NORTH AMERICAN DRÄGER Evita User manual

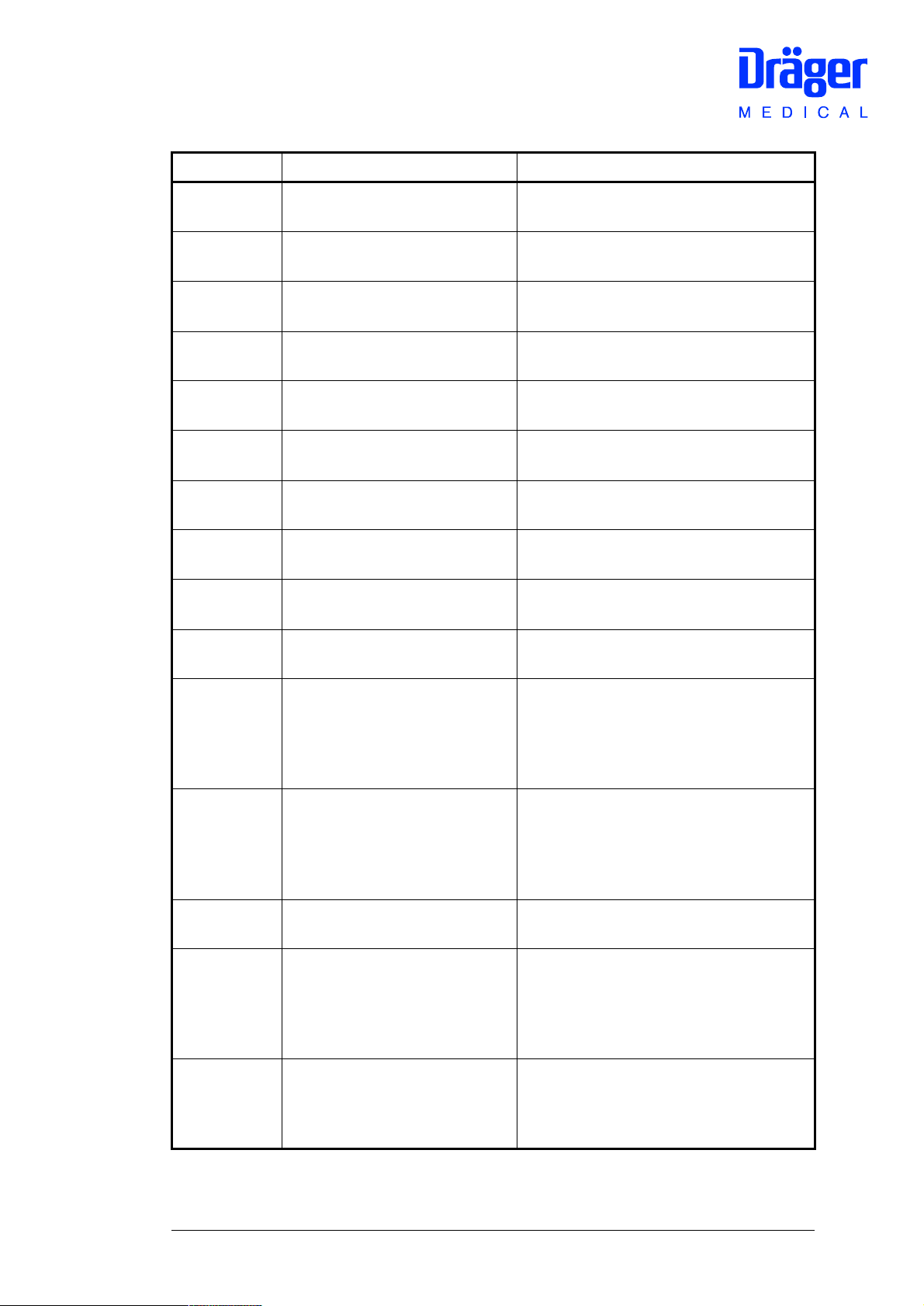

Repair Instructions – Service No./Modi, Error list

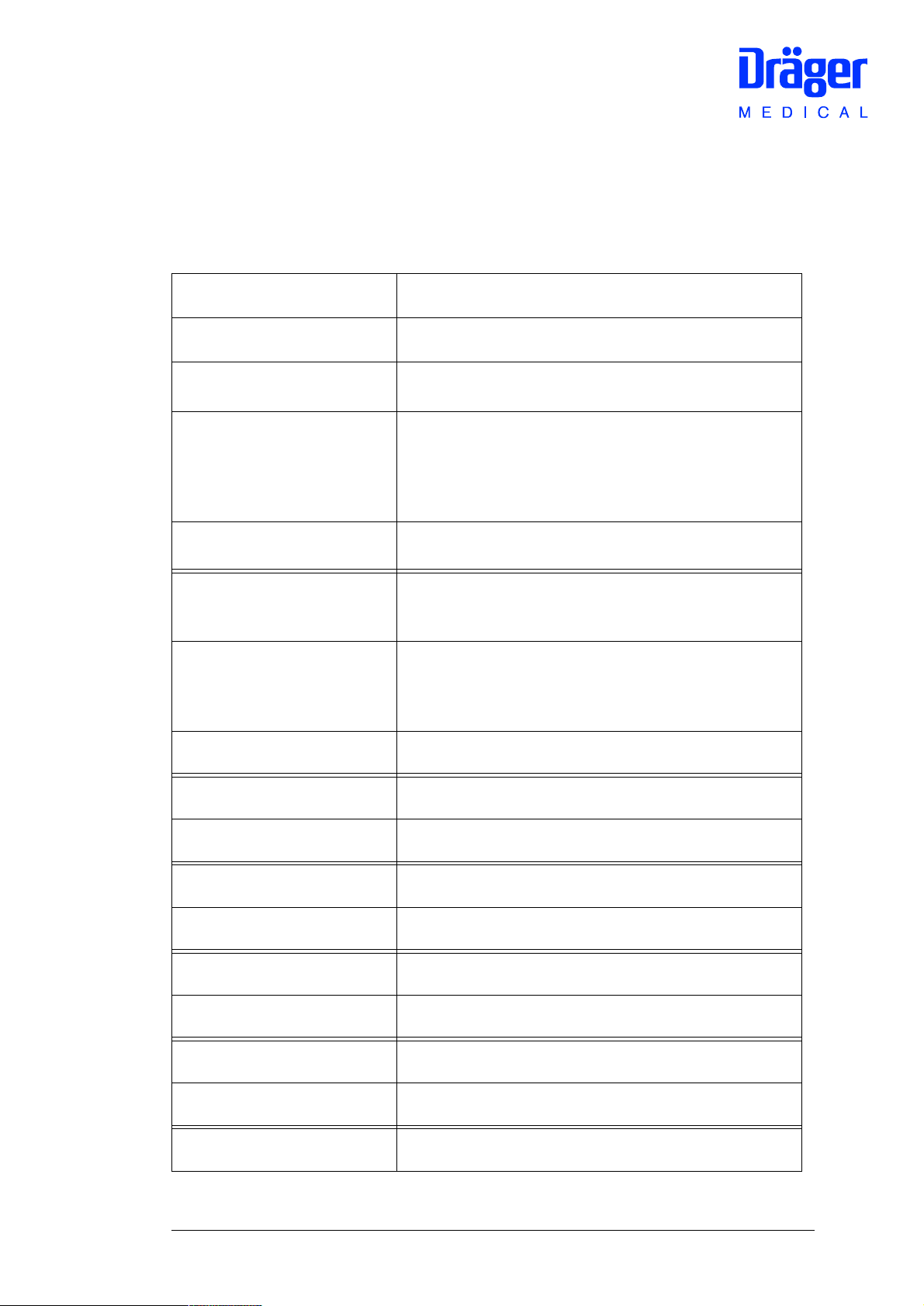

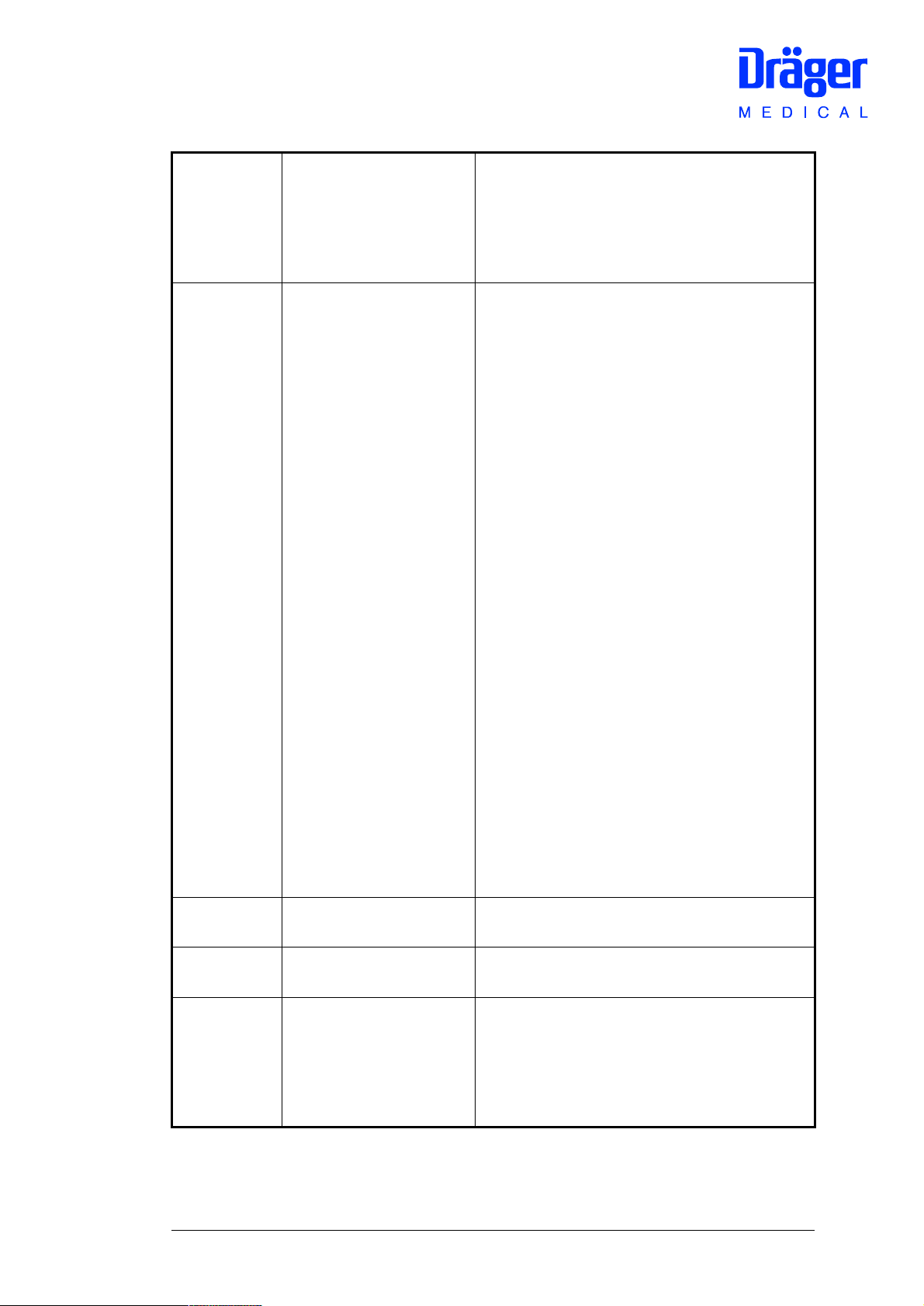

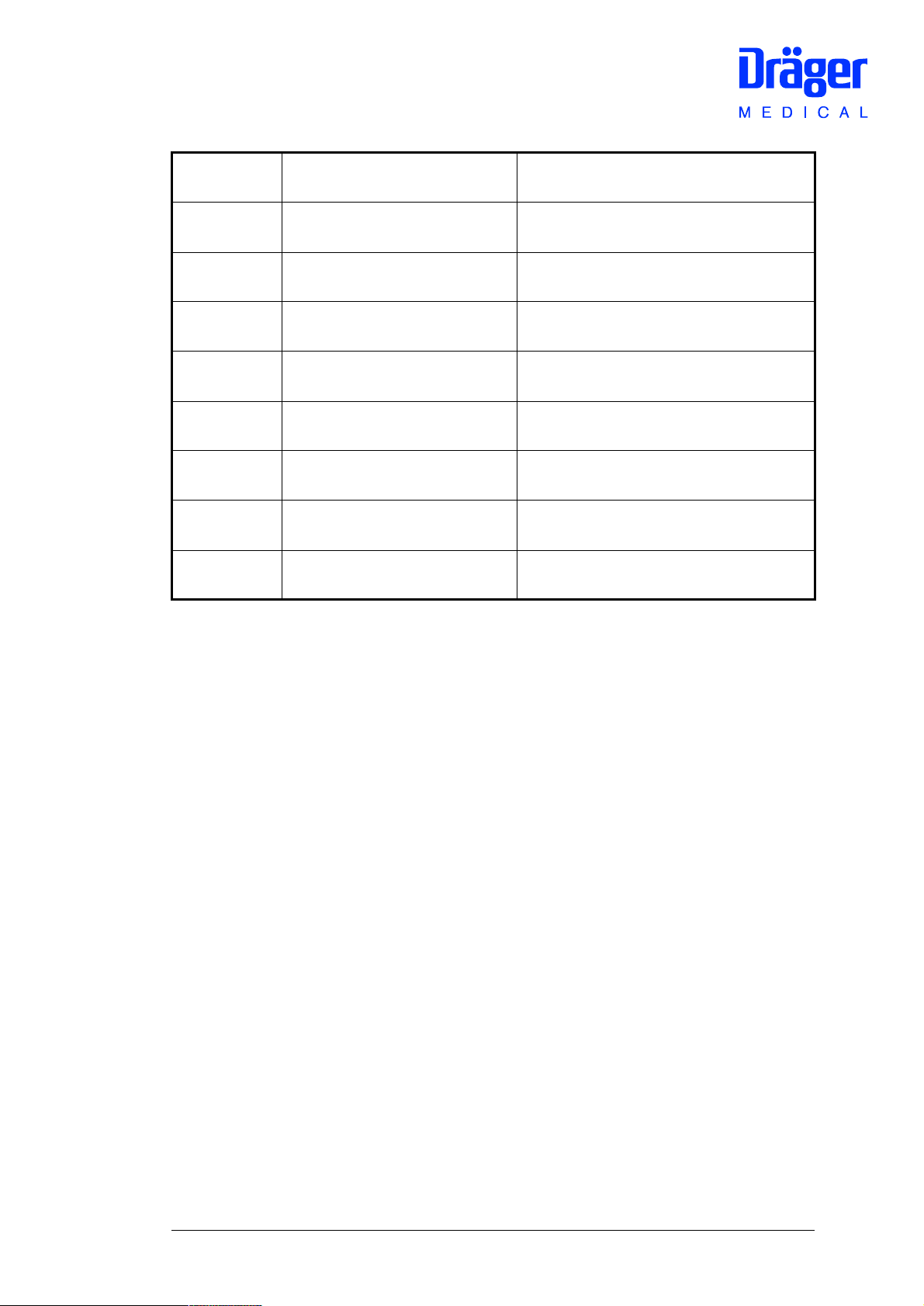

1 Service and Access Codes/Release Option

Enter the number under “service diagnosis” (Evita) or ventilation (Evita 2 dura) during

operation. For release Hardware Option wait 30 seconds and switch Evita off and on.

Release Software Option:

Refer to section of "Repair Instructions - Service No./ Modi, Error list" chapter 3.5.2,

Diagnosis page “Option Release” (release of software options), page 76.

1.1 Service Numbers for Software Versions 1.00 to 1.04 and 1.08

3 0 3 2 to change configuration of ventilation

1 3 1 1 to clear user logbook

4 6 5 5 to select Service Mode

4 6 4 4

+

4 6 5 5

to select Service Mode with info text in DS error list

1 3 2 2 to clear DS error list

4 7 4 7 to select calibration of PEEP valve

4 7 4 8 to clear PEEP valve calibration data

4 8 1 1 to activate DC module

4 8 1 0 to deactivate DC module

6 7 9 5 to activate CO

8 3 9 6 to activate SpO

module

2

module

2

9 4 9 5 to deactivate all options

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 1

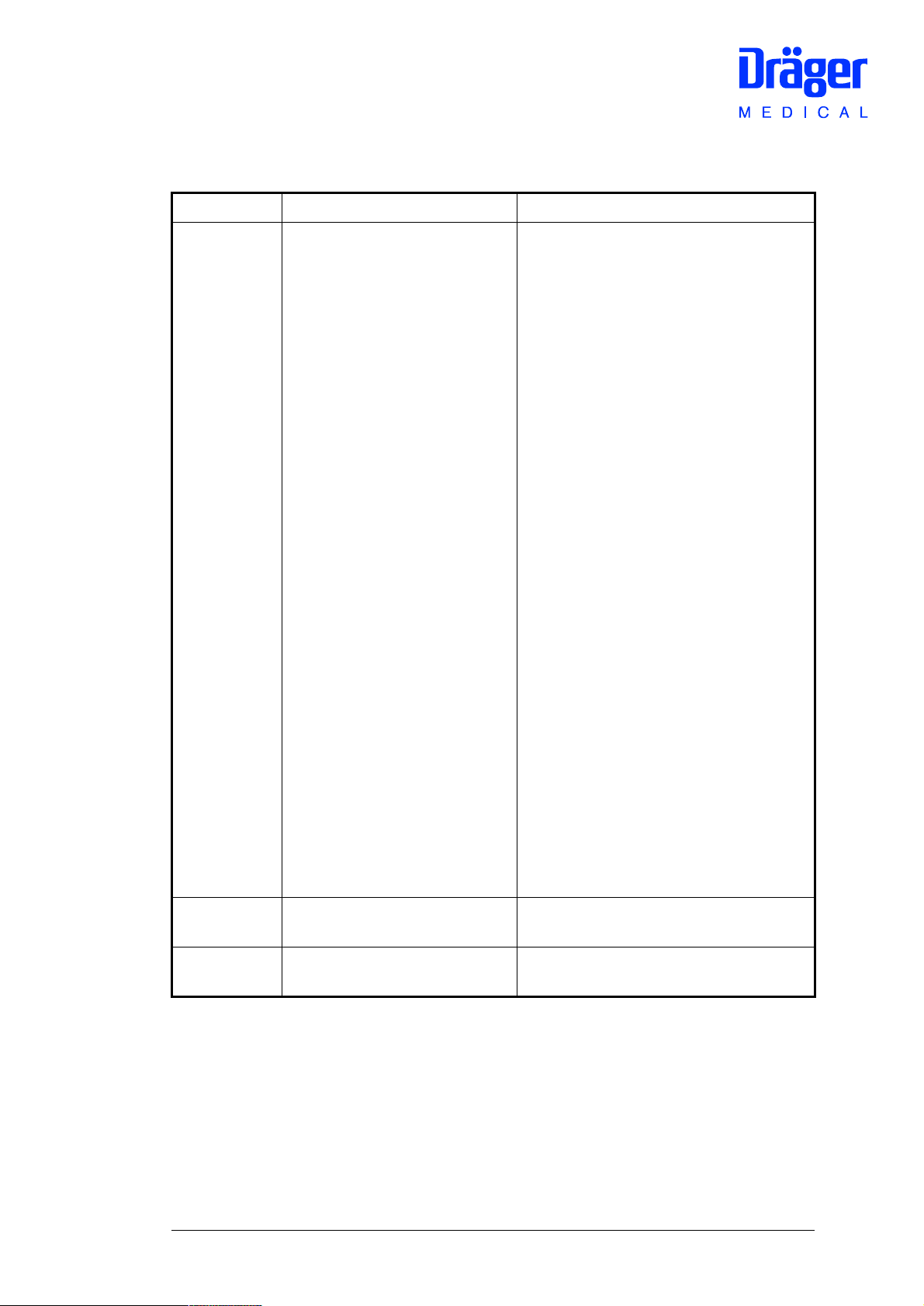

1.2 Service Numbers for Evita 4 and Evita 2 dura

Evita 4 with Software 1.05, 1.06, 1.07, 1.09 and 2.n and higher; for Evita 2 dura as of

Software 3.00

3 0 3 2 To change configuration of ventilation.

