Page 1

HAND-HELD

CAPNOGRAPHY MONITOR

Service Manual

Model 610

April 17, 2000

Catalog No. 6700-90-01

Novametrix Medical Systems Inc.

PO Box 690

5 Technology Drive

Wallingford, Connecticut, U.S.A. 06492

Page 2

Page 3

Contents

Safety ..................................................................................................... 1

Introduction ........................................................................................... 3

Indication for use ..................................................................................3

Operational Overview ........................................................................... 3

Configuration Menu ...................................................................... 4

Theory of Operati on ............... ............. ............ .................................... .7

2738 Main Board ..................................................................................7

System Memory ............. .................................... ........................10

Serial Communications .............................................................. 10

User Interface Control Circuitry ..................................................11

Real Time Clock, Power on RESET Generation and Glue Logic .......12

CO2 System Analog Subsections ......................................................12

CO2 Pulser Source Drive ................................. ............ .............. 12

Capnostat Case and Detector Heater Control ...................................14

CO2 Input Signal Path ....................................................... .. .. ....... .... .15

Capnostat Interface ............................................................................ 15

Barometric Pr e ssure Circuitry .......................... ............ ............. .15

Power Supply and Battery Charger .................................................... 16

2737 Board ................................................................................ 17

Functional Tes ts ....................................................... .......................... 19

Equipment Required ..........................................................................19

Procedure ...........................................................................................19

Accuracy Tests ............................. ....... .. .. .. .... .. .. ....... .. .. .... .. .. .. ....... .. .. .21

Equipment Required ..........................................................................21

Test Procedure .................................................... ..................... .......... 21

Electronic Tes ts .................... ............. ............ ............. ........................25

Equipment Required ..........................................................................25

Test Procedure .................................................... ..................... .......... 25

Safety Testing .......................... ............. ............ ............. ....................28

Maintenance ........................................................................................ 29

General ............................................................................................ .29

Maintenance Schedules ..................................................................... 29

Cleaning and Sterilization .......... ..................................................... ... 30

Monitor ....................................................................................... 30

CAPNOSTAT CO

Sensor .........................................................30

2

Single Patient Use Airway Adapters ..........................................30

Battery and AC Oper a tio n ..................... ............ ............. ............. .......30

Rev. 00

M610 Service Manual

iii

Page 4

Battery Indicator ........... ............. ................................... .............. 31

Rechargeable Batteries .............................................................31

AA Lithium Batt e ries ............... ............ .................................... ...32

AC wall adapter/charger (External DC supply) ..........................32

Removing and installing the battery ...........................................33

Assembly Exchanges ......................................................................... 33

Disassembling the Monitor .........................................................33

Reassembling the mon i to r .................... ............. ............ ............36

Serial Communications/Power Interface Connector .......................... 36

Software Update In structions .............. ............ ............. ............. .........37

Equipment Required .................................................................. 3 7

Setup ..........................................................................................37

Procedure ..................................................................................37

Display Status Messages ....... .. .... ..... .... .. .. .. .... .. ..... .... .. .. .. .... .. ....... .. .. .39

System Messages ...................................................................... 39

Battery Status and Alerts ...................................................................41

Status Messages and Codes .....................................................41

Specifications .....................................................................................43

Monitor Spec ifications ........................... ............ ............. ............. .......43

Physical ...................................................................................... 43

Monitor and CAPNOSTAT

CO2 Sensor .....................................43

Symbol Descrip tio n s ........ ............. .................................... .........44

Accessories .........................................................................................45

Parts ..................................................................................................... 47

Drawings and Sche matics ..... ............. ...............................................55

Rev. 00

M610 Service Manual

iv

Page 5

Guarantee

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is fully guaranteed,

covering materials and workmanship, for a period of one year from the date of shipment, except for

certain dispo sable pr oducts and products wit h stated gu arantees other than one year. Nov ametr ix reserv es

the right to per form gu ara ntee s ervi ce(s) at it s f actor y, at an aut horiz ed rep air s tati on, o r at t he cus tome r’s

installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at Novametrix’ option,

replacement of any defective parts of our equipment, except fuses, b atteries, and calibration gasses,

without charge, if said defects occur during normal service.

Claims fo r damage s durin g shipme nt must be filed pro mptly wi th the tr ansportati on compa ny. All

correspond ence co ncerning the equipme nt mu st sp eci fy both the model na me and number, and the serial

number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without following specific

operating instructions will void this guarantee and release Novametrix from any further guarantee

obligations.

Service Department

For factory repair service, call toll free

1-800-243-3444

In Connecticut, call Col lect (2 03) 265-7701

(203) 284-0753

FAX

http://www.novametrix.com

techline@novametrix.com

Email

Caution:

license d medical practitioner.

Copyright 1998, 2000 Novametrix Medical Systems Inc. This document contains information which

is proprietary and the property of Novametrix Medical Systems Inc., and may not be reproduced, stored

in a retrieval system, translated, transcribed, or transmitted, in any form, or by any means, without prior

explicit written permission f rom Novametrix Medical Systems Inc.

Novam etrix res er ves the right to change spe cif icat ions wit hou t notic e. TID AL WAVE is a trademark and

CAPNOSTAT is a registered trademark of Novametrix Medical Systems Inc.

Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order of a

Declaration of Conformity with European Union Directive

The Authorized Representative for Novametrix equipment is:

D.R.M. Green

European Compliance Services Limited

Oakdene House

Oak Road

Watchfield

Swindon, Wilts SN6 8TD

Rev. 01 Model 610 Service Manual

v

Page 6

Revision History

00 Release 23-Mar-00

01 R-N746 17-Apr-00

Service Policy

Novametrix Medical Systems Inc. will provide Warranty Service Support to its customers within 48

hours of receiving a telephone request for technical support. This 48 hour period begins once a service

request is placed through the Factory Technical Support Department in Wallingford, Connecticut.

Novametrix provides factory direct technical support to its customers through a technical support group

located in Wallingford, Connecticut and company service representatives located throughout the United

States. All Technical Support for Novametrix products is provided “Factory Direct”.

Novametrix provides 24 hour a day technical support accessibility via telephone numbers (800) 2433444 or (203) 265-7701. After hours technical support requests (before 8:00 AM and after 5:00 PM

Eastern Time) will be resp onde d to promptly by the Technical Support On-Call st aff. It is suggest ed t ha t

any person calling in for technical support have the inoperative equipment available for preliminary

trouble sho o ti ng a s wel l a s p rod u ct id e n tifica tio n. Novam etr ix re ser ves the ri gh t t o re p ai r or r ep l ace any

product found to be defective during the warranty period. Repair may be provided in the form of

replacement exchange parts or accessories, on-site technical repair assistance or complete system

exchanges. Repairs provided due to product abuse or misuse will be considered “non-warranty” and

invoiced at the prevailing service rate. Any replaced defective material is expected to be returned to

Novametrix within 10 days of being provided in order to avoid additional charges. Exchanged material

should be retu rned promptl y and direct ly to Nov ametr ix using the r eturn paper work and shi pping label (s)

provided. Transferring return materials to local sales or dealer representatives does not absolve return

responsibility.

Novametrix manufactures equipment that is generally “user serviceable” and can usually be repaired

with the r eplacement of a plug-in e lectro- mechanical assem bly by the clinic al end user . When repair parts

are provided, the recipient can call into Novametrix for on-line replacement assistance and repair

assurance. In the ev ent a repla cement par t requires increased te chnical cap abilit y , Technical Support may

request Biomedical assistance, provide on-site technical support or complete replacement equipment. If

the customer requ ires the return of th eir original product, the exchange materia l will be considered

“loaner material” and exchanged again after the customer equipment is repaired.

Novametrix promotes customer participation in warranty repairs should they become necessary. This

program all ows f or cus tomer tr aining an d a smoot h trans ition i nto self -maintena nce afte r war ranty , which

can provide substantial cost savings on repairs throughout the product’s life.

The Novametrix Technical Support D epartment can provide technical product support at a level

appropriate to most customers protocol and budget requirements. Please contact the Technical Support

Group at Novametrix for additional information.

Additional Novametrix Technical Support Programs

• Focus Series Technical Training Seminars

• Test Equipmen t and Test Kits

• Service Contract / Part Insurance Plans

• On-Site Technical Support

• 24 hr. telephone support

• “Demand Services”

Flat rate parts-exchange,

Flat rate return for repair

Time and Material,

Full warranty, discounted replacement sensors

Model 610 Service Manual Rev. 01

vi

Page 7

Section 1

Safety

The

TIDALWAVE

instrument to ground is limited to less than 100 uA.

For maximum patient and operator safety, you must follow the following warnings and cautions.

handneld capnograph is electrically isolated. Patient leakage current flowing from the

WARNINGS

!

Explosion Hazard:

•

instrument in such an environment may present an explosion hazard.

Electrical Shock Hazard:

•

source before cleaning it. Do NOT use a damaged sensor or one with a damaged cable. Refer

servicing to qualified service personnel.

Failure of Operatio n:

•

has been corrected by qualified personnel.

• Do not operate the monitor if it appears to have been damaged.

• Never sterilize o r immerse the monit or in liquids.

• The monitor does not alert for NO RESPIRATION if the airway adapter is removed from the

CAPNOSTAT CO

• Do not position the CAPNOSTAT CO

strangulation.

• Use the external battery charger in non-patient areas o nly.

• Do not apply tension to the sensor cable.

Indicates a potentially harmful condition that can lead to personal injury.

Do NOT use the moni tor in the presence of flammable anesthetics. Use of this

Always turn the monitor off and disconnect the external DC power

If the monitor fails to respond as described, do not use it until the situation

sensor.

2

sensor’s cable in a manner that may cau se e n t angl ement or

2

!

• Federal (USA) law restricts this device to sale by or on the order of a licensed medical practitioner.

• Use only a Novametrix approved power supply. Use of any other power supply may damage the

• The Tidal Wave is not intended to be used as a primary diagnostic apnea monitor and/or recording

• Refer servicing to qualified personnel.

• Never sterilize o r immerse the monit or in liquids.

• Do not sterilize or immerse the sensor except as directed in this manual.

• Do not store the monitor or sensors at temperatures below 14° F (-10° C) or above 131° F (55° C).

• Do not operate the monitor or sensor at temperatures below 32° F (0° C) or above 104° F (40° C).

• Where electr omagnetic devic es (i.e., ele ctrocautery) ar e used, patient monitoring may be interrupted

Rev. 01

Indicates a condition that may lead to equipment damage or malfunction.

Tidal Wave and void the warranty.

device.

due to electromagnetic interference. Electromagnetic fields up to 3 V/m will not adversely affect

system performance.

CAUTIONS

Model 610 Service

Manual

1

Page 8

Section 1

NOTES

Indicates points of particular interest or emphasis for more efficient or convenient operation.

• The Tidal Wave monitor is intended for operation with Novametrix Single Patient Use airway

adapters.

• Certain rebreathing circuits, or the presence of artifact such as cardiogenic oscillations, may cause

the monitor to react to non-respiratory CO

affects only the RESP (respiration) numeric values on the display.

• Refer to the User’s Manual (Cat. No. 6700-23) foradditional operational information.

• Operating the TIDAL WAVE below 50° F (10° C) will result in longer warm-up time and reduce

battery life.

• Components of this product and its associated accessories which have patient contact are free of

latex.

fluctua tions as if they were br eaths. This condition

2

2

Model 610 Service

Manual Rev. 01

Page 9

Section 2

g

g

g

g

g

g

g

g

g

Introduction

The TIDAL WAVE hand-held capnograph from Novametrix is designed to monitor CO2 whenever

capnography is required. The monitor combines full graphics capabilities, a no-respiration alert and

rugged CAPNOSTAT CO

sensor technology.

2

2.1 Indication for use

The TID AL WAVE capnograph is a hand-hel d non -i nvasive CO2 monitor spec ifically desi gne d f or short

term monitoring during transport, emergency, anesthesia, post anesthesia recovery, respiratory care and

intensive car e.

