North Star M157305H User Manual

Quick Facts

Pump Oil

Pump is shipped with oil. Change oil plug and check pump oil level before starting.

Use Universal Tractor Transmission Oil (UTTO) or Mobil1 Synthetic15w50 for Comet

pumps and Cat pump oil (item# 22158) for Cat oil changes.

Water

Make sure your water flow is 20% higher than the pressure washer’s flow rate.

Make sure your water is clean and particle free.

Storage

Do not allow water to freeze in the pump, hose, coil, or spray gun.

Spraying

Chemicals

Use any NorthStar brand or equivalent pressure washer chemicals.

Maintenance

Schedule

Pump Oil: change after first 50 hours, then every 3 months or 500 hours.

Read and understand all manuals before operating.

ITEM NUMBER: 157305,306,307,308

SERIAL NUMBER:

HP:______ Volts:______ Amp:______ Ph:_____

RPM:____ PSI:____ GPM:____ Nozzle Size:_____

Pump:___________ Hose:______ Lance:_______

Max. Discharge Temperature:_____________

M157305R.2

Installation, Operation, and Maintenance Manual

HOT WATER PRESSURE WASHER:

Cleans dirty surfaces with high-pressure hot water.

To the Owner:

Thank you for purchasing a NorthStar hot water pressure washer. Your machine is designed for long life,

dependability, and the top performance you demand! Take time now to read through this manual so you will

better understand the machine’s operation, maintenance and safety precautions. Everyone who operates this

machine must read and understand this manual. The time you take now will prolong your machine’s life and

prepare you for its safe operation. Enjoy the exceptional performance of your NorthStar hot water pressure

washer, the industry leader! The manufacturer reserves the right to make improvements in design and/or

changes in specifications at any time without incurring any obligation to install them on units previously sold.

Any Questions, Comments, Problems or Parts Orders

NorthStar Product Support 1-800-270-0810

2

Table of Contents

Important Safety Instructions

2

Safety Features

13

Grounding Instructions

3

Maintenance Instructions

13-17

Extension Cords

3

Moving and Handling Instructions

18

Specifications

4

Long Term Storage

18

Machine Component Identification

5

Troubleshooting

19

Installation Instructions

6-9

Parts Breakdowns

20-22

Operation Instructions

10-12

Wiring Diagram

23-25

Limited Warranty

26

Important Safety Instructions

WARNING -Risk of Injection or Injury to Persons - Do Not Direct Discharge Stream at Persons - Do not use a

hose if exterior damage is evident.

-Risk of explosion - Do not spray flammable liquids - Do not operate in a flammable environment.

CAUTION -Risk of Asphyxiation - Exhaust fumes are deadly. For outdoor use only. Avoid inhaling exhaust

fumes.

-Risk of fire. Do not add fuel when the product is operating or hot.

-Gun kicks back. Hold with both hands.

-To reduce the risk of injury, read operating instructions carefully before use.

WARNING - When using this product basic precautions should always be followed, including the following:

1.) Read all the instructions before using the product.

2.) To reduce the risk of injury, close supervision is necessary when the product is used near children. Do

not allow irresponsible use by children. Always stop the product and bleed pressures before leaving

unattended, disconnecting hoses, or servicing the pump.

3.) Know how to stop the product and bleed pressures quickly. Be thoroughly familiar with the controls.

4.) Stay alert - watch what you are doing.

5.) Do not operate the product when fatigued or under the influence of alcohol or drugs. Never smoke while

operating or fueling this machine.

6.) Keep operating area clear of all persons.

7.) Do not overreach or stand on unstable support. Keep good footing and balance at all times. Wear

footwear capable of maintaining a good grip on wet surfaces - Do not place the machine on soft or

unstable ground.

8.) Follow the maintenance instructions specified in all manuals. Do not run machine without sufficient

lubrication or sufficient water to cool the pump.

9.) Wear safety glasses, gloves, face protection and appropriate clothing when operating the machine.

10.) Do not operate this machine with broken or missing parts - Never alter the manufacturer’s original design

or deactivate any safety device on the machine.

11.) Risk of exposure to dangerous chemicals. Wear protective gloves when handling and cleaning with

chemicals. Follow the chemical manufacturer’s directions. Understand all safety hazards and first aid for

all chemicals being used. Check whether dangerous chemicals have been used and take any

precautions that may have been recommended by the supplier of these chemicals when cleaning filters.

Do not pump highly abrasive fluids or use with incompatible chemicals or solvents.

12.) Know the pressure and temperature limits of your machine. Be sure all high pressure accessories meet

or exceed your machine’s limits. Do not set the pressure relief valve above the machine’s limit.

13.) Do not move this machine by pulling on the hose. Do not use the pump to support other items of

equipment that impose unacceptable loads on the pump. Do not attempt to use this machine as a prop.

14.)To reduce risk of injury, do not secure the spray gun open. Your spray gun is equipped with a built-in

trigger safety latch to guard against accidental trigger release and potentially dangerous high pressure

spray. Rotate the safety latch to the locked position when not spraying.

15.) Do not clean this machine with its own spray. Cleaning should be done with a damp sponge with the

motor OFF.

16.) NEVER attempt to immediately run or re-light the burner if it doesn’t ignite the first time. Unburned oil or

gas may have accumulated causing potential explosion or fire hazard.

17.) Always make sure all switches and controls are in the OFF position prior to plugging in the electrical

cord. Do not stand in water while plugging and unplugging electrical cord.

18.) This product is provided with a ground fault circuit interrupter built into the power cord plug. If

replacement of the plug or cord is needed, use only identical replacement parts.

3

Grounding Instructions

This product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electrical shock. This product is equipped with a cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

DANGER - Improper connection of the equipment - grounding conductor can result in a risk of electrocution. Check with a

qualified electrician or service personnel if you are in doubt as to whether the outlet is properly grounded. Do not modify

the plug provided with the product. If it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not

use any type adapter with this product.

1. For a product rated 125 volts or less:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

This pressure washer is provided with a ground fault circuit interrupter (GFCI) built into the plug of the power supply cord.

This device provides additional protection from the risk of electric shock. Should replacement of the plug or cord become

necessary, use only identical replacement parts that include GFCI protection.

2. For a product rated more than 125 volts:

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION

To comply with the National Electric Code (NFPA 70) and to provide additional protection from the risk of electric shock,

this pressure washer should only be connected to a receptacle that is protected by a ground fault circuit interrupter (GFCI).

Extension Cords

Use only 3-wire extension cords that have 3 prong grounding-type plugs and 3-pole cord connectors that accept the plug

from the product. Use only extension cords that are intended for outdoor use. These extension cords are identified by a

marking “Acceptable for use with outdoor appliances; store indoors while not in use.” Use only extension cords having an

electrical rating not less than the rating of the product. Do not abuse extension cord and do not yank on any cord to

disconnect. Keep cord away from heat and sharp edges. Always disconnect the extension cord from the receptacle before

disconnecting the product from the extension cord.

Warning - To reduce the risk of electrocution, keep all connections dry and off the ground. Do not touch plug with wet

hands.