1 3 9 9 + 1 3 1 1 To clear user logbook.

3 9 9 9 + 3 9 4 8 Deactivation of leakage compensation (re-activated by

switching the Evita off/on).

3 9 9 9 + 3 9 5 8 Deactivation of BTPS conversion (re-activated after

switching the Evita off/on). Important: This is only

possible if P Ambient is larger than 960 mbar,

otherwise the Evita will perform a re-start (see Test

Certificate).

7 2 9 9 + 7 2 3 5 + 0 0 0 0 Deactivation of the hose compliance correction (re-

activated after switching the Evita off/on).

4 6 5 5 To select Service Mode. With Evita 2 dura units without

“Service Plus” option, connect a download cable

(service coding) to COM1.

4 6 4 4 + 4 6 5 5 To select Service Mode with info text in DS error

list.(Evita 4 only). With Evita 2 dura units, software

version 3.00 or higher, without “Service Plus” option,

connect a download cable (service coding) to COM1.

1 3 9 9 + 1 3 2 2 To clear DS error list

4 7 9 9 + 4 7 4 7 To select calibration of PEEP valve

4 7 9 9 + 4 7 4 8 To clear PEEP valve calibration data

4 8 1 1 To activate DC module

4 8 9 9 + 4 8 1 0 To deactivate DC module

6 7 9 5 To activate CO

6 7 9 9 + 6 7 9 4 To deactivate CO

8 3 9 6 To activate SpO

8 3 9 9 + 8 3 9 5 To deactivate SpO

module

2

module

2

module

2

module

2

For internal use only. Copyright reserved.

R5664500T025664800.fm

9 4 9 9 + 9 4 9 5 To deactivate all options

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 2

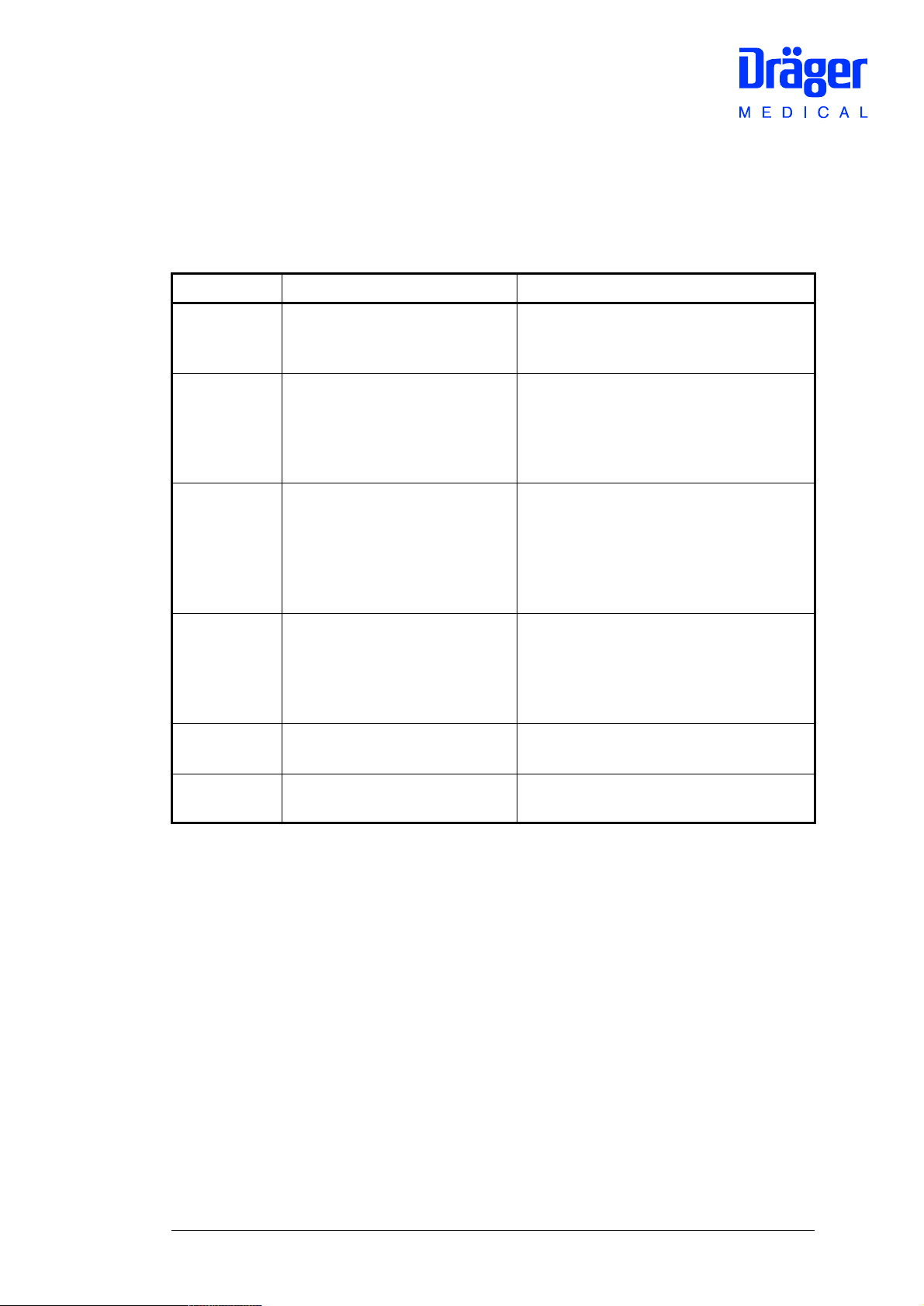

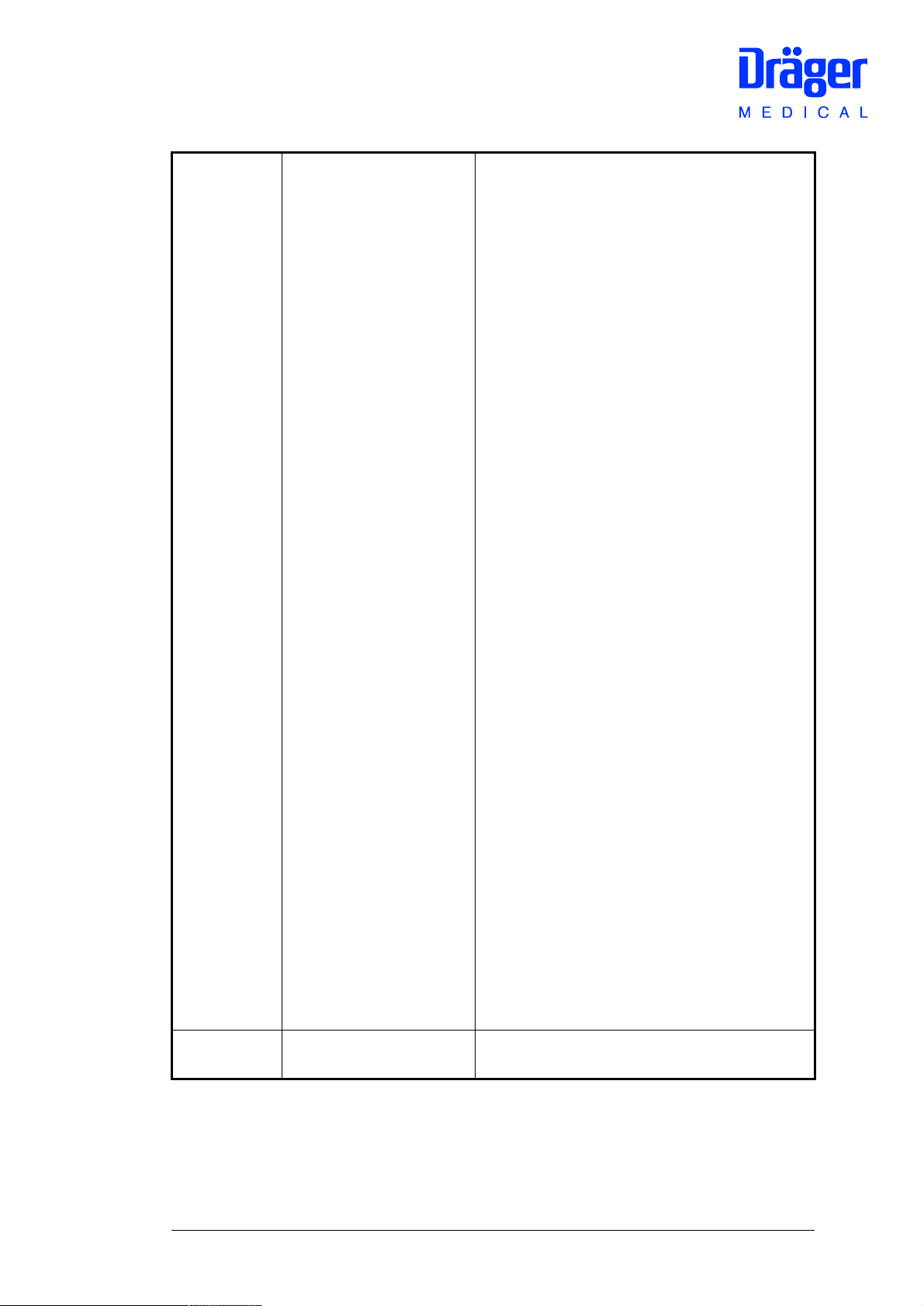

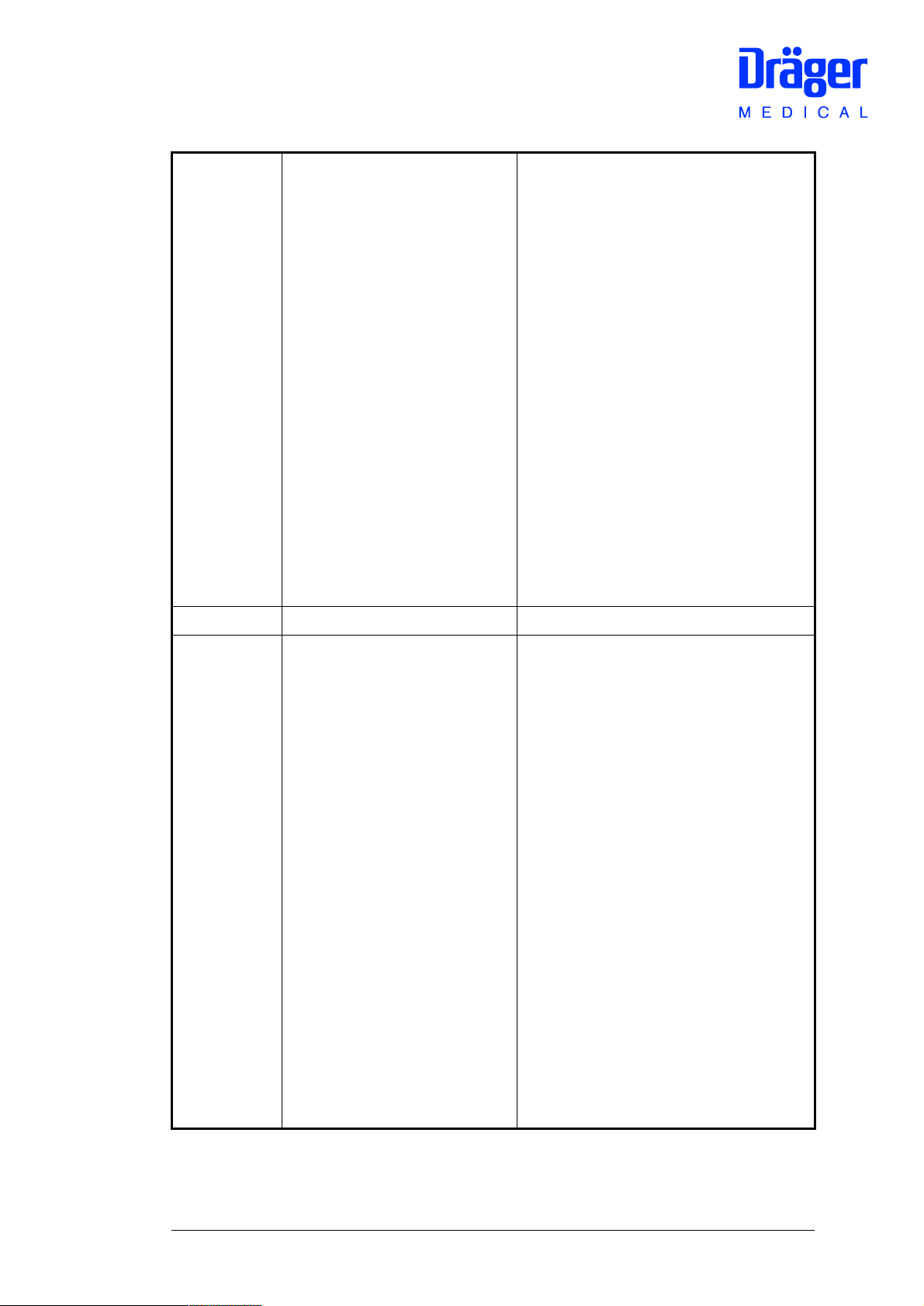

2 List of Evita 2 dura/Evita 4 error numbers

Error list as at February 1998 (corresponding to SW 3.n of Evita 4/Evita 2 Dura)

Overview of error number assignment

02 Error recognised by safety software which runs on CPU 68332 PCB,

Pneumatic Controller PCB and Graphics Controller PCB (Evita 4) or Front

Panel PCB (Evita 2 dura)

03 Error in control console components not located on printed circuit card of

Graphics Controller PCB (Evita 4) or Front Panel PCB (Evita 2 dura), e.g.

Touchscreen

04 Error in electronic unit components not located on printed circuit cards, e.g.

power pack

05 Error in pneumatic system components

06 Error in extension box components

07 Software error in Rosy operating system which runs on CPU 68332 PCB,

Pneumatic Controller PCB, Graphics Controller PCB (Evita 4) or Front Panel

PCB (Evita 2 dura) and Communication PCB.

08 Exception

09 For future expansion

10 Error on Pneumatic Controller PCB

11 Error on HPSV Controller (Air) PCB or in Air mixer cartridge. On the Evita 4,

such errors are stored with software version 1.09 and as of version 2.21; on the

Evita 2 dura with versions greater than 3.00. With older software versions, such

errors are only displayed as "mixer fault". The error status can be read out in

diagnosis mode if the error is currently present.

12 Error on HPSV Controller (O2) PCB or in O2 mixer cartridge. On the Evita 4,

such errors are stored with software version 1.09 and as of version 2.21; on the

Evita 2 dura with versions greater than 3.00. With older software versions, such

errors are only displayed as "mixer fault". The error status can be read out in

diagnosis mode if the error is currently present.

