Page 1

B 8 0 8 0

LI-PO CHARGER Manual

1.Input voltage range 9~15V DC

2.Output 8.4V (4.2V x 2) x 2, or 12.6V (4.2V x 3) x 1, or 16.8V (4.2V x 4) x 1.

3.CC (2.0A charging current) and CV (4.2V charging voltage) charging technique.

4.Auto adjustment of the charging current at voltage peak region. Auto cutoff when battery cell

is fully charged.

5.This is an innovative charger for 1- 4 cells of (Minimum 360 mAh) Li-ion or Li-poly battery

packs. It can be used to charge 4 ea 1 cell packs (optional by using 2 ea series charge

adaptor cables for port of 7.4V), or 2 ea 2 cell packs, or 1 ea 3 cell packs or 1 ea 4 cell packs.

6.LED indication, red color for charging, green color for charger ready or battery cell fully

charged.

7.Instead of charging all cells of the battery pack in series, this charger will independently

control the charging process of each cell of the battery pack. It will completely eliminate the

interference between cells of the battery pack during charging process. It will also avoid the

possibility of fire or explosion caused by a problem battery pack with defective cell(s) inside.

8.Load polarity & short protection. In-put polarity protection.

9.Sturdy aluminum case & exhaust fan for maximum heat dissipation.

10.Auto cutoff charger operation when voltage of the power source is lower than 8V.

11.Size : 132 x 82 x 35 mm. Weight :313 gm (~11oz)

