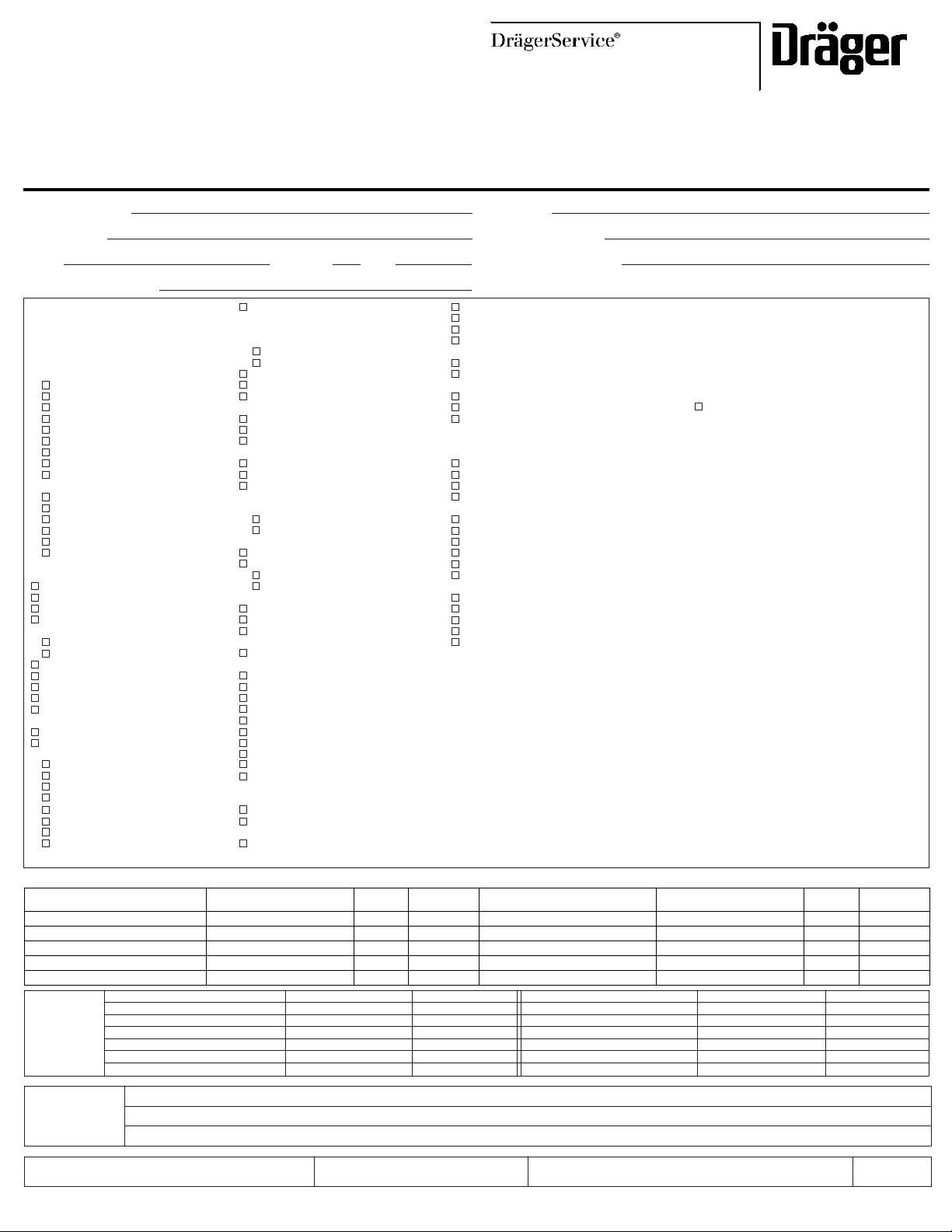

NORTH AMERICAN DRÄGER Evita Parts

Evita 2 Dura

Evita 4 PWS

3122 Commerce Drive

Telford, PA 18969 / USA

(215) 721-5402

(800) 543-5047

(215) 723-5935 FAX

INSTITUTION

ADDRESS

CITY STATE ZIP

TELEPHONE ( )

