Northern Airborne Technology 806 User Manual

Installation and Operation Manual

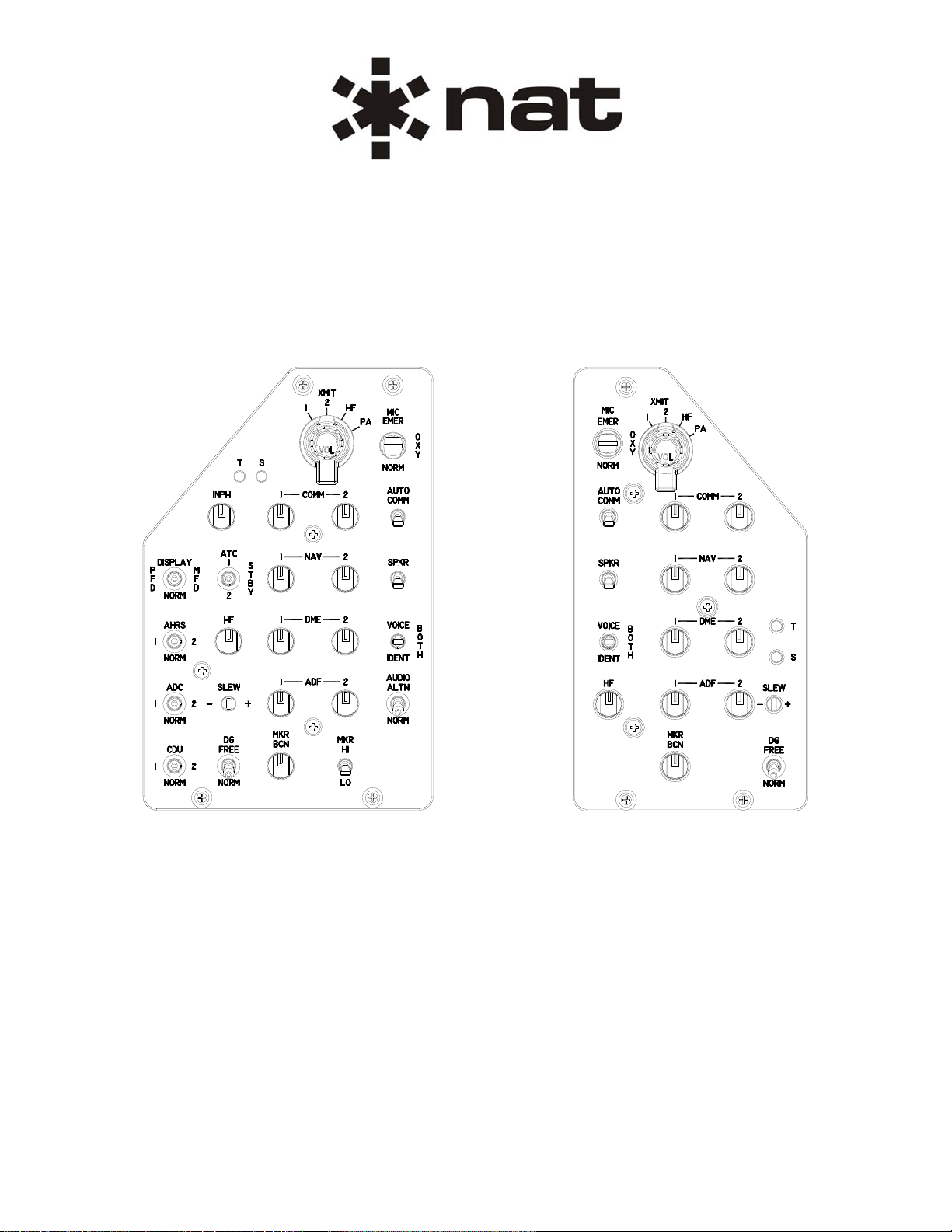

806 and 807

Audio Selector Panels

806

807

SM806

ISSUE 4.01

Northern Airborne Technology Ltd.

1925 Kirschner Road

Kelowna, BC, Canada.

V1Y 4N7

Telephone (250) 763-2232

Facsimile (250) 762-3374

Issued on the authority of Northern Airborne Technology Ltd.

