Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

DrägerService

RETURN TO CD-ROM TABLE OF CONTENTS

®

Technical

Service

Manual

Part Number: 4111556-001

Date: 20 May 2002

© 2002 Draeger Medical, Inc.

Rev: AB

Narkomed 4

Anesthesia System

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO CD-ROM TABLE OF CONTENTS

DrägerService

®

Narkomed 4 Service Manual Table of Contents

Summary of What's New in Rev. AB

DESCRIPTION PAGE

SECTION 1:

Introduction ............................................................... 1-1

SECTION 2:

Diagnostics ............................................................... 2-1

2.1 Main Service Screen ............................................. 2-2

2.2 Service Log Screen .............................................. 2-4

2.3 PMS Criteria Screen ............................................ 2-9

2.4 Monitors .................................................... 2-10

2.5 Peripherals .................................................. 2-17

2.6 O.R. DATA MANAGER Diagnostics ................................ 2-20

2.7 O.R. DATA MANAGER Software Version Window ..................... 2-21

2.8 O.R. DATA MANAGER Printer Configuration ........................ 2-22

SECTION 3:

Troubleshooting ............................................................ 3-1

3.1 Power Supply and Voltage Distribution .............................. 3-1

3.2 Processor Test ................................................. 3-6

3.3 Troubleshooting Guide Flow Charts ................................. 3-6

3.4 O.R. DATA MANAGER Troubleshooting ............................ 3-27

SECTION 4:

Replacement Procedures ..................................................... 4-1

4.1 Cylinder Yoke Assemblies ........................................ 4-2

4.2 Cylinder Pressure Regulators ...................................... 4-5

4.3 Cylinder Cutoff Valves (Canada) ................................... 4-8

4.4 Cylinder and Pipeline Pressure Gauges ............................. 4-11

4.5 Flowmeters .................................................. 4-15

4.6 Flow Control Valves ............................................ 4-19

4.7 Oxygen Supply Failure Protection Device ............................ 4-22

4.8 Oxygen Supply Pressure Alarm Switch (earlier machines) ............... 4-25

4.9 Oxygen Supply Pressure Alarm Whistle (Canada) ..................... 4-28

4.10 Oxygen Ratio Monitor/Controller .................................. 4-30

4.11 Oxygen Ratio Controller (later machines) ............................ 4-34

4.12 Vaporizers ................................................... 4-37

4.13 O

4.14 AV-E Ventilator Controller Assembly ............................... 4-43

4.15 AV-E Ventilator Solenoid Valve ................................... 4-45

4.16 AV-2 and AV2+ Ventilator Controller Assembly ....................... 4-48

4.17 Convenience Outlet AC Power Filter ............................... 4-51

4.18 AV-E Inspiratory Flow Regulator .................................. 4-54

4.19 Ventilator Bellows Valve & Guide Assembly (AV-E Ventilator) ............ 4-56

4.20 Ventilator Bellows Valve & Guide Assembly

Flush Valve ................................................ 4-40

2

with Pressure Limit Control (AV-2 Ventilator) .................. 4-61

Rev. W

i

Page 4

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

CONTENTS (continued) NM4

DESCRIPTION PAGE

4.21 Alarm Channel (without oxygen supply pressure alarm switch) ...... 4-65

4.22 Alarm Channel and Oxygen Supply Pressure Alarm Switch ......... 4-68

4.23 Caster ................................................. 4-72

4.24 Battery ................................................ 4-74

4.25 Power Supply Circuit Board ................................. 4-76

4.26 Processor Boards ......................................... 4-78

4.27 Serial Interface Assembly .................................. 4-80

4.28 Backplane Circuit Board Assembly ........................... 4-82

4.29 Multispec Analyzer Assembly (Model 4600) ..................... 4-85

4.30 Multispec Analyzer Assembly (Model 4610) ..................... 4-94

4.31 Front Bezel Assembly .................................... 4-103

4.32 Remote Display Assembly (without Datagrip) .................. 4-106

4.33 Remote Display Assembly (with Datagrip) ..................... 4-108

4.34 Datagrip Assembly ....................................... 4-110

4.35 NIBP Pump and Sensor Circuit Assembly ..................... 4-113

4.36 Pulse Oximeter (SpO

) Assembly ............................ 4-117

2

4.37 VPO Assembly .......................................... 4-119

4.38 SPIROMED Respiratory Volume Sensor ...................... 4-122

4.39 Oxygen Sensor .......................................... 4-124

4.40 Manual Sphygmomanometer ............................... 4-125

4.41 Boom Arm Assembly (earlier machines) ....................... 4-127

4.42 Display Arm Assembly (later machines) ....................... 4-130

4.43 Internal Strip Chart Printer ............................... 4-133

4.44 O.R. DATA MANAGER CPU Assembly (earlier machines) ......... 4-135

4.45 O.R. DATA MANAGER Sub-Assembly (later machines) ........... 4-138

4.46 Keyboard .............................................. 4-141

4.47 Auxiliary Oxygen Flowmeter ............................... 4-143

4.48 PEEP Valve Magnet Assembly Replacement ................... 4-145

SECTION 5:

Adjustment and Calibration Procedures ...................................5-1

5.1 Cylinder Pressure Regulator Adjustment (except CO

5.1A CO

Cylinder Pressure Regulator Adjustment ....................5-4

2

) ..............5-2

2

5.2 Oxygen Supply Pressure Alarm Switch Adjustment (earlier machines) . 5-5

5.3 Oxygen Supply Pressure Alarm Switch Adjustment

(later machines with switch on alarm channel) ..............5-8

5.4 Oxygen Ratio Monitor/Controller (ORMC) Adjustment ............. 5-11

5.5 Oxygen Ratio Controller (ORC) Adjustment ..................... 5-15

5.5A Low Flow Oxygen Ratio Controller (ORC) Adjustment ............5-17A

5.6 Boom Arm Tension Adjustments ............................. 5-18

5.7 Display Arm Tension Adjustments ............................ 5-20

5.8 Oxygen Sensor Zero Calibration .............................. 5-22

5.9 Breathing Pressure Monitor Calibration ........................ 5-24

5.10 Respiratory Flow Monitor Calibration ......................... 5-26

5.11 SpO

Monitor Calibration Check - Nellcor ...................... 5-28

2

5.11A SpO2 Monitor Calibration Check - Novametrix .................5-29A

5.12 NIBP Inflation Pressure Calibration Check ..................... 5-30

ii

Rev. Z

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 CONTENTS (continued)

DESCRIPTION PAGE

5.13 Multispec Span and Line Block Calibration ....................... 5-32

5.14 Vaporizer Interlock Adjustment ................................ 5-43

5.15 Vaporizer Select Switch Adjustment ............................. 5-45

SECTION 6:

PMS Procedures ........................................................ 6-1

6.1 Safety Testing ............................................... 6-2

6.2 Battery Circuit Test .......................................... 6-3

6.3 Manual Sphygmomanometer .................................... 6-4

6.4 Vapor Exclusion System and Agent Indicator Lamp Test .............. 6-5

6.5 High Pressure Leak Test ...................................... 6-6

6.6 Oxygen Supply Failure Protection ................................ 6-8

6.7 Flowmeter Test ............................................. 6-10

6.8 NAD O

Monitor ............................................ 6-12

2

6.9 Oxygen Concentration Tests ................................... 6-14

6.10 Gauges ................................................... 6-16

6.11 Freshgas Leak test .......................................... 6-17

6.12 Absorber System ............................................ 6-18

6.13 Ventilator Test ............................................. 6-24

6.14 Bellows Drive Gas Leak Test .................................. 6-26

6.15 "F" Bellows Test ............................................ 6-26

6.16 Pressure Limit Control Test ................................... 6-27

6.17 Ventilator Relief Valve Test ................................... 6-28

6.18 SPIROMED or Ultrasonic Flow Sensor Test ....................... 6-28

6.19 Alarm Circuit Delay Test ..................................... 6-30

6.20 Apnea Pressure Test ......................................... 6-30

6.21 High Pressure Alarm Test .................................... 6-31

6.22 Sub-Atmospheric Pressure Alarm Test ........................... 6-31

6.23 Continuing Pressure Alarm Test ................................ 6-31

6.24 Oxygen Ratio Monitor Control (ORMC) Test ....................... 6-31

6.24A Oxygen Ratio Control (ORC) Test ............................... 6-33

6.25 SpO

/Pulse - Nellcor ......................................... 6-34

2

6.25A SpO2 Monitor Calibration Check - Novametrix .................... 6-34A

6.26 NIBP Alarm and Pressure Tests ................................ 6-35

6.27 Agent Analyzer Accuracy Test .................................. 6-37

6.28 Open Reservoir Scavenger ..................................... 6-41

6.28A Scavenger Interface, A/C ...................................... 6-43

6.28B Scavenger Interface ......................................... 6-44

6.29 Service Screens ............................................. 6-47

6.30 Oxygen Flush and 100% O

Final Test ........................... 6-48

2

6.31 Final Check ............................................... 6-49

SECTION 7:

Software Update Procedure ................................................ 7-1

7.1 Software Transfer to PC via Modem .............................. 7-2

7.2 Installing NM4 Software from a PC .............................. 7-2

7.3 Installing NM4 Software from the ORDM .......................... 7-4

7.4 Installing NM4 Software from a PC using the SST ................... 7-5

7.5 Installing NM4 Software from the ORDM using the SST .............. 7-6

Rev. K

iii

Page 6

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

CONTENTS (continued) NM4

SECTION 8:

Spare and Replacement Parts

ASSEMBLY/PART PAGE

Monitor Chassis and related assemblies ............................... 8-2, 8-3

Front Bezel Assembly ............................................. 8-4, 8-5

Serial Interface Assembly, Pulse Oximeter Assembly ...................... 8-6, 8-7

Multispec Analyzer Assembly, Model 4600 ............................. 8-8, 8-9

Multispec Analyzer Assembly, Model 4610 ............................8-10, 8-11

AV-E Ventilator Box Assembly .....................................8-12, 8-13

AV-2 Ventilator Controller Assembly .................................8-14, 8-15

AV-E Ventilator Bellows, Valve Case Assembly .........................8-16, 8-17

AV-2 Ventilator Bellows, Valve Case Assembly and Pressure Limit Control . . . 8-18, 8-19

Boom Arm Assembly .............................................8-20, 8-21

Remote Display, Datagrip .........................................8-22, 8-23

Display Arm Assembly ...........................................8-24, 8-25

Pipeline Inlets ..................................................8-26, 8-27

Failsafe Assemblies, Minimum O

Flow Valve Assembly ..................8-28, 8-29

2

Exclusion System, 3-vapor ...................................... 8-29A, 8-29B

Vapor Select Switches, Vapor Ind. Circuit Board, Gas Selector Switch Assembly 8-30, 8-31

ORMC (Earlier Config.) O

Alarm Switch, Alarm Channel, Alarm Whistle ....8-32, 8-33

2

ORC Assembly .................................................8-34, 8-35

Alarm Channel Assembly with O

Alarm Switch (Later Configurations) ......8-36, 8-37

2

Flowmeter Shields, Knobs, Labels, Gauges ............................8-38, 8-39

Flow Tubes, Flow Control Valves ....................................8-40, 8-41

Cylinder Pressure Regulators, O

Flush Valve ..........................8-42, 8-43

2

Fresh Gas Outlet ............................................. 8-43A, 8-43B

Cylinder Cutoff Valve Assemblies ...................................8-44, 8-45

Canada Fresh Gas Outlet ...................................... 8-45A, 8-45B

Cylinder Yokes and Related Parts ...................................8-46, 8-47

VPO, AC Power, Batteries, Power Supply, Casters ......................8-48, 8-49

O.R. Data Manager, 386 and earlier, Incl. Keyboard .....................8-50, 8-51

Absorber Assembly, Breathing Pressure Hoses, Oxygen Sensor .............8-52, 8-53

