Page 1

READ ALL CAUTIONS CAREFULLY BEFORE

P/N 32040

Rev B

NOTE: Prime Performance Series Addendum starts on page 13

INSTALLING PUMP

INSTRUCTION

MANUAL

Page 2

TABLE OF CONTENTS

NOTE: Prime Performance Series Addendum starts on page 13

Page

SAFETY INSTRUCTIONS ......................................................................................................................................... 2

INTRODUCTION ........................................................................................................................................................ 2

PRECAUTIONS FOR OPERATION .......................................................................................................................... 3

INSTALLATION, PIPING AND WIRING .................................................................................................................... 4

BLEED VALVE INSTALLATION (Optional) ............................................................................................................... 6

MAINTENANCE ......................................................................................................................................................... 8

SERVICE AND REPAIRS .......................................................................................................................................... 9

TROUBLESHOOTING ............................................................................................................................................. 10

PARTS LIST (EXPLODED PUMP ASSEMBLY) ...................................................................................................... 11

REPLACEMENT KITS (EXPLODED WET END ASSEMBLY) ................................................................................ 12

SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS PRIOR TO USE

Secure chemicals & metering pumps, making them inaccessible to children & pets.

*** DO NOT PUMP FLAMMABLE LIQUIDS.

*** Do not cut the plug or ground lug off the electrical cord. Consult a licensed electrician for proper installation or

replacement.

To reduce the risk of electrical shock-before maintenance, repair, or moving, always disconnect the power

to the pump by unplugging from wall outlet.

Always wear protective clothing, including gloves and safety glasses, when working on or near chemical

metering pumps.

** Inspect tubing regularly for cracking or deterioration and replace as necessary. (Always wear protective clothing and

safety glasses when inspecting tubing.)

** Use CAUTION to keep fingers away from rotating parts.

** If pump is exposed to direct sunlight, use a UV resistant tubing.

** Follow directions and warnings provided from the chemical manufacturer. The user is responsible for determining the

chemical compatibility with the chemical feed pump.

** Make sure the voltage on the pump name tag matches the installation voltage. If pump fails to start, check line voltage.

** Consult with local health officials and/or qualified water conditioning specialists when treating potable water.

** Always depressurize system prior to installation or disconnecting the metering pump tubing.

** If injection point is lower than the chemical tank and pump, install an anti-siphon valve.

** DO NOT MODIFY PUMP. This poses a potentially dangerous situation and will void the warranty. Hand tighten plastic

connections (Do not use wrench).

All pumps are factory tested with water. Remove tubing and thoroughly dry if the chemical being pumped

will react with water (for example sulfuric acid).

* Hand tighten plastic connections (Do not use wrench).

* Consult licensed plumber and electrician before installation to conform to local codes.

* NOTE: For accurate volume output, pump must be calibrated under all operating conditions.

INTRODUCTION

Series 100/150 are diaphragm-type metering pumps. A fluid is pumped from a

chemical storage tank to the point of injection by the pulsing action of the

diaphragm. The four check valves (top and bottom of pump head, strainer

assembly, and injection assembly) keep the fluid flowing toward the point of

discharge. To insure the solution being pumped can only go forward, it is

important that all check valves provide positive, non-leaking backflow

prevention. The wetted end (those parts that contact the solution being

pumped) is constructed of SAN, PVC, TFE, Hypalon®, and polyethylene.

These materials are very resistant to most chemicals. However, there are

some chemicals, such as strong acids or organic solvents, which cause

deterioration of some elastomer and plastic parts, such as diaphragm, valve seat, or head. Alternate materials such as

Viton®, polypropylene is available on request. Contact chemical supplier for chemical compatible materials.

2

Page 3

MANUFACTURER’S PRODUCT WARRANTY

The manufacturer warrants its equipment of its manufacture to be free of defects in material or workmanship. Liability

under this policy extends for twenty-four (24) months from the date of purchase or one (1) year from date of installation or

whichever comes first. The manufacturer’s liability is limited to repair or replacement of any device or part which is

returned, prepaid, to the factory and which is proven defective upon examination. This warranty does not include

installation or repair cost and in no event shall the manufacturer’s liability exceed its selling price of such part.

The manufacturer disclaims all liability for damage to its products through improper installation, maintenance, use or

attempts to operate such products beyond their functional capacity, intentionally or otherwise, or any unauthorized repair.

Replaceable elastomeric parts are expendable and are not covered by any warranty either expressed or implied. The

manufacturer is not responsible for consequential or other damages, injuries or expense incurred through use of its

products.

The above warranty is in lieu of any other warranty, either expressed or implied. The manufacturer makes no warranty of

fitness or merchantability. No agent of ours is authorized to make any warranty other than the above.

For warranty and service matters within the European Union, contact the seller first or:

Pulsafeeder, Inc. Europe

Units 12 and 13, Edison Road

Highfield Industrial Estates

Eastbourne, East Sussex BN23 6PT

PRECAUTIONS FOR OPERATION

Each Series 100/150 chemical feeder has been tested to meet prescribed specifications and certain safety standards.

