Page 1

M165939M.2

ITEM NUMBER: 165939

®

Owner’s Manual

Instructions for Installation/Set-up, Operation, Servicing, & Storage

Portable, Outdoor Use-Only, Triple Fuel Generator

SERIAL NUMBER: _____________

10,500 Watt Continuous (13,000 Watt Surge) Capacity

Can be used to power individual appliances plugged directly into the generator’s outlets, or as a

back-up connection to a building’s power supply (via a professionally installed UL-approved

transfer switch.

WARNING

READ and UNDERSTAND this manual completely before using the generator! Failure to properly set up,

operate, and maintain this generator could result in serious injury or death from carbon monoxide poisoning,

electric shock, fire/explosion, or burns. In particular, be aware of the following hazards:

Generators give off carbon monoxide, a poisonous gas that can kill you. You CANNOT smell it, see it, or taste it.

• ONLY run generator OUTDOORS and AWAY from building air intakes. NEVER run generator inside any enclosed or

semi-enclosed spaces, including homes, basements, garages, sheds , boxes , RVs, boats or pick-up truck beds. These

spaces can trap poisonous gases, EVEN if you run a fan or open windows.

• Carbon monoxide is given off whether you are using gasoline, natural gas, or propane to powe r the ge nerator.

• Install carbon monoxide alarms inside nearby struct u res/b ui l di n gs (batt e r y -o perat ed , or pl u g-in with battery backup).

Electric shock / Electrocution

• High voltage electricity from generator can kill. DO NOT operate in wet locations. Be sure generator is properly

grounded. Use only UL-listed, outdoor-rated grounded extension cords of proper size.

• NEVER plug the generator directly into a wall outlet. ANY connection to a building’s electrical system MUST

ISOLATE THE GENERATOR FROM UTILITY POWER via a UL-approved transfer switch installed by a licensed

electrician. Otherwise, back feed from the generator into the power grid could kill utility workers.

• DO NOT overload generator (per rated capacity), and OPERATE ONLY in an area with adequate cooling ventilation so

engine does not overheat. Exhaust can be extremely hot. Keep muffler at least 7’ from all combustible objects.

• All fuels are flammable. Never fuel a running or hot engine. Never pump fuel directly into generator at gas station – use

approved container to transfer fuel. Ensure there are no fuel leaks, and keep sources of sparks and flames away.

• LPG/NG hook-ups must be completed by a certified gas technician and comply with all federal and local requirements.

• ALWAYS keep a fire extinguisher rated “ABC” nearby.

CO Poisoning

Fire / Explosion

STOP!

CHOOSE THE RIGHT GENERATOR FOR YOUR NEEDS. See the “Power load Planning & Management” section

of this manual to determine your power load requirements and then compare to the generator’s rated capacity.

INSPECT COMPONENTS: Closely inspect to make sure no components are missing or damaged. See the “Unpacking

& Delivery Inspection” section for instructions on whom to contact to report missing or damaged parts.

ARRANGE FOR PROFESSIONAL INSTALLATION of transfer switch and/or NG/LPG hook-ups, if they will be used.

See the “Installation/Initial Set-Up” section for more information about these requirements.

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

Page 2

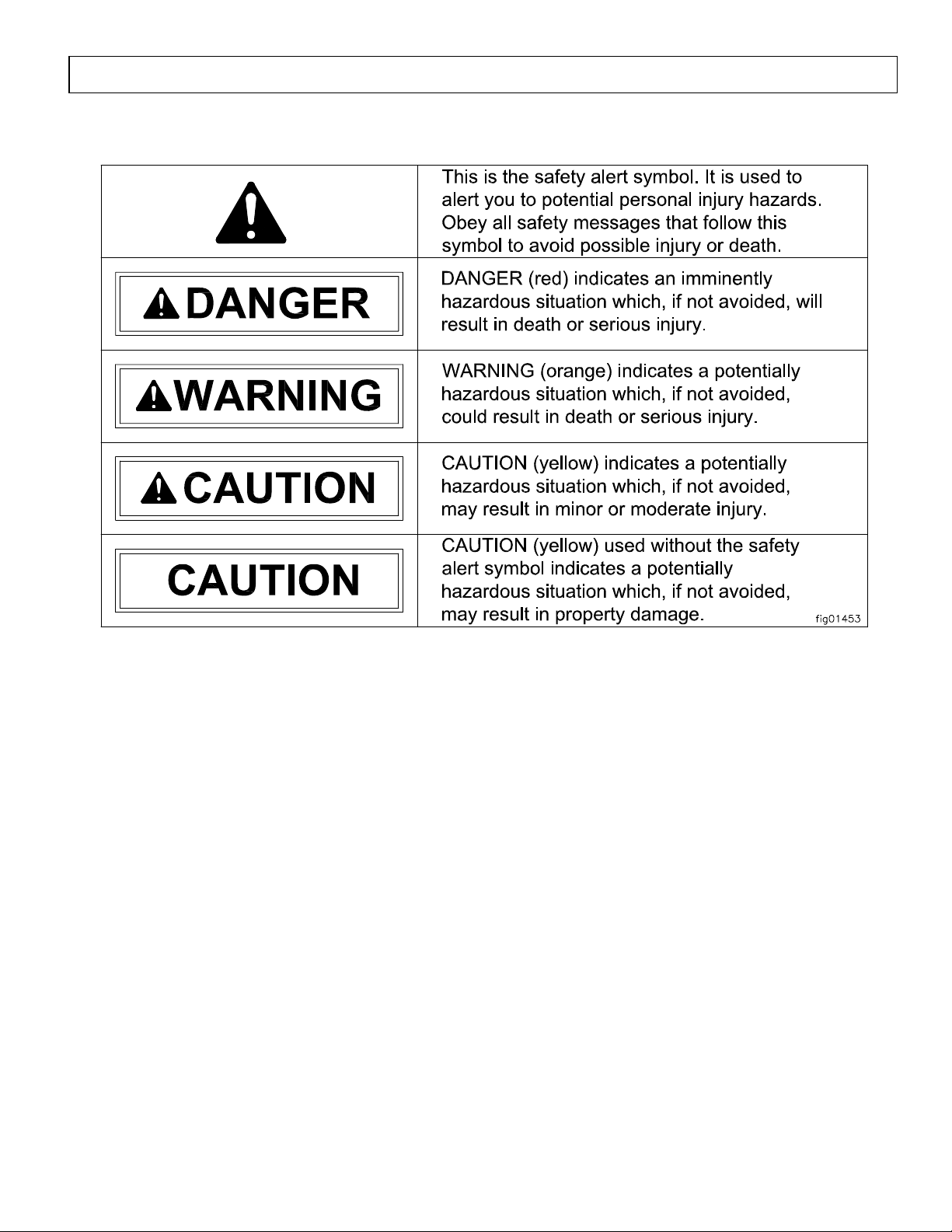

Hazard Signal Word Definitions

2

Page 3

Table of Contents

Hazard Signal Word Definitions ................................................................................................. 2

About Your Generator ................................................................................................................. 4

Specifications ................................................................................................................................. 6

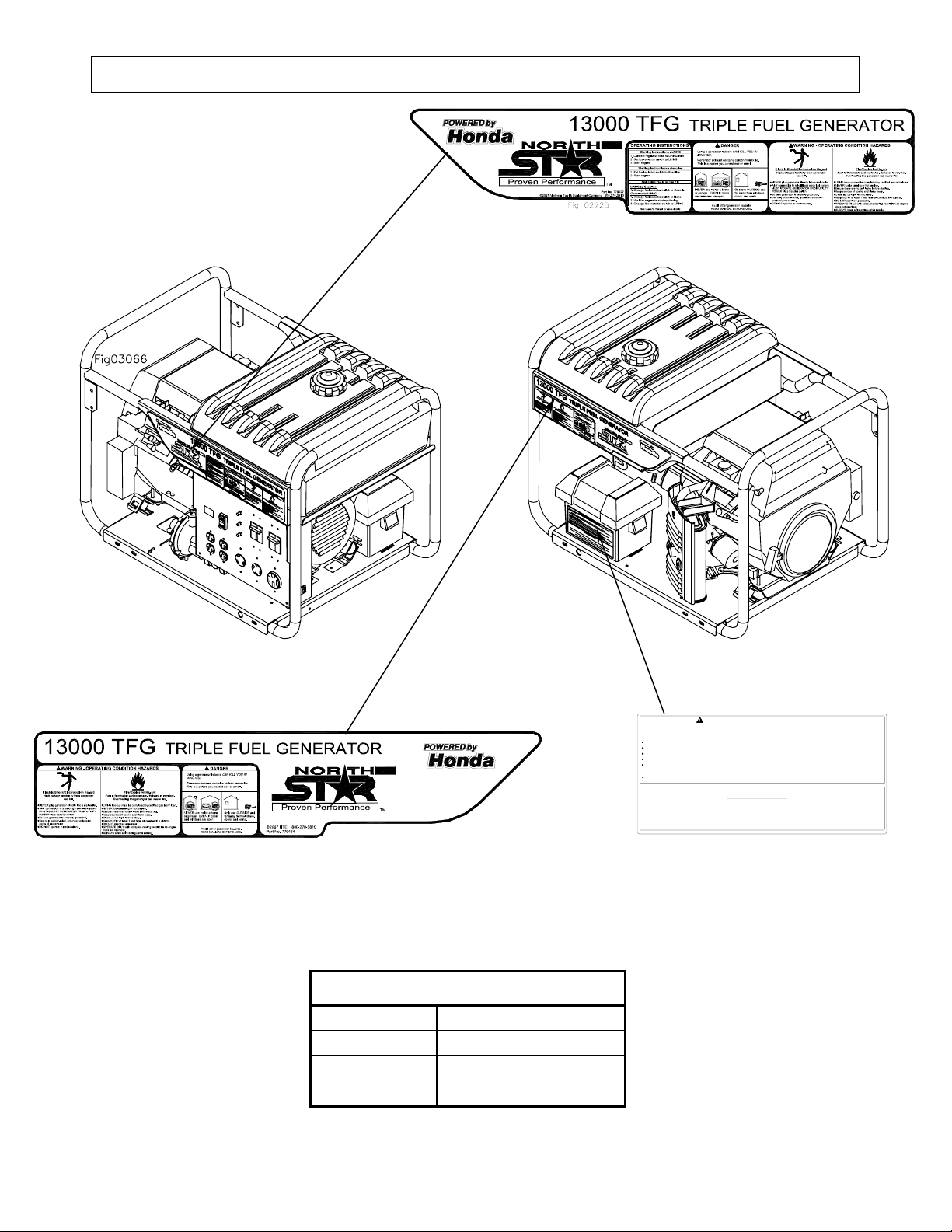

Safety Label Locations .................................................................................................................. 7

