Page 1

GC INDICATOR

(

P.N. 3056610550, Revision C6, August 2010)

Software Rev 2.18 and up

Adam Equipment

© Adam Equipment Company 2010

Page 2

Easy Reference:

Model name of the indicator/scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2010

Page 3

CONTENTS

1.0 INTRODUCTION...................................................................................3

2.0 SPECIFICATIONS ................................................................................4

3.0 INSTALLATION....................................................................................6

3.1 UNPACKING......................................................................................6

3.2 LOCATING.........................................................................................6

3.3 CONNECTION ...................................................................................7

4.0 KEY DESCRIPTIONS ...........................................................................8

5.0 DISPLAYS ............................................................................................9

5.1 WEIGHT DISPLAY.............................................................................9

5.2 UNIT WEIGHT DISPLAY..................................................................10

5.3 COUNT DISPLAY ............................................................................10

5.4 OTHER SYMBOLS ..........................................................................10

6.0 OPERATION.......................................................................................11

6.1 ZEROING THE DISPLAY.................................................................11

6.2 TARING............................................................................................11

6.3 PARTS COUNTING .........................................................................12

7.0 USER PARAMETERS ........................................................................15

7.1 SETTING OF PIN.............................................................................16

7.2 ENABLE WEIGHING UNITS ............................................................16

8.0 CALIBRATION....................................................................................17

9.0 RS-232 INTERFACE...........................................................................18

9.1 INPUT COMMANDS FORMAT ........................................................21

9.2 RS-232 SETUP ................................................................................22

9.3 REAL TIME CLOCK SETUP ............................................................24

9.4 AUTO SLEEP FUNCTION ...............................................................25

10.0 BATTERY AND BACKLIGHT OPERATION....................................25

10.1 BATTERY......................................................................................25

10.2 BACKLIGHT FOR LCD .................................................................26

11.0 ERROR CODES...............................................................................27

12.0 SERVICE PARAMETERS................................................................28

12.1 USING “0000” TO ENTER THE CALIBRATION PARAMETER .....28

12.2 USING “2006” TO ENTER THE SERVICE PARAMETERS...........30

13.0 REPLACEMENT PARTS AND ACCESSORIES..............................36

14.0 SERVICE INFORMATION ...............................................................38

15.0 WARRANTY INFORMATION ..........................................................40

P a g e 1 © Adam Equipment Company 2010

Page 4

P a g e 2 © Adam Equipment Company 2010

Page 5

1.0 INTRODUCTION

• The GC series provides accurate, fast and versatile parts counting scales.

• There are 2 types of scales within the GC series : GC indicators are

kilogram/gram scales and the GC-a indicators are changeable from pounds to

kilograms if the user requires it. The indicators have the same functions except

that GC-a scales have the ability to toggle between the two weighing units.

• The indicators can be set to display up to 30000 divisions

• All indicators are supplied with a RS-232 bi-directional interface and real time

clock (RTC).

• The indicator has a sealed keypad with colour coded membrane switches and

there is a large, easy to read liquid crystal type display (LCD). The LCD is supplied

with a backlight.

• The indicators include automatic zero tracking, audible alarm for pre-set counts,

automatic tare, pre-set tare, an accumulation facility that allows the count to be

stored and recalled as an accumulated total.

P a g e 3 © Adam Equipment Company 2010

Page 6

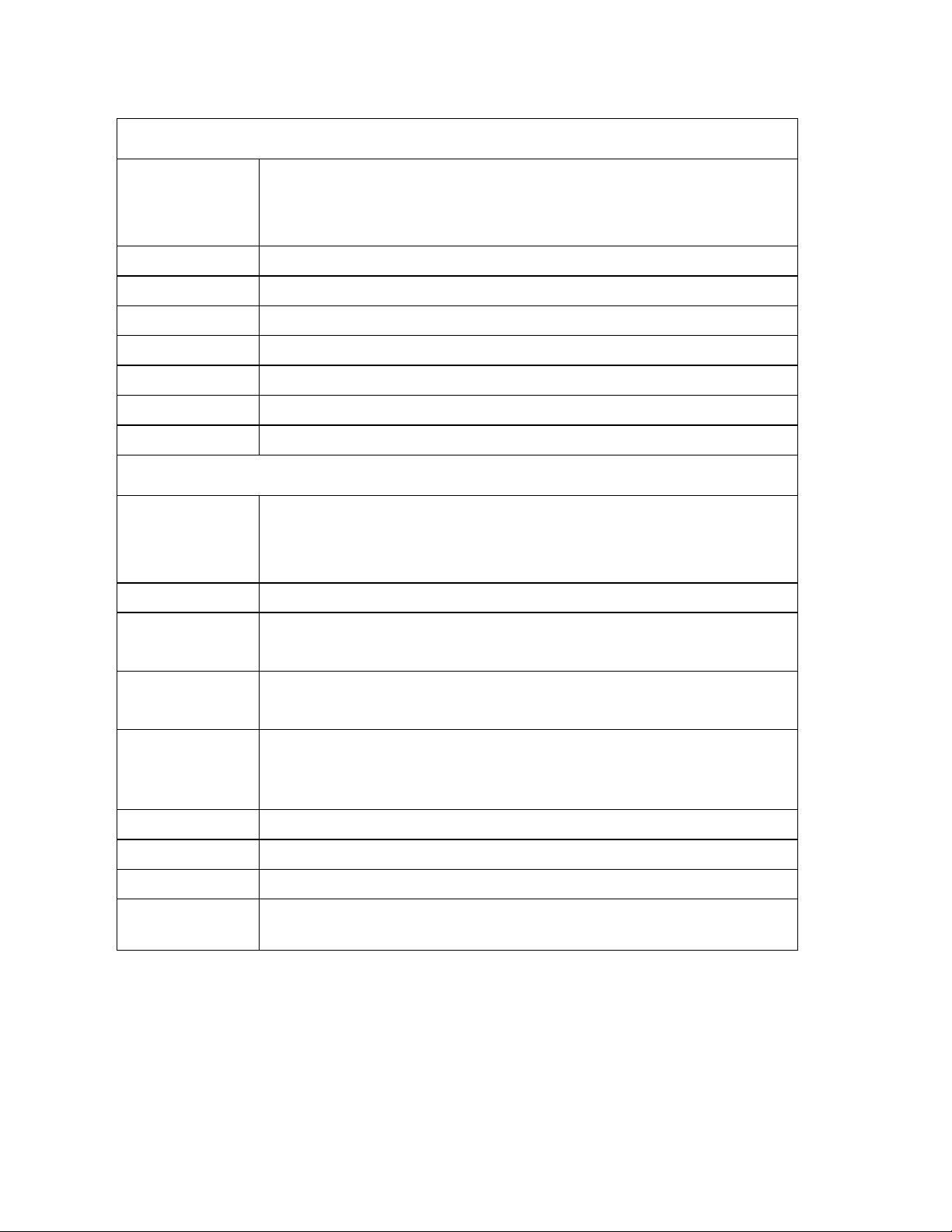

2.0 SPECIFICATIONS

INPUT SECTION

Load Cells

Minimum 87 ohms, maximum 1120 ohms

Connection

Excitation

Sensitivity

Linearity

Zero Range

Signal range

ADC Sensitivity

DIGITAL SECTION

Maximum Range 100 g – 30000 g

Divisions Up to 30,000

Up to 4, 350 ohm load cells

4 wire or 6 wire load cells

5Vdc

0.15uv/d

0.01% FS

0-10mv

0-40mv

Approximately 0.015 uv/ADCount

1 kg – 30000 kg

1 lb to 30000 lb

Stabilization Time

Operating

Temperature

Power supply 230 VAC 50/60 Hz

12VDC @ 800ma adaptor for CKa type units.

