Page 1

Air Compressor Pump

Item # 45929 & 45930

®

M35982F

OWNER’S MANUAL

Quick Facts

Pump Oil

Maximum

RPM

Minimum

Horsepower

Displacement 45929: 11.3 CFM

CFM @ 90 psi 45929: 8.2

Rotation Pump crankshaft MUST rotate in direction of arrow cast into flywheel.

Drive Belt Flywheel requires “A” style belt

Air Flow Belt guard MUST allow maximum air flow past pump.

Check pump oil level before starting.

Use Non-detergent pump oil (item # 35605).

45929: 1570 RPM (700 RPM Minimum)

45930: 1450 RPM (700 RPM Minimum)

45929: 5.0 hp gas engine, 3.0 hp electric motor

45930: 5.5 hp gas engine, 4.0 hp electric motor

45930: 16.9 CFM

45930: 13.2

Any Questions, Comments, Problems, or Parts Orders

Call NorthStar Product Support 1-800-270-0810

Page 2

THANK YOU

Thank you for purchasing a NorthStar compressor pump. Your pump is designed for

long life, dependability, and the top performance you demand. Please take time now to

read through this manual so you can better understand the pump’s safety precautions.

Everyone who uses this pump must read and understand this manual. Enjoy the

exceptional performance of your NorthStar pump.

IMPORTANT

Make certain the operator:

- Reads and understands the manuals pertaining to this tank.

- Is instructed in safe and proper operation of this air compressor tank.

NOTICE

Northern Tool + Equipment reserves the right to make improvements in design and/or

changes in specifications at any time without incurring any obligation to install them on

units previously sold.

WARNINGS

ALWAYS bleed pressure from tank before servicing.

ALWAYS use air handling parts that are rated above the maximum allowable working

pressure of the tank.

ALWAYS drain tank daily or after each use. Rusted tanks can cause explosion and

cause severe injury or death.

ALWAYS read your owners manual before operating.

ALWAYS use at least one ASME safety relief valve rated at 200 psi or below.

ALWAYS use an ASME certified air receiver tank.

ALWAYS use Teflon tape on all treads to reduce leaks.

NEVER exceed the nameplate rating of the tank (200 psi working pressure). Exceeding

this rating can cause explosion and cause severe injury or death.

NEVER operate machine without a belt guard in place.

NEVER bypass, modify, or remove safety/relief valves.

NEVER direct air stream at people or animals

NEVER modify or repair tank, obtain an ASME replacement from a service center or

Product Support at 1-800-270-0810.

NEVER breathe receiver air. Can contain Carbon Monoxide or other contaminants.

Will cause serious injury or death.

NorthStar air compressor tanks are not designed for breathing air.

2

Page 3

COMPRESSOR LUBRICATION

CAUTION! Do not operate without lubricant or with inadequate lubricant.

Use of compressor without lubricant or inadequate lubricant voids all warranties.

Synthetic Lubricants

Synthetic lubricants are recommended after 50 hour break-in. Compressor life is greatly increased with the

use of synthetic lubricants. CAUTION! If you will be using synthetic lubricant, all downstream piping material

and system components must be compatible.

Suitable Viton®, Teflon®, Epoxy (Glass Filled), Oil Resistant Alkyd, Fluorosilicone, Flourocarbon,

Polysulfide, 2-Component Urethane, Nylon, Delrin®, Celcon®, High Nitrile Rubber (Buna N. NBR more

than 36 Acrylonite), Polyurethane, Polyethylene, Epichlorohydrin, Polyacrylate, Melamine,

Polypropylene, Baked Phenolics, Epoxy, Modified Alkyds

( ® indicates trademark of DuPont Corporation)

Not Recommended

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer, Varnish, Polystyrene, PVC, ABS,

Polycarbonite, Cellulose Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene Acrylonitile

(San), Butyl

Alternate Lubricants.

You may use petroleum-based lubricant that is premium quality, does not contain detergents, contains only

anti-rust, anti-oxidation, and anti-foam agents as additives, has a flashpoint of 440°F (227°C) or higher, and

has a auto-ignition point of 650°F (343°C) or higher.