However, a few precautionary notes should be adhered to at all times. THOROUGHLY READ ALL CAUTIONS PRIOR TO

INSTALLING METERING PUMP.

1. Chemicals used may be dangerous and should be used carefully and according to warnings on the label. Follow

the directions given with each type of chemical. Do not assume chemicals are the same because they look alike.

Always store chemicals in a safe location away from children and others. We cannot be responsible for the

misuse of chemicals being fed by the pump.

2. Always wear protective clothing (protective gloves and safety glasses) when working on or near chemical

metering pumps.

3. Tampering with electrical devices can be potentially hazardous. Always place chemicals and feeder installation

well out of the reach of children and others.

4. Be careful to check that the voltage of the installation matches the voltage indicated on the specification label.

Each pump is equipped with a three prong plug. Whether plugging into a receptacle or wiring into a system,

always be sure the feeder is grounded. If receptacle is utilized, to disconnect, do not pull wire but grip the plug

with fingers and pull out.

5. Never repair or move the metering pump while operating. Always disconnect electrical current. Before handling

the pump always allow sufficient time for the motor housing to cool off. Handling the pump too soon after

shutdown may cause hand burns. For safety use protective gloves.

6. All pumps are pretested with water before shipment. Remove head and dry thoroughly if you are pumping a

material that will react with water, (e.g. sulfuric acid). Valve seats, ball checks, gaskets, and diaphragm should

also be dried. Before placing feeder into service, extreme care should be taken to follow this procedure.

7. Arrows on the pump head and injection fitting indicate chemical flow. When properly installed, these arrows

should be pointing upward.

8. When metering hazardous material DO NOT use plastic tubing. Strictly use proper rigid pipe. Consult supplier for

special adaptors.

9. Pump is NOT to be used to handle or meter flammable liquids or materials.

3

Page 4

10. Standard white polyethylene discharge tubing is not recommended for installations exposed to direct sunlight.

Consult supplier for special black polyethylene tubing.

11. Manufacturer will not be held responsible for improper installation of pumps, or local plumbing conducted. All

cautions are to be read thoroughly prior to hook-up and plumbing. For all installations a professional plumber

should be consulted. Always adhere to local plumbing codes and requirements.

12. Note the maximum pressure rating of the metering pump. When used with pressurized systems, always be sure

the pressure of the system does not exceed maximum pressure rating listed on the specification label.

