MEI 10-9-12

1

M157305?

Owner’s Manual

Electric Hot Water/Steam Pressure Washer

Instructions for Set-up, Operation, Maintenance & Storage

This pressure washer produces cold or hot water high-pressure spray as well as steam spray. Cleaning chemicals

may be incorporated into the spray if desired. The pressure pump is powered by an electric motor and water is

heated by an open flame burner fueled by diesel/kerosene or fuel-oil. Read and understand this Owner’s Manual

completely before using and keep this manual for review. Failure to properly set up, operate, and maintain could

result in serious injury or death to operator or bystanders.

WARNING: SPECIAL HAZARDS

• Skin/Eye Injury: High-pressure spray can cause serious skin or eye injury, including injection injury if fluid pierces the skin.

Injection injury can result in blood poisoning and/or severe tissue damage.

• Burns: Hot spray can scald and burn skin. Hot surfaces of wand and burner, as well as hot exhaust from the burner can

cause burns.

• Slips/Falls: Spray discharge can cause puddles and slippery surfaces. Spray-gun kickback can cause operator loss of

balance and falls.

• Flying Debris: High-pressure spray can cause surface damage and flying debris.

• Fire/Explosion: Burner sparking can ignite fuel or other flammable liquids or vapors in the vicinity. Hot exhaust from burner

can ignite combustible materials.

• Chemical Exposure: Cleaning chemical vapors or contact with skin may be hazardous.

• Electric shock: Spray contact with electrical sources can cause electric shock.

• Electrocution: Improper connection of the equipment or grounding conductor can result in a risk of electrocution.

• CO Poisoning: Exhaust from burner contains carbon monoxide, a poisonous gas that can cause carbon monoxide poisoning

and possible death if inhaled.

Equipment Protection Quick Facts

Inspect Upon Delivery: STOP! Closely inspect to make sure no components are missing or damaged. See the

“Assembly and Initial Set-Up” section for instructions on whom to contact to report missing or damaged parts.

Check Pump Oil: Pump is shipped with oil. Check pump oil level before starting.

Water Flow Requirements: Make sure your supply water flow rate is 20% higher than the pressure washer’s flow

rate (3 gal/min preferred), and that your water is clean and particle free.

Chemical Spraying: Use only NorthStar brand or equivalent washer chemicals designed for pressure washer use.

Maintenance Schedule: Pump, burner fuel filter, burner coil and electrodes require periodic checking and servicing

to keep pressure washer functioning efficiently. See “Maintenance Schedule Summary” for frequency of servicing.

ITEM NUMBER: 157305, 157306,

157307, 157308

SERIAL NUMBER: _____________

®

MEI 10-9-12

2

Table of Contents

Equipment Protection Quick Facts ......................................................................................................................................... 1!

TABLE OF CONTENTS ................................................................................................................................................. 2!

ABOUT YOUR PRESSURE WASHER .......................................................................................................................... 4!

SPECIFICATIONS ......................................................................................................................................................... 5!

COMPONENT IDENTIFICATION .................................................................................................................................. 6!

SPECIAL EQUIPMENT SAFETY FEATURES .............................................................................................................. 7!

High Pressure Relief Valve .................................................................................................................................................... 7!

Temperature Control Switch .................................................................................................................................................. 7!

Pump Thermal Relief Valve ................................................................................................................................................... 7!

Spray Gun Safety Latch ........................................................................................................................................................ 7!

SAFETY ......................................................................................................................................................................... 8!

Hazard Signal Word Definitions ............................................................................................................................................. 8!

SAFETY LABELING ...................................................................................................................................................... 9!

ASSEMBLY AND INITIAL SET-UP ............................................................................................................................. 10!

Step 1. Inspect & Unpack ...................................................................................................................................................... 10!

Step 2. Assembly .................................................................................................................................................................... 10!

Step 3. Verify Electrical Connection ..................................................................................................................................... 10!

Grounding ............................................................................................................................................................................ 10!

Ground Fault Circuit Interrupter Protection .......................................................................................................................... 10!

Extension Cord and Usage .................................................................................................................................................. 11!

Electric Shock Accident ....................................................................................................................................................... 11!

MOVING AND HANDLING .......................................................................................................................................... 11!

Moving your pressure washer around ................................................................................................................................. 11!

BEFORE EACH USE ................................................................................................................................................... 12!

Step 1: Inspect Equipment ................................................................................................................................................... 12!

Electrical .............................................................................................................................................................................. 12!

