Page 1

®

TCO

M

2

Transcutaneous CO2/O2 Monitor

User’s Manual

Model 860

October 4, 1996

Catalog No. 6590-23-00

March 25, 1997

Catalog No. 6590-23-01

Copyright ©1997. Novametrix Medical Systems Inc.

5 Technology Drive

Wallingford, Connecticut, U.S.A. 06492

All rights reserved.

Page 2

Page 3

Revision History

04-Oct-96 Release Version Rev.00

25-Mar-97 Revision 01

25-Mar-97 Rev. 01 TCO

®

M

User’s Manualiii

2

Page 4

Revision History

iv TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 5

16Guarantee

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is fully

guaranteed, covering materials and workmanship, for a period of one year from the

date of shipment, except for certain disposable products and products with stated

guarantees other than one year. Novametrix reserves the right to perform guarantee

service(s) at its factory, at an authorized repair station, or at the customer’s

installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at

Novametrix’ option, replacement of any defective parts of our equipment, except

fuses, batteries, and calibration gasses, without charge, if said defects occur during

normal service.

Claims for damages during shipment must be filed promptly with the transportation

company. All correspondence concerning the equipment must specify both the model

name and number, and the serial number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without

following specific operating instructions will void this guarantee and release

Novametrix from any further guarantee obligations.

Call toll free: 1-800-243-3444

To Call Direct: (203) 265-7701

Facsimile (203) 284-0753

http://www.novametrix.com

Caution: Federal (U.S.A.) law restricts this device to sale, distribution, or use by or

on the order of a licensed medical practitioner.

Copyright 1997. Novametrix Medical Systems Inc. 5 Technology Drive,

Wallingford, Connecticut, 06492. This document contains information which is

proprietary and the property of Novametrix Medical Systems Inc., and may not be

reproduced, stored in a retrieval system, translated, transcribed, or transmitted, in any

form, or by any means, without prior explicit written permission from Novametrix

Medical Systems Inc.

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual97

2

Page 6

16 Guarantee

98 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 7

Table of Contents

Revision History ...................................................................................................... iii

Table of Contents ..................................................................................................... v

Introduction ............................................................................................................... 1

About this manual ................................................................................................ 1

Indications for Use ............................................................................................... 1

Summary of features ............................................................................................ 2

Principles of Operation ......................................................................................... 2

Oxygen .............................................................................................................. 2

Carbon Dioxide ................................................................................................. 2

Local Power ...................................................................................................... 3

Technical Description ........................................................................................... 3

Safety ......................................................................................................................... 5

Patient Safety ....................................................................................................... 5

Contraindications ................................................................................................. 6

Warnings .............................................................................................................. 6

Cautions ............................................................................................................... 7

Quick Start Guide ..................................................................................................... 9

Connect Sensor ................................................................................................ 9

Power Up ........................................................................................................ 10

Calibrator Setup ..............................................................................................10

Calibration ....................................................................................................... 10

Alert Limits ...................................................................................................... 10

Apply to Patient ............................................................................................... 10

Handling Alerts ................................................................................................ 10

Removal from Patient ...................................................................................... 10

Monitor Shutdown ...........................................................................................10

System Overview .................................................................................................... 11

M Monitor Front Panel .............................................................................. 11

TCO

2

or Power ......................................................................................................... 11

Low Bat ...........................................................................................................11

AC ON ............................................................................................................. 11

Two Minute Silence ......................................................................................... 12

Audio key ........................................................................................................ 12

Audio Icon .......................................................................................................12

Alert Reset ...................................................................................................... 12

Alert Icon ......................................................................................................... 12

Softkeys .......................................................................................................... 12

Event ............................................................................................................... 12

Contrast ........................................................................................................... 12

M Monitor Rear Panel ............................................................................... 12

TCO

2

Symbols ............................................................................................................. 13

Equipotentiality ............................................................................................... 13

Ground ...........................................................................................................13

25-Mar-97 Rev. 01 TCO

®

M

User’s Manualv

2

Page 8

Table of Contents

Dangerous Voltage ........................................................................................ 13

Patient Isolation ..................................................................................... 13

Attention ......................................................................................................... 13

Mains Fuse ...................................................................................................... 13

Mains Power ................................................................................................... 13

M Monitor Display ..................................................................................... 13

TCO

2

Transcutaneous Sensor Overview ..................................................................... 14

Select sensor .................................................................................................. 14

Connect sensor ............................................................................................... 14

TCO2M Calibrator, Model 868 ........................................................................... 14

Setting up the Calibrator ................................................................................. 15

Disconnecting Gas Cylinders .......................................................................... 16

Connect the calibrator ..................................................................................... 16

Operating the Monitor ............................................................................................17

TCO2M Power-up .............................................................................................. 17

Power On/Off .................................................................................................. 17

AC/Battery operation ....................................................................................... 17

AC Line Power ................................................................................................18

Battery Power .................................................................................................. 18

Operating on battery ....................................................................................... 18

Low battery alert .............................................................................................. 18

Charging the battery ........................................................................................ 18

Long Term Storage .........................................................................................18

Battery replacement ........................................................................................ 18

Monitoring CO

and O2 Tension ........................................................................ 19

2

Sensor Stabilization ........................................................................................ 19

Carbon Dioxide and Oxygen Alerts ................................................................. 19

Sensor Temperature Alerts ............................................................................. 19

PtcCO2 Display Values ...................................................................................... 19

Menu Operation and Setup .................................................................................... 21

Menu Structure ................................................................................................... 21

LIMIT — CO2 and O2 Alert Limits ..................................................................... 21

Set Alert Limits ................................................................................................ 22

Auto Alert Limits .............................................................................................. 23

Limit Alerts ...................................................................................................... 23

TRND — Real time trend displays ..................................................................... 24

Real Time Trend ............................................................................................. 24

Show CO

/O2/LP ........................................................................................... 24

2

Set Trend Time ............................................................................................... 24

Set CO2/O2 scale ...........................................................................................25

Local Power

(LP and LPR) .................................................................................................. 26

TRND — Trend Page (stored trend memory) displays ...................................... 27

Show trend page ............................................................................................. 28

Moving in trend ................................................................................................ 28

Select trend page parameter ........................................................................... 29

Select trend scale ............................................................................................ 29

Show histogram .............................................................................................. 29

Erase trend memory ........................................................................................ 30

Trend Data Compression ................................................................................ 31

CAL — Sensor calibration .................................................................................. 31

Calibrate sensor .............................................................................................. 31

Set temperature .............................................................................................. 32

vi TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 9

Table of Contents

Site Timer ........................................................................................................ 33

Reset site timer ...............................................................................................33

Adjust site timer ............................................................................................... 34

Last Calibration information ............................................................................ 35

DELAY — Suppress limit alerts ......................................................................... 35

Set Alert Delay ................................................................................................35

Cancel Alert Delay .......................................................................................... 36

LITE — Display brightness ................................................................................. 36

AUDIO — Adjust alert volume ............................................................................ 36

Sensor Calibration .................................................................................................. 37

Sensor Calibration with the TCO2M Calibrator Model 868 ................................ 37

Manual Calibration of the O2 Sensor ................................................................. 39

O2 Sensor Initial Calibration ........................................................................... 39

O2 Sensor Recalibration ................................................................................. 40

Apply Sensor to Patient .........................................................................................43

Sensor Site Selection ......................................................................................... 43

Sensor to Patient Application ............................................................................. 44

Removing the Sensor from the Patient .............................................................. 45

Combination O

Sensor Identification ........................................................................................ 47

Sensor Construction ........................................................................................ 47

Sensor Operation ............................................................................................ 47

Membrane Schedule ....................................................................................... 47

4474-00 Sensor Membraning Procedure ........................................................ 48

Long Term Combination Sensor Storage ........................................................ 50

Cleaning the Combination Sensor face ........................................................... 50

4474-39 Sensor Membraning Procedure ........................................................ 51

Carbon Dioxide Sensor .......................................................................................... 55

CO2 Sensor Construction ...............................................................................55

CO2 Sensor Operation .................................................................................... 55

Membrane Schedule ....................................................................................... 55

CO2 Sensor Membraning Procedure .............................................................. 55

Long Term CO2 Sensor Storage .................................................................... 57

Cleaning the CO2 Sensor face ....................................................................... 57

Oxygen Sensor ....................................................................................................... 59

O2 Sensor Construction .................................................................................. 59

O2 Sensor Operation ......................................................................................59

Membrane Schedule ....................................................................................... 59

Cleaning and Membraning the O2 Sensor face .............................................. 59

Long Term O2 Sensor Storage ....................................................................... 61

Advanced Controls and Features ......................................................................... 63

Display Menu ..................................................................................................... 63

Temperature or Power Display ....................................................................... 63