13. Be sure to depressurize system prior to hook-up or disconnection of metering pump.

INSTALLATION, PIPING AND WIRING

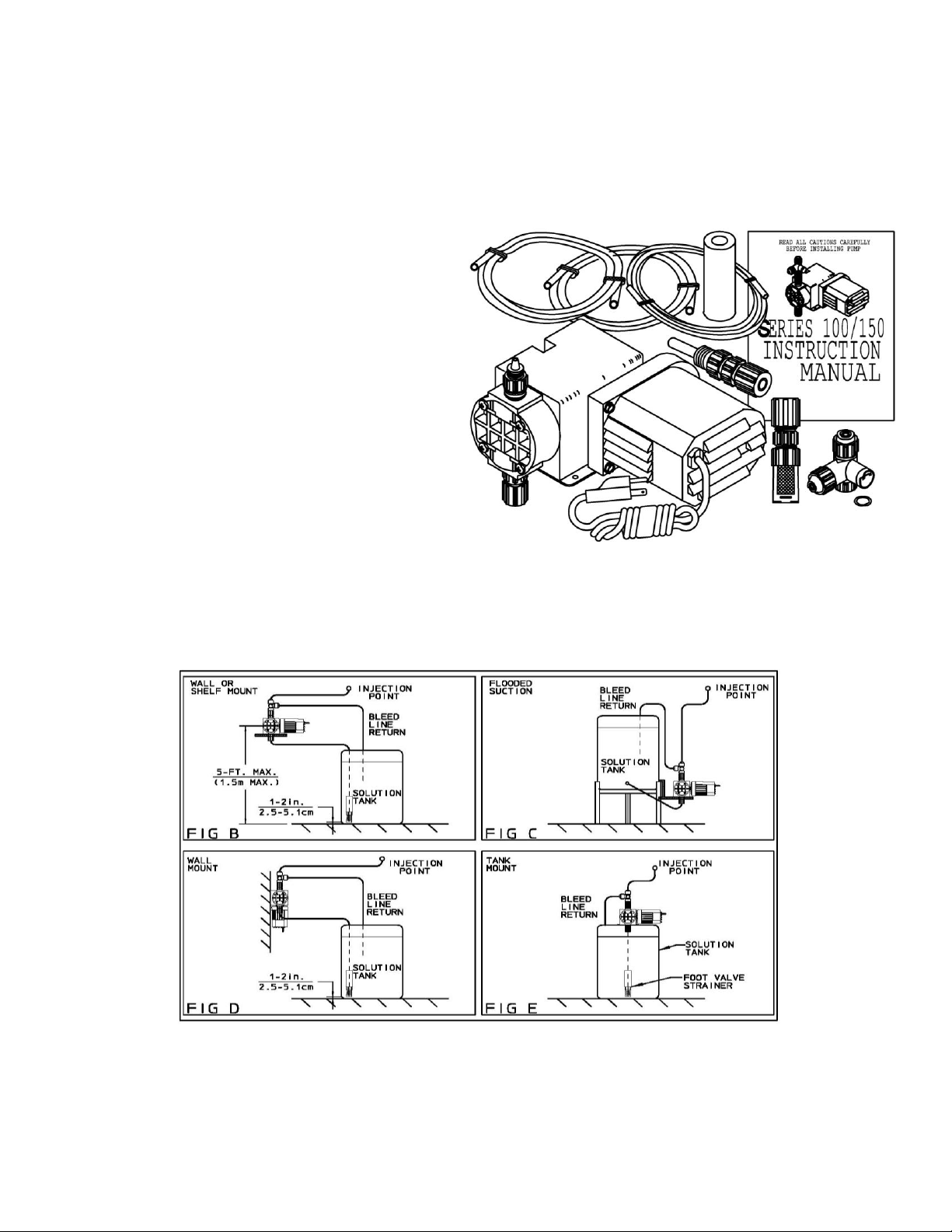

UNPACKING, ASSEMBLING AND MOUNTING:

The carton should contain:

Metering Pump

4 ft. (1.21 m) Clear Flexible Suction Tubing

4 ft (1.21 m) Stiff White Return Tubing

Feeder can be mounted on a wall shelf bracket

(Figure B), tank stand platform (Figure C),

directly on the wall (Figure D), or directly on the

tank cover (Figure E).

Bleed Valve Assembly

Instructions

Strainer Assembly w/Tube Weight

Back Check Valve Assembly

8 ft (2.43 m) Stiff White Discharge Tubing

(Optional black tubing for UV protection

available from the factory)

To mount the feeder directly on the wall, place the feeder base against the wall with the motor below the pumping head,

remove four head mounting bolts, and turn head quarter turn so suction is in bottom position.

IMPORTANT: Injection point must be higher than top of solution tank to prohibit gravity feeding. Maximum head

in meters is 70m/H2O for Series 100 Model pumps and 42m/H2O for Series 150 Model pumps.

NOTE: Make sure the arrow on the outside of the pump head is pointing upward. The pump must be positioned

so that the plug is accessible.

4

Page 5

Flooded suction mounting Fig. C (installing feeder at the base of tank on a platform) is the most trouble free type of

installation. (Tank stands and platforms are available for all

size feeders and tanks). The pump is secured on the

platform, and then the clear suction tubing is attached to a

bulkhead fitting assembly and the suction valve housing on

the pump head. Since the suction tubing is always filled

with solution, priming is accomplished much more quickly

and the chance of losing prime on an installation where the

feeder is used only a few hours a day, is greatly reduced.

The feeder comes with a bleed valve assembly that

attaches to the discharge valve in the pump head. The

bleed valve allows you to manually prime the feeder and

depressurize the discharge line without disconnecting the

feeder from the tubing connections.

NOTE: To operate without bleed valve, replace bleed

valve (item #49) and 0.38 in. (0.96 cm) -tubing size discharge valve housing (item # 42) with a 0.50 in. (1.27 cm) -tubing

size discharge valve housing (item #42) and coupling nut (item #43). See page 12 (Wet End Assembly). Items #42 and

#43 are available from factory.

