Page 1

Model 515B

and

Model 515C

Service Manual

Pulse Oximeter

This manual covers Model 515B (Cat. No. 6500-00) and Model 515C (Cat. No. 6550-00)

November 15, 1995

Catalog No. 6500-90-01/6550-90-01

Novametrix Medical Systems Inc. Wallingford, Connecticut, U.S.A. 06492.

Copyright 1995. All rights reserved. No part of this manual may be reproduced

without the written permission of Novametrix Medical Systems Inc. Printed in U.S.A.

Page 2

Page 3

R

Revision History

19-May-95 Release at revision 00.

15-Nov-95 Updated, revision 01.

Rev. 01 Model 515B/C Service Manual

iii

Page 4

[This page intentionally blank.]

iv

Model 515B/C Service Manual Rev. 01

Page 5

G

Guarantee

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is fully

guaranteed, covering materials and workmanship, for a period of one year from the date of

shipment, except for certain disposable products and products with stated guaran tees other th an

one year. Novametrix reserves the right to perform guarantee service(s) at its fac tory, at an

authorized repair station, or at the customer’s installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at Novametrix’ option,

replacement of any defective parts of our equipment, except fus es, batteries, and cal ibration

gasses, without charge, if said defects occur during normal service.

Claims for damages during shipment must be filed promptly with the transportation company.

All correspondence concerning the equipment must specify both the model name and number,

and the serial number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without following

specific operating instructions will v oid this g uarantee and r elease Nov ametrix from any further

guarantee obligations.

Service Department

For factory repair service, call toll free

1-800-243-3444

In Connecticut, call Collect (203) 265-7701

Telex 956-054

Facsimile (203) 284-0753

Caution: Federal (U.S.A.) law restricts this device to sale, distrib ution, or u se by or on the order

of a licensed medical practitioner.

Copyright 1995, Novametrix Medical Systems Inc. This document contains information

which is proprietary and the property of Novametrix Medical Systems Inc ., and may not be

reproduced, stored in a retrieval system, translated, transcribed, or transmitted, in any form, or

by any means, without prior explicit written permission fro m No vametrix Medical Systems Inc.

Rev. 01 Model 515B/C Service Manual

v

Page 6

Service Policy

Novametrix Medical Systems Inc. will provide Warranty Service Support to its customers

within 48 hours of receiving a telephone request for technical support. This 48 hour period

begins once a service request is placed through the Factory Technical Support Department in

W allingford, Connecticu t. Nov ametrix provides factory direct technical support to its customers

through a technical support group located in Wallingford, Connecticut and company service

representatives located throughout the United States. All Technical Support for Novametrix

products is provided “Factory Direct”.

Novametrix p rov ides 24 hour a day techn ical supp ort accessibility via telephone numbers (800 )

243-3444 or (203) 265-7 701. After ho urs technical supp ort requests (before 8:00 AM and after

5:00 PM Eastern Time) will be responded to promptly by the Technical Support On-Call staff.

It is suggested that any person calling in for technical support have the inoperative equipment

available for preliminary troubleshoo ting as well as product identif ication. No v ametrix reserv es

the right to repair or replace any product found to be defective during the warranty period.

Repair may be provided in the form of replacement exchange parts or accessories, on-site

technical repair assistance or complete system exchanges. Repairs provided due to product

abuse or misuse will be considered “non-warranty” and invoiced at the prevailing service rate.

Any replaced defective material is expected to be returned to Novametrix within 10 days of

being provided in order to avoid additional charges. Exchanged material should be returned

promptly and directly to Nov ametrix using the retur n paperwor k and shipp ing label(s) pro vided.

Transferring return materials to local sales or dealer represent atives does not absolve return

responsibility.

Novametrix manufactures equipment that is generally “user se rviceable” and can us ually be

repaired with the replacement of a plug-in electro-mechan ical assembly by the clinical end user.

When repair parts are provided, the recipient can call into Novametrix for on-line replacement

assistance and repair assurance. In the event a replacement part requires increased technica l

capability, Technical Support may request Biomedical assistance, provide on-site technical

support or complete replacement equ ipment. If the custom er requires the retur n of their original

product, the exchange material will be considered “loaner material” and exchanged again after

the customer equipment is repaired.

Novametrix pro motes customer participation in warr anty repairs should the y become necessary .

This program allows for customer training and a smooth transition into self-maintenance after

warranty, which can provide substantial cost savings on repairs throughout the product’s life.

The Novametrix Techn ical Suppor t Department can pro vide technical prod uct support at a le vel

appropriate to most customers protocol and budget requirements. Please contact the Technical

Support Group at Novametrix for additional information.

Additional Novametrix Technical Support Programs

• Focus Series Technical Training Seminars

• Test Equipment and Test Kits

• Service Contract / Part Insurance Plans

• On-Site Technical Support

• 24 hr. telephone support

• “Demand Services”

Flat rate parts-exchange,

Flat rate return for repair

Time and Material,

Full warranty, discounted replacement sensors

vi

Model 515B/C Service Manual Rev. 01

Page 7

C

Contents

1 Description .................................................................................................... 1

1.1 Trademark Acknowledgments ...................................................................1

2 Patient Safety ................................................................................................3

2.1 Indications and Usage ..................................... .... ........................ .... ..... .....3

2.2 Warnings ................................................................................................... 4

2.3 Cautions ....................................................................................................5

3 Front and Rear Panel Illustrations .................... .... ..... ..... ....................... .....7

4 Summary of Operation .................................................................................9

4.1 Turning the monitor ON/OFF ................................................................ .....9

4.2 Displays .....................................................................................................9

4.3 Adjusting Alert Limits .................................................................................9

4.4 Adjusting Volume Levels .........................................................................10

4.5 Muting Alerts ............................................................................................10

4.6 Contrast ...................................................................................................10

5 Electronic Theory of Operation .................................................................11

5.1 2532/2725 Power Supply Board ..............................................................11

5.1.1 AC Mains and Battery Operation Overview ..............................................................11

5.1.2 AC Mains Operation ..................................................................................................11

5.2 Main Board ..............................................................................................12

5.2.1 Power On/Off Control Circuitry ..................................................................................12

5.2.2 Power Supplies and Voltage References ..................................................................13

5.2.3 Sensor LED Drive Circuits ........................................................................................13

5.2.4 Sensor Photodiode Return Path ...............................................................................13

5.2.5 20-Bit Analog-to-Digital Convertor Self Calibration ...................................................14

5.2.6 20-B it Ana lo g-to-Dig ita l Conversion ............................... ....... ....................................14

5.2.7 Sensor Status Decoding and Conversion .................................................................15

5.2.8 Front End Timing Signals ..........................................................................................15

5.2.9 Sensor Status Parameters ........................................................................................16

5.2.10 Serial I/O Controller ...................................................................................................17

5.2.11 Microprocessor and Memory .....................................................................................18

5.2.12 Decoding ................................................................................................................... 18

5.2.13 Microprocessor Supervisor ......................................................... ..............................19

5.2.14 System Output Ports .................................................................................................19

5.2.15 Displays ............................. ................... .......................... .................... .......................2 0

5.2.16 Audio Drive Circuitry .................................................................................................20

5.2.17 Keypanel and Configuration Header .........................................................................21

5.2.18 Graphics Display .......................................................................................................21

Rev. 01 Model 515B/C Service Manual

vii

Page 8

6 Maintenance ................................................................................................ 23

6.1 Cleaning and Sterilization ........................................................................23

6.1.1 Mon itor ..................................................... .................................................................23

6.1.2 SpO

6.1.3 SpO

6.1.4 Y-S trip Ta pes and Foam Wraps ................................. ....... ...... ....... ...... ....................23

6.1.5 Ea r Cli ps ..................................... ....... ...... ...... ....... ...... ....................................... ....... 23

Finger Sensor ..................................................................................................23

2

Y-Sensor ......................................................................................................... 23

2

6.2 Battery Maintenance ................................................................................24

6.3 Replacing AC Mains Fuses .....................................................................24

6.3.1 Assemblies with the earlier Power Entry Modules .................................................... 25

6.3.2 Assemblies with the newer Power Entry Module ...................................................... 25

6.4 Changing AC Mains Voltage ..................... .... ........................ .... ..... ..... ....26

6.4.1 Assemblies with the earlier Power Entry Module ......................................................26

6.4.2 Assemblies with the newer Power Entry Module ...................................................... 27

6.5 Assembly Exchanges ..............................................................................29

6.5.1 Internal Assemblies ...................................................................................................29

6.5.2 Main Board/Keypanel Assembly ...............................................................................29

6.5.3 Power supply assembly ............................................................................................ 29

6.5.4 Replacing the internal battery ...................................................................................29

6.6 Changing System Software ......................................... ............................29

7 Troubleshooting ..........................................................................................31

8 Functional Test ...........................................................................................33

8.1 Equipment require d ................ ..... .... ..... ....................... ..... ..... .... ..............33

8.2 Functional Test ........................................................................................34

9 Electronic Tests ..........................................................................................37

9.1 Assembly Tests .......................................................................................37

9.1.1 Equipment Required .................................................................................................37

