North Star M459211B Maintenance Manual

M459211B

®

459211; Honda GX160, 8 Gal. Twin Tank

459221; Honda GX270, 8 Gal. Twin Tank

Gasoline Portable Air Compressor

Installation, Operation and Maintenance Manual

To the Owner:

Thank you for purchasing a NorthStar Air Compressor. Your machine is designed for long life, dependability,

and the top performance you demand! Please take time now to read through this manual so you better

understand the machine’s operation, maintenance and safety precautions. Everyone who operates this machine

must read and understand this manual. The time you take now w ill prolong your machine’s life and prepare you

for its safe operation. Enjoy the exceptional performance of your NorthStar Air Compressor, the industry leader!

The manufacturer reserves the right to make improvements in design and/or changes in specifications at any

time without incurring any obligation to install them on units previously sold.

Quick Facts

Engine Oil Engine is shipped without oil. Fill before starting.

Use SAE 10W-30 motor oil.

Pump Oil

Air Filter Replacement air filter part number is AB2281000 for Item #459211,

Maximum

Pressure

Maintenance

Schedule

Tank: Drain water daily

Compressor

Check pump oil level before starting.

Use non-detergent pump oil (part # 4043).

and filter #35409 for Item #459221

Item #459211 maximum pressure = 130 psi.

Item #459221 maximum pressure = 175 psi

Engine: Oil: change after first 20 hours, then annually or every 100 hours.

Spark Plug: clean every 100 hrs, replace annually or every 300 hrs.

Air Filter: clean weekly, replace annually or every 1000 hrs.

Refer to your Honda engine owner’s manual for further instructions.

Oil: change after first 50 hours, then every 3 months or 500 hours.

Pump:

Read and understand all manuals before operating.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