Battery Internal rechargeable battery

Calibration Automatic External

Display 3 x 6 digits LCD digital displays

Indicator

Housing

2 Seconds typical

-10°C - 40°C

14°F - 104°F

OR

ABS Plastic

P a g e 4 © Adam Equipment Company 2010

Page 7

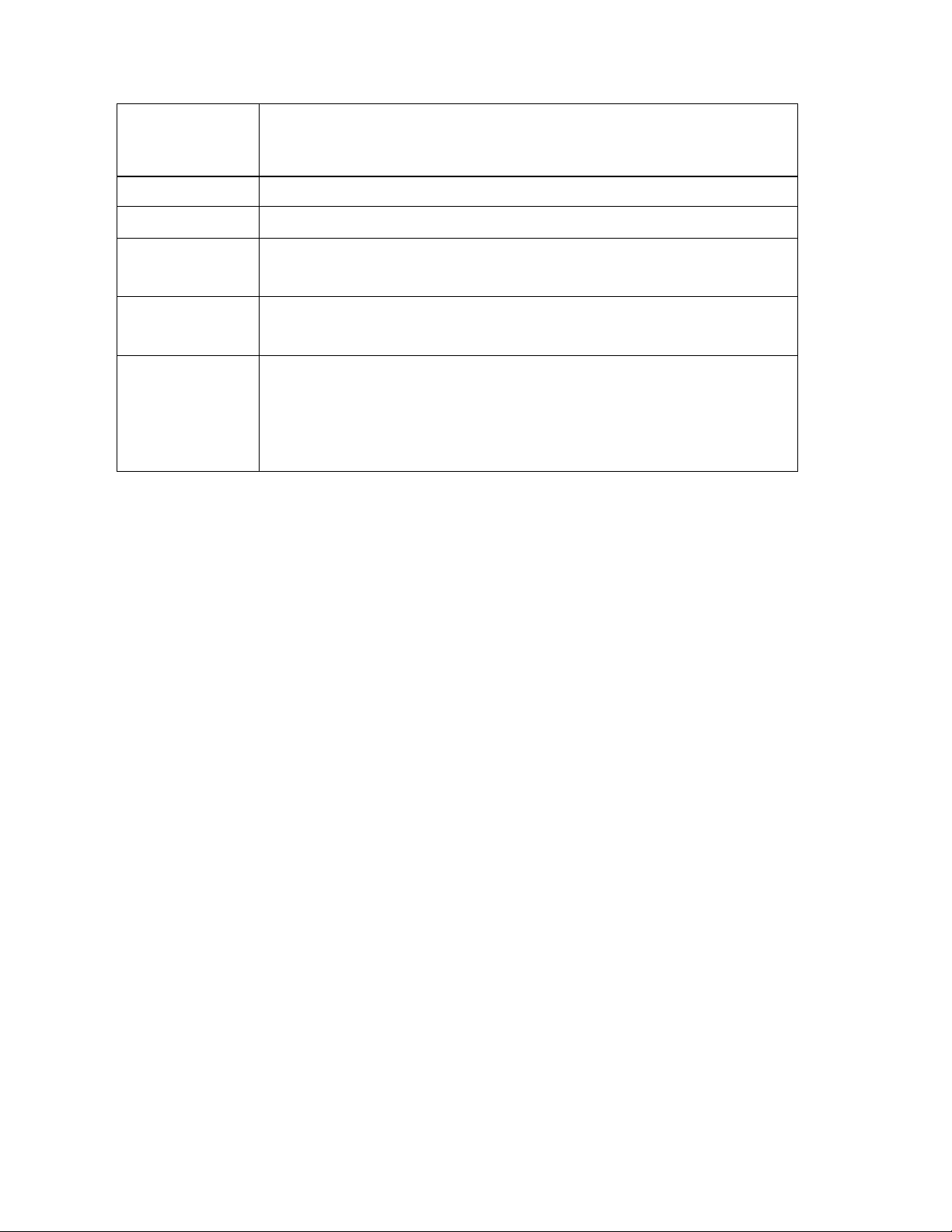

Overall

Dimensions

(wxdxh)

Net Weight

Applications

Functions

Interface

Date/Time

260 x 110 x 170mm

10.2” x 4.3” x 6.7”

1.1 kg / 2.4 lb

Counting Scales

Parts counting, weighing, accumulating memory,

pre-set count with alarm

RS-232 bi-directional interface

English, German, French, Spanish selectable text

Real Time Clock (RTC),

To print date and time information

(Dates in year/month/day, day/month/year or

month/day/year formats- Battery backed)

P a g e 5 © Adam Equipment Company 2010

Page 8

3.0 INSTALLATION

3.1 UNPACKING

This indicator must be connected to a load cell platform and calibrated as necessary

to match the platform and user requirements. See Section 12.0 for set-up

information.

The user’s application and the technical specifications of the platform or load cell

will determine the necessary configuration.

3.2 LOCATING

• The scales should not be placed in a location

that will reduce the accuracy.

• Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

• Avoid unsuitable tables. The table or floor must

be rigid and not vibrate.

• Avoid unstable power sources. Do not use near

large users of electricity such as welding

equipment or large motors.

• Do not place near vibrating machinery.

• Avoid high humidity that might cause

condensation. Avoid direct contact with water.

Do not spray or immerse the scales in water.

• Avoid air movement such as from fans or

opening doors. Do not place near open windows

or air-conditioning vents.

• Keep the scales clean. Do not stack material on

the scales when they are not in use.