1. Device configuration and options

1.1 Operating data and configuration

SW Version:

Hours of operation:

S/N E4 control panel:

ID number:

1.2 Hardware options

Capno plus (CO2)

S/N CO2 sensor:

Sat (SpO2)

DC

Link

NeoFlow

Multi function PCB

2nd ambient pressure sensor

Remote pad

1.3 Software options

Breathing Support Package

ATC

SW4 Plus

Monitoring Plus (E2d only)

Ventilation Plus (E2d only)

Service Plus (E2d only)

2 General condition Evita

2.1 Labeling

2.1.1 Operating Instructions

2.2.2 Labels on Evita

2.2 Electronic System

2.3 Pneumatic System

2.4 Expiratory Valves

Valve No. 1, S/N: _______________

Valve No. 2, S/N: _______________

2.5 Control Unit Evita 4

2.6 Front panel Evita 2 dura

2.7 CO2 measurement (option)

2.8 SpO2 measurement (option)

2.9 Remote pad (option)

2.10 Trolleys

2.10.1 Two-column trolley

2.10.2 Single-column trolley

2.11 Accessories (if available)

Hinged arm

AW Temperature sensor

Dräger tubing system

Dräger test lung

Dräger neonatal test lung

NeoFlow sensor

Central supply hoses

High pressure line filters

REPLACEMENT PARTS

PARTS DISCRIPTION

3 Replacement of routine

maintenance parts

3.1 Parts in the pneumatics

3.1.1 Expiratory diaphragm System:

Exp. valve No. 1

Exp. valve No. 2

3.1.2 Cooling air filter

3.1.3 Filter in gas supply block

3.1.4 Pressure regulators

3.2 Parts in electronics

3.2.1 Cooling air filter

3.2.2 Battery on CPU PCB

3.2.3 Real time clock on CPU PCB

3.3 Parts in DC module

3.3.1 Internal batteries

3.3.2 External batteries

3.4 Option High Pressure Line Filters

4 Functional test

4.1 Ex.-Valve, non-return valve D5.1

Exp. valve No. 1

Exp. valve No. 2

4.2 Self test and check in standby

4.2.1 Self test after power on

4.2.2 Device check in standby

Leakage exp. valve No. 1

Leakage exp. valve No. 2

4.3 Testing of pneumatic safety valves

4.3.1 Pneumatic valve D3.1

4.3.2 Pneumatic valve D3.2 and D3.1

4.3.3 Pneumatic valve D3.3 (100 mbar)

4.4 Testing of pressure sensors

4.4.1 Supply and ambient pressure

sensors at ambient pressure

4.4.2 Supply pressure sensors

4.4.3 Paw sensors at ambient pressure

4.4.4 Paw sensors

4.5 O2 sensor

4.6 Touch screen Evita 4

4.7 Display type: _________________

4.8 Tests in CMV ventilation mode

4.8.1 Calibration of sensors

4.8.2 Pressure reducer and dosing R1.2