Pump Oil .............................................................................................................................................................................. 12!

Spray System ...................................................................................................................................................................... 12!

Burner Fuel System (if heated water to be used) ................................................................................................................ 12!

Periodic Maintenance .......................................................................................................................................................... 12!

Step 2. Check and Fill Burner Fuel Tank ............................................................................................................................. 13!

Filling Burner Fuel Tank (if heated water to be used) .......................................................................................................... 13!

Step 3. Select Suitable Worksite Guidelines ...................................................................................................................... 13!

For All Indoor and Outdoor Uses ......................................................................................................................................... 13!

For Indoor Hot Water/Burner Use ........................................................................................................................................ 14!

OPERATION ................................................................................................................................................................ 14!

Step 1. Connect Hoses, Water Supply, and Spray Nozzle .................................................................................................. 14!

Hose and Water Supply ....................................................................................................................................................... 14!

Connect Water Supply to Pump .......................................................................................................................................... 14!

Connect Pressure Hose to Pump ........................................................................................................................................ 14!

Quick Connect Procedure ................................................................................................................................................... 14!

Selecting and Connecting Spray Nozzle ............................................................................................................................. 15!

Step 2. Pre-Spraying Procedure .......................................................................................................................................... 15!

Safety Rules ........................................................................................................................................................................ 15!

Personal Protective Gear .................................................................................................................................................... 16!

Purging ................................................................................................................................................................................ 16!

MEI 10-9-12

3

Step 3. Spraying .................................................................................................................................................................... 16!

Starting ................................................................................................................................................................................ 16!

Spraying Procedure ............................................................................................................................................................. 16!

Using Chemicals for Cleaning (if desired) ........................................................................................................................... 16!

Hot Spray Procedure ........................................................................................................................................................... 18!

Step 4. Stopping ..................................................................................................................................................................... 18!

STORAGE .................................................................................................................................................................... 18!

Between-Use Storage ......................................................................................................................................................... 18!

Long-Term Storage Preparation (between infrequent uses and at end of season) ............................................................. 18!

Winter Storage Preparation ................................................................................................................................................. 19!

MAINTENANCE & REPAIR ......................................................................................................................................... 20!

MAINTENANCE SCHEDULE ...................................................................................................................................... 20!

DETAILED INSTRUCTIONS – MAINTENANCE & REPAIR ....................................................................................... 20!

Dust/Debris Removal ........................................................................................................................................................... 20!

Inspect Fuel System(s) ........................................................................................................................................................ 20!

Inspect Spray System .......................................................................................................................................................... 20!

Clean Inlet Filter for Garden Hose ....................................................................................................................................... 21!

Check Tire Pressure ............................................................................................................................................................ 21!

Change Pump Oil ................................................................................................................................................................ 21!

Drain Burner’s Fuel Filter/Water Separator ......................................................................................................................... 21!

Descale Heating Coil ........................................................................................................................................................... 21!

Inspect and Clean Flow Switch ........................................................................................................................................... 22!

Inspect Heating Coil and Desoot as Needed ....................................................................................................................... 23!

Inspect/Clean/Adjust Electrodes .......................................................................................................................................... 23!

Perform Engine Maintenance .............................................................................................................................................. 24!

OIL BURNER ADJUSTMENT (ONLY NEEDED IF WHITE EXHAUST SMOKE APPEARS) ..................................... 25!

TROUBLESHOOTING ................................................................................................................................................. 26!

PARTS EXPLOSION – REV NEW ............................................................................................................................... 27!

PUMP EXPLOSIONS ................................................................................................................................................... 29!

WIRING DIAGRAMS .................................................................................................................................................... 34!

LIMITED WARRANTY ................................................................................................................................................. 37!

MEI 10-9-12

4

About Your Pressure Washer

Thank you for purchasing a NorthStar hot water

pressure washer! It is designed for long life,

dependability, and top performance.

Intended Use. Washing siding, windows, walkways,

driveways, patios, decks, fences, vehicles, boats,

lawnmowers, ATVs and other equipment by:

• Producing a high-pressure water spray (heated or

unheated), and

• Incorporating cleaning chemicals into a low-

pressure water spray.

Note: Do not use for other purposes, as unforeseen

hazards or equipment damage may result.

Water Supply. The pump requires a clean, standard tap

water supply provided through a garden hose at a flow

rate of at least 3 gallons per minute. Use of a backflow

preventer on the water supply hose is recommended

and may be required by local code.