Ultrasonic Flow Sensor ........................................ 8-53A, 8-53B

Ultrasonic Flow Sensor Mounting Bracket .......................... 8-53C, 8-53D

Man/Auto Selector Valve ..........................................8-54, 8-55

Man/Auto Selector Valve (Later Design) ..............................8-56, 8-57

Auxiliary O

Flowmeter Assembly ...................................8-58, 8-59

2

Open Reservoir Scavenger .........................................8-60, 8-61

Open Reservoir Scavenger, old style .................................8-62, 8-63

A/C Scavenger ..................................................8-64, 8-65

Suction Scavenger ...............................................8-66, 8-67

iv

Rev. AA

Page 7

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 8

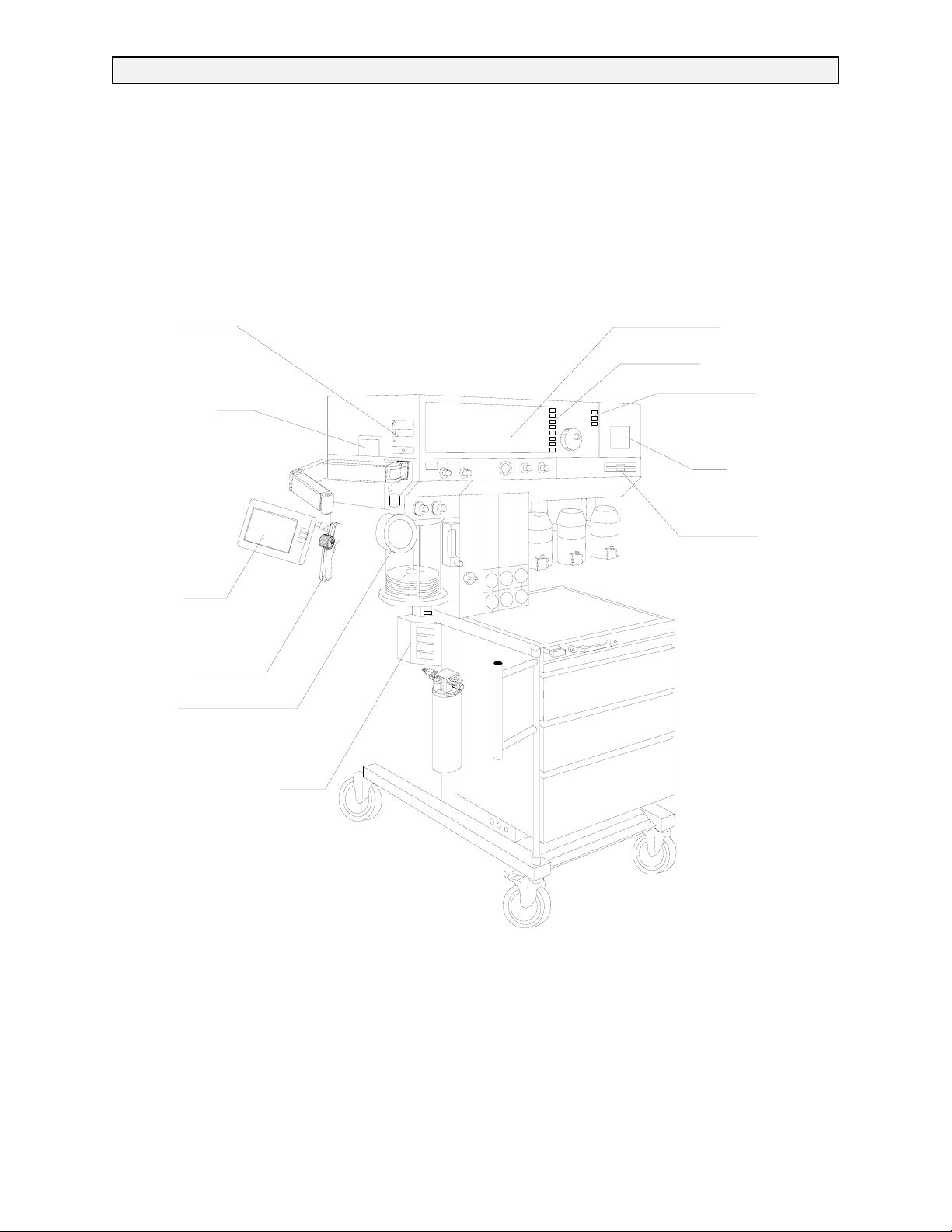

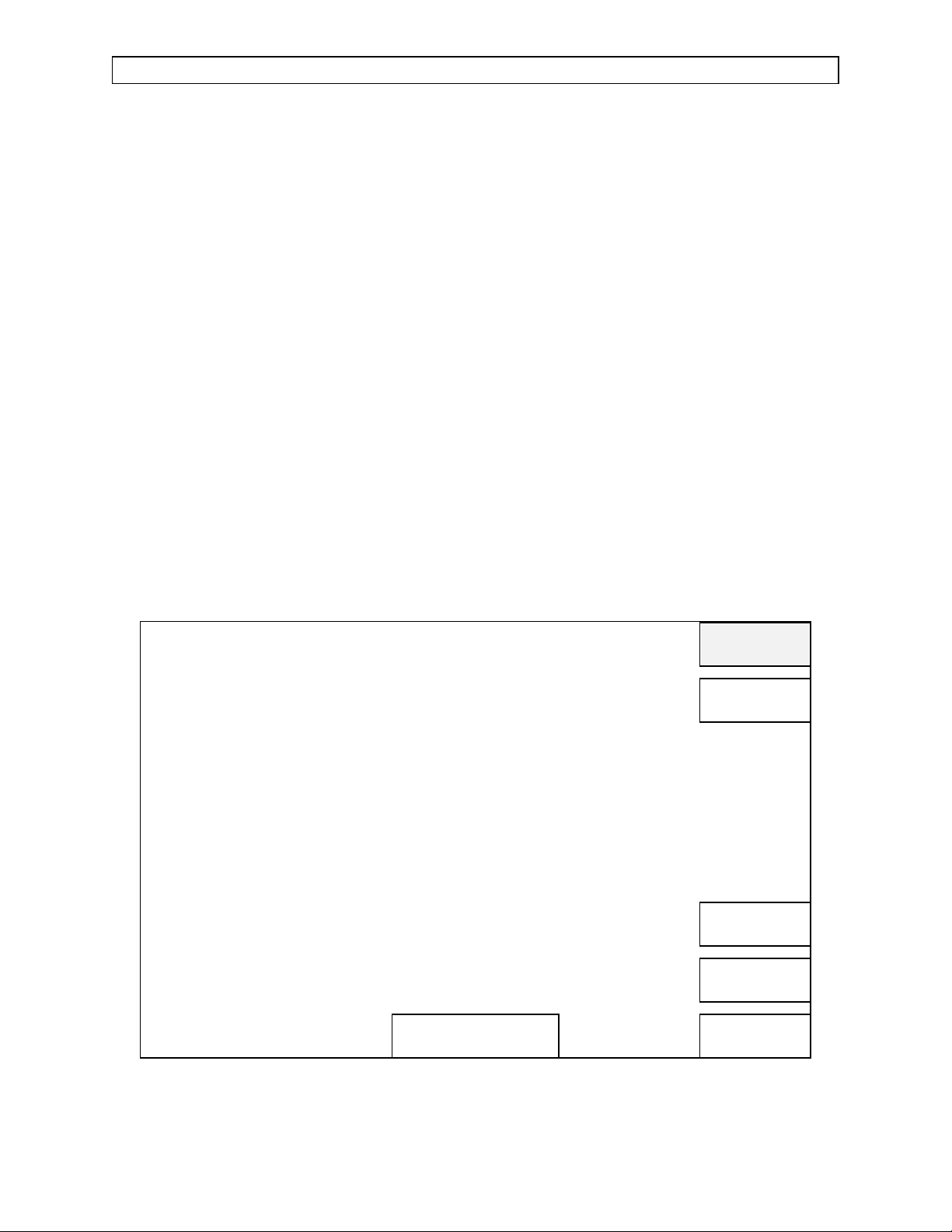

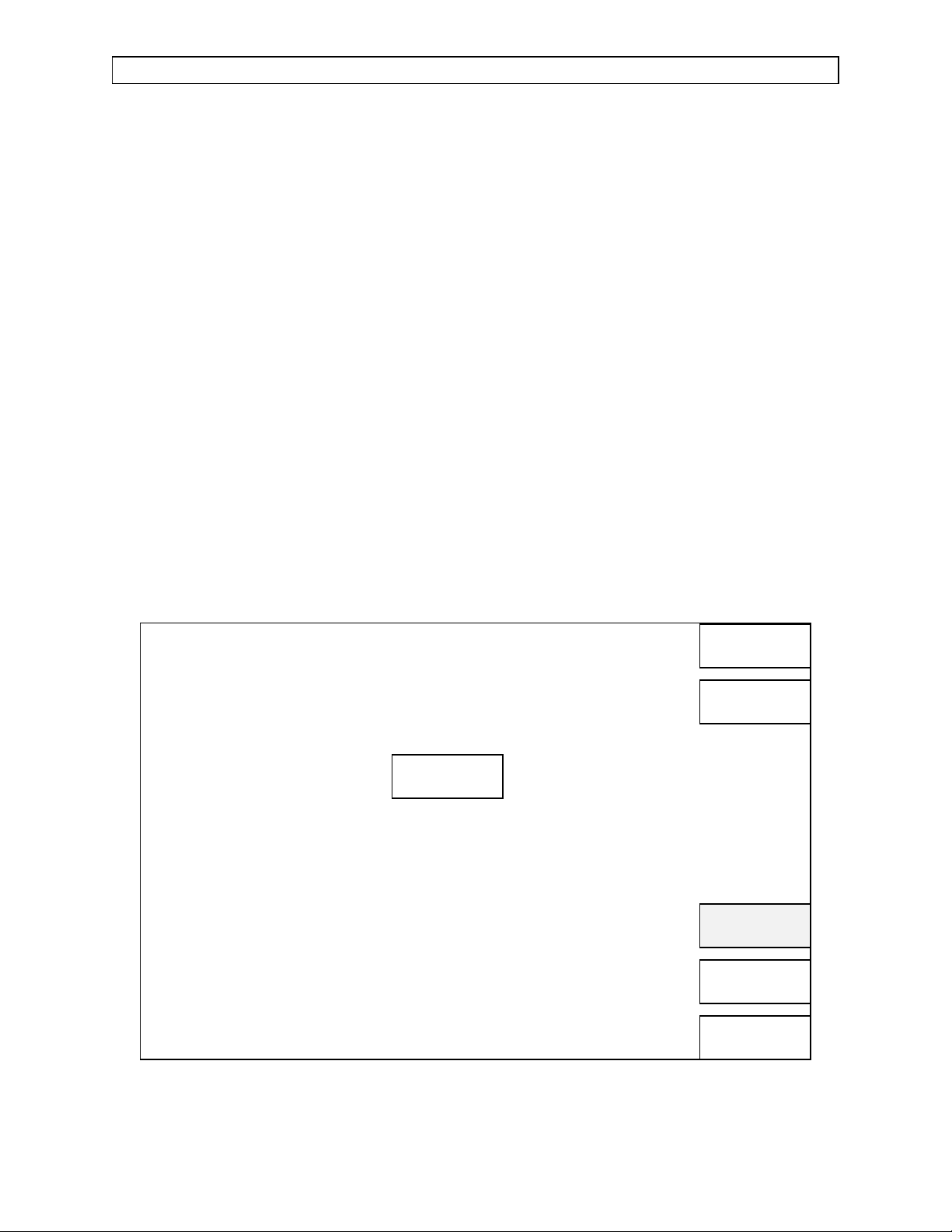

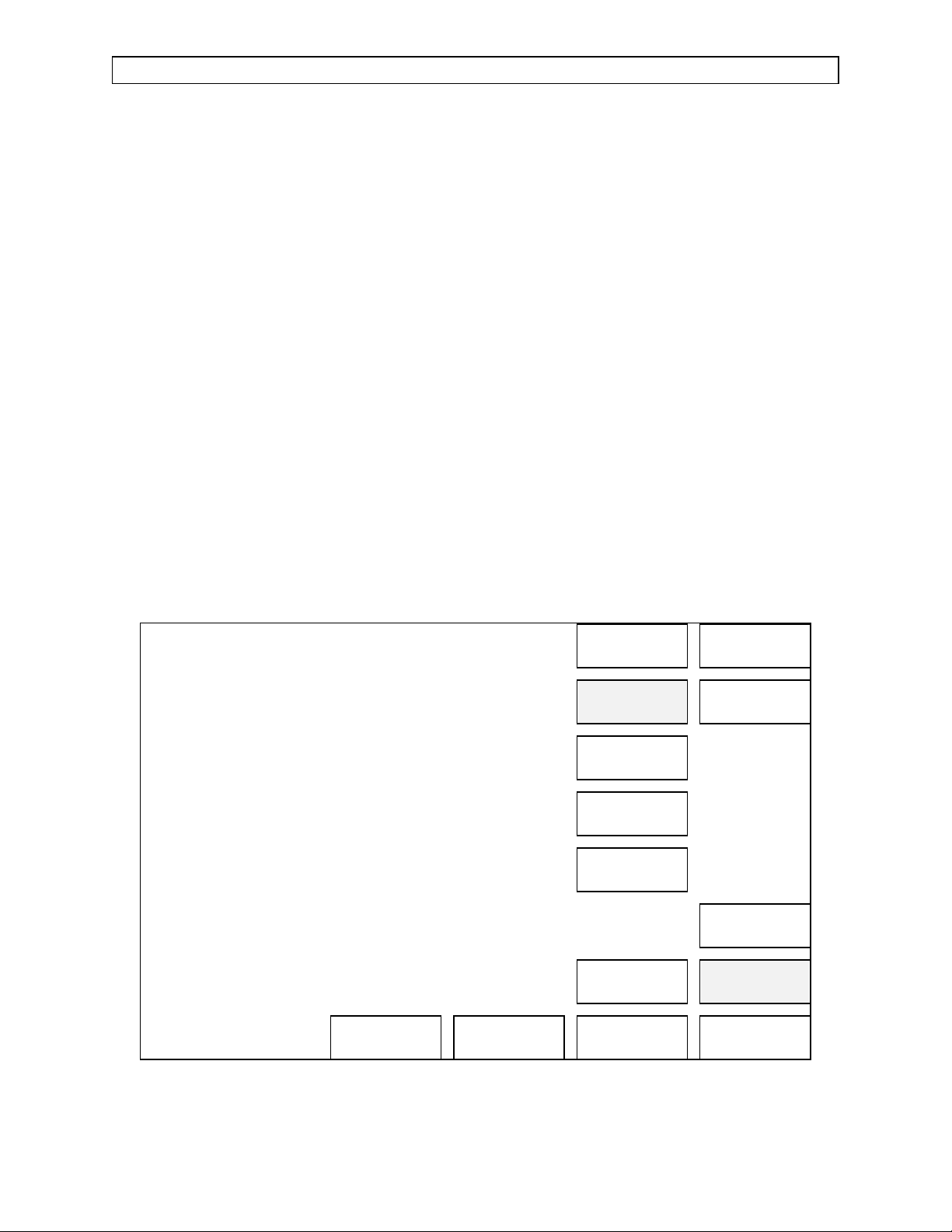

NARKOMED 4 ANESTHESIA SYSTEM

Y

A

R

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

PATIENT

INTERFACE

PANEL

DISPOSABLE

WATER TRAP

REMOTE

DISPLAY

DATAGRIP

MANUAL

SPHYGMOMANOMETER

MAIN DISPLA

MAIN KEY PANEL

CONTROL

KEY PANEL

STRIP CHART

PRINTER

O.R.DAT

MANAGE

BREATHING SYSTEM

SENSOR INTERFACE PANEL

(VPO ASSEMBLY)

SV45024

1-0 Rev. F

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 INTRODUCTION

1.0 Recommendations

Because of the sophisticated nature of Draeger Medical, Inc. anesthesia equipment and its critical

importance in the operating room setting, it is highly recommended that only appropriately

trained and experienced professionals be permitted to service and maintain this equipment.

Please contact DrägerService® at (800) 543-5047 for service of this equipment.

Draeger Medical, Inc. also recommends that its anesthesia equipment be serviced at three-month

intervals. Periodic Manufacturer’s Service Agreements are available for equipment manufactured

by Draeger Medical, Inc. For further information concerning these agreements, please contact us

at (800) 543-5047.

Draeger Medical, Inc. products/material in need of factory repair shall be sent to:

DrägerService

3124 Commerce Drive

Telford, PA 18969

(Include RMA Number)

HOW TO USE THIS MANUAL

The manual is divided into several sections. The DIAGNOSTICS section describes self-test and

service diagnostics for checking the system functions. An understanding of the on-board service

capabilities is necessary before any attempt is made to troubleshoot the unit. The

TROUBLESHOOTING section lists error codes and provides troubleshooting guides to assist the

TSR in locating the source of a problem. The REPLACEMENT PROCEDURES section contains

instructions for removal and replacement of the assemblies that are considered field-replaceable.

The ADJUSTMENT AND CALIBRATION PROCEDURES section contains the field procedures

needed to restore original system specifications. The Periodic Manufacturer’s Service (PMS)

PROCEDURE section outlines the steps required to verify the electrical, mechanical and

pneumatic safety of the unit and also identifies components requiring periodic replacement.

GENERAL TROUBLESHOOTING GUIDELINES

Troubleshooting the Narkomed 4 should always begin by communicating withthose who observed

or experienced a problem with the unit. This may eliminate unnecessary troubleshooting steps.

Once a general problem is identified, refer to the troubleshooting flow charts in Section 3 to

determine the proper corrective action to be taken.

After a component has been replaced, verify that the unit is operating properly by running the

appropriate diagnostic procedure. The PMS PROCEDURE in Section 6 must also be performed

after any component has been replaced.

The general arrangement of the Narkomed 4 Anesthesia System is shown on the opposite page.

WARNINGS are used in this manual before procedures which if not performed correctly could

result in personal injury.

CAUTIONS are used in this manual to alert service personnel to the possibility of damage to the

equipment if a procedure is not performed correctly.

Rev. K

1-1

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION NM4

Copyright

Copyright © 1999 by Draeger Medical, Inc. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, or stored in a retrieval system in any form or

by any means, electronic or mechanical, including photocopying and recording, without the

written permission of Draeger Medical, Inc.

Trademark Notices

CliniDAS, Datagrip, NAD Information Systems, NAD Logo, Narkomed, O.R. Data Manager,

O.R. Link, ORM, PC Prep/View, Quality Service For Life, Vigilance Audit, Vitalert, Vitalink

and Narkomed GS are registered trademarks of Draeger Medical, Inc. All other products or

name brands are trademarks of their respective owners.

Disclaimer

The content of this manual is furnished for informational use only and is subject to change

without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

1-2

Rev. M

Page 11

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS

2.0 DIAGNOSTICS

The NARKOMED 4 contains a diagnostic system that monitors certain system functions and

records their operational status. A series of tests is performed when the system is powered

up and the results are displayed on the diagnostics screen shown in Figure 2-1. Further

diagnostic functions are available through a series of service screens that can be called up

by a Technical Service Representative at the display panel. The following paragraphs provide

a description of each of the service screens that can be accessed through touch keys on the

display panel. If no display is present upon system power-up, refer to Section 3 of this

manual for troubleshooting assistance.

A PREVENTIVE MAINTENANCE DUE message will appear on the screen if the current

date exceeds the Periodic Manufacturer’s Service due date stored in the machine.

