Page 1

Page 2

Thank you for choosing the Biomega BioClave

steam sterilizer.

Your steam sterilizer has been CE certified and

designed with durability, reliability, and safety in

mind. It is your responsibility to install this

instrument in conformance with local electrical

codes.

This manual contains important operating and

safety information. Please read and understand

the contents of this manual prior to operating

this instrument.

Instructions manual

Page 3

TABLE OF CONTENTS

1. GENERAL ------------------------------------------------------------ 1

2. TECHNICAL SPECIFICATIONS----------------------------------- 2

3. PACKING CONTENT ----------------------------------------------- 3

4. INSTALLATION ---------------------------------------------------- 4

5. CONTROL PANEL --------------------------------------------------- 5

6

. OPERATION --------------------------------------------------------- 6

6.1 POWER ON ------------------------------------------------------ 6

6.2 FILLING THE DISTILLED WATER ----------------------------- 6

6.3 PREPARING THE MATERIAL FOR STERILIZATION ----- 6

6.4 SELECTING THE STERILIZATION PROGRAM -------------- 7

6.5 RUNNING THE STERILIZATION PROGRAM ----------------- 7

7. DRAINING THE WATER TANKS ---------------------------------- 9

8. ADVANCED SETTING ---------------------------------------------10

9. PRINTER (OPTIONAL) --------------------------------------------11

10. MAINTENANCE -------------------------------------------------- 12

11. TRANSPORT AND STORAGE ----------------------------------- 15

12. ERROR CODES-----------------------------------------------------16

13. SERVICE AND CONTACT---------------------------------------- 17

APPENDIX

1. WATER PROPERTIES / CHARACTERISTICS -------------- 18

2. DIAGRAMS OF THE STERILIZATION PROGRAMS ----- 19

3. ELECTRICAL DRAWING----------------------------------------- 23

4. HYDRAULIC DRAWING ----------------------------------------- 24

Instructions manual

Page 4

1. General

The sterilizer described in this manual is intended for the sterilization

of research tools. It operates automatically with 134°C and 121°C

sterilization temperatures. This sterilizer is in compliance with the

European Directive 93/42/CEE and it has been produced in accordance

with the EN 13060. In addition the chamber has been ASME certified.

1

10

2

11

12

3

13

4

7

8

9

1 Distilled (clean) water tank

2 Display

3 Control panel

4 Power switch

5 F

uses

6

Drain connector, clean water tank

7

Door handle

6

5

14

8 Door

9 Drain connector, used water tank

10 Safety valve

11 Condenser ventilation

12 Serial / Electrical Label

13 Printer port (printer is optional)

14 Power supply cord

For safe operation, please pay close attention to the alert symbols

below which cab be found throughout this manual. Please

carefully read and understand the contents of this manual prior to

operating this instrument.

This symbol represents an electrical caution - ground protection

HOT SURFACE.

This symbol represents a hot surface

This symbol is used to draw the attention of the reader to

particularly important notions for operator safety.

1

1

Instructions manual

Page 5

2. Technical Specifications

(1)Chamber Dimensions: 9in. x 14.2in. / 230mm x 360mm

(2)RatedVoltage:AC110V-120V or 220-240V, 50-60Hz

(3)Nominal power: 1600W (120V) 1250W(220V)

(4)Sterilization Temperature: 121°C / 134°C

(5)Main Fuses:T20A/250V

(6) Capacity of the distilled water tank:

Approx 2.5L (water at level MAX)

(7)OperatingEnvironment: 5 - 40°C

(8)External Dimensions:

17.5in. (width) x 16.7in. (height) x 23in. (depth)

445mm (width) x 400mm (height) x 590mm (depth)