Limit Display .................................................................................................... 64

Display Colors ................................................................................................. 64

Display Units ...................................................................................................65

System Menu ..................................................................................................... 65

Serial Out ........................................................................................................65

Set Clock ......................................................................................................... 66

Site Timer (Maximum Duration) ......................................................................66

Metabolic Correction Factor ............................................................................ 67

Barometric pressure determination ................................................................. 67

/CO2 Sensor .................................................................................47

2

25-Mar-97 Rev. 01 TCO

®

M

User’s Manualvii

2

Page 10

Table of Contents

Alerts Menu ........................................................................................................ 68

Latch Alerts .....................................................................................................68

10 second Alert Delay Option ......................................................................... 69

Retain Alert Limits ........................................................................................... 69

Red Alert Bar ................................................................................................... 69

Audio Menu ........................................................................................................ 70

Allow Audio Off ................................................................................................ 70

Keyclick Volume .............................................................................................. 70

Sensor Menu ...................................................................................................... 71

Restoring factory defaults settings ..................................................................... 71

External Devices ..................................................................................................... 73

NovaCARD ......................................................................................................... 73

NovaCARD Configuration ...............................................................................74

Using NovaCARD ........................................................................................... 74

Analog Output Module ....................................................................................... 75

Connecting the Analog Output Module ...........................................................75

Calibrating an External Recorder .................................................................... 76

Printer ................................................................................................................. 77

Setup Printer ...................................................................................................77

Setup TCO2M .................................................................................................78

Types of Printouts ...........................................................................................78

Displayed Trend printout ................................................................................. 78

Compressed Trend printout ............................................................................ 79

Zoom Trend printout ........................................................................................ 79

Stopping a printout .......................................................................................... 80

Trend Printout ................................................................................................. 81

Tabular Printout ............................................................................................... 85

NovaCOM .......................................................................................................... 86

NovaCOM Configuration ................................................................................. 86

NovaCOM Data Format .................................................................................. 86

Real Time ........................................................................................................ 86

Trend Dump ....................................................................................................87

Date and Time ................................................................................................. 89

Clear Trends ................................................................................................... 89

Exit Command ................................................................................................. 89

Flexport .............................................................................................................. 90

Terminal ............................................................................................................. 90

Maintenance ............................................................................................................ 91

Cleaning and Disinfecting .................................................................................. 91

Monitor ............................................................................................................91

Sensors ........................................................................................................... 91

Calibrator ......................................................................................................... 91

Battery Maintenance .......................................................................................... 92

Long Term Storage .........................................................................................92

Charging the battery ........................................................................................ 92

Battery replacement ........................................................................................ 92

Line Cord ......................................................................................................... 92

Fuses ................................................................................................................. 92

Specifications ......................................................................................................... 95

Monitor Model 860 ............................................................................................. 95

Sensors .............................................................................................................. 96

Gas Calibrator Model 868 .................................................................................. 96

Guarantee ................................................................................................................ 97

Accessories ............................................................................................................. 99

viii TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 11

1 Introduction

The TCO2M® Transcutaneous CO2/O2 Monitor, Model 860 is designed to be an easyto-operate stand-alone transcutaneous monitoring system. It is intended to be used in

patient monitoring environments by technically skilled clinical personnel.

About this manual

This manual is written for clinical personnel using the TCO2M® Transcutaneous

CO

transcutaneous sensors and accessories intended for use with the monitor and

calibrator from Novametrix Medical Systems Inc.

This document contains information which is proprietary and the property of

Novametrix Medical Systems Inc., and may not be reproduced, stored in a retrieval

system, translated, transcribed, or transmitted, in any form, or by any means, without

the prior explicit written permission of Novametrix Medical Systems Inc.

Monitor, Model 860, the Transcutaneous Calibrator, Model 868, and the

2/O2

Novametrix reserves the right to change specifications without notice. TCO

NOVADISK are registered trademarks, and NovaCARD and NovaCOM are

trademarks of Novametrix Medical Systems Inc.

M and

2

Indications for Use

The TCO2M Transcutaneous CO2/O2 Monitor, Model 860 is indicated for use as a

trend monitor for CO

an adjunct to arterial CO

blood gas device.

Regulatory review (U.S.A.) of safety and effectiveness for transcutaneous oxygen

monitors is not required at this time. However, the oxygen-monitoring portion of this

device has been found to be substantially equivalent to devices marketed in interstate

commerce prior to May 28, 1976.

and O2 tension at the skin surface for neonates and adults as

2

and O2 blood gas measurements. This equipment is not a

2

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual1

2

Page 12

1 Introduction Summary of features

Summary of features

The TCO2M Transcutaneous CO2/O2 Monitor provides reliable, continuous

measurement, displays and alerts for transcutaneous oxygen tension (PtcO

transcutaneous carbon dioxide tension (PtcCO

) and sensor temperature. Sensor

2

heater power is also trended and can be displayed. The monitor’s real time graphic

onscreen trends along with the numeric values provide truly continuous CO

monitoring. A simple menu system with helpful messages guides the user through

setup and alert conditions. Built-in 24-hour trend memory with graphic and

histogram displays are available for viewing of patient history. The lightweight

portable monitor can operate from AC power or from its internal battery. Sensor

calibration is quick, fully automatic, barometric pressure compensated, and uses a

true two-point method for accurate calibrations. The Calibrator is completely

powered from the Monitor and the sensor can be inserted and removed from the

calibrator with a single hand. TCO

as CO

only or O2 only sensors for optimum versatility. Sensors provide superior

2

M accepts combination CO2/O2 sensors as well

2

performance, fast response, are rugged, reliable and can be membraned in seconds.

An automatic site timer enhances patient safety.

and O

2

2

),

2

Principles of Operation

Oxygen Transcutaneous oxygen is measured with an oxygen sensor consisting of two parts;

1) a modified Clark-type polarographic electrode, a silver anode and platinum

cathode, electrolyte and an oxygen permeable membrane, and 2) a heating section

with two precision thermistors for measuring and controlling the sensor temperature.

When the sensor is subjected to oxygen, the oxygen molecules diffuse through the

membrane and create an electro-chemical reaction which causes current to flow

through the cathode. An amplifier connected to the cathode measures current flowing

and converts it to a value proportional to the oxygen tension at the sensor/membrane

interface. This is PtcO

selected by the user).

Carbon Dioxide Transcutaneous carbon dioxide is measured with a sensor that utilizes a unique pH

electrode based on the Stow-Severinghaus principle. The carbon dioxide sensor is

composed of two parts; 1) a carbon dioxide sensor consisting of a pH electrode,

reference electrode, electrolyte and a carbon dioxide permeable membrane, and 2) a

heating section with two precision thermistors for measuring and controlling the

sensor temperature. When the sensor is subjected to carbon dioxide, the carbon

dioxide molecules diffuse through the membrane and react with the electrolyte. This

reaction alters the pH of the electrolyte solution, which in turn changes the voltage

across the pH and reference sensors. Since carbon dioxide is the only gas that can

affect the pH of the electrolyte, there is a direct correlation between pH and the

amount of CO

present. This relationship is expressed by the Henderson-Hasselbach

2

and is displayed as a O2 value (in either mmHg or kPa as

2

2 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 13

Technical Description Introduction 1

0.03 pCO

2

equation:

HCO

pH = pKa + log

3

An amplifier measures this voltage change and converts it to a value corresponding

to the carbon dioxide tension at the sensor/membrane interface. This is PtcCO

and

2

is displayed as a CO2 value (in either mmHg or kPa as selected by the user).

Local Power Local Power is the measure of electrical power, measured in milli-watts (mW),

required by the sensor to maintain the selected sensor temperature setting. The Local

Power value is proportional to the blood flow beneath the sensor site. Because the

sensor set temperature is above blood temperature, blood flowing past the sensor site

provides a cooling action. As blood flow (and its associated cooling action) increases,

the sensor requires more power to maintain its temperature setting and the LP value

increases. Conversely, as blood flow decreases, sensor heater power and LP also

decrease.

Abrupt changes in PtcO

blood flow at the sensor site, while abrupt changes in PtcO

significant LP changes may indicate consistent blood flow but a change in PaO

coupled with significant LP changes may indicate reduced

2

unaccompanied by

2

.

2

Important: Sensor heater power requirements (LP) are also influenced by body

temperature and ambient temperature changes. Body temperature changes tend to be

gradual over time and produce minor changes in LP. Ambient temperature changes

from air-conditioners, patient warmers, radiant heaters, etc., can have significant

effects on the LP value. If monitoring the LP value, it may be necessary to insulate

the sensor from ambient temperature changes with a light covering such as a

bedsheet, or with material designed to reflect radiant heat energy.

Technical Description

Per requirements of IEC 601-1, TCO2M is classified as class I equipment, internally

powered, with type BF applied part, and IPX0.