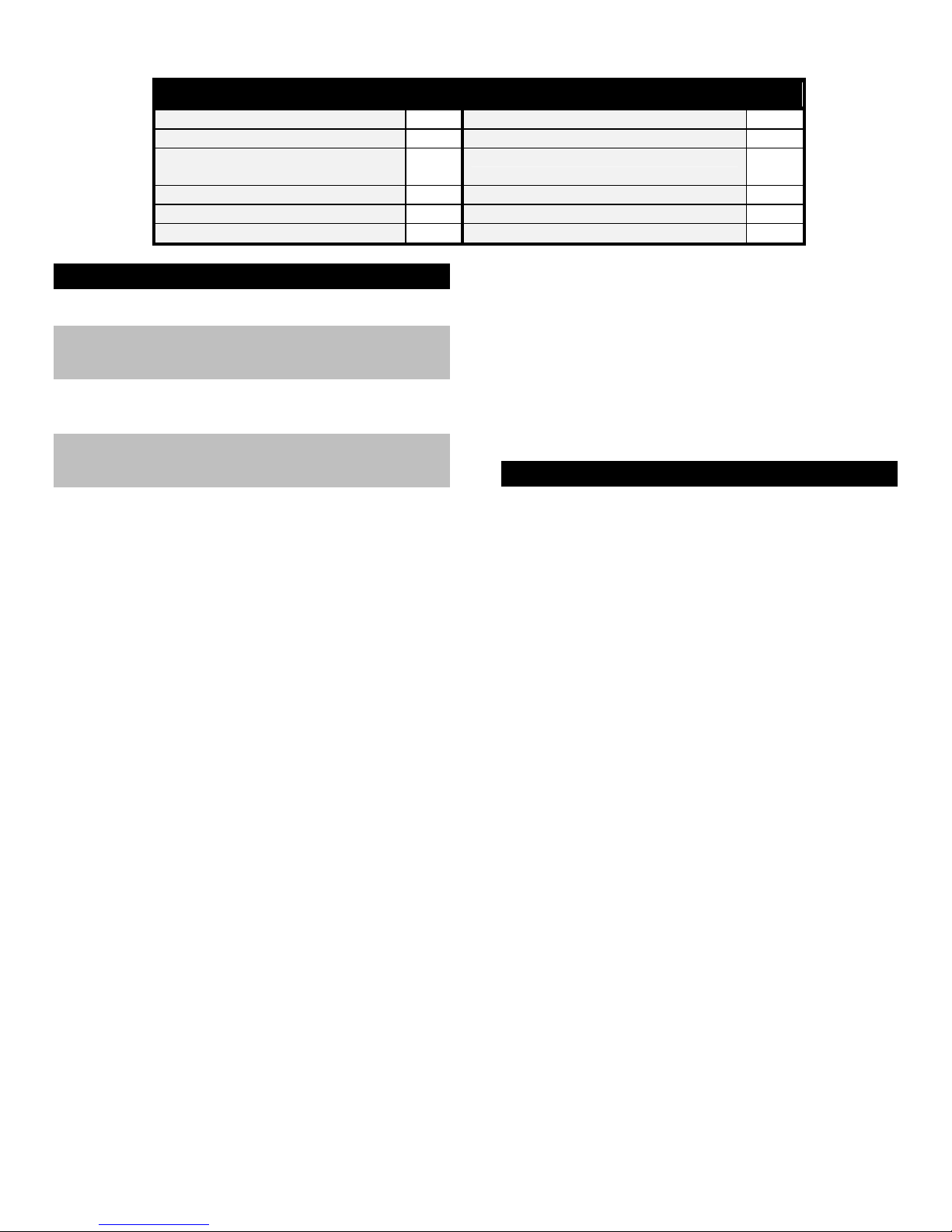

Table of Contents

Important Safety Instructions 2 Maintenance 6

Receipt and Inspection 2 Kits & Service Parts 6

Machine Component

Identification

Assembly 4 Pneumatic Schematic Diagrams 10

Operation 5 Troubleshooting 11

Limited Warranty 13

3 Exploded View / Component List 7-9

Safety

DEFINITIONS

DANGER!

WILL cause DEATH, SEVERE INJURY or substantial

property damage.

WARNING!

CAN cause DEATH, SEVERE INJURY or substantial

property damage.

CAUTION!

WILL or CAN cause MINOR INJURY or property

damage.

GENERAL SAFETY PRECAUTIONS

ALWAYS wear eye protection when operating or

servicing compressor.

NEVER operate where flammable or explosive liquids or

vapors such as gasoline, natural gas and solvents are

present.

NEVER remove, paint over, or deface decals. Replace

any missing decals.

NEVER operate with guards or shields removed,

damaged or broken.

NEVER operate indoors, this compressor intended for

outdoor use only. Avoid inhaling exhaust fumes, risk of

asphyxiation. Exhaust fumes are deadly.

NEVER add fuel when the product is operating or hot.

NEVER directly inhale compressed air.

NEVER over-pressurize the receiver tank or similar

vessels beyond design limits.

NEVER use a receiver tank or similar vessels that fail to

meet the design requirements of the compressor.

NEVER drill into, weld or otherwise alter the receiver

tank or similar vessels.

NEVER remove, adjust, bypass, change, modify or

make substitutions for safety/relief valves, pressure

switches or other pressure control related devices.

NEVER use air tools or attachments without first

determining the maximum pressure recommended for

that equipment.

NEVER point air nozzles or sprayers toward people or

animals.

NEVER touch the compressor pump, engine or

discharge tubing during or shortly after operation. These

parts become hot.

BREATHING AIR PRECAUTION

NorthStar air compressors are not designed, intended

or approved for breathing air. Compressed air should not

be used for breathing air applications unless treated in

accordance with all applicable codes and regulations.

Receipt and Inspection

Before signing the delivery receipt, inspect for

damage and missing parts. If damage or missing parts

are apparent, make the appropriate notation on the

delivery receipt, then sign the receipt. Immediately

contact the carrier for an inspection. All material must be

held in the receiving location for the carrier’s inspection.

Delivery receipts that have been signed without a

notation of damage or missing parts are considered to

be delivered “clear” Subsequent claims are then

considered to be concealed damage claims. Settle

damage claims directly with the transportation company.

If you discover damage after receiving the air

compressor (concealed damage), the carrier must be

notified within 15 day of receipt and an inspection must

requested by telephone with confirmation in writing. On

concealed damage claims, the burden of establishing

that the compressor was damaged in transit reverts back

to the claimant.

Read the compressor nameplate to verify it is the

model ordered, and read the motor nameplate to verify it

is compatible with your electrical conditions. Make sure

electrical enclosures and components are appropriate.