Machine Component Identification ............................................................................................. 8

Power Load Planning & Management ........................................................................................ 11

Installation / Initial Set-Up:

1. Unpacking & Delivery Inspection .......................................................................................... 13

2. Planning the Power Load ........................................................................................................ 13

3. Gas Hook-up Installation for Natural Gas or Propane (LPG) – if using ................................ 14

4. Set-up as a PORTABLE or BUILDING BACK-UP Power Source ...................................... 16

5. Selecting a Suitable Site ......................................................................................................... 19

6. Grounding the Generator ........................................................................................................ 21

7. Battery Installation ................................................................................................................. 22

8. Spark Arrester Installation ...................................................................................................... 22

Operation:

1. General Safety Rules for Operation ....................................................................................... 23

2. Preparing for Operation .......................................................................................................... 26

3. Starting the Engine ................................................................................................................. 30

4. Checking Generator Output .................................................................................................... 32

5. Connecting Loads ................................................................................................................... 33

6. Switching Fuels (during operation) ........................................................................................ 34

7. Stopping the Engine ............................................................................................................... 34

8. Storage & Exercise ................................................................................................................. 35

Maintenance & Repair .................................................................................................................. 37

Troubleshooting ............................................................................................................................. 39

Summary of Important Safety Information for Operation ....................................................... 40

Generator Exploded View ............................................................................................................ 45

Wiring Diagram ............................................................................................................................. 47

Fuel Delivery System ..................................................................................................................... 49

Generator Head Exploded View .................................................................................................. 50

Limited Warranty ......................................................................................................................... 51

3

Page 4

About Your Generator

Thank you for purchasing your NorthStar portable generator!

About Your Generator

This engine-driven, portable generator is designed to provide up to 8000 Watts of

electrical power (10,500 watts continuous, 13,000 watts surge). It can supply power:

1. As a portable power source. You can plug appliances directly into the generator’s

electrical outlets.

2. As a back up, standby power source for a building. A licensed electrician can connect

the generator to your building’s electrical system via the installation of an UL-approved

transfer switch. (See the “Installation & Initial Set-up” section of this manual to learn

more about specific requirements and precautions relating to wiring the generator to your

building’s electrical system.)

You must select a generator adequately sized for your power needs. You need to

determine the power needs of all the appliances/tools you wish to power at the same time and

choose a generator rated to provide at least that power level. See the “Power Load Planning &

Management” section of this manual to determine your specific power load requirements and

then compare them to this generator’s rated capacity. You must not overload the generator.

Overloading will cause damage to the generator and attached electrical devices, and may also

result in fire.

You can power this generator with gasoline, natural gas (NG), or propane (LP) gas. The

generator is designed so that it is easy to switch between fuel sources. However, there are

special initial hook-up requirements for natural gas and propane. See the “Specifications”

section of this manual with regard to specific gas flow and pressure requirements. In addition,

note the following:

♦ Natural gas. The standard delivery pressure provided to your building by your utility

company may not match the requirements of your generator.

a) If your standard delivery pressure is higher than allowable for this generator, you

may need to have a pressure-reducing regulator installed. (Note: The regulator

supplied with this generator is NOT a pressure-reducing regulator).

b) If your standard delivery pressure is lower than allowable for this generator, you will

need changes to your natural gas service to elevate the delivery pressure.

ALL natural gas hook-ups must be completed by trained personnel from your natural gas

utility company and inspected as required by your local building code.

♦ Propane (LP). You will need a minimum 100 lb. LPG gas tank to run this generator – the

vaporization rate is insufficient with smaller tank sizes. A qualified propane gas

technician must set up the valve and hose connection between the propane tank and

generator in accordance with all local regulations and electric code.

See the “Installation / Initial Set-Up: Step 3” section of this manual for more detailed

information.

Be sure to read about site selection and grounding requirements for running this

generator. More detailed information can be found in the “Installation & Initial Set-up, Steps

5 & 6” of this manual.

4

Page 5

About Your Generator (cont’d)

This generator is too heavy for one person to lift without mechanical assistance. An

optional wheel kit is available from NorthStar and is recommended if you will be moving the

generator unassisted. Other optional accessories available from NorthStar include a vinyl

cover for storage, UL-approved transfer switches, and extension cords.

Contact NorthStar Product Support at 1-800-270-0810

with questions about optional accessories or to order.

Read this Manual

Improper use or maintenance of this generator can result in serious injury or death from

carbon monoxide poisoning, electric shock/electrocution, fire/explosion, or burns.

Read this manual completely before using the generator and follow all instructions and

safety rules.

You must follow all instructions and safety precautions presented throughout this manual. A

summary of important safety information can be found at the end of the manual. Keep this

manual for reference and review.

Proper preparation, operation, and maintenance will result in operator safety, as well as best

performance and long life of the generator. For detailed engine operation and maintenance

information, always refer to the engine Owner’s Manual furnished with the generator.

NorthStar is constantly improving its products. The specifications outlined herein are subject

to change without prior notice or obligation. The purchaser and/or user shall assume liability

for any modification and/or alterations of this equipment from original design and

manufacture.

Before using, the user shall determine the suitability of this product for its intended use and

assumes liability therein.

Contact NorthStar Product Support at 1-800-270-0810 for any questions about the

appropriate use of this generator.

WARNING

Warranty Registration

Please fill out and submit the warranty registration card so that we have your contact

information for any future product literature or replacement parts you may need.

ATTENTION:

All Rental Companies and Private Owners who loan this

equipment to others!

All persons to whom you rent/loan this generator must have access to and read this manual.

Keep this owner’s manual with the generator at all times and advise all persons who will

operate the machine to read it. You must also provide personal instruction on how to safely

operate the generator and remain available to answer any questions a renter/borrower might

have.

5

Page 6

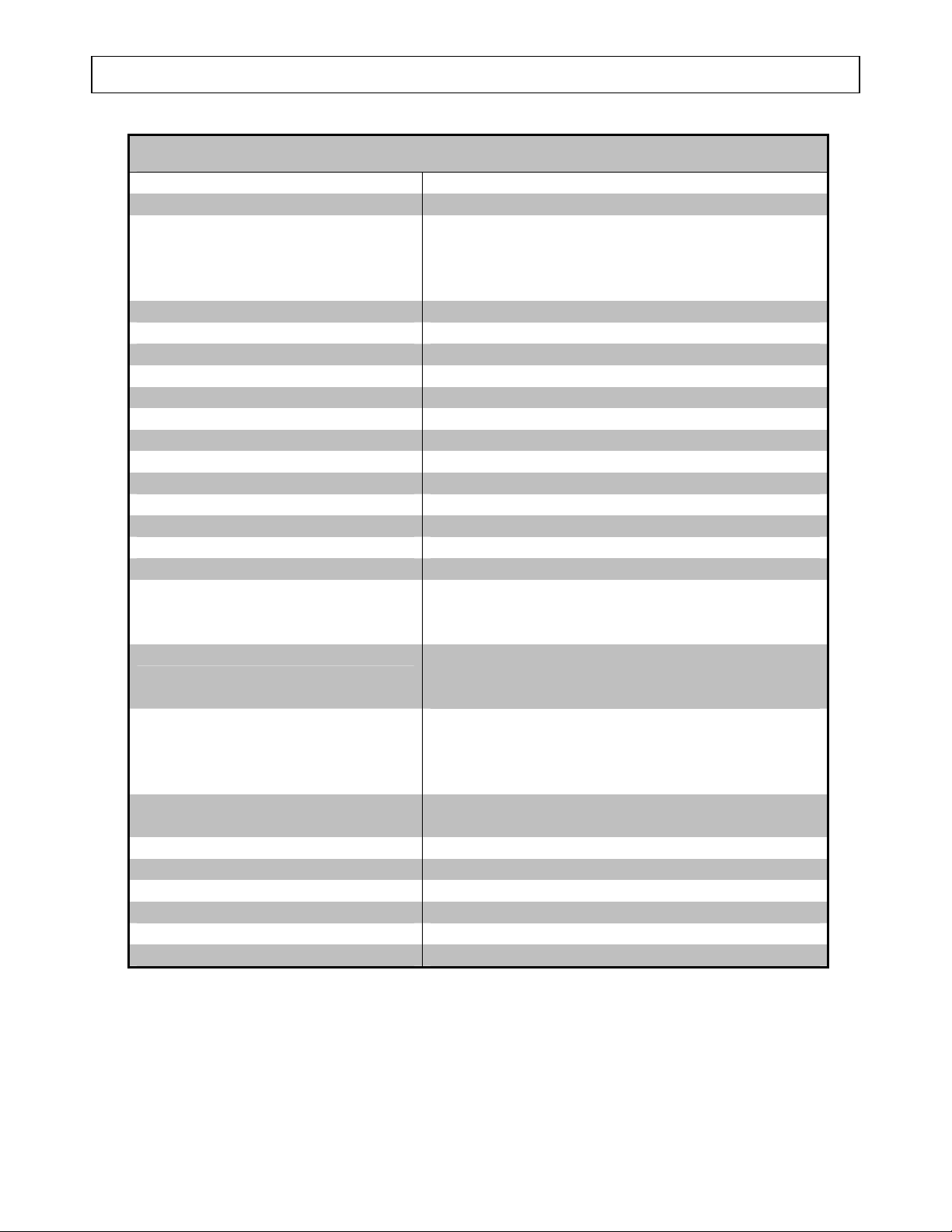

Specifications

SPECIFICATIONS

Item Number #165939

Maximum Output 13500 Watts (W)

Continuous Output:

Gasoline

Liquid Petroleum Gas (LPG)

Natural Gas (NG)

Voltage 120 / 240 Volt (V)

Phase Single phase (4-wire)

Frequency Regulation 56.5 - 63.3 Hertz (Hz)

Voltage Regulation 218 - 258 V

Power Factor 1.0 p.f.

Engine 20 HP Honda

Engine Speed 3390 - 3798 RPM

Fuel Type Unleaded gasoline/LPG/NG

Pressure Range (LPG, NG) 7-11” Water Column, 4-6 oz.