(9)Net weight: 99lbs. /45kg

(10)Noise: <60dB

(11)Relative Humidity: max 80%, non condensing

(12)Atmospheric Pressure: 76kPa -106kPa

Instructions manual

2

Page 6

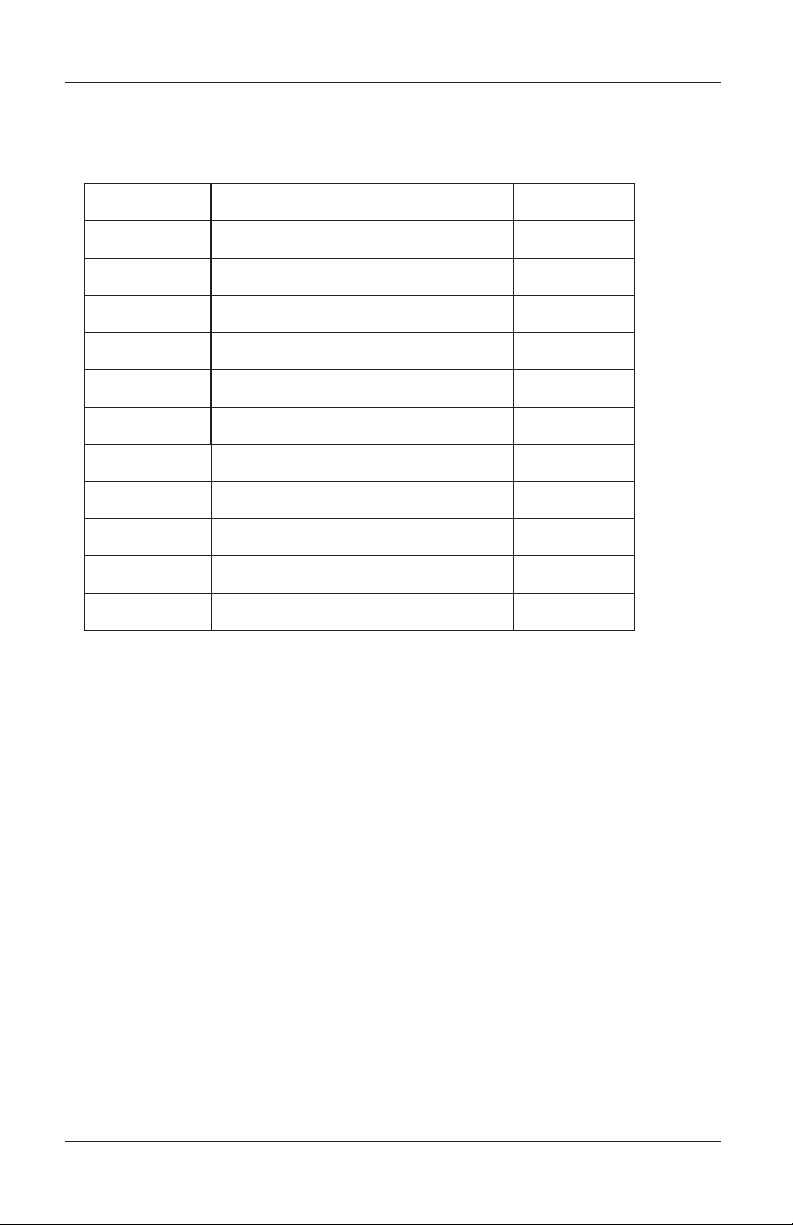

3. Packing Content

No

1

2

3

4

5

6

7

8

9

10

11

Accessory

16LSteam sterilizer

Loading tray

Tray rack

Tray handling tool

Door adjustment tool

Draining hose

Instructions manual

Spare fuse power

Spare fuse for valve (3A)

Spare fuse for mainboard (1A)

(20A)