The TCO

serviceable parts. Refer servicing to qualified service personnel.

See “Accessories” on page 99 for listings of the Service Manual and Service Test kit

for use by technical personnel.

M Transcutaneous CO2/O2 Monitor, Model 860, contains no user

2

Transport and storage conditions: -10 to +55° C (14-131° F) < 90% relative humidity

non-condensing. Operating conditions:10-40° C (50-104° F).

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual3

2

Page 14

1 Introduction Technical Description

4 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 15

2 Safety

Patient Safety

• The location of the sensor on the patient should be changed periodically to

minimize the risk of heat induced skin damage. The risk of such skin damage

is dependent upon the sensor temperature, duration of application and

physiological parameters including local perfusion, body temperature, and

skin thickness.

• TCO

• In areas where electromagnetic devices (i.e., electrocautery) are used, patient

• The PtcCO

• Components of this product and its accessories which have patient contact

• Connect only Novametrix supplied transcutaneous sensors and gas

M monitor has electrically isolated inputs. Patient leakage current

2

flowing from the instrument to ground is limited to less than 10

60 Hz. Patient isolation is greater than 10 M

maximum patient and operator safety, the following procedures are

recommended;

•Keep the TCO

•Do not operate the TCO

•Do not touch the patient while making adjustments on the TCO

monitor.

•Whenever possible, the TCO

circuit as other equipment in use on the same patient. Outlets that are on

the same circuit can be identified by your hospital’s engineering

department.

monitoring may be interrupted due to electromagnetic interference.

Electomagnetic fields up to 3 V/m will not adversely affect system

performance.

factor for pCO

not during calibration. See “PtcCO2 Display Values” on page 19.

are latex free.

calibrators to the TCO

Refer to “Accessories” on page 99 for listings and catalog numbers.

M and its accessories clean.

2

M when it is wet due to spills or condensation.

2

M monitor should be connected to the same

2

display reading (CO2) is factory set to reflect the metabolic

2

and the value is corrected only during patient monitoring—

2

M Model 860 monitor front panel input connectors.

2

Ω, 2500 V rms at 60 Hz. For

µA at 120 V,

2

M

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual5

2

Page 16

2 Safety Contraindications

Contraindications

• In patients who are hemodynamically compromised, transcutaneous gas

values may no longer reflect arterial gas values due to changes in blood flow

to the tissue.

• Patients with extremely sensitive skin should be carefully evaluated prior to

monitoring as sensor heat or adhesive ring application may cause skin

irritation. Skin irritation due to the adhesive ring can be minimized by

loosening the adhesive with alcohol or water prior to its removal from the

patient.

• HALOTHANE INTERFERENCE. Halothane is the only known anesthetic

gas affecting the reliability of transcutaneous oxygen (PtcO

as demonstrated in in-vitro testing of the Transcutaneous Combination O

CO

Sensor (PN:4474). The affect of halothane on transcutaneous oxygen

2

measurements in-vivo has not been determined. Halothane does not affect

the transcutaneous carbon dioxide (PtcCO

Transcutaneous Combination O

/CO2 Sensor. No known anesthetic gasses

2

) measurement of the

2

affect the performance of the Transcutaneous Oxygen Sensor (PN:6754) or

the Transcutaneous Carbon Dioxide Sensor (PN:6752).

) measurement

2

2

/

• PtcO

levels in excess of 150 mmHg may cause drift of PtcCO2 portion of

2

the 4474-00 Combination O

NOVADISK

O

/CO2 Sensor and 8575 NOVADISK, nor with the Transcutaneous Oxygen

2

. This drift is not experienced with the 4474-39 Combination

/CO2 Sensor using an 8900 Split Membrane

2

Sensor (PN:6754) or the Transcutaneous Carbon Dioxide Sensor (PN:6752).

Warnings

WARNING: Indicates a potentially harmful condition that can lead to personal injury.

• Explosion Hazard: Do NOT use the TCO2M in the presence of flammable

anesthetics. Use of this instrument in such an environment may present an

explosion hazard.

• Electrical Shock Hazard: Always turn the monitor off before cleaning it.

Do NOT use a damaged sensor or one with exposed electrical contacts. Do

NOT remove covers or panels. Refer servicing to qualified service

personnel.

• Failure of Operation: If the monitor fails to respond as described, do not

use it until the situation has been corrected by qualified personnel.

• Fire Hazard: The TCO

oxygen levels at elevated pressures. Use of this instrument in such an

environment may present a fire hazard.

M and its sensors should not be exposed to elevated

2

6 TCO

• For installations where the integrity of the external protective earth

conductor arrangement is in doubt, the equipment should be operated from

its internal battery only.

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 17

Cautions Safety 2

• No user serviceable parts inside. Refer servicing to qualified service

personnel.

Cautions

CAUTION: Indicates a condition that may lead to equipment damage or malfunction.

• Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on

the order of a licensed medical practitioner.

• No tension should be applied to the sensor cable.

• Avoid storing the monitor and sensors at temperatures less than -10

greater than +55

° C (<14° F or >131° F).

• Do NOT immerse the monitor or sensors in liquids.

• Do NOT sterilize the monitor or the sensors.

• Electric Shock Hazard. Always turn the monitor off before cleaning it. Do

NOT use a damaged sensor or one with exposed electrical contacts. Do NOT

remove covers or panels. Refer servicing to qualified service personnel.

° C or

• Connect the line cord only to a grounded hospital-grade outlet.

• For continued protection against fire hazard, replace fuses only with those of

the same type and rating.

• No user serviceable parts inside. Refer servicing to qualified service

personnel.

• Operate at temperatures between +10° C to +40° C (50-104° F), < 90%

relative humidity (non-condensing).

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual7

2

Page 18

2 Safety Cautions

8 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 19

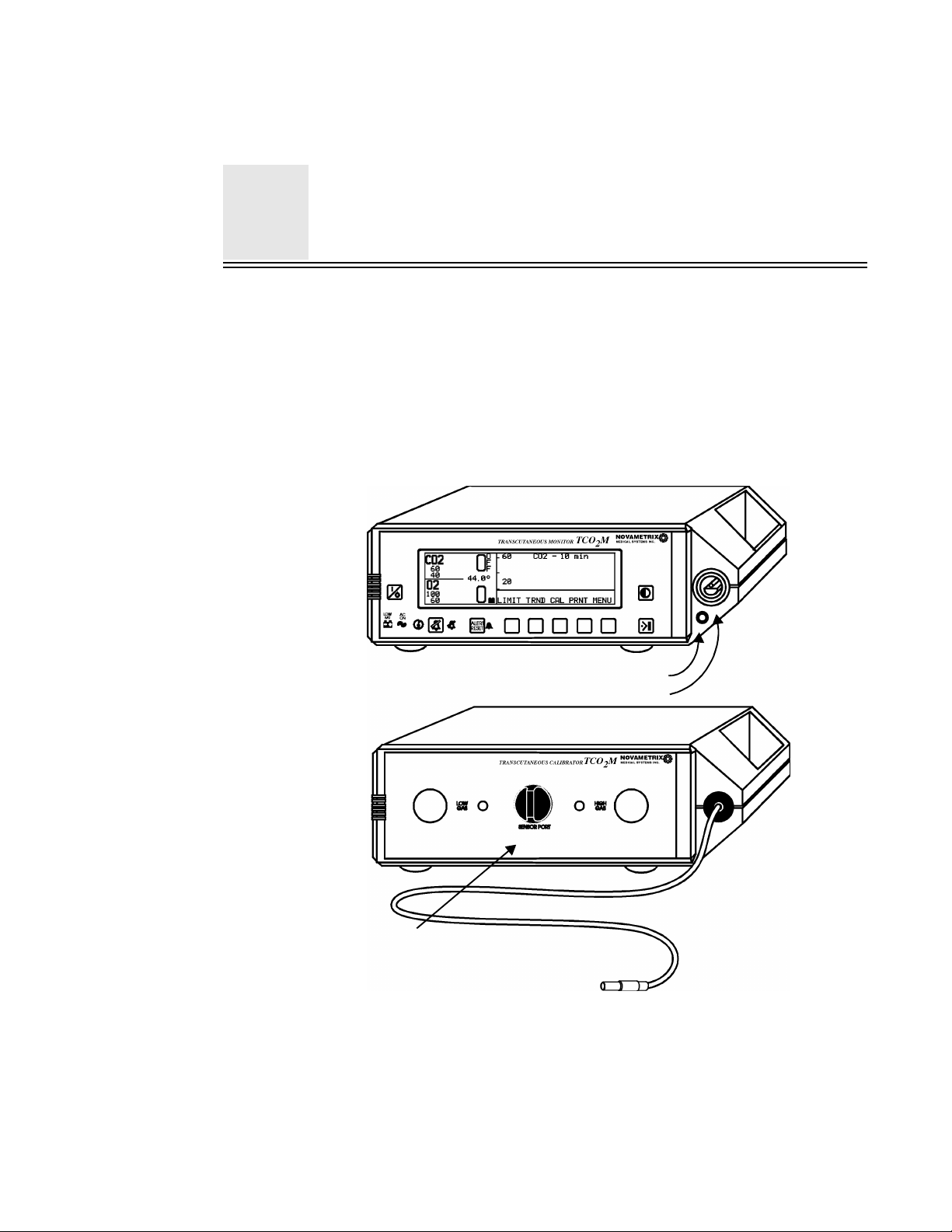

3 Quick Start Guide

This section summarizes and highlights the key steps and processes required to

properly configure the TCO

sensor, apply the sensor to the patient, handle any associated alerts, and remove the

sensor from the patient.