13 Error on CPU 68332 PCB

14 Error on CO2 Carrier PCB

15 Error on Communication PCB

16 Error on Paediatric Flow PCB

17 Error on Graphics Controller PCB (Evita 4) or Front Panel PCB (Evita 2 dura)

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 3

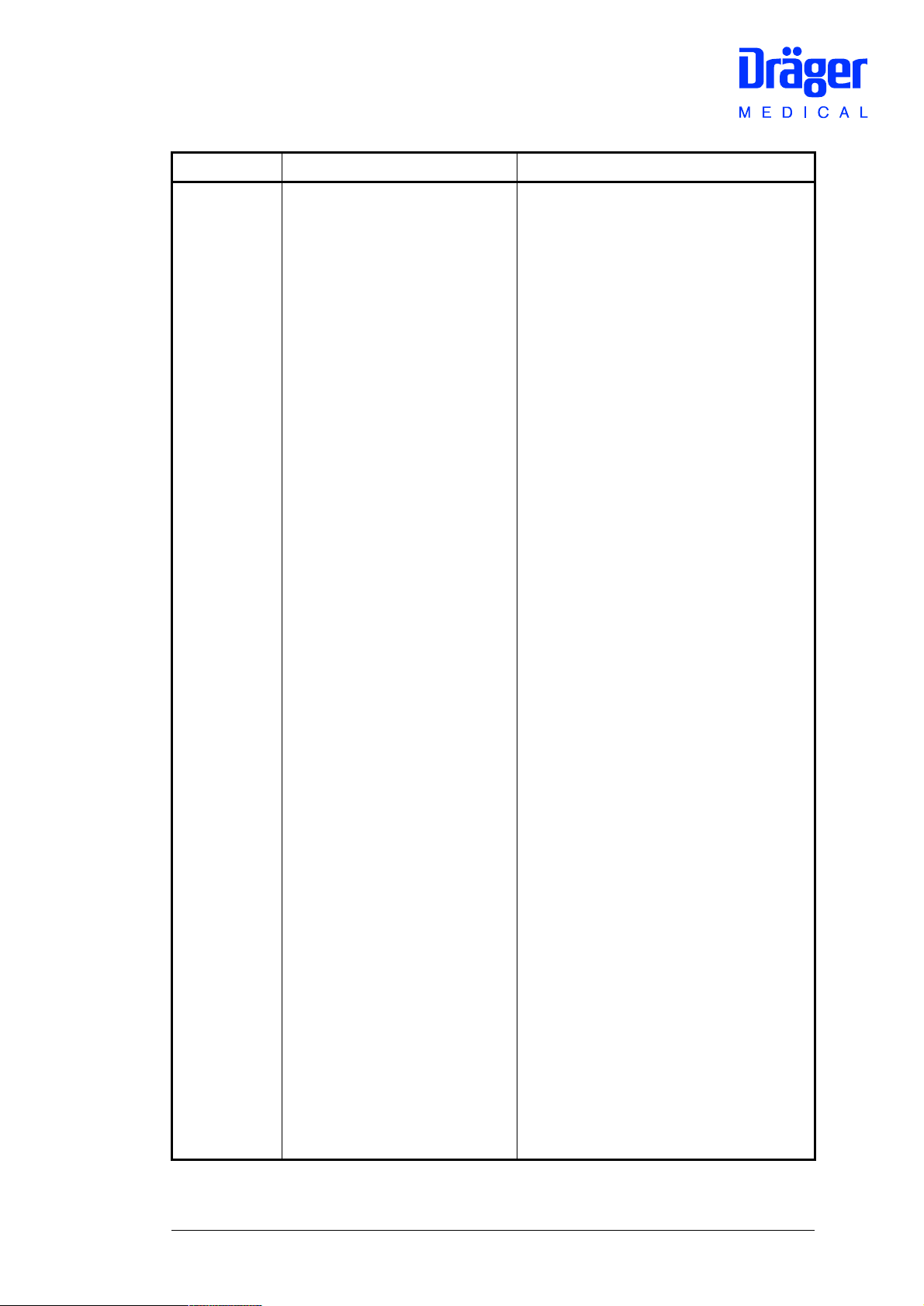

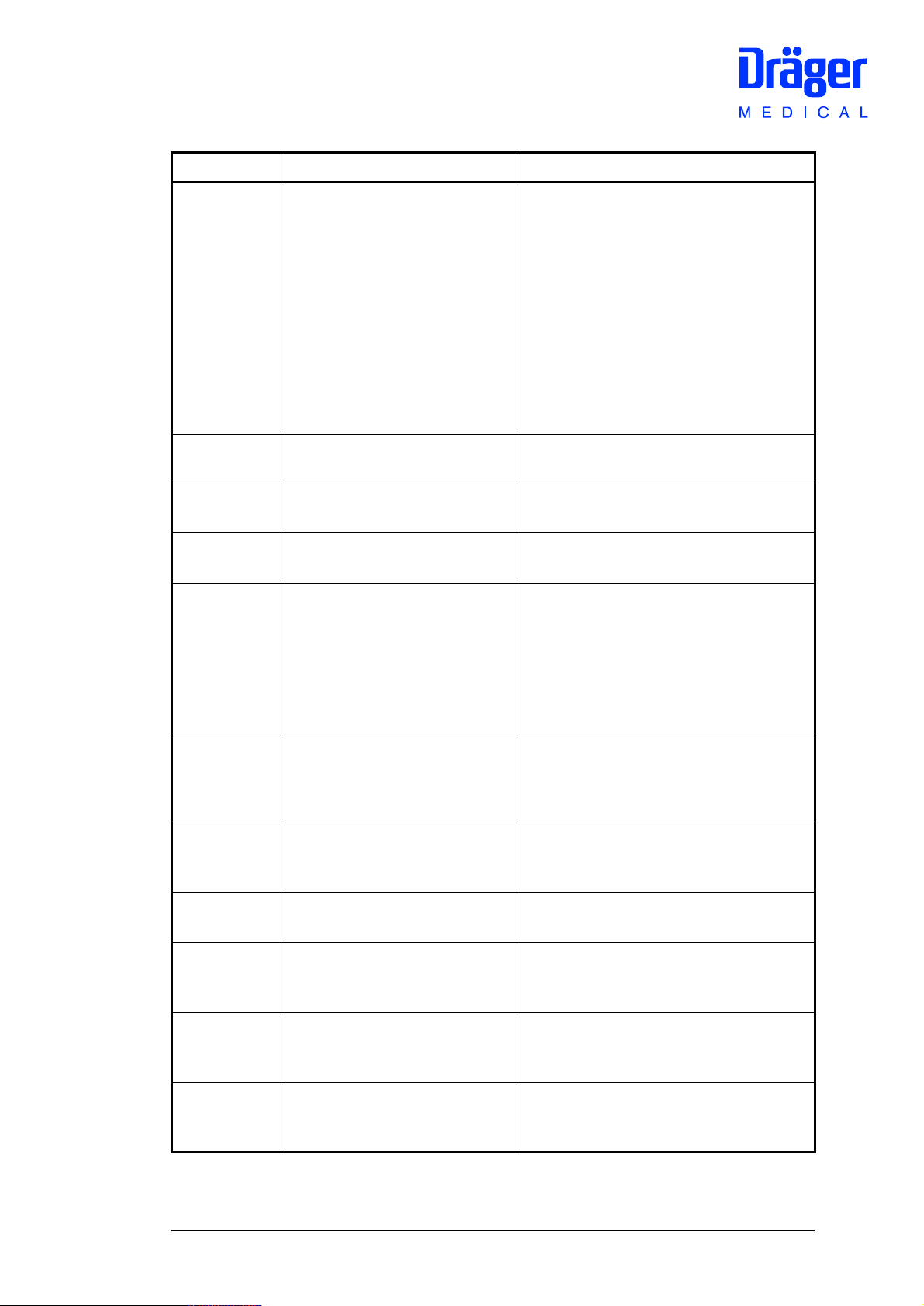

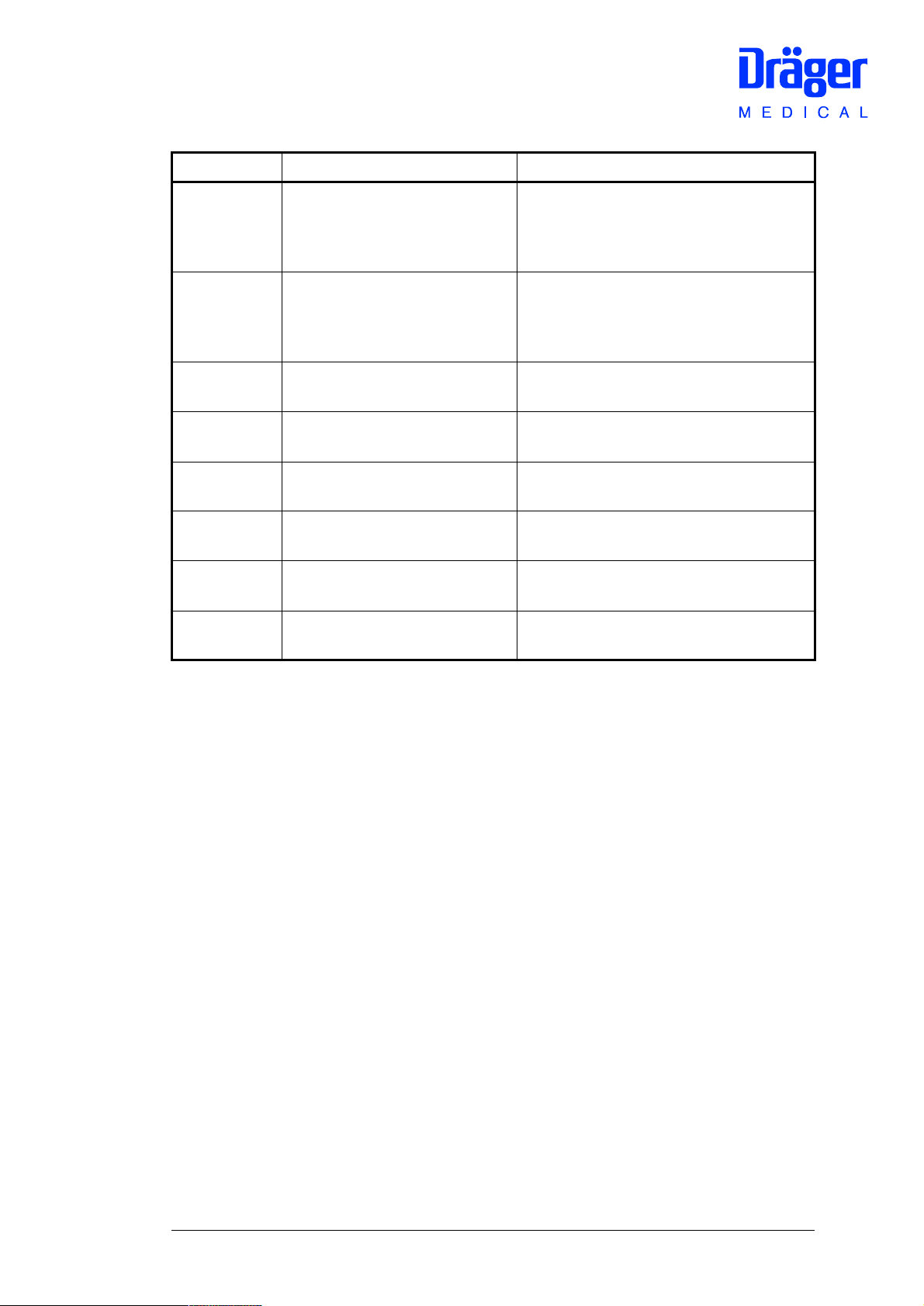

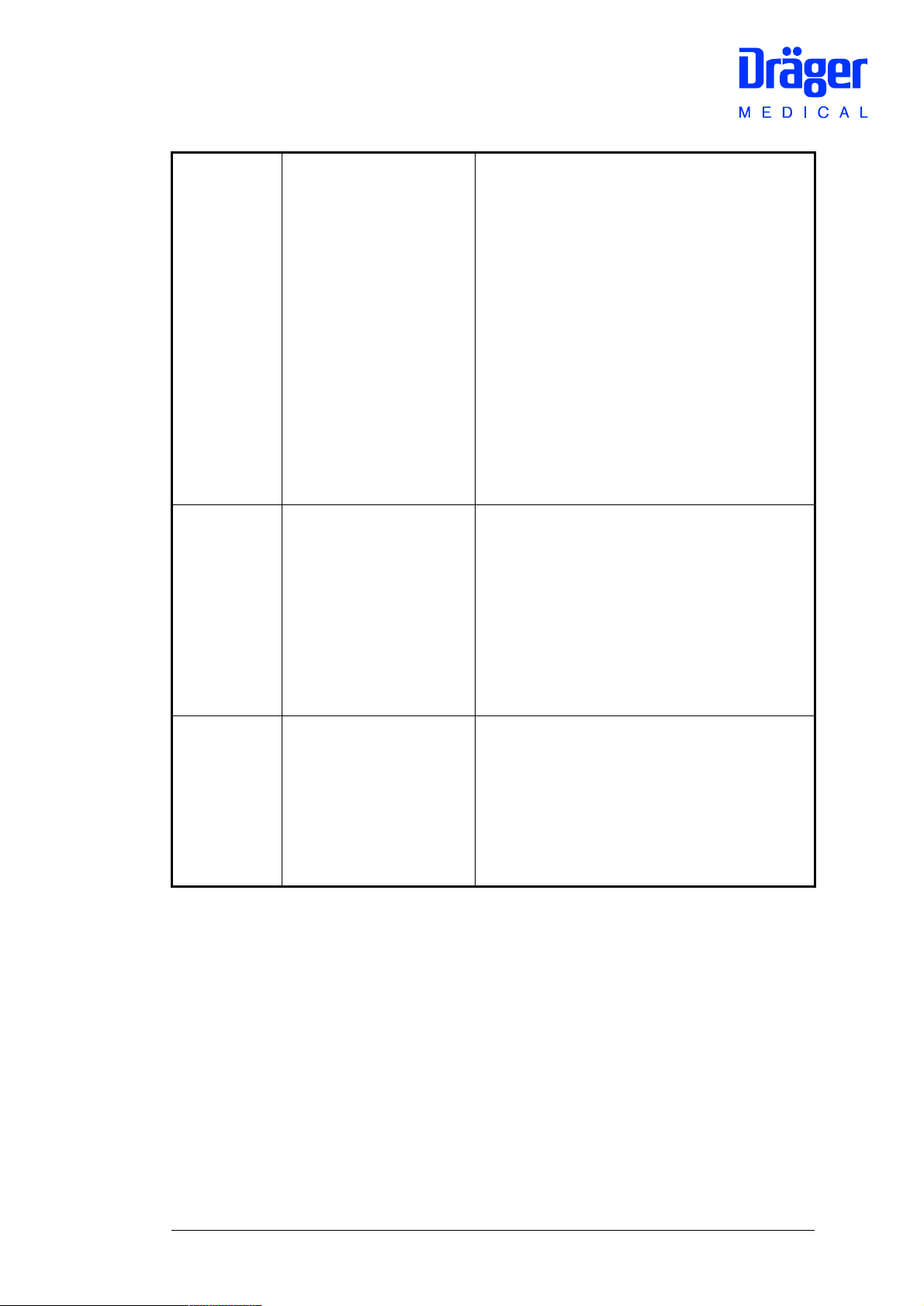

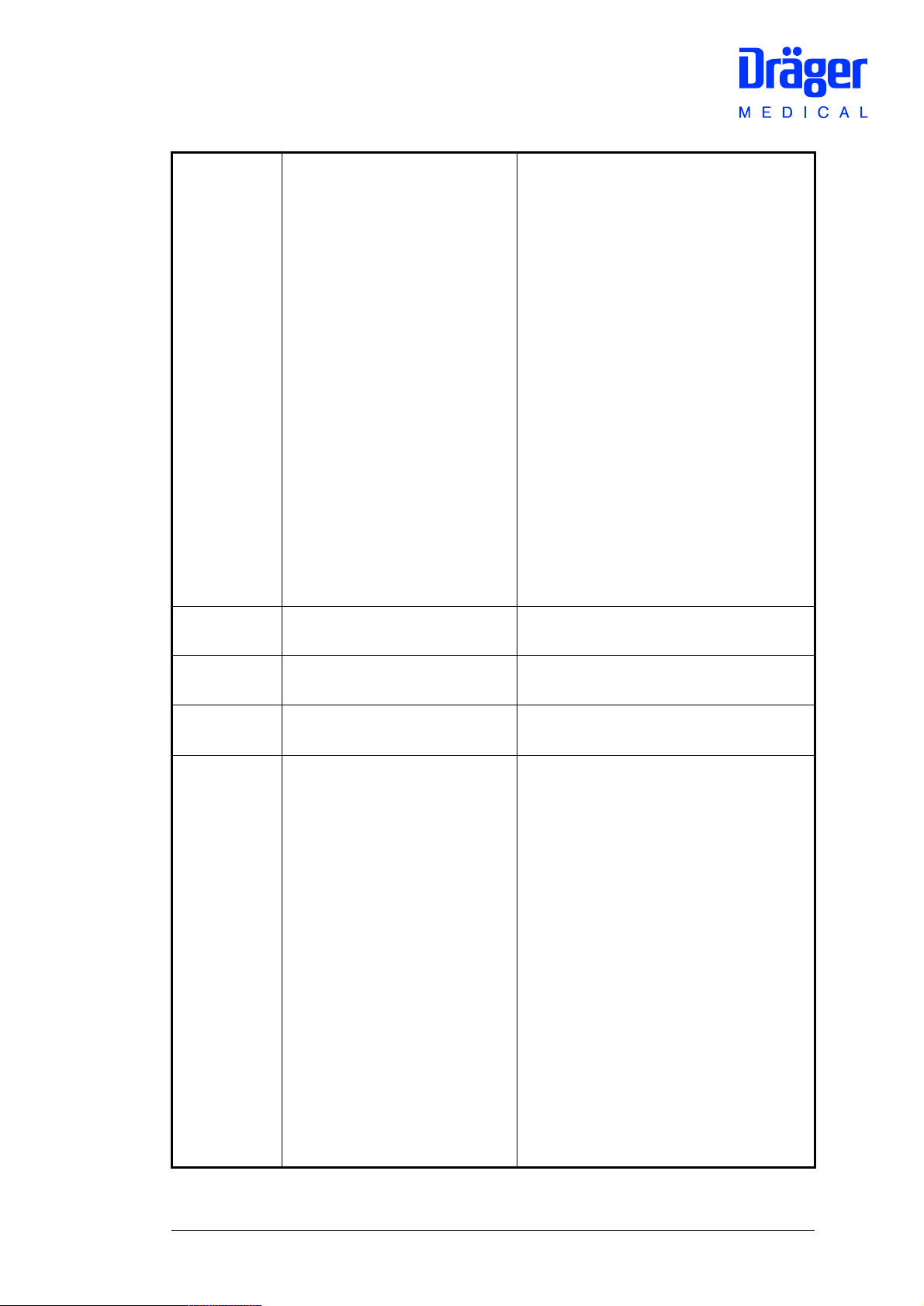

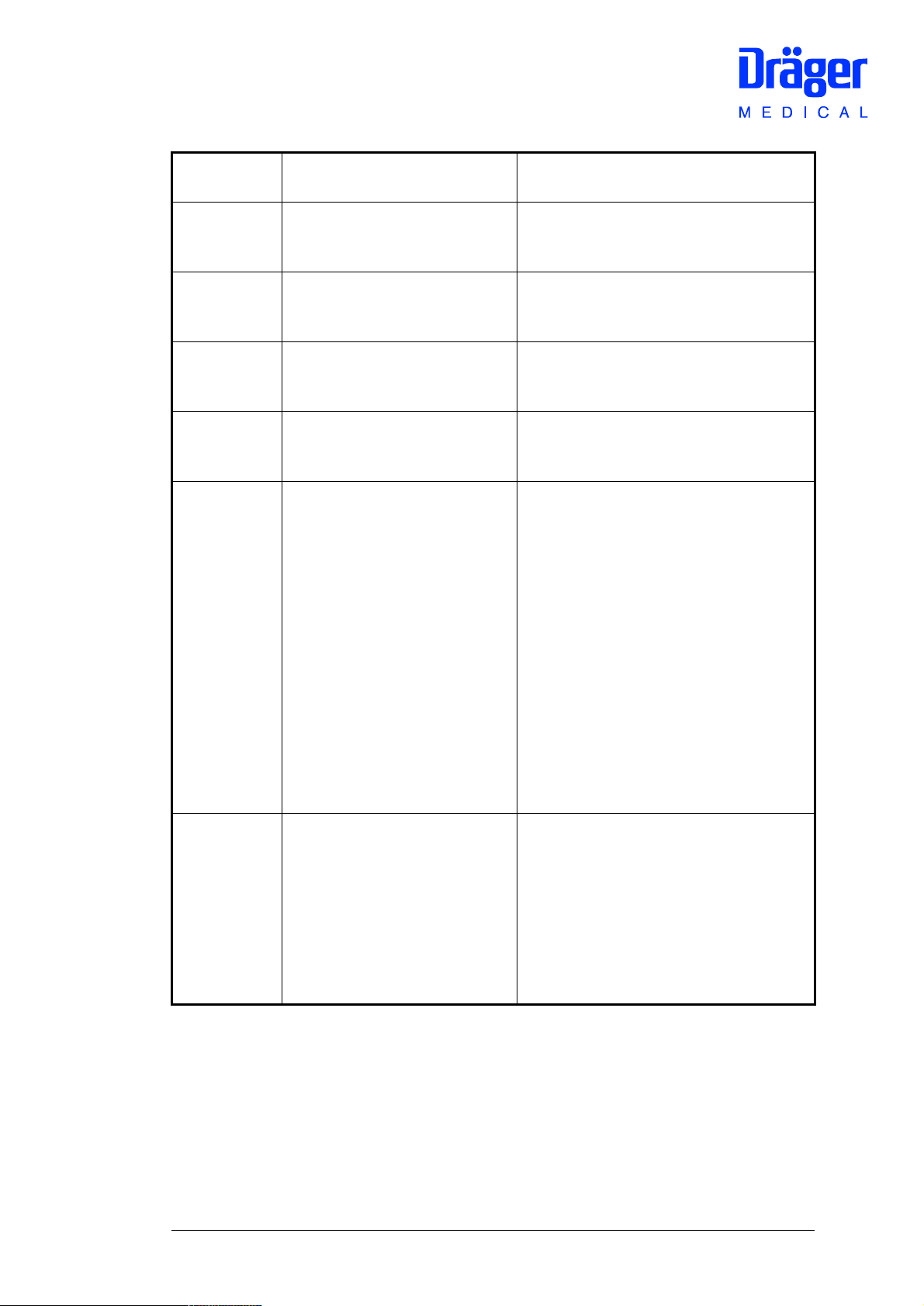

2.1 Error code 02 Safety Software

The service codes 02.00.. to 02.22.. are recognised on the CPU 68332 PCB; they

correspond to 02.40.. to 02.62.. as recognised on the Pneumatic Controller PCB.