DIAGNOSTICS

VIDEO TEST PASS

FIRMWARE TEST PASS

MEMORY TEST BANK1 PASS

MEMORY TEST BANK2 PASS

TIMER/INTERRUPT TEST PASS

ANALOG TEST PASS

AUDIO TEST -PRIMARY PASS

-BACKUP PASS POWER SUPPLY STATUS:

-SpO2 PASS FULLY FUNCTIONAL

SERIAL I/O TEST PASS

CLOCK TEST PASS

NON-VOLATILE MEMORY TEST PASS

ALTERNATE PROCESSOR TEST PASS

FUNCTIONAL

NARKOMED 4 SYSTEM SOFTWARE

(C) COPYRIGHT 1988-1995, NAD INC.

VERSION: 1.30 97 CF

MONITOR CHECKOUT

Rev. C

Figure 2-1: POWER-UP DIAGNOSTICS SCREEN

2-1

Page 12

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

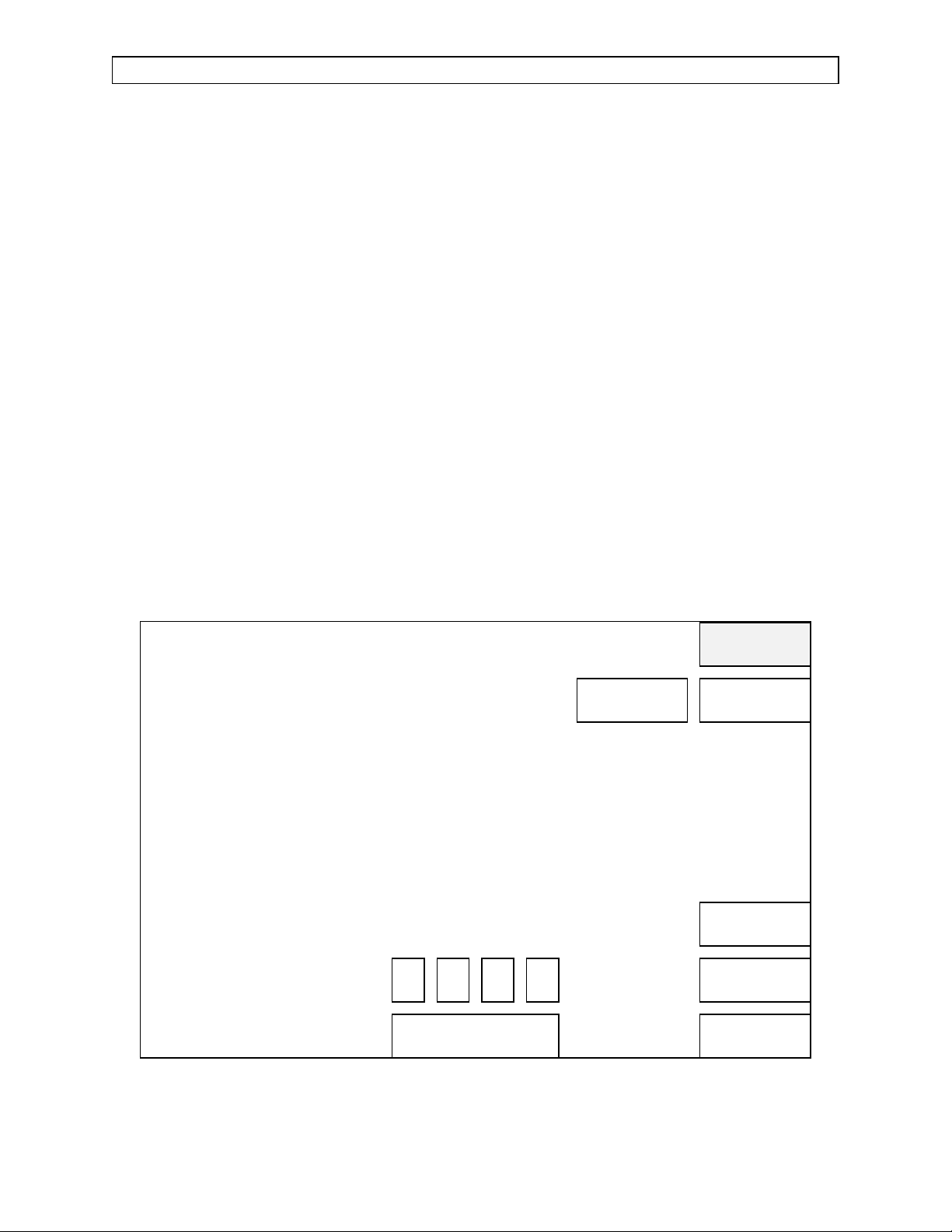

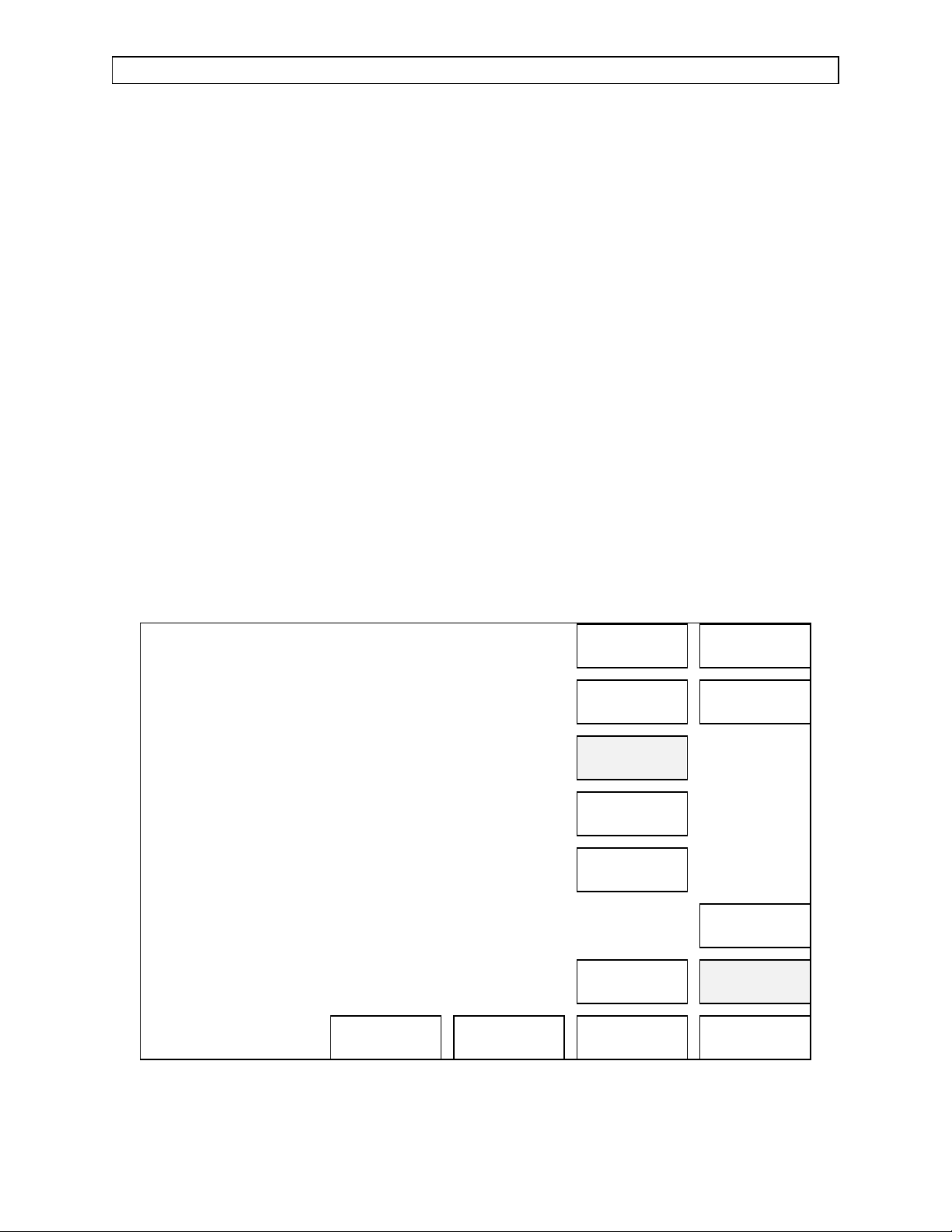

2.1 Main Service Screen

2.1.1 View Mode

To access the Main Service Screen, press and hold the Selection DIAL, and

simultaneously press the MONITOR and SYSTEM CONFIG keys. The View

mode service screen shown in Figure 2-2 will appear, displaying the machine

serial number, last service date and machine hours accumulated. Version

numbers for each software set in the machine are also displayed.

If the MONITORS service screens are accessed in the View mode, current

values will be displayed but the operator will not be able to perform

calibrations. A VIEW entry will not be logged into the Service Log.

MACHINE SERIAL NUMBER : 00124001

LAST SERVICE DATE : 03-14-96

HOURS RUNNING SINCE LAST SERVICE : 97

TOTAL HOURS RUNNING : 5610

SYSTEM SOFTWARE VERSION : 1.40

TOUCH PANEL SOFTWARE VERSION : 1.02

DATAGRIP SOFTWARE VERSION : 1.01

MULTISPEC SOFTWARE VERSION : 1.04

VPO SOFTWARE VERSION : 1.72

POWER SUPPLY SOFTWARE VERSION : 1.01

PURITAN BENNETT SW VERSION : 1.00 0016FF00

CRITICAR 1100 SW VERSION : 1.01 00171900

CRITICAR POET IQ SW VERSION : 1.00 00173D00

TRAM NET SW VERSION : 1.01 00175E00

SPACELAB LOGGER SW VERSION : 1.00 00178600

SERVICE CODE

VIEW

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-2: VIEW MODE SERVICE SCREEN

2-2

Rev. H

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

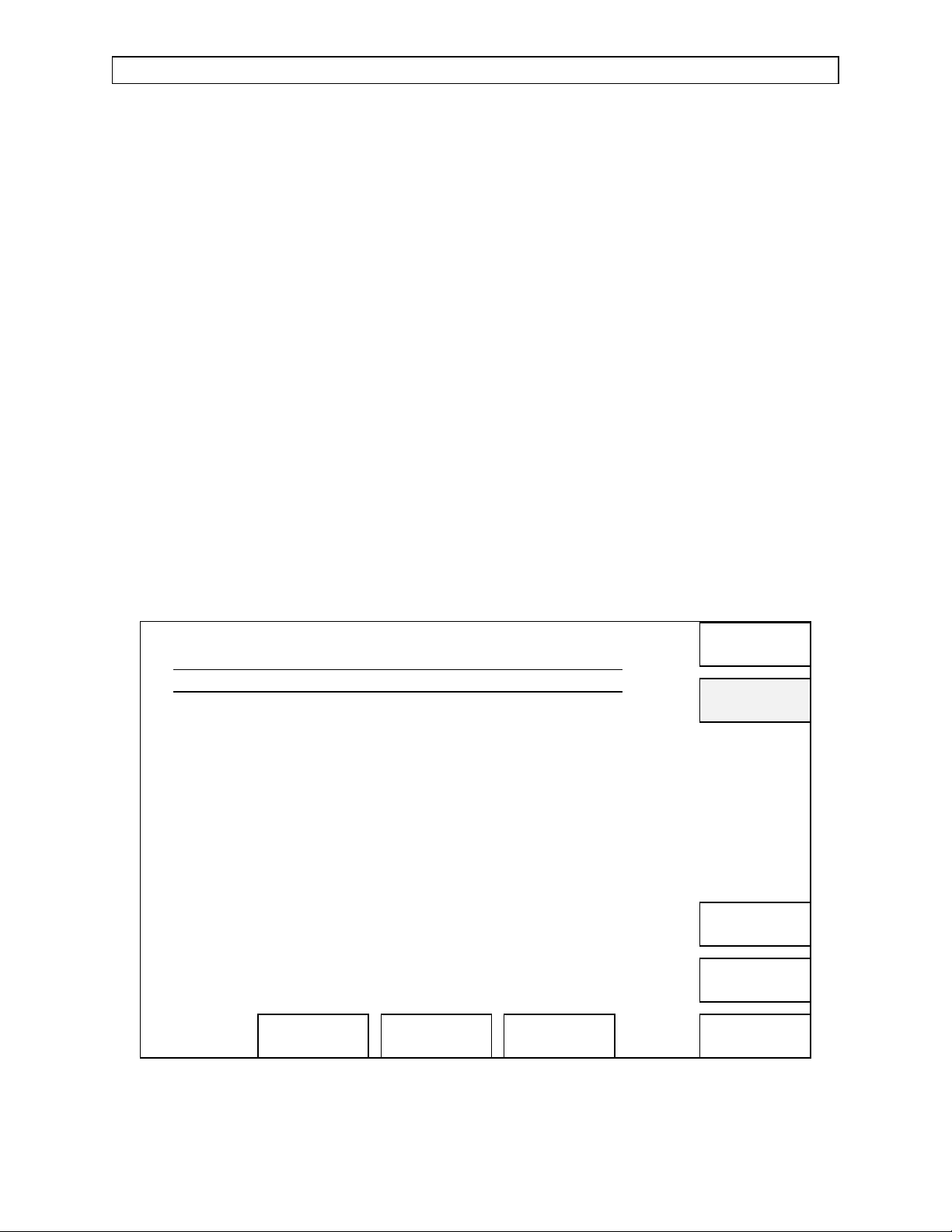

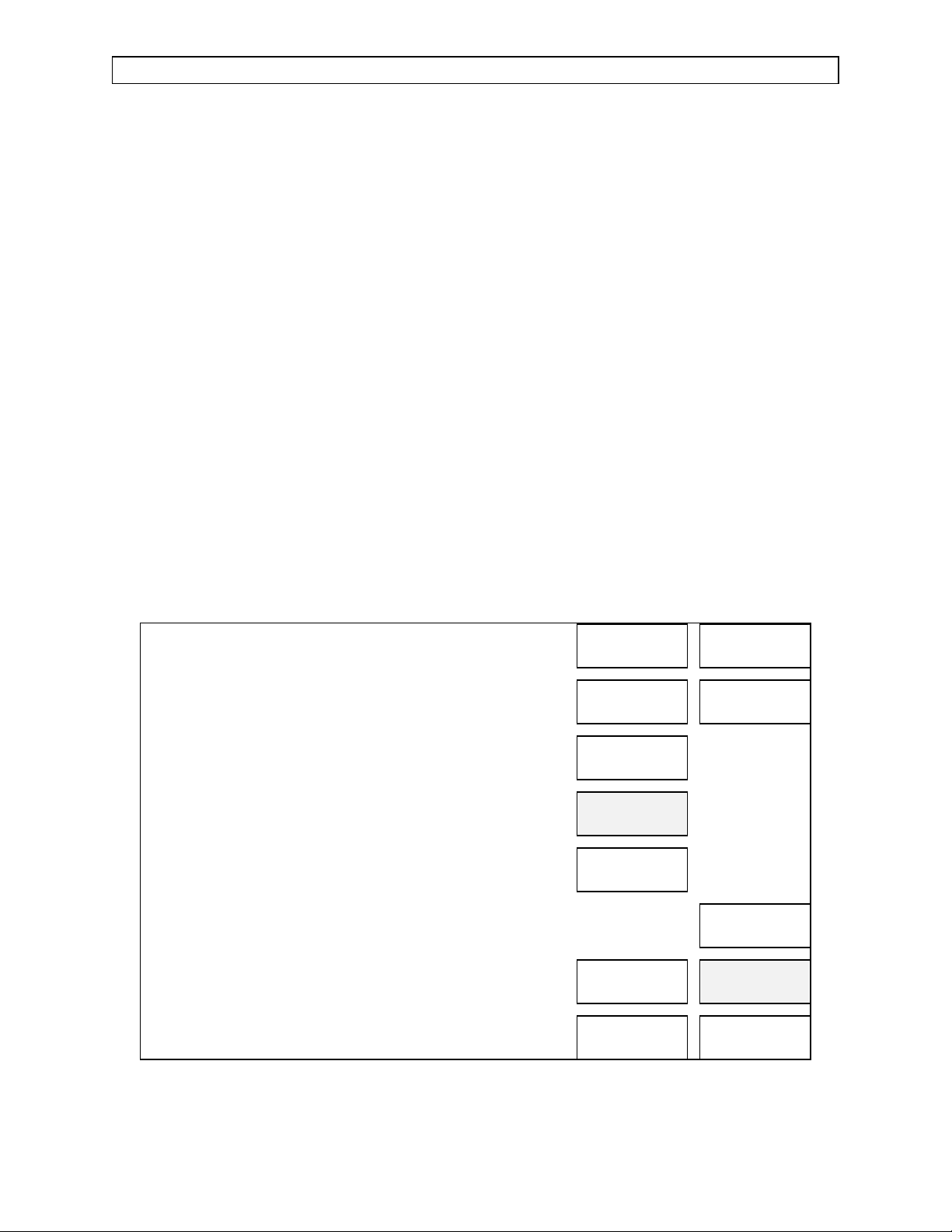

2.1.2 Service Mode

Touch the Service Code box on the screen, then scroll through the following list

of service codes with the Selection DIAL:

PMS: When performing scheduled Periodic Manufacturer’s Service.