This section is an adjunct to other sections of this manual where these steps or

processes are explained in more detail. Refer to the appropriate sections for more

information. Use of equipment other than mentioned here may yield different results.

M® monitor for operation, connect and calibrate the

2

Calibrator connection

Sensor connection

Sensor Port

Connect to TCO

Connect Sensor

25-Mar-97 Rev. 01 TCO

1 Attach an appropriate sensor to the TCO2M’s front panel connector. The

sensor will “click” into place when properly installed.

Ensure the sensor is in good physical condition and that the NOVADISK

membrane assembly is intact and clean—use an alcohol wipe if needed.

®

M

User’s Manual9

2

M

2

Page 20

3 Quick Start Guide

Power Up 2 Press the key to turn the TCO

AC ON illuminates if the monitor is connected to the AC line and the

rear panel power switch is set to “|”. This also causes the internal battery

to charge.

A battery icon appears on the display if the monitor is operating from its

internal battery.

3 The base menu display appears after the power-up and self-test messages.

4 Press the (Contrast) key to adjust the display for optimum viewing.

M on.

2

Calibrator Setup 5 Connect the Model 868 Calibrator to the small connector on the monitor’s

front panel.

Ensure that the gas cylinders are properly installed. They are color coded

to make it easy. Check that the cylinders are not empty. Both gauges

should be registering pressure.

If using an O2 only sensor, the Model 868 Calibrator is not required.

Calibration 6 Place the sensor into the Calibrator’s Sensor Port.

If using an O2 only sensor, refer to the appropriate section of the manual

for calibration.

7 Press the CAL softkey. Verify the calibration settings, including site timer

duration and temperature are correct. Press START to begin calibration.

If calibration settings need adjustment, press SET to adjust them.

Calibration will not begin if the sensor is not yet up to operating

temperature. Wait until temperature is achieved and try calibration again.

8 When the TCO2M beeps and the CALIBRATION DONE message appears,

press RUN and remove the sensor from the calibrator.

Alert Limits 9 Verify the alert limits are properly set. If needed, press LIMITS to adjust.

Apply to Patient 10 Attach an adhesive ring to the sensor face, apply a drop of contact gel, and

apply the sensor to a properly prepared site.

Handling Alerts 11 To temporarily silence an audible alert and to keep the red alert bar from

flashing for two minutes, press the key.

12 Once the parameter comes back within limits (or limits are widened), press

ALERT RESET to clear the displayed message and flashing limit display.

Removal from

Patient

Monitor Shutdown 14 To turn the TCO

13 To remove the sensor from the skin, gently peel the adhesive ring from the

skin. Wiping the ring with water or alcohol will loosen the adhesive and aid

removal.

M off, press the key.

2

10 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 21

4 System Overview

This section provides an overview of the TCO2M Transcutaneous Monitoring System

including the Model 860 Monitor, Model 868 Calibrator, and transcutaneous sensors.

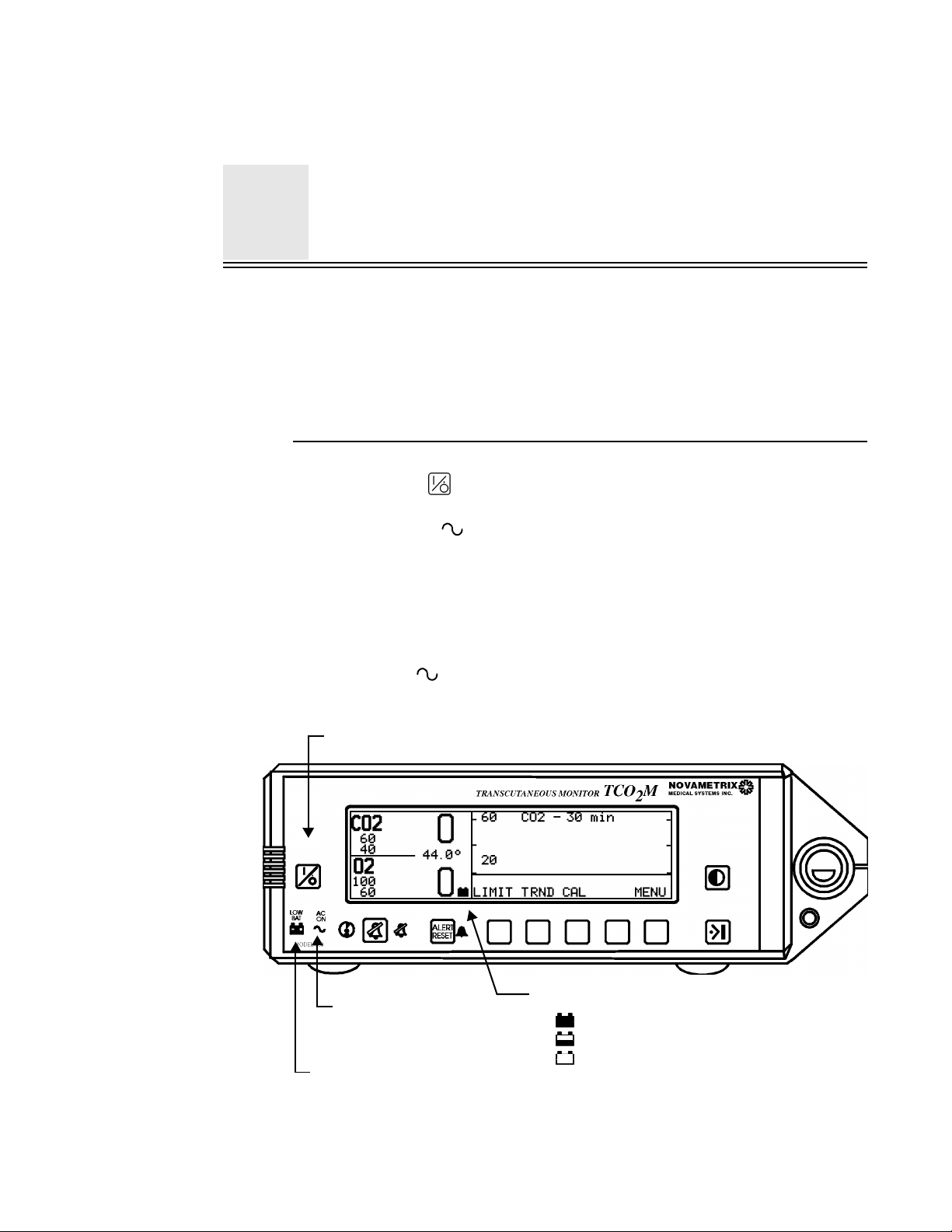

TCO2M Monitor Front Panel

The TCO2M Monitor, Model 860 front panel includes dedicated function keys, menu

dependent “softkeys” and illuminating icon symbols. A Red Alert Bar, sensor, and

Model 868 Calibrator input connections also appear on the front panel.

Sample Display

TCO2M Calibrator Model 868 connection

or Power Turn the monitor power on and off.

Low Bat Icon illuminates red when operating on battery power and 15 minutes of battery life

remain.

• A similar icon appears in the display when the monitor is running on battery

power and gives a visual indication of the charge left on the battery.

Red Alert Bar

Sensor input

AC ON Icon illuminates green when the monitor is connected to AC power and the rear panel

power switch is set to “|” (ON). Also indicates the battery is charging.

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual11

2

Page 22

4 System Overview TCO

M Monitor Rear Panel

2

Two Minute

Silence

Icon illuminates yellow when the audio has been temporarily silenced using the Two

Minute Silence feature.

Audio key Enable or disable audible alerts.

Audio Icon Flashes yellow to indicate an Audio Off condition in which audible limit alerts will

be prevented.

Alert Reset Acknowledge and reset alerts.

Alert Icon Flashes red to indicate an alert condition.

Softkeys Five keys that function according to the command shown above each key in the

display.