Specification

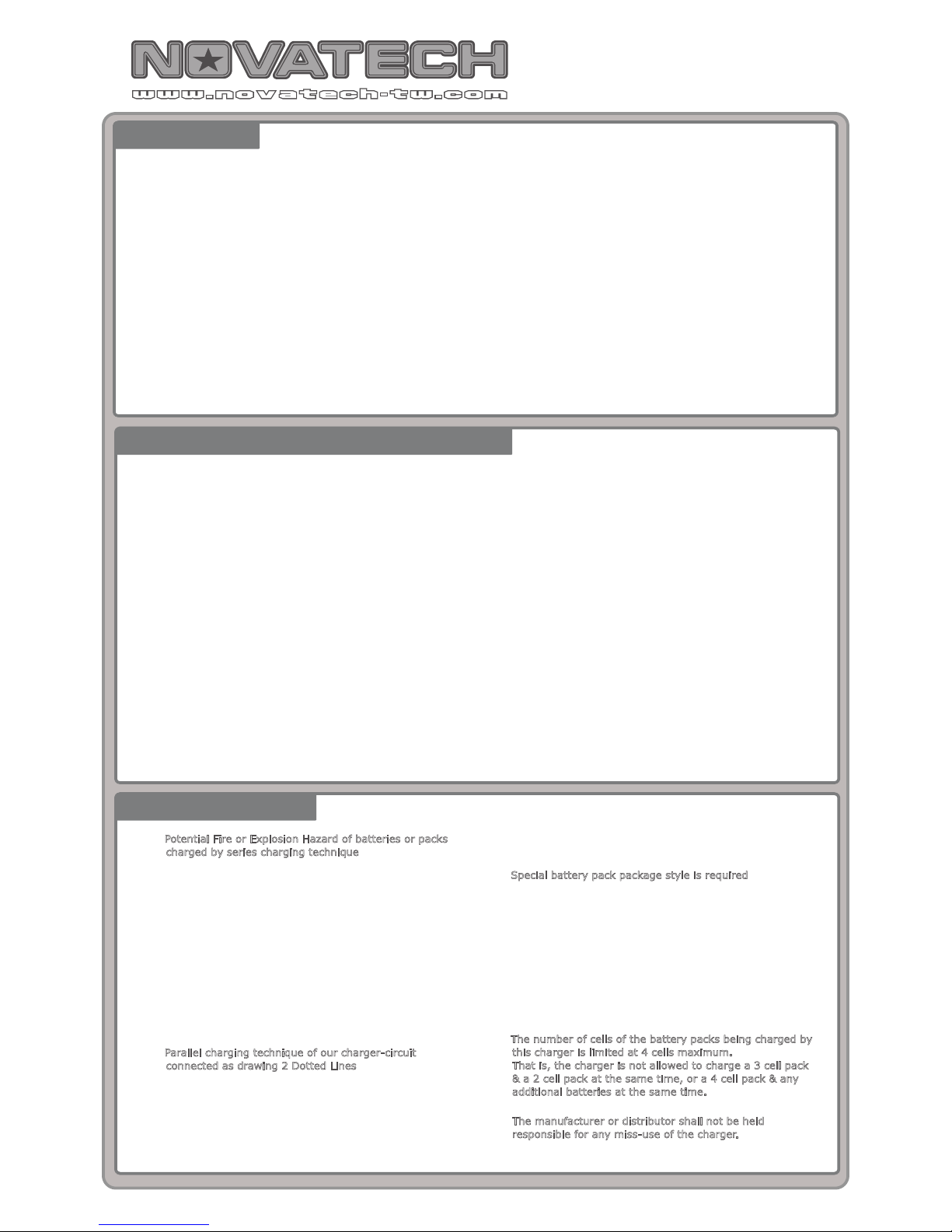

1.Potential Fire or Explosion Hazard of batteries or packs

charged by series charging technique

Most of the Li-ion/polymer chargers on the market are

using series charging technique to charge the Li-xx

batteries. The series charging technique is circuit

connected as Drawing 1 indicated. In case, if one of the

cells of the battery pack is defective & can’t be full

charged up to its defined full voltage level, the other good

cell or (cells) will then be over charged. Take cells in

drawing 1 for example, if cell A is defective & can only be

charged up to 2.8V or lower, the good cell B will then be

overcharged up to 4.2 + (4.2-2.8) = 5.6V or higher. A

Li-xx battery can only stand its maximum voltage up to

4.6~4.9. If it is over 4.9V, it can burn or explode. Series

charging is necessary for battery packs that must be

charged through the discharge wires.

2.Parallel charging technique of our charger-circuit

connected as drawing 2 Dotted Lines

Instead of charging all cells of the battery pack in series,

our charger is designed to control the charging process of

each cell of the battery pack independently or in parallel.

It will completely eliminate the interference between cells

of the battery pack during charging process. It will also

reduce and avoid the possibility of fire or explosion caused

by a problem battery pack with defective or unbalanced

capacity cells inside.

3.Special battery pack package style is required

The battery packs to be charged on this charger should be

assembled as in drawing 2. Every battery pack should

have one additional charge connector. By connecting this

connector to the respective charger out-put port, you are

now safely charging to your Li-xx battery packs.

4.Life of the Li-xx battery packs

When in storage and not in use, the Li-xx battery will have

a self-discharge process. It will be severely damaged or

rendered unusable if it is allowed to discharge to less than

2.4V. It is strongly recommended to check / recharge all

Li-xx batteries once every 3 months.

5.The number of cells of the battery packs being charged by

this charger is limited at 4 cells maximum.

That is, the charger is not allowed to charge a 3 cell pack

& a 2 cell pack at the same time, or a 4 cell pack & any

additional batteries at the same time.

6.DISCLAIMER

The manufacturer or distributor shall not be held

responsible for any miss-use of the charger.

1.Connecting charger to power source, LED display will be

green, indicating that the charger is in good status &

ready to use. Set Current Select to suitable position: 0.5A

--- For cells with 360 mAh or higher, 1.0A --- For cells with

750 mAh or higher, 1.5A --- For cells with 1200 mAh or

higher. 2A --- For cells with 1800 mAh or higher. When

charging multiple cells or packs of different capacities at

the same time, charger must be set to the setting of the

lowest cell.

2.Select correct charger output ports (connectors) for the

battery packs to be charged. There are 4 out-put ports of

the charger, the two ports labeled 7.4V are for 2 cells

(3.7V x 2), the port labeled 11.1V is for the 3 cell battery

packs & the port labeled 14.8v is for the 4 cell battery

packs. After connecting battery packs to the charger, a

short auto-check of each cell of the battery pack will be

done by the charger. After the auto-check, the charger will

start charging each cell of the battery pack independently.

During charging process, if the cell is good the

corresponding LED display will change to red; otherwise, if

the cell is defective, the corresponding LED display light

will be green.

3.When charging starts, for a good battery pack, the number

of the LED displays which change color into red shall be

the same as the number of the cells of the battery pack.