4.8.3 Flow sensor switch

4.9 Testing mixer, expiratory flow

measurements and O2 measurement

4.9.1 O2 metering and O2 measurement

4.9.2 Volume metering and flow

measurement at 500 ml

4.9.3 Volume metering and flow

measurement at 50 ml

PART NUMBER QTY S/N

DEVICE

PART NUMBER

SERIAL NUMBER

4.10 Paw measurement and control

4.10.1 Testing/calibration PEEP valve

4.10.2 Testing Paw measurement/control

4.10.3 Testing bronchial suction program

4.11 Temperature measurement

4.11.1 Testing electronics with sensor simulator

4.11.2 Testing temperature sensor (option)

4.12 Testing keypad and Remote pad

4.12.1 Testing keypad

4.12.2 Testing Remote pad

4.13 Mains failure and data saving for

units w/o DC option

4.14 DC Module (option)

4.14.1 Function with external batteries

4.14.1.1 Charging external battery

4.14.1.2 Function with external battery

4.14.1 Function with internal batteries

4.15 SpO2 measurement (option)

4.16 CO2 measurement (option)

4.16.1 Lamp in CO2 sensor

4.16.2 Calibration with test gas

4.16.3 Testing with span check filter

4.17 Canceling error list

4.18 Mains failure and data saving for units with DC option

4.19 Patient section heating with fan

4.20 Testing interfaces (option

4.20.1 COM 1

4.20.2 COM 2 and COM 3

4.20.3 Analog outputs

4.20.4 Nurse Call

4.20.5 ILV interface

5 Electrical safety tests

5.1 Chassis Resistance:___________

5.2 Enclosure leakage current (Chassis leakage testing)

N.C. normal polarity: ____________

N.C. reverse polarity: ___________

S.F.C. normal polarity: __________

S.F.C. reverse polarity: __________

5.3 Earth leakage current (Ground wire leakage testing)

N.C. normal polarity: ____________

N.C. reverse polarity: ___________

S.F.C. normal polarity: __________

S.F.C. reverse polarity: __________

PARTS DISCRIPTION

PART NUMBER QTY S/N

5.4 Patient leakage current entire electronics to earth

N.C. normal polarity: _____________

N.C. reverse polarity: ____________

S.F.C. normal polarity: ___________

S.F.C. reverse polarity: __________

5.5 Patient leakage current SpO2 to earth

N.C. normal polarity: _____________

N.C. reverse polarity: ____________

S.F.C. normal polarity: ___________

6 Unit ready for operation

DEVICE

TEST

EQUIP.

RECOMMENDATIONS/

GENERAL

COMMENTS

DrägerService is a division of Draeger Medical, Inc.