Copyright 2008

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

Table of Contents

Section Title Page

1. Description

1.1 Introduction 1-1

1.2 Product Description 1-1

1.3 Design Features 1-1

1.4 Specifications 1-1

1.4.1 Electrical Specifications 1-1

1.4.2 Physical Specifications 1-4

1.4.3 Environmental Specifications 1-4

1.4.4 Product Approval 1-4

2. Installation

2.1 Introduction 2-1

2.2 Unpacking and Inspection 2-1

2.2.1 Warranty 2-1

2.3 Continued Airworthiness 2-1

2.4 Installation Procedures 2-1

2.4.1 Warnings 2-1

2.4.2 Cautions 2-2

2.4.3 Cabling and Wiring 2-2

2.4.4 Mounting 2-2

2.4.5 Post-Installation Checks 2-3

2.5 Adjustments and Connections 2-3

2.6 Accessories Required But Not Supplied 2-4

2.7 Installation Drawings 2-4

3. Operation

3.1 Introduction 3-1

3.2 General Information 3-1

3.3 Controls and Indicators 3-1

3.3.1 806 and 807 Control Functions 3-2

3.3.2 Row 1 Controls 3-2

3.3.3 Row 2 Controls 3-3

3.3.4 Row 3 Controls 3-3

3.3.5 Row 4 Controls 3-4

3.3.6 Row 5 Controls 3-5

3.3.7 Row 6 Controls 3-6

Installation and Operation Manual Page iii

ENG-FORM: 820-0114.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

Section 1 Description

1.1 Introduction

Information in this section consists of product description, design features and specifications for the 806

and 807 Audio Selector Panels. All derivative product information shall be contained in the applicable

manual supplement, which may be obtained from NAT as required.

Review all notes, warnings and cautions.

1.2 Product Description

The 806 and 807 Audio Selector Panels are each designed to control a separate 700 serie s Digital Audio

Control Amplifier. They provide microphone audio switching and keying operations for radio transmitters,

receivers and passenger address (PA) amplifier control.

1.3 Design Features

The 806 and 807 Audio Selector Panels continuously read the status of their own front panel switches

and potentiometers and compile this information into the form of a digital signal, which is sent to the

appropriate Model 700 in RS-422 serial format. The Model 700 receives, demultiplexes and converts this

digital signal into useful audio control information.

The 806 and 807 Audio Selector Panels are capable of digitally controlling all Model 700 amplifier

functions. These include the receiver input switches and individual volume controls, the sidetone input

switches and sidetone volume control, the microphone input switch, the interphone switches and volume

control, the cockpit speaker switch and volume control, the headphone volume control and the NAV/ADF

Voice/Ident filter switching functions.

The Audio Selector Panels have several dedicated hardwired switches. Both the 806 and 807 Audio

Selector Panels have MIC, HF, AUTO-COMM, SPKR, BOTH/VOICE/IDENT, GYRO MODE SEL and

SLEW switches. In addition, the 806 has AUDIO, MKR, ADC, CDU REV, AHRS and TDR switches.

1.4 Specifications

1.4.1 Electrical Specifications

Operating Voltage 27.5 Vdc nominal

(normal) 22.0 Vdc minimum

30.3 Vdc maximum

18.0 Vdc emergency

Operating Voltage 27.5 Vdc nominal

(abnormal) 20.5 Vdc minimum

32.2 Vdc maximum

Input Current 150 mA maximum

Lighting Voltage 115Vac, 400Hz, 20 mA rms max.