Min. Flow Range (LPG, NG) 2.2 Gal/Hr (LPG), 3.25 CFM (NG)

Fuel Capacity 10.0 Gallons (38.0 L)

Oil Capacity See Honda Manual

Starting Method Electric

120V Receptacle 20 Amp (A) duplex (NEMA 5-20R)

120/240V Receptacle 30 Amp (A) locking device

50 Amp (A) straight blade (NEMA 14-50R)

Circuit Breaker (1) 50 Amp (A) thermal magnetic

(1) 30 Amp (A) thermal magnetic

(1) 30 Amp (A) thermal, push to reset

(2) 30 Amp (A) thermal, push to reset

Battery (not included) 12 Volt, 400 CCA minimum,

Dimensions

Length 35.75” (90.8 cm)

Width 24.25” (61.6 cm)

Height 26.25” (66.7 cm)

Dry Weight 340 lb. (155 kg)

Gross Weight 410 lb. (186 kg)

10500 Watts (W)

9600 Watts (W)

8400 Watts (W)

30 Amp (A) locking device

(NEMA L5-30R)

(NEMA L14-30R)

Group size U1

6

Page 7

Safety Label Locations

BATTERIES:

1) contain caustic acid, 2) em it e xplosive gases, 3) can cause electric shock

ALWAYS use eye protection. Caustic acid and ex plosive gas es can cause blindness or severe burns.

NO smoking, sparks, or flames.

NEVER touch both battery terminals at the same time with your hand or any non-insulated tools.

FLUSH immediately with w at er if ba ttery acid c ontacts eyes, skin, or clothing.

CONNECT c ables in correct se quence: FIRST RED to POS ITIVE terminal, th e n BLACK to NEG A TIVE

terminal. When disconnecting, DISCONNECT BLA CK cable first, then RED.

NEVER charge a visibly damaged or frozen battery. ALWAYS read and follow charger instructions.

IF GENERATO R IS TO BE STORED LONGER THA N 2 M ONTHS,

charge battery with a trickle charger that is rated for 3 amps maximum.

©2007 NT+E 1-800-270-0810

Always make sure safety labels are in place and in good condition. If a safety label is

missing or not legible, order new labels or unsafe operation could result.

To order replacement safety labels, call NorthStar Product Support at 1-800-270-0810.

WARNING - BATTERY HAZARDS

ATTENTION

A charged battery ensures reliable engine starting.

PN 779396

On-Product Warning Labels

Part numbers Description

779396 Battery Warning

779427 Warning 1

779464 Warning 2

7

Page 8

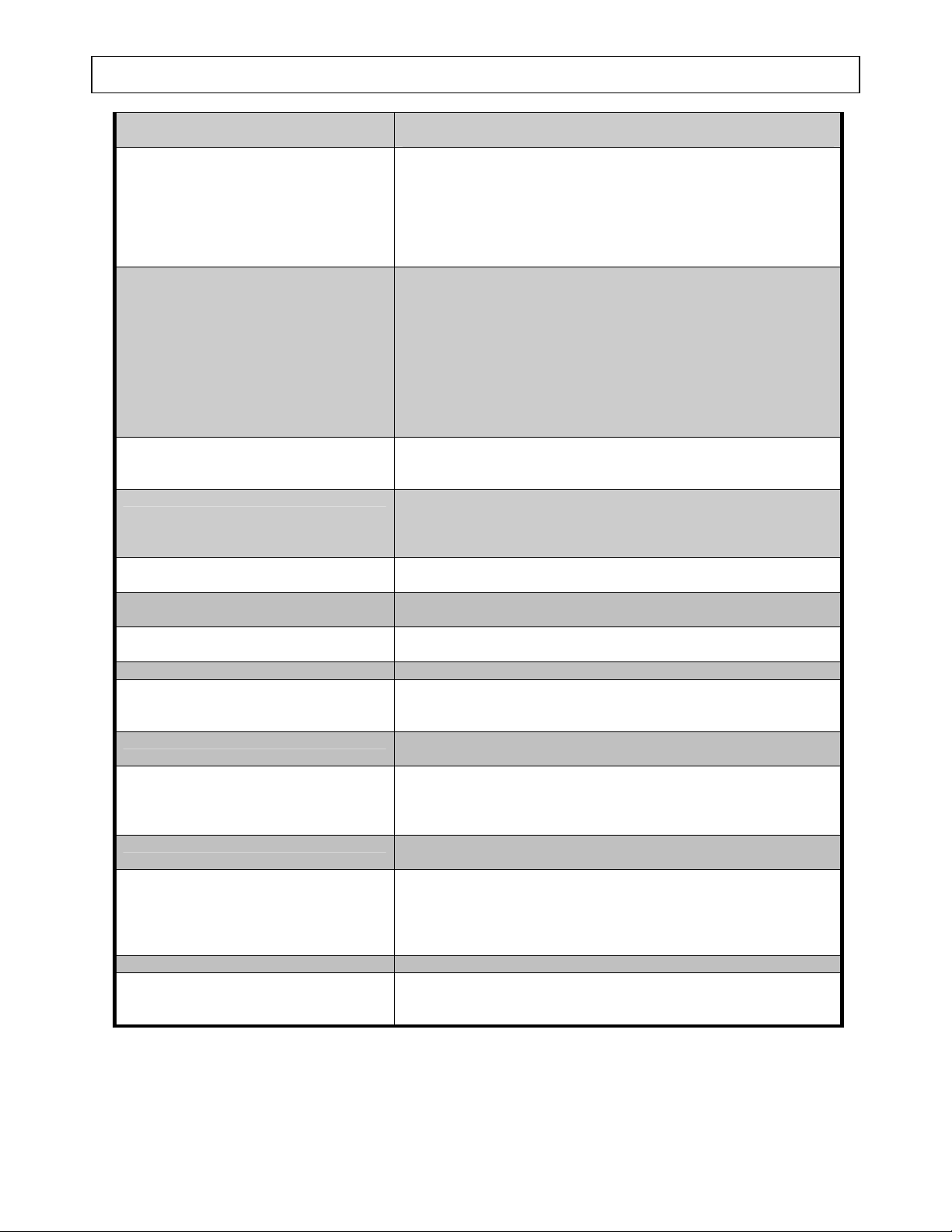

Machine Component Identification - Item #165939M.2

Figure 1 (Ref. 1-19)

Ref. Description Ref. Description

1 Air Cleaner 15 Hour Meter

2 Gas Cap with Gauge 16 Oil Drain Area

3 10.0 Gallon Gas Tank 17 Demand Regulator Assembly

4 Battery Box 18 Engine Oil Drain Plug

5 LPG/NG-3/4” NPT Gas Inlet 19 Oil Level Dip Stick

6 120/240V, 50A, Circuit Breaker 20 Engine Oil Fill Port

7 120/240V, 50A Receptacle 21 Engine Key Switch

8 120/240V, 30A Receptacle 22 Engine Choke Lever

9 120/240V, 30A, Circuit Breaker 23 Vibration Isolation Mount

10 120V, 30A Receptacle 24 Engine Oil Filter

11 120V, 30A Circuit Breaker 25 Muffler

12 120V, 20A Circuit Breaker 26 Generator Head

13 120V, 20A, Duplex Receptacle 27 Gas Line Shutoff Valve

14 Fuel Selector Switch

Figure 2 (Ref. 20-27)

8

Page 9

Machine Component Identification - Item #165939M.2

REFERENCE GUIDE

Reference 1 – Air Cleaner

Reference 2 – Gas Cap with Gauge

Reference 3 – 10.0 Gallon Gas Tank Large tank allows for extended run capabilities. Always allow

Reference 4 – Battery Box

Reference 5 - LPG/NG-3/4” NPT Gas

Inlet

Reference 6 - 120/240V, 50A, Circuit

Breaker

Reference 7 - 120/240V, 50A

Receptacle

Reference 8 - 120/240V, 30A

Receptacle

Reference 9 - 120/240V, 30A, Circuit

Breaker

Reference 10 - 120V, 30A Receptacle

Reference 11 - 120V, 30A Circuit

Breaker

Reference 12 - 120V, 20A Circuit

Breaker

Refer to your Honda engine manual for air cleaner care.

The gas cap is extra large, creating a large hole for refueling

and a comfortable grip. You can always monitor the fu el level

without removing the cap by using the fuel level indicator built

into the gas cap.

room for gasoline expansion by not filling the gas tank

completely full.

The battery box provides protection for the battery and will accept

the standard lawn tractor size battery (Group U1-7). The engine

requires a 12 volts battery. See battery section for sizing.

WARNING Hookup must comply with the Federal and Local

jurisdiction of Liquid Petroleum (LP) and Natural Gas (NG).

ALWAYS have a qualified technician complete the LP/NG

hookup. Improper installation can cause injury or death. LP/NG

are lethal and explosive gases. If you smell gas, exit area

immediately, if possible shut off the LP/NG supply. Before you

start engine, smell next to floor for gas, if you do smell gas:

• DO NOT start engine.

• DO NOT light a match.

• DO NOT flip on an electrical switch.

• Exit area immediately and call gas supplier or fire

department.

Minimum flow range required: NG - 3.25 CFM;

LPG - 9.33 LB/hr., or 2.2 GAL/hr.

Pressure Range: 4-6 ounces, OR 7-11 inches of water column.

NEVER over pressurize.

This portable generator has one 120/240 volt, 50 Amp thermal

magnetic 2 pole circuit breaker. This circuit breaker is the main

line circuit breaker and will sever power to the control panel

receptacles when in the off or tripped position. To reset this circuit

breaker, move the circuit breaker handle to the OFF position.

Then move the breaker handle to the ON position. If the circuit

breaker continues to trip, reduce load to the generator. If

nuisance tripping continues one or more electrical loads may be

defective and must be repaired by a qualified electrician.

The generator control panel has one 120/240 volt, 50 amp NEMA

14-50R receptacle. This receptacle is protected by Reference 6.

The mating plug for this receptacle is a NEMA 14-50P. This

receptacle is useful when installing a transfer switch.

The generator control panel has one 120/240 volt, 30 amp

NEMA L14-30R locking device receptacle. This receptacle is

protected by Reference 9. The mating plug for this receptacle is

a NEMA L14-30P.

This generator has one 120/240 volt, 30 Amp thermal magnetic

2 pole circuit breaker. To reset this circuit breaker, move the

circuit breaker handle to the OFF position. Then move the

breaker handle to the ON position.

The control panel has one 120 volt, 30 amp NEMA L5-30R

receptacle. This receptacle is protected by Reference 11. The

mating plug for this receptacle is a NEMA L5-30P.

The generator control panel has a 120-volt, 30 amp thermal

circuit breaker. To reset the circuit breaker, wait 15 seconds

and press the extended button back into the circuit breaker

housing.