Event Mark a user defined “Event” in trend memory (viewed from Trend Page).

Contrast Press to vary the display’s contrast setting for optimum viewing.

TCO2M Monitor Rear Panel

1 2

3

4 5 6

1 Ground stud. Use to connect monitor’s chassis to earth ground.

2 Indicates fuse rating information for mains fuse.

3 Data Input/Output port for external peripherals.

4 Power cord receptacle and power cord retaining clip. Plug power cord into

this receptacle. Use only hospital grade three wire plugs for connection via

supplied power cord.

12 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 23

Symbols System Overview 4

5 AC Line Power (Mains) Switch. Set to “|” allows AC mains to power the

monitor, set to “O” switches AC mains power off.

6 Voltage select/fuse compartment - Sets mains operating voltage and houses

mains fuses.

Symbols

Equipotentiality Connection to monitor’s chassis.

Ground Protective earth ground connection.

Dangerous

High voltages present.

Voltage

Patient

Identifies patient isolation connection as type BF.

Isolation

Attention Consult manual for detailed information.

Mains Fuse Mains fuse rating for replacement fuses

250V

Mains Power AC mains switch “|” ON-connection to mains; “O” OFF-disconnection from mains.

TCO2M Monitor Display

The display is arranged in different sections; parameter information for PtcCO2 and

PtcO

, real time waveform display, and the menu display. A full screen trend display

2

is also available. TCO

M allows great flexibility in the way that data is displayed, so

2

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual13

2

Page 24

4 System Overview Transcutaneous Sensor Overview

your screen may not match this one; especially if you are using a single parameter

(CO

or O2) sensor.

2

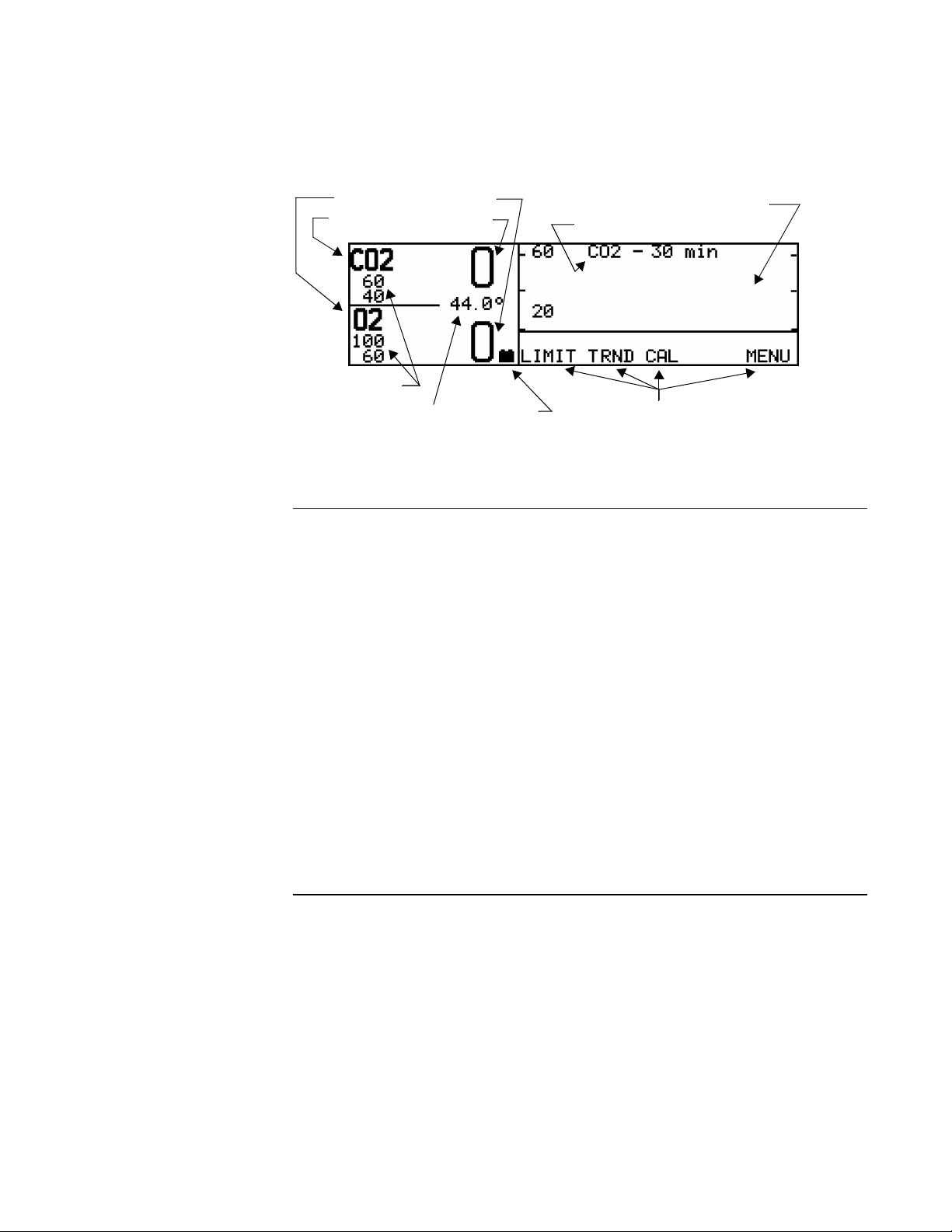

indentifier & value

PtcO

2

PtcCO

identifier & value

2

Alert Limits

Sensor Temperature Menu softkey identifiersBattery Icon

Real Time Waveform Display

Trend Parameter & Display Time

Transcutaneous Sensor Overview

Select sensor Select a sensor based on monitoring need and availability. Several transcutaneous

sensors can be used with the TCO

split membrane

Transcutaneous O

NOVADISK 4474-00, Combination O

Sensor 6754-00, and Transcutaneous CO2 Sensor 6752-00.

2

M including; Combination O2/CO2 Sensor with

2

/CO2 Sensor 4474-39,

2

Ensure the selected sensor is mechanically sound; with no broken, frayed, or exposed

wiring. Ensure the

NOVADISK membrane assembly is intact and clean, use a alcohol

wipe to clean the sensor and membrane face if necessary. Refer to the appropriate

sections of this manual for specific sensor preparation instructions.

Connect sensor Connect a sensor to the TCO

M, by aligning the pins of the sensor connector with

2

those on the monitor’s front panel input connector and pushing the sensor connector

into place. The sensor should “click” into place when correctly seated.

TCO2M Calibrator, Model 868

The TCO2M Calibrator, Model 868 is intended to be used with the TCO2M

Transcutaneous Monitor, Model 860. The calibrator is used to expose a

transcutaneous sensor to two precision gas mixtures as part of the sensor’s

14 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 25

TCO2M Calibrator, Model 868 System Overview 4

calibration. The Monitor controls the actions of the Calibrator as well as providing

power to the Calibrator.

