Page 1

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Technical

Service

Manual

Part Number: 4114210

Date: 4 May 2004

© 2004 Draeger Medical, Inc.

Rev: T

Narkomed MRI

Narkomed MRI-2

Anesthesia Systems

Page 2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 3

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Narkomed MRI Service Manual Table of Contents

What's New in Rev. T

DESCRIPTION

SECTION 1: Introduction

1.1 Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 How to use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 General Troubleshooting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.4 General Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SECTION 2: Diagnostics

2.1 Power-up Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Main Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 Service Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4 PMS Criteria Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.5 Oxygen Monitor Service Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.6 Pressure Monitor Service Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

SECTION 3: Troubleshooting

3.1 Power Supply and Voltage Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.3 Troubleshooting Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

PAGE

SECTION 4: Replacement Procedures

4.1 Cylinder Yoke Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Cylinder Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3 Cylinder Cutoff Valves (Canada) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4 Cylinder and Pipeline Pressure Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4.5 Flowmeters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.6 Flow Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

4.7 Auxiliary O2 Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4.8 Oxygen Supply Failure Protection Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

4.9 Alarm Channel and Oxygen Supply Pressure Alarm Switch . . . . . . . . . . . . . 4-27

4.10 Oxygen Ratio Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

4.11 Vaporizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

4.12 O2 Flush Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

4.13 Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

4.13A VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41A

4.14 AV2+ Ventilator Controller (MRI) (Bezel Assembly) . . . . . . . . . . . . . . . . . . 4-42

4.15 Ventilator Solenoid Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-45

4.16 Ventilator Bellows Valve & Guide Asm w/Press Lim Ctrl . . . . . . . . . . . . . . 4-47

4.17 Caster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-51

Rev. L

i

Page 4

CONTENTS (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

DESCRIPTION

4.18 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-53

4.19 Power Supply PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-55

4.20 Primary Power supply (early models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-57

4.20A Primary Power supply (later design) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-58A

4.21 Power Supply Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-59

4.22 Flow Sensor: Machines with VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-61

SECTION 5: Adjustment And Calibration Procedures

5.1 Cylinder Pressure Regulator Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 Oxygen Supply Pressure Alarm Switch Adjustment . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Oxygen Ratio Controller (ORC) Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.4 Oxygen Monitor Calibration: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

5.5 Flow and Pressure Calibration: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . 5-11

5.6 Oxygen Sensor Calibration: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.7 Breathing Pressure Monitor Calibration: VPO Monitor . . . . . . . . . . . . . . . . . 5-14

5.8 Vaporizer Interlock Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

SECTION 6: Periodic Manufacturer’s Service (PMS) Procedure

6.1 Safety Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.2 Self-Diagnostics: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2A Self-Diagnostics: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4A

6.2B Configuration: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4A

6.2C Service Data: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4B

6.3 Battery Circuit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.4 High Pressure Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.5 High Pressure Regulator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

6.6 Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

6.7 Oxygen Supply Failure Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.8 Flowmeter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

6.9 Freshgas Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

6.10 Absorber System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.10A Bain Circuit Adapter - if applicable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17A

6.10B Vapor Exclusion System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17B

6.11 Flow and Pressure Calibration: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . 6-17C

6.11A Flow and Pressure Calibration: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . 6-17D

6.12 Oxygen Cal and Alarm Test: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.12A O2 MED: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18A

6.13 Pressure Accuracy Test: Core-M Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

6.13A Baromed: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19A

6.14 APNEA and Volume Alarm Test: Core-M Monitor. . . . . . . . . . . . . . . . . . . . . 6-20

6.14A Ultrasonic Flow Sensor: VPO Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21A

6.15 Ventilator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

6.16 Bellows Drive Gas Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.17 “F” Bellows Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.18 Ventilator Relief Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.19 Inspiratory Pressure Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

PAGE

ii

Rev. L

Page 5

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

CONTENTS (continued)

DESCRIPTION PAGE

6.20 Oxygen Concentration Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

6.21 Oxygen Ratio Control (ORC) Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

6.22 Oxygen Flush and 100% O2 Final Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

6.23 Scavenger Interface, A/C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

6.24 Open Reservoir Scavenger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

6.25 Suction Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

6.26 Final Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

SECTION 7: Software Update Procedure

7.1 Software Transfer to PC via Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.2 Installing NM MRI Software from a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

SECTION 8: Spare and Replacement Parts

AV-2+ Ventilator Controller (Bezel) Assembly and Remote Solenoid . . . . . . . . . . . . . . 8-2, 8-3

Bellows Valve Assembly, Pressure Limit Control, Bellows Assembly. . . . . . . . . . . . . . 8-4, 8-5

Bellows Valve Assembly details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6, 8-7

DISS Pipeline Inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8, 8-9

Failsafe Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10, 8-11

ORC Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12, 8-13

Alarm Channel Assembly and related cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14, 8-15

Flowmeter Shields, Knobs, Labels, Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16, 8-17

Flow Tubes, Restrictor Assemblies, Flow Control Valve . . . . . . . . . . . . . . . . . . . . . . 8-18, 8-19

Auxiliary O

Cyl. Regulator Assemblies, O

Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20, 8-21

2

Flush Valve and related parts . . . . . . . . . . . . . . . . . 8-22, 8-23

2

CSA Items: Relief Valve, Cylinder Cutoff Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24, 8-25

Yokes, Common Parts, Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26, 8-27

Absorber Pole, Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-28, 8-29

Power Supply/Charger Assembly, Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30, 8-31

Filter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32, 8-33

Battery Box Assembly, machines with Core-M monitor . . . . . . . . . . . . . . . . . . . . . . 8-34, 8-35

Battery Box Assembly, machines with VPO monitor. . . . . . . . . . . . . . . . . . . . . . . . . 8-36, 8-37

Absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38, 8-39

Man/Auto Selector Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40, 8-41

Open Reservoir Scavenger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42, 8-43

A/C Scavenger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44, 8-45

Core-M Monitor, Vol & O2 Sensors, Touch-up paint: Euro white, Euro blue . . . . . . 8-46, 8-47

VPO Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48, 8-49

Ultrasonic Flow Sensor Assembly and related parts . . . . . . . . . . . . . . . . . . . . . . . . . 8-50, 8-51

Suction Assembly with Re-usable Canister . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52, 8-53

Vaporizer Mounting and Exclusion System parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54, 8-55

Rev. L

iii

Page 6

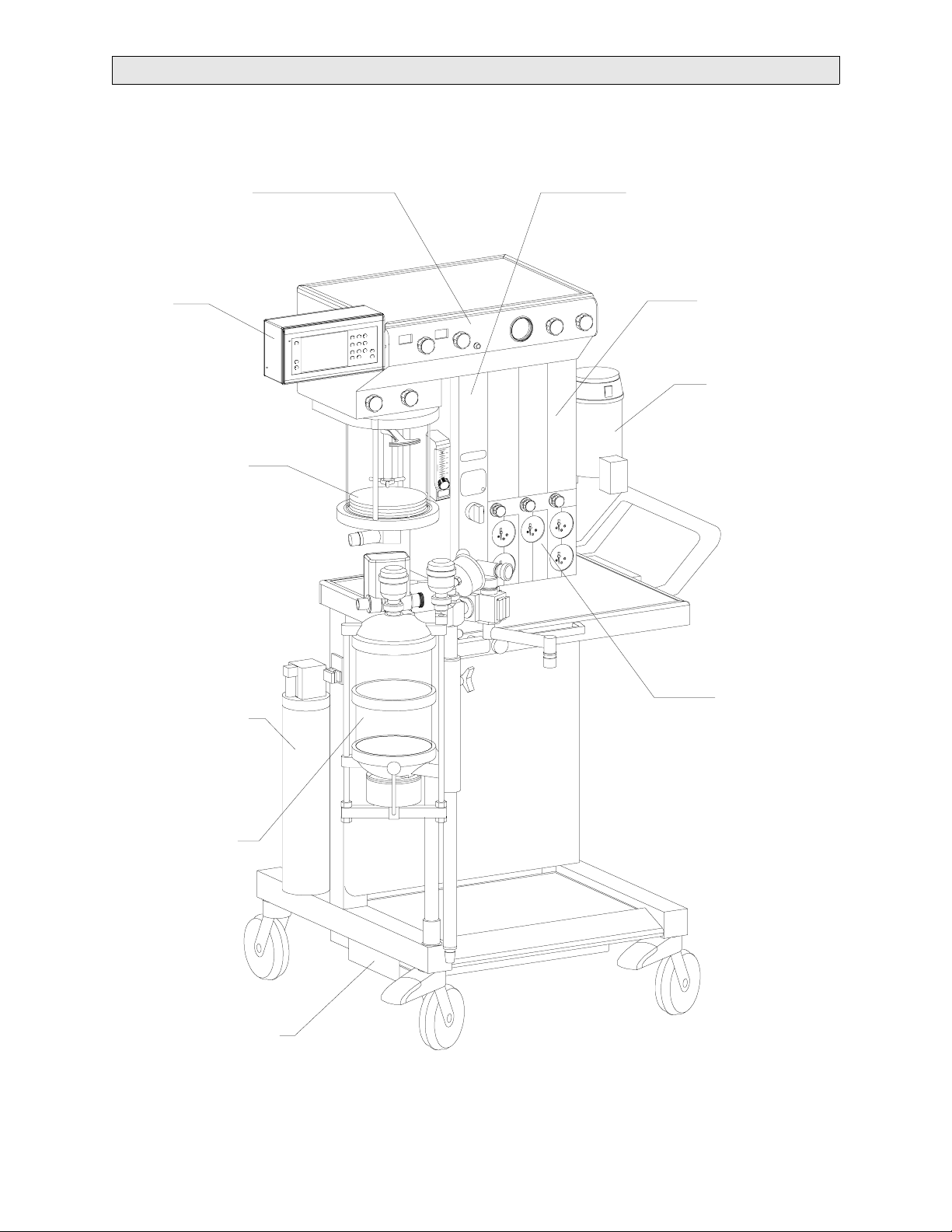

Narkomed MRI Anesthesia System

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

VENTILATOR

VPO

MONITOR

VENTILATOR

BELLOWS

MAIN SWITCH PANEL

FLOWMETER

BANK

VAPORIZER

SCAVENGER

(OPEN

RESERVOIR)

ABSORBER

POWER SUPPLY

PRESSURE

GAUGES

SV00070

1-0

Rev. E

Page 7

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

INTRODUCTION

1.0 INTRODUCTION

1.1 Recommendations

Because of the sophisticated nature of Draeger Medical, Inc. anesthesia equipment and its

critical importance in the operating room setting, it is highly recommended that only

appropriately trained and experienced professionals be permitted to service and maintain this

equipment. Please contact DrägerService

Draeger Medical, Inc. also recommends that its anesthesia equipment be serviced at three-

month intervals. Periodic Manufacturer's Service Agreements are available for equipment

manufactured by

Draeger Medical, Inc. For further information concerning these agreements,

please contact us at (800) 543-5047.

Draeger Medical, Inc. products/material in need of factory repair shall be sent to:

1.2 How to use this Manual

®

at (800) 543-5047 for service of this equipment.