Section 1 Rev: 1.00 Issue 4 Page 1-1

ENG-FORM: 800-0113.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

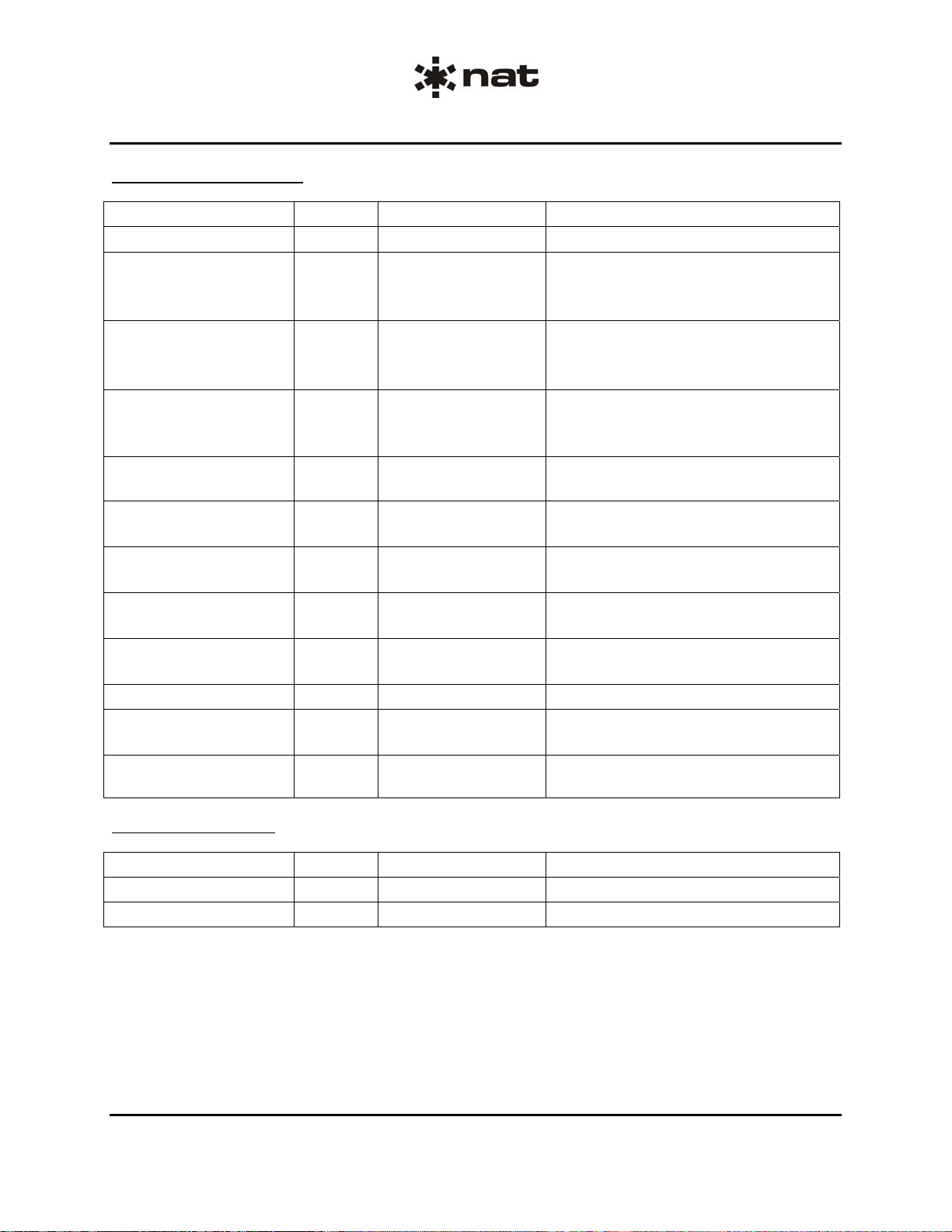

Input Signals (806 and 807)

NAME TYPE LABEL SPECIFICATION

Speaker input Audio SPKR INPUT HI Passive feed through

Normal Microphone Audio NORMAL MIC HI

Oxygen Microphone Audio OXY MIC HI

Hand Microphone Audio HAND MIC HI Impedance: External

Aural Warning Bypass Audio AW BYPASS IN

Oxygen Microphone

Interconnect

(Yoke) Push to Talk Key Control PTT KEY SWITCH Active Low

Normal / Oxygen

Microphone Key

Hand Microphone Key Control HAND MIC PTT Active Low

Vox Threshold Control VOX THLD 10 mA maximum

Interphones Listen Control INPH LISTEN Active Low

Test Mode Jumper In Control

Input Signals (807 only)