Chemical Usage. Any cleaning chemicals that are used

must be specifically approved for use in pressure

washers.

Power Source. The pump is powered by an electric

motor. The spray water is heated (when desired) by a

spark-ignited, open flame burner fueled by

diesel/kerosene/fuel-oil.

Supplies Required. Normal operation will require you

to supply:

• Pump oil

• Burner fuel if heating water (kerosene, diesel, or

fuel oil)

• Input water supply

• Input water supply hose

See “Specifications” section of this manual for more

detail.

Site Selection. Pressure washers used while the open

flame burner heats the water are for OUTDOOR USE

ONLY unless specific exhausting guidelines are met.

Read additional details in “Before Each Use” section of

this manual.

Personal Protection. Wear safety apparel during

operation, including waterproof insulated gloves, safety

glasses with side and top protection, and non-slip

protective footwear. Some cleaning chemicals may

require the use of a respirator mask (as instructed on

chemical label).

Adult Control Only. Only trained adults should set up

and operate the pressure washer. Do not let children

operate. Pressure washers can generate forces greater

than children can control and require judgment beyond

what can be expected of them.

Under The Influence. Never operate, or let anyone else

operate, the pressure washer while fatigued or under

the influence of alcohol, drugs, or medication.

Keep this manual for reference and review.

ATTENTION: Rental Companies and Private

Owners who loan this equipment to others!

All persons to whom you rent/loan this pressure washer

must have access to and read this manual. Keep this

owner’s manual with the pressure washer at all times

and advise all persons who will operate the machine to

read it. You must also provide personal instruction on

how to safely set-up and operate the pressure washer

and remain available to answer any questions a

renter/borrower might have. Owner’s Manuals are

available from NorthStar at 1-800-270-0810.

MEI 10-9-12

5

Specifications

MODEL

Model #

157305

157306

157307

157308

FLOW OUTPUT

Pressure Rating

1700 psi

2700 psi

2000 psi

2750 psi

Flow Rate

1.5 gpm

2.5 gpm

1.5 gpm

2.5 gpm

Maximum Temperature

250° F

POWER REQUIREMENTS

Dedicated NEMA

Receptacles

5-20R

6-30R

5-20R

6-30R

Volts

115V

230V

115V

230V

Amps

20A

30A

20A

30A

Hertz

60Hz

Phase

Single

DIMENSIONS/COMPONENTS

Length

38”

Width

26”

Height

43”

Weight (fueled)

385 lbs.

415 lb.

385 lb.

415 lb.

Pump Type

Ceramic Triplex Plunger

Motor Horsepower

1.5 hp

5 hp

2 hp

5 hp

High Pressure

Discharge Hose

3/8” x 50’

Chemical Injection Point

Injection dilution ratio 15-to-1

SUPPLIES REQUIRED (not included)

Burner Fuel

#1 or #2 Diesel, B5 or lower Biodiesel, Kerosene, or Fuel Oil

(Capacity: 8.25 gal.)

Pump Oil

(shipped with oil, but

refills required)

Comet: Universal Tractor Transmission Oil

or Mobil 1 Synthetic 15W-50

Cat: SAE Non-Detergent Oil

Input Water Supply

Standard tap water @ 20-100 psi, delivered @ 3.0 gpm or higher

Input Water Supply

Hose

Standard garden hose with inside diameter at least 5/8”

(at least 3/4” diameter if hose longer than 100 ft.)