DrägerService

3124 Commerce Drive

Telford, PA 18969 U.S.A.

(Include RMA Number)

The manual is divided into several sections. The DIAGNOSTICS section describes self-test and

service diagnostics for checking the system functions. An understanding of the on-board service

capabilities is necessary before any attempt is made to troubleshoot the unit. The

TROUBLESHOOTING section provides troubleshooting guides to assist the Technical Service

Representative (TSR) in locating the source of a problem. The REPLACEMENT PROCEDURES

section contains instructions for removal and replacement of the assemblies that are considered

field-replaceable. The ADJUSTMENT AND CALIBRATION PROCEDURES section contains the

field procedures needed to restore original system specifications. The Periodic Manufacturer's

Service (PMS) PROCEDURE section outlines the steps required to verify the electrical,

mechanical and pneumatic safety of the unit and also identifies components requiring periodic

replacement.

1.3 General Troubleshooting Guidelines

Troubleshooting the Narkomed MRI should always begin by communicating with those who

observed or experienced a problem with the unit. This may eliminate unnecessary

troubleshooting steps. Once a general problem is identified, refer to the troubleshooting flow

charts in Section 3 to determine the proper corrective action to be taken.

After a component has been replaced, verify that the unit is operating properly by running the

appropriate diagnostic procedure. The PMS PROCEDURE in Section 6 must also be performed

after any component has been replaced.

The general arrangement of the Narkomed MRI Anesthesia System is shown on the opposite

page.

WAR NING S are used in this manual before procedures which if not performed correctly could

result in personal injury.

CAUTIONS are used in this manual to alert service personnel to the possibility of damage to the

equipment if a procedure is not performed correctly.

1-1

Page 8

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION (continued)

NM MRI

1.4 General Warnings and Cautions

The following list of warnings and cautions apply to general operation and maintenance of the

Narkomed MRI. Warnings and cautions about installing and operating specific parts appear

with those topics.

WARNING: The user of this anesthesia machine must comply with warnings, cautions,

and checkout procedures printed on the machine or on the pullout panel.

Failure to do so may result in injury to the patient, operator, others, or

equipment.

WARNING: Any person involved with the setup, operation, or maintenance of the

Narkomed MRI anesthesia system must be thoroughly familiar with this

instruction manual.

WARNING: Do not place any object on this machine unless it is specifically labeled to be

used in an MRI scanning room and on the Narkomed MRI anesthesia system.

Objects placed on this machine that are not designed for use with this

anesthesia system may be strongly attracted to the magnet and may cause

serious injury or death when the machine is used in an MRI scanning room.

WARNING: Always lock the casters after this anesthesia machine has been positioned in

the MRI scanner room. Magnetic attractive forces between the magnet and

the anesthesia machine may cause unintentional movement of the anesthesia

machine if the casters are unlocked.

WARNING: The power supply charger assembly must not be taken into the magnet room.

Damage to the equipment, MRI system, or personal injury could result.

WARNING: The Narkomed MRI has been tested only with magnets having field strengths

of up to 1.5 tesla. Moving the machine near higher strength magnets (greater

than 1.5 tesla) could result in machine malfunction or unmanageable

attractive forces that could lead to serioius injury or death.

WARNING: The Narkomed MRI-2 has been tested with magnets having field strengths of

up to 3.0 tesla. Moving the machine near higher strength magnets (greater

than 3.0 tesla) could result in machine malfunction or unmanageable

attractive forces that could lead to serious injury or death.

WARNING: This anesthesia system will not respond automatically to certain changes in

patient condition, operator error, or failure of components. The system is

designed to be operated under the constant surveillance and control of a

qualified operator.

WARNING: Use only nonmagnetic (aluminum) E-cylinders with this machine. Steel

cylinders can cause serious injury or death if brought into an MRI scanning

room.

1-2

Rev. F

Page 9

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

INTRODUCTION (continued)

WARNING: No third-party components shall be attached to the anesthesia machine,

ventilator, or breathing system (except for certain approved exceptions).

Contact

DrägerService

®

for further information. DrägerService

®

is a division of

Draeger Medical, Inc.

WARNING: Not for use with flammable anesthetics. To avoid explosion hazards, do not

use flammable anesthetic agents such as diethyl-ether and cyclopropane with

this machine. Only anesthetic agents which comply with the requirements for

non-flammable anesthetic agents per IEC standard or national equivalent

shall be used with this anesthesia machine.

CAUTION: When moving the machine, be sure to set the absorber to its lowest position on

the absorber pole. To avoid personal injury or damage to the unit, do not use

the absorber pole to push or pull the machine. It is recommended that two

people move the machine to aid in maneuverability on inclines, around

corners, and over raised thresholds.

CAUTION: The Narkomed MRI is designed for MRI use only as a system. The user should

not assume that individual components of the system can be safely used with

MRI scanners.

CAUTION: Although the Narkomed MRI is designed to minimize the effects of ambient

radio-frequency interference, machine functions may be adversely affected by

the operation of electrosurgical equipment or short-wave or microwave

diathermy equipment in the vicinity.

The following messages appear in French on the Narkomed MRI:

ATTENTION: Lors du déplacement de l'appareil, veiller à placer l'absorbeur le plus bas

possible sur le montant. Pour éviter tout risque de blessure corporelle ou

endommagement de l'appareil, ne pas pousser ou tirer sur le montant de

l'absorbeur pour déplacer l'appareil. Il est recommandé que deux personnes

déplacent l'appareil sur des plans inclinés, dans des angles et pour passer

des seuils surélevés.

AVERTISSEMENT: L'utilisateur de l'appareil d'anesthésie doit se conformer aux

avertissements, mises en garde et procédures de vérification

imprimés sur l'appareil ou sur le panneau rétractable. Négliger de

faire cela risque de provoquer des blessure chez le patient, l'opérateur

ou d'autres personnes et risque également d'endommagement

l'appareil.

AVERTISSEMENT: Toute personne chargée de la préparation, de l'utilisation ou de

l'entretien de l'appareil d'anesthésie Narkomed MRI doit très bien

connaître le contenu de ce manuel d'utilisation.

1-3

Page 10

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION (continued)

NM MRI

AVERTISSEMENT: Ne placer aucun objet sur cet appareil à moins qu'il n'ait été

spécifiquement approuvé pour l'utilisation dans une salle IRM avec

un appareil d'anesthésie Narkomed MRI. Tout objet non conforme

déposé sur cet appareil pourrait être fortement attiré par l'aimant et

pourrait occasionner des blessures graves ou fatales lorsque l'appareil

d'anesthésie est utilisé dans la salle IRM.

AVERTISSEMENT: Toujours bloquer les roues après avoir placé cet appareil d'anesthésie

à l'endroit voulu dans la salle IRM. Les forces d'attraction magnétique

entre l'aimant et l'appareil d'anesthésie peuvent provoquer un

déplacement imprévu de ce dernier si les roues ne sont pas bloquées.

AVERTISSEMENT: Ne pas amener le chargeur de batterie dans la salle IRM car cela

présenterait un risque d'endommagement du matériel et du système

IRM, ou de blessure corporelle.

AVERTISSEMENT: Cet appareil d'anesthésie Narkomed MRI a été vérifiée avec des

aimants possédant des champs magnétiques jusqu’á 1,5 tesla. Installé

l’appareil prés d’un aimant plus puissant (plus de 1,5 tesla) pourrait

amener l’appareil á mal monctionner ou produire des forces

d’attractions incontrôlables qui pourait causer des blessures sérieuses

ou la mort.

AVERTISSEMENT: Cet appareil d'anesthésie Narkomed MRI-2 a été vérifiée avec des

aimants possédant des champs magnétiques jusqu’á 3,0 tesla. Installé

l’appareil prés d’un aimant plus puissant (plus de 3,0 tesla) pourrait

amener l’appareil á mal monctionner ou produire des forces

d’attractions incontrôlables qui pourait causer des blessures sérieuses

ou la mort.

AVERTISSEMENT: Ce système d'anesthésie ne réagit pas automatiquement à certains

changements de l'état physiologique du patient, aux erreurs de

l'opérateur ou aux défaillances des composants. Il a été conçu de

manière à être utilisé sous le contrôle permanent de l'opérateur.

AVERTISSEMENT: Utiliser uniquement des bouteilles de type E non magnétiques (en

aluminium) avec cet appareil. L'utilisation de bouteilles en acier dans

la salle IRM pourrait occasionner des blessures graves ou mortelles.

AVERTISSEMENT: Ne pas utiliser de composants en provenance d'autres fabricants avec

l'appareil d'anesthésie, le ventilateur ou le circuit d'anesthésie, à

moins qu'ils n'aient été approuvés au préalable. Contacter le service

technique de Draeger Medical, Inc. pour des informations

complémentaires.

Rev. A

1-4

Page 11

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

INTRODUCTION (continued)

AVERTISSEMENT: Ne pas utiliser l'appareil d'anesthésie avec des anesthésiques

inflammables. Pour éviter tout risque d'explosion, ne pas utiliser

d'anesthésiques inflammables tels que l'éther et le cyclopropane.

Seuls les anesthésiques conformes aux exigences relatives aux

anesthésiques ininflammables de la norme CEI ou toute norme

nationale équivalente pourront être utilisés avec cet appareil.

AVERTISSEMENT: Lors du déplacement de l'appareil d'anesthésie, enlever tous les

moniteurs et autre matériel de l'étagère supérieure, retirer

l'absorbeur et n'utiliser que les poignées ou les barres de poussée/

traction. L'appareil d'anesthésie ne doit être déplacé que par des

personnes suffisamment fortes pour en supporter le poids. Draeger

Medical, Inc. recommande que deux personnes déplacent l'appareil

d'anesthésie afin de le manouvrer plus facilement. Veiller à ce que

l'appareil ne bascule pas lors du déplacement sur des plans inclinés,

dans des angles et au passage de seuils (portes et ascenseurs, par

exemple). Ne pas faire passer l'appareil sur des tuyaux, des fils

électriques ou d'autres obstacles se trouvant sur le sol.

ATTENTION: L'appareil d'anesthésie Narkomed MRI doit être utilisé uniquement en tant

que système pour l'imagerie à résonance magnétique. L'utilisateur ne doit

pas présumer que chaque composant du système peut être utilisé seul pour

l'IRM sans présenter de risques.

ATTENTION: Bien que l'appareil d'anesthésie Narkomed MRI soit conçu de manière à

minimiser le parasitage électromagnétique, son fonctionnement peut être

affecté par l'utilisation de générateurs d'électrochirurgie ou d'appareils de

diathermie à ondes courtes ou d'appareils à micro-ondes se trouvant aux

alentours.

ATTENTION: Ne pas placer plus de 23 kg (50 livres) sur l'appareil.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5

Page 12

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

INTRODUCTION (continued)

Copyright

Copyright © 2004 by Draeger Medical, Inc. All rights reserved. No part of this publication may

be reproduced, transmitted, transcribed, or stored in a retrieval system in any form or by any

means, electronic or mechanical, including photocopying and recording, without the written

permission of Draeger Medical, Inc.

