Page 1

HAND-HELD

CAPNOGRAPHY

Service Manual

Model 615

Mar 23, 2000

Catalog No. 9425-90-00

Novametrix Medical Systems Inc.

5 Technology Drive

Wallingford, Connecticut, U.S.A. 06492.

Page 2

Page 3

About This Manual

About This Manual

Revision Histor

Declaration of Conformity with European Union Directives

This manual is intended for use by technical personnel for servicing the Model 615. Refer to the

Model 615 User’s Manual (Cat. No. 9425-23) for detailed information on normal operation.

®

TIDAL WAVE and CAPNOSTA

Inc. Nafion is a registered trademark of Dow Corning Corp. The Model 615 is Year 2000

compliant.

Copyright 2000 Novametrix Medical Systems Inc. This document contains information which

is proprietary and the property of Novametrix Medical Systems Inc., and may not be

reproduced, stored in a retrieval system, translated, transcribed or transmitted in any form, or by

any means, without prior explicit written permission from Novametrix Medical Systems Inc.

23-Mar-00 Release, revision 00

are registered trademarks. Cidex is a trademark of Arbook,

The authorized representative for Novametrix Equipment is:

European Compliance Services Limited

Oakdene House

Oak Road

Watchfield

Swindon, Wilts SN6 8TD

UK

Manufacturing, Quality and Safety

Novametrix manufacturing facility is certified to ISO 9001 and EN46001 (MDD93/42/EE

Annex II). Novametrix Medical Systems Inc. products bear the “CE 0086” mark. The product

is certified by Underwriter’s Laboratories (UL) to bear the UL mark; and tested by TUV

Rheinland to IEC601-1 / EN60601-1.

Rev. 00

Model 615 Service Manual

iii

Page 4

[This page intentionally blank.]

Manufacturing, Quality and Safety

iv

Model 615 Service Manual

Rev. 00

Page 5

Contents

General Description .....................................................................................................1

Indication for use .........................................................................................................1

Keypanel Controls and Indicators ...............................................................................1

Connections and Labeling ...........................................................................................3

Principle of operation ..................................................................................................3

Safety .............................................................................................................................4

Theory of Operation .....................................................................................................7

Digital Control System .................................................................................................7

Background Mode Debugging .........................................................................11

System Memory ...............................................................................................11

Serial Communications ....................................................................................12

User Interface Control Circuitry .......................................................................12

Real Time Clock, Power on RESET Generation and Glue Logic .................... 13

CO2 System Analog Subsections .............................................................................13

CO

Source Drive ............................................................................................13

2

CAPNOSTAT® CO2 sensor Case and Detector Heater Control ....................15

CO

Input Signal Path .....................................................................................16

2

CAPNOSTAT® CO2 sensor Interface .............................................................16

Barometric Pressure Circuitry ..........................................................................16

Sampling Pump ...............................................................................................17

Digital and Analog Control Lines .....................................................................17

Power Supply and Battery Charger ...........................................................................18

Supply and Reference Voltage Generation .....................................................18

Battery Charger Circuitry .................................................................................20

Functional Tests .........................................................................................................23

Equipment Required .................................................................................................23

Procedure ..................................................................................................................23

Power up .........................................................................................................23

Capnography Tests .........................................................................................24

Sidestream Tests .............................................................................................25

Miscellaneous Tests ........................................................................................25

Accuracy Tests ...........................................................................................................27

Equipment Required .................................................................................................27

Procedure ..................................................................................................................27

Electronic Tests ..........................................................................................................31

Equipment Required .................................................................................................31

Test Procedure ..........................................................................................................31

Safety Testing ...........................................................................................................34

Status Messages ........................................................................................................35

System Messages .....................................................................................................35

Capnography Messages ...........................................................................................35

Maintenance ................................................................................................................37

General ....................................................................................................................37

Rev. 00

Model 615 Sevice Manual

v

Page 6

Contents

Maintenance Schedules ............................................................................................37

Cleaning and Sterilization ......................................................................................... 38

Monitor, BaseStation and External Power Supply .......................................... 38

CAPNOSTAT® CO

Single Patient Use Airway Adapters ............................................................... 38

External Sampling System Components ......................................................... 38

Internal Sampling System Components .......................................................... 38

Battery Maintenance .................................................................................................39

AC/Battery Operation ...................................................................................... 39

Battery Status and Alerts ................................................................................ 40

Removing and Installing the Battery ............................................................... 41

Charge using External Power Supply ............................................................. 41

Charge using optional BaseStation ................................................................. 42

Charging with External Charger ...................................................................... 42

AA Lithium Batteries ........................................................................................ 43

Battery Life and Recharge Times .................................................................... 44

Assembly Exchanges ................................................................................................ 44

Disassembling the Monitor .............................................................................. 44

Reassembling the monitor .............................................................................. 47

Serial Communications/Power Interface Connector ................................................. 47

Software Update Instructions .................................................................................... 48

Equipment Required ....................................................................................... 48

Setup ...............................................................................................................48

Procedure ........................................................................................................ 48

Specifications ............................................................................................................. 53

Specifications ............................................................................................................ 53

General ........................................................................................................... 53

Capnograph .................................................................................................... 53

EtCO2 Section (Mainstream) ..........................................................................53

Respiratory Rate (Mainstream) ....................................................................... 53

EtCO2 Section (Sidestream) ........................................................................... 54

Respiratory Rate (Sidestream) ........................................................................ 54

Monitor Specifications ............................................................................................... 54

Additional Features ......................................................................................... 55

Accessories ................................................................................................................ 57

Sensor ........................................................................... 38

2

vi

Model 615 Service Manual

Rev. 00

Page 7

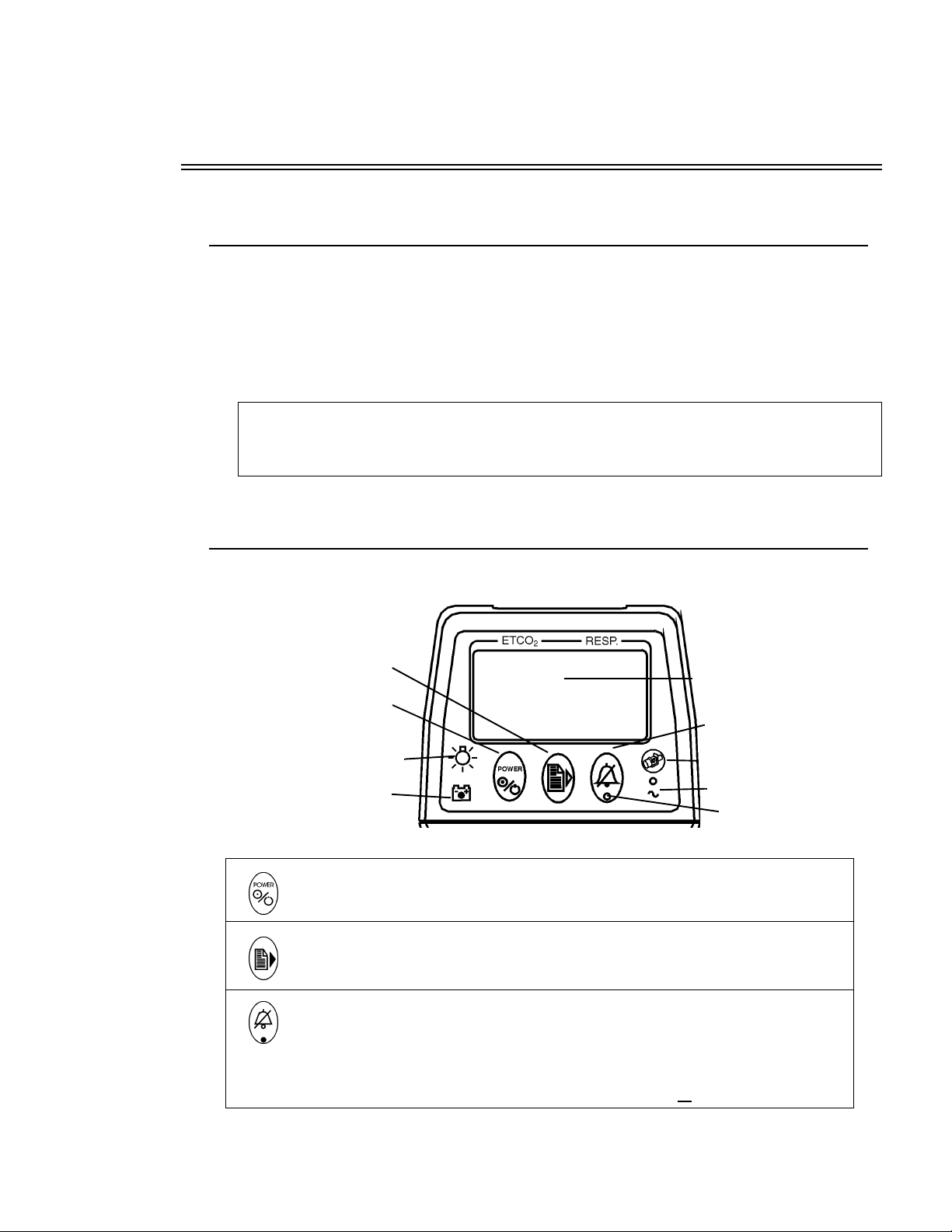

General Description

Power key

Page key

Backlight key

Battery charge indicator

Alert key

Adapter key

AC indicator

Display screen

and LED

Alert LED

Section 1

Section 1

1.1 Indication for use

The Model 615 hand-held, portable Capnograph is intended to be used for monitoring end tidal

CO

and respiration rate in monitoring environments such as ventilatory support, emergency

2

and anesthesia. The Model 615 incorporates a miniature vacuum pump to draw expired

respiratory gases through the CAPNOSTAT

nasal cannula. The Model 615 is designed to monitor adult, pediatric and neonatal patients and

is not intended for any other purpose.

Components of this product and its associated accessories which have patient contact are

free of latex.

1.2 Keypanel Controls and Indicators

General Description

®

CO2 Sensor using a sampling airway adapter and

NOTE

Rev. 00 Model 615 Service Manua

Switches power on/off.

Displays, Capnogram, EtCO

enter the PRINT SELECTION menu.

Sets 2 minute silence and displays the SET ALERTS menu. Press and hold for

3 seconds to disable audible alerts. Press and hold again to cancel.

The Alert Key LED:

Steady yellow: audio silenced for 2 min., no alert in progress.

Flashing yellow: audio off , no alert in progress.

Flashing red and yellow: alert in progress; audio is off or

trend or respiration rate trend. Press and hold to

2

2 minute silence.

1

Page 8

Section 1

General Description

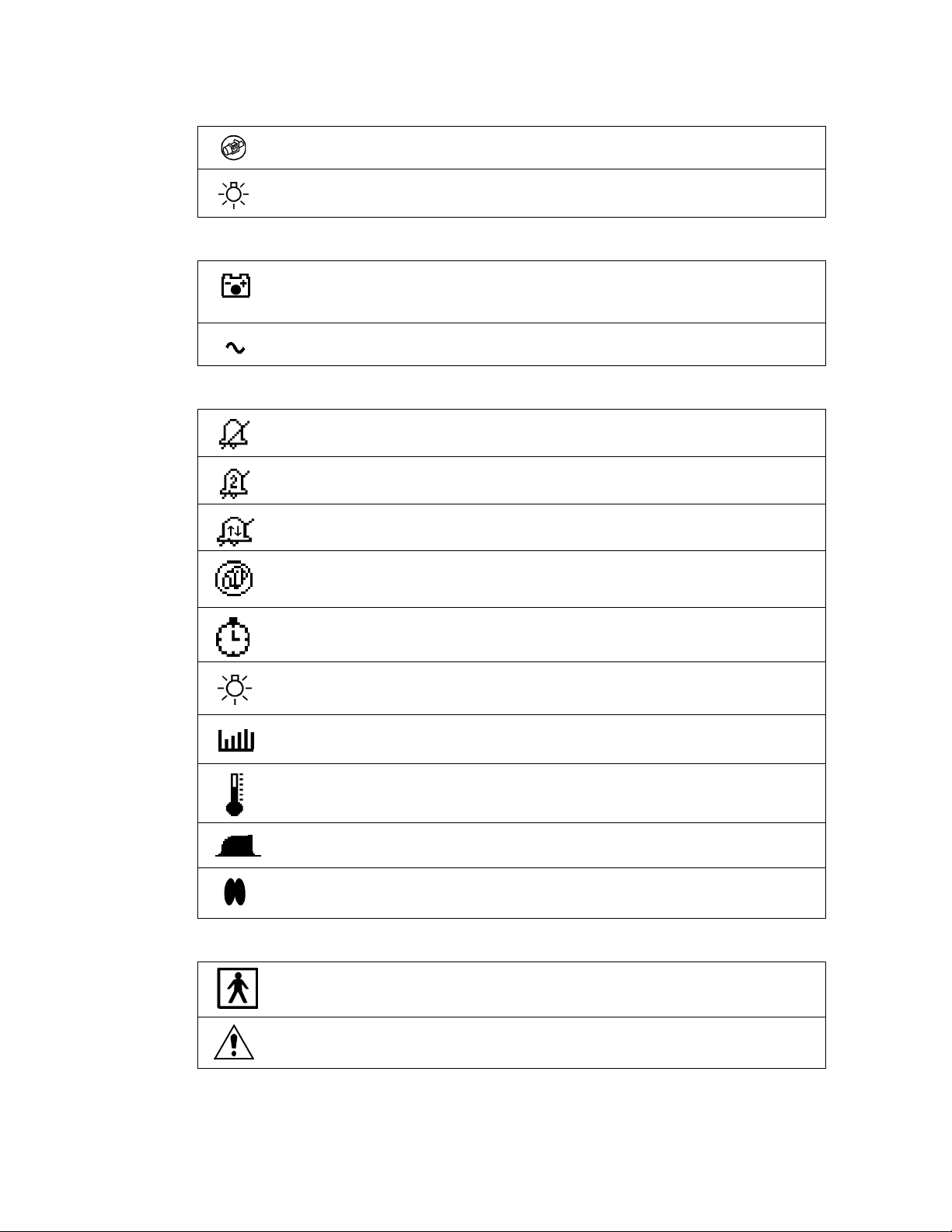

Press to set adapter type. Press and hold for 4 seconds to zero adapter.