9.1.2 Power Supply ............................................................................................................37

9.1.3 Main Board ................................................................................................................38

9.2 Accuracy Test ..........................................................................................40

9.2.1 Equipment Required .................................................................................................40

9.2.2 Test ...... ................................................................. ....................................................40

10 Specifications ..............................................................................................43

10.1 Pulse Oximeter ........................................................................................43

10.1.1 Principle of Operation ...............................................................................................43

10.1.2 SpO

10.1.3 Pulse Rate ................................................................................................................ 43

10.1.4 Se nsors .............................................. ............................................. ..........................43

10.1.5 Pl eth ysmo gram (Mode l 515C onl y) .... ...... ...... ....................................... ....... ...... ....... 43

(Oxygen Saturation) ....................................................... ................................. 43

2

10.2 General Specifications .............................................................................43

10.2.1 Al erts ..................................... ................................ ....................................... .............43

10.2.2 Display ...................................................................................................................... 44

10.2.3 Ph ysical ............. ............. ............. ............. ...... ............. ............. ............. ....... ............. 44

10.2.4 Electrical ................................................................................................................... 44

11 Accesories ................................................................................................... 45

12 Parts Lists ....................................................................................................49

12.1 Model 515C .............................................................................................49

viii

Model 515B/C Service Manual Rev. 01

Page 9

12.2 Model 515B ..............................................................................................53

12.3 Common Assemblies to both Models 515B & 515C ................................59

13 Schematics and Assembly Drawings ........................................................63

Rev. 01 Model 515B/C Service Manual

ix

Page 10

x

Model 515B/C Service Manual Rev. 01

Page 11

1

Description

This manual is written for personnel who service and/or maintain the No vametrix Model 515B

or 515C Pulse Oximeter. The Model 515B/C provides reliable continuous measurement,

display, and alerts for oxygen saturation (SpO

from its rechargeable internal battery or from the AC Mains.

The Model 515B/C measures oxygen saturation using sensors that contain red and infrared (66 0

and 940 nanometer) light sources, called LEDs. The light e nergy from each LED is beamed

through a sample cell—a pulsating vascular bed, the patient’s finger or toe for example. The

remaining light energy not absorbed by the sample cell reaches a light receptor in the sensor,

called a photodiode. Oxygen saturated blood absorbs different amounts of light at each

wavelength as compared to unsaturated blood. Therefore, the amount of light absorbed by the

blood in each pulse can be used to calculate oxygen saturation.

The Model 515B/C is calibrated to display “functional” saturation. This differs from the

“fractional” saturation value displayed by most co-oximeters. Functional saturation is defined

as:

Functional Saturation =

= Percentage of hemoglobin saturated with oxygen

HbO

2

COHb = Percentage of carboxyhemoglobin

METHb = Percentage of methemoglobin

) and pulse rate. The monitor can be powered

2

HbO

2

100 - (COHb + METHb)

This can be considered to re present the amount of oxyhem oglobin as a percentage of the

hemoglobin that can be oxygenated. Dysfunctional hemoglobins (COHb and METHb) are not

included in the measurement of functional saturation.

Pulse Rate is calculated by measuring the time interval between peaks of the infrared light

waveform. The inverse of this measurement is displayed as pulse rate.

The oxygen saturation and pulse rate values are upda ted once each second. Presence of a pulse

is indicated visibly by a b ar graph display, a plethysmogram graphic disp lay (Models 515C

only), and audibly by a “beep.”

The Model 515B/C must be used in conjunction with Su perBright™ Sensors. These sensors

have an 8700 series part number (e.g., 8776 or 8791).

1.1

Rev. 01 Model 515B/C Service Manual

Trademark Acknowledgments

SuperBright, Y-STRIP and Y-SENSOR are trademarks of Novametrix Medical Systems Inc.

1

Page 12

1

Description

Trademark Acknowledgments

[This page intentionally blank.]

2

Model 515B/C Service Manual Rev. 01

Page 13

2

Patient Safety

Pulse oximetry is a non-invasive method of monitoring the oxygen saturation of arterial blood.

Pulse oximeters display oxygen saturation of functional hemo globin an d ther efor e the accuracy

may be interfered with by carboxyhemoglobin or other dyshemoglobins present in significant

concentrations. Oxygen saturation monitoring is intended to be used in a variety of clinical

situations, including, but not limited to respiratory therapy, anesthesia, intensive care, and

emergency.

The Model 515B/C Pulse Oximeter has electrically isolated inputs. Patient leakage current

flowing from the instrument to ground is limited to less than 10 µA at 120 V, 60 Hz. Patient

isolation is greater than 10 MΩ, 2500 V rms at 60 Hz. For maximum patient and operator safety ,

the following procedures are recommended;

• Failure of Operation: If the monitor fails to respond as described, do not use until the

situation has been corrected by qualified personnel.

• Keep the Model 515B/C and its accessories clean.

• Do not operate the Model 515B/C when it is wet due to spills or condensation.

• Do not operate the Model 515B/C

• Connect the line cord only to a grounded hospital grade outlet. Th e Model 515B/C should

be connected to the same electrical circuit as other equipment in use on the patient.

Outlets on the same circuit can be identified by the hospital’s engineering department.

if it appears to have been dropped or damaged.

2.1

Indications and Usage

The Model 515B/C is intended to be used for monitoring functional oxygen satur ation and pulse

rate in circumstances where it is desirable to monitor patient oxygenation. The monitor is

designed to monitor all patients including adult, pediatric, and neonatal. The Model 515B/C is

not intended for any other purpose.

NOTE: Components of this product and its associated accessories which may have patient

contact are free of latex.

Rev. 01 Model 515B/C Service Manual

3

Page 14

2

Patient Safety

Warnings

2.2

!

Warnings

• Explosion Hazard: Do NOT use the Model 515B/C in the presence of flammab le

anesthetics. Use of this instrument in such an environment may present an explosion

hazard.

• Electrical Shock Hazard: Always turn the ox imeter off, and remov e the AC power cord

before cleaning it. Do NOT use a damaged sensor or one with exp osed electrical contacts.

Refer servicing to qualified service personnel.

• Patient Safety: Extreme care should be exercised with neonates to assure continued

circulation distal to the sensor site after application.

• Failure of Operation: If the oximeter fails to respond as described, do not use it until

the situation has been corrected by qualified personnel.

• Data Validity: The Pulse Oximeter should NOT be used as a substitute for an ECG

monitor. The oximeter’s Pulse Rate display reflects the pulsatile flow found at the patient

extremity connected to the sensor. This rate can be affected by many factors and may

occasionally be “frozen.”

• Care should be exercised to assure continued peripheral perfusion distal to the SpO

sensor site after application.

• Data Validity: Do NOT attach a sensor distal to a blood pressure cuff. Valid data

CANNOT be processed when the cuff is inflated. Attach the sensor to the limb opposite

to the site used for the blood pressure cuff.

• Data Validity: Inaccurate SpO

of the following:

• Do Not apply Y-Sensor tapes or wraps so tightly that circulation is restricted. Inspect site

often for adequate circulation - at least once every four hours. When applying sensors

take note of patient’s physiological condition. For example, burn patients may exhibit

more sensitivity to heat and pressure and therefore additional consideration such as more

frequent site checks may be appropriate.

Warning

Indicates a potentially harmful condition

that can lead to personal injury.

2

and/or Pulse Rate measurements can be caused by any

2

• Incorrect application or use of a sensor

• Significant levels of dysfunctional hemoglobins such as

carboxyhemoglobin or methemoglobin

• Significant levels of indocyanine green, methylene blue, or other

intravascular dyes

• Exposure to excessive illumination such as surgical lamps - especially ones with

a xenon light source, or direct sunlight

• Excessive patient movement, venous pulsations.

• Electrosurgical interference.

4

Model 515B/C Service Manual Rev. 01

Page 15

Cautions

Patient Safety

2

2.3

Cautions

Caution

Indicates a condition that may lead to

equipment damage or malfunction.

• Do not operate the Model 515B/C when it is wet due to spills or condensation.

• Do not operate the Model 515B/C if it appears to have been dropped or damaged.

• Never sterilize or immerse the monitor in liquids.

• Do not sterilize or immerse sensors except as directed in this manual.

• Excessive tension should not be applied to the sensor cable.

• Do not store the monitor or sensors at temperatures less than 14 °F (-10 °C) or greater

than 131 °F (55 °C).

• Do not operate the monitor or sensors at temperatures less than 50 °F (10 °C) or greater

than 104 °F (40 °C).

• Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order

of a licensed medical practitioner.

• Do not stretch the finger sensor open beyond the limit for which it was designed.

Overstretching the pulse oximeter finger sensor can damage the sensor and potentially

affect pulse oximeter readings. Overstretching can be prevented: avoid opening the

sensor by any means other than squeezing the grips; DO NOT force the sensor onto large

objects such as a bedrail.

Rev. 01 Model 515B/C Service Manual

5

Page 16

2

Patient Safety

Cautions

[This page intentionally blank.]

