price List for the proper Spare Parts Kit or RPM Pro

™

kit number or contact your local LMI stocking distributor.

Pac

1. Be sure the Injection Check Valve is properly installed and is operating. If a shut off

valve has been installed downstream of the Injection Valve, it should be closed.

Be sure your relief tubing is connected to your FastPrime™ valve and runs back to your solution drum or tank.

Turn the FastPrime™ Knob one-and-a-half turns counter-clockwise Q. This will de-

2.

pressurize the head. Keep valve open. Carefully remove the return line by gently pulling

tubing and moving it from side to side to gradually back tubing off of the barbed

tting.

Hold return line tubing upright until solution drains back into solution drum or

3.

tank.

4. Using a 3/4" (or 19mm) socket or wrench remove Retaining Nut, and pull out the

entire FastPrime™ Valve assembly. Remove and replace the two small O-rings.

5. Reinsert the FastPrime™ Valve assembly and retighten the Retaining Nut. Then turn

™

the FastPrime

Knob clockwise P to tighten knob to closed position. To avoid dam-

aging the parts, it is important that the ange on the FastPrime™ Valve is ush with

the Retaining Nut prior to reassembly.

Note gap between Flange

INCORRECT

CORRECT

and Retaining Nut.

No gap between Flange

and Retaining Nut.

28

Page 29

5.6 FastPrime™ Valve O-Ring Replacement (continued)

6. Recut 1 to 2 inches off the tip of the return line and ensure the end is squared. Press

the return line tubing on completely past the barbs.

O-Rings

O-Rings

Retaining Nut

FastPrimeTM Valve

FastPrimeTM Valve

FastPrimeTM Knob

MAINTENANCE

3/8" Clear Vinyl Tubing

29

Page 30

MAINTENANCE

5.7 Stroke Length Setting

The Stroke Adjustment Knob is calibrated for each pump, and does not need to be removed during Liquifram™ replacement or during most other maintenance. If the Stroke

Knob is removed for any reason it becomes necessary to reset the stroke length. Follow

the procedure below to approximate the proper factory setting. If a more accurate setting

is required contact your distributor or manufacturer.

1. Install a new Stroke Shaft. Note that there will be some resistance as the O-ring slides

into the control panel. The Stroke Knob can be used to turn the Stroke Shaft. Continue

to turn the Stroke Shaft until there is no longer any diaphragm movement. It may be

necessary to turn on the pump in order to get the Stroke Knob completely forward;

however, care should be taken to ensure that the Stroke Shaft is contacting the Plunger

before turning on the unit. Otherwise the pump could be damaged.

2. Once the Stroke Shaft is completely forward, you can reset the stroke length. Press in

the Stroke Knob so that the Stroke Knob Pointer indicates 0 (zero).

3. Use a Phillips head screwdriver to install the Stroke Knob Screw.

4. Insert the Stroke Knob Pointer into the Stroke Knob.

30

Page 31

5.8 Series A Drive Parts List

140

300

130

80

90

340

220

270

230

505

502

506

310

501

240

320

250

155

150

195

170

125

75

503

504

MAINTENANCE

Bubble

Number

Description

75 PolePiece O-Ring 250 Drive Assembly Screws

80 EPU Return Spring 270 Stroke Shaft O-Ring

90 EPU Shim 300 Warning Label

Bubble

Number

Description

125 Plunger O-Ring 310 Shaft Seal

130 Retaining Ring 320 Adapter Disk

140 Drive Housing 340 Clear Cover

150 EPU Attachment Bolt 501 Control Panel Assembly

155 EPU Attachment Washer 502 EPU Assembly

170 Power Cord 503 Plunger Assembly

195 Stroke Dial Label 504 Pole Piece Assembly

220 Speed Knob O-Ring 505 Stroke Knob Assembly

230 Control Panel O-Ring 506 Speed Knob Assembly

240 Wire Harness

31

Page 32

MAINTENANCE

A3/A7/A8 PULSER

A0/A1 PULSER

EPU ASSEMBLY

EPU ASSEMBLY

POWER CORDPOWER CORD

BLK OR BRN

WHT OR BLU

GRN OR GRN/YEL

WHT OR BLU

BLK OR BRN

GRN OR GRN/YEL

YEL

YEL

YEL

YEL

P1

P2

P3

P2

P1

P3

P4

P4

615

608

617

40

100

230

607

603

615

40

250

100

270

260

90

A.

