Page 1

!

W

E

N

PANCRETE

Pan in a Can!

THAT’S RIGHT... Protect your investment now

After a few short years when the condensate Pouring Pancrete in your pan keeps it new,

pan in your HVAC system becomes corroded

and surfaces become irregular, troublesome

leaks start. Forget about rotting pans, expensive

replacement, and down time. You need the

Pan in a Can.

extending the life dramatically. It’s better than

the factory installed pan. Pancrete is more

than the pan in a can, it’s your silent partner

in pan maintenance. Prevention is always the

best economical policy.

Imagine pouring a brand new pan. Pancrete

covers the rotted pan and makes the surface

like new again. It automatically fills in pitts

and irregular surface characteristics,

providing a smooth, enamel surface that is

unaffected by harsh coil cleaners.

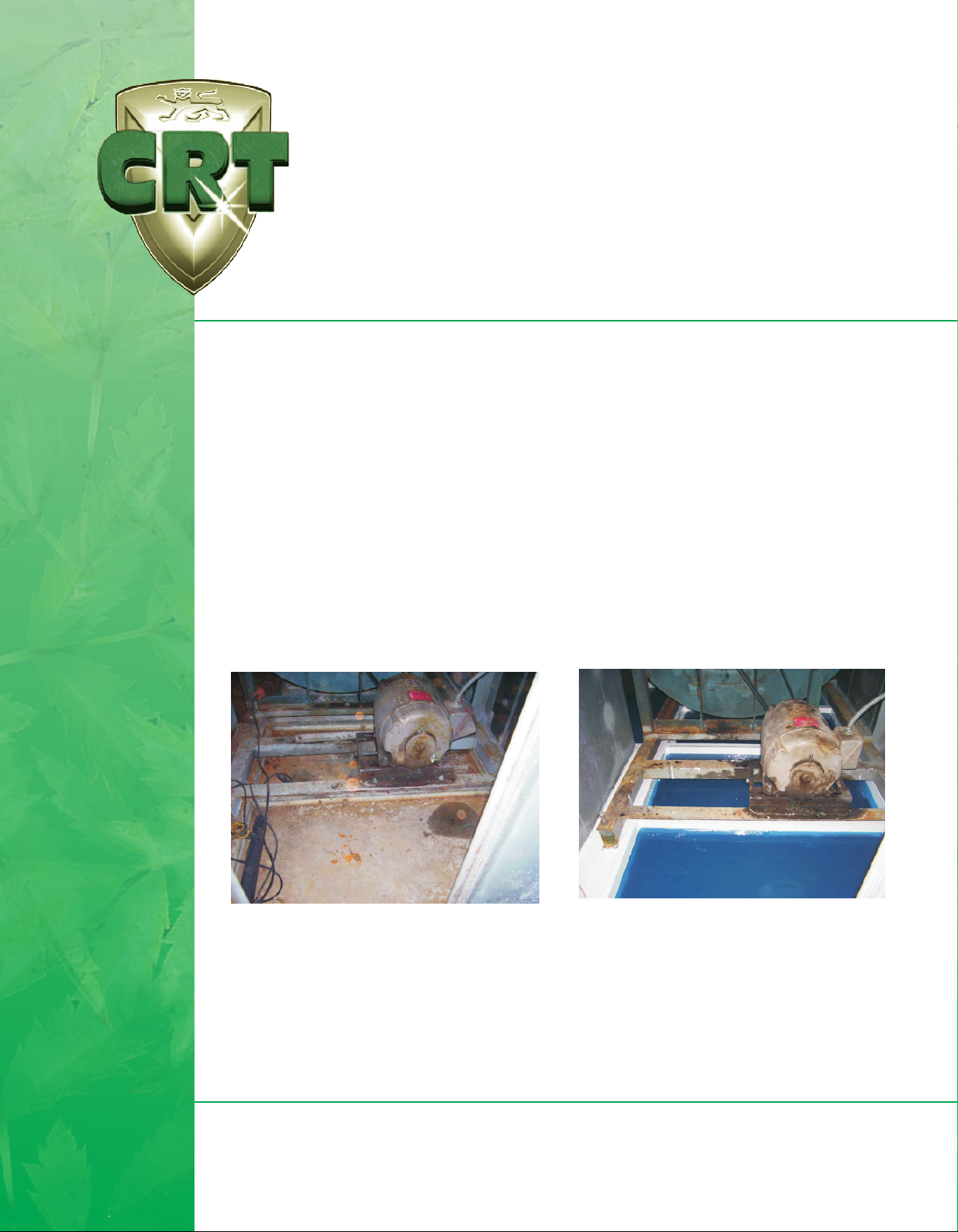

A Rusted HVAC Pan

Pancrete forms a durable level pan,

eliminating low spots that inhibit drainage.

Water goes where it should—down the drain.

A Rusted HVAC Pan

treated with Pancrete

PANCRETE

Pour your pan today!

Controlled Release Technologies, Inc.

1016 Industry Drive • Shelby • North Carolina 28152

(800) 766-9057 • (704) 487-0878 • fax (704) 487-0877 • www.cleanac.com

Page 2

PANCRETE

sales@novatech-usa.com

www.novatech-usa.com

Tel: (866) 433-6682 Fax: (866) 433-6684

Tel: (281) 359-8538 Fax: (281) 359-0084

Submersible, Chemical-Resistant

Anti-Corrosion, Metal Resurfacer

Pancrete is a high performance, corrosion proof

product with high adhesion to metal and plastic

surfaces. Resists corrosion on aluminum, galvanized,

copper and stainless steel.

• Stops pan leaks

• Automatic pan levelling

• Not affected by coil cleaners

• Ensures long life to new pans

• Strengthens your pan

Characteristics

HMIS:

Boiling Point: N/A

Specific Gravity (water=1): 1.2

Vapor Pressure (MM HG): 17mm @ 20ºC

Material V.O.C: 0.32 lb/gal (20 G/L)

Coating V.O.C: 0.32 lb/gal (20 G/L)

Vapor Density (AIR=1): Heavier than air

Evaporation Rate (Water=1): Slower than ether

Solubility in Water: Infinitely soluble

%Volatile (by wgt): 94%