Trademark Notices

NM MRI

Datagrip, DrägerService, Narkomed, Narkomed GS, O.R. Data Manager, ORM, Quality Service

For Life, Respitone,

trademarks of

respective owners.

Disclaimer

The content of this manual is furnished for informational use only and is subject to change

without notice. Draeger Medical, Inc. assumes no responsibility or liability for any errors or

inaccuracies that may appear in this manual.

Draeger Medical, Inc. All other products or name brands are trademarks of their

Vigilance Audit, Vitalert, Vitalink, and Fabius GS are registered

1-6

Page 13

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

DIAGNOSTICS

2.0 DIAGNOSTICS

The Narkomed MRI anesthesia system includes a volume, pressure, and oxygen monitor.

If your system is equipped with an Omicron (Core-M) monitor, refer to the

Monitor Instructions for Operation

(Part No. 4114448) for power-up diagnostic indications,

NAD Omicron

calibration, and setting of alarm parameters. Power to the monitor is supplied by the

Narkomed MRI anesthesia system. A description of the power distribution scheme along

with a troubleshooting guide is given in the next section.

The descriptions that follow apply to systems equipped with a VPO monitor.

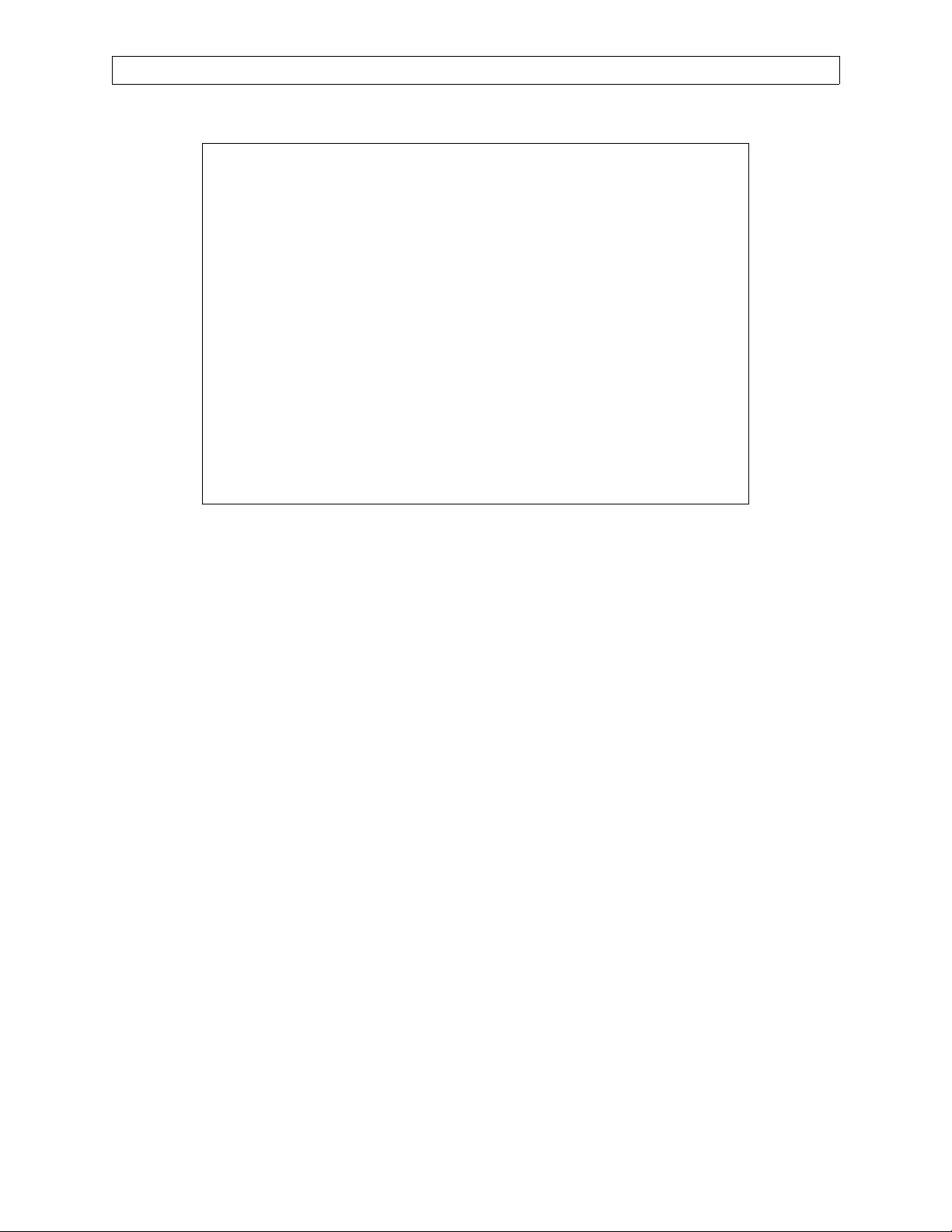

2.1 Power-up Diagnostics

The VPO monitor contains a diagnostic system that monitors certain system functions

and records their operational status. Following a brief System Startup display at

power up, the diagnostics screen shown in Figure 2-1 appears. This display includes

one of three messages at the completion of the diagnostics:

FUNCTIONAL: This message indicates that the Narkomed MRI has passed all

power-up tests and is fully functional. The machine will proceed to

the MACHINE MONITOR screen after a short delay.

CONDITIONALLY This message indicates that a minor problem has been

FUNCTIONAL: detected. The Narkomed MRI will retain this display until any key is

pressed, then the MACHINE MONITOR screen will be displayed.

NON-FUNCTIONAL: This message indicates that a serious problem has been detected. The

machine will not proceed into the MACHINE MONITOR or SYSTEM

MONITOR screen.

The PREVENTIVE MAINTENANCE DUE message will appear on the screen if the

current date exceeds the Periodic Manufacturer's Service due date stored in the

machine.

Further diagnostic functions are available through service screens that can be called

up at the display panel. The following paragraphs provide a description of each service

screen that can be accessed at the display. If no display is present upon system powerup, refer to Section 3 of this manual for troubleshooting assistance.

Rev. E

2-1

Page 14

DIAGNOSTICS (continued)

NARKOMED MRI

COPYRIGHT 2000 DRAEGER MEDICAL, INC.

VERSION: 1.00 NM MRI

SOFTWARE ID: 3B31

DIAGNOSTIC TESTS

FIRMWARE PASS

RAM PASS

VIDEO PASS

A/D CONVERTER PASS

AUDIO PASS

CLOCK PASS

NON-VOLATILE MEMORY PASS

PERIODIC CERTIFICATION DUE

FUNCTIONAL

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

Figure 2-1. Power-up Diagnostics Screen

2-2

Rev. E

Page 15

NM MRI

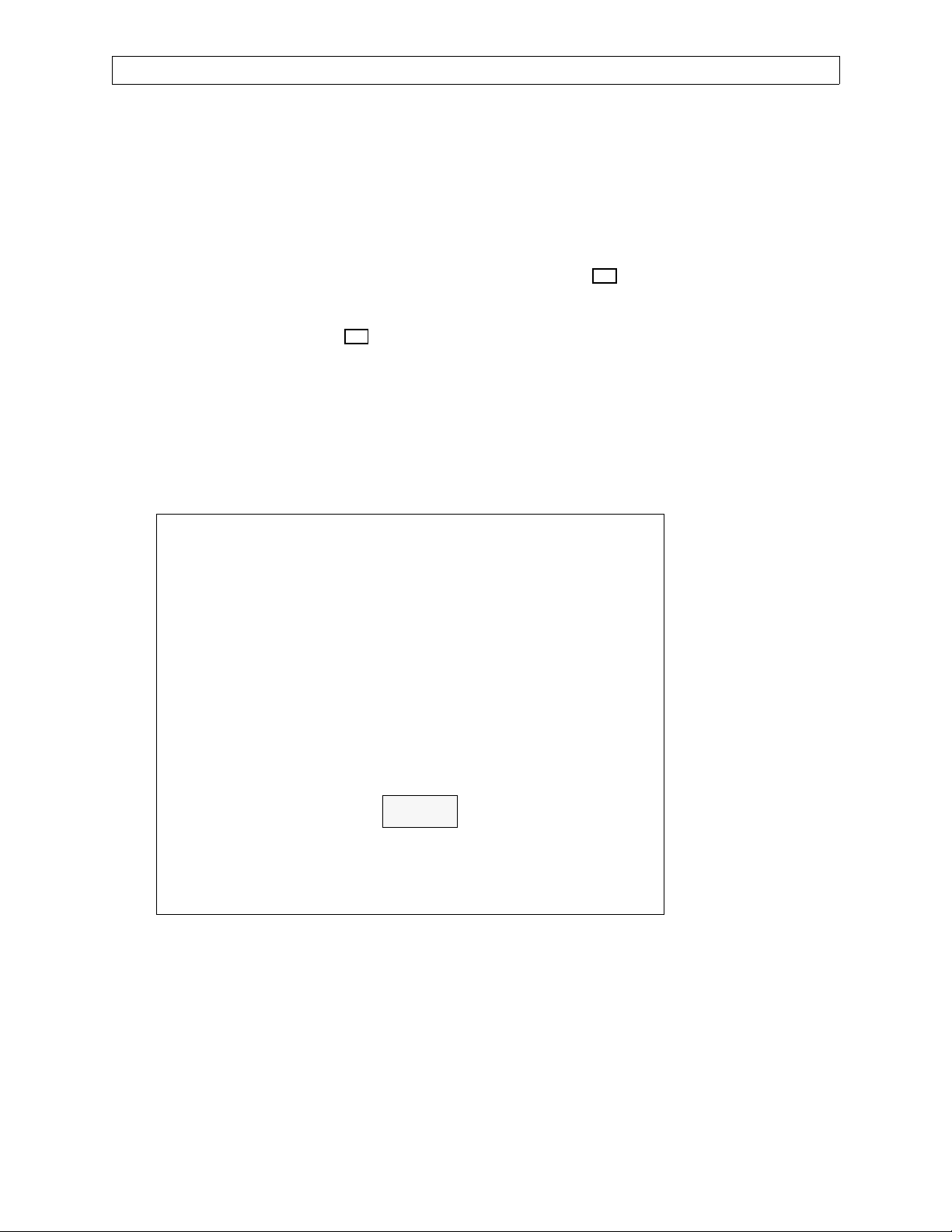

2.2 Main Service Screen

2.2.1 View Mode

The Main Service Screen displays the machine serial number, the last

service date, hours run since last service and total hours run.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued)

SRVC

LOG

PMS

SCHED

To access the Main Service Screen, press and hold the Oxygen

and Volume

screen shown in Figure 2-2 will then appear.

Press the

paragaph), or press the key next to

screen.