B.

5.9 EPU Wiring Diagram

5.10 Liquid End Parts List

Bubble

Number

Description

10 Pump Head

40 Tube Connect O-Ring

90 Seat O-Ring

100 Cartridge Valve O-Ring

120 SS FastPrime™ Valve

140 FastPrime™ Valve Gasket

150 FastPrime™ Valve O-Ring

180 Liquid End Cover

190 Liquifram™

230 Injection Check Valve Body

250 Ceramic Weight

260 Foot Valve Coupling Nut

270 Foot Valve Strainer

601 FastPrime™ Discharge Check Valve

602 Suction Check Valve

603 Cartridge Valve

604 FastPrime™ Cartridge Valve

605 FastPrime™ Valve

606 Liquid End Hardware

607 Foot Valve

608 Injection Valve

609 AutoPrime™ Discharge Check Valve

610 AutoPrime™ Discharge Cartridge Valve

611 AutoPrime™ Shuttle Valve

612 AutoPrime™ Shuttle Cartridge Valve

613* Tubing Connection Kit*

614 AutoPrime™ Return Tubing Connection Kit

615 Single Ball Fitting Assembly

616 Double Ball Fitting Assembly

Injection Valve

Foot Valve

617 Injection Cartridge Valve

618 SS Discharge Check Valve

619 SS Suction Check Valve

32

Refer to Section 3.3 for tubing connections.