SAVE THESE INSTRUCTIONS

4

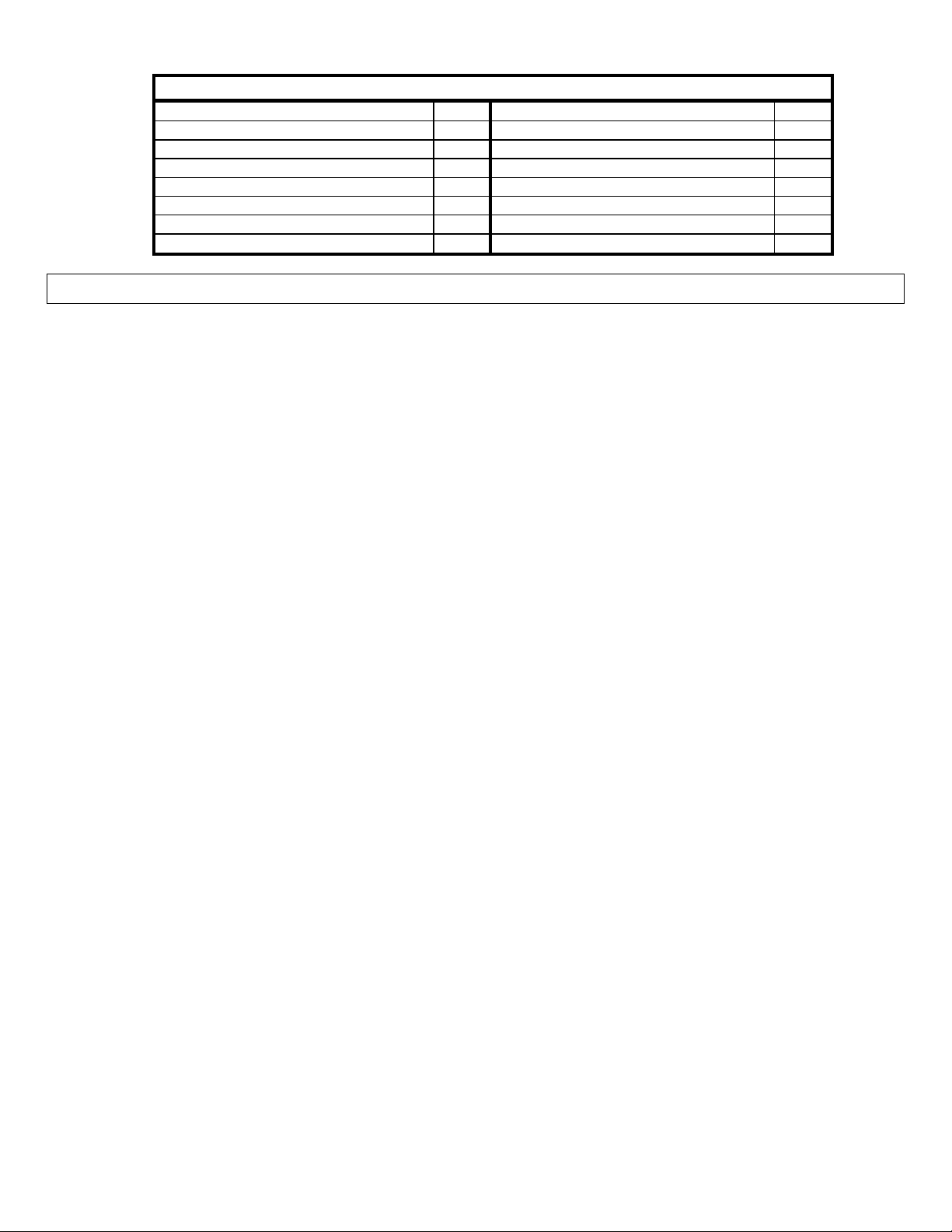

Item Number

157305

157306

157307

157308

Pressure Rating

1700 psi

2700 psi

2000 psi

2750 psi

Flow Output

1.5 gpm

2.5 gpm

1.5 gpm

2.5 gpm

Pump Type

Ceramic Triplex

Plunger

Ceramic Triplex

Plunger

Ceramic Triplex

Plunger

Ceramic Triplex

Plunger

Water Supply

Standard tap water @

20-100psi

Standard tap water @

20-100psi

Standard tap water @

20-100psi

Standard tap water @

20-100psi

Motor Horsepower

1.5 hp

5 hp

2.0 hp

5 hp

Maximum

Temperature

250F

250F

250F

250F

Approved Fuels

#1 or 2 Diesel,

Kerosene, Fuel Oil

#1 or 2 Diesel,

Kerosene, Fuel Oil

#1 or 2 Diesel,

Kerosene, Fuel Oil

#1 or 2 Diesel,

Kerosene, Fuel Oil

Fuel Capacity

8.25 gal.

8.25 gal.

8.25 gal.

8.25 gal.

Discharge Hose

3/8” x 50’

3/8” x 50’

3/8” x 50’

3/8” x 50’

Power

Requirements

Dedicated NEMA

Receptacles

5-20R

6-30R

5-20R

6-30R

Volts

115V

230V

115V

230V

Amps

20A

30A

20A

30A

Hertz

60Hz

60Hz

60Hz

60Hz

Phase

single

single

single

single

Dimensions

Length

38”

38”

38”

38”

Width

26”

26”

26”

26”

Height

43”

43”

43”

43”

Ship Weight

385 lb.

415 lb.

385 lb.

415 lb.