CAL DUE

ID DEVICE

Customer SignatureT. S. R. Signature I. D. No. Date

REGULATORY AFFAIRS

CAL DUE

ID

AW4115068 REV A

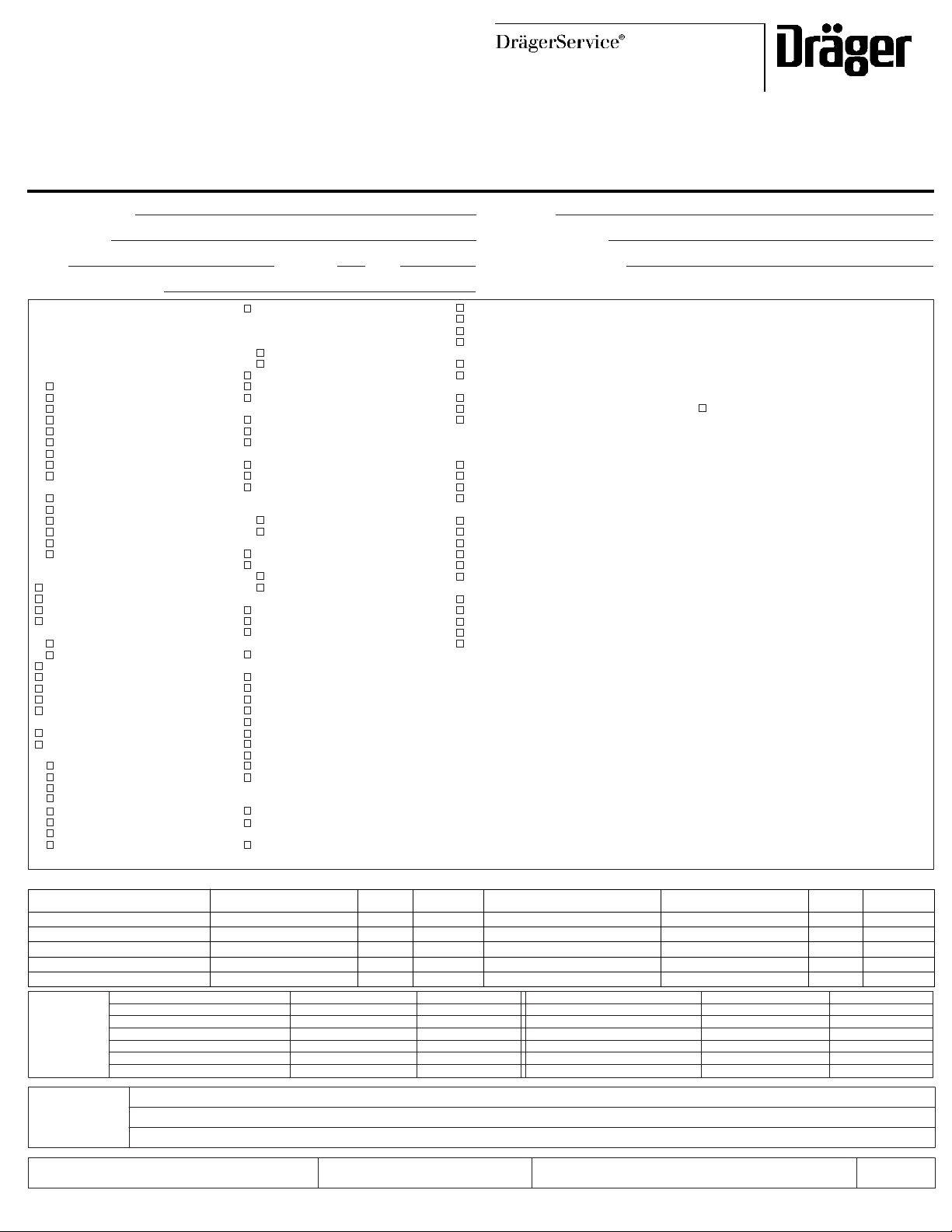

Evita 2 Dura

Evita 4 PWS

3122 Commerce Drive

Telford, PA 18969 / USA

(215) 721-5402

(800) 543-5047

(215) 723-5935 FAX

INSTITUTION

ADDRESS

CITY STATE ZIP

TELEPHONE ( )

1. Device configuration and options

1.1 Operating data and configuration

SW Version:

Hours of operation:

S/N E4 control panel:

ID number:

1.2 Hardware options

Capno plus (CO2)

S/N CO2 sensor:

Sat (SpO2)

DC

Link

NeoFlow

Multi function PCB

2nd ambient pressure sensor

Remote pad

1.3 Software options

Breathing Support Package

ATC

SW4 Plus

Monitoring Plus (E2d only)

Ventilation Plus (E2d only)

Service Plus (E2d only)