2

Machine Component Identification

Machine Component Identification

1. Engine - Engine is NOT shipped with oil. Refer to engine owners’ manual for proper viscosity and

capacity of oil for your engine.

2. On/Off Switch - Make sure switch is at “ON” position when starting engine.

3. Compressor Air Filter - Make sure your air filter is clean and particle free. See pump exploded view for

replacement filter part number.

4. Belt Guard - Covers the belt, motor pulley and flywheel. NEVER operate compressor without belt

guard.

5. Regulated Pressure Gauge - Easy to read liquid filled gauge indicates regulated pressure.

6. Port at Tank Pressure – To access full tank pressure, attach hose to this port. Thread size is ¼” NPT.

7. Tank Drain – Location of tank drains. Drain tank daily or after each use.

8. Regulator – Adjust outlet pressure, not to exceed pressure rating of the tool.

9. Quick Connect - This is a ¼” quick connect.

10. Unloader - Lift knob to relieve pressure when starting the engine.

11. ASME Safety Valve - This valve automatically releases air if the tank pressure exceeds the preset maximum.

12. Pneumatic Tire - Keep tire pressure at 20 psi for easy movement.

13. Tank Pressure Gauge - Easy to read liquid filled gauge indicates pressure in the tank.

14. Discharge Tube - This tube carries compressed air from the pump to the check valve. This tube

becomes very hot during use. To avoid the risk of severe burns, never touch the discharge tube.