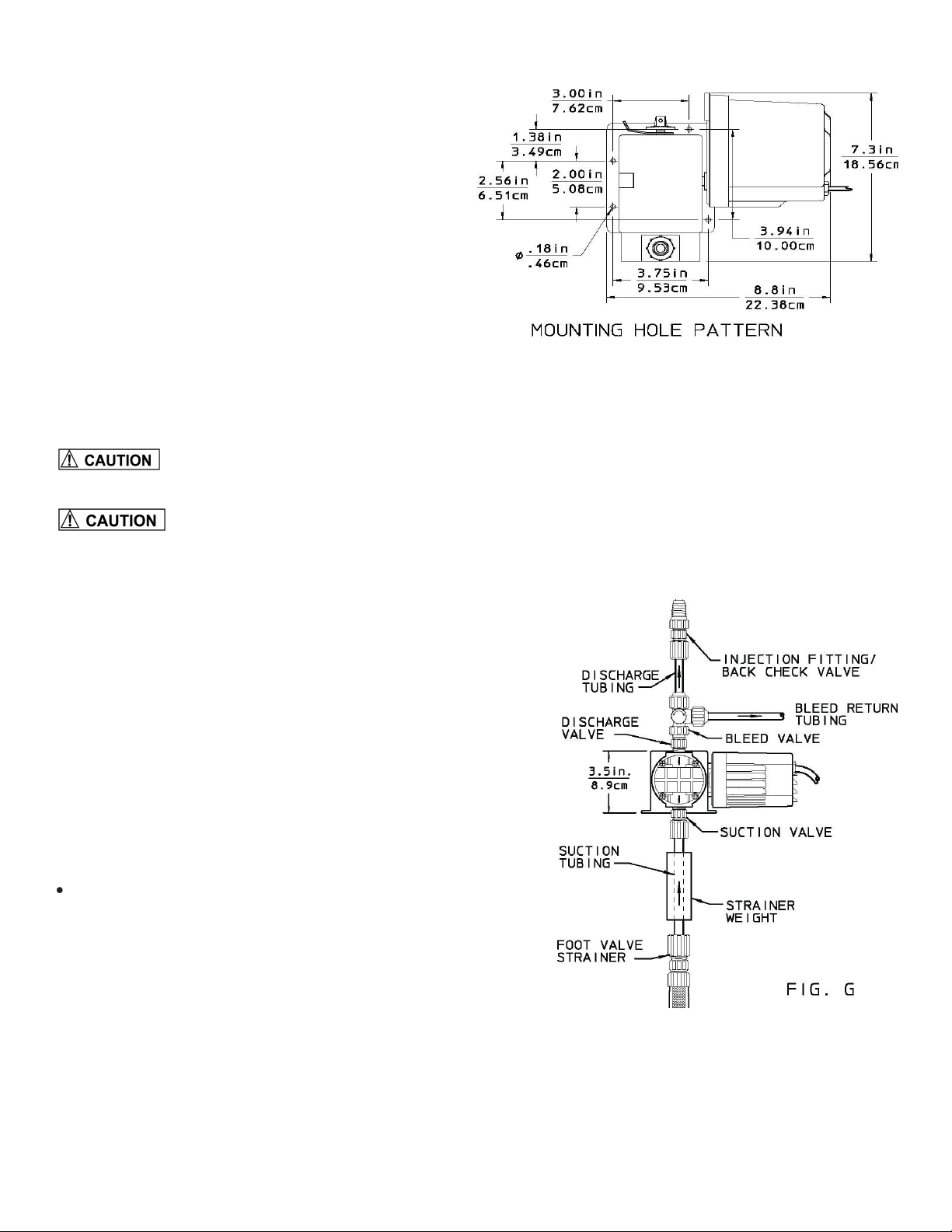

Assemble tubing and fittings to the feeder (Fig. G).

Do not force fittings, HAND TIGHTEN ONLY. Do not use additional sealants, such as pipe tape, on

tubing fittings. Use additional sealants, such as pipe tape, on pipe fittings and tighten normally.

If water is used to dissolve solid chemicals or create a dilute solution, the chemical tanks should be

manually filled or an approved means must be used to prevent a cross connection between the chemical tank contents

and the potable water line. Check local plumbing regulations.

CHEMICAL INJECTION:

Chemical injection into an open tank: The discharge tubing can be

placed in an open tank with or without the injection valve assembly.

Each feeder is shipped with a spring loaded back check injection

valve. This assists in a positive seal on the discharge side of the pump

head preventing back flow.

Pumps carrying the 'NSF' or the 'ETL Sanitation' (tested to NSF

standard-50) approval are listed for swimming pools, spas, and hot

tubs, and when proper materials are selected, are capable of handling

but not limited to the following chemical solutions.

121/2% sodium hypochlorite 2% calcium hypochlorite 12% aluminum

sulfate 10% hydrochloric acid 10% sodium hydroxide 5% sodium

carbonate.

INSTALLATION INTO A WELL PUMP SYSTEM:

Make sure the voltage of the feeder matches the voltage of the

well pump. Install the injection fitting into a tee which is installed into

the water line going to the pressure tank. The end of the injection

check valve should be in the main stream of the water line. A typical

installation is shown in Figure H. For installation of pump for

operating swimming pools, pump is to be supplied by an

isolating transformer or thru an "RCD" (residual current device).

NOTE: It is recommended to install the injection assembly in a vertical position on the bottom side of the water

line (Figure J).

This will insure proper sealing of the injection assembly check valve and prevent a back flow into the feeder's discharge

line. Be sure arrow on injection fitting is pointing upward.

5

Page 6

DOWN-THE-WELL INSTALLATION:

Often it is desirable to provide chemical

feed near the intake of the well pump for

additional retention time and mixing of the

chemicals. An additional length of

discharge tubing will be required for this

installation. Secure the end of the discharge

tubing to the pump cylinder, drop pipe, or

foot valve and lower it into the well. An antisiphon valve must be installed on systems

such as this where the discharge is lower

than the feeder and the chemical storage

tank.

Failure to install anti-siphon valve may

allow siphoning to occur.

