Page 1

HAND-HELD RESPIRATORY

MECHANICS MONITOR

Service Manual

Model 101

April 17, 2000

Catalog No. 6800-90-01

Novametrix Medical Systems Inc.

PO Box 690

5 Technology Drive

Wallingford, Connecticut, U.S.A. 06492

Page 2

Page 3

Revision History

Revision History

22-May-98 Release

17-Apr-00 Revision 01, R-N746

Rev. 01

Model 101 Service Manual

iii

Page 4

[This page intentionally blank.]

Revision History

iv

Model 101 Service Manual

Rev. 01

Page 5

Table of Contents

y

Safety ..................................................................................................... 1

Introduction ...........................................................................................3

Keypad Controls and Indicators ........................................................................4

S

mbols ............................................................................................................. 4

Theory of Operati on ............................ .......... ........... .......... ........... .......5

Main Board ........................................................................................................5

Power Su pply ................. ..................... .................... ..................... ........... ....................5

Reference Voltages .............................. ................ .. ................ ................ ................ .....5

Battery Charger ...........................................................................................................5

On/Off Co n tr ol .. ... ........... ............ .................... ..................... .................... ............ ........6

Digital Control and Microprocessor ...................................... .. .. ................. .. .. .. ............6

Serial Communication .................................................................................................7

Audio ...........................................................................................................................7

Interface ......................................................................................................................8

Analog Control Signals ................................................................................................8

Sensor Identification ....................................................................................................8

Flow Zeroing ...............................................................................................................8

Flow Circuitry ..............................................................................................................9

Baromet ric a nd A ir w a y P re s s u re .... .. ..................... ..................... .................... ...........10

Interface Board ................................................................................................11

Key panel Interface . .................................................................................................. 11

Display interface ........................................................................................................11

LED control ...............................................................................................................11

Power Su pplies ....................... ..................... ..................... .................... ............ ........11

Functional Tes ts ................... ........... ............................. .......... ........... .13

Equipment Required ........................................................................................13

Procedure ........................................................................................................ 13

Accuracy Tests ............................................ .. .. ....... .. .. .... .. .. .. ....... .. .... .15

Equipment Required ........................................................................................15

Procedure ........................................................................................................ 15

Electrical Tests ...................................................................................17

Equipment Required ........................................................................................17

Rev. 01

Model 101 Service Manual

v

Page 6

Table of Contents

g

y

Procedure ........................................................................................................ 17

Power Supp lies ........ ............ .................... ..................... .................... ............ ............17

Airway Pre s s u re Ca l ib ra tion . .. .. ..................... .................... ..................... ........... ........18

Differen t ia l P re s s ur e Calibration ............ .. ..................... ........... ..................... ........... . 19

Barometric Pressure Calibration .....................................................................19

Maintenance ........................................................................................21

General ...........................................................................................................21

Maintenance Schedules .................................................................................. 21

Cleanin

Batter

Battery Installation .................................................................................................... 23

External B a ttery Char ger ........... ... .. ..................... .................... ............ .................... . 23

Features Connector .............. .. .................. .. ............... .. .................. .................. .. .......23

and Sterilization ................................................................................22

and AC Operation ............................................................................... 22

Assembly Exchanges ...................................................................................... 24

Disassembling the Monitor ........................................................................................ 24

Reassembling the monitor ........................................................................................ 26

Accessories ......................................................................................... 27

Parts Lists ............................................................................................29

6800-00 Final Assembly, Model 101 ............ .................. .................. .................. .......29

6800-01 Main Assembly, Model 101 ................ .. ................................................... .. ..29

2740-01 01 Main Board Assy, Model 101 ........................ .................. .......................30

2740-17 01 Main Board Subassy, Model 101 ......................................................... ..30

2739-01 00 Battery & Comm Interface Board Assy ..................................................32

2741-01 00 Interface Boa rd Assy, Model 101 .............................. .. .............. .............32

6935-48 00 Test Fixture, Flow Leak Test ................................................................. 33

Drawings and Sche matics ................... ........... .......... ........... .......... ....35

vi

Model 101 Service Manual

Rev. 01

Page 7

Guarantee

Equipment manufactured or distributed by Novametrix Medical Systems Inc., is fully guaranteed,

covering materials and workmanship, for a period of one year from the date of shipment, except for

certain dispo sable pr oducts and products wit h stated gu arantees other than one year. Novametrix r eserve s

the right to per form gu ara ntee s ervi ce(s) at it s f actor y, at an authorized rep air s tati on, o r at t he cus tome r’s

installation.

Novametrix’ obligations under this guarantee are limited to repairs, or at Novametrix’ option,

replacement of any defective parts of our equipment, except fuses, b atteries, and calibration gasses,

without charge, if said defects occur during normal service.

Claims fo r damage s durin g shipme nt must be filed pro mptly wi th the tr ansportati on compa ny. All

correspond ence co ncerning the equ ip ment must specify bot h t he model name and number, an d t he serial

number as it appears on the equipment.

Improper use, mishandling, tampering with, or operation of the equipment without following specific

operating instructions will void this guarantee and release Novametrix from any further guarantee

obligations.

Service Department

For factory repair service, call toll free

1-800-243-3444

In Connecticut, call Col lect (2 03) 265-7701

(203) 284-0753

FAX

http://www.novametrix.com

techline@novametrix.com

Email

Caution:

license d medical practitioner.

Copyright 1998, 2000 Novametrix Medical Systems Inc. This document contains information which

is proprietary and the property of Novametrix Medical Systems Inc., and may not be reproduced, stored

in a retrieval system, translated, transcribed, or transmitted, in any form, or by any means, without prior

explicit written pe rmissio n from Novametrix Medical Systems Inc.

Federal (U.S.A.) law restricts this device to sale, distribution, or use by or on the order of a

Declaration of Conformity with European Union Directive

The Authorized Representative for Novametrix equipment is:

D.R.M. Green

European Compliance Services Limited

Oakdene House

Oak Road

Watchfield

Swindon, Wilts SN6 8TD

Rev. 01 Model 101 Service Manual

vii

Page 8

Guarantee

Service Policy

Novametrix Medical Systems Inc. provides 24-hour a day access to technical support through its

Technical Suppo rt Depa rtment in Wallingford, C onnecti cut, and company S ervice Re presen tatives

located throug hout th e United Sta tes. (Outside the U.S., prim ary technica l suppor t is handled t hrough ou r

qualified international sales and service distributors.)

Novamet ri x wil l provide Warranty Service suppor t wi thi n 48 ho urs of receiv in g a re quest for assistanc e.

Contact the Technical Support Department by telephone toll free at 800- 243 -3444, or 203-265-7701; by

facsimile at 203-284-0753; or, by e-mail at techline@novametrix.com. After hours telephone support

requests (before 8:00 AM and after 5:00 PM Eastern Time) will be responded to promptly by the

Technical Support on-call staff. After hours facsimile and e-mail requests will be answered the next

busines s day. It is suggested tha t an y perso n cal ling in for techni cal su pport h a ve t he equi pmen t a va ilabl e

for product identification and preliminary troubleshooting.

Novamet ri x reserves the right to repair or replace any product found to be defective during the warr ant y

period. Repair may be provided in the form of replacement exchange parts or accessories, on-site

technical repair assistance or complete system exchanges. Repairs provided due to product abuse or

misuse will be considered “non-warranty” and invoiced at the prevailing se rvice rate. Repl aced or

exchanged materials are expected to be returned to Novametrix within 10 days in order to avoid

(additional) charges. Return materials should be cleaned as necessary and sent directly to Novametrix

using the r et urn paperwork an d shipping label ( s) provided. (Transferri ng r et u rn m at eri al s t o a local sale s

or dealer representatives does not absolve you of your return responsibility.)

Novametrix manufactures equipment that is generally field serviceable. When repair parts are provided,

the recipient can call Technical Support for parts replacement assistance and repair assurance. In the

event a replacement part requires increased technical ca pability, Technical Support may request

Biomedical assistance, provide on-site technical suppo rt or complete replaceme nt equipment. If the

customer requires the return of their original product, the exchange material will be considered “loaner

material” and exchanged again after the customer equipment is repaired.

Novametrix promotes customer part icipation in w arranty repairs, should they beco me necessary. A

longer useful product life, and quicker, more cost-effective maintenance and repair cycles—both during

and after the warranty period, are benefits of a smooth transition into self-maintenance. The Technical

Support Department can provide technical product support at a level appropriate to your protocol and

budget requirements.

Please contact Technical Support for information on these additional programs and services:

• Focus Series Technical Training Seminars

• Test Equipment and Test Kits

• Service Contract / Parts Insurance Plans

• On-Site Technical Support

•“Demand Services” including

Flat rate parts -exchange

Flat rate return for repair

Time and Material

• Full warranty, discounted replacement sensors

Model 101 Service Manual Rev. 01

viii

Page 9

Section 1

The VENT✔ Handneld Resp iratory Mecha nics Monitor, Model 10 1, is electrically is olated. Patient

leakage current flowing from the instrument to ground is limited to less than 10 uA.

• Keep the VENT✔ and its accessories clean. Do not operate the VENT✔ when it is wet due to sp ills

or condensation.

• Connect only Novametrix Series 3 Flow Sensors to the VENT✔. For maximum performa nce ; keep

the pressure sensor ports oriented upward, and keep the sensor clear of moisture and secretions by

proper breathing circuit maintenance.

• Connect the sensor first to the VENT✔ and then to the patient breathing cir cuit in order to limi t

circuit volume loss and to avoid excessive moisture build-up in the flow sensor tubing.

• VENT✔ has electrically isolated inputs. Patient leakage current flowing from the instrument to

ground is limit ed to less than 10 µA at 120 V, 60 Hz. Pa tient iso lati on is grea ter t han 1 0 MΩ, 2500V

rms at 60 Hz.

• Where electr omagnetic devic es (i.e., ele ctrocautery) ar e used, patient monitoring may be interrupted

due to electromagnetic interference. Electromagnetic fields up to 3 V/m will not adversely affect

system performance.

• VENT✔ contains no user serviceable parts. Refer servicing to qualified service personnel.

• This product and its accessories which have patient contact are latex free.

For maximum patient and operator safety, observe the following warnings and cautions.

Safety

WARNINGS

!

Indicates a potentially harmful condition that can lead to personal injury.

Explosion Haza rd:

•

instrument in such an environment may present an explosion hazard.

Electrical Sho ck Hazard:

•

monitor or sensor. Refer servicing to qualified service personnel.

Fire Hazard:

•

Use in such an environment may present a fire hazard.

Failure of Operatio n:

•

has been corrected by qualified personnel.

• Do not apply tension to t he sensor tubing whi le connected to a patie nt breathing ci rcuit, as accid ental

extubation may result.

• Do not position the flow sensor’s tubing in any manner that may cause entanglement or

strangulation.

• Use the optional external battery charger in non-patient areas only.

