Page 1

RESPIRATORY PROFILE MONITOR

Service Manual

Model 8100

October 27, 1999

Catalog No. 6758-90-01

Novametrix Medical Systems Inc.

P.O. Box 690

5 Technology Drive

Wallingford, Connecticut, U.S.A. 06492

Page 2

Page 3

Revision History

27-Jan-98 Release revision 00

27-Oct-99 Software version 3.1, revision 01 R-N705

Declaration of Conformity with European Union Directives

The authorized representative for Novametrix Equipment is:

European Compliance Services Limited

Oakdene House

Oak Road

Watchfield

Swindon, Wilts SN6 8TD

United Kingdom

Page 4

[This page intentionally blank.]

Page 5

G

Guarantee

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is full y guaranteed,

covering materials and workmanship, for a period of one year from the date of shipment, except for

certain disposable products and products with stated g uarantees other than one year. Novametrix reserves

the right to perform guarantee service(s) at its factory, at an authorized repair station, or at the cu stomer’ s

installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at Novametrix’ option,

replacement of any defective parts of our equipment, except fuses, batteries, and calibration gasses,

without charge, if said defects occur during normal service.

Claims for damages during shipment must be filed promptly with the transportation company. All

correspondence concerning the equipment must s pecify both the model name and num ber, and the serial

number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without following specific

operating instructions will void this guarantee and release Novametrix from any further guarantee

obligations.

Service Department

For factory repair service, call toll free

1-800-243-3444

In Connecticut, call Collect (203) 265-7701

(203) 284-0753

FAX

http://www.novametrix.com

techline@novametrix.com

Email

Caution: Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order of a

licensed medical practitioner.

Novametrix reserves the right to change specifications without notice.

CO

SMO Plus!

2

are trademarks of Nov ametrix Medical Sys tems Inc. Velcro is a registered trademark of Velcro USA, Inc.

Cidex is a trademark of Arbook, Inc. Nafion is a registered trademark of Dow Corning Corp.

Copyright 1999, Novametrix Medical Systems Inc. This document contains information which is

proprietary and the property of Novametrix Medical Systems Inc., and may not be reproduced, stored in

a retrieval system, translated, transcribed or transmitted in any form, or by any means, without prior

explicit written permission from Novametrix Medical Systems Inc.

Rev. 01

and CAPNOSTAT are registered trademarks and Y-Sensor, SuperBright and OxySnap

Model 8100 Service

Manual

v

Page 6

Service Policy

Novametrix Medical Systems Inc. will provide Warranty Service Support to its customers within 48

hours of receiving a telephone request for technical support. This 48 hour period begins once a service

request is placed through the Factory Technical Support Department in Wallingford, Connecticut.

Novametrix provides factory direct technical support to its customers through a technical support group

located in Wallingford, Connecticut and company service representatives located throughout the United

States. All Technical Support for Novametrix products is provided “Factory Direct”.

Novametrix provides 24 hour a day technical support accessibility via telephone numbers (800) 243-3444

or (203) 265-7701. After hours technica l support requests (b efore 8:00 AM and a fter 5:00 PM Easter n

Time) will be responded to promptly by the Technical Support On-Call staff. It is suggested that any

person calling in for technical support have the inoperative equipment available for preliminary

troubleshooting as well as product identification. N ovametrix reserves the right to repair or replace any

product found to be defec tive during the warranty period. Repair may be provided in the form of

replacement exchange parts or accessories, on-site technical repair assistance or complete system

exchanges. Repairs provided due to product abuse or misuse wil l be considered “non-warranty” an d

invoiced at the prevailing service rate. Any replaced defective material is expected to be returned to

Novametrix within 10 days of being provided in order to avoid additio nal charges. Exch anged material

should be returned promptly and directly to Novametrix using the return paperwork and shipping label(s)

provided. Transferring return materials to local sales or dealer representatives does not absolve return

responsibility.

Novametrix manufactures equipment that is generally “user serviceable” and can usually be repaired

with the replacement of a plug-in electro-mechanical assembly by the clinical end user . When repair parts

are provided, the recipient ca n call into Novametrix for on-line replacement assist ance and repair

assurance. In the ev ent a rep lacement part requires in creased technical capability, Technical Support m ay

request Biomedical assistance, provide on-site technical support or complete replacement equipment. If

the customer requires the return of their original product, the exchange material will be considered

“loaner material” and exchanged again after the customer equipment is repaired.

Novametrix promotes customer participation in warranty repairs should they become necessary. This

program allows for customer training and a s mooth transition into self-maintenance after warranty, which

can provide substantial cost savings on repairs throughout the product’s life.

The Novametrix Technical Support Department can provide technical product support at a level

appropriate to most customers protocol and budget requirements. Please contact the Technical Support

Group at Novametrix for additional information.

Additional Novametrix Technical Support Programs

• Focus Series Technical Training Seminars

• Test Equipment and Test Kits

• Service Contract / Part Insurance Plans

• On-Site Technical Support

• 24 hr. telephone support

• “Demand Services”

Flat rate parts-exchange,

Flat rate return for repair

Time and Material,

Full warranty, discounted replacement sensors

vi

Model 8100 Service

Manual Rev. 01

Page 7

Table of Contents

Safety ..................................................................................................... 1

Introduction ........................................................................................... 5

Indication for use .........................................................................................................5

Operational Overview .. ............................................. ............................................. ......5

Rear Panel Connections and Labeling ........................................................................9

Theory of Operation ...........................................................................11

2726 Power Supply Board ........................................................................................11

Digital Control System ...............................................................................................13

CO

System Analog Subsections .............................................................................19

2

Saturation Analog Subsections ...... ...... ....... ............................................. .................22

Flow System Analog Subsections .............................................................................23

Digital Logic List ........................................................................................................27

Functional Tests .................................................................................39

Equipment Required .................................................................................................39

Functional Testing .....................................................................................................39

Accuracy Tests ...................................................................................43

Equipment Required .................................................................................................43

Test Procedure ..........................................................................................................44

Electronic Tests ..................................................................................49

General .....................................................................................................................49

Power Supply Testing ...............................................................................................50

CO

Testing ..............................................................................................................51

2

Saturation Testing ............. ....... ...... ...... ....... ...... ....... ...... ....... ....................................5 4

Flow Testing ..............................................................................................................55

Barometric Pressure ......... ............................................. ...........................................56

Isolation and Leakage Checks ..................................................................................56

Test Fixtures .............................................................................................................56

Test Fixture Construction ..........................................................................................57

Maintenance ........................................................................................ 59

General .....................................................................................................................59

Maintenance Schedules ............................................................................................59

Cleaning and Sterilization ............................................................................... .......... 6 0

Mains Voltage Configuration .....................................................................................63

Battery Maintenance .................................................................................................65

Assembly Exchanges ................................................................................................66

Software Update Instructions ......... ...... ....... ............................................. .................69

Rev. 01

Model 8100 Service

Manual

vii

Page 8

Specifications ......................................................................................73

General ..................................................................................................................... 73

Capnograph .............................................................................................................. 73

Pulse Oximeter .........................................................................................................74

Flow Sensor Specifications .......................................................................................74

Monitor Specifications ...............................................................................................75

Additional Features ...................................................................................................75

Accessories .........................................................................................77

Parts Lists ............................................................................................81

6758-00 06 CO2SMO Plus! Monitor, Model 8100 ....... ....... ...... ....... ...... ....... ...... ....... 81

6758-01 02 Main Assy ..............................................................................................81

6765-01 02 Top Cover Assy ....................................................................................82

6868-01 00 Bottom Cover Assy ...............................................................................82

6660-01 01 Front Panel Assy ..................................................................................83

6692-01 01 Rear Panel Assy ................................................................................... 83

6693-01 02 Flow Connector Assy ............................................................................84

6699-01 00 Chassis Assy ........................................................................................ 84

2731-01 04 Main Board Assy ...................................................................................84

2731-17 04 Main Board Subassy .............................................................................85

2726-17 03 Power Supply Board Subassy ..............................................................88

Drawings ..............................................................................................91

viii

Model 8100 Service

Manual Rev. 01

Page 9

Section 1

Safety

The

CO2SMO Plus!

to ground is limited to less than 100 uA at 120/220 VAC, 50-60Hz.

For maximum patient and operator safety, you must follow the following warnings and cautions.

monitor is electrically isolated. Patient leakage current flowing from the instrument

WARNINGS

!

• Explosion Hazard: DO NOT use

this instrument in such an environment may present an explosion hazard.

• Electrical Shock Hazard: Always turn

it. Refer servicing to qualified service personnel.

• Never sterilize or immerse the monitor in liquids.

• Do not operate

• Do not operate

• Failure of Operation: If the monitor fails to respond as described, do not use it until the situation has

been corrected by qualified personnel.

•The

recording device.

• Patient Safety: Care shou ld be ex ercised to ass ure con tinued peri pheral perf usi on dist al to the S pO

sensor site after application.

• Inspect the SpO

applying sensors take note of patient’s physiological condition. For example, burn patients may

exhibit more sensitivity to heat and pressure and therefore additional consideration such as more

frequent site checks may be appropriate.

• Data Validity: As with all pulse oximeters, inaccurate SpO

• A “NO RESPIRATION” alert is not generated when both the CAPNOSTAT CO

CO

•The

pediatric/adult) or flow sensor (neonatal or pediatric/adult) when it is connected. If a flow sensor

identification message is not displayed when a flow or CO

use the sensor. If the condition persists, refer the monitor to qualified service personnel.

Indicates a potentially harmful condition that can lead to personal injury.