The generator control panel has two 120 volt, 20 amp thermal

circuit breakers. To reset the circuit breaker, wait 15 seconds

9

Page 10

Machine Component Identification - Item #165939M.2

and press the extended button back into the circuit breaker

housing.

Reference 13 - 120V, 20A, Duplex

Receptacle

Reference 14 - Fuel Selector Switch Switching from LP or NG to gasoline:

Reference 15 – Hour Meter

Reference 16 – Oil Drain Area

Reference 17 – Demand Regulator

Assembly

Reference 18 – Oil Drain Plug

Reference 19 – Oil Level Dip Stick

Reference 20 – Engine Oil Fill Port

Reference 21 – Engine Key Switch

Reference 22 – Engine Choke Lever

Reference 23 – Vibration Isolation

Mount

Reference 24 – Engine Oil Filter Replace the oil filter at each oil change. Replace with Honda

Reference 25 – Muffler

Reference 26 – Generator Head

Reference 27 – Gas Line Shutoff

Valve

The generator has a control panel with two duplex (two

receptacles in a common housing) receptacles. This duplex is a

120-volt (V) 20 amp (A) straight blade receptacle, National

Electrical Manufacturer’s Association (NEMA) number 5-20R.

This receptacle accepts NEMA plug number 5-20P. The

duplex is capable of drawing 20A out of either receptacle or a

combination of both.

1. Disconnect all loads to generator.

2. Turn the gas line valve to ON position.

3. Flip the fuel selection switch to the GASOLINE position.

Switching from gasoline to LP or NG:

1. Disconnect all loads to generator.

2. Make sure LP or NG fuel is being supplied.

3. Flip the fuel selection switch to the LP/NG position.

4. Momentary sputtering is common.

5. Turn gasoline line valve to OFF position.

The control panel includes an hour meter to monitor engine run

time. The hour meter will not work if the 120 volt, 20 amp circuit

breaker is OFF (Reference 12).

This product was designed with a large window in the base

directly below the engine oil drain plug (Reference 18). The

large window facilitates a quick and clean process to change

engine oil.

Controls the flow of LP or NG gas into the engine carburetor.

Refer to your Honda engine manual for oil change

recommendations.

Refer to your Honda engine manual for proper oil level

recommendations.

Remove the oil fill cap to add engine oil.

The engine key switch is located on the front of the engine.

Always locate this switch and be familiar with its location before

operating the generator.

Used during cold starts. Refer to the Honda engine manual for

usage.

The engine and generator head is mounted on rubber cylinders

that absorb most of the engine vibration. This feature

eliminates the tendency of the machine to “walk” which is

common with engine-powered equipment.

genuine replacement parts.

This generator is equipped with a quiet style muffler. The

muffler is designed to allow moisture (condensation) to drain

from the bottom of the canister. Always check for loose

fasteners. Included spark arrestor is shipped loose. See Spark

Arrestor Installation section of this manual for information.

The electricity producing part of the generator.

The fuel tank has an ON-OFF valve mounted underneath.

Always keep this valve closed (OFF) when the generator is not

in use.

10

Page 11

Power Load Planning & Management

NEVER exceed the rated wattage capacity of your generator.

WARNING

OVERLOADING may cause SERIOUS DAMAGE to the generator and

attached electrical devices, and may result in fire.

Your generator MUST BE SIZED PROPERLY to provide both the running and starting (surge)

wattage of the devices you will be powering. Before using your generator, determine the running

and starting wattage requirements of all the electrical devices you will be powering simultaneously.

The sum of the running and starting wattages of the devices being powered must not exceed the

continuous output rating of your generator. (The continuous output rating of your generator is listed

in the “Specifications” section of this manual.) Note that:

• Devices without electric motors such as light bulbs, radios, and televisions have the same

running and starting wattage.

• Devices with electric motors such as refrigerators, compressors, and hand tools typically

require a starting wattage that is 3 to 5 times greater than the running wattage.

The running and starting wattage requirements are often listed on a device’s nameplate. If wattage

is not given on the device’s nameplate, the wattage may be calculated by multiplying the nameplate

voltage by nameplate amperage, Watts = Volts X Amps.

Example conversion to watts:

120 Volts X 5 Amps = 600 Watts

If only the running voltage is given on the nameplate for a device with an electric motor, the starting

wattage can be approximated to be three to five times the running wattage.

Estimates for the running wattage requirements for common devices are listed in Table 1 below.

Guidance for starting wattages is provided in the table’s footnotes.

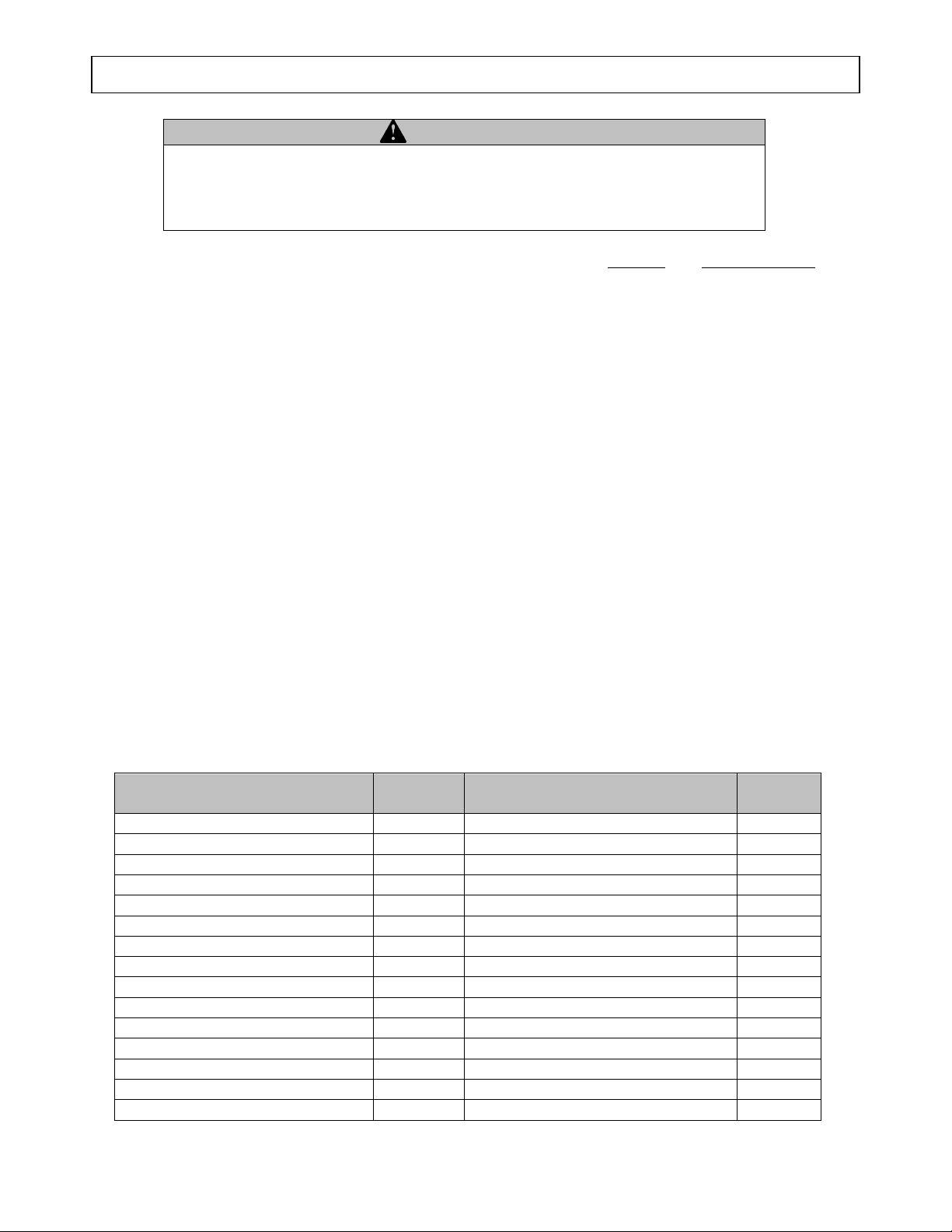

Table 1

Device

Air conditioner (12.000 BTU) 1700 (a,b) Jet pump 800 (a)

Battery charger (20 Amp) 500 Lawn mower 1200

Belt sander (3”) 1000 Light bulb (100 Watt) 100

Chain saw 1200 Microwave oven 700

Circular saw (6½”) 2000 (a,b) Milk cooler 1100 (a)

Coffee maker 1800 (a,b) Oil burner on furnace 300

Compressor (1 HP) 1400 (a,b) Oil-fired space heater (140,000 Btu) 400

Compressor (3/4 HP) 1800 (a) Oil-fired space heater (85,000 Btu) 225

Compressor (1/2 HP) 1400 (a) Oil-fired space heater (30,000 Btu) 150

Curling iron 700 Oven 4500

Dishwasher 1200 Paint sprayer, Airless (1/3 HP) 600 (a)

Edge trimmer 500 Paint sprayer, Airless (handheld) 150

Electric nail gun 1200 Radio 200

Electric range (1 element) 1500 Refrigerator 600 (b)