P a g e 6 © Adam Equipment Company 2010

Page 9

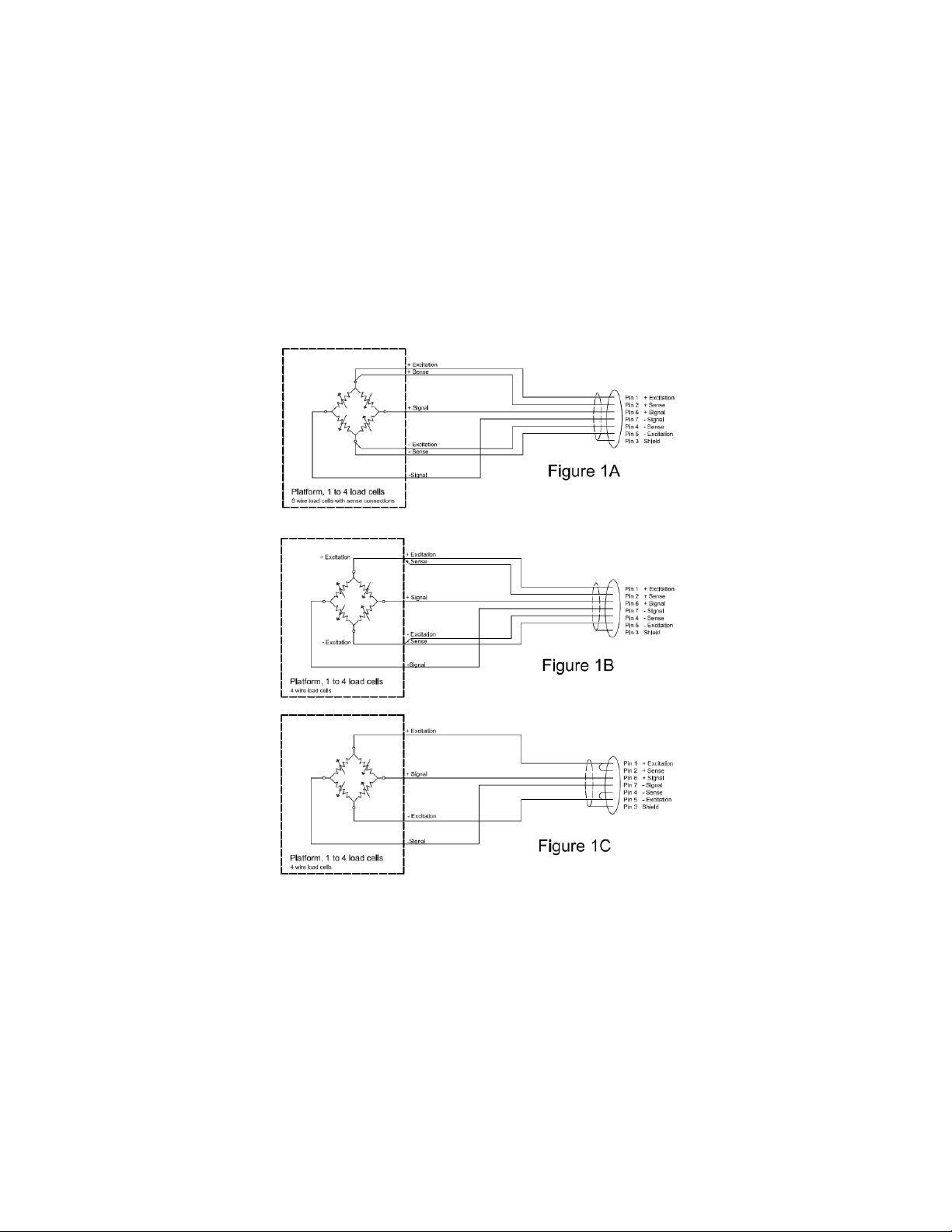

3.3 CONNECTION

This indicator must be connected to a load cell platform and calibrated as necessary

to match the platform and user requirements.

The GC has a connector configured for either 4 or 6 wire load cells. Connect the

load cells/platform to the indicator as shown below. The cable length should be as

short as possible, using a large size wire to minimise errors due to resistance in the

leads.

Figure 1A shows the connections to a 6 wire load cell. Figure 1B and 1C show 2

different ways to attach a 4 wire load cell, 1B uses a 6 conductor cable to go from

the indicator to the platform or load cell where it connects to the 4 wires from the

load cells.

The Excitation and sense wires are connected internally in the GC indicator.

P a g e 7 © Adam Equipment Company 2010

Page 10

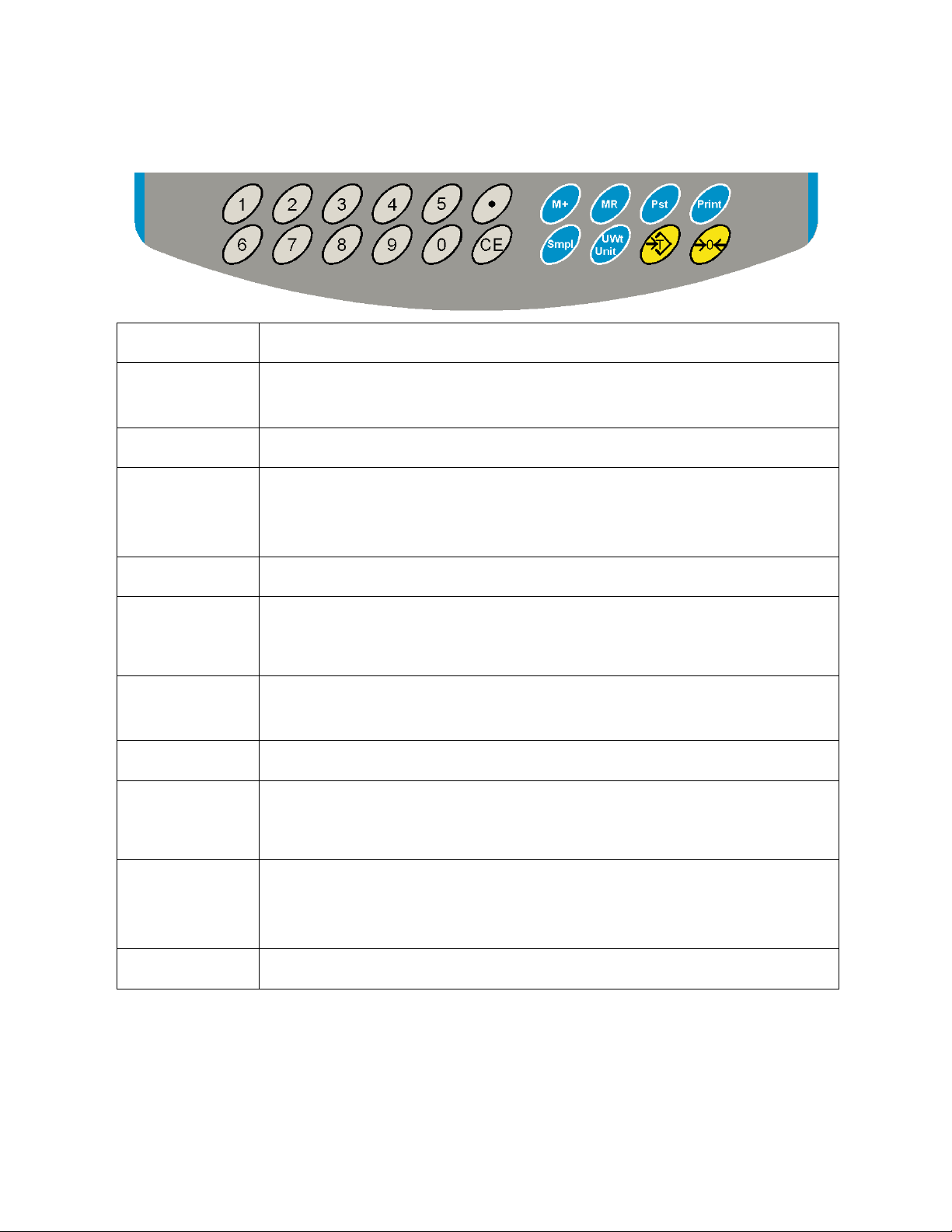

4.0 KEY DESCRIPTIONS

Keys

[0-9, .] Numeric entry keys, used to manually enter a value for tare weights, unit

weight, and sample size.

[CE] Used to clear the unit weight or an erroneous entry.

[M+] Add the current count to the accumulator. Up to 99 values or full capacity of

the weight display can be added. Also prints the displayed values when Auto

print is switched off.

Functions

[MR] To recall the accumulated memory.

[Pst]

To set the upper limit for the number of items counted. When this upper limit

is exceeded the scale will sound the beeper.

[Print] To print the weight/ unit weight and count to a PC or printer using the RS-232

interface. Print the totals from memory when [MR] is pressed first.

[Smpl] Used to input the number of items in a sample.

[U.Wt./Units] Used to enter the weight of a sample manually.

Select the weighing unit when the “Unit Weight” display is at zero if enabled.

[Tare] Tares the scale. Stores the current weight in memory as a tare value, subtracts

the tare value from the weight and shows the results. This is the net weight.

Entering a value using the keypad will store that as the tare value.

[Zero] Sets the zero point for all subsequent weighing to show zero.