Specifications

5

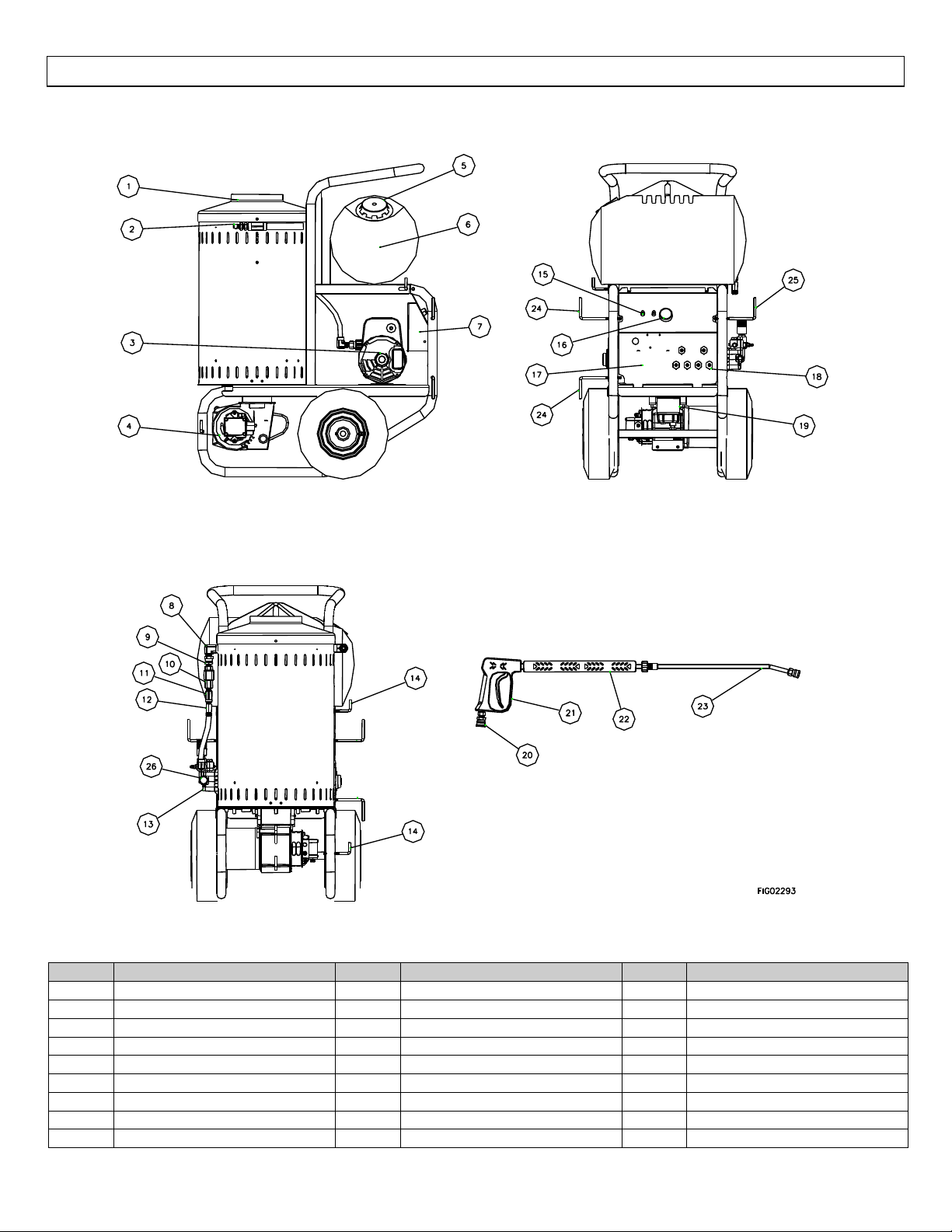

Machine Component Identification

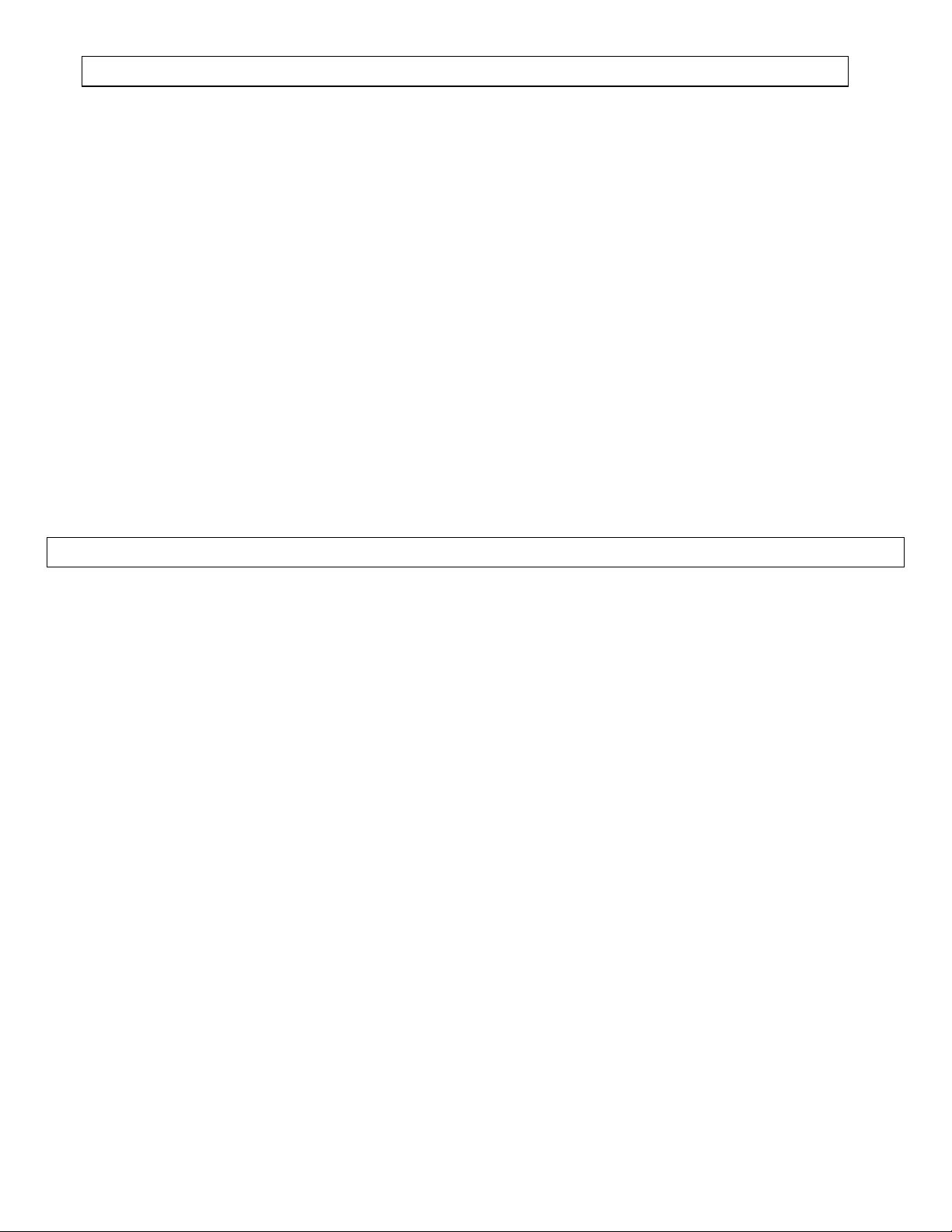

Ref #

Description

Ref #

Description

Ref #

Description

1

Exhaust Vent

10

Flow Switch

19

Fuel Filter

2

High Pressure Water Outlet

11

Tee

20

Quick Connector

3

Motor

12

Safety Relief Valve

21

Spray Gun

4

Burner

13

Pump

22

Grip

5

Fuel Fill Cap

14

Gun Hooks

23

Lance Wand

6

Fuel Tank

15

Power Switch

24

Power Cord Hangers

7

Control Box

16

Thermostat

25

High Pressure Hose Hanger

