Page 1

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTS

NM2BANDNM3NETWORKHARDWARE

UPGRADEWITHADJUSTABLEDISPLAYARM

ANDDATAGRIP

INSTALLATIONPROCEDURE

CAUTION: UseproperESDcontrol

during all removal and

installationprocedures.

1. TurntheSystemPowerswitchto

STANDBYandremoveACpower

fromthemachine.

2. Disableallcircuitbreakersby

pullingouteachbuttonwithaknife

orsharpobject.

3. UnplugtheORDMACpowercord

fromtheACconveniencereceptacle

attherearofthemachine.

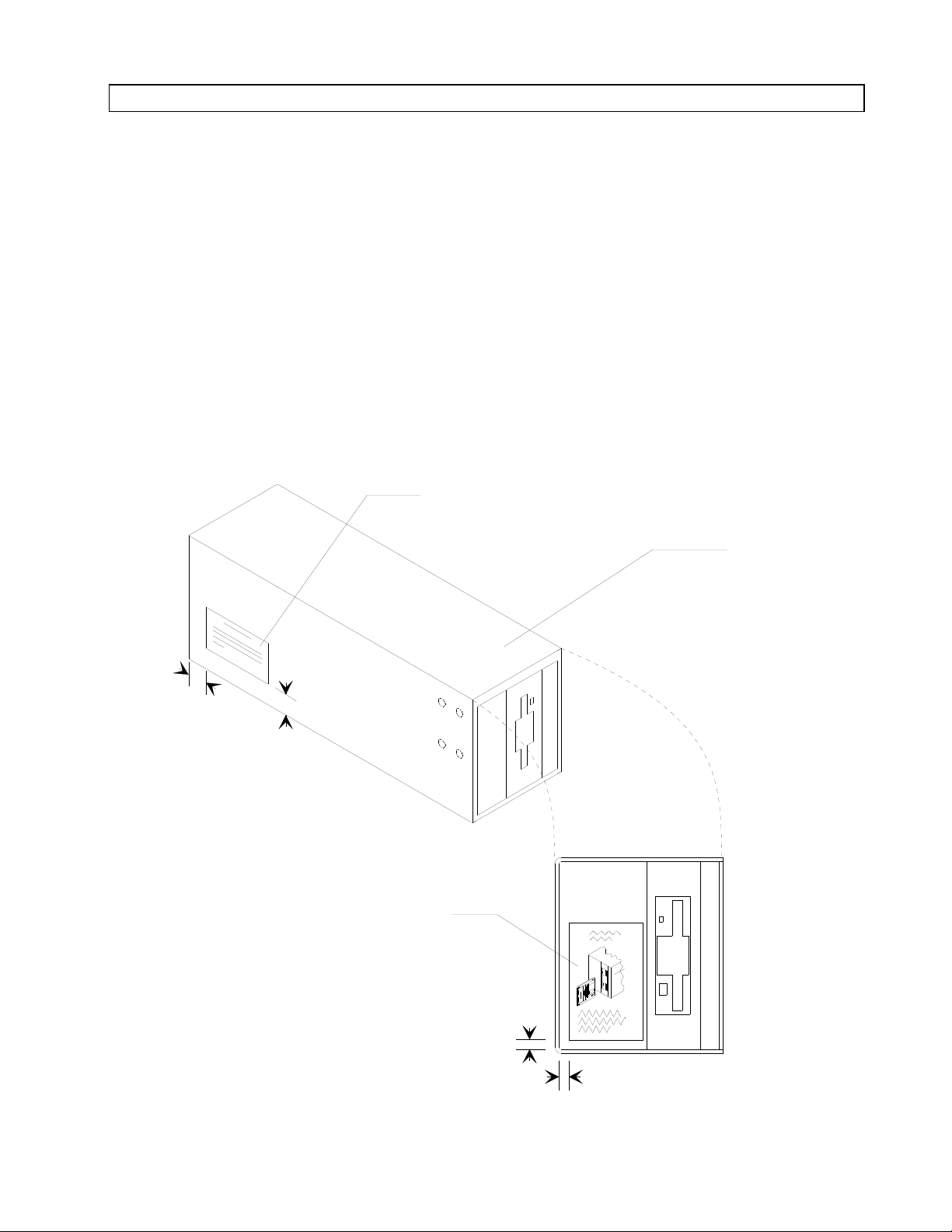

RefertoFigure1forSteps4thru6

4. UnplugtheACpowercordfromthe

rearoftheORDMCPUassembly.

5. DisconnecttheVitalinkdatacable,

keyboardcableandprintercable(if

applicable)fromtheirportsonthe

rearpaneloftheCPU.

CAUTION: Donotplugorunplugthe

remotedisplaycablewith

powerapplied.

6. Disconnecttheremotedisplaycable

fromitsportontherearpanelof

theCPU.

7. RemovetheCPUretainerscrew

andlockwasherfromtheunderside

oftheCPUhousingasshownin

Figure2.

8. RemovetheCPUassemblyfromthe

housingbygentlyslidingitout

fromtherear.