Door seal

Quantity

1

3

1

1

1

2

1

2

2

2

1

3

Instructions manual

Page 7

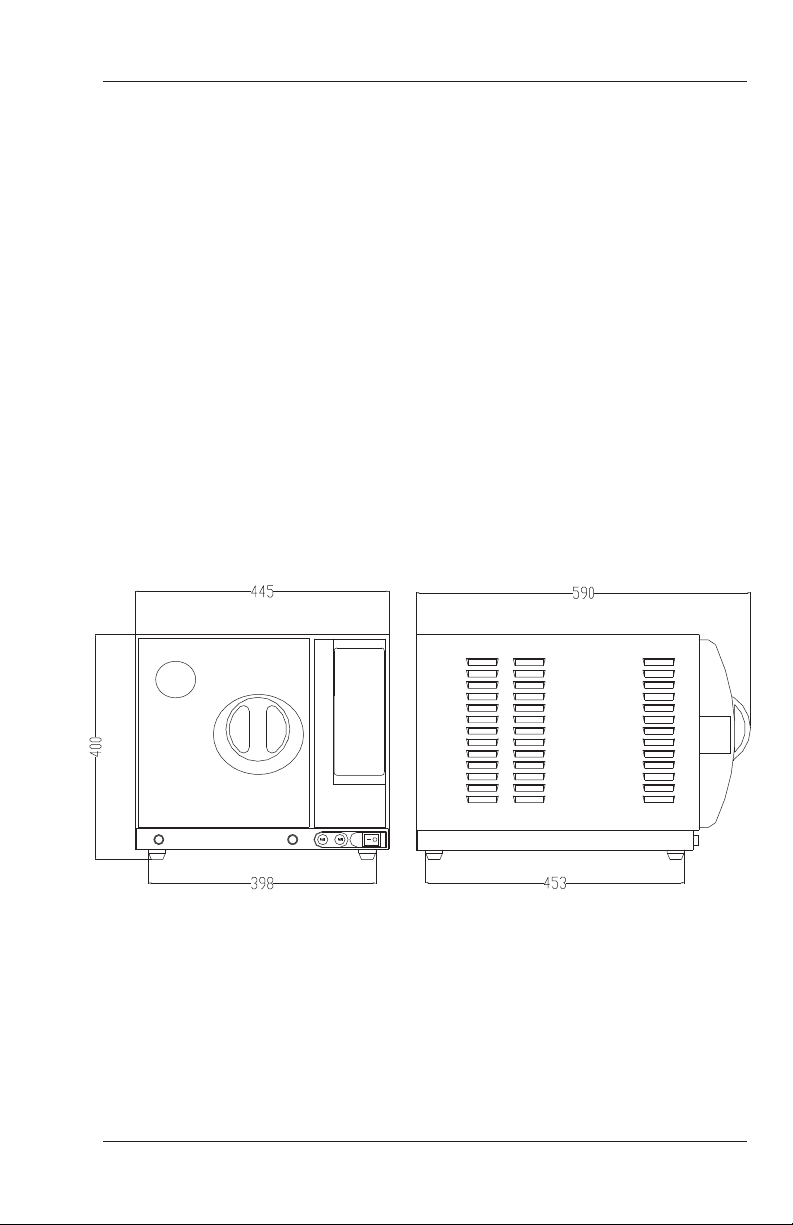

4. Installation

*

Ensure that the sterilizer is installed with 2.5in. (10cm) ventilation space

on all sides of the sterilizer, and 5 in. (20cm) on top side. The clearance

required to open the door is 15.5in. (40cm).

*

The sterilizer should be placed on a level worktable.

*

Do not cover or block the door, ventilation or radiation openings on the

sterilizer.

*

Do not install the sterilizer near a sink or in a location where it is likely to

be splashed.

*

Do not install the sterilizer nearby a heat source.

Instructions manual

Above dimensions are shown in mm.