15. Engine Control - Location of choke, engine speed and fuel valve.

3

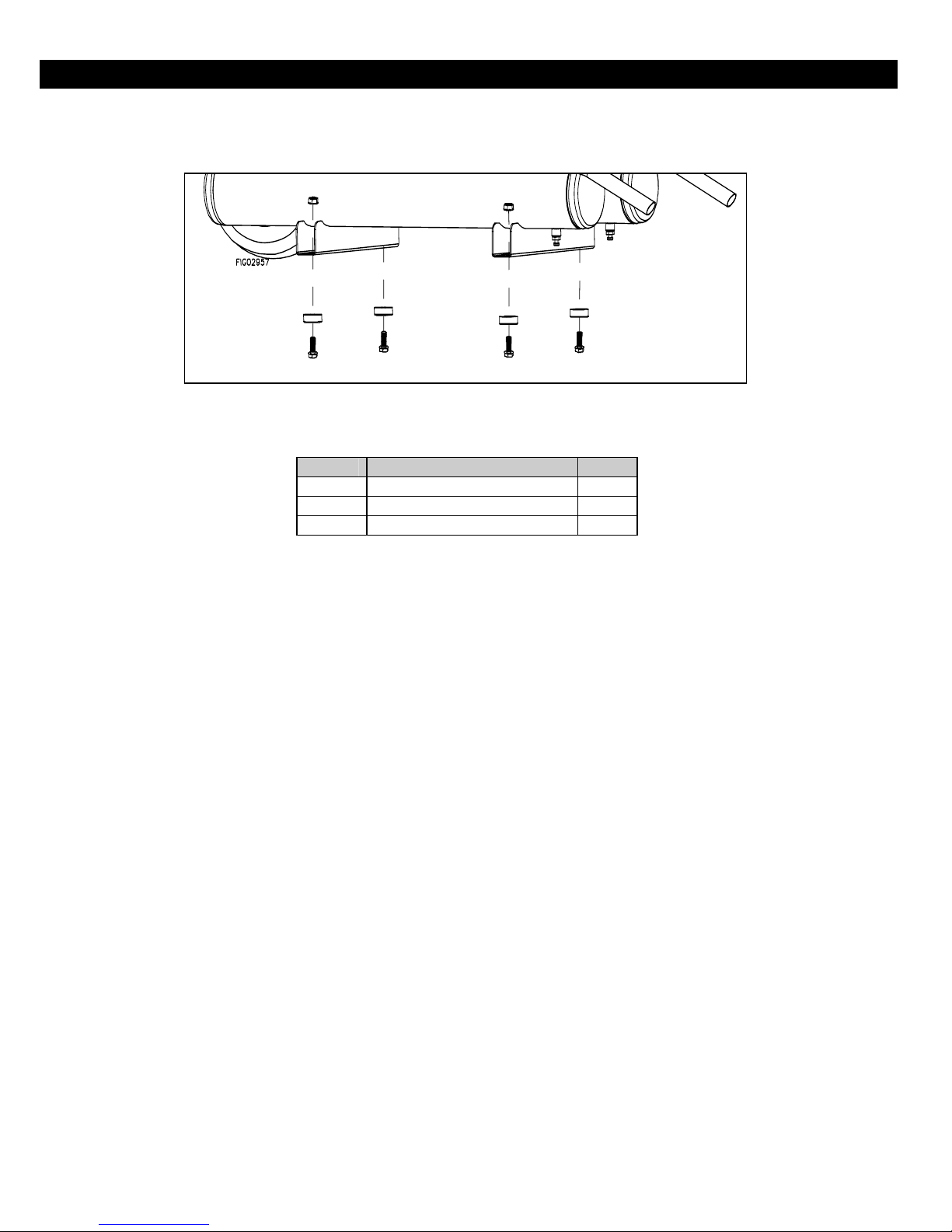

Assembly

Attach rubber feet as shown

Item# Description Qty

2215 Rubber Foot 4

82017 5/16 X 3/4” Flange Bolt 4

82019 5/16 Flange Nut 4

4

p

Operation

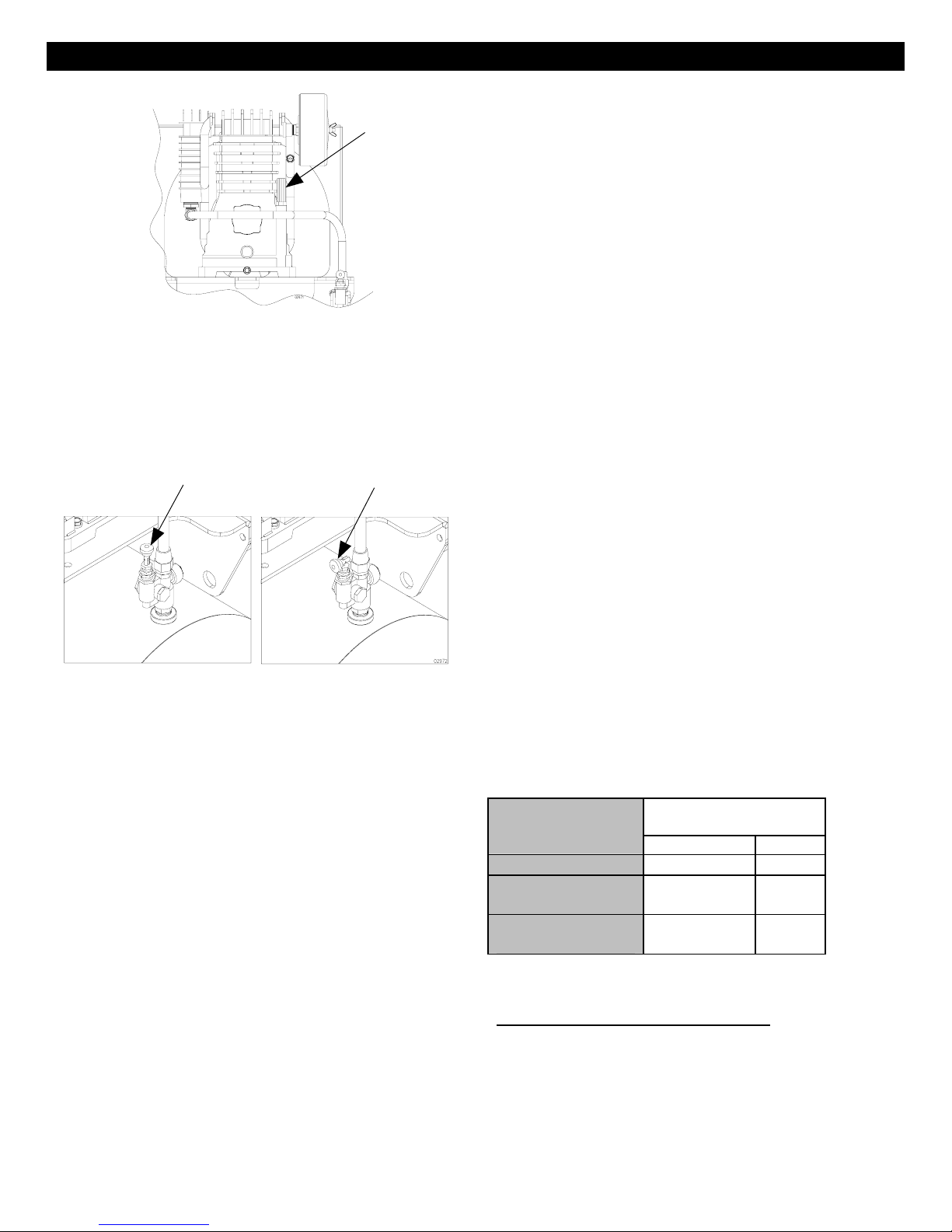

INITIAL START-UP

1. Pump is shipped with oil. Remove the oil cap

and check pump oil level. Add SAE 30 nondetergent pump oil (NorthStar part #4043), if

necessary. Hand tighten breather cap.

2. Turn pressure relief knob to engine start

position.

Engine

Start

3. The engine is shipped without oil. Refer to the

engine manual for oil capacity and viscosity

recommendations.

4. Refer to engine manual to start your engine.

5. Once the engine has started, move the pressure

relief knob to the engine run position.

CAUTION! Unusual noise or vibration indicates a

problem. Do not continue to operate until you

identify and correct the source of the problem.

CAUTION! Do not attach air tools to open end of

the hose until start-up is completed and the unit

checks out OK.

6. Run the unit for 30 minutes, with ball valve open,

to break in pump parts.

7. Close the ball valve to shut off airflow. The

compressor is now ready for use.

8. After 50 hours of operation change the

compressor oil.

Breather

ca

Engine

Run

WARNING!

Never disconnect threaded joints with pressure in

the tank.

NOTE: Reduce tank pressure below 10 psi, and

then drain moisture from tank daily to avoid tank

corrosion. Drain moisture from tank(s) by opening

the drain petcock located at the bottom of the tank.

COMPRESSOR LUBRICATION

CAUTION! Do not operate without lubricant or with

inadequate lubricant. Use of compressor without

lubricant or inadequate lubricant voids all warranties.