8

Elbow

17

Service Panel

26

Garden Hose Water Inlet

9

Swivel Fitting

18

Nozzles

6

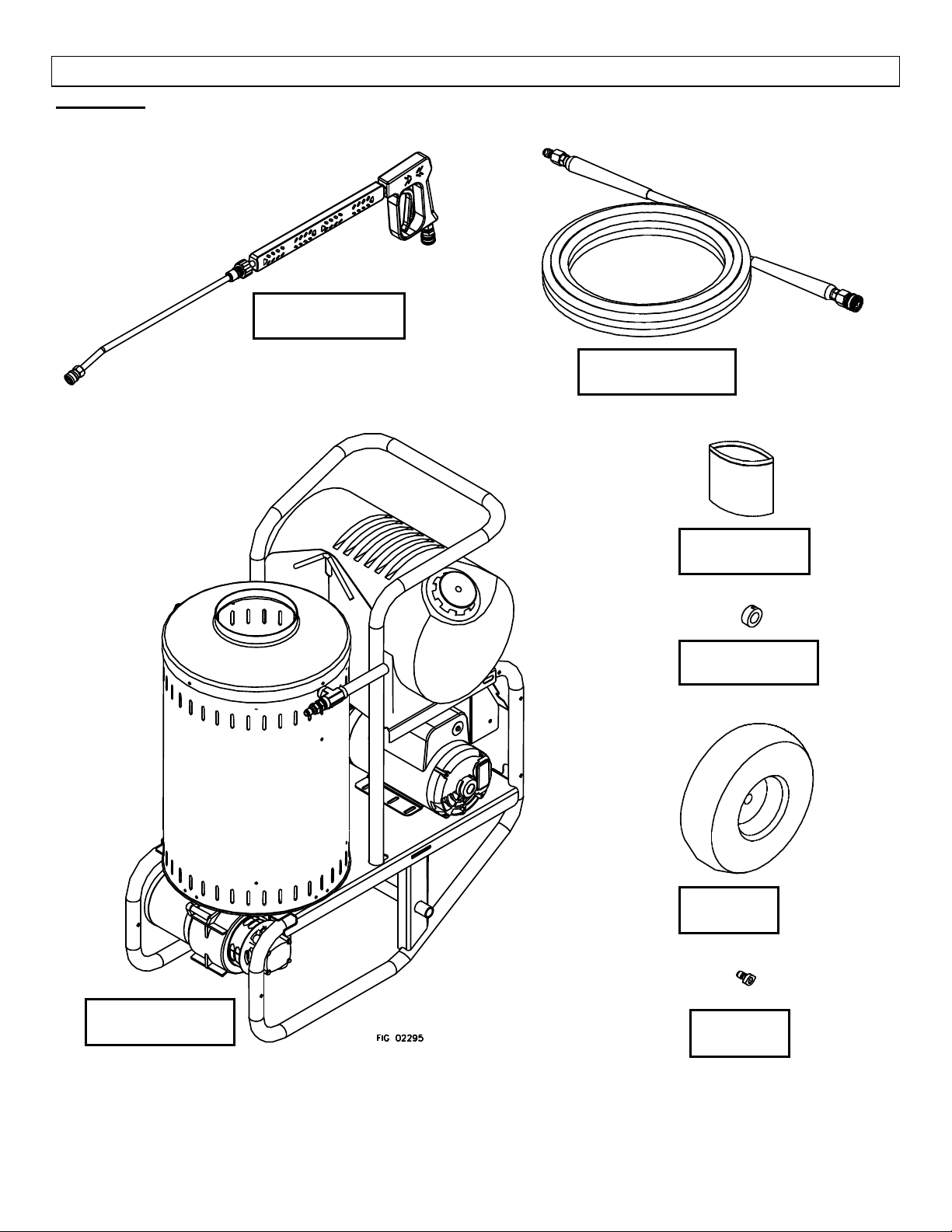

157305, 157306, 157307, 157308

Installation Instructions

High Pressure Hose

Qty-1

Wheel Retainer

Qty-2

Spray Gun & Grip

Qty-1

Wheel

Qty-2

Pressure Washer

Qty-1

Fastener Bag

Qty-1

Nozzle

Qty-6

I.) Unpack

Separate and identify all components. Use the assembly instructions in this manual for assembly.

7

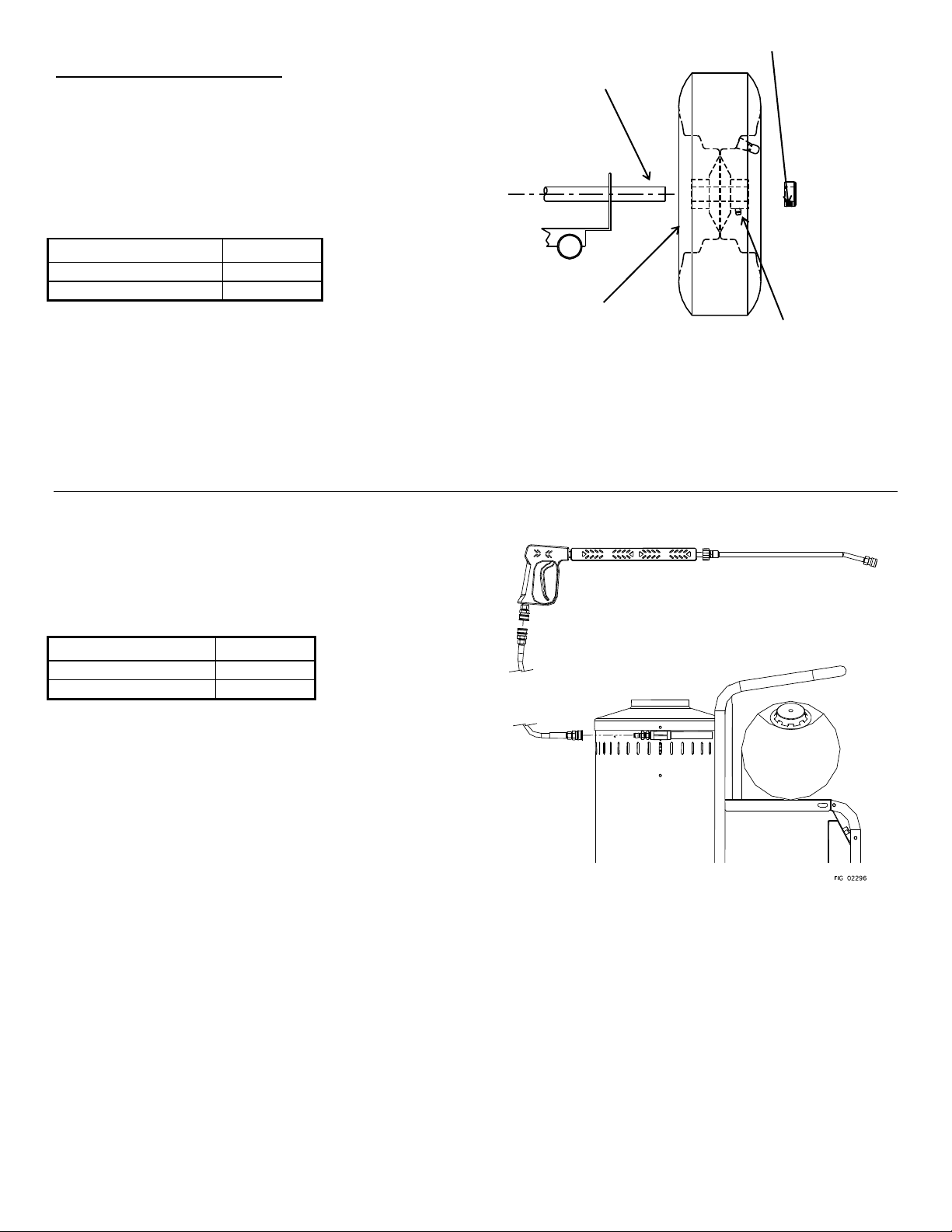

II.) Assembly Instructions

Description

Qty.