Fault Item Cause/Remedy

02.00.001 si0_Err, New start, cause

incorrect, reset

02.00.002 si0_Err, Fast data chksum

error, reset

02.00.003 si0_Err, Safety software of

partner CPU not started, reset

02.00.004 si0_Err, Input data, chksum

error, reset

02.00.005 si0_Err, Vector for NMI

incorrect, reset

Monitoring of cold/warm start storage in

RAM on CPU 68332 PCB. Cause:

Software error on CPU 68332 PCB

Data packets between CPU 68332

PCB and Pneumatic Controller PCB

cannot be transferred in full. CPU

68332 PCB or Pneumatic Controller

PCB defective.

After starting, it was not possible within

10 seconds to establish synchronisation

between CPU 68332 PCB and

Pneumatic Controller PCB. Cause:

CPU 68332 PCB or Pneumatic

Controller PCB defective.

Data packets between CPU 68332

PCB and Pneumatic Controller PCB

cannot be transferred in full. CPU

68332 PCB or Pneumatic Controller

PCB defective.

RAM or SW error on CPU 68332 PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

02.00.020 si0_Err, Si boot, case

incorrect, reset

5664.500/800 Evita 4/Evita 2 dura 01.2002

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Repair Instructions

– 4

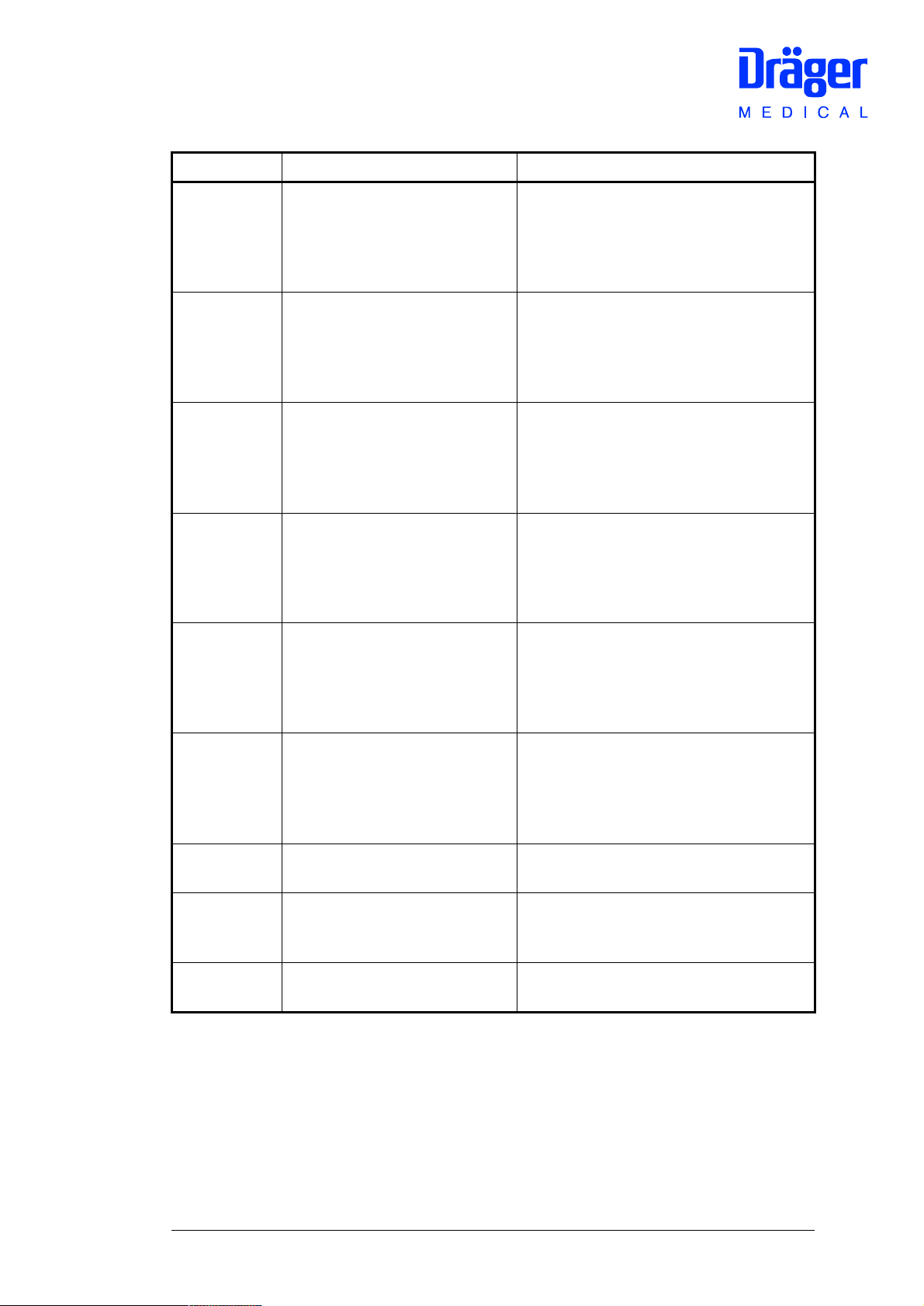

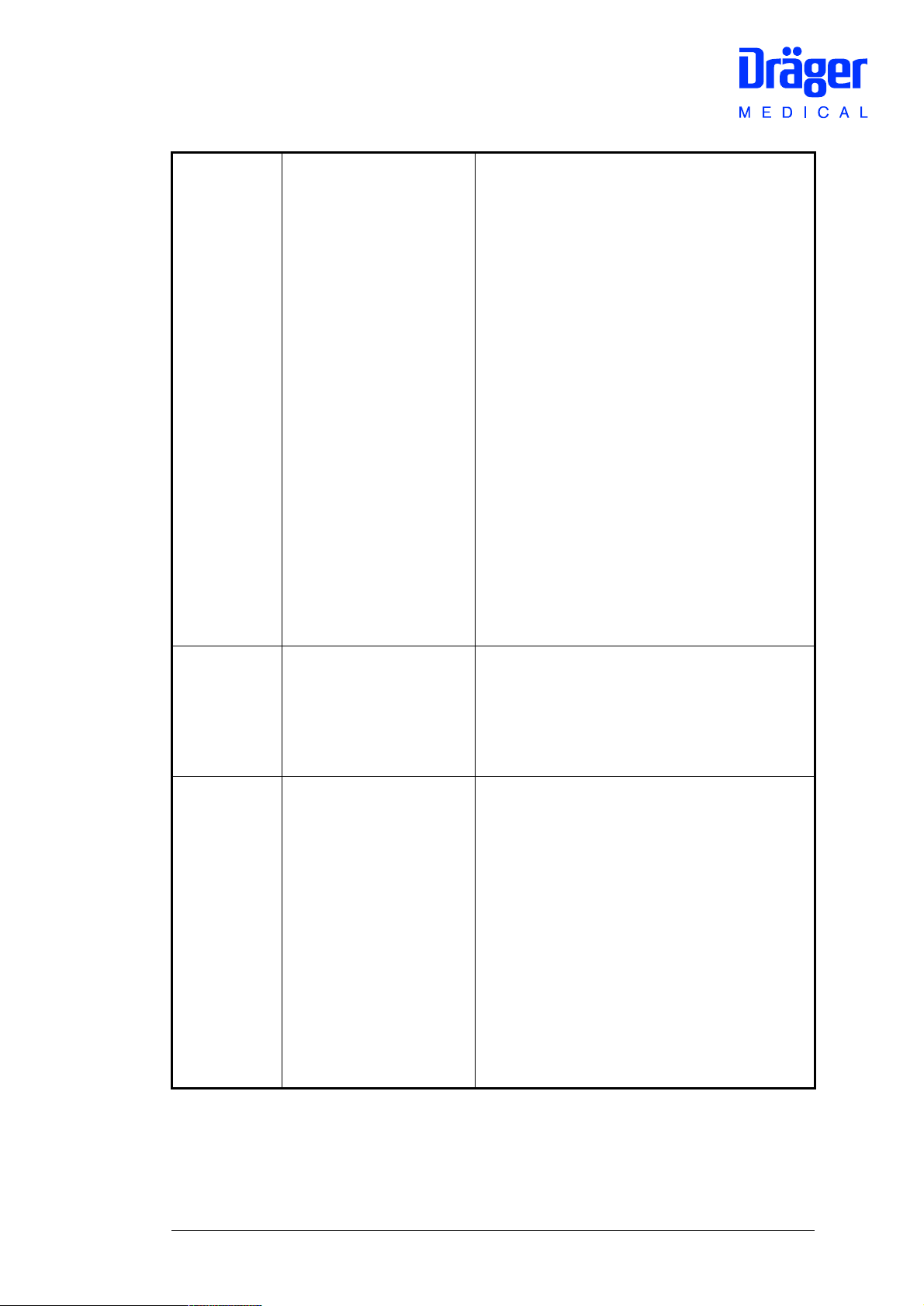

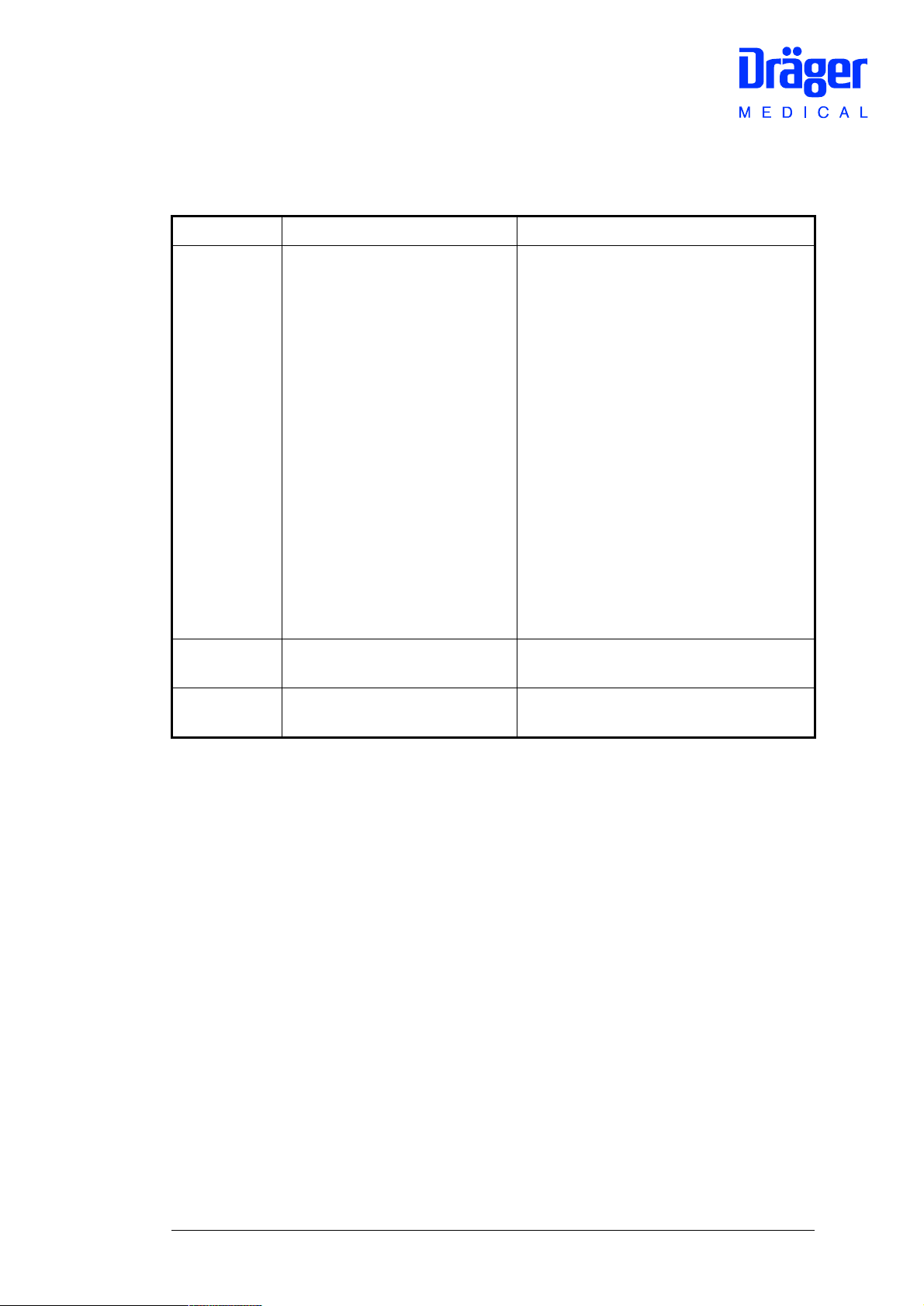

Fault Item Cause/Remedy

02.01.001 si1_ Err, Adjuster has incorrect

pixel sum, X alarm, reset:

Screen content (with Evita 2 dura also 7segment displays) is read out and

compared to request. Cause: Hardware

or SW error on Graphics Controller

PCB (Evita 4)/Front Panel PCB

(Evita 2 dura) or CPU 68332 PCB or

Pneumatic Controller PCB. If display

plausible, then SW error; otherwise

high probability of hardware error on

Graphics Controller PCB (Evita 4) or

Front Panel PCB (Evita 2 dura). Table

for X:

1 Paw high adjuster selected

2 Paw high arrow selected

3 MV min adjuster selected

4 MV min arrow selected

5 O2 adjuster selected

6 Last adjuster plus one

7 Paw high adjuster not selected

8 Paw high arrow not selected

9 MV min adjuster not selected

10 MV min arrow not selected

11 O2 adjuster not selected

12 Paw high line 30 top

13 Pressure scale values top 30

14 Paw high line 60 top

15 Pressure scale values top 60

16 Paw high line 100 top

17 Pressure scale values top 100

18 Paw high line 30 bottom

19 Pressure scale values bottom 30

20 Paw high line 60 bottom

21 Pressure scale values bottom 60

22 Paw high line 100 bottom

23 Pressure scale values bottom 100

24 Paw high line 30 bargraph

25 Pressure scale values bargraph 30

26 Paw high line 60 bargraph

27 Pressure scale values bargraph 60

28 Paw high line 100 bargraph

29 Pressure scale values bargraph

100

30 Paw high display 1

31 Paw high display 2

32 MV min display 1

33 MV min display 2

34 Cold start screen

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 5

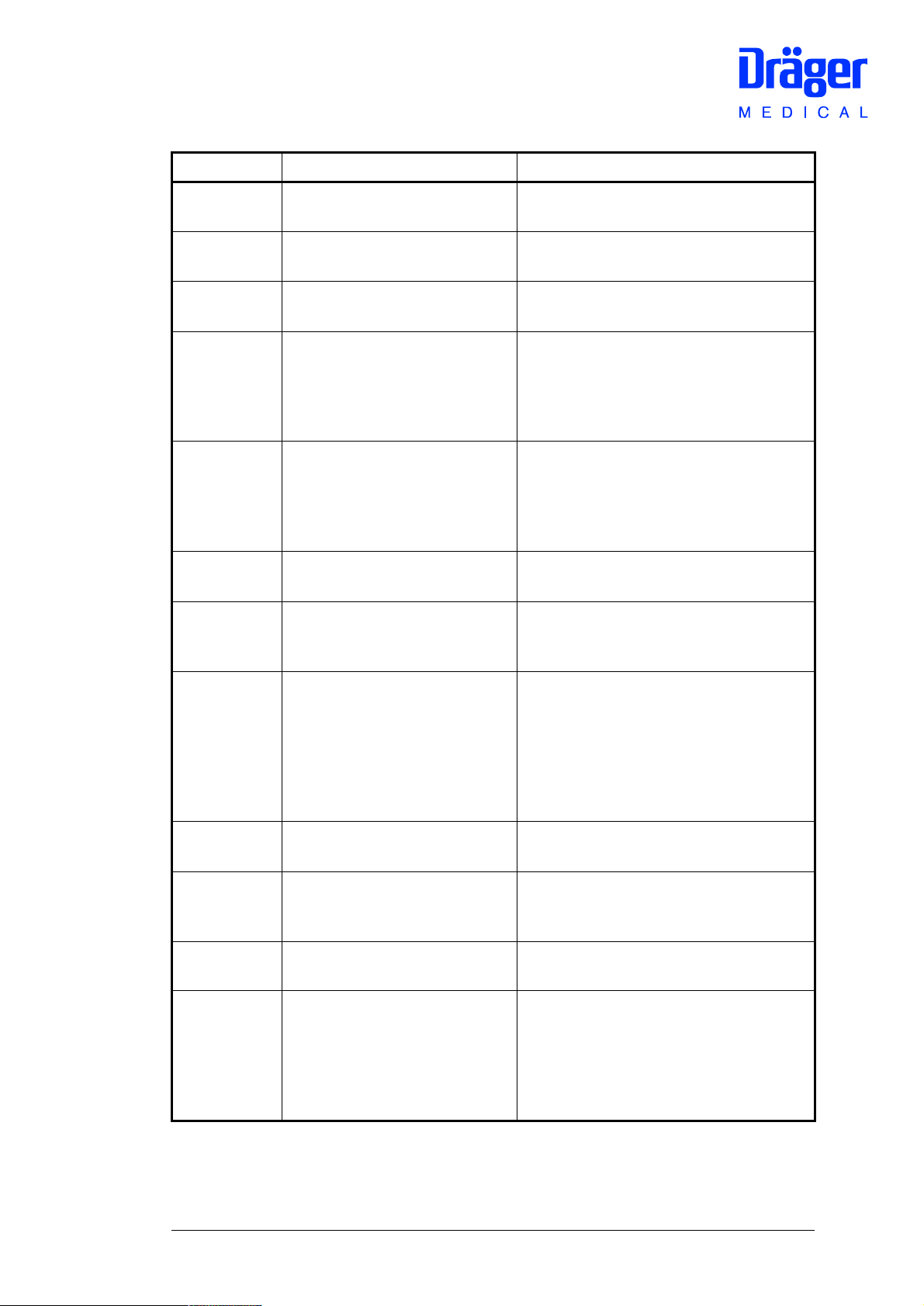

Fault Item Cause/Remedy

02.01.002 si1_Err, Paw high, Si copy,

consistency X alarm, reset

02.01.003 si1_Err, MV min, Si copy,

consistency X alarm, reset

02.01.004 si1_Err, O2 adjust, Si copy,

consistency X alarm, reset

02 .01.005 si1 _Er r, Paw high, invalid value,

reset

02.01.006 si1_Err, MV min, invalid value,

reset

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

02.01.007 si1_Err, O2 adjustment, invalid

value, reset

02.01.020 si1_Err, Si boot, case

incorrect, reset

02.01.021 si1_Err, Xxx is set, case

incorrect, reset

02.01.022 si1_Err, Control console,

status, case incorrect, reset

Alarm values relevant to safety are

checked for plausibility.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Only applies up to SW 1.04. RAM or