INST: For initial installation of the NM4. This selection will establish

the start date for the warranty period.

SRVC: For unscheduled service visits requiring component

replacements or calibrations.

Press the Selection DIAL to enter the service event into the Service Log.

The Technical Service Representative ID boxes will appear on the screen as

shown in Figure 2-3. Touch the first box, scroll to the desired alpha-numeric

with the Selection DIAL, and press the dial to enter the first character of the

ID. Enter the remaining three characters in the same manner.After the ID has

been entered, the RESET key will be displayed.

NOTE: Following any service procedures, return to this screen and touch the

RESET key to enter the current date as the last service date, and to reset the

Hours Running Since Last Service to zero. Touching the RESET key also

places an entry into the service log.

MACHINE SERIAL NUMBER : 00124001

LAST SERVICE DATE : 03-14-96

HOURS RUNNING SINCE LAST SERVICE : 97

TOTAL HOURS RUNNING : 5610

SYSTEM SOFTWARE VERSION : 1.40

TOUCH PANEL SOFTWARE VERSION : 1.02

DATAGRIP SOFTWARE VERSION : 1.01

MULTISPEC SOFTWARE VERSION : 1.04

VPO SOFTWARE VERSION : 1.72

POWER SUPPLY SOFTWARE VERSION : 1.01

PURITAN BENNETT SW VERSION : 1.00 0016FF00

CRITICAR 1100 SW VERSION : 1.01 00171900

CRITICAR POET IQ SW VERSION : 1.00 00173D00

TRAM NET SW VERSION : 1.01 00175E00

SPACELAB LOGGER SW VERSION : 1.00 00178600

RESET

MAIN

SERVICE

LOG

PMS

CRITERIA

TECHNICAL SERVICE

REPRESENTATIVE I.D.

SERVICE CODE

0 0 0 0

SRVC

Figure 2-3: SERVICE MODE SERVICE SCREEN

Rev. H

MONITORS

PERIPHERALS

2-3

Page 14

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

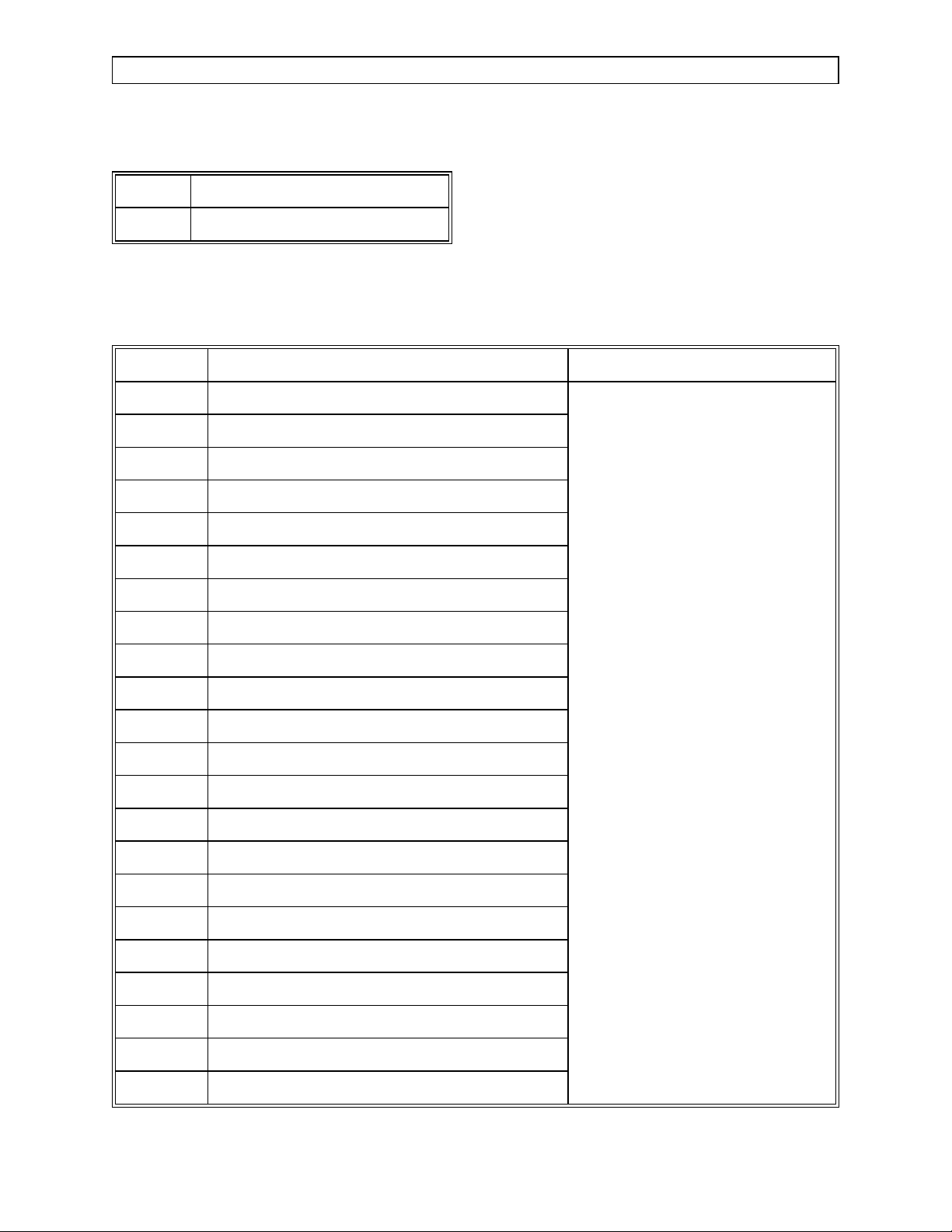

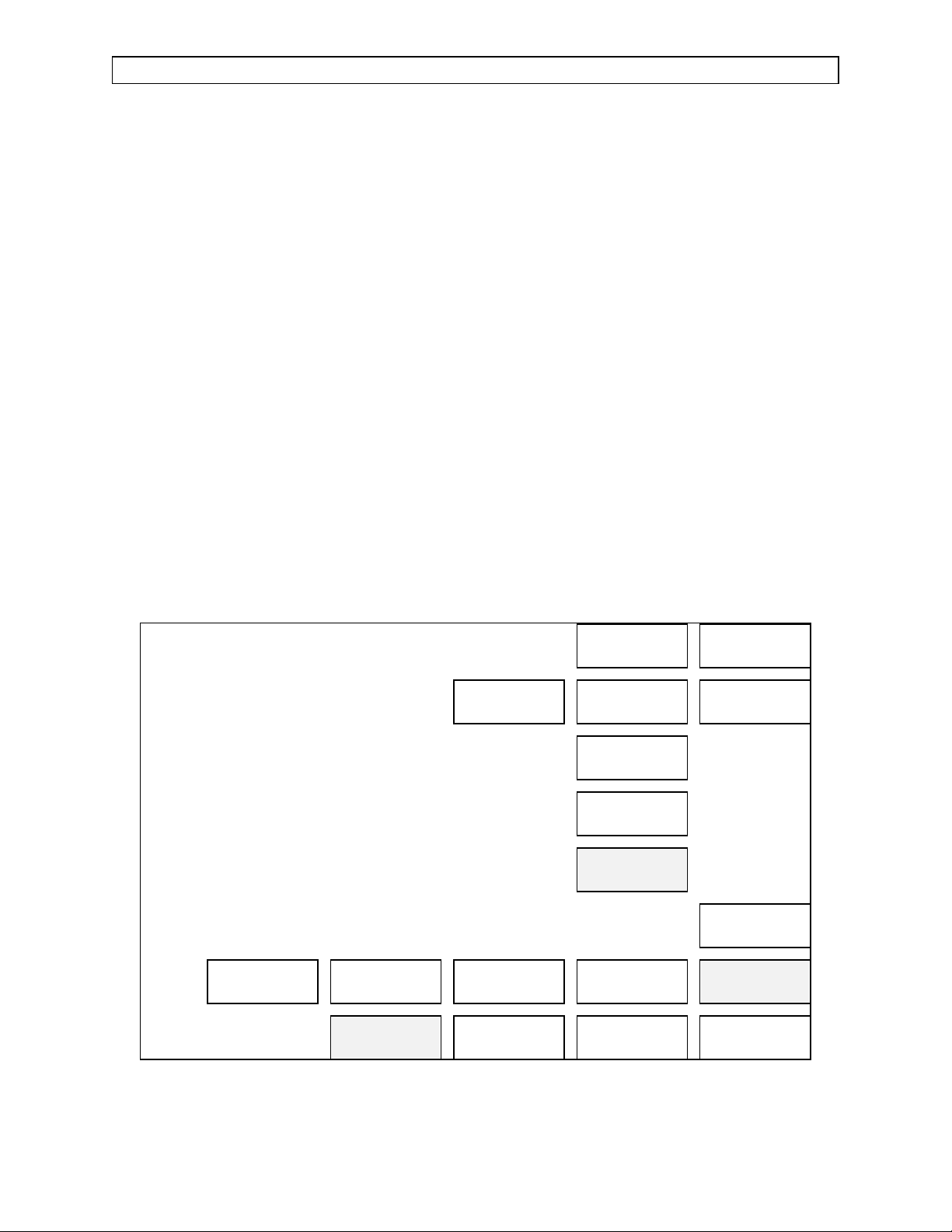

2.2 Service Log Screen

Touch the SERVICE LOG key to display a list of stored events. Figure 2-4

shows a typical service log screen. The codes displayed are classified as Normal

Events, Failed Events, Error Events, Service Events, and Calibration Events.

These are listed in Tables 2-1 thru 2-6.

Up to 1000 events may be logged. Touching the PREV PAGE key will move the

display backward in time; touching the NEXT PAGE key will move the display

forward in time.