4

Page 8

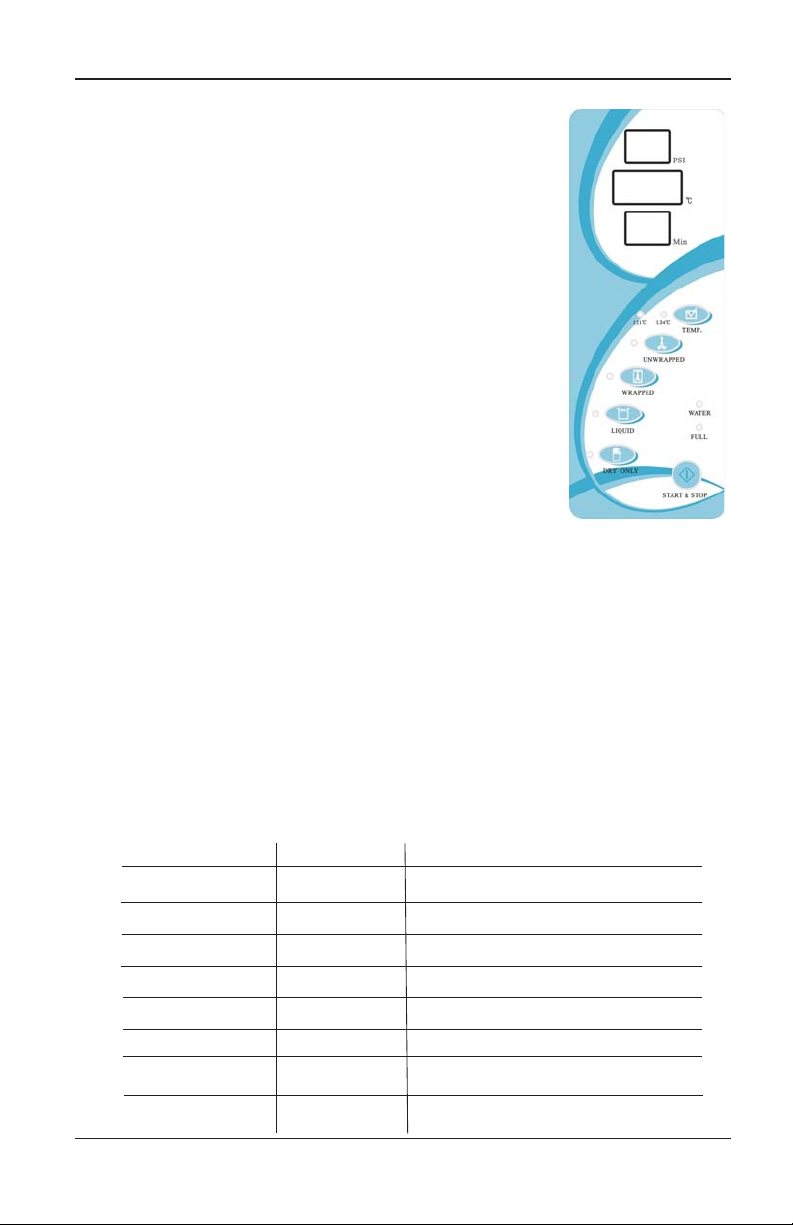

5. Control panel

5.1 Pressure display window.

Displays the current pressure (PSI)

inside the chamber

5.2 Temperature display window.

Display the current temperature (°C)

inside the chamber

5.3 Timer display window

Displays the cycle state (see below)

or the remaining cycle time

5.4 TEMP button

Select the desired sterilization temperature

according to your instrument.

5.5 Sterilization Cycles

UNWRAPPED

-

- WRAPPED

LIQUID

-

- DRY ONLY

(Please seeAppendix 2)

5.6 WATER indication lamp

This lamp will illuminate when the distilled water tank .

is low on water. The tank should then be filled (with distilled water).

5.7 FULLindication lamp

This lamp will illuminate when the used water tank is full.The used water

tank must be drained to continue operation.

5.8 START & STOP button

Once the parameters have been chosen, press this button to start the sterilization

cycle. To cancel or stop the cycle, press and hold this button for 3 sec.

StateCycle

Time Display

Ld

Do

Po

HE

Time in Min.

PL

Ed

E1 - E9

5

State

preheating / loading

Door state

vacuuming

heating

sterilization/drying

exhaust

end

Error state

The machine is prepared for sample loading

Door is open

The machine is vacuuming during a cycle

The machine is in heating mode

Time remaining in program

The machine is cooling and releasing steam.

The cycle is completed, you can open the door

and take out the sterilized sample.

Error - Please see section 12

State description

Instructions manual

Page 9

6. Operation

6.1 Power on

6.1.1 Open the chamber door and remove all inner packing and

accessories.

6.1.2 Plug the power cord into the proper electrical outlet. (Please

check that the power source is in accordance to the electrical

specifications of the machine (listed on the power label).