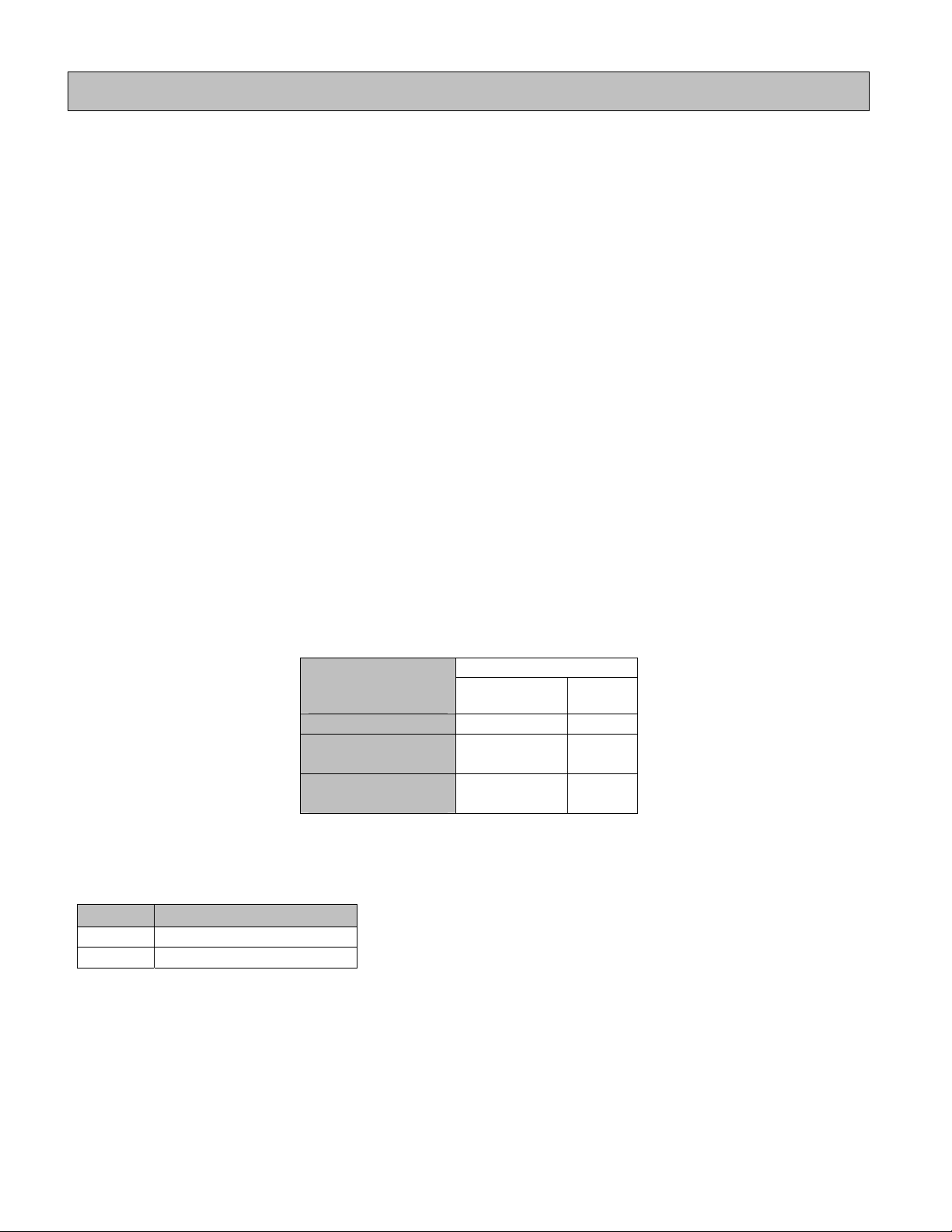

See the petroleum lubricant viscosity table below. The table is intended as a general guide only. Heavy duty

operating conditions require heavier viscosities. Refer specific operating conditions to NorthStar Product

Support at 1-800-270-0810

Temperature

around

Compressor

Below 40°F (4°C)

40°F to 80°F

(4°C to 27°C)

80°F to 100°F

(27°C to 37°C)

Pump Capacities.

Refer to the following table for crankcase capacity

Item # Crankcase Capacity

45929 24 oz.

45930 36 oz.

Viscosity Grade

ISO SAE

100 30

100

150

30

40

Page 4

779100 & 779101 Pump Assembly

Ref Description Model Part # Qty

1 Head

Head Bolt

2

(M8 x 45mm SHCS)

3 Aftercooler Gasket ALL AB3670200 1

4 Aftercooler, 118mm ALL AB2870100 1

Aftercooler Bolt

5

(M6 x 20mm SHCS)

6 Head Gasket ALL AB2850400 1

7 Valve Plate Assembly ALL AB2840050 1

8 Cylinder Gasket ALL AB2850300 1

9 Reducer ALL AB9050283 1

10 Cylinder

11 Crankcase Gasket ALL AB3650201 1

12 Cover N.D.E. ALL AB2060690 1

13 Bearing Cover Gasket ALL AB2050500 2

14 Bearing ALL AB9170030 2

15 Oil Sight Glass ALL AB9022001 1

16 Crankcase

Cylinder Bolt

17

(M6 x 20 mm SHCS)

18 Oil Drain Plug ALL AB9101154 1

Crankcase Bottom Bolt

19

(M5 x 15mm HHCS)

20 Oil Pan

45929 AB2860400 1

45930 AB3860400 1

ALL AB9101594 6

ALL AB9101144 2

45929 AB2830000 1

45930 AB3630000 1

45929 AB2860100 1

45930 AB3660100 1

ALL AB9107254 6

ALL AB9119273 8

45929 AB2660160 1

45930 AB3660160 1

00896

Ref Description Model Part # Qty

45929 AB2650101 1 21 Oil Pan Gasket

45930 AB3650100 1

22 Crankshaft

23 Cover D.E. ALL AB2060590 1

24 Oil Seal ALL AB9163010 1

25 Screw, Reverse Thread ALL AB9110014 1

26 Flywheel Washer ALL AB9004008 1

Flywheel, 280 mm 45929 AB2600100 1

27

Flywheel, 350 mm 45930 AB3600100 1

28 Bearing Housing Bolt

(M6 x 15mm SHCS)