6

Model 515B/C Service Manual Rev. 01

Page 17

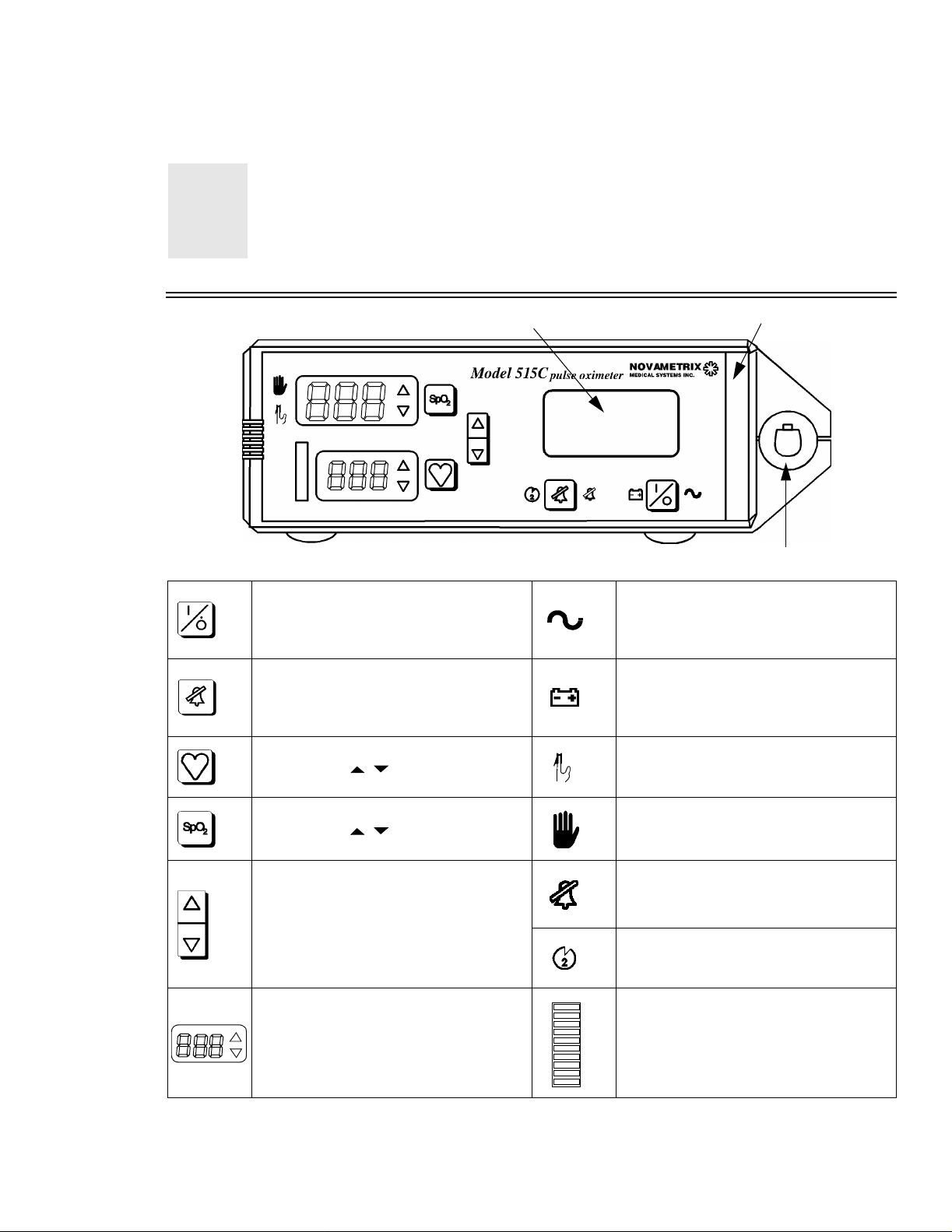

3

Front and Rear Panel Illustrations

WAVEFORM DISPLAY ON MODEL 515C ONLY

POWER button - Press to turn the monitor

on or off.

Audio key - Press to toggle two minute

silence, and reset alert conditions (when

active). Press and hold for audio disable.

Pulse Key - Sets pulse rate alert limits when

used with the keys. Press and hold

to set auto alert limits.

SpO

key - Sets saturation alert limits when

2

used with the keys. Press and hold

to set auto alert limits.

ALERT BAR

SENSOR INPUT

AC indicator - Green when the monitor is

connected to AC power and rear panel

power entry module switch is set to “|”

(ON). Also indicates the battery is charging.

Battery icon - Green when operating on ba ttery with a charged battery, orange when

battery power is diminished, flashes red

when battery power is at a critical low.

Finger probe icon -Flashes red when no

probe connected or probe off patient. Red

for any sensor errors.

Hand icon - Yellow when monitor is searching for valid signal and data is being held.

Increase/decrease keys - Press to set pulse

and alert audio level. Sets alert limits when

used in conjunction with SpO

keys. Press and hold to control graph ics display contrast on Models 515C (Model 515B

does not have graphics display option).

Saturation and pulse rate displays - Saturation and pulse rate values will appear. Status

messages will appear if necessary, see

“Troubleshooting ” on p age 31. Arrows indicate alert status or that alerts are being set.

Rev. 01 Model 515B/C Service Manual

and Pulse

2

Audio disabled icon - Flashes yellow when

the audio has been disabled.

Two minute silence indictor - Illuminates

yellow when the audio has been muted for

two minutes.

Signal bar - Pulses with respect to monitored pulse rate. Amplitude corresponds to

signal strength.

7

Page 18

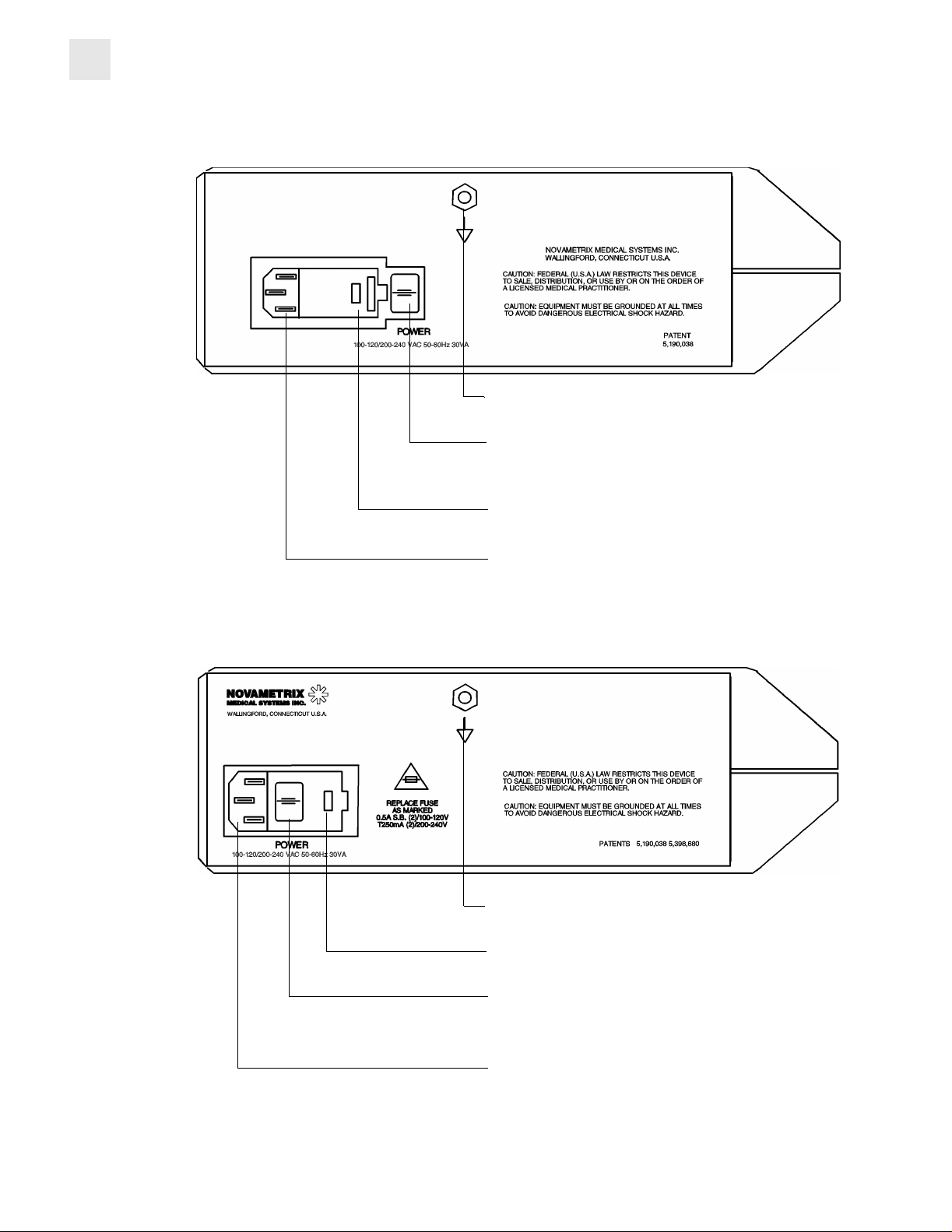

3

Front and Rear Panel Illustrations

EARLIER REAR PANEL

Ground stud - Use to connect monitor’ s chassis to earth

ground.