NAME TYPE LABEL SPECIFICATION

Emergency Switch In Control EMER SWITCH IN 28 Vdc, 100 mA maximum

Control OXY MIC MODE

INTERCONNECT

Control NORM/OXY

MIC TIP PTT

TEST MODE

JUMPER IN

Impedance: 130 Ω -65/+390 Ω

Circuitry: Single ended

Mic bias: 26 ±5mA dc

Impedance: 130 Ω -65/+390 Ω

Circuitry: Single ended

Mic bias: 26 ±5mA dc

Circuitry: Single ended

Mic bias: External

1.5 Vrms when AW BYPASS OUT

terminated into 600 Ω

Active Low

10 mA maximum

10 mA maximum

Active Low

10 mA maximum

10 mA maximum

10 mA maximum

10 mA maximum

Section 1 Rev: 1.00 Issue 4 Page 1-2

ENG-FORM: 800-0113.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

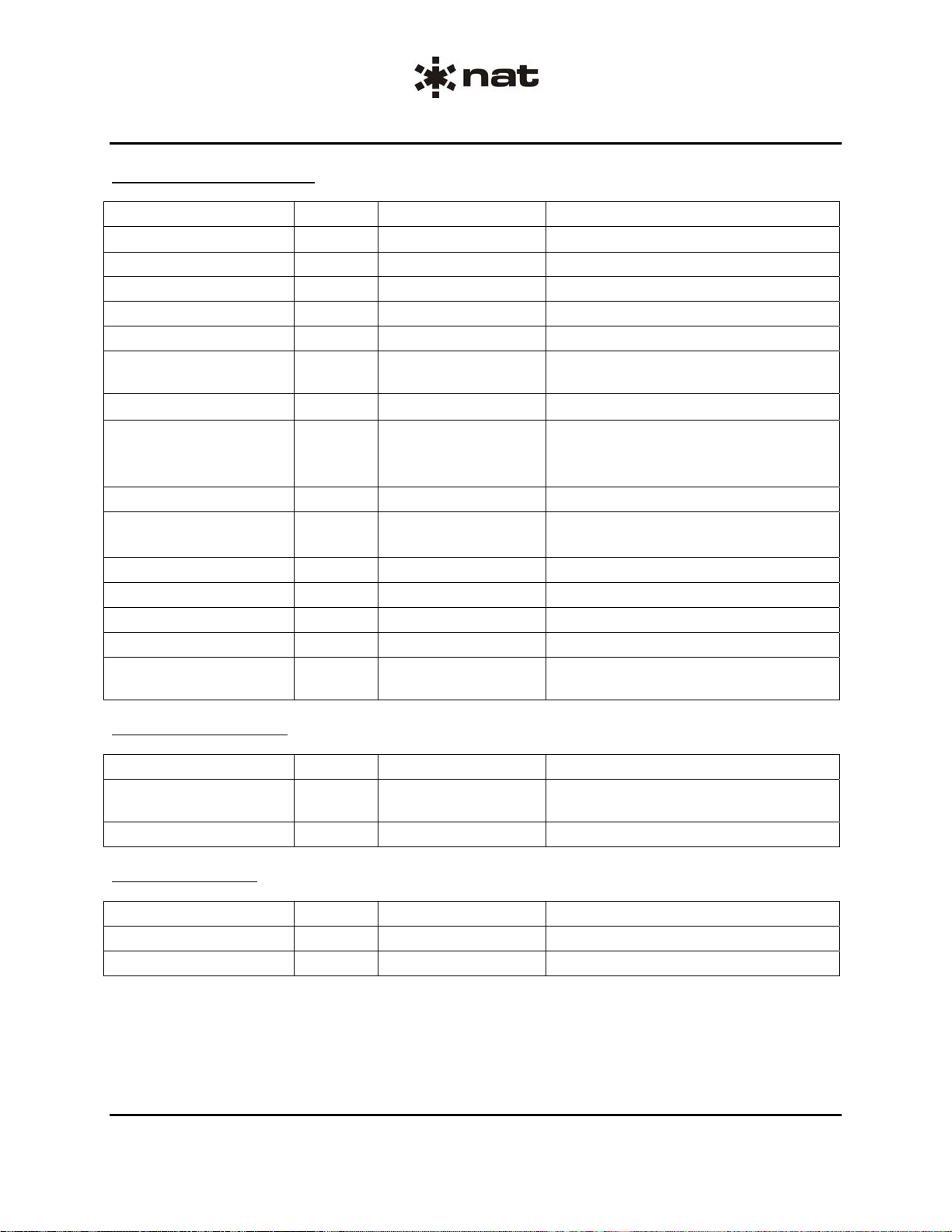

Output Signals (806 and 807)

NAME TYPE LABEL SPECIFICATION

Speaker Output Audio SPKR OUTPUT HI Passive feed through

Com 1 Microphone Audio COM 1 MIC HI Passive feed through

Com 2 Microphone Audio COM 2 MIC HI Passive feed through

HF Microphone Audio HF MIC HI Passive feed through

PA Microphone Audio PA MIC HI Passive feed through

Interphone Microphone

Out

Aural Warning Bypass Audio AW BYPASS OUT

Normal Switch Out Control NORM SWITCH OUT Optional

Interphone Switch Control INPH SWITCH 10 mA maximum

PA Volume Control PA VOL Optional

Com 1 Key Control COMM 1 KEY 10 mA maximum

Com 2 Key Control COMM 2 KEY 10 mA maximum

HF Key Control HF KEY 10 mA maximum

PA Key Control PA KEY 10 mA maximum

Test Mode Jumper Out Control

Output Signals (806 only)