CO2SMO Plus!

CO2SMO Plus!

CO2SMO Plus!

CO2SMO Plus!

CO2SMO Plus!

- Incorrect application or use of sensor;

- Significant levels of dysfunctional hemoglobin; carboxyhemoglobin or methemoglobin;

- Significant levels of indocyanine green, methylene blue, or other intravascular dyes;

- Exposure to excessive illumination such as surgical lamps-especially those with a xenon

light source, or direct sunlight;

- Excessive patient movement;

- Venou s puls ations;

- Electrosurgical interference.

/flow or flow sensor a re disconnected from t he

2

CO2SMO Plus!

is not intended to be used as a primary diagnostic apnea monitor and/or

sensor site often for adequate circulation - at least once every four hours. When

2

automatically identifies the type of CO2/flow sensor (neonatal, pediatric or

when it is wet due to spills or condensation.

if it appears to have been dropped or damaged.

in the presence of flammable anesthetics. Use of

off and remove the line cord before cleaning

and Pulse Rate values may be caused by:

2

sensor and the

CO2SMO Plus!

/flow sensor is first connected, DO NOT

2

.

2

2

Rev. 01

Model 8100 Service

Manual

1

Page 10

Section 1

• Periodically check the CO2/flow sensor and tubing for excessive moisture or secretion build up.

Although the

CO2SMO Plus!

automatically purges the lines, excessive moisture or secretions may

still remain.

• While using the CO

or a damaged CO

volume, pressure, deadspace, CO

• Connect the line cord to a grounded hospital-grade outlet.

/flow sensor, a system leak, such as that caused by uncuffed endotracheal tubes

2

/flow sensor may significantly effect flow related readings. These include flow,

2

production and other respiratory mechanics parameters.

2

CO2SMO Plus!

should be connected to the

same electrical circuit as other equipment in use on the patient. Outlets of the same circuit can be

identified by the hospital’s engineering department.

•The

CO2SMO Plus!

has no protection against the ingress of water.

CAUTIONS

!

• Do not operate

• Do not operate

• Keep

Indicates a condition that may lead to equipment damage or malfunction.

CO2SMO Plus!

CO2SMO Plus!

CO2SMO Plus!

and its accessories clean.

when it is wet due to spills or condensation.

if it appears to have been dropped or damaged.

• Never sterilize or immerse the monitor in liquids.

• Do not sterilize or immerse sensors except as directed in this manual.

• Do not apply excessive tension to any sensor cable or pneumatic tubing.

• Do not store the monitor or sensors at temperatures less than 14°F (-10°C) or above 131°F (55°C).

• Do not operate the monitor or sensors at temperatures below 50°F (10°C) or above 104°F (40°C).

• Federal (U.S.A.) law restricts this devi ce to sale, distribut ion, or use by or on the order of a licen sed

medical practitioner.

• DO NOT attach an SpO

sensor distal to a blood pressure cuff. Valid data CANNOT be processed

2

when the cuff is inflated. Attach the sensor to the limb opposite to the site used for the blood pressur e

cuff.

• Excessive moisture in the CO

• To avoid the effects of excessive moisture in the measurement circuit, in sert the CO

/flow sensor may affect the accuracy of the flow measurement.

2

/flow sensor in

2

the ventilator circuit with the tubes upright (as shown by arrows). The striped tube is positioned

closest to the patient. Improper placement will result in erroneous data.

• It is recommended that the CO

/flow sensor be removed from the circuit whenever an aerosolized

2

medication is delivered. This is due to the increased viscosity of the medications which may

contaminate the sensor windows, causing the sensor to fail prematurely.

• In case of interference with our equipment or another manufacturer’s equipment, notify your

Novametrix representative.

2

Model 8100 Service

NOTES

Indicates points of particular interest or emphasis for more efficient or convenient operation.

• Components of this product and its associated accessories which have patient contact are free of

latex.

• As with all flow measuring devices, adverse conditions may affect the accuracy of the flow

measurement.

•If CO

Manual Rev. 01

is being measured while not using a CO2/flow sensor, certain rebreathing circuits, or the

2

presence of artifacts such as cardiogenic oscillations, may cause

respiratory CO

fluctuations as if they were breaths. This condition affects only the numerical

2

CO2SMO Plus!

to react to non-

displays; the capnogram display continues to provide an accurate picture of the CO

waveform.

2

Page 11

Safety

• When a new CAPNOSTAT CO2 sensor is attached to the monitor, or is moved from one monitor to

another, it must be initialized before use. The CAPNOSTAT CO

initialized again as long as it is used with the same monitor.

• The Sample Pump will not turn on if a combined CO

CO2SMO Plus!

. If the Sample Pump is already on and a combined CO2/flow or flow sensor is

/flow or flow sensor is connected to the

2

connected, the Sample Pump will turn off.

• If you use the

CO2SMO Plus!

CO2SMO Plus!

, the CO2/flow sensor must be manually re-zeroed.

for transport or if you drastically change the orientation of the

• After the life cycle of our equipment and all accessories has been met, disposal of the equipment

should be accomplished following the national requirements. Contact the local Novametrix

representative for questions concerning disposal.

sensor does not have to be

2

Rev. 01

Model 8100 Service

Manual

3

Page 12

Section 1

[This page intentionally blank.]

4

Model 8100 Service

Manual Rev. 01

Page 13

Section 2

2.1 Indication for use

Introduction

The

CO2SMO Plus!

oxygen saturation, pulse rate and respiratory mechanics in monitoring environments such as ventilatory

support, emergency and anesthesia.

patients.

CO2SMO Plus!

is intended to be used for monitoring end tidal CO2, respiration rate, functional

CO2SMO Plus!

is not intended for any other purposes.

is design ed to m o nit or ad u lt, p edi a tri c an d neo n a tal

NOTE

Components of this product and its associated accessories which have patient contact are

free of latex.

Gas compositions other than those selected in the SETUP screen can influence CO

measurement.