MAIN SERVICE SCREEN

MACHINE SERIAL NUMBER : XXXXXXXX

LAST SERVICE DATE : 2-29-2000

HOURS RUN SINCE LAST SERVICE: 263

TOTAL HOURS RUN : 624

Low Limit keys, and press the key. The View Mode service

key to proceed to the Service Mode (described in the next

5

EXIT to return to the monitoring

5

High Limit

Rev. E

MON

CAL

PORT

SERVICE CODE

Figure 2-2. Main Service Screen, View Mode

VIEW

2-3

SELECT

EXIT

Page 16

DIAGNOSTICS (continued)

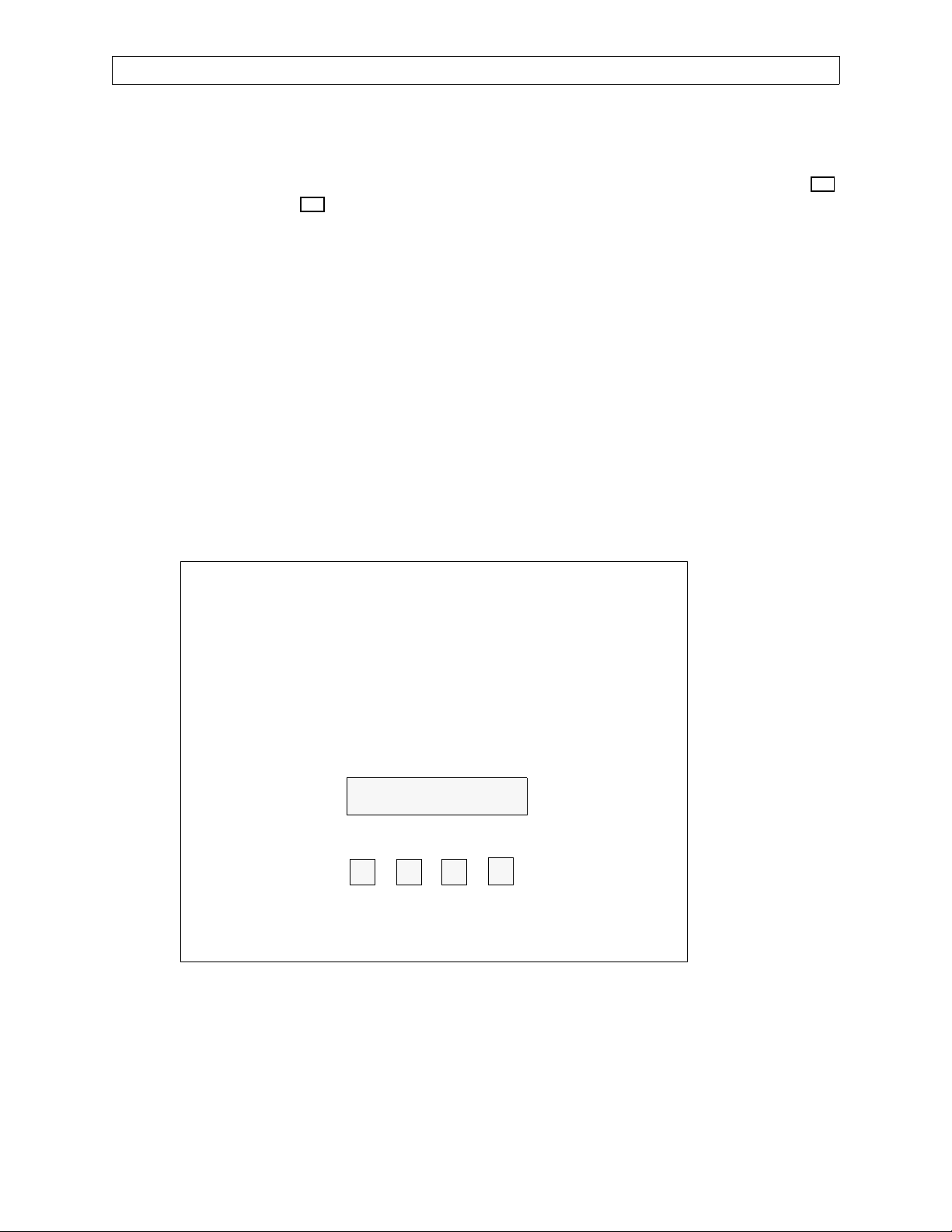

2.2.2 Service Mode

In this screen, the Service Code Changes to SRVC.

Press the key next to SELECT to enable the Technical Service ID entry

as described on the next page.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

SRVC

LOG

PMS

SCHED

MON

CAL

PORT

Figure 2-3. Main Service Screen, Service Mode

MAIN SERVICE SCREEN

MACHINE SERIAL NUMBER : XXXXXXXX

LAST SERVICE DATE : 2-29-2000

HOURS RUN SINCE LAST SERVICE: 263

TOTAL HOURS RUN : 624

SERVICE CODE

SRVC

SELECT

EXIT

2-4

Rev. E

Page 17

NM MRI

2.2.3 Service Mode: I.D. Entry

The Service Mode screen appears as shown in Figure 2-4. Press the key

next to

and keys to display the desired character. Press the key next to

SELECT to advance to the next digit, and enter the next and remaining

I.D. characters in the same manner.

When this screen is entered, an entry is made in the Service Log.

To access any of the other service screens described on the following

pages, press the key next to the desired function on the left side of the

screen: Service Log, PMS Schedule, Monitor Calibration, or Port

communication settings.

SELECT. Enter the first digit of your service code by using the

6

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued)

5

RESET

SRVC

LOG

PMS

SCHED

MON

CAL

PORT

Pressing the key next to

LAST SERVICE to zero, and the LAST SERVICE DATE to the current

date.

If desired, press the key next to

MAIN SERVICE SCREEN

MACHINE SERIAL NUMBER : XXXXXXXX

LAST SERVICE DATE : 2-29-2000

HOURS RUN SINCE LAST SERVICE: 263

TOTAL HOURS RUN : 624

TECHNICAL SERVICE

REPRESENTATIVE I.D.

0 0 0

RESET will reset the HOURS RUN SINCE

EXIT to return to the monitoring screen.

SELECT

0

EXIT

Rev. E

Figure 2-4. Main Service Screen, Service Mode

2-5

Page 18

DIAGNOSTICS (continued)

2.3 Service Log

From the Service Screen (described earlier), press the key next to SRVC LOG.

Figure 2-5 shows an example of the screen that will appear. This screen allows

you to view the events recorded in the machine's service log. Use the and

keys to scroll down or up through the log entries.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

6

5

Press the key next to

EXIT to return to the Main Service Screen.

SERVICE LOG

DATE TIME PARAMETER CODE

02-11-00 10:26 00000000 0000

SYSTEM POWERUP

02-11-00 10:30 00000000 E400

AUDIOGEN SPKR CHK

02-13-00 07:30 00000004 E100

Figure 2-5. Service Log

2-6

EXIT

Rev. E

Page 19

NM MRI

2.4 PMS Criteria Screen

The PMS Criteria Screen allows you to select the month when the

PREVENTIVE MAINTENANCE DUE message appears on the power-up

diagnostics screen.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued)

From the Service Screen (described earlier), press the hidden key next to

SCHED

Figure 2-6 shows an example of the screen that will appear. Use the and

keys to set the desired month.

Press the key next to

SELECT CRITERIA FOR

“PREVENTIVE MAINTENANCE” MESSAGE

.

EXIT to return to the Main Service Screen.

PMS

5

6

Rev. E

MONTH

SEP

2000

Figure 2-6. PMS Criteria Screen

EXIT

2-7

Page 20

DIAGNOSTICS (continued)

2.5 Oxygen Monitor Service Screen

The Oxygen Monitor Service Screen shown in Figure 2-7 displays current

readings for the O

values.

cells, a zero calibration procedure, and the stored calibration

2

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

From the Service Screen (described earlier), press the key next to

To perform a zero calibration, follow the calibration procedure shown on the

screen. Pressing the key next to

calibration.

To proceed to the Pressure Monitor Service Screen, press the key next to

. To return to the Main Service Screen, press the key next to EXIT.

MON

ZERO stores the current values as the new zero

MON CAL.

OXYGEN MONITOR SERVICE SCREEN

CURRENT CELL A: 238

CURRENT CELL B: 250

ZERO

PRES

ZERO CALIBRATION PROCEDURE:

- REMOVE O2 CELL FROM HOUSING

- LET CURRENT CELL VALUES STABILIZE

- PRESS “ZERO” KEY TO ENTER

CALIBRATION VALUES

- REINSTALL O2 CELL IN SENSOR HOUSING

STORED ZERO CELL A: 250

STORED ZERO CELL B: 250

Figure 2-7. Oxygen Monitor Service Screen

2-8

PRES

MON

EXIT

Rev. E

Page 21

NM MRI

2.6 Pressure Monitor Service Screen

The Pressure Monitor Service Screen shown in Figure 2-8 displays the current

reading for airway pressure, a procedure for zero and span calibration, and the

stored calibration values.

To enter the Pressure Monitor Service Screen from the Oxygen Monitor Service

Screen (described earlier), press the key next to

To perform a zero calibration, follow the procedure shown on the screen.

Pressing the key next to

calibration.

To perform a span calibration, follow the procedure shown on the screen.

Pressing the key next to

calibration.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

DIAGNOSTICS (continued)

PRES MON (ref. Figure 2-6).

ZERO stores the current value as the new zero

SPAN stores the current value as the new span

To return to the Oxygen Monitor Service Screen, press the key next to

. To return to the Main Service Screen, press the key next to EXIT.

MON

PRESSURE MONITOR SERVICE SCREEN

CURRENT PRESSURE VALUE: 250

ZERO CALIBRATION PROCEDURE:

- REMOVE PRESSURE SAMPLE LINE FROM

ABSORBER, EXPOSE TO AIR.

- LET CURRENT PRESSURE VALUE STABILIZE

- SELECT “ZERO” KEY TO

ENTER CALIBRATION VALUES.

SPAN CALIBRATION PROCEDURE:

- REMOVE PRESSURE SAMPLE LINE FROM

ABSORBER, APPLY 50 CMH2O CONSTANT

PRESSURE AT THE SAMPLE LINE, VERIFIED

BY A KNOWN, CALIBRATED METER.

- LET PRESSURE VALUE STABILIZE

- SELECT THE “SPAN” KEY TO

ENTER THE CURRENT VALUE.

ZERO

SPAN

OXY

MON

EXIT

OXY

Rev. E

Figure 2-8. Pressure Monitor Service Screen

2-9

Page 22

DIAGNOSTICS (continued)

2.7 Deleted

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

2-10

Rev. L

Page 23

NM MRI

3.0 TROUBLESHOOTING

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE

This section contains information to assist the DrägerService

®

qualified Technical

Service Representative (TSR) in locating electrical faults affecting the Narkomed MRI

anesthesia system. Since most troubleshooting efforts begin with verifying power

supply voltages, the following paragraph outlines the voltage distribution scheme

within the machine along with test points for each of the voltages.