NAME TYPE LABEL SPECIFICATION

Audio Alternate Switch Control

Emergency Switch Out Control EMER SWITCH OUT Passive feed through

Bi-directional Signals

NAME TYPE LABEL SPECIFICATION

Multiplexed Data Control MUX DATA OUT RS422 differential data transmission

Audio INPH MIC OUT Passive feed through

1.5 Vrms when terminated into 600 Ω

Active Low

10 mA maximum

10 mA maximum

TEST MODE

10 mA maximum

JUMPER OUT

AUDIO ALTN

28 Vdc, 100 mA maximum

SWITCH

Section 1 Rev: 1.00 Issue 4 Page 1-3

ENG-FORM: 800-0113.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

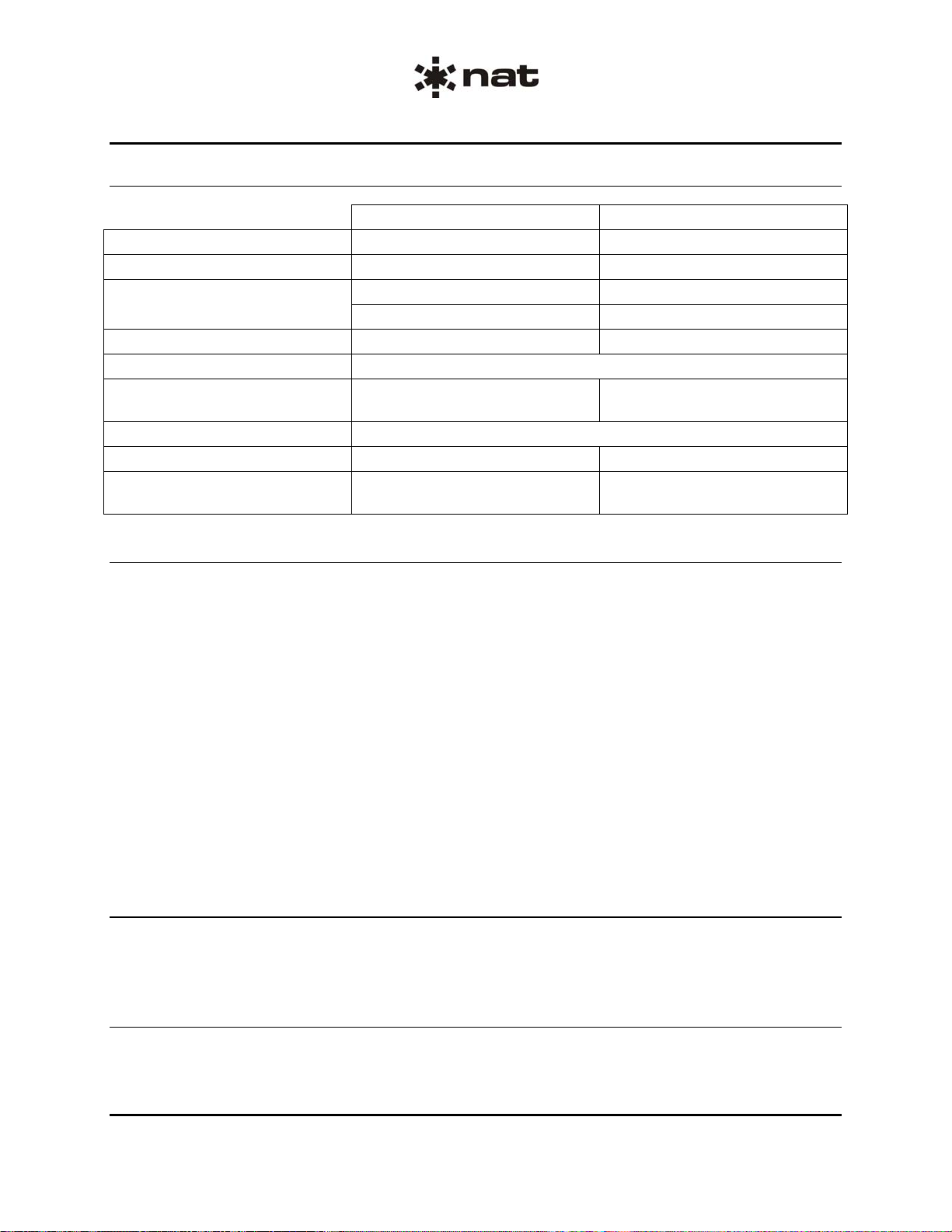

1.4.2 Physical Specifications

Model 806-000 Model 807-000

Height 8.07" (205.0 mm) max. 8.08" (205.2 mm) max.

Width 5.32" (135.1 mm) max. 4.30" (134.6 mm) max.

4.08" (103.6 mm) behind panel 4.58" (116.3 mm) behind panel Depth

5.47" (138.9 mm) max. 6.97" (151.6 mm) max.

Weight 2.81 lbs (1.28 kg) max. 2.35 lbs (1.07 kg) max.

Faceplate Grey, electro-luminescent

Mounting

Four 6-32, 513-4233

captive screws.