and flow

2

2.2 Operational Overview

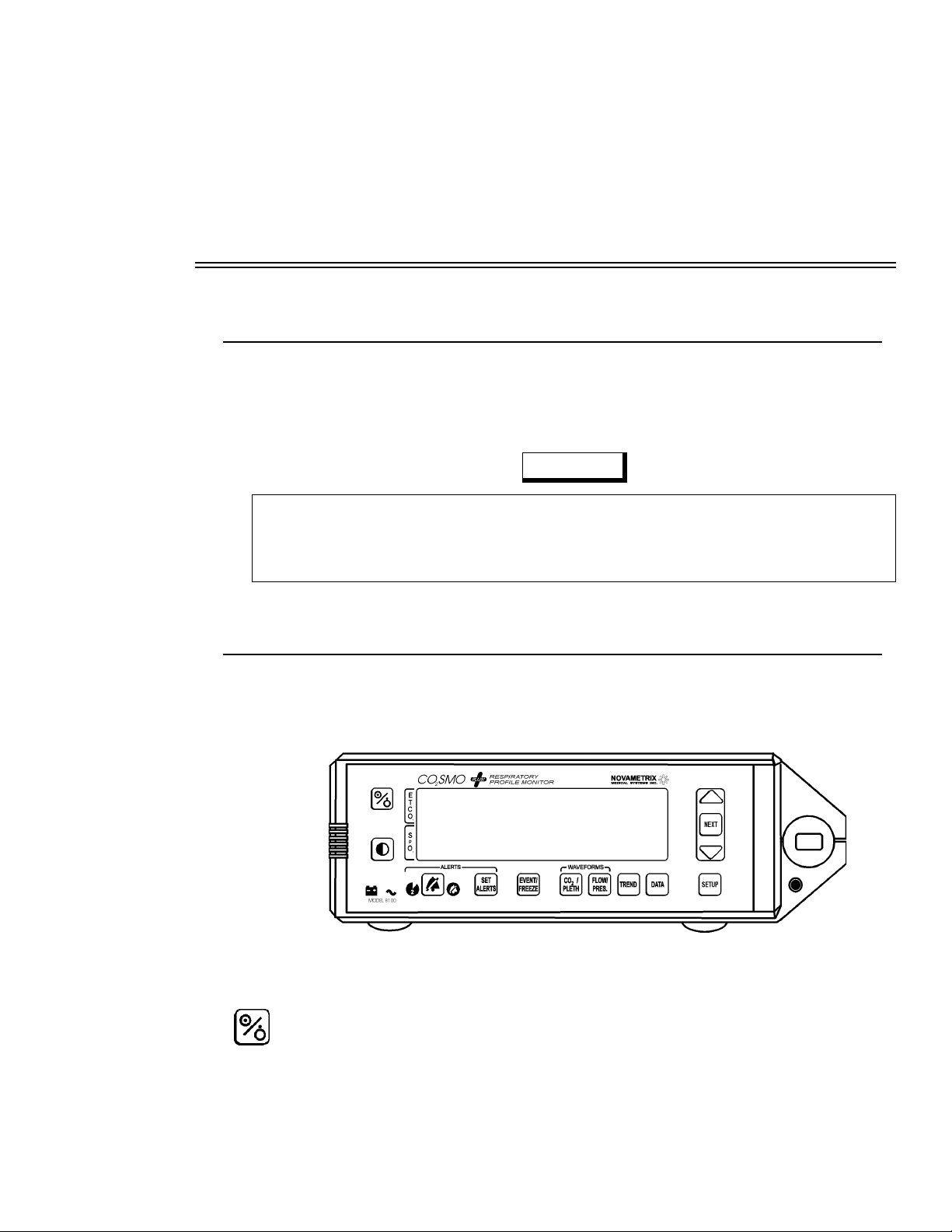

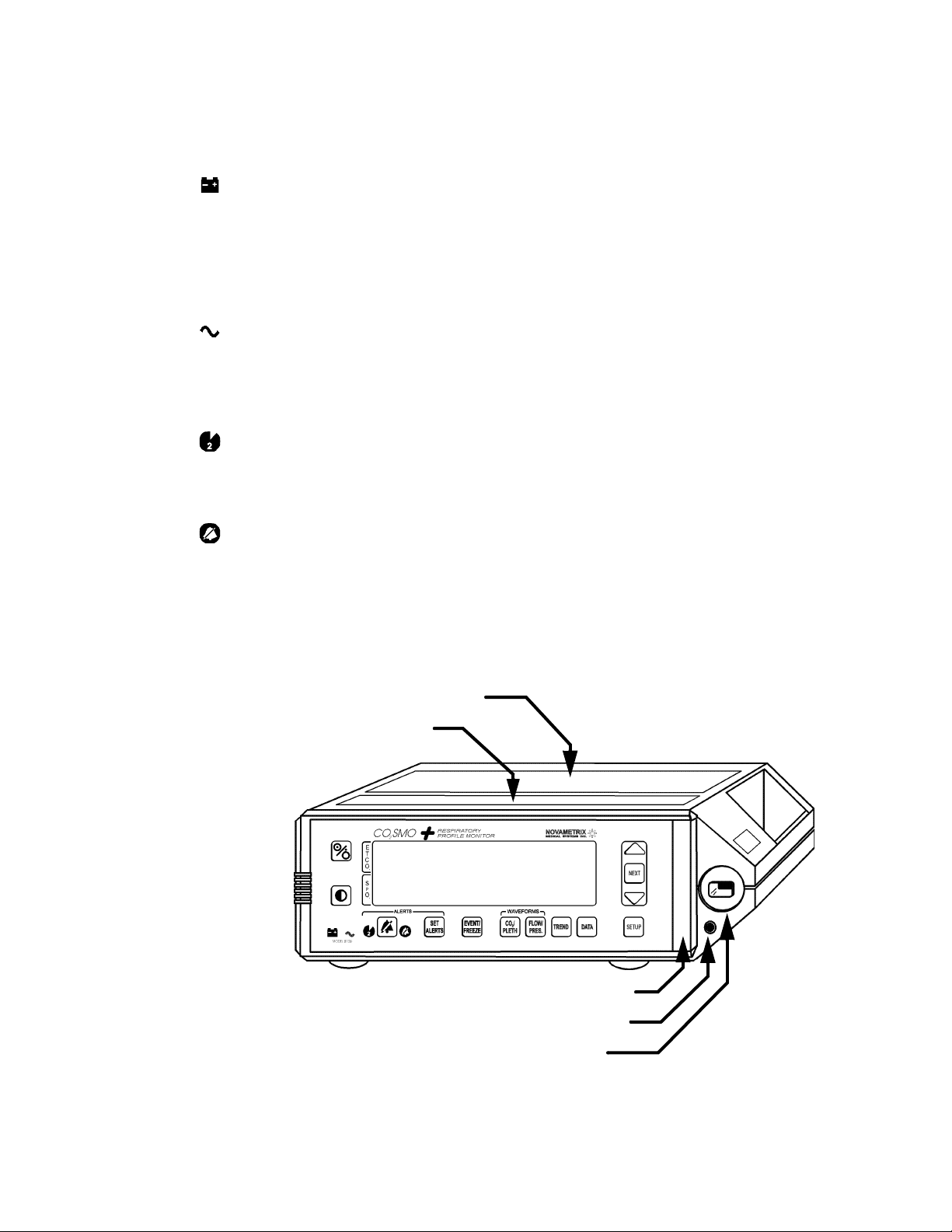

Front Panel Controls and Indicators

2.2.1 Controls

Power Key

Press the POWER key to place the unit into operate mode (ON) or to place the unit into standby (OFF).

There are four states of the unit:

Rev. 01

Model 8100 Service

Manual

5

Page 14

Section 2

Operation al Overview

• No AC Power, power icon off, not in operate mode

In this condition the AC switch is off, or the power cord is not plugged into an AC outlet, or the

outlet is not powered. No monitoring may occur in this state. Battery is not being charged.

• AC Power, power icon on, not in operate mode (standby)

In this condition the unit may be placed into operate mode by pressing the key. Battery is

charging in this mode.

• AC Power, power icon on, in operate mode

In this condition the unit is in operating mode and the battery is being charged.

• Battery power, power icon off, battery is not bein g charged

In this condition the unit is in the operating mode and the battery is not being charged.

When the monitor powers up a self test is performed in which all ind icators will t emporarily ill umin ate

and the monitor will emit a short beep. Following the self test the monitor will display:

“ERASE STORED TRENDS?

YES: NO: ”

If the or key is not pressed within five seconds, trends will be retained. The monitor is now ready

for operation.

1

Contrast

Press or hold to adjust the display’s contrast for different up/d own viewing angles.

Alert Silence

Press for 2 minute silence (audible alerts muted for two minutes). The icon will illu minate for the

duration of the two minute silence. Press again to cancel.

Press and hold for 3 seconds to disable audible alerts, and the icon will flash. Press and hold again

to cancel.

Press to acknowledge a latched alert.

If preconfigured not to allow the audio off function, the key will not disable the audible alerts when

pressed (the two minute silence is still active).

Set Alert Lim its

Press to set alert limits manually, or hold to set automatically. Press again to accept the displayed limits

and return to the previous screen.

Event/Freeze

6

Model 8100 Service

Press the key to freeze the wav eforms and loops for sixty seconds . An EVENT MARKER with time

and date will appear in the message center for three seconds followed by “WAVEFORM FROZEN

1. The monitor must be in “stand-by” mode in order for the CAPNOSTAT CO2 sensor to remain heated when

the monitor is off.

Manual Rev. 01

Page 15

Operational Overview

Introduction

UNFREEZE: PRESS EVENT KEY”. To resume normal display press again, otherwise the

waveform will resume again in 60 seconds.

Pressing this key when viewing the DATA entry screen allows you to enter the patient’s PaCO

calculation of Vd/Vt phy, Vd phy and Vd alv.

CO2 Waveform/Plethysmogram

Press to switch wav eform display between capnogram and capnogram with plethysmogram.

Flow/Pressure Waveforms

Press to switch wa veform disp lay between flow and pr essure wa veforms, or flo w and volume w avefo rms,

or flow vs. volume and volume vs. pressure loops.

Trend

Press to switch between trend screens.

2

for

Data Screen

Press to switch between data screens (numeric values only), and data entry screen (to enter weight and

PaCO

).

2

Setup/Configuration

Press to display SETUP scre en, or hold for three seconds to d isplay CONFIGURATION scre en (for

advanced settings). Press again to accept the displayed settings and return to the previous screen.

Adjustment Keys

Press to select different parameters in SETUP, CONFIGURA TION, SET ALERTS or DAT A ENTR Y

screen. Press and to change value or state of the currently selected parameter.

The key is also used to:

• Select different time bases on the Trend screens

• Rescale various waveforms if scaling is set to manual.

The and keys are also used to respon d to monitor promp ts such as “ERASE STORED TRENDS?

YES: NO: .”

From the FLOW/PAW screen, use the keys to adjust the spontaneous threshold line.

Rev. 01

Model 8100 Service

Manual

7

Page 16

Section 2

Operation al Overview

2.2.2 Indicators

Battery Alert Icon

Illuminates when the unit is on b attery power an d the battery char ge is critically lo w. When battery is near

exhaustion an audible alert will sound and “BATTERY VER Y LOW PLUG IN AC PO WER” will appear

in the display screen. Refer to Bat tery Mai ntenance on page 65 for i nformati on on co nnecting AC power

and charging the battery.

AC Power Indicator Icon

Illuminates when the monitor is connected to an AC po wer source and the rear panel po wer switch is ON

“|”. In this condition the internal battery is charging.

Two Minute Silence Icon

Illuminates when the two minute silence is active.

Audible Alert Disabled Icon

Flashes when audible alerts have been disabled.