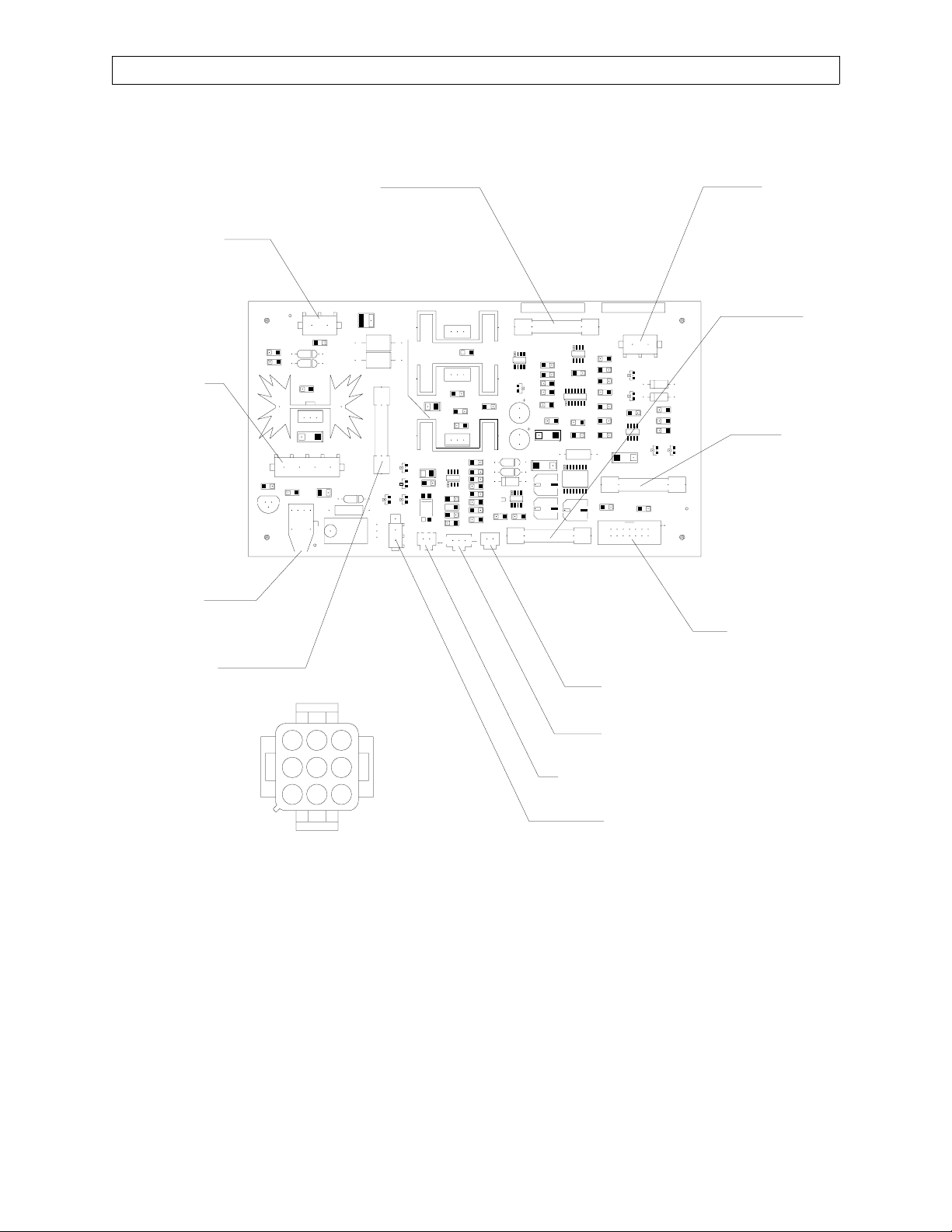

3.1 Power Supply and Voltage Distribution

Power is distributed from the battery box PCB assembly to the alarm channel,

monitor, and flow sensor electronics module on machines with a VPO monitor.

Power for the ventilator controller is obtained from the alarm channel. Table 3-1

lists the test points and acceptable ranges for each voltage; Figures 3-1 and 3-2

show test point locations. Simplified electrical block diagrams are shown in

Figures 3-3 and 3-4.

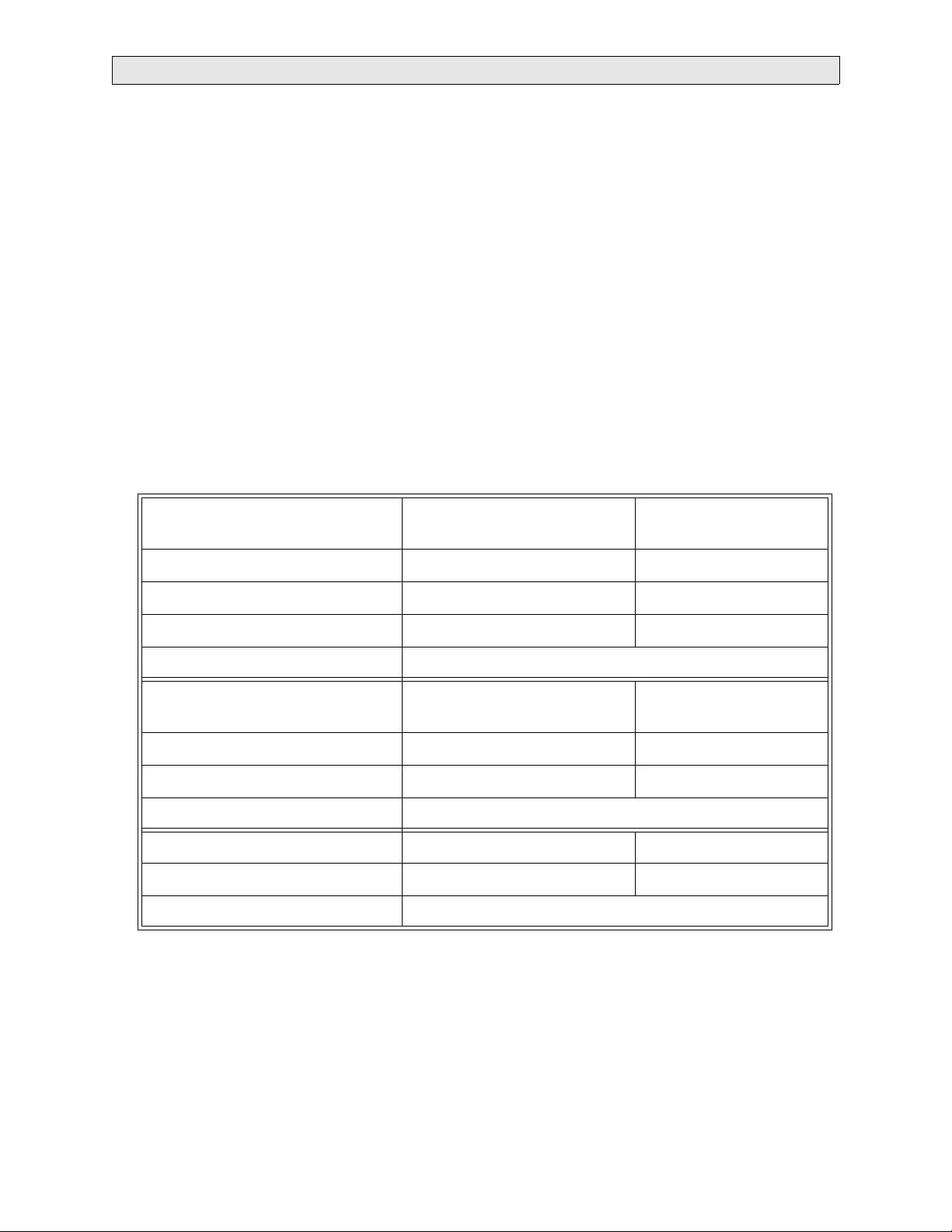

TABLE 3-1: TEST POINTS AND ALLOWABLE RANGES

BATTERY BOX PCB

VOLTAGE ACCEPTABLE RANGE

(Machines with Core-M monitor)

J1-1 + 13.8 VDC input* 13.6 to 14.0 VDC

J4-1 + 9 VDC to monitor 8.45 to 9.55 VDC

J3-1 + 8 VDC to alarm channel 7.55 to 8.45 VDC

J1-2, J4-2, J3-14 Common

BATTERY BOX PCB

VOLTAGE ACCEPTABLE RANGE

(Machines with VPO monitor)

J7-1 + 8 VDC to monitor 7.72 to 8.36 VDC

J4-1 + 12 VDC to Gill flow sensor 11.61 to 12.54 VDC

J7-2, J4-2 Common

ALARM CHANNEL VOLTAGE ACCEPTABLE RANGE

J3-9 (Wht) + 8 VDC to vent controller 7.55 to 8.45 VDC

J3-3 (Orn) Common

* Applies to early models, measured with battery fully charged and System Power switch at

STANDBY.

On later models with Jerome power supply including machines with VPO monitor, input

voltage is measured at DC power cable Pins 1& 2, with cable unplugged. Range: 13.6 to 14.5

VDC.

Rev. L

3-1

Page 24

TROUBLESHOOTING GUIDE (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

J1 FROM

BATTERY

CHARGER

J2 FROM

BATTERY

FI BATTERY

FUSE

(TYPE 3AG,

FAST, 10A,

250V,

312 010)

F3 8V SUPPLY FUSE

(TYPE 3AG, SLO-BLO,

1A, 250V, 313 001)

SV00034

J3 TO

ALARM

CHANNEL

J4 TO

CORE-M

MONITOR

CONNECTION FOR

FIBER OPTIC CABLE

ALARM

CHANNEL

CONNECTOR J3

(TYPE 3AG, FAST, 0.75A, 250V, 312.750)

987

654

321

F2 9V SUPPLY FUSE

FIGURE 3-1. Power Supply Voltage Test Points: Machines with Core-M Monitor

3-2

Rev. E

Page 25

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

F1 BATTERY FUSE, 10A, 3AG FAST J2 FROM

J1 POWER IN

J7 TO NAD

MONITOR

TROUBLESHOOTING GUIDE (continued)

BATTERY

F4

FLOW SENSOR

POWER FUSE

0.5A, 3AG, FAST

F2 8V

SUPPLY FUSE

1A, 3AG,

SLO-BLO

RX1 FIBER

OPTIC CABLE FROM

VENT CONTROLLER

F3 MONITOR

POWER FUSE

3A, 3AG, FAST

ALARM

CHANNEL

CONNECTOR J3

987

654

321

J4 FLOW SENSOR MODULE J1

J5 FLOW SENSOR MODULE J2

J8 HIGH FIELD SIGNAL TO MONITOR

J6 TO VENTILATOR SOLENOID

FIGURE 3-2. Power Supply Voltage Test Points: Machines with VPO Monitor

SV00181

J3 TO ALARM

CHANNEL

Rev. E

3-3

Page 26

TROUBLESHOOTING GUIDE (continued)

FLOWMETER

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

LIGHTS

FEED

THRU

J2

FILTERS

9V POWER

FOR

MONITOR

J4

BATTERY

BOX PCB

ALARM

CHANNEL

J4

J3

J1

J6

J3

30 PSI

SW

RX1

J2

BATTERY

VENTILATOR

CONTROLLER

FIBER OPTIC

INTERFACE

TX1

VENT

SOLENOID

J1

FIBER

OPTIC

CABLE

FILTER

BOX

MAINS

POWER

SUPPLY

FIGURE 3-3. Narkomed MRI Block Diagram: Machines w/Core-M Monitor

3-4

Rev. E

Page 27

NM MRI

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued)

FLOWMETER

LIGHTS

FEED

THRU

J2

FILTERS

NAD MONITOR

FLOW

SENSOR

MODULE

J1

J4

J7

BATTERY

BOX PCB

J1

ALARM

CHANNEL

J8

J3

J4

J3

30 PSI

SW

RX1

J2

BATTERY

VENTILATOR

CONTROLLER

FIBER OPTIC

INTERFACE

TX1

VENT

SOLENOID

J1

FIBER

OPTIC

CABLE

J6

FILTER

BOX

MAINS

J1

POWER

SUPPLY

FIGURE 3-4. Narkomed MRI Block Diagram: Machines w/VPO Monitor

Rev. F

3-5

Page 28

TROUBLESHOOTING GUIDE (continued)

3.2 Battery

With the System Power switch at STANDBY and the power supply/charger box

disconnected, the battery voltage at full charge should be within the range of 12.5

to 13.2 VDC. Battery voltage can be measured at J2 on the battery box PCB.

