Page 1

PRELIMINARY

Model 511

Service Manual

July 18, 1994

Part Number 6116-90-00

Novametrix Medical Systems Inc.

Wallingford, Connecticut, U.S.A. 06492.

Copyright 1994. All rights reserved. No part of

this manual may be reproduced without the written

permission of Novametrix Medical Systems Inc.

Page 2

PRELIMINARY

Page 3

PRELIMINARY

R

18-Jul-94 Release Version 00

Revision History

18-Jul-94 Model 511 Service Manual III

Page 4

Section Revision History

PRELIMINARY

[This page intentional ly bl ank.]

IV

Model 511 Service Manual 6116-90-00

Page 5

PRELIMINARY

G

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is

fully guaranteed, covering materials and workmanship, for a period of one year

from the date of shipment, except for certain disposable products and products with

stated guarantees other than one year. Novametrix reserves the right to perform

guarantee service(s) at its factory, at an authorized repair station, or at the

customer’s installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at

Novametrix’ option, replacement of any defective parts of our equipment, except

fuses, batteries, and calibration gasses, without charge, if said defects occur during

normal service.

Claims for damages during shipment must be filed promptly with the transportation

company. All correspondence concerning the equipment must specify both the

model name and number, and the serial number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without

following specific operating instructions will void this guarantee and release

Novametrix from any further guarantee obligations.

Guarantee

Service Department

For factory repair service, call toll free

1-800-243-3444

In Connecticut, call Collect (203) 265-7701

Telex 956-054

Facsimile (203) 284-0753

Caution: Federal (U.S.A.) law restricts this device to sale, distribution, or use by or

on the order of a licensed medical practitioner.

Copyright 1994, Novametrix Medical Systems Inc. This document contains

information which is proprietary and the property of Novametrix Medical Systems

Inc., and may not be reproduced, stored in a retrieval system, translated, transcribed,

or transmitted, in any form, or by any means, without prior explicit written

permission from Novametrix Medical Systems Inc.

18-Jul-94 Model 511 Service Manual V

Page 6

Section Guarantee

PRELIMINARY

Service Policy

Novametrix Medical Systems Inc. will provide W arranty Service Support to its customers within 48

hours of receiving a telephon e request for technical su pport. This 48 hour pe riod begins once a

service request is placed through the Factory Technical Support Department in Wallingford,

Connecticut. Novametrix provides factory direct technical support to its customers through a

technical support group located in Wallingford, Connecticut and company service representatives

located throughout the United States. All Technical Support for Novametrix products is provided

“Factory Direct”.

Novametrix provides 24 hour a day technical support accessibility via telephone numbers (800) 2433444 or (203) 265-77 01 . Aft er hou rs technical support requests ( before 8:00 AM and after 5:00 PM

Eastern Time) will be responded to promptly by the Technical Support On-Call staff. It is suggested

that any person calling in for technical support have the inoperative equipment available for

preliminary troubleshooting as well as product identification. Novametrix reserves the right to repair

or replace any product found to be defecti ve during the warranty period. Repair may be pro v ided in

the form of replacement exchange parts or accessories, on-site technical repair assistance or

complete system exchanges. Repairs provided due to product abuse or misuse will be considered

“non-warranty” and invoiced at the prevailing service rate. Any replaced defective material is

expected to be return ed to Novametrix within 10 days of be ing pr ov ided in or der to avoid addit ional

charges. Exchanged material should be returned promptly and directly to Novametrix using the

return paperwork an d shipping label(s) provid ed. Transferring return materia ls to local sales or

dealer representatives does not absolve return responsibility.

Novametrix manufactures eq uipment that is generally “user serviceable” and can usually be repaired

with the replacement of a plug-in electro-mechanical assembly by the clinical end user . When repair

parts are provided, the recipi ent can call into Novametrix for on-line replacement assistance and

repair assurance. In the event a replacement part requires increased technical capability, Technical

Support may request Biomedical assistance, provide on-site technical support or complete

replacement equipment. If the customer requires the return of their original product, the exchange

material will be considered “loaner material” and exchanged again after the customer equipment is

repaired.

Novametrix promotes customer participation in warranty repairs should they become necessary. This

program allows for customer training and a smooth transition into self-maintenance after warranty,

which can provide substantial cost savings on repairs thro ughout the product’s life.

The Novametrix Technical Support Department can provide technical product support at a level

appropriate to most customers protocol and budget requirements. Please contact the Technical

Support Group at Novametrix for additional information.

Additional Novametrix Technical Support Programs

• Focus Series Technical Training Seminars

• Test Equipment and Test Kits

• Service Contract / Part Insurance Plans

• Equipment Calibration Services

• On-Site Technical Support

• 24 hr. telephone support

• “Demand Services”

Flat rate parts-exchange,

Flat rate return for repair

Time and Material,

Full warranty, discounted replacement sensors

VI

Model 511 Service Manual 6116-90-00

Page 7

PRELIMINARY

C

Title Section Page

Revision History...............................................................R..................III

Guarantee......................................................................... G ..................V

Table of Contents.............................................................C.................VII

List of Figures.......................... .... ..... ...............................F..................IX

List of Tables................................................... .................T........ ..... .... .XI

Introduction................................................ ..... ..... .... ........1 ...................1

Purpose ......................................................................................... 1.1.................... 1

Technology Description ................................................................. 1.2....................1

Conventions Used In This Manual................................................. 1.3....................2

Acknowledgments.......................................................................... 1.4....................2

Patient Safety...................................................................2...................3

Warnings...........................................................................3 ...................4

Table of Contents

Cautions............................................................................ 4 ...................5

Front Panel.......................................................................5...................6

Summary of Operation....................................................6...................7

Power On/Off................................................................................. 6.1....................7

Audible Alert Enable/Disable......................................................... 6.2....................7

Battery Life..................................................................................... 6.3....................8

Electronic Theory of Operation......................................7 ................... 9

2710 Analog Board........................................................................ 7.1....................9

Power Supply.......................................................................... 7.1.1.................9

Voltage Reference .................................................................. 7.1.2...............11

Sensor LED Drive Circuits ...................................................... 7.1.3...............11

Sensor Photodiode Return Path ............................................. 7.1.4...............14

Calibrating the 20-Bit Analog-to-Digital Convertors ................ 7.1.5...............15

20-Bit Analog-to-Digital Conversion........................................ 7.1.6...............16

Sensor Status Decoding and Conversion ............................... 7.1.7...............16

Sensor Status Parameters ...................................................... 7.1.8...............17

2711 Digital Board ......................................................................... 7.2..................18

Microprocessor and Memory................................................... 7.2.1...............18

Decoding................................................................................. 7.2.2...............19

18-Jul-94 Model 511 Service Manual VII

Page 8

Section Table of Contents

PRELIMINARY

Microprocessor Supervisor ..................................................... 7.2.3............... 20

Front End Timing Signals........................................................ 7.2.4 ...............21

System Output Ports............................................................... 7.2.5...............22

Serial I/O Controller................................................................. 7.2.6...............23

Display .................................................................................... 7.2.7............... 24

Maintenance.....................................................................8 .................25

General.......................................................................................... 8.1 .................. 25

Maintenance Schedules ................................................................ 8.2 ..................25

Cleaning and Sterilization.............................................................. 8.3..................26

Model 511 Monitor .................................................................. 8.3.1............... 26

Finger Sensor.......................................................................... 8.3.2...............26

Y-SENSOR™ and Y-STRIP™ Taping System....................... 8.3.3...............26

Battery Installation ......................................................................... 8.4..................26

Assembly Exchanges .................................................................... 8.5 .................. 28

Changing System Software........................................................... 8.6 .................. 30

Status Messages..............................................................9.................31

Status Messages and Fault Indicators........................................... 9.1..................31

Functional Test ................................................................10...............35

Introduction.................................................................................... 10.1................35

Monitor Functional Test ................................................................. 10.2 ................ 35

Accuracy Test ..................................................................11 ...............39

Introduction.................................................................................... 11.1................39

Monitor Accuracy Test................................................................... 11.2................ 39

Electronic Test.................................................................12 ...............43

Introduction.................................................................................... 12.1................43

Monitor Functional Test ................................................................. 12.2 ................ 43

2710 Analog Board ................................................................. 12.2.3.............44

2711 Digital Board................................................................... 12.2.7 .............44

System Check......................................................................... 12.2.13...........45

Specifications................................................................... 13 ...............49

General.......................................................................................... 13.1 ................ 49

Oxygen Saturation (SpO2)...................................................... 13.1.1.............49

Pulse Rate............................................................................... 13.1.2 .............49

General Specifications ............................................................ 13.1.3.............49

Parts Lists.........................................................................14 ...............51

Model 511 Assemblies................................................................... 14.1................51

Schematic and Assembly Drawings..............................15...............59

VIII

Model 511 Service Manual 6116-90-00

Page 9

PRELIMINARY

F

Figure Description Page

Figure 1.........Front panel illustration ................................ ...................... .. ........ 6

Figure 2. ........ Revision 00 power turn on circuitry........................................... 10

Figure 3. ........ Fuse protection modification..................................................... 10

Figure 4.........Fuse protection modificati on on newer revision boards............ 11

Figure 5. ........ Revision 00 LED drive circuitry................................................. 12

Figure 6. ........ Revision 01 board drive circuitry............................................... 13

Figure 7. ........ Revision 02 LED drive circuitry................................................. 14