29 Connecting Rod

30 Circlip ALL AB9140040 4

31 Pin ALL AB3021200 2

32 Piston

33 Piston Ring, ROF ALL AB9020071 1

34 Piston Ring, ROS ALL AB9020041 1

35 Piston Ring, AC ALL AB9020011 1

36 Breather Cap ALL AB9024003 1

37 Filter Assembly ALL AB2281000 1

Filter Assembly Bolt

38

(M6 x 30mm SHCS)

Complete Gasket Kit

45929 AB2860200 1

45930 AB3660200 1

ALL AB9101094 8

45929 AB2810100 2

45930 AB3610100 2

45929 AB1421100 2

45930 AB1021100 2

ALL AB9114279 2

45929 AB2850055 1

45930 AB3650055 1

4

Page 5

Air Compressor Exploded View

Note: We have included this exploded view of one of our air compressors to aid you in re-building your air

compressor. You can order any of the parts seen below by calling our Product Support at 1-800-270-0810.

Item Description Item Description

1 Belt Guard 20 5/8” Axle

2 Decal 21 Tire

3 GX Honda Decal 22 5/8” Jam Nut

4 Decal 23 5/8” Nut

5 Rotating Equip. Decal 24 Safety Valve, 150 psi

6 Stand-off 25 Skid Mount Leg

7 Guard Bracket 26 Unloader, 100-130 psi

8 Belt, A53 27 5/8” Compression Sleeve

9 Pump, B2800B 28 5/8” Compression Nut

10 Left Handle 29 5/8” Copper Tube

11 Right Handle 30 1/2” Elbow

12 Rubber Grip 31 Engine, Honda GC160

13 Drain Valve 32 Idle Solenoid Cable

14 33 CO Warning Decal

15 8 Gallon Tank 34 Nameplate

16 3/8” NPT Male Elbow 35 Operation Instr. Decal

17 3/8” Ball Valve 36 Warning Hot Decal

18 Decal 37 H Bushing

19 Air Gauge, Liquid Filled

38 Sheave, AK49K

00890

5

Page 6

This page has intentionally been left blank.

6

Page 7

Limited Warranty

Dear Valued Customer:

The NorthStar Product you just purchased is built with the finest material and craftsmanship. Use this

product properly and enjoy the benefits from its high performance. By purchasing a NorthStar product, you

show a desire for quality and durability. Like all mechanical equipment this unit requires a due amount of care.

Treat this unit like the high quality piece of machinery it is. Neglect and improper handling may impair its

performance. Please thoroughly read the instructions and understand the operation before using your product.

Limited Warranty

NorthStar shall warranty any piece of equipment manufactured, or parts of equipment manufactured, to be free

from defects in material or workmanship for a period of 90 days for noncommercial/nonrental use and a period

of 90 days for commercial/rental use from the date of purchase by user.

NorthStar shall warranty any wear item, including, but not limited to, valves, seals, pump diaphragms, hoses, and

filter elements to be free from defects in material or workmanship for a period of 90 days from the date of

purchase by user. This warranty applies to the original purchaser of the equipment and is non transferable.

Verification of purchase is the responsibility of the buyer. Parts will be replaced or repaired at no charge, except

when the equipment has failed due to lack of proper maintenance. Any misuse, abuse, alteration or improper

installation or operations will void warranty. Determining whether a part is to be replaced or repaired is the sole

decision of NorthStar.

NOTE: Some services performed by parties other than NorthStar may void warranty.

This warranty covers parts only. It will not provide for replacement of complete products due to defective parts.

Components not manufactured by NorthStar are guaranteed by their manufacturer and can be serviced at factory-

authorized locations near you. Any costs incurred due to replacement or repair of items outside of a NorthStar

approved facility is the responsibility of the buyer and not covered under warranty. NorthStar can supply you

with the service center location in your area.

This warranty specifically excludes the following; failure of parts due to damage caused by accident, fire, flood,

windstorm, acts of God, applications not approved by NorthStar in writing, corrosion caused by chemicals, use

of replacement parts which do not conform to manufacturer’s specifications, and damage caused by vandalism.

Additional exclusions: loss of running time, inconvenience, loss of income, or loss of use, including any implied

warranty of merchantability of fitness for a specific use.

Warranty does not cover items subject to normal wear such as tires, receptacles or any part subject to direct

physical contact by the public. This warranty does not cover any personal injury or damage to surrounding

property caused by failure of any part.

This warranty is in lieu of any other warranty expressed or implied and NorthStar assumes no other

responsibility or liability outside that expressed within this warranty.

Please fill in the following information and have it on hand when you call in on a warranty claim.

Customer Number: ______________________________________________________________

Date of Purchase: _______________________________________________________________

NorthStar Serial Number: ________________________________________________________

Item Number: __________________________________________________________________

7

Page 8

Manufactured by

Northern Tool + Equipment Co.,

2800 SouthCross Drive West

P.O. Box 1499 Burnsville, MN 55337-0499

®

8

Loading...

Loading...