Do NOT use the VENT✔ in the presence of flammable anesthetics. Use of this

Always turn the monitor off befor e c le ani ng i t. Do NOT us e a damaged

The VENT✔ should not be exposed to elevated oxygen levels at elevated pressures.

If the monitor fails to respond as described, do not use it until the situation

Rev. 01

Model 101 Service

Manual

1

Page 10

Section 1

CAUTIONS

Indicates a condition that may lead to equipment damage or malfunction.

• Federal (U.S.A.) law re stri cts th is devi ce to sal e, dist ribut ion, or us e by or on the order of a licens ed

medical practitioner.

• Electrical Shock Hazard: Always turn the monitor off before cleaning. Do NOT use a damaged

monitor.

• Do NOT use a damaged flow sensor.

• Do NOT immerse the monito r or senso rs in liquids.

• Do NOT sterilize the monitor or the sensors.

• No user serviceable parts inside. Refer servicing to qualified service personnel.

• Operate at temp era tu res between +10° C to +40° C (50-104° F), < 90% relative humidity (non-

condensing).

• Avoid storing the monitor at temp eratures less than -20° C or greater than +55° C (<-4° F or >131°

F).

NOTES

Indicates points of particular interest or emphasis for more efficient or convenient operation.

• The VENT✔ operates with Novametrix Series 3 Flow Sensors only.

• The VENT✔ performs an automatic zero (self calibration) periodically and as needed. During this

time, monitoring is interru pted for le ss than th ree seconds.

• The automatic zero can be manually initiated by simultaneously pressing the DATA and GRAPH

keys. After cha ngi ng th e sensor from Adult to Neon at al ( whil e t he VENT✔ is operation al ), w ai t 30

seconds then perform an automatic zero.

• This product and its accessories which have patient contact are free of latex.

• The C

• To determine the VENT✔ software version, turn the monitor on. During the self test performed at

power up, the softwar e lev el is sho wn on the thir d line as “main-101-xx”, where “xx” is the software

version.

• Some VENT✔ monitors were produced with the statement “Use only Novamet rix approved devic es,

13 VDC, 1A” located on the label at the Flow Sensor Input Connector. This erroneous statement

does NOT apply to the VENT✔ monitor and should be ignored.

/C Compliance Ratio (neonatal) parameter is not supported.

20

2

Model 101 Service

Manual Rev. 01

Page 11

Section 2

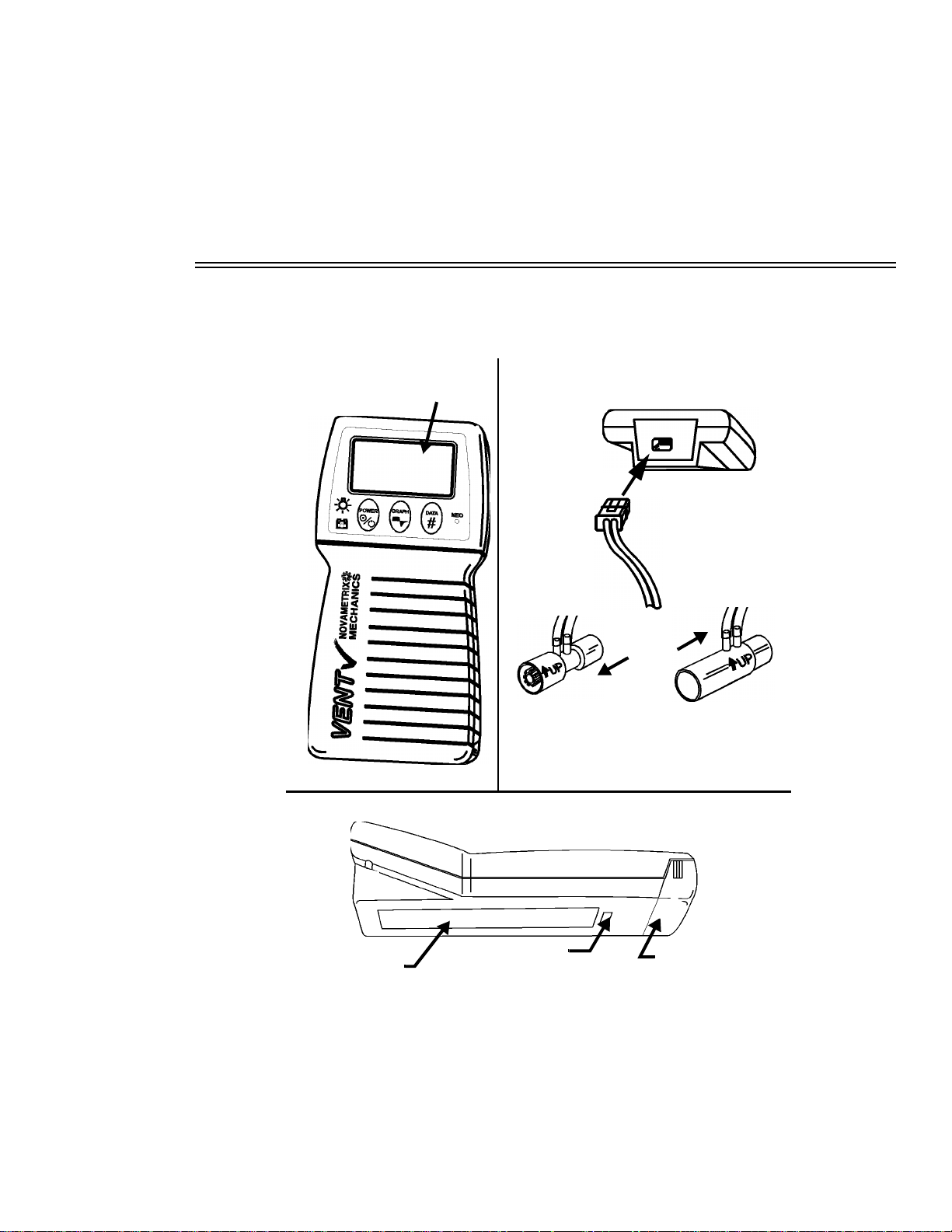

The VENT✔ Handheld Respiratory Mechanics Monitor, Model 101 is shown below.

Keypad &

Display

Introduction

Connect Series 3

Flow Sensor

t

n

e

i

t

a

P

o

T

r

o

t

a

l

i

t

n

e

V

o

Neonatal Pediatric/Adult

Sensor

#6718/6720

T

Sensor

#6717

Features

Quick Guide

Rev. 01

Connector

Battery Access

Compartment

Model 101 Service

Manual

3

Page 12

Section 2

g

g

g

g

g

g

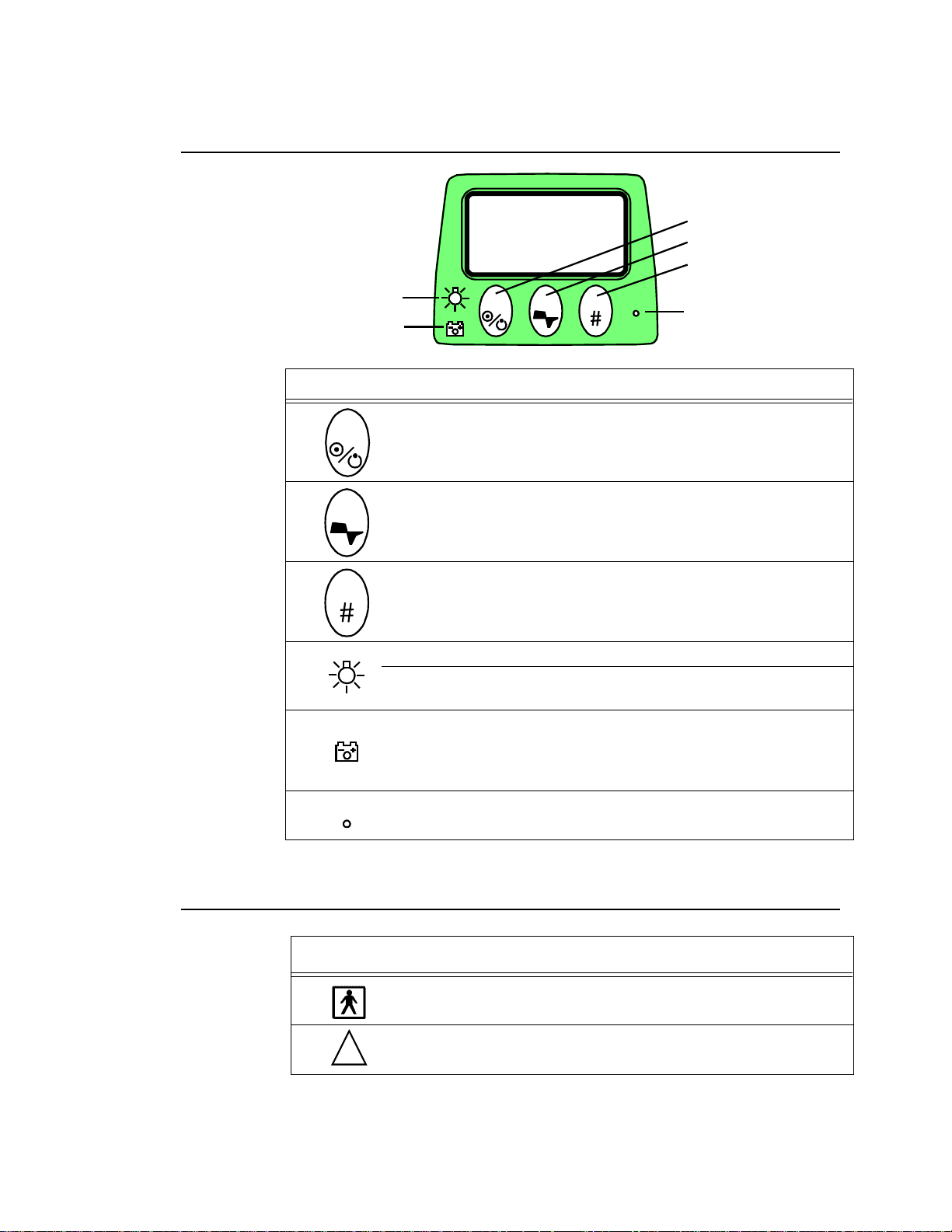

Keypad Controls and Indicators

2.1 Keypad Controls and Indicators

1

2

3

4

POWER GRAPH DATA

A

# Key Action Function

POWER

1 Press Turns

GRAPH

2Press

DATA

3Press

Press Turns displ ay backlight on/off.

4

Press &

Hold

A None

VENT

Display Graph Screens.

Additional presses caus es

h available Graph Screens.

throu

Display Data Screens.

Additional presses caus es

h available Data Screens.

throu

Adjusts contrast/viewin

(1 step/sec.)

Illuminated if powered from battery

Green; battery char

Yellow flash in

Red flashin

NEO

B

✔ on/off.