Figure 8.........Revision 00 PRAMCS* configuration........................................ 19

Figure 9.........Revision 00 watchdog circuitry................................................. 21

Figure 10. ......Battery orientation..................................................................... 27

List of Figures

Figure 11. ......Removing the top cover............................................................ 28

Figure 12. ...... Monito r disassembled........................... ................ ............... ..... 28

Figure 13.......Disconnecting keypanel ribbon cable. ................................ ...... 29

Figure 14.......Changing the system software EPROM................................... 30

Figure 15. ...... Statu s me s s age s an d n um e ric a l c o d es .. ................ ............... ... 31

Figure 16.......Front panel................................................................................ 35

Figure 17. ......Sensor off patient display ......................................................... 36

Figure 18. ......Applying sensor for functional test............................................ 36

Figure 19. ......Sensor off patient display ......................................................... 37

Figure 20. ......LCD display with all segments on............................................. 40

Figure 21. ...... Alert display ........... .. ................ ............... ................ ............... ... 41

Figure 22.......Application of Y-sensor and Finger sensor............................... 41

Figure 23.......Cutaway showing location of C24 on the 2710 analog board... 44

Figure 24.......Connecting external DC supply to the 2711 Digi tal Board........ 45

Figure 25.......2711 Digital board power up display . ........................................ 45

18-Jul-94 Model 511 Service Manual IX

Page 10

Section List of Figures

PRELIMINARY

Figure 26.......Connecting membrane keypanel...................................... .. ...... 46

Figure 27.......Connecting external DC supply................ ................................ 46

Figure 28. ......Display at power up with all segments active ........................... 47

X

Model 511 Service Manual 6116-90-00

Page 11

PRELIMINARY

T

Table Description Page

Table 1. .........2711 digital board decoding lines ............................. .. .. ............19

Table 2. .........Front end timing signals .......................................... ..................22

Table 3. .........Output port li nes ...................................... .................................23

Table 4. .........CSI/O decode lines ........................................ ...........................23

Table 5. .........Status messages ......................................... .............................32

Table 6. .........Error codes ...............................................................................32

Table 7. .........Saturati on values using sensor simulator .................................40

Table 8. .........2710 analog board voltage checks ......... ..................................44

Table 9. .........Schematic and Assembly Drawings ..........................................59

List of Tables

18-Jul-94 Model 511 Service Manual XI

Page 12

Section List of Tables

PRELIMINARY

XII

Model 511 Service Manual 6116-90-00

Page 13

1

Introduction

Purpose

This manual has been prepared for technicians servicing the Novametrix Model 511

Pulse Oximeter. It presents technical informa tion relating to t he monitor’s theory of

operation, maintenance, calibration and repair. Refer to the Pulse O ximeter Model

511 User’s Manual (Catalog Number 6116-23) for additional information.

Technology Description

The Model 511 measures oxygen saturation and pulse rate with sensors that contain

red and infrared light sources, called LEDs. Since oxygen saturated blood absorbs

different amounts of light at each wavelength (red a nd infrared) as compared to

unsaturated blood, the amount of light absorbed by the blood in each pulse can be

used to calculate oxygen saturation.

The light energy from red (660 nm) and infrared (940 nm) LEDs is beamed through

a sample cell—a pulsating vascular bed, the patient’s finger or toe for example. The

remaining light energy not absorbed by the sample cell reaches a light receptor,

called a photodiode, on the opposing side of the sensor. The data received at the

photodiode is sent back to the monitor where it is split into its red and infrared

components, digitized, processed by a microprocessor chip, and finally displayed

as a numerical value for oxygen saturation and a plethysmogram.

1.1

1.2

The Model 511 is calibrated to display “functional” saturation. This differs from the

“fractional” saturation value displayed by most co-oximeters. Functional saturation

represents the amount of oxyhemoglobin as a percentage of the hemoglobin that can

be oxygenated. Dysfunctional hemoglobins (COHb and METHb) are not included

in the measurement of functional saturation.

Calculating

Functional Oxygen

Saturation

Pulse Rate is calculated by measuring the time interval between the peaks of the

infrared light waveform. The inverse of this measurement is displayed as pulse rate.

The Model 511 must be used in conjunction with OxySnap SuperBright™

saturation sensors. These sensors have an 8700 series part number (e.g., 8744 or

8793).

18-Jul-94 Model 511 Service Manual 1

Functional Saturation =

100 - (COHb + METHb)

HbO

2

HbO2 = Fractional Hemoglobin

COHb = Carboxyhemoglobin

METHb = Methemoglobin

Page 14

Section 1 Introduction

Conventions Used In This Manual

The following conventions will be used throughout this manual:

• Normal text will be shown in this type.

• Message Center alerts and displays will be shown

• The names of the front panel pushbuttons (keys) will be shown

in this type

.

in this type.

Acknowledgments

SuperBright, Y-STRIP and Y-SENSOR are trademarks of Novametrix Medical

Systems Inc.

1.3

1.4

2

Model 511 Service Manual 6116-90-00

Page 15

2

For maximum patient and operator safety, the following are recommended;

• Failure of Operation: If the monitor fails to respond as described, do not use

it until the situation has been corrected by qualified personnel.

• Keep the Model 511 and its accessories clean.

• Do not operate the Model 511 when it is wet due to spills or condensation.

• Do not operate the Model 511 if it appears to have been dropped or damaged.

• Care should be exercised to assure continued peripheral perfusion distal to the

SpO2 sensor site after application.

Patient Safety

Do

be processed when the cuff is inflated. Attach the sensor to the limb opposite to the site

used for the blood pressure cuff.

attach an SpO2 sensor distal to a blood press ure cuf f. Va lid data

NOT

CANNOT

18-Jul-94 Model 511 Service Manual 3

Page 16

3

• Explosion Hazard: Do NOT use the Model 511 in the presence of flammable

anesthetics. Use of this instrument in such an environment may present an

!

explosion hazard.

• Electrical Shock Hazard: Always turn the oximeter off before cleaning it. Do

NOT use a damaged sensor or one with exposed electrical contacts.

• Patient Safety: Care should be exercised to assure continued peripheral

perfusion distal to the SpO2 sensor site after application.

• Failure of Operation: If the oximeter fails to respond as described, do not use

it until the situation has been corrected by qualified personnel.

• Data Validity: Do NOT attach a sensor distal to a blood pressure cuff. Valid

data CANNOT be processed when the cuff is inflated. Attach the sensor to the

limb opposite to the site used for the blood pressure cuff.

• Data Validity: As with all pulse oximeters, ina ccurate SpO2 and Pulse Rate

values may be caused by:

Warnings

Warning

Indicates a potentially harmful condition

that can lead to personal injury.

• Incorrect application or use of a sensor

• Significant levels of dysfunctional hemoglobin; carboxyhemoglobin or

methemoglobin

• Significant levels of indocyanine green, methylene blue, or other intravascular dyes

• Exposure to excessive illumination such as surgical lamps—especially

ones with a xenon light source, or direct sunlight

• Excessive patient movement

• Venous pulsations

• Electrosurgical interference

4 Model 511 Service Manua l 6116-90-00

Page 17

4

• Do not operate the Model 511 when it is wet due to spills or condensation.

• Do not operate the Model 511 if it appears to have been dropped or damaged.

• Never sterilize or immerse the monitor in liquids.

• Do not sterilize or immerse sensors except as directed in this manual.

• No tension should be applied to any sensor cable.

• Do not store the monitor or sensors at temperatures less than 14° F (-10° C) or

greater than 131° F (55° C).

• Do not operate the monitor or sensors at temperatures less than 50° F (10° C) or

greater than 104° F (40° C).

• Caution: Federal (U.S.A.) law restricts this device to sale, distribution, or use by

or on the order of a licensed medical practitioner.

Cautions

Caution

Indicates a condition that may lead to

equipment damage or malfunction.