Press to turn backlight on/off, or press and hold to adjust contrast.

INDICATORS

Illuminates when on battery power. Green; battery is fully charged, slow flashing yellow; battery power is low (approximately 20 minutes of operation), Fast

flashing red; battery is exhausted (approximately 5 minutes of operation).

Green when the monitor is connected to an AC power source.

ICONS

Audible alerts permanently silenced.

Audible alert silenced for two minutes.

Alert limits disabled.

Indicates adapter key.

Time/Date Icon

Indicates backlight key.

Displayed beside any Trend screen.

Displayed when performing an adapter zero and the sensor is not at operating

temperature.

Displayed when performing an adapter zero and breaths are detected.

®

Displayed when CAPNOSTAT

are detected.

CO2 sensor is attached to patient and breaths

SYMBOLS

Patient isolation: Identifies connection as type BF

Attention: Consult manual for detailed information

Model 615 Service Manual Rev. 00

2

Page 9

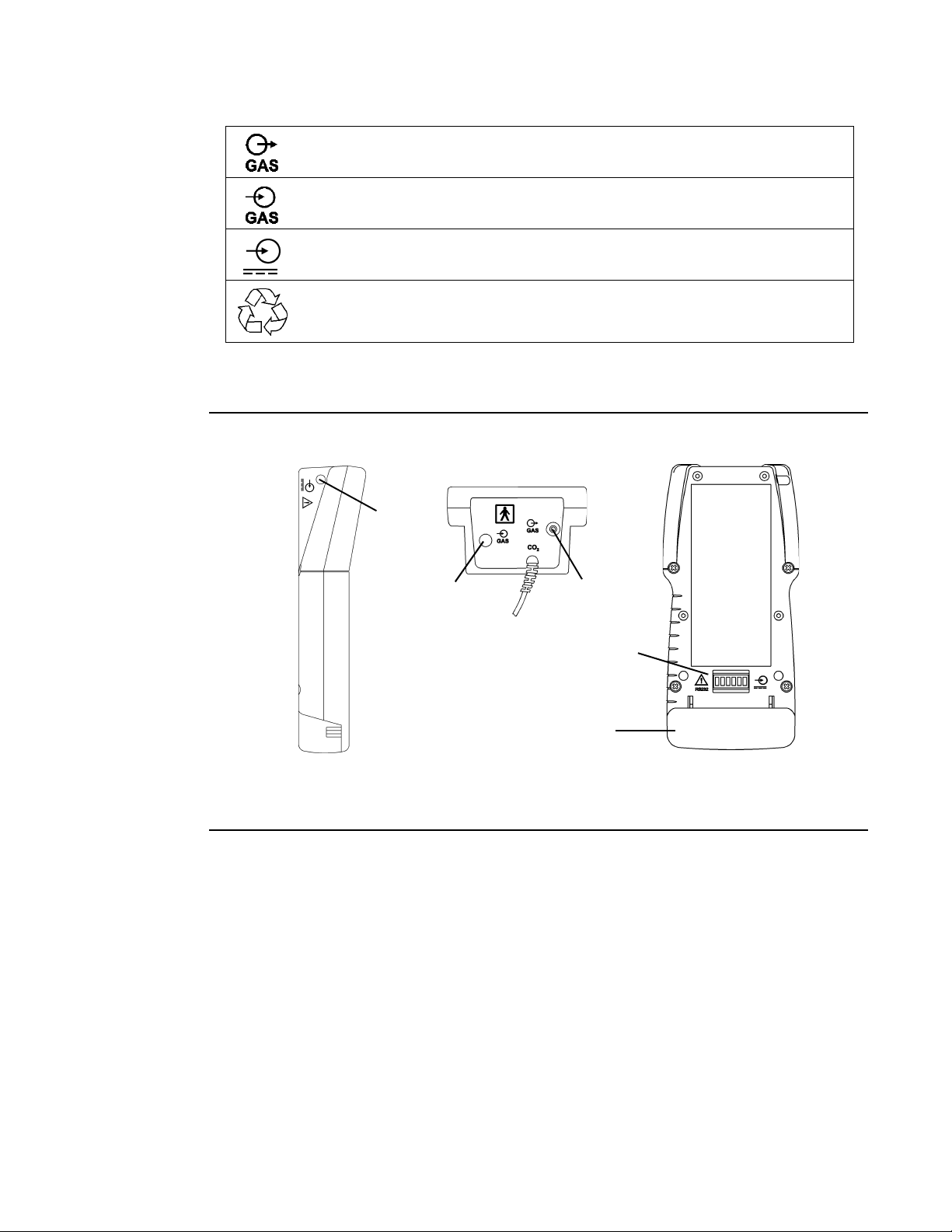

General Description

Sa mpling sy ste m inpu t

Sam pling system output

Endview

Model 615

Rearview

Model 615

RS232 connection

DC input

Battery c om pa rtme nt

Sideview

Model 615

and external power

input from BaseStation

1.3 Connections and Labelin

Section 1

Sampling System: Gas output

Sampling System: Gas input

DC input. Connect external power supply to this port. Use only Novametrix

external power supply, Catalog number 9220-10.

Recyclable item. This symbol is found on the internal battery and should not

concern the common user. Refer to qualified service personnel when battery

replacement is required.

1.4 Principle of operation

The Model 615 uses the CAPNOSTAT® CO2 sensor to measure CO2 by using the infrared

absorbtion technique, which has endured and evolved in the clinical setting for over two

decades and remains the most popular and versatile technique today.

The principle is based on the fact that CO

specific wavelengths, with the amount of energy absorbed being directly related to the CO

concentration. When an IR beam is passed through a gas sample containing CO2, the

electronic signal from the photodetector (which measures the remaining light energy) can be

obtained. This signal is then compared to the energy of the IR source and calibrated to

accurately reflect C

concentration in the sample. To calibrate, the photodetector’s response

2

to a known concentration of CO

channel accounts for optical changes in the sensor, allowing the system to remain in calibration

without user intervention.

Rev. 00 Model 615 Service Manua

is stored at the factory in the monitor’s memory. A reference

2

molecules absorb infrared (IR) light energy of

2

2

3

Page 10

Section 2

Safety

Section 2

For maximum patient and operator safety, you must follow the following warnings and cautions.

Indicates a potentially harmful condition that can lead to personal injury.

•

Explosion Hazard:

of this instrument in such an environment may present an explosion hazard.

•

Electrical Shock Hazard:

before cleaning it. Refer servicing to qualified service personnel.

•

Failure of Operation:

situation has been corrected by qualified personnel.

• Do not operate Model 615 if it appears to have been dropped or damaged.

• Do not operate Model 615 or its accessories when it is wet due to spills or condensation.

• Never sterilize or immerse the monitor, sensor or accessories in liquids.

• The monitor does not alert for NO RESPIRATION if the airway adapter is removed from the

CAPNOSTAT

• Verify the “No Resp Timer” setting prior to use.

• Do not position any sensor cable in a way that may cause entanglement or strangulation.

• The Model 615 is not intended to be used as a primary diagnostic apnea monitor and/or

recording device.

• The external battery charger should NOT be used to recharge the battery near or in close

proximity to patients and/or other medical equipment in operation. It is intended for use in

service areas only (i.e. nurses station, biomed lab, etc.).

• Connection of an external device (e.g. printer or computer) to the RS232 serial port on the

BaseStation may compromise patient safety.

DO NOT

If the monitor fails to respond as described, do not use it until the

®

CO2 sensor.

Safety

WARNINGS

use Model 615 in the presence of flammable anesthetics. Use

Always turn Model 615 off and remove any external devices

CAUTIONS

Indicates a condition that may lead to equipment damage or malfunction.

• Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order of a

licensed medical practitioner.

• Use only an external power supply approved by Novametrix for use with this device. Use

of any other power supply may damage the Model 615 and void the warranty.

• Do not operate Model 615 or its accessories when it is wet due to spills or condensation.

• Do not operate Model 615 if it appears to have been dropped or damaged.

• Keep Model 615 and its accessories clean.

• Inspect the integrity of the Model 615 and its accessories prior to use.

• Never sterilize or immerse the monitor, sensor or accessories in liquids.

• Do not sterilize or immerse sensors except as directed in this manual.

• Do not apply excessive tension to any sensor cable or pneumatic tubing.

• Do not store the monitor or sensors at temperatures less than 14°F (-10°C) or above 131°F

(55°C).

• Do not operate the monitor or sensors at temperatures below 50°F (10°C) or above 104°F

(40°C).

Model 615 Service Manual Rev. 00

4

Page 11

Safety

Section 2

• If a Single Patient Use Sampling Adapter becomes occluded, replace and discard the

adapter.

• It is recommended that the CAPNOSTAT

®

CO2 sensor be removed from the circuit

whenever an aerosolized medication is delivered. This is due to the increased viscosity of

the medications which may contaminate the sensor windows, causing the sensor to fail

prematurely.

• Where electromagnetic devices (i.e. electrocautery) are used, patient monitoring may be

interrupted due to electromagnetic interference. Electromagnetic fields up to 3V/m will not

adversely affect system performance.

• Refer servicing to qualified personnel.

NOTES

Indicates points of particular interest or emphasis for more efficient or convenient operation.

• The Model 615

monitor is intended for operation with Novametrix Single Patient Use airway

adapters.

• Operating the Model 615

below 50°F (10°C) will result in longer warm-up time and reduce

battery life.

• Components of this product and its associated accessories which have patient contact are

free of latex.

• Certain rebreathing circuits, or the presence of artifacts such as cardiogenic oscillations,

may cause Model 615 to react to non-respiratory CO

fluctuations as if they were breaths.

2

This condition affects only the RESP numerical displays; the capnogram display continues

to provide an accurate picture of the CO

waveform.

2

• After the life cycle of our equipment and all accessories has been met, disposal of the

equipment should be accomplished following the national requirements. Contact the local

Novametrix representative for questions concerning disposal.

Rev. 00 Model 615 Service Manua

5

Page 12

Section 2

Safety

[This page intentionally blank.]

Model 615 Service Manual Rev. 00

6

Page 13

Section 3

The Model 615 is a microprocessor based handheld instrument that measures the clinica

parameters of CO

the Model 615 is explained in detail in the subsections that follow.

3.1 Digital Control System

Refer to 2754-03 schematic sheet 1.