1

Page 2

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

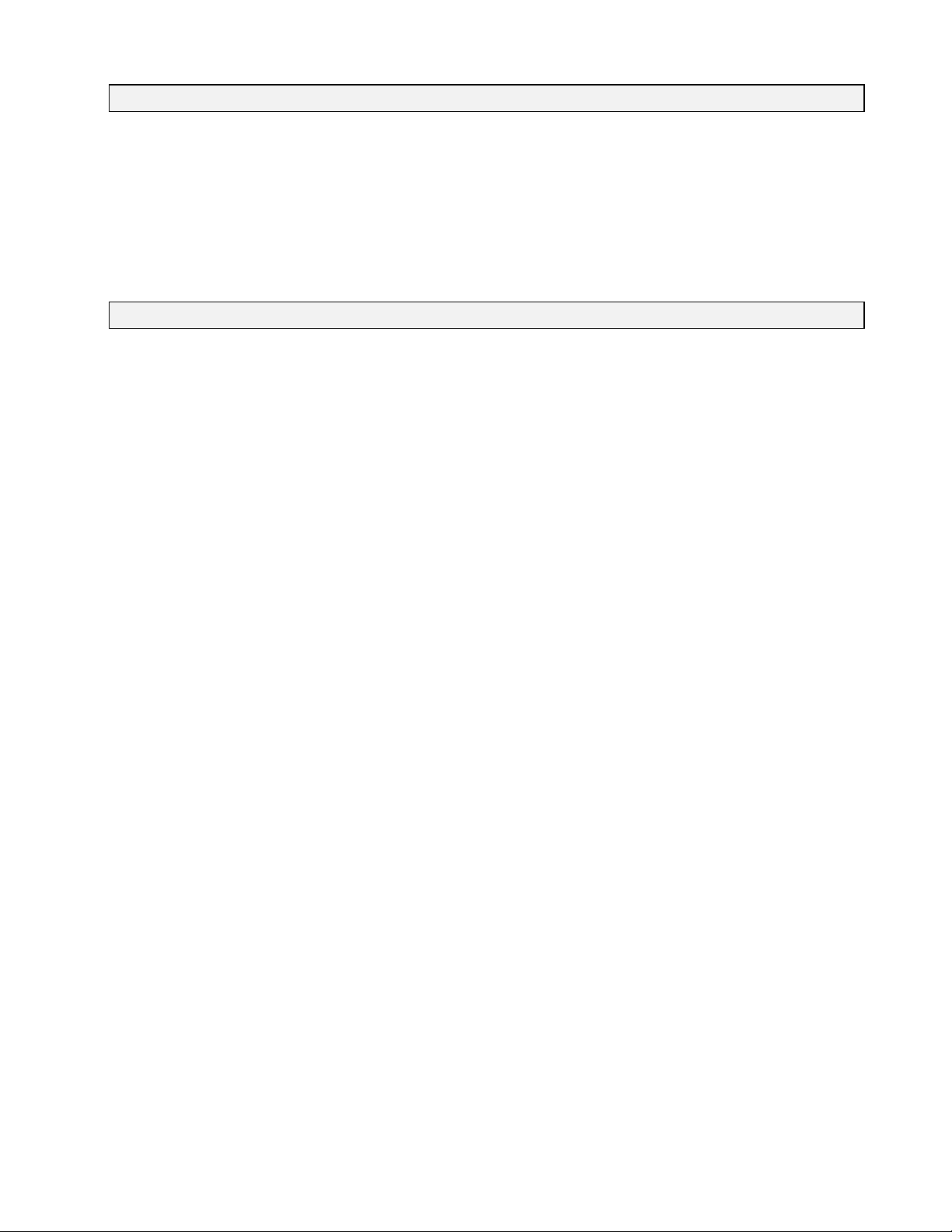

PRINTER

PORT

VITALINK

PORT

REMOTE

DISPLAY

PORT

POWER ON

LIGHT

RESET

BUTTON

AC POWER

CONNECTOR

CPU ASSEMBLY

REAR PANEL

SP13201

HOUSING

KEYBOARD

CONNECTOR

Figure 1: 286 CPU REAR PANEL CONNECTIONS

CPU ASSEMBLY

CPU HOUSING

(BOOM ARM

MOUNT NOT SHOWN)