During battery operation, the low battery cutoff voltage should be within the

range of 10.7 to 11.3 VDC.

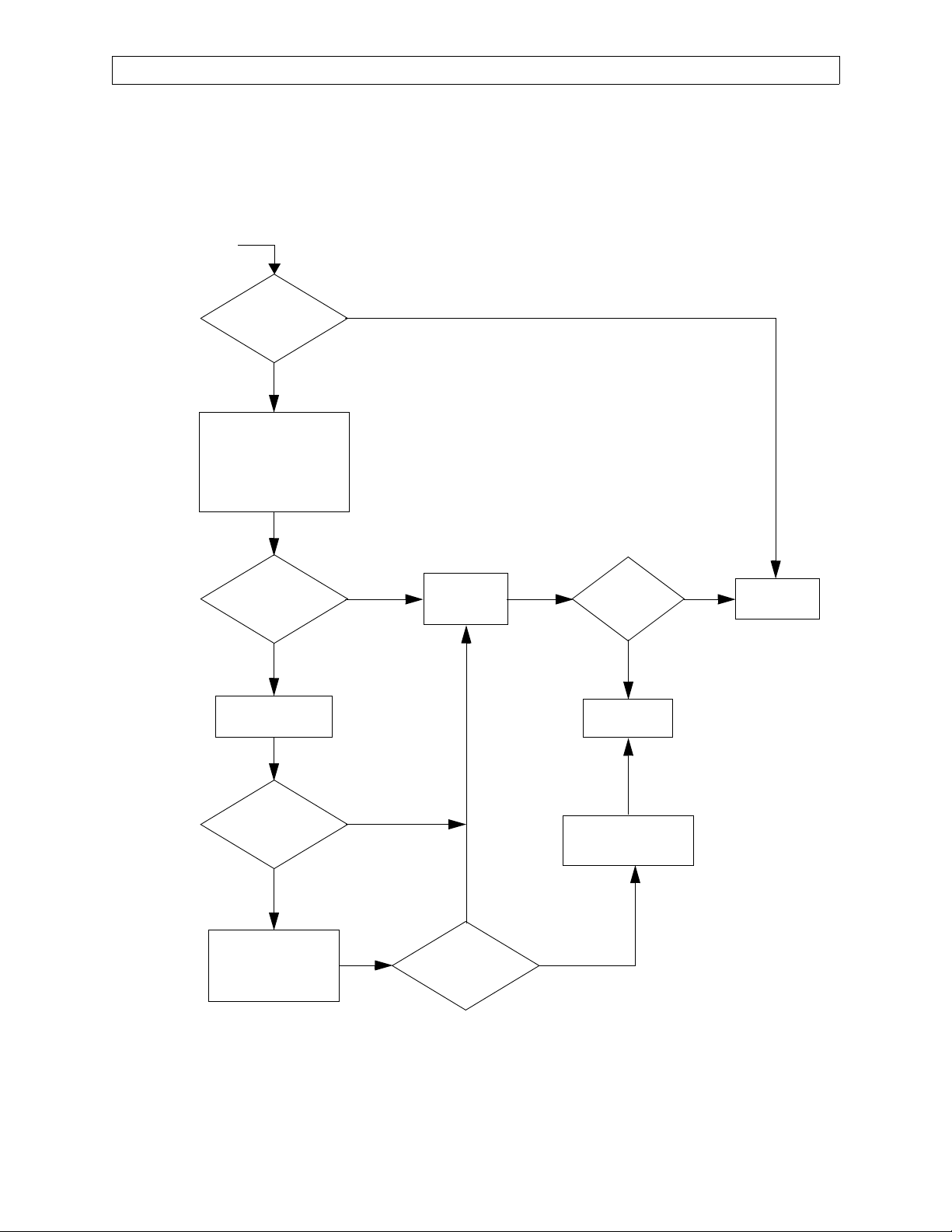

3.3 Troubleshooting Guides

Table 3-2 lists common failure modes and symptoms (excluding simultaneous

multiple faults) for the Narkomed MRI. Each failure mode or symptom is keyed to

a troubleshooting guide flow chart at the back of this section to assist the TSR in

locating a problem. These flow charts assume that the machine is plugged into an

AC outlet with the correct voltage, and the machine is not running on its backup

battery.

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

TABLE 3-2: NARKOMED MRI FAILURE MODE AND SYMPTOM LIST

FAILURE MODE / SYMPTOM CORRECTIVE ACTION

Monitor Inoperative (Core-M Monitor) Guide 1

No O

Supply Pressure Alarm Guide 2

2

Ventilator Inoperative Guide 3

No Audio Alarms, Display Blank,

Guide 4

Keypad Inoperative (VPO Monitor)

Serial Port Communication Failure

Guide 5

(VPO Monitor)

Loss of Breathing Pressure Monitor

Guide 6

(VPO Monitor)

Loss of Respiratory Volume Monitor

Guide 7

(VPO Monitor)

3-6

Rev. E

Page 29

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

NM MRI

GUIDE 1: Monitor Inoperative (Core-M Monitor)

START

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued)

CONNECT

POWER CORD

N

Y

ARE

ALL MONITOR

FUNCTIONS

WORKING?

N

IS

POWER CORD

CONNECTED?

Y

IS POWER

AVAILABLE AT

CONNECTOR?

Y

ARE

ALL MONITOR

FUNCTIONS

WORKING?

Y

CHECK: POWER TO

BATTERY BOX PCB

..................................

REPLACE BATTERY BOX

PCB ASSEMBLY

N

IS

N

POWER

AVAILABLE AT

BATTERY BOX

PCB?

Y

CHECK INTERNAL

CABLE TO POWER

CONNECTOR

ARE

ALL MONITOR

FUNCTIONS

WORKING?

N

REINSTALL ORIGINAL

BATTERY BOX PCB

CONTACT NAD

SERVICE DEPT.

Y

N

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES

UNIT PASS

PMS?

Y

Rev. E

N

CHECK:

-SENSOR INTERFACE

CONNECTIONS

-SENSOR ELEMENTS:

REFER TO

MANUFACTURER’S

OPERATOR’S MANUAL

ARE

ALL MONITOR

FUNCTIONS

WORKING?

Y

3-7

UNIT IS

FUNCTIONAL

N

Page 30

TROUBLESHOOTING GUIDE (continued)

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

START

IS

O2 SUPPLY

PRESSURE ALARM

FUNCTIONAL?

N

CHECK:

-O2 PRESSURE SWITCH

-CABLE FROM BATTERY BOX

PCB TO ALARM CHANNEL

-SUPPLY VOLTAGE TO

ALARM

CHANNEL

IS

O2 SUPPLY

PRESSURE ALARM

FUNCTIONAL?

GUIDE 2: No O

Y

Y

PERFORM A

COMPLETE PMS

ON THE UNIT

DOES

UNIT PASS

PMS?

Supply Pressure Alarm

2

Y

UNIT IS

FUNCTIONAL

N

REPLACE

ALARM CHANNEL

IS

O2 SUPPLY

PRESSURE ALARM

FUNCTIONAL?

N

REINSTALL ORIGINAL

ALARM CHANNEL

..................................

REPLACE BATTERY

BOX PCB ASSEMBLY

N

CONTACT NAD

SERVICE DEPT.

Y

REINSTALL ORIGINAL

BATTERY BOX

PCB ASSEMBLY

Y

IS

O2 SUPPLY

PRESSURE ALARM

FUNCTIONAL?

N

3-8

Rev. E

Page 31

NM MRI

GUIDE 3: Ventilator Inoperative

START

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

TROUBLESHOOTING GUIDE (continued)

IS VENTILATOR

WORKING

PROPERLY?

N

VERIFY CORRECT SETTINGS:

VENTILATOR SWITCH ON,

INSP. FLOW, FREQUENCY,

I:E RATIO, TIDAL VOLUME

PRESS. LIMIT CONTROL

CHECK CYLINDER AND

PIPELINE SUPPLIES FOR

ADEQUATE O2 PRESSURE

VERIFY CORRECT BREATHING

HOSE AND SCAVENGER

HOSE CONNECTIONS TO

BELLOWS ASSEMBLY

Y

CHECK REMOTE SOLENOID,

REPLACE IF DEFECTIVE

IS VENTILATOR

WORKING

PROPERLY?

Y

N

CHECK CABLES AND TUBING

CONNECTIONS AT

VENTILATOR

CONTROLLER, REPLACE

CONTROLLER ASSEMBLY

REINSTALL ORIGINAL

VENTILATOR CONTROLLER

.........................................

REPLACE VALVE AND

GUIDE ASSEMBLY

N

IS VENTILATOR

WORKING

PROPERLY?

IS VENTILATOR

WORKING

PROPERLY?

N

IS 8V

POWER PRESENT

AT FEED THRU FILTERS

ON VENTILATOR

CONTROLLER?

N

CHECK WIRE HARNESS FROM

ALARM CHANNEL J3, CABLE

FROM BATTERY BOX PCB

ASSEMBLY J3 TO ALARM

CHANNEL J4, FIBER OPTIC

CABLE FROM CONTROLLER

TX1 TO RX1 IN BATTERY BOX,

CABLE FROM BATTERY BOX

J6 TO VENT SOLENOID;

REPLACE BATTERY BOX PCB

ASSEMBLY IF DEFECTIVE

Y

IS VENTILATOR

WORKING

PROPERLY?

Y

REINSTALL ORIGINAL

GUIDE ASSEMBLY

N

VALVE AND

Y

COMPLETE PMS

Y

PERFORM A

ON UNIT

DOES UNIT

PASS PMS?

Y

UNIT IS

FUNCTIONAL

N

IS VENTILATOR

WORKING

PROPERLY?

Y

CONTACT NAD

SERVICE DEPT.

N

Rev. E

3-9

Page 32

TROUBLESHOOTING GUIDE (continued)

Guide 4: No Audio Alarms, Display Blank, Keypad Inoperative (VPO Monitor)

START

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

AUDIO

ALARMS

FAIL?