2.2.3 Miscellaneous

Top cover instructions

Explosion hazard WARNING

8

Model 8100 Service

Alert bar

Sampling system inlet

/flow sensor connection

CO

2

Manual Rev. 01

Page 17

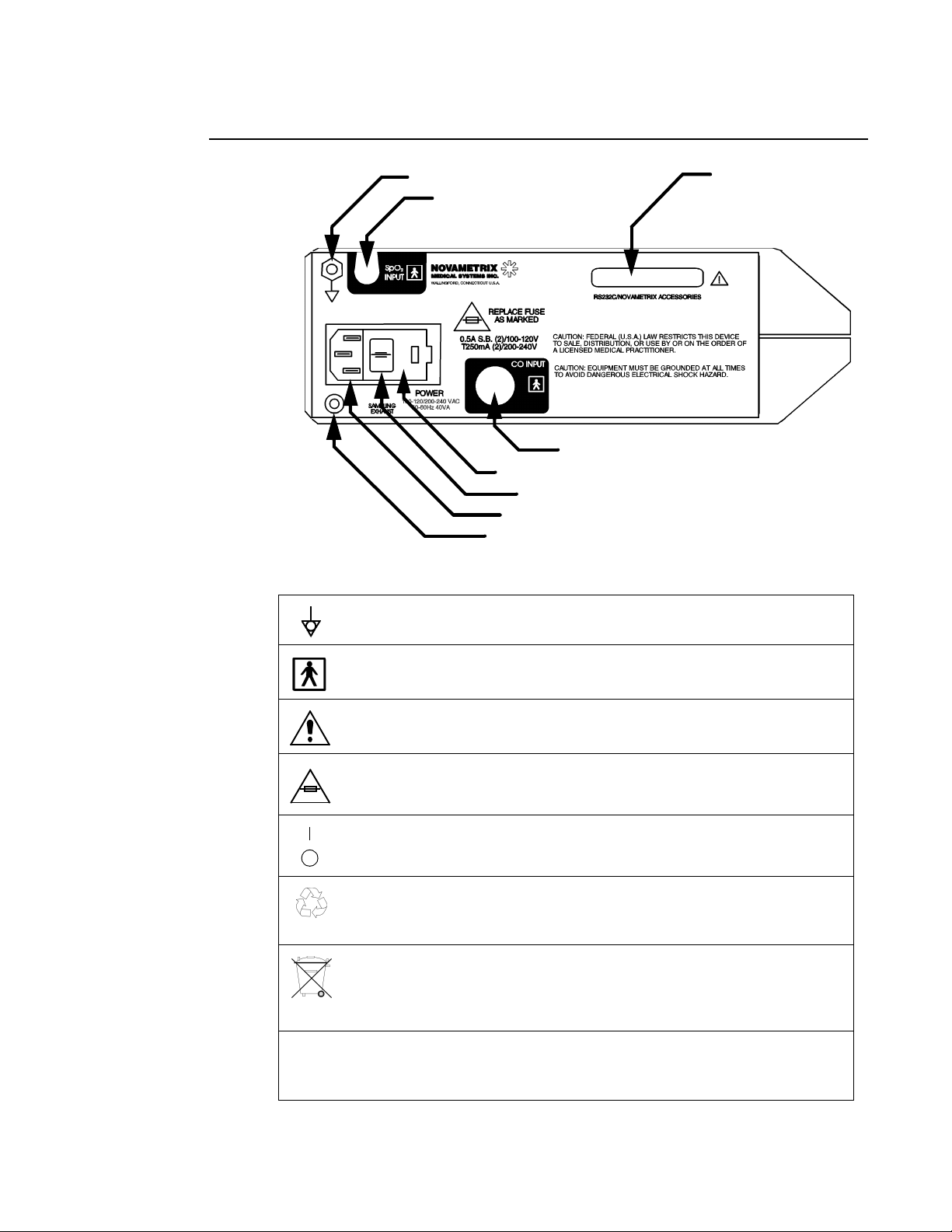

Rear Panel Connections and Lab eling

Equipotential connection

SpO2 sensor connection

CO

2

sensor connection

25 pin D connector

Sampling system exhaust

Power cord receptacle

Fuse/power setting compartment

AC power switch

(for communications)

CONNECT ONLY TO

IEC601 APPROVED

DEVICES

2.3 Rear Panel Connections and Labeling

Introduction

250V

Pb

Equipotential: Connection to monitor’s chassis

Patient isolation: Identifies connection as type BF

Attention: Consult manual for detailed information

Mains fuse rating for replacement fuses

AC mains switch “|” ON-connection to mains; “O” OFF-disconnection from

mains

Recyclable item. This symbol is found on the internal battery and should not

concern the common user. Refer to qualified service personnel when battery

replacement is required.

Separate collection. Appropriate steps must be taken to ensure that spent batteries are collected separately when disposed of. This symbol is found on the

internal battery and should not concern the common user. Refer to qualified

service personnel when battery replacement is required.

Indicates heavy metal content, specifically lead. This symbol is found on the

internal battery and the monitor enclosure and should not concern the common

user. Refer to qualified service personnel when battery replacement is required.

Rev. 01

Model 8100 Service

Manual

9

Page 18

Section 2

Rear Panel Connections and Labeling

[This page intentionally blank.]

10

Model 8100 Service

Manual Rev. 01

Page 19

Section 3

Theory of Operation

The

CO2SMO Plus!

saturation, pulse rate, respiration rate, airway pressure and flow. Other parameters are deriv ati v e of these

primary properties. The system contains all the circuitry necessary for controlling, collecting,

conditioning and displaying patient information gathered from the CAPNOSTAT®, Saturation and

FloTrak® sensors. The

subsections that follow.

monitor measures the primary parameters of CO2 production, blood oxygen

CO2SMO Plus!

monitor’s theory of operation is explained in detail in the

3.1 2726 Power Supply Board

The 2726 Power Supply Board contains the circuitry needed to power the monitor from the AC Mains

(line voltage). The power supply board also connects to the battery and contains the battery charging

circuitry.

Model 8100 units shipped to Japan have an alternate power supply board assembly (2748-01) installed.

These boards are identical to the 2726-01 board with the exception of the power transformer T301. The

transformer in the Japanese board (2748-01) is rated for operation at slightly lower line voltage (down to

90 VAC). The operation and testing are identical and the manual text that ap plies to th e 2726-01 bo ard

also applies to the 2748-01 board.

The schematic and assembly print for th e 2748-01 bo ard are included. The parts list for th e 2748-01 is

listed on the assembly print 2748-01-00.

3.1.1 AC Mains and Battery Operation Overview

The Model 8100 can be powered from its internal 12 volt battery or from the AC Mains. The green

(sine wave shaped) front panel indicator illuminates when the line cord is connected and the rear panel

power switch is in the “|” (On) po sition. This indicates that A C Mains power is reach ing the power s upply ,

that the battery is being charged, and that if the monitor is turned on, it is being powered from the line

voltage.

If AC Mains power is removed by unplugging the line cord or setting the rear panel power switch to the

“0” (Off) position, the monitor will operate for up to two hours from its internal 12 volt lead-acid battery.

As the battery voltage runs low (≈11.5 volts), the red (battery indicator) on the fron t panel

illuminates. At this point, the AC Mains should be reconnected to power the monitor and charge the

battery.

If the monitor continues to be powered from a battery in a low voltage situation, at approximately 11

volts, a continuous alarm sounds for thirty seconds while an alert message is displayed. If this alarm/

message is ignored, the monitor displays will shu t down and the battery indicator will flash on and off

about every 5 s econd s. If AC power is now restored, the monitor will re-init ialize (g o t hro ug h the power

up and self-test routines) and resume normal operation. However, continued battery operation will

eventually activate a hardware low voltage circuit (≈10.0 volts) that shuts the monitor off to prevent

damage to the battery. Once the unit is shut down with the hardware circuit, the AC Mains must be

connected and the front panel power key pressed before the monitor will turn back on.

Rev. 01

Model 8100 Service

Manual

11

Page 20

Section 3

2726 Power Supply Board

3.1.2 AC Mains Operation

The AC Mains voltage enters the monitor at the rear panel Power Entry M odule (PEM). This device

contains a built in RFI power line f ilter , a d ouble-pole single- thro w switch that opens and closes both A C

input lines, fuses, and an input voltage selection card.

The filtered, switched and fused output of the Power Entry Module is fed to the primary coils of the rear

panel mounted sys tem transformer, T301, this is m ounted on the 2726 Power Supply Bo ard. The

secondary output from T301 is fed to the Power Supply Board and is rectified by D1 (bridge rectifier)

and filtered by C1. The (loaded) DC voltage at this point is approximately 20 volts.

The 20 VDC is fed to the 27 31 Main Board through fuse F301 to co nnecto r P 10 2, an d i s s w itch ed to t he

battery charging regulator IC1 (pin 5) through Q1. Biasing for Q1 is accomplished by D2, R1 and R2

when AC power is applied. When running on battery power Q1 is biased off by R1, R2 and D3, this

prevents the battery from trying to power the battery char ger regulator IC1. Power to IC2 is also remo ved,

this informs the monitor of the loss of AC via the LINEST line.

The output of switching regulator IC1 pin4 is rectified and filtered by D4, C4 and L1 then fed to the

battery through current sen se resistor R3 and fuse F3 02 to J3 02 pin 1 (VBAT+). The battery float charge

voltage is maintained at 13.2 volts except for fast charge which is regulated at 14.4 volts. The output is

also monitored for over current conditions. These parameters are controlled by IC3 and associated

circuitry. When the battery charge current exceeds 120mA of current IC3 pin 7 goes high which biases

Q2 on, this in turn shorts out R12 which affects the feedback control (FB) to IC1 (pin 1). With R12

shorted out the control resistors R14 and R13 s et the output voltage to 14.4 volts. When the charge cur rent

lowers IC3 pin 7 goes low which biases Q2 off, this puts R12 back into the feedback control which now

consists of R12, R13 and R14 sett ing the volt age to 13.2 v olts. When too much current fl ows t hrough R3,

IC3 pin 1 shorts IC1 pin 2 to ground which shuts IC1 off until its next switching cycle, when the current

reaches a safe level IC3 pin 1 allows IC1 to remain on.

The voltage switched by Q1 is also fed to IC2 as VCH (Voltage Charge). The output of this 5 volt

regulator provides the LINEST (Line Status) signal to the main board at E302 pin 3. With AC applied,

LINEST is high. LINEST goes low when the AC is disconnected. The LINEST line is also routed to the

power on/off circuitry.

3.1.3 Battery Operation

Without AC power there will be no secondary voltage rectified by D1. Power for the monitor will be

supplied from the battery at J102 pins 1 (VBA T+) and 2 (VB AT -). The battery power will conduct through

D3 and F301 to the 2731 Main Board. The arrangement of R1, R2 and D2 bias Q1 off in this condition

which prev ents power from reaching IC1, IC2 and IC3 . Th e o utput of IC1 is also pr otected b y D5 which

is now reverse biased, the bridge D1 is also reverse biased and prevents T301 from discharging the

battery. With no voltage at IC2 the LINEST will be low which indicates to the main board that there is

no AC power, and the front panel LED will be off.