2.2 Operational Overview

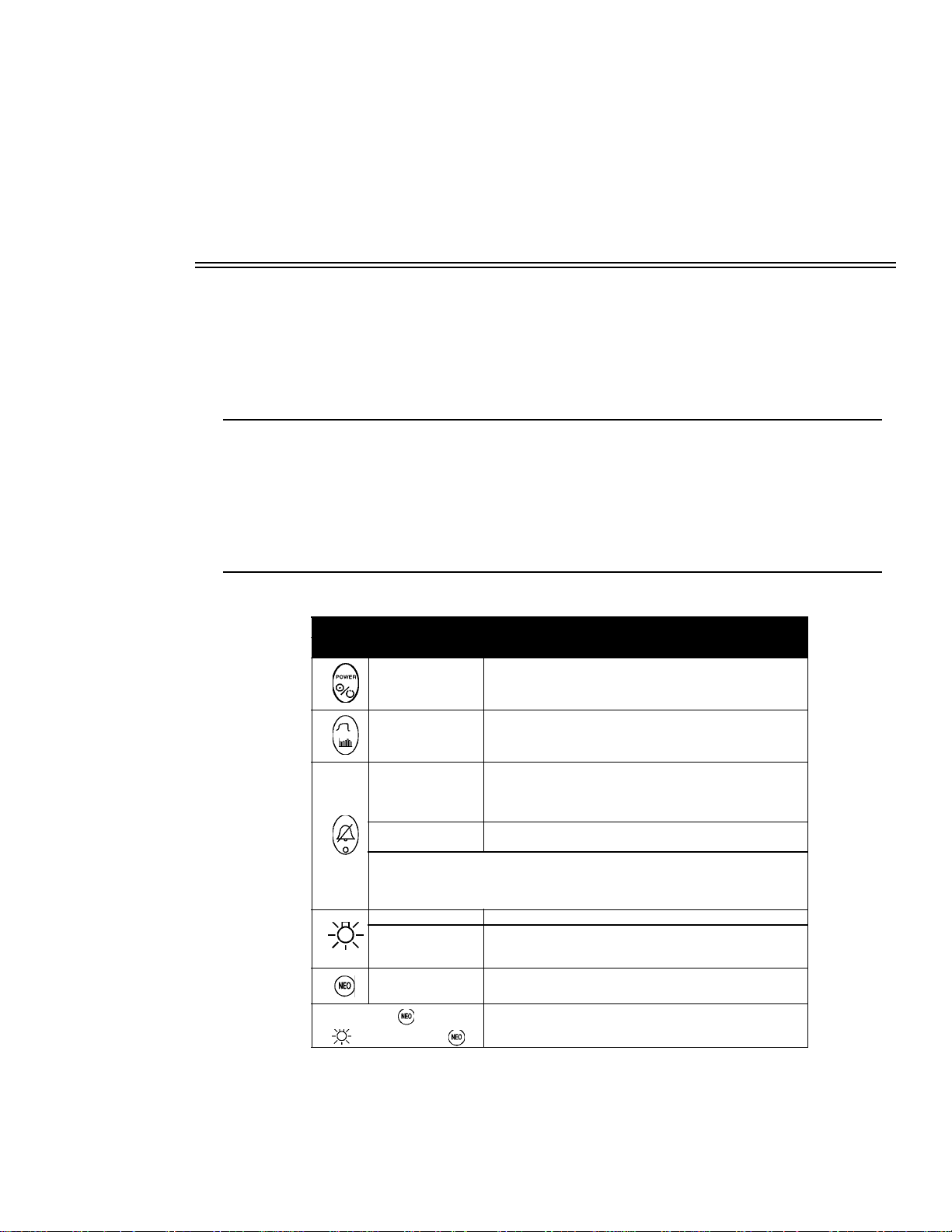

KEYS AND INDICATORS

Key Operator Action Function

1Press

Switches power on/off.

Capnogram available immediately after self test, fully

operational in 60 seconds.

2 Press Selects Capno

Press

3

4

5

Press and hold , then pres s

Press and hold for 2

seconds

NOTE: -Refer to alert indica tor below.

-Key inactive if audio disabled in confi

-The monitor may be factory confi

function (two minut e silence is still availab l e).

Press Sets display back light off/on.

Press and hold

Press , then follow

screen instructions

before releasin

Rev. 01

ram (waveform) or trend di s pl ay .

Silences audi bl e alerts for two minutes. Press a

deactivate. Al so resets (cancels) audio if pressed durin

an active alert (audio will not alert for the duration of the

NO RESPIRATION event that was silenced).

Silences audible alerts until the key is pressed a

held. This function is reset upon the next power-up.

uration menu.

ured as to not allow the audio off

Chan

es contrast/viewing angle of display (changes one

step every second).

e application mode: adult/pediatric or neonatal

Chan

airway adapter use.

Displays CONFIGURATION screen (Select compensation

O and high O2, CO2 scales, etc.).

for N

2

ain to

ain and

Model 610 Service

Manual

3

Page 10

Section 2

g

y

g y

g

y y

g y

g

g

g

y

y

g

y

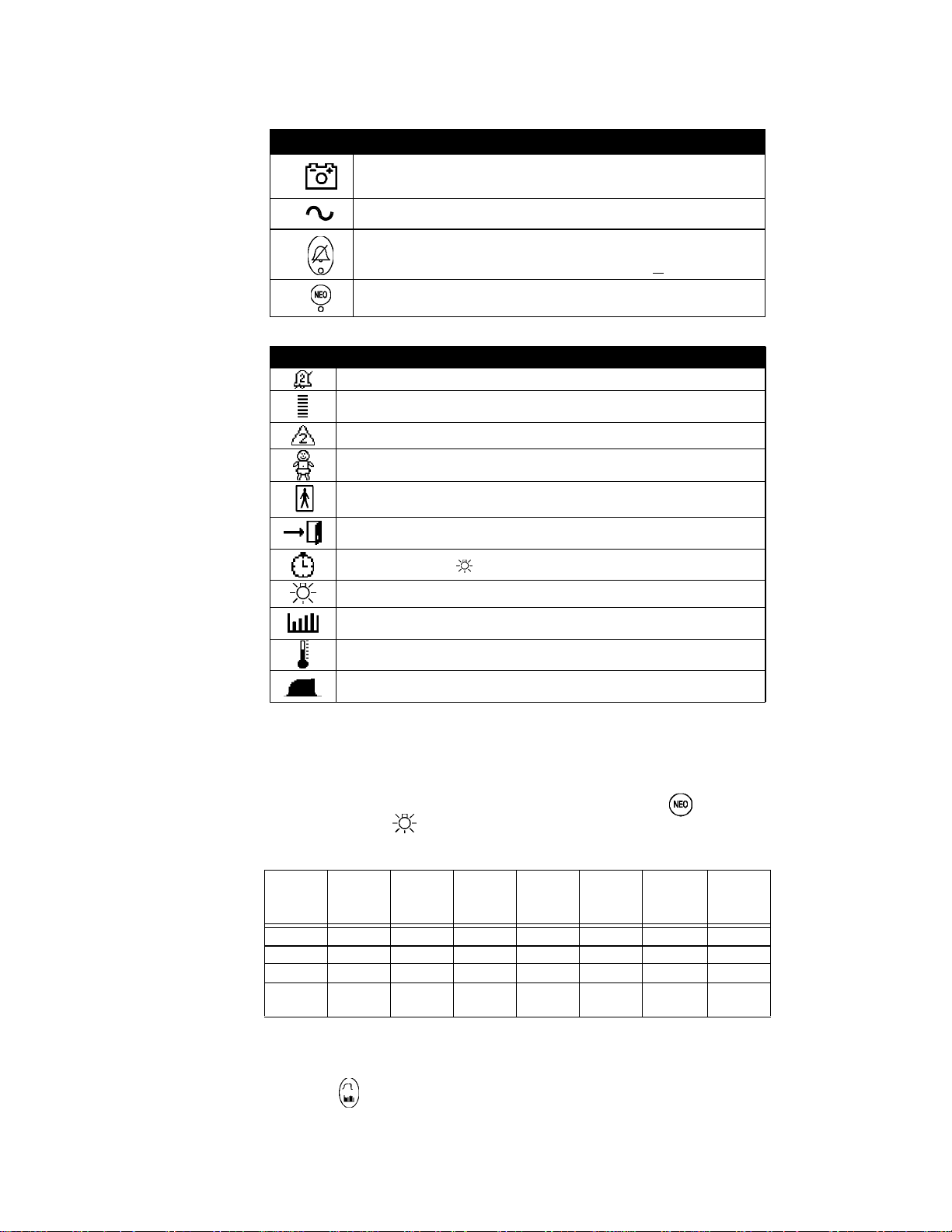

Indicators Function/Meanin

A

B Illuminated when "external" power is connected.

C

D Illumina tes when in NEO mode (see #5 above).

Green; batter

Slow flashin

Fast flashin

Stead

Flashin

Flashin

is fully charged.

ellow; battery power is low.

red; battery is exhausted (10 - 15 minutes monitor time left).

ellow: audio sil enced for 2 min., no alert in progress.

ellow: audio silenced (no alert in progress).

red and yellow: alert in progress; audio is off or 2 minute silence.

Icons Function/Meanin

Audible aler t s ilenced for two minutes.

Breath bar. Gi ves real time indication of breaths.

Status indica tor. Numbers 1-8 indicate speci fic conditions.

Neonatal icon. Used to indicate neonatal mode selected.

Adult icon. Used to indicate pediatric/adult mode selected.

Operational Overview

Exit CONFIGURAT ION or time/date screen.

Set time/date. Press from CONFIGURATION screen to set time/date.

Indicates ba ck l i

Trend screen icon. Displa

Sensor not up to te mperature icon. Displa

zero and the sensor is not at operatin

Breaths detec ted icon. Displa

monitor detect s breaths.

ht key.

ed in Trend screen.

ed when performing an adapter

temperature.

ed when performing an adapter zero and the

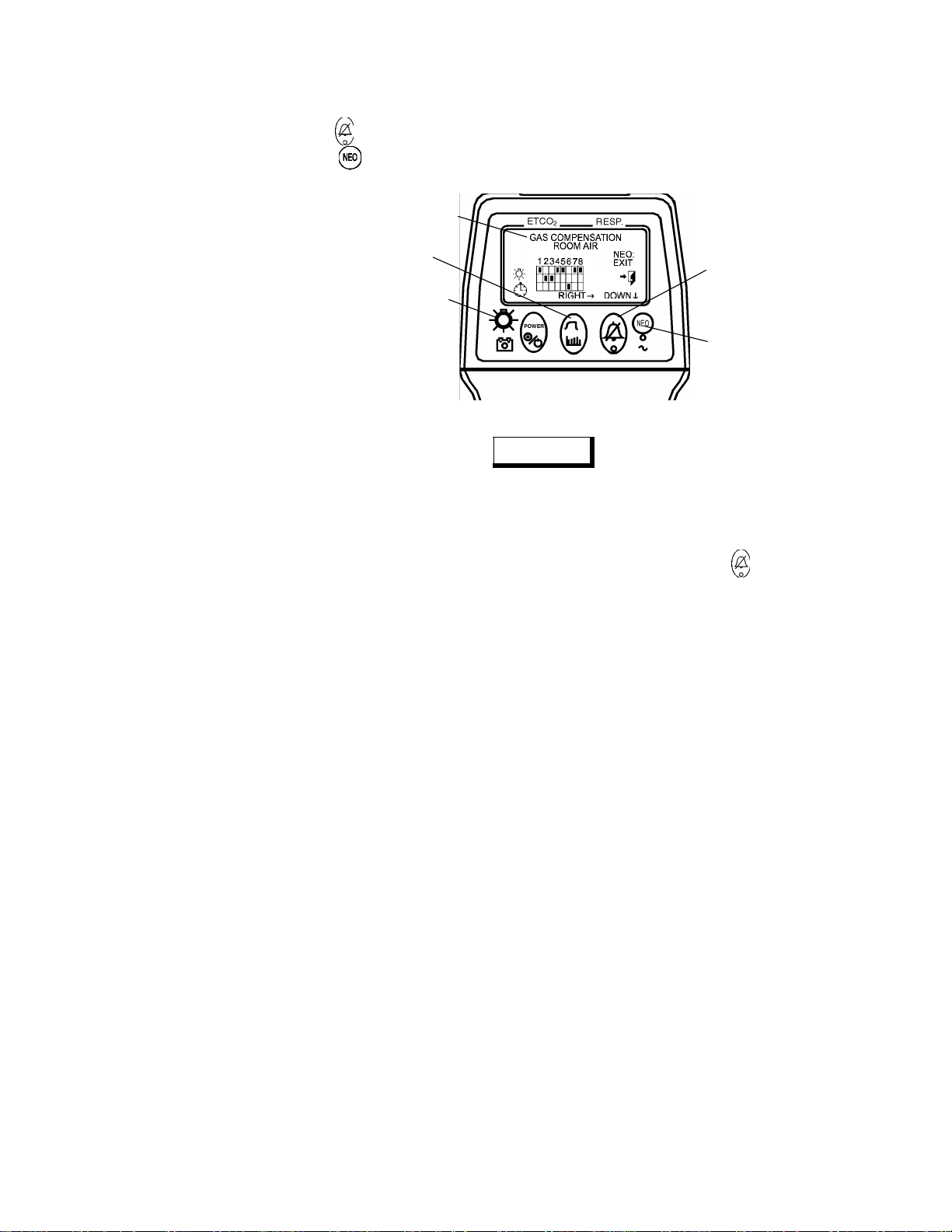

2.2.1 Configuration Menu

A CONFIGURATION menu is provided on the TIDAL WAVE in order to allow customizing of various

settings. To access the CONFIGURA TION menu, pr ess and hold t he NEO key , then , simultaneousl y

press and hold the Backlight key until the CONFIGURATION screen is displayed. The grid on the

screen corresponds to the following chart, which indicates the available selections:

Units

Gas

sation

Compen-

12345678

*Room air

O

>60%

2

N

O >60%

2

balance O

2

Scale

Waveform

Small Slow

*Medium *Medium

Large Fast 60 seconds %

Speed

Waveform

Time

NO RESP

*20 seconds *mmHg

40 seconds kPa *Low Reserved Filled

2

CO

Alert

Volume

Disabled

*High

RS232

Interface

*NovaCOM *Unfilled

--

Fill

Waveform

4

Model 610 Service

*-default settings

Changing CONFIGURATION settings:

Press the Waveform key to select among columns 1 through 8 (Gas comp., Waveform scale, etc.).

Manual Rev. 01

Page 11

Operational Overview

Section 2

Press the Alert key to change the setting of the selected column.

Press the NEO key to exit the CONFIGURATION menu and return to normal monitoring mode

(selections will be saved).

Displays selected setting

Selects column

Press to set time/date

Changes settings of

selected column

Press to exit

NOTE

When formatting, the selected column is described on the first line of the text at the top of the screen. A

flashing, f il le d b ox in dic at es the current settin g. The se tt ing is des cr ibed on the second line of text at t he

top of the screen.

units are attempted to be changed after data has been collected a message warning that trend

If CO

2

memory will be erased is displayed. To change units and erase trends press the key a second time.

Rev. 01

Model 610 Service

Manual

5

Page 12

Section 2

Operational Overview

[This page intentionally blank.]

6

Model 610 Service

Manual Rev. 01

Page 13

Section 3

The TID AL WAVE is a microprocessor -based han dheld i nstru ment th at me asures the cl inic al par amet ers

production and respiration rate. The system contains all the circuitry necessary for displaying

of CO

2

patient information gathered from the CAPNOSTAT® sensor. The theory of operation of the TIDAL

WAVE is explained in detail in the subsections that follow.

3.1 2738 Main Board

For circuit diagrams of the digital section described below, refer to sheet 1 of the Main Board (2738-03)

schematics. Embedded control for the system is provided by IC 1, a Motor ola MC6833 2 integrated

microcontroller. In addition to a full 32-bit Central Processing Unit (CPU), this device also contains

circuitry for system clock gen eration, peri pheral chip sel ect generati on, data control, interrupt gene ration,

a sophisticated timing co-processor, synchronous and asynchronous serial communication. In general,

functional signals are grouped together into por ts , and each signal can be independently programmed by

software to be its pre-defined port function or as discrete I/O. Additionally, the functionality for several

ports (Port C, E and F) can be pre-defined by the state of the data bus on system power-up. A special

“background mode” port allows the device to be controlled by an external source for system debugging

and testing. Also integrated on-chip are several activity monitors, as well as a software watchdog to

ensure proper device and system operation. Refer to Table 1.

Theory of Operation

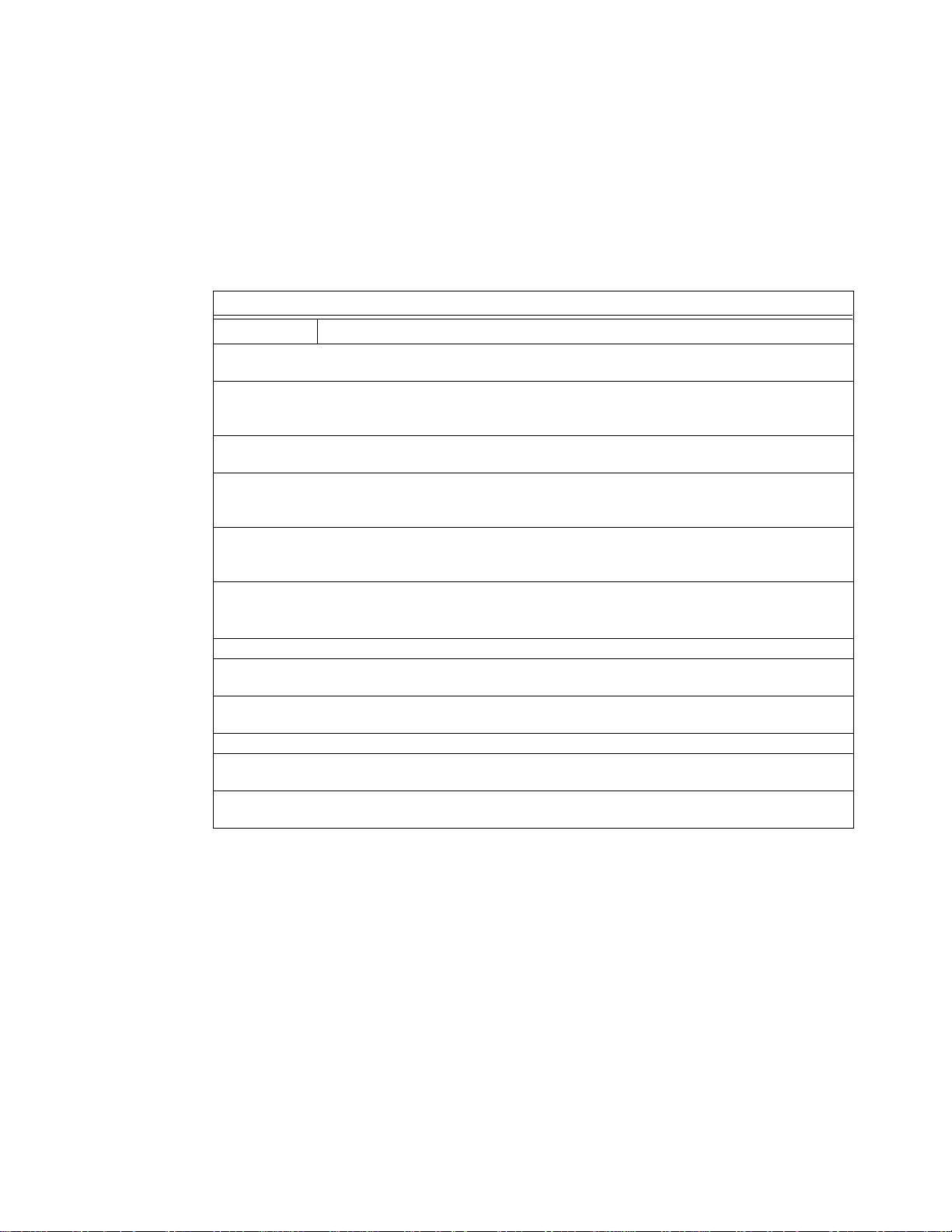

Table 1. CPU Port Functions

Functionality Control,

Port Defined Function

TPU

16 Channels

QSM

4 Synchronous Serial

Chip Selects & one

asynchronous

serial channel

Background Mode System debugging Allows an appropriate external device to

C Chip Selects D0: CSBOOT* Data Width, 8 or 16-bit

E Bus Control D8: Control Signals or Discrete I/O

F MODCK and Interrupts D9: MODCK & IRQ or Discrete I/O

Timing Signal Generation Each channel independently user

programmable as TPU function or as

Discrete I/O

Serial Communications Port:

QSPI: Queued Serial Peripheral

Interface

SCI: Serial Communications

Interface

QSPI chip selects independe ntly use r programmable, can be used as

Discrete I/O or decoded to create u p to 16

chip selects. SCI transmit can be programmed as Discrete I/O

control the microprocessor and system

D1: CS0*-CS3* or BR*,BG*,BGACK*

D2: CS3*-CS5* or FC0-FC2

D3-D7: CS6*-CS10* or A19-A23

Data Bus Control

(Alt Functions: D pulled low)

Rev. 01

Model 610 Service

Manual

7

Page 14

Section 3

2738 Main Board

The maximum operating frequency of the integrated processor is 16.78 MHz. The operating frequency

is software sel ecta ble and gene rated by an internal VCO operatin g from Y1, a 32.768KHz wat ch crystal .

The Timing Processor Unit (TPU) co-processor of the MC68332 provides timing generation derived

from the system clock. This feature is utilized to control the precise timing required for the acquisition

of the End T idal Ca rbon Dioxid e (etCO

) signals. Th e TPU is also u se to gener ate the PWM (pul se W idth

2

Modulation) control for the CAPNOSTAT case and detector heaters, generate clock output for the LED

backlight, monitor keypanel input, generate the DAC load pulse, as well as provide the frequency

generation for the audio tones. See Table 2.

Table 2. TPU Timing Genera tion for the etCO2 subsystem

Signal Name Function / Timing

CO2AZ Auto Zero Clears the Sample/Hold circuitry prior to data acquisition.

Active High, 90 us

CO2PWENB Pulse Width Enable Defines the active time for both phases of the bipolar source

pulse, used for pulse width protection circuitry.

Active High, 830 us

SRCDRV0 Source Drive 0 First source drive signal.

Active High, 405 us

CS*/H Current Sample/Hold Enables circuitry for source current measurement. Sample is

taken when SRCDRV0 is active.

Low = Sample, 90 us, High = Hold

SRCDRV1 Source Drive 1 Second source drive signal delayed for 30 microseconds after

SRCDRV0 ends.

Active High, 395 us

SS*/H Signal Sample/Hold Enables circuitry for CO2 and Reference channel data

acquisition.

Low = Sample, 90 us, High = Hold

CASEPWM Case Heater PWM PWM control for the case heater servo

DETPWM Detector Heater

PWM

SW1 - SW4 Switch1 through

Switch4

TOUT1 Tone Generation Variable frequency outputs to generate system audio

BACKLITE LED Backlight 2kHz Frequency generated to modulate the backlight in order

DACLD* D-A Load Pulse When asserted, all 4 channels of the DAC latches are

PWM control for the detector heater servo

Membrane ke ypan el input

to reduce power consumption.

simultaneously updated with the contents of the input latches.

8

Model 610 Service

Ferrite and L-C filters and 100pF capacitors have been placed on selected microprocessor signals with

fast rise and fall times (including timing, clock, and address lines) in order to help reduce and suppress

the radiation of e lectro-magnetic inte rference (L1-L6 , & C154-C159). In addition, good E MI/EMC

design techn iques ha ve been inc orporate d in the co mponent layou t and prin ted circu itboard manu factur e.

T abl e 3 lists the chip select , contro l and discr ete I/ O functio ns for the TIDAL WAVE system module. On

power-up, Ports E and F are programmed as discrete inputs by pulling down their controlling data lines,

DB8 and DB9. After power -up, the sof twar e sets up eac h pin funct ion indi vidua lly and per forms a ser ies

of self tests to check the integrity of the system. The state of configuration inputs on Port E (TST*,

CNEG0*, CNEG1* and JP0*) are read. These inputs allow the software to identify different operating

states such as Test Mode, or different hardw are conf igur ation s. After the in itia li zatio n perio d is comp lete

Manual Rev. 01

Page 15

2738 Main Board

Section 3

and all system functions have been set, the LED output toggles at a 1Hz rate switching transistor Q3

which drives the status LED D3, indicating that the system is ready for operation.