For example, a 2 cell battery pack will have 2 LEDs in red

color during charging, a 3 cell battery pack will have 3

LEDs in red color during charging, a 4 cell battery pack

will have 4 LEDs in red color during charging.

4.When the battery pack is fully charged, all corresponding

cell - LED colors will change from red to green. This

indicates the battery pack is fully charged and ready to

use any time. If the battery pack remains on the charger

after fully charged, the charger will re-charge the batteries

when the voltage of the battery cell (cells) is less than

4.15V.

5.Within 20-30 seconds after the battery or pack is fully

charged, the charger will detect and indicate any problems

by changing the LED colors from green to red for a

defective or failing battery. If the charger detects a

defective or failing battery, the defective or failing battery

should not be used.

Operation instruction – PARALLEL CHARGING

Special instructions

Page 2

TEL+886-04-25606216 FAX:+886-04-25606217

E-mail | novatech@novatech-tw.com , awanacorp@yahoo.com.tw

COPYRIGHT NOVATECH ENTERPRISE CO.,LTD ALL RIGHTS RESRVED.

No.17, Ln. 423, Sec. 1, Shenlin Rd., Daya Township,Taichung County 42856, Taiwan (R.O.C.)

1.Connecting charger to power source, all LED displays will

be green, indicating that the charger is in good status &

ready to use. Set Current Select to suitable position; 0.5A

--- For cells with 360 mAh or higher, 1.0A --- For cells with

750 mAh or higher, 1.5A --- For cells with 1200 mAh or

higher, 2A --- For cells with 1800 mAh or higher. When

charging multiple cells or packs of different capacities at

the same time, charger must be set to the setting of the

lowest cell.

2.Select correct charger out - put ports (connectors) for the

battery packs to be charged. There are 4 out-put ports of

the charger, the 2 ports labeled 7.4V are for 1 or 2 cells

(3.7V x 2), the port labeled 11.1v is for the 3 cells battery

pack, the port labeled 14.8V is for the 4 cells battery pack.