SW error on CPU 68332 PCB or

Pneumatic Controller PCB

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 6

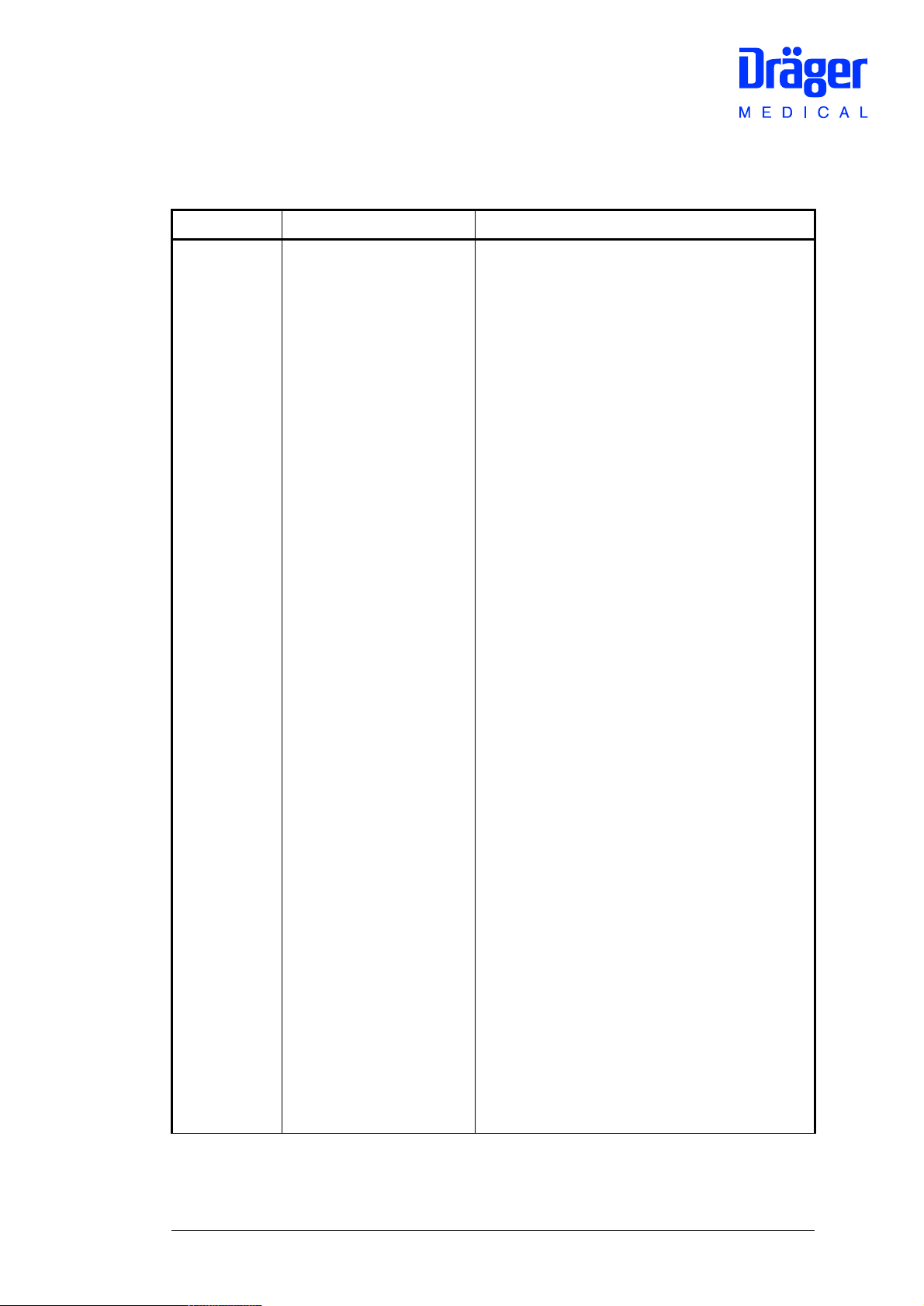

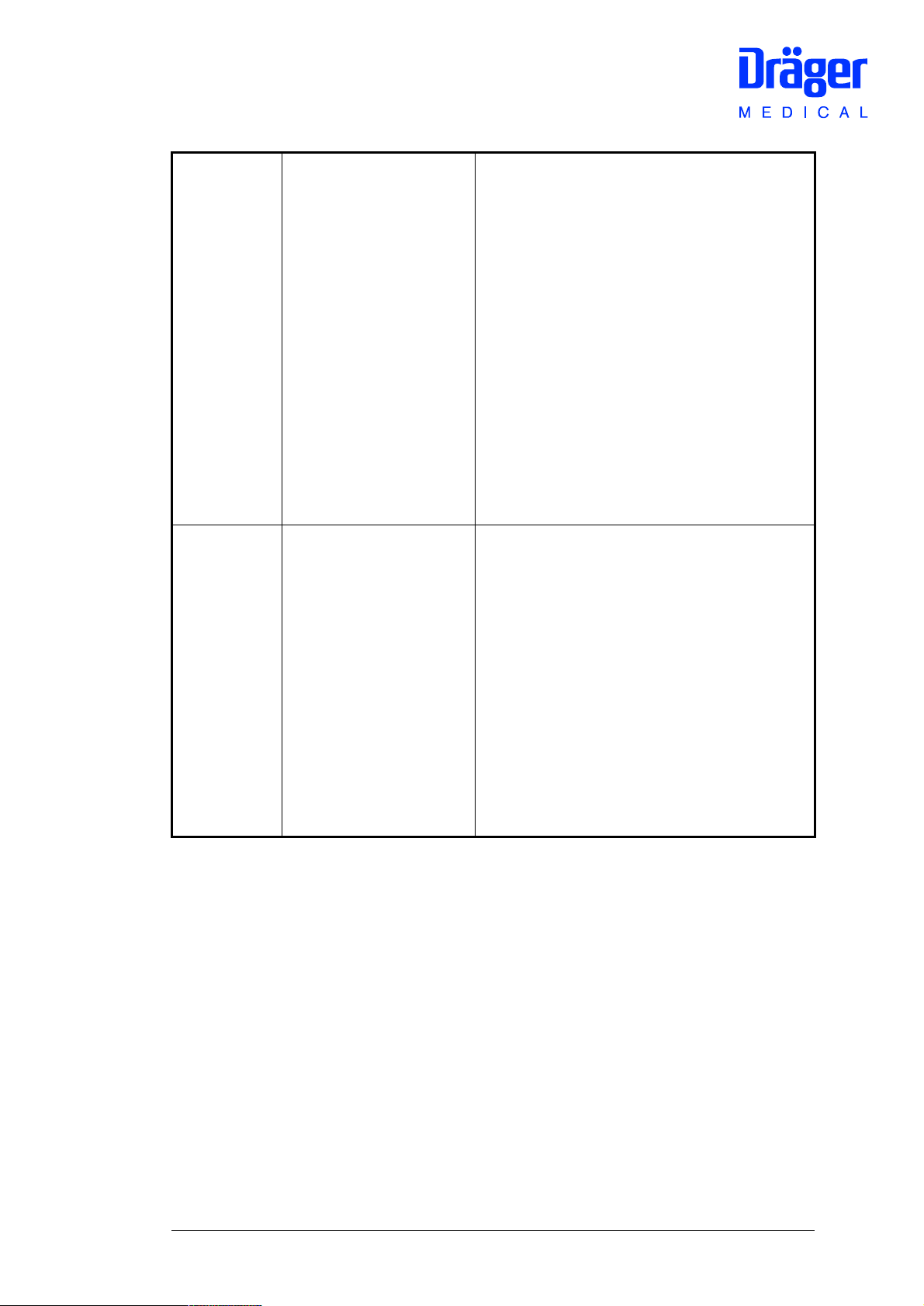

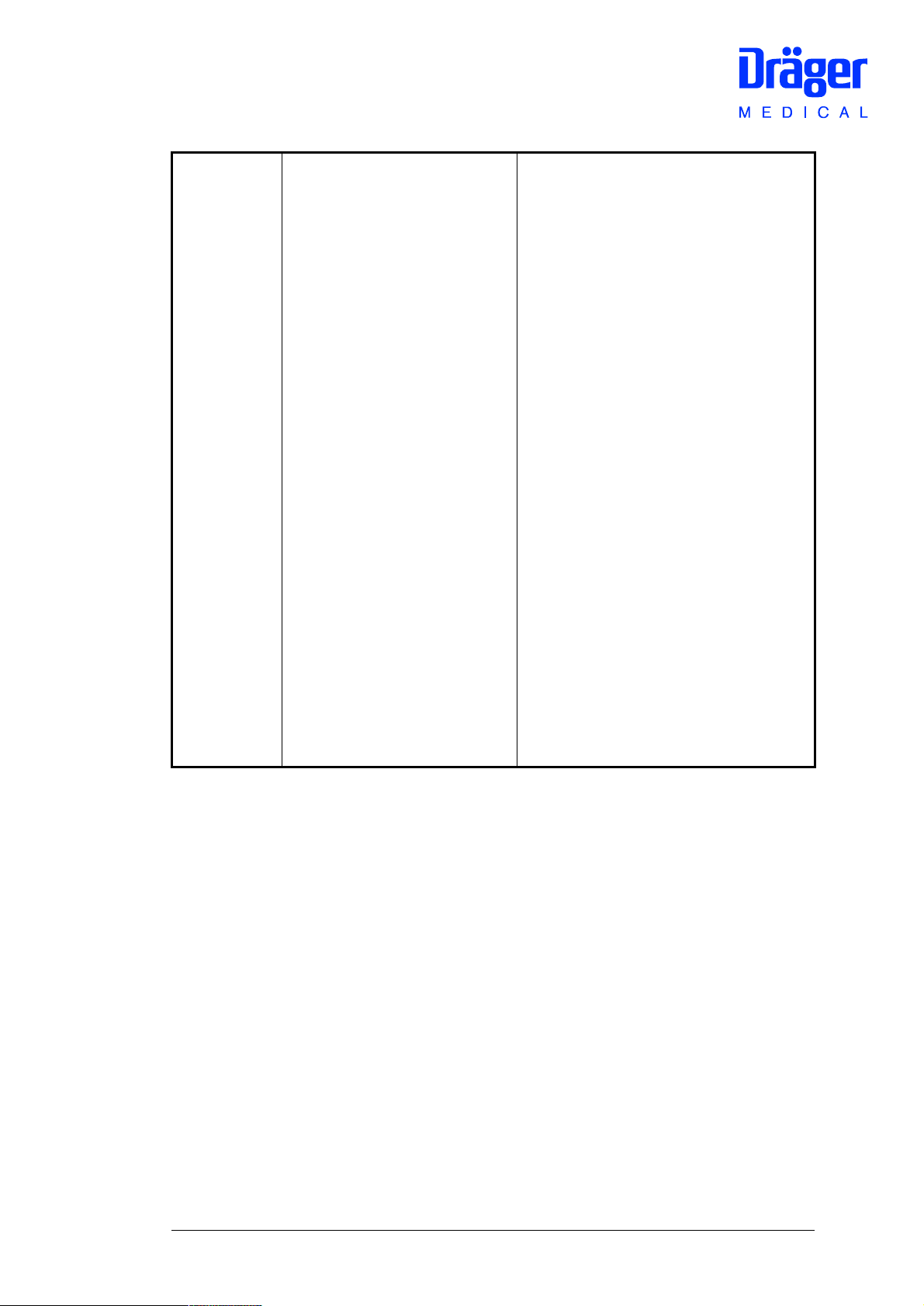

Fault Item Cause/Remedy

02.02.001 si2_Err, Identifier has incorrect

pixel sum, X alarm, reset

02.02.002 si2_Err, Identifier not

announced, X alarm, reset

02.02.003 si2_Err, Value has incorrect

pixel sum, X alarm, reset

02.02.020 si2_Err, Si boot, case

incorrect, reset

02.03.001 si3_Err, Keypad input

sequence, counter incorrect,

reset

Screen content (with Evita 2 dura also 7segment displays) is read out and

compared to request. Cause: Hardware

or SW error on Graphics Controller

PCB (Evita 4) / Front Panel PCB (Evita

2 dura) or CPU 68332 PCB or

Pneumatic Controller PCB. If display

plausible, then SW error; otherwise

high probability of hardware error on

Graphics Controller PCB (Evita 4) or

Front Panel PCB (Evita 2 dura). Refer to

error 02.01.001 for X table.

Refer to error 02.02.001.

Refer to error 02.02.001.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

SW or transmission error from

Graphics Controller PCB (Evita 4) or

Front Panel PCB (Evita 2 dura) via CPU

68332 PCB to Pneumatic Controller

PCB. Cause: Probably error on

Graphics Controller PCB (Evita 4) or

Front Panel PCB (Evita 2 dura).

02.03.002 si3_Err, Rotary knob button

pressed, incorrectly displayed,

reset

02.03.003 si3_Err, Silence button

pressed, incorrectly displayed,

reset

02.03.004 si3_Err, Reset button pressed,

incorrectly displayed, reset

02.03.005 si3_Err, Extraction button

pressed, incorrectly displayed,

reset

02.03.006 si3_Err, Inspiration hold button

pressed, incorrectly displayed,

reset

02.03.007 si3_Err, Expiration hold button

pressed, incorrectly displayed,

reset

SW or hardware error when reading out

keys on Graphics Controller PCB

(Evita 4) or Front Panel PCB

(Evita 2 dura).

Refer to error 02.03.002.

Refer to error 02.03.002.

Refer to error 02.03.002.

Refer to error 02.03.002.