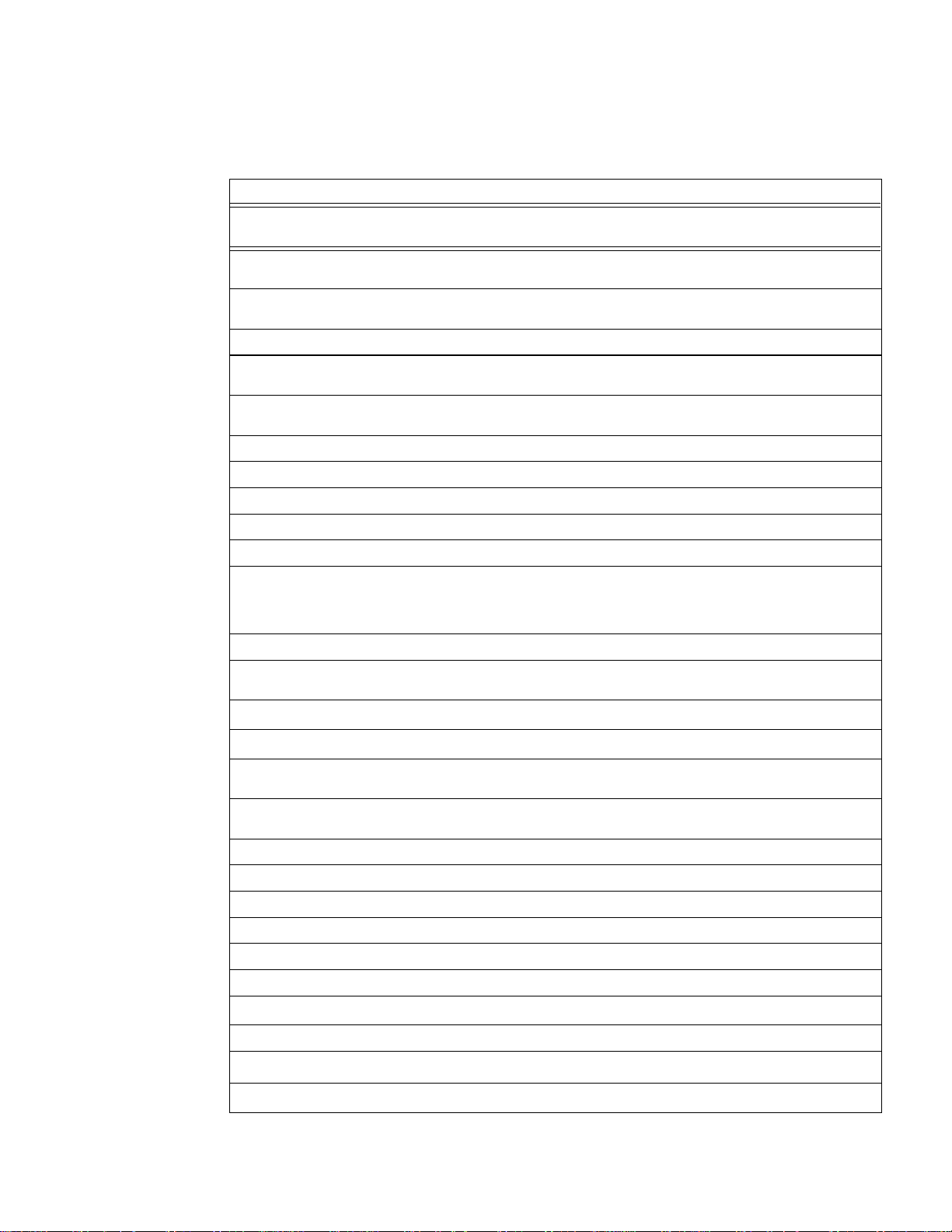

Table 3. Chip Select, Control and Discrete I/O

Port Pin Functions

C

CSBOOT** BOOTCS* O

CS0* / PC0 / BR* SRAMWR* O SRAM Write Enable

CS1*/ PC1 / BG* TP15 O

CS2* / PC2 /

BGACK*

CS3* / PC3 / FC0 ROMWR* O FLASH PROM Write Enable, Byte Mode

CS4* / PC4 / FC1 DISPCS1* O LCD Chip select #1

CS5* / PC5 / FC2 DISPCS2* O LCD Chip select #2

CS6* / PC6 / A19 LEDCS* O Chip select for front panel LEDs

CS7* / PC7 / A20 RTCCS* O Real Time Clock Chip Select

CS8* / PC8 / A21 ROMWREN O

CS9* / PC9 / A22 PROFILE* O Enables soft ware pro filing d ata out put latc h

CS10* / ECLK /

A23

System Signal

Name

SRAMRD* O SRAM Read Enable, Byte Mode

ECLK O Enable Clock for the Liquid Crystal D i splay

I/O Comments

D0 pulled low, D1 -D7 pul l ed hig h, Pins are

Chip Select on powe r-up

Program PR OM Chip Selec t

Byte wide mode, (8-bits) D0 = LOW

Test Point Available For Expansion Or Debugging

Port C Discrete Output, prevents unintentional wri tes to FLASH EPROM. This signal

must be asserted b efore ROMWR* in order

to overwrite the flash.

Rev. 01

E D8 pulled low, Discrete I/O on power-up

DSACK0* / Port

E0

DSACK1* / Port

E1

AVC* / Port E2 CNFG0* I Configuration Switch 0

RMC* / Port E3 CNFG1* I Configuration Switch 1

DS* / Port E4 DS* O Data Strobe

AS* / Port E5 AS* O Address St robe

SIZ0* / Port E6 JP0* I Hardware Jumper Mode Select 0

SIZ1* / Port E7 JP1* I Hardware Jumper Mode Select 1

R/W* RD* O Data Read Strobe

TST* I Initiate System TEST if Low

DS1* I Data and Si ze Acknowledge 1*

WR* O Data Write Strobe

Model 610 Service

Manual

9

Page 16

Section 3

2738 Main Board

Table 3. Chip Select, Control and Discrete I/O

Port Pin Functions

F D9 pulled low, Discrete I/O on power-up

MODCK / Port F0 LED O L ED CPU Activity Indicator

IRQ1* / Port F1 AUD_EN O Audio Enabl e Si gnal

IRQ2* / Port F2 CASEOT O

IRQ3* / Port F3 DETOT O

IRQ4* / Port F4 EXTDCIN I

IRQ5* / Port F5 PWRKEY I Power Key Status Input

IRQ6* / Port F6 I/O Spare I/O

IRQ7* / Port F7 NMI I Non-Maskable Interrupt

System Signal

Name

I/O Comments

Case Heater Over Temperature Shut

Down

Detector Heater Over Temperature Shut

Down

Indicates e xternal A C MAINS po wer operation

3.1.1 System Memory

An 8-bit wide data path is used for FLASH PROM and SRAM transfers. Program code storage is

contained in a 1-M eg 5V FLASH or EEPROM (IC3) device. T he FLASH PROM is protected fro m

unintentional overwrites of th e program code by trans istor Q1 and the ROMWREN si gnal. The

ROMWREN line must be high prior to writing new code into the FLASH devices. Volatile data storage

is contained in the SRAM (IC4). The SRAM i s p o w er ed by a 2.5 Volt level (VB ACK) when main power

is removed fr om th e s yste m. T his allows no n-vola tile data sto rag e wh en t he moni tor is off . Ca paci tors

C149 and C150 retain the data for approximately one minute during quick battery changes. During the

battery b ack-up stat e, tran sisto r Q 2 kee ps the CS 1* cont ro l of the S RAM in th e ina cti v e s tate. Thi s fo rces

the data b us to a high i mpedance stat e, isol atin g th e SRAM from the re st of t he syst em. T r ue non- vol atil e

storage for system parameters is provided by a serial EEPROM (IC2).

10

Model 610 Service

3.1.2 Serial Communications

Reference page 6 on schematic.

The on-chip asynchronous serial communi ca ti ons int er f ace (SCI) channel is contained in the MC68332.

The signals are level shifted to standard RS232 levels by IC29 which is a Dual RS232 Communications

Driver/Rece iver. The tr ans m it ters i n the R S2 3 2 level sh ifte r a re un de r so f twar e co ntr o l t o m i ni miz e the

patient leakage current to the rear panel connector J101 when communication is not being used. The

signal COMMPWR cont r ols th e t ransmitters operati on a nd i s derived fro m IC11 pin 14 (schematic pa ge

2). The serial connection to external nonpatient contact devices is electrically isolated from the patient

through the CAP NOSTAT airway adapt er. Connector J101 is design ed t o interface with external devi ce s

when placed in the base station. There is a 4 pin connector (J403) available for test and service which

offers an internal connection to the RS232 communications. The data signals ASRxD and ASTxD are

Manual Rev. 01

Page 17

2738 Main Board

Section 3

logic le vel signals an d a re dio de protected against over v ol t age by D38 and D35 should I C29 breakdown

from ESD. Refer to the table below for the pinout of J101.

Table 4: Power/Communications 6-pin modular connector J101 (rear panel).

Pin Number Signal Function

1 RxD Internal MC68332 UAR T Receive, RS232 Signal , Level Shifted

2 TxD Internal MC68332 UART Transmit, RS232 Signa l , Level Shifted

3 DGND Digit al Ground

4 DGND Digit al Ground

5

6 +VCHG External DC input supply to power unit and battery charger

3.1.3 User Interface Control Circuitry

Refer to schematic page 2.

The user interface features a 64 ro w by 128 column Liquid Crystal Displ ay ( L CD) modul e wit h an LED

backlight. Pa tien t an d syste m inform ati on is pre sente d in both gra phical and te xtua l fo rmats or ga nized t o

fit into a few simple screen configurations. A 5-switch membrane keypanel is provided for operator entry

of screen select ion, cal ibratio n, adapte r selec tion, di splay con trol, unit po wer , and user confi guratio n. The

user interface also contains four LEDs which represent various system conditions, such as input power

status (AC or Battery), adapter mode selection and alarm state. Control of the user interface is provided

by the LEDCS* c hip s elect s ignal to gether wi th the TPU input sig nals fr om t he micr oproce ssor. TP9 thru

TP12 (S W1 - SW 4 r es pec tively ) a re i n pu t buffe rs wh i ch re ad in t he pr ese n t s ta t e of t h e me mb ra ne keys.

Depressing a key causes the signal line to be pulled low in contrast to its normally high state. IC11

provides a latched output for controlling the status LEDs. The LCD backlight is a series of LEDs which

are driven by the TPU (BACKLITE) signal in order to lower the LCD backlight power requirement and

is activ ated by the backl ight mem brane ke y . Th e BA CKLITE si gnal is a 2 kHz logic l ev el signal generated

by TP14 which modulat es the LED backl ight throu gh FET switch Q5. This si gnal is capa citi vely co upled

by C30 in order to prevent the backlight from remaining on in the event of a system failure. Reference

page 6 on schematic. Contrast control for the LCD is provided by DAC IC36 and amplifiers IC45A and

IC35B. When the CPU detects a press and hold of the backlight membrane key, the CPU sends a digital

ramp input to the DAC which causes the its output to change accordingly. Inverting amplifier IC35B

controls the base current into transistor Q18, which changes the level of the display contrast voltage,

VDISP.

Refer to schematic page 6.

An audio frequenc y tone is gener ated by the TPU proc essor of the MC683 32 (TOUT1). Thi s signal is f ed

into the reference input of the 8-bit DAC IC36, providing a means for attenuating the signal under CPU

control. From the DAC, the signal (TOUT) is am plified by IC35A and Q4 w hich drives the system

speaker (LS1) to produce system audio. The audible signal can be disabled by the AUD-EN line. When

AUD- EN is high, Q22 will be on , eff ecti vely g rounding the i nput to I C35A, pre venti ng any au dible si gnal

from sounding.