MEI 10-9-12

6

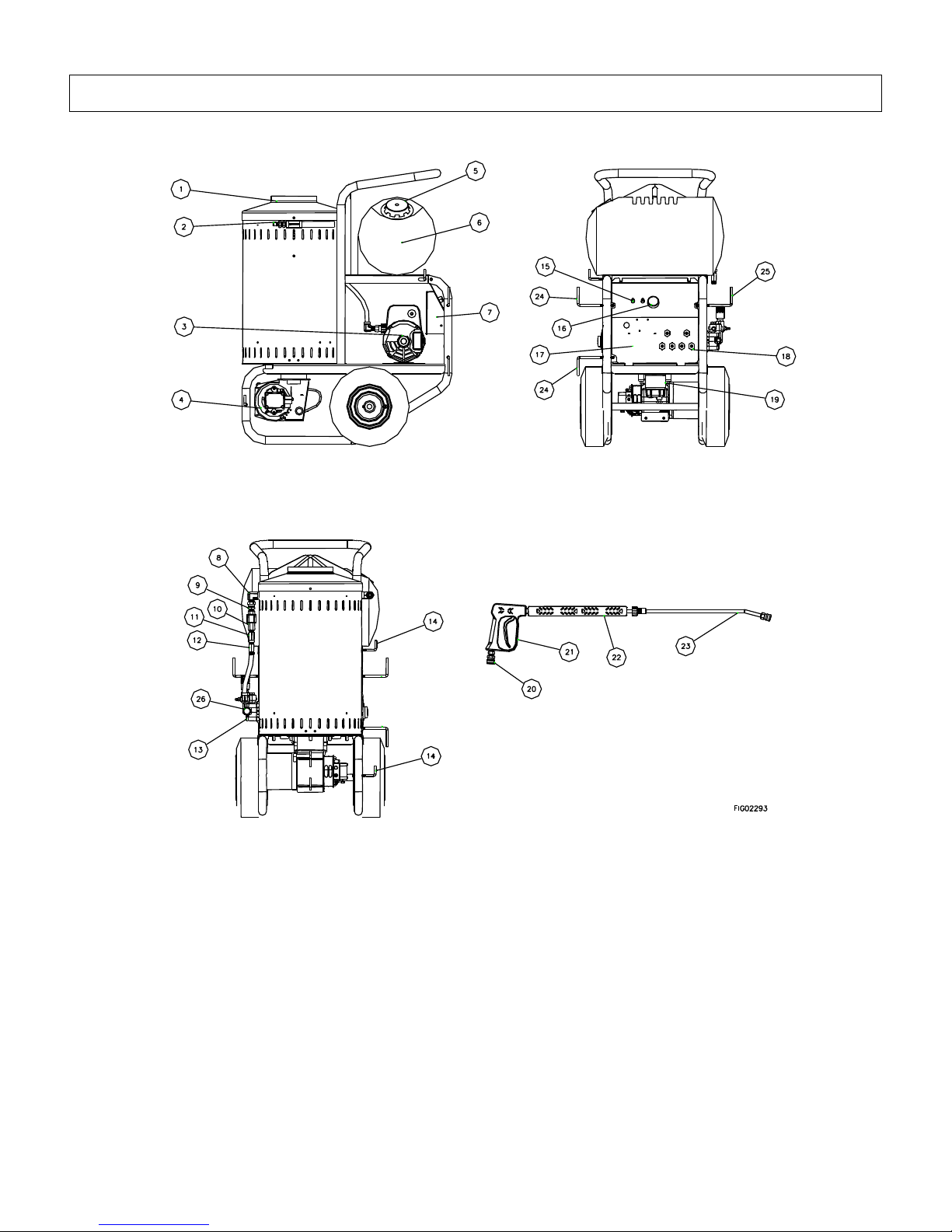

Component Identification

1. Exhaust Vent: Provides an exit for burner exhaust

gases.

2. High Pressure Water Outlet: A passage for water

to exit pump and enter the hose.

3. Motor: Electric motor powers the pump.

4. Burner: The oil burner is preset and performance

tested at the factory. The Burner may need initial

adjustment for peak performance. See “Oil Burner

Adjustment” section for instructions on initial

adjustment of the oil burner. You will need to use

the handle to tip the pressure washer up in order to

access the Burner from underneath.

5. Fuel Fill Cap: Vented cover for fuel tank.

6. Fuel Tank: The Burner has a 8.25 gal. fuel tank-

kerosene, #1 or #2 diesel, or fuel oil may be used.

Do not mix fuel types.

7. Control Box: Flat surface for mounting switches.

8. Elbow: Junction between Swivel Fitting (Reference

9) and coil inlet.

9. Swivel Fitting: Connection point of Flow Switch

(Reference 10) to Elbow (Reference 8).

10. Flow Switch: Water activated switch to control on

and off of burner.

11. Tee: Junction between Safety Relief Valve

(Reference 12) and Flow Switch (Reference 10).

12. Safety Relief Valve: Controls over pressure (Pop

Off Valve).

Machine Component Identification

157305, 157306, 157307, 157308

MEI 10-9-12

7

13. Pump: A mechanical device that moves and

pressurizes fluid. [Pump oil must be changed after

first 40 hours of use, and then changed every three

months or 500 hours of use. See “Maintenance and

Repair” section for pump oil change instructions

and recommendations.]

14. Gun Hooks: Spray gun storage location.

15. Power Switch: Flip up for on.

16. Thermostat: Controls power to fuel solenoid for

firing.