12

Model 8100 Service

Manual Rev. 01

Page 21

Digital Control System

3.2 Digital Control System

For circuit diagrams of the digital section describ ed below, refer to schematic 2731-03, sheet 1, of the

schematic. Embedded control for the system is provided by IC1, a Motorola MC68332 integrated

microcontroller. In addition to a full 32-bit Central Processing Unit (CPU), this device also contains

circuitry for system clo ck generation, peripher al chip select generati on, data control, i nterrupt generation,

a sophisticated timing co-processor, synchronous and asynchronous serial communication. In general,

functional signals are grouped together into ports, and each sign al can be independently pr ogrammed b y

software to be its pre-defined port function or as discrete I/O. Additionally, the functionality for several

ports (Port C, E and F) can be pre-defined by the state of the data bus on system power-up. A special

“background mode” port allows the device to be controlled by an external source for system debugging

and testing. Also integrated on-c hip are several activity monitors, as well as a software watchdog to

ensure proper device and system operation. Refer to Table 1.

Table 1. CPU / Digital Control System

Theory of Operation

Port Defined Function

TPU

16 Channels

QSM

4 Synchronous Serial Chip

Selects & one asynchronous serial channel

Background Mode System debugging Allows an appropriate external device

C Chip Selects D0: CSBOOT* Data Width, 8 or 16-bit

E Bus Control D8: Control Signals or Discrete I/O

F MODCK and Interrupts D9: MODCK & IRQ or Discrete I/O

Timing Signal Generation Each channel independently user

Serial Communications Port:

QSPI: Queued Serial Peripheral Interface

SCI: Serial Communications Interface

Functiona l it y C o ntrol ,

Data Bus Control

(Alt Functions: D pulled low)

programmable as TPU function or as

Discrete I/O

QSPI chip selects independently user

programmable, can be used as

Discrete I/O or decoded to create up

to 16 chip selects. SCI transmit can be

programmed as Discrete I/O

to control the microprocessor and

system

D1: CS1*-CS3* or BR*,BG*,BGACK*

D2: CS3*-CS5* or FC0-FC2

D3-D7: CS6*-CS10* or A19-A23

The maximum operating frequency of the integrated processor is 20.97 MHz. The operating frequency

is software selectable and generated b y an internal VCO o perating from Y2, a 32.768 KHz watch cry stal.

The Timing Processor Unit (TPU) co-processor of the MC68332 provides timing generation derived

from the system clock. This feature is utili zed to control the precise timing req uired for the acquisiti on

of the End Tidal Carbon Dioxide (etCO

) and saturation (SpO2) signals. The TPU is also used to generate

2

the PWM (Pulse Width Modulation) control for the CAPNOSTAT case and detector heaters, as well as

provide the frequency generation for the audio tones. See Tables 2 and 3.

Rev. 01

Model 8100 Service

Manual

13

Page 22

Section 3

Digital Control System

Table 2. TPU Timing Generation for the etCO2 subsystem

Signal Name Function / Ti m i ng

CO2AZ A uto Zero Clears the Sample/Hold circuitry prior

CO2PWENB Pulse Width Enable Defin e s t he ac t iv e t im e fo r b o th p has es

SRCDRV0 Source Drive 0 First source drive signal.

CS*/H Current Sample/Hold Enables circuitry for source current

SRCDRV1 Source Drive 1 Second source drive signal delayed

SS*/H Signal Sample/Hold Enables circuitry for CO

CASEPWM Case Heater PWM PWM control for the case heater servo

DETPWM Detector Heater PWM PWM control for the detector heater

TOUT1, TOUT2, TOUT3 Tone Generation Variable frequency outputs to

to data acquisition.

Active High, 90 us

of the bipolar source pulse, used for

pulse width protection circuitry.

Active High, 810 us

Active High, 405 us

measurement. Sample is taken when

SRCDRV0 is active.

Low = Sample, 90 us, High = Hold

for 10 microseconds after SRCDRV0

ends.

Active High, 395 us

and Refer-

ence channel data acquisition.

Low = Sample, 90 us, High = Hold

servo

generate system audio

2

Table 3. TPU Timing Generation for the SpO

Signal Name Function / Ti m ing

ASAMP* Auto Zero Clears the Sample/Hold circuitry prior

RDLED* Red Channel LED control pulse Defines the active time for the Red

IRLED* Infra-Red Channel LED control pulse Defines the active time for the Infra-

RSAMP* Red Channel Sample/Hold Enables circuitry for the Red Channel

ISAMP* Infra-Red Channel Sample/Hold Enables circuitry for the Infra-Red

subsystem

2

to data acquisition.

Active Low

LED

Red LED

signal measurement. Sample is taken

when SRCDRV0 is active.

Low = Sample, 90 us, High = Hold

Channel signal measurement. Sample is taken when SRCDRV0 is active.

Low = Sample, 90 us, High = Hold

Ferrite filters have been placed on the microprocessor signals with fast rise and fall times (including

timing, clock, data and address lines) in order to help reduce and suppress the radiation of electromagnetic interference (L1-L14). In addition, good EMI/EMC design techniques have been incorporated

in the component layout and printed circuit board manufacture.

14

Model 8100 Service

Manual Rev. 01

Page 23

Digital Control System

Theory of Operation

Table 4 lists the chip select, control and discrete I/O functions for the

CO2SMO Plus!

system module. On

power-up, Ports E and F are programmed as discrete inputs by pulling down their controlling data lines,

DB8 and DB9. After power -u p, the softw are sets up each pin fu nction individually and performs a series

of self tests to check the integrity of the system. During this initialization period, the MPU holds the

SYSUP line low which keeps the system in an idle state. The state of configuration inputs on Port E

(TST*, CNFG0*, C NFG1* and JP0*) ar e read. These in puts allow the software to id entify different

operating states such as Test Mode, or different hardware configurations. After the initialization period

is complete and all system functions have been set, the MPU brings SYSUP high, indicating that the

system is ready for operation.

Table 4. Chip Select, Control and Discrete I/O

Pot Pin Functions System Signal Name I/O Comments

C D0-D7 pulled high, Pins are Chip Select on power-up

CSBOOT** BOOTCS* O Program PROM Chip Select

CS0* / PC0 / BR* UBRAMWR* O Upper Byte SRAM Write Enable

CS1*/ PC1 / BG* LBRAMWR* O Lower Byte SRAM Write Enable

CS2* / PC2 /

BGACK*

CS3* / PC3 / FC0 ROMWR* O F LAS H PROM W rite Enable, Word

RAMRD* O SRAM Read Enable, Word

Word (16-bits) wide mode, D0 = HIGH

Allows for byte (8-bit) or word writes

Allows for byte (8-bit) or word writes

CS4* / PC4 / FC1 IORW* O Control for external System and CO

output latch

CS5* / PC5 / FC2 ROMWREN O P ort C Discrete Output, prevents unintentional writes

CS6* / PC6 / A19 UARTCS* O High Speed UART Chip Select

CS7* / PC7 / A20 PROFILE* O Enables profiling data output latch

CS8* / PC8 / A21 DISPCS* O Display Chip Select for LCD control

CS9* / PC9 / A22 FLOWIO* O Control for external Flow sub-system input buffer and

CS10* / ECLK /

A23

E D8 pulled low, Discrete I/O on power-up

DSACK0* / Port E0 TST* I Initiate System TEST if Low

DSACK1* / Port E1 DS1* I Data and Size Acknowledge 1*

AVC* / Port E2 CNFG0* I Configuration Switch 0

RTCCS* O Real Time Clock Chip Select

to FLASH EPROM. This signal must be asserted

before ROMWR* in order to overwrite the FLASH

output latch

input buffer and

2

Rev. 01

RMC* / Port E3 CNFG1* I Configuration Switch 1

DS* / Port E4 DS* O Data Strobe

Model 8100 Service

Manual

15

Page 24

Section 3

Digital Control System

Pot Pin Functions System Signal Name I/O Comments

AS* / Port E5 AS* O Address Strobe

SIZ0* / Port E6 JP0* I Configuration Switch 2, Hardware Jumper Mode

SIZ1* / Port E7 JP1* I Hardware Jumper Mode Select 1

R/W* RD* O Data Read Strode

WR* O Data Write Strobe

F D9 pulled low, Discrete I/O on power-up

MODCK / Port F0 LED O LED CPU Activity Indicator

IRQ1* / Port F1 S YSUP O S ystem Initialization Complete

IRQ2* / Port F2 CASEOT O Case Heater Over Temperature Shut Down

IRQ3* / Port F3 DETOT O Detector Heater Over Temperature Shut Down

IRQ4* / Port F4 EXTDCIN I Indicates external AC Mains power operation

IRQ5* / Port F5 UARTIRQ* I External UART Int e rr u pt

IRQ6* / Port F6 PWRDWN* O System power down enable

IRQ7* / Port F7 NMI I Non-Maskable Interrupt

Select 0

3.2.1 Background Mode Debugging

External system debugging is possible by connecting an appropriate device (emulator or debugger) to

header J400 then momentarily bringing the BERR* on J400 low. This halts the bus activity and turns

control of the system over to the external de vice. In this mode, internal MPU registers can be viewed and

altered, special test features can be invoked, and system memory can be read and written to.

3.2.2 System Memory

A 16-bit wide data path is used for FLASH PROM and SRAM transfers to maximize system throughput.