SERVICE LOG

DATE TIME PARAMETER CODE DESCRIPTION

07-14-91 18:10 0000FB64 0000 POWER ON

07-14-91 18:13 JOHN C009 RESP FLOW ZERO

07-14-91 18:19 JOHN C008 RESP FLOW SPAN

PREV

PAGE

NEXT

PAGE

PRINT

SERVICE LOG

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-4: SERVICE LOG SCREEN

2-4

Rev. A

Page 15

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

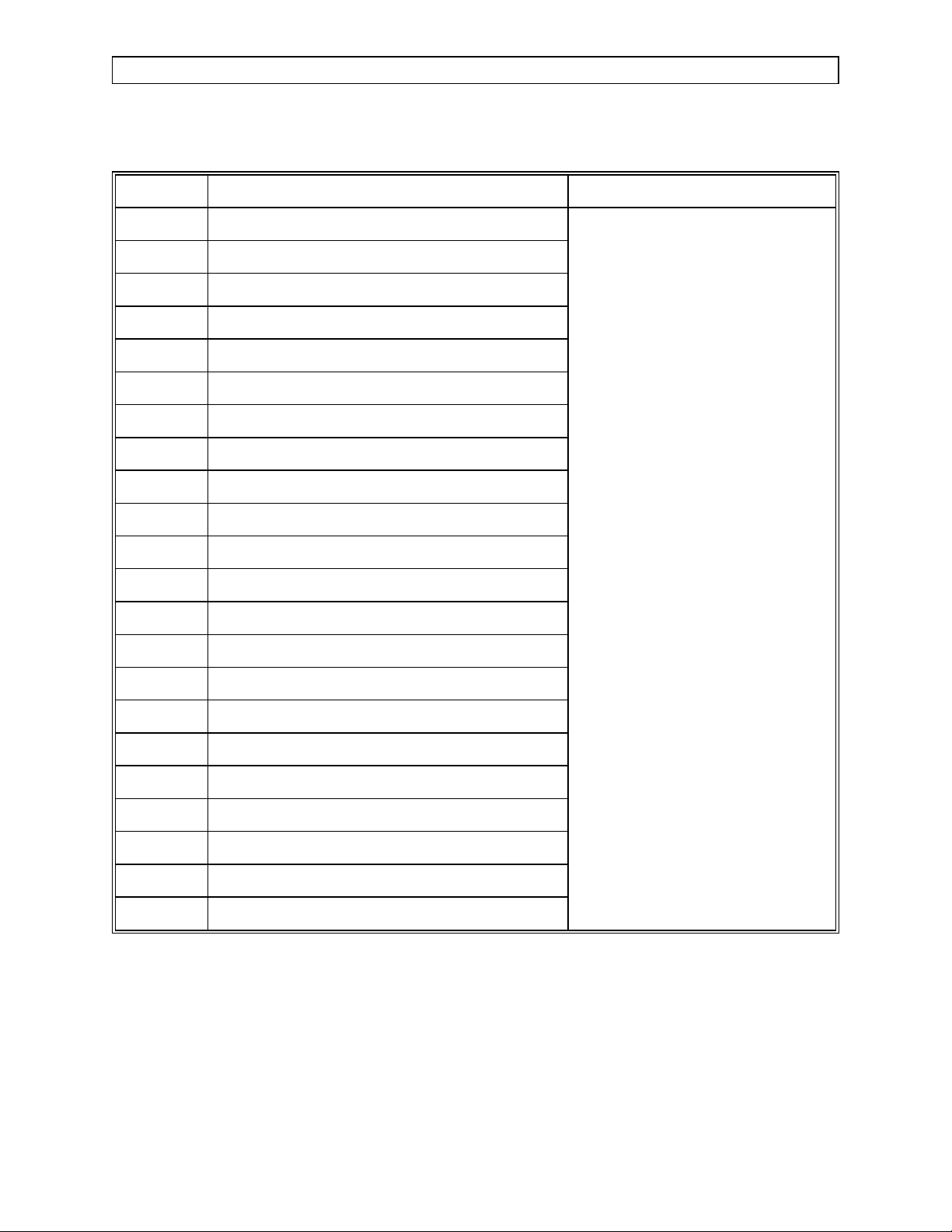

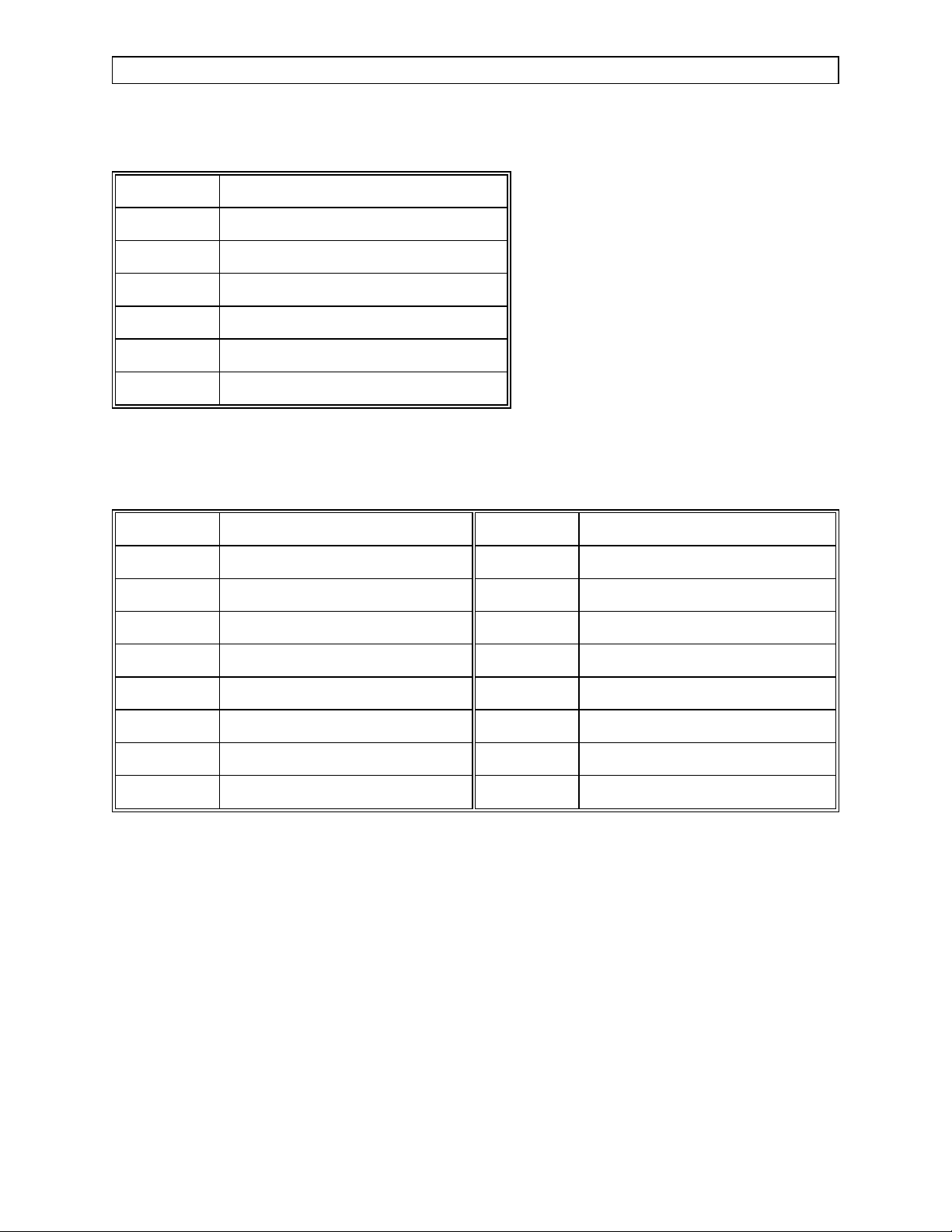

Table 2-1: NM4 SERVICE LOG NORMAL EVENT CODES

Code Description

0000 Power on

Table 2-2: NM4 SERVICE LOG FAILED EVENT CODES

Code Description Recommended Action

F011 QPDM Address Register Error

F012 QPDM Data Register Error

F013 QPDM Vblank Int Timeout Err

F014 QPDM VRAM Memory Error

F021 PROM CRC Test Error

F031 SRAM Memory Test Error

F051 MFP Bus Error

F052 MFP TimerA Error

F053 MFP TimerB Error

F054 MFP TimerC Error

F055 MFP TimerD Error

F056 System Clock Error

F057 FIFO Empty Interrupt Error

F058 ADC Interrupt Error

F059 CNTOVF Interrupt Error

F061 ADC Interrupt Error

F062 12V to -12V Out of Tol Error

Replace Processor

F063 5V to GND Out of Tol Error

F071 Pri Spkr Static Test Error

F072 Pri Spkr Dynamic Test Error

F073 Pri Spkr FIFO Test Error

F074 Pri Spkr No Vol Test Error

Rev. L

2-5

Page 16

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

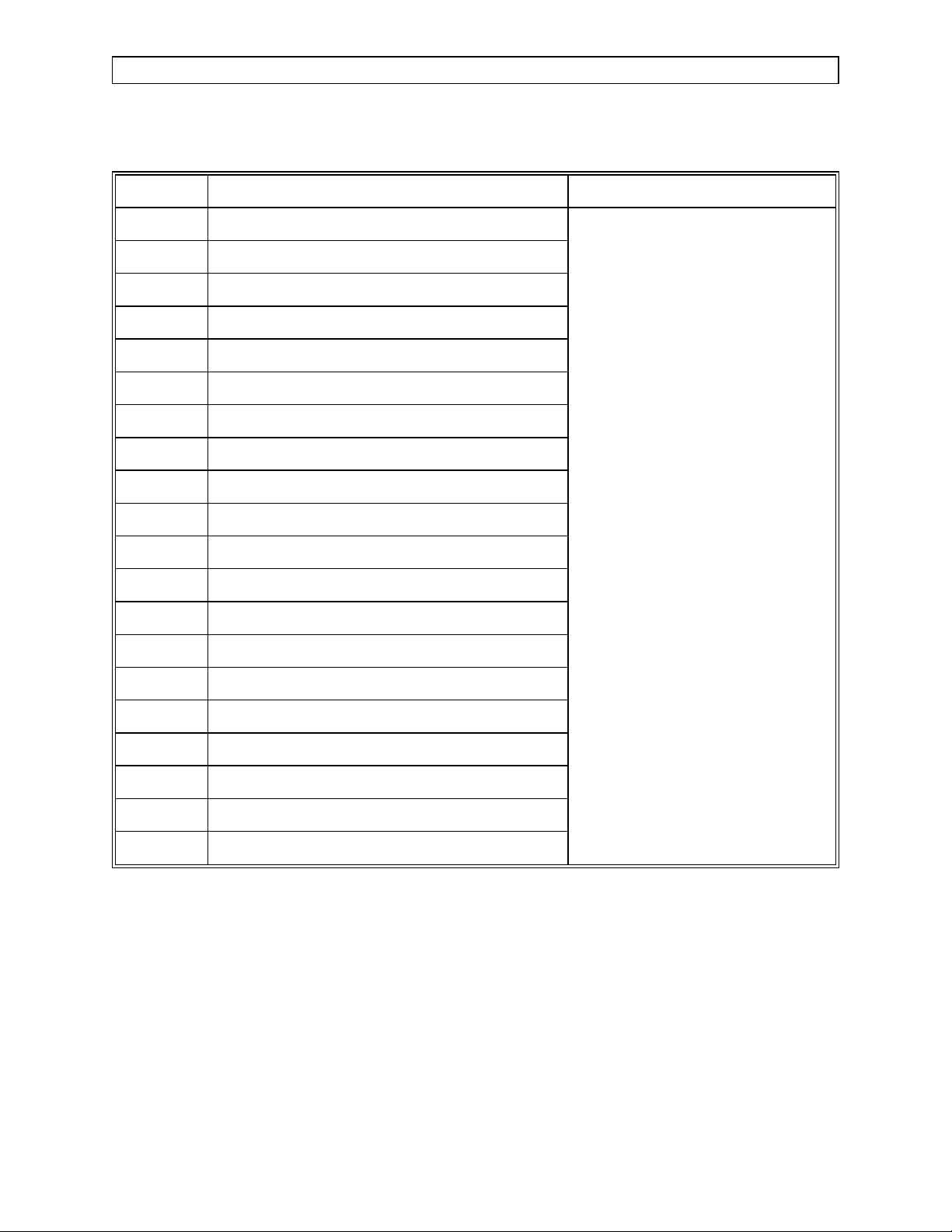

Table 2-2 (continued): NM4 SERVICE LOG FAILED EVENT CODES

Code Description Recommended Action

F081 Backup Spkr Dynamic Test Err

F082 Backup Spkr No Vol Test Err

F091 SAO2 Spkr Static Test Error

F092 SAO2 Spkr Dynamic Test Error

F093 SAO2 Spkr No Vol Test Error

F111 Real Time Clock Test Error

F121 Bad File Warning

F122 Bad Files Error

F123 Event Memory Error

F130 Alt Processor Fail

F200 UART1 Internal Init Fail

F201 UART1 Register Readback Fail

F202 UART1 Transmit Interrupt Fail

F203 UART1 Receive Interrupt Fail

F204 UART1 Receive Err Int Fail

F205 UART1 Baud Rate Test 1 Fail

F206 UART1 Baud Rate Test 2 Fail

F207 UART1 Baud Rate Test 3 Fail

F210 UART1 Channel 0 Fail

F211 UART1 Channel 1 Fail

F212 UART1 Channel 2 Fail

F213 UART1 Channel 3 Fail

Replace Processor

2-6

Rev. L

Page 17

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

Table 2-2 (continued): NM4 SERVICE LOG FAILED EVENT CODES

Code Description Recommended Action

F214 UART1 Channel 4 Fail

F215 UART1 Channel 5 Fail

F216 UART1 Channel 6 Fail

F217 UART1 Channel 7 Fail

F300 UART2 Internal Init Fail

F301 UART2 Register Readbk Fail

F302 UART2 Transmit Interrupt Fail

F303 UART2 Receive Interrupt Fail

F304 UART2 Receive Err Int Fail

F305 UART2 Baud Rate Test 1 Fail

F306 UART2 Baud Rate Test 2 Fail

F307 UART2 Baud Rate Test 3 Fail

F310 UART2 Channel 0 Fail

F311 UART2 Channel 1 Fail

F312 UART2 Channel 2 Fail

F313 UART2 Channel 3 Fail

F314 UART2 Channel 4 Fail

F315 UART2 Channel 5 Fail

F316 UART2 Channel 6 Fail

F317 UART2 Channel 7 Fail

Replace Processor

Rev. L

2-7

Page 18

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

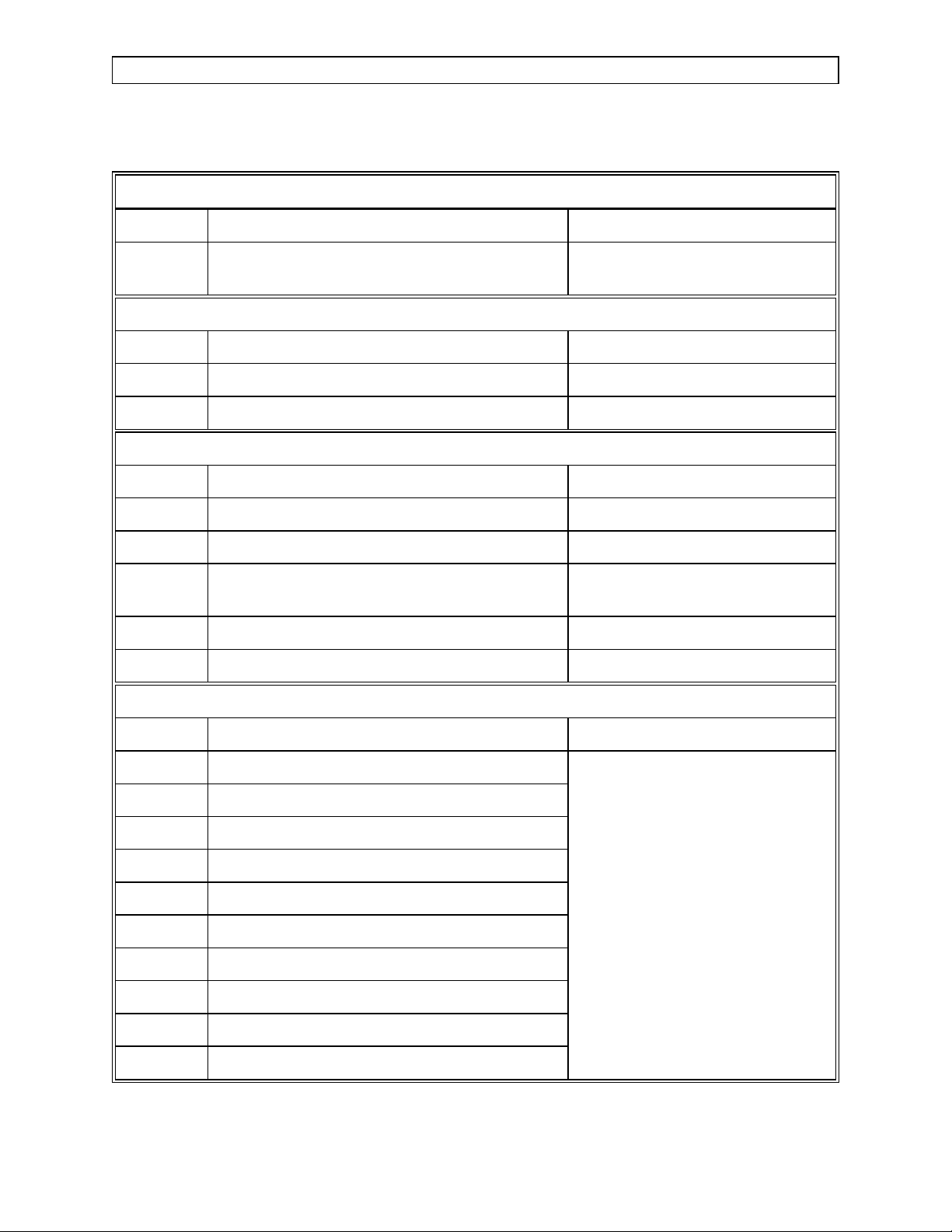

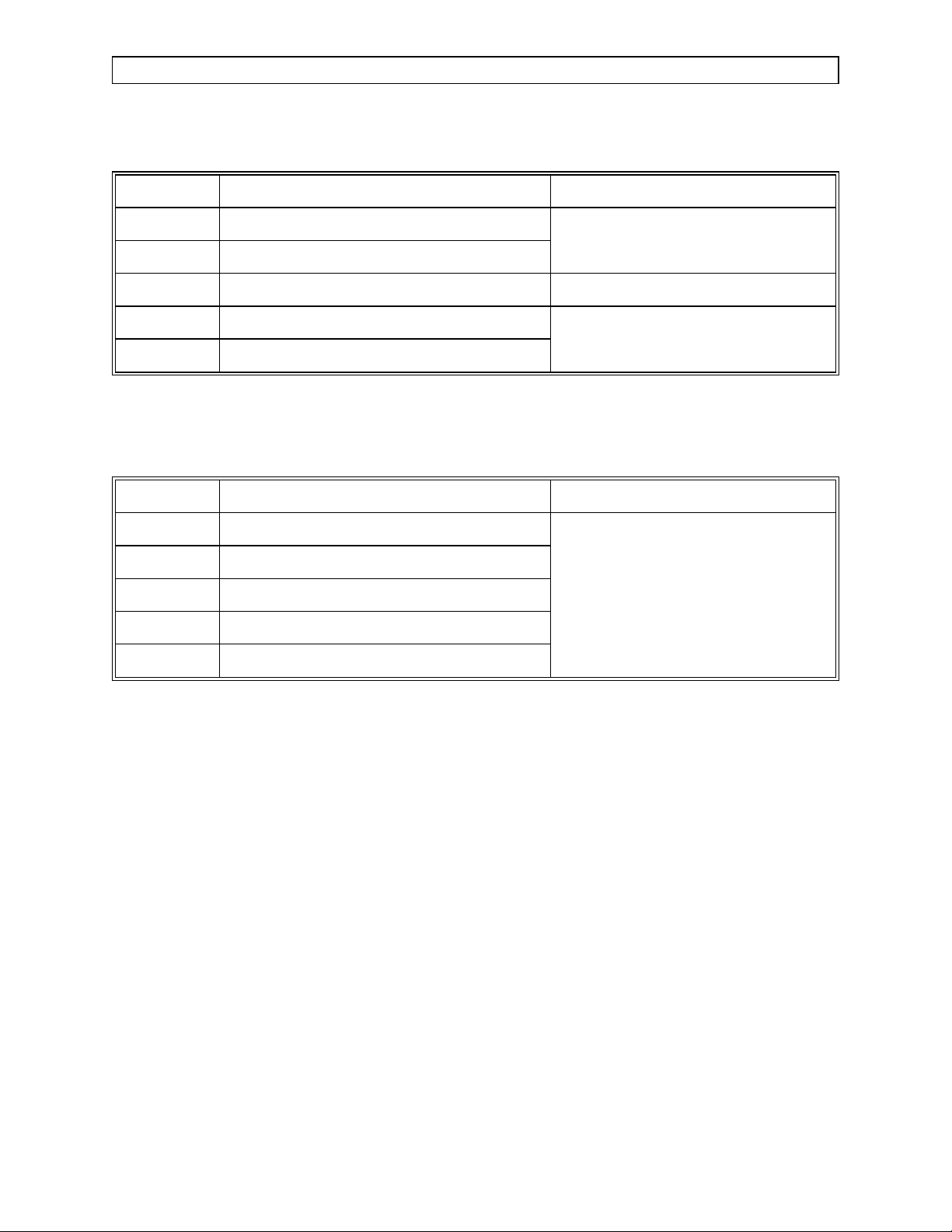

Table 2-3: NM4 SERVICE LOG ERROR EVENTS

Touch Panel Events

Code Description Recommended Action

T001 Bad Device Recalibration Clear obstructions. If recurring,

replace touch panel

Head Assembly Events

Code Description Recommended Action

H001 Head Temperature Error Call Tech. Service

A001 Pattern Adjusted None

Power Supply Events

Code Description Recommended Action

P001 AC Fail Restore AC power

P002 AC Good None

P003 Battery Low Recharge battery. If persistent,

replace battery

P004 Battery Good None

P005 Brick Bad Replace Pwr Supply PCB

MSPEC Events

Code Description Recommended Action

M001 Channel Err Active CPU

M002 Channel Err Inactive CPU

M003 Command Retry

M004 Comm Error

M005 System Fault Max

Replace MSPEC

M006 Versiion ID Retry

M007 Span Fail

M008 Solenoid Stuck

M009 Zero Timeout

M010 Zero Fail Max

2-8

Rev. L

Page 19

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

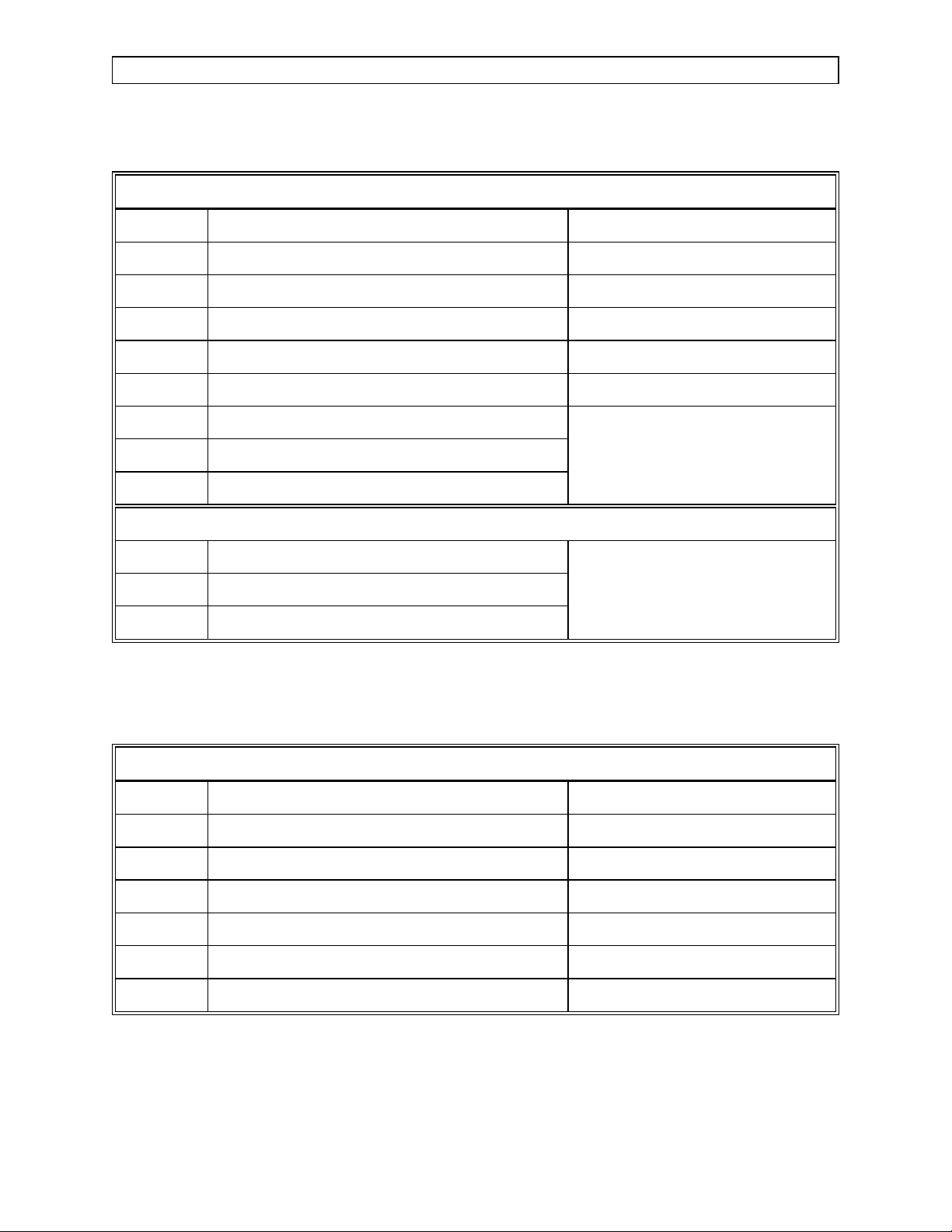

NM4 DIAGNOSTICS (continued)

Table 2-3 (continued): NM4 SERVICE LOG ERROR EVENTS

MSPEC Events (continued)

Code Description Recommended Action

M011 RX Buffer Overflow Replace MSPEC

M012 No Continuous Data Replace MSPEC

M013 Line Block Diff Clear Blockage

M014 Line Block Less Than Min Clear Blockage

M016 Multispec Shutdown Replace MSPEC

M101 CD Chan Err

M102 Chan Err O2 Info P1

Call Tech. Service

M103 Chan Err O2 Info P2

Datagrip Events

DG00 Datagrip Internal Error

DG01 Datagrip Internal Error

Replace Datagrip

DG02 Datagrip Internal Error

Table 2-3 (continued): NM4 SERVICE LOG ERROR EVENTS

NIBP Events

Code Description Recommended Action

N001 NIBP Mon Error Replace NIBP

N002 NIBP Com Error Replace NIBP

N003 NIBP Bad Data Call Tech. Service

N004 Infl Pres Not GT 30 Check for Leaks

N005 Error Rcvd from NIBP Replace NIBP

N006 NIBP Mode Conflict Replace NIBP

2-8A Rev. L

Page 20

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

Table 2-4: NM4 SERVICE LOG SERVICE EVENT CODES

Code Description

S001 INST

S002 PMS

S003 SRVC

S004 Secondary Serv Screen Entry

S005 Reset Service Date

S006 Service Log Clear

Table 2-5: NM4 SERVICE LOG CALIBRATION EVENT CODES

Code Description Code Description

C001 O2 Store Zero A C009 Respiratory Flow Store Span

C002 O2 Store Zero B C010 Respiratory Flow Store Zero

C003 Line Block Store Reference C011 Pressure Store Span

C004 Gas Analyzer - Start C012 Pressure Store Zero

C005 Gas Analyzer - Continue C013 NIBP Infl Check

C006 NIBP Inflate C014 NIBP Defl Ck

C007 NIBP Stop C015 NIBP Leak Ck

C008 NIBP Take Reading

Rev. L 2-8B

Page 21

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