Embedded control for the system is provided by IC1, a Motorola MC68332 integrated

microcontroller. In addition to a full 32-bit Central Processing Unit (CPU), this device also

contains circuitry for system clock generation, peripheral chip select generation, data control,

interrupt generation, a sophisticated timing coprocessor, synchronous serial communication

and asynchronous serial communication. In general, functional signals are grouped together

into ports, and each signal can be independently programmed by software to be its predefined

port function or as discrete I/O. Additionally, the functionality for several ports (Port C, E and F)

can be predefined by the state of the data bus on system power-up. A special “background

mode” port allows the device to be controlled by an external source for system debugging and

testing. Also integrated on-chip are several activity monitors, as well as a software watchdog to

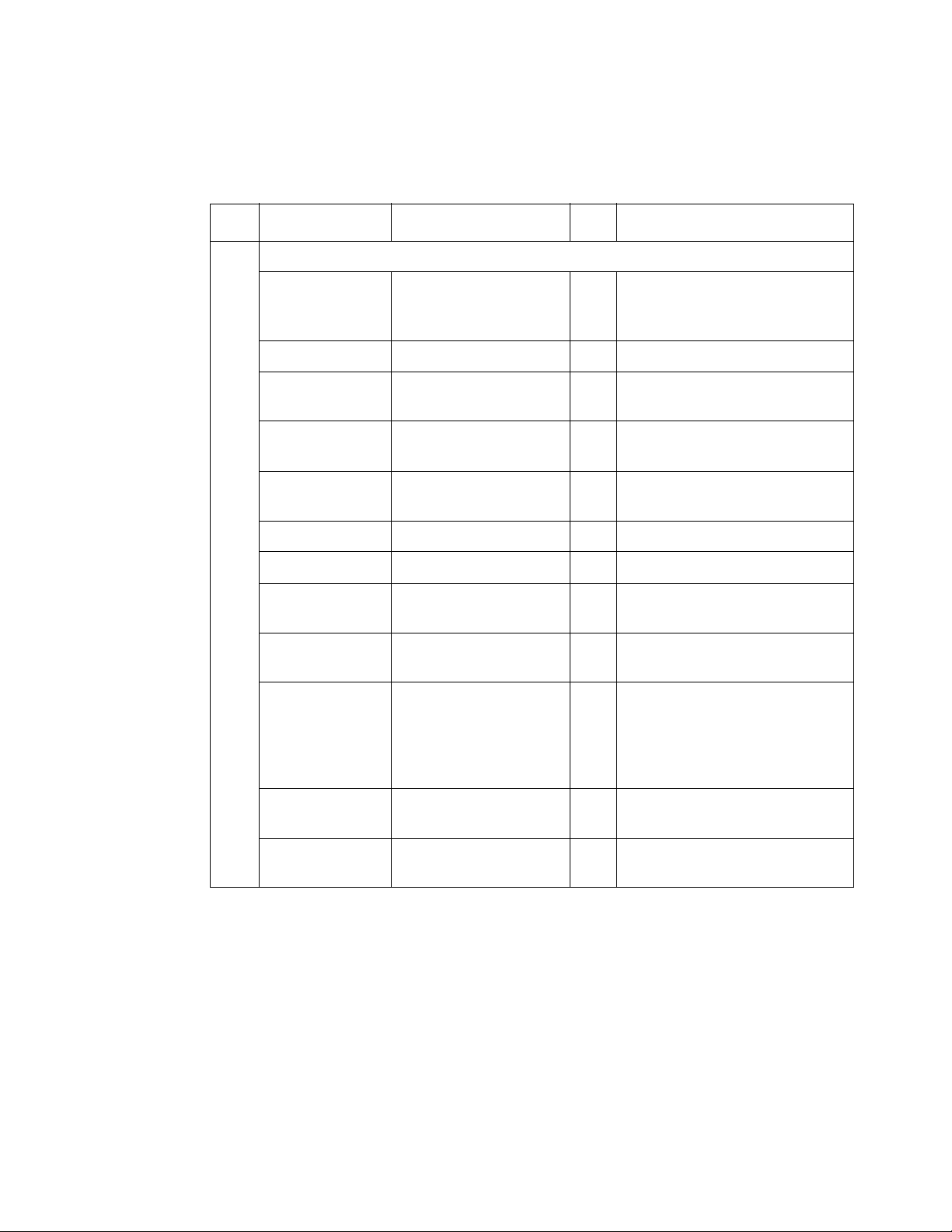

ensure proper device and system operation. Refer to table 1.

production and respiration rate (RR). The electronic theory of operation of

2

Theory of Operation

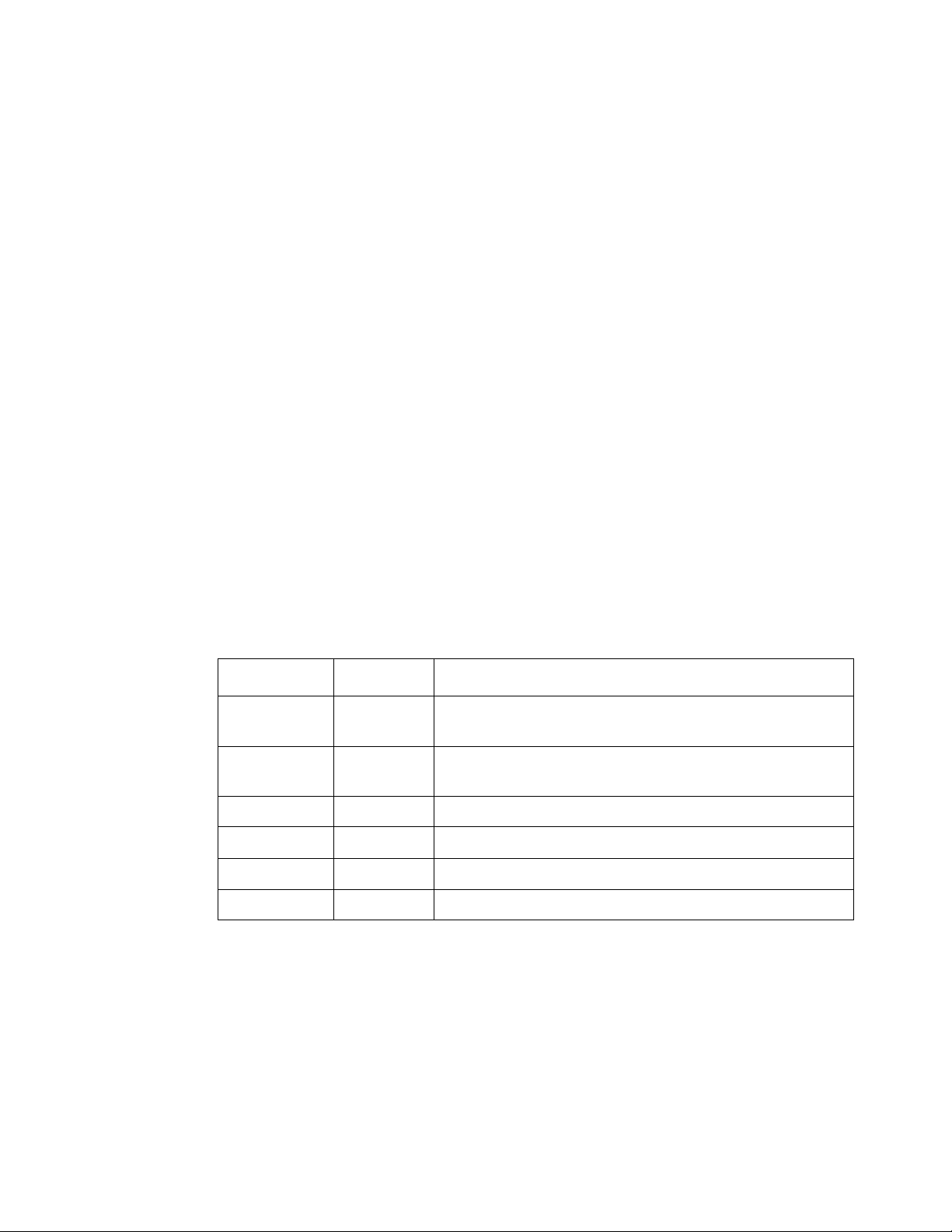

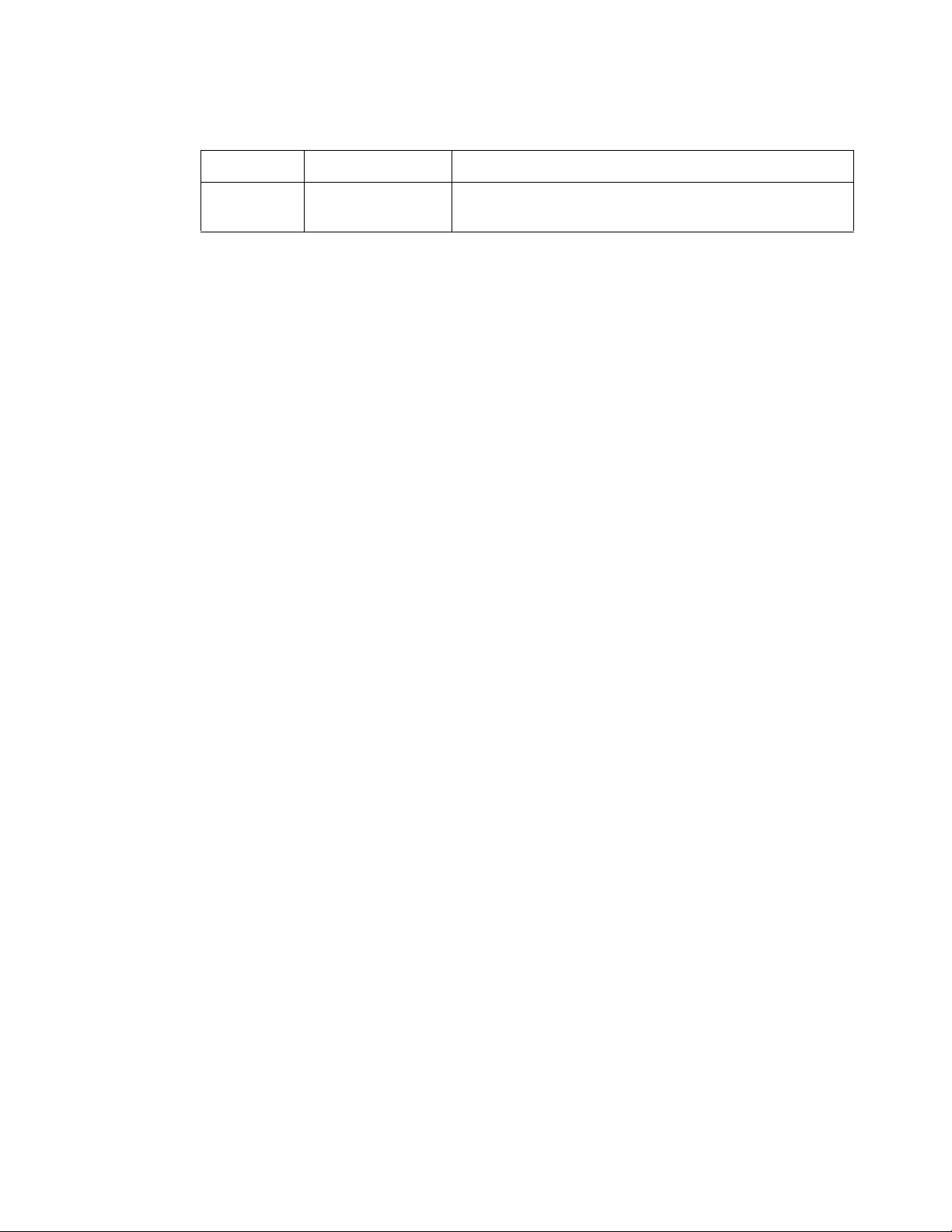

Table 1: CPU Port Functions

Functionality Control ,

Port Defined Function

TPU

16 Channels

QSM

4 Synchronous Serial

Chip Selects & one

asynchronous serial

channel

Background Mode System debugging Allows an appropriate external

Timing Signal Generation Each channel independently user

programmable as TPU function or

as Discrete I/O

Serial Communications Port:

QSPI: Queued Serial Peripheral

Interface

SCI: Serial Communications

Interface

QSPI chip selects independently

user programmable, can be used as

Discrete I/O or decoded to create up

to 16 chip selects. SCI transmit can

be programmed as Discrete I/O

device to control the microprocessor

and system

Data Bus Control

(Alt Functions: D pulled low)