✔ to sequence

VENT

✔ to sequence

VENT

angle of display

ed

slowly; capacity getting low

quickly; exhausted in 10-15 min.

4

Model 101 Service

NEO

B None Illuminates when a Neonatal sensor is connected.

2.2

Symbols

Symbol Description

Patient Iso lation

Identifies patient isolation connection as type BF.

!

Manual Rev. 01

Attention

Consult manual for detailed information.

Page 13

Section 3

3.1 Main Board

3.1.1 Power Supply

Refer to page 4 of the schematic 2740-03. An external power source can be connected to J403 to power

the monitor and charge a rechargeable battery (only Novametrix approved rechargeable batteries and

chargers should be used with the model 101). The internal battery connects to the cathode of D11, fuse

F1 provides overload protection. Since the monitor has the possibility of being powered by the internal

battery or an external charger, diodes D4 and D11 isolate each of these sources from one another.

3.1.2 Reference Voltages

Refer to page 5 of the 2740-03 schematic. A 2.5 volt reference (AVCC_2) is generated by U10 and

buffered by U1A. This voltage is amplified by U1B and Q1 and supplies a 5 volt line (AVCC). The 2.5

volt reference is divided down by resistors R6 and R7, buffered by U2B to supply a 1.5 volt reference

(A_1_5V). A neg ative 2.5 volt reference (NEG_AVCC_2) is gene ra ted by U9B and Q9 which are set up

as a unity gain inverting amplifier fed by the 2.5 volt reference (AVCC_2).

Theory of Operation

3.1.3 Battery Charger

Refer to page 9 of the 2740-03 schematic. The internal NiMH battery will charge when the monitor is

connected to the DC wall mount adapter or installed in the cradle option. Battery charging is controlled

by U11, a frequency modulated fast charge controller. U11 monitors temperatu re, voltage, and time

throughout the charging proc ess to safely and effectively charge the internal batte ry. The charger is

configured to terminate charging using the ∆T/∆t (delta temperature/delta time) method of charge

termination. Charging is ma in ta ined at the C/4 (600mA) rate whi le cu rr ent t o the battery i s controlled by

Q11, Q2 , Q1 2, a nd th e MO D ou tpu t of U11. Q2 pr ovid es b ase drive fo r Q11 whi le Q 12 se rves t o sh ut

Q11 off very quickly on a cycle by cycle basis allowing the large currents required for charging to pass

through Q11 which is a surface mount SOT-23 package capable of 500mW power dissipation.

T empera ture is moni tored usi ng the batt ery’s internal th ermistor , R115, R11 6, and R118. Resis tors R115,

R116, and R118 set the ∆T/∆t charge termination parameter to 1ºC per minute. R39 and R106 set the

maximum temperature for charge termination (a safety override) to 45ºC. Battery charging is initiated in

one of two w ays . Ei t her by ap ply ing 13 VDC t o +VCHG, therefore prov idi ng power (BVDD) to U11, o r

by inserti ng a r ech arg eab le batt er y in t o the ba tter y co mp ar tme nt (p r ovi ded exte rna l p ower is availa ble ).

Resistors R34 and R36 set up a divider which determines whether the installed battery is within the

correct voltage range for charging. BVDD is regulated by D1, a 5.1V zener diode while R35 keeps D1

Rev. 01

Model 101 Service

Manual

5

Page 14

Section 3

Main Board

operating in the knee region and C68 and C69 provide filtering. Over current protection is provided by

F2, a 1A slo-blo replaceable fuse. Reverse leakage protection is provided by D2 and D7 which prevents

the battery from trying to power BVDD and +VCHG in the battery operation state.

3.1.4 On/Off Control

Refer to page 4 of the 2740-03 schematic. When the power key is pressed the cathode of D3 is brought

to ground, br ing ing t he anode lo w, this biases Q3 B on and allows VDCI N t o p o w e r the unit. Pressing the

power key again will signal the processor that the unit must power down. The processor will assert the

POWER_HOLD line (low) to bias Q4 off, this will turn Q3B off and power the unit down.

The voltage level of the battery (or power source) is monitored by U13A. If the VSWDC level drops

below a certain thres hol d then comparator U13A will go l o w, this will pu ll the POWER_H OL D l ine low

through D19 and shut the monitor down.

3.1.5 Digital Control and Microprocessor

Refer to page 1 of t he 2740-03 schemat ic. Th e syst em i s contro ll ed by mi cropr ocesso r U18. Ei ght a nalog

channels are monit o r ed and proc essed and sev er al digi tal lines are genera ted for vario us ope ra ti ons. The

analog channels are monitored and converted to digital information by the microprocessor. These

channels are listed below:

ANALOG

CHANNEL

ACH_0 Airway flow channel X1

ACH_1 Airway flow channel X10

ACH_2 Airway flow channel X100

ACH_3 Airway flow channel X1000

AWPRESS Airway pressure zero

ABPRESS Barometric pressure

F5V CPU power plane measurement

VBATTADC Battery voltage measurement

The digital lines are listed below:

DIGITAL LINES DESCRIPTION

8255_CS Chip select for programmable peripheral interface, U22

DAC_SDI Serial data input line for U8 and U25

DAC_LD Load assert line for U8

DESCRIPTION

6

Model 101 Service

DAC_CLK Clock signal for U8

OCDRV_0 Drive signal for opto isolator 1

OCDRV_1 Drive signal for opto isolator 2

Manual Rev. 01

Page 15

Main Board

Section 3

OCDRV_2 Drive signal for opto isolator 3

POWER_HOLD Signal line asserted low for powering down the monitor

VLV_CNTL Valve control line used for zeroing pressure sensors

CLKOUT 1/2 of the system clock output (6MHz)

MPU_TXD Serial communic ation tran smit line

MPU_RXD Serial communication receive line

750KHz Clock input signal for audio output pulse width modulated signal

EE_OUT Erasable EPROM data output signal

LED_PWM Clock output signal for display back light

EE_CS Erasable EPROM chip select

COMMPWR Enable/sleep control for RS232 Transceiver, U17

AUD_CLK Audio drive output signal

ALE Address line enable (A0-A7)

INST Control line for R AM and ROM a ccess

WR Write enable

RD Read enable

Crystal Y1 sets the operating fre quency at 12MHz. System softw are is stored in U21, a flash ROM

device, and system RAM in U19. Decoding for the RAM and ROM is handled by U27, U28 and U20.

Address lin es A0-A 7 are s hared wi th dat a line s D0- D7, U15 d ecodes the dat a line s as add ress l ines w hen

needed through the ALE line.

The digital supply is monitored by U26, if the voltage drops below a certain threshold then the SRST*

signal will reset the system. The SRST* line will also bias Q8 off, this will assert the RESET line that

will reset other chips on the board at the same time that the microprocessor is reset.

3.1.6 Serial Communication

Refer to page 2 of the 2740-03 schematic. Serial communication is handled by U17, the transmit

(MPU_TXD) and receive (MPU_RXD) lines are converted into RS232 levels by U17. Diodes D13 and

D14 are for prot ectio n on the p roc essor side of U17. Ca pac itors C62- C65 are u sed b y U17 for genera ting

the requir ed voltages fo r the RS23 2 levels. L1 and L 2 are hig h frequency filte rs for imm unity and

susceptibility. The RS232 signals appear at the rear connector of the unit and at J401 (circuit board

mounted header connector). The COMMPWR line from the microprocessor enables U17 when high,

when set low U17 is put in sleep mode to conserve power.

Rev. 01

3.1.7 Audio

Refer to page 2 of the 2740-03 sch emat ic. Audibl e tones ar e genera ted by LS1 when dri v en by Q13. The

AUD_CLK line from the microprocessor biases Q13 on and off creating the desired tone output from

LS1. A 750KHz clock signal is generated by U31 from the 6MHz system clock. This clock input is

Model 101 Service

Manual

7

Page 16

Section 3

Main Board

required by the p rocessor for generati ng the aud io tones of A UD_CL K. The RESET line on U31 pr ev ents

any audio from inadvertently being generated by disabling the chip during power up and power down.

Audio is used for low battery only. There are no other alert outputs in this monitor.

3.1.8 Interface

Refer to page 3 of the 2740-03 schematic. The microprocessor interfaces to the display, key panel, and

LED’s on the 2741 board through U22. U22 also interfaces to the optical isolators (located on the 2740

board), which determine which type of flow sensor is installed (adult, neonatal, or neonatal/CO2). The

microproces sor comm unicates to U22 via t he A0, A1 add ress line s, D0-D7 dat a lines , 8255 _CS, RD and

WR lines. The PA0-PA7 lines are a b u ffered data b us whi ch go to the 2741 boar d wher e t he y are used as

latched I/O. The PB5-PB7 lines decode the appropriate latch on the 2741 board for display and LED

indicator output and key-panel input and the PC5-PC7 lines drive the opto isolators on the 2740 board.

3.1.9 Analog Control Signals

Refer to page 5 of the 2740-03 schematic. The serial to DAC (digital to analog converter) U8 contains

four independent DACs for control signals in the system. A 1.5 volt reference (A_1_5V) is used as the

reference input to all four DACs via U12A, an amplifier with a gain of 2. The clock (DAC_CLK), load

(DAC_LD) and data (DAC_SDI) lines are directly controlled by the microprocessor.

DAC_A and DAC_B’s out puts a re used f or gai n cont rol i n t he fl o w meas uring circu itry. DA C_C’s output

is used for offset adjustments in the airway pressure measuring circuitry. DAC_D controls the VDISP

voltage through U9A and Q10, this varies the contrast on the monitor’s display.

3.1.10 Sensor Identification

Refer to page 8 of the 2740-03 schem atic. When a flow sensor is plugged into the monitor it is

automat ically ident ified by means of a reflective/non -reflective lab el that is read b y the monitor ’s

circuitry. Three opto isolators are used to emit a light and measure any reflection from the label. There

are three bands that can r ef le ct or a bsorb light, this enables eig ht dis ti nct possibilities . The opto isolator s

are driv en by OCDR V_0 th rough OCDRV_2 which drive Q5-Q7 respec tiv ely . If an opto isolat or recei ves

a reflec ti on then the tran si st or portion will conduct and t ri gg er a comparator o u tp ut (U13) to go l ow . T he

outputs OCRD-0, OCRD_1 and OCRD_2 will be read by U22 and allow the processor to determine the

type of flow sensor connected.