LOCK WASHER

RETAINER

SCREW

SP13202

Figure 2: ORDM CPU HOUSING

2

Page 3

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

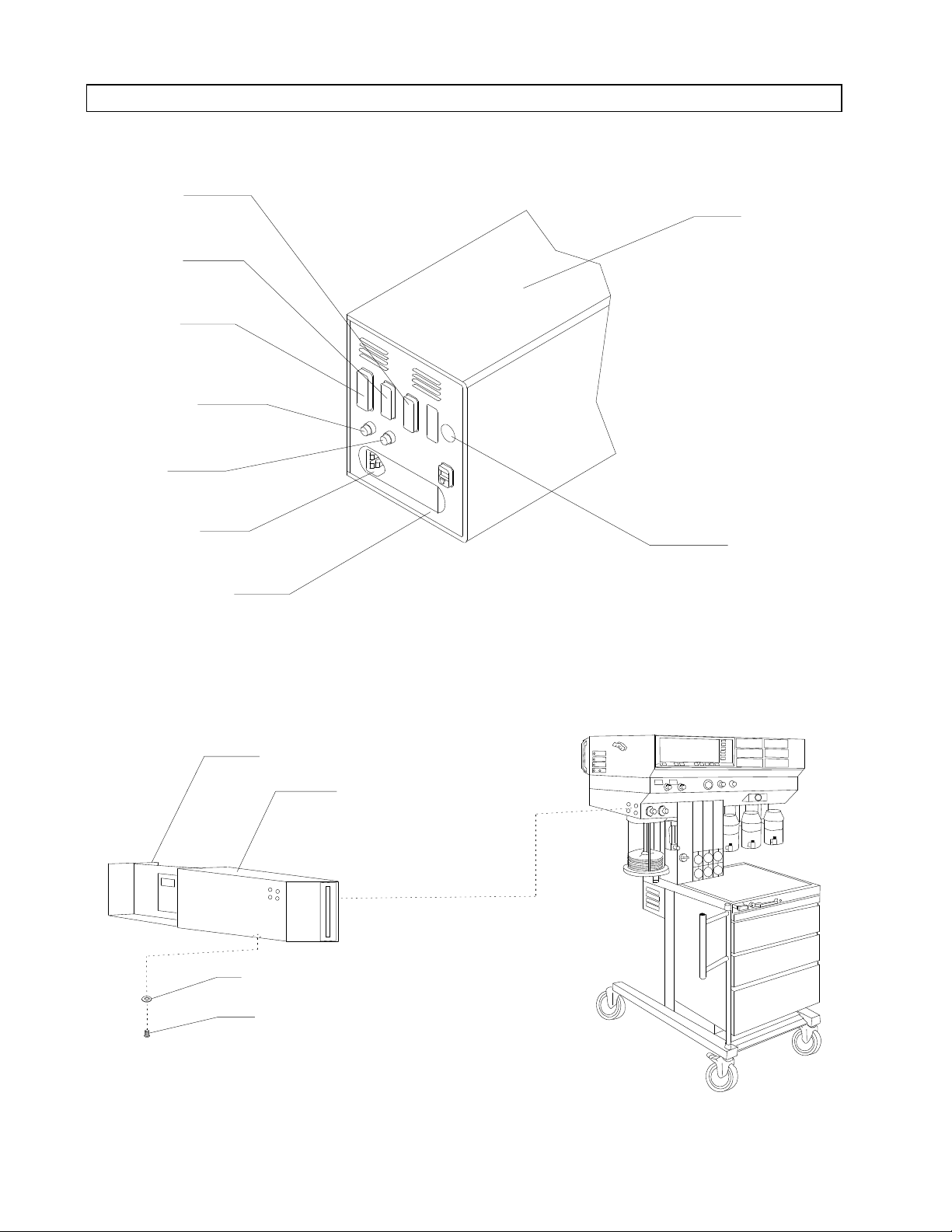

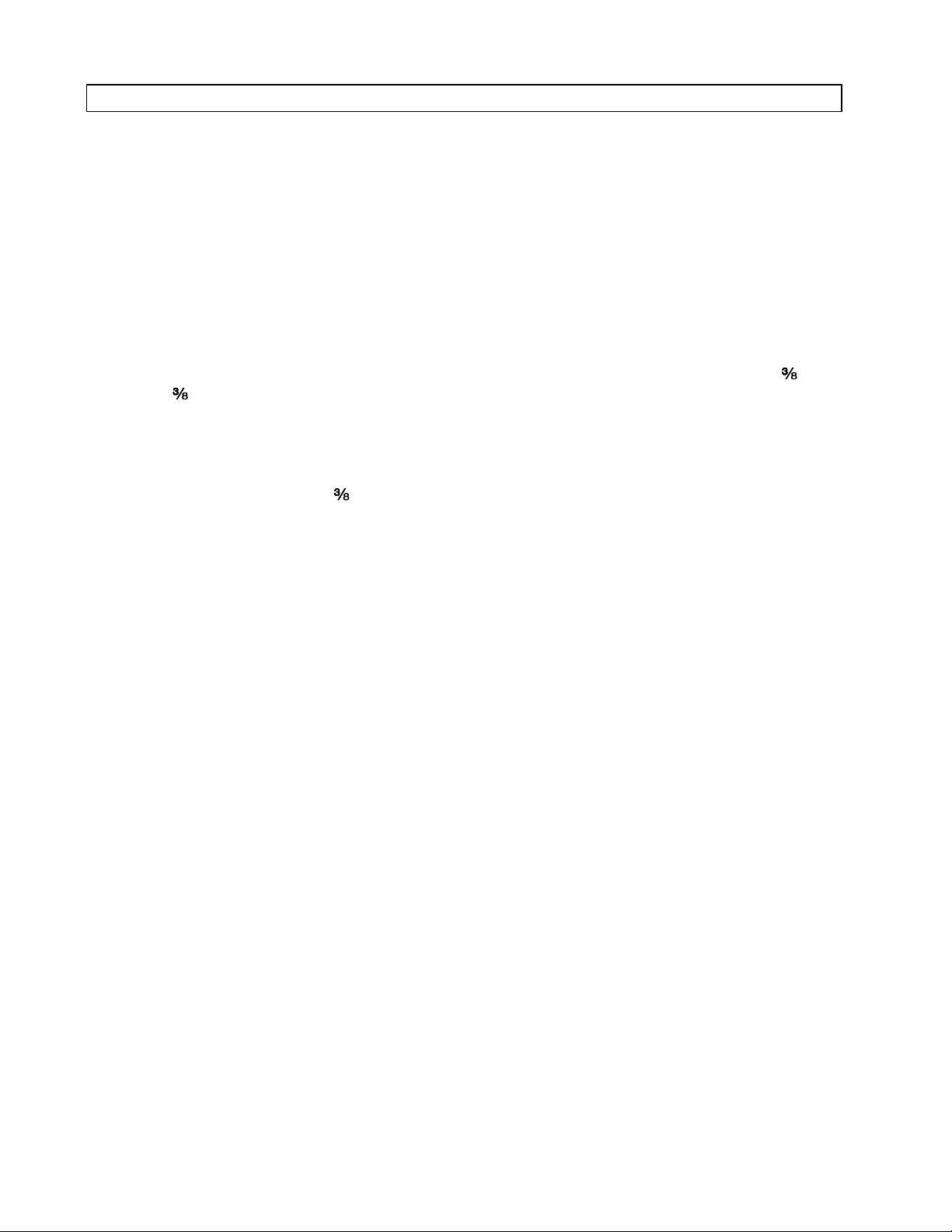

9. If the machine is equipped with a

manual sphygmomanometer,

disconnect the gauge line from the

interface panel. Unscrew the

threaded mounting ring from the

gauge mount and set the gauge

aside.