Rev. 00 Model 615 Service Manua

7

Page 14

Section 3

Theory of Operation

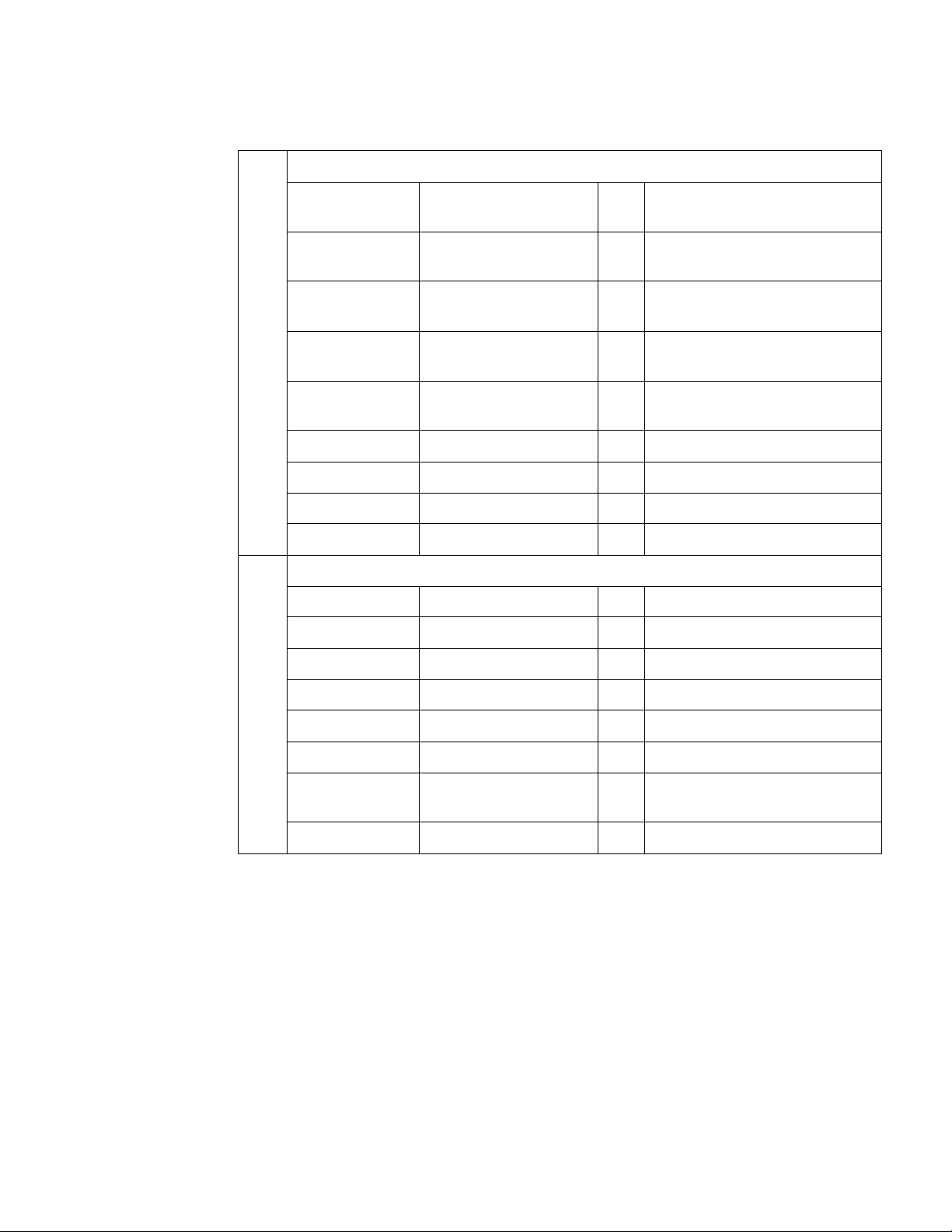

Table 1: CPU Port Functions

C Chip Selects D0: CSBOOT* data width, 8 or 16-

bit

D1: CS1*-CS3* or

BR*,BG*,BGACK*

D2: CS3*-CS5* or FC0-FC2

D3-D7: CS6*-CS10* or A19-A23

E Bus Control D8: Control Signals or discrete I/O

F MODCK and Interrupts D9: MODCK & IRQ or discrete I/O

The maximum operating frequency of the integrated processor is 20.97 MHz. The operating

frequency is software selectable and generated by an internal VCO operating from Y1, a

32.768KHz watch crystal. The Timing Processor Unit (TPU) coprocessor of the MC68332

provides timing generation derived from the system clock. This feature is utilized to control the

precise timing required for the acquisition of the end tidal carbon dioxide (EtCO

) signals. The

2

TPU is also use to generate the PWM (Pulse Width Modulation) control for the CAPNOSTAT

CO2 sensor case and detector heaters, as well as to provide the frequency generation for the

audio tones. See Tables 2 & 3.

®

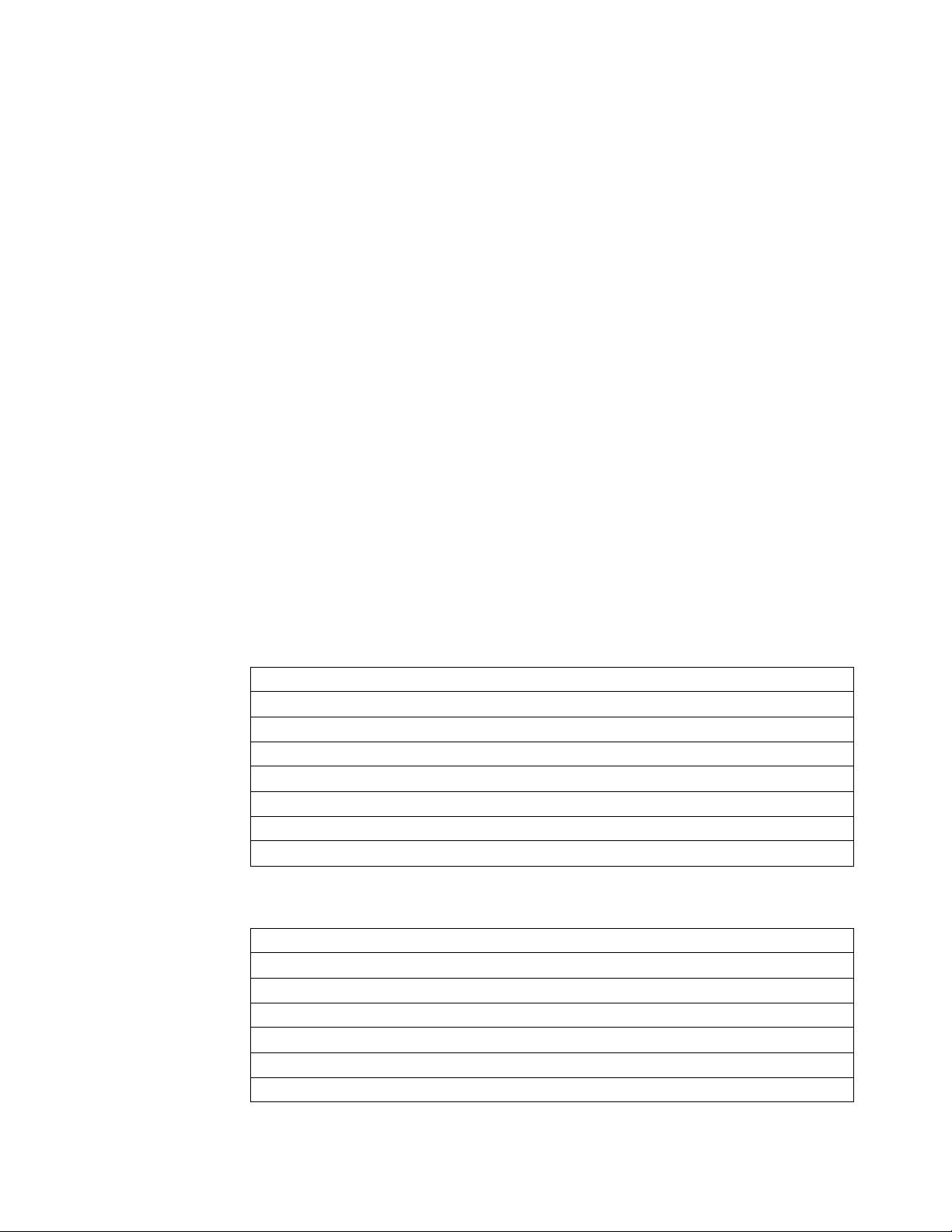

Table 2: TPU Timing Generation for the EtCO

subsystem

2

Signal Name Description Function / Timing

CO2AZ Auto Zero Clears the sample/hold circuitry

prior to data acquisition.

Active high, 2.84 ms

CO2PWENB Pulse Width Enable Defines the active time for both

phases of the bipolar source

pulse, used for pulse width protection circuitry.

Active high, 830 µs

SRCDRV0 Source Drive 0 First source drive signal.

Active high, 405 µs

CS*/H Current Sample/Hold Enables circuitry for source cur-

rent measurement. Sample is

taken when SRCDRV0 is

active.

Low = sample, 270 µs, High =

hold

SRCDRV1 Source Drive 1 Second source drive signal

delayed for 30 microseconds

after SRCDRV0 ends.

Active high, 395 µs

Model 615 Service Manual Rev. 00

8

Page 15

Theory of Operation

Section 3

Table 2: TPU Timing Generation for the EtCO

SS*/H Signal Sample/Hold Enables circuitry for CO

subsystem

2

and

2

reference channel data acquisition.

Low = sample, 270 µs, High =

hold

CASEPWM Case Heater PWM PWM control for the case

heater servo

DETPWM Detector Heater PWM PWM control for the detector

heater servo

TONE Audio Tone Generation Variable frequency outputs to

generate system audio

CASEOT Case Heater Over Temperature Case heater over temperature

shut down

DETOT Detector Heater Over Temperature Detector heater over tempera-

ture shut down

Ferrite and L-C filters, 100pF capacitors, and 100 ohm resistors have been placed on selected

microprocessor signals with fast rise and fall times (including timing, clock, and address and

data lines) in order to help reduce and suppress the radiation of electromagnetic interference

and decouple unwanted power supply noise. In addition, good EMI/EMC design techniques

have been incorporated in the component layout and printed circuit board layout and

manufacture.

Table 4 lists the chip select, control and discrete I/O functions for the

Model 615

system module.

On power-up, Ports E and F are programmed as discrete inputs by pulling down their controlling

data lines, DB8 and DB9. After power-up, the software sets up each pin function individually

and performs a series of self tests to check the integrity of the system. The state of configuration

inputs on Port E (TST*, CNFG0*, CNFG1*, and CNFG2) are read. These inputs allow the

software to identify different operating states such as Test Mode, or different hardware

configurations. After the initialization period is complete and all system functions have been set,

Rev. 00 Model 615 Service Manua

9

Page 16

Section 3

Theory of Operation

the LED output (PF0) toggles at a 1Hz rate switching transistor Q3 which drives the status LED

D3, indicating that the system is ready for operation.

Table 3: Chip Select, Control and Discrete I/O

Port Pin Functions System Signal Name I/O Comments

C D0 pulled low, D1-D7 pulled high, pins are chip select on power-up

CSBOOT* ROMOE* O Program PROM chip select

byte wide mode, (8-bits) D0 =

LOW

CS0* / PC0 / BR* SRAMWR* O SRAM write enable

CS1*/ PC1 / BG* AUD_CS* O Audio attenuation control chip

select

CS2* / PC2 /

BGACK*

CS3* / PC3 / FC0 ROMWR* O FLASH PROM Write Enable,

CS4* / PC4 / FC1 DISPCS1* O LCD chip select #1

CS5* / PC5 / FC2 DISPCS2* O LCD chip select #2

CS6* / PC6 / A19 LATCH1_CS* O System control signals latch 1

CS7* / PC7 / A20 LATCH2_CS* O System control signals latch 2

CS8* / PC8 / A21 ROMWREN O Port C discrete output, prevents

CS9* / PC9 / A22 PROFILE* O Enables software profiling data

CS10* / ECLK /

A23

SRAMRD* O SRAM read enable, byte mode

Byte Mode

chip select

chip select

unintentional writes to FLASH

EPROM. This signal must be

asserted before ROMWR* in

order to overwrite the flash.

output latch

ECLK O Enable clock for the liquid crystal

display

Model 615 Service Manual Rev. 00

10

Page 17

Theory of Operation

Section 3

Table 3: Chip Select, Control and Discrete I/O

E D8 pulled low, discrete I/O on power-up

DSACK0* / Port E0TST* I Initiate system TEST if low

DSACK1* / Port E1DS1* I Data and size acknowledge 1*

AVC* / Port E2CNFG0* I Configuration switch 0

RMC* / Port E3CNFG1* I Configuration switch 1

DS* / Port E4DS* O Data strobe

AS* / Port E5 AS* O Address strobe

SIZ0* / Port E6 CNFG2* I Configuration switch 2

SIZ1* / Port E7 SLP* I Not used in Model 615

R/W* WR* O Data write strobe

F D9 pulled low, discrete I/O on power-up

MODCK / Port F0 LED O LED CPU activity Indicator

IRQ1* / Port F1 SW1 I Keypanel switch 1 input

IRQ2* / Port F2 SW2 I Keypanel switch 2 input

IRQ3* / Port F3 SW3 I Keypanel switch 3 input

IRQ4* / Port F4 SW4 I Keypanel switch 4 input

IRQ5* / Port F5 PWRKEY I Power key status input

IRQ6* / Port F6 EXTDCIN I Indicates external AC mains

power operation

IRQ7* / Port F7 NMI I Non-maskable interrupt

Background Mode Debugging

External system debugging is possible by connecting an appropriate device (emulator or

debugger) to header J401 and momentarily bring the BERR* (J401/2) low. This halts the bus

activity and turns control of the system over to the external device. In this mode, internal MPU

registers can be viewed and altered, special test features can be invoked and system memory

can be read and written to.