18-Jul-94 Model 511 Service Manual 5

Page 18

5

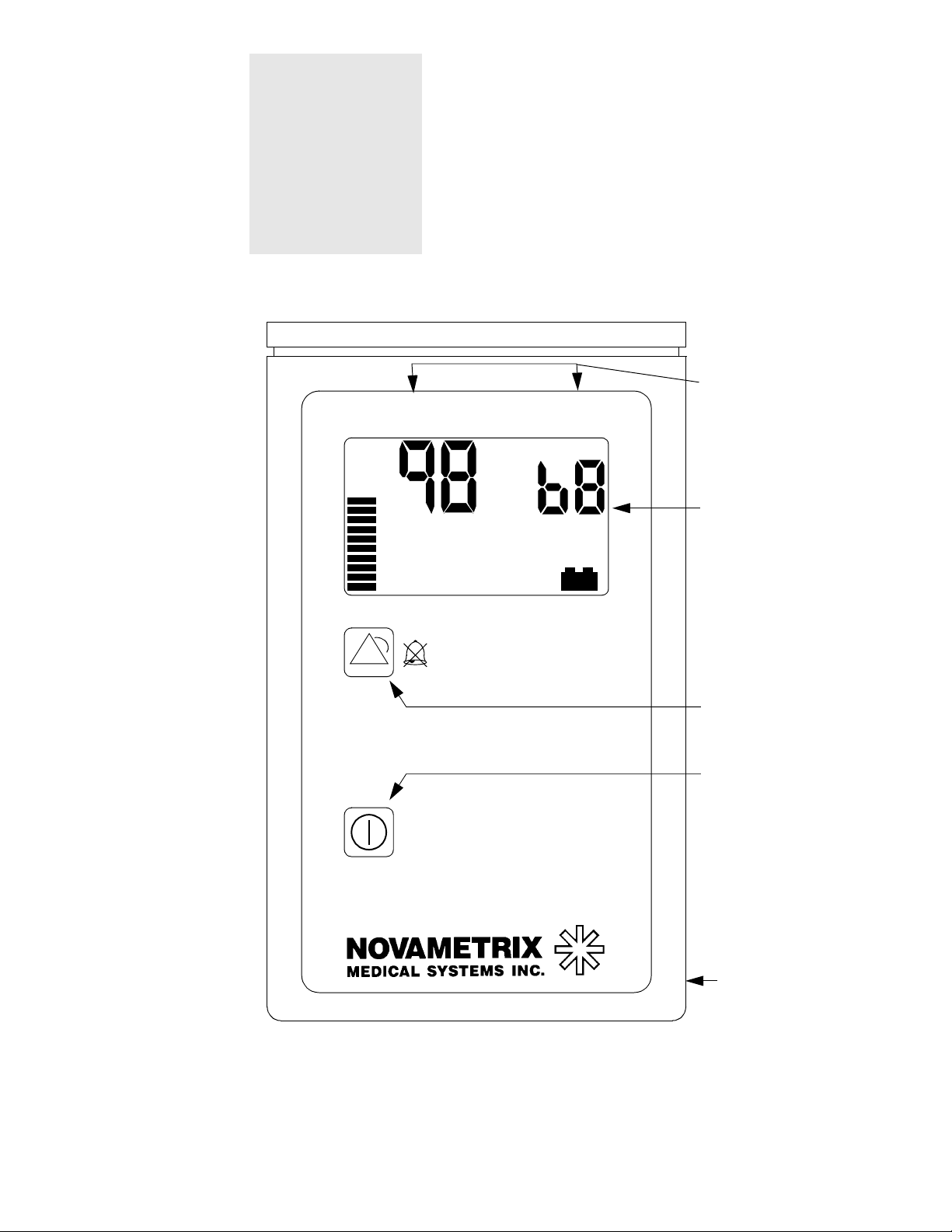

Front Panel

SpO

2

SATURATION PULSE RATE

%

beats/min

511

Pulse Oximeter

Saturation and

Pulse Rate

display

identifiers

LCD Display

Audible Alert

Enable/Disable

control

Po wer On/Off

and Illumination

control

DC input jack

Figure 1. Front panel illustration

6 Model 511 Service Manua l 6116-90-00

Page 19

6

Summary of Operation

Power On/Off

1. To turn the monitor on, press the power control.

A tone sounds to verify audio is functional, the monitor performs a system

self-test, all display segments are briefly illuminated, the software version is

displayed in the

RATE

section, and finally the operational display appears.

2. To illuminate the display for better viewability under low ambient lighting

conditions, press the power control key and hold until the backlight

illuminates when turning the monitor on.

The display illumination will remain on until the monitor is turned off.

3. To turn the monitor off, press the power control.

SATURATION

section and the model number in the

Audible Alert Enable/Disable

1. To toggle between enabled and disabled audible alarms, press and release the

alarm key.

If pressing and releasing the alarm key causes the alarms to be enabled, the

monitor shall display the saturation auto alert limit settings (in the SpO2 and

pulse rate displays) for three seconds, beep once, and turn off the alarm icon.

The alarm display icon will not be displayed while audible al arms are enabled.

All visible alerts continuously active for longer than 10 seconds will cause an

unlatched audible alarm to sound.

6.1

PULSE

6.2

If pressing and releasing the alarm key causes the alarms to be disabled, the

monitor shall beep once, and turn on the alarm icon. The alarm display icon

will illuminate as a warning that the audible alarms are disabled.

2. To set alert limits, press and hold the alert key for more than 3 seconds. The

monitor will beep twice if new limits are set (based on valid SpO2 values). If

no SpO2 is displayed, the monitor will use default limits and will beep three

times.

18-Jul-94 Model 511 Service Manual 7

Page 20

Section 6 Summary of Operation

The Model 511 will display the high limit in the SpO2 display, the low limit

in the pulse rate display for three seconds. The monitor will then return to

normal operation.

NOTE: Setting alert limits automatically enables the audible alarms.

To display limits without setting new limits if audio is enabled, press and

release the alarm key twice. The first press turns off the alarms and the second

turns then back on and causes the high and low limits to be displayed for one

second. The monitor will then return to normal operation.

To display limits without setting new limits if the audio is disabled, press and

release the alarm key. The high and low limits will be displayed for one

second before the monitor returns to normal operation. Press the alarm key to

disable the audible alarms.

Battery Life

The Model 511 displays a battery icon to indicate:

• fully charged batteries

• approximately one half the initial battery charge remains

• indicates less than 30 minutes of battery life remain.

The battery icon may appear fully charged for the first minute after power up,

after which it will reflect the true battery charge. If the monitor continues

operating while in the low battery st ate, the monitor eventually shuts itself off.

NOTE: The battery icon will remain on the display when the external DC supply is

connected and powering the monitor. The icon will indicate the fully charged batteries

condition, this in reality is an indication of the external DC supply, not the condition of the

batteries. For proper indication of battery life the external DC supply must be unplugged

from the monitor.

6.3

8

Model 511 Service Manual 6116-90-00

Page 21

7

Electronic Theory of Operation

The electronic theory of operation of the Model 511 Pulse Oximeter monitor is

detailed in the subsections below. Section 15,

on page 59 for more information.

There are subtle differences between the first rele ase circuit boards and the later

revision, these are noted in the text with an explanation of the circuit operation.

Schematic and Assembly Drawings

,

2710 Analog Board

The 2710 Analog board contains the drive circuitry for the sensor’s LEDs, the

photodiode’s detection circuitry, the power supply, and the turn on circuitry. The

batteries and sensor are connected to the analog board, this is then connected to the

2711 digital board by two header connectors.

Power Supply

Power for the Model 511 Pulse Oximeter is derived from four 1.5 volt Alkaline

batteries (see page 2 of schematic). These are connected to J404 on the 2710 Analog

Board. Check the serial number suffix on the unit to determine the type of power up

circuitry the monitor contains as described below. Different revision levels of the

2710 analog board will have differences in this circuitry.

Units with a “Z“ in the serial number suffix. Power enters J404 as VBAT, F202

protects against excessive current flow. When the PWRSWIN line pulses high the

N-channel FET of IC17 will be biased on, this in turn biases the P-channel portion

7.1

7.1.1

18-Jul-94 Model 511 Service Manual 9

Page 22

Section 7 Electronic Theory of Operation

VBATT

PWRSWIN

F202

500ma

R13 100K

R12 511

D9 MMDB301L

J404 1,2

To IC15

IC17 Si9942

To Drain of Q2 and

R18 junction

R25

R23

C24

J401 11, 13

VBATT

VBATTF

1

2

3

4

5,

6

7,

8

on and allows power to flow through to IC15. Switching regul ator IC15 will supply

6.5 volts DC with an input voltage ranging from 4-6 volts DC.

Figure 2.

Revision 00 power turn on circuitry

In order to prevent F202 from blowing in the event that the batteries are installed

incorrectly, a MOSFET is used. The modification is shown below.1 Later revision

boards have this modification designed in.

pins 1, 2, 3 to units positive input (red)

MOSFET

pins 5, 6, 7, 8 to positive

terminal of DC input jack (red)

Model 511 bottom case half

MOSFET: PN: 485538

(Si 9405)

pin 4 to battery ground (black)