ANTI-SIPHON VALVE: (optional)

Under any installation condition where the

possibility of siphoning or suction may

occur on the discharge side of the pump,

install an anti-siphon valve on the discharge

side of the feeder. The anti-siphon valve is

not part of the standard package. This item can be furnished by your dealer at

extra cost.

PRESSURE RELIEF VALVE: (optional)

Series 100/150 chemical pumps are rated to pump against a line pressure up to

100 PSI (7 BAR). If the line pressure on an installation could fluctuate above 100

PSI (7 BAR), install a pressure relief valve on the discharge side of the pump

head. Once the pressure reaches a certain level, the pre-set relief valve will

return the solution being pumped back to the solution tank. This will prevent

motor burnout or diaphragm rupture. The relief valve is not part of the standard

package. This item can be furnished by your dealer at extra cost. Read relief

valve instructions carefully before installing.

BLEED VALVE INSTALLATION: (optional)

NOTE: After disconnecting power to the pump and taking necessary safety

precautions regarding the chemical and system.

1. Remove the coupling nut and tubing from the discharge port of the pump.

2. Remove the valve housing from the discharge side of the pump head and

replace it with the .38inch valve housing from the kit (this step is not required

if the pump is already fitted for .38inch tubing.

3. Install the TFE gasket (ChemTech) over the discharge fitting.

4. Install the bleed valve assembly over the discharge fitting and gasket.

(ChemTech)

6

Page 7

5. Install the bypass tubing from the kit into the bypass port of the bleed valve and hand tighten the coupling nut.

Bypass tubing should be connected to return bypassed liquid back to the solution tank.

6. Install the discharge tubing into the discharge port of the bleed valve and hand tightens the coupling nut.

7. Return the system to operating conditions and reconnect the power to the pump.

The pump is now ready for priming and operation. Always use caution and check for leaks at newly assembled

connections.

Air Bleed Operation:

1. While pump is running, turn the bleed valve knob counter clockwise.

2. Run with valve open until a solid stream of fluid comes out of the bypass tubing (.38inch tubing supplied with valve)

3. Close air bleed valve by turning the bleed valve knob clockwise.

HAND TIGHTEN FITTINGS:

When connecting tubing to suction and discharge fittings, the coupling nuts should be tightened hand tight only. Excessive

tightening can cause cracks in pump head.

POINT OF INJECTION:

Pipe corrosion can result if dillution at the injection point does not occur rapidly. This problem is easily prevented by

observing this simple rule: install injection fitting so that the end is in the flow stream of the line being treated. NOTE:

Extended injection assemblies are available for large water lines. Consult your dealer.

COMMON ERRORS IN THE INJECTION OF CHEMICALS:

Do not insert the injection fitting into a pipe stub in the tee. A full strength solution will often cause corrosion or scale in the

pipe stub when it is not in the flowing stream (Figure J). The maximum lift of the chemical feeder is five feet. Be sure not

to exceed this height. It is very important that the arrow on the fittings and the pump head point vertically upward

in order to prevent backflow. Arrows indicate the proper flow of the chemical.

POWER

The standard chemical feeder is available in115 volt 60 cycle single phase. 230 volt 60 cycle and 230 volt 50 cycle single

phase can also be made available upon request.

Be sure the voltage of the feeder matches the power supply. (Figure M)

Figure M

When working on or around metering pump installation, protective gloves and safety glasses should be worn at

all times.

PRIMING

All pumps are tested with water (e.g. sulfuric acid, polymer) the pump head should be removed and

dried thoroughly along with the diaphragm and valve seats.

If the discharge line is connected directly to a pressurized system it should be temporarily bypassed during priming of the

pump. This pump is equipped with a bleed valve to simplify this operation by allowing easy bypass of the discharge fluid.

7

Page 8

All air must be purged from the pump head before the pump will pump against pressure. Turn on the power to the pump.

FIG K

Loosen the locking lever by turning it counter-clockwise and turn the output adjusting knob counter-clockwise to full

capacity, (one full turn only) then tighten the locking lever by turning clockwise to a hand tight position. Solution should be

primed to the head within a few minutes. (Refer to Figure K)

Air Bleed Operation: A) While pump is running, turn adjustment screw counterclockwise. B) Run with valve open until a

solid stream of fluid comes out of the bypass tubing (0.25 in (0.63 cm) ID x 0.38 in (0.96 cm) OD) supplied with valve, no

air bubbles. C) Close air bleed valve by turning adjustment screw clockwise.

NOTE: The feeder is adjustable only while running; never force the output adjustment knob. Do not turn the adjustment

knob while the pump is stopped. If the solution hasn't reached the head in a few minutes, disconnect power to the pump,

make sure the system is depressurized, remove the discharge tubing and discharge fitting and dampen the discharge

valve area (ball check and valve seats) with a few drops of solution being fed by the pump. For safety, use protective

gloves and safety glasses and a proper container to hold chemical. Replace the fitting and tubing and restart the pump.