17. Control Panel: Power Switch (Reference 15),

Thermostat (Reference 16) and Nozzle Storage

(Reference 18) are located on control panel.

18. Nozzle Storage: Control Panel (Reference 17) has

space for storing nozzles.

19. Fuel Filter/Water Separator: Filter in fuel line that

removes water and screens out dirt and debris from

fuel.

20. Quick Connector: Connection point on spray gun

for high pressure hose.

21. Spray Gun: Pressurized water is discharged.

22. Grip: Protected area on spray gun for additional

hold.

23. Lance Wand: Unprotected area on spray gun.

24. Power Cord Hangers: Storage location.

25. High Pressure Hose Hanger: Storage location.

26. Garden Hose Water Inlet: Connection point for

standard garden hose. Garden hoses less than

100’ in length must have a minimum inner diameter

of 5/8.” Garden hoses over 100’ in length must

have a minimum inner diameter of 3/4.”

Note: See “Parts Explosion” for additional detail.

Special Equipment Safety Features

This unit is equipped with the following safety features:

High Pressure Relief Valve

Acts as a backup safety feature. If the Pressure Control

Valve (Unloader) malfunctions, this separate highpressure relief valve will open and relieve excess

system pressure. Repair is required.

WARNING: Relief valve failure

If the high-pressure relief valve ever discharges water,

turn the unit off and do not use the machine. Call

Product Support at 1-800-270-0810.

Temperature Control Switch

Measures water temperature and automatically turns

burner off when temperature setting is reached. When

water temperature drops, burner automatically reignites.

Figure 1

Pump Thermal Relief Valve

This valve, on the Unloader bypass port, protects the

pump from overheating. The pump continues to work in

bypass mode when you are not spraying. If high

temperatures are developed during bypass mode, the

Thermal Relief Valve will open and discharge hot water

onto the ground, protecting the pump from overheating.

Note: One of two pumps will be on your machine.

Figure 2

Spray Gun Safety Latch

Has a built-in trigger safety latch to guard against

accidental trigger actuation.

Figure 3

High Pressure

Relief Valve

Note: Shield not

shown for clarity

Pump

Thermal

relief valve

Cat pump

Comet

pump

00417

Safety Latch

MEI 10-9-12

8

Safety

Hazard Signal Word Definitions

DANGER

WARNING

CAUTION

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury

or death.

DANGER (red) indicates a hazardous situation, which if

not avoided, will result in death or serious injury.

WARNING (orange) indicates a hazardous situation,

which if not avoided, could result in death or serious

injury.

CAUTION (yellow), used with the safety alert symbol,

indicates a hazardous situation, which if not avoided,

could result in minor or moderate injury.

CAUTION (yellow), without the safety alert symbol, is

used to address practices not related to personal injury.

NOTICE is used to address practices not related to

personal injury.

MEI 10-9-12

9

Safety Labeling

On-Product Warning Labels

Part numbers

Description

34131

Warning & Operating Instructions

305410

Caution Hot

778070

Risk of Electrocution

305427

Danger Label

Always make sure safety labels are in place and in good condition. If a safety label is missing or not legible, order

new labels or unsafe operation could result. To order replacement safety labels, call NorthStar Product Support at

1-800-270-0810.

Part No. 778070

RISK OF ELECTROCUTION

1. Connect only to properly grounded

outlet. Do not remove ground pin.

2. Inspect cord before using - Do not

use if cord is damaged.

3. Keep all connections dry and off

the ground.

4. Do not touch plug with wet hands

5. This product is provided with a

Ground Fault Circuit Interrupter built

into the power cord plug. If

replacement of the plug or cord is

needed use only identical

replacement parts.