PATIENT CABLE

BOOM ARM

10. Loosen the clamp screw in the

boom arm mounting block, and

remove the patient cable (upper)

boom arm. See Figure 3.

SP13203

BOOM ARM

MOUNTING

BLOCK

CLAMP SCREW

MANUAL

SPHYGMOMANOMETER

GAUGE

Figure 3: SPHYGMOMANOMETER GAUGE AND UPPER BOOM ARM REMOVAL

3

Page 4

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

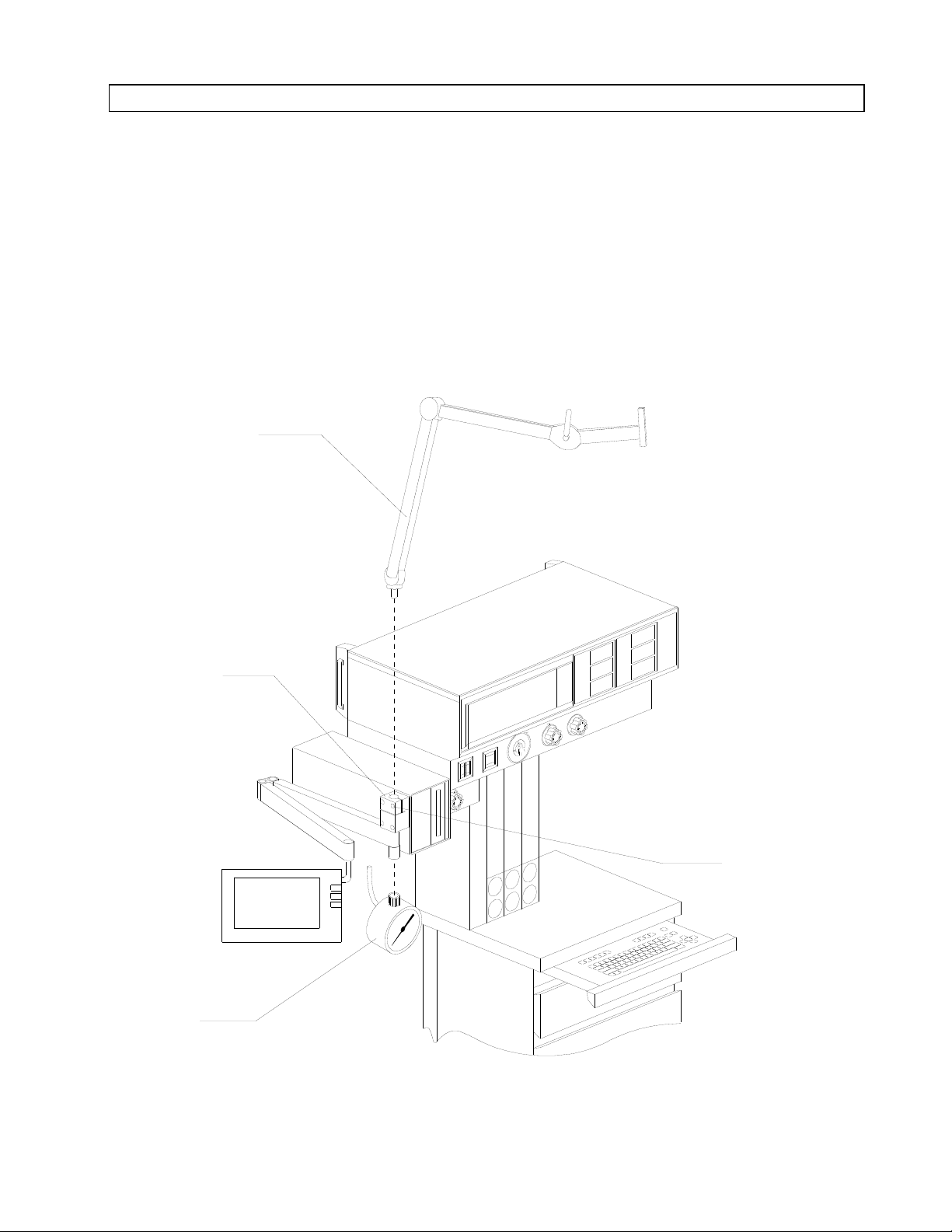

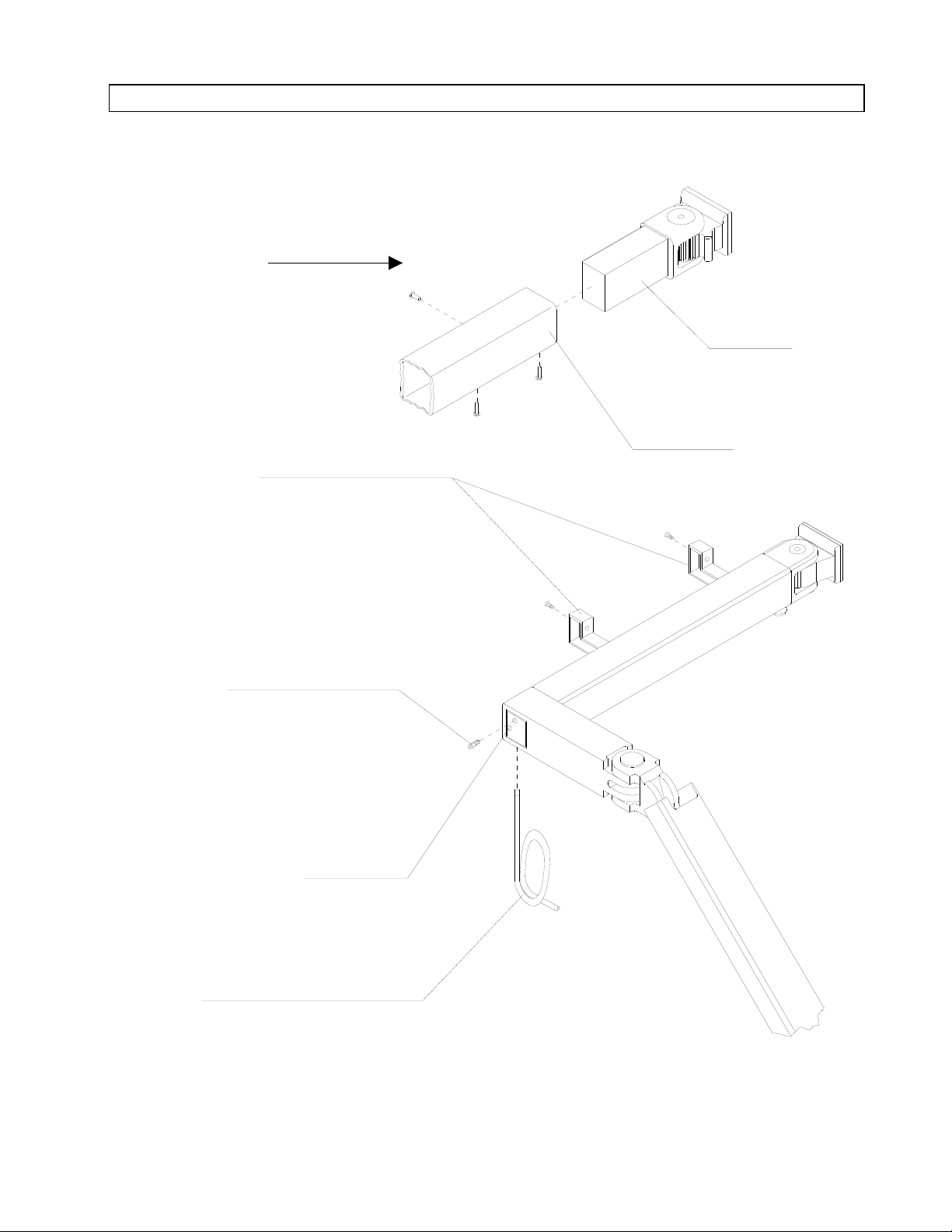

11. Remove the screws securing the

cable clamps to the underside of the

boom arm. Remove the remote

display cable from the clamps.

12. Remove the plastic cap at the end

of the boom arm to expose the

remotedisplaymountingscrew. See

Figure 4.

MOUNTING BLOCK

CLAMP SCREW

1/4-20 x 11/4 in.

MOUNTING BLOCK

SCREWS (3X)

1/4-20 x 1in.

13. While holding the remote display

assembly, loosen the mounting

screw until the assembly separates

from the boom arm. The display

shouldnow be completely separated

from the boom arm.

14. Remove the boom arm assembly

from the ORDM CPU housing by

removing the three boom arm

mounting block screws.

CPU HOUSING

CAP

(DISPLAY

MOUNTING SCREW

RECESS)