Rear panel power switch - Set to “|” allows AC mains

to power monitor, set to “O” switches A C main s p ower

off.

Voltage select/fuse comp artment - Sets mains operating

voltage and houses mains fuses.

Power cord entry - P lug power co rd into this recep tacle.

Use only hospital grade three wire plugs for connection

via supplied power cord.

NEWER REAR PANEL

Ground stud - Use to connect monitor’ s chassis to earth

ground.

Voltage select/fuse comp artment - Sets mains operating

voltage and houses mains fuses.

Rear panel power switch - Set to “|” allows AC mains

to power monitor , set to “O” switches AC mains power

off.

Power cord entry - P lug power co rd into this recep tacle.

Use only hospital grade three wire plugs for connection

via supplied power cord.

8

Model 515B/C Service Manual Rev. 01

Page 19

4

Summary of Operation

This section gives a brief description of the operation of the Model 515B/C monitor. For more

detailed information refer to the Model 515B/C User’ s Manual (Cat. No. 6500-23/65 50- 23).

4.1

4.2

Turning the monitor ON/OFF

The key controls powering the monitor on and off. To charge the battery from AC mains

ensure that the power cord is connected and plu gged into a hospital grade three prong outlet. Set

the rear panel power switch to | (ON). Che ck that the front panel icon is gree n, this

indicates that AC mains power i s connected to the monitor and chargin g the internal battery . The

monitor will operate on its internal battery power when the rear panel power switch is set to O

(OFF), or if the power cord is removed.

When operating on a fully charged battery the icon on the front panel will turn green. As

the battery charge dimini shes and reaches a low le vel the icon will turn orange. When the battery

has reached a critical low the icon will flash red . If AC mains po wer is not connected at this time

to power the unit and rechar ge the battery, the monitor will flash a red icon, emit an alarm

tone, then shut itself off.

Displays

When a sensor is connected to the monitor and detecting pulsatile data the SpO2 and pulse rate

values will appear in their respective displays. The signal bar will pulse in accordance to the

pulse rate, and on Model 515C, the graphics display will show a plethysmogram (the wa v eform

will travel from left to right).

The and indicate conditions regarding sensor activity; poor signal, probe not

connected, etc. Refer to the User’s Manual for more detailed information (Cat. No. 6500-23/

6550-23).

4.3

Rev. 01 Model 515B/C Service Manual

Adjusting Alert Limits

The Model 515B/C can have its alert limits manually adjusted, or automatically adjusted1. To

manually set the alert limits press eithe r for SpO

Pressing the appropriate key once will allow adjustment of the high limit using the up/down

arrow keys. Pr essing the same button twice will allow adjustment of the lo wer aler t limit. If the

key is pressed a third time the m onitor will exit the alert limits setting mode and retur n to normal

operation and displays.

For example: Press once, use to adjust upper alert limit. Press again, use

to adjust lower alert limit. Press a third time to exit alert limits mode, or wait

for 10 seconds.

1. For automatically set alert limits the monitor must first have acquired valid data on which to base the limits on for a specified amount of time.

2

limits, or for pulse rate limits.

2

9

Page 20

4

Summary of Operation

Adjusting Volume Levels

T o acti v ate auto alert limits press and hold either the k ey f or saturation, or the k ey for

pulse rate. The monitor will temporarily display the new upper, then lower limits on the

saturation or pulse rate display, depending upon which limits were set, then return to normal

operating mode.

4.4

4.5

4.6

Adjusting Volume Le vel s

Both pulse beep and alert volume can be separatel y adjusted. To adjust the pulse beep press

, “Pul” will appear in the SpO

through 7. To adjust the alert volume press , “Alr” appears in the SpO

to adjust the alert volume level from 1 through 7.

NOTE: When the monitor is sounding an alert (with audible alerts enabled - not

illuminated), the keys will control the alert volume only.

display, use to adjust the volume level from 0

2

display, use

2

Muting Alerts

The key controls two minute audio muting, audible alert disable, and alert acknowledge.

Pressing will activate the two minute audible alert mute. Press and hold until

illuminates to activate audible alert disable. Pressing again will cancel either the two

minute mute or the audio disable (which ever is active). Press to acknowledge and reset

alert conditions.

Contrast

Press and hold the key to vary the contrast of the graphics display ( on Model 51 5C only ).

The SpO

the keys to vary the contrast. The moni tor will return to norm al operating mode ten

seconds after the last key depression.

display will show “Con” to indicate that the monitor is in contrast adjust mode. Use

2

2. There is a ten second time-out counter that starts each time the SpO2 or pulse key is pressed. When the counter times-out

the monitor will return to its normal operating mode.

10

Model 515B/C Service Manual Rev. 01

Page 21

5

Electroni c Theory of Operation

The electronic theory of operation of the Model 515B/C Pulse Oximeter is detailed in the

subsections below. Refer to Section 13, Schematics and Assembly Drawings, on page 63 for

schematics and assembly prints.

5.1

2532/2725 Power Supply Board

The Power Supply Board co ntains the circuitry needed to char ge the battery from th e A C Mains

(line voltage). The monitor may be supplied with either the 2532 or the 2725 power supply

board. The 2532 board is manufactured with thru-hole components while the 2725 is mostly

surface mount technology. The circuitry is identical therefore the theory of operation that

follows applies to both assemblies.

5.1.1

AC Mains and Battery Operation Overview

The Model 515B/C is powered from its internal 12 v olt battery that is charg ed when the monitor

is connected to the A C line. The g reen (sine wave shaped) fron t p anel indicator illuminates

when the line cord is connected and the rear pan el po wer switch is in th e “|” (On) p osition. This

indicates that AC Mains power is charging the battery.

If AC mains power is removed by unplugging the line cord, or setting the rear panel power

switch to the “0” (Off) position, the monitor will operate for up to eight hours from its internal

12 volt lead-acid battery on a full charge. As the battery voltage runs low ( ≈11.5 volts), the

(battery icon) on the front panel will turn orange. At this point, the AC Mains should be

reconnected to charge the battery.

If the monitor continues to be powered from a battery in a low voltage situation, at

approximately 10.5 volts, a continuous alarm sounds for sixty seconds while the battery

indicator will flash red. A “bAt” and “Lo” message will appear in the SpO

displays respectively. If this alarm is ignored, the monitor will shut down . The A C mains sho uld

be connected to the monitor to recharge the battery before this occurs.

and pulse rate

2

5.1.2

Rev. 01 Model 515B/C Service Manual

AC Mains Operation

Reference the Overall Wiring Diagram. The AC Mains voltage enters the monitor at the rear

panel Power Entry Module (PEM10 1). This device contains a built in RFI power line filter, a

double-pole single-throw switch that opens and closes both AC input lines, fuses, and an input

voltage selection key.

The filtered, switched, and fused output of the Power Entry Module is fed to the primary coils

of the system transformer, T301. Reference the Power Supply schematic 2532-03 or 2725-03.

The secondary output from T301 is rectified by D1 (bridge rectifier) and filtered by C1. The

(loaded) DC voltage at this point is approximately 20 volts.

The 20 volts DC is fed to the battery charging regulator IC1 (pin 5) through Q1. Biasing for Q1

is accomplished by D2, R1, and R2 when A C po wer is applied. When running on battery po wer ,

11

Page 22

5

Electronic Theory of Operation

Q1 is biased off by R1, R2, and D3. This prevents the battery from trying to power the battery

charger regulator.

The output of switching regulator IC1 pin4 is rectified and filtered by D4, C4, and L1, then fed

to the battery through current sense resistor R3 and fuse F302, to J302 pin 1 (VBAT+). The

battery float charge voltage is maintained at 13.2 volts ex cept for f ast char ge that is re gulated at

14.4 volts. The output is also monitored for over current conditions. These parameters are

controlled by IC3 and associated circuitry. When the battery charge current exceeds a preset

limit, IC3 pin 7 goes high w hich biases Q2 on, this i n turn shorts out R12 which affects the

feedback control (FB) to IC1 (pin 1). With R12 shorted out, the control resistors R14 and R13

set the output voltage to 14.4 volts. When the charge current lowers, IC3 pin 7 goes low which

biases Q2 off, this puts R12 back into the feedback con trol which no w consists of R12, R13 and

R14; setting the voltage to 13.2 volts. When more than the maximum charge current flows

through R3, IC3 pin 1 shorts IC1 pin 2 to ground, that shuts IC1 o ff until its ne xt switching cycle.

When the current reaches a safe level IC3 pin 1 allows IC1 to remain on.