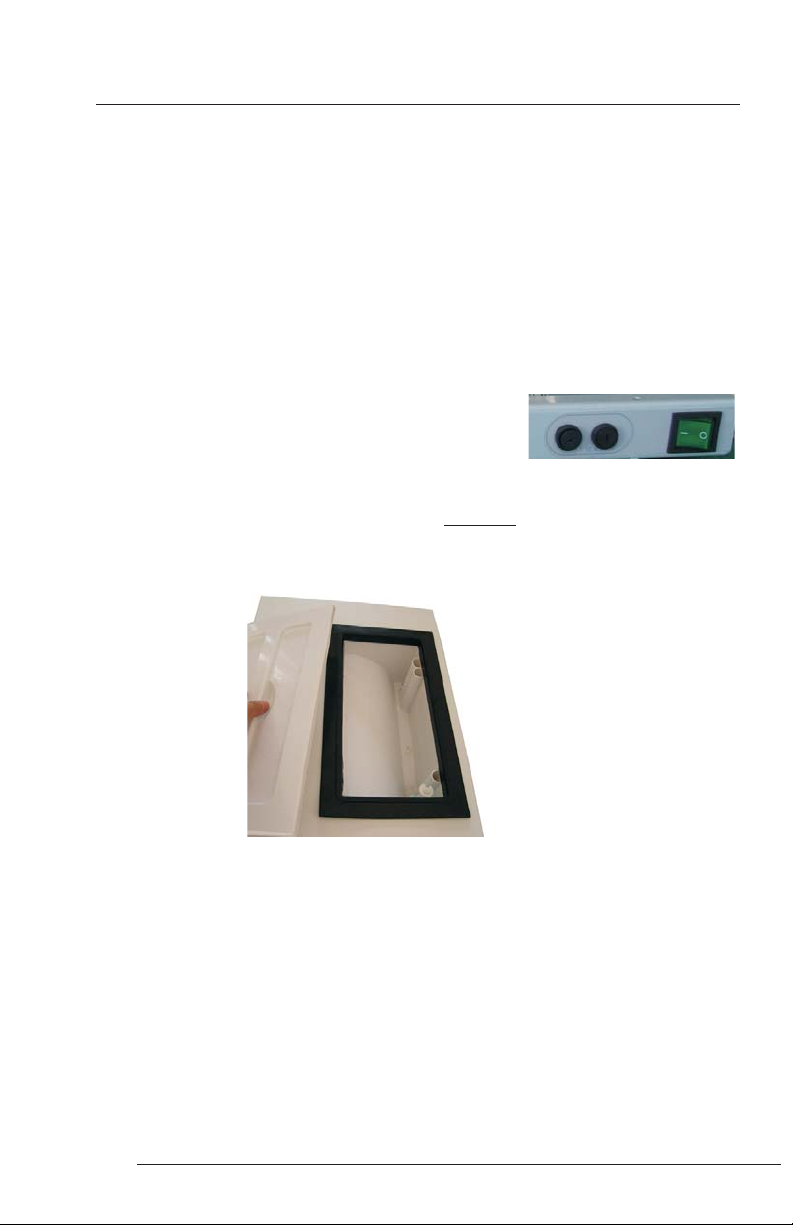

6.1.3 Power on - The switch is located underneath the control panel

on the front side of the machine.

Following power up, the control panel illuminates.

TheTime window will display “Ld” .

6.2 Filling the water tank

Open the top lid, and fill the tank with water. The water should

be filled within approximately 1 inch of the black seal. If you hear a beep

signal, the max water level is exceeded. Please stop filling immediately.

distilled

6.3 Sample Preperation

For the most effective sterilization and to preserve the sample, please

follow below:

*Arrange the samples of different material on different trays or with at least

2in. of space between them.

*Always insert a sterilization paper or cloth between the tray and sample,

to avoid direct contact between the different materials.

Instructions manual

6

Page 10

* Verify all samples are not sealed, capped or closed.

* Don't overload the trays above the stated limit (seeAppendix 1).

* Don't stack the trays one above the other or put them in direct contact with

the walls of the sterilization chamber.

* When handling the trays, always use the tray removal tool.