Turn the power on once more and adjust the pump to the proper rate, using the locking lever as before.

When working on or around metering pump installation, protective gloves and safety glasses

should be worn at all times.

Check calibration of the pump before leaving the installation site. A test for chemical residual in

the treated water is the best indication of the correct pump setting.

MAINTENANCE:

SCALE: GASKETS AND CHECK VALVES

When checking the metering pump or providing routine maintenance, replace all valve seats or ball checks if any of them

show any wear or deterioration. (Valve seats should be checked approximately every 4-6 months depending upon the

application.) Repeated deterioration of valve seats and other rubber or plastic parts within a few months period usually

indicates another material should be used for the defective part. Contact your supplier or see the parts list for parts

affected for possible alternate materials.

OUTSIDE INSTALLATION:

In many areas where freezing conditions are not a problem it is common to install a metering pump outside. Adequate

protection should be provided to keep the pump from being exposed to direct sunlight or rain. Any simple covering

adequately ventilated will afford the necessary protection from weather. NOTE: When discharge tubing is exposed to

direct sunlight, black polyethylene tubing should be used in lieu of the stiff white translucent tubing supplied with each

pump.

SOLUTION TANK:

Check the solution tank for settling of chemicals. If there is sludge on the bottom of the solution tank, clean the strainer,

the foot valve, and the solution tank. Installing the foot valve a few inches above the bottom of the tank will pr event future

clogging. NOTE: If the chemical being pumped regularly precipitates out of solution or does not dissolve easily or

completely (calcium hydroxide), mixers are readily available in different motor configurations and mountings.

OUTPUT ADJUSTING KNOB:

Sometimes the output adjusting knob can move on its shaft and cause a false

output indication. This can happen if the knob set-screw slips or if the unit is

disassembled for any reason. The unit can be reset to "0" as follows:

1. Remove the dial stop.

2. With the pump running, loosen the locking lever and turn the adjusting

knob counter-clockwise until it is "loose" to touch.

3. SLOWLY re-screw the knob clockwise, using very light finger pressure. It

will soon start to advance in pulses as the internal cam comes in and out

of contact.

4. When light finger pressure will no longer allow movement of the knob between cam contacts, grasp the knob securely

and tighten the locking lever (turning clockwise) making sure that the knob does not move. To check for zero point,

turn on pump. There should be no liquid coming out of discharge fitting.

5. Replace dial stop.

6. If the pointer is not at "0", loosen the set-screw on the knob (use a .078 in Hex key), and turn pointer to "0", then

retighten the set-screw while holding the knob in place.

8

Page 9

7. A setting of "0" will now give zero output. One full revolution of the knob counter clockwise will give maximum output.

The knob should never be turned more than one full revolution.

SERVICING AND REPAIRS

REPLACEMENT OF PUMP HEAD ASSEMBLY OR DIAPHRAGM:

Before performing any repairs on Series 100/150 chemical

feeders, be sure to disconnect all electrical connections and

relieve pressure from suction/discharge tubing.

The Series 100/150 feeder was designed so that servicing can be

quick and simple. Proper part replacement procedures are

described below.

NOTE: Use protective gloves and safety glasses when

working on or around chemical feeder.

1. Disconnect the tubing. Remove the suction valve and

discharge valve being careful not to lose the ball checks and

any other small parts. (Figure N)

2. Remove the four screws from the face of the head and

remove the head.

3. Remove the diaphragm by inserting one or two of the head

bolts into the holes of the diaphragm and turning counterclockwise. (Figure O)

4. A new pump head or diaphragm should be installed if either is broken or cracked (see parts list at the end of this

manual). The new pump head can be installed by going through the above steps in reverse.

5. Be sure the drive bracket assembly is in the fully retracted position when installing the new diaphragm. Install the

new diaphragm by screwing it in hand tight, then, back off one-fourth turn or until screw holes are lined up.

6. Replace the head and the head screws, being certain the discharge fitting is up. NOTE: Arrow on outside of pump

head should be in vertical position pointing upward. Tighten the head screws evenly and carefully to prevent cracking

the head.

7. Replace the suction and discharge fittings making sure all gaskets and valves are fitted properly. Do not use pipe tape

or other sealants. HAND TIGHTEN ONLY. Restart the system as in the start up procedures (INSTALLATION).

BALL CHECKS AND VALVE SEAT REPLACEMENT:

The following procedure is the same for any of the four

valves.

Make sure all electrical connections are disconnected

and pressure valves off.

NOTE: Use protective gloves and safety glasses while

replacing parts.

1. Unscrew compression nut and remove tubing.

2. Unscrew check valve body from pump head, foot valve,

or injection fitting.

3. Remove all seats, ball checks, and gaskets and

replace.

4. Replace the check valve body so fitting makes contact

with the gasket and the pump head, foot valve or

injection fitting, whichever the case may be. HAND

TIGHTEN FITTINGS ONLY. Do not use pipe tape or

other sealants on these threads.