System Memory

An 8-bit wide data path is used for FLASH PROM and SRAM transfers. Program code storage

is contained in a 1-Meg 5V FLASH or EEPROM (IC2) device. The FLASH PROM is protected

from unintentional overwrites of the program code by transistor Q1 and the ROMWREN signal.

Rev. 00 Model 615 Service Manua

11

Page 18

Section 3

Theory of Operation

The ROMWREN line must be high prior to writing new code into the FLASH devices.

Nonvolatile data storage is contained in the 1-Meg SRAM (IC3). The SRAM is backed-up to

retain it’s contents by applying a voltage on VBACKUP generated by BT1 (a 3.0V lithium

battery) when power is off or the battery is removed from the monitor. During the battery backup

state, transistor Q2 keeps the CS1* control of the SRAM in the inactive state. This forces the

data bus to a high impedance state, isolating the SRAM from the rest of the system. True

nonvolatile storage for the bootstrap parameters for the CAPNOSTAT

®

CO2 sensor are stored

in a serial EEPROM (IC2) located on the Interface (2753) board.

Serial Communications

Refer to 2754-03 schematic sheet 6.

The on-chip (IC1) asynchronous serial communications interface (SCI) channel is contained in

the MC68332. The signals are level shifted to standard RS232 levels by IC26 which is a Dual

RS232 Communications Driver/Receiver. The transmitters in the RS232 level shifter are under

software control to minimize the patient leakage current to the rear panel connector (J101

when communication is not active. The signal COMMPWR controls the transmitters operation

and is derived from IC9 pin 14 (schematic sheet 2). The serial connection to external, nonpatient contact devices is electrically isolated from the patient through the CAPNOSTAT

sensor airway adapter. This connector, J101 is located on the rear panel and is designed to

interface with external devices (i.e. computer, printer) when placed in a base station which

contains the mating connector. In addition there is a 4 pin connector (J403) available for test

and service which offers an internal connection to the serial communications at a TTL level. The

data signals ASRxD and ASTxD are logic level signals and are diode protected against over

voltage by D22 and D23 should IC26 breakdown from ESD (schematic page 6). Refer to Table

5 for the pinout and signals of serial interface connector J101.

®

CO

2

Table 4: Power/Communications 6-pin modular connector J101 located on the rear panel.

Pin Number Signal Function

1 RxD Internal MC68332 UART Receive, RS232 Signal, Level

Shifted

2 TxD Internal MC68332 UART Transmit, RS232 Signal, Level

Shifted

3 DGND Digital Ground

4 DGND Digital Ground

5

6 +VCHG External DC input supply to power unit and battery charger

User Interface Control Circuitry

Refer to 2754-03 schematic sheet 2.

The user interface features a 64 row by 128 column Liquid Crystal Display (LCD) module with

an LED backlight. A 5-switch membrane keypanel is provided for operator entry. The use

interface also contains three LED’s which represent various system conditions.

Control of the user interface is provided by the LATCH1_CS* chip select signal together with

the Port F input signals from the microprocessor. SW1-SW4 are inputs which read in the

Model 615 Service Manual Rev. 00

12

Page 19

Theory of Operation

Section 3

present state of the membrane keys. Depressing a key causes the signal line to be pulled low

in contrast to its normally high state. IC9 provides a latched output for controlling the status

LED’s. The LCD backlight is a series of LED’s which are driven by a 5.12kHz clock signal in

order to lower the LCD backlight power requirement and is activated by the backlight

membrane key. The LITE_CLK signal is a 5.12kHz logic level signal generated by IC7 (sheet

7) which modulates the LED backlight through FET switch Q4 (BKLGHT_OUT) when asserted

by IC10 (BACKLIGHT). This signal is capacitively coupled by C42 in order to prevent the

backlight from remaining on in the event of a system failure.

Contrast control for the LCD is provided by DAC IC33 (sheet 6) and amplifier IC34A and

transistor Q18 (schematic sheet 6). When the CPU detects a press and hold of the backlight

membrane key, the CPU sends a digital ramp input to the DAC which causes the output to

change accordingly. Inverting amplifier IC34A controls the base current into transistor Q18,

which changes the level of the display contrast voltage, VDISP.

Refer to schematic sheet 6.

An audio frequency tone is generated by the TPU (Time Processor Unit) of the MC68332

(TONE). This signal is fed into the divider network consisting of R183 and IC32. IC32 is a 10k

2

ohm E

for attenuating the signal under CPU control. From the divider output the signal is amplified by

IC34B and Q17 which drives the system speaker (LS1) to produce system audio. The AUD_EN

line from IC9 controls Q19, when high the input to IC34B is grounded thus muting the audio.

potentiometer whose value (when written to under software control) provides a means

Real Time Clock, Power on RESET Generation and Glue Logic

Refer to 2754-03 schematic sheets 1 and 2.

Time-keeping for date and time stamping of patient trend information is provided by IC8. This

device contains a built-in crystal for precise time and date measurement. In the absence of

digital power, the time keeping function is maintained by the battery backed supply, VBACKUP

which is generated by the 3V lithium backup battery (BT1).

On power-up, the system is forced into a “Reset” state by IC4 (sheet 1). When the suppl

voltage VDD, approaches 1V, the SRST* line is asserted to prevent undefined operation. IC4

also provides supervision over the VDD logic supply. If the logic supply falls below 4.55V

±120mV then IC4 generates a reset condition until the supply returns to a safe level. Inverter

IC5 is used to generate the active high RESET signal.

The

Model 615

the glue logic required is a minimum. Chip selection for the serial peripherals is provided by

decoding the queued serial module (QSM) (PCS0-PCS3) of the microprocessor IC1 (sheet 1

on schematic) using decoder IC12 (sheet 2) while parallel interface peripherals are selected by

the internal chip select registers of Port C (BOOTCS* and CS0*:CS10*). Latch IC10 is used to

control the saturation analog signal processing, the LCD backlight, the sidestream sampling

pump, and to power the monitor off.

makes use of the high level of integration offered by the MC68332. Therefore

3.2 CO2 System Analog Subsections

CO2 Source Drive

Refer to 2754-03 schematic page 3 and Table 2 of this document.

The source drive circuitry is designed to drive the source with a bipolar signal to prevent the

migration of charges within the source that may result from unidirectional electrical fields. The

Rev. 00 Model 615 Service Manua

13

Page 20

Section 3

Theory of Operation

resistance of the source is monitored constantly to ensure the integrity of the system by

sampling the current through the source while it is active.

The SRCDRV0 and SRCDRV1 lines are used to control the bipolar signal that drives the

source. The SRCDRV0 signal goes high as soon as the CO2AZ (Auto Zero) line goes low and

the CO2PWENB (Pulse Width Enable) line goes high. The duration of SRCDRV0 is 405 us

(microseconds), and drives the source in the positive direction. The SRCDRV1 line drives the

source with an opposite polarity signal when high for the same duration. There is a 30 us delay

from the time the SRCDRV0 line goes low to when the SCRDRV1 line goes high. This delay is

to prevent the possibility of both SRCDRV0 and SRCDRV1 being active at the same time, thus

creating a low impedance path between the two supplies (power supply shoot-through).

SRCDRV1 steers current through the source in an opposite direction from SRCDRV0.

When SRCDRV0 and CO2INH (Inhibit) are high, the output of MOSFET Driver IC13A pin 7 will

go low. This turns the P-Channel half of MOSFET Q5 on. At the same time, the output of

MOSFET Driver IC14B pin 6 will be high biasing on the N-Channel half of MOSFET Q6 on. With

both Q5B P-Channel and Q6A N-Channel on, current will flow from +VSRC through Q5B to the

positive source terminal, then back from the source negative terminal through Q6A, through

R97 to -VSRC. When SRCDRV0 returns low, both Q5B and Q6A are turned off and no current

flows through the source. After the 30 us delay, SRCDRV1 will go high. The output of IC14A pin

8 will go high, biasing the N-Channel section of MOSFET Q5 on. The output of IC13B pin 5 will

go low, turning the P-Channel of Q6 on. Current will now flow from +VSRC through Q6B to the

source negative terminal, back from the source positive terminal through Q5A and R97 to VSRC. Current will cease to flow when SRCDRV1 goes low. The bridge circuit of Q5 and Q6 in

effect switches the polarity of the drive signal of the source between +VSRC and -VSRC.

CO2PWENB also falls with the falling edge of SCRDRV1, signaling the end of source activity.

When current flows through the source, it will also flow through current sensing resistor R97,

creating a differential voltage proportional to the source current:

V

= (VSR / RSR) * RS * A

SRC

V

=voltage out of difference amplifier proportional to current

SRC

V(DA)

where:

through the source element = 24V +/- 0.625V

V

=differential voltage across the source element

SR

R

=resistance of the source element

SR

=resistance of the current sensing resistor = 1 ohm

R

S

=difference amplifier gain = 5

A

V(DA)

V

=[120 (Volts*Ohms) / SR]

SRC

The voltage signal out of difference amplifier IC15B is level shifted through C52 and fed to the

sample and hold IC16A via buffer amplifier IC15A. A low level on the CS*/H (Current Sample

and Hold) signal allows the source current signal to be sampled. On the rising edge of CS*/H,

the present voltage level of the source current signal is held and appears at the input to channel

A2 of the Analog to Digital Converter IC6 (sheet 2 on schematic) for processing by the MPU.

When CO2AZ is high, the input to the sample and hold of IC16A is grounded to discharge any

residual charge that may be on C52.

In order to prevent the source from being driven until the system is up and ready, there i

protection circuitry that inhibits the source drive until enabled. During system power-up, the

RESET line keeps Q7 on. This causes the CO2INH line to be brought low, preventing source

pulses by pulling down SRCDRV0 and SCRDRV1 through D6. Protection circuitry also guards

against extended pulse width as well as shortened duty cycle. On the rising edge of

CO2PWENB, the trip point of IC17B is exceeded, allowing C55 to charge through R100. If the

Model 615 Service Manual Rev. 00

14

Page 21

Theory of Operation

CAPNOSTAT® CO2 sensor Case and Detector Heater Control

Section 3

SRCDRV signals do not turn the Source Pulse off within 200 us after the 830 us pulse period,

the trip point for IC17A will be exceeded, pulling the CO2INH line low turning the Pulse off.

After the CO2PWENB signal returns low, capacitor C57 discharges through R101, keeping the

output of comparator IC17B at the voltage acquired by C55. After approximately 10.4 ms, C57

will have discharged below the comparator trip point. The comparator output goes low,

discharging C55 and the circuit is ready for the next source pulse cycle.

Refer to 2754-03 schematic sheet 4.

The temperature of the system directly affects its ability to accurately measure CO

therefore must be precisely maintained at a controlled value. Two separate heaters and control

circuitry are used; one regulates the temperature of the detectors for the CO

reference channels; the other regulates the temperature of the transducer case (and loosely

maintains the temperature of the airway adapter). While the purpose of the detector heater is

to keep the detectors' sensitivity to infrared radiation constant, the function of the case heater

is to keep condensation from forming on the airway windows by elevating the window

temperature above the ambient airway temperature. Both heaters use an efficient pulse-width

modulation scheme designed to decrease power consumption, with the PWM timing generated

by the TPU under microprocessor control. This control loop is run by the CPU which does the

calculations and passes the duty cycle to the TPU. For the purpose of describing the regulation

loop, the case heater circuitry will be considered. The detector and case heater circuitry are

identical.

Inside the CAPNOSTAT

module. Initially, the CAPNOSTAT

®

CO2 sensor, a sensing thermistor is thermally connected to the heater

®

CO2 sensor is at the ambient temperature and the

resistance of the thermistor is large. A small current flows through the signal path

“CASETHERM” and only a small voltage is developed across R117. The microprocessor

programs the TPU to allow a maximum duty cycle of 90% to power the PWM heater circuitry.

This causes the heater control MOSFET Q9B to be pulsed on and off with a duty cycle that is

under direct control of the program software. As the heater warms up the case, the thermistor's

resistance decreases, raising the voltage appearing at the input of the control loop. As

described below, the MPU looks at this voltage and decreases the duty cycle of the PWM

control circuitry, gradually reducing the power output into the heater. When the desired

temperature set point is reached, a balance is struck between the energy delivered to the

system and the heat flow out of the system.