10

Model 511 Service Man ual 6116-90-00

1. Units with this modification can be identified by a “Z” in the serial number suffix.

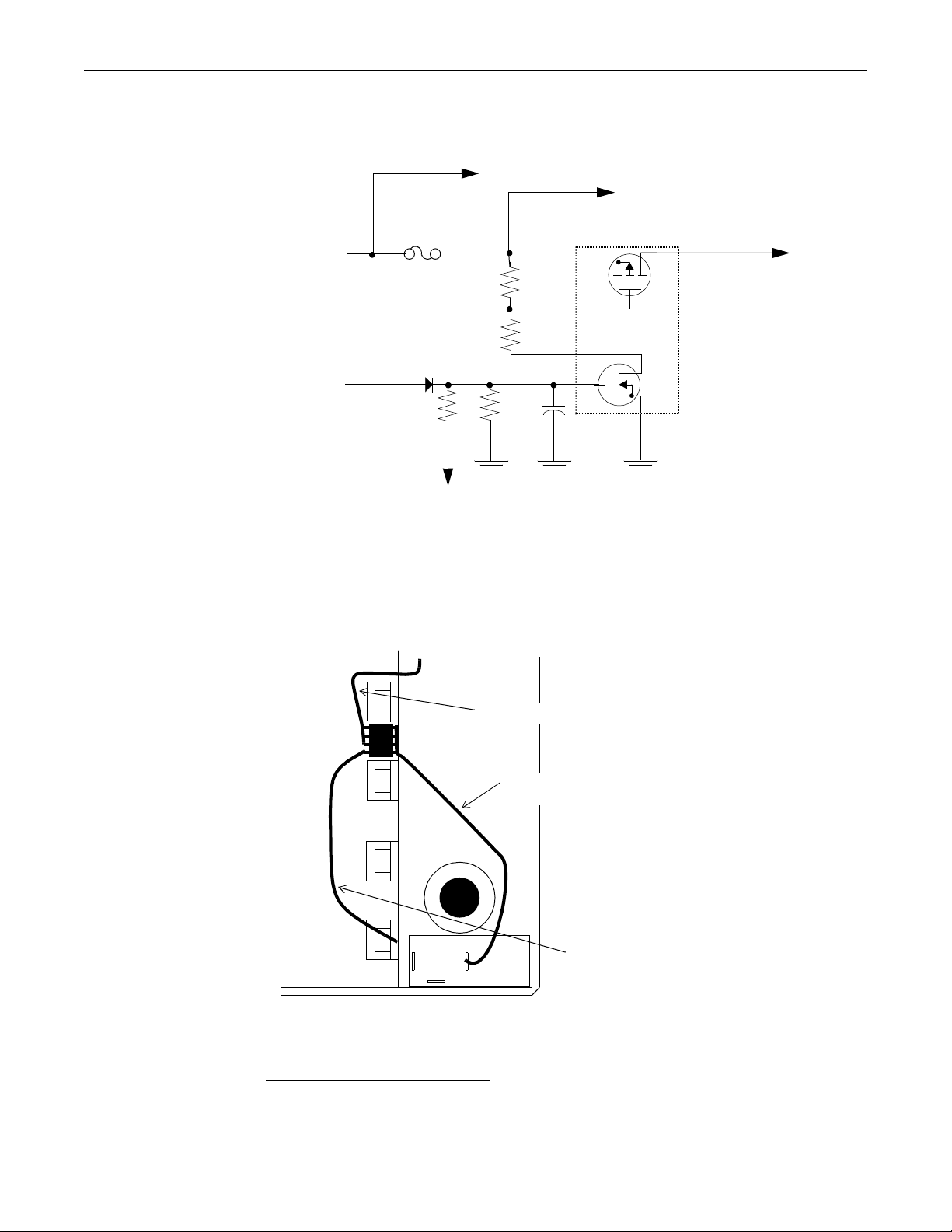

Figure 3.

Fuse protection modification

Page 23

2710 Analog Board

For units with a “W“ and/or “X” in the ser ial number suff ix. Power enter s J404 as

BATTERY, provided that the batteries are properly installed, 1/2 of IC17 (pins 1,

2, 7, and 8) will be biased on. F202 protects against excessive current flow and

diode D9 protects against over-voltage. When the PWRSWIN line pulses high then

Q9 will be biased on, this in turn biases the second P-channel portion of IC17 on

and allows power to flow through to IC15. Switching regulator IC15 will supply 6.5

volts DC with an input voltage ranging from 4-6 volts DC.

BATTERY

J404 1

PWRSWIN

1/2 IC17

Si9947

Figure 4.

D9

F202

500ma

D9

MMDB301L

Fuse protection modification on newer re vision boards

7,

8

R23

To Drain of Q2 and

R18 junction

8.2V

PMLL5237B

1

R13

100K

2

R12 511

R25

C24

VBATT

1/2 IC17 Si9947

3

5,

6

4

Q9 2N7002

To IC15

and

VDCIN

The VDD supply is regulated by IC10, a low drop-out voltage regulator. A DC-DC

converter IC16, develops the -VA supply from the VDD supply, this is required by

the operational amplifiers used in the system. The LED power (LEDSRC) is

regulated and current limited by IC11, fuse F201 protects against over-current.

Voltage Reference

A positive reference voltage VREF2.5 is developed by IC9 (see page 1 on

schematic), the +2.5 volts DC is derived from the +VA supply. A negative reference

voltage is developed by IC13a (pin1) by inverting the +2.5 volt supply. This

negative reference is -VREF at TP6. The analog to digital converter IC5 uses the

VREF2.5, the -VREF is used by the digital to analog converter IC12. On revision

01 boards an alternate combination of R63 (3.92K) and D8 (LM4040 - 2.5V) may

be substituted for IC9.

Sensor LED Drive Circuits

The drive circuitry differs between revisions 00, 01 and 02 on the 2710 board.

Check the revision of the board to determine the appropriate circuitry for the unit.

18-Jul-94 Model 511 Service Manual

7.1.2

7.1.3

11

Page 24

Section 7 Electronic Theory of Operation

The drive circuitry for earlier revision 00 boards is shown below. The diagram and

description that follow explains the drive circuitry for the earlier boards. The

diagram below lists the components for the red LED drive circuitry, only a portion

of the circuitry is shown, refer to the schematic for components not shown. The

corresponding components for the infrared channel are listed in [ ].

IRLED*

[RDLED*]

IC7a pin 1

[IC7b pin 7]

4

2

LEDSRC

3

1

IC14

[IC18]

5, 6

7, 8

LED1SK

[LED2SK]

Q1

[Q6]

R63*

[R64]*

*May not be installed

Figure 5.

Revision 00 LED drive circuitry

R62

[R65]

C27

[C29]

When the RDLED* signal goes low (logic 0), Q3 turns off and the VLED signal is

divided down by R42 and R41, at IC7a (pin 3). The N-channel portion of IC14 is

driven by IC7a pin 1, this will bias Q1 on when high, current will flow through the

red LED in the sensor, then through Q1 and R29 to ground (the P-channel portion

of IC14 is not biased on).

When RDLED* returns high (logic 1), Q3 is biased on, forcing IC7a pin3 to ground

potential, this results in 0 volts at the output of IC7a (pin 1). The N-channel portion

of IC14 is biased off, therefore biasing Q1 off, and as a result, the Red LED in the

sensor is also off.

The Infrared LED drive circuit operates in the same manner as the Red LED drive

discussed above. The IRLED* signal activates Q4 which controls IC7b, this in turn

controls IC18. The source of the N-channel FET of IC18 will bias Q6 either on or

off controlling the Infrared LED of the sensor.

12

Model 511 Service Man ual 6116-90-00

Page 25

2710 Analog Board

IRLED*

[RDLED*]

IC7a pin 1

[IC7b pin 7]

1/2 IC14*

Q7 [Q8]

R62

[R54]

LEDSRC

LED1SK

[LED2SK]

Si9947

2N7002

R33

[R30]

R32

[R31]

C28

[C30]

ADCRDLED

Q1

[Q6]

C27

[C29]

to R29 [R28]

T3904

*not installed

Revision 01 boards drive circuitry is described below. Refer to the sc hematic for

components not shown in the diagram, only the differences are displayed below.

The infra-red channel components are listed in [ ].

Figure 6.

Revision 01 board drive circuitry

The VLED line voltage is derived from IC13b pin 7 which is controlled by the

Digital to Analog Converter IC12. (See sheet 1 of 2 on schematic.) When the

DACWR* line is brought Low IC12 is enabled. The data on lines D0-D7 now

control the output voltage of IC13b pin 7(VLED) based on the -VREF voltage from

IC13a pin 1 (TP6).

2

When the RDLED* signal goes low (logic 0), Q3 turns off and the VLED signal is

divided down by R42 and R41, at IC7a (pin 3). FET Q7 is in turn driven on by IC7a

(pin 1). This will bias Q1 on and current will flow through the red LED in the

sensor, then through Q1 and R29 to ground.

When RDLED* returns high (logic 1), Q3 is biased on, forcing IC7a pin3 to ground

potential, this results in 0 volts at the output of IC7a (pin 1). FET Q7 is biased off,

therefore biasing Q1 off, and as a result, the Red LED in the sensor is also off.

The Infrared LED drive circuit operates in the same manner as the Red LED drive

discussed above. The IRLED* signal activates Q4 which controls IC7b, this in turn

controls Q8. The source of Q8 will bias Q6 either on or off controlling the Infrared

LED of the sensor.

The drive circuitry for later revision 02 boards is shown below. The drive is simi lar

except that the bipolar transistor are not installed, a different operational amplifier

18-Jul-94 Model 511 Service Manual

is used, and discrete MOSFETS are used in place of the dual package used in earlier

2. On certain units pin 13 of IC12 will have a separate wire connected to J402 pin 9. This is to allow

a revision 00 analog board to operate with a revision 01 digital board.

13

Page 26

Section 7 Electronic Theory of Operation

revisions. The differences between the drive circuitry are displayed below, refer to

the schematic to view components not shown below.

IRLED*

[RDLED*]

IC7a pin 1

[IC7b pin 7]

R66

[R67]

215

to R29 [R28]

4 [2]

4 [2]

R62

[R54]

100K

*not installed

LEDSRC

3 [1]

3 [1]

1/2 Q7*

Si9947

5, 6 [7, 8]

5, 6 [7,8]

1/2 Q6

Si9955

[R31]

R32

LED1SK

[LED2SK]

R33

[R30]

ADCRDLED

C28

[C30]

Figure 7.

Revision 02 LED drive circuitry

When the RDLED* signal goes low (logic 0), Q3 turns off and the VLED signal is

divided down by R42 and R41, at IC7a (pin 3). FET Q6 (pins 3, 4, 5, 6) is in turn

driven on by IC7a (pin 1). Current will flow through the red LED in the sensor,

through Q6, then through R29 to ground.

When RDLED* returns high (logic 1), Q3 is biased on, forcing IC7a pin3 to ground

potential, this results in 0 volts at the output of IC7a (pin 1). FET Q6 is biased off,

and as a result, the Red LED in the sensor is also off.