Electric skillet 1250 Slow cooker 200

Running

Watts Device

Running

Watts

11

Page 12

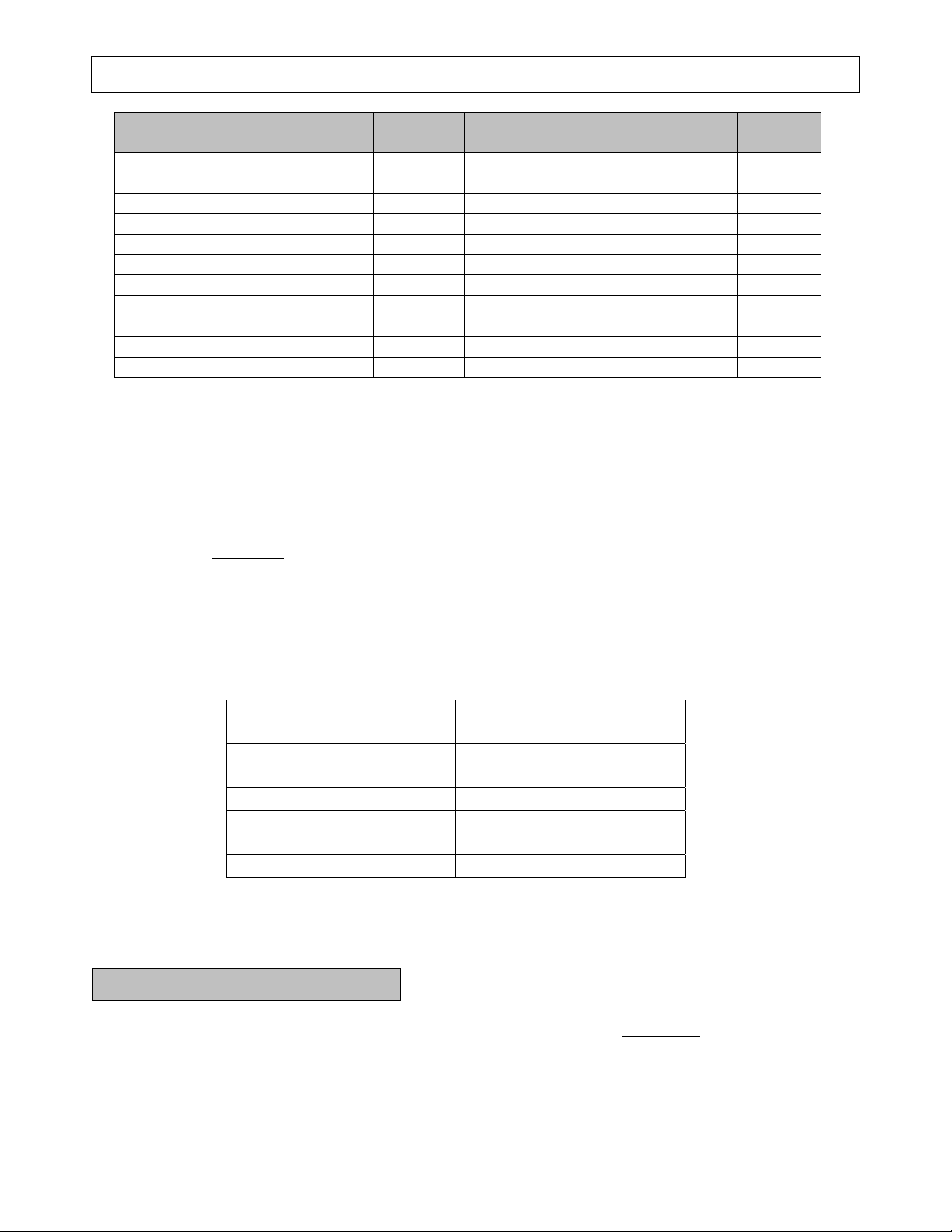

Power Load Planning & Management (cont’d)

Device

Furnace fan (1/3 HP) 1200 (a) Submersible pump (1-1/2 HP) 2800 (a)

Freezer 800 (b) Submersible pump (1 HP) 2000 (a)

Hair dryer 1200 Submersible pump (1/2 HP) 1500 (a)

Hand drill (1”) 1100 Sump pump 600 (a)

Hand drill (1/2”) 875 Table saw 2000 (a)

Hand drill (3/8”) 500 Television 500

Hand drill (1/4”) 250 Toaster 1000

Hedge trimmer 450 Vacuum cleaner 250

Home computer 150 VCR 70

Impact wrench 500 Water Heater 3000

Weed trimmer 500

Running

Watts Device

Running

Watts

(a) Hard-starting motors require 3-5 times the rated running watts

(b) For extremely hard to start loads such as air conditioners and air compressors, consult the

equipment dealer to determine maximum wattage

To calculate the running and starting wattage requirements for the devices you will be

powering, follow these steps:

1. Make a list of all electrical devices you will be powering at the same time with the generator.

2. List the greater of the running or starting wattage next to each device as obtained from the

devices’ nameplate or Table 1. If only the running wattage for a device with an electric

motor is known, the starting wattage can be estimated to be at least 3 times the running

wattage.

3. Add the wattages for all devices on your list. This total must be lower than the continuous

output rating of your generator.

Example:

Device to be Powered

Starting/Running Wattage

Greater of

Light Bulb 75 W

Refrigerator – 18 Cu. Ft. 1600 W

Microwave 700 W

Window AC 1800 W

Sump pump (1/3 hp) 2100 W

Total 6275W

In this example, the generator must have a continuous output of at least 6275 W in order to

power all of the devices simultaneously.

STAGGERING LOADS

You can increase the number of devices your generator can power by staggering the load on the

generator. For example, you could alternately power your refrigerator and air conditioner for

limited periods of time -- powering only one of the devices at a time and never powering both at the

same time.

12

Page 13

Installation / Initial Set-Up

There are a number of important steps required to set up your generator for initial use. These

steps are:

Steps for Installation / Initial Set-Up

1. Unpacking & delivery inspection.

2. Planning the power load to stay within the generator’s rated

capacity.

3. Getting gas hook-ups installed if natural gas or LP gas will be used as

a fuel source.

4. Setting up generator for the type of power generation you need:

a. portable power source, or

b. connected to a building as a back-up power source.

5. Selecting a site for using the generator.

6. Grounding.

7. Battery installation (electric start models only).

Each of these steps is discussed in detail below:

1. Unpacking & Delivery Inspection

You should inspect the generator immediately after you receive delivery.

See the “Machine Component Identification” section of this manual for a

• If you have missing components, contact Product Support at 1-800-270-0810.

• If you have damaged components, contact the freight company that delivered the unit and file a

Plan your power load so that you do not exceed the generator’s rated capacity.

See the “Power Load Planning & Management” section of this manual to review how to plan and

manage power loads for the generator.

diagram of the generator and its components.

claim.

2. Planning the Power Load

13

Page 14

Installation / Initial Set-Up

3. Gas Hook-up Installation for Natural Gas or LPG (if needed)

You can power this generator with gasoline, natural gas (NG), or propane (LP) gas. The generator

is designed so that it is easy to switch between fuel sources. However, there are special initial

hook-up requirements for natural gas and propane:

WARNING:

If you choose to operate the generator on NG or LPG, you must have the fuel line system

installed by a certified gas technician.

Specific requirements for each type of hook-up are given below:

Natural Gas (NG)

Hook-up

Contact your gas utility company for installation of a natural gas hookup for the generator.

WARNING:

Natural gas is a highly explosive gas. All natural gas hook-ups must

be completed by trained personnel from your natural gas utility

company and inspected as required by your local building code.

♦ This product is designed to operate on NG at a gas pressure range of 4 to

6 ounces per square inch (7”-11” of water column) and requires a

minimum NG flow rate of 3.25 CFM.

♦ The standard gas pressure normally delivered to your building by your

utility company may be higher or lower than the required 4-6 ounces per

square inch (7”-11” of water column):

o If your standard delivery pressure exceeds 4-6 ounces per square

inch (7”-11” water column), you will need a pressure-reducing

regulator installed. Excessive gas pressure will permanently

damage this product and void the warranty if the generator is not

installed correctly with a pressure-reducing regulator as needed.

Note: The regulator supplied with this product is NOT a

o If your standard delivery pressure is lower than 4-6 ounces per

square inch (7”-11” water column), you will need changes to your

natural gas service to provide elevated delivery pressure. In

addition you will need to have a pressure-reducing devices installed

for your other natural gas appliances.

Propane (LPG)

Hook-up

Contact your local propane supplier to install a propane fuel system for

the generator.

WARNING:

LPG is a highly explosive gas. A qualified propane technician

must make the valve and hose connection between the propane

tank and generator in accordance with all local regulations and

electrical codes. All LPG hook-ups should be completed by

trained personnel from propane supplier and inspected as

required by your local building code.

pressure-reducing regulator, but one can be supplied

and installed by your gas utility technician at the time

of fuel system hook-up.

14

Page 15

Installation / Initial Set-Up

♦ This product is designed to operate at an LPG gas pressure range of 7” to

11” of water column and requires a minimum LPG gas flow rate of 9.33

lb/hr, 2.2 Gal/hr, or 201,718 BTU/hr.

Note: All gas cylinders produce gas pressure in excess of 11” water

column. Introduction of gas pressure into the generator in

excess of 11” water column will permanently damage this

product and void the warranty. You will need a pressure-

♦ You will need a minimum 100 lb. LPG gas tank to operate the generator.

This generator will not work with 20-lb gas cylinders used in gas grills

and recreational equipment, or 40-lb gas cylinders used in forklifts and

tractors. These smaller gas tanks do not have a sufficient vaporization

rate to run the generator.

Some installations may require tanks even larger than 100-lb as a result

of low surrounding air temperature and other appliances drawing fuel

from the same tank.

reducing regulator installed as part of your LP gas fuel system.

15

Page 16

Installation / Initial Set-Up

4. Set-up either as a BUILDING BACK-UP or PORTABLE Power Source

This generator is designed to provide up to 13,000W of electrical power. It can supply electricity in

two ways:

1. As a back up, standby power source for a building. For this application, you must arrange

for a licensed electrician to connect the generator to your building’s electrical system via the

installation of an UL-approved transfer switch. The transfer switch must be installed in

accordance with building electrical code and guidelines supplied by your power company.

2. As a portable power source. You can plug appliances or tools directly into the generator’s

electrical outlets.

Specific requirements for each are given below.

Note: Regardless of whether you use your generator as a back-up power source connected to a

building or as a portable power source, you must not overload the generator. Overloading

may cause serious damage to the generator and attached electrical devices.

Using as a

Back-up Power

Source for a

Building

Contact a licensed electrician to install an UL-approved transfer switch if

you want to use your generator as a back-up power source for a building.

What does a transfer switch do? It:

a) Safely connects the generator to your building’s electrical system by

isolating your generator from your utility company’s power lines,

AND

b) Connects your generator to a critical subset of your building’s circuits

that are needed for emergency power needs.

If your generator will be connected to your building’s electrical system, it

MUST ALWAYS be isolated from the utility power grid with a UL-approved

transfer switch installed by a licensed electrician in compliance with all

applicable building and electrical codes, and in accordance with guidelines

supplied by your power company.

DANGER:

A transfer switch must be installed in order to isolate your

generator from the utility power grid. If your generator is NOT

properly isolated from the utility system, serious hazards will

arise:

When your generator is running, it’s output will back feed into

♦

the utility power line and transformer that are normally used to

provide you with power. The transformer will step up the

current to the normal line voltage. An unsuspecting utility line

worker working on what he thinks is a deactivated line could

be electrocuted.

♦ If your generator is connected (running or not) when utility

power is restored, your generator will be destroyed. It could

also explode or cause fire.