Main Board

5.2

Main Board

5.2.1

The 2721 or 2723 Main Board contains all the analog and digital circuitry that controls the

sensor, front panel display, and user interface. The isolated power supplies, microprocessor,

analog circuits, and memory are all contained on this board . The 2722 or 272 4 ver sion contains

the graphics display for model 515C, otherwise the circuitry is identical. Units with the newer

2723 (for Model 515B) or 2 724 (Model 515C) board can be identified with an “X” in the serial

number suffix.

Power On/Off Control Circuitry

When connected to the AC line (front panel AC icon illuminates green) the internal battery is

charging, this occurs whether or not the monitor itself is turned on. The monitor is powered on

by pressing the front panel power key, pressing this key while the monitor is on will shut it off.

The actual turning off is contro lled b y the pr ocessor, this enables the processor to control when

the power is removed to avoid corrupting RAM contents (e.g. turning power off while writing

to, or reading from RAM).

Power enters the main board through J404, see page 4 on schematic. When the monitor is

connected to the AC mains power, the LINEST voltage will be high indicating that AC line

power is available and charging the battery. The LINEST line will bias the green LED D16 on

through current limiter R28 (see page 2 on schematic). This LED illuminates the AC indicator

icon on the front panel. When the monitor is running off of its internal battery (no AC mains

power av ailab le), the V B ATTERY line will be supplying power for the monito r. This will cause

D17 to be reverse biased (LINEST low, VBATTERY @ battery voltage) and no voltage will

appear at LINEST, therefore D16 will be biased off.

When the front panel power key is pressed VBATT biases Q8 on through R31, R97, and D18.

When Q8 is on, VBATT biases Q10 on thro ugh R9 1 and R92, this in turn powers IC17, a pulse

width modulated switching power supply. The LEDPWR supply is generated by IC17, Q11,

D32, T1 and filtered by C59-C63 (C89 added on 2723/2724 board). The voltages used by the

main board are all derived from the LEDPWR supply.

When the monitor is on and the front panel power key is pressed (to turn the monitor of f), IC10

pin 12 will go low (se e page 1 on schema tic). This will drive the ou tput of IC8 pin 8

(PWRNMI*) low when the KEYS* line is brought low by the processor (IC1 pin 9). The

PWRNMI* line drives the NMI line of the processor , when this line is brought lo w the processor

will bring the PWROFF line high thr ough IC14 pin 12. When the PWROFF line is high, Q13

will turn on, this in turn sets the PFI input (pin 4) of IC4 low. This will set the PWROFF* line

12

Model 515B/C Service Manual Rev. 01

Page 23

Main Board

Electronic Theory of Operation

IC4 pin 5 low, biasing Q2 on (page 4 on schematic). W i th Q2 on, Q8 and Q1 0 will be biased of f,

shutting down IC17 which turns the monitor off.

5

5.2.2

5.2.3

Power Supplies and Voltage References

See page 4 on schematic. The 5 vol t supply VDD is re gulated b y IC18 , a lo w dropout re g ulator.

The -VA supply is generated by IC19 from the LEDPWR supply. This supply is synchronized

to front end timing signals by the SYNC line via C82, R127, R120, D35, and Q7. Without this

synchronization, ailiasing frequencies m ay interfere with sensor measureme nts. The +VA

supply is drawn from the LEDPWR line through filter coil L2.

The LEDSRC supply , used by the sensor LEDs, is regulated by IC20. Fuse F201 protects against

over current conditions. This supply is connected to the sensor‘s LED anodes when a sensor is

connected.

See page 3 on schematic. A -5 volt, and a 2.5 volt reference (VREF2.5) are needed for the 8 bit

D/A conv erter I C31 , the A/D co nverter IC26, and for the 20 bit A/D converters IC23 and IC24.

The 2.5 volt reference is generated by IC29 from the +VA supply. The output of IC29 pin 6

(VREF2.5) feeds the input of inverting amplifier IC30a. The output of IC30 a drives the base of

Q12 which creates a low impedance -5 v olt source -V5 at i ts emitter. The -5 volt source is used

by the eight channel multiplexor IC25, t he 20 bit A/D converters IC23, IC24, and the eight bit

D/A converter IC31.

Sensor LED Drive Circuits

Each LED (one red and one infrared) in the sensor is driven separately. Since the circuitry is

similar only one channel will be discussed, the corresponding co mponents for the other chan nel

will appear in brackets. See page 3 on schematic.

The VLED voltage is used b y b oth chan nel’s drive circuitry. When IC31 is enabled b y the WR*

and DA CCS* lines, the processor programs a voltage b y inserting a particu lar v alue on the data

lines D0-D7. This voltage appears at the output of IC30b pin 7 and is labelled as VLED.

When the REDLED* [IRLED*] line is low Q3 [Q4] will turn off, this allo ws the VLED volta ge,

divided by R48 [R46 ] and R47 [ R49 ], to dr ive the non-inverting inp ut of I C27 a [IC27b ]. Wh en

IC27a [IC27b] output is high, Q6 pins 3, 4, 5, 6 [1, 2, 7, 8] will turn on, this pulls current through

the sensor LED from the LEDSRC supply (fed to the sensor from J403 pin 1). When the

REDLED* [IRLED*] line is high, the input of IC27a [IC27b] is brought to ground potential

because Q3 [Q4] is biased on. This shuts Q6 off resulting in no current flow through the LED.

5.2.4

Sensor Photodiode Return Path

Light, from the sensor’s Red or Infrared LED, shines through the pulsating vas cular bed (the

patient’s finger, toe, etc.) placed between the LEDs and the photodiode. Some of this light

emerges from the tissue and impinges on the photodiode, causing the photodiode to conduct

current. See page 3 on schematic. IC21b pins 5-7 are set up as a differential amplifier that

converts this input current to a voltage at the amplifier output. The sensors are wired such that

photodiode current produces a positive v o ltag e at IC21b pin 7

The voltage at IC21b pin 7 is presented to an analog switch IC28b p in 6. This switch is

controlled at pin8 by INSIG*

except if the monitor is in a Probe Off Patient condition or is undergoing its self-test at system

power up. The switch IC28c pins 9- 11, contro lled from SIGND*

1. The Model 515B/C uses SuperBright™ sensors (part number 87xx series). If a non-SuperBright™ (Novametrix part number 86xx series) sensor is connected, IC4b p in 7 will go negative.

(Input Signal), and will be closed (IC28b pins 6 and 7 connected)

1

.

(Signal Ground), will be open

Rev. 01 Model 515B/C Service Manual

13

Page 24

5

Electronic Theory of Operation

(no connection between IC28c pins10 and 11) except as noted above for the switch at IC28b

pins 6-8. As a result, the IC21b pin 7 voltage passes undisturbed to the high pass filter consisting

of R70 and C28.

Main Board

5.2.5

The ASAMP*

turn off and the signal at C28 passes through to IC21a pin 3. The ASAMP*

high when neither LED is being driv en, causing Q5 to turn on. W ith Q5 conducting, any voltage

at C28 is discharged to ground and the ne xt pulse will char ge C28 from a kno wn le vel. If it were

not for Q5, any charge remaining on C28 from the previous pulse, or from ambi ent light

reaching the photodiode, would be added to the charge from a new pulse—creati ng

measurement errors.

If the signal at IC21a pin 1 is the product of the Red LED being turned on, then RDSAMP*

go low and close the switch at IC28a pins 2-3. This sen ds the signal to a sample and hold circuit

consisting of R75 and C41 (that maintains the signal until next sample pulse arrives), a gain

stage (IC22a), a filter/divider network (C40, R81 and R82), and finally, to the Red channel

Analog-to-Digital Con vertor (ADC) IC24.

If the signal at IC21a pin 1 is the product of the Infrared LED being turned on, then IRSAMP

will go low and close the switch at IC28d pins 14 -15. This sends the s ignal to a sample and hold

circuit consisting of R73 and C27 (that maint ains the signal until next sample pulse arrives), a

gain stage (IC22b), a filter/divider network (C24, R78 and R79), and finally, to the Infrared

channel Analog-to-Digital Convertor IC23.

signal is active low whenever either sensor LED is turned on. This causes Q5 to

line returns to a logic

will

20-Bit Analog-to-Digital Convertor Self Calibration

The 20-bit ADCs are calibrated as part of the syst em self-test which occurs each time the

monitor is turned on. At power up, the microprocessor sets the CA L line, and the system

calibration input SC1 high. The CS5503 ADC will not operate while the CAL line is high. On

the falling edge of the CAL signal, the ADC will initiate a calibration cycle determined by the

state of the SC1.

*

5.2.6

The high at SC1 causes INSIG*

opens the switch at IC28b pin8 so that IC28b pins 6 and 7 are no longer connected—

disconnecting the returning photodiode signal from the rest of the circuitry. The low SIGND*

signal closes the switch at IC28c pin9 and as a result, the input to the C28-R70 high pass filter

(and thus the entire ADC input circuitry) is broug ht to ground potential.