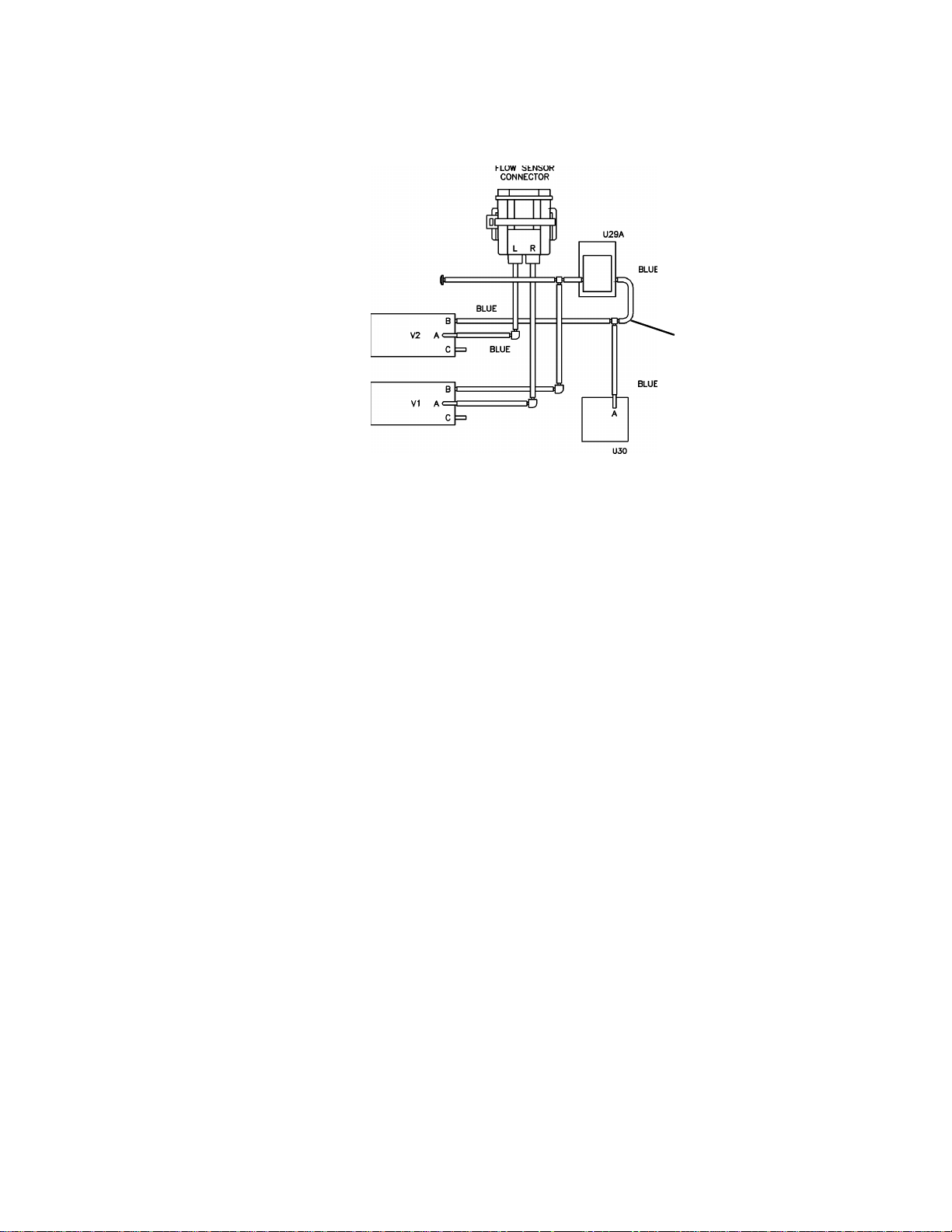

3.1.11 Flow Zeroing

Reference p age 3 of the 2740-0 3 schematic. The zero process begin s when the CPU brings the

VL V_CNTL li ne high, this biases Q3A on ener gizing v alv es V1 and V2. This disc onnects the diff erential

pressure transducer U29 (via V1 and V2) and the absolute pressure transducer U30 (via V2) from the

8

Model 101 Service

Manual Rev. 01

Page 17

Main Board

Section 3

patient airway, and opens all pressur e transducer ports to atmosphere. Diod es D16 and D17 ar e for

protection against back EMF from the valves coils.

AIRWAY PRESSURE

TRANSDUCER

VALVE 2

VALVE 1

PNEUMATIC TUBING

BAROMETRIC PRESSURE

TRANSDUCER

The pressure t ransducer s are “zeroed” by adj usting th e amplif ied and condit ioned pres sure output signals

so that each reading reads approxim ately mid-scal e (512 coun ts) using a s uccessive approxim ation

algorithm. With a reference v oltag e of 5.0 Volts, e ach count retu rne d by the 10-bit ADC is equa l to 4.8 83

mV. Centering the no flow (ambient) signal to the ADC's mid-scale allows the sensor to report both

positi ve and negati v e airw ay pressu res. U8 , a Digit al to A nalog Con ver ter (DA C) provid es the adjustmen t

under microprocessor control. The DAC maintains each adjustment voltage obtained during the zeroing

process until a new zero cycle is initiated.

The patient ai rway pressure t ran sduc er is "zeroed" fir st by adjusting the UB_DAC_A output of the DAC

until the Airway Pressure signal reads mid-scale. The barometric (ambient) pressure as sensed by the

processor is recorded after the airway pressure zero is completed. Next the flow channels are zeroed. A

non-inverting summing amplifier U6A combines two of the DAC's outputs and a constant voltage from

AVCC equal to the mid-scale of the ADC. The output voltage produced by the summer is fed into U14,

a monolithic instrumentation amplifier, which takes the differential output of the pressure transducer,

U29, and adds an of fset equal to the re feren ce v oltag e input . D A C output s UB_D A C_ A and UB_D A C _B

serve to provide the flow channels with a fine and a course adjustment. The result from each channel is

stored in SRAM and used as an offset in the flow calculations. Valves V1 and V2 are then de-energized,

reconnecting the pressure transducers with the patient airway.

Rev. 01

3.1.12 Flow Circuitry

Reference page 6 of the 2740-03 schematic. Differential Pressure Transducer, U29, is a silicon-based,

piezoresistive bridge with four active elements. When pressure is applied between transducer ports P1

and P2, a di f feren tial outpu t v olta ge prop orti onal t o the appli ed pr ess ure is pro duced. The ful l-sc ale i nput

pressure range for the transducer is 0 to 4 inches of water (P1>P2) . By sett i ng the 0 differenti al pres sur e

(no-flow) point to mid-scale (during the zeroing process described earlier), negative pressure readings

(P2>P1) are also available. The transducer is temperature compensated at 25 degrees Celsius and

designed to be driven by a constant current source (U6B).

In the no rmal system operating mode, al l valves are de -energized . Transducer p orts P1 and P2 are

connected to the patient airway. As air flows through the flow sensor, a pressure difference between P1

and P2 is created. This signal is dependent on both the magnitude and the direction on the air flow. The

greater the flo w vol ume, the lar ger the press ure dif f erenc e creat ed betw een the tw o trans duce r ports . The

transducer senses an inspired flow as a positive pressure difference (P1>P2), while an expiratory flow is

Model 101 Service

Manual

9

Page 18

Section 3

Main Board

seen as a ne gative pressure (P2>P1) . With a source vo lt age of approximately 5.0V, the s ensor transform s

this pressure difference into an electrical signal with a nominal absolute magnitude of 50 mV Full-scale

Output. This signal is conditioned and amplified by U14, which is a monolithic Instrumentation

Amplifie r (IA) . The flo w IA U14 als o of fset s th e signa l to the mid-rang e of the ADC obt ained du ring t he

zeroing p rocess. A positive p ressure difference (inspira tory flow) c reates a signal a bove the offs et

(approximately 1.25 to 2.5V). A negative pressure difference (expiratory flow) becomes a 1.25 to 0V

signal. The nom inal ga in of U14 i s set by f ix ed res istor R59 and va riabl e res istor VR1. T he o utput for t he

transducer is adjusted using VR1 and a known pressure input as a calibration reference. With an input

differential pressure of 10 inH

O, the gain of the amplifier is set to give an ADC count of 3498.

2

The signal out of the flow U14 is ta ken through a two-pole low pass filter U7B with a 31Hz cuto ff

frequency to remove unwanted high frequency electronic noise before it is passed on to the four gain

stages (U4 and U5). The four flow differential gain amplifiers provide signal gains of 1 (ACH_0), 10

(ACH_1) , 100 (A CH_2) a nd 1000 (ACH_3). The gain of 1 amplifier is used to b uf fer the fl o w sign al and

provide sign al conditionin g consiste nt with the ot her channe ls. The x10 , x100 and x10 00 chann els

amplify the flow signal according to the following equation:

V

out

= (V

where A

R

R

-Vrefo/2)(Av) + (Vrefo/2)

flow

is the amplifier gain, Rfb/Rv (1, 10, 100 or 1000)

v

is the feedback resistor (R51,R58, R68, R78)

fb

is the reference resistor (R131,R61, R73, R82)

v

The circuit is designed to amplify the difference between the flow signal into each gain stage and the

reference voltage so the zero point of each stage remains at mid-scale.

The output from each gain stage appears at the microprocessor for conversion into digital information.

An alternate pressure transducer, U29A may be installed in place of U29. The principal of operation is

the same a s d esc ri be d above wi th th e ex ce pti on th at it ’s full scale pressure input range is 0 to 10 inches

of water and it is excited by a constant 5.0 volt (AVCC) reference.

3.1.13 Barometric and Airway Pressure

Refer to page 7 of the 2740-03 schematic. U30 is a piezoresistive differential pressure transducer with

port P2 held at a vacuum (0 psi). It measures the absolute pressure difference at port P1 relative to the

vacuum at port P2. The transducer is calibrated for a full scale output of 0 to 30 psi, has internal

temperature com pensati on and is desig ned to be dri ven by a con stant cur rent source. Resi stor R99 is us ed

to set the current through the sensing bridge by amplifier U7A. Instrumen tation amplifier (IA) U23

conditions thi s sign al to corr espond t o the cur rent ba ro metric pressu re , which is set by adj usti ng VR2 for

span and VR3 for of fset. The nomina l gain of thi s amplif ier is 68.75. The out put signal from U23 appears

as an input to both the 10-bit ADC and a second IA, U24. U24 provides gain adjustment via VR4 and

offsets the output signal from the barometric amplifier to mid-scale during the zeroing state. This is

handled by the AW_DAC line fro m U2 A (pa ge 5 of the 2740-0 3 sc hem a ti c) , the output is then fed to the

low pass filter circuit of U12B. The nominal gain of the airway pressure amplifier is 2.1. This signal

connects t o the P1 ( proxi mal to t he p atien t) si de of t he dif f eren tia l pres sure t ransdu cer dur ing m onito ring

and provides patient airway pressure sensing (AWPRESS).

10

Model 101 Service

Manual Rev. 01

Page 19

Interface Board

Section 3

3.2 Interface Board

3.2.1 Key panel Interface

Refer to page 1 on 2741-03 schemat ic. The ke y panel ke ys are moni tored by the system thro ugh latch U4.

When any key is depressed the associated pull-up resistor (R9-R13) is brought low and the appropriate

line will appear as a low on the PD0-PD7 line. The latch is read by U22 from the main board (lines PD0PD7) when the 0xF800 line is asserted.