P a g e 8 © Adam Equipment Company 2010

Page 11

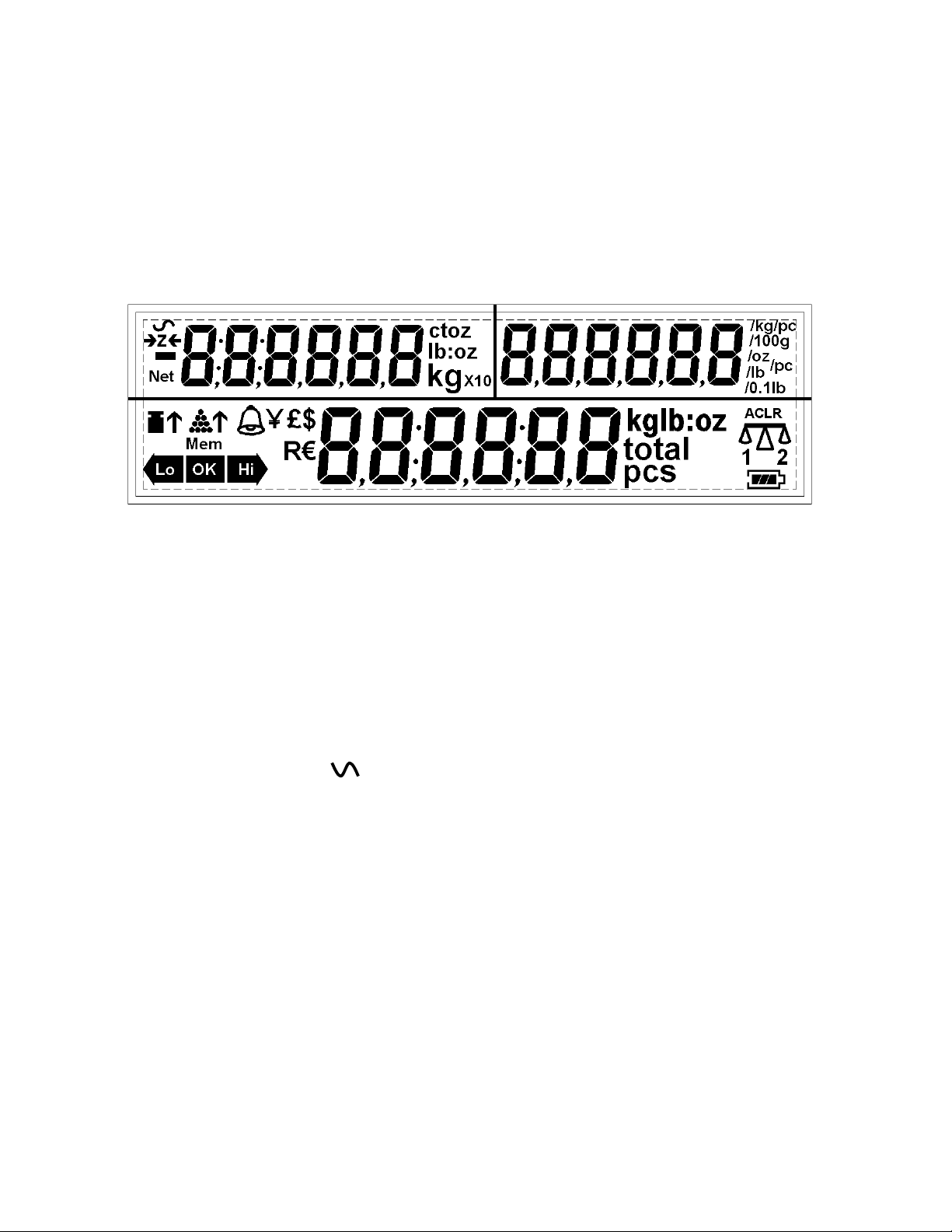

5.0 DISPLAYS

The scales have three sections. These are “Weight”, “Unit Weight” and “Count”.

The LCD design is:

WEIGHT UNIT WEIGHT

5.1 WEIGHT DISPLAY

It has 6-digit display to indicate the weight on the scale.

Net Weight Display, "Net"

Stability indicator, symbol

Zero indicator, 0 symbol

The weighing unit: kg, lb

COUNT

P a g e 9 © Adam Equipment Company 2010

Page 12

5.2 UNIT WEIGHT DISPLAY

This display will show the unit weight of a sample. This value is either input by

the user or computed by the scale. The unit of measurement is grams if grams if

kilograms is selected for the weighing unit, or pounds if pounds is selected.

5.3 COUNT DISPLAY

This display will show the number of items on the scale or the value of the

accumulated count. See the next section on OPERATION.

5.4 OTHER SYMBOLS

• The symbol, when there is insufficient number of samples to

accurately determine the count.

• When the unit weight is not large enough to determine an accurate count,

the symbol will be on.

• In both cases the scale continues to operate and the indications are to

alert the user for a potential problem.

• If a preset count has been stored the symbol will be on.

• A low battery symbol will turn on if the battery should be recharged.

• The Lo, OK, Hi symbols will be used when the preset count has been set.

• The symbol “Mem” will be seen when the internal memory has a record of

previous weighings stored in it.

P a g e 10 © Adam Equipment Company 2010

Page 13

6.0 OPERATION

NOTE: GC-a Scales only

SETTING THE WEIGHING UNIT, lb or kg

The scale will turn on displaying the last weighing unit selected, either kilograms or

pounds. To change the weighing unit press the [U. Wt./Units] key when the “Unit

Weight” display shows zero. If necessary press the [CE] key to clear the unit weight

before changing.

6.1 ZEROING THE DISPLAY

• You can press the [Zero] key at any time to set the zero point from which

all other weighing and counting is measured. This will usually be necessary

only when the platform is empty. When the zero point is obtained the

“Weight” display will show the indicator for zero, “>Z<”.

• The scale has an automatic re-zeroing function to account for minor

drifting or accumulation of material on the platform. However you may

need to press [Zero] to re-zero the scale if small amounts of weight are

still shown when the platform is empty.

6.2 TARING

• Zero the scale by pressing the [Zero] key if necessary. The indicator

“>Z<” will be ON.

• Place a container on the platform and its weight will be displayed.

• Press [Tare] to tare the scale. The weight that was displayed is stored as

the tare value which is subtracted from the display, leaving zero on the

display. The indicators “Net” and “>Z<” will be ON.

• As a product is added only the weight of the product will be shown. The

scale could be tared a second time if another type of product was to be

added to the first one. Again only the weight that is added after taring

will be displayed.

• When the container is removed a negative value will be shown. If the

scale was tared just before removing the container, this value is the

gross weight of the container plus all products those were removed.

The indicator “>Z<” will also be ON because the platform is back to the

same condition as it was when the [Zero] key was pressed last.

P a g e 11 © Adam Equipment Company 2010

Page 14

6.2.1 Preset Tare

• The user can enter a preset tare value if the display is at zero or gross

weight. Enter the value for preset tare using the keypad, then press the

[Tare] key to set the preset zero value.

• If the display was at zero the weight will show a negative value equal to

the preset tare value entered and the “Net” indicator will be on. If a

weight was on the platform then the preset value will be subtracted

from the weight, displaying the NET weight only.

6.3 PARTS COUNTING

6.3.1 Setting Unit Weight

In order to do parts counting it is necessary to know the average weight of the items

to be counted. This can be done by weighing a known number of the items and

letting the scale determine the average unit weight or by manually inputting a

known unit weight using the keypad.

A. Weighing a sample to determine the Unit Weight

To determine the average weight of the items to be counted, you will need to

place a known quantity of the items on the scale and then to key in the

number of items being weighed. The scale will then divide the total weight by

the number of items and display the average unit weight. Press [CE] anytime

to clear the unit weight.

• Zero the scale by pressing the [Zero] key if necessary. If a container is to

be used, place the container on the scale and tare by pressing [Tare] as

discussed earlier.

• Place a known quantity of items on the scale. After the weight display is

stable, enter the quantity of items using the numeric keys and then

press the [Smpl] key.

• The number of units will be displayed on the "Count" display and the

computed average weight will be shown on the "Unit Weight" display.

• As more items are added to the scale, the weight and the quantity will

increase.

• If a quantity which is smaller than the sample is placed on the scale,

then the scale will automatically enhance the Unit Weight by recalculating it. To lock the Unit Weight and avoid re-sampling, press [U.

Wt./Units].

P a g e 12 © Adam Equipment Company 2010

Page 15

• If the scale is not stable, the calculation will not be completed. If the

weight is below zero, the “Count” display will show negative count.

B. Entering a known Unit Weight

• If the unit weight is already known then it is possible to enter that value

using the keypad.

• Enter the value of the unit weight in grams, using the numeric keys

followed by pressing the [U. Wt./Units] key. The "Unit Weight" display

will show the value as it was entered.

• The sample is then added to the scale and the weight will be displayed

as well as the quantity, based on the unit weight.

6.3.2 Counting more parts

• After the unit weight has been determined or entered, it is possible to

use the scale for parts counting. The scale can be tared to account for

the container weight as discussed in the earlier section.

• After the scale is tared the items to be counted are added and the

"Count" display will show the number of items, computed using the

total weight and the unit weight.