Y

CHECK POWER & DATA

CABLES FROM SOURCE TO

MONITOR

CHECK POWER SUPPLY

VOLTAGE

----------------------------------------REPLACE POWER SUPPLY

PCB OR PRIMARY POWER

SUPPLY IF APPLICABLE

ARE

MONITOR FUNCTIONS

WORKING

CORRECTLY?

N

N

DISPLAY

BLANK

Y

Y

PERFORM A

COMPLETE PMS

ON UNIT

N

KEYPAD

INOPERATIVE

N

Y

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

N

Y

REPLACE NAD

MONITOR AS

OUTLINED IN

SECTION 4

ARE

MONITOR FUNCTIONS

WORKING

CORRECTLY?

3-10

N

REINSTALL

ORIGINAL

MONITOR

CONTACT NAD

SERVICE DEPT.

Rev. E

Page 33

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

TROUBLESHOOTING GUIDE (continued)

Guide 5: Serial Port Communication Failure (VPO Monitor)

START

CONNECT

PERIPHERAL CABLE

TO SERIAL INTERFACE

PORT

PORT COMMUNICATION

CHECK PERIPHERAL

PORT CONFIGURATION

PORT COMMUNICATION

CABLE CONNECTED TO

N

SERIAL INTERFACE

SERIAL

FAILURE?

Y

AND HOST SERIAL

SETTINGS

SERIAL

FAILURE?

Y

IS

PERIPHERAL

PORT?

Y

N

N

Rev. E

SUBSTITUTE

ANOTHER CABLE

N

SERIAL

PORT COMMUNICATION

FAILURE?

REPLACE NAD MONITOR

AS OUTLINED IN

SECTION 4

REPLACE

CABLE

N

PERFORM A

COMPLETE PMS

ON UNIT

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

SERIAL

PORT COMMUNICATION

FAILURE?

Y

REINSTALL ORIGINAL

NAD MONITOR

Y

CONTACT NAD

SERVICE DEPT.

N

3-11

Page 34

TROUBLESHOOTING GUIDE (continued)

Guide 6: Loss of Breathing Pressure Monitor (VPO Monitor)

START

IS

BREATHING

PRESSURE

MONITOR WORKING

PROPERLY?

Y

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

CHECK PILOT

LINE CONNECTION

AT BOTH ENDS

N

N

IS

PILOT LINE

CONNECTED?

Y

PERFORM THE

PRESSURE MONITOR

CALIBRATION

GIVEN IN SECTION 5

IS

BREATHING

PRESSURE

MONITOR WORKING

PROPERLY?

N

REPLACE NAD

MONITOR AS OUTLINED

IN SECTION 4

Y

IS

BREATHING

PRESSURE

MONITOR WORKING

PROPERLY?

Y

PERFORM A

COMPLETE PMS

ON THE UNIT

UNIT IS

FUNCTIONAL

Y

DOES

UNIT PASS

PMS?

3-12

N

REINSTALL ORIGINAL

NAD MONITOR

N

CONTACT NAD

SERVICE DEPT.

Rev. E

Page 35

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

TROUBLESHOOTING GUIDE (continued)

Guide 7: Loss of Respiratory Volume Monitor (VPO Monitor)

START

IS

RESPIRATORY

VOLUME MONITOR

WORKING

PROPERLY

Y

CHECK HOSE

CONNECTIONS,

VALVE MOUNTING

& GASKETS

N

SENSOR INSTALLED

CHECK FLOW

SENSOR ELEMENTS

& O-RINGS

VOLUME MONITOR

N

IS FLOW

CORRECTLY?

Y

IS

RESPIRATORY

WORKING

PROPERLY

N

REINSTALL ORIGINAL

NAD MONITOR

N

IS

RESPIRATORY

VOLUME MONITOR

WORKING

PROPERLY

REINSTALL ORIGINAL

FLOW SENSOR ASM

Y

------------------------------REPLACE NAD

MONITOR AS OUTLINED

IN SECTION 4

N

Y

CONTACT NAD

SERVICE DEPT.

N

DOES

UNIT PASS

PMS?

Y

UNIT IS

FUNCTIONAL

Rev. E

CHECK POWER TO

FLOW SENSOR

ELECTRONICS MODULE,

DATA CABLE FROM

MODULE TO MONITOR

IS

RESPIRATORY

VOLUME MONITOR

WORKING

PROPERLY

Y

VOLUME MONITOR

REPLACE COMPLETE

N

FLOW SENSOR ASM AS

OUTLINED IN SECTION 4

IS

RESPIRATORY

WORKING

PROPERLY

3-13

Y

COMPLETE PMS

PERFORM A

ON THE UNIT

Page 36

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

Page 37

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

REPLACEMENT PROCEDURES

4.0 REPLACEMENT PROCEDURES

This section outlines removal and replacement procedures for the field-replaceable

assemblies of the Narkomed MRI Anesthesia System.

These procedures are to be performed only by a Draeger Medical, Inc. qualified

Technical Service Representative (TSR).

The following are the only procedures authorized by Draeger Medical, Inc. to be

performed in the field. All other service procedures shall be referred to Draeger Medical,

Inc.'s Technical Service Department.

NOTE: The PMS PROCEDURE given in Section 6 must be performed after

any replacement, removal, calibration or adjustment procedure.

WARNING: Do not place any object on this machine unless it is specifically labeled to

be used in an MRI scanning room and on the Narkomed MRI anesthesia

system. Objects placed on this machine that are not designed for use with

this anesthesia system may be strongly attracted to the magnet and may

cause serious injury or death when the machine is used in an MRI

scanning room.

WARNING: Always lock the casters after this anesthesia machine has been positioned

in the MRI scanner room. Magnetic attractive forces between the magnet

and the anesthesia machine may cause unintentional movement of the

anesthesia machine if the casters are unlocked.

WARNING: The power supply charger assembly must not be taken into the magnet

room. Damage to the equipment, MRI system, or personal injury could

result.

WARNING: The anesthesia machine must be removed from the MRI scanner room

before servicing the machine. Do not enter the MRI scanner room with any

tools or instruments. These items may be strongly attracted to the magnet

and may cause serious injury or death when brought into an MRI scanning

room.

Rev. B

4-1

Page 38

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

4.1 Cylinder Yoke Assemblies

Each cylinder yoke contains a replaceable filter and check valve assembly. Figure 4-1

shows a typical cylinder yoke mounting arrangement. Access to the yoke mounting

screws and gas line connection requires that the table top and the table bottom cover

be removed from the machine.

4.1.1 Disconnect all pipeline hoses and turn the System Power switch to ON.

NM MRI

4.1.2 Close all cylinder valves except the O

valve.

2

4.1.3 Set the oxygen flow to 5 liters per min.

4.1.4 Open the other gas flow control valves to drain pressure from the system.

4.1.5 Close the O

cylinder valve, and close the flow control valves. Press the O2

2

Flush valve to drain oxygen pressure from the system.

4.1.6 Turn the System Power switch to

STANDBY.

4.1.7 Remove the cylinder where the yoke is to be replaced. Store the cylinder in a

safe place and lay it on its side.

4.1.8 Loosen the screws holding the table top to the machine and lift out the table

top.

4.1.9 Remove the screws securing the table bottom cover to the machine frame,

and remove the bottom cover. (These screws are accessible after the table top

is removed.)

4.1.10 Disconnect the gas line fitting at the yoke and remove the two yoke

mounting screws.

4.1.11 Remove the filter and check valve assembly from the yoke and install a

replacement assembly.

NOTE: If the entire yoke assembly is being replaced, verify that the pin indexing

arrangement and the label are in agreement with the gas designation

stamped on the mounting surface of the yoke. Refer to the parts list section

for parts identification.

4-2

Page 39

NM MRI

REAR FRAME RAIL

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

YOKE ASSEMBLY

(TYPICAL)

GAS LINE

FILTER AND

CHECK VALVE

ASSEMBLY

SV00096

FIGURE 4-1. Cylinder Yoke Assembly

4-3

Page 40

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

4.1.12 Position the yoke on the spacer, and install the two mounting screws and

lockwashers. Tighten the screws securely. Connect the gas line fitting to the

yoke.

4.1.13 If a new cylinder is being installed, remove the old sealing washer from the

gas inlet of the yoke and install a new washer.

4.1.14 Install the correct cylinder in the yoke, making sure that the index pins are

properly engaged before tightening the handle bolt. The cylinder should

hang vertically after the handle is tight.

4.1.15 Perform the following leak test on the yoke assembly:

4.1.15.1 Open the cylinder valve and check for a pressure indication on the

corresponding gauge at the gas instrumentation panel.

NOTE: The cylinder used for this test must contain the following

minimum pressure:

NM MRI

O

: 1000 Psi

2

N

O: 700 Psi

2

4.1.15.2 Close the cylinder valve and remove the cylinder from the yoke.

4.1.15.3 For any gas, the pressure should not drop more than 50 Psi in two

minutes.

4.1.16 Reinstall the cylinder in the yoke.

4.1.17 Reinstall the table bottom cover.

4.1.18 Reinstall the table top and tighten its retaining screws.

4.1.19 Reconnect the pipeline hoses.

4.1.20 Carefully inspect the machine to verify that no loose screws, washers, or

tools are left on or in any part of the machine.

4.1.21 Perform the PMS Procedure given in Section 6.

4-4

Page 41

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

REPLACEMENT PROCEDURES (continued)

4.2 Cylinder Pressure Regulators

Access to the cylinder pressure regulators requires removal of the table top and the

table bottom cover from the anesthesia machine. Figure 4-2 shows the mounting

arrangement of the regulators and typical connections.

4.2.1 Disconnect all pipeline hoses and turn the System Power switch to ON.

4.2.2 Close all cylinder valves except the O

valve.

2

4.2.3 Set the oxygen flow to 5 liters per min.

4.2.4 Open the other gas flow control valves to drain pressure from the system.

4.2.5 Close the O

cylinder valve, and close the flow control valves. Press the O2

2

Flush valve to drain oxygen pressure from the system.

4.2.6 Turn the System Power switch to

STANDBY.

4.2.7 Remove the cylinder corresponding to the regulator to be replaced.

4.2.8 Loosen the screws holding the table top to the machine and lift out the table

top.

4.2.9 Remove the screws securing the table bottom cover to the machine frame,

and remove the bottom cover. (These screws are accessible after the table top

is removed.)

4.2.10 Disconnect the compression fittings at the regulator.

4.2.11 Loosen the two setscrews holding the regulator to its mounting bracket and

remove the regulator.

4.2.12 Record the serial number of the regulator that was removed, and record the

serial number of the replacement regulator.

NOTE: If fittings must be installed in the replacement regulator, use Loctite #271

(red). Refer to the parts list section for parts identification.

4.2.13 Position the replacement regulator in its mounting bracket, and connect the

three compression fittings. Do not tighten the fittings yet.

4-5

Page 42

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

N2O CYLINDER

PRESSURE

REGULATOR

SET SCREW

(2X PER

REGULATOR)

SV00069

O2 CYLINDER

PRESSURE

REGULATOR

ACORN NUT

FIGURE 4-2. Cylinder Pressure Regulators

O2 TEST

CONNECTION

N2O TEST

CONNECTION

SIDE VIEW OF REGULATOR (TYP.)