The Infrared LED drive circuit operates in the same manner as the Red LED drive

discussed above. The IRLED* signal activates Q4 which controls IC7b, this in turn

controls Q6 (pins 1, 2, 7, 8). The source of Q6 will control the Infrared LED of the

sensor.

Sensor Photodio de Return Path

7.1.4

Light, from the sensor’s Red or Infrared LED, shines through the pulsating vascular

bed (the patient’s finger, toe, etc.) placed between the LEDs and the photodiode.

Some of this light emerges from the tissue and impinges on the photodiode, causing

the photodiode to conduct current. IC4b pins 5-7 is set up as a differential amplifier

that converts this input current to a voltage at the amplifier output. The sensors are

wired such that photodiode current produces a positive voltage at IC4b pin 73.

The voltage at IC4b pin 7 is presented to an analog switch IC3b pin 6. This switch

is controlled at pin8 by INSIG* (Input Signal), and will be closed (IC3b pins 6 and

7 connected) except if the monitor is in a Probe Off Patient condition or is

3. The Model 511 uses SuperBright™ sensors (part number 87xx series). If a non-SuperBright™

(Novametrix part number 86xx series) sensor is connected, IC4b pin 7 will go negative.

14

Model 511 Service Man ual 6116-90-00

Page 27

2710 Analog Board

undergoing its Self-Test at system power up. The switch IC3c pins 9-11, controlled

from SIGND* (Signal Ground) will be open (no connection between IC3c pins10

and 11) except as noted above for the switch at IC3b pins 6-8. As a result, the IC4b

pin 7 voltage passes undisturbed to the high pass filter consisting of R53 and C5.

The ASAMP* signal is active whenever either sensor LED is turned on. This causes

Q5 to turn off and the charge at C5 passes through to IC4a pin 3. The ASAMP* line

returns to a logic high when neither LED is being dr iven, causing Q5 to turn on.

With Q5 conducting, any charge at C5 is discharged to ground and the next pulse

will charge C5 from a known level. If it were not for Q5, any charge remaining on

C5 from the previous pulse or from ambient light reaching the photodiode would be

added to the charge from a new pulse—creating measurement errors.

If the signal at IC4a pin 1 is the product of the Red LED being turned on, then

RDSAMP* will go low and close the switch at IC3a pins 2-3, thereby presenting

the signal to a sample and hold circuit consisting of R17 and C8 (that mainta ins the

signal until next sample pulse arrives), a gain stage, (IC2b), a filte r/divider network

(C7, R14 and R55), and finally, to the Red channel Analog-to-Digital Convertor

(ADC) IC8.

If the signal at IC4a pin 1 is the product of the Infrared LED being turned on, then

IRSAMP* will go low and close the switch at IC3d pins 14-15, thereby presenting

the signal to a sample and hold circuit consisting of R6 and C4 (that maintains the

signal until next sample pulse arrives), a gain stage, (IC2b), a filter/divide r network

(C3, R3 and R54), and finally, to the Infrared channel Analog-to-Digital Convertor

IC1.

Calibrating the 20-Bit Analog-to-Digital Convertors

7.1.5

The 20-bit ADCs are calibrated as part of the system self-t est which occurs each

time the monitor is turned on. At power up, the microprocessor sets the CAL line

high. The System Calibrations input SC1 is set high. The CS5503 ADC will not

operate while the CAL line is high. On th e falling edge of the CAL signal, the ADC

will initiate a calibration cycle determined by the state of the SC1.

The high at SC1 causes INSIG* to go high and reset SIGND* to a logic low. The

high INSIG* opens the switch at IC3b pin8 so that IC3b pins 6 and 7 are no longer

connected—disconnecting the returning photodiode signal from the rest of the

circuitry. The low SIGND* signal closes the switch at IC3c pin9 and as a result, the

input to the C5-R53 high pass filter (and thus the entire ADC input circuitry) is

brought to ground potential.

The CAL line (which went high at power up) is reset low and ADCs IC1 and IC8

begin their calibration cycles. Because the analog input circuitry is grounded via

SIGND*, only circuit offset voltages can be present at the (pin 9 AIN) inputs. The

calibration cycle sets the ADC “zero” point to equal this voltage, thus compensating

18-Jul-94 Model 511 Service Manual

15

Page 28

Section 7 Electronic Theory of Operation

for any circuitry offsets. The ADC then sets its “full scale” point to equal the voltage

at its VREF (pin 10) input. This completes the calibration cycle.

The ADC can now start sampling its input and converting it to a 20-bit digital word.

The processor resets SC1 to a logic low, causing IC3c pin9 to open and IC3b pin8

to close. The photodiode signal can now reach the ADCs. See Sensor Photodiode

Return Path on page 14.

20-Bit Analog-to-Digital Conversion

7.1.6

Data from the Red and Infrared channels is sampled by the 20-bit measurement

ADCs, IC1 and IC8 respectively. The analog input at pin 9 is converted to a digital

representation with 20-bit resolution based on the input magnitude.

The CS5503 convertor continuously samples its input, converts the value to a

digital word, puts the word in its output buffer (overwriting previous buffer

contents), then repeats the process by again sampling its input. The frequency of the

sample/convert/overwrite-buffer sequence is based on the 3.2768 MHz clock signal

at the ADC pin 3 (ADCCLK) input.

The microprocessor starts a read cycle of the Infrared channel by bringing IC1 pin

16 (Chip Select Channel 1) low. A Red channel read starts when IC8 pin 16 (Chip

Select Channel 2) is brought low.

On the falling edge of the ADC’s CS*, the output word’s MSB (most significant

bit) appears at the pin-20 SDATA (Serial Data) output. The SDATA line connects

directly to the microprocessor’s serial input (RXS) pin. The remaining bits (in

descending order) are output from SDATA with subsequent falling edges of the

Serial Clock (SCLK) input at pin 19. The SDATA output automatically goes to a 3state (high impedance) condition after completing a word transmission, thus freeing

the data line for other uses (i.e., the other ADC channel).

The Serial Clock speed is controlled through the digital board. This clock rate is

significantly slower than the ADC sampling rate. As a result, the ADC rewrites its

output buffer with new information at a faster rate than the data can be read from

the buffer. No conflict occurs, however, because while CS* is low (during the read

cycle), the ADC does not update its output buffer—the current word is not

overwritten. After the processor receives the entire word, it allows the convertor’s

CS* to return high, and the ADC resumes its sample/convert/overwrite-buffer

cycle.

Sensor Status Decoding and Conversion

The microprocessor monitors several sensor parameters in addition to the Red and

Infrared data channels. It monitors the status parameters, as well as the voltage of

the monitor’s internal battery.

16

Model 511 Service Man ual 6116-90-00

7.1.7

Page 29

2710 Analog Board

The 8-to-1 multiplexor, IC6, decodes the A0MUX-A2MUX input address lines and

connects one of eight status paramet er inputs to the multip lexor output at IC6 pin 3.

Resistor R38 and diode D5 prevent negative voltages from reaching the input t o the

analog-to-digital convertor, IC5.

IC5 is an 8-bit analog-to-digital convertor with a serial data output. While the IC5

Chip Select (ADC3CS*) input is high, the CLK input and ADC3DOUT output are

in 3-state mode. When CS is brought low (under processor control), the most

significant bit (D7) of the PREVIOUS data conversion becomes available at the

ADC3DOUT pin. The remaining bits (D6-D0) are shifted out on subsequent falling

edges of the CLK input. On the clock pulse following the one that shifts out the least

significant bit (D0), the CLK and ADC3DOUT lines are returned to 3-state and the

ADC performs a new conversion based on the input it receives from the IC6 channel

selected by the A0MUX-A2MUX input address lines.

The ADC sample/convert/store-result cycle is based on internal chip timing and not

the CLK input which (along with CS) only controls serial data output. Thus the CS

line is free to return high once the ADC cycle begins.

Sensor Status Parameters

7.1.8

The sensor (and battery) status parameters input to the multiplexor IC6 are

described below.

ADCVRD: This signal is not used as of this writing.

ADCVIR: This signal is not used as of this writing.

ADCFEDC: Photodiode DC Level.

Resistors R19, R20 and capacitor C13 form a voltage divider and low pass filter that

provide a measure of the mean DC level at the output of the photodiode current-tovoltage amplifier IC4b pin 7. This signal is used in determining ambient light

interference. If this line is examined while the sensor’s Red and Infrared LEDs are

turned off, then any DC level at IC4b pin 7 must be the result of ambient light

impinging on the photodiode. If the DC shift is in excess of limits set in the

software, a Light Interference message appears on the monitor’s display.

ADCLPWR: Sensor LED Supply Voltage.

This channel, at IC6 pin 12, monitors the sensor LED supply voltage through a

voltage divider consisting of R26 and R27. If a fault occurs that causes the LED

supply fuse F2 01 to blow, or if the sensor wires are shorted, this channel reports

the condition and the monitor will indicate an error condition.

ADCIRLED: Infrared LED Cathode Voltage.

A low pass filter consisting of R30, R31 and C30 provides a means to measure the

cathode voltage of the sensor’s Infrared LED. If the channel at IC6 pin 5 is sampled

the monitor can determine if the LED is open circuit (zero volts at IC6 pin 5) or

operational (approximately 2.5 volts at IC6 pin 5).