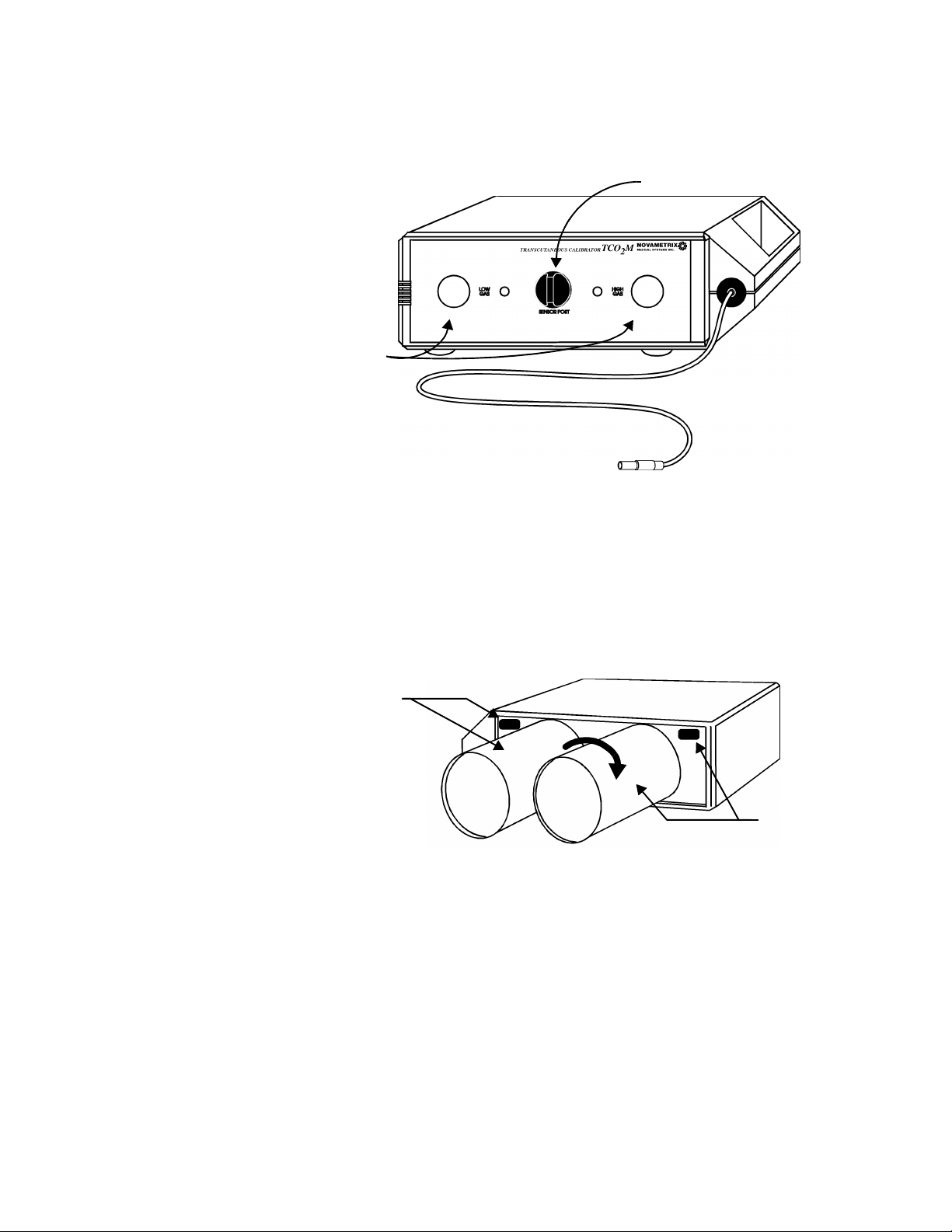

Sensor port with cover

Gas

gauges

Setting up the

Calibrator

Connection to

TCO2M

To install calibration gas cylinders:

1 Check the cylinder part number and label color against the part number and

color identifier on the rear panel.

High Point Gas

Cat. No. 8965

(Yellow)

Tighten

Low Point Gas

Cat. No. 8964

(Orange)

2 Insert a Low Point Calibration Gas (Cat. N0. 8964) cylinder into the

appropriate opening at the rear of the calibrator. Hand tighten the cylinder by

rotating it in a clockwise direction until is firmly seated against the in the

calibrator, then 1/4 turn more. The cylinder should turn easily, if not, remove

and try again. Do not force it.

3 Install High Point Calibration Gas (Cat. N0. 8965) cylinder in the same

manner.

4 Verify that both front panel pressure gages indicate pressures above zero.

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual15

2

Page 26

4 System Overview TCO2M Calibrator, Model 868

Disconnecting Gas

Cylinders

Connect the

calibrator

When the front panel pressure gauge reads 0 (while a cylinder is connected) the

cylinder is empty and must be replaced. Do not attempt to calibrate a sensor with an

empty cylinder.

To remove a cylinder:

1 Rotate the cylinder in a counter clockwise direction until free.

2 Dispose of cylinder in accordance to local regulations.

CAUTION: Do not attempt to refill empty cylinders or to dispose of in fire.

Refer to labeling on cylinder for proper handling and disposal.

Connect the calibrator to the TCO2M by aligning the red dot on the calibrator cable

connector with the red dot on the monitor’s front panel calibrator input connector and

pushing the calibrator connector into place. It “clicks” into place when correctly

seated.

16 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 27

5 Operating the Monitor

This section includes information on operating the TCO2M Transcutaneous Monitor, Model

860 including power on/off and AC/Battery operation. This section also details the

monitoring of oxygen and carbon dioxide tension, and the principles of sensor operation.

TCO2M Power-up

Power On/Off Press the front panel key to turn the monitor on or off. At power-up the monitor will:

• Perform a “lamp test” where the display and indicators light

(AC ON icon will not light when powered by battery).

• Produce an audible “beep” indicating the audio is functional.

• Performs a self test; “MONITOR PERFORMING SELF TEST” is displayed.

• Display the base menu.

AC/Battery operation The TCO

panel AC ON icon illuminates green when operating from the AC line, and remains off

when TCO

Press to turn monitor on and off

Lights green when on

AC power (battery charging)

Low battery alert lights

when 15 minutes remain

M can be powered from the AC line (Mains) or from its internal battery. The front

2

M is being powered from its battery.

2

Icon appears only when on battery power

Full charge (>3 hours)

Half charge

Nearly depleted

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual17

2

Page 28

5 Operating the Monitor TCO2M Power-up

AC Line Power To power TCO2M from the AC line power source:

1 Set the rear panel power switch to the “|” (ON) position.

2 Plug the line cord into the rear panel power cord receptacle and into a

properly grounded 3-wire outlet.

3 Verify the green AC ON icon illuminates.

Battery Power To power TCO2M from its internal battery:

1 Do either or both of the following;

— Set the rear panel power switch to the “O” (OFF) position, or

— Unplug the line cord from the rear panel power cord receptacle or AC

outlet.

2 Verify the green AC ON icon is NOT illuminated.

Operating on battery A fully charged battery will power the monitor for over three hours. While on battery

power, the display shows a battery icon that “drains” as battery charge is depleted;

from a full charge , to half-charge , to nearly depleted .

power up on battery power if the battery is not sufficiently charged. See “Charging

the battery” below.

The monitor may not

NOTE: Excessive alerting reduces battery life when operating on battery power.

Low battery alert When 15 minutes of battery life remain, the LOW BAT low battery indicator

illuminates red. If the monitor continues to be powered from its internal battery for

more than 15 minutes after a low battery alert occurs, the monitor’s display blanks

except for the message

BATTERY VERY LOW PLUG IN AC POWER. All indicators

(except AC ON ) illuminate and a continuous audible tone sounds. Reconnect the

AC power or the monitor will automatically shut itself off.

Charging the battery To recharge the battery, plug in the line cord and set the rear panel power switch to

the (|) ON position. A discharged battery will be fully recharged within 12 hours. The

monitor may be operated, on AC power, while the battery is being recharged.

Long Term Storage If the TCO

M has not been used or connected to AC power (AC ON icon

2

illuminated) for an extended time (e.g., 3 months or more) allow the battery to charge

for 12 hours before use.

Battery replacement The internal TCO

M battery is not user replaceable. Should replacement become

2

necessary, contact qualified technical service personnel. Replace only with a battery

of the same type and rating.

18 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 29

Monitoring CO2 and O2 Tension Operating the Monitor 5

!

Monitoring CO2 and O2 Tension

Sensor Stabilization After the properly membraned and calibrated sensor is appropriately applied to the

skin, the CO

value will drop from its room air value, then slowly increase to a stabilized value.

Stabilization typically occurs within 10-15 minutes.

will gradually rise from its room air value to a stabilized value. The O

2

2

Carbon Dioxide and

Oxygen Alerts

Sensor

Temperature Alerts

The TCO

M has audible and visual alerts for both carbon dioxide and oxygen

2

tension. Refer to “LIMIT — CO2 and O2 Alert Limits” on page 21.

Any time the actual sensor temperature differs from the user-selected temperature by

more than 0.2

° C, a temperature alert will occur. If a temperature alert occurs, the

alert indicator and the red alert bar start to flash. The message center displays

TEMP > 0.2° C and audible alarm (that overrides Audio Off) sounds. The visible and

audible alarms will automatically reset if the temperature returns within the 0.2

° C

limits. The temperature audio is disabled for the first three minutes after the monitor

is turned on—allowing the sensor to heat up without generating an alarm condition.

Do not confuse a Site Timer Expired induced sensor heater power shutdown with a

temperature fault. Refer to “Site Timer” on page 33.

A temperature fault condition may occur if the sensor is damaged or if the monitor

fails. The message center will display “

MONITOR ERROR TEMPR. ERR-HTR OFF”

and an audible alarm (that overrides Audio Off) will sound. The monitor will

automatically shut down the heater power to the sensor, thus eliminating the risk of a

sensor-induced heat-related skin damage. A temperature fault can only be reset by

turning the monitor off and then back on.

WARNING: If a temperature fault occurs, the sensor should

immediately be removed from the patient. Contact qualified service

personnel before putting either the monitor or sensor back into use

.

PtcCO2 Display Values

The CO2 display reading is factory set to reflect the metabolic factor for pCO2. This

means that the CO

of CO

and the anaerobic temperature coefficient induced by the application of a

2

heated sensor. The CO

significantly greater than the pCO

• Anaerobic temperature coefficient of blood for carbon dioxide.