Page 33

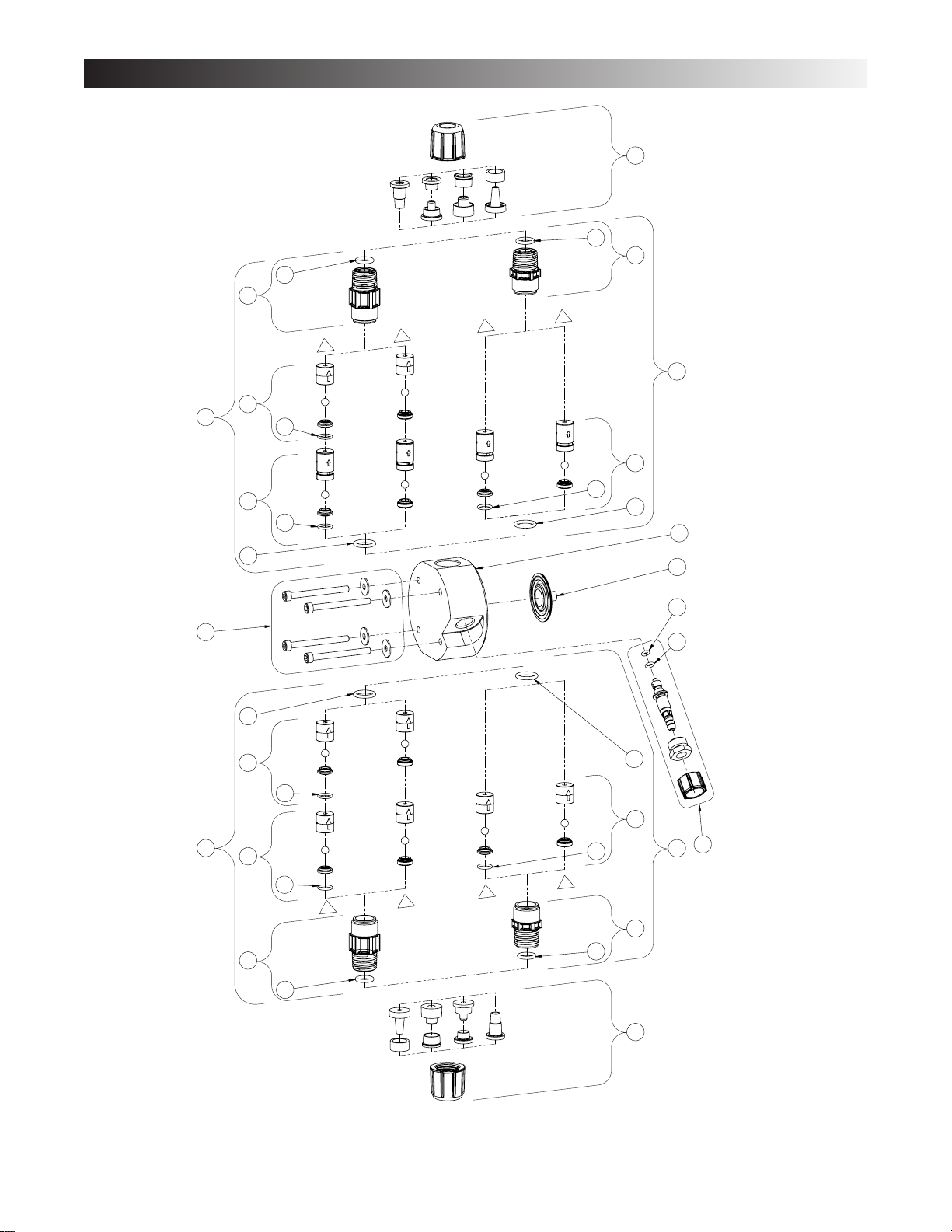

190

100

90

100

90

90

100

90

A.

B.

C.

D.

C.

D.

B.

A.