5. Re-install the tubing and tighten coupling nut HAND TIGHT.

6. Restart the system as in the INSTALLATION PROCEDURES.

9

Page 10

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

REMEDY

LOSS OF

CHEMICAL

RESIDUAL

1. Pump setting too low.

2. Scale at injection point

3. Solution container allowed to

run dry

1. Adjust to higher setting (feeder must be operating during the stroke length

adjustment).

2. Clean injection parts with 8% muriatic acid or undiluted vinegar.

3. Refill the tank with solution and prime. See Start-Up Section

TOO MUCH

CHEMICAL

1. Pump setting too high.

2. Chemical in solution tank too

rich.

3. Siphoning of chemical into

well or main line

1. Lower pump setting (pump must be operating to adjust the dial).

2. Dilute chemical solution. NOTE: For chemical that reacts with water, it may

be necessary to purchase a more dilute grade of chemical direct from

chemical supplier.

3. Test for suction or vacuum at the injection point. If suction exists, install an

anti-siphon valve. See Figure G.

LEAKAGE

AROUND TUBING

CONNECTIONS

1. Worn tube ends

2. Chemical attack

1. Cut off end of tubing (about 1") and then slip on as before or replace

suction valve housing and compression fitting to prevent leakage.

2. Consult your chemical supplier for compatible materials.

FAILURE TO

PUMP OR FEED

1. Leak in suction side of pump.

2. Valve seats not sealing.

3. Low setting on pump.

4. Low solution level.

5. Diaphragm ruptured.

6. Pump head cracked or

broken.

7. Pump head contains air or

chlorine gas.

1. Examine suction tubing. If worn at the end, cut approximately an inch off

and replace or replace valve body and coupling nut.

2. Clean valve seats if dirty or replace with proper material if deterioration is

noted.

3. When pumping against pressure, the dial should be set above 40%

maximum rated capacity for a reliable feed rate.

4. Solution must be above foot valve.

5. Replace diaphragm as shown in "Service" Section. Check for pressure

above 100 PSI (7 BAR) at the injection point. NOTE: Chemical incompatibility

with diaphragm material can cause diaphragm rupture and leakage around

the pump head.

6. Replace pump head as shown in "Service" Section, Do not use pipe tape

or other sealants. Make sure fittings hand tight only. Using pliers or wrench

can crack pump head. Also, chemical incompatibility can cause cracking and

subsequent leakage.

7. While pump is running, turn bleed valve adjustment screw counterclockwise until air is purged. Close bleed valve.

PUMP LOSES

PRIME

1. Dirty check valve.

2. Ball checks not seating or not

sealing properly.

3. Solution container allowed to

run dry

1. Remove and replace or clean off any scale or sediment.

2. Check seat and ball checks for chips, clean gently. If deformity or

deterioration is noted, replace part with proper material. Chemical

crystallization can hold check valves open, therefore the valves must be

disassembled and cleaned. Be sure to replace all parts as shown in the Parts

Diagram (at the end of the manual).

3. Refill the tank with solution and prime.

LEAKAGE AT

FITTING

1. Loose fittings

2. Broken or twisted gasket

3. Chemical attack

1. All fittings can be hand tightened to prevent leakage. Clean off chemicals

which have spilled on pump.

2. Check gaskets and replace if broken or damaged.

3. Consult your chemical supplier for compatible materials.

PUMP WILL NOT

PRIME

1. Too much pressure at

discharge

2. Check valves not sealing

3. Output dial not set at

maximum

1. Open bleed valve and circulate fluid until all air is purged from pump head

assembly. Close bleed valve.

2. Disassemble, loosen, clean and check for deterioration or swelling.

Reassemble and wet the valve assembly, then prime. See INSTALLATION

Section.

3. Always prime pump with output dial set at maximum rated capacity.

ANTI-SIPHON

VALVE

MALFUNCTION

1. Scale or particles have

plugged diaphragm

2. Ruptured valves

1. Remove, clean and reassemble, being careful not to wrinkle the

diaphragm. Check sequence and position of parts to be sure reassembly is

correct.

2. Consult your distributor for replacement.

PUMP MOTOR

STALLS

1. Pumping against excessive

pressure

2. Low voltage to pump

1. Test pressure to determine if it exceeds pump specifications. If so, consult

your distributor.

2. Make sure voltage of power source matches the voltage on the pump

specifications label. If not transformers are available.

MOTOR RUNNING

VERY HOT

1. Low voltage.

2. If using a step-down

transformer, it may be

undersized for the pump

1. Power supply voltage should match voltage on pump specification label.

2. Check the transformer to be sure it has at least 100 watts capacity.

10

Page 11

11 12

Page 12

Page 13

Chem-Tech Prime Performance Series Addendum

13

Addendum Chem-Tech Prime Performance

Degassing Pump Head Instructions

NOTE: Head is for use on 15, 24 and 30 GPD models only!!