1. Monaco, F., McQuitty, J.C., Nickerson, B.G. Calibration of a Heated Transcutaneous CO2 Electrode to Reflect Ar-

2. Am. Rev. Resp. Dis. 1983; 127:322.

terial CO

25-Mar-97 Rev. 01 TCO

values have been adjusted for the increased metabolic production

2

value measured with a heated transcutaneous sensor is

2

in the arteries for the following reasons:

2

®

M

User’s Manual19

2

1

Page 30

5 Operating the Monitor PtcCO2 Display Values

• Increased local CO2 production due to increased metabolism of heated

epidermal tissue beneath the sensor.

• The arteriole-cellular CO

The TCO

M automatically corrects the PtcCO2 during patient monitoring (not during

2

difference.

2

sensor calibration) to compensate for these metabolic factors related to the

temperature effect and CO

following formula;

2

pCO2(37°C) = PtcCO2 × (10

production. The correction is accomplished via the

2

0.019× (37-Tsensor °C)

) - 4

pCO2(37° C) - PtcCO2 value in mmHg corrected to 37° C

assuming a patient temp of 37

PtcCO

- value of PtcCO2 in mmHg measured by the sensor

2

° C

If the correction factor has been disabled, the message “OFF” (metabolic correction

factor off) flashes beside and to the right of the displayed CO

value. Refer to

2

“Metabolic Correction Factor” on page 67 for details.

20 TCO

2. Severinghaus, J.W. Transcutaneous Blood Gas Analysis Respiratory Care 1983; 27(2): 152

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 31

6 Menu Operation and Setup

The TCO2M uses a simple menu system with helpful messages to guide the user

through setup and alert conditions. To operate the menu system, press the softkey

beneath the desired menu command. System prompts and alert messages are

displayed in the “Message Center” above the menu commands.

LIMIT TRND CALMENU

Message Center (top line)

Menu commands

Softkeys

Menu Structure

The TCO2M menu structure is divided into two parts; the User and Advanced menus.

The User menu includes basic menu commands needed to operate the monitor on a

daily basis. The Advanced menu contains setup/configuration commands that affect

how the system operates, but that are typically not used in everyday monitoring. The

User menu commands are detailed below. The Advanced menu commands are

detailed in “Advanced Controls and Features” on page 63.

LIMIT — CO2 and O2 Alert Limits

The TCO2M has audible and visual alerts for both carbon dioxide and oxygen

tension. The TCO

alert options.

M is very flexible in handling alerts because it provides several

2

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual21

2

Page 32

6 Menu Operation and Setup LIMIT — CO2 and O2 Alert Limits

• Alert limits can be adjusted manually or automatically with the Auto Alerts

feature.

• Each individual limit may be turned off.

• Limit alerts require user action to be reset; but can be set to automatically

reset.

• Alert limit settings are retained in memory and restored each time the

monitor is turned on; but the monitor can be set to power up each time using

default settings.

• Audible alerts are delayed 10 seconds from the occurrence of a limit alert;

but the delay can be eliminated to allow instant activation.

• Audible alert volume can be adjusted.

• The audible alert and red alert bar suppressed for two or ten minutes.

• Audible alerts can be suppressed altogether via the Audio Off feature; and

the Audio Off feature can itself be disabled if suppressing audible alerts is

undesired.

• The red alert bar stops flashing automatically if the parameter that caused a

limit alert returns within its limits but it can instead be set to continue

flashing until the user presses

turned off altogether.

ALERT RESET, or the red alert bar can be

Set Alert Limits To set the CO

1 Press LIMIT and SET ALERT LIMITS appears.

LIMIT TRND CALMENU

2 Use the SEL key to move the (left pointing arrow) to highlight a limit value.

3 Use the ↑ and ↓ (up/down arrows) to increase/decrease the limit value.

The monitor will not allow a parameter’s high and low limits to be set within

5 mmHg (0.5 kPa) of each other. If the lower limit is raised to within 5

mmHg of the upper limit, the upper limit will automatically increase to

maintain the 5 mmHg difference. If the upper limit is adjusted downward to

within 5 mmHg of the lower limit, the lower limit will automatically decrease

to maintain the 5 mmHg difference.

Decreasing an upper limit below 5 or a lower limit below 1 causes that limit

to be turned OFF. If alert limits are displayed the limit shows as OFF; if alert

limits are not displayed, the message center indicates that the alert is

turned off.

and O2 alert limits:

2

CO2 ↑ 60

↓ 40

O2

↑ 100

↓ 60

SET ALERT LIMITS

RUNSEL

Select Increase Decrease

↑ ↓ AUTO

22 TCO

4 Press RUN to return to the main menu.

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 33

LIMIT — CO2 and O2 Alert Limits Menu Operation and Setup 6

Auto Alert Limits Auto Alerts allow the user to bracket alert limits about the CO2 and O2 display values.

To set Auto Alert Limits:

1 Press LIMIT and SET ALERT LIMITS appears

2 Press AUTO. The alerts are bracketed about the display value.

CO2 ↑ 60

↓ 40

O2

↑ 100

↓ 60

SET ALERT LIMITS

LIMIT TRND CALMENU

RUNSEL

Auto alerts are bracketed about the display value for CO2 and O2. If one or both

parameters is displaying a value less than 10 mmHg (1 kPa) when AUTO is pressed,

the message NOT ENOUGH DATA TO SET AUTO LIMITS is briefly displayed and that

parameter’s limits are not adjusted; however, the other parameter’s limits will be

adjusted.

↑ ↓ AUTO

Carbon Dioxide Auto Alert-Limit Determinations:

PtcCO2 Display Value PtcCO2 Limit Setting

PtcCO

≤ 10 mmHg no change

2

10 mmHg < PtcCO

PtcCO

> 40 mmHg PtcCO

2

< 41 mmHg PtcCO

2

± (PtcCO

2

± 10 mmHg

2

/4) mmHg

2

Oxygen Auto Alert-Limit Determinations:

PtcO

Display Value PtcO2 Limit Setting

2

PtcO

≤ 10 mmHg no change

2

10 mmHg < PtcO

PtcO

> 100 mmHg PtcO

2

< 101 mmHg PtcO

2

± 10 mmHg

2

± 20 mmHg

2

Limit Alerts Definitions: Limit Alerts—audible and visible signals from the monitor, are

generated in response to CO

maximum and minimum allowable values for CO

If the PtcCO

or PtcO2 value violates an alert limit setting;

2

or O2 values outside the range of the Alert Limits—the

2

or O2.

2

• The violated alert limit (if displayed) starts to flash. If limit values are not

displayed, an

↑ or ↓ arrow flashes beside the CO

or O2 display identifier.

2

• The red (bell-shaped) indicator beside the ALERT RESET key flashes.

• A message flashes in the Message Center (e.g., CO2-LOW).

If the value returns within its limits within 10 seconds (if 10 sec alert delay is on);

• The red indicator, violated limit display and alert message stop flashing.

If the limit alert lasts for more than 10 seconds (or the 10 sec alert delay is off);

25-Mar-97 Rev. 01 TCO

®

M

User’s Manual23

2

Page 34

6 Menu Operation and Setup TRND — Real time trend displays

Low End Point

Scale Span Here is ∆40 torr

Select a parameter to trend

• An audible alarm will sound and the red alert bar flashes. Two Minute

Silence, Audio Off and Alert Delay will suppress the audible alert. Two

Minute Silence and Alert Delay will suppress the flashing red alert bar.

If the value returns within limits after 10 seconds of alerting

• The audible alarm and red alert bar will turn off.

• The red indicator and violated limit display (value or arrow) continue to

flash until the user presses the ALERT RESET key. (This allows the user to

determine which limit was violated.)

TRND — Real time trend displays

Real Time Trend The TCO2M can display real time graphic trends of CO2, O2 and Local Power data.

The user can easily customize the real time trends to show the most recent 10, 20 or

30 minutes of CO

needed.

, O2 or Local Power data, and to change the vertical scale as

2

Show CO

Vertical Scale

High End Point

Vertical Scale

/O2/LP To change real time graphic trend to reflect CO2, O2, or LP data:

2

1 Press TRND and SELECT TREND DISPLAY appears.

2 Press CO2, O2 or LP to select the desired parameter.

The softkey for the currently displayed parameter flashes.

LIMIT TRND CALMENU

Displayed Time Scale

(Real Time Trend Display)

SELECT TREND DISPLAY

RUNFULLCO2O2LP

3 Press RUN to return to the base menu.

Set Trend Time To change real time graphic trend time scale:

1 Press TRND and SELECT TREND DISPLAY appears.

24 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 35

TRND — Real time trend displays Menu Operation and Setup 6

then press & hold

Press twice Select time

Select time

then press and hold

2 Press and hold CO2, O2 or LP until ADJUST TREND SETTINGS appears.

SELECT TREND DISPLAY

LIMIT TRND CALMENU

RUNFULLCO2O2LP

Select a parameter,

3 If in Step 2, you pressed CO2 or O2, now press SEL twice to highlight TIME.

Press ↑ or ↓ (up/down arrows) to select a 10, 20, or 30 minute time scale.