The CAL line (which went high at power up) is reset low and ADCs IC23 and IC24 begin their

calibration cycles. Because the analog input circuitry is grounded vi a SIGND*

offset voltages can be present at the (pin 9 AIN) inputs. The calibration cycle sets the ADC

“zero” point to equal this voltage, thus compensating for any circuitry offsets. The ADC then

sets its “full scale” point to equal the voltage at its VREF (pin 10) input. This completes the

calibration cycle.

The ADC can now start sampling its input and converting it to a 20-bit digital word. The

processor resets SC1 to a logic low, causing IC28c pin9 to open and IC28b pin8 to close. The

photodiode signal can now reach the ADCs. See Sensor Photodiode Return Path on page 13.

to go high and reset SIGND* to a logic low. The high INSIG*

, only circuit

20-Bit Analog-to-Digital Conversion

Data from the Red and Infrared channels is sampled by the 20-bit measurement ADCs, IC23

and IC24 respectively. The analog input at pin 9 is converted to a digital repr esentation with 20bit resolution based on the input magnitude.

14

Model 515B/C Service Manual Rev. 01

Page 25

Main Board

Electronic Theory of Operation

The CS5503 conv er ter continuo usly samples its input, converts the value to a digital word, puts

the word in its output buffer (overwriting previous buff er conten t s), then repeats the process b y

again sampling its input. The frequency of the sample/convert/overwrite-buffer sequence is

based on the 3.2768 MHz clock signal at the ADC pin 3 (ADCCLK) input.

The microprocessor starts a read cycle of the Infrared channel by bringing IC23 pin 16

(ADCIRCS*) low . A Red chan nel read star ts when IC24 pin 16 (ADCREDCS*) is brought low.

5

5.2.7

On the falling edge of the ADC’ s CS*

the pin-20 SDATA (Serial Data) output. The SDATA line connects directly to the

microprocessor’s serial input (RXS) pin. The remaining bits (in descending order) are output

from SDATA with subsequent falling edges of the Serial Clock (SCLK) input at pin 19. The

SDATA output automatically goes to a 3-state (high impedance) condition after completing a

word transmission, thus freeing the data line for other uses (i.e., the other ADC channel).

The Serial Clock rate is significantly slower than the ADC sampling rate. As a result, the ADC

rewrites its outpu t buf fer with new inf ormation at a f aster rate than the data can be read from the

buffer. No conflict occurs, however , because while CS*

does not update its output buffer—the current word is not overwritten. After the processor

receives the entire word, it allows the convertor’s CS*

sample/convert/overwrite-buffer cycle.

, the output word’s MSB (most significant bit) appears at

is low (d uring th e read cy cle), the AD C

to return high, and the ADC resumes its

Sensor Status Decoding and Conversion

The microprocessor monitors se veral sensor parameters in addition to th e Red and Infrared data

channels. It monitors the status parameters, as well as the voltage of the monitor’s internal

battery . See page 3 on schematic.

The 8-to-1 multiplexer, IC25, decodes the A0MUX-A2MUX input address lines and connects

one of eight status parameter inputs to the multiplexer output at IC25 pin 3. Resi stor R88 and

diode D19 preve nt negative voltages from reaching the input to the analog-to-digital converter,

IC26.

IC26 is an 8-bit analog-to-digital con vertor with a serial data output. While the IC26 Chip Select

(ADC3CS*

brought low (under processor control), the most significant bit (D7) of the PREVIOU S data

conv ersion becom es a v ailable at the SDA TA pin. The remaining bits (D6- D0) ar e shifted out o n

subsequent falling edges of the CLK input. On the clock pulse following the one that shif ts out

the least significant bit (D0), the CLK and SDATA lines are returned to 3-state and the ADC

performs a new con v ersion based on the input it recei ves from the IC25 channel selected by the

A0MUX-A2MUX input address lines.

) input is high, the CLK input and SDATA output are in 3-state mode. When CS is

The ADC sample/convert/store-result cycle is based o n internal chip timing and not the CLK

input which (along with CS

high once the ADC cycle begins.

5.2.8

Rev. 01 Model 515B/C Service Manual

Front End Timing Signals

See page 1 on schematic. A 14 stage divider IC6, acts as a timing sequencer. The ADCCLK

input is the clock input, the RESET line is the clear input, used for clearing the chip at power

up. The Q4-Q11 outputs of IC6 are divided down from the clock input and feed IC13, the data

sampling controller. The Q14 output of IC6 is used as an interrupt that is genera ted every 5

milliseconds (INT5MS).

The data sampling controller IC13 is a Programmable Electrically Erasable Logic device

(PEEL). The PEEL uses the outputs from IC6 and generates th e front en d timing s ignals. These

) only controls serial data output. Thus the CS line is free to return

15

Page 26

5

Electronic Theory of Operation

signals control the sensor LED drive and the photodiode’s return path circuitry during normal

operation and calibration.

The RESET and SC1 lines control when the outputs of IC13 are active, both these lines must be

low in order for IC13 to operate normally. The RES ET line controls IC13 during power up,

while the SC1 line is under processor control and will toggle when a probe o ff patient alert e xists

and during the power up self test.

Main Board

Signal Description

5.2.9

INSIG*

Input Signal

RDLED*

Red LED

IRLED*

Infrared LED

SIGND*

Signal Ground

ASAMP*

Analog Sample

SYNC

Synchronization

IRSAMP*

Infrared Sampling

RDSAMP*

Red Sampling

This line will enable signals from the phot odiode, or prevent signals from the photodiode from reaching the detection circuitry.

Controls the signals for the Red Led in the sensor.

Controls the signals for the Infrared Led in the sensor.

This is used to short out the inputs of the detection circuitry so that

the system can compensate for offsets.

This line is used to short out the capacitor used in the sample and

hold circuitry to avoid having residual charge i nterfere with data

sampling.

Synchronization signal used for the -VA supply.

Used for sampling the Infrared signal response from the photodiode.

Used for sampling the Red signal response from the photodiode.

Sensor Status Parameters

The sensor (and battery) status parameters input to the multiplexer IC25 (page 3 on schematic)

are described below.

ADCFEDC: Photodiode DC Level.

Resistors R66, R67 and capacitor C33 f orm a voltage divider and low pass filter that provide a

measure of the mean DC level at the output of the photodiode current-to-voltage amplifier

IC21b pin 7. This signal is used in determining ambient light interference. If this line is

examined while the sensor’s Red and Infrared LEDs are turned of f, then any DC level at IC21b

pin 7 must be the result of ambient light imp inging on the photodiode. I f the DC shift is in excess

of limits set in the software, a light interference message appears on the monitor’s display.

ADCLPWR: Sensor LED Supply Voltage.

This channel, at IC25 pin 12, monitors the sensor LED supply v oltage thr ough a voltage di vider

consisting of R113 and R114. If a fault occurs that causes the LED supply fuse F201 to blow,

or if the sensor wires are shorted, this channel reports the condition and the monitor will indicate

an error condition.

ADCIRLED: Infrared LED Cathode Voltage.

A low pass filter consisting of R60, R61 and C51 provides a means to measure the cathode

voltage of the sensor’s Infrared LED. If the channel at IC25 pin 5 is sampled the monitor can

determine if the LED is open circuit (zero volts at IC25 pin 5) or operational (approximately 2.5

volts at IC25 pin 5).

16

Model 515B/C Service Manual Rev. 01

Page 27

Main Board

Electronic Theory of Operation

BATLEV1: Battery Level 1

The monitor’s battery voltage is divided down by R9 4 and R106. The voltage at IC25 pin 1 is

monitored, and if its magnitude is less th an a pre determined v alue ( encoded in th e softw are) the

monitor indicates a low battery warning.

BATLEV2: Battery Level 2, this signal is not used as of this writing.

LINEST: The LINEST line from the power supply is divided down by R94 and R106. The

voltage at IC25 pin 2 is monitored to determine if the AC mains is connected and charging the

battery.

ADCRDLED: Red LED Cathode Voltage.

A low pass filter consisting of R58, R59, and C50 provides a means to measure the cathode

voltage of the sensor’s Red LED. If the channel at IC25 pin 4 is sampled the monitor can

determine if the LED is open circuit (zero volts at IC25 pin 4) or operational (approximately 2.5

volts at IC25 pin 4).

ADCVRD: This signal is not used as of this writing (not shown on 2723/2724 board).

ADCVIR: This signal is not used as of this writing (not shown on 2723/2724 board).

5

5.2.10

Serial I/O Controller

See page 1 on schematic. Digital data from the three Analog-To-Digital Convertors is read by

the CPU through its clocked serial data inp ut (SD ATA) at IC1 pin 56. The PEEL IC7 acts as the

Clocked Serial Input/Output (CSI/O) Controller .

Except during power up or Watchdog Timer reset, IC6 pin 3 prov ide s an interrup t to the CSI/O

controller in the form of a 5 millisecond period square-wave input to IC7 pin 7 (INT5MS).

On the rising edge of INT5M S, a CPU interrupt request is generated whe n IC7 pin 18

(CPUINIT*

at IC7 pin 6 low . (Th is CKS line is inactive h igh unless a serial receiv e operation is in progress.)