3.2.2 Display interface

Refer to page 1 on 2741-03 schematic. Communication to the display is handled by latches U1 and U2,

these in turn are controlled by U22 on the main board. U1 i s ena bl ed by t he oxF806 line and han dle s the

display data lines DS0-DS7. The remaining control lines are handled through U2 and the 0xF807 line.

3.2.3 LED control

Refer to page 1 on 2741-03 schematic. The LEDs on the front panel display are controlled by latch U2

and the 0xF807 li ne. LEDs D1 an d D2 are bico lor LED s that are con tro lled b y two li nes each . D3and D4

are unicolor LEDs.

3.2.4 Power Supplies

Refer to page 2 on 2741- 03 sch ematic . The VSW DC suppl y from the main b oard i s re gula ted t o a + 5 v olt

supply by U3, a VALVE_SUPPLY supply by U7 and ±12 volt supplies by U5 and U6. U7 is used as a

separate5 volt regulator for the main board valves. The other supplies are connected to the main board

through J2.

Rev. 01

Model 101 Service

Manual

11

Page 20

Section 3

Interface Board

12

Model 101 Service

Manual Rev. 01

Page 21

Section 4

Functional Tests

4.1 Equipment Required

1. Adult Flow Sensor Cat. No. 6717-01

2. Neonatal Flow Sensor Cat. No. 6718-01

3. Battery Case Cat. No. 6862-00

4. AA 1.5 VDC Alkaline Batteries (Qty 7) Cat. No. 400038

(Panas onic AM3X or equivalent)

4.2 Procedure

1. Inspect the unit for cosmetic defects, verify no damage.

2. Install the Battery Case (loaded with seven good AA Alkaline batteries).

3. Press the

4. Connect the 6717-01 Adult Flow sensor to the unit.

5. Breathe into the flow sensor.

6. Press the

7. Remove the flow sensor from the unit. Verify the unit displays “NO SENSOR

DETECTED INSERT FLOW SENSOR”

8. Connect the 6718-01 Neonatal Flow Sensor to the unit under test. Verify a “NEW

SENSOR D ETECTED TY PE: Neonata l” is temporar ily displayed. Verify the

LED illuminates.

9. Remove the flow sensor.

10. Press the lamp key and verify that the backlite shuts off.

POWER

GRAPH

key to power up the unit.

key and ve rify that all of the Graph screen is functioning prope rly;

VOLUME GRAPH

• Automatically scaled.

• Breath-by-breath reporting.

NEO

11. Press the lamp key again and verify the backlite turns back on.

Rev. 01

Model 101 Service

Manual

13

Page 22

Section 4

Procedure

12. Press and hold the lamp key and verify that the contrast is adjustable. Set the

contrast to a desirable level.

13. Power the unit down by pre ssing the

14. Press and

engineering menu.

15. Verify the AC LED is off and the battery LED is on.

16. Press the

17. Press the

the displayed LED test is ON.

18. Press the

return to normal operating mode.

19. Power the unit down by pre ssing the

20. The Functional Test Procedure is complete.

hold

GRAPH

DATA

GRAPH

DATA

the

(next) key until the arrow is beside “TEST LEDs”.

(select) k ey to s tart the LED test. Verify the LED that corresponds to

LED Test

Neo Neo Green

LED TEST Battery Red

Battery OK Battery Green

Low Battery Batt e ry Yellow

(next) k e y unt il th e arro w is next to “EXIT”. Press

key, then press t he

POWER

LED On LED Color

POWER

key.

POWER

key.

key to powe r up the unit in the

DATA

(select) to

14

Model 101 Service

Manual Rev. 01

Page 23

Section 5

Accuracy Tests

5.1 Equipment Required

1. Calibrated Barometer

2. Adult Flow Sensor, PN: 6717-01

3. Neonatal Flow Sensor, PN: 6718-01

4. 500 cc Calibration Syringe, Hans Rudolph 5550 or equivalent

5. 10 cc Calibration Syringe , Hans Rudol ph, Model 5520 or equivalent PN: 550032

6. Flow Leak Test Adapter, PN: 6935-48

7. Common Mode Test Adapter, PN: 6937-48

8. Pressure Source, Penwalt Pneumatic Cali brator, Model 65- 120 or equi valent

9. Battery Case Cat. No. 6862-00

10. AA 1.5 VDC Alkaline Batteries (Qty 7) Cat. No. 400038

(Panas onic AM3X or equivalent)

5.2 Procedure

1. Install a Battery Case (Cat No 6862-00) with seven fully charged AA batteries (Cat

No 400038) in the Model 101.

DATA

2. Press and

engineering menu.

3. Verify the AC LED is off and the battery LED is on.

4. Press the

DATA

key (select).

5. Read the current barometric pressure from the calibrated barometer. Verify Pbar

equals the current barometric pressure ± 2.

6. Connect the 6935-48 Flow Leak Test Adapter to the unit.

7. With the stop cock on the FLow Leak Test Adapter open, set the airway pressure

(Paw) to 100 - 110 cmH

8. Close the stop cock.

9. Verify the airway pressure (Paw) remains the same for at least 30 seconds.

10. Disconnect the Flow Leak Test Adapter .

the

hold

GRAPH

key (nex t) unti l the ar row is beside “CALIBRATION” then press t he

key, then press t he

O.

2

POWER

key to powe r up the unit in the

Rev. 01

Model 101 Service

Manual

15

Page 24

Section 5

Procedure

11. Connect the 6937-48 Common Mode Test Adapter to the unit.

12. Using the pressure source , apply 20 cmH

O to the Common Mode Test Adapter.

2

13. Verify a Paw value of 20.0 ± 2.0.

14. Increase the pressure sour ce to 80 cmH

O.

2

15. Verify a Paw of 80.0 ± 2.0.

16. Press the

POWER

key (EXIT) to e xit t he Calibr ation scr een. Press t he

key until the arrow is beside “EXIT”, then press the

DATA

(select) key to exit.

GRAPH

(next)

17. Connect the 6717-01 Adult Flow Sensor to the 500cc Calibration Syringe, then

connect to the Model 101.

18. Press the

DATA

key to display the Flow/Volume screen (repeated key depressions

may be required).

19. Pump the Calibration Syringe at approximately 20 cycles per minute (one stroke

every 3 seconds), use a smooth and steady action when pumping the syringe.

20. Verify VTi and VTe read 500ml ± 25ml.

21. Press the

GRAPH

key. Verify the Volume screen is displayed (repeated key

depressions may be required).

22. Verify a Vt of 500ml ± 25ml with a volume waveform present.

23. Remove the Adult Flow Sensor. Verify the unit displays “NO SENSOR DETECTED

INSERT FLOW SENSOR”

24. Install the 6718-01 Neonatal Flow Sensor. Verify a “NEW SENSOR DETECTED

TYPE: Neonatal” is temporarily displayed. Verify the

NEO

LED illuminates and the

Volume waveform screen is then displayed.

25. Connect the Neonatal Flow Sensor to the 10cc Calibration Syringe.

26. Pump the syringe at approximately 40 cycles per minute (one stroke every one and

one-half second).

27. Press the

DATA

key to display the Flow/Volume screen (repeated key depressions

may be required).

28. Verify a VTi and VTe of 10ml ±2 ml.

29. Remove the flow sensor.

30. Power the unit down by pre ssing the

POWER

key.

31. The Accuracy Test Procedure is complete.

16

Model 101 Service

Manual Rev. 01

Page 25

Section 6

g

g

g

g

g

g

6.1 Equipment Required

1. Digital Multimeter, Fluke model 8840A or equivalent

2. Oscilloscope, Tektronix model 2236 or equivalent

3. Pneumatic Calibrator, Pennwalt Model 65-120 or equivalent

4. Calibrated Barometer

5. Flow Leak Test Adapter, PN: 6935-48

6. Differential Test Adapter, PN: 6936-48

7. Common Mode Test Adapter, PN: 6937-48

8. Adult Flow Sensor, PN: 6717-01

9. Neonatal Flow Sensor, PN: 6718-01

Electrical Tests

10. 500cc Calibration Syrin

11. 10cc Calibration Syrin

e, Hans Rudolph Model 5550 or equivalent

e, Hans Rudolph Model 5520 or equivalent, PN: 550032

6.2 Procedure

6.2.1 Power Supplies

1. With the monitor off, remove the bottom cover to expose the internal circuit boards.

Refer to "Disassembling the Monitor" on page 25.

2. Measure the followin

nal Name Location Voltage Tolerance

Si

BVDD TP15 5.10 Vdc ± 100 mV

THERM TP16 2.25 Vdc ± 50 mV

3. Press the

4. Measure the followin

POWER

Si

nal Name Side Location Voltage Tolerance

voltages. Use TP4 as ground reference.

key on the monitor.

voltages. Use TP2 as ground reference.

F5V Front IC19 pin 28 5.10 Vdc ± 100 mV

Rev. 01

Model 101 Service

Manual

17

Page 26

Section 6

g

g

g

g

g

g

g

g

g

g

Procedure

TP_POS_12V Front IC16 pin 8 12.0 Vdc +100 mV

- 300mv

TP_NEG_12V Front IC16 pin 4 -11.5 Vdc ± 500 mV

TP_AVCC Front TP1 5.00 Vdc ± 25 mV

TP_AVCC_2 Front TP2 2.50 Vdc ± 25 mV

TP_1.47V Front TP3 1.47 Vdc ± 25 mV

NEG_AVCC_2 Back IC24 pin 4 2. 50 Vdc ± 25 mV

5. Measure the voltage at IC7 pin 3 on the 2741-01 board. Verify 5.00 Vdc ± 100 mV.

6. Monitor IC11 pin 8. Verify a volta

e < 4.1 Vdc.

7. Monitor IC11 pin 10. V erify 0 VDC.

8. Monitor IC11 pin 14. Verify a switchin

pulse with a frequency of approximately 85

KHZ.

Note: The frequency, pulse width, and period will chan

e status.

char

9. Usin

a clip lead short TP15 to TP16. Verify the switching frequency at IC11 pin 14

es from approximately 85 KHZ to < 50 HZ. Verify IC1 pin 10 goes high.

chan

e depending on the battery

6.2.2 Airway Pressure Calibration

10. Press the

11. Press and

engineering menu.

12. Press the

the display. Press the

Note:

They are (in order):

PAW_ADU The A/D counts reading for the airway pressure channel.

PAW The airway pressure in cmH

1. Press the

POWER

hold

GRAPH

key to turn the u ni t off.

the

DATA

key, then press t he

POWER

key to powe r up the unit in the

(next) key until th e select ion arrow i s point in

(select) key to enter the Calibration screen.

DATA

The second line of the calibration screen (Paw) has 2 parameters.

O.