• It is possible to increase the accuracy of the unit weight at any time

during the counting process by entering the count displayed and then

pressing the [Smpl] key. You must be certain that the quantity

displayed matches the quantity on the scale before pressing the key.

The unit weight can be adjusted based upon a larger sample quantity.

This will give greater accuracy when counting larger sample sizes.

6.3.3 Check-counting

• Check-counting is a procedure to cause an alarm to sound when the

number of items counted on the scale meets or exceeds a number

stored in the memory by using the [Pst] key.

• The value to be stored is entered from the keyboard. Enter the numeric

value to be stored using the numeric keys. Then press the [Pst] key to

store the value.

• To clear the value from the memory and thereby turn off the check-

counting feature, enter the value "0" and press [Pst].

• During counting if the count is below the setpoint the “Lo” indicator will

be on, if it is equal to the set point the “OK” indicator will be on and if it

is above the limit the “Hi” indicator will be on.

P a g e 13 © Adam Equipment Company 2010

Page 16

6.3.4 Manually Accumulated Totals

• The values (weight and count) shown on the display can be added to

the values in the memory by pressing the [M+] key. The "Weight"

display will show the total weight, the "Count" display will show the

total accumulated count and the "Unit Weight" display shows the

number of times, the items have been added to the memory for

accumulation. The values will be displayed for 2 seconds before

returning to normal. If the accumulated number exceeds 6 digits the

display will show “diSPEr”, the count is still being stored correctly and

the RS232 printout will still show the correct values.

• The “Mem” symbol will be on when there are values stored in the

accumulation memory.

• The scale must return to zero or a negative number, before another

sample can be added to the memory.

• More products can then be added and the [M+] key to be pressed

again. This can continue for up to 99 entries or until the capacity of the

“Weight” display is exceeded. When the weight exceeds 6 digits the

display will show “diSPEr”.

• To observe the total stored value, press the [MR] key. The total will be

displayed for 2 seconds.

• To clear the memory- first press [MR] to recall the totals from memory

and then press the [CE] key to clear all values from the memory.

6.3.6 Automatic Accumulated Totals

• The scale can be set to automatically accumulate totals when a weight

is placed on the scale. This eliminates the need to press the [M+] key to

store values into the memory. However the [M+] key is still active and

can be pressed to store the values immediately. In this case the values

will not be stored when the scale returns to zero.

• See the Section 9.0 on RS-232 Interface for details on how to enable

Automatic Accumulation.

P a g e 14 © Adam Equipment Company 2010

Page 17

7.0 USER PARAMETERS

The parameters are set to customise the scale to suit the weighing applications. You

need to enter a secure menu by entering a password when requested.

• Press [Tare] once, during the initial counting of the display after the

power is turned on.

• The “Weight” display will show "PIn " requesting for the password

number.

• The default password is "0000" but other numbers can be set using the

parameter menus. Press the [0] key four times.

• Press the [Tare] key.

• There are 3 functions that can be cycled through using the [U.

Wt./Units] key. The Weight window will show the parameter number

and the Unit Price window will show the word describing the function.

• The first parameter is “F1” “CAL”. (See section 8.0 for details)

• To enter into Calibration function, press the [Tare] key.

• To exit a parameter, press the [Zero] key.

• To select the second parameter press the [U. Wt./Units] key.

P a g e 15 © Adam Equipment Company 2010

Page 18

7.1 SETTING OF PIN

• Display will show “F2” “Pin”. This parameter allows setting of a new

password number. The default password is “0000”.

• Press [Tare]. The “Weight” display will show "Pin 1".

• Enter the new password number. The “Unit Weight” display will show

dashes. Press [Tare].

• The “Weight” display will change to "Pin 2 ", Enter the password again

and press [Tare].

• The display will show "donE" to show the new password has been

accepted and will return to the menu. Record the new password in a

secured place.

• To exit a parameter, press the [Zero] key.

7.2 ENABLE WEIGHING UNITS

• Display will show “F3” “Unit”. This parameter allows weighing units to be

enabled or disabled. If enabled the weighing units will change when the

[U.Wt./Unit] key is pressed. See section 6.0.

• To enter this function press the [Tare] key.

• The display will show the first weighing unit and if it is currently On or

Off. Press the [U.Wt./Unit] key to change the setting and then press

the [Tare] key to go to the next weighing unit. The weighing units

selected will depend upon the model and the capacity of the scales.

See Section 12.2, Service Parameters.

• Press the [Zero] key to return to the weighing mode.

P a g e 16 © Adam Equipment Company 2010

Page 19

8.0 CALIBRATION

• The GC scales are calibrated using metric weights and GCa scales are

calibrated using metric or pound weights depending on the unit in use

before calibration. See the Service parameters section for more

information.

• The scale will display a value of the weight to be used for calibration,

this value is the last weight used for calibration. You can enter a

different value, if desired.

• For entering Calibration, see section 7.0 Parameters

• When “F1” “CAL” is displayed, press [Tare].

• The display will then show "unLoAd" to request all weight be removed

from the platform.

• Press the [Tare] key to set the zero point.

• The displays will then show the calibration weight suggested, the value

is shown as an integer number, it is not possible to have fractions of a

kilogram or pound. For example:

LoAd 00004

KiLoS

• Place the calibration weight on the platform If the calibration weight is

different from the value shown, Press [CE] to clear the current value

then enter the correct value.

• Press [Tare] to calibrate.

• When calibration is done the display will show “SPAn” “PASS”.

• Remove the weight. The scale will return to normal weighing.

• If an error message “SPAn” “FAIL” is displayed, then repeat the process.

• After calibration, the scale should be checked whether the calibration is

correct. If necessary, repeat calibration.

NOTE: GCa scales will have the lb or kg indicator on, to show the unit of the weight

requested. If the scale was in pounds before starting the calibration, the weights

requested will be in pound values or if the scale was weighing in kilograms then

metric weights will be requested.

P a g e 17 © Adam Equipment Company 2010

Page 20

RS-232 output of weighing data

9.0 RS-232 INTERFACE

The GC Series are supplied with a RS-232 bi-directional interface. The scale when

connected to a printer or computer through the RS-232 interface, outputs the

weight, unit weight and count.

Specifications:

ASCII code

Adjustable Baud rate, 600, 1200, 2400, 4800, 9600 and 19200 baud

8 data bits

No Parity

Connector:

9 pin D-subminiature socket

Pin 3 Output

Pin 2 Input

Pin 5 Signal Ground

The scale can be set to print text in English, French, German or Spanish. See the RS232 parameters section for details.

All lines end with line feed <lf>, and carriage return <cr>characters.

P a g e 18 © Adam Equipment Company 2010

Page 21

Data Format-Normal Output:

<lf><cr>

<lf><cr>

DATE 12/09/2006

TIME 14:56

<lf><cr>

GROSS Wt 1.234 Kg Net Wt. if net weight is displayed

Unit Wt. 123 g Kg or g for metric weights and lb for pounds.

Pcs 10 pcs

<lf><cr> Includes 2 line feeds with carriage return

<lf><cr> at beginning and end of the form

Data Format- Memory Recall Print:

<lf><cr>

DATE 12/09/2006

TIME 14:56

<lf><cr>

-----------------TOTAL

No. 5

Wt. 1.234 Kg

Pcs 10 pcs

<lf><cr>

-----------------<lf><cr>

2 line feeds, carriage return

<lf><cr>

Includes 1 line feed

P a g e 19 © Adam Equipment Company 2010

Page 22

Data Format- Continuous Print:

ST,GS, 0.9080 kg

U.W. 0.90798 g/pcs

PCS 1000 pcs

<lf><cr> Includes 2 line feeds with carriage return

<lf><cr> between sets of data

In other languages the format is the same but the text will be in the language

selected. See Section 9.2

Description ENGLISH FRENCH GERMAN SPANISH

Print gross

weight

Net weight

Weight per

unit counted

Number of

items

counted

Number of

weighings

added to

subtotals

Total weight

and count

printed

Gross Wt Pds Brut Brut-Gew Pso Brut

Net Wt. Pds Net Net-Gew Pso Net

Unit Wt. Pds unit Gew/Einh Pso/Unid

Pcs Pcs Stck. Piezas

No. Nb. Anzhl Num.