Table 2-6: NM4 O.R. DATA MANAGER EVENT CODES

Code Description Recommended Action

V001 VTLK Com Error

Replace ORDM if recurring

V002 VTLK Com Lost

V003 VTLK Com Regained None

V010 ORDM Startup Failure

Replace ORDM

V011 ORDM Inact Startup Failure

Table 2-7: NM4 TEMPLATE EVENT CODES

Code Description Recommended Action

TEM0 Template Defaults Loaded

TEM1 Recreating Tmplt Database

TEM2 Templates Reinitalized

None

TEM3 Templates Reinitalized

TEM4 Factory Defaults Installed

2-8C Rev. L

Page 22

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

Touch the PRINT LOG key to obtain a Service Log Printout from the internal

printer. Figure 2-5 shows the format of the printed service log.

^^^^^^^^^^^^^^^^^^^^^^^^

************************

SERVICE LOG PRINTOUT

-----------------------MMDDYYHHMM PARAM CODE

0/714911819 JOHN C0/0/8

0/714911813 JOHN C0/0/9

0/714911810/0/0/0/0/FB64 0/0/0/0/

************************

Figure 2-5: SERVICE LOG PRINTOUT

Rev. L 2-8D

Page 23

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.3 PMS Criteria Screen

Touch the PMS CRITERIA key to bring up the screen shown in Figure 2-6.

Touch the Month window, scroll to the next PMS due month with the Selection

DIAL, and press the dial to enter the month in which the PREVENTIVE

MAINTENANCE DUE message will appear on the power-up screen.

SELECT CRITERIA FOR "PREVENTIVE MAINTENANCE" MESSAGE

MONTH : 1991

DEC

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-6: PMS CRITERIA SCREEN

2-9

Page 24

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.4 Monitors

Touch the MONITORS key to bring up a second column of touch keys. These

keys select the calibration screens for the system sensors.

2.4.1 Oxygen Monitor Screen

The Oxygen Monitor Screen displays current oxygen cell readings and

provides a calibration procedure forthe oxygen sensor circuitry. A touch

key allows entry of a new zero value. See Figure 2-7.

CURRENT CELL A: 110

CURRENT CELL B: 108

ZERO CALIBRATION PROCEDURE:

- REMOVE FUEL CELL FROM SENSOR HOUSING.

- LET CURRENT CELL VALUES STABILIZE.

- TOUCH "STORE ZERO" KEY TO ENTER

CURRENT VALUES AS CALIBRATED VALUES.

- DISCONNECT O2 SENSOR HOUSING CABLE

BEFORE RE-INSTALLING FUEL CELL.

- RE-INSTALL FUEL CELL.

- RE-CONNECT CABLE

STORED CELL A ZERO: 3

STORED CELL B ZERO: 6

STORE

ZERO

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-7: OXYGEN MONITOR SCREEN

2-10

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.4.2 Breathing Pressure Monitor Screen

The Breathing Pressure Monitor Screen displays current airway

pressure and provides a calibration procedure for the pressure sensing

circuitry. Touch keys allow entry of new zero and span settings. See

Figure 2-8.

CURRENT PRESSURE VALUE : 205

ZERO CALIBRATION PROCEDURE:

- REMOVE PRESSURE SAMPLE LINE FROM

ABSORBER; EXPOSE TO AIR.

- LET CURRENT VALUE STABILIZE.

- TOUCH "STORE ZERO" KEY TO ENTER THE

CURRENT VALUE AS THE CALIBRATION ZERO.

SPAN CALIBRATION PROCEDURE:

- REMOVE PRESSURE SAMPLE LINE FROM

ABSORBER.

- APPLY 50 CM H2O CONSTANT PRESSURE AT

SAMPLE LINE, VERIFIED BY A KNOWN,

CALIBRATED METER.

- LET CURRENT VALUE STABILIZE.

- TOUCH "STORE SPAN" KEY TO ENTER THE

CURRENT VALUE AS THE CALIBRATION SPAN.

STORED ZERO: 244

STORED SPAN: 540

STORE

SPAN

STORE

ZERO

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-8: BREATHING PRESSURE MONITOR SCREEN

2-11

Page 26

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.4.3 Respiratory Flow Monitor Screen

The Respiratory Flow Monitor Screen displays the current flow reading

and also shows a calibration procedure for the flow sensing circuitry.

Touch keys are provided for entry of new zero and span settings. See

Figure 2-9.

CURRENT FLOW VALUE : 76

ZERO CALIBRATION PROCEDURE:

- REMOVE SPIROMED SENSOR FROM ABSORBER.

- LET CURRENT VALUE STABILIZE.

- TOUCH "STORE ZERO" KEY TO ENTER THE

CURRENT VALUE AS THE CALIBRATION ZERO.

SPAN CALIBRATION PROCEDURE:

- REMOVE SPIROMED SENSOR FROM ABSORBER.

- ATTACH A GAS SUPPLY AT INPUT OF SENSOR,

AND A CALIBRATED FLOWMETER AT OUTPUT.

- PROVIDE A STEADY 10 L/MIN FLOW THROUGH

SPIROMED SENSOR.

- LET CURRENT VALUE STABILIZE.

- TOUCH "STORE SPAN" KEY TO ENTER THE

CURRENT VALUE AS THE CALIBRATION SPAN.

STORED ZERO: 78

STORED SPAN: 161

STORE

SPAN

STORE

ZERO

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-9: RESPIRATORY FLOW MONITOR SCREEN

2-12

Page 27

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.4.4 SpO2 Monitor Screen

The SpO2Screen displays current values for SpO2, Pulse, SpO2Pleth

and SpO

Bargraph. See Figure 2-10.

2

SpO2 VALUE : 98

PULSE VALUE : 75

PLETH VALUE : 125

BARGRAPH VALUE : 12

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-10: SpO2MONITOR SCREEN

2-13

Page 28

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.4.5 NIBP Monitor Screen

The NIBP Monitor Screen displays Real Time, Systolic, Diastolic and

Mean blood pressure and Pulse.

The TAKE READING touch key will initiate a single NIBP

measurement cycle.

A procedure for checking NIBP cuff inflation pressure against an

external gauge is also displayed, with touch keys to perform the test.

See Figure 2-11.

Refer to Section 6 of this manual for inflation, deflation, and leak

testing procedures.

REAL TIME PRESSURE : 0

SYSTOLIC : 130

DIASTOLIC : 78

MEAN : 98

PULSE : 75

NIBP PRESSURE CALIBRATION VERIFICATION:

- PLACE A "T" IN LINE WITH THE BP CUFF.

- ATTACH A PRESSURE GAUGE AT "T".

- TOUCH THE "INFLATE" KEY.

- NIBP MODULE WILL INFLATE CUFF TO

180 MM Hg.

- VERIFY WITH PRESSURE GAUGE.

- TOUCH THE "STOP" KEY TO END THE TEST.

NIBP INFLATION, DEFLATION, AND LEAK CHECKS:

- REFER TO SERVICE MANUAL FOR PROCEDURES.