Wheel

2

Wheel Retainer

2

Description

Qty.

Spray Gun/ Lance

1

Spray Hose

1

Wheel Retainer

Wheel

Axle

Grease Zerk

A. 1. Carefully raise the pressure washer off the floor by

using blocks or ramps. Make sure the pressure

washer is secure before proceeding.

2. Install the two wheels as shown with grease zerk

away from frame.

3. Slide the two wheel retainers onto the end of the

axle. Tighten the setscrew with a hex wrench.

B. 1. Install the pressure hose onto the pressure washer

as shown.

2. Connect the other end of the pressure hose to the

spray gun as shown.

3. Make sure all plumbing connections are tight.

8

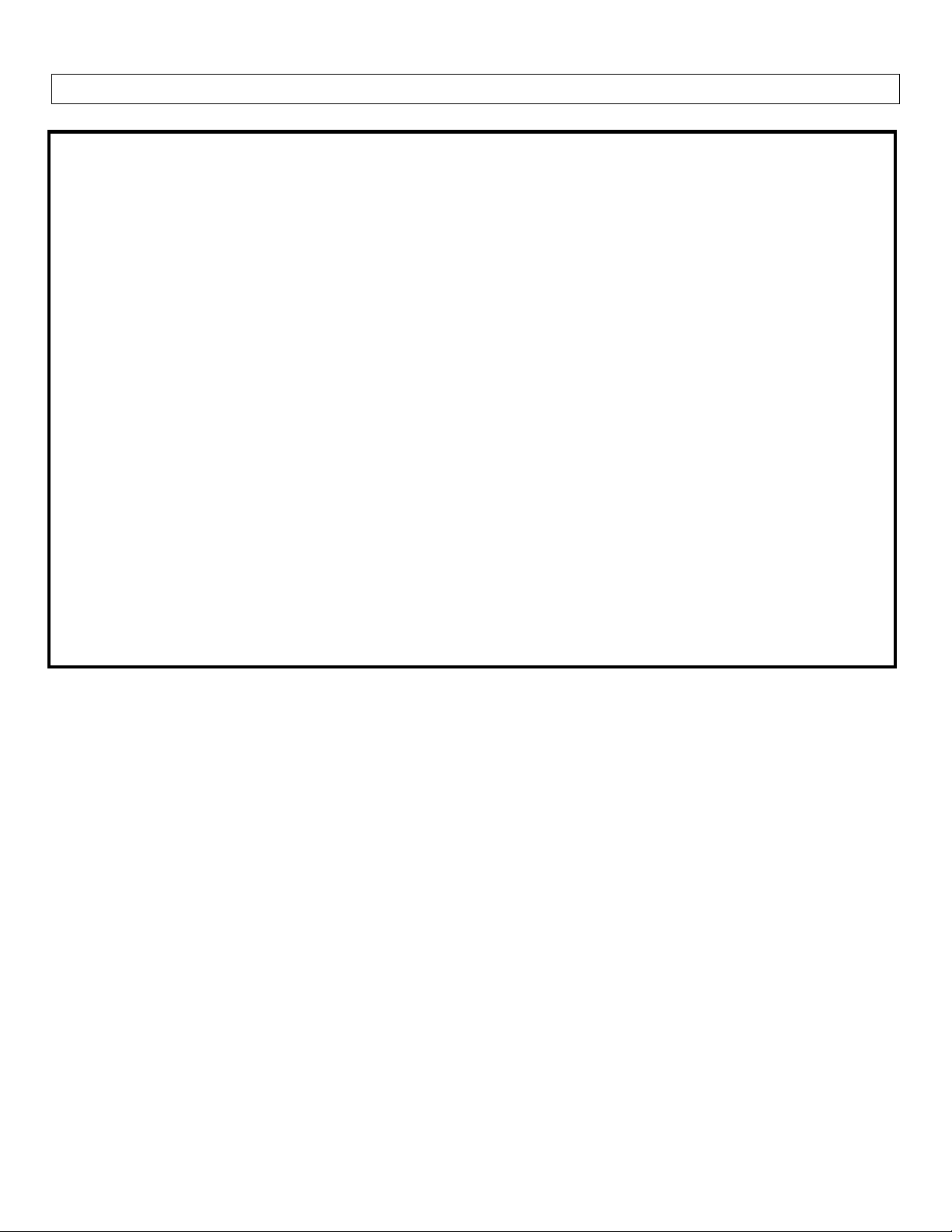

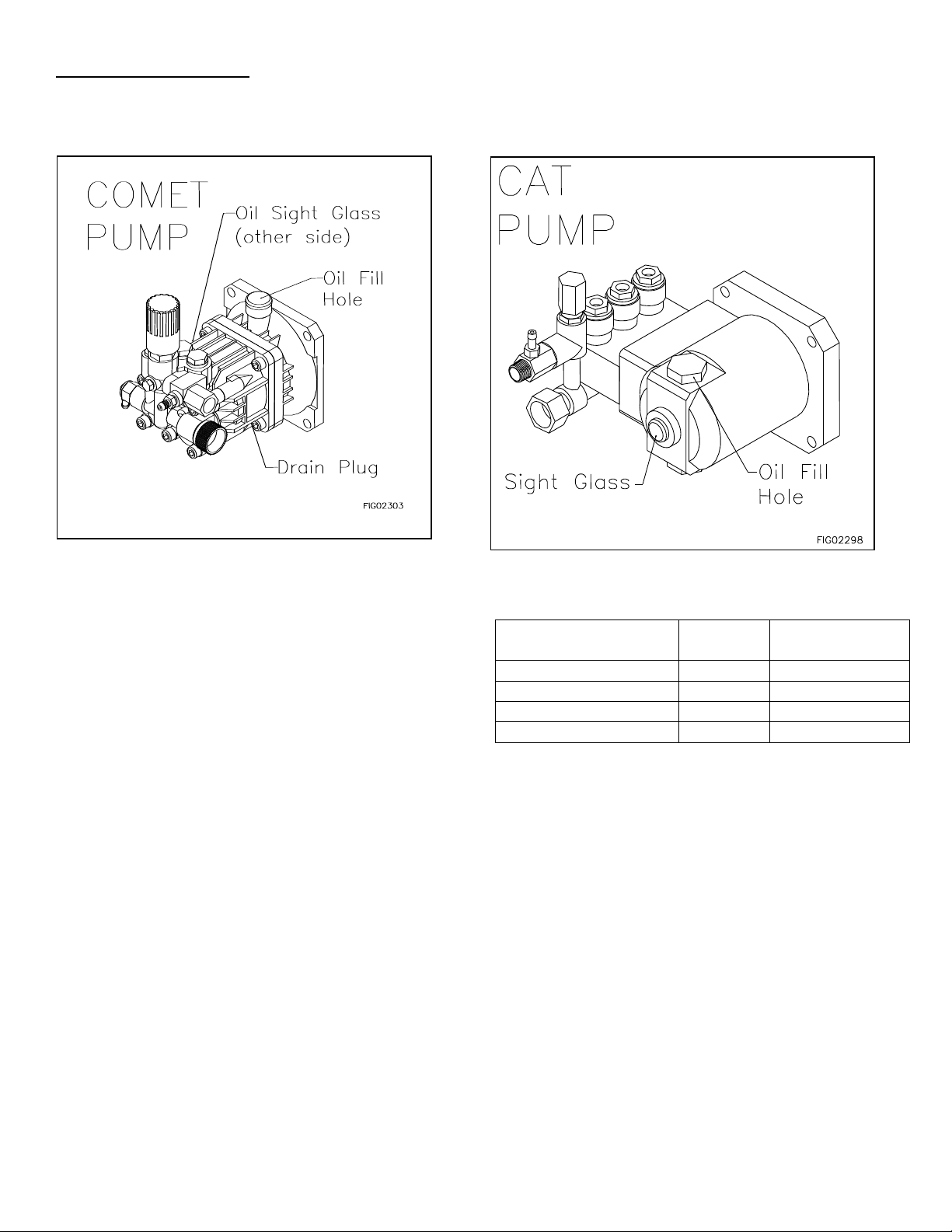

III.) Pump Preparation

Pump

Type of

Fluid

QTY

Comet BXD 1617

UTTO*

4.3oz (0.13L)

Comet BXD 2527G-E

UTTO*

4.3oz (0.13L)

Cat 2DX

SAE 30**

8.5oz (0.25L)

Cat 4DNX

SAE 30**

8.5oz (0.25L)

*Comet Pumps Only

A.) Replace shipping oil plug with vented plug.

B.) Make sure the oil is 1/2 way up oil sight glass.

**Cat Pumps Only

A.) Remove shipping tape from oil fill cap

B.) Make sure the oil is 1/2 way up oil sight glass.

Quantities Of Fluid

*Universal Tractor Transmission Oil or Mobil 1 15W50