Total Total Gesamt Total

Print date

Print time

P a g e 20 © Adam Equipment Company 2010

Date Date Datum Fecha

Time Heure Zeit Hora

Page 23

9.1 INPUT COMMANDS FORMAT

The scale can be controlled with the following commands. The commands must be

sent in upper case letters, i.e. “T” not “t”. Press the Enter key of the PC after each

command.

T<cr><lf>

Z<cr><If>

P<cr><lf>

R<cr><lf>

C<cr><lf>

Tares the scale to display the net weight. This is the same as

pressing [Tare] key.

Sets the zero point for all subsequent weighing. The display shows

zero. Same as pressing the [Zero] key.

Prints the weight, unit weight and totals same as pressing the

[Print] key.

Recall and Print, Same as if first the [MR] key and then the [Print]

key is pressed. Will display the current accumulated memory and

print the total results.

Same as pressing [MR] first and then the [CE] key to erase the

current memory.

P a g e 21 © Adam Equipment Company 2010

Page 24

9.2 RS-232 SETUP

The RS-232 interface uses parameters set by the user for language, baud rate and

date format.

Press and hold the [Print] key for 4 seconds to access the parameters.

Press [U. Wt./Units] to scroll through the options and [Tare] to confirm the change

and then advance to the next parameter.

When a parameter is entered by pressing [Tare], the displays will guide you through

the parameter selected and the options available.

The parameters and their functions are:

Displays

Weight

Unit

Weight

Port

9600 bPS

Print mAn

AC mAn

on

Count

Options

On

oFF

600

1200

2400

4800

9600

19200

Cont to PC

Print Auto

Print mAn

AC Auto

AC mAn

AC oFF

Functions

Enable or disable the RS232 interface.

Set baud rate.

Select printing options for

continuous printing, print

automatically or printing

manually.

Select the operation of

accumulating

automatically, manually or

turned off.

LAnG EnGLiS

P a g e 22 © Adam Equipment Company 2010

EnGLiS

FrEnCH

GErMAn

SPAniS

Select Language for

printing.

Page 25

The scale will perform the following functions depending on the Accumulation and Print

Accumulate and print

settings:

ACCUMULATION FUNCTIONS

PRINT

FUNCTIONS

Print Auto

Print mAn

Cont to PC

AC Auto AC mAn AC oFF

Accumulate and

print automatically

Automatically

Accumulate but not

print, Print only

when [Print] key

pressed

Print continuously

and accumulate

automatically when

stable , [Print] key

no function

Print automatically ;

Accumulate and print

when [M+] is pressed

when [M+] or [Print] is

pressed

Print continuously and

accumulate when [M+] is

pressed, [Print] key no

function

Print automatically,

[M+] key has no

function

Print when [Print] key

is pressed, [M+] key

has no function

Print continuously ,

[M+] and [Print] key

have no function

P a g e 23 © Adam Equipment Company 2010

Page 26

9.3 REAL TIME CLOCK SETUP

The Real Time Clock (RTC) is used only for the RS-232 output. The Date and Time

can be set as required. The scale will keep the clock running even when the power

is off.

Setting up the clock

• Press and hold the [CE] key for 4 seconds, release when the date and time is

displayed. The initial displays show the current date and time set.

“ rtC “ “11,14,06” “16,41,35”

• Press the [CE] key to change the date and time. The display will show the

current time in the format, “H-m-S”.

“timE” “H-m-S” “142929” or if no time has been set show “000000”

• Enter the time using the numeric keys using a 24 hour clock format, 3:41PM is

“154100”.

“timE” “H-m-S” “154100” new time overwrites the old

• Press the [Tare] key to accept the time. The display will show the current

date format.

“dAtE” “y-m-d”

• Press the [U.Wt./Unit] key to change the date format. Available formats are:

“Y-m-d” year, month, day

“m-d-Y” month, day, year

“d-m-Y” day, month, year

• Press the [Tare] key to accept the chosen format and then enter the date in

this format.

“dAtE” “m-d-y” “051209” note current date is in current format, will

show 000000 if no date has been set.

• Press the [Tare] key to accept the date.

An error code will be shown if the time (Err 1) or the date (Err 2) is not the

permissible values. For example, 34th day of a month is an invalid entry.

P a g e 24 © Adam Equipment Company 2010

Page 27

9.4 AUTO SLEEP FUNCTION

This function may be enabled or disabled by the user. If enabled, when the scale is

not used for some time (as pre-set by the user under this function) it automatically

switches off. To set this parameter-

• Press and hold the [Zero] key for 4 seconds, release when the display

shows “SLEEP nodE”.

• Press [U/Wt/Unit] key to scroll through the auto sleep values.

“0” Auto sleep mode disabled

“1” Auto sleep after 1 minute

“5” Auto sleep after 5 minutes

“10” Auto sleep after 10 minutes

• Press [Tare] to set the value. The scale returns to zero.

10.0 BATTERY AND BACKLIGHT OPERATION

10.1 BATTERY

• The scales can be operated from the battery, if desired. The battery life

is approximately 70 hours.

• When the battery needs charging the battery symbol will appear to be

empty. The battery should be charged as possible. Once the “LO bAT”

message is shown the scale will still operate for about 10 minutes after

which it will automatically switch off to protect the battery.

• To charge the battery, simply apply power to the scale. The scale does

not need to be turned on.

• The battery should be charged for at least 12 hours for full capacity.

• Just above the “Unit Weight” display is an LED to indicate the status of

battery charging. When the scale is plugged into the mains power, the

internal battery will be charged. If the LED is green the battery is fully

charged. If it is red, the battery is nearly discharged and yellow

indicates the battery should be charged longer, preferably overnight.

• If the battery has not been used properly or it is used for a number of

years it may eventually fail to hold a full charge. If the battery life

becomes unacceptable then contact your supplier.

P a g e 25 © Adam Equipment Company 2010

Page 28

10.2 BACKLIGHT FOR LCD

• The backlight of the LCD can be set to be-

“1”: ON at all the time,

“2”: ON only when a weight is placed on the scale or

“3”: Turned off.

• To set the backlight press and hold [Pst] key for 4 seconds.

• The weight display will show “EL xx” where xx is the current setting for

the backlight.

Press [U. Wt./Units] to scroll through the options.

Sets the backlight to be on at all times.

“EL on”

Sets the backlight to operate automatically when a

“EL Au”

weight is placed on the scale or a key is pressed.

Sets the backlight to be off.

“EL OFF”

Press the [Tare] key to store the value or press the [Zero] key to escape from this

setting and return to weighing.

P a g e 26 © Adam Equipment Company 2010

Page 29

11.0 ERROR CODES

During the initial power-on testing or during operation, the scale may show an error

message. The meaning of the error messages is described below.

If an error message is shown, repeat the step that caused the message, turning the

balance on, carry out the calibration or other functions. If the error message is still

shown contact your dealer for further support.

ERROR CODE DESCRIPTION POSSIBLE CAUSES

Err 1

Err 2

Err 4

Err 6

Time input error. Tried to set an illegal time, i.e.

26hours

Date input error

Tried to set an illegal date, i.e. 36th

day

Initial Zero is greater

than allowed (typically

Weight is on the pan when turning

the scale on.

4% of the maximum

capacity) when power is

turned on or when the

[Zero] key is pressed,

Excessive weight on the pan when

zeroing the scale.

Improper calibration of the scale.

Damaged load cell.

Damaged Electronics.

A/D count is not correct

Platform is not installed.

when turning the scale

on.

Damaged Load cell.