Program code storage is contained in two 2-Meg 5V FLASH or EPROM (IC3 and IC5) devices. The

FLASH PROMs are protected from uni ntentional over-writes of the program code by transistor Q1 and

the ROMWREN signal. The ROMWREN line must be high prior to writing new code into the FLASH

devices. Volatile data storage is contained in two 1-Meg SRAM (IC4 and IC6). The SRAMs can also be

backed-up to retain the ir c onte nts by appl ying a 2.5 Volt level on VBACK when main power is removed

from the system. During the battery back-up state, transistor Q2 keeps the CS1* control of the SRAMs in

the inactive state. This forces the data bus to a high impedance state, isolating the SRAMs from the rest of

the system. True non-volatile storage for system parameters is provided by a serial EEPROM (IC8).

3.2.3 Serial Communications UART

In addition to the on-chip asynchronous serial communications interface (SCI) channel contained in the

MC68332, a single channel UART (Universal Asynchronous Receiver/T ransmitter), IC2, is provided for

buffered hig h speed data communication to an ex ternal computer. The serial connection to external, nonpatient, contact devices is electrically isolated from the patient applied sections by optical data couplers

16

Model 8100 Service

Manual Rev. 01

Page 25

Digital Control System

(IC68, IC71, IC73, IC7 4) and is olated p o wer supply (see page 9 of sch emati c). This co nnector i s located

on the rear panel. The data Input/Output pins 15-22 of the UART are bi-directional and their direction is

controlled by the RDN and WRN when CEN is held Low. The bus is p ut into tri-st ate condition when

CEN is High. Crystal Y1 is required for driving the internal baud rate generator and other clocking

circuitry in the chip. The A0-A2 lines selec t the UART's registers for read/write operati ons. The data

signals URxD and UTxD are diode protected against over voltage by D1 and D2. Refer to schematic

2731-03, sheet 9 and Table 5 for the pinout and signals of serial interface connector J100.

Table 5: Serial Connector, 25-pin D-subminiature connector (located on rear panel)

Theory of Operation

Pin Number Signal Function

1NC

2 RC1IN Internal MC68332 UART Receive, RS232 Signal Level

3 TR1OUT Int ernal MC68332 UART Transmit, RS232 Signal Level

4 TR2OUT External UART Transmit, RS232 Signal Level

5 V- Non-Patient RS232 Level Minus Supply Out

6 RC2IN External UART Receive, RS232 Signal Level

7 IGND Non-Patient Signal Ground

8NC

9NC

10 NC

11 NC

12 NC

13 NC

14 IRAW Unregulated Power Supply Output

15 NC

16 NC

17 NC

18 NC

19 ASTxD Internal MC68332 UART Transmit, TTL Signal Level

20 V+ Non-Patient RS232 Level Positive Supply Out

21 NC

22 NC

23 NC

24 NC

Rev. 01

25 IVDD Non-Patient 5V Logic Supply Out

Model 8100 Service

Manual

17

Page 26

Section 3

Digital Control System

3.2.4 User Interface Control Circuitry

Refer to schematic 2731-03, sheet 2.

The user interface features a 64 row by 240 column Liquid Crystal Display (LCD) module with a cold

cathode florescent backlight. Patient and system information is presented in both graphical and textual

formats organized into several screen configurations. A 13-switch membrane keypanel is provided for

operator entry of screen selection, data entry and user input. The membrane panel also contains several

LEDs which represent various system conditions, such as input power status (AC or Battery) and alarm

state. Control of the user interface is provided by the IORW* chip select signal together with the RD*

and WR* signals from the microprocessor. IC13 and IC15 are input buffers which read in the present

state of the membrane keys. Depressing a key causes the signal line to be pulled low in contrast to its

normally high state. Also located on the input buffer IC13 are the CAPNOSTAT C O2XDISC,

CO2ZERO* and CO2SPAN* signals, which inf orm the system that a CAPNOSTAT sensor is

disconnected, if it is connected and currently on the Zero Cell, or if it is connected and currently on the

Reference Cell. IC17 provides a latched output for controlling the membrane and Alert LEDs and the

LCD backlight. When the BACKLITE signal is pulled high (IC17 pin 13), transistor Q5A turns on

allowing maximum display brightness. Otherwise, the current through the display must also pass through

fixed resistor R103, causing the display to dim. Contrast control for the LCD is provided by DAC IC78

and amplifier IC77B (schematic 2731-03, sheet 9). When the CPU de tects the closure of the contrast

membrane key, the CPU sends a digital ramp input to the DAC which causes the its output to change

accordingly. Inverting amplifier IC77B controls the base current into transistor Q31, which changes the

output of the display contrast voltage, VDISP.

(See page 7) To supplement the visual indicators associated with the membrane keypanel and display, an

audio output signal is generated to provide an addi tional mod e to co nvey information to the user. Up to

three tone frequencies are generated by the TPU processor of the MC68332 (DTOUT1, DTOUT2,

DTOUT3). These signals are fed into sep arate reference inputs of the 8-bit DAC IC53, providing a means

for independently attenuating each signal under CPU control. From the DAC, the individual signals are

summed together by IC79A and filtered by L33 and C220 (see page 9). Audio amplifier IC76 drives the

system speaker to produce system audio.

3.2.5 Real Time Clock, Power on RESET Generation and Glue Logic

Time-keep ing for date and time stamping of patient tr end information is provided by IC16 (s ee schematic

2731-03, sheet 2). This device contains a built in crystal for precise time and date measurement. In the

absence of digital power, the time keeping function is maintained by the battery backed-up supply,

VBACK.

On power-up, the system is forced into a RESET state by IC9 (schematic 2731-03, sheet 1). This chip

creates the master active low system reset signal SRST*. An inverter is used to generate the active high

RESET signal.

Chip selection for the serial peripherals are provided b y decoders IC10 and IC14 and by the in verter IC1 1

(schematic 2731-03, sheet 2). IC18 and IC20 are used to determine CPU utilization during system

development, latching various status bits out on connector J404. Latch IC19 i s used to control the

saturation analog signal processing and to drive the optical reflectors on the auxiliary pressure connector

J411. On schematic 2731 -03, sheet 8 , input b uf fer I C62 is used to input the decoded output f rom the fl ow

and auxiliary reflectors, while latch IC66 is used to cont rol the flow pneumatics and provide the drive

signals for the flow optical reflectors.

18

Model 8100 Service

Manual Rev. 01

Page 27

CO2 System Analog Subsections

3.3 CO2 System Analog Subsections

3.3.1 CO2 Pulser Source Drive

Refer to schematic 2731-03, sheet 3.

The source drive circuitry is designed to drive the source with a bipolar signal to prevent the migration

of charges within the source that may result from unidirectional electrical fields. The resistance of the

source is monitored constantly to ensure the integrity of the system by sampling the current through the

source while it is active.

The signals for source drive are generated by the TPU co-processor in the MC68332, IC1. The

SRCDRV0 and SRCDRV1 lines are used to control the bipolar signal that drives the source. The

SRCDRV0 signal goes High as soon as the CO2AZ (Auto Zero) line goes Low and the CO2PWENB

(Pulse Width Enable) line goes High. The duration of SRCDRV0 is 405 us (micro-seconds), and drives

the source in the positive direction. The SRCDRV1 line drives the source with an opposite polarity signal

when High. There is a 20 us delay from when the SR CDRV0 line goes Low and the SCRDRV1 line goes

High. This delay is to prevent the possibility of both SRCDRV0 and SRCDRV1 being activ e at the same

time, thus creating a low impedance path between the two supplies. SRCDRV1 steers current through the

source in the opposite direction from SRCDRV0.

When SRCDRV0 and CO2INH (Inh ibit) ar e High th e output o f MOSFET Dr iver IC23A pin 7 w ill go

Low. This turns the P-Channel half of MOSFET Q6 on. At the same time the output of MOSFET Driver

IC24B pin 6 will be Hig h bias i ng o n the N -C hann el half of MOSFET Q7 on. With both Q6B P- Chan nel

and Q7A N-Channel on current will flow from +VSRC through Q6B to the positive source terminal, then

back from the source ne g ati ve terminal through Q 7A, throu gh R118 to -VSRC. Wh en SRCD RV0 returns

Low both Q6B and Q7A are turned off and no current flows through the source. After the 20 us delay,

SRCDRV1 will go High. The output of IC24A pin 8 will go High biasing the N-Channel section of

MOSFET Q6 on. The output of IC23B pin 5 will go Low turning the P-Channel of Q7 on. Current will

now flow from +VSRC through Q7B to t he source negative terminal, back fr om the source positive

terminal through Q6A and R118 to -VSRC. Current will cease to flow when SRCDRV1 goes Low. The

bridge circuit of Q6 and Q7 in effect switches th e polarity of the drive signal of the source between

+VSRC and -VSRC. CO2PWENB als o falls with the falling edge of SC RDRV1, signaling the end of

source activity.

When current flows through the source, it will also flow through current sensing resistor R118, creating

a differential voltage proportional to the source current:

The voltage signal out of difference amplifier IC25A is level shifted through C36 and fed to the sample

and hold IC26A. A low level on the CS*/H (Current Sample and Hold) signal allows the source current

signal to be sampled. On the rising edge of CS*/H, the present voltage level of the source current signal

is held and appears at the input to the Analog to Digital Converter IC12 (on page 2) for processing by the

MPU. When CO2AZ is High the input to the sample and hold of IC26A is grounded to discharge any

residual charge that may be on C36.