2

GRAPH

(ZERO) ke y.

to “CALIBRATE” on

18

Model 101 Service

2. Connect the Common Mode Test Adapter t o the uni t and to t he Pennwalt. Adj ust t he

Pennwalt to 90 cmH

Note: The pressure settin

O.

2

s for the Airway Pressure adjustment is stated in cmH2O.

Use the Inner scale on the Pennwalt when setting the pressure to cmH2O.

3. Adjust VR4 until the PAW readin

4. Press the

GRAPH

(ZERO) ke y.

5. Repeat steps 3 and 4 until the PAW readin

matches the Pennwalt reading of 90 cmH2O.

is within ± 0.5 cmH2O as read from the

Pennwalt meter.

6. Disconnect the Common Mode Test Adapter.

Manual Rev. 01

Page 27

Barometric Pressure Calibration

g

g

g

6.2.3 Differential Pressure Calibration

The calibration scr een displays 2 c olumns of v alues for the x1, x10, x100, and x 1000 chan-

Note:

nels of the differenti al pr essure sensor. They are (in order):

ACTUAL_CNTS The actual A/D counts f or the respective channel.

DIFF_CNTS

1. Connect the 6936-48 Differential Test Adapter to the 2740-01 board.

Section 6

The diffe rence between the actual A/D c ounts and the A/D

counts at the zero point.

2. Press the

3. Connect the Pennwalt to the positive pressure port (blue tube).

4. Adjust the Pennwalt to 11 cmH

5. Adjust VR1 until the x1 channels DIFF_CNTS reads 887 counts.

6. Press the

7. Repeat steps 5 and 6 until the x1 channels DIFF_CNTS is 887 counts ± 2 counts.

8. Switch the Pennwalt’s output from the positive port to the ne

of the Differenti al t e st fixture.

9. Verify the x1 channel reads -887 counts ± 25.

10. Disconnect the Differ ential Test Adapter.

GRAPH

GRAPH

(ZERO) ke y.

(ZERO) ke y.

O.

2

ative port (clear tube)

6.3 Barometric Pressure Calibra tion

Perform the following only if the barometric pressur e r eading of the monitor does not mat ch the

currrent baromet ric pres sure as recorde d f rom a cal i brated baro meter. This procedure requires

adjustments for offsets within the electronic circuitry and mu st be performed accurately and

carefully.

1. Connect the 6937-48 Common Mode Test Adapter to the monitor.

Rev. 01

2. Press and

engineering menu.

3. Press the

the display. Press the

4.

Note:

They are (in order):

BARO_ADU The A/D counts reading for the barometric pressure channel

ADDED_PRESSURE

BARO_PRESSURE

5. Adjust VR3 so that the BARO_ADU readin

hold

GRAPH

The top line of the calibration screen (Pbar) has 3 parameters displaye d.

DATA

the

(next) key until th e select ion arrow i s point in

key, then press t he

(select) key to enter the Calibration screen.

DATA

The applied gage pressure (mmHg) to the unit. This parameter

must be read after a ZER O. Chang ing the offs et or span wi ll make

this number meaningless until the next zero.

The TOTAL pressure (mmHg). Barometric plus added

pressure. With no pressure applied, this will equal the

barometric pressure.

POWER

is about 1000 counts.

key to powe r up the unit in the

to “CALIBRATE” on

Model 101 Service

Manual

19

Page 28

Section 6

g

g

g

g

g

g

g

g

g

g

Barometric Pressure Calibration

6. Press the

7. Connect the Pennwalt pneumatic calibrator to the Common Mode Test Adapter.

8. Adjust the Pennwalt for an output pressure of 50 mmH

Note: The pressure settin

mmHg not cmH2O. Use the outer scale on the Pennwalt when setting the pressure

to mmH

9. Adjust VR2 until the ADDED_PRESSURE readin

VR3 if BARO_ADU becomes

10. Press the

11. Repeat steps 9 and 10 until the ADDED_PRESSURE is within ± 2 mmH

Pennwalt setting.

12. Adjust the Pennwalt for an output pre ssure of 100 mmH

13. Adjust VR2 until the ADDED_PRESSURE readin

14. Press the

15. Repeat steps 13 and 14 until the ADDED_PRESSURE is within ± 1 mmH

Pennwalt settin

16. Disconnect the Pennwalt from the Common Mode Test Adapter.

17. Press the

18. Obtain the current Barometric Pressure from the calibrated Barometer.

GRAPH

.

GRAPH

GRAPH

GRAPH

(ZERO) ke y.

.

s for the Barometric Pressure adjustments are stated in

is 50 (you may need to readjust

reater than 3500 counts).

(ZERO) ke y.

.

is 100.

(ZERO) ke y.

.

(ZERO) ke y.

of the

of the

19. Adjust VR3 until the BARO_PRESSURE value matches the Barometric pressure

obtained from the calibrated Baromet er.

20. Press the

21. Repeat steps 19 and 20 as needed.

GRAPH

(ZERO) ke y.

20

Model 101 Service

Manual Rev. 01

Page 29

Section 7

7.1 General

This section presents recommended maintenance schedules for the Model 101 and information on

general maintenance, such as battery replacement, disassembly and assembly instructions, and system

software updates.

7.2 Maintenance Schedules

The electronic circuits within the Model 101 do not require scheduled calibration or service. However,

in order to maximize battery life, the monitor’s intern al ba ttery s hould be tes ted mo nthly. Novametr ix

recommends the following maintenance schedules.

• Cleaning and Sterilization:

Perform as required. See Cleaning and Sterilization on page 22.

• Battery and AC Operation:

Contains information on use of disposabl e al kal i ne and rechargeable ba tt er ie s. See Battery and AC

Operat ion on page 22.

• Functional Tests:

The test verifi es overall function al integr ity of the moni tor and sensor. See Func tional Tes ts on page

13.

• Accuracy Tests:

The test verifies the calibrati on accuracy of the monit or using specifi ed test apparatu s. See Accuracy

Tests on page 15.

• Electric al T est s:

These tests contain information on testing the electronic circuits within the Model 101 and should

only be perf ormed if the monito r fails to pass t he Func ti onal and or Accurac y Tes ts . Only qualified

service personnel should attempt to perform the Electrical Tests. See Electrical Tests on page 17.

Maintenance

*

*.

At the customer’s request, Novametrix will provide repair and calibration services under terms of a Service Contract. Contact the

Novametrix Service Department for contract details.

Rev. 01

Model 101 Service

Manual

21

Page 30

Section 7

Cleaning and Sterilization

7.3 Cleaning and Ster ili za tio n

Follo w the c leani ng and s teri liza tion inst ruct ion s liste d be lo w to cl ean and/ or st eril ize t he mon itor and it s

accessories.

CAUTION

The airway adapter is designed for single patient use. Sterilizing may affect system performance.

• Turn the monitor off and disconnect from any other devices before cleaning.

• Do not immerse the monitor.

• Do not attempt to sterilize the monitor.

• The monitor can be cleaned and disinfected with solutions such as a 70% isopropyl alcohol, 2%

glutheralhyd e, or 10% ble ach solut ion. Then wip e down with a water-dam pened cl ean clot h to rins e.

Dry before use.

• Treat Series 3 Flow Sensors in accordance with hospital protocol for single-patient use items.

7.4 Battery and AC Operation

The Model 101 ca n be powered from seven “AA” disposable alkaline batteri es or a rechar geab le batte ry.

Battery capaci ty is sho wn in the ch art belo w . T ime s may be reduced in colder tem peratur es or with po wer

cycling; operation with the backlight off may slightly increase these times. Any batteries used with the

6862-00 case cannot be charged, it is for use with disposable type batteries only.

Standard

AA alkaline batteries

(7 ea. - disposable)

Power Source

Capacity, continuous 8 hours 12 hours

Recharge Time n/a 4.5 hours

Catalog Number

AA Alkaline Batteries.

batteries (Panasonic AM3X or equivalent) into the Battery Case (Cat. No. 6862-00) following the

polarity markings on the case.

T o power Model 101 from AA alkaline bat teries, inse rt sev en disposable alkal ine

400038 (battery)

6862-00 (case)

Optional

Rechargeable battery,

(NiMH 7.2 vdc)

400043

WARNING:

Do not recharge or incinerate alkaline batteries. Attempting to do so may

!

cause the batteries to leak or explode.

22

Model 101 Service

Rechargeable Battery.

battery. If a rechargeable battery has not been used for three months or more, recharge it before use.

Model 101 can operate from the optional NiMH (or equivalent) rechargeable

WARNING:

Battery can explode, leak or catch on fire if heated or exposed to fire or high

!

temperatures.

Manual Rev. 01

Page 31

Battery and AC Operation

• New batteries, or batteries stored for extended periods of time may need to be

• With a new battery, or a battery that has not been used for 30 days, charge the

• Ref er to inst ructions packaged wi th rechargeab l e battery for complete operati ng

Additi onal Batt ery Information.

• Dispose of batteries in accordance with local laws.

• Do not mix battery types (e.g. disposable and rechargeable AA batteries).

• Model 101 may not power up if the batteries are nearly depleted.

7.4.1 Battery Installation

To install or remove the battery, grasp the finger grips on each end of the Mo del 101 battery cover.

Squeeze together and pull so that the hinged cover opens. The battery is keyed and can be installed in

only one orientation (see illustration inside battery compartment). The contacts should go in first and be

located toward the to p left of the monitor. Close the battery cover before operating the monitor.

Section 7

NOTE:

fully charged and discharged up to five (5) times before performing at full

capacity.

battery for 24 hours prior to use.

instructions.

Connect only Novamet rix approved devices

Hinged Battery Compartment Cover

Finger Grips

Swing battery

cover open

7.4.2 External Battery Charger

An optional external charger for the NiMH rechareable battery pack is available. The external charger

allows the battery to be recharged outside of the Model 101 monitor.

• The external charger is for use with the rechargeable NiMH battery only.

• In a non-patient area, connect the external charger to an AC source. Remove the battery from the

Model 101 and insert it into the external charger. The battery will be fully charged in approximately

4.5 hours.

• Refer to the instructions supplied with the charger for additional information.

WARNING:

The external battery charger should NOT be operated near or in close

!

proximity to patients and/or other medical equipment in operation.

Rev. 01

Model 101 Service

Manual

23

Page 32

Section 7

Battery and AC Operation

7.4.3 Features Connector

Located on t he enclo sure rea r is a six pin modu lar cont act which provid es a po wer i nput for unit ope ration

and battery ch ar ging when connect ed to N ov am etrix acc ess orie s. This co nnector meets t he pati ent saf ety

requirements of the following agencies: IEC 601-1, UL544, and TUV.

24

Model 101 Service

Manual Rev. 01

Page 33

Assembly Exchanges

7.5 Assembly Exchanges

7.5.1 Disassembling the Monitor

1. Ensure that the monitor is OFF. Remove the battery pack.

2. Turn the monitor upside down and remove the four cover screws from the bottom

Section 7

The disassembl y inst ruct ions bel o w are intend ed as a gui de to ena ble com ponent exc hanges i f nece ssa ry.