The case thermistor is sensed by amplifier IC18A pin 3. The difference between the signal at

the non-inverting input and the reference appearing at the inverting terminal generates an error

voltage proportional to the sensed temperature at the amplifier's output:

and

2

data and

2

e

(V) = [83.133V / (Rth+3.32K)] - 10.2V where:

o

= amplifier output voltage

e

o

R

= resistance of the thermistor = 4.36933K at 45°C

th

°

Te m p (

where e

C) = 4.1288 (°C/V) * e

= amplifier output voltage at temperature T

o

V + 41.7321°C

o (T)

This error voltage is low pass filtered by amplifier IC20A, sent to the ADC (IC6) and processed

by the CPU to regulate the output pulses from the TPU. The TPU PWM signal is buffered by

MOSFET Driver IC19A and capacitively coupled to the gate of the heater drive MOSFET, Q9B.

Capacitive coupling the signal prevents a system fault that would allow the PWM to be stuck at

a level that would cause too high of a heater output. In the absence of a pulse, the gate drive

Rev. 00 Model 615 Service Manua

15

Page 22

Section 3

Theory of Operation

will be pulled high, disabling the output to the heater. The pulsed voltage signal out of the

MOSFET is filtered by D12, L6, C68 and C69 to produce a DC output level for the heater. Since

the TPU generated PWM signal is based on the system clock, it is synchronized with the

generation of the source pulse timing. This minimizes the effect of any random disturbance

caused by the heater circuit on the detection of the CO

data and reference signals.

2

The error voltage out of amplifier IC18A also appears at the temperature watchdog comparator

IC17C. If the error voltage reaches a voltage equivalent to 56 degrees Celsius, the comparator

trips, turning Q10 off. The gate of MOSFET Q9A is pulled high by R116, which turns it off and

VHTR is prevented from reaching the source of transistor Q9B. The temperature of the sensor

is also monitored by the MPU which will disable the heater when a temperature of 50 degrees

Celsius is exceeded. To shut off the heater, the MPU asserts the CASEOT signal, turning Q11

on which turns Q10 and Q9A off.

CO2 Input Signal Path

Refer to 2754-03 schematic sheet 5.

The signals from the sensor “CO2DATAIN” (CO

have similar signal paths. The CO2DATAIN passes through a high pass filter with a gain of 3.8

consisting of C80, R148 and buffer amplifier IC21B. The signal is fed to a Butterworth low pass

filter IC21A and associated components. This filter has a gain of 2 with a corner frequency of

1.5 KHz. The output from the low pass filter is fed to a 12-bit digital to analog converter IC22.

The signal, “CO2DIN” comes into the reference of the DAC, which acts as a programmable gain

stage followed internally by an amplifier with a fixed gain of 2. Here under processor control the

signal's gain is adjusted to an acceptable level for conversion. The gain setting is adjusted using

the digitized signal out of the A/D Converter (IC6) as part of the feedback loop. Similarly,

“CO2REFIN” is conditioned by high pass filter IC21D with a gain of 1.75 and low pass filter

IC21C with a gain of 2. The equivalent fixed gains for the two input signals are not equal in order

to compensate for differences in the output signal levels of the infra-red detectors in the sensor.

The output from IC22 is buffered by IC24A and AC coupled through C91 to IC23A. The

“CO2DATAIN” signal received from the sensor is ac coupled prior to the initial gain stage and

high pass filtered to remove any DC bias by C80. Prior to sampling CO

(Auto Zero) pulse biases Q15 on, causing any residual charge on C91 to discharge to ground.

At the start of the source pulse, the “CO2AZ” pulse goes low and the CO

is attained, and appears at the input of the sample and hold amplifier, IC16B. Near the end of

the source pulse, the “SS*/H” (Signal Sample and Hold) goes low and the peak signal is

acquired on the internal sample and hold capacitor. “SS*/H” returns high at the end of the cycle,

and the CO

signal on the sample capacitor is held at the peak value. The signal then passes

2

through a low pass filter of R159 and C92 before being converted by the ADC into digital data

and analyzed by the processor. The signal “CO2REFIN” follows an identical zeroing and

acquisition path.

Data) and “CO2REFIN” (reference signal)

2

signal, the “CO2AZ”

2

signal from the sensor

2

CAPNOSTAT

®

CO2 sensor

Interface

Refer to schematics 2754-03 sheet 5 and 2753-03 sheet 1.

®

Twenty pins of 60 pin connector J404 interface the CAPNOSTAT

CO2 sensor with the system

electronics. Ferrite and L-C filters have been placed on selected lines to suppress radiated EMI

and reduce susceptibility from external sources of interference.

Barometric Pressure Circuitry

Refer to 2754-03 schematic sheet 6.

Model 615 Service Manual Rev. 00

16

Page 23

Theory of Operation

Sampling Pump

Section 3

IC28 is a piezoresistive differential pressure transducer with port P2 held as close to 0 psi (a

perfect vacuum) as is possible. It measures the absolute pressure difference at port P1 relative

to the vacuum at port P2. The transducer is calibrated for a full scale output of 0 to 15 psi, has

internal temperature compensation and is designed to be driven by a constant voltage source.

Instrumentation amplifier IC30 conditions this signal to correspond to the current barometric

pressure, which is set by adjusting VR1. The nominal gain of this amplifier is 93.56, which

corresponds to an ADC count of 3800 at 760 mmHg. The output signal from IC30 is low pass

filtered by IC29A and appears as an input (ABPRESS) to the 12-bit ADC.

Refer to 2754-03 schematic sheet 2.

To enable the monitoring of non-intubated patients, a single tapered sampling port is provided

on the sensor interface panel. Voltage regulator IC49 adjusts the pump motor speed to set the

flow rate of air through the tubing system for 180ml/min. Resistor’s R275 and R277 set the

voltage to approximately 2.5V. VR2 is a potentiometer in parallel with R277, which can be

installed if more accuracy is required for a flow rate adjustment. Pump motor current is sensed

by measuring the voltage developed across resistor R278 using amplifier IC50 that provides a

gain of 63. This provides an output of 8mA per 1/2 Volt {

ADC, or approximately 2.5 uA per bit resolution {Vref

31 Hz filter composed of IC29B provides high frequency attenuation. The VPUMP signal is

digitally converted by IC6 and monitored by the processor.

= (I

o

/ (212*Gain)}* {4mA/V}. A two-pole

(ADC)

*R) / Gain} into the 12-bit

pump

Digital and Analog Control Lines

Refer to 2754-03 schematic sheet 2.

IC10 is enabled by the LATCH2_CS* line from the processor, the D8-D15 data lines then control

the following signals:

SPO2CAL Not used

SPO2SC1 Not used

SPO2LPON Not used

INSIG Not used

SIGND Not used

BACKLIGHT Used with LITE_CLK for display’s backlight control

POWER_ON Powers the monitor down (active low)

PUMP_CTRL Controls sampling pump

Analog signals in the system are converted to digital values by IC6 then analyzed by the

processor

CO2DATA CO2 data channel

CO2REF CO2 reference channel

CO2ISRC Current through CO2 sensor’s source

CO2CASE CO2 sensor case temperature

CO2DET CO2 sensor detector temperature

ABPRESS Barometric pressure

SPO2FEDC Not used

Rev. 00 Model 615 Service Manua

17

Page 24

Section 3

Theory of Operation

SPO2IRLED Not used

SPO2IRLED Not used

VPUMP Monitors current through the sampling pump

VBATTADC Battery voltage level

3.3 Power Supply and Battery Charger

Supply and Reference Voltage Generation

Refer to 2754-03 schematic sheet 8.

The monitor operates from either an isolated external DC power supply or from the internal

battery. There are two options presently for the internal battery, a Nickel Metal Hydride battery

pack (NiMH), or a Disposable AA Lithium cell pack. The NiMH battery pack operates from a

nominal voltage of 7.2V down to 6.0V while the AA Lithium pack operates from 10.5V down to

6.0V. This battery voltage range is monitored in hardware by the 12-bit ADC for level and

comparator IC37A in order to shut the unit down at approx. 6.0V. The NiMH battery can be

charged either externally via a separate charger or internally when the DC input is connected

and a NiMH battery is installed. The internal battery charging circuitry is located on the 275301 assembly and is described in a later section of this document. The Lithium battery pack has

a schottkey diode in series with the positive battery terminal to prevent accidental charging of

the Lithium cells.

The core of the power supply design for the system is a 500 KHz switching regulator, IC36, that

utilizes a flyback transformer configuration to generate the analog DC supply voltages. The

primary of the transformer is designed to accept 6.0 to 13 V DC input and provides secondary

outputs of nominally +13.75VDC, and -13.75VDC which are regulated by R204 and R210 off of

the +VA supply. These supplies (±VA) feed all of the analog circuitry in the monitor. All supplies

are L-C filtered to minimize noise in the analog front end. An additional switching regulato

(IC41) generates the 5VDC supply (VDD) which feeds all the logic circuitry in addition to a

filtered version (CVDD) which supplies the logic level requirements of the CO

data converters e.t.c.). The 5V supply is L-C filtered to provide clean logic supplies for the

analog sections of the CO

clean, well regulated supplies (±CVA) for the CAPNOSTAT

designed as a tracking regulator pair to provide a 24VDC differential voltage for powering the

CAPNOSTAT

®

CO2 sensor source (+VSRC, -VSRC). Power for the CAPNOSTAT® CO2 sensor

(CVDD) system. IC35 and IC40 are linear regulators which provide

2

®

CO2 sensor. IC38 and IC39 are

heaters is supplied by VDCIN for maximum efficiency.

signal path (i.e.

2

Model 615 Service Manual Rev. 00

18

Page 25

Theory of Operation

Section 3

Refer to Table 6 for power supply breakdown.

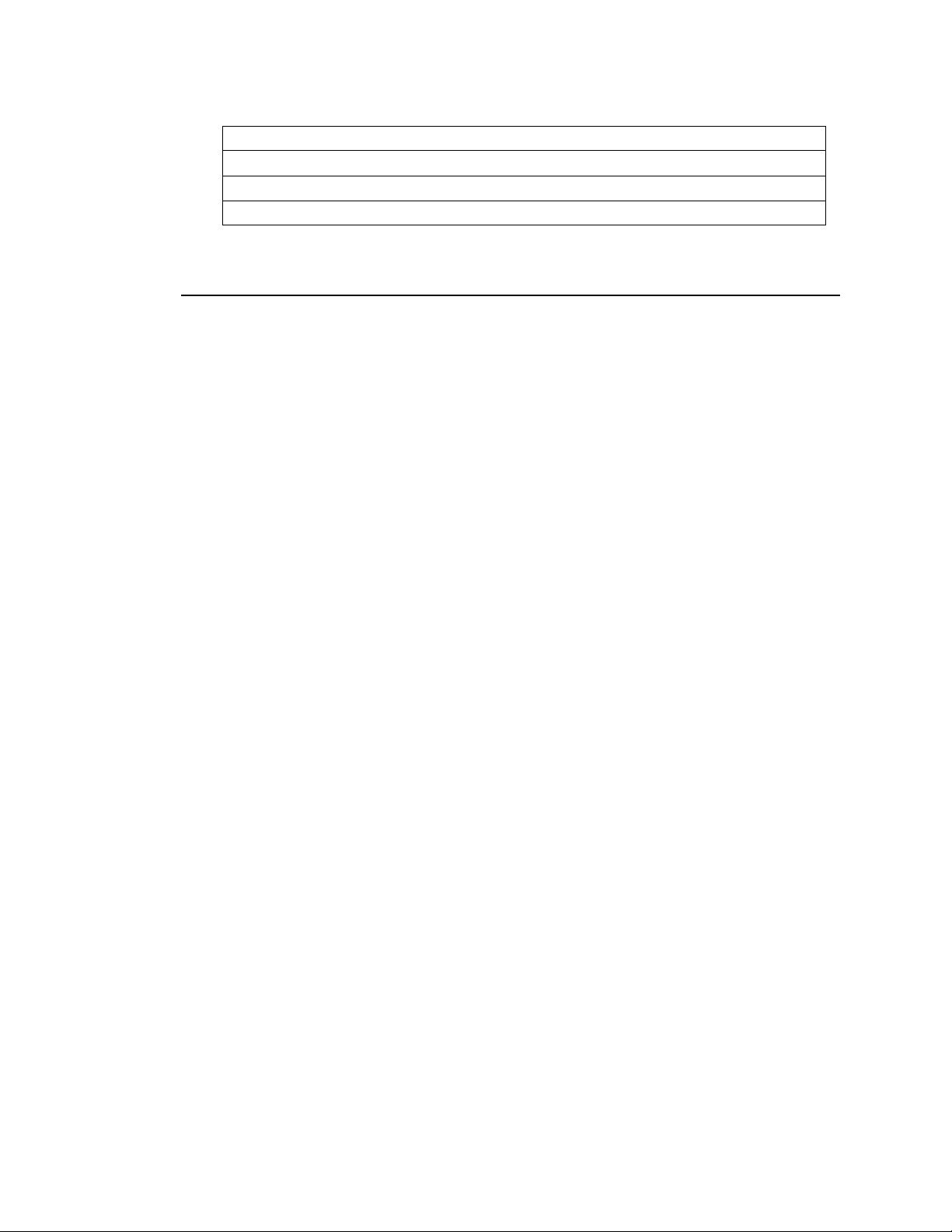

Table 5: Power Supply and Reference Outputs

Signal Supply Description

VDCIN +6.0 V to +13 VDC Main DC input generated from external DC input or inter-

nal battery.