* Wrap each sample separately, if samples are wrapped together verify that

they are of the same material.

* Seal the wrap with sterilization adhesive ribbon or by a thermal sealer.

* Never seal with metallic clips, pins, etc. as this jeopardizes the maintenance

of the sterility;

* When using sterilization paper, set the plastic part downward (tray side)

and the paper side facing upward.

Always wrap samples.

6.4 Select the sterilization program

Select the appropriate sterilizationtemperature

and cycle. (For additionalinformation, see

appendix 2.)

6.5 Running the sterilization program

After selecting the appropriate sterilization

settings, load the samples onto the loading tray

and insert the tray into the autoclave using the

tray handling tool.

7

Instructions manual

Page 11

6.6 After the samples are loaded, close

and lock the door by turning the door

handle clockwise until it stops.

Caution: You must turn the door handle to the maximum position,

otherwise the machine will alarm and an error message will

be displayed during the cycle.

6.7 Starting the sterilization program.

Press the STARTbutton, the machine will begin

the sterilization cycle and complete all phases

(fill, sterilize, exhaust and dry) automatically.

The cycle will complete in 12-65 minutes.

(See )

Appendix 2

Caution: When you press the "Start" button and the door handle has not

been turned to the maximum position, “ will flash

on theTime display window. The cycle will not begin

until the door has been completely closed and the "Start"

button is pressed again.

do”

6.8 Sterilization cycle completion

After a cycle is completed the time display will show “Ed”

Once the pressure has reached 0 PSI on the display the door can be

opened and samples can be removed.

Always use the tray removal tool to load or unload the tray in

order to avoid touching the hot surface of the trays.

Instructions manual

8

Page 12

7. Draining the water tanks

1.

Connect the supplied drain hose to

the drain valve by pressing it on firmly.

2.

Set the drain valve to the open

position by turning it counter clockwise

3.Pull the drain valve outward, the

tank will begin to drain through the hose.

water, push the drain valve inward and

set to the closed position

The sterilizer includes two draining valves. The left valve is used

for draining the used water tank. The right valve is used for draining

the cleanwater tank. Always be sure that the hose is draining into

a vessel with at least 2L capacity.

4.After you have completed draining the

9

Instructions manual

Page 13

8 Advanced adjustment settings

8.1 Adjustment of sterilization time and drying time

8.1.1 Hold the UNWRAPPED button for 30seconds. The machine will beep

to signify that you have enetered the advanced settings mode.

8.1.2 The pressure display window shows“0” and the temperature display

window shows - - -. The timer display windowwill show the preprogrammes sterilization time parameter.

8.1.3 Select the sterilization program that you wish to adjust. For example,

If you want to adjust the parameter of Press the

WRAPPED

8.1.4 Press button, the value of time parameter will plus one.

8.1.5 After finishing the adjustment, press button to confirm it.

8.1.6 When adjusting the program, there is only one option,

2. This is to adjust the drying time.

Caution:Always ensure that the sample being sterilized can

withstand the sterilization time that is being programmed.

button. Press the button again ,the time display shows“1”.

0 means the 121 sterilization time.(The range from 3 to 40 min.)

1 means the 134 sterilization time.(The range from 3 to 40 min.)

2 means the drying time.(The range from 3 to 20 min.)

TEMP

DRYING

,

WRAPPED.

START

Instructions manual

10

Page 14

9. Printer (Optional)

9.1 If you have purchase the BioClave printer device, you can connect the

printer cable to the back of the sterilizer.

9.2 Connect the printer power cord to the socket with the proper electrical

specifications.

9.3 Power on the sterilizer and press the“sel” button.

9.4After the sterilization cycle has completed, the printer will begin printing

the details of the sterilization cycle (see below).