**SAE Non-Detergent (order Cat Pump Oil Item# 22158)

9

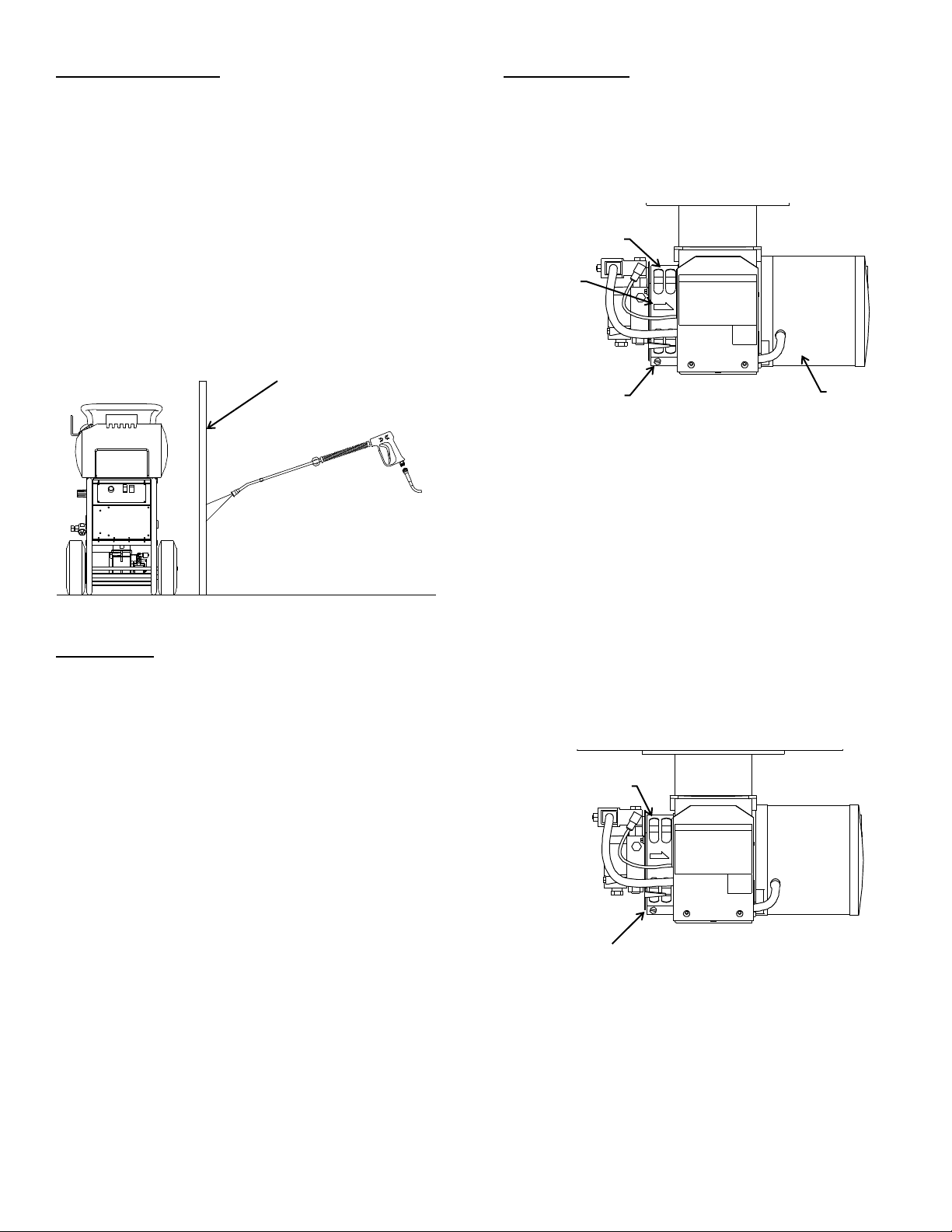

V.) Getting Started

Partition

Locking

Screw

Air Band

Burner

White

Arrow

Shutter Lock

Screw

Shutter

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer

service life and lower maintenance cost.

Make sure the pressure washer is on a level surface and

in a protected area where it is not readily influenced by

outside forces such as strong winds, freezing

temperatures, rain, etc. Locate the pressure washer for

easy access for filling fluids, adjustments and

maintenance.

It is recommended that a partition be made between the

wash area and the pressure washer to prevent direct

nozzle spray from coming in contact with the pressure

washer. Moisture reaching the equipment will reduce the

pressure washer’s service life.

V.) Venting

DANGER: Do not run machine indoors or in an

enclosed area without adequate ventilation or in

areas where flammable vapors (gasoline, solvents,

etc.) may be present. Do not vent exhaust gases into

a wall, a ceiling or a concealed space.

CAUTION: All venting must be in accordance with

applicable federal and state laws and local

ordinances. Consult local heating contractors.