150

140

90

606

10

605

90

604

601

603

604

601

603

602

602

603

603

616

613

615

613

615

616

100

40

40

40

40

MAINTENANCE

Machined FastPrimeTM Liquid End

33

Page 34

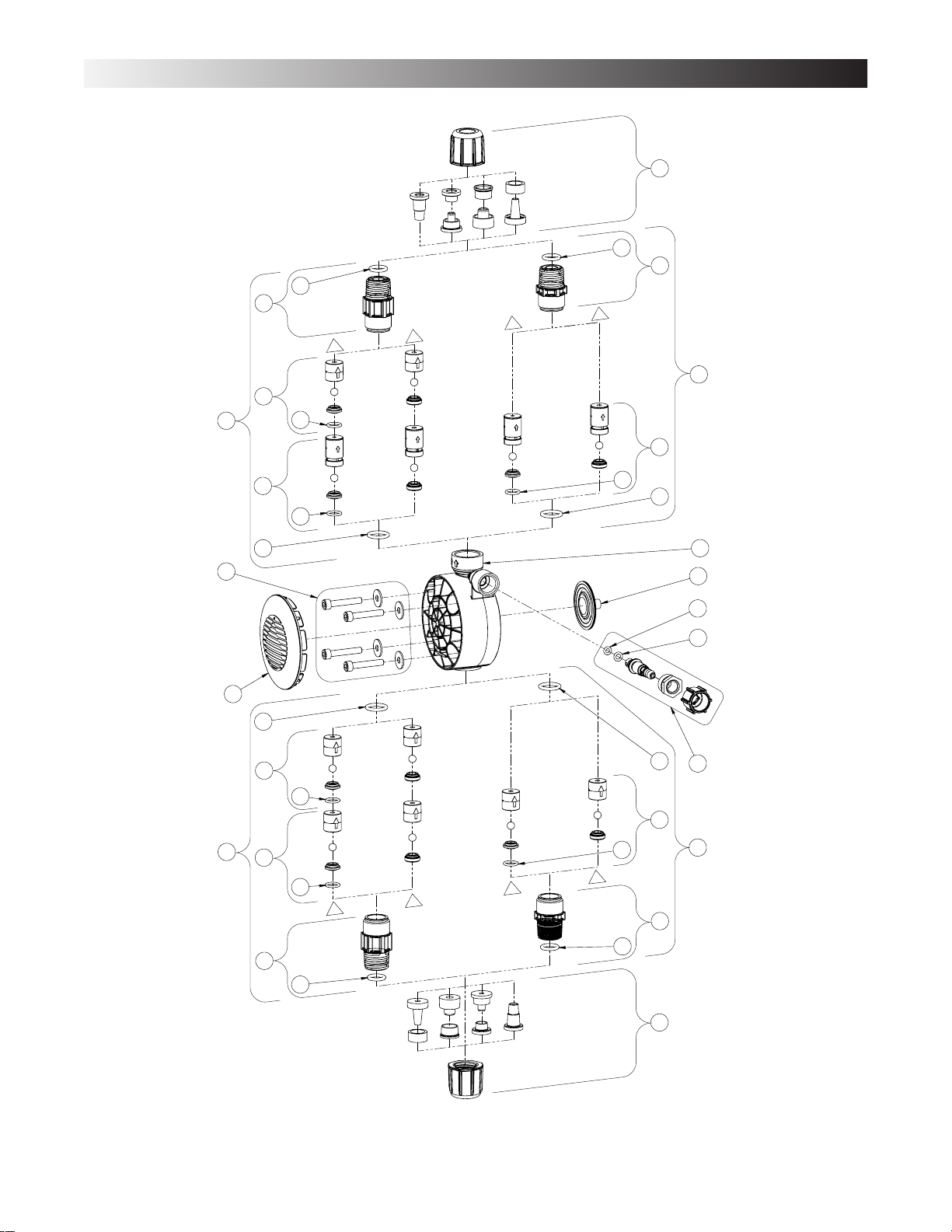

MAINTENANCE

190

100

90

90

90

100

90

A.

B.

C.

D.

C.

D.

B.

A.