Rev. 01

Model 610 Service

Manual

11

Page 18

Section 3

Real Time Clock, Power on RESET Generation and Glue Logic

3.2 Real Time Clock, Power on RESET Generation and Glue Logic

Reference sheet 2 on schematic.

Timekeeping for date, and time stamping of patient trend information, is provided by IC9. This device

contains a built-in crystal for precise time and date measurement. In the absence of digital power, the

timekeeping function is maintained by the battery backed-up supply, VBACKUP.

On power -u p, the syst em is for ced int o a "Res et " st at e by IC6 ( Shee t 1) . When the suppl y v o lt age VDD,

attains a value approaching 1V, the SRST* line is asserted to prevent undefined operation. IC 6 also

provides sup ervisio n ov er th e VDD logic sup ply. If the logic supply falls bel ow 4.5 5V ±120mV then I C6

generates a reset condition until the supply returns to a safe level. Inverter IC5 is used to generate the

active high RESET signal.

The TIDAL W AVE makes use of the high level of integration offered by the MC68332. Therefore, the glue

logic required is a minimum. Chip selection for the serial peripherals is provided by the queued serial

module (QSM) (P CS0- PC S3) of the m icrop roc ess or IC1 w hi le pa rallel inte rface peri phera ls are selec ted

by the internal chip select registers of Port C (BOOTCS* and CS0*:CS10*) (see schematic sheet 1).

3.3 CO2 System Analog Subsections

3.3.1 CO2 Pulser Source Drive

Refer to schematic page 3 and Table 2 of this document.

The source drive circuitry is designed to drive the source with a bipolar signal to prevent the migration

of charges within the source that may result from unidirectional electrical fields. The resistance of the

source is monitored consta ntly to ensure the integrity of the system by sampling the c urrent through the

source while it is active.

The signals fo r the source drive are ge nerated by the TP U co-process or in the MC68332 , IC1. The

SRCDRV0 and SRCDRV1 lines are used to control the bipolar signal that drives the source. The

SRCDRV0 signal goes High as soon as the CO2AZ (Auto Zero) line goes Low and the CO2PWENB

(Pulse Width Enable) line goes High. The duration of SRCDRV0 is 405 us (micro-seconds), and drives

the sourc e in the po siti v e di recti on. The SRCDRV1 line driv es t he sou rce wi th an opp osite polar ity signa l

when High for the same duration. There is a 30 us delay from the time the SRCDRV0 line goes Low to

when the SCRDRV1 line goes High. This delay is to prevent the possibility of both SRCDRV0 and

SRCDRV1 being active at the same time, thus creating a low impedance path between the two supplies.

When SRCDRV0 and CO2INH (Inhibit) are High, the output of MOSFET Driver IC14A pin 7 will go

Low . This turns the P- Channel ha lf of M OSFET Q6 on. At the s ame time, th e output of MOSFET Dri v er

IC15B pin 6 will be High, biasin g on the N-Channe l half of MOSFET Q7 on. W it h both Q6B P-Channe l

and Q7A N-Channe l on, cur rent will flo w from +VSRC through Q6 B to the positi ve source t erminal, th en

back from t he sour ce ne gat i ve t ermina l through Q7A, thr ough R110 to -VSRC. Wh en SRCDRV0 returns

Low, both Q6B and Q7A are turned off and no current flows through the source. After the 30 us delay,

SRCDRV1 will go High. The output of IC15A pin 8 will go High, biasing the N-Channel section of

MOSFET Q6 on. The output of IC14B pin 5 will go Low, turning the P-Channel of Q7 on. Current will

now flow from +VSRC through Q7B to the source negative terminal, back from the source positive

terminal through Q6A and R110 to -VSRC. Current will cease to flow when SRCDRV1 goes Low. The

bridge circuit of Q6 and Q7 in effect switches the polarity of the drive signal of the source between

+VSRC and -VSRC. CO2PWENB also falls with the falling edge of SCRDRV1, signaling the end of

source activity.

12

Model 610 Service

Manual Rev. 01

Page 19

CO2 System Analog Subsections

When current flows through the source, it will also flow through current sensing resistor R110, creating

a differential voltage proportional to the source current:

The voltage signal out of difference amplifier IC16B is level shifted through C36 and fed to the sample

and hold IC17A. A low level on the CS*/H (Current Sample and Hold) signal allows the source current

signal to be sampled. On the rising edge of CS*/H, the present voltage level of the source current signal

is held and appears at the input to channel A2 of the Analog to Digital Converter IC8 for processing by

the MPU. When CO2AZ is High, the input to the sample and hold of IC17A is grounded to discharge

any resi dual cha rge th at may be o n C36. Thi s clear s the sampl e and hol d outp ut for t he next measurement .

In order to prevent the source from being driven until the system is up and ready, protection circuitry

inhibits the source drive until enabled. During system power-up, the RESET line keeps Q8 on. This

causes the CO2INH line to be brought Low, preventing source pulses by pulling down SRCDRV0 and

SCRDRV1 through D8. Protection circuitry also guards against extended pulse width as well as

shortened duty cycle. On the rising edge of CO2PWENB, the trip point of IC18B is exceeded, allowing

C39 to charge thr ough R114. If the SRCDRV signals do not turn the Source Pulser off wit hin 200 us afte r

the 830 us pulse period, the tr ip point for IC18A will be e xceede d, pullin g the CO2INH line lo w, turning

the Pulser off. After the C O2PWENB signal retu rns Low, capacitor C41 di scharges thro ugh R115 ,

keeping the output of comparator IC18B at the voltage acquired by C39. After approximately 10.4 ms,

C41 will have discharged below the comparator tri p poi nt . T he comp arator output goes lo w, discharging

C39 and the circuit is ready for the next source pulse cycle.

= (VSR / RSR) * RS * A

V

SRC

proportional to current through the source element

= 24V +/- 0.625V

V

SR

R

SR

= resistance of the current sensing resistor

R

S

= 1 ohm

A

V(DA)

= 5

= [120 (Volts*Ohms) / RSR]

V

SRC

V(DA)

where V

= voltage out of difference amplifier

SRC

= differential voltage across the source element

= resistance of the source element

= differen ce amplifier gain

Section 3

Rev. 01

Model 610 Service

Manual

13

Page 20

Section 3

Capnostat Case and Detector Heater Control

3.4 CAPNOSTAT Case and Detector Heater Control

Refer to schematic page 4.

The temperature of the system directly affects its ability to accurately measure CO

be precisely maintained at a controlled value. Two separate heaters and control circuitry are used; one

regulates the temperature of the detectors for the CO

Data and Reference channels; the other regulates

2

the temperature of the transducer case (and loosely maintains the temperature of the airway adapter).

While the pur pose of th e Detector heater i s to ke ep the det ectors' se nsiti vity t o infrar ed radiat ion const ant,

the functio n of the Case heate r is to keep cond ensation fr om forming on the airway wind ows by el ev ating

the window temperature above the ambient airway temperature. Both heaters use an efficient PulseWidth Modul atio n scheme desig ned to dec rease po wer con sumpt ion, wi th th e PWM t iming ge nerat ed by

the TPU under microprocessor control. This control loop is run by the CPU which does the calculations

passes the duty cycle to the TPU. For the purpose of describ ing the regulation loop, the case heater

circuitry will be considered. The detector and case heater circuitry are identical.

Inside the CAPNOSTAT, a sen si ng thermistor is ther mal ly connected to the hea te r module. Initially, the

CAPNOSTAT is at the a mbient t emperat ure and t he resi stanc e of the therm istor is lar ge. A small curr en t

flows through the signal path CASETHERM and only a small voltage is developed across R131. The

microprocessor programs the TPU to allow a maximum duty cycle of 90% to power the PWM heater

circuitry. This causes the heate r c ont rol MOSFET Q13A to be pulsed on and off with a duty cycle t hat i s

under dire ct cont rol of the pr ogram soft wa re. As t he h eater warm s up th e ca se, the th ermist or's r esi stanc e

decreases, raising the voltage appearing at the input of the control loop. As described below, the MPU

looks at thi s outpu t vol tage and d ecreases the duty cycle o f the PWM c ontrol ci rcuitr y , gr adually r educing

the power output into the heater. When the desired temperature set point is reached, a balance is struck

between the energy delivered into the system and the heat flow out of the system.

The case thermistor is sensed by amplifier IC20A pin 3. The difference between the signal at the noninverting input and the reference appea ring at the inverting termin al generates an e rror voltage

proportional to the sensed temperature at the amplifier's output:

(V) = [83.133V / (Rth+3.32K)] - 10.2V

e

o

where e

R

= amplifier output voltage

o

= resistance of t he thermistor

th

= 4.36933K at 45°C

Temp (°C) = 4.1288 (°C/V) * e

where e

= amplifier output voltage at temperature T

o

V + 41.7321°C

o (T)

This error voltage is low pass filte re d by am pl ifier IC19A, sent t o t he ADC and processed by th e CPU t o

regulate the output pulses from the TPU. The TPU PWM signal is buffered by MOSFET Driver IC22B

and capacitively cou pled to the gate of the heater drive MOSFET, Q13 A. Capac itive coupling the signal

prevents a system fault that would allow the PWM to be stuck at a level that would cause too high of a

heater output. In the absence of a pulse, the gate drive will be pulled high, disabling the output to the

heater. The pulsed voltage signal out of the MOSFET is filtered by D15, L7, C52 and C54 to produce a

DC output level for the heater. Since the TPU generated PWM signal is based on the system clock, it is

synchronized with the generation of the source pulse timing. This minimizes the effect of any random

disturbance caused by the heater circuit on the detection of the CO

Data and Reference signals.

2

The error voltage out of amplifier IC20A also appears at the temperature watchdog comparator IC21A.

If the error voltage reac hes a voltage equi valent to 56 de g ree s Celsius, the comparator trips, tur ning Q11

off. The ga te of MOSFET Q10A is pulled high by R1 30, whi ch turns it off and VHTR is preve nted from

reaching the Source of transistor Q13A. The temperature of the sensor is also monitored by the MPU

which will di sable t he heat er when a tempe rature of 50 de grees Celsius is ex ceeded. T o shut off the heat er ,

the MPU asse rts the CASEOT signal, turning Q12 on which turn s Q1 1 and Q10A of f, which in turn s huts

Q13A off.

and th er ef ore m ust

2

14

Model 610 Service

Manual Rev. 01

Page 21

CO2 Input Signal Path

3.5 CO2 Input Signal Path

Refer to schematic page 5.

The signals from the sensor CO2DATAIN (CO

signal paths. The CO2DATAIN passes through a high pass filter with a gain of 3.8 consisting of C70,

R164 and b uf fer amplif ie r IC 25B. The signal is fed t o a But terw orth l o w pas s f ilt er IC2 4B and a ssoci ated

components. Thi s f ilte r has a g ain of 2 wit h a corne r freq uenc y of 1.5 KHz. Th e output from the lo w pas s

filter is fed to a 12-bit digital to analog converter IC36 (refer to sheet 6). The signal, CO2DIN comes into

the reference of the DAC, which acts as a programmable gain stage followed internally by an amplifier

with a fixed gain of 2. Here under processor control, the signal's gain is adjusted to an acceptable level

for conversion. The gain setting is adjusted using the digitized signal out of IC8 as part of the feedback

loop. Similarly, CO2REFIN is conditioned by high pass filter IC25A with a gain of 1.75 and low pass

filter IC24A with a gain of 2. The equivalent fixed gains for the two input signals are not equal in order

to compensate for differences in the output signal levels of the infra-red detectors in the CAPNOSTAT.

The output from IC36, CO2DOUT, is buffered by IC27A and AC coupled through C139 to IC44B. The

CO2DATA signal rece ived from the CAPNOST AT is AC coupled prior to the high pass filter to remove

any DC bias by C70. Pri or to s ampling CO

any residual charge on C139 to discharge to ground. At the start of the source pulse, the CO2AZ pulse

goes Low and the CO

amplifier, IC17B. Near the end of the source pulse, the SS*/H (Signal Sample and Hold) goes Low and

the peak signal is acquired on the internal sample and hold capacitor. SS*/H returns high at the end of

the cycle, and the CO

through a low pass filter of R181 and C78 before being converted by the ADC into digital data and

analyzed by the processor. The signal CO2REF follows an identical zeroing and acquisition path.