Synthetic Lubricants

Synthetic lubricants are recommended after 50-hour

break-in. Compressor life is greatly increased with

the use of synthetic lubricants. CAUTION! If you will

be using synthetic lubricant, all downstream piping

material and system components must be

compatible.

Suitable

Alkyd, Fluorosilicone, Flourocarbon, Polysulfide, 2-Component

Urethane, Nylon, Delrin®, Celcon®, High Nitrile Rubber (Buna N.

NBR more than 36

Epichlorohydrin, Polyacrylate, Melamine, Polypropylene, Baked

Phenolics, Epoxy, Modified Alkyds

Viton®, Teflon®, Epoxy (Glass Filled), Oil Resistant

Acrylonite), Polyurethane, Polyethylene,

( ® indicates trademark of DuPont Corporation)

Not Recommended

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer,

Varnish, Polystyrene, PVC, ABS, Polycarbonite, Cellulose

Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene

Acrylonitile (San), Butyl

Alternate Lubricants. You may use petroleum-based lubricant

that is premium quality, does not contain detergents, contains

only anti-rust, anti-oxidation, and anti-foam agents as additives,

has a flashpoint of 440°F (227°C) or higher, and has a autoignition point of 650°F (343°C) or higher.

See the petroleum lubricant viscosity table below. The table is

intended as a general guide only. Heavy-duty operating conditions

require heavier viscosities. Refer specific operating conditions to

NorthStar Product Support at 1-800-270-0810.

Temperature

around

Compressor

Below 40°F (4°C)

40°F to 80°F

(4°C to 27°C)

80°F to 100°F

(27°C to 37°C)

Viscosity Grade

ISO SAE

60 20

100

150

30

40

Pump Capacities.

Refer to the following table for crankcase capacity

Item # Crankcase capacity

459211 36 oz

459221 48 oz

5

Loading...

Loading...