150

140

90

606

605

90

604

601

603

604

601

603

602

602

603

603

616

613

615

613

615

616

100

40

40

40

40

100

10

180

34

Molded FastPrimeTM Liquid End

Page 35

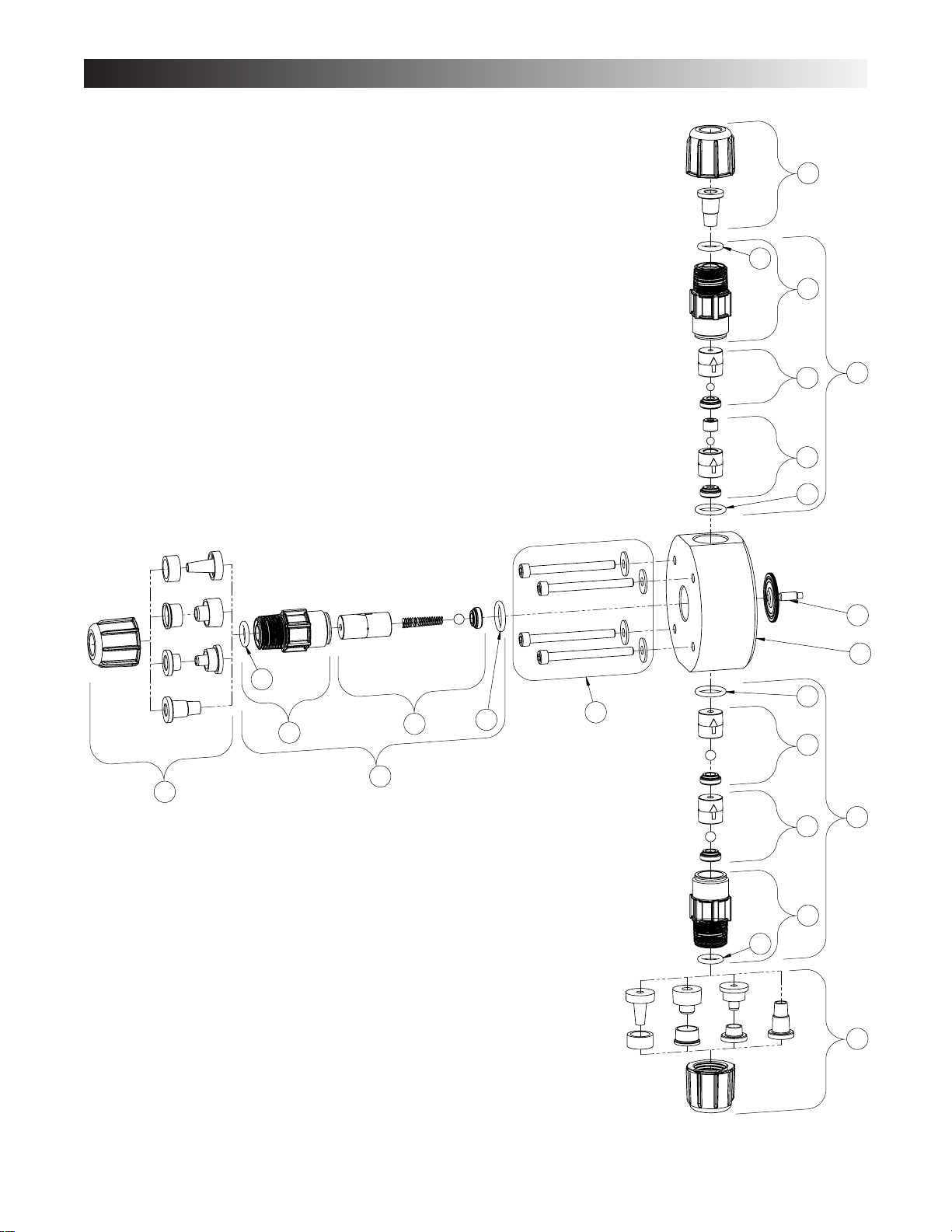

MAINTENANCE

606

190

40

40

40

10

611

602

612

609

603

603

100

603

610

100

100

616

616

613

614

616

613

AutoPrimeTM Liquid End

35

Page 36

MAINTENANCE

618

619

606 120

10

190

100

90

36

SS Liquid End

Page 37

TROUBLESHOOTING

6.0 Troubleshooting

PROBLEM POSSIBLE CAUSE SOLUTION

Pump Will Not Prime 1. Pump not turned on or plugged in. 1. Turn on pump/plug in pump.

2. Output dials not set properly. 2. Always prime pump with speed and

stroke at 100%.

Pump Loses Prime

3. Foot Valve not in vertical position on

bottom of tank.

4. Pump suction lift too high. 4. Maximum suction lift is 5 ft (1.5 m).

5. Suction tubing is curved or coiled in

tank.

6. Fittings are over tightened. 6. Do not overtighten ttings. This causes

7. Air trap in suction valve tubing. 7. Suction tubing should be as vertical as

8. Too much pressure at discharge.

(Pumps without multi-function valve.)

1. Solution container ran dry. 1. Rell container with solution and reprime

2. Foot Valve is not in a vertical

position on the bottom of the tank.

3. Pump suction lift is too high. 3. Maximum suction lift is 5 ft (1.5 m).

4. Suction tubing is curved or coiled

in tank.

5. Fittings are over tightened. 5. DO NOT OVERTIGHTEN FITTINGS.

6. Air trap in suction valve tubing. 6. Suction tubing should be as vertical

7. Air leak on suction side. 7. Check for pinholes, cracks. Replace if

3. Foot Valve must be vertical (see Foot

Valve Installation, Section 3.7).