SP13204

Figure 4: DISPLAY AND EXISTING BOOM ARM REMOVAL

4

BOOM ARM

MOUNTING BLOCK

DELRIN SPACER

Page 5

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

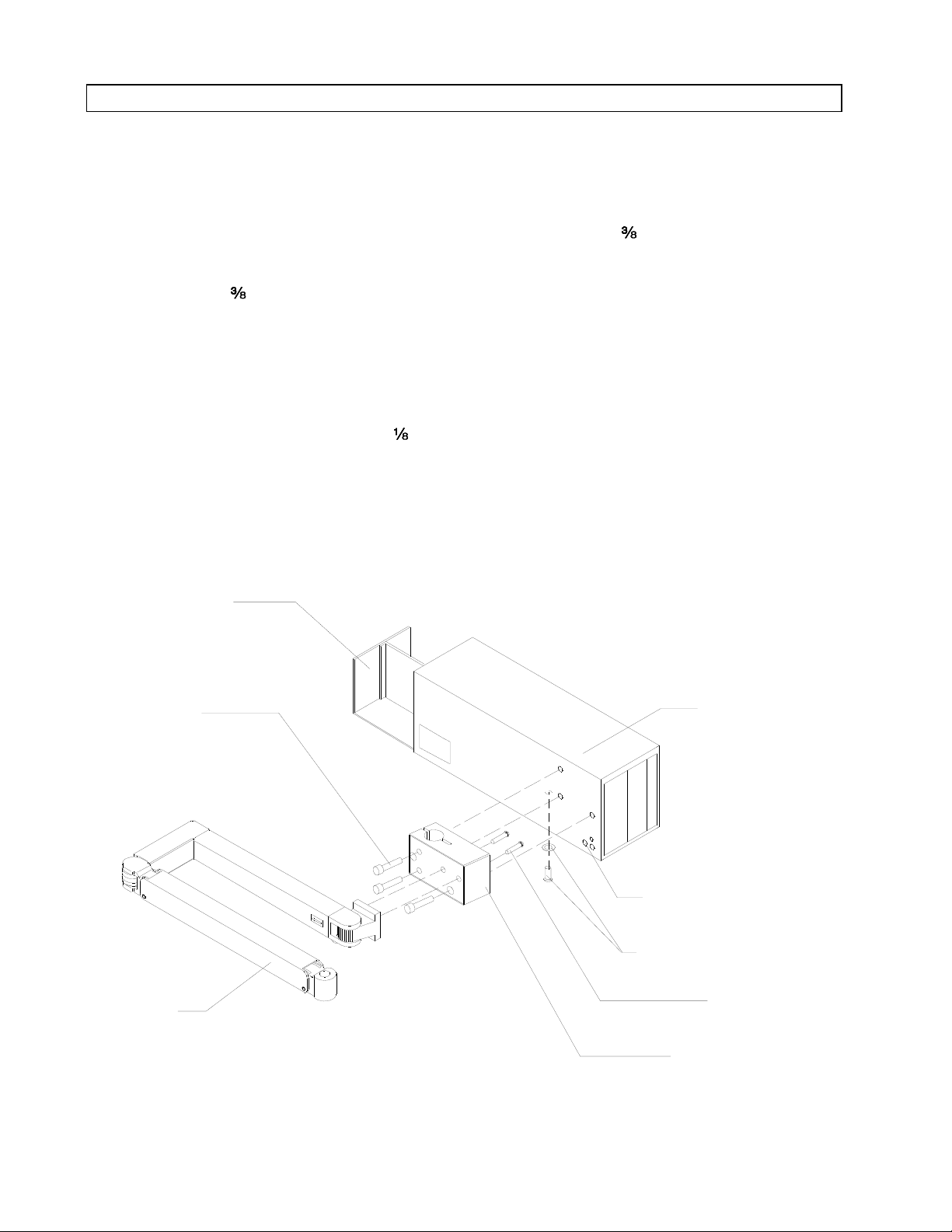

15. If the installation includes an

optional patient line boom arm,

remove the existing CPU housing

from the machine and install the

new CPU housing (P/N 4112875).

16. Carefully slide the new 386 CPU

assembly (P/N 4112432) into the

housing and ensure that the disk

drive is correctly aligned with the

front panel opening.

17. Reinstall the retainer screw and

lock washer that was removed in

Step 7.

CAUTION/ SALE

LABEL (P/N 4104294)

18. Apply the disk insertion label (P/N

4112339) to the front of the CPU

housing, positioned and oriented as

shown in Figure 5. Ensure that the

sticker area is clean, dry and free of

cleaning solution residue.

19. Apply the CAUTION/SALE label

(P/N 4104294) to the side of the

CPU housing as shown in Figure 5.

Ensure that the sticker area is

clean, dry and free of cleaning

solution residue.

CPU HOUSING

1/2 IN.

SP13205

1/2 IN.

DISK INSERTION

LABEL (P/N 4112239)

FRONT VIEW

OF CPU

1/4 IN.

1/4 IN.

Figure 5: PLACEMENT OF LABELS

5

Page 6

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

NOTE: Steps 21 thru 25 are

performed using the

hardware provided in the

packet supplied with the

adjustable remote arm.

Refer to Figure 6 for these

steps.

19A. If the joint assembly is not pre-

assembled to the display arm,

insert the joint assembly into the

arm and secure it with three 10-32

x in. button head socket screws

(P/N HW09005). See assembly

detail in Figure 6.

20. Install the patient IV line plastic

looms using a 6-32 x in. button

head socket screw (P/N HW09000)

to secure each loom. Apply a small

amount of Loctite #222 (purple) to

the threads of each screw before

installation. (An additional

mounting screw will be installed

through the bottom of each loom

when the Datagrip and display

cables are installed.)

If the patient IV line wire loom block was

pre-assembled to the arm, skip to Step 26.

21. If not already assembled, install a

10-32 x 1 in. socket head cap screw

(wire loom tension adjustment

screw) and 10-32 hex nut in the

wire loom block. Do not tighten the

screw.

Place the ¼ in. flat washer in the

recess in the wire loom block.

22. Insert the block into the arm and

secure it with two 6-32 x in.

button head socket screws through

the bottom of the arm. Apply a

small amount of Loctite #222

(purple) to the threads of each

screw before installation.

23. Insert the patient IV line wire loom

up into the display arm elbow. Turn

the wire loom as needed to align its

tapped hole with the access hole in

the end of the block.

24. Apply a small amount of Loctite

#222 (purple) to the threads of a 632 x ½ in. flat point set screw, and

thread the screw into the hole in

the wire loom until the loom can be

rotated 360° on its axis.

25. Tighten the wire loom tension

adjustment screw until the wire

loom has the desired tension.

6

Page 7

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

ASSEMBLY DETAIL

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

JOINT

ASSEMBLY

DISPLAY ARM

PATIENT IV LINE

PLASTIC LOOMS

SET SCREW

WIRE LOOM TENSION

ADJUSTMENT SCREW

PATIENT

IV LINE WIRE LOOM

SP13206

Figure 6: ASSEMBLING THE DISPLAY ARM HARDWARE

7

Page 8

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

NOTE: Follow Step 26A if the installation

is receiving an optional patient line boom

arm.

26. If the display arm was not preassembled to the boom arm block,

attach the display arm to the block

with two -24 x 1½ in. socket head

cap screws (P/N HW01101). See

Figure 7.

27. Position the display arm and block

assembly at the left side of the CPU

housing and attach the block to the

housing with three ¼-20 x 1 in.

socket head cap screws (P/N

HW01038).

CPU ASSEMBLY

If the machine is equipped with a

manualsphygmomanometer,attach

the gauge mount to the lower front

corner of the CPU housing with a

¼-20 x 1 in. button head socket

screw.

SP13207

BOOM ARM

BLOCK MOUNTING

SCREWS (3X)

DISPLAY

ARM

Figure 7: DISPLAY ARM INSTALLATION ON OUTBOARD ORDM

CPU HOUSING

THREADED HOLE FOR

CABLE CLAMP SCREW

CPU RETAINER SCREW

AND LOCKWASHER

DISPLAY ARM

MOUNTING SCREWS (2X)

BOOM ARM BLOCK

8

Page 9

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

26A. If the display arm was not pre-

assembled to the boom arm block,

attach the display arm to the block

with two -24 x 1½ in. socket head

cap screws. See Figure 7A.