Before performing any maintenance or repairs on chemical metering pumps, be sure to

disconnect all electrical connections and insure that all pressure valves are shut off and pressure in

the pump and lines has been bled off.

Always wear protective clothing, gloves and safety glasses when performing any

maintenance or repairs on chemical metering pumps.

INTRODUCTION

The degassing head is designed to return a small percentage of the pumps output back into the tank

through the degas valve when the pump is operating. The fluid that is being returned via the return

line to the tank is part of the normal operation of the degassing head. As a result, the pumps

maximum output will be reduced and its output should be verified and adjusted as necessary. Install

the pump as show in figure 1 while adhering to the following installation instructions:

INSTALLING A PRIME PERFORMANCE PUMP WITH A DEGASSING HEAD

1. Connect one end of the clear PVC suction tubing to the suction valve on the bottom of the

pump head.

2. Slide the other end of the suction tubing through the strainer weight and install the foot valve

on the end, see figure 1.

3. Connect the discharge tubing to the discharge valve coming out of the side of the pump head.

J32079 Revision B

Figure 1

Page 14

Chem-Tech Prime Performance Series Addendum

14

4. Connect the return tubing to the degas valve on the top of the pump head.

5. Secure the other end of the degas return tubing to the top of the solution tank above the level

of the chemical.

TIP: For best results, insure the strainer / tubing hangs vertically and is as short as possible with the

strainer near the bottom of the solution tank but above any sediment, see figure 1.

DEGASSING HEAD, FLOODED SUCTION INSTALLATION

(NOT RECOMMENDED)

Figure 2

CONVERTING AN EXISTING PUMP TO A DEGASSING HEAD

1. Disconnect the suction, discharge and return tubing (if applicable) from the existing pump

head.

2. Remove the four head screws / washers from the pump head. Remove the head assembly

from the pump.

3. Place the degassing pump head assembly on the pump with the head arrow pointing up.

4. Reinstall the four head screw / washers. Tighten the screws evenly in a crisscross pattern

until they are hand tight (18-22 in/lbs (8-10kg)).

NOTE: Although not included, bleed valve may still be used on discharge valve for convenient

manual pressure relief and drain of discharge line.

PRIMING THE PUMP

1. Turn on the power to the pump.

2. Adjust the stroke length to 100%.

3. At this point, the pump will automatically purge the air from the pump head via the degas

valve. Once the fluid starts pumping out of the discharge line, re-adjust the pump flow to the

desired rate.

J32079 Revision B

Page 15

2

3

4

NOTE SPRING

ORIENTATION

SMALL

SPACER

LARGE

SPACER

NOTE

NOTCH

ON TOP

1

NOTE

ARROW

IS UP

DISCHARGE

SUCTION

DEGAS

RETURN

NOTE: PRIME PERFORMANCE DEGASING HEAD IS FOR USE ON

15, 24 and 30-GPD MODELS ONLY.

ITEM PART # PART DESCRIPTION QTY QTY QTY QTY

AS'Y J60176 HEAD AS'Y, S100 DEGAS HYP.5in.-T 15,24,30 REF - - AS'Y J60178 HEAD AS'Y, S100 DEGAS HYP.38in.-T 15,24,30 - REF - AS'Y J60180 HEAD AS'Y, S100 DEGAS VTN.5in.-T 15,24,30 - - REF AS'Y J60182 HEAD AS'Y, S100 DEGAS VTN.38in.-T 15,24,30 - - - REF

1 J28869 HEAD(PVC), S100 DEGAS MOLDED 1 1 1 1

2 J41805 VLV AS'Y, DEGAS PVC/TFE/CER, .50in. REF --- REF -- J41806 VLV AS'Y, DEGAS PVC/FTF/CER, .38in. --- REF --- REF

3 J41807 VALVE AS'Y, DISC/PVC/HYP/CER w/SPRG .5-T REF --- --- -- J41808 VALVE AS'Y, DISC/PVC/HYP/CER w/SPRG .38-T --- REF --- -- J41809 VALVE AS'Y, DISC/PVC/VTN/CER w/SPRG .5-T --- --- REF -- J41810 VALVE AS'Y, DISC/PVC/VTN/CER w/SPRG .38-T --- --- --- REF

4 J41811 VALVE AS'Y, SUCT/PVC/HYP/CER .5-T REF --- --- -- J41812 VALVE AS'Y, SUCT/PVC/HYP/CER .38-T --- REF --- -- J41813 VALVE AS'Y, SUCT/PVC/VTN/CER .5-T --- --- REF -- J41814 VALVE AS'Y, SUCT/PVC/VTN/CER .38-T --- --- --- REF

5 J32079 ADDENDUM, 2100 DEGASSING HEAD AS'Y 1 1 1 1

2g

Chem-Tech Prime Performance Series Addendum

15

J32079 Revision B

Loading...

Loading...