Section 3

Data) and CO2REFIN (Reference Signal) have similar

2

signal, the CO2AZ (Aut o Zero) pulse b iases Q16 on cau sing

2

signal from the sen sor is at taine d, and appear s at the inpu t of th e sample and hol d

2

signal on the sample capacitor is held at the peak value. The signal then passes

2

3.6 CAPNOSTAT Interface

(Refer to schematics 2738 sheet 5 and 2737 sheet 1)

Twenty pins of 60 pin connector J404 interfaces the CAPNOSTAT with the system electronics. Ferrite

and L-C filters have been placed on all lines to suppress radiated EMI and reduce susceptibility from

external sources of interf erence.

3.6.1 Barometric Pressure Circuitry

(Refer to schematic sheet 6)

IC34 is a piezoresistive differential pressure transducer with port P2 held as close to 0 psi (a perfect

vacuum) as is possible. It measures the absolute pressure difference at port P1 relative to the vacuum at

port P2. The t ransducer is cali brated for a fu ll scale output o f 0 to 15 psi, ha s internal tempe rature

compensatio n an d i s designed to be driven by a co nst ant c urr ent source. An on-boa rd ca li bration resistor

is trimmed by the manufacturer and is used to set the current through the sensing bridge by amplifier

IC31B. Ins trumentation a mplifier (IA) IC3 3 conditions th is signal to corre spond to the current

baromet ri c pr ess ur e , w hic h is set b y adj us ti n g V R1. The n om in al g a in o f th is am pli fier is 9 3. 56 , w hic h

correspond s t o an ADC count of 3800 at 760 mmHg. The output si gnal from IC33 is low pass f i lt er ed by

IC31A and appears as an input (ABPRESS) to the 12-bit ADC.

Rev. 01

Model 610 Service

Manual

15

Page 22

Section 3

Power Supply and Battery Charger

3.7 Power Supply and Battery Charger

Supply and Reference Voltage Generation (refer to schematic sheet 7).

The monitor operates from either an isolated DC Mains power or from the internal Battery. There are two

options prese ntly for the in ternal ba ttery, a Nickel Metal Hydride Ba ttery P ack (NiM H), or a High E nergy

Lithium Cell Pac k. The NiM H batt ery pa ck oper ates from a nomina l v oltag e of 7.2 V do wn to 6.0V wh ile

the Lithium pack operates fr om 10.5V down to 6. 0V. This battery voltage ra nge is monit ored in hardw are

by IC37B and fed to the 12 -bit ADC for le v el moni tori ng and com parat or IC43B in or der to shu t the uni t

down at 6.0V. The NiMH battery can be charged either externally via a separate charger or internally

when the DC input is connected and a NiMH battery is installed. The internal battery charging circuitry

is located on the 2737-01 asse m bly and is described in a previous s ect io n of this document. Th e Lithium

battery pack has a s chottkey diode in ser ies with the positive battery te rminal to prevent accidental

charging of the Lithium cells.

The core o f the p ower s upply des ign for the sys tem is a 500 KHz switchi ng re gulator , I C41, which utilize s

a flyback transf ormer configuration to g enerate the analog D C supply voltages. The primary of the

transformer is designed to accept 6.0 to 13 V DC input and provides secondary outputs of nominally

+13.5VDC, and -13.5VDC which are regulated by R11 and R13 off of the +VA supply. These supplies

(±VA) feed all of the analog circuitry in the monitor. All supplies are L-C filtered to minimize noise in

the analog front end. An additiona l switch ing re gul ator (IC2 6) genera tes the 5VDC supply (VDD) which

feeds all the logi c circuitry in a ddition to a filtered vers ion (CVDD) wh ich supplies the logic level

requirement s of the CO2 signal path (data con ve rters, etc.). The 5V supply is L-C f iltered to pro vide clean

logic supplies for the analog sections of the CO

which provide clean, well re gul at ed supplies (±CVA) for the CAPNOSTAT . I C 23 and IC42 are designed

as a tracking regulator pair to provide a 24VDC differential voltage for powering the CAPNOST AT

source (+VSRC, -VSRC). Power for the CAPNOSTAT Heaters is supplied by VDCIN for maximum

efficiency. Refer to Table 5 for power supply descriptions.

(CVDD) system. IC10 and IC12 are linear regulators

2

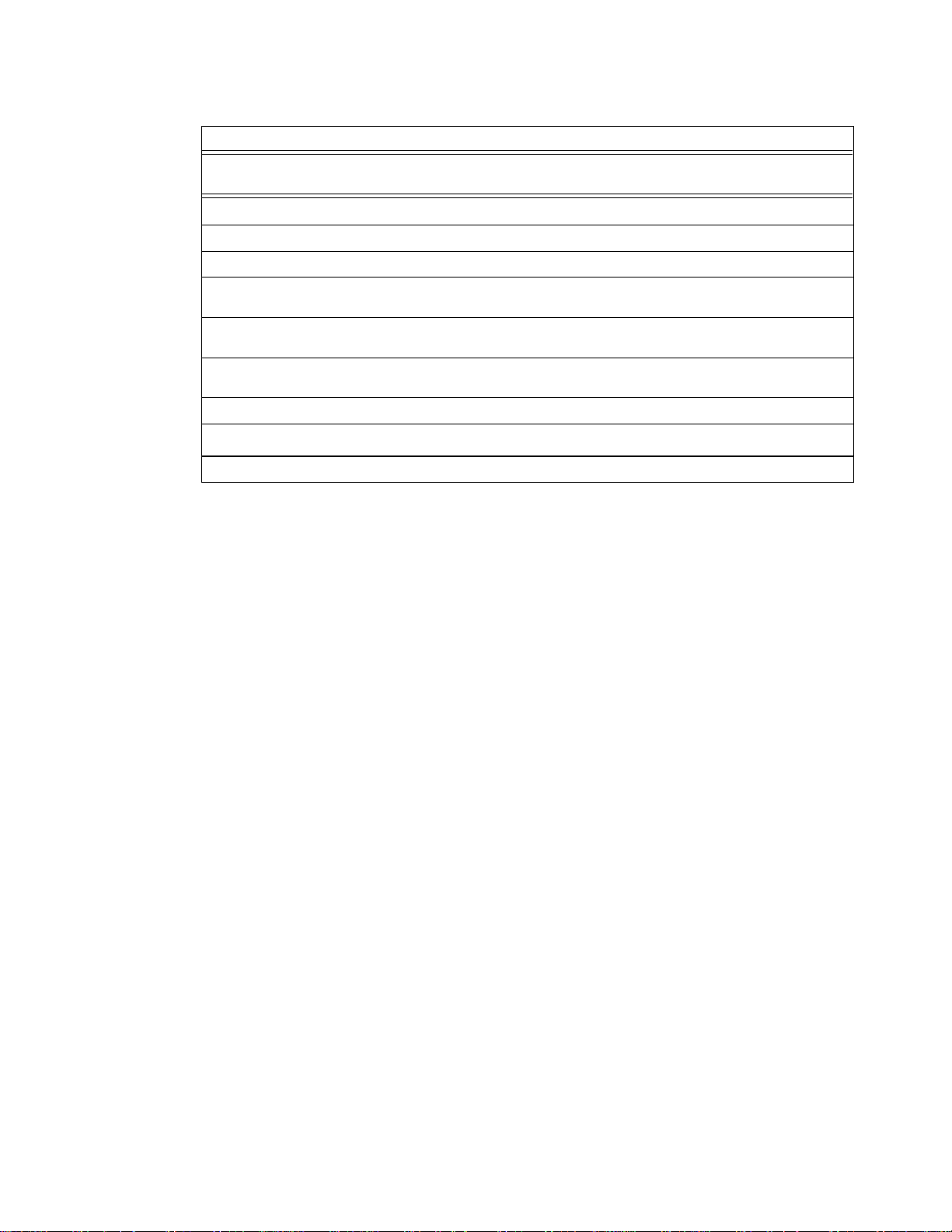

Table 5: Power Supply and Reference Outputs

Signal Supply

VDCIN +6.0V to +13VDC Main DC input gene rated from external DC input or internal battery.

VBATT +6.0V to +10.2VDC Internal Battery DC input, max level dependent on battery installed.

VBACKUP +2.5VDC or +5VDC

VHTR VDCIN

VDD +5VDC Regulated digital logic supply.

CVDD +5VDC

+VA +13.5VDC (nomi nal) Tig htly regulated +13.5V DC supply.

+CVA +12VDC Linearly Regulated and filtered positive supply for the

+VSRC +12VDC

-VSRC -12VDC

-VA -13.5VDC (nominal) Loosely reg ul ated off of the +13.5VDC feedback line.

- CVA -12VDC Linearly Regulate d and filtered negative supply for the

Supply for SRAM and R eal Time Clock, either VDD or 2.5V to maintain

SRAM data during power down.

Supply for the

or external DC input. When powered by battery heater power follows input

power.

Regulated and f iltered logic supply for C O

Linearly Regul ated and fil tered posi tive supply fo r the

Tracks -VSRC to provide a 24V +/- 2.5% differential voltage across the

source.

Linearly Regulated and filtered negative supply for the

Source. Track ed by +VSRC to provide a 24V +/- 2.5% di fferential voltage

across the source.

CAPNOSTAT

Case and Detector heaters, supplied by battery

analog front end.

2

CAPNOSTAT

CAPNOSTAT

CAPNOSTAT

CAPNOSTAT

.

Source.

.

16

Model 610 Service

Manual Rev. 01

Page 23

Power Supply and Battery Charger

Signal Supply

CVREF +2.5VDC Buffered reference for the A/D Converter.

2CVREF +5.0VDC Buffered reference used in the

-2CVREF -5.0VD C Buffered reference used for the contrast control circuitry.

VREFO/2 +1.25VDC Buffered reference used for DC excitation for the barometric pressure sensor.

See page 6 on schematic

Stable reference voltages for the sensors and analog circuitry are derived from IC28, a precision 2.5V

reference generator with low drift. Five (2CVREF) and 2.5 (CVREF) Volt references for the CO

are generated by IC30A and IC30B, while a separate 1.25 (VREFO/2) Volts is generated directly from

IC32B.

When the monitor is operated from the DC input power source, the green AC ON indicator on the front

panel is lit (refer to the 2737 schematics). If the monitor is on, pressing the Power key on the front

membrane keypanel will not completely power the monitor down. Instead, the monitor is placed in a

standby oper at ing mo de. Th e di spl ay, backlight and othe r non -e ssential control functions are inactivated

by the software, giving the monitor the appearance of power down. While in standby however, the core

system continues to operate, keeping the CAPNOSTA T heaters within temperature regulation. This

reduces the time required to bring the system up to full operating specifications during the following

power-up cy cle.

If DC input power is lost or is not available, the monitor automatically operates from its internal battery

without interruption. The AC ON indicator is extinguished and a Battery LED on the front

panel lights u p, in dicat ing the curre nt po wer le v el of the batte ry. While on int ernal DC powe r , the c urr ent

state of the battery is monitored by both software and hardware (IC37B and IC43B, schematic page 7).

Should the bat t ery power le vel become crit ic al ly l ow, t he m oni t or s o ft ware alerts the u ser. If the monitor

is not placed on ext ernal DC input power within appro ximately te n minutes, the software will put the uni t

in standby. Should the user fail to turn the monitor off when the low battery alarm sounds, the hardware

cutoff (IC43B) activates (+VBATT=6.0V), turning the unit off. While on battery operation, depressing

the Power key on the front keypanel will turn the monitor off; stand-by mode is disabled and power

to the system is turned off.