VBATT +6.0 V to +10.2

VDC

VBACKUP +2.5 VDC or +5

VDC

VHTR VDCIN

Internal battery DC input, max level dependent on battery

installed.

Supply for SRAM and real time clock, either VDD or 2.5V

to maintain SRAM data during power down.

Supply for the CAPNOSTAT

®

CO2 sensor case and

detector heaters, supplied by battery or external DC input.

When powered by battery heater power follows input

power.

VDD +5 VDC Regulated digital logic supply .

CVDD +5 VDC Regulated and filtered logic supply for CO

analog front

2

end.

+VA +13.75 VDC (nomi-

Tightly regulated +13.75V DC supply.

nal)

+CVA +12 VDC Linearly regulated and filtered positive supply for the

CAPNOSTAT

®

CO2 sensor and CO2 front ends.

+VSRC +12 VDC Linearly regulated and filtered positive supply for the

®

CAPNOSTAT

CO2 sensor source. Tracks -VSRC to pro-

vide a 24V +/- 2.5% differential voltage across the source.

-VSRC -12 VDC Linearly regulated and filtered negative supply for the

CAPNOSTAT

®

CO2 sensor source. Tracked by +VSRC to

provide a 24V +/- 2.5% differential voltage across the

source.

-VA -13.75 VDC (nomi-

Loosely regulated off of the +13.75VDC feedback line.

nal)

- CVA -12 VDC Linearly regulated and filtered negative supply for the

®

CAPNOSTAT

CO2 sensor and CO2 front ends.

CVREF +2.5 VDC Buffered reference for the A/D converter.

2CVREF +5.0 VDC

Buffered reference used in the CAPNOSTAT

®

CO2 sen-

sor heater control circuitry.

-2CVREF -5.0 VDC Buffered reference used for the contrast control circuitry.

VREFO/2 +1.25 VDC Buffered reference used for DC excitation for the baro-

metric pressure sensor

Rev. 00 Model 615 Service Manua

19

Page 26

Section 3

Theory of Operation

Table 5: Power Supply and Reference Outputs

SPO2VLED 0 to 2.5 VDC Not used

VDISP -6.5 to -11.5 VDC Negative bias supply for the LCD used to adjust the con-

trast level.

Refer to 2754-03 schematic sheet 6.

Stable reference voltages for the sensors and analog circuitry are derived from IC25, a

precision 2.5V reference generator with low drift. Five (2CVREF) and 2.5 Volt (CVREF)

references for the CO

circuits are generated by IC27, while a separate –5.0 Volt (-2CVREF)

2

supply is generated directly from IC31A for –VA and -VD on the 20 bit ADC’s for the saturation

front end.

Refer to 2753-03 schematic

When the monitor is operated from the DC input power source the green AC ON indicator on

the front panel is lit. If DC input power is lost or is not available, the monitor automaticall

operates from its internal battery without interruption. The AC ON indicator is extinguished and

a BATTERY LED on the front panel lights up, indicating the current voltage level of the battery.

While on internal DC power, the current state of the battery is monitored by both software and

hardware (IC37 2754-03 schematic sheet 8). Should the battery power level get critically low,

the monitor software alerts the user. If the monitor is not placed on external DC input power

within approximately five minutes, the software will shut the unit off. Should the software fail to

turn the monitor off when the low battery alarm sounds, the hardware cutoff (IC37A) activates

(+VBATT=6.0V), turning the unit off. The trend memory data stored in SRAM is retained by the

presence of VBACKUP power which is generated by a 3 Volt on-board Lithium battery.

Battery Charger Circuitry

Refer to 2753-03 schematic sheet 1.

The internal NiMH battery (7.2V, 3Ahr) will charge when the monitor is connected to the external

DC power supply (9220-10) or installed in the Base Station option (PN. 6998-00) with the

external adapter connected to the Base Station.

Battery charging is controlled by IC1, a frequency modulated fast charge controller. IC1

monitors temperature, voltage, and time throughout the charging process to safely and

effectively charge the internal battery. The charger is configured to terminate charging using the

(delta temperature/delta time) method of charge termination. Charging is maintained at the C/

4 (750mA) rate while current to the battery is controlled by Q1, Q2, Q3, and the “MOD” output

of IC1. Q3 provides base drive for Q1 while Q2 serves to shut Q1 off very quickly on a cycle by

cycle basis, allowing the large currents required for charging to pass through Q1 which is a

surface mount SOT-23 package PNP transistor capable of 500mW’s of power dissipation.

Charge current is monitored at the SNS input (IC1/9) and is set by R13 (I

2*R

). Temperature is monitored using the battery’s internal thermistor, in conjunction with

SNS

R9, R10, and R12. R9, R10, and R12 set the deltaT/dt charge termination parameter to 1°C per

minute. R7 and R8 set the maximum temperature for charge termination (a safety override) to

45°C.

Battery charging is initiated in one of two ways: either by applying 13.0 VDC to +VCHG,

therefore providing VCC (BVDD) to IC1; or by inserting a rechargeable battery into the battery

compartment. Resistors R2 and R4 form a divider which sets the battery voltage window. If a

battery with a voltage below the lower threshold (V

, end discharge voltage, V

EDV

0.4*BVDD +/- 30mV or, 2.04V, +VBATT = 5.26V) is installed, the charger will remain in

maintenance mode until the threshold is reached. Conversely, if the battery exceeds the upper

= 0.2225V/

REG

EDV

=

Model 615 Service Manual Rev. 00

20

Page 27

Theory of Operation

Section 3

threshold for maximum cell voltage (V

, maximum cell voltage, V

MCV

= 0.8*BVDD +/- 30mV

MCV

or, 4.08V, +VBATT = 10.5V), charging will terminate. After fast charge is terminated, either by

deltaT/dt or by time-out, the charger switches over to a maintenance charge of C/64 to keep the

battery topped off. BVDD (VCC for IC1 and D4, the AC on indicator) is regulated by D10, a 5.1V

zener diode, while R3 keeps D10 operating in the knee region and C5 and C6 provide filtering.

Over-current protection is provided by F1, a 1A slo-blo replaceable fuse. Reverse leakage

protection is provided by D5 and D6 which prevent the battery from trying to power BVDD and

+VCHG in the battery operation state.

Rev. 00 Model 615 Service Manua

21

Page 28

Section 3

Theory of Operation

[This page intentionally blank.]

Model 615 Service Manual Rev. 00

22

Page 29

Section 4

The Functional Test verifies overall functional integrity of the monitor and sensor. If the Model

615 monitor does not pass these tests, remove from use and contact the Novametrix Service

Department for repair/replacement assistance.

Functional Tests

4.1 Equipment Required

1. Single Patient Use Adult Airway Adapter PN: 6063-01

2. Single Patient Use Neonatal Airway Adapter PN: 6312-01

3. NiMH rechargeable battery pack PN:400043 or equivalent,

(batteries (7) “AA” 1.5V PN: 400050 and case PN: 6862-01, if supplied)

4. External DC power supply PN: 9220-10 and hospital grade line cord PN: 600026

5. Single Patient Use Sampling Adapter PN: 8954-01

6. Sample line tubing and cannula

4.2 Procedure

Power up

1. Visually inspect the monitor and verify that there is no external damage.

2. Open hinged cover and install the NiMH rechargeable battery pack (fully charged)

PN: 400043 into the unit.

3. Connect the external DC power supply PN: 9220-10 to an AC outlet using a hospital

grade line cord, then plug the other end into the unit under test.

4. Verify the LED on the keypanel illuminates.

5. Power the unit up by pressing the POWER key on the keypanel. The monitor will

display “Novametrix Medical Systems Inc. Model 615 Checking System” then the

adapter mode that was last selected and the current setting for the alert limits

(enabled or disabled). The keypanel LEDs will illuminate in sequence during the

power up sequence.

6. Verify the monitor displays “CAPNO WARMING” then “CHECK ADAPTER” at the top

of the display.

Rev. 00 Model 615 Service Manua

23

Page 30

Section 4

Functional Tests

7. Press both and keys simultaneously to display the configuration settings.

Before changing any parameter record the current settings so that the unit may be

returned to its’ original configuration. Use the PAGE and SELECT keys to set

the following parameters (these are also the factory default settings):

GAS COMPENSATION ROOM AIR

CO2 WAVEFORM SCALE MEDIUM

CO2 WAVEFORM SPEED MEDIUM

NO RESP TIMER 20 sec.

CO2 UNITS mmHg

ALERT VOLUME HIGH

RS232 INTERFACE NOVACOMM

WAVEFORM FILL UNFILLED

ETCO

AVERAGING 10 SEC

2

ALERT LIMITS DISABLED

RESP TREND SCALE MEDIUM

AUTO POWER OFF ENABLED

When all the parameters are set press the ADAPTER key to exit.

Capnography Tests

8. Press the ADAPTER key and use the SELECT key to select ADULT, then

press EXIT

9. Connect a Single Pateint Use Adult Airway Adapter PN: 6063-01 to the

CAPNOSTAT

10. Press the PAGE key to display the CO

11. Breathe into the airway adapter at a normal breath rate for at least 30 seconds, verify

both the readings and the waveform displayed on the unit are acceptable.

®

CO2 sensor. (Perform adapter zero only if requested by the monitor).

Waveform Screen.

2

Sample Waveform*

*(Waveform appearance will vary depending

upon breath rate and CO

Model 615 Service Manual Rev. 00

24

waveform speed.)

2

Page 31

Functional Tests

Section 4

12. Stop breathing into the adapter and verify an alert condition after approximately 20

seconds (alert LED flashing red and an audio alert). Press the ALERT key and

verify the alert tone silences. Verify a 2 minute audio silence is initiated and the LED

on this key is flashing red then yellow.

13. Press the PAGE key until the ETCO

Trend Screen is displayed, verify a trend

2

waveform is present (waveform starts from right).

14. Press the ALERT key.

15. Change the airway adapter on the CAPNOSTAT

®

CO2 sensor from the adult to the

neonatal.

16. Verify that “CHECK ADAPTER” is displayed.

17. Press the ADAPTER key and use the SELECT key to select NEONATAL,

press EXIT . Verify the unit is in the Neonatal Mode as indicated by the “NEO” on

the screen. (Perform adapter zero only if requested by the monitor).

Sidestream Tests

18. Connect a Single Patient Use Sampling Adapter to the CAPNOSTAT CO2 sensor.

CAPNOSTAT CO

connect cannula to here

sensor

2

sampling adapter

19. Press the ADAPTER key then use the SELECT key to select SAMPLING,

press EXIT . Verify the sampling pump turns on.

20. With all sources of CO

removed from the adapter and tubing, press and hold the

2

ADAPTER key for 4 seconds, then use the ZERO key to zero the adapter.

21. When the zero is complete, remove the Single Patient Use Sampling Adapter and

verify the pump turns off. Attach a Single Patient Use Adult Adapter.

22. Press the ADAPTER key and use the SELECT key to select ADULT, then

press EXIT

Miscellaneous Tests

23. Press the Backlight key and verify that the back light turns off. Press the backlight

key again and verify the back light turns on.

24. Press and hold the Backlight key and verify that the display contrast is adjustable

from light to dark. Set the contrast of the display to a viewable level.

25. Remove the external DC power supply from the unit and verify that the AC ON

LED is off and the Battery LED is illuminated (green).

Rev. 00 Model 615 Service Manua

25

Page 32

Section 4

Functional Tests

26. Power the unit down then power it back up again. Ensure the monitor functions

properly on battery operation.

27. Power the unit down and remove the rechargeable battery pack from the unit.

NOTE: The following steps do not apply if the monitor does not have an “AA” battery

pack.

28. Install (7) seven “AA” batteries into the battery case PN:6862-01 ensuring proper polarity.

29. Install the battery case into the unit, power up the unit and ensure it functions properly

on battery power.

30. Turn the unit off by pressing the Power key. Remove the battery pack from the

unit. Remove the “AA” batteries from the battery case.