Damaged Electronics.

diSPEr

Shows when a number

is too large tot fit the

display

P a g e 27 © Adam Equipment Company 2010

The accumulated totals for weight

or count exceed 999999. The data

on RS232 is still shown accurately

Page 30

12.0 SERVICE PARAMETERS

12.1 USING “0000” TO ENTER THE CALIBRATION PARAMETER

• Press the [Tare] key during the display counting when turned on. The

display will ask for a code number, “Pin “ on the Weight Display.

• Enter the number 0000 when “Pin “ is displayed and then press

[Tare]. If another PIN number has been previously stored enter that

number instead.

• The displays will show the first parameters, called “F1” “CAL”.

• To select another parameter press the [U.Wt./Units] key to advance

through the parameters.

• Press the [Tare] key to enter a parameter.

• To exit a parameter, press the [Zero] key.

• The Weight window will show the parameter number and the Unit

Price and Count windows will show the word describing the function.

• When a parameter is entered by pressing the [Tare] key, the displays

will guide you through the parameter selected and the options

available.

The parameters available are:

“F1” “CAL”

To enter the Calibration

“F2” “Pin” To set a new Pin number for access

“F3” “Unit” Enable Weighing Units

P a g e 28 © Adam Equipment Company 2010

Page 31

12.1.1 F1 -CALIBRATION

To enter the calibration parameter, press the [Tare] key when “F1” “CAL” is displayed.

The scale should be calibrated using a mass of approximately 2/3Maximum to

Maximum. If the scale has been calibrated previously the value will be stored.

Details of calibration are given is section 8.

12.1.2 F2 –PIN

• To enter this parameter, press the [Tare] key when “F2” “Pin” is shown.

• The “Weight” display will show “Pin 1”

• Enter the new password. The “Unit Weight” display will show dashes.

Press [Tare].

• The “Weight” display will change to “Pin 2 “, Enter the password again

and press [Tare].

• The display will show “donE” indicating the new password has been

accepted and will return to the menu. “F3” “Unit” is shown.

• Record the new password in a secured place.

• Press [Zero] to return to weighing.

12.1.3 F3 –Unit

• To enter this parameter, press the [Tare] key when “F3” “unit” is

shown.

• This parameter allows the user to enable or disable the weighing units

available in his scales.

• The display will show the first available weighing unit and if it is On or

Off.

• Press the [U.Wt./Units] key to change the value. Press [Tare] to

accept the displayed setting and go to the next unit.

• Press the [Zero] key to return to the menus. Press the [Zero] key again

to return to normal weighing.

P a g e 29 © Adam Equipment Company 2010

Page 32

12.2 USING “2006” TO ENTER THE SERVICE PARAMETERS

Before setting the parameters for units, decimal point, capacity and increment the

user should make sure they understand how the scale should be configured. The

scale is limited to 30,000 scale divisions. To determine the number of scale divisions

divide the capacity by the desired increment. For example a 500kg scale reading to

0.01kg would have 50,000 divisions, a value not allowed. However a 500kg scale

with interval of 0.02kg is 25,000 divisions, an acceptable number.

The order of the settings will request the default weighing unit first. This is to

assign a weighing unit to the first calibration, regardless of what he user may select

later. If the indicator has been configured for use in the USA the choice can be

grams, kilograms or pounds. For the rest of the world it is kilograms or grams only.

This setting should match the type of masses you have for calibration, imperial or

metric.

The next 2 parameters will set the decimal point position, capacity and increment. It

will be necessary for the settings to be within allowable limits for a setting to be

accepted. For example, it is only allowed that the grams can be set to 45,000 or

less. If you try to set the capacity to 50,000 grams it is not allowed, use kilograms

for the default unit and set the capacity to 50kg. When setting the interval the

options shown will only be those that allow the number of divisions to be 30,000 or

less. For example setting capacity to 5000g and the decimal point to 0.0, the

increment of 1 (=0.1g) is not allowed. Only the increment of 2, 5, 10 or 20 is

allowed.

PROCEDURE:

• Press the [Tare] key during the display counting when turned on. The

display will ask for a code number, “Pin “ on the Weight Display.

• Enter the number 2006 when “Pin “ is displayed and then press

[Tare].The displays will show the first parameters, called “F1” “CAL”.

• To select another parameter press the [U.Wt./Units] key to advance

through the parameters.

• Press the [Tare] key to enter a parameter. To exit a parameter, press

the [Zero] key.

• The Weight window will show the parameter number and the Unit

Price and Count windows will show the word describing the function.

• When a parameter is entered by pressing the [Tare] key, the displays

will guide you through the parameter selected and the options

available.

P a g e 30 © Adam Equipment Company 2010

Page 33

The parameters available are:

“F1” “Unit”

“F2” “dPP”

“F3” “CAP”

“F4” “CAL”

“F5” “init” “ZEro”

“F6” “rE” “ Zero”

“F7” “SCSivE” “ tArE”

“F8” “Ad” “CoUnt”

“F9” “Pin”

Default Weighing Unit

Decimal Point Position

Select capacity and increment

To enter the Calibration

Initial Zero Range

Re-Zero range

Successive Tare Enable

Display the A/D counts

To set the password

“F10” “Lvd” “mode” Low voltage detection

“F11” “trACk” “ZEro” Zero track setting

12.2.1 F1 –DEFAULT WEIGHING UNIT

To set the weighing unit that will be used initially for calibration and setting the

calibration. This weighing unit will always be available to the user.

• To enter this parameter, press the [Tare] key when “F1” is shown. The

display will show the current setting.

• Press the [U.Wt./Units] key to change the value. Select from the units

displayed, typically kilograms (kg), grams (g) or pounds (lb) for USA

sales and kilogram or grams for the rest of the world.

• Press [Tare] to accept the displayed value.

12.2.2 F2 –DECIMAL POINT POSITION

• To set the value for the decimal point location. The options are 0, 0.0,

0.00, 0.000, 0.0000

• To enter this parameter, press the [Tare] key when “F2” is shown.

• The display will show the current setting.

P a g e 31 © Adam Equipment Company 2010

Page 34

• Press the [U.Wt./Units] key to change the value. Select from 0, 0.0,

0.00, 0.000, 0.0000

• Press [Tare] to accept the displayed value.

12.2.3 F3 – CAPACITY

• To enter this parameter, press the [Tare] key when “F3” is shown. The

display will show the current capacity.

• Enter the numeric values using the keypad. The scale will check the

number of divisions n = maximum/increment is less than 30,000

divisions.

• Press [Tare] to accept the displayed value.

NOTE: The scale use load cells suitable for the capacity selected.

• The display then will go to the increment setting.

• To set the value for the increment of the scale. For example 100kg x

0.01kg the increment is 10grams. but the last digit increments by 1.

• The display will show the current increment value.

• Press the [U.Wt./Units] key to change the value. The indicator will

determine what the minimum and maximum increment is possible for

the capacity and decimal point you have set.

• Press [Tare] to accept the displayed value.

12.2.4 F4 -CALIBRATION

• To enter the calibration parameter, press the [Tare] key when “F4” is

displayed. The scale will be calibrated using 2 masses of approximately

1/3Maximum and Maximum. If the scale has been calibrated once the

values will be stored. If this is the first time the scale is calibrated the

user must enter the values for the calibration masses.

• The display will instruct you to remove any weight from the scale,

“UnloAd”. Press [Tare].

• The display will tell you to add the first weight to the scale: “LoAd 1” “

40” “kiloS”

• Add the weight shown, wait for stability then press the [Tare] key.

P a g e 32 © Adam Equipment Company 2010

Page 35

• The display will tell you to add the second weight to the scale: “LoAd 2 “

100” “kiloS”

• Remove the weight.

• The display will show “SPAn” “PASS” if the calibration is OK. Or it will

show “SPAn” “FAIL” if calibration could not be completed correctly. After

calibration the scale will return to normal operation. If you wish to set

any of the following parameters enter the Service menu again and skip

the first settings by pressing the [U.Wt./Unit] key.