2 General condition Evita

2.1 Labeling

2.1.1 Operating Instructions

2.2.2 Labels on Evita

2.2 Electronic System

2.3 Pneumatic System

2.4 Expiratory Valves

Valve No. 1, S/N: _______________

Valve No. 2, S/N: _______________

2.5 Control Unit Evita 4

2.6 Front panel Evita 2 dura

2.7 CO2 measurement (option)

2.8 SpO2 measurement (option)

2.9 Remote pad (option)

2.10 Trolleys

2.10.1 Two-column trolley

2.10.2 Single-column trolley

2.11 Accessories (if available)

Hinged arm

AW Temperature sensor

Dräger tubing system

Dräger test lung

Dräger neonatal test lung

NeoFlow sensor

Central supply hoses

High pressure line filters

REPLACEMENT PARTS

PARTS DISCRIPTION

3 Replacement of routine

maintenance parts

3.1 Parts in the pneumatics

3.1.1 Expiratory diaphragm System:

Exp. valve No. 1

Exp. valve No. 2

3.1.2 Cooling air filter

3.1.3 Filter in gas supply block

3.1.4 Pressure regulators

3.2 Parts in electronics

3.2.1 Cooling air filter

3.2.2 Battery on CPU PCB

3.2.3 Real time clock on CPU PCB

3.3 Parts in DC module

3.3.1 Internal batteries

3.3.2 External batteries

3.4 Option High Pressure Line Filters

4 Functional test

4.1 Ex.-Valve, non-return valve D5.1

Exp. valve No. 1

Exp. valve No. 2

4.2 Self test and check in standby

4.2.1 Self test after power on

4.2.2 Device check in standby

Leakage exp. valve No. 1

Leakage exp. valve No. 2

4.3 Testing of pneumatic safety valves

4.3.1 Pneumatic valve D3.1

4.3.2 Pneumatic valve D3.2 and D3.1

4.3.3 Pneumatic valve D3.3 (100 mbar)

4.4 Testing of pressure sensors

4.4.1 Supply and ambient pressure

sensors at ambient pressure

4.4.2 Supply pressure sensors

4.4.3 Paw sensors at ambient pressure

4.4.4 Paw sensors

4.5 O2 sensor

4.6 Touch screen Evita 4

4.7 Display type: _________________

4.8 Tests in CMV ventilation mode

4.8.1 Calibration of sensors

4.8.2 Pressure reducer and dosing R1.2

4.8.3 Flow sensor switch

4.9 Testing mixer, expiratory flow

measurements and O2 measurement

4.9.1 O2 metering and O2 measurement

4.9.2 Volume metering and flow

measurement at 500 ml

4.9.3 Volume metering and flow

measurement at 50 ml

PART NUMBER QTY S/N

DEVICE

PART NUMBER

SERIAL NUMBER

4.10 Paw measurement and control

4.10.1 Testing/calibration PEEP valve

4.10.2 Testing Paw measurement/control

4.10.3 Testing bronchial suction program

4.11 Temperature measurement

4.11.1 Testing electronics with sensor simulator

4.11.2 Testing temperature sensor (option)

4.12 Testing keypad and Remote pad

4.12.1 Testing keypad

4.12.2 Testing Remote pad

4.13 Mains failure and data saving for

units w/o DC option

4.14 DC Module (option)

4.14.1 Function with external batteries

4.14.1.1 Charging external battery

4.14.1.2 Function with external battery

4.14.1 Function with internal batteries

4.15 SpO2 measurement (option)

4.16 CO2 measurement (option)

4.16.1 Lamp in CO2 sensor

4.16.2 Calibration with test gas

4.16.3 Testing with span check filter

4.17 Canceling error list

4.18 Mains failure and data saving for units with DC option

4.19 Patient section heating with fan

4.20 Testing interfaces (option

4.20.1 COM 1

4.20.2 COM 2 and COM 3

4.20.3 Analog outputs

4.20.4 Nurse Call

4.20.5 ILV interface

5 Electrical safety tests

5.1 Chassis Resistance:___________

5.2 Enclosure leakage current (Chassis leakage testing)

N.C. normal polarity: ____________

N.C. reverse polarity: ___________

S.F.C. normal polarity: __________

S.F.C. reverse polarity: __________

5.3 Earth leakage current (Ground wire leakage testing)

N.C. normal polarity: ____________

N.C. reverse polarity: ___________

S.F.C. normal polarity: __________

S.F.C. reverse polarity: __________

PARTS DISCRIPTION

PART NUMBER QTY S/N

5.4 Patient leakage current entire electronics to earth

N.C. normal polarity: _____________

N.C. reverse polarity: ____________

S.F.C. normal polarity: ___________

S.F.C. reverse polarity: __________

5.5 Patient leakage current SpO2 to earth

N.C. normal polarity: _____________

N.C. reverse polarity: ____________

S.F.C. normal polarity: ___________

6 Unit ready for operation

DEVICE

TEST

EQUIP.

RECOMMENDATIONS/

GENERAL

COMMENTS

DrägerService is a division of Draeger Medical, Inc.

CAL DUE

ID DEVICE

Customer SignatureT. S. R. Signature I. D. No. Date

TECHNICAL SERVICE REPRESENTATIVE/ SERVICE ORGANIZATION

CAL DUE

ID

AW4115068 REV A

Loading...

Loading...