18-Jul-94 Model 511 Service Manual

17

Page 30

Section 7 Electronic Theory of Operation

ADCBATT: Battery Supply Voltage

The monitor’s battery voltage is divided down by R15 and R16. The voltage at IC6

pin 2 is monitored and if its magnitude is l ess than a predet ermined value (encoded

in the software) the monitor indicates a low battery warning.

ADCRDLED: Red LED Cathode Voltage.

A low pass filter consisting of R33, R32, and C28 provides a means to measure the

cathode voltage of the sensor’s Red LED. If the channel at IC6 pin 4 is sampled the

monitor can determine if the LED is open circuit (zero volts at IC6 pin 4) or

operational (approximately 2.5 volts at IC6 pin 4).

2711 Digital Board

The microprocessor, memory, display driver, and supportive digital circuitry is all

contained in the 2711 digital board. Mounted on the digital board is the Liquid

Crystal Display (LCD), the Keypanel connects to the 2711 board at J405.

Microprocessor and Memory

The Model 511 is controlled by IC1, an 8 bit microprocessor running at 6.14 MHz.

Crystal Y1 controls the operating frequency, system address lines are labelled as

A0-A17, system data lines are labelled D0-D7.

The system program is contained in IC3 a 27C512 EPROM (or 27C101), when both

RD* and ROMCS* are low a read operation is performed on IC3. The ROMCS*

line is controlled by the ME* line (Memory Enable) and address line A17. When

both the ME* line and address line A17 are low the ROMCS* line will go low (IC9

pin 6), this enables IC3.

System RAM is contained in IC2. When both the RD* and RAMCS* lines are

brought low a read operation is performed on IC2. With both WR* and RAMCS*

low a write operation will be performed. The RAMCS* line is controlled by the

ME* (Memory Enable) line and address line A17. When address line A17 is

brought high, and the ME* line brought low, IC9 pin 3 will go low activating the

RAMCS* line.

7.2

7.2.1

For revision 00 boards the operation is as follows: System RAM is contained in IC2.

When both the RD* and PRAMCS* lines are brought low a read operation is

performed on IC2. With both WR* and PRAMCS* low a write operation will be

performed. The PRAMCS* line is controlled by the ME* (Memory Enable) line

and address line A17. When address line A17 is brought high, and the ME* line

brought low, IC9 pin 3 will go low. This will bias Q3 on and the PRAMCS* will be

brought low enabling the chip select of IC2. The purpose of Q3 is to isolate the

18

Model 511 Service Man ual 6116-90-00

Page 31

2711 Digital Board

PRAMCS* line from VDD when power is turned on or off, this will avoid spurious

oscillations from inadvertently enabling the chip.

Decoding

IC9

74HC32

1

2

A

Figure 8.

VDD

3

R26

100

G

DS

Q3

2N7002

Revision 00 PRAMCS* configuration

VBACK

R27

100K

PRAMCS*

7.2.2

A three to eight line decoder IC11, is used f or decoding va rious write, e nable, and

interrupt lines for the system. Address lines A4, A5, A6, and A7 will enable one of

the Q outputs of IC11. The table below lists the lines that are controlled by IC11,

the WR*, DISPLED, and PWRSWIN lines.

Name Function

DACCS*

[DACWR* for rev 00 boards]

Digital to Analog Controller Write

RTCCS*

Real Time Clock Chip Select

DISPWR*

Display Write

DISPCS*

Display Chip Select

SPCS3*

Serial Printer Chip Select #3

INT1*

Interrupt #1

Table 1.

This line will enable writing to IC12 on th e 2710 Analog board.

This line corr esponds to t he Q1 output of IC11 and is

used for the optional printer for time stamping on

printouts.

When both the processor’s WR* line and the DISPCS*

line from IC11 are low the DISPWR* line will initiate

a write to the display controller IC4.

This line enables the display controller IC4 for writing.

This line is sent to the printer o ption and corresponds

to the Q3 output of IC11.

This interrupt line is controlled by the INTCS* line

from IC11 and the DISPLED line. The DISPLED line

will be brought low when the front panel key is

pressed. This activates the backlight on the display.

2711 digital board decoding lines

18-Jul-94 Model 511 Service Manual

19

Page 32

Section 7 Electronic Theory of Operation

Name Function

PWRNMI*

Power Non-Maskable Interrupt

PORT1WR

Port #1 Write

PORT2WR

Port #2 Write

SPCS7*

Serial Printer Chip Select #7

Table 1.

Microprocessor Supervisor

This line turns the monitor off. When the PWRSWIN

line is brought high (by pressing the front panel

POWER key) and the INTCS* line is low, the

PWRNMI line will signal the processor to shut off.

This line is controlled by the WR* line of the processor

and the PORT1CS* line from IC11. It enables writing

to IC12, this controls the multiplexor lines, SC1 and

CAL lines for the 20 bit A/D Converters, nad control

lines for IC7.

Controlled by the WR* line and PORT2CS* from

IC11. This line will enable writing to IC14. The

SPOUT lines (for serial printer), 20 bit A/D converter

sleep line, backlight control, and power off control are

handled by IC14.

This line is sent to the printer o ption and corresponds

to the Q7 output of IC11.

2711 digital board decoding lines

7.2.3

A microprocessor supervisory integrated circuit, IC5 monitors the power supply,

and shuts the monitor off when the front panel power key is pressed. When the

PWROFF line is brought high (under control of the processor) Q1 will be biased on.

The PFI input of IC5 will in turn be brought low, this will cause the PWRO FF* line

to go low. The PWROFF* line will shut the monitor off by biasing Q2 (located on

the 2710 Analog Board) on, this in turn shuts the power off on the monitor, see

Section 7.1.1, P ower Supply, on page 9. The MRIN* (Manual Reset In) line enables

an external device to reset the system if brought low, this line enters the system at

J2 pin 15 (see page 2).

The WDOG line under control of the processor must be toggled before a specific

time-out (1.6 seconds) otherwise the RESET* line is brought low, this will result in

the system resetting. Therefore the processor toggles the WDOG line pe riodically

to avoid the reset, this ensures that the processor is working and not lost in a loop

or task. If the VDD supply drops below a certain level the RESET* line will also be

brought low to reset the system.

For revision 00 boards: The microprocessor’s supervisor (or watchdog) is made up

of IC5 and IC6. The battery voltage is converted to a 2.5 volt reference by IC6, this

is used as the backup supply when the monitor is off. When the monitor is powered

on and VDD is at +5 VDC the VBACK supply is taken from VDD, when the

20

Model 511 Service Man ual 6116-90-00

Page 33

2711 Digital Board

VBATT

C3

0.1u

IC6

MAX872

2.5V REF

C1

0.1u

VDD VDD

VBACK

C4

0.1u

IC5

MAX690A

VDD

1

2 VIN

3

4 GND

5

VOUT 6

7

COMP 8

IC10

74HC14

R6

10K

R1

1M

C2

10u16V

+

Q1

2N7002

R3

100K

R2

100K

PWROFF

1 VOUT

2 VCC

3 GND

4 PFI PFO 5

WDI 6

RST* 7

VBAT 8

MPU Supervisor

SOIC - 8

1011

RESET

RESET*

WDOG

PWROFF*

E

monitor is off the VBACK supply is taken from VBAT (the 2.5 volt reference), this

switching is controlled by IC5.

18-Jul-94 Model 511 Service Manual

Figure 9.

Revision 00 watchdog circuitry

When the PWROFF line is brought high (under control of the processor) Q1 will be

biased on. The PFI input of IC5 will in turn be brought low, this will cause the

PWROFF* line to go low. The PWROFF* line will shut the monitor off by biasing

Q2 (located on the 2710 Analog Board) on, this in turn shuts the pow er off on the

monitor, see Section 7.1.1, Power Supply, on page 9.

The WDOG line under control of the processor must be toggled before a specific

time-out (1.6 seconds) otherwise the RESET* line is brought low, this will result in

the system resetting. Therefore the processor toggles the WDOG line pe riodically

to avoid the reset, this ensures that the processor is working and not lost in a loop

or task. If the VDD supply drops below a certain level the RESET* line will also be

brought low to reset the system.

Front End Timing Signals

A 14 stage divider IC6 (IC15 on rev 00 boards), acts as a timing sequencer. The

ADCCLK input is the clock input, the RESET line is the clear input, used for

clearing the chip at power up. The Q4-Q11 outputs of IC6 are divided down from

the clock input and feed IC13, the data sampling controller. The Q14 output of IC6

is used as an interrupt that is generated every 5 milliseconds (INT5MS).

The data sampling controller IC13 is a Programmable Electrically Erasable Logic

device (PEEL). The PEEL uses the outputs from IC6 (IC15 on rev 00 boards) and

7.2.4

21

Page 34

Section 7 Electronic Theory of Operation

generates the front end timing signals. These signals control the sensor LED drive

and the photodiode’s return path circuitry during normal operation and calibration.

The RESET and SC1 lines control when the outputs of IC13 are active, both these

lines must be low in order for IC13 to operate normally. The RESET line controls

IC13 during power up, while the SC1 line is under processor control and will toggle

when a probe off patient alert exists and during the power up self test.

Signal Description

INSIG*

Input Signal

RDLED*

Red LED

IRLED*

Infrared LED

SIGND*

Signal Ground

ASAMP*

Analog Sample

SYNC

Synchronization

IRSAMP*

Infrared Sampling

RDSAMP*

Red Sampling

This line will enable signals from the photod iode, or

prevent signals from the photodiode from reaching

the detection circuitry.