Material/Finish Aluminum / Chromate Conversion

Connector J1 61-Pin Circular, Male, Crimp 61-Pin Circular, Male, Crimp

Connector J2

61-Pin Circular, Male, Crimp,

Alt Keying

Three 6-32, 513-4233 captive

screws

61-Pin Circular, Male, Crimp

1.4.3 Environmental Specifications

Temperature -55 to +70°C (operating)

-55 to +85°C (survival)

Altitude 70,000 feet

Humidity 95%, 48 hours

Shock 12g (any axis)

Vibration Conforms to DO -160B category ‘P’

Qualification of the 806 and 807 Audio Selector Panels was completed in accordance with DO-160C

Env. Cat. [A2F2]–BA[BM]XXXXXXZ[BZ]AZZUZLXX. Tested to DO-160C pre-change 1, 2 and 3.

Note: Refer to Environmental Qualification Form located in Section 2 of this Manual for complete details

of the environmental categories.

1.4.4 Product Approval

FAA: TSO-C50c (RTCA/DO-170, RTCA/DO-160C, RTCA/DO-178B Level C)

Section 1 ends

Section 1 Rev: 1.00 Issue 4 Page 1-4

ENG-FORM: 800-0113.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

Section 2 Installation

2.1 Introduction

Information in this section consists of unpacking and inspection procedures, installation procedure s, po stinstallation checks and installation drawings for the 806 and 807 Audio Selector Panels.

Review all notes, warnings and cautions.

2.2 Unpacking and Inspection

Unpack the equipment carefully and locate the warranty card. Inspect the unit visually for damage due to

shipping and report all such claims immediately to the carrier involved. Check that all items listed below

are present before proceeding and report any shortage immediately to your supplier:

- Warranty Card

- Operators Manual

- Certificate of Conformity or Release Certification

2.2.1 Warranty

All Northern Airborne Technology Ltd. products are warranted for 2 years from date of installation by an

authorized NAT dealer, to be free of defects in workmanship or performance. This warranty covers all

materials and labour, but is exclusive of any transport to deliver the defective unit to and from NAT or its

designated warranty repair center, or any labour to remove or re-install the defective unit in the aircraft.

Contact NAT for any questions regarding this warranty, its applicability to your units and/or for return

authorization. NAT is the final arbitrator concerning warranty administration. Units which have been

physically damaged, burned, immersed in water or otherwise abused beyond the scope of normal use will

not be considered for warranty. WARRANTY IS VOID UNLESS THE PRODUCT IS INSTALLED BY AN

AUTHORIZED NAT DEALER. Product for which a warranty card is not returned shall be warranted from

date of manufacture.

2.3 Continued Airworthiness

Maintenance of the 806 and 807 Audio Selector Panels is ‘on condition’ only. Periodic maintenance of

this product is not required.

2.4 Installation Procedures

2.4.1 Warnings

WARNING:

High volume settings can cause hearing damage.

Set the headset volume control to the minimum volume setting prior to

conducting tests, and slowly increase the headset volume to a

comfortable listening level.

Section 2 Rev: 1.00 Issue 4 Page 2-1

ENG-FORM: 805-0115.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

2.4.2 Cautions

CAUTION:

In all installations, use shielded cable exactly as shown and ground as

indicated. Significant ground loop and noise problems may result from not

following these guidelines. Check that the chassis is grounded to provide

proper shield terminations.

Check that the microphone and headphone jacks are isolated from the

airframe ground. Use caution when routing microphone wiring, as it carries

low-level signals prone to coupling from other sources.

Do not take a ground from the instrument panel or similar location that shares

a ground return with a turn and bank, horizon or other motor driven

instrument. This may cause the unit to pick up the sound of the motor as

ground loop interference.

2.4.3 Cabling and Wiring

All wire shall be selected in accordance with the original aircraft manufacturer's Maintenance Instructions

or AC43.13-1B Change 1, Paragraphs 11-76 through 11-78. Unshielded wire types shall qualify to

MIL-W-22759 as specified in AC43.13-1B Change 1, Paragraphs 11-85, 11-86, and listed in Table 11-11.

For shielded wire applications, use Tefzel MIL-C-27500 shielded wire with solde r sleeve s (fo r shield

terminations) to make the most compact and easily terminated interconnect. Follow the connector map in

Section 2.7 as required.

Allow 3" from the end of the shielded wiring to the shield termination to allow the connector hood to be

easily installed. Reference the interconnect drawing in Section 2.7 for shield termination details. Aircraft

harnessing shall permit the unit to be lowered from the panel for easy access to all side adjustments. Do

NOT mount the unit until all adjustments have been performed.