Example of the print report

¨¨¨¨¨¨¨¨¨¨¨¨

Program: wrapped

Temperature: 134

Pressure: 39 PSI

Vacuum Num.: 3

Dry Time: 15min

Ster Time: 12min

Cycle No: 00009

¨¨¨¨¨¨¨¨¨¨¨¨¨

MAX.Temp: 135.1

MIN. Temp: 134.1

AVG. Temp: 134.6

MAX. Pres.: 41PSI

MIN. Pres.: 38PSI

AVG. Pres.: 39 PSI

¨¨¨¨¨¨¨¨¨¨¨¨¨

Start Time: 22:38

End Time: 23:17

Date: 2008-07-19

¨¨¨¨¨¨¨¨¨¨¨¨

¡

11

Instructions manual

Page 15

10 Maintenance

7. Maintenance

Frequency

Daily

Weekly

Annually

Clean the door seal

Wipe dry the inner chamber

Clean the clean water reservoir

Clean the inner-chamber

Replace the door seal

Operation

8.1 Cleaning the door seal

Clean the door seal daily with a softy cloth saturated in

distilled water

8.2 Cleaning the clean water tank

Clean the clean water tank every

week with medical disinfectant .

Instructions manual

12

Page 16

10.3 Cleaning the inner-chamber, weekly

Remove the trays and tray rack from the inner-chamber

-

- Wipe the inner chamber with a soft cloth saturated in distilled water

-Apply the same procedure to the trays and tray rack.

10.4 Door adjustment

Below are the instructions for the door adjustment. This should only be

performed if the door is not providing the proper seal or if the door seal has

just been replaced.

10.4.1 Open the door and insert the door adjustment tool in the gap beneath the

plastic cover (Fig. 2).

10.4.2 To tighten the door seal, use this tool to adjust the door adjustment nut

counter clockwise (Fig. 1).

10.4.3 If the door seal is too tight (it is difficult to lock/unlock the door),

you may also adjust the door adjustment nut clockwise to loosen it.

Fig. 1

Caution:

Never attempt to adjust the door seal when the door is in the

closed position.

13

Fig. 2

Instructions manual

Page 17

10.5 Replacement of the door seal

10.5.1 Fully open the door.

10.5.2 Remove the door seal carefully by pulling it by hand away from

the door

10.5.3 Clean the new door seal carefully with a soft cloth saturated

with distilled water.

10.5.4 Moisten the new seal with medical disinfectant .

10.5.5 Insert the new seal following the instruction below:

1). Press on the top of the seal.

3). Press on the left and right

portions of the seal.

Caution:Always ensure the chamber and the door have

been cooled down before attempting to change the seal.

Instructions manual

2). Press on the bottom of the

seal.

4). Press the remaining seal surface

and ensure that it is smooth.

14

Page 18

10.6 Replace fuse

1). Switch off the power.

2). Push inward with a flat head

screw driver, then unscrew the fuse

counter clockwise).holder (

4).Replace the fuse with a fuse

of the proper electrical

requirements (see pg.2).

.

3). Pull out the fuse holder by

hand.

5). Place the fuse holder back in

place and use a flat head screw

driver to fully push it in. Then

tighten (clockwise).

11. Transport and Storage

11

.1 Switch off the sterilizer before transportation or storage. Pull out the plug

and let the machine cool down.

11.2 Drain both the clean and the used water tank.

11.3 Conditions for transportation and storage:

Temperature: -20 C /~ +55C

Relative humidity: 85%

Atmospheric pressure: 50kPa~106kPa

15

Instructions manual

Page 19

12. Error Codes

Code

E1

E2

E3

E4

E5

E6

E7

E8

E9

EE

Description Proposed solution

Steam generator temperature

sensor error

Inner temperature sensor error

Temperature sensor of chamber

wall error

Failure to raise temperature

Failure to release steam

Door has opened during the cycle

Time Error

Steam generator overheat

Failure to hold temperature

Program manually interrupted

Check steam generator temperature

sensor

Check inner temperature sensor

Check temperature sensor of chamber

wall

Check the water pump or the door seal

Check the air release valve

Make sure you have turned the door handle

to the max. position or check the door switch

Check the water pump and the

air release valve

Check steam generator temperature

sensor

Ensure that the clean water tank is not

empty or contactyourdealer to checkthe

heating system and temperature sensors.