6. Read owner's manual before using.

DO NOT REMOVE THIS TAG

WARNING

NT+E Co. 800-270-0810

MEI 10-9-12

10

Assembly and Initial Set-Up

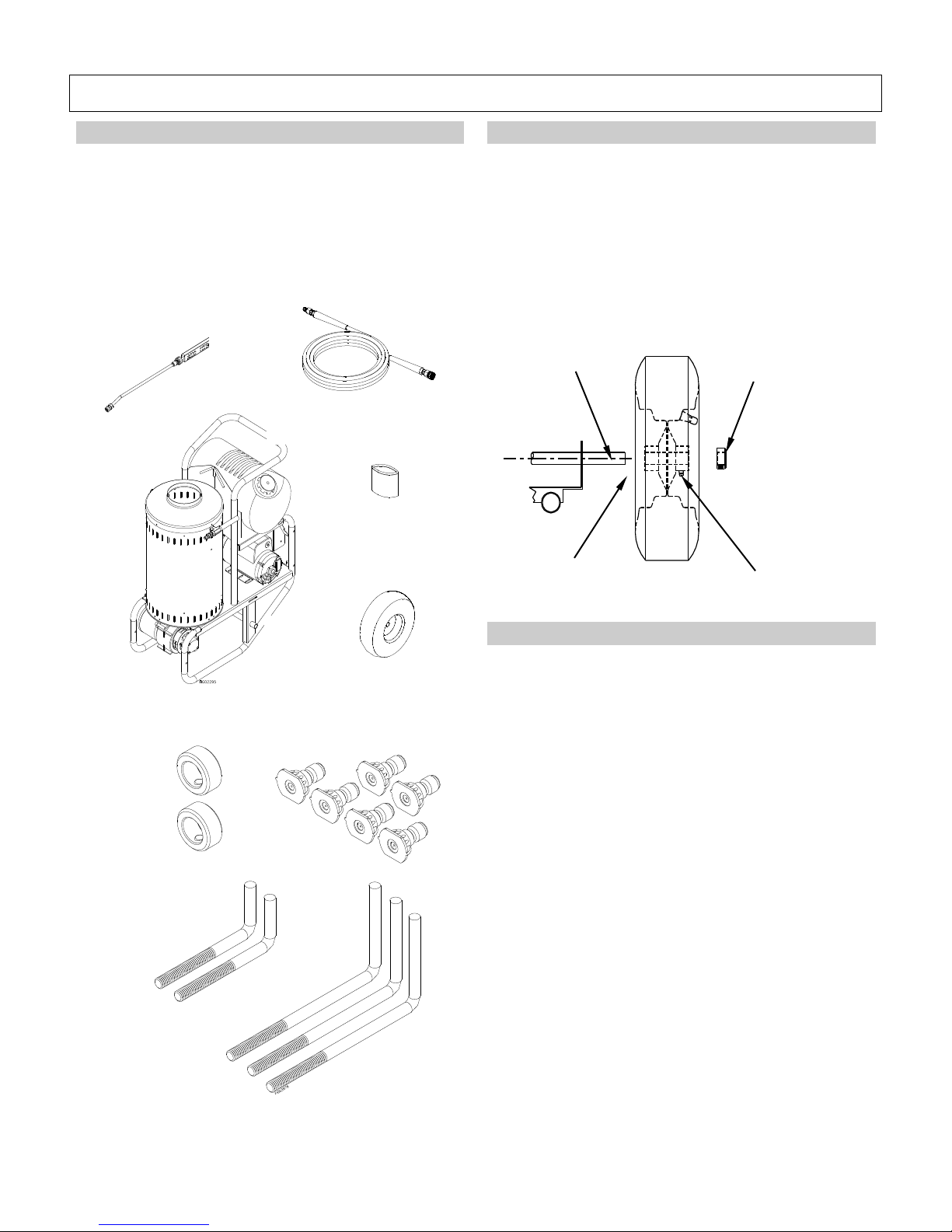

Step 1. Inspect & Unpack

Inspect pressure washer immediately after delivery for

missing parts or damage. Find and separate

components identified in Figure 4 and Figure 5.

• For missing components, contact Product

Support at 1-800-270-0810.

• For damaged components, contact the freight

company that delivered the unit and file a claim.

Figure 4 – Pressure Washer Components

Figure 5 – Parts to be Installed

Step 2. Assembly

Insert nozzles in spaces provided on the control panel.

To install wheels, refer to Figure 6:

• Raise pressure washer off floor using blocks or

ramps and secure.

• Install two wheels with grease zerk away from

frame.

• Slide wheel retainers onto end of each axle.

Tighten retainer setscrew with a hex wrench.

Figure 6

Step 3. Verify Electrical Connection

Grounding

Product must be grounded. The supply cord is equipped

with an equipment-grounding conductor and a

grounding plug. This plug must be plugged into an outlet

that is properly installed and grounded in accordance

with all local codes and ordinances.

Ground Fault Circuit Interrupter Protection

Connecting the pressure washer through some type of

ground fault circuit interrupter (GFCI) protector is

required to comply with the National Electric Code

(NFPA 70) and to provide additional protection from the

risk of electric shock.

Note: Before use, your GFCI should be tested

at either built-in or receptacle base.