Poor draft will cause the pressure washer to soot and not

operate properly. When selecting the location for

installation, beware of poorly ventilated locations or areas

where exhaust fans may cause an insufficient supply of

oxygen. Proper combustion can only be obtained when

there is a sufficient supply of oxygen available for the

amount of fuel being burned. If it is necessary to install a

unit in a poorly ventilated area, outside fresh air may

have to be piped to the burner and a fan installed to bring

sufficient air into the unit

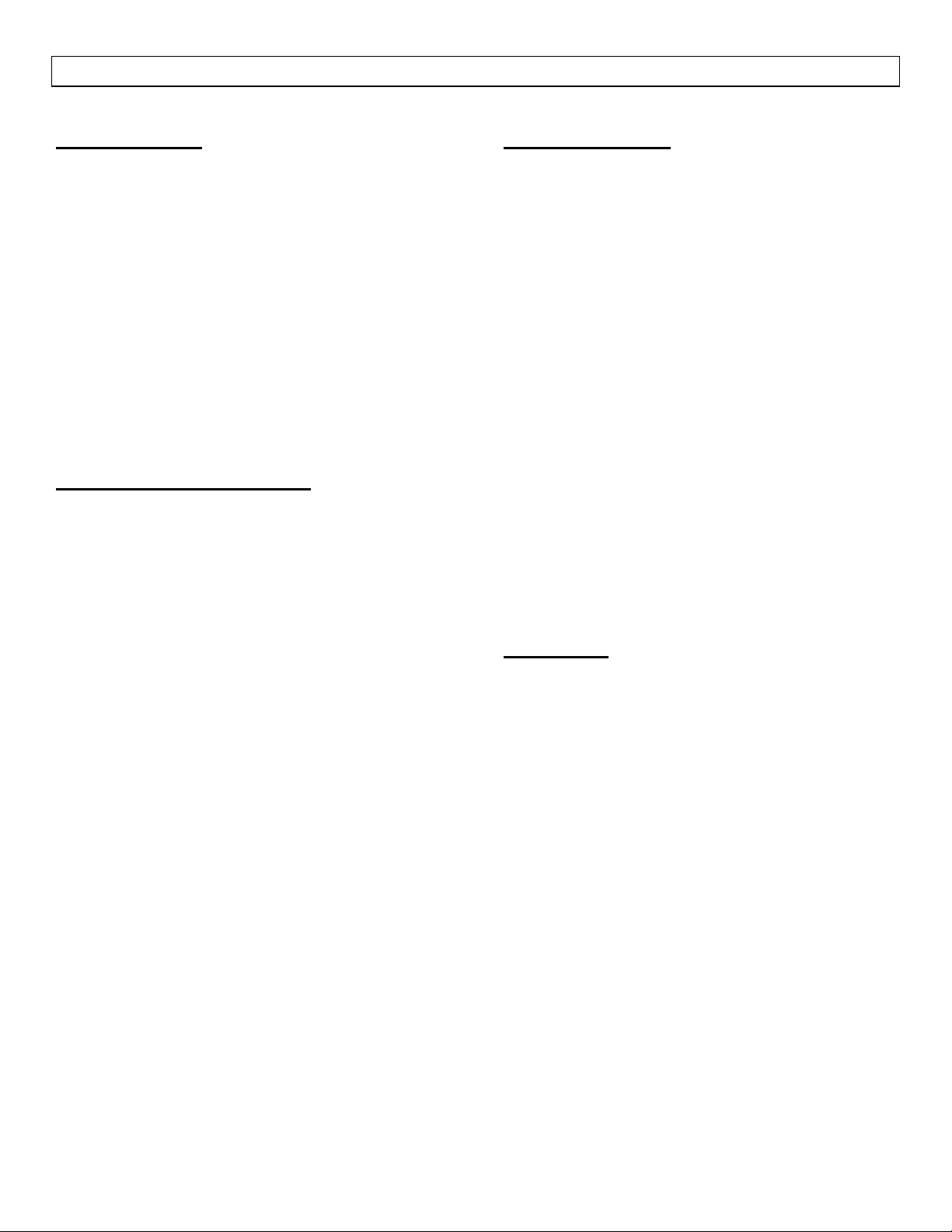

VI.) Oil Burner

Burner Air Adjustment: The oil burner is preset and

performance tested at the factory (elevation 1100 feet).

A one-time initial correction of the burner for your

location will pay off in economy, performance and

extended service life.

1.) Turn the pump and heat switches on (Refer to

“Operation” for details). Have someone operate the

spray gun so the burner fires.

2.) Loosen the locking screw and close the air band until

black smoke appears from the burner exhaust vent.

Note the position of the white arrow on the air band.

3.) Slowly open the air band until white smoke just starts

to appear.

4.) Turn the air band half way back to the black smoke

position previously noted. Tighten the locking screw.

5.) Fine tune the burner air by loosening the shutter lock

screw and turning the shutter until the exhaust is

cleanest. Tighten the shutter lock screw.

CAUTION: If white smoke appears from the burner

exhaust vent during start-up or operation,

discontinue use and readjust air bands.

10

Operating Instructions

Follow these instructions every time you use the pressure washer.

I.) Pre-Operation

A.) Position the machine for easy access to all

controls.

B.) Position the machine on a solid surface, with

less than a three degree slope and so it is

protected from external damage.

C.) Position the machine so that ambient lighting is

sufficient for the surface you are cleaning to be

seen with ease. Use artificial light if needed.

D.) Check hoses, fittings, wand, trigger gun and fuel

connections for signs of wear, cracks and

looseness and replace as required.

E.) Check and clean the nozzle orifice.

F.) Check and clean the water inlet screen and filter.

G.) Read entire manual, especially the important

safety instructions listed on page 2.

H.) Check and maintain proper oil level in the pump.

II.) Check Your Water Supply

A.) Make sure the water supply is clean. Debris can

cause excess pump wear and reduce

performance.

B.) An insufficient water supply will damage your

pump. Make sure the water supply is steady and

is 20% over the rated flow of your pump. Use a

stopwatch to time how long it takes to fill a 5

gallon bucket with your garden hose.

Example: If the rated flow is = 3 gpm

Then required flow = 3 x 1.20 = 3.6 gpm

5 gallons / 3.6 gpm = 1.39 minutes

1.39 min x 60 sec/min = 83 seconds

Therefore, you must be able to fill a

5 gallon bucket in 83 seconds or faster.

C.) The water supply garden hose must have an

inside diameter of at least 5/8”. If the hose is

more than 100 ft. long, the diameter must be at

least 3/4”.

D.) Never use a reservoir tank as a water source.

This pressure washer is designed for a

pressurized water source such as a city water

faucet. Sucking water out of a tank may cause

pump cavitation and damage to your pump.

However, the inlet pressure of the pump must

not exceed 115 psi (8 bar).

E.) Always use a flexible rubber hose for your water

supply. Do not use rigid piping.

F.) Do not pump flammable liquids or liquids

containing incompatible chemicals or solvents.

III.) Before Starting

WARNING: Make sure all switches and controls are

in the OFF position prior to plugging in the cord.

DO NOT stand in water while plugging or unplugging

electrical cord.

WARNING: Use a UL recognized receptacle

protected by a ground fault interrupter and

extension cord of proper voltage and amperage at all

times.

1. Connect electrical cord to specified NEMA receptacle.

See page 4.

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness. Replace as required.