In addition to isolating your generator from the utility system, the transfer

switch connects your generator to a limited set of circuits in your building

that have been chosen as critical to operate during a power outage.

16

Page 17

N

N

R

R

Using as a

Portable Power

Source

Installation / Initial Set-Up

The generator cannot power your entire home -- you must work with the

installing electrician to determine which devices/appliances you wish to

power during an outage. The electrician can help you determine which

circuits and devices can be powered simultaneously without overloading the

generator.

(See the previous section of this manual entitled “Power Load Planning &

Management” for more information on load application and selection.)

When using the generator as a portable power source, you can plug

electric devices and appliances directly into the generator’s electrical

outlets.

There are four different kinds of electrical outlets on the generator:

1. One 120/240 Volt, 50 Amp straight-blade receptacle (NEMA 14-50R

receptacle compatible with NEMA 14-50P mating plug)

2. One 120/240 Volt, 30 Amp locking receptacle (NEMA L14-30R

locking receptacle compatible with L14-30P mating plug)

3. One 120 Volt, 30 Amp locking receptacle (NEMA L5-30R receptacle

compatible with NEMA L5-30P mating plug)

4. Two 120 Volt, 20 Amp duplex straight-blade receptacles (NEMA 5-

20R duplex receptacles compatible with NEMA 5-20P or 5-15P

mating plugs).

(2)

NEMA

5-20

Duplex

LP/N

NEMA

L5-30

EMA

L14-30R

(See more technical detail about these receptacles and their associated

circuit breakers in the “Machine Component Identification” section of this

manual.)

♦ Make sure you plug each electrical device/appliance into the correct

generator outlet based on the device’s plug configuration and

voltage/amperage rating. Never exceed the amperage rating of an outlet.

EMA

14-50R

17

Page 18

Installation / Initial Set-Up

♦ Extension cords may be used to power devices that are located at a

distance from the generator. However, use only UL-listed, outdoor-rated,

grounded extension cords of the proper size. Use Table 2 below to choose

an adequately sized extension cord according to the amperage of the

device being used and the length of the cord.

Table 2

♦ All extension and appliance cords must be in good condition and not worn,

Northern Tool is NOT responsible for damage or injury resulting from

customer use of inadequate extension cords.

Current/Power Maximum Extension Cord Length

Amps at

240V

Load

(watts)

#10 Ga.

Cord

#12 Ga.

Cord

#14 Ga.

Cord

#16 Ga.

Cord

10 2400 250' 150' 100' 75'

20 4800 125' 75' 50' 25'

30 7200 60' 35' 25' 10'

40 9600 30' 15' 10' *

50 12000 15' * * *

WARNING:

Use of under sized extension cords can cause electric shock,

fire, or damage to connected devices.

bare, frayed, or otherwise damaged.

WARNING:

Use of damaged electric cords can cause electric shock or fire.

Note: If an extension cord becomes hot to the touch, it is overloaded or

damaged and must be replaced.

18

Page 19

Installation / Initial Set-Up

5. Select a Suitable Site

Before using the generator, you must select a suitable OUTDOOR location for installation and

operation. This location should meet all of the criteria listed below.

WARNING:

You must choose a suitable site for operating your generator to avoid equipment

damage and/or injury and possible death from carbon monoxide poisoning, electric

shock, or fire. Choose a site that meets all of the criteria specified.

Dry, level surface The generator should be positioned on a dry, firm, level surface.

Ensure that the generator sits level and will not slide or shift during operation.

If applicable, block the generator’s wheels to prevent sliding and shifting.

Outdoors only –

dangerous carbon

monoxide exhaust

Adequate cooling

ventilation

WARNING: Carbon monoxide poisoning hazard

The exhaust from your generator contains carbon monoxide (CO), a

poisonous gas that can kill. You cannot smell it, see it, or taste it.

Carbon monoxide exhaust is given off whether you are using gasoline,

natural gas, or propane as the fuel source to power the generator.

Follow the directions below for choosing a location to operate your

generator in order to avoid carbon monoxide poisoning.

The location you choose to operate the generator must be OUTDOORS

and away from all air intakes:

• Never run the generator inside any closed or semi-enclosed spaces (even if

outdoors), including homes, garages, basements, sheds, or boxes. These

spaces can trap poisonous gases, even if you run a fan or open windows.

• Place the generator so that the exhaust fumes will not be directed towards

people or building air intakes.

• Ensure that working, battery-operated or battery back-up carbon monoxide

alarms are used in any dwelling/structure that is in close proximity to the

running generator.

• Note that this generator is NOT designed or approved for use in vehicles

or marine applications. Never run the generator inside RVs or other

vehicles, on boats, or on pick-up truck beds.

WARNING:

Never attempt to attach ductwork to the muffler system to allow

for installation inside an enclosure. This could cause hot air

deflection, heat build-up, and increased exhaust back-pressure,

resulting in possible exhaust leakage or damage to the generator.

The generator needs adequate, unobstructed flow of air to allow for

proper cooling of engine and generator head.

WARNING:

Heat build-up from inadequate ventilation can result in fire, posing a

serious risk to nearby persons and structures.

• Situate so there is adequate clearance around generator to allow for

cooling airflow so that heat does not build up.

19

Page 20

Installation / Initial Set-Up

• Never place the generator immediately adjacent to a building or other

structure – allow at least a 7’ clearance.

• Do not run the generator in close proximity to other heat-generating

equipment, such as another generator. The combined heat that is

generated may raise air temperature in the immediate area and there will

not be adequate cooling ventilation.

• Do not allow debris to accumulate and block airflow.

• Do not operate with a tarp, blanket, or cover surrounding the generator.

No wet conditions Choose a location where the generator will NOT be exposed to rain,

snow, or direct sunlight. Exposure to water can cause electric shock.

You may operate the generator under an outdoor, canopy-like structure of

heat-resistant material that is open on all sides. Make sure that all parts of

canopy are at least 7’ from exhaust, and allow for adequate clearance above

generator so that heat does not build up.

Hot exhaust

clearance

Away from

dust/dirt

Hearing

protection

The exhaust gas from your generator is extremely hot and can cause

combustible materials to catch on fire.

• Make sure your generator’s exhaust system is at least 7 feet from all

combustible materials and buildings/structures.

• Equip the engine with a spark arrestor if the generator will be used near

any ignitable forest, brush, or grassy land. (See the “Specifications”

section of this manual to determine if your generator is already equipped.)

Make sure you comply with applicable local, state, and federal codes.

• Keep a fire extinguisher rated “ABC” nearby. Keep it properly charged

and be familiar with its use.

Do not use the generator in extremely dusty or dirty conditions.

Excessive dust and dirt can cause premature failure of the machine.

Generators can produce noise levels of up to 95 dB in close proximity,

which can be dangerous to human hearing with prolonged exposure.

Hearing protection may be required for persons working within 15-20 feet of

the running generator for an extended period of time.

WARNING:

Never attempt to attach ductwork to the muffler system to lower noise

levels. This could cause hot air deflection, heat build-up, and

increased exhaust backpressure, resulting in possible exhaust leakage

or damage to the generator.

20

Page 21

Installation / Initial Set-Up

t

d

6. Grounding the generator

Always ensure the generator is properly grounded to prevent electrical shock.

You must always ground the generator by the following method when using the generator as a

portable electrical source:

1) Drive a ¾” or 1” copper pipe or rod into the ground close to the generator. The pipe/rod

must penetrate moist earth – the depth required will be dictated by local soil conditions.

Consult with an electrician.

2) Connect an approved ground clamp to the pipe.

3) Run a 10 gauge wire from the clamp to the generator grounding post located on the rear of

the generator head.

4) Do not connect the generator grounding post to a water pipe or a ground used by a radio

system.

10 Ga.

wire

If a licensed electrician installs the generator with a connection to your building’s electrical circuit

for use as a back-up power system, grounding may alternatively be completed through the

building’s grounding system. Ask your electrician. If the generator is not grounded through your

building’s electrical system, follow the procedure above.

Grounding

Pos

Groun

Copper

Pipe/Rod

WARNING:

Operating the generator when it is not properly grounded can result in electrical shock.

21

Page 22

Installation / Initial Set-Up

r

7. Battery Installation

Your generator’s engine is equipped with an electric starter which requires the installation of a 12volt lawn tractor size battery (Group U1). See the “Specifications” section of this manual for more

specific battery requirements for this generator model, such as minimum amperage or CCA rating.

The battery is to be supplied by the customer and should be installed in the protective battery box

located near the engine. Follow the instructions detailed below for connecting and disconnecting

the battery.

WARNING: Battery hazards

Batteries are hazardous because they contain caustic acid, can emit explosive gases, and can

cause electric shock. Caution must be exercised when making connections to a battery to

avoid shock and contact with the acid, and to prevent any sparking that could lead to an

explosion.

ALWAYS follow the general battery safety rules and instructions listed below.

General Battery

Safety Rules

Connecting the

battery

Disconnecting the

battery

Installing the

spark arrestor

• ALWAYS use eye protection when handling batteries.

• NEVER smoke or work near sparks or other sources of ignition.

• NEVER touch both battery terminals at the same time with your hand or

any non-insulated tools.

• If battery acid contacts skin or clothing, flush immediately with water and

neutralize with baking soda.

Always connect the cables in the following sequence to avoid possible shock:

1. Find the battery cables located inside the battery box.

2. Connect the red cable to the positive(+) terminal of the battery.

3. Then connect the black cable to the negative(-) terminal of the battery.

Always disconnect cables in the following sequence to avoid possible shock.

1. First, disconnect the black cable from the negative(-) terminal of the

battery.

2. Next, disconnect the red cable from the positive(+) terminal of the

battery.

8. Spark Arrestor Installation

1. Push spark arrestor into outlet

pipe.

2. Attach the spark arrestor to the

outlet pipe with screw as

shown. (Screw is designed to

drill through the outlet pipe.)

3. Maintenance – Remove

arrestor and clean screen

annually or as required.

Outlet pipe

Arresto

Screw

22

Page 23

Operation

Once you have set up your generator for use, it is time to start your generator. The following

are the procedures necessary for safe, successful operation of your generator.