The GFCI is built into the power cord plug.

• This GFCI device provides additional protection

from the risk of electric shock. If replacement of

the plug or cord is needed, use only identical

replacement parts.

Wheel

Qty-2

Manual Bag

Qty-1

High Pressure Hose

Qty-1

Spray

Gun

Qty-1

Pressure

Washer

Qty-1

Gun

Hooks

Qty-2

Wheel

Retainers

Qty-2

Hose

Hooks

Qty-3

Nozzles

Qty-6

Wheel

Retainer

Wheel

Axle

Grease Zerk

MEI 10-9-12

11

DANGER: Electrocution hazard

Improper connection of the equipment or grounding

conductor can result in a risk of electrocution. Check

with a qualified electrician or service personnel if you

are in doubt as to whether an outlet is properly

grounded. Do not modify the plug provided with the

product. If it will not fit the outlet, have a proper outlet

installed by a qualified electrician. Do not use any type

adapter with this product.

Extension Cord and Usage

Use only 3-wire extension cords that:

• Have 3 prong grounding-type plugs and 3-pole

cord connectors that accept the plug from the

product.

• Are intended for outdoor use, identified by the

marking, “Acceptable for use with outdoor

appliances; store indoors while not in use.”

• Have an electrical amperage rating not less than

the rating of the product.

Usage Precautions:

• Do not yank on any cord to disconnect.

• Keep cord away from heat and sharp edges.

• Always disconnect the extension cord from the

receptacle before disconnecting the product from

the extension cord.

Electric Shock Accident

If an electric shock occurs to a victim, immediately shut

down the source of electrical power. If this is not

possible, avoid direct contact with victim. Use a nonconducting implement, such as a dry rope or board, to

free the victim from the live conductor. Apply first aid

and get immediate medical help.