Controls the signals for the Red Led in the sensor.

Controls the signals for the Infrared Led in the sensor.

This is used to short out the inputs of the detection

circuitry so that the system can compensate for offsets.

This line is used to short out the capacitor used in the

sample and hold circuitry to avoid having residual

charge interfere with data sampling.

Synchronization signal, not used in this system.

Used for sampling the Infrared signal response from

the photodiode.

Used for sampling the Red signal response from the

photodiode.

Table 2.

Front end timing signals

System Output Ports

There are two output port chips IC12 and IC14, these control various lines for

system control. The first port IC12, enabled when PORT1WR is high controls the

CSIO PEEL IC7, the analog multiplexor IC6 on the 2710 board, and the 20 bit

analog to digital converters IC1 and IC8 on the 2710 board. The second port IC14,

enabled by the PORT2WR line, handles the serial printer control lines ADCSLP*,

SPOUT1-SPOUT3, the DISPBLK* and BKLITE lines that control the display. The

second port also controls turning the monitor off through the PWROFF line.

22

Model 511 Service Man ual 6116-90-00

7.2.5

Page 35

2711 Digital Board

The output ports are selected by the decoding performed by IC11 and the WR* line.

The signals controlled by the ports are listed below with a brief description of their

function.

Signal Description

AA0-AA1 Decode line for selecting ADCs.

SC1 Used for 20 bit ADC calibration.

CAL De-activates the 20 bit ADCs prior to calibration.

A0MUX-A1MUX Selects one of six channels that will be switched to the

serial A/D converter for conversion.

NEXT* Used in decodi ng selection of ADCs.

ADCSLP* Signal used for the serial printer.

BKLITE Controls the backlight for the LCD display.

PWROFF Turns the monitor off, under processor control.

DISPBLK* Blanks out the display by de-activatin g IC4.

SPOUT1-SPOUT3 Used for the serial printer option.

Table 3.

Serial I/O Controll e r

Output port lines

7.2.6

Digital data from the three Analog-To-Digital Convertors is read by the CPU

through its clocked serial data input (RXS) at IC1 pin 56. The PEEL IC7 acts as the

Clocked Serial Input/Output (CSI/O) Controller.

Except during power up or Watchdog Timer reset, IC6 (IC15 on rev 00 boards) pin

3 provides an interrupt to the CSI/O controller in the form of a 5 millisecond period

square-wave input to IC7 pin 7 (INT5MS).

On the rising edge of INT5MS, a CPU interrupt request is generated when IC7 pin

18 (CPUINIT*) goes low. The CPU responds by sending the clock input to CSI/O

controller (CKS) at IC7 pin 6 low. (This CKS line is inactive high unless a serial

receive operation is in progress.) The CPU also sets up the ADC decode lines AA1

and AA0 at IC7 pins 5 and 4, and as a result, one of the ADC chip select lines

(ADCIRCS*, ADCREDCS*, ADC3CS*) is brought low, and the CPUINIT* line is

disabled.

On the rising CKS signal a CLKS output pulse at IC7 pin 14 is sent as a serial clock

input to the ADC selected by the decode lines. Decode results are shown below.

AA1 AA0 Decode

0 0 Red LED 20-bit ADC

0 1 Infrared LED 20-bit ADC

Table 4.

18-Jul-94 Model 511 Service Manual

CSI/O decode lines

23

Page 36

Section 7 Electronic Theory of Operation

AA1 AA0 Decode

1 1 Sensor Status 8-bit AD C

1 0 Internal CSI/O signal (TEND)

Table 4.

CSI/O decode lines

Successive CKS/CLKS pulses cause the ADC data to be shifted out of the ADC

(most significant bit first) along the serial data line (SDATA) to the CPU serial

input (RXS) at IC1 pin 56.

After receiving the correct number of bits for the ADC being read, the CPU changes

the AA1 and AA0 decode lines and exerts the Next line (NEXT*) at IC12 pin 12

low. This restarts the serial data shifting out of the newly selected ADC.

After all three ADCs have been read, the CPU sets the AA1 and AA0 decode lines

to exert the internal TEND signal and set the 8-bit ADC to the next channel (so that

it has time to settle before the ne xt read of the ADC). This re-enabl es the C PUINIT

line. At this point the CSI/O controller is reset awaiting an INT5MS pulse to begin

the cycle again.

Display

7.2.7

The display is interfaced to the microprocessor by IC4, a Liquid Crystal Display

(LCD) decoder/driver. The DISPWR* line will enable IC4 on its positive going

edge. Parallel operation is performed on the address lines A0-A1, and data lines D0D3.

VDISP: Display Voltage Control, when this input i s brought to a lower voltage than

one volt from VDD the display will be shut down. This is accomplished when the

DISPBLK* line is brought low, Q2 will be biased off and the VDISP line voltage

will be close to VDD. When the DISPBLK* line is high then Q2 is on, current will

flow through D3-D7 (diodes are used for temperature compensation), through the

parallel combination of R9 and R12 then through Q2 to ground. The voltage at

VDISP will be about 2 volts and the display will operate.

The backlight for the display is controlled by the BKLITE line (IC14 pin 18). When

BKLITE is brought high both Q5 and Q4 (Q6 on the rev 00 boards) will be biased

on, this will allow current to flow through DS1 and DS2, the display will light.

24

Model 511 Service Man ual 6116-90-00

Page 37

8

Maintenance

General

This section presents recommended maintenance schedules for the Model 511 and

information on general maintenance, suc h as ba ttery repl ac ement, disa ssembly a nd

assembly instructions, and system software updates.

Maintenance Schedules

The electronic circuits within the Novametrix Model 511 Pulse Oximeter monitor

do not require scheduled calibration or service. However, in order to maximize

battery life, the monitor’s internal battery should be exercised monthly. Novametrix

recommends the following maintenance schedules.

• Cleaning and Sterilization:

Perform as required. See

• Battery Installation:

Battery Installation

See

• Functional Test:

Perform on each Model 511 and sensor to verify overall functional integrity of

the monitor and sensors. See

• Accuracy Test:

This test, which requires the use of the Model TB500B Sensor Simulator,

verifies the performance accuracy of the Model 511. This test is typically

performed in conjunction with (after) the Monitor Functional Test. If the

monitor does not pass the accuracy test, the Electronic test should be performed.

Accuracy Test

See

on page 39.

Cleaning and Sterilization

on page 26.

Functional Test

1

on page 26.

on page 35.

8.1

8.2

• Electronic Tests:

These tests contain information on checking the electronic circuits within the

Model 511 and should only be performed if the monitor fails to pass the

Functional and/or Accuracy Tests. Only qualified service personnel should

attempt to perform the Electronic Test. See

1. At the customer’s request, Novametrix will provide repair and calibration services under the terms

of a Service Contract. Contact the Novametrix Service Department for contract details.

18-Jul-94 Model 511 Service Manual 25

Electronic Test

on page 43.

Page 38

Section 8 Maintenance

Cleaning and Sterilization

Model 511 Monitor

• Turn the monitor off before cleaning.

• Clean the monitor surface with a damp cloth.

• Do not immerse the monitor.

• Do not attempt to sterilize the monitor.

Finger Sensor

• Clean the sensor surface with a damp cloth.

• Ensure the sensor windows are clean and dry.

• Do not immerse the sensor.

• Do not attempt to sterilize the sensor.

Y-SENSOR™ and Y-STRIP™ Taping System

• The Y-SENSOR may be immersed (up to the connector) in a cold liquid

sterilant (i.e., Cidex™). Refer to sterilant manufacturer’s instructions and

standard hospital protocol.

8.3.1

8.3.2

8.3.3

8.3

• Rinse thoroughly with water and dry before use.

• Do not immerse Y-SENSOR connector.

• Treat Y-STRIP Taping System in accordance with hospital protocol

for single-patient use.

Battery Installation

The Model 511 operates on four (4) 1.5 volt “AA” alkaline batteries. Other

battery types should not be used with the monitor.

WARNING: Use of improper batteries may present a risk of fire or explosion.

To install batteries into the monitor:

1. Locate the battery compartment cover on the back side of the monitor.

2. Press the “OPEN” area of the compartment cover, slide the cover in the

direction indicated by the arrow, and remove the cover.

8.4

26

Model 511 Service Man ual 6116-90-00

Page 39

Battery Installation

OPEN

NOTE: Use only 1.5 volt

“AA” size Alkaline

3. Install new batteries according to the “+” and “-” symbols on the bottom of

the battery compartment and on each battery.

Figure 10.

WARNING: Alkaline batteries may explode or leak if recharged, inserted improperly, or

disposed of in a fire. Do not open batteries.

Battery orientation

4. Slide the battery cover back into place. The cover latches into place when

properly seated.

18-Jul-94 Model 511 Service Manual

27

Page 40

Section 8 Maintenance

Assembly Exchanges

8.5

Disassembly should be performed by qualified personnel. Follow proper grounding

procedures to avoid damage to internal components from static discharge.

1. Turn the Model 511 Off. Disconnect the sensor, external DC supply if

connected, and remove the batteries. Remove the four cover screws from the

bottom cover. Holding both case halves together, flip the monitor right-side

up.

Figure 11.

Removing the top cover

2. Use a gentle rocking motion to separate the left side first, lift the top cover

from the monitor. Be careful of the keypanel ribbon cable, it is attached

between the top cover and digital board.

Keypanel ribbon cable

Figure 12.