Maintain wire segregation and route wiring in accordance with the original aircraft manufacturers

Maintenance Instructions.

Unless otherwise noted, all wiring shall be a minimum of 24 AWG, except power and ground lines, which

shall be a minimum of 22 AWG. Reference the Interconnect drawing for additional specifications. Check

that the ground connection is clean and well secured, and that it shares no path with any electrically noisy

aircraft accessories such as blowers, turn and bank instruments or similar loads. Power to this unit must

be supplied from a separate circuit breaker or fuse (fast blow), and not attached to any other circuit

breaker without additional protection. Verify that the selected circuit breaker size and wire gauge are

adequate for the installation using the techniques specified in AC43.13-1B Change 1, Paragraphs 11-47

through 11-51 and 11-66 through 11-69.

2.4.4 Mounting

No shock or vibration isolators are required for mounting. The unit should be mounted to a metal surface

and grounded to the aircraft ground structure. The unit and mounting surface is finished with an

electrically conductive film, which should not be removed for electrical bonding to any metal aircraft

ground structure because the coating prevents corrosion. The 806 is mounted using 4 ca ptive 6-32

screws, and the 807 is mounted using 3 captive 6-32 screws, which are supplied with the unit as part of

the enclosure front panel assembly.

Section 2 Rev: 1.00 Issue 4 Page 2-2

ENG-FORM: 805-0115.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

2.4.5 Post Installation Checks

2.4.5.1 Voltage/Resistance Chec ks

Do not attach the 806/807 until the following conditions are met.

Check the following:

a) Check P1-p for +28 Vdc relative to ground.

b) Check pins P1-CC and P1-DD for 110 Vac 400 Hz.

c) Check pins P1-q, P1-T and P1-H for continuity to ground (less than 0.5 Ω).

d) Check pin P1-BB for continuity to ground (less than 0.5 Ω) when the yoke PTT KEY switch is

activated.

e) Check all shielded cable grounds for continuity to ground (less than 0.5 Ω).

f) Check all speaker and mic inputs and outputs for correct Hi/Lo orientation.

2.4.5.2 Power On Checks

Power up the aircraft’s systems and confirm normal operation of all functions of the 806/807. Refer to

Section 3 (Operation) for specific operational details.

a) Begin with only the Pilot's headset installed, no hand mic. Confirm correct radio operation,

both receive and transmit. Check yoke (or cyclic) switch action. Check radio audio inputs a nd

selection of same.

b) Plug in the Co-pilot's headset. Check for correct ICS and SPLIT transmit operation. Check

that the Co-pilot loses transmit capability during PLT ISO. Check yoke switch functions.

c) Plug in the hand mic, if installed, and test for correct operation in all modes.

d) Plug in any remaining headsets, and check for correct ICS operation.

e) To verify proper operation, all functions and levels shall be checked in-flight.

f) Check that preset adjustments are completed before aircraft departure.

Upon satisfactory completion of all performance checks, make all required log book entries, electrical

load, weight and balance amendments and other documentation as required by your local regulatory

agency before releasing the aircraft for service.

2.5 Adjustments and Connections

The OXY MODE INPH VOL can be adjusted by rotating the potentiometer at the rear of the unit, which

can be accessed through an aperture in the chassis. The volume is increased by rotating the

potentiometer clockwise and decreased by rotating it counter clockwise.