Skip to Step 5.

REAL TIME TREND - CO2

SCALE:

HI/LO: 060/020

TIME: 30 minutes

ADJUST TREND SETTINGS

RUNSEL

∆040 torr

↑ ↓ PREV

REAL TIME TREND - CO2

SCALE:

HI/LO: 060/020

TIME: 30 minutes

ADJUST TREND SETTINGS

RUNSEL

4 If in Step 2, you pressed LP, now press TIME repeatedly to select a 10, 20,

or 30 minute time scale.

LP=+117mWLPR = 000mW

RUNSETTIMEPREV

5 Press RUN to return to the base menu.

Set CO2/O2 scale To change the real time graphic trend scale for CO2 or O2:

1 Press TRND and SELECT TREND DISPLAY appears.

∆040 torr

↑ ↓ PREV

2 Press and hold CO2 or O2 until ADJUST TREND SETTINGS appears.

SELECT TREND DISPLAY

LIMIT TRND CALMENU

RUNFULLCO2O2LP

3 To change the scale, press the ↑ or ↓ (up/down arrows) to select the desired

delta—the distance between HI and LOW values.

25-Mar-97 Rev. 01 TCO

Select parameter

®

M

User’s Manual25

2

Page 36

6 Menu Operation and Setup TRND — Real time trend displays

The vertical scale changes in units of 40 (e.g., 40, 80 120, etc.).The actual

start and end points are determined by the HI/LO selection detailed next.

REAL TIME TREND - CO2

SCALE:

HI/LO: 060/020

TIME: 30 minutes

ADJUST TREND SETTINGS

RUNSEL

∆040 torr

↑ ↓ PREV

4 To change the actual HI and LOW scale values, press SEL to highlight HI/

and then press the ↑ or ↓ (up/down arrows) to select the desired points

LO

on the scale.

The selected scale requires a start and stop point for display on the vertical

axis. These points can be adjusted here. The end points for the vertical

axis will change keeping the chosen scale as the determining factor of the

high and low values. For example; if the scale is set at 40, the HI/LO values

will always be 40 units part, the high end point will be 40 units higher than

the low point.

REAL TIME TREND - CO2

SCALE:

HI/LO: 060/020

TIME: 30 minutes

ADJUST TREND SETTINGS

RUNSEL

∆040 torr

↑ ↓ PREV

REAL TIME TREND - CO2

SCALE:

HI/LO: 060/020

TIME: 30 minutes

ADJUST TREND SETTINGS

RUNSEL

∆040 torr

↑ ↓ PREV

Local Power

(LP and LPR)

5 Press RUN to return to the base menu.

Once the sensor is stabilized on the skin, the Local Power Reference (LPR) can be

set. The LPR shows the amount of electrical power required by the sensor to maintain

its operating temperature. The unit of power measure is the milliwatt (mW). Once set,

the LPR value will not vary until a new value is set by the user (see below). Any realtime fluctuations to the LPR value (caused by changes in heater power requirements)

are displayed as a plus or minus value in the Local Power (LP) display and in the real

time LP trend as values above (more power) and below (less power) the centerline

(the LPR value).

1

To set the local power reference:

1. For further information refer to; Peabody, J.L. Willis, M.M. et al. Reliability of Skin (tc)PO2 Electrode Heating Power

as a Continuous Noninvasive Monitor of Mean Arterial Pressure in Sick Newborns. Continuous Transcutaneous Blood

Gas Monitoring 1979: 127-133. Refer also to; A User’s Guide to Transcutaneous Gas Monitoring Novametrix Medical

Systems Inc., Medical Education Division, September 1983.

26 TCO

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 37

TRND — Trend Page (stored trend memory) displays Menu Operation and Setup 6

Press & Hold

Set LP value as new LPR value

1 Press TRND and SELECT TREND DISPLAY appears.

SELECT TREND DISPLAY

LIMIT TRND CALMENU

RUNFULLCO2O2LP

2 Press and hold the LP softkey until the LP and LPR values appear.

3 Press SET to set the local power reference.

LP=+117mWLPR = 000mW

RUNSETTIMEPREV

LP=+000mWLPR = 117mW

RUNSETTIMEPREV

4 Press RUN to return to the base menu.

TRND — Trend Page (stored trend memory) displays

The TCO2M maintains trend information for CO2, O2, and local heater power. The

24-hour battery backed trend memory is continually and automatically updated every

eight seconds. Trend displays are user selectable to show any 12, 8, 4, or 2 hour, or

30 minute portion of trend memory as a graphical trend or histogram. User selected

“Events” are stored in trend memory and displayed. Trend memory can be erased via

the monitor startup or Trend Page menus—trend memory is not erased by a simple

power off-power on cycle.

Month and Date Time

Cursor

Values at Cursor location

Trend Identifier &

Alert Messages

Power On/Off indicator

Event marked

Trend Duration

New trend data is continually collected and enters the graph from the right—pushing

older already displayed data towards the left. (If less than 12 hours of data have been

collected, the graph will be shortened accordingly.) Points in the trend where the

monitor was turned off are indicated by dotted vertical lines.

25-Mar-97 Rev. 01 TCO

Moves Cursor Left/Right

®

M

User’s Manual27

2

Page 38

6 Menu Operation and Setup TRND — Trend Page (stored trend memory) displays

A cursor, the dashed vertical line flashing in the display, can be moved along the time

base to display the CO

cursor is controlled by left and right arrow keys. Press and hold the softkey to increase

cursor speed.

Information displayed above the graph is specific to the data at the cursor. The

information above the graph includes; the date in the form

time in 24 hour format in the form

mmHg or kPa as the monitor is configured, and LP in mW.

EVENT is displayed when the cursor is moved over a area in the trend where an

Event was marked by the user.

The TCO2M continues uninterrupted patient monitoring while displaying trends.

Alerts that occur are identified in the lower left corner of the trend page display.

If no keys are pressed for 5 minutes, the base menu replaces the trend display.

, O2, and local power value at any point in the trend. The

2

DDMMMYY (30SEP96), the

HH:MM:SS (13:30:00 = 1:30 p.m.), CO2 and O2 in

Show trend page To display the full trend page:

1 Press the TRND softkey and SELECT TREND DISPLAY appears.

2 Press FULL and the Trend Page display appears.

LIMIT TRND CALMENU

3 Press RUN to return to the base menu.

Moving in trend To navigate through the trend page display:

1 Display the trend page (press TRND then FULL).

2 Move the cursor by pressing the <- or -> (arrow keys) to the desired time.

Press the <- (arrow left) key to move the cursor towards older data.

Press the -> (arrow right) key to move the cursor towards more recent data.

TREND-CO2 12HrRUN EXPAND<-->NEXT

Information displayed above the graph is specific to the data at the

cursor—the flashing dashed vertical line in the display.

SELECT TREND DISPLAY

RUNFULLCO2O2LP

older newer

28 TCO

3 Press the EXPAND softkey.

Successive presses of the EXPAND key cycles through the 12, 8, 4 and 2

hour and 30 minute trend displays. Expansion occurs about the cursor.

4 Use the arrow keys to fine tune the cursor to the desired location in the trend.

®

M

User’s Manual Rev. 01 25-Mar-97

2

Page 39

TRND — Trend Page (stored trend memory) displays Menu Operation and Setup 6

5 Press RUN to return to the base menu.

Select trend page

parameter

When first selected, the trend page will display the same parameter as displayed by

the real time trend. The user can change the trend page to display LP as well as CO

or O2 (provided the sensor in use supports those parameters).

To change to the trend page display parameter:

1 Display the trend page (press TRND then FULL).

2 Press NEXT. The available trend page parameters are listed.

3 Press the CO2, O2, or LP key to display that parameter in the trend page.

CO2 Displayed

O2 Displayed

LP Displayed

TREND-CO212HrRUNSCALEO2LPNEXT

TREND-O212HrRUNSCALECO2LPNEXT

TREND-LP12HrRUNSCALECO2O2NEXT

Select trend scale Each of the trend page supported parameters, CO2, O2 and LP, can be viewed using

a “half” or “full” scale display setting. Each parameter scale is independent of the

others.

To change the trend page display scale of a parameter.

2

1 Display the trend page and select the parameter you desire.

2 Press NEXT.

3 Press SCALE and then select either the HALF or FULL scale setting.

CO2: Half 0-60, Full 0-100. O2 and LP: Half 0-100, Full 0-200

TREND-CO212HrRUNSCALEO2LPNEXT

TREND-CO2HALFFULL