Appearance and Odor: Blue or Black Liquid;

Ammonia Odor

Respiratory Protection: None required if good

ventilation is maintained. Otherwise use NIOSH

approved respirator designed to remove particles.

Ventilation: Local exhaust needed at point of

release to maintain exposure below TLV.

Eye Protection: Chemical splash goggles

recommended to avoid eye contact.

Protective Gloves: Rubber gloves.

0-0-0

See Material Safety Data Sheet for more detailed

information.

DATA

APPLICATIONPERFORMANCE

The HVAC system must be shut down during the

procedure.

Prep everything first. Pancrete begins to set up

in about 20 minutes. Pancrete will set up in it’s

container within 30 minutes.

Estimation usage: 2 gallons are required for each 10

sq./ft. of condensate pan pouring at a depth of onequarter inch.

Valleys and unlevel pans may require more than

originally calculated.

Build up a capped drain opening to higher than

expected Pancrete level. Vertically fixed drains

required a ninety-degree capped elbow to raise just

to the expected level of Pancrete.

Prep new surfaces by abraiding with acidic acid and

Scotch Brite pad, rinse and dry.

Old, rusted pans are prepped by removing all dirt

and loose rust completely. A drill with wire brush

attachment and/or pressure sprayer can be used

where practical. In areas where grease is possible

wash the surface with TSP. Blow surface dry with

compressed air if available.

Mix full amount of each can only. Partial mixing is

not recommended. Screws, bolts or anything which

may need to be taken out later needs to be taken into

consideration.

Pancrete will be sufficiently set up so that unit may

be turned back on within 4-6 hours. Cut or file any

PVC pipe inserted into drain holes so that it is flush

with the Pancrete level prior to turning unit back

on. Pancrete will be cured within 24 hours. Follow

can directions carefully

See MSDS for detailed product description and safe handling.

Controlled Release Technologies, Inc.

1016 Industry Drive • Shelby • North Carolina 28152

(800) 766-9057 • (704) 487-0878 • fax (704) 487-0877 • www.cleanac.com

Loading...

Loading...