The CPU also sets up the ADC decode lines AA1 and AA0 at IC7 pins 5 and 4, and as a result,

one of the ADC chip select lines (ADCIRCS*

the CPUINIT*

On the rising CKS signal a CLKS output pulse at IC7 pin 14 is sent as a serial clock input to the

ADC selected by the decode lines. Decode results are shown below.

) goes low . The CPU responds by sending the clock input to CSI/O controller (CKS)

, ADCREDCS*, ADC3CS*) is brought low, and

line is disabled.

AA1 AA0 Decode

0 0 Red LED 20-bit ADC

0 1 Infrared LED 20-bit ADC

1 1 Sensor Status 8-bit ADC

1 0 Internal CSI/O signal (TEND)

Successive CKS/CLKS pulses cause the ADC data to be shifted out of the ADC (most

significant bit fir st) along the serial data line (SDA TA) to the CPU serial input (RXS) at IC1 pin

56.

After receiving the correct number of bits for the ADC being read, the CPU changes the AA1

and AA0 decode lines and exerts the Next line (NEXT*) at IC12 pin 12 low. This restarts the

serial data shifting out of the newly selected ADC.

Rev. 01 Model 515B/C Service Manual

17

Page 28

5

Electronic Theory of Operation

After all three ADCs have been read, the CPU sets the AA1 and AA0 decode lines to exert the

internal TEND signal and set the 8-bit AD C to the next channel (so that it has time to settle

before the next read of the A DC). This re-enables the CPUINIT line. At this point the CSI/O

controller is reset awaiting an INT5MS pulse to begin the cycle again.

Main Board

5.2.11

5.2.12

Microprocessor and Memory

The Model 515B/C is controlled by IC1, an 8 bit microp rocessor running at 6.14 MHz (see p age

1 on schematic). Crystal Y1 controls the operating frequency, system address lines are labelled

as A0-A17, system data lines are labelled D0-D7.

The system program is contained in IC3 a 27CC101 EPROM, when both RD* and ROMCS*

are low a read operation is perfor med on IC3. The ROMCS* line is controlled by the ME* line

(Memory Enable) and ad dress line A17 . When bo th the ME* line and add ress line A17 are low,

the ROMCS* line will go low (IC9 pin 6), this enables IC3.

System RAM is contained in IC2. When both the RD* and RAMCS* lines are brought low, a

read operation is performed on IC2. With both WR* and RAMCS* low, a write operation will

be performed. The RAMCS* line is controlled by the ME* line and address line A17. When

address line A17 is brought high, and the ME* line bro ught low, IC9 pin 3 will go low activ ating

the RAMCS* line. The ability of the RAMCS* line to reach the chip select of IC2 is controlled

by Q15, unless the VDD supply is established, neither a read nor write can be perf ormed on IC2

(system RAM).

Decoding

A three to eight line decoder I C11, is used for decod ing variou s write, enable, and interrupt lines

for the system. Address lines A4, A5 , A6, and A7, an d the IOE* (inpu t output enab le) and LIR*

(load instruction register) lines from the processor , will enable one of the Q outputs of IC11. The

table below lists the lines that are controlled by IC11.

Name Function

DACCS*

Digital to Analog Controller Write

DISPCS1*

Display Chip Select 1

DISPCS2*

Display Chip Select 2

TONECS

Tone Chip Select

INT1*

Interrupt #1

PWRNMI*

Power Non-Maskable Interrupt

PORT1WR

Port #1 Write

Enables IC31 for writing, this controls the LED voltage VLED.

Control signal for the graphics display (if installed)

Control signal for the graphics display (if installed)

Chip select for the tone generator IC32, and digital

potentiometer IC33.

Spare interrupt (not shown on 2723/2724 board)

This line turns the monitor off. When the PWRSWIN

line is brought high (by pressing the front panel

POWER key) and the KEYS* line is low, the

PWRNMI line will signal the processor to shut off.

This line is controlled by the WR* line of the processor

and the PORT1CS* line from IC11. It enables writing

to IC12, this controls the multiplexer lines, SC1 line

for the 20 bit A/D Converters, control lines for IC7,

and the LOAD line for the displays.

18

Model 515B/C Service Manual Rev. 01

Page 29

Main Board

PORT2WR

Port #2 Write

RDKEY*

Read Keypanel

Electronic Theory of Operation

Name Function

Controlled by the WR* line and PORT2CS* from

IC11. This line will enable writing to IC14. The 20 bit

A/D converter CAL line, front panel LEDs, and power

off control are handled by IC14.

The KEYS* and RD* control this line that enables IC5

to read the keypanel for key depressions and the configuration header J406.

5

CNTRCS*

Contrast Chip Select

5.2.13 Microprocessor Supervisor

A microprocessor supervisory integrated circuit IC4 monitors the VDD power supply for low

voltage conditions, and the WDOG (watchdog) line to verify that the processor is st ill in control

of the monitor. A failure of either of these two conditions will result in the monitor being shut

off. It also controls turning the monitor off during a normal power down, see Power On/Off

Control Circuitry on page 12.

5.2.14

System Output Ports

There are two output port chips IC12 and IC14, that control various lines for system control.

The first port IC12, enabled when POR T1WR is high, contr ols the CSIO PEEL IC7, the analog

multiplexor IC6, and the 20 bit analog to digital converters IC23, and IC24. The second port

IC14, enabled by the PORT2WR line, handles the front panel LEDs and the CAL line for the

20 bit A/D convertors. The second port also controls turning the monitor off through the

PWROFF line.

The output ports are selec ted by th e decoding perfor med by IC11 and the W R* line. The sign als

controlled by the ports are listed below with a brief description of their function.

Signal Description

AA0-AA1 Decode line for selecting ADCs.

Select line for the digital potentiometer IC34, used to

adjust the contrast on the optional graphics display.

SC1 Used for 20 bit ADC calibration.

LOAD Control line for the display driver IC15

A0MUX-A2MUX Selects one of six channels that will be switched to the serial A/D

converter for conversion.

NEXT* Used in decoding selection of ADCs.

CAL De-activates the 20 bit ADCs prior to calibration.

2MIN_LED Illuminates the 2 minute mute LED, D13.

AUD_OFF_LED Illuminates the audio off LED, D14.

WAIT_LED Biases Q9 on, which in turn illuminates the hand LED, D8.

KJL Biases Q1 on, which in turn illuminates the four alert bar LEDS,

D28-D31.

RED_BAT Illuminates the red battery icon LED, D15.

GREEN_BAT Illuminates the green battery icon LED, D15.

Rev. 01 Model 515B/C Service Manual

19

Page 30

5

Electronic Theory of Operation

PWROFF Turns the monitor off, under processor control.

5.2.15 Displays

The front panel visual interfac e is made up of LE Ds, the only exception is t he Model 515C

graphic display (an LCD DOT matrix). Both saturation and pulse rate displays consist of three

seven segment displays with decimal points (for a total of six displays). The signal bar is a 10

segment LED array, the remaining indicators are LEDs. See page 2 on schematic.

The saturation and pulse rate displays are seven segment LED displays that are controlled by

IC15, a display driver. In addition to controlling the eight segment displays, IC15 also handles

the pulse bar, up/down arrow LEDs for saturation and pulse rate error displays, and the finger

sensor icon LED. The remaining LEDs are controlled by their own signal lines.

Main Board

Signal Description

5.2.16

LED

Alert Bar (D28-D31)

Battery (D15)

D14

D13

D8

D33

Audio Drive Circuitry

Signal Line

When the KJL line is brought high (from IC14 pin 15) MOSFET Q1 will turn on drawing current through LEDs D28-D31.

Diode D15 is a bicolor LED that is controlled by the RED_BAT

and GRN_BAT lines. When both lines are high the LED will

appear orange, otherwise it will be the color of the active line

(red or green).

The AUD_OFF_LED (audio off) is generated from IC14 pin 17.

The 2MIN_LED line from IC14 pin 18 will illuminate the 2

minute audio mute LED when brought high.

Diode D8 is an LED bar that is actually made up of four LEDs

housed in a common package. When the WAIT_LED signal

from IC14 pin 16 is brought high then MOSFET Q9 will turn

on, this will draw current through the four LEDs illuminating

D8.

Diode D33 is an LED bar that actually consists of four LEDs in

a single package (same as D8). When the SEG_DP line from

IC15 is brought high, and the DIG1_1-DIG1_4 lines are brou ght

low diode D33 will illuminate.

The audio in the Model 515B/C is both frequency and volume adjusted, see page 4 on

schematic. The speaker LS1 is driven b y audio amplifier IC16, volu me is controlled by a digital

potentiometer IC33, located in the feedback loop. The digital potentiometer is controlled by the

AUD_INC* line and address line A0. When the TONECS* line from IC11 (pin 12) and the

WR* lines are brought low, the AUD_INC* line from IC9 pin 8 will be brought low. At this

time, the state of the A0 line will dete rmine if IC33 is incremented or decrement ed (high =

incremented, low = decremented). When incremented the volume will in crease, and when

decremented the volume will decrease.