INFLATION

CHECK

DEFLATION

CHECK

READING

LEAKAGE

INFLATESTOP

TAKE

CHECK

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-11: NIBP MONITOR SCREEN

2-14

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.4.6 Gas Analyzer Screen

Current values of CO2,N2O and anesthetic agent are displayed on the

Gas Analyzer Screen along with a span calibration procedure. See

Figure 2-12. (The scrubber bottle replacement instruction is not

displayed on machines having a Model 4610 gas analyzer.)

The MODE window on the gas analyzer screen displays the following

messages: INHIBIT during warm-up

READY after 30 minute warm-up

The STATUS window on the gas analyzer screen displays the following

messages: IDLE before starting calibration

ZERO IN PROGRESS during calibration

ZERO COMPLETE during calibration

SPAN IN PROGRESS during calibration

PASSED or FAILED after calibration

The complete calibration procedure is outlined in Section 5.

CURRENT CO2 : *INV* MODE:

CURRENT N2O : 10 STATUS:

CURRENT AGENT : *INV*

SPAN CALIBRATION PROCEDURE:

- WAIT FOR MODE = "READY".

- PERFORM GAS ANALYZER ACCURACY TEST.

- IF TEST FAILS, PERFORM SPAN CAL:

- WITH PATIENT CIRCUIT ENABLED:

- TOUCH "START" KEY,

- WAIT FOR STATUS = "ZERO COMPLETE"

- ATTACH SAMPLE LINE TO CALIBRATION BOTTLE.

- TURN FLOW ON BOTTLE TO 250 ML/MIN

- LET THE CURRENT CELL VALUES STABILIZE

- REMOVE THE SAMPLE LINE FROM THE BOTTLE

- TOUCH "CONTINUE" KEY.

- WAIT FOR STATUS = "PASSED" OR "FAILED"

- REPLACE SCRUBBER BOTTLE ANNUALLY.

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

Figure 2-12: GAS ANALYZER SCREEN

Rev. C

2-15

STARTCONTINUE

LINE BLOCK

CALIBRATION

PERIPHERALS

Page 30

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.4.7 Line Block Screen

The current sample pressure is displayed on the Line Block screen

along with a calibration procedure and a touch key to enter a setpoint

value. See Figure 2-13. The stored reference value is displayed at the

lower left corner of the screen.

CURRENT SAMPLE PRESSURE: 200

LINE BLOCK CALIBRATION PROCEDURE:

- WITH PATIENT CIRCUIT ENABLED:

- ENSURE THAT SAMPLE LINE IS

CONNECTED AND UNOCCLUDED.

- PLACE A FLOWMETER AT THE SAMPLE

EXHAUST.

- ATTACH FLOW RESTRICTOR, FIX 0336, TO

PATIENT SAMPLE LINE.

- WAIT FOR VALID CURRENT SAMPLE PRESSURE.

- ADJUST RESTRICTION IN ORDER TO

OBTAIN A FLOW OF 100 ML/MIN.

- TOUCH "STORE REFERENCE" KEY.

- FULLY OCCLUDE SAMPLE LINE AND OBSERVE

THAT LINE BLOCK ALARM BECOMES

ACTIVE AFTER AT LEAST 15 SECONDS.

- REMOVE FLOW RESTRICTOR FROM SAMPLE LINE.

STORED REFERENCE : 200

REFERENCE

STORE

OXYGEN

PRESSURE

RESPIRATORY

FLOW

SpO2

NIBP

GAS

ANALYZER

LINE BLOCK

CALIBRATION

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-13: LINE BLOCK CALIBRATION SCREEN

2-16

Page 31

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.5 Peripherals

Touching the PERIPHERALS key brings up a second column of touch keys

that are used to select additional service screen functions. When

PERIPHERALS is selected, the Relays Status And Control Screen will appear

as shown in Figure 2-14.

2.5.1 Relays Status And Control Screen

Printer Relay:

When the ORDM key is selected, the external printer port is

connected to the O.R. DATA MANAGER. See Paragraph 2.8

Remote Panel Relay:

When the ORDM key is selected, the Remote Display will show

the O.R. DATA MANAGER functions. See Paragraph 2.6. When

the NM4 key is selected, the Remote Display shows the NM4

data and alarms.

RELAYS STATUS AND CONTROL SCREEN

PRINTER RELAY:

REMOTE PANEL RELAY:

ORDM NM4

ORDM NM4

RELAYS

DUMP

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-14: RELAYS STATUS AND CONTROL SCREEN

Rev. A

2-17

Page 32

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.5.2 Service Dump Screen

The DUMP key will bring up the Service Dump Screen shown in Figure

2-15. This screen displays processor address and register debug

information. This screen should be checked whenever the machine is

serviced, and any non-zero codes that appear should be recorded and

reported to the N.A.D. Engineering Department.

Touch the PRINT DUMP key to print out the codes on the strip chart

recorder. Figure 2-16 shows the printed format of the Service Dump.

SERVICE DUMP SCREEN

D0-D3:

D4-D7:

A0-A3:

A4-A7:

SR/FO:

USP:

MSP:

ORVEC:

COUNT:

PSOS:

PSOS:

PSOS:

PSOS:

STACK:

STACK:

STACK:

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000

PC:

00000000

00000000

00000000

ISP:

00000000

00000000

00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

00000000 00000000 00000000 00000000

PRINT

DUMP

RELAYS

DUMP

MAIN

SERVICE

LOG

PMS

CRITERIA

MONITORS

PERIPHERALS

Figure 2-15: SERVICE DUMP SCREEN

2-18

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

^^^^^^^^^^^^^^^^^^^^^^^^

************************

SERVICE DUMP

------------------------

D0/-D1: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

D2-D3: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

D4-D5: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

D6-D7: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

A0/-A1: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

A2-A3: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

A4-A5: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

A6-A7: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

SR/FO: 0/0/0/0/0/0/0/0/

PC: 0/0/0/0/0/0/0/0/

USP: 0/0/0/0/0/0/0/0/

MSP: 0/0/0/0/0/0/0/0/

ISP: 0/0/0/0/0/0/0/0/

ORVEC: 0/0/0/0/0/0/0/0/

COUNT: 0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

PSOS: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

STACK: 0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/0/

Figure 2-16: SERVICE DUMP PRINTOUT

2-19

Page 34

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.6 O.R. DATA MANAGER Diagnostics

During Power Up/Initialization and following completion of the NM4 boot

sequence, the O.R. DATA MANAGER performs diagnostic tests on its CPU.

Figures 2-17A and 2-17B show the O.R. DATA MANAGER boot information

that appears on the Remote Display.

Error messages may appear in the display at this time. If the keyboard is not

connected at power-up, a keyboard error message appears as shown in the

illustration. System configuration or set-up errors may also appear in the area

shown in the illustration. If an error message is displayed, the screen display

will freeze with a choice of options at the bottom of the screen. The

Troubleshooting Guides in Section 3 provide additional information that

correlates error messages to recommended hardware replacement.

386 Modular BIOS V 3.10/

Copyright (c) 1984 - 90/ Award Software Inc.

LB/386SX R2.0/ 4 Copyright (c) 1985 - 92 Ampro Computers, Inc.

TESTING INTERRUPT CONTROLLER #1 .............................. PASS

TESTING INTERRUPT CONTROLLER #2 .............................. PASS

TESTING CMOS BATTERY ........................................ PASS

TESTING CMOS CHECKSUM ...................................... PASS

SIZING SYSTEM MEMORY ...................................640/ K FOUND

TESTING SYSTEM MEMORY .................................. 640/ K PASS

TESTING UNEXPECTED INTERRUPTS AND STUCK NMI ................. PASS

TESTING PROTECTED MODE ...................................... PASS

SIZING EXTENDED MEMORY ............................... 0/ 7168K FOUND

TESTING MEMORY IN PROTECTED MODE ......................0/780/ 8K PASS

TESTING PROCESSOR EXCEPTION INTERRUPTS ...................... PASS

BIOS SHADOW RAM ......................................... ENABLED

CONFIGURATION OR SET-UP ERRORS APPEAR HERE

KEYBOARD ERROR OR NO KEYBOARD PRESENT

<PRESS CTRL-ALT-ESC FOR SETUP>

Figure 2-17A: O.R. DATA MANAGER POWER-UP DIAGNOSTICS SCREEN

2-20

Rev. A

Page 35

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

Press ESC to abort Hard disk boot

Booting Hard Drive

Loading...

EMM 386 V1.21 /Frame = C0/0/0/ /Kb = 7168 /Bdos = FFFF

DR DOS Release 5.0/

Copyright (c) 1976, 1982, 1988, 1990 Digital Research Inc. All rights reserved.

Ampro Computers, Inc.

Executing runtime.bat on the hard drive.

Executing numoff.com.

Checking the CRC on ordm386.EXE with the CRC saved in the file CRC_ordm.

CRC calculation taking place.

Figure 2-17B: O.R. DATA MANAGER DIAGNOSTICS - SECOND SCREEN

2.7 O.R. DATA MANAGER Software Version Window

After power-up and when the O.R. DATA MANAGER is in its normal display

mode, the software version can be displayed by pressing the ALT and V keys

simultaneously. The window shown in Figure 2-18 will appear at the center of

the display for approximately three seconds. The message in parenthesis

(xxxxH) is an identifier that is unique to the particular software installation.

ORDM S/W Ver x.x (xxxxH)

Rev. A

Figure 2-18: SOFTWARE VERSION WINDOW

2-21

Page 36

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued) NM4

2.8 Printer Configuration

The O.R. DATA MANAGER is configured to operate with the Hewlett Packard

LaserJet IIP Printer or the Hewlett Packard LaserJet IIIP Printer in the serial

port configuration. The following paragraphs describe how to runa printer selftest, and illustrate the configuration menus that appear on the self-test

printout page.

2.8.1 Hewlett Packard LaserJet IIP Printer Self-Test:

If the printer ON LINE indicator light is on, press the ON LINE key to

take the printer off-line.

While holding the down the ALT key, press the TEST key. The printer

display window will show 05 SELF TEST.

A few seconds later, 06 PRINT TEST will appear in the display window.

Two pages will print: the self-test printout page and a "cleaning" page.

The self-test printout page lists the settings for both the printer menu

and the configuration menu. The list should read as follows:

PRINTING MENU

COPIES 1

FONT SRC I (Internal)

FONT NUM 0

TRAYS LC ONLY

JOB SIZE LETTER

ORIENT P (Portrait)

LINES OF TXT 60

MAN FEED OFF

SYM SET ROMAN-8

CONFIGURATION MENU:

AUTOCONT ON

I/O SERIAL

BAUDRATE 9600

ROBUST XON ON

DTRPOLAR HI

RAM size: 1536K bytes

Firmware Datecode: 19890523

Internal Font Datecode: 19890213

Font Cartridges Installed: NO

Installed options: LC TRAY (LETTER)

If the self test printout differs from that shown in the illustration (with

the exception of Firmware Datecode and Internal Font Datecode), the

printer’s internal setup must be changed. Refer to the instructions in

the H-P LaserJet IIP Printer User’s Manual, Chapters 3 and 4,

supplied with the printer, for making any changes.

2-22

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 DIAGNOSTICS (continued)

2.8.2 Hewlett Packard LaserJet IIIP Printer Self-Test:

If the printer ON LINE indicator light is on, press the ON LINE key to

take the printer off-line.

While holding the down the ALT key, press the TEST key. The printer

display window will show 05 SELF TEST.

A few seconds later, 06 PRINT TEST will appear in the display window.

Two pages will print: the self-test printout page and a "cleaning" page.

The self-test printout page lists the settings for both the printer menu

and the configuration menu. The list should read as follows:

PRINTING MENU:

MP SIZE LETTER

COPIES 1

FONT SRC I (Internal)

FONT NUM 0

TRAYS LC ONLY

JOB SIZE LETTER

ORIENT P (Portrait)

LINES OF TXT 60

MAN FEED OFF

SYM SET ROMAN-8

CONFIGURATION MENU:

AUTOCONT ON

I/O SERIAL

BAUDRATE 9600

ROBUST XON ON

DTRPOLAR HI

RET MEDIUM

RAM size: 1024K bytes

Page Count: 6574

Firmware Datecode: 19910523

Internal Font Datecode: 19910213

Font Cartridges Installed: NO

Installed options: LC TRAY (LETTER)

If the self test printout differs from that shown in the illustration (with

the exception of Page Count, Firmware Datecode and Internal Font

Datecode), the printer’s internal setup must be changed. Refer to the

instructions in the H-P LaserJet IIIP Printer User’s Manual,

Chapters2-4,supplied with the printer, for making any changes.

2-23

Page 38

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 39

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE

3.0 TROUBLESHOOTING

This section contains information to assist the Draeger Medical, Inc. qualified

Technical Service Representative (TSR) in locating electrical faults affecting the

NARKOMED 4 monitoring and display devices. Since most troubleshooting efforts

begin with verifying power supply voltages, the following paragraphs outline the

voltage distribution scheme on the backplane along with power supply and test

connector pin identification.

Also contained in this section are troubleshooting guide flow charts that provide a

method of tracing faults to specific field replaceable assemblies or sub-assemblies in

response to observed failure modes or symptoms.

3.1 Power Supply and Voltage Distribution

3.1.1 In the NARKOMED 4, voltages are distributed to the processor boards

and peripheral devices from the backplane assembly. The TSR should

start the troubleshooting procedure with voltage checks at the

backplane. The wire harnesses originating at the power supply circuit

board are connected to J28, J29, and J30 on the backplane.

3.1.2 These voltages can also be measured at test connector J15 on later

model backplane assemblies. The acceptable voltage levels are listed in

Table 3-1. Figure 3-1 shows the location of these connectors on the

backplane. Refer to the replacement procedures in Section 4 for

instructions on access to the backplane assembly. Be sure to observe all

cautions that are listed.

3.1.3 If all the voltages are present, then ensure that all interconnecting

ribbon cables and wire harnesses between suspected assemblies are

properly seated. If all cables are properly seated, then proceed to the

troubleshooting guides.

3.1.4 If any voltage is missing from backplane connectors J28, J29 or J30,

proceed to the power supply voltage measurements in Paragraph 3.1.5.

Rev. H

3-1

Page 40

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

TABLE 3-1: BACKPLANE VOLTAGES

LOCATION

VOLTAGE ACCEPTABLE

TEST

CONNECTOR

POWER SUPPLY

CONNECTORS

RANGE

J15-30

J15-32

J15-33

J15-31

J15-17

J15-12

J15-18

J15-23

J15-24

J15-25

J15-27

J15-10

J15-13

J15-20

J15-14

J15-19

J15-21

J28-1

J28-4

J28-5

J28-2,3

J29-1,2

J29-5,6,7

J29-10,11

J29-16

J29-17

J29-18

J29-20

J29-12,13

J30-1,2

J30-5,6

J30-9,10

J30-13,14

J30-3,12

+5SaO2

+15SaO2

-15SaO2

COMMON

+12CRTA

+5VMAIN

+12CRTB

+5VNIBP

0**

+5VNIBP *

+12VPUMP

COMMON

+5VBKUP

+12VPP

+5VXTRA

+12CRTC

COMMON

* Was -12 V on machines with early NIBP assembly.

** Was +12 V on machines with early NIBP assembly.

4.85 to 5.15 VDC

14.25 to 15.75 VDC

-14.25 to -15.75 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

3-2

Rev. K

Page 41

NARKOMED 4 BACKPLANE CIRCUIT BOARD ASSEMBLY

J15 J28 J29 J30

NARKOMED 4 BACKPLANE CIRCUIT BOARD ASSEMBLY (EARLY MODELS)

SV49031

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

Figure 3-1: BACKPLANE CONNECTORS FOR POWER SUPPLY CABLES

Rev. A

3-3

Page 42

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

3.1.5 The red lamps on the power supply circuit board assembly provide

diagnostic information on the status of the power supply. Figure 3-2

shows the location of these lamps. Refer to the replacement procedures

in Section 4 for instructions on access to the power supply circuit board.