Table 5: Power Supply and Reference Outputs

CAPNOSTAT

Section 3

heater control circuitry.

circuits

2

Rev. 01

3.7.1 2737 Board

(refer to 2737 schematic sheet 1)

The internal NiMH battery will charge when the monitor is connected to the DC wall mount adapter or

installed in the cradle option. Battery charging is controlled by IC1, a frequency modulated fast charge

controller. IC1 monitors temperature, voltage, and time throughout the charging process to safely and

effectively charge the internal battery. The charger is configured to terminate charging using the ∆T/∆t

(delta temperature/delta time) method of charge termination. Charging is maintained at the C/4 (600mA)

rate while current to the battery is controlled by Q1, Q2, Q3, and the MOD output of IC1. Q3 provides

base dri v e for Q1 while Q2 s erv es to shu t Q1 of f ver y quic kly on a cy cle by c ycle basis allo wi ng the lar ge

currents required for charging to pass through Q1 which is a surface mount SOT-23 package capable of

500mW power dissipation. Temperature is monitored using the battery’s internal thermistor, R16, R17,

and R19. R16, 17 & 19 set the ∆T/∆t charge termination parameter to 1ºC per minute. R14 and R15 set

the maximum temperature for charge termination (a safety override) to 45ºC. Bat tery char ging i s initia ted

in one of two ways. Either by applying 13 VDC to +VCHG, therefore providing VCC (BVDD) to IC1,

or by inserting a rechargeable battery into the battery compartment (provided external power is available).

BVDD (VCC for IC1 and D4, the AC ON

indicator) is regulat ed by D10, a 5.1V zener diode whil e

Model 610 Service

Manual

17

Page 24

Section 3

Power Supply and Battery Charger

R9 keeps D10 operating in the knee region and C5 and C7 provide filtering. Over current protection is

provided by F1, a 1A slo-blo replaceable fuse. Reverse leakage protection is provided by D5 and D6

which prevents the battery from trying to power BVDD and +VCHG in the battery operation state.

18

Model 610 Service

Manual Rev. 01

Page 25

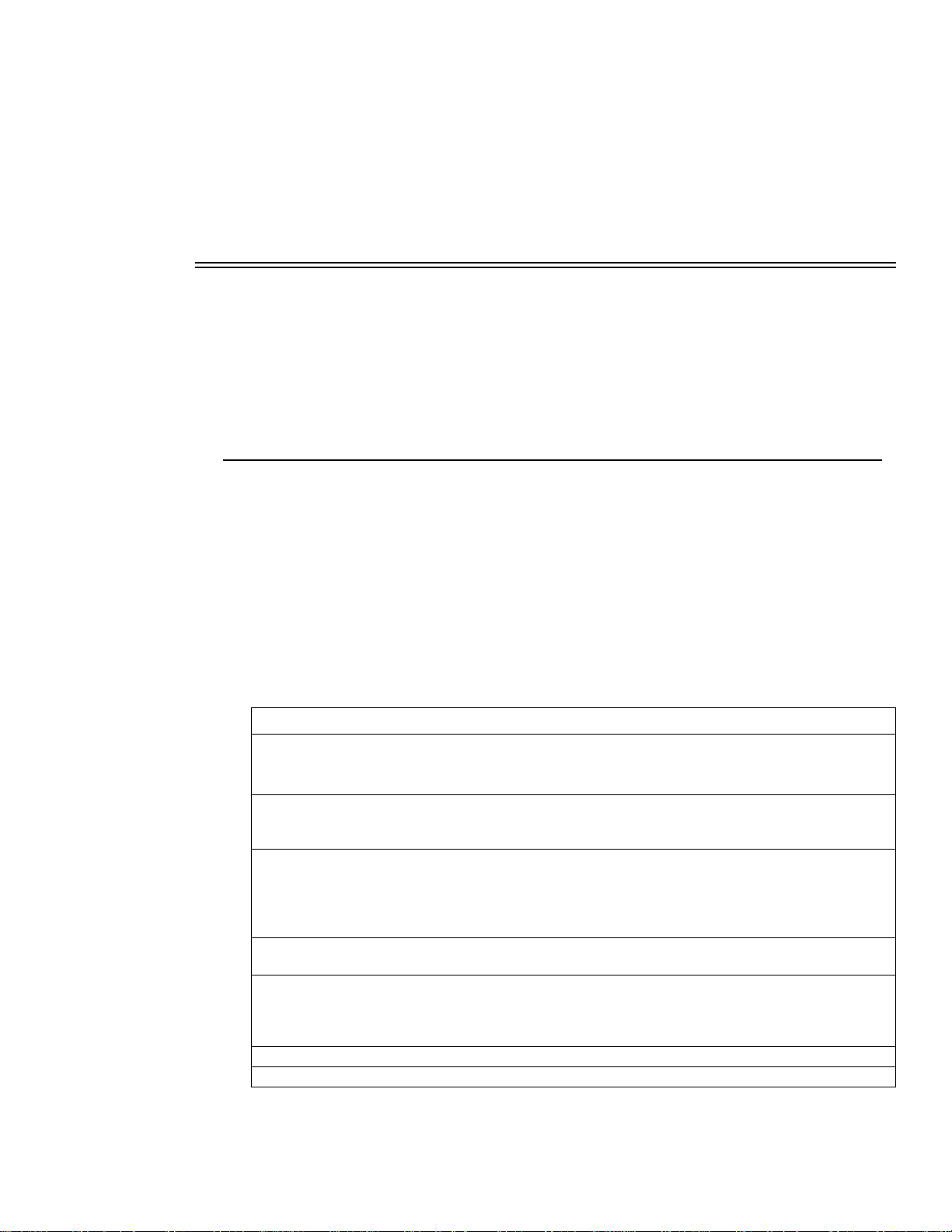

Equipment Required

g

y

Section 4

Section 4

The Functiona l Test described belo w veri f ies o v eral l func tiona l int egri ty of the moni tor and sen sor. If the

TIDAL WAVE monitor does not pass these tests, remove from use and contact the Novametrix Service

Department for repair/replacement assistance.

4.1 Equipment Required

1. Disposable Adult Airway Adapter PN: 6063-01

2. Disposable Neonatal Airway Adapter PN: 6312-01

3. NiMH rechargeable battery pack PN:400043 or equiv alent,

(batteries (7) “AA” 1.5V PN: 400050 and case PN: 6862-01, i f supplied)

4. AC to DC adapter PN: 6879-10

4.2 Procedure

Functional Tests

1. Visually inspect the monitor and v erify that there is no external damage.

2. Open hinged cover and install the NiMH rech argeable battery pack

PN: 400043 into the unit.

Rechargeable

Batter

Pack

Power jack

!

!

Serial Communica tions/Power Interface connec tor

WARNING: Do NOT connect to an y device not approved

!

by Novametrix.

3. Plug the DC adapter PN: 6879-10 into an AC outlet, then plug the other end into the

unit under test.

4. Verify the LED on the keypanel illuminates.

5. Power the uni t up by pressing the Power key on the keypanel.

Hin

ed battery cover

Rev. 01

Model 610 Service

Manual

19

Page 26

Section 4

Procedure

6. Verif y the uni t di splays error

then “CHECK ADAPTER” at the top of the display.

2

7. Connect the Disposable Adult Airway Adapter PN: 6063-01 to the CAPNOSTAT.

8. Breathe into the airway adapter and verify both the readings and the waveform

displayed on the computer are acceptable.

Sample Waveform*

*(Waveform appearance will v ary dependin g

upon breath rate and display sweep speed.)

9. Press the Backlight key and verify that the back light t urns off. Press the bac kligh t

key again and verify the back light turns on.

10. Press and hold the Bac klight key and ve rify t hat th e displ ay contrast is adj ustab le

from light to dark. Set the contrast of the di splay to a viewabl e level.

11. Press the Waveform key and verify a trend wa veform is present.

12. Press the Wav eform key again. Stop breathing into the adapt er and verify an alert

condition after appro ximatel y 20 seconds (alert LED flashing red and an audio alert).

13. Press the Alert key. Verify a 2 minute audio silence is initiated and the LED on

this key is flashing red then yellow.

14. Change the airway adapter from the adult disposable to the neonatal disposable.

Allow the airway adapter to warm up on the CAPNOSTAT for approximately two

minutes.

15. Press the Neonatal key and verify that “CHANGE ADAPTER TYPE TO

NEONATAL - YES NO” is displayed.

16. Press the YES softkey and verify a drawing of an adult and an infant (flashing) is

displayed. Verify the unit is in the Neonatal Mode as indicated by the NEO LED

being illuminated.

17. Remove the DC adapter from the unit and verify that the AC ON LED is off and

the Battery LED is illuminated (green).

18. Power the unit down then power it back up again. Ensure the monitor functions

properly on battery operation.

19. Power the uni t down and remove the rechargeable battery pack from the unit.

NOTE: Steps 3.36 to 3.38 do not app ly if the monitor does not come w ith a “AA”

battery pack.

20. Install (7) se ven “AA” batteries int o the batte ry case PN:6862-01 ens uring prop er polarity.

21. Install the battery case into t he unit, po wer up the uni t and ensure i t functions properly

on battery power .

22. Turn the unit off by pressing the Power key. Remove the battery pack from the

unit. Remove the “AA” batteries from the batt ery case.

20

Model 610 Service

Manual Rev. 01

Page 27

Equipment Required

Section 5

Section 5

The Accuracy Test verifies the performance accuracy of the Model 610. This test is typically performed

in conjunction with (after) the Functional Tests described on page 19. If the monitor does not pass the

accuracy test, remove from use and contact the Novametrix Service Department for repair/replacement

assistance.

This proced ure assumes the techn ici an performs each s tep as indicate d—leaving the monitor in a known

state prior to performing the next step. If steps are omitted or performed out of order, be sure that the

monitor is set to the correct state before continuing.

5.1 Equipment Required

• 400043 TIDAL WAVE rechargeable battery (fully charged)

• 6879-00 TIDAL WAVE AC wall adapter/charger

• 6063-01 Adult Disposable Airway Adapter (Qty 3)

• 8364-00 Low Point Calibration Gas

• 6080-00 Gas Regulator (for use with calibration gas above)

• Calibrated barometer (for checking monitor’s automatic barom etric pres sure reading)

• Room thermometer

• Calculator

Accuracy Tests

Rev. 01

5.2 Test Procedure

1. Install t h e battery in the TIDA L WAVE.

2. Connect the AC wall adapter/charger jack to the TIDAL WAVE. Verify the LED

illuminates.

3. Press the Pow er key th en immediately pre ss and hold the and keys. The

monitor should power up and displ ay "Resetting to factory defaults".

Note: A "Sensor W arming" message ma y appear o n initial po wer up. This is a normal

condition.

4. Press and hold the NEO key immediately fol lo wed b y the ba c klig ht / co ntras t

key to enter th e CONFIGURATION screen.

5. Verify the setting in the #1 position is GAS COMPENSATION: ROOM AIR.

6. Press the

7. Connect the CAPNOSTAT CO

airway adapter to warm up on the sensor for a minimum of two minutes .

EXIT) softkey to return to the main screen.

(

sensor to the disposable airway adapter. Allow the

2

Model 610 Service

Manual

21

Page 28

Section 5

Test Procedure

8. Press and hold the key until the monitor displays the "Zero/Verify" menu. Press

the key to enter the "Verify" menu. T he insta ntaneous value should be .4 (+.5 -. 4

torr). The value may take a few seconds to stabilize.

NOTE

While the zero calibration is in process there should be no CO

in the immediate area of

2

the airway adapter.

9. Follow the inst ructi ons supplied with the Gas Regulator to connect the CAPNOSTAT

sensor.

CO

2

10. Record the barometric pressure (in mmHg) and temperature (in °C) of the room.

1 1. Calculate the nominal CO2 readings using the following:

(Pbaro)

(CO2%)

·

N=

1-0.003

(33-T)

·

Where:

Pbaro=barometric pressure in mmHg

T=temperature in degrees centigrade

N=the nominal corrected CO

value for the given CO2%

2

CO2%=per centage of CO2 test gas used, e.g. 5% CO2 test gas = .05

Example:

If T=23 and Pbaro=760

then

N=((CO

N=CO

%) · 760) / 1-0.003 · 10)

2

% · 783.505

2

N=39.2 (for CO2%=.05 or 5% test gas)

For N<40; Low=N-2, High=N+2

For 40<N<70; Low=0.95

For N>70; Low=0.92

%=.05 N=39.2 Low=37.2 High=41.2

CO

2

12. Flow gas for thirty seconds. Record the CO

the Low and High limits for CO

% gas calculated above.

2

N, High=1.05 · N

·

N, High=1.08 · N

·

reading. Verify the reading is between

2

13. Stop gas flow. Disconnect the gas regulator and additional adapters from the

CAPNOSTAT CO

sensor (leave the one connected to the sensor).