Model 615 Service Manual Rev. 00

26

Page 33

Accuracy Tests

Section 5

Section 5

The Accuracy Test verifies the performance accuracy of the Model 615. This test is typically

performed in conjunction with (after) the Functional Tests described on page 23. If the monitor

does not pass the accuracy test, remove from use and contact the Novametrix Service

Department for repair/replacement assistance.

This procedure assumes the technician performs each step as indicated—leaving the monitor

in a known state prior to performing the next step. If steps are omitted or performed out of order,

be sure that the monitor is set to the correct state before continuing.

Accuracy Tests

5.1 Equipment Required

1. Single Patient Use Adult Airway Adapter, PN: 6063-01, Qty 3

2. NiMH rechargeable battery pack (fully charged), PN: 400043 or equivalent.

3. External power supply, PN: 9220-10 and hospital grade line cord PN: 600026

4. Model 1298 Gas Regulator, PN: 6081-00

5. Precision gas mixture, PN: 8364-10

6. Nova Princo Barometer or equivalent

7. Thermometer (measure ambient room temperature)

5.2 Procedure

1. Visually inspect the monitor and verify that there are no cosmetic defects.

2. Install a fully charged MiMH rechargeable battery pack (PN: 400043) into the unit

under test.

3. Plug the external power supply (PN: 9220-10) into an AC outlet, then plug the other

end into the unit’s DC input.

4. Hold the and keys down, press the POWER key to turn the monitor on

and reset to factory defaults.

5. The monitor will display "Resseting Monitor to Factory Defaults", then “Novametrix

Medical Systems Inc. Model 615 Checking System” then the adapter mode and the

current setting for the alert limits (enabled or disabled). The keypanel LEDs will

illuminate in sequence during the power up sequence.

Rev. 00 Model 615 Service Manua

27

Page 34

Section 5

6. Calculate the nominal CO2 readings using the following equation:

(Pbaro)

2

%)

·

(CO

N=

1-0.003

(33-T)

·

Where:

Pbaro=barometric pressure in mmHg

T=temperature in degrees centigrade

N=the nominal corrected CO

CO

%=percentage of CO2 test gas used, e.g. 5% CO2 test gas = .05

2

value for the given CO2%

2

Example:

If T=23 and Pbaro=760

then

N=((CO

N=CO

N=39.2 (for CO

%) · 760) / 1-0.003 · 10)

2

% · 783.505

2

%=.05 or 5% test gas)

2

For N<40; Low=N-2, High=N+2

For 40<N<70; Low=0.95

For N>70; Low=0.92

%=5 N=39.2 Low=37.2 High=41.2

CO

2

N, High=1.05 · N

·

N, High=1.08 · N

·

Accuracy Tests

7. Connect a Single Patient Use Adult Airway Adapter (PN: 6063-01) to the

CAPNOSTAT

®

CO2 sensor.

8. Press and hold the key until ">0< ?" appears on the screen. Ensure that the

sensor and adapter are clear of any source of CO

, including your breath. Press the

2

ZERO key. Verify the adapter zeros then returns to the normal operating screen.

NOTE: The CAPNOSTAT® CO

sensor mush reach operating temperature before

2

zeroing. If the thermometer icon appears then the sensor has not reached proper

temperature, wait one minute then attempt to zero again.

9. Connect the Model 1298 Gas Calibrator with 5% CO

gas and airway adapter stack

2

to the airway adapter (see instructions with the calibrator).

10. Enter the Configuration menus on the unit by pressing both the ADAPTER key

and key simultaneously.

11. Press the key until CAPNOSTAT SERIAL # and VERIFY ACCURACY appears.

12. Press the VERIFY ACCURACY key. Check that the value is 0.4 +0.5/-0.4 (no gas

flowing through adapters).

13. Flow gas through the adapter for thirty seconds, record the reading. Verify the

reading is between the Low and High limits for the CO

% of 5 (5% CO2 gas) a

2

calculated in step 6.

14. Shut the gas flow off. Remove the Model 1298 Gas Calibrator from the airway

adapter.

15. Press the EXIT key.

16. Enter the Configuration menus on the unit by pressing both the ADAPTER key

and key simultaneously.

Model 615 Service Manual Rev. 00

28

Page 35

Accuracy Tests

Section 5

17. Press the key until CAPNOSTAT SERIAL # and VERIFY ACCURACY appears.

18. Press and hold the key for three seconds. Verify the following displayed

parameters:

From Model 615 display units (not displayed)

SRCI 180-300 mA

CTMP 45.00 ± 0.1 °C

DTMP 45.00 ± 0.1 °C

DCHN 3400 ± 200 A/D counts

RCHN 3400 ± 200 A/D counts

19. Pressing the EXIT key.

20. Remove the external power supply from the unit and verify that unit continues to

function properly without interruption and that the Battery LED is illuminated (green).

21. Power the unit down by pressing the key.

22. Remove the rechargeable battery pack from the unit.

23. The Accuracy Tests are complete.

Rev. 00 Model 615 Service Manua

29

Page 36

Section 5

Accuracy Tests

[This page intentionally blank.]

Model 615 Service Manual Rev. 00

30

Page 37

Section 6

The Electronic Tests verify the calibration and operation of the electronic circuits within the

Model 615. These tests DO NOT need to be performed on a regular (preventative) basis.

Perform these tests only if the monitor fails to operate as expected or fails the Accuracy Tests

or the Functional Tests. The Electronic Tests should be performed only by qualified personnel.

The Electronic Tests require access to the internal components of the monitor. Refer to page

44 for disassembly.

!

The Model 615 contains static sensitive devices. Be sure to follow proper grounding

procedures when handling the internal components to avoid damage from static discharge.

CAUTION

Electronic Tests

6.1 Equipment Required

1. External power supply, PN: 9220-10 and hospital grade line cord PN: 600026

2. Single Patient Use Sampling Adapter PN: 8954-01

3. Sample line tubing and cannula (to be modified) PN: 8957-01

4. Dehumidification tubing PN: 8908-01

5. Mass Flow Meter, Aalborg GFM17* or equivalent

1/8" Y - fitting

1/8" ID PVC tubing (1 1/2" length)

3/32" ID PVC tubing (2 - 1" lengths)

6. Nova Princo Barometer* or equivalent

7. D.M.M., Fluke Model 8840A* or equivalent

8. Oscilloscope, Tektronix Model 2236* or equivalent

9. Leakage Tester*

* Calibrated

6.2 Test Procedure

1. Remove the battery (trends, date and time will be lost).

2. Disassemble unit to expose circuit boards.

3. Situate the boards so that no shorting can occur. Connect the external DC power

supply.

Rev. 00 Model 615 Service Manua

31

Page 38

Section 6

Electronic Tests

4. Press the POWER key to power up the main board. Verify the proper power up

sequence is on the LCD display.

5. Measure the following voltages. Use TP 37 as ground reference.

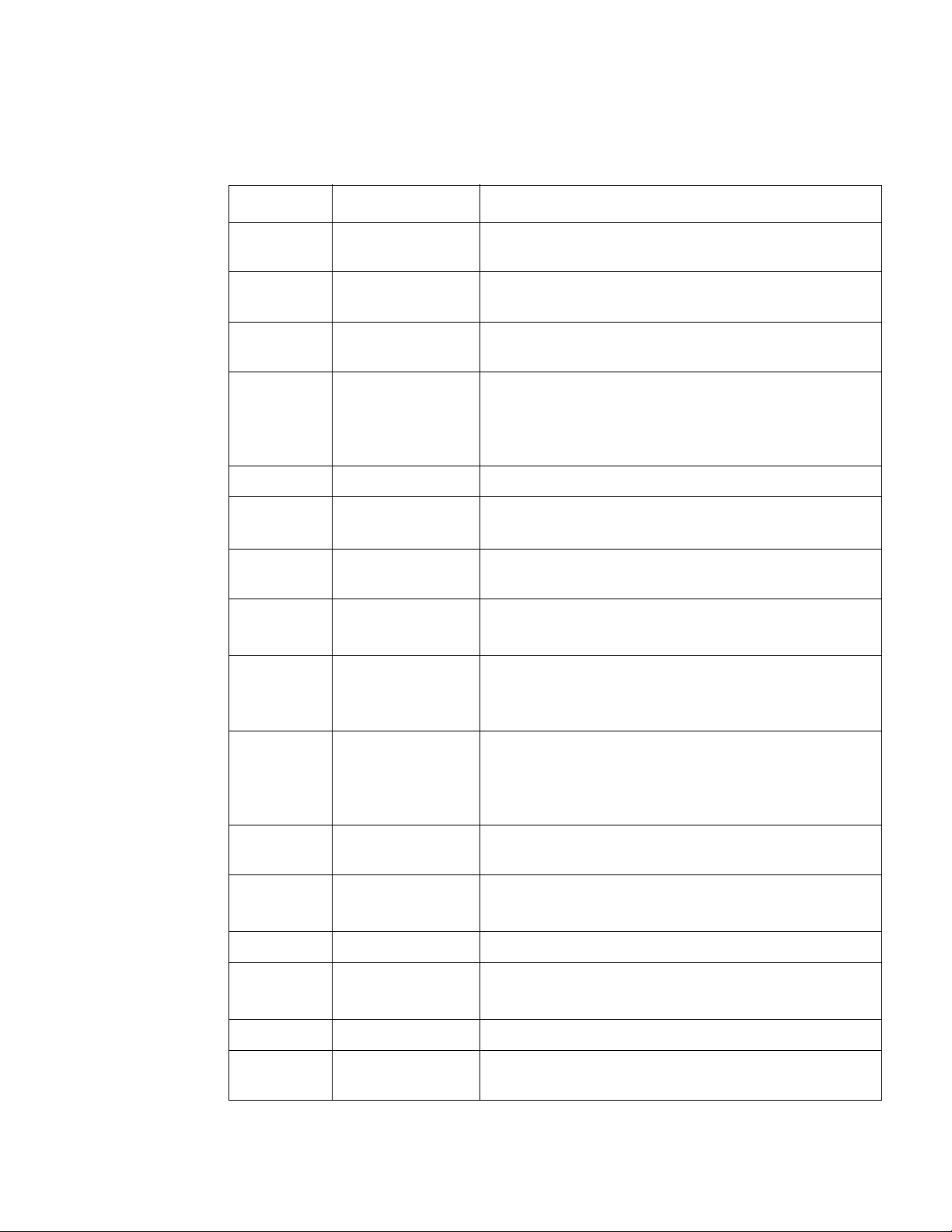

Signal Name Location Side Voltage Tolera nce

VDD TP 43 Front 5.00 V ± 100 mV

+ VA TP 31 Front + 13.75 V ± 500 mV

- VA TP 40 Front - 13.75 V ± 500 mV

+ CVA IC 35 pin 2 Front + 12.00 V ± 500 mV

- CVA IC 40 pin 3 Front - 12.00 V ± 500 mV

+ VSRC IC 38 pin 2 Front + 12.00 V ± 500 mV

- VSRC IC 39 pin 3 Front - 12.00 V ± 500 mV

VBATTADC IC 37 pin 3 Front + 1.80 V ± 100 mV

VHTR C148 Positive Front + 8.00 V ± 1.00 V

CVREF TP 24 Back + 2.50 V ± 25 mV

2CVREF TP 23 Back + 5.00 V ± 50 mV

- 2CVREF TP 26 Back - 5.00 V ± 50 mV

VBACKUP IC 8 pin 8 Front + 4.60 V ± 150 mV

LEDSRC TP 45 Back + 11.50 V ± 1.00 V

6. Monitor pin 4 of IC36 (or pin 5 of IC41) and insure that a 655 kHz sync frequency is

present. Check that pulse amplitude is switching between 0 and 5VDC.

7. Monitor IC13-2 with an Oscilloscope. Verify a positive pulse 405

8. Monitor IC14-2 with an Oscilloscope. Verify a positive pulse 393

10 us wide.

±

10 us wide.

±

9. Monitor Q5 pins 5-8 with an oscilloscope. Verify the following waveform:

+12V

-12V

828 us ± 40 us

Model 615 Service Manual Rev. 00

32

Page 39

Electronic Tests

Section 6

10. Monitor Q6 pins 5-8 with an oscilloscope. Verify the following waveform:

+12V

-12V

828 us ± 40 us

11. Enter the Configuration menus on the unit by pressing and holding the ADAPT E

key immediately followed by the key.

12. Press the key until CAPNOSTAT SERIAL # appears and VERIFY ACCURACY.

13. Press and hold the key.

14. Using a calibrated barometer, read the barometric pressure.

15. Adjust VR1 (on the 2754 bd.) until the PB equals the actual barometric pressure

16. Cut the nasal cannula as shown below. Bond the 3/32" PVC tubing to each cut end,

then connect to the Y fitting. Connect the 1/8" PVC tubing to the to the output of the

Y fitting.

Cut here, then connect