Refer to error 02.03.002.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 7

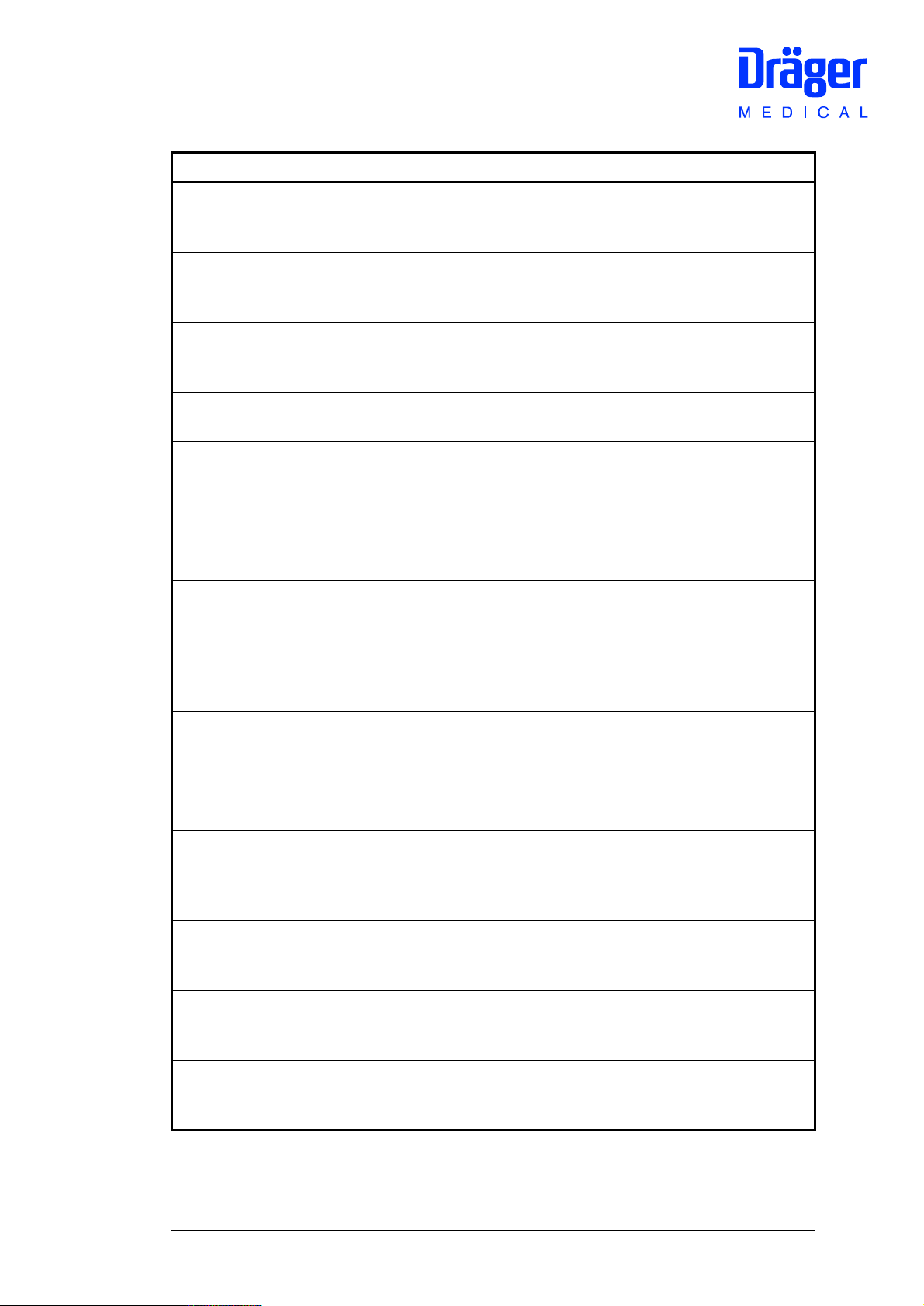

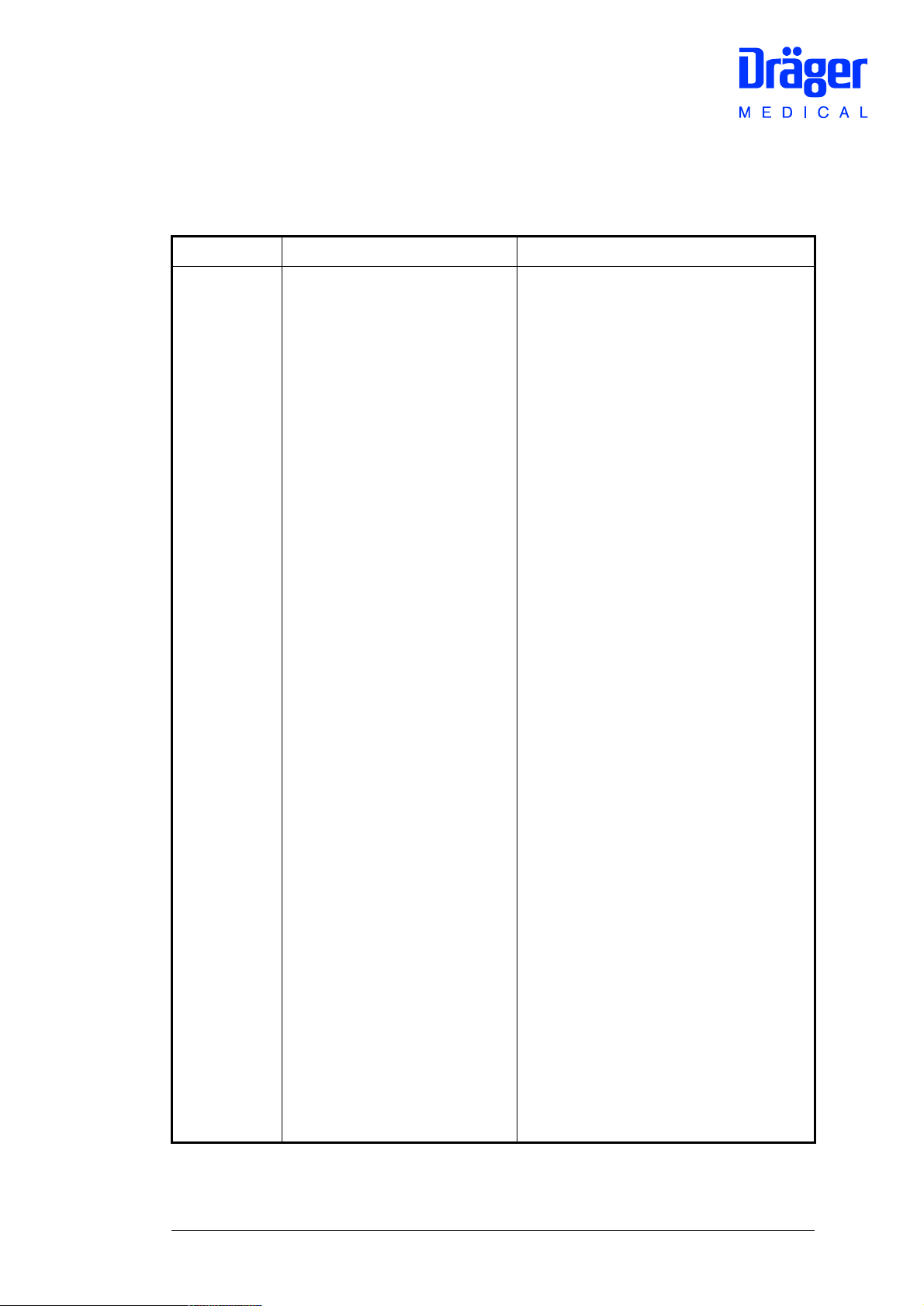

Fault Item Cause/Remedy

02.03.020 si3_Err, S boot, case incorrect,

reset

02.04.001 si4_Err, MV exp, 12

consistency, reset

02.04.002 si4_Err, Flow exp, quotient, 12

consistency, reset

02.04.003 si4_Err, Standard flow sensor

in neo-mode, X alarm, reset

02.04.004 si4_Err, Neo flow sensor in

adult mode, X alarm, reset

02.04.020 si4_Err, Si boot, case

incorrect, reset

02.05.001 si5_Err, Factor for NTPD to

BTPS incorrect, X alarm, reset

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

According to safety software, wrong

flow sensor being used in neo-mode.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

According to safety software, wrong

flow sensor being used in adult mode.

Cause: RAM or SW error on CPU

68332 PCB or Pneumatic Controller

PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

SW error or impermissible activation of

BTPS deactivation at ambient pressure

less than 961 mbar.

02.05.002 si5_Err, Flow insp, counter

current, reset

02.05.003 si5_Err, MV insp, 12

consistency, reset

02.05.004 si5_Err, Factor for NTPS to

BTPS incorrect, X alarm, reset

02.05.020 si5_Err, Si boot, case

incorrect, reset

02.06.001 si6_Err, MV deactivation,

confirmation X signal incorrect,

reset

HPSV actuation monitoring signals

error. Cause: HPSV cartridge (Air or

O2) or one of the two HPSV actuation

PCBs or Pneumatic Controller PCB

defective. Error status can be read out in

diagnosis mode “Valves“ if error is

present at the time.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

SW error or impermissible activation of

BTPS deactivation at ambient pressure

less than 961 mbar.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Probably software error on Graphics

Controller PCB (Evita 4) or Front Panel

PCB (Evita 2 dura) or also CAN

communication problem with CPU

68332 PCB and Pneumatic Controller

PCB.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 8

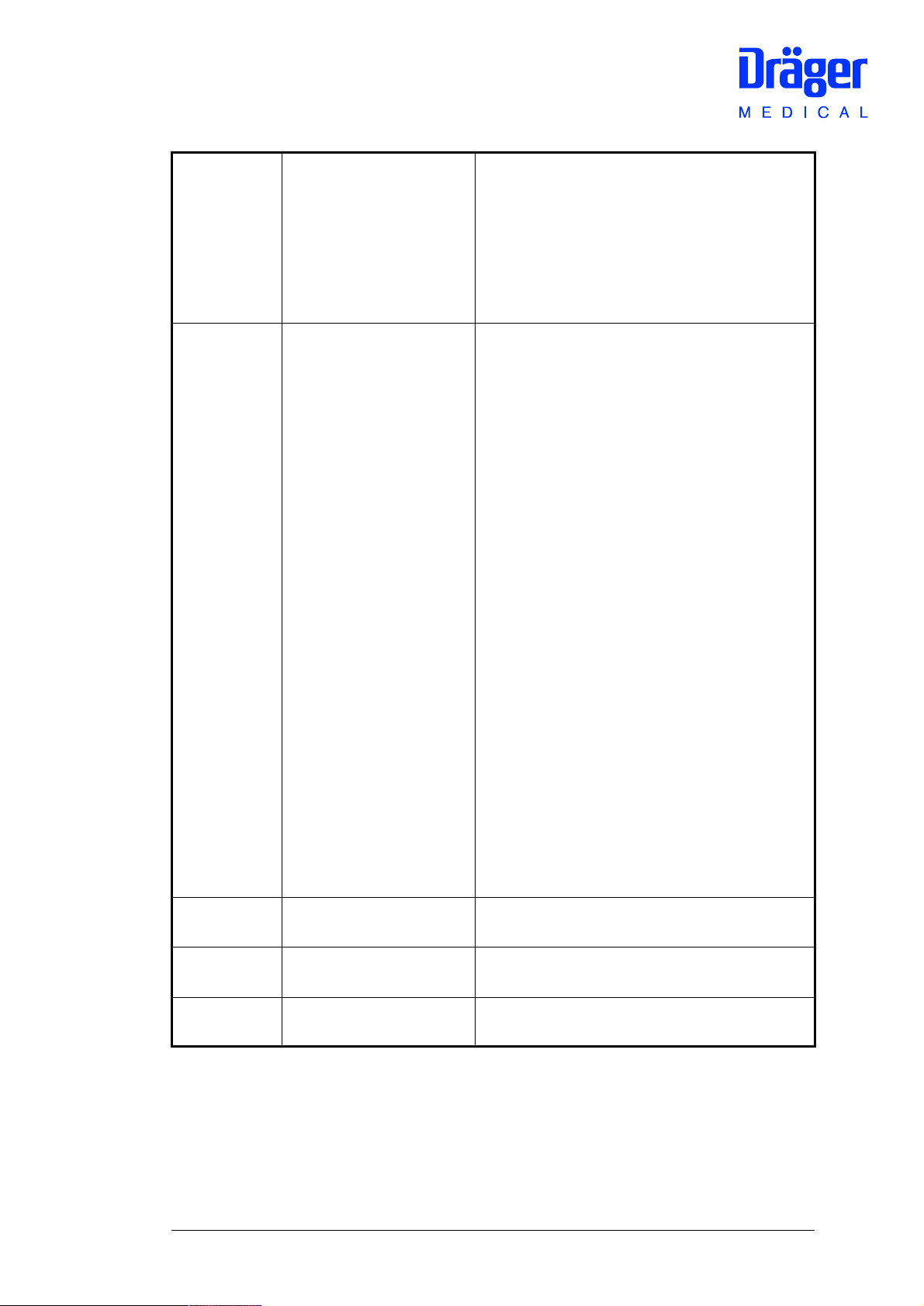

Fault Item Cause/Remedy

02.06.002 si6_Err, MV deactivation,

request Y signal incorrect,

reset

02.06.003 si6_Err, Paed MV deactivation,

confirmation X signal incorrect,

reset

02.06.004 si6_Err, Paed MV deactivation,

request Y signal incorrect,

reset

02.06.020 si6_Err, Si boot, case

incorrect, reset

02.06.021 si6_Err, Si Y signal, case

incorrect

02.07.020 si7_Err, Si boot, case

incorrect, reset

02.08.001 si8_Err, O2 measurement

deactivation, confirmation X

signal incorrect, reset

Refer to error 02.06.001.

Refer to error 02.06.001.

Refer to error 02.06.001.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Refer to error 02.06.020, however

defective Graphics Controller PCB

(Evita 4) or Front Panel PCB (Evita 2

dura) also possible.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Probably software error on Graphics

Controller PCB (Evita 4) or Front Panel

PCB (Evita 2 dura) or also CAN

communication problem with CPU

68332 PCB and Pneumatic Controller

PCB.

02.08.002 si8_Err, O2 measurement

deactivation, request Y signal

incorrect, reset

02.08.020 si8_Err ,Si boot, case

incorrect, reset

02.08.021 si8_Err, Si Y signal, case

incorrect, reset

02.09.001 si9_Err, Disconnection

manoeuvre, disconnection too

long, reset

02.09.002 si9_Err, Disconnection

manoeuvre, post-oxygenisation

too long, reset

02.09.003 si9_Err, Disconnection

manoeuvre, pre-oxygenisation

too long, reset

Refer to error 02.08.001.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Refer to error 02.08.021, however

defective Graphics Controller PCB

(Evita 4) or Front Panel PCB (Evita 2

dura) also possible.

CPU 68332 PCB monitors timing of

Pneumatic Controller PCB. One of the

two systems is defective.

Refer to error 02.09.001.

Refer to error 02.09.001.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 9

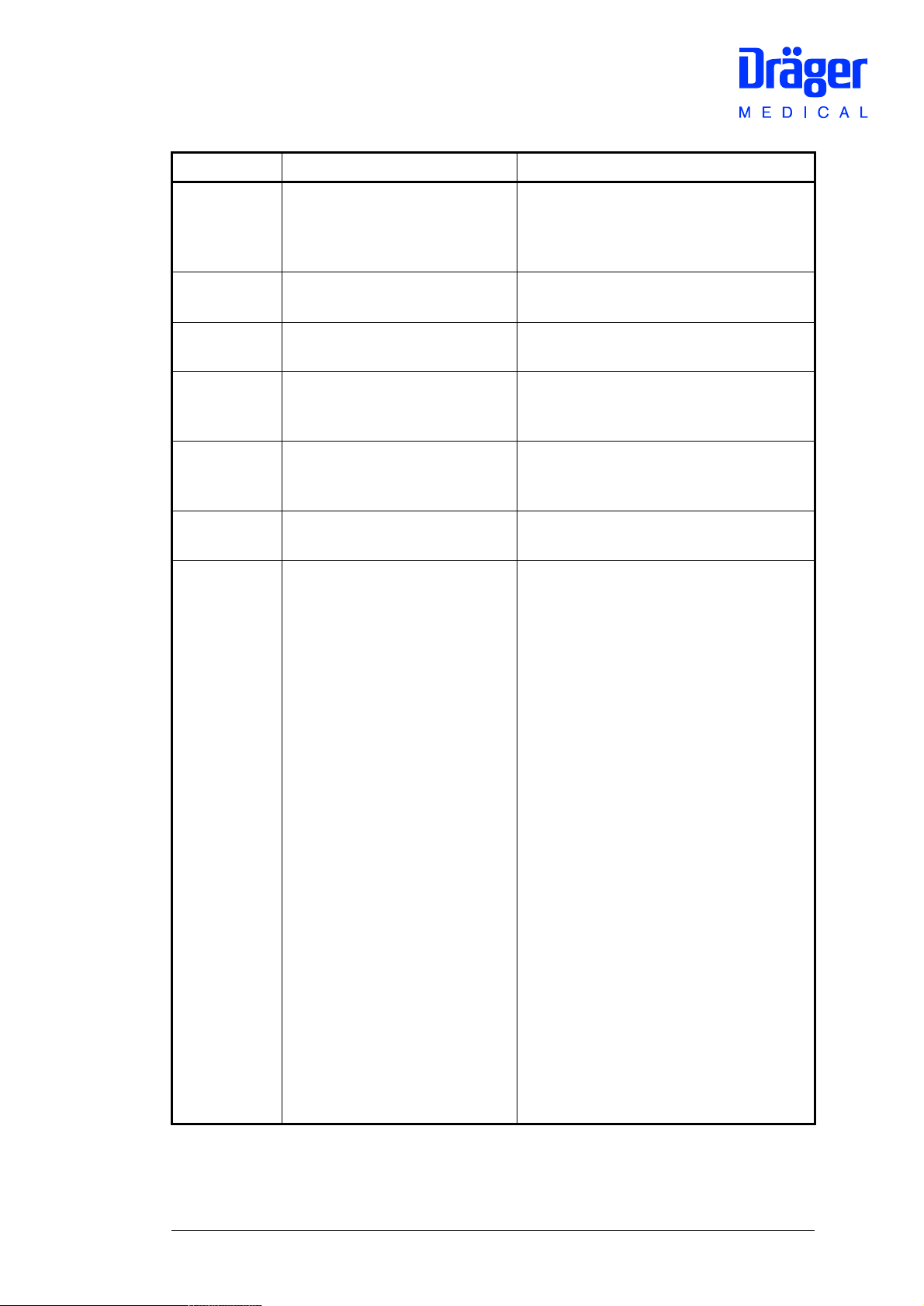

Fault Item Cause/Remedy

02.09.004 si9_Err, Disconnection

manoeuvre, no button, reset

02.09.020 si9_Err, Si boot, case

incorrect, reset

02.09.021 si9_Err, Si status change, case

incorrect, reset

02.11.001 si11_Err, O2 cal. too long,

reset

02.11.002 si11_Err, O2 calibration

sequence incorrect, reset

02.11.020 si11_Err, Si boot, case

incorrect, reset

02.12.001 si12_Err, Paw high too long,

reset

SW error on Graphics Controller PCB

(Evita 4) / Front Panel PCB (Evita 2

dura) or CPU 68332 PCB or

Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

CPU 68332 PCB monitors timing of

Pneumatic Controller PCB. One of the

two systems is defective.

CPU 68332 PCB monitors timing of

Pneumatic Controller PCB. One of the

two systems is defective.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

Inspiration pressure too high for more

than 1 second and cannot be dissipated

via emergency vent Y1.3. Inspiration

pressure is measured on Pneumatic

Controller PCB and CO2 Carrier PCB.

Possible causes:

− Measurement of inspiration

pressure on Pneumatic Controller

PCB (1st channel) or CO2 Carrier

PCB (2nd channel) defective. Read

out values by way of service mode.

If error is on CO2 Carrier PCB,

contact problems may be the

cause. CO2 Carrier PCB must be

secured in position with both

screws.

− Inspiration pressure sensor

defective.

− Pneumatic fault.

− Too high a measured value from

the expiratory pressure sensor

(Note: If ground (GND) is missing,

the Paw sensors will measure

approx. 115 mbar.)

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 10

Fault Item Cause/Remedy

02.12.020 si12_Err, Si boot, case

incorrect, reset

02.13.020 si13_Err, Si boot, case

incorrect, reset

02.14.001 si14_Err, Breathing cycle, insp.

timer, 12 consistency, reset

02.14.002 si14_Err, Breathing cycle, exp.

timer, 12 consistency, reset

02.14.020 si14_Err, Si boot, case

incorrect, reset

02.15.001 si15_Err, Nebuliser des., Si

copy, consistency, reset

02.15.020 si15_Err, Si boot, case

incorrect, reset

02.16.001 si16_Err, Hardware boot, test

data not reset, reset

02.16.002 si16_Err, Hardware datum, Si

copy, inconsistent, reset

02.16.020 si16_Err, Si boot, case

incorrect, reset

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

02.17.001 si17_Err, Reset alarm, Xxx

incorrect, reset

02.17.002 si17_Err, Incorrect tone

recognition by loudspeaker

monitoring, reset

02.17.020 si17_Err, Si boot, case

incorrect, reset

02.17.021 si17_Err, Si Reset alarm, case

incorrect

02.18.001 si18_Err, Silence incorrectly

activated, reset

RAM or SW error probably on Graphics

Controller PCB (Evita 4) or Front Panel

PCB (Evita 2 dura), but may also be on

CPU 68332 PCB or Pneumatic

Controller PCB.

RAM or SW error probably on Graphics

Controller PCB (Evita 4) or Front Panel

PCB (Evita 2 dura), but may also be on

CPU 68332 PCB or Pneumatic

Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB, but may

also be on Graphics Controller PCB

(Evita 4) or Front Panel PCB (Evita 2

dura).

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB or

Graphics Controller PCB (Evita 4) /

Front Panel PCB (Evita 2 dura).

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 11

Fault Item Cause/Remedy

02.18.002 si18_Err, Silence too long,

reset

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB or

Graphics Controller PCB (Evita 4) /

Front Panel PCB (Evita 2 dura).