12.2.5 F5 –INITIAL ZERO RANGE

• To enter this parameter, press the [Tare] key when “F5” is shown.

• The display will show the current initial zero range.

• Press the [U.Wt./Units] key to change the value and press [Tare] to

accept the value.

• Press [Zero] to return to weighing.

12.2.6 F6 -RE-ZERO RANGE

• To enter this parameter, press the [Tare] key when “F6” is shown.

• The display will show the current re-zero range.

• Press the [U.Wt./Units] key to change the value.

• Press [Tare] to accept the value.

• Press [Zero] to return to weighing.

12.2.7 F7 -SUCCESSIVE TARE

• To enter this parameter, press the [Tare] key when “F7” is shown.

• The display will show if the successive tare is on or off.

• Press the [U.Wt./Units] key to change the value.

• Press [Tare] to accept the displayed value.

• Press [Zero] to return to weighing.

P a g e 33 © Adam Equipment Company 2010

Page 36

12.2.8 F8 –ADC COUNTS

• To enter this parameter, press the [Tare] key when “F8” is shown.

• This parameter allows you to view the A/D counts from the internal A/D

converter. This can be an aid to service.

• Press the [Tare] key to return to the PARAMETER menu.

• Press the [Zero] key to return to weighing.

• Typical value at zero is 30,000-90,000 (approx.) Typical value at full

capacity is 500,000 (approx.)

12.2.9 F9 –PIN

This parameter allows setting of password to enter the user parameters, see section

12.1. The default value is “0000”.

• To enter this parameter, press the [Tare] key when “F9” “Pin” is shown.

• The “Weight” display will show “Pin 1”

• Enter the new password. The “Unit Weight” display will show dashes.

Press [Tare].

• The “Weight” display will change to “Pin 2 “, Enter the password again

and press [Tare].

• The display will show “donE” indicating the new password has been

accepted and will return to the menu. “F9” “Pin” is shown. Record the

new password in a secured place.

• Press [Zero] to return to weighing.

12.2.10 F10 –LOW VOLTAGE DETECTION

• This parameter allows detection of low voltage when the battery wears

down.

• To enter this parameter, press the [Tare] key when “F10” is shown.

• The display will show if the LVD Mode is set to “on” or “oFF”.

• Press the [U.Wt./Units] key to change the value.

• Press [Tare] to accept the displayed value.

• Press [Zero] to return to weighing.

P a g e 34 © Adam Equipment Company 2010

Page 37

12.2.11 F11 –ZERO TRACK SETTING

• This parameter allows the amount of zero track correction. To enter

this parameter, press the [Tare] key when “F11” is shown.

• The display will show the current setting, i.e. “ 0.5d “ resenting one-half

a division. Other possible settings are 1d, 2d, 4d and Off.

• Press the [U.Wt./Units] key to change the value. Press [Tare] to accept

the displayed value.

• Press [Zero] to return to weighing.

P a g e 35 © Adam Equipment Company 2010

Page 38

13.0 REPLACEMENT PARTS AND ACCESSORIES

If you need to order any spare parts and accessories, contact your supplier or Adam

Equipment. A partial list of such items is as follows-

• Main Power cord

• Power supply (GC-a)

• Replacement Battery

• In use cover

• Printer

P a g e 36 © Adam Equipment Company 2010

Page 39

P a g e 37 © Adam Equipment Company 2010

Page 40

14.0 SERVICE INFORMATION

This manual covers the details of operation. If you have a problem with the scale

that is not directly addressed by this manual then contact your supplier for

assistance. In order to provide further assistance, the supplier will need the

following information which should be kept

ready:

A. Details of your company

-Name of your company:

-Contact person’s name:

-Contact telephone, e-mail,

fax or any other methods:

B. Details of the unit purchased

(This part of information should always be available for any future correspondence.

We suggest you to fill in this form as soon as the unit is received and keep a print-out in

your record for ready reference.)

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

C. Brief description of the problem

Include any recent history of the unit. For example:

-Has it been working since it’s delivered

-Has it been in contact with water

-Damaged from a fire

-Electrical Storms in the area

GC _____

-Dropped on the floor, etc.

P a g e 38 © Adam Equipment Company 2010

Page 41

P a g e 39 © Adam Equipment Company 2010

Page 42

15.0 WARRANTY INFORMATION

Adam Equipment offers Limited Warranty (Parts and Labour) for the components failed due to defects

in materials or workmanship. Warranty starts from the date of delivery.

During the warranty period, should any repairs be necessary, the purchaser must inform its supplier or

Adam Equipment Company. The company or its authorised Technician reserves the right to repair or

replace the components at any of its workshops depending on the severity of the problems. However,

any freight involved in sending the faulty units or parts to the service centre should be borne by the

purchaser.

The warranty will cease to operate if the equipment is not returned in the original packaging and with

correct documentation for a claim to be processed. All claims are at the sole discretion of Adam

Equipment.

This warranty does not cover equipment where defects or poor performance is due to misuse,

accidental damage, exposure to radioactive or corrosive materials, negligence, faulty installation,

unauthorised modifications or attempted repair or failure to observe the requirements and

recommendations as given in this User Manual. Additionally rechargeable batteries (where supplied)

are not covered under warranty.

Repairs carried out under the warranty does not extend the warranty period. Components removed

during the warranty repairs become the company property.

The statutory right of the purchaser is not affected by this warranty. The terms of this warranty is

governed by the UK law. For complete details on Warranty Information, see the terms and conditions

of sale available on our web-site.

P a g e 40 © Adam Equipment Company 2010

Page 43

Manufacturer’s Declaration of Conformity

This product has been manufactured in accordance with the harmonised European

standards, following the provisions of the below stated directives:

Electro Magnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Adam Equipment Co. Ltd.

Bond Avenue, Denbigh East

Milton Keynes, MK1 1SW

United Kingdom

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. The equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Shielded interconnect cables must be employed with this equipment to insure compliance with the

pertinent RF emission limits governing this device.

Changes or modifications not expressly approved by Adam Equipment could void the user's authority to

operate the equipment.

WEEE COMPLIANC E

Any Electrical or Electronic Equipment (EEE) component or assembly of parts intended to be

incorporated into EEE devices as defined by European Directive 2002/95/EEC must be recycled or

disposed using techniques that do not introduce hazardous substances harmful to our health or the

environment as listed in Directive 2002/95/EC or amending legislation. Battery disposal in Landfill Sites is

more regulated since July 2002 by regulation 9 of the Landfill (England and Wales) Regulations 2002 and

Hazardous Waste Regulations 2005. Battery recycling has become topical and the Waste Electrical and

Electronic Equipment (WEEE) Regulations are set to impose targets for recycling.

© Adam Equipment Company 2010

Page 44

ADAM EQUIPMENT

years experience in the production and sale of electronic weighing equipment.

Adam products are predominantly designed for the Laboratory, Educational, Medical, retail

and Industrial Segments. The product range can be described as follows:

-Analytical and Precision Balances

-Compact and Portable Balances

-High Capacity Balances

-Moisture analysers / balances

-Mechanical Scales

-Counting Scales

-Digital Weighing/Check-weighing Scales

-High performance Platform Scales

-Crane scales

-Medical Scales

-Retail Scales for Price computing

For a complete listing of all Adam products visit our website at www.adamequipment.com

is an ISO 9001:2000 certified global company with more than 35

© Copyright by Adam Equipment Co. Ltd. All rights reserved. No part of this publication may be reprinted or

translated in any form or by any means without the prior permission of Adam Equipment.

Adam Equipment reserves the right to make changes to the technology, features, specifications and design of

the equipment without notice.

All information contained within this publication is to the best of our knowledge timely, complete and accurate

when issued. However, we are not responsible for misinterpretations which may result from the reading of

this material.

The latest version of this publication can be found on our Website.

www.adamequipment.com

© Adam Equipment Company 2010

Loading...

Loading...