Moving and Handling

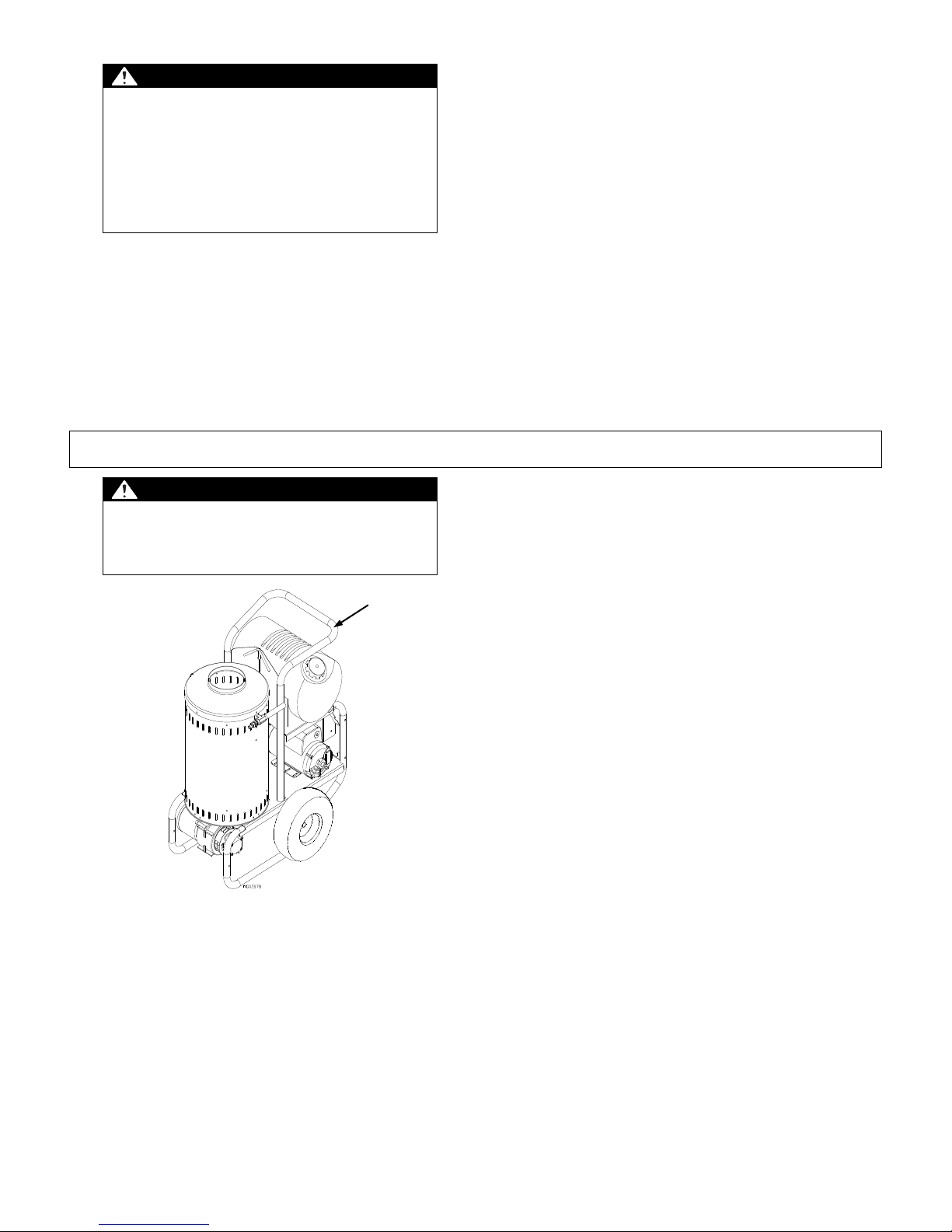

WARNING: Lifting hazard

The pressure washer is heavy. It can crush and cause

serious injury if it rolls out of control or tips over. Follow

the instructions below for safely moving the pressure

washer.

Figure 7

Moving your pressure washer around

• Use handle to manually move pressure washer.

• To turn, push down slightly on handle and pivot

pressure washer on its wheels. Do not move or

operate cross-wise on a slope. High center of gravity

can cause tipping.

• Block wheels to prevent inadvertent movement.

• Never pull by hose. Do not move this machine by

pulling on the hose. Hose or connections could fail

and result in catastrophic high-pressure release of

fluid as well as hose whipping.

To reduce risk of injury, do not attempt to manually lift

the pressure washer. Use a shallow ramp to raise or

lower pressure washer to a different elevation.

Handle

MEI 10-9-12

12

Before Each Use

Follow the steps below prior to each use.

Step 1: Inspect Equipment

Electrical

• Inspect cord before using. Do not use if cord is

damaged.

• Connect only to properly grounded outlet.

• Keep all connections dry and off the ground.

• Do not touch plug with wet hands.

• If product is provided with a GFCI built into the power

cord plug, use only identical parts if replacement is

necessary.

Pump Oil

Check oil level with sight glass (or dip stick). If low, add

type of oil indicated below.

See “Specifications” section of this manual to determine

type of pump you have.

a. Comet pumps: Use Universal Tractor

Transmission Oil or Mobil 1 Synthetic 15W-50 oil.

b. Cat pumps: Use SAE30 non-detergent oil or Cat

Pump Oil Item #22158.

Replace oil fill cap after any additions.

Figure 8

Spray System

Because of the high-pressure fluid hazards, a special

check must be made before each use to look for signs

of wear, cracks, looseness or leaks in the hoses, fittings,

wand, trigger gun and connections. See special

instructions for checking and repairing high-pressure

hoses within “Maintenance & Repair” section.

• Check and clean nozzle orifice.

• Clean garden hose water inlet filter. (See

Maintenance instructions.)

WARNING: High pressure fluid injection

hazard

High-pressure fluid discharge from leaks (even pinsized) or ruptured components can pierce skin and

inject fluid into the body. Injection injury can result in

blood poisoning and/or severe tissue damage leading to

infection, gangrene, and possibly amputation.

WARNING: Respond to fluid injection

immediately

If injured by high-pressure fluid, no matter how small

the wound is, see a doctor at once. A typical injection

injury may be a small puncture wound that does not

look serious. However, severe infection or reaction can

result if proper medical treatment is not administered

immediately by a doctor who is familiar with injection

injuries.

Burner Fuel System (if heated water to be

used)

Inspect burner fuel system for leaks BEFORE starting

pressure washer. Look for:

• Signs of leaks, wetted areas, or deterioration

• Chafed or spongy fuel hose

• Loose connections

• Loose or missing fuel hose clamps

• Damaged fuel tank

WARNING: Fuel leak hazard

Burner fuels are highly flammable and fuel leaks can

result in fire or explosions. You can be burned and

seriously injured if there is a fuel leak when you start

the pressure washer.

Periodic Maintenance

Other periodic maintenance is listed within

“Maintenance & Repair” section.

Note: Do not start pressure washer until all

needed repairs have been completed.

Oil Sight

Glass

Oil Fill

Cap

Drain Plug

Loading...

Loading...