02.18.003 si18_Err, Confirmation signal

for standby incorrect, reset

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB or

Graphics Controller PCB (Evita 4) /

Front Panel PCB (Evita 2 dura).

02.18.020 si18_Err, Si boot, case

incorrect, reset

02.19.001 si19_Err, Memory consistency,

reset

02.19.002 si19_Err, Auxiliary alarm mute,

number 1 incorrect, reset

02.19.003 si19_Err, Auxiliary alarm mute,

number 2 incorrect, reset

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

02.21.000 sic_Err, Task recognises error RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

02.22.000 sil_Err, Task recognises error RAM or SW error on CPU 68332 PCB

or Pneumatic Controller PCB.

The service codes 02.40.. to 02.62.. are recognised on the Pneumatic Controller PCB; they

correspond to 02.00.. to 02.22.. as recognised on the CPU 68332 PCB.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 12

Defective Hardware

Fault Item Cause/Remedy

02.71.001 No acoustic alarm Actuation signal from CPU 68332 PCB to

loudspeaker (approx. 50 ohms) is tapped via

series resistor (5 ohms) on Graphics

Controller / Front Panel PCB and supplied to

the system as digital information. This signal is

used for desired/actual comparison of the

loudspeaker actuation. The loudspeaker is in

the control console/front section.

Possible cause of trouble:

-Software error

if error occurs between several aspiration

modes without intervening ventilation. This

error has been rectified on the Evita 4 as of

SW 2.21 (Japan as of SW 1.09) and on the

Evita 2 dura with versions greater than 3.00.

-Cable fault between CPU 68332 PCB and

loudspeaker in control console

-Loudspeaker defect

Trouble-shooting:

-Measure resistance of loudspeaker via

connecting cable of control console, incl.

cable between pins 9 and 10 of SUB-D cable

connector. Test value = 55 plus/minus 8

ohms. This value incl. shunt resistance must

be 5 ohms higher than loudspeaker value,

which can be measured after opening control

console.

-Using diagnosis mode with lowest volume

setting, Refer to section of "Repair

Instructions - Service No./ Modi, Error list"

chapter 3.2.1, Diagnosis page

“Microprocessor” of “Front”, page 57.

- Using external DS mode via PC with lowest

volume setting, Refer to section of "Repair

Instructions - Service No./ Modi, Error list"

chapter 9.4.7, Loudspeaker test, page 141. or

Refer to section of "Repair Instructions Service No./ Modi, Error list" chapter 9.5.7,

Testing of loudspeaker, page 151.

instructions.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Note: See also error s 02.71.012 and

02.71.013

Repair Instructions

– 13

02.71.002 Flow measurement on

Pneumatic Controller

PCB defective

Remedy:

As of SW 1.05: Renew Pneumatic Controller

PCB.

Up to SW 1.04: Fault is set if ambient

pressure is less than 961 mbar on switch-on,

but is not displayed on screen. Only renew

Pneumatic Controller PCB if error message is

displayed on screen during operation.

02.71.003 Gold Cap capacitor,

capacitance too low

In the event of power failure, Gold Cap on

CO2 Carrier PCB supplies piezo alarm tone

generator with voltage and thus signals mains

failure. The duration of this mains failure alarm

is governed by the capacitance of the Gold

Cap. Both the function and the capacitance

are therefore tested once an hour, starting 5

minutes after switch-on of the unit. A unit fault

is signalled if one of the following criteria is

met:

a. Final charging voltage too high

(greater than 11 V), voltage regulator

defective

b. Final charging voltage too low (less

than 8 V), charging circuit defective

c. Reference voltage too high (greater

than 6.3 V), discharge circuit

defective

d. Reference voltage too low (less than

4.5 V), no Gold Cap

e. Capacitance less than 30mF, Gold

Cap capacitance too low

For internal use only. Copyright reserved.

R5664500T025664800.fm

02.71.004 Gold Cap capacitor,

voltage too high

02.71.005 Gold Cap capacitor,

voltage too low

02.71.006 Gold Cap capacitor,

tester defective

5664.500/800 Evita 4/Evita 2 dura 01.2002

Remedy:

refer to section of "Repair Instructions Electronic Components" Chapter 5.5,

Conversions, page 34 CO2 Carrier PCB.

see error 02.71.003

see error 02.71.003

see error 02.71.003

Repair Instructions

– 14

02.71.007 Boot test defective Cause of trouble:

CPU 68332 PCB (more likely) or Pneumatic

Controller PCB defective

Note:

Additionally displayed with other error

messages

02.71.008 Piezo alarm generator,

auxiliary alarm triggering

defective

In addition to signalling mains failure, the

piezo assumes the alarm function of the

loudspeaker if CPU 68332 is defective

(stopped). To ensure that this is the case, the

piezo on the CO2 Carrier PCB is suppressed

by the CPU 68332 PCB with a square-wave

signal. If this cyclical clocking fails, the

associated muting of the piezo is cancelled

and a continuous beep sounds. Muting is

deliberately cancelled to test the piezo. The

current through the piezo, which then

increases as a result of cancelling the muting,

can be measured as voltage drop across a

series resistor by the A/D converter on the

CO2 Carrier PCB.

Possible cause of trouble:

a. CO2 Carrier PCB defective

b. CPU 68332 PCB defective

Trouble-shooting:

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.3.2, Diagnosis page

“Microprocessor” of “Electronics”, page 63.

- With external DS mode via PC, Refer to

section of "Repair Instructions - Service No./

Modi, Error list" chapter 9.4.6, Horn test, page

140.

instructions

For internal use only. Copyright reserved.

R5664500T025664800.fm

02.71.009 Piezo alarm generator,

current too high

02.71.010 Piezo alarm generator,

current too low

02.71.011 Monitoring of nebuliser

valve defective

5664.500/800 Evita 4/Evita 2 dura 01.2002

refer to error 02.71.008

refer to error 02.71.008

The required nebuliser valve position is

constantly compared to the checkback signal

of the actuation electronics.

Remedy: Renew Pneumatic Controller PCB

Note: There is no recognition of whether or

not valve is connected.

Repair Instructions

– 15

02.71.012 Loudspeaker too seldom

recognised

The actuation signal from the CPU 68332

PCB to the loudspeaker (approx. 50 ohms) is

tapped via a series resistor (5 ohms) on the

Graphics Controller PCB and supplied to the

system as digital information. This signal is

used for desired/actual comparison of the

loudspeaker actuation. A unit fault is signalled

if an error is established in the course of this

desired/actual comparison. The loudspeaker

is located in the control console/front section.

Possible cause:

a. Cable fault between CO2 Carrier

PCB and loudspeaker in control

console

b. Loudspeaker defective

c. Graphics Controller PCB defective

d. CPU 68332 PCB defective

Trouble-shooting:

- Measure resistance of loudspeaker

via connecting cable of control

console incl. cable between pins 9

and 10 of SUB-D cable connector.

Test value = 55 plus/minus 8 ohms.

This value incl. shunt resistance must

be 5 ohms higher than loudspeaker

value, which can be measured after

opening control console.

- Using diagnosis mode with lowest

volume setting, Refer to section of "Repair

Instructions - Service No./ Modi, Error list"

chapter 3.2.1, Diagnosis page

“Microprocessor” of “Front”, page 57.

- Using external DS mode via PC with

lowest volume setting, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 9.4.7, Loudspeaker test, page

141. or Refer to section of "Repair

Instructions - Service No./ Modi, Error list"

chapter 9.5.7, Testing of loudspeaker, page

151.

instructions.

Note: Refer also to error 02.71.001

For internal use only. Copyright reserved.

R5664500T025664800.fm

02.71.013 Loudspeaker recognised

too frequently

5664.500/800 Evita 4/Evita 2 dura 01.2002

refer to error 02.71.012

Repair Instructions

– 16

02.71.014 + 15 V too low The operating voltages accessible via an A/D

converter on the CO2 Carrier PCB are

cyclically compared to the defined tolerances.

An undershoot of + 14 V produces a unit fault

message.

Possible cause:

a. Power pack defective (source)

b. CO2 Carrier PCB defective

Check voltages from power pack, various

possibilities:

- Measure voltage with multimeter,

refer to section of "Repair Instructions -

Electronic Components" Chapter 1, Power

Supply Unit, page 1

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.2.1, Diagnosis page

“Microprocessor” of “Front”, page 57.

- With external service mode, Refer to

section of "Repair Instructions - Service No./

Modi, Error list" chapter 9.4.1, Testing

voltages, page 131.

If OK = Renew CO2 Carrier PCB

If not OK = Renew power pack

02.71.015 +10V reference voltage

too low

02.71.016 AD conversion for O2

measurement defective

This voltage is stepped down from the +15 V

on the CO2 Carrier PCB, where it is also

measured. An undershoot of + 9 V produces

this unit fault message.

Remedy:

Renew CO2 Carrier PCB

The pre-amplified O2 sensor voltage is read in

on the Pneumatic Controller PCB by two

independent AD converters. These values

differ.

Trouble-shooting:

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.4.2, Diagnosis page “Sensors”

of “Pneumatics”, page 70.

- With external service mode, Refer to

section of "Repair Instructions - Service No./

Modi, Error list" chapter 9.3.4, Sensors, page

123.

Remedy:

Renew Pneumatic Controller PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 17

02.71.017 O2/Air switching-valve

actuation defective

The required O2/Air switching valve position

is constantly compared to the checkback

signal of the actuation electronics on the

Pneumatic Controller PCB.

Trouble-shooting:

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.4.1, Diagnosis page “Valves” of

“Pneumatics”, page 67.

- With external service mode, Refer to

section of "Repair Instructions - Service No./

Modi, Error list" chapter 9.3.1, Valve switching,

page 121.

Remedy:

Renew Pneumatic Controller PCB

Note:

There is no recognition of whether or not valve

is connected

02.71.018 Incorrect nebuliser gas During nebulisation, the required air/O2

switching valve position is thus constantly

compared to the checkback signal of the

actuation electronics.

Trouble-shooting:

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.4.1, Diagnosis page “Valves” of

“Pneumatics”, page 67.

- With external service mode, Refer to

section of "Repair Instructions - Service No./

Modi, Error list" chapter 9.3.1, Valve switching,

page 121.

Remedy:

Renew Pneumatic Controller PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 18

02.71.019 Cold/warm start

recognition defective

Cold/warm start recognition is effected by

way of mains-switch auxiliary contacts in

power pack, which are read in via CO2

Carrier PCB.

Trouble-shooting:

- With diagnosis mode, Refer to section of

"Repair Instructions - Service No./ Modi, Error

list" chapter 3.3.2, Diagnosis page

“Microprocessor” of “Electronics”, page 63.

- With external service mode, Refer to section

of "Repair Instructions - Service No./ Modi,

Error list" chapter 9.4.2, Power pack status,

page 133.

Possible cause of trouble:

- Mains-switch auxiliary contacts in power

pack defective

- CO2 Carrier PCB defective

02.71.020 Hardware initialisation,

interrupt masks defective

The data for initialising the interrupt masks

have not been properly stored on the CPU

68332 PCB.

Cause:

Fault in one of the following printed circuit

cards (RAM or SW error):

a. CPU 68332 PCB

b. Pneumatic Controller PCB

c. Graphics Controller / Front Panel

PCB

02.71.021 Quartz time discrepancy Quartz times of CPU 68332 PCB and

Pneumatic Contoller PCB are compared and

an error message generated if the two differ

Cause:

Defect in one of the following printed circuit

cards:

a. CPU 68332 PCB

b. Pneumatic Controller PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 19

2.2 Error Code 03 Control-Console Components

Fault Item Cause/Remedy

03.01.001 Touchscreen is not recognised

during BOOT

Following switch-on of Evita 4,

touchscreen is not recognised by

Graphics Controller PCB. The

touchscreen communicates with the

Graphics Controller PCB via RS232.

Trouble-shooting:

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.2.1,

Diagnosis page “Microprocessor” of

“Front”, page 57.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.5.5,

Testing of touchscreen, page 148.

Defect in one of the following printed

circuit cards:

a. Touchscreen

b. Graphics Controller PCB

03.01.002 TOUCHSCREEN NO RESET ACK

similar to error 03.01.001, but occurs

during operation

03.01.003 OUCHSCREEN NO REPORT similar to error 03.01.001, but occurs

during operation

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 20

03.07.001 Reset line fault Reason:

Interruption in reset line between CPU

68332 PCB and Graphics Controller /

Front Panel PCB.

Possible cause:

a. Control console / Front Panel PCB

not connected

b. Fault in cable to control console /

Front Panel PCB

c. CPU 68332 PCB defective

d. Graphics Controller / Front Panel

PCB defective

e. Connector between printed circuit

cards defective

Trouble-shooting:

1. Check and if necessary renew front-

section cable

2. Remove housing cover to reveal

service LEDs on CPU 68332 PCB. If

necessary, insert card in one of the

upper slots (all identical).

3. Connect up control console ready for

operation.

4. Switch on unit.

5. LED 6 must light briefly after

switching on:

If not = CPU 68332 PCB defective

If yes = CPU 68332 PCB probably

OK, renew Graphics Controller /

Front Panel PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 21

2.3 Error Code 04 Components of Electronics Unit

Fault Item Cause/Remedy

04.01.001 Power pack fault, 5V supply

voltage greater than 6 V

The operating voltages accessible via an

A/D converter on the CO2 Carrier PCB

are cyclically compared to the defined

tolerances of plus/minus 20 %.

Possible cause:

a. Power pack defective (source)

b. CO2 Carrier PCB defective

(monitoring)

Trouble-shooting:

Check voltages from power pack,

various possibilities:

- Measure voltage with multimeter,

refer to section of "Repair Instructions Electronic Components" Chapter 1,

Power Supply Unit, page 1

instructions

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.3.2,

Diagnosis page “Microprocessor” of

“Electronics”, page 63.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.4.1,

Testing voltages, page 131.

If OK = Renew CO2 Carrier PCB

If not OK = Renew power pack

Important:

001Power pack +5V too high

(for digital components)

002Power pack +5 V too low

003Power pack +12V too high

(for HPSVs, fan in power pack)

004Power pack +12V too low

005Power pack +15V too high

(for analog components)

006Power pack +15V too low

007Power pack -15V too high

(for analog components)

008Power pack -15V too low

009Power pack +24V too high

(for valves and control console)

010Power pack +24V too low

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 22

04.01.002 Power pack fault, 5V supply

voltage less than 4 V

refer to error 04.01.001

04.01.003 Power pack fault, 12V supply

voltage greater than 14.4 V

04.01.004 Power pack fault, 12V supply

voltage less than 9.6 V

04.01.005 Power pack fault, 15V supply

voltage greater than 18 V

04.01.006 Power pack fault, 15V supply

voltage less than 12 V

04.01.007 Power pack fault, -15V supply

voltage greater than -18 V

04.01.008 Power pack fault, -15V supply

voltage less than -12 V

04.01.009 Power pack fault, 24V supply

voltage greater than 28.8 V

04.01.010 Power pack fault, 24V supply

voltage less than 19.2 V

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

refer to error 04.01.001

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 23

2.4 Error Code 05 Pneumatic System Components

Fault Item Cause/Remedy

05.01.001 Short circuit in fan in

pneumatic system

Fan for cooling pneumatic-system

printed circuit cards defective or not

connected

Recognition:

a. Actuation current of fan is measured

with an A/D converter via a shunt. In

normal operation, this fan current

must be subject to fluctuations

greater than 50 mV. The minimum

and maximum levels of this fan

voltage are measured for 60 s each.

If the max./min. difference is less

than 50 mV, this indicates a fault.

b. Measured value of fan voltage = 0 V

(open circuit)

c. Measured value of fan voltage

greater than or equal to 2.9 V (short

circuit)

Trouble-shooting:

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.4.3,

Diagnosis page “Microprocessor” of

“Pneumatics”, page 74.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.3.5,

Voltages, page 127.

- Fan connected?

-Fan operation?

No = Renew fan

Yes = Renew Pneumatic Controller

PCB

For internal use only. Copyright reserved.

R5664500T025664800.fm

05.01.002 Fan in pneumatic system not

connected

05.01.003 No operation of fan in

pneumatic system

5664.500/800 Evita 4/Evita 2 dura 01.2002

refer to error 05.01.001

refer to error 05.01.001

Repair Instructions

– 24

05.02.001 Reset-up line fault Interruption in reset line between CPU

68332 PCB and Pneumatic Controller

PCB.

Possible cause:

a. CPU 68332 PCB defective

b. Pneumatic Controller PCB defective

c. Connector between printed circuit

cards defective

Trouble-shooting:

1. Remove housing cover to reveal

service LEDs on CPU 68332 PCB.

If necessary, insert card in one of the

upper slots (all identical).

2. Switch on unit.

3. Following LEDs must light briefly

after switching on:

LED 4 (together with 3) for reset-up

LED 5 for reset-down

If not = CPU 68332 PCB defective

If yes = CPU 68332 PCB probably

OK, renew Pneumatic Controller

PCB

05.02.002 Reset-down line fault refer to error 05.02.001

05.02.003 Interruption in disable line Interruption in disable line between

CPU 68332 PCB and Pneumatic

Controller PCB.

Possible cause:

a. CPU 68332 PCB defective

b. Pneumatic Controller PCB defective

c. Connector between printed circuit

cards defective

Trouble-shooting:

1. Removing housing cover to reveal

service LEDs on CPU 68332 PCB.

If necessary, insert card in one of the

upper slots (all identical).

2. Switch on unit.

3. LED 7 must flash/light after switching

on until pneumatic system is activated

(approx. 10 s):

If not = CPU 68332 PCB defective

If yes = CPU 68332 PCB probably

OK, renew Pneumatic Controller

PCB

Note:

Only possible with software versions

1.00 to 1.05, 2.00 and 2.10

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 25

05.04.001 O2/Air switching valve cannot

be switched on

The required O2/Air switching valve

position is constantly compared to the

checkback signal of the actuation

electronics

If required position and checkback

signal do not tally, a unit fault message

is generated.

Trouble-shooting:

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.4.1,

Diagnosis page “Valves” of

“Pneumatics”, page 67.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.3.1,

Valve switching, page 121.

Remedy:

Renew Pneumatic Controller PCB

Note:

There is no recognition of whether or

not valve is connected.

05.04.002 O2/Air switching valve not

switched off

05.04.003 O2/Air switching valve not

switched over

05.04.004 Incorrect O2/Air switching

valve position

05.04.005 O2/Air switching valve does

not switch to Air

refer to error 05.04.001

refer to error 05.04.001

refer to error 05.04.001

In unit check, a test pressure of 30 mbar

is only built up in tubing system with one

connected pressure supply (O2 or Air)

in each case. The O2/Air switching

valve Y1.1 then effects switching to the

other compressed gas. This causes the

tubing system to be vented to below

10 mbar.