In order to prevent the source from being driven until the system is up and ready there is protection

circuitry that inhibits the source drive until enabled. During system power-up, the RESET line k eeps Q8

Theory of Operation

V

= (VSR / RSR) * RS * A

SRC

V

= voltage out of difference amplifier proportional to current through the source

SRC

element = 24V +/- 0.625V

= differential voltage across the source element

V

SR

R

= resistance of the source element

SR

R

= resistance of the current sensing resistor = 1 ohm

S

= difference amplifier gain = 5

A

V(DA)

V

= [120 (Volts*Ohms) / RSR]

SRC

V(DA)

where

Rev. 01

Model 8100 Service

Manual

19

Page 28

Section 3

CO2 System Analog Subsections

on. This causes the CO2INH line to be brought Low, preventing source pulses by pulling down

SRCDRV0 and SCRDRV1 through D5. Protection circuitry also gu ards agai n st e x t ended puls e width as

well as shortened duty cycle. On the rising edge of CO2PWENB, the trip point of IC27B is exceeded,

allowing C39 to charge through R122. If the SRCDRV signals do not turn the Sou rce Pulser off within

200 us after the 810 us pulse period, the trip point for IC27A will be exceeded, pulling the CO2INH line

low turning the Pulser off. After the CO2PWENB signal returns Low, capacitor C41 discharges through

R123, keeping the o utput of comparator IC 27B at the v ol tage acquired by C39. After appr oximately 10.4

ms, C41 will have discharged below the comparator trip point. The comparator output goes low,

discharging C39 and the circuit is ready for the next source pulse cycle.

3.3.2 CAPNOSTAT Case and Detector Heater Control

Refer to schematic 2731-03, sheet 4.

The temperature of the system directly affects its ability to accurately meas ure CO

be precisely maintained at a controlled value. Two separate heaters and control circuitry are used; one

regulates the temperature of the detectors for the CO

Input and Reference channels; the other regulates

2

the temperature of the transducer case (and loosely main tains the temperature of the airway adapter).

While the purpose of the Detector heater is to keep the detectors' sensitivity to infrared radiation constant,

the function of the Case heater is to keep condensation from forming on the airway windo ws by ele v ating

the window temperature above the ambient airway temperature. Both heaters use an efficient PulseWidth Mod ulation scheme design ed to decrease p ower consumpti on, with t he PWM timing ge nerated b y

the TPU under microprocessor contro l. F or the purpos e of descr ibing the re gulation loop, the case heater

circuitry will be considered. The detector and case heater circuitry are identical.

Inside the CAPNOSTAT, a sensing thermistor is thermally connected to the heater module. Initially, the

CAPNOSTAT is at the ambient temperature and the resistance of the thermistor is lar ge. A small cur rent

flows through the signal path CASETHERM and only a small voltage is developed across R139. The

microprocessor programs the TPU to allow a maximum duty cycle of 30% to power the PWM heater

circuitry . This causes the heater control MOSFET Q13A to be pulsed on and off with a duty cycle that is

under direct control of the program softw are. As the heater w arms up the case, the ther mistor's resistance

decreases, raising the voltage appearing at the input of the control loop. As described below, the MPU

looks at this output voltage and decreases the duty cycle of the PWM control circuitry , gradually reducing

the power output into the heater. When the desired temperature set point is reached, a balance is struck

between the energy delivered into the system and the heat flow out of the system.

The case thermistor is sensed by amplifier IC29B pin 5. The difference between the signal at the noninverting input and the reference appearing at the inverting terminal generates an error voltage

proportional to the sensed temperature at the amplifier's output:

e

(V) = [83.133V / (Rth+3.32K)] - 10.2V where eo = amplifier output voltage

o

R

= resistance of the thermistor

th

= 4.36933K at 45°C

Temp (°C) = 4.1288 ((C/V) * e

where e

= amplifier output voltage at

o

V + 41.7321°C

o (T)

temperature T

This error voltage is low pass filtered by amplifier IC28A, sent to the ADC and processed by the CPU to

regulate the outpu t pulses from t he TPU. The TPU PW M signal is b uffer ed by MOSFET Driv er IC31 and

capacitively coupled to the gate of the heater drive MOSFET, Q13A. Capacitive coupling the signal

prevents a system fault that would allow the PWM to be stuck at a level that would cause a high heater

output. In the absence of a pulse, the gate drive will be pulled high, disabling the output to the heater . The

pulsed voltage signal out of the MOSFET is filtered by D12, L15, C53 and C54 to produce a DC output

level for the h eater . Since the TPU generated PWM signal is based on the s ystem clock, it is synchronized

and therefore must

2

20

Model 8100 Service

Manual Rev. 01

Page 29

CO2 System Analog Subsections

with the generation of t he source pulse timing. This minimizes the effect of any random disturbance

caused by the heater circuit on the detection of the CO

The error voltage out of amplifier IC29B also appears at the temperature watchdog comparator IC30B.

If the error vo ltage reaches appro ximately 56 de grees Celsius, the co mparator trips, tur ning Q11 of f . The

gate of MOSFET Q10A is pulled high by R138, which turns it of f and VHTR is pre v ented from reaching

the Source of transistor Q13A. The temperature of the sensor is also monitored by the MPU which will

disable the heater when a temperature of 50 de grees Celsius is e xceeded. To shut off the heater, the MPU

asserts the CASEOT signal, turning Q12 on which turns Q11 and Q10A off.

3.3.3 CO2 Input Signal Path

Refer to schematic 2731-03, sheet 5.

The signals from the sensor CO2DATAIN (CO

similar signal paths. The CO2DATAIN passes through a high pass filter with a gain of 3.8 consisting of

C68, R173 and buffer amplifier IC34B. The signal is fed to a Butterworth low pass filter IC33A and

associated components. This filter has a gain of 2 with a corner frequency of 1.5 KHz. The output from

the low pass filter is fed to a 12-bit digital to analog converter IC78 (refer to schematic 2731-03, sheet 9).

The signal, CO2DIN comes into the refe rence of the DAC, which acts as a programmable gain stage

followed internally by an amplifier with a fixed gain of 2. Here under processor control the signal's gain

is adjusted to an acceptable level for conversion. The gain setting is adjusted u sing the digitized signal

out of IC12 (page 2) as part of the feedback loop. Similarly , CO2REFIN is conditioned by high pass filter

IC34A with a gain of 1.75 and low pass filter IC33B with a gain of 2. The equivalent fixed gains for the

two input signals are not equal in order to compensate fo r differences in the output signal levels of the

infra-red detectors in the CAPNOSTAT.

The output from IC78 (page 9), CO2DOUT, is buffered by IC35B (page 5) and AC coupled through C270

to IC94B. The CO2DATA signal received from the CAPNOSTAT is AC coupled by C68 prior to the high

pass filter to remo v e an y DC bia s. Prior to sampling the CO

Q16 on causing any residual charge on C270 to di scharge to gro und. At the start of t he sourc e pulse , the

CO2AZ pulse goes Low and the CO

sample and hold amplif ie r, IC26B. Near the end of the sourc e pulse, the SS*/H (Signa l Sample a nd Hold)

goes Low and the peak signal is acquired on the internal sample and hold capacitor. SS*/H returns high at

the end of the cycle, and the CO

passes through a low pass filter of R191 and C80 before being converted by the ADC into digital data and

analyzed by the processor. The signal CO2REF follows an identical zeroing and acquisition path.

Theory of Operation

Data and Reference signals.

2

Data) and CO2REFIN (CO2 Reference Signal) have

2

signal, the CO2AZ (Auto Zero) pulse biases

2

signal from the sensor is attained, and appears at the inpu t of the

2

signal on the sample capacitor is held at the peak value. The signal then

2

Rev. 01

3.3.4 CAPNOSTAT Interface

A twenty pin connector, J408, interfaces the CAPNOSTAT with the system electronics. F errite filters

have been placed on all lines to suppress radiated EMI and reduce susceptibility from high frequency

external sources of interference.

3.3.5 Sampling Pump (see page 5)

To enable the monitoring of non-intubat ed patients , a single t apered samp ling port is pro vided bel o w the

Flow connector. Regulator IC36 adjusts the pump motor speed and the fl ow r ate of air through the tubing

system via VR1. Pump motor current is sensed b y measuring the v o ltage de v elop ed across res istor R207

using amplifier IC37B which provides a gain of 125. This provides an output of 8mA per Volt {V

(I

*R) / Gain} into the 12-bit ADC IC12 (page 2), or approximately 5 uA per bit resolution

pump

{Vref

frequency attenuation.

/ (212*Gain)}* {8mA/V}. A two-pole 31 Hz filter composed of IC37A provides high

(ADC)

Model 8100 Service

Manual

=

o

21

Page 30

Section 3

Saturation Analog Subsections

3.4 Saturation Analog Subsections

3.4.1 LED Power Generation and LED Drive

Refer to schematic 2731-03, sheet 6.

Adjustable voltage regulator IC38 is configured as a constant current supply for the Red and Infra-Red

(IR) sensor LEDs. R210 limits the current to Vref/R {1.25V/26.7 ohms} or 50mA, while D31 sets the

maximum output voltage at 7.5 Volts. Capacitors C90 and C119 provide a reservoir for providing the

instantaneous current demanded when the LE Ds are turn ed on . Transistor Q19 allows shutting d own the

power to the sensor LEDs by the microprocessor.

Refer to schematic 2731-03, sheet 9.

The SPO2VLED voltage is used by both channels’ drive circuitry. The DAC output portion “C” from

IC78 is programmed by the processor and is buffered by amplifier IC67B. This voltage appears at the

output of IC67B pin 7 and is labelled as SPO2VLED.