The red LED (DS2) will be lighted if any of the power supply voltages

are out of tolerance. This lamp will also be lighted if the levels of the

two backup batteries differ by more than 1.1 volt. The red LED (DS4)

will be lighted during the power up self-test period, and will be off after

the self-test is completed. This lamp will remain lighted if there is a

powerup self-testfailure of themonitoring andcommunication circuitry

on the power supply board.

The DC-DC converters supplying the 5V bus are protected by

replaceable fuses F1 and F2, and the DC-DC converters supplying the

12V bus are protected by replaceable fuses F3, F4, and F5. Figure 3-2

shows the location of these fuses on the power supply circuit board.

Measure the voltages at connectors J1, J2 and J5 of the Power Supply

Circuit Board assembly. The acceptable voltage levels are listed in

Table 3-2. Figure 3-2 shows the location of these connectors on the

circuit board.

TABLE 3-2: POWER SUPPLY VOLTAGES

LOCATION VOLTAGE ACCEPTABLE RANGE

J1 - 1,2

J1 - 5,6

J1 - 9,10

J1 - 13,14

J1 - 17,18

J1 - 3,4,7,8

J2 - 1,2

J2 - 5,6,7

J2 - 10,11

J2-16

J2-17

*J2-18

J2-20

J2 - 3,4,8,9

+5VBKUP

+12VPP

+5VXTRA

+12CRTC

+12VMGM

COMMON

+12CRTA

+5VMAIN

+12CRTB

+5VNIBP

+12VNIBP

-12VNIBP

+12VPUMP

COMMON

4.85 to 5.15 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

11.40 to 12.60 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

4.85 to 5.15 VDC

11.40 to 12.60 VDC

-11.40 to -12.60 VDC

11.40 to 12.60 VDC

J5-1

J5-4

J5-5

J5 - 2,3

+5SaO2

+15SaO2

-15SaO2

COMMON

* Not used in later design

3-4

4.85 to 5.15 VDC

14.25 to 15.75 VDC

-14.25 to -15.75 VDC

Rev. C

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

TO BACKPLANE J23

TO ALARM

CHANNEL J4

DS3 (GREEN)

DS1 (GREEN)

DS4 (RED)

DS2 (RED)

POWER SUPPLY

CIRCUIT BOARD

ASSEMBLY

TO BACKPLANE J30

TO BACKPLANE J29

TO

BACKPLANE

J28

J3

J4

J1 J2

J5

TO MULTISPEC

POWER SUPPLY BOARD J2

F1

F2

F7

F6

J7

J8

F3

F4

F5

F8

J6

FROM BATTERY

AND POWER

TRANSFORMER COMPARTMENT

SV49032

Figure 3-2: POWER SUPPLY CIRCUIT BOARD CONNECTORS, LAMPS AND FUSES

Rev. A

3-5

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

3.2 Processor Test

If a Processor related failure is reported, it will be flagged either as the "Main" or

the "Back-Up" processor board. When the System Power switch is turned ON, the

unit performs extensive self-diagnostics on its internal hardware. As the

diagnostics are performed, each test and its result (PASS - FAIL) appear on the

display. First the "Main" or upper processor board is tested and then the "BackUp" or lower processor board is tested. If the "Back-Up" processor is reported

defective, press the BACKUP key to obtain a more detailed display of what is nonfunctional on that board.

When diagnosing a processor related problem, use the BACKUP key to toggle

between processors. As an additional diagnostic aid, the green lamp on the edge

of each processor board, when lighted, indicates the presence of +5 VDC supplied

to that board. Refer to the replacement procedures Section 4 for instructions on

access to the processor boards.

3.3 Troubleshooting Guide Flow Charts

Table 3-3 lists failure modes that could be detected during the power-up self test

and the service diagnostic tests. Each failure mode is keyed to a troubleshooting

guide flow chart to assist the Technical Service Representative in locating the

problem. These flow charts assume that the machine is plugged into an AC outlet

with the correct voltage, and the machine is not running on its backup battery.

Table 3-3: NARKOMED 4 TROUBLESHOOTING GUIDES

FAILURE MODE CORRECTIVE ACTION

New Patient Alarm Not Displayed

Loss of O2Monitor

Loss of Breathing Pressure Monitor

Loss of GAS Monitor

Loss of Pulse Oximeter Monitor

Loss of Respiratory Volume Monitor

Loss of Blood Pressure Monitor

Touch Screen Failure

No Audio Alarms

DataScan function not Logging Data

Alarm Silence Failure

Vitalink Failure

Incorrect Display

Measure Data Incorrect

No Oxygen Ratio Monitor Alarm

No Oxygen Supply Pressure Alarm

Display Screens Blank upon System Power-Up

Power Supply Voltages Out of Tolerance

No Keypanel or Selection Dial Response

Internal Printer Not Working

GUIDE 1

GUIDE 2

GUIDE 3

GUIDE 4

GUIDE 5

GUIDE 6

GUIDE 7

GUIDE 8

GUIDE 9

GUIDE 10

GUIDE 11

GUIDE 12

GUIDE 13

GUIDE 14

GUIDE 15

GUIDE 16

GUIDE 17

GUIDE 18

GUIDE 19

GUIDE 20

3-6

Rev. A

Page 45

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

GUIDE 1: New Patient Alarm Not Displayed

START

PROCESSOR TEST

N

PROCESSOR TEST

INDICATE PROCESSOR

PROCESSOR BOARD

ARE NEW

PATIENT ALARMS

PRESENT ON

CENTRAL ALARM

PANEL?

N

PERFORM

AS OUTLINED IN

PROCEDURE 3.2

DID

PROBLEM?

Y

REPLACE

AS OUTLINED IN

PROCEDURE 4.26

Y

ARE NEW

PATIENT ALARMS

PRESENT ON

CENTRAL ALARM

PANEL?

N

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

--------------------------------------

REPLACE REMOTE

DISPLAY AS

OUTLINED IN

PROCEDURE 4.32 OR 4.33

ARE NEW

PATIENT ALARMS

PRESENT ON

CENTRAL ALARM

PANEL?

Y

Y

Rev. A

ARE NEW

PATIENT ALARMS

PRESENT ON

CENTRAL ALARM

PANEL?

N

REINSTALL ORIGINAL

PROCESSOR BOARD

---------------------------------REPLACE BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

Y

REINSTALL ORIGINAL

REMOTE DISPLAY

N

CONTACT NAD

SERVICE DEPT.

N

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

3-7

Page 46

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

GUIDE 2: Loss of O

START

CONNECT OXYGEN

SENSOR CABLE TO

INTERFACE PANEL

Y

Monitor

2

IS

"O2 MON ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

IS

"O2 SENS DISC"

DISPLAYED ON

CENTRAL ALARM

PANEL?

REPLACE

OXYGEN SENSOR

AS OUTLINED IN

PROCEDURE 4.39

N

Y

REINSTALL ORIGINAL

VPO BOARD

----------------------------------

PERFORM PROCESSOR

BOARD TEST

AS OUTLINED IN

PROCEDURE 3.2

N

N

DID

PROCESSOR TEST

INDICATE PROCESSOR

PROBLEM?

IS

"O2 MON ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

REINSTALL ORIGINAL

OXYGEN SENSOR

---------------------------------REPLACE VPO BOARD

AS OUTLINED IN

PROCEDURE 4.37

IS

"O2 MON ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

Y

N

N

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS

"O2 MON ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

CONTACT NAD

SERVICE DEPT.

N

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

N

3-8

Rev. A

Page 47

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

GUIDE 3: Loss of Breathing Pressure Monitor

START

CONNECT

PILOT LINE TO

INTERFACE PANEL

IS "BAROMED

ERROR" PRESENT

ON CENTRAL ALARM

N

LINE CONNECTED

TO INTERFACE

VPO BOARD

AS OUTLINED IN

PROCEDURE 4.37

IS "BAROMED

ERROR" PRESENT

ON CENTRAL ALARM

REINSTALL ORIGINAL

VPO BOARD

----------------------------------

PERFORM PROCESSOR

BOARD TEST

AS OUTLINED IN

PROCEDURE 3.2

PANEL?

IS PILOT

PANEL?

Y

REPLACE

PANEL?

N

Y

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS "BAROMED

ERROR" PRESENT

ON CENTRAL ALARM

PANEL?

Y

N

REINSTALL ORIGINAL

PROCESSOR BOARD

Y

CONTACT NAD

SERVICE DEPT.

N

N

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

Rev. A

DID

PROCESSOR TEST

INDICATE PROCESSOR

PROBLEM?

Y

N

3-9

Page 48

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

GUIDE 4: Loss of GAS Monitor

START

REPLACE OCCLUDED

SAMPLE LINE OR

WATER TRAP

AGT ERR"PRESENT

ON CENTRAL ALARM

Y

LINE BLK" PRESENT

ON CENTRAL ALARM

REPLACE MULTISPEC

ANALYZER ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.29

N

AGT ERR"PRESENT

ON CENTRAL ALARM

IS "CO2/

PANEL?

IS "CO2

PANEL?

OR 4.30

IS "CO2/

PANEL?

N

Y

N

N

IS "CO2/

AGT ERR"PRESENT

ON CENTRAL ALARM

PANEL?

N

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS "CO2/

AGT ERR"PRESENT

ON CENTRAL ALARM

PANEL?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

Y

REPLACE BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

IS "CO2/

AGT ERR"PRESENT

ON CENTRAL ALARM

PANEL?

Y

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

N

Y

REINSTALL ORIGINAL

MULTISPEC ANALYZER

----------------------------------

PERFORM PROCESSOR

BOARD TEST

AS OUTLINED IN

PROCEDURE 3.2

3-10

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

N

CONTACT NAD

SERVICE DEPT.

Rev. A

Page 49

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

GUIDE 5: Loss of Pulse Oximetry Monitor

START

CHECK

CONNECTIONS

BETWEEN SENSOR

AND SPO2

CABLE

CONNECTOR

CONNECT

SPO2 CABLE TO

INTERFACE PANEL

"OXIMETER ERR"

DISPLAYED ON

CENTRAL ALARM

Y

SENS DISC" PRESENT

ON CENTRAL ALARM

N

CABLE CONNECTED

TO INTERFACE

PULSE OXIMETER

(SPO2) ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.36

IS

PANEL?

IS "OXI

PANEL?

IS SPO2

PANEL?

REPLACE

N

Y

N

N

Y

IS SPO2

MONITOR DISPLAY

PANEL BLANK?

Y

REPLACE

BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

IS SPO2

MONITOR DISPLAY

PANEL BLANK?

Y

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

N

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS SPO2

MONITOR DISPLAY

PANEL BLANK?

Y

REINSTALL ORIGINAL

PROCESSOR BOARD

N

Rev. A

N

IS SPO2

MONITOR DISPLAY

PANEL BLANK?

REINSTALL ORIGINAL

SPO2 SENSOR

CIRCUIT ASSEMBLY

-----------------------------------PERFORM PROCESSOR

BOARD TEST

AS OUTLINED IN

PROCEDURE 3.2

PERFORM A

Y

COMPLETE PMS

ON THE UNIT

DOES UNIT

PASS PMS

Y

UNIT IS

FUNCTIONAL

N

CONTACT NAD

SERVICE DEPT.

3-11

Page 50

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

GUIDE 6: Loss of Respiratory Volume Monitor

START

CONNECT

SENSOR CORD TO

INTERFACE PANEL

Y

IS

"SPIROMED ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

IS

"VOL SEN DISC"

DISPLAYED ON

RESP. VOLUME

MONITOR?

N

REPLACE

RESPIRATORY

VOLUME SENSOR

AS OUTLINED IN

PROCEDURE 4.38

IS

"SPIROMED ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

N

REINSTALL ORIGINAL

VPO BOARD

-------------------------------------REPLACE BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

IS

"SPIROMED ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

N

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

N

PERFORM A

COMPLETE PMS

ON THE UNIT

REINSTALL ORIGINAL

RESP. VOLUME SENSOR

-------------------------------------REPLACE VPO BOARD

AS OUTLINED IN

PROCEDURE 4.37

IS

"SPIROMED ERR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

CONTACT NAD

SERVICE DEPT.

N

3-12

N

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

Rev. A

Page 51

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

GUIDE 7: Loss of Blood Pressure Monitor

CHECK CUFF

CONNECTION

AT PATIENT

INTERFACE

PANEL

CHECK FOR

LEAKS AT

NIBP CUFF,

REPLACE CUFF

IF NECESSARY

START

Y

Y

IS "NIBP

MON ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

N

IS "NIBP

CUFF DISC"

DISPLAYED ON

CENTRAL ALARM

PANEL?

N

IS "NIBP

CUFF ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

N

PERFORM

PROCESSOR TEST

AS OUTLINED IN

PROCEDURE 3.2

IS "NIBP

MON ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

N

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS "NIBP

MON ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

REPLACE NIBP PUMP

AND SENSOR CIRCUIT

Y

REINSTALL ORIGINAL

NIBP PUMP AND SENSOR

CIRCUIT ASSEMBLY

-----------------------------------------REPLACE BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.35

IS "NIBP

MON ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

Y

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

IS "NIBP

MON ERROR"

DISPLAYED ON

CENTRAL ALARM

PANEL?

N

NN

Rev. A

REINSTALL ORIGINAL

PROCESSOR BOARD

CONTACT NAD

SERVICE DEPT.

3-13

YY

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

PERFORM A

COMPLETE PMS

ON THE UNIT

N

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

Page 52

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued) NM4

GUIDE 8: Touch Screen Failure

START

Y

RESPONSIVE?

PROCESSOR TEST

AS OUTLINED IN

PROCEDURE 3.2

RESPONSIVE?

REPLACE FRONT

BEZEL ASSEMBLY

AS OUTLINED IN

PROCEDURE 4.31

IS TOUCH

SCREEN

N

PERFORM

IS TOUCH

SCREEN

N

REINSTALL ORIGINAL

FRONT BEZEL ASSEMBLY

-----------------------------------------REPLACE BACKPLANE

ASSEMBLY AS

OUTLINED IN

PROCEDURE 4.28

IS TOUCH

SCREEN

RESPONSIVE?

Y

REINSTALL ORIGINAL

BACKPLANE ASSEMBLY

REPLACE

PROCESSOR BOARD

AS OUTLINED IN

PROCEDURE 4.26

IS TOUCH

SCREEN

RESPONSIVE?

NN

REINSTALL ORIGINAL

PROCESSOR BOARD

YY

IS TOUCH

SCREEN

RESPONSIVE?

Y

PERFORM A

COMPLETE PMS

ON THE UNIT

N

CONTACT NAD

SERVICE DEPT.

3-14

N

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

Rev. A

Page 53

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM4 TROUBLESHOOTING GUIDE (continued)

GUIDE 9: No Audio Alarms

START

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

CHECK

WIRING HARNESS

FROM SPEAKER

TO BACKPLANE

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

REPLACE

SPEAKER

Y

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

REPLACE

BACKPLANE PCB

ASM OUTLINED IN

SECTION 4.28

Y

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

Y

Y

REPLACE MAIN

PROCESSOR BOARD

AS OUTLINED IN

SECTION 4.26

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

Y

Rev. A

ARE WARNINGS

AND CAUTIONS AUDIBLY

ANNUNCIATED?

N

REINSTALL

ORIGINAL SPEAKER

--------------------------------

PERFORM PROCESSOR

BOARD TEST

AS OUTLINED IN

SECTION 3.2

REINSTALL ORIGINAL

BACKPLANE PCB