Section 2 Rev: 1.00 Issue 4 Page 2-3

ENG-FORM: 805-0115.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

806 and 807 Audio Selector Panels

SM806 Installation and Operation Manual

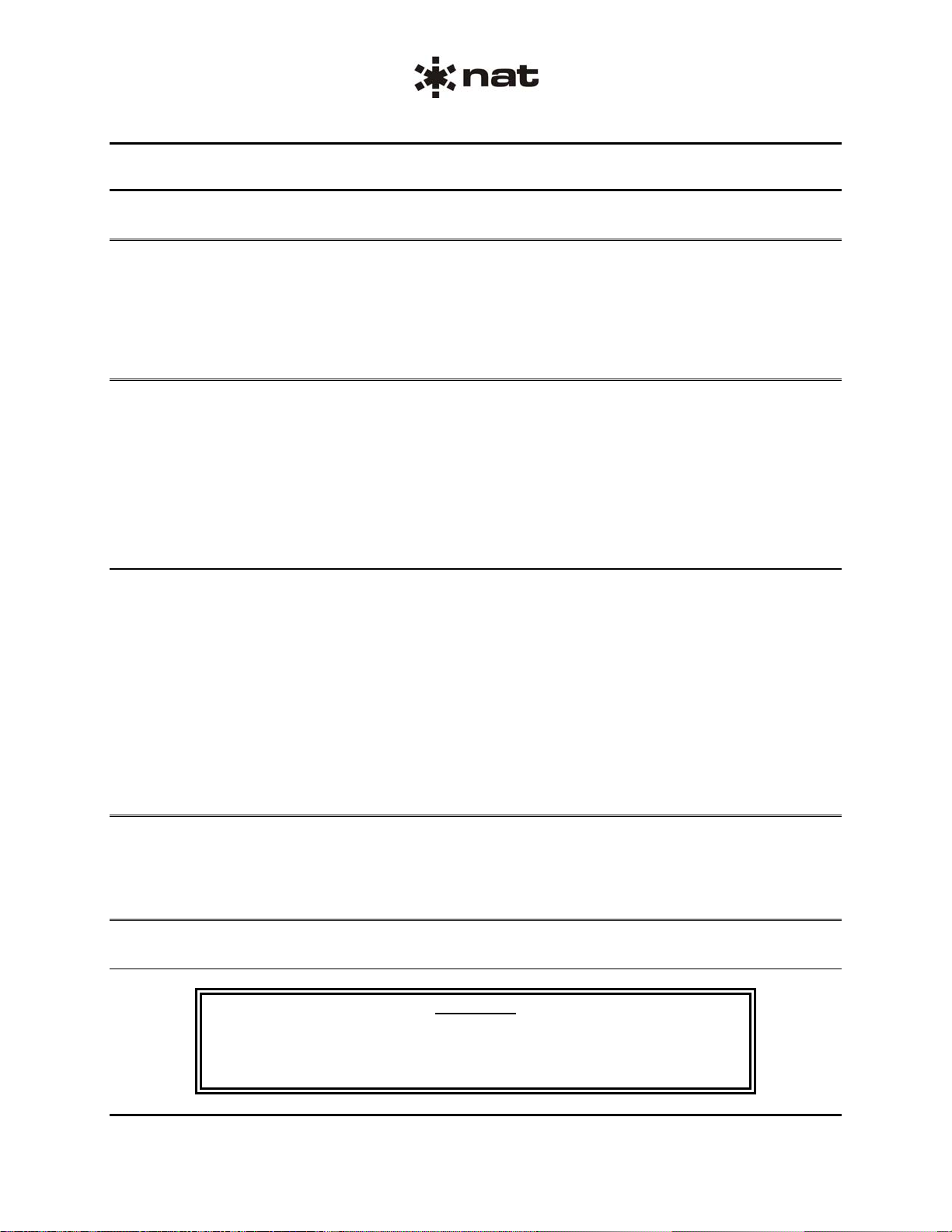

2.6 Accessories Required But Not Supplied

The aircraft connectors required to complete the installation are:

Item Ident Description Part No.

External Connector 1 J1 61 Pin Circular, Female, Crimp D38999/26WJ61SN

Models 806 and 807

External Connector 2 J2 Pin Circular, Female, Crimp, Alt Keying D38999/26WJ61SC

Models 806 only

Backshell, Strain Relief N/A N/A M85049/38-25W

Models 806 and 807

2.7 Installation Drawings

DOCUMENT REV. DESCRIPTION TYPE SERIAL NO.

806-000

806\000\403-0 1.00 Audio Selector Panel Interconnect All

806\000\403-1 1.00 Audio Selector Panel Interconnect All

806\000\403-2 1.00 Audio Selector Panel Interconnect All

806\000\403-3 1.00 Audio Selector Panel Interconnect All

806\000\405-0 1.00 Audio Selector Panel Connector Map All

806\000\952-0 1.01 Audio Selector Panel Custom Mechanical Installation Up to 1126

806\000\952-0 1.02 Audio Selector Panel Custom Mechanical Installation 1127 and up

806\521-0 1.00 Audio Selector Panel Environmental Qualification Form All

807-000

807\000\403-0 1.00 Audio Selector Panel Interconnect All

807\000\403-1 1.00 Audio Selector Panel Interconnect All

807\000\403-2 1.00 Audio Selector Panel Interconnect All

807\000\405-0 1.00 Audio Selector Panel Connector Map All

807\000\952-0 1.01 Audio Selector Panel Custom Mechanical Installation All

807\521-0 1.01 Audio Selector Panel Environmental Qualification Form All

Section 2 ends following the above documents

Section 2 Rev: 1.00 Issue 4 Page 2-4

ENG-FORM: 805-0115.DOT

CONFIDENTIAL AND PROPRIETARY TO NORTHERN AIR BORNE TECHNOLOGY LTD.

Loading...

Loading...