Operation Procedures

1. General Safety Rules for Operation

2. Preparing for Operation

3. Starting the Engine:

a) Using LP/NG

b) Using Gasoline

4. Checking Generator Output

5. Connecting Electrical Loads (Portable Power Generation)

6. Switching Fuels:

a) From LP/NG to Gasoline

b) From Gasoline to LP/NG

7. Stopping

8. Storage & Exercise of Generator

Each of these procedures is discussed in detail below:

1. General safety rules for operation

Before starting the generator, review the following general safety rules for operation:

• Know proper use/how to stop. Be thoroughly familiar with proper use of the equipment and all

• Instruct operators. The generator owner must instruct all operators in safe generator set-up and

• Intended use. Carefully read about and understand the intended use of this generator. Do not

• Under the influence. Never operate, or let anyone else operate, the generator while under the

• Safety equipment / controls. Do not operate the generator unless all safety covers, guards, and

• Damaged. Do not operate the generator with damaged, missing, or broken parts.

• Modifications. Do not modify the generator in any way. Modifications can create serious

• Engine speed. Never attempt to modify the engine speed setting. The engine speed is preset at

WARNING:

Failure to follow safety rules may result in serious injury or death to the operator or

bystanders.

generator controls, output receptacles, and connections. Know how to stop the generator quickly

if needed (see “Operation, Step 7 - Stopping the Engine”).

operation. Only trained adults should set up and operate the generator – Do not let children

operate.

use for other purposes, as unforeseen hazards or equipment damage may result.

influence of alcohol, drugs, or medication.

barriers are in place and in good working order, and all controls are properly adjusted for safe

operation.

safety hazards and will also void the warranty.

3600 RPM for safe and optimal performance of the generator. If speed needs adjusting, it must

23

Page 24

Operation (cont’d)

be done by factory-authorized personnel.

• External fuel sources. Never attempt to connect external gasoline/diesel sources in order to

increase engine run time. Larger tank at pressure or higher elevation will cause gasoline to leak

from carburetor during operation. Fire or explosion could result.

• Malfunction during operation. Immediately turn off the generator if any of the following

conditions arise during operation:

o Excessive change in engine speed, slow or fast

o Overheating in load connecting devices

o Sparking or arcs from generator

o Loss of electrical output

o Receptacle damage

o Engine misfire

o Excessive vibration

o Flame or smoke

o Abnormal noise

• Adjusting / repairing. Always turn off generator and remove spark plug(s) or spark plug

wire(s) before working on the generator to prevent accidental starting. Always discharge the

capacitor before working on the generator head to prevent electrical shock. (See Maintenance &

Repair section of this manual for instructions on how to do this.)

• Carbon monoxide poisoning. The running engine gives off carbon monoxide, a poisonous gas

that can kill you. You CANNOT smell it, see it, or taste it. Follow all instructions for site

selection and positioning the generator, and avoid inhaling the exhaust. If you start to feel sick,

dizzy, or weak while using the generator, shut off the engine and get to fresh air RIGHT AWAY.

See a doctor. You may have carbon monoxide poisoning.

• Other exhaust dangers. This product contains or emits chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm. Avoid inhalation of

exhaust.

• Wet conditions. Do not operate the generator or handle any electrical equipment while standing

in water, while barefoot, while hands are wet or while in the rain or snow. Electric shock may

result.

• Ground fault circuit interrupter. Always use a ground fault circuit interrupter (GFCI)

protected extension cord (or outlet, if generator is equipped) in damp or highly electrical

conductive areas and on construction jobsites to prevent electrical shock.

• Avoid contact. Avoid contact with bare wires, terminals, connections, etc. while the unit is

running.

• Electric shock accident. If an electric shock accident occurs, immediately shut down the source

of electrical power. If this is not possible, attempt to free the victim from the live conductor.

Avoid direct contact with victim. Use a nonconducting implement, such as a dry rope or board,

to free the victim from the live conductor. Apply first aid and get immediate medical help.

• Smoking/sparks. Never smoke near the running generator, and never operate near sources of

sparks or flames.

• Hot muffler. Never touch hot muffler, hot exhaust manifold, or engine cooling fins. Exhaust

and engine parts can be very hot and will burn you.

• Moving parts. Keep hands, feet, and apparel away from drive belts, fans, and other moving

parts. Never remove any drive belt or fan guard while the unit is operating

24

Page 25

Operation (cont’d)

Static electricity and filling the gasoline tank:

Static electricity can initiate from ungrounded gasoline tanks or containers, from flowing

Static electricity can explosively ignite gasoline vapors that are present during the fueling process,

resulting in serious burns to nearby persons. To avoid static electricity while fueling, certain steps

must be followed before and during the fueling process in order to minimize and safely dissipate

static charge build-up:

• Touch a grounded metal object before starting. Always dissipate static charge from your

body before beginning the fueling process by touching a grounded metal object at a safe

distance away from fuel sources.

• Use a portable container to fill tank. Never fill the generator’s gas tank directly from the

fuel pump – the generator’s tank is not grounded and the high velocity flow of gasoline from a

fuel pump can cause static electric build-up. Use an approved portable container to transfer

gasoline to the generator’s tank.

• Fill container on the ground. Never fill the portable gas container while it is sitting inside a

vehicle, trailer, trunk, or pick-up truck bed. ALWAYS place container on the ground to be

filled.

• Keep nozzle in contact with container. Keep nozzle in contact with the portable container at

all times while filling. Manually control the flow of gasoline; do NOT use the nozzle’s lockopen device.

• Use a portable container made of metal or conductive plastic. It will dissipate charge to

ground more readily.

About static electricity and fueling

Many common objects can accumulate and retain a static electric charge. Objects made of non-conductive

materials (e.g. plastics) easily accumulate and retain static electric charge, as can objects made of conductive

material (e.g. metal, water) if they are not electrically grounded. The static electric charge on an object, such

as a human body or plastic fuel tank/container, can reach as high as several thousand volts!

A static electric spark can be generated if the static electric charge stored on an object “jumps” to another,

less charged object. Such a spark can ignite invisible gasoline vapors that are present during fueling

situations.

Typical sources of static electric hazards during fueling

The following objects can accumulate a static electric charge and cause an ignition spark in typical fueling

situations:

1) Ungrounded tanks/containers. Any ungrounded fuel tank or container can accumulate a static electric

2) Flowing gasoline. Most people are not aware that gasoline accumulates static electric charge while

Persons. A person dispensing the gasoline can carry a static electric charge on their body, typically

3)

charge as a result of contact with other objects or friction during transportation. This static electricity

can discharge as a spark to the grounded gasoline dispenser nozzle, as the nozzle is first brought close to

the tank/container at the beginning of the fueling process.

flowing through a hose or pipe. This charge then transfers to and accumulates in the gas tank or container

that is being filled. The total amount of charge accumulation depends on the amount of gas pumped into

the container, the speed with which it is pumped, and whether or not the tank/container is grounded. If

sufficient static electric charge accumulates in the fuel tank or container during the fueling process, the

tank/container may discharge a spark to the grounded gasoline dispenser nozzle.

resulting from contact with their car seat or electronics. The static electricity can discharge as a spark

between that person’s hand and either the grounded dispenser nozzle or the fuel tank opening.

gasoline, and from persons carrying a static electric charge

25

Page 26

Operation (cont’d)

2. Preparing for Operation

Position

generator

Ground

generator

Perform

scheduled

maintenance as

needed

Check/add oil Check the oil level us ing the dipstick and add oil as needed.

Position generator in accordance with the instructions given in

“Installation & Initial Set-up, Step 5: Select a Suitable Site” of this

manual.

Operate outside only, on dry, level ground with adequate clearance and

ventilation.

WARNING: Carbon monoxide poisoning hazard

Generators give off carbon monoxide exhaust, a poisonous gas that can

kill. You CANNOT smell it, see it, or taste it. ONLY run generator

OUTDOORS and away from air intakes. NEVER run generator inside

any enclosed or semi-enclosed spaces, including homes, garages,

basements, sheds, boxes, pick-up truck beds, RVs, or boats. These spaces

can trap poisonous gases, EVEN if you run a fan or open windows.

Carbon monoxide exhaust is given off whether you are using gasoline,

natural gas, or propane to power the generator.

Make sure the generator is grounded in accordance with instruction given

in “Installation & Initial Set-up, Step 6: Grounding the Generator” of

this manual.

WARNING: Electric shock hazard

Always ensure generator is properly grounded to prevent electrical shock.

Make sure that any regular maintenance has been performed as prescribed

in this manual in the “Maintenance & Repair” section.

1. Refer to the engine owner’s manual for engine maintenance instructions.

2. Make sure battery is charged. Charge as needed according to your

battery manufacturer’s instructions.

Using a funnel, add oil up to the FULL mark on the dip stick with the

recommended oil type for your engine and expected ambient conditions.

(See engine Owner’s Manual for oil type and capacity, and more detailed oil

check/fill instructions.)

WARNING: Burn hazard

Never open oil port while engine is running. Hot oil can spray over face

and body.

Notes:

o Low oil shutdown feature prevents the generator from starting without

sufficient oil.

o Engine is shipped without oil. You must add oil before first use.

IMPORTANT:

Under long, continuous-run operating conditions, be prepared to:

• Check engine oil level every time you refuel the engine if using gasoline,

or every 24 operating hours if using NG/LPG.

• Change oil after the first 20 operating hours, and at least every 100

operating hours thereafter, or as directed in engine owner’s manual.

26

Page 27

Operation (cont’d)

Fill gasoline

tank (if using

gasoline)

Check the gasoline level in the generator’s tank if you will be operating the

generator on gasoline.

If needed, fill tank with fresh unleaded gasoline from a portable container,

after first reading the warnings and instructions below.

WARNING: Gasoline fire/explosion hazard

Gasoline is highly flammable and explosive. Heat, sparks, and flames

can ignite gasoline vapors, which can become widespread during fueling.

A flash fire and/or explosion could result and cause serious injury or

death. Use extreme care when handling gasoline. Carefully follow all

the instructions in this section to avoid the following conditions which

could result in gasoline ignition:

• gas vapor collection inside enclosures

• static electric sparks

• sparks from electric wiring, batteries, or running engines

• sources of heat (such as a hot engine or exhaust)

• open flames, including pilot lights

1) Before starting, review the following general safety precautions for fueling:

a) Never pump gasoline directly into the generator’s gas tank at a gas station –

high velocity flow from the pump could result in a static electric build-up

in the generator’s tank. Always use a portable container to fill the tank.

See warning box about static electric spark hazards below.

b) Fill gasoline tank OUTDOORS – never indoors.

c) Stay away from all sources of heat, sparks, and flames. Do not smoke.

2) Turn generator engine off and allow to cool for at least two minutes before

removing gas cap.

Note: A running or still-hot engine is hot enough to ignite fuel.

3) Remove generator gasoline cap.