2. Connect water supply hose to the garden hose

connector located on the pump.

3. Fill the burner fuel tank. We recommend kerosene

because it burns cleanest. #1 grade home heating

oil, #1 or #2 diesel can also be used. DO NOT USE

GASOLINE OR CRANKCASE OIL.

4. If detergents will be used, only use detergents

intended for pressure washers. Follow instructions on

the detergent container.

IV.) To Start

DANGER: Do not point the spray wand at yourself or

at any person. Bodily injury may result from water

under high pressure.

WARNING: Wear eye, ear, hand, foot and skin

protection at all times while operating this pressure

washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

1. Turn water supply ON.

2. Squeeze the trigger to allow air to purge from the

system. (This step goes faster with the pressure nozzle

removed)

11

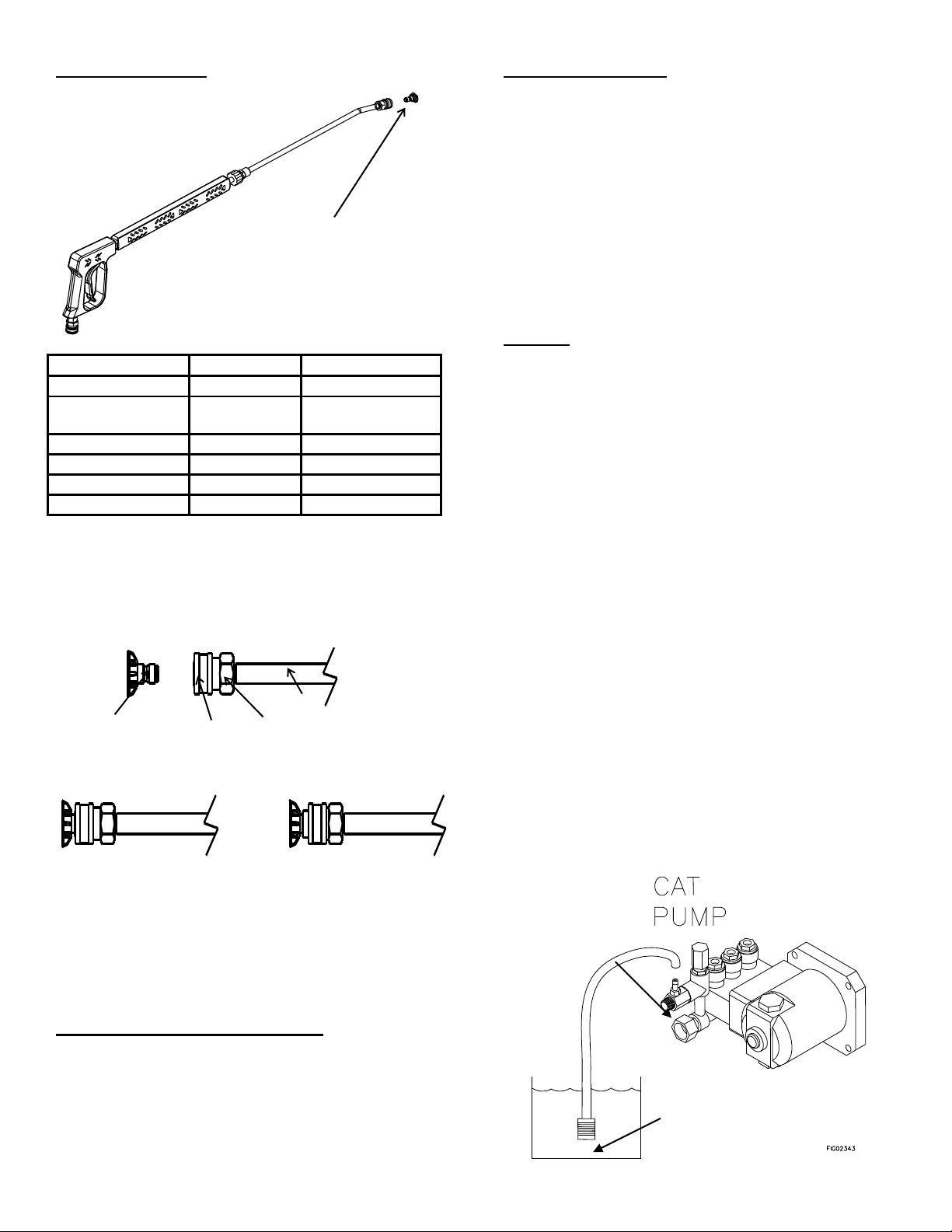

V.) Attach Nozzle

Color of Nozzle:

Spray Angle

Used For:

Red

0

Highest Impact

Yellow

15

Tough Stains/

Stripping

Green

25

General

White

40

Light Cleaning

Yellow

15

Steaming

Black

65

Chemical

Nozzle

Chemical

Injector

Braided Hose

and Strainer

Diluted

Chemical

CORRECT

INCORRECT

Nozzle

Collar

Coupler

Lance

Your pressure washer is equipped with six nozzles. To

install a nozzle simply pull back the collar towards the

lance and push the nozzle into the coupler. Once the

connection is made, pull on the nozzle to assure a tight

connection.

WARNING: Make sure the nozzle is correctly

inserted. The nozzle may become a projectile if not

inserted correctly. Do not attempt to use different

types of nozzles that may not fit the coupler.

VI.) Turn the pump switch ON.

1. Make sure the hose is not kinked. A kinked hose

will provide insufficient water supply to the pump and

will reduce its life. Make sure the hose remains

unkinked after moving the pressure washer.

VII.) For Hot Water

1. If HOT water is desired, make sure there is fuel in

the fuel tank, turn the heat switch ON and adjust the

thermostat to the desired temperature. The burner

will fire when the trigger is squeezed. You may need

to initially adjust your burner for peak performance.

See the “Oil Burner” section under INSTALLATION.

When the trigger is released or the temperature

setting is reached, the burner will automatically turn

off.

IMPORTANT: Do not run the machine in hot mode

without any fuel in the fuel tank. The fuel pump will

be damaged if it is run dry.

To Clean

WARNING: Wear eye, ear, hand, foot and skin

protection at all times while operating this pressure

washer.

DANGER: Do not point the spray wand at yourself or

at any person. Bodily injury may result from water

under high pressure.

CAUTION: Be careful on painted or delicate surfaces.

The pressure may damage the surface if the nozzle

is too close.

IMPORTANT: Your spray gun is equipped with a

built-in trigger safety latch to guard against

accidental trigger actuation and potentially

dangerous high pressure spray. Rotate the safety

latch to the locked position when not spraying.

NOTE: Your pressure washer is equipped with a low

pressure chemical injector. You do not need to use

chemicals for every job, however, the proper

chemical used for the proper application can speed

up cleaning jobs tremendously.

WARNING: Only use NorthStar pressure washer

chemicals or chemicals specifically formulated for

pressure washers. Follow the chemical

manufacturer’s recommendations. Understand all

safety precautions and first aid for all chemicals.

1. Press the braided chemical hose over the chemical

injector on the pump and submerge the suction

strainer connected to the braided chemical hose into

the chemical solution.