Shut off the power and restart the

machine

Failure to initialize

EF

Instructions manual

Shut off the power and restart the

machine

16

Page 20

13. Service and Contact

For additional information on any of the error codes listed in section

10, please contact your sales representative, or contact Biomega

Research Products Service Department at 1-908-769-5555. Please

have the unit’s serial number (located on the back panel of the

instrument) available when calling. Do not send in a unit for service

without first calling to obtain a repair authorization number and a

decontamination form. The unit should be properly packed to avoid

damage.Any damage resulting from improper packing shall be the

responsibility of the user.

17

Instructions manual

Page 21

APPENDIX 1

Water Properties/Characteristics:

DESCRIPTION

Evaporate residue

Silicium oxide sio

Iron

Cadmium

Lead

Rest of heavy metals, excluding

iron, cadmium, lead

Chloride

Phosphates

Conductivity (at 20 )。

pH value

Appearance

Hardness

2

WATER

。10 mg/l

。1 mg/l

。0.2 mg/l

。0.005 mg/l

。0.05 mg/l

。0.1 mg/l

。2 mg/l

。0.5 mg/l

。ヲ15 s/cm

5-7.5

Colorless, clean,

without sediments

。0.02 mmol/l

CONDENSATE

。1.0 mg/kg

。0.1 mg/kg

。0.1 mg/kg

。0.05 mg/kg

。0.1 mg/kg

。0.1 mg/kg

。0.1 mg/l

。0.1 mg/l

。ヲ3s/cm

5-7

Colorless, clean,

without sediments

。0.02 mmol/l

Instructions manual

18

Page 22

APPENDIX 2

DIAGRAMS OFTHE STERILIZATION PROGRAMMES

PROGRAM

UNWRAPPED

WRAPPED

LIQUID

DRY ONLY

(°C)

Temperature

134

121

134

121

134

121

<100

(PSI)

Pressure

30

16

30

16

30

16

0

4

15

6

15

12

30

15

(min.)

Holding time

12~30

30~45

30~40

35~50

30~65

45~65

(min.)

Total time

TYPE

Unwrapped solid

material

Unwrapped hollow

material

Single-wrapped solid

material

Wrappedliquid

Wrappedliquid

The max. temperature of the 134 C sterilization cycle is 136C

The max. temperature of the 121 C sterilization cycle is 123C

(kg)

MAXLOAD

5.00

5.00

5.00

4.00

0.50

0.50

19

Instructions manual

Page 23

Pressure psi

30

15

0

30

UNWRAPPED

134°C

Time (min)

Pressure psi

UNWRAPPED

121°C

15

0

Instructions manual

Time (min)

20

Page 24

Pressure psi

30

15

0

30

WRAPPED

134°C

Time (min)

Pressure psi

WRAPPED

121°C

15

0

21

Time (min)

Instructions manual

Page 25

Pressure psi

30

15

0

30

15

LIQUID

134°C

Time (min)

Pressure psi

LIQUID

121°C

0

Instructions manual

Time (min)

22

Page 26

APPENDIX 3

ELECTRICAL DRAWING

TANK MAX. LEVEL

PUBLIC

TANK MIN. LEVEL

USED WATER TANK

MAX. LEVEL

DOOR SWITCH

KEYBOARD

DATA LINE

PRINTER

OUTPUT

TP 1

TP 2

TP 3

V4

T12A

20

T12A

20

¡ 220V

110

V1

PRESSURE SENSOR

Tp1: Steam generator temperature sensor

TP2: Inner-Chamber temperature sensor

TP3:Temperature sensor of chamber wall

V1:Air release valve

V4:Water release valve

¡ 21V

¡ 9V

THERMAL

PROTECTOR

THERMAL

PROTECTOR

AC220V

110

OUTPUT

FAN

WATE R

PUMP

STEAM

HEATER

CHAMBER

HEATER

23

Instructions manual

Page 27

APPENDIX 4

HYDRAULIC DRAWING

Safety valve

Pressure

sensor

Pump

Condenser

V1:Air release valve

V4:Water release valve

Chamber

Distilled water tank

Used water tank

Instructions manual

24

Page 28

Loading...

Loading...