28

Model 511 Service Man ual 6116-90-00

Monitor disassembled

Page 41

Assembly Exchanges

3. Carefully disconnect the keypanel ribbon cable from the display board.

Carefully pull the sliding portion of the connector upward, this will release the

ribbon cable.

Keypanel ribbon cable

Pull this section upward to

release ri bbon cable

J405 on 2711 Digital board

Figure 13.

Disconnecting keypanel ribbon cable.

4. The circuit boards of the monitor can now be removed from the bottom case

assembly. Be careful not to damage the speaker or battery wires.

5. Remove/replace the various assemblies as needed.

IMPORTANT:

The monitor

will be damaged if power is applied to it while cables or assemblies are

improperly connected.

18-Jul-94 Model 511 Service Manual

29

Page 42

Section 8 Maintenance

Changing System Software

8.6

The system software is contained in EPROM IC3 on the 2711 Digital Board. New

software releases are made available from time-to-time. These new releases may

add features or be maintenance upgrades. To install a new EPROM:

1. Follow the steps listed in Assembly Exchanges on page 28 to open the

monitor. Be sure that the external DC supply is disconnected, and batteries are

removed from the unit before disassembly.

2. Use a small flat-blade screwdriver (or IC extraction tool) to pry the EPROM

IC3 from the socket—be careful not to bend the pins.

EPROM IC3

Pin 1

Figure 14.

Changing the system software EPROM

3. Install the new EPROM into the socket. Align the EPROM so that IC3 pin-1

is properly aligned with the socket.

4. Reassemble the monitor.

30

Model 511 Service Man ual 6116-90-00

Page 43

9

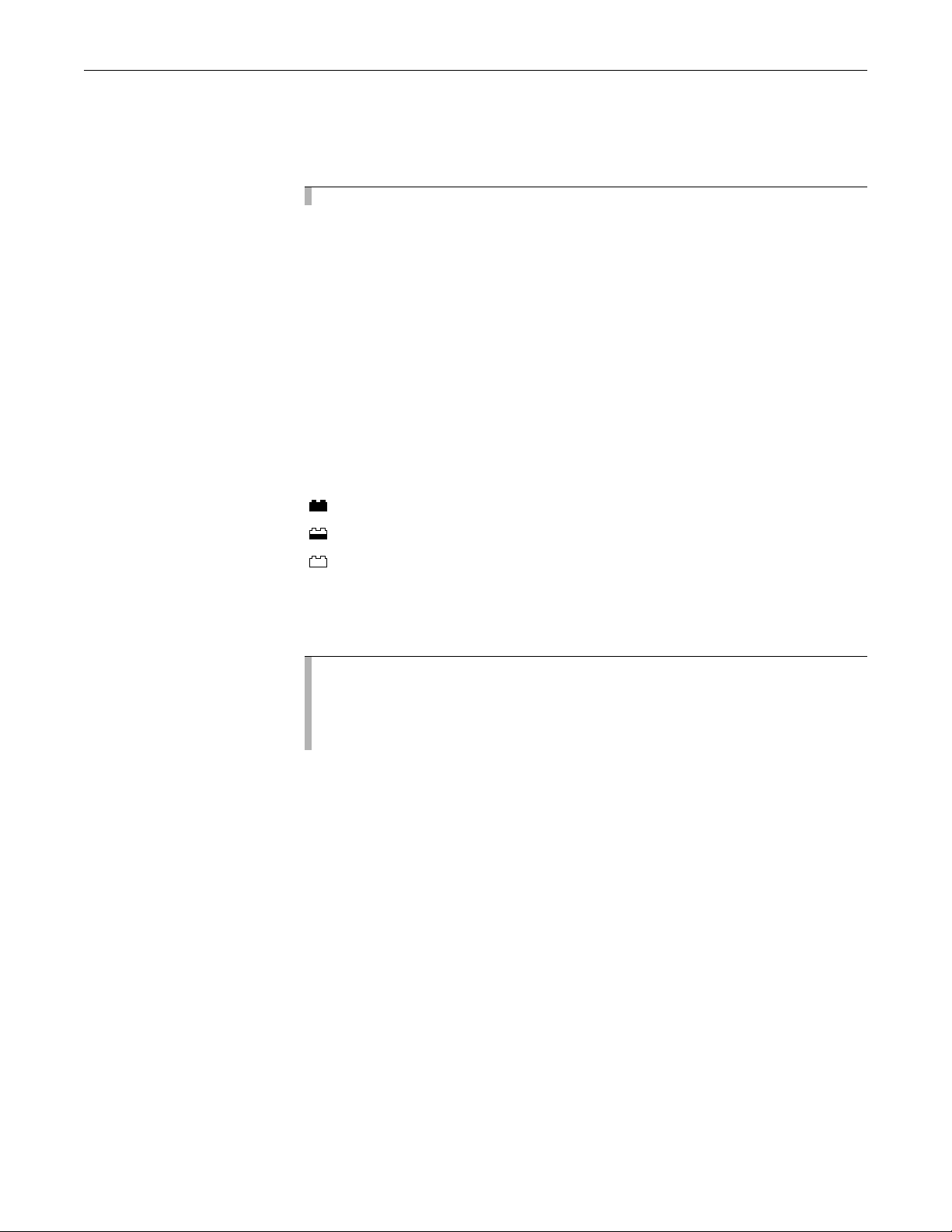

The information listed below c onstitute the various fault, ale rt, and status mes sages

that can be indicated by the Model 511 display.

Status Messages

Status Messages and Fault Indicators

The Model 511 Pulse Oximeter can indicate messages as text in conjunction with

numerical codes on the display. This combination will correspond to specific

conditions that are explained in the following table.

SpO2 Value

or upper alert limit

UNIT/SENSOR ERROR

REPOSITION SENSOR

SENSOR OFF PATIENT

SENSOR DISCONNECT

Pulse Bar

Text Status Messages

(only one will appear at a time

except at power up)

Numerical code will appear in some cases (see table)

%

Battery Indica tor

Numerical Indicator

Pulse Rate

or lower

alert limit

Audible Alert

Indicator

9.1

Figure 15. Status messages and numerical codes

18-Jul-94 Model 511 Service Manual 31

Page 44

Section 9 Status Messages

Text Message

Sensor Disconnect 1

Sensor Off Patient 2

Reposition Sensor 3

Reposition Sensor 4

Reposition Sensor 5

Reposition Sensor 6

Unit/Sensor Error 7

Unit/Sensor Error 8

Numerical

Indicator

Explanation

Sensor not connected to monitor.

Sensor not applied to the patient.

Low signal strength. Pulse strength as detected by

the sensor is too small for proper monitor

operation.

Insufficient light. Sensor placed on a site too thick

(or opaque) for adequate light transmission.

Pulse out of range. Pulse must be 30-250 bpm

inclusive.

Light Interference. Ambient light sources

(sunlight, warming lights, etc) are interfering with

sensor operation. Shield sensor from these light

sources.

Sensor fault. Remove sensor from use and contact

qualified service personnel.

Monitor fault. Record the error number that

appears in the

monitor from use and contact qualified service

personnel.

PULSE RATE

display. Remove the

Reposition Sensor 9

Table 5. Status messages

Bad signal time-out. Monitor not receiving valid

signals from sensor, reposition sensor.

All status conditions except for Unit /Sen sor Error will rese t au toma tical ly onc e the

condition is corrected. Unit/Sensor Error conditions are latching conditions—that

is you must replace the sensor for a sensor fa ult, or turn the Mode l 511 off and fix

the problem before the monitor fault is reset.

If the Unit/Sensor Error message appears and status triangle numerical indicator is

8, then another numerical code will be displayed in the

PULSE RATE

display. The

numerical codes with the error detected is listed below.

PULSE RATE

Numerical Code

1 RAM Self Test Failed

3 ROM Self Test Failed

10 Stack pointer error-not at top of stack

11 MMU error-not at base page

12 250 ms interrupt-illegal task

Explanation

Table 6. Error codes

32

Model 511 Service Man ual 6116-90-00

Page 45

Status Messages and Fault Indicators

PULSE RATE

Numerical Code

13 Stack error-stack overflow

14 Display buffer overflow

15 Front end offset error

20 10 ms overrun

21 250 ms overrun

22 illegal int1 interrupt

23 illegal int2 interrupt

24 illegal prt1 interrupt

25 illegal dma0 interrupt

26 illegal asc0 interrupt

27 illegal nmi interrupt

28 Trap error-illegal command executed

40 Unknown error

Table 6. Error codes

Explanation

18-Jul-94 Model 511 Service Manual

33

Page 46

Section 9 Status Messages

[This page intentionally blank]

34

Model 511 Service Man ual 6116-90-00

Page 47

10

POWER key

Audible Alert

Display

%

SpO

2

beats/min

SATURATION PULSE RATE

511

Pulse Oximeter

Enable/Disable

Functional Test

Introduction

The Functional Test described below should be performed on each Model 511 Pulse

Oximeter and sensor to verify overall functional integrity of the monitor and

sensors. If the monitor or sensors do not pass these tests, remove from use and

contact the Novametrix Service Department for repair/replacement assistance.

Monitor Functional Test

1. Equipment Required:

Model 511 to be tested (with fully charged batteries)

Finger Sensor (Cat. No. 8744) or Y-Sensor™ (Cat. No. 8793)

2. Check that the sensor is not connected to the monitor. Press and hold the