2

14. Press the key to exit the "Zero/Verify" screen.

15. Press and hold the key followed by pressing and holding the key. Press the

key until the "CAPNOSTAT S/N" screen is displayed (should be t hree times).

Press and hold the key to enter the "Parameter" screen.

16. Verify the following:

From Model 610 display units (not displayed )

SRCI 180-300 mA

22

Model 610 Service

Manual Rev. 01

Page 29

Test Procedure

Section 5

CTMP 45.00 ± 0.2 °C

DTMP 45.00 ± 0.2 °C

DCHN 3600 ± 200 A/D counts

RCHN 3600 ± 200 A/D counts

17. Press the key to exit, then press the key to power down the monitor.

18. This completes the Accuracy Tests for the Model 610.

Rev. 01

Model 610 Service

Manual

23

Page 30

Section 5

Test Procedure

[This page intentionally blank.]

24

Model 610 Service

Manual Rev. 01

Page 31

Section 6

The Electron ic Tests verify the cali bration and operation of the electronic circuits within t he Mode l 6 10.

These tests DO NOT need to be performed on a regular (preventative) basis. Perform these tests only if

the monitor fails to opera te as e xpected or fa ils the Accuracy T es ts or the Functiona l Tests. The Electronic

Tests should be performed only by qualified service personnel.

The Electronic Tests require access to the internal components of th e monitor. Refer to page 33 for

disassembly instructions.

Electronic Tests

CAUTION

!

The Model 610 contains static sensit ive devices. Be sure to follow proper grounding

procedures when handling the internal components to avoid damage from static discharge.

6.1 Equipment Required

• AC to DC adapter PN: 6879-00

• DVM

• Oscilloscope

• Single Patient Use Airway Adapter (6063-adult, 6312-neonatal)

6.2 Test Procedure

1. Remove the battery (trends, date and time will be lost).

2. Disassemble unit to expose circuit boards.

3. Situate the boards so that no shorting can occur. Connect the AC to DC adapter.

4. Press the Power key to power up the main board. Verify the proper power up

sequence is on the LCD display.

5. Verify “Sensor Warming” and a “1” are flashing on the display.

6. Connect the airway adapter to the CAPNOSTAT CO

Rev. 01

sensor.

2

Model 610 Service

Manual

25

Page 32

Section 6

Test Procedure

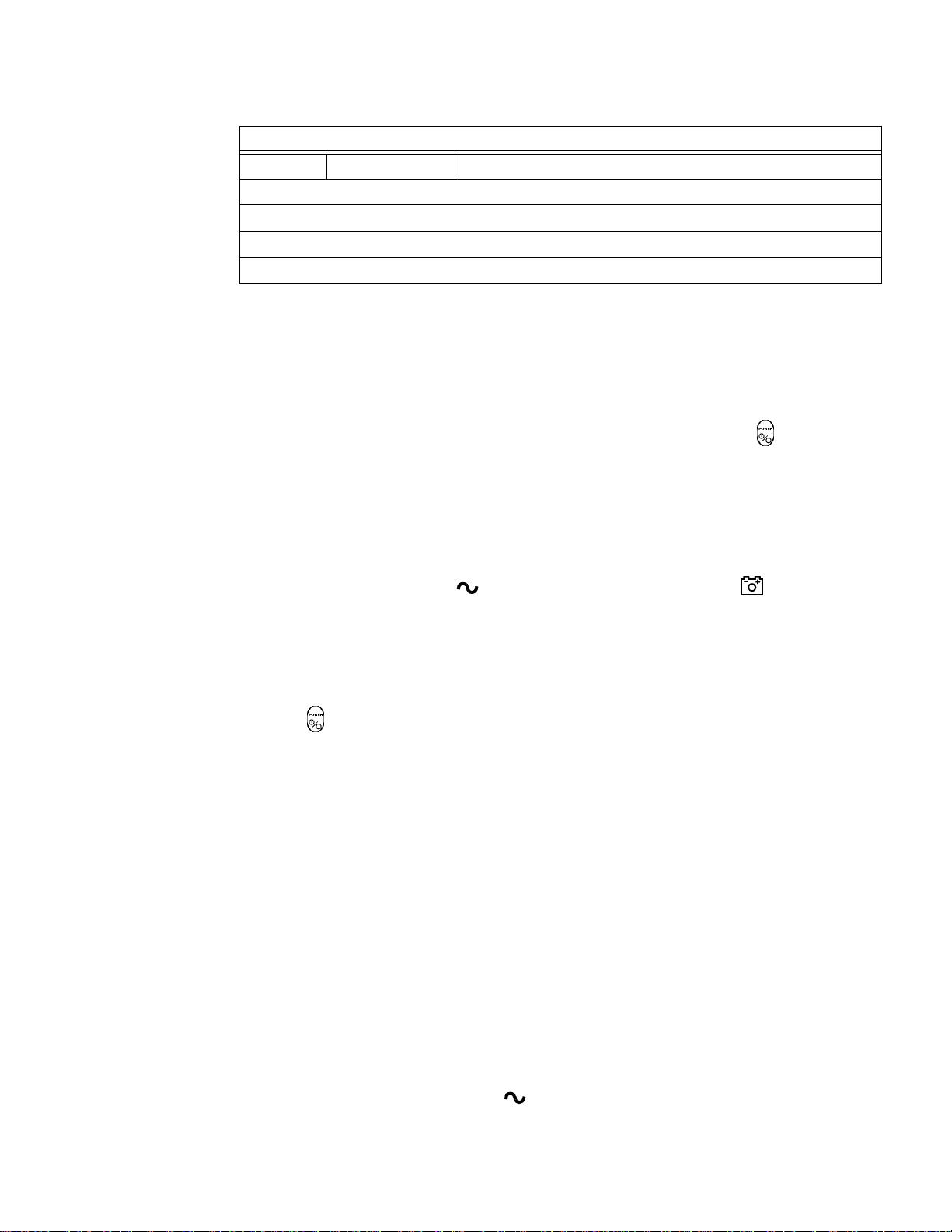

7. Measure the following voltages on the 2738 board. Use TP 12 as ground reference.

Refer to the il lustration for test point locations.

2

3

4

10

5

6

7

8

9

11

1

Signal Name Location Voltage Tolerance

1 VDD TP 17 feed through 5.00 V ± 100 mV

2 + VA D26 cathode + 13.75 V ± 500 mV

3 - VA C130 neg. lead - 13.75 V ± 500 mV

4 + CVA L9 or IC 10 pin 2 + 12.00 V ± 500 mV

5 - CVA IC 12 pin 3 - 12.00 V ± 500 mV

6 + VSRC C32 pos lead + 12.00 V ± 500 mV

7 - VSRC C40 neg lead - 12.00 V ± 500 mV

8 VHTR D18 cathode + 8.00 V ± 1.00 V

9 CVREF C92 Positive + 2.50 V ± 25 mV

10 VREFO/2 C96 Positive + 1.25 V ± 25 mV

11 - 2CVREF TP23 - 5.00 V ± 50 mV

26

Model 610 Service

Manual Rev. 01

Page 33

Test Procedure

Section 6

8. Enter the configuration menu b y pressing and holding the NEO key i m mediately

followed by the backlight / contr ast key.

9. Press the backlight / contrast key f our times to display the engin eering screen.

±

10. Verify the CTMP and DTMP rise and stabilize to 45.00 °C

11. Verify PB equals the recorded barometric pressure ±2. If not adjust using VR1 until

the reading equals the recorded barometric pressure.

12. Verify the SRCI rea ds between 180 and 300 mA.

13. Press the EXIT softkey.

14. Press and hold the NEO key for five seconds. Verify the Zero calibration screen

is displayed.

15. Press the ZERO softkey. Verify a Zero calibration is performed, the monitor will

“countdown” from 20 seconds.

16. Monitor D8 with the Oscilloscope. Verify a positive pulse 405

17. Monitor D8 with an Oscilloscope. Verify a positive pulse 393

18. Monitor TP33 with an oscilloscope . Verify the following waveform:

0.1 °C.

±

10 us wide.

±

10 us wide.

+12V

828 us ± 40 us

19. Monitor TP1 with an oscilloscope. Verify the following waveform:

+12V

828 us ± 40 us

-12V

-12V

Rev. 01

20. Power down the board by pressing the Power key.

Model 610 Service

Manual

27

Page 34

Section 6

Safety Testing

6.3 Safety Testing

21. Using a leakage test fixture, and with the external AC adapter/charger connected,

measure the leakage current:

• Normal

• Normal reverse ground

• Normal ungrounded

Verify a leakage current <50 uA.

28

Model 610 Service

Manual Rev. 01

Page 35

Section 7

7.1 General

This section presents recommended maintenance schedules for the Model 610 and information on

general maintenance, such as battery and fuse replacement, disassembly and assembly instructions, and

system software updates.

7.2 Maintenance Schedules

The electronic circuits within the Model 610 hand-held capnograph monitor do not require scheduled

calibration or service. However, in order to maximize battery life, the monitor’s internal battery should

be tested monthly. Novametrix recommends the following maintenance schedules.

• Cleaning and Sterilization:

Perform as required. See see Cleaning and Sterilization on page 30.

• Battery and AC Operation:

Contains information on use of disposable lithium and rechargeable batteries. See see Battery and

AC Operation on page 30.

• Functional Test s:

The test verifi es ove ra ll functional integri ty of the moni tor and sensor. See see Functional Tests on

page 19.

• Accuracy Tests:

The test verifies the calibration accuracy of the monitor using specified test apparatus. See see

Accuracy Tests on page 21.

• Electronic Tests:

These tests contain information on testing the electronic circuits within the Model 610 and should

only be performed if the monitor fail s to pass the Functi onal Tests. Only qualified ser vice person nel

should attempt to perform the Electronic Tests. See see Electronic Tests on page 25.

Maintenance

*

*.

At the customer’s request, Novametrix will provide repair and calibration services under terms of a Service Contract. Contact the

Novametrix Service Department for contract details.

Rev. 01

Model 610 Service

Manual

29

Page 36

Section 7

Cleaning and Sterilization

7.3 Cleaning and Sterilization

Follo w the c leani ng and s teri liza tion inst ruct ion s liste d be lo w to cl ean and/ or st eril ize t he mon itor and it s

accessories.

CAUTION

The airway adapter is designed for single patient use. Sterilizing may affect system performance.

7.3.1 Monitor

• Turn the monitor off and unplug the AC wall adapter/charger from the AC line before cleaning.

• The monitor can be cleaned and disinfected with solutions such as a 70% isopropyl alcohol, 2%

glutheralhyd e, or 10% ble ach solut ion. Then wip e down with a water-dam pened cl ean clot h to rins e.

Dry before use.

• Do not immerse the monitor.

• Do not attempt to st erilize the monitor.

7.3.2 CAPNOSTAT CO2 Sensor

• Clean the sensor surface with a damp cloth.

• Make certain that the sensor windows are clean and dry.

• Do not immerse the CAPNOSTAT CO

• Do not attempt to s terilize the CAPNOSTAT CO2 sensor.

sensor.

2

7.3.3 Single Patient Use Airway Adapters

• Treat all single patient use airway adapters in accordance with hospital protocol for single-patient

use items.

7.4 Battery an d AC Operation

The TID AL WAVE can be p owered from se ve n “AA” disposable li thium b atteri es, a rech arg eable bat tery,

or an AC wall adapter/charger available from Novametrix. With continuous operation a rechargeable

battery will l ast app rox imatel y four an d a half ho urs . Batter y capac ity is sho wn in t he char t belo w. Times

may be reduced in colder temperatures or with power cycling; operation with the backlight off may

slightly increas e these times. The op tional AC wall adapter/charger will also charge a rechargeable

battery in the monitor . Alternati v el y, the rechargeabl e b at te ry can be charged i n i t s e xt ernal charger. Any

batteries used with the 6862-00 case cannot be charged, it is for use with disposable type batteries only.

Power Source

Standard

AA lithium batteries

(7 ea. - disposable)

Optional

Rechargeable battery,

(NiMH 7.2 vdc)

30

Model 610 Service