ADJUSTMENT SCREW

4-6

Page 43

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

REPLACEMENT PROCEDURES (continued)

4.2.14 Tighten the regulator mounting setscrews to a torque of 50 to 55 in. lbs.

4.2.15 Tighten the compression fittings.

4.2.16 Locate the TEE fitting in the ¼ in. diameter regulator output line, and

remove the plug from the TEE fitting.

4.2.17 Set the regulator output pressure in accordance with the Cylinder Pressure

Regulator Adjustment given in Section 5.

4.2.18 Perform the following leak test on the high pressure side of the regulator:

4.2.18.1 Open the cylinder valve and check for a pressure indication on the

corresponding gauge at the gas instrumentation panel.

NOTE: The cylinder used for this test must contain the following

minimum pressure:

O

: 1000 Psi

2

O: 700 Psi

N

2

4.2.18.2 Close the cylinder valve and remove the cylinder from the yoke.

4.2.18.3 For any gas, the pressure should not drop more than 50 Psi in two

minutes.

4.2.19 Reinstall the cylinder in the yoke.

4.2.20 Reinstall the table bottom cover.

4.2.21 Reinstall the table top and tighten its retaining screws.

4.2.22 Reconnect the pipeline hoses.

4.2.23 Carefully inspect the machine to verify that no loose screws, washers, or

tools are left on or in any part of the machine.

4.2.24 Perform the PMS Procedure given in Section 6.

4-7

Page 44

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

NM MRI

4.3 Cylinder Cutoff Valves (Canada)

Access to the cylinder cutoff valves requires removal of the table top and the table

bottom cover from the anesthesia machine. Figure 4-3 shows the locations of the cutoff

valve assemblies. The instructions apply to all assemblies.

NOTE: Replacement of the O

Cutoff Valve Assembly shall be performed every 24

2

months. Documentation shall be created by the service person and a copy distributed

to the owner institution. Testing of the O

Cutoff Valve shall be performed at each

2

PMS. (Perform the flow test given at the end of the following procedure)

4.3.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.3.2 Close all cylinder valves except the O

valve.

2

4.3.3 Set the oxygen flow to 5 liters per min.

4.3.4 Open the other gas flow control valves to drain pressure from the system.

4.3.5 Close the O

cylinder valve, and close the flow control valves. Press the O2

2

Flush valve to drain oxygen pressure from the system.

4.3.6 Set the System Power switch to

STANDBY.

4.3.7 Loosen the screws holding the table top to the machine and lift out the table

top.

4.3.8 Remove the screws securing the table bottom cover to the machine frame,

and remove the bottom cover. (These screws are accessible after the table top

is removed.)

4.3.9 Disconnect the compression fittings indicated at points marked

C on the

illustration.

4.3.10 Disconnect the flexible tubing from the cutoff valve assembly at the point

marked

A on the illustration.

4.3.11 Remove the cylinder cutoff assembly.

4.3.12 Connect the flexible tubing to the replacement cutoff valve assembly and

secure it with the hose clamp.

4.3.13 Connect and tighten the compression fittings at points marked

C on the

illustration.

4-8

Page 45

NM MRI

SV00062

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

C

A

C

O2 CYLINDER

CUTOFF VALVE

ASSEMBLY

FIGURE 4-3. Cylinder Cutoff Valves (Canada)

4-9

C

C

A

N2O CYLINDER

CUTOFF VALVE

ASSEMBLY

Page 46

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

4.3.14 Perform the following test: --Remove the plug from the test gauge

connection at the Tee fitting in the regulator outlet piping, and install a test

gauge.

NOTE:The cylinders used for this test must contain the following minimum

pressure: O

: 1000 PSI N2O: 745 PSI

2

--Set the System Power switch to ON.

--For the O

cutoff valve: open the O2 cylinder valve and set the oxygen flow

2

to 4 liters per min.

--For the N

O cutoff valve: open the O2 cylinder valve and the N2O cylinder

2

valve. Set each flow to 4 liters per min.

--Verify that regulator outlet pressure is between 43 and 49 PSI.

--Connect the pipeline hoses and pressurize to 50 PSI.

--Turn off the pipeline supply and observe the pipeline pressure gauge.

--The cutoff valve shall open when the pipeline pressure drops through the

range of 45 to 40 PSI.

--Close the cylinder valve(s), and close the flow control valve(s).

--Disconnect test pressure gauge and reinstall the plug in the regulator

outlet piping.

NM MRI

4.3.15 Reinstall the table bottom cover.

4.3.16 Reinstall the table top and tighten its retaining screws.

4.3.17 Connect the pipeline hoses.

4.3.18 Carefully inspect the machine to verify that no loose screws, washers, or

tools are left on or in any part of the machine.

4.3.19 Perform the PMS Procedure given in Section 6.

O2 Flow Test:

--Disconnect all pipeline supplies.

--Install a full O

cylinder on the machine, and open the cylinder valve.

2

--Turn the System Power switch to ON.

--Set the Inspiratory Flow control to maximum high, and turn the ventilator

switch to ON.

--Set the oxygen flow to 10 l/min.

--Verify that the oxygen flow does not drop below 8 l/min. while the

ventilator is running.

--Press and hold the O

FLUSH button while observing the O2 flowmeter,

2

and verify that the oxygen flow does not drop below 8 l/min.

--If the oxygen flow in either of the above two steps drops below 8 l/min.,

replace the O

cutoff valve assembly.

2

4-10

Page 47

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

REPLACEMENT PROCEDURES (continued)

4.4 Cylinder and Pipeline Pressure Gauges

Replacement of the cylinder and pipeline pressure gauges requires that the

plexiglass front flowmeter cover be removed, and also the flowmeter housing rear

cover for access to the gauge connections. Figure 4-4 shows gauge mounting and

connection details.

NOTE: The gauges used in the Narkomed MRI are non-magnetic and are not

interchangeable with gauges from the other Narkomeds.

4.4.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.4.2 Close all cylinder valves except the O

valve.

2

4.4.3 Set the oxygen flow to 5 liters per min.

4.4.4 Open the other gas flow control valves to drain pressure from the system.

4.4.5 Close the O

cylinder valve, and close the flow control valves. Press the O2

2

Flush valve to drain oxygen pressure from the system.

4.4.6 Set the System Power switch to

STANDBY.

4.4.7 Remove the screws holding the rear cover, and remove the cover.

4.4.8 Loosen the screws holding the table top to the machine and lift out the table

top.

4.4.9 Remove the screws holding the angled plate at the top of the flowmeter

shield, and remove the plate.

4.4.10 Remove the oxygen flow control knob. The knob has two setscrews.

NOTE: If the knob must be rotated to allow access to a setscrew, carefully note its

position so that it can be re-assembled in the same position with the "Off

Stop" properly set.

4.4.11 Remove the two screws holding the knob guard in place, and remove the

knob guard.

4.4.12 Carefully remove the plexiglass cover from the front of the flowmeter

housing.

4-11

Page 48

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

REAR VIEW OF

FLOWMETER HOUSING

WITH REAR COVER REMOVED

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

FLEXIBLE

TUBING

CONNECTION

(PIPELINE

PRESSURE

GAUGES)

COMPRESSION FITTING

(CYLINDER PRESSURE GAUGES)

GAUGE

MOUNTING

NUTS (TYPICAL)

SV00086

FIGURE 4-4. Cylinder and Pipeline Pressure Gauges

4-12

Page 49

NM MRI

NOTE: Intermediate assemblies may need to be removed to allow access to

the gauge connections and mounting hardware. Be sure to keep a record of

the disassembly sequence so that all tubing can be correctly re-assembled.

4.4.13 A: For the cylinder pressure gauges:

Disconnect the compression fitting at the back of the gauge.

Remove the gauge mounting nuts, and remove the gauge from the front of

the panel.

Install the replacement gauge in the panel using the flat washers, lock

washers and mounting nuts that were previously removed.

Connect the gas line to the gauge and tighten the compression fitting.

4.3.13 B: For the pipeline pressure gauges:

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

Locate the flexible tubing connecting the gauge to the pipeline inlet

assembly and disconnect the tubing.

Remove the gauge mounting nuts, and remove the gauge from the front of

the panel.

Disconnect the flexible tubing from the gauge.

Connect a new length of tubing to the replacement gauge and secure it with

a hose clamp.

Place the gauge in the panel and secure it with the flat washers, lock

washers and mounting nuts that were previously removed.

Place a hose clamp on the other end of the flexible tubing; connect the tubing

to the pipeline inlet assembly and secure it with the hose clamp.

4.4.14 If a cylinder pressure gauge was replaced, perform the following leak test:

4-13

Page 50

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

REPLACEMENT PROCEDURES (continued)

4.4.14.1 Open the cylinder valve and check for a pressure indication on the

corresponding gauge at the gas instrumentation panel.

NOTE: The cylinder used for this test must contain the following

minimum pressure:

O

: 1000 Psi

2

O: 700 Psi

N

2

4.4.14.2 Close the cylinder valve and remove the cylinder from the yoke.

4.4.14.3 For any gas, the pressure should not drop more than 50 Psi in two

minutes.

4.4.15 Re-install the cylinder in the yoke.

4.4.16 Place the plexiglass cover over the gauges and flow tubes, and ensure that

the cover is fitted properly over the flow control valves.

NM MRI

4.4.17 Place the knob guard over the flow control valves and install its two

retaining screws.

4.4.18 Install the oxygen flow control knob and tighten its setscrews. If the knobs

are installed properly, their labels will be straight when the knobs are

against their clockwise stops.

4.4.19 Replace the angled plate at the top of the plexiglass cover and secure it with

the hardware that was previously removed.

4.4.20 Replace the rear cover and its retaining screws.

4.4.21 Reinstall the table top and tighten its retaining screws.

4.4.22 Connect the pipeline hoses.

4.4.23 Carefully inspect the machine to verify that no loose screws, washers, or

tools are left on or in any part of the machine.

4.4.24 Perform the PMS Procedure given in Section 6.

4-14

Page 51

RETURN TO THIS MANUAL'S TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM MRI

REPLACEMENT PROCEDURES (continued)

4.5 Flowmeters

The flowmeter tubes are held by compression in gaskets at the top and bottom of each

tube. Each upper gasket is seated in an adjustable retainer that allows removal of the

tube as shown in Figure 4-5. Access to the flow tubes requires removal of the

plexiglass front cover.

4.5.1 Disconnect all pipeline hoses and set the System Power switch to ON.

4.5.2 Close all cylinder valves except the O

valve.

2

4.5.3 Set the oxygen flow to 5 liters per min.

4.5.4 Open the other gas flow control valves to drain pressure from the system.

4.5.5 Close the O

cylinder valve, and close the flow control valves. Press the O2

2

Flush valve to drain oxygen pressure from the system.

4.5.6 Set the System Power switch to

STANDBY.

4.5.7 Loosen the screws holding the table top to the machine and lift out the table

top.

4.5.8 Remove the screws holding the angled plate at the top of the flowmeter

shield, and remove the plate.