Pumps with High Viscosity Liquid

Handling Assemblies require ooded

suction.

5. Suction tubing must be vertical. Use

LMI ceramic weight supplied with pump

(see Section 3.7).

seal rings to distort and not seat properly which causes pump to leak back

or lose prime.

possible. AVOID FALSE FLOODED

SUCTION! (see Section 3.2.1).

8. Shut off valves in pressurized line.

Disconnect tubing at injection check

valve (see Priming Section 4.2). When

pump is primed, reconnect discharge

tubing.

(see Section 4.2).

2. Foot Valve must be vertical (see Foot

Valve Installation, Section 3.7).

Pumps with High Viscosity Liquid

Handling Assemblies require ooded

suction.

4. Suction tubing must be vertical. Use

LMI ceramic weight supplied with pump

(see Section 3.7).

This causes seal rings to distort and

not seat properly which caused pump

to leak back or lose prime.

as possible. AVOID FALSE FLOODED

SUCTION! (see Section 3.2.1).

necessary.

37

Page 38

TROUBLESHOOTING

6.0 Troubleshooting (continued)

PROBLEM POSSIBLE CAUSE SOLUTION

Leakage at tubing 1. Worn tubing ends. 1. Cut about 1 in (25 mm) off tubing and

then replace as before.

2. Loose or cracked tting. 2. Replace tting if cracked. Carefully

hand tighten ttings. DO NOT USE

PIPE WRENCH. An additional 1/8 or

1/4 turn may be necessary

3. Worn seal rings. 3. Replace balls and seal rings (see Section 5.4)

4. Solution attacking Liquid Handling

Assembly

Low Output or Failure

to Pump Against

Pressure

Failure to Run 1. Pump not turned on or plugged in. 1. Turn on or plug in pump.

Excessive Pump

Output

1. Pump’s maximum pressure rating is

exceeded by injection pressure.

2. Worn Seal Rings. 2. Worn seal rings or cartridge valves may

3. Ruptured Liquifram™. 3. Replace Liquifram™ (see Section 5.3).

4. Incorrect stroke length. 4. Reca librate Output (see Section

5. Tubing run on discharge may be

too long.

6. Clogged Foot Valve strainer. 6. Remove Foot Valve strainer when

2. EPU failure. 2. Disassemble pump and measure the

3. Pulser failure. 3. The pulser should be replaced if EPU

1. Syphoning. (Pumping downhill

without a multi-function valve).

2. Little or no pressure at injection

point.

3. Excessive strokes per minute. 3. Replace pulser or resistor. Consult

4. Consult your local distributor for alternate materials.

1. Injection pressure cannot exceed

pump’s maximum pressure. See pump

data plate.

need replacement (see Section 5.4).

4.3.2)

5. Longer tubing runs may create frictional

losses sufficient to reduce pump’s pressure rating. Consult factory for more

information.

pumping slurries or when solution particles cause strainer to clog.

resistance of the EPU across the EPU

wires. Consult supplier or factory. (see

Section 5.8).

checks out OK. Consult supplier or

factory.

1. Move injection point to a pressurized

location or install an LMI 4-FV (see

Section 3.4).

2. If pressure at injection point is less than

25 psi (1.7 Bar), an LMI 4-FV should be

installed (see Section 3.4).

factory.

38

Page 39

NOTES

39

Page 40

© 2009 LMI Milton Roy - All Rights Reserved

Printed in USA

Specications subject to change without notice.

201 Ivyland Rd.

Ivyland, PA 18974

TEL: (215) 293-0401

FAX: (215) 293-0445

http://www.lmipumps.com

Liquifram, Liquitron, Micropace, FastPrime, AutoPrime,

and Pro Pac are trademarks of Milton Roy Company,

Roytronic is a registered trademark of Milton Roy Company,

Teon is a registered trademark of E. I. du Pont de Nemours

& Co., Inc.

Loading...

Loading...