27A Position the display arm and block

assembly at the left side of the CPU

housing and attach the block to the

housing with three ¼-20 x 1 in.

socket head cap screws.

CPU ASSEMBLY

If the machine is equipped with a

manualsphygmomanometer,attach

the gauge mount to the lower front

corner of the CPU housing with a

¼-20 x 1 in. button head socket

screw.

BOOM ARM

BLOCK MOUNTING

SCREWS (3X)

DISPLAY

ARM

SP13207A

PATIENT LINE

BOOM ARM

CPU HOUSING

THREADED HOLE FOR

CABLE CLAMP SCREW

CPU RETAINER SCREW

AND LOCKWASHER

DISPLAY ARM

MOUNTING SCREWS (2X)

BOOM ARM BLOCK

Figure 7A: DISPLAY ARM INSTALLATION ON OUTBOARD ORDM WITH OPTIONAL

PATIENT LINE BOOM ARM

9

Page 10

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

28. Remove the six screws holding the

rear cover of the remote display and

separate the rear cover from the

remote display. Use caution when

separating the cover so that cables

are not pulled from the display.

29. Loosen the remote display clamp

screws. See Figure 8. Remove the

outer retaining ring from the

remote display mounting rod, and

withdraw the rod approx. 3 in. until

the end of the rod clears the first

clamp. Remove the inner retaining

ring and fully withdraw the display

mounting rod.

30. Examine the mounting rod hole in

the remote display cover. If the hole

does not have a notch as shown in

Figure 9, carefully cut or file a in.

wide notch in the cover that will

clear the stop pins on the new

Datagrip display mounting rod.

31. Replace any cracked display

mounting clamps (P/N 4112685-

001) at this time with the extra

clamps provided in the kit.

32. Reinstall the rear cover on the

remote display with the screws that

were previously removed. (Install

the two shorter screws at the

bottom.)

EXISTING

DISPLAY

MOUNTING

ROD (REMOVE)

NOTCH

SP13208

MOUNTING BLOCK (2X)

(P/N 112685-001)

PS1

PS2

J1

J2

J1

J2

CUTAWAY - REAR VIEW OF REMOTE DISPLAY

J3

INNER RETAINING

RING (REMOVE)

OUTER RETAINING

RING (REMOVE)

REAR

COVER

SCREWS (4X)

CLAMP

SCREWS

REAR COVER

SCREWS (2X)