There are no user serviceable parts inside. Disassembly should be performed by qualified service

personnel only.

CAUTION

The Model 101 contains static sensit ive devices. Be sure to follow proper grounding

procedures when handling the internal components to avoid damage from static disc harge.

cover.

cover screws

3. Carefully lift the r ear cover from the monitor. The separate assemb l ies of the monito r

can now be remov ed.

4. Lift the Main Board a nd disconnect ribbon cab le f rom the Interf a ce Board b y graspi ng

the connector (not the cable) and gently rocking from side to side to loosen. Be

careful not to bend any pi ns when pull ing the connector off of the header strips.

ribbon cable

main board

Rev. 01

side view

Model 101 Service

Manual

25

Page 34

Section 7

Assembly Exchanges

5. Remove the Main Board.

6. The Interfac e Board and batt ery connector can now be accessed.

7. To disconnect ribbon cable J3, grasp the edge of the ZIF (zero insertion force)

connector with one forefinger on either side. Pull gently

mechanism. Slide the ribbon cable out.

ZIF connector

ribbon cable

sideways

to release the

8. Remove four screws from the Interface Board. Disconnect the screw on the battery

connector (black and red wires).

inerface board screws

J1 header

9. Slide the battery connector out of the brac ket and remo ve the inter face bo ard, rocking

gently to releas e the header strip J1 which c onnects through th e Interf ace Board from

the Display Board below.

battery connector screw

battery connector

26

Model 101 Service

Manual Rev. 01

Page 35

Assembly Exchanges

10. Remove 4 screws holding the Display Board in place. Do not bend the tabs on the

Section 7

board, the LCD display can not be removed from the board. Be sure not to lose the

plastic bezel located in between the LCD display and the display window.

display board

screws

ribbon cable

7.5.2 Reassembling the monitor

1. Check the inside of the display window and the LCD display for dirt/finger prints,

clean if nece ssary. Replace the plastic be zel around the displ ay window. Set the

Display Board i n place and secure with 4 screws.

2. Place the battery connector (red and black wires) into the bracket and push in.

Secure in place with 1 screw.

3. Place the Interface Board in the case, taking care to align the pins at header strip J1

underneath—line the LEDs up with the openi ngs in the ca se, thi s will giv e y ou a point

of reference. When you are sure the pins are lined up with the holes, gently push

down, do not f orce . Place the stra in rel ief sec tion on t he sensor cab le i nto the eg ress

slot, push down to lock in.

4. Secure the Interface Board with 4 screws.

5. Slide ribbon cable J3 into the ZIF locking connector, pushing gently to be sure that

the cable is as fa r into the lock ing mechanism as possibl e. Push the connector cl osed

to lock in the ribbon cable. Pull lightly on the ribbon cable to ensure that it is secure.

6. Replace ribbon cable from the Main Board to the Interface Board and align the main

board with the standoffs.

7. Ensure the battery gasket is set in place, refer to the assembly print 6800-01 (page

3) for placement . Pla ce the back cover on the monitor. Secure with 4 screws.

8. Opened hinged cover and replace the rechargeable battery or battery pack. Battery

is keyed to fit in only one direction. When the monit or is powered it will default to the

factory default settings.

Rev. 01

Model 101 Service

Manual

27

Page 36

Section 7

Assembly Exchanges

28

Model 101 Service

Manual Rev. 01

Page 37

Section 8

g

g

g

g

g

Cat. No. Description

Accessories

Monitor (En

6800-00

6800-23

6800-90

420037

420038

420039

Flow Sensors

6717-00 Series 3, Pediatric/Adult Flow Sensor. 10/Box

6718-00 Series 3, Neonatal Flow Sensor. 10/Box

6720-00 Series 3, Neonatal Combined CO

Power Options

6862-00 Battery Case for AA Batteries (batteries not included)

400038 Alkaline Battery, 1.5 vdc, AA Size

lish language)

✔ Handheld Respiratory Mechanics Monitor, Model 101

VENT

User's Manual

Service Manual

✔ Quick Guide Inservice Video

VENT

VHS video tape, NTSC format (U.S.A.)

VHS video tape, PAL format

VHS video tape, SECAM format

(Panasonic AM3X or equivalent)

/Flow Sensor. 10/Box

2

400043 Rechar

(Duracell® DR30 or equivalent)

400049 External Battery Char

(power line cord not included)

600026 Power Line Cord, 120 vac, (U.S.A.) for External Battery Char

Miscellaneous

140084 Pole/Shelf Mount Kit

315107 Carryin

Rev. 01

eable Battery, NiMH, 7.2V, 2.4AH,

er (DR30), Universal Voltage, NiMH

Case

Model 101 Service

er

Manual

27

Page 38

Section 8

[This page intentionally blank.]

28

Model 101 Service

Manual Rev. 01

Page 39

Section 9

9.1 6800-00 Final Assembly, Model 101

LINE PART NO REV QPA DESCRIPTION

0001 6800-01 02 1 MAIN ASSY, MODEL 101 - VENTCHECK

0002 6800-04 XX 0 TEST PROCEDURE, SYSTEM, MODEL 101 - VENTCHECK

0003 6800-09 P0 0 OVERALL WIRING DIAGRAM, MODEL 101 - VENTC H EC K

0004 6800-23 02 1 USERS MANUAL, MODE L 101 - VENTCHECK

0005 6800-33 XX 0 ASSY PROCEDURE, SHIPPING INSTRUCTIONS, MODEL 101

0006 6800-40 00 0 DESIGN DOCUMENTATION, MODE L 101 - VENTCHECK

0007 6800-43 XX 0 DATA SHEET, MODEL 101 - VENTCHECK

0008 6800-75 02 0 DEVICE MASTER RECORD, MODEL 101 - VENTCHECK

0009 6835-32 00 1 LABEL, PATIENT ISOLATION, MODEL 101

0010 6874-32 00 1 LABEL, SERIAL NO. & BATTERY ALIGNMENT

0011 6877-32 00 1 QUICK GUIDE LABEL, BOTTOM COVER, MODEL 101

0012 6886-13 00 1 CARTON, SHIPPING, HAND HELD MONITOR

0013 6920-13 00 1 SHIPPING CARTON, ACCESSORIES, HAND HELD MONITOR

0014 6965-32 00 1 REGULATORY LABEL, UL MARK FOR USA & CANADA

0015 9026-32 01 1 LABEL, "MANUFACTURED IN USA"

0019 240059 0 SCREW COVER, BLK, PVC, .25DIA X .06T, ACRYLIC

0020 315033 0 POUCH, PLASTIC, ZIP LOCK, 4" X 6", 2 MIL THICK

Parts Lists

9.2 6800-01 Main Assembly, Model 101

LINE PART NO REV QPA DESCRIPTION

0001 2740-01 01 1 MAIN BOARD ASSY, MODEL 101 - VENTCHEC K

0002 2741-01 00 1 INTERFACE BOARD ASSY, MODEL 101 - VENTCHECK

0003 6680-13 01 1 BOTTOM COVER W HOLE AND SHIELDING, HAND HELD

0004 6685-16 00 1 BATTERY DOOR, HAND HELD ENCLOSURE

0005 6773-10 00 1 SHIELD, MYLAR, BOTTOM COVER, MODEL 101

0006 6823-10 01 1 FILLER, KEYPANEL

0007 6824-27 01 1 MEMBRANE KEYPANEL, MODEL 101 - VENTCHECK

0008 6838-10 01 1 GASKET, BATTERY DOOR

0009 6839-10 00 1 GASKET, BATTERY

0010 6855-13 00 1 TOP COVER WITH SHIELDING, MODEL 101

0012 161082 0 TAPE, UHMW POLYETHYLENE, .002 THK

0013 161102 0 ADHESIVE, RTV162, SILICONE, WHITE

0014 160044 0 ALCOHOL, ISOPROPYL, TECHNICAL GRADE

0015 281211 0 SCREW, 2-56 X 1/4L, SELF TAPPING, BINDING HEAD

0016 286223 0 SCREW, 6-32 X 3/8 IN. L, PAN HD, PHILLIPS, ST

0017 482605 1 LCD DISPLAY, W LED BACKLIGHT & CONN W GOLD PL

0018 600068 1 RIBBON CABLE, 40 PIN, RCPT TO RCPT, 3.5 IN. L

0019 600518 1 BATTERY INTERCONNECTION CABLE, 5 PIN, 2.3 IN.