4) Add gasoline through the fill opening:

- Use only a UL-approved portable gasoline container to transfer the gasoline

to the generator’s tank. Follow the safety warning and instructions below

for avoiding static electric sparking.

- Do NOT overfill the gasoline tank. Allow at least 1/2” of empty space

below the fill neck to allow for fuel expansion.

WARNING: Static electric spark hazard

A static electric spark can explosively ignite gasoline vapor,

resulting in a flash fire that could cause serious injury or death.

To avoid static electric sparking while filling the gasoline tank, the

following steps must be followed to minimize and safely dissipate

static electric charge build-up before and during the fueling

process:

• Always dissipate static charge from your body before beginning

the fueling process by touching a grounded metal object at a safe

distance from fuel sources.

• Never fill the generator’s gas tank directly from the fuel pump – the

27

Page 28

Start LPG/NG

supply

(if using)

Operation (cont’d)

generator’s tank is not grounded and high velocity flow from the

pump can cause static electricity build-up. Use an approved

portable container to transfer gas to the generator’s tank.

• Never fill the portable gas container while it is sitting inside a

vehicle, trailer, trunk, or pick-up truck bed. ALWAYS place

container on the ground to be filled.

• Keep nozzle in contact with portable container while filling.

Manually control the flow of gasoline; do NOT use nozzle’s

lock-open device.

• A portable container made of metal or conductive plastic is

preferred because it dissipates charge to ground more readily.

5) Clean up gasoline spills /splashes immediately.

• If possible, move the generator away from spilled gasoline on the

ground.

• Wipe up spilled gasoline, and wait 5 minutes for excess gasoline to

evaporate before starting engine.

• Gasoline soaked rags are flammable and should be disposed of properly.

• If gasoline is spilled on your skin or clothes, change clothes and wash

skin immediately.

6) Replace gasoline cap securely before starting engine.

7) Store extra gasoline in a cool, dry place in an UL-approved, tightly sealed

container.

IMPORTANT:

For continuous operation, be prepared to check and refuel the engine on a

regular basis. A tank of gasoline should last about 4 hours under 100%

load, and about 8 hours under 50% load.

Propane (LPG):

1) Make sure the fuel hose is securely connected to the propane tank regulator

on one end, and the ¾” NPT gas inlet on the generator base on the other end.

2) Open the propane tank main valve.

3) Check ¾” NPT gas inlet connection for leaks each time you connect. Use the

leak test method described below.

Natural Gas:

1) Make sure the gas line is securely connected to the ¾” inlet on the generator

base.

2) Open line valve, if gas line is so equipped.

Check ¾” NPT gas inlet connection for leaks each time you connect. Use the

leak test method described below.

28

Page 29

Operation (cont’d)

Inspect Fuel

System / Check

for Leaks

Personal

Protection

Inspect fuel system & check for leaks BEFORE starting generator.

Do not start generator until all needed repairs have been completed.

WARNING: Fuel leak hazard

Gasoline, LP gas (propane) and NG (natural gas) are highly explosive and

fuel leaks can result in fire or explosions. You can be burned and

seriously injured if the fuel system is not properly hooked up or there is a

fuel leak when you start the engine.

1) Inspect the entire fuel system. Look for: Signs of leaks or deterioration,

chafed or spongy fuel hose, loose connections, loose or missing fuel hose

clamps, a damaged gasoline tank, or a defective gasoline shut-off valve.

2) If you are using LPG or NG, check for leaks after opening supply valve:

a) Leak test method. Test for leaks on a regular basis by applying a soap

and water solution over pipes, hoses, and connections. Soap bubbles will

form if there is a leak. Use this method to test after each reconnection to

NG/LPG supply (for example, after moving the generator), and on a

regular basis thereafter. This method will help you detect small leaks.

b) Also beware of gas odor. Both LP and NG have an odorant added (rotten

egg/sulfur smell) that will aid in the detection of more dangerous

quantities of leaking gas. Note:

• Natural gas. Natural gas is lighter than air and tends to collect in high

areas.

• LP gas (propane). LP gas is heavier than air and tends to settle in low

areas. Smell next to floor for gas.

If you smell gas, DO NOT start engine! DO NOT light a match. DO NOT flip

on an electrical switch. If possible, shut off LPG or NG supply. Exit area

immediately and call gas supplier or fire department.

1) Hearing can be damaged from prolonged, close-range exposure to the type of

noise produced by this generator. The use of ear plugs or other hearing

protection device is recommended for persons working within 15-20 feet of

the running generator for an extended period of time.

2) Loose or dangling apparel can become entangled in moving parts. Metal

jewelry can conduct electricity. Never wear jewelry or loose-fitting

clothing when starting or operating the generator.

29

Page 30

Operation (cont’d)

A

t

w

3. Starting the Engine

After you have completed the pre-start checklist procedures, you are ready to start the engine.

The following directions detail how to start the engine with either LP/NG or Gasoline as the fuel

source:

Using LP/NG To start engine using LP or Natural Gas:

WARNING:

DO NOT start engine if you smell gas. Exit area immediately

and call gas supplier or fire department. If possible, shut off

gas supply.

1) Disconnect all loads to the generator.

2) Flip fuel selector switch to the LP/NG position.

3) Start the engine:

a) Turn the engine key switch to the START position and hold it there

until the engine starts.

b) When the engine starts, release the key, allowing it to return to the

ON position.

4) It may be necessary to momentarily depress the primer button while

starting the engine, especially for cold starts.

NOTE: If you have trouble starting the engine with LP/NG, you may

need to adjust the load block:

a. Loosen the lock nut, then turn the adjustment screw clockwise

until resistance is felt. At this point the load block is

completely shut-off.

djustmen

Scre

Lock Nut

b. While LP or NG is being supplied to the generator, turn the

ignition key to the start position and slowly turn the adjustment

screw counterclockwise until the engine starts. (Depress the

primer button when cold starting the engine.)

c. Once the engine is running, turn the adjustment screw very

slowly to smooth out engine performance.

d. Once the proper setting is achieved turn the brass lock nut to

secure the adjustment screw.

30

Page 31

Operation (cont’d)

5) Under long, continuous-run operating conditions, be prepared to:

a) Check engine oil level every 24 operating hours,

b) Change oil after the first 20 operating hours, and at least every 100

Using Gasoline To start engine using gasoline:

1) Disconnect all loads to the generator.

2) Flip the fuel selector switch to the GASOLINE position.

3) Turn the gasoline line valve to the ON position.

4) For cold engine, move choke lever to full choke position. To restart a

5) Start the engine:

6) When engine starts, move choke lever to RUN position.

7) Under long, continuous-run operating conditions, be prepared to:

operating hours thereafter, as directed in the engine owner’s manual.

WARNING:

Never open oil port while engine is running. Hot oil can spray

over face and body.

warm engine, move choke lever to half choke or to RUN position.

a) Turn the engine key switch to the START position and hold it there

until the engine starts.

NOTE: If the engine fails to start after 5 seconds, release key and

wait 10 seconds before attempting to start again. Cranking

the electric starter for more than 5 seconds continuously

can overheat and damage the starter motor.

b) Release the key when the engine starts.

a) Check and refuel the engine on a regular basis. A tank of gas should

last about 4 hours under 100% load, and about 8 hours under 50%

load. See engine owner’s manual for more detail.

WARNING:

A running engine is hot enough to ignite fuel. Never add

fuel or remove gas cap if engine is running or still hot.

Let cool at least 2 minutes.

b) Check engine oil level each time you refuel.

c) Change oil after the first 20 operating hours, and at least every 100

operating hours thereafter, as directed in the engine owner’s manual.

WARNING:

Never open oil port while engine is running. Hot oil can

spray over face and body.

31

Page 32

Operation (cont’d)

4. Checking Generator Output

Although the speed of the engine was carefully adjusted at the factory so that the generator

produces the proper voltage and frequency, output voltage should be checked periodically to

ensure the generator is working properly before connecting loads to the generator.

Output voltage should be checked with a portable voltage meter:

1. Start engine and allow to warm up for five minutes. Do not connect any loads.

2. Use voltage meter to check output voltage

at the generator’s outlets/receptacles.

3. Measured voltage should be within the

following ranges:

4. If measured voltage is not within the specified range, have generator adjusted by factory

authorized personnel. Do not attempt to adjust the engine speed yourself.

WARNING:

The generator must be run at the correct speed in order to produce the

proper electrical voltage and frequency. Failure to do so could result

in damage to equipment powered by the generator and possible injury

to the individual.

a. 120V +/- 10% at 120V receptacles.

b. 240V +/- 10% at 240V receptacles.

NOTE:

Slight variation in

voltage/speed with

changing electrical

loads

All engines have a tendency to slow down when a load is applied. When

electrical loads are connected to the generator, the engine is more heavily

loaded and as a result the speed drops slightly.

This slight decrease in speed, together with the voltage drop within the

generator itself, results in a slightly lower voltage when the generator is

loaded to its full capacity than when it is running with no load.

Additionally, there may be small brief surges and drops in voltage as motors

connected to the generator cycle on or off.

The slight variation has no appreciable effect in the operation of motors,

lights, and most appliances.

32

Page 33

Operation (cont’d)

5. Connecting Loads

You will want to be careful when connecting loads so as not to overload the generator, especially if

you are powering devices with motors that require a higher starting power load.

Instructions are provided below for connecting loads when you are using the generator:

o As a portable power source

o Connected to a building as a back-up power source

Using as a

Portable Power

Source

Using as a

Back-up Power

Source for a

Building

WARNING:

Do not overload generator. Make sure that combined starting and running

loads do not exceed rated capacity of generator. Overloading the generator

can cause damage to the generator and attached electrical devices, and may

result in fire.

Connect electrical loads one at a time according to the following

instructions:

1. Allow engine to reach operating speed by allowing it to warm up for

approximately 5 minutes before connecting electrical devices.

2. After engine is warmed up, begin by connecting the items that require

the highest wattage first. The recommended sequence is as follows:

a. Connect items with motors such as refrigerators, freezers, air

conditioners, or small hand tools, one at a time. Let each motor

stabilize before connecting the next device.

b. Connect any lights you are planning on powering.

c. Connect voltage sensitive equipment such as electronics via surge

protectors. Plug devices such as TV’s, computers, and microwaves

into a UL listed voltage surge protector, then plug the surge

protector into the generator.

Each transfer switch installation will be unique.

Proper instructions for how to safely bring the generator online with the

building’s electrical system should be provided by the installing electrician,

who should also provide personal instruction to the owner/operator.