The tone frequenc y is controlled b y IC32, a tone gen erator. When the TONE_CS line is brought

high IC32 is written to by data lines D0-D5. The data on these lines will select the desired tone

for amplification by the audio amp IC16.

20

Model 515B/C Service Manual Rev. 01

Page 31

Main Board

5.2.17 Keypanel and Configuration Header

The processor continually scans the keypanel for a ke y depression, see page 2 on schematic. The

keypanel inputs enter the board at J402, these inputs are tied high by pull up resistors R33-40.

When a front panel key is pressed the appropriate line is brought low.

When a key is pressed the corresponding input to IC5 is brought to a logic low, thi s is then

transferred to the appropriate output pin. When the RDKEY* line is brought low that s ignal is

read by the processor’s data lines. The configuration headers are r ead in the same manner. When

activated, a jumper connects a TSW line to ground (either TSW1-TSW3). At power up these

lines are read by the processor and the configuration, if any, is performed.

5.2.18 Graphics Display

The Model 515C includes a graphic display for the plethysmogram, see page 2 on schematic.

The display connects to the main board at J401. The following lines are used to communicate

with the display:

A0 When high signals data in, when low signals instruction commands.

D0-D7 Data/command input lines

Electronic Theory of Operation

2

5

DISPCS1*

DISPCS2*

RESET* Reset line from the processor.

WR* Write line from the processor.

E Clock signal from the processor.

VLC Contrast control voltage from Q16/IC34.

2721/2722 contrast circuit

The contrast is controlled by digital potentiometer IC34, and transistor Q16 (see page 4 on

schematic). A voltage divider is set up by R121, IC34, and R122 from -VA to ground. The

“wiper” position of IC34 is controlled by the CTRSTCS* and A0 lines. The v oltage le v el at pin

5 is then varied and controls the bias on Q16. The output voltage at the emitter of Q16 (VLC)

controls the contrast level of the display.

2723/2724 contrast circuit

The contrast is controlled by digital potentiometer IC34, and amplifier IC35 (see page 4 on

schematic). A voltage divider is set up by R121, IC34, R122/R130 from the -V5 supply to

ground. The “wiper” position of IC34 is controlled by the CTRSTCS* and A0 line s. The voltage

level at pin 5 is then varied and this is reflected at the output of IC35 (VLC), controlling the

contrast level of the display.

The backlight for the display on the 2723/2724 boards is pulsed rather than dri ven continu ously

in order to conserve energy. The circuitry is displayed on page 1 of the schematic. The Q8 and

Q9 outputs from IC6 drive the input of OR gate IC8 pins 11, 12, 13. The output is then AC

coupled to Q16 which turn on and o ff in a 75% duty cycle. When Q16 is biased on the back light

is on, when Q16 is biased o f f the back light is off (R32 is not installed int he 2723/2724 boar ds).

Display chip enable lines. Each line enables 1/2 of the display.

2. The TSW1 configuration header will disable the audible alert muting if set, the remaining lines are for internal Novametrix

use.

Rev. 01 Model 515B/C Service Manual

21

Page 32

5

Electronic Theory of Operation

Main Board

[This page intentionally blank.]

22

Model 515B/C Service Manual Rev. 01

Page 33

6

Maintenance

This section contains maintenance information for the Mod el 515B/ C monitor and accessories.

6.1

Cleaning and Sterilization

Follow the cleaning and sterilization instruc tions listed below to clean and/or sterilize the

monitor and its accessories.

6.1.1

6.1.2

6.1.3

Monitor

• Turn the monitor off and unplug the line cord from the AC mains before cleaning.

• Clean the monitor surface with a damp cloth.

• Do not immerse the monitor.

• Do not attempt to sterilize the monitor.

SpO2 Finger Sensor

• Clean the finger sensor surfaces with a damp cloth.

• Ensure that the finger sensor windows are clean and dry before reuse.

• Do not immerse the finger sensor.

• Do not attempt to sterilize the finger sensor.

• Perform a “Quick Check” to verify the integrity of the sensor. See User’s Manual.

SpO2 Y-Sensor

• The Y-Sensor may be immersed (up to the connectors) in a cold liquid sterilant (e.g.

Cidex™). Refer to sterilant manufacturer’s instructions and standard hospital protocol.

• Clean the Y-Sensor surfaces with a damp cloth.

• Rinse thoroughly with water and dry before use.

• Do not attempt to sterilize Y-Sensor except as stated above.

• Do not immerse connectors on the Y-Sensor.

• Perform a “Quick Check” to verify the integrity of the sensor. See User’s Manual.

6.1.4

6.1.5

Rev. 01 Model 515B/C Service Manual

Y-Strip Tapes and Foam Wraps

• Treat Y-Strip tapes and foam wraps in accordance with hospital protocol for singlepatient use.

Ear Clips

• Clean the ear clip with a damp cloth.

• Do not immerse the ear clip.

23

Page 34

6

Maintenance

Battery Maintenance

6.2

6.3

Battery Maintenance

If the monitor has not been us ed or powered by AC mains for an ext ended time (3 months or

more) allow the battery to charge overnight before use. To charge the battery connect the AC

mains and set the rear panel power switch ON (|). Check that the front panel battery icon is

green. This will ensure a fully charged battery in the event battery p ower is desired. See

“Assembly Exchanges” on page 29 for instructions on battery replacement.

Replacing AC Mains Fuses

Depending upon which power supply assembly is install ed in the monitor, replacing the fuses

and adjusting the mains supply voltage will differ. Determine which as sembly is installed then

follow the appropriate instructions.

EARLIER POWER ENTRY MODULE

NEWER POWER ENTRY MODULE

CAUTION: Replace fuses with same type and rating. Verify proper fuse value for mains

!

voltage setting (see table below).

Mains Voltage Fuses (Slo Blo) Part Number

100-120 VA C 0.5 A 250V 515023

200-240 VAC 250mA 250V 515033

24

Model 515B/C Service Manual Rev. 01

Page 35

Replacing AC Mains Fuses

6.3.1 Assemblies with the earlier Power Entry Modules

1. Turn off the monitor. Set the rear panel AC mains power switch to “0” and disconnect

2. Place a screwdriver into the fuse access slot and pry open the fuse access door.

the line cord from the monitor.

Maintenance

6

LINE CORD RECEPTACLE

115Vac

VOLTAGE SELECT INDICATOR

3. W ith the fuse access door open pull the fuse(s) out by pulling on the point of the arrow

indicator, the fuse holder assembly will slide out.

FUSE HOLDER ASSEMBLY

115Vac

FUSE HOLDER ASSEMBLY

4. After replacing the fuse(s), snap the fuse-holder assemblies into the power entry

module assembly and shut the fuse access door.

POWER SWITCH

O

FUSE ACCES SLOT

O

6.3.2

Assemblies with the newer Power Entry Module

1. Check that the monitor is OFF.

2. S et the rear panel power entry module switch to OFF (“O”). Remove the line cord from

the power entry module (if connected).

3. Using a flat blade screwdriver, pry the fuse access door open to expose the fuse

housing. Note the orientation of the fuse housing (this determines the mains operating

voltage).

POWER ENTRY MODULE

FUSE ACCESS DOOR

FUSE HOUSING

Rev. 01 Model 515B/C Service Manual

25

Page 36

6

Maintenance

4. Pry the fuse housing out from the power entry module.

NOTE: 5mm X 20mm fuses

OR

FUSE HOUSING

3AG TYPE 5 X 20mm TYPE

5. Replace the blown fuse(s) with the proper type and rating.

are installed t oward t he

“back” of the fuse ho using

as shown

Changing AC Mains Voltage

6.4

6. Re-install the fuse housing. When positioning the housing into the power entry module

ensure that it is ori ented correctly. Pre ss the fuse housing back into the power entr y

module.

7. Close the fuse access door and verify the proper mains operating voltage is displayed.

MAINS OPERATING VOLTAGE

115V

Changing AC Mains Voltage

Depending upon which power supply assembly is install ed in the monitor, replacing the fuses

and adjusting the mains supply voltage will differ. Determine which as sembly is installed then

follow the appropriate instructions.

CAUTION: Replace fuses with same type and rating. Verify proper fuse value for mains

!

voltage setting (see table below).

Mains Voltage Fuses (Slo Blo) Part Number

100-120 VA C 0.5 A 250V 515023

200-240 VAC 250mA 250V 515033

6.4.1 Assemblies with the earlier Power Entry Module

1. Turn off the monitor. Set the rear panel AC mains power switch to “0” and disconnect

the line cord from the monitor.

2. Place a screwdriver into the fuse access slot and pry open the fuse access door.

26

Model 515B/C Service Manual Rev. 01

Page 37

Changing AC Mains Voltage

3. Using needle-nosed pliers, pull the voltage selector drum from the power entry module.

4. Set the voltage selector drum so that the printed side of the correct voltage faces you.

Maintenance

Note the orientation of the drum; the proper voltage should face out.

VOLTAGE SELECTOR DRUM

115Vac

O

The voltage selections are pictured below.

6

6.4.2

115Vac

O

115Vac

230Vac

OR