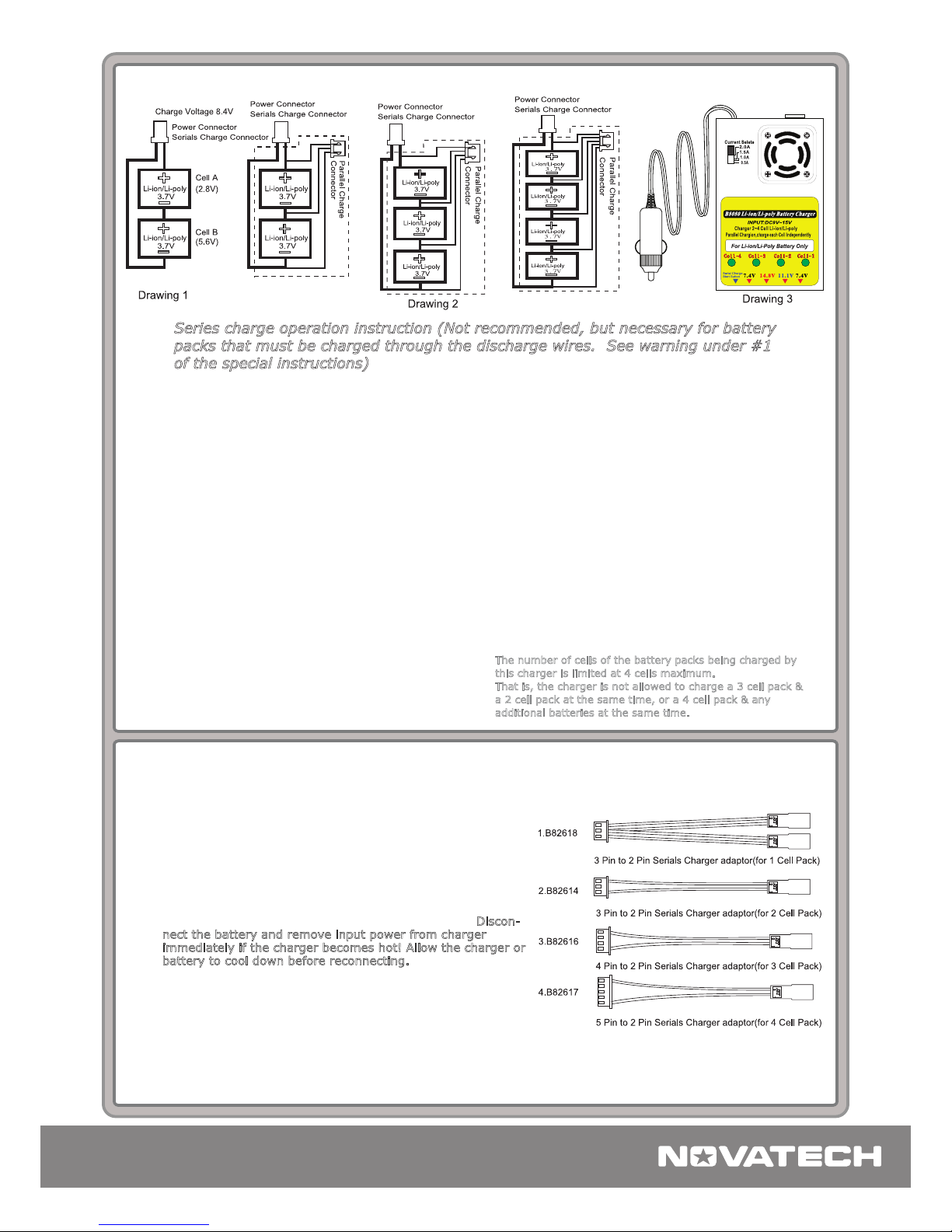

3.Connect the serial charge adaptor to the relative charger

out-put ports. P/N B82618 series charge adaptor matches

to 7.4V out-put port for 2 ea single cell battery pack . P/N

B82614 series charge adaptor matches to 7.4V out-put

port for 1 ea 2-cell battery pack. P/N B82616 series charge

adaptor matches to 11.1V out-put port for 3-cell battery

pack. P/N B82617 series charge adaptor matches to 14.8V

out-put port for 4-cell battery pack.

4.Connect the battery packs to the series charger adaptors

& push down the start button. The charger will start

charging. During charging process, the corresponding LED

displays on the charger will turn red. While charging, the

number of the LEDs which change color to red will be the

same as the number of the cells of the battery pack. For

example, a 2 cell battery pack will have 2 LEDs in red

during charging, a 3 cell battery pack will have 3 LEDs in

red during charging, a 4 cell battery pack will have 4 LEDs

in red during charging. If the number of the lighted LED

displays are not the same as the number of the cells of the

battery packs, reset the charger by pushing down the start

button again to make both numbers the same. If it’s not

possible to get the both numbers at the same figure after

pushing down the button again, the battery pack has a

defective or failing cell and should no longer be used.

5.When the battery pack is fully charged, all relative LED

colors will change from red to green. It indicates the

battery pack is fully charged and ready to use any time.

6.The number of cells of the battery packs being charged by

this charger is limited at 4 cells maximum.

That is, the charger is not allowed to charge a 3 cell pack &

a 2 cell pack at the same time, or a 4 cell pack & any

additional batteries at the same time.

IMPORTANT PRECAUTIONS

※Do not attempt to charge incompatible type rechargeable

batteries as permanent damage to the battery and charger

could result.

※Do not allow water, moisture or foreign objects into the

charger.

※Do not block the air intake holes or the fan vent, which could

cause the charger to overheat.

※Do not attempt to use batteries with more cells or total

voltage more than listed in the specifications.

※Do not leave the charger unattended while charging. Discon-

nect the battery and remove input power from charger

immediately if the charger becomes hot! Allow the charger or

battery to cool down before reconnecting.

※DO not place the charger or battery on a flammable surface or

near a flammable object while in use. Keep away from

carpets, cluttered work b enches, etc.

※Always disconnect from power source when not in use.

※Do not overcharge batteries as permanent damage could

result. Do not use a charge or discharger current rate which

exceeds the safe level of the battery. Do not attempt to

charge or discharge a battery if it is hot.

※Keep out of reach of children.

Series charge operation instruction (Not recommended, but necessary for battery

packs that must be charged through the discharge wires. See warning under #1

of the special instructions)

Loading...

Loading...