Trouble-shooting:

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.4.1,

Diagnosis page “Valves” of

“Pneumatics”, page 67.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.3.1,

Valve switching, page 121.

Remedy:

Renew valve Y1.1 in gas connection.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 26

05.04.006 O2/Air switching valve does

not switch to O2

refer to error 05.04.005

05.05.001 Safety valve cannot be

switched on

Up to SW 1.04 only

Cause: Safety valve or actuation on

Pneumatic Controller PCB defective

05.05.002 Safety valve cannot be

switched off

Up to SW 1.04 only

Cause: Safety valve or actuation on

Pneumatic Controller PCB defective

05.05.003 Safety valve cannot be

switched

Up to SW 1.04 only

Cause: Safety valve or actuation on

Pneumatic Controller PCB defective

05.05.004 Incorrect safety valve position Up to SW 1.04 only

Cause: Safety valve or actuation on

Pneumatic Controller PCB defective

05.05.005 Pressure venting via safety

valve Y1.3 defective

Test pressure of 30 mbar is built up in

patient system during unit check. This is

followed by venting via safety valve Y1.3

to below 10 mbar.

Trouble-shooting:

- With diagnosis mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 3.4.1,

Diagnosis page “Valves” of

“Pneumatics”, page 67.

- With external service mode, Refer to

section of "Repair Instructions - Service

No./ Modi, Error list" chapter 9.3.1,

Valve switching, page 121.

Remedy:

Renew valve Y1.3 in gas connection.

For internal use only. Copyright reserved.

R5664500T025664800.fm

05.05.006 Test pressure of 30 mbar

cannot be built up during unit

check

5664.500/800 Evita 4/Evita 2 dura 01.2002

Pressure of 30 mbar should be built up

in tubing system during unit check with

test lung connected.

Cause:

- Leak in tubing system

- Test lung not connected

Note:

As of SW 1.04, this fault is only

indicated by an “ F “ in the unit check.

Repair Instructions

– 27

2.5 Error Code 07 ROSY (operating-system software errors)

The following applies to all Rosy errors: Operating-system software errors. The operating

system runs on the CPU 68332 PCB, the Pneumatic Controller PCB, the Graphics

Controller PCB (Evita 4)/Front Panel PCB (Evita 2 dura) and the Communication PCB.

Please report any problems to Lübeck.

2.6 Error Code 08 Exceptions (SW)

The following applies to all Exception errors: Software problem on CPU 68332 PCB,

Pneumatic Controller PCB, Graphics Controller PCB (Evita 4) / Front Panel PCB (Evita 2

dura) or Communication PCB. Please report any problems to Lübeck.

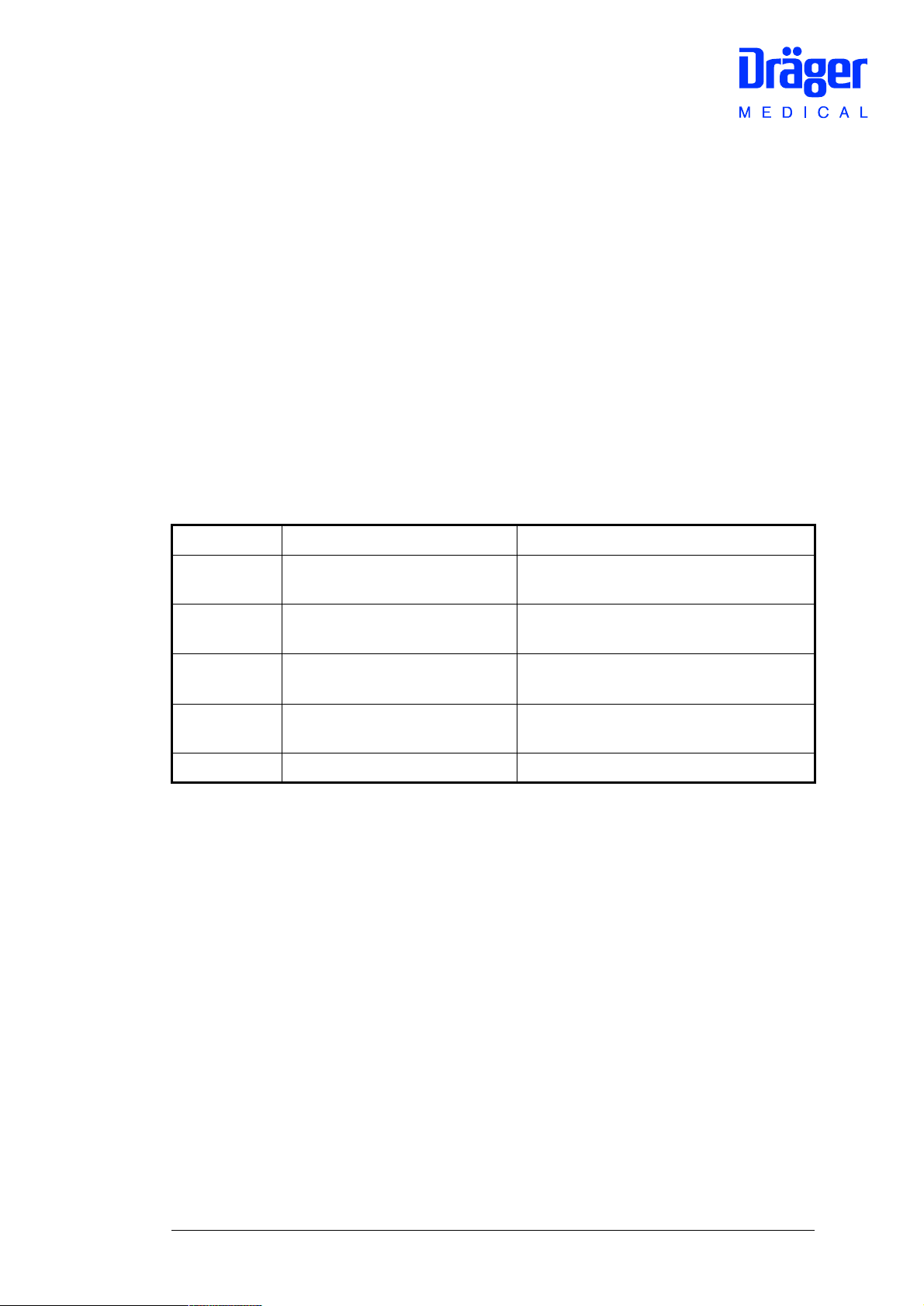

2.7 Error Code 10 Pneumatic Controller

Fault Item Cause/Remedy

10.01.020 Pneumatic Controller PCB

defective (Timeout)

10.01.040 Pneumatic Controller PCB

defective (Timeout)

10.02.001 Pneumatic Controller PCB

defective (RAM error)

10.03.001 Pneumatic Controller PCB

defective (Flash EPROM error)

Remedy: Renew Pneumatic Controller

PCB

Remedy: Renew Pneumatic Controller

PCB

Remedy: Renew Pneumatic Controller

PCB

Remedy: Renew Pneumatic Controller

PCB

10.97.xxx ROSY SHUTDOWN refer to: Rosy error codes (07..)

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 28

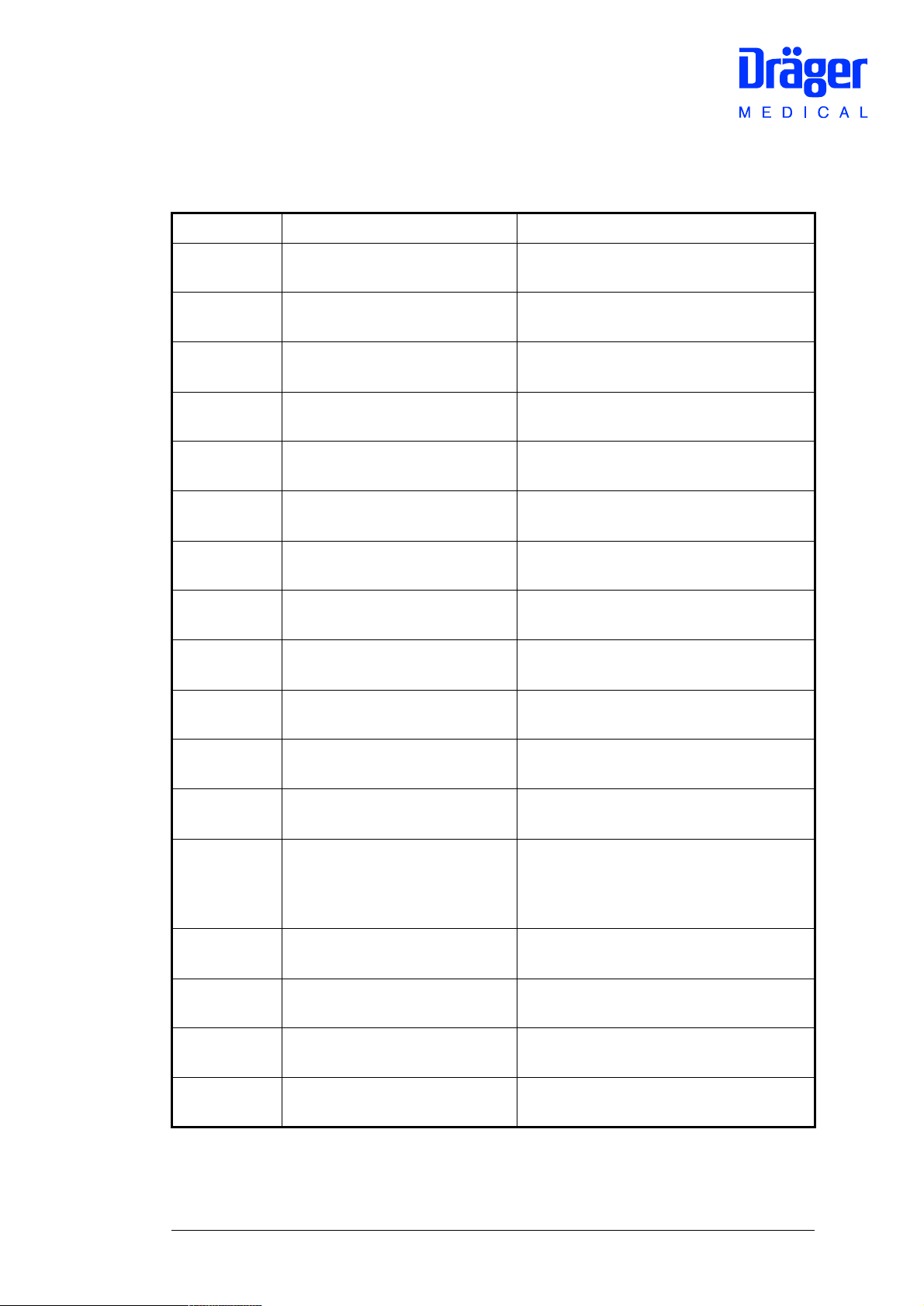

SW:

Fault Item Cause/Remedy

10.99.000 PNT UNEXPECTED END

OF_TASK

10.99.020 LM UNEXPECTED END OF

TASK

10.99.030 DSPT UNEXPECTED END OF

TASK

Software error on Pneumatic Controller

PCB.

Software error on Pneumatic Controller

PCB.

Software error on Pneumatic Controller

PCB.

10.99.040 VS INVALID MSG RECEIVED Software error on Pneumatic Controller

PCB.

10.99.050 UE INVALID MSG RECEIVED Software error on Pneumatic Controller

PCB.

10.99.060 BEAT ILLEGAL MSG Software error on Pneumatic Controller

PCB.

10.99.061 BEAT ILL MSGSIZE Software error on Pneumatic Controller

PCB.

10.99.062 BEAT ILL BREATH STATE Software error on Pneumatic Controller

PCB.

10.99.063 BEAT ILL VENTILATION

MODE

Software error on Pneumatic Controller

PCB.

10.99.064 BEAT ACTIVATE ILL BMODE Software error on Pneumatic Controller

PCB.

10.99.065 BEAT ILL DEACTIVATION Software error on Pneumatic Controller

PCB.

10.99.070 bau: BAU Task should never

reach this point

10.99.071 BAU ILLEGAL SETTING,

incorrect Ti Te, calculation in

Software error on Pneumatic Controller

PCB.

Software error on Pneumatic Controller

PCB.

parameter adjustment, apnoea

ventilation

10.99.080 eba: EBA Task should never

reach this point

Software error on Pneumatic Controller

PCB.

10.99.081 EBA ILL MSG ID Software error on Pneumatic Controller

PCB.

10.99.082 EBA LONG MSG Software error on Pneumatic Controller

PCB.

10.99.083 EBKB TERMINATE

OPERATION

Software error on Pneumatic Controller

PCB.

For internal use only. Copyright reserved.

R5664500T025664800.fm

5664.500/800 Evita 4/Evita 2 dura 01.2002

Repair Instructions

– 29

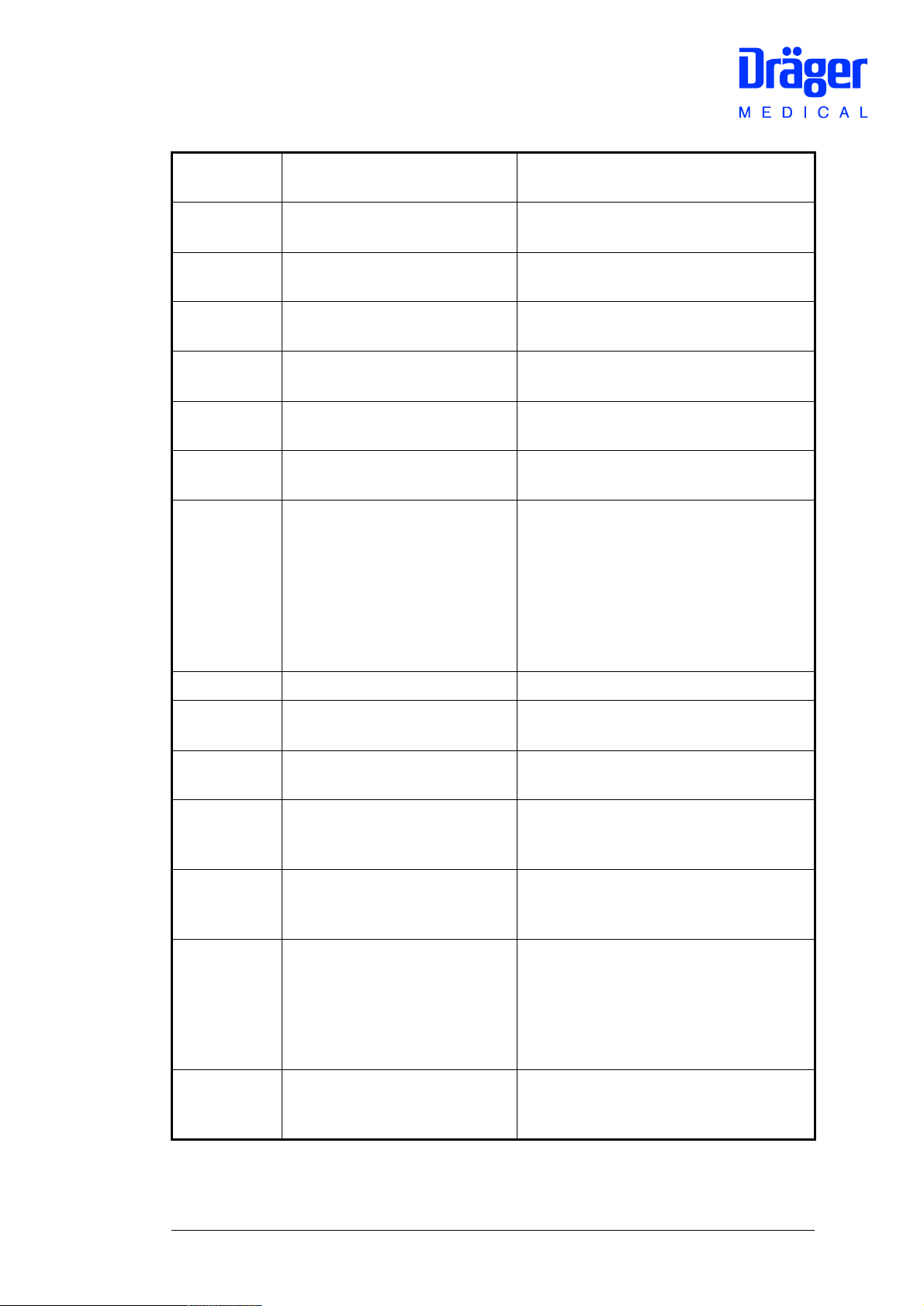

10.99.084 EBKB O2 ILL STATE Software error on Pneumatic Controller

PCB.

10.99.085 EBKB PAED ILL STATE Software error on Pneumatic Controller

PCB.

10.99.086 EBKB ILL BRONCHSTATE Software error on Pneumatic Controller

PCB.

10.99.087 EBKB ILL FLOWSTATE1 Software error on Pneumatic Controller

PCB.

10.99.088 EBKB ILL FLOWSTATE2 Software error on Pneumatic Controller

PCB.

10.99.101 BB INVALID MSG RECEIVED Software error on Pneumatic Controller

PCB.

10.99.110 MSF INVALID MSG

RECEIVED

Software error on Pneumatic Controller

PCB.

10.99.111 MSF, AD VALUES shifted Incorrect AD conversion on Pneumatic

Controller PCB.

Cause:

Pneumatic Controller PCB defective or

supply voltages not stable. Further

cause: In the case of abnormal mixer

noise on switch-on, an HPSV is

impermissibly loading the minus 15 V.

10.99.112 MSF, AD VALUES on ZERO Refer to error 10.99.111.

10.99.801 EEPROM WRITE QUEUE

FULL

10.99.901 DL UNEXPECTED END OF

TASK

10.99.911 1ST CD LENGTH CORRUPT,

false central data length for

Software error on Pneumatic Controller

PCB.

Software error on Pneumatic Controller

PCB.

Software error on Pneumatic Controller

PCB.

first object in frame arrived

10.99.912 1ST LONG MSG CORRUPT,

start frame data of multi packet

Software error on Pneumatic Controller

PCB.

receive message RPC corrupt

For internal use only. Copyright reserved.

R5664500T025664800.fm

10.99.913 CAN ERROR INT, CAN

controller marked ill interrupt

by sending error frames

10.99.914 NET QUEUE OVERFLOW,

data overflow in applications

receive queue

5664.500/800 Evita 4/Evita 2 dura 01.2002

CAN Controller error on CPU 68332

PCB or Pneumatic Controller PCB or

Graphics Controller PCB

(Evita 4)/Front Panel PCB

(Evita 2 dura). Most likely cause:

Pneumatic Controller PCB.

Software error on Pneumatic Controller

PCB.

Repair Instructions

– 30

Loading...

Loading...