Refer to schematic 2731-03, sheet 6.

Connector J102 couples the saturation sensor to the monitor. Each sensor LED is controlled by an

amplifier configured as a constant current driver. IC39A and IC39B are non-inverting amplifiers. The

voltage appearing at the positive terminal will also appear at the negative terminal, and across current

programming resistors R222 and R231. This voltage creates a current through R222 of 225mA {0.74V/

3.3 ohms} when the RDLED* signal is asserted and Red LED is turned on. The driver for the IR LED

creates a constant current source of 111mA across R231 and is controlled by asserting the IRLED*

signal. The two control signals operate at 33 Khz with a 10% duty cycle and are staggered so that one

LED is active during the middle of the other LED’s off period.

Each LED (one red and one infr ared) in the sens or is dri v en separately. Since the circuitry is similar, only

one channel will be discussed; the corresponding com ponents for the other channel will appear in

brackets.

When the REDLED* [IRLED*] line is low Q21 [Q22] will turn of f, this allo ws the SPO2VLED v oltage,

divided by R212 [R223] and R215 [R226], to drive the non-inverting input of IC39A [IC39B]. When

IC39A [IC39B] output is high, Q20 [Q35] will turn on, this pulls current through the sensor LED from

the IC38 supply (fed to the sensor from J102 pin 6). When the REDLED* [IRLED*] line is high, the

input of IC39A [IC39B] is brought to ground potential because Q21 [Q22] is biased on. This shuts Q20

[Q35] off resulting in no current flow through the LED.

22

Model 8100 Service

3.4.2 Saturation Input Signal Path and Signal Conversion

Refer to schematic 2731-03, sheet 6.

Light from the sensor’s Red or Infrared LED shines through the pulsating vascular bed (the patient’s

finger , toe, etc.), placed between the LEDs and the photodiode. Some of this light emerges from the tissue

and impinges on the photodiode, causing the photodiode to conduct current. IC44A pins 2-3 are set up

as a differential amplifier that conv erts this input current to a voltage at the amplifier output. The sensors

are wired such that photodiode current produces a positive voltage at IC44A pin 1

The voltage at IC44A pin 1 is pr esented to an analog switc h IC43A. This switch is cont rolled at pin 1 b y

INSIG* (Input Signal), and will be closed (IC43A pins 2 and 3 connected) except if the monitor is in a

Probe Off Patient condition or is undergoing its self-test at system power up. The switch IC43B,

controlled from SIGND* (Signal Ground), will be open (no connection between IC43B pins 6 and 7)

except as noted abo ve for the switch at IC43A. As a result, the IC44A output voltage passes undisturbed

to the high p ass filter consisting of R239 and C108.

1. This is true for SuperBright™ sensors. If a non-SuperBright™ (Novametrix part number 86xx series) sensor is connected,

IC44A pin 1 will go negative.

Manual Rev. 01

1

.

Page 31

Flow System Analog Subsections

The ASAMP* signal is active low whenever either sensor LED is turned on . This cause s Q23 to tur n off

and the signal at C108 passes through to IC44B. The ASAMP* line returns to a logic high when neither

LED is being dri v en, caus ing Q23 to turn on . With Q23 conducting, an y v o ltage at C 108 i s dis char ged to

ground and the next pulse will charge C108 from a known level. If it were not for Q23, any charge

remaining on C108 from the previous pulse, or from ambient light reaching the photodiode, would be

added to the charge from a new pulse—creating measurement errors.

If the signal at IC44B is the product of the Red LED being turned on, then RDSAMP* will go low and

close the switch at IC43D. This se nds the signal to a sample and hold circu it consisting of R247 and C12 4

(that maintains the signal until next sample pulse arrives), a gain stage (IC42A), a filter/divider network

(C120, R218 and R409), and finally, to the Red channel Analog-to-Digital Convertor (ADC) IC45.

If the signal at IC44B is the product of the Infrared LED being turned on, then I RSAMP* will go low

and close the switch at IC43C. This sends the sign al to a samp le and hold circuit co nsisting of R236 an d

C111 (that maintains the signal until next sample pulse arrives), a gain stage (IC42B), a filter/divider

network (C103, R214 and R408 ), and finally, to the Infrared channel Analog-to-Digital Convertor IC41.

On power up, the system performs a self-calibration cycle to establish the level of background circuit

offset. Calibration is performed by coordinating the control signals SPO2CAL, SPO2SC1, ASAMP*,

RSAMP*, ISAMP*, SIGND* and INSIG*. Once th e system baseline has been acqu ired, the Red and

Infra-Red ADCs, IC41 and IC45, adjust their output to compensate for any system offsets found.

The main timing signal generation for saturation sig nal acquisition is generated by the TPU. Auxili ary

signals for calibration and signal acquisition (SPO2CAL, SPO2SC1, SIGND* and INSIG*) are

generated by the MPU control of output latch IC19 (reference page 2 on schematic).

Theory of Operation

3.5 Flow System Analog Subsections

3.5.1 Flow Zeroing and Patient Line Back-flushing

Refer to schematic 2731-03, sheets 7 and 8.

The zero process begins when the CPU brings the VALVE1, VAL VE2, VAL VE3 and VALVE4 lines high,

energizing valves V1, V2, V3 and V4. This disconnects the differential pressure transducer IC50/IC95

(via V1 and V2) and the absolute pressure trans ducer IC59/IC9 6 (via V2) from th e patient airway, shunts

the differential p ressure s ens or p orts ( V 4) and o pens all p res sure tr ans ducer p orts to atmo sp here thr oug h

V3. Note that there are two possible installations for IC50/IC95 and IC59/IC96, depending upon the

model configuration.

The pressure transducers are “zeroed” by adjusting the amplified and conditioned pressure output signals

into the 12-bit Analog to Digital Converter (ADC, IC46) so that each reading reads approximately midscale (2048 counts) usi ng a successive approximation algori thm. With a reference voltage of 2.5 Volts,

each count returned by the ADC is equal to 0.6103 mV. Centering the no flow (ambient) signal to the

ADC's mid-scale allows the sensor to report both positive and negative airway pressures. IC53, an octal 8bit Digital to Analog Converter (DAC) provides the adjustment under micr oprocessor co ntrol. Th e DAC

maintains each adjustmen t voltage obtained during the zeroin g proc ess u ntil a new zero cycle is initiated.

The patient airway pressure transducer is "zeroed" first by adjusting the AUXTRIM output of the DAC

until the Airway Pressure signal into the ADC, IC46, reads mid-scale. The barometric ( ambient) pressure

as sensed by IC59/IC96 is recorded after the airway pressure zero is completed. Next the flow channels

are zeroed. A non-inverting summing amplifier (IC52B) combines two of the DAC's outputs and a

constant voltage from IC52A equal to the mid-scale of the ADC. The output voltage produced by the

summer is fed into IC49, a monolithic instrumentati on amplifier, which takes the differential output of

the pressure transducer , IC50/IC 95, and a dds an offset equal to the reference voltage input. D AC outputs

VOUTA and VOUTB serve to provide the flow channels with a fine and a course adjustment. VOUTB,

the course adjustment, is altered until the X10 Flow gain channel input into the ADC, FLOW10, reads

Rev. 01

Model 8100 Service

Manual

23

Page 32

Section 3

Flow System Analog Subsections

mid-scale. VOUTA, whose ratio is 1/256 that of VOUTB, is then used to fine tune the system by bringing

the x100 Flow gain channel, FLOW100, to mid-scal e. Finally, the x1000 gain channel is adjusted if

required by changing the value of DAC output VOUTA. Once the x1000 gain channel is set, a reading is

taken from all four flow gain channels. The result from each channel is stored in SRAM and used as an

offset in the flow calculations. Valves V1, V2, V3 and V4 are then de-energized, reconnecting the

pressure transducers with the patient airway.

If patient line purging is set, the system turns on the pum p by bringing the PURGE line high after the

zero values are recorded. A slight pressure is allowed to build in the pump tubing line that will aid in

flushing out the patient airway tubing. To purge patient line 1, the CPU brings the VALVE1 and VALVE4

signals high, energizing Valves V1 and V4. V1 connects the pump with the P1 patient line, flushing out

the patient P1 line while V4 shunts across the differential pressure transducer, preventing a differential

pressure from appearing across the transducer . During pur ging, the system is able to monitor the pressure

that is present in the selected patient line by reading the AWPRESS signal. VALVE1 is brought low and

V1 is then de-energized, once again isolating the pump from the patient airway and allowing a pressure

head to build once more. The VAL VE2 line is then broug ht high and valve V2 is then energized, flushing

out the patient P2 line. After all lines have been flushed out, V1 and V3 are re-energized allowing any

residual pressure to be vented to atmosphere. All valves are then de-energized and the PURGE signal is

brought low, turning the pump off. The purging-process is complete and normal patient monitoring

continues.

A hardware watchdog , consi sti ng of IC3 2B and the su rro und in g circui t ry, limits the maximum pump on

time, preventing overpressure from building in the patient lines.

3.5.2 Flow Circuitry

Differential Pressure Transducer, IC50/IC95, is a silicon-based, piezoresistive bridge with four active

elements. When pressure is applied between t ransducer ports P1 and P2, a differential output voltage

proportional to the applied pressure is pro duced . Th e fu ll- scale outpu t rang e fo r th e trans ducer is 0 to 1 0

inches of water (P1>P2). By setting the 0 differential pressure (no-flow) point to mid -scale (during the

zeroing process described earlier), ne g ati v e pres sure readings (P2>P1) are also available. The transducer