Rev. 01

Model 101 Service

Manual

29

Page 40

Section 9

9.3 2740-01 01 Main Board Assy, Model 101

PART NO REV QPA DESCRIPTION

161102 0 ADHESIVE, RTV162, SILICONE, WHITE

2740-03 01 0 SCHEMATIC, MAIN BOARD, MODEL 101 - VEN T C HE C K

2740-04 XX 0 TEST PROCEDURE, MAIN BOARD, MODEL 101

2740-17 01 1 MAIN BOARD SUBASSY, MODEL 101 - VENTCHECK

487128 1 IC, DUXL01D, DIFF PRESSURE SNSR, 1 IN, H20, 4

608012 0 CABLE TIE, SELF -LKG, .094W X 8L, 1/16 TO 2" B

6837-10 01 1 GASKET, CONNECTOR CRADL E, MODEL 101

6961-01 01 1 FLOW CONNECTOR AND TUBING ASSY, 101

6962-07 12 1 PROGRAM, EPROM ASSY, SYSTEM, 101 - VENT C HECK

9.4 2740-17 01 Main Board Subassy, Model 101

PART NO REV QPA DESCRIPTION

130015 1 TRANSDUCER, AUDIO, 2400 HZ, 12V, 40MA, .5 DIA

154062 23 CAPACITOR, .01UF, 50V, 10%, X7R, SURFACE MOUNT

154072 59 CAPACITOR, .1UF, 50V, 10%, X7R, CER CHIP, S M

154078 1 CAPACITOR, 1000PF, 50VDC, 10%, NPO, MONO CERA

154079 7 CAPACITO R, 10UF, 25V, 10%, TANTAL UM, SURFACE

154080 8 CAPACIT OR, 47UF, 10VDC, 10%, TAN TALUM, SURFAC

154081 1 CAPACITOR, 100PF, 100V, 10%, NPO, MLTILYR CER

154082 2 CAPACITOR, 22PF, 100V, 10%, NPO , MLTILYR CERA

154093 2 CAPACIT OR, 68UF, 16VDC, 10%, TAN TALUM, SURF M

180022 3 INDUCTOR, 10UH, 10%, SURFACE MOUNT

180029 15 INDUCTOR, 50MHZ CUT-OFF FREQUENCY, SURFACE MO

180030 2 INDUCTOR-CAP, 4700PF, 50VDC, 2A, 3 TERM, SURF

180046 1 INDUCTOR, 18UH @ 2.5M HZ, +25% -15%, SURFACE

180047 4 INDUCTOR, 50 OHMS @ 100M HZ, 3A, 1206 STYLE,

210141 1 CONNECTOR, DC PWR JACK, SOLDER TERM, PC/PNL M

211415 1 CONNECTOR, 4 PIN, H EADER, .079 SP, R ANG, PC

213412 1 CONNECTOR, 40 PIN, HEADER, DIL, STR, .05 SP,

215073 1 SOCKET, PLCC, 32 PIN, .05 SP, LOW PROFILE, S

216029 0 TEST POINT, SPRING LOADED, 475 DEG C MAXIMUM

230027 1 CRYSTAL, 12.00 MHZ, .192 SP, HC-49/US STYLE,

250146 2 VALVE, SOLENOID, 5V, 0-30 PSIG, 10 PSID MAX,

2739-01 00 1 BAT TERY & COMM INTERFACE BOARD ASSY, MODEL 61

2740-02 01 1 FAB, MAIN BOARD, MODEL 101 - VENTCHECK

474127 1 RESISTOR, 511K OHM, 1/8W, 1%, SURFACE MOUNT

474136 1 1 RESISTOR, 1K OHM, 1/8W, 1%, SURFACE MOUN T

474137 3 RESISTOR, 1M OHM, 1/ 8W, 1%, SURFACE MOUNT

474138 30 RESISTOR, 100 OHM, 1/8W, 1%, SURFACE MOUNT

474141 2 RESISTOR, 249K OHM, 1/8W, 1% , SURFACE MOUNT

474152 2 RESISTOR, 3.01K OHM, 1/8W, 1%, SURFACE MOUNT

474157 3 RESISTOR, 511 OHM, 1/8W, 1%, SURFACE MOUNT

474161 1 RESISTOR, 5.9K OHM, 1/8W, 1%, SURFACE MOUNT

474165 26 RESISTOR, 10K OHM, 1/8 W, 1%, SURFACE MOUNT

474166 19 RESISTOR, 100K OHM, 1/ 8W, 1%, SURFACE MOUNT

474170 2 RESISTOR, 301K OHM, 1/8W, 1% , SURFACE MOUNT

474182 2 RESISTOR, 150K OHM, 1/8W, 1% , SURFACE MOUNT

474185 1 RESISTOR, 150 OHM, 1/8W, 1%, SURFACE MOUNT

30

Model 101 Service

Manual Rev. 01

Page 41

PART NO REV QPA DESCRIPTION

474186 1 RESISTOR, 15K OHM, 1/8W, 1%, SU R FACE MOUNT

474211 7 RESISTOR, 49.9K OHM, 1/8W, 1%, 1206 STYLE, S

474216 1 RESISTOR, 4.99K OHM, 1/8W, 1%, 1206 STYLE, SR

474220 7 RESISTOR, ZERO OHM, 1/4W, 5%, 1206 STYLE, SUR

474263 1 RESISTOR, 28K OHM, 1/8W, 1%, 1206 SIZE, SURF

474273 1 RESISTOR, 14.7K OHM, 1/8W, 1%, 1206 STYLE, SU

474274 8 RESISTOR, 20K OHM, 1/8W, 1%, 1206 STYLE, SURF

474275 2 RESISTOR, 1.5K OHM, 1/8W, 1% , 1206 STYLE, SUR

474277 1 RESISTOR, .15 OHM, 1/2W, 2010 STYLE, SURFACE

474278 1 RESISTOR, 237K OH M, 1/8W, 1%, 1206 STYLE, SUR

474279 1 RESISTOR, 562 OHM, 1/8W, 1%, 1206 STYLE, SURF

474280 1 RESISTOR, 243 OH MS, 1/8W, 1%, 1206 STYLE, SUR

474281 1 RESISTOR, 71.5K OHM, 1/8W, 1%, 1206 STYLE, SR

474282 1 RESISTOR, 4.64K OHM, 1/8W, 1%, 1206 STYLE, SR

474285 1 RESISTOR, 255 OHM, 1/8W, 1%, 1206 STYLE, SURF

474287 6 RESISTOR, 200K OH M, 1/8W, 1%, 1206 STYLE, SUR

474288 2 RESISTOR, 499 OHM, 1/8W, 1%, 1206 STYLE, SURF

474289 1 RESISTOR, 8.06K OHM, 1/8W, 1%, 1206 STYLE, SR

474290 1 RESISTOR, 12.1K OHM, 1/8W, 1%, 1206 STYLE, SR

474291 1 RESISTOR, 34K OHM, 1/8W, 1%, 1206 STYLE, SURF

474293 1 RESISTOR, 40.2K OHM, 1/8W, 1%, 1206 STYLE, SU

475050 3 POTENTIOMETER, 20K OHM, 10%, M TURN, T ADJ, S

475052 1 POTENTIOMETER, 1K OHM, 10%, TOP ADJ, M-TURN,

481045 1 DIODE, ZENER, BZT52-C 5V1, 5.1V

481546 10 DIODE, MMBD914L, SWITCHING, SURFACE MOUNT

481547 1 DIODE, BAT54, HOT CARRIER SCHOTTKY, SURFACE M

481549 2 DIODE, MBRS140T3, RECTIFIER, SURFACE MOUNT

481552 3 DIODE, MBRS340T3, SCHOTTKY, 40V, 3A, SURFACE

481555 2 DIODE, MMBD7000LT1, DUAL SWITCHING, SURFACE M

483019 2 TRANSISTOR, MMBT2907ALT1, PNP, SOT-23, SURFAC

483020 1 TRANSISTOR, FMMT7 17, PNP, SOT23 CASE, SURFACE

484060 3 TRANSISTOR, MMBT3904T, NPN, SURFACE MOUNT

485532 6 TRANSISTOR, 2N7002T1, N-CHAN ENHAN MODE, SURF

485543 1 TRANSISTOR, SI 9939DY, MOSFET , N-CH & P-CH, -2

486042 1 IC, AT93C66-10SC, SERIAL 4K EEPROM, 8 PIN, SR

486306 1 IC, MCM60L256AF10, 32K X 8 CMOS SRAM, 100NS

486317 2 IC, MC74HC00AD, QUAD 2-IN NAND GATE, SURFACE

486323 1 IC, SN74HC573DW, OCTAL D-TYPE LATCH W 3-ST OU

486349 1 IC, MC74HC08AD, QUAD 2 INPUT AND GATE, 14 PIN

486351 1 IC, S80C196KB-16, 16 BIT MICROCONTROLLER

486353 1 IC, CS82C55A, PROGRAMA BLE PERIPH INTFC, 8MHZ,

486354 1 IC, LTC1384CS, L PWR RS232 RECEI VER, 18 PIN,

486481 1 IC, TLC5620CD, QUAD 8-B D-TO-A CNVRTR, 14 P,

486785 1 IC, LP339M, QUAD VOLTAGE COMPARA TOR, ULTRA-LO

486808 1 IC, AD680JR, 2.5 VOLTAGE REF, L PWR, 8 PIN S

486811 1 IC, TLC2262AIDR, DUAL OP AMP, RAIL TO RAIL, S

486820 1 IC, BQ2004SN, FAST CHARGE, 16 PIN, SURFACE MO

486821 9 IC, AD822AR, FET-IN OP AMP, L POWER, 8 PIN, S

486824 1 IC, MC74HC4024D, BINA RY RIPPLE CNTR, 7- STAGE,

487108 1 IC, TL7757CD, VOLTAGE SUPERVISOR, 8 PIN, S MN

487115 3 IC, AD620BR, INSTR AMPLIFIER, L PWR , 8 PIN, S

Section 9

Rev. 01

Model 101 Service

Manual

31

Page 42

Section 9

PART NO REV QPA DESCRIPTION

487124 3 IC, ERT-3281, RE FLECTIVE SENSOR, H SPD , 4 PIN

487126 1 IC, SCC30AD4, PRESSURE SNSR, 30 PSIA, 6 PI N,

515087 1 FUSE W FUSEHOLDER, 1A, 125V, SLO-BLO, SUBMIN,

515090 1 FUSE, 2A, 63V, VERY FAST-ACTIN G, THIN FILM, S

9.5 2739-01 00 Battery & Comm Interface Board Assy

LINE PART NO REV QPA DESCRIPTION

0001 2739-02 00 1 FAB, BATTERY & COMM INTERFACE BOARD, MODEL 101

0002 2739-03 00 0 SCHEMATIC, BATTERY & COMM INTERFACE BD, MODEL 101

0008 211512 2 CONNECTOR, 5 PIN, HEADER, STRAIGHT, .1 SP, PC MNT

0009 21 1638 1 CONNECTOR, 6 PIN, RECEPTACLE, MOD CONTACT

9.6 2741-01 00 Interface Board Assy, Model 101

PART

NO

152096 6 CAPACITOR, 220UF, 35V, 20%, ELCTLT, 8X10.8 CA

154062 4 CAPACITOR, .01UF, 50V, 10%, X7R, SURFACE MOUN

154072 3 CAPACITOR, .1UF, 50V, 10%, X7R, CER CHIP , S M

154079 2 CAPACIT OR, 10UF, 25V, 10%, TANTALUM, SURFACE

154081 1 CAPACITOR, 100PF, 100V, 10%, NP O, MLTILYR CER

154114 3 CAPACITO R , .022UF, 50V, 10%, X7R, 1206 SIZE,

180022 3 INDUCTOR, 10UH, 10%, SURFACE MOUNT

180043 1 FERRITE BEAD, 30 OHMS AT 100MHZ, 0603 STYLE,

211514 1 CONNECTOR, 5 PIN, HEADER, RT ANGLE, .1 SP, PC

211639 1 CONNECTOR, 6 PIN, RCPT, ZIF, R ANG, .05 SP, P

213411 1 CONNECTOR, 40 PIN, RCPT, PASS THRU, DIL, STR,

213412 1 CONNECTOR, 40 PIN, HEADER, DIL, STR, .05 SP,

216029 0 TEST POINT, SPRING LOADED, 475 DEG C MAXIMUM

2741-02 01 1 FAB, INTERFACE BO ARD, MODEL 101 - VENTCHECK

2741-03 00 0 SCHEMATIC, INTERFAC E BOARD, MODEL 101 - VENT

2741-04 00 0 TEST PROCEDURE, INTERFACE BOARD, MODEL 101

280233 0 SPACER, LED, FOR 2 LEADS, .2 DIA X .1 LONG, B

280234 0 SPACER, LED, FOR 3 LEADS, .255 DIA X .185 L,

280235 0 SPACER, LED, FOR 2 LEADS, .25 DIA X .2 LONG,

474136 6 RESISTOR, 1K OHM, 1/8W, 1%, SURFACE MOUNT

474165 7 RESISTOR, 10K OHM, 1/8W, 1%, SURFACE MOUNT

474166 1 RESISTOR, 100K OHM, 1/8W, 1%, SURFACE MOUNT