Figure 8: REMOTE DISPLAY DETAILS

10

Page 11

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

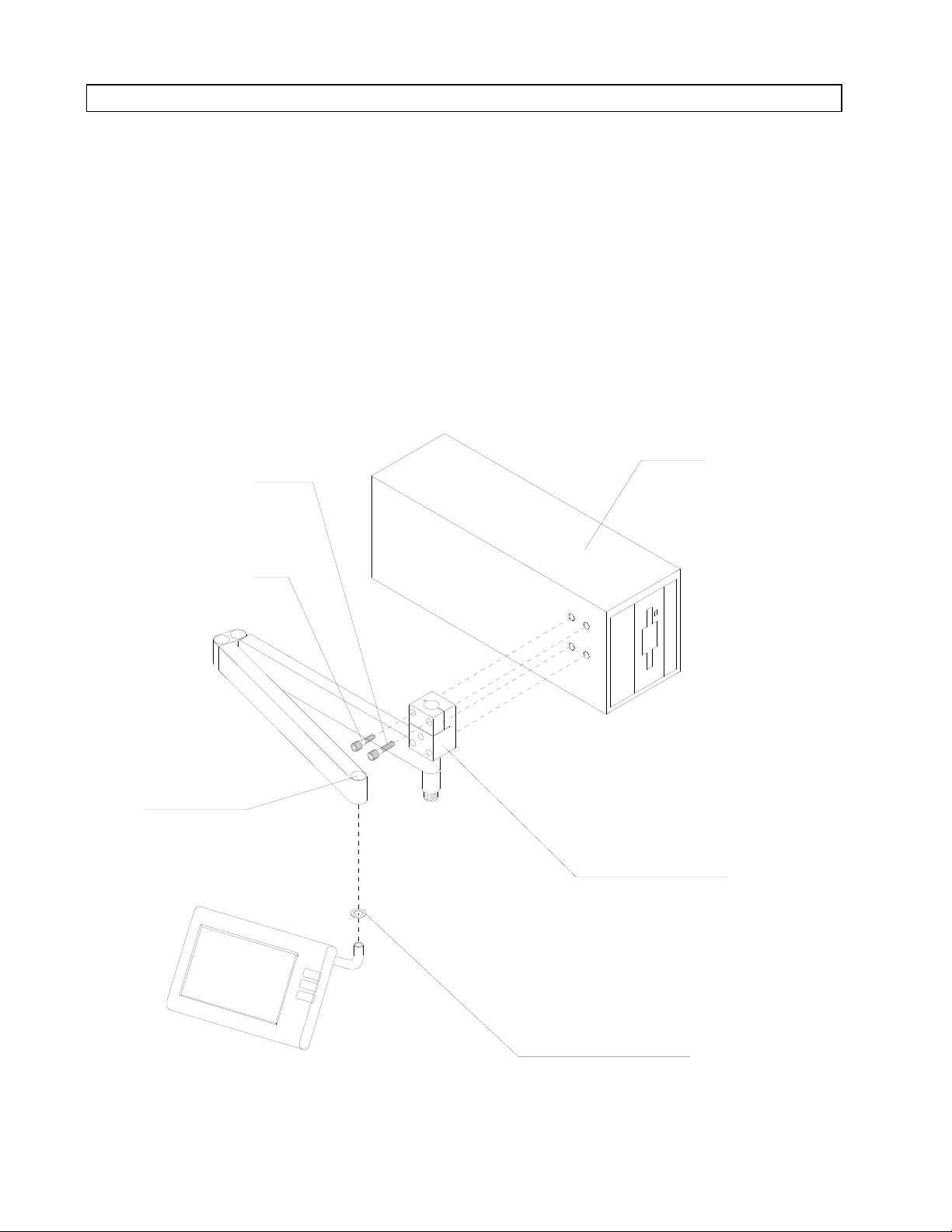

33. Install the Datagrip assembly (P/N

4111907) at the outboard end of the

display arm. See Figure 9. Be sure

the delrin spacer is in place

between the assembly and the

display arm. Tighten the mounting

screw to a torque of 4 foot pounds.

Reinstall the plastic cap at the end

of the arm.

PATIENT IV

LOOM

DETAIL:

CABLES

34. Slide the remote display onto the

Datagrip display mounting rod.

Orient the display with its face

toward the floor so that the stop

pins on the rod will pass through

the slots in the mounting clamps,

and continue sliding the display

into position.

CABLE CLAMP

CAP

(P/N 4111184)

CABLE CLAMPS

(APPROXIMATE

LOCATION)

SP13209

SPACER

(P/N 4110792-064)

REMOTE

DISPLAY

MOUNTING

SCREW

(P/N 4111199-005)

LOCKWASHER

(P/N HW65010)

BEARING

(P/N 4111181)

SPACER

(P/N 4117092-064)

DELRIN SPACER

(P/N 4110792-044)

DATAGRIP

ASSEMBLY

Figure 9: REMOTE DISPLAY/DATAGRIP INSTALLATION

11

Page 12

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

35. Tighten the mounting clamps

(accessible through clearance holes

in the rear cover) until the remote

display has the desired amount of

friction on the mounting rod.

36. Attach the Datagrip and remote

display cables to the underside of

the arm using three in. plastic

cable clamps and three 6-32 x in.

button head screws as shown in

Figure 9. (The clamps and screws

are included in the hardware kit

supplied with the adjustable arm.)

Slide the cables under the patient

IV line plastic looms (see detail in

Figure 9) and install a 6-32 x in.

button head socket screw through

each loom into the display arm.

37. Attach the cables to the adapter

plate using a in. plastic cable

clamp (P/N 4112300) and 6-32 x

in. button head socket screw (P/N

HW09000). (Ref. Figure 7.)

For installations with a patient line

boom arm, install the cable clamp

screw in the threaded hole in the

CPU housing ref. Figure 7A).

38. Connect the Datagrip and remote

display cables to their ports on the

rear panel of the ORDM CPU

panel. See Figure 10 for port

location and labeling.

39. Pull the release lever on the display

arm and verify that the arm has

full range of motion with no binding

caused by the cables. Position the

cables in their clamps as needed,

and tighten the clamp screws. Coil

excess cable in the bottom loops of

the plastic IV looms.

40. If the machine is equipped with a

manual sphygmomanometer, screw

the threaded mounting ring of the

gauge onto the gauge mount.

REAR VIEW OF

DATAGRIP PORT

REMOTE DISPLAY

PORT

POWER "ON"

INDICATOR

ORDM ON-OFF

SWITCH

AC POWER CONNECTOR

386 ORDM CPU

USE ONLY WITH.ER.FUSES.

250V FUSES.H.ER.FUSES.

DISCONNECT POWER.FUSES.

BEFORE REPLACING FUSES.

100V

120V

220V

240V

Figure 10: 386 ORDM CPU REAR PANEL CONNECTIONS

PRINTER PORT

VITALINK PORT

KEYBOARD

CONNECTOR

NETWORK

CONNECTOR

SP13210

12

Page 13

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

41. Loosen the friction adjustment

screw on the underside of the

display arm (no more than one

turn). (It may be necessary to raise

or lower the arm to align the screw

with the access hole.) See Figure

11.

42. Raise and release the arm, and

verify that it returns to an

approximately horizontal position.

Lower and release the arm, and

verify that it returns to an

approximately horizontal position.

Contact the NAD Service

Department if the display arm fails

to return to a near-horizontal

position.

43. Slowly re-tighten the friction

adjustment screw until the arm

stays in position when raised or

lowered. (Do not over-tighten the

screw as this will cause the arm to

loose tension in the raised position.)

SP13211

Figure 11: DISPLAY ARM ADJUSTMENT

FRICTION ADJUSTMENT

SCREW ON UNDERSIDE

OF DISPLAY ARM

(USE 7/64 in. HEX WRENCH)

13

Page 14

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

44. On the rear panel of the ORDM

CPU, check the voltage indicator

window on the AC power connector

assembly and ensure that the unit

is configured for the mains voltage

on which it is to operate. For 100 or

120 volt operation, the index pin

should appear in the 120 V window;

for 220 or 240 volt operation, the

index pin should appear in the 220

V window. See Figure 12.

AC POWER

CONNECTOR

ASSEMBLY

45. If it is necessary to change the

voltageconfiguration, insert asmall

screwdriver at the location shown

in the illustration and pry out the

fuse holder.

46. Remove the jumper card by

grasping it with long nose pliers

and pulling it straight out.

USE ONLY WITH

250V FUSES

DISCONNECT POWER

BEFORE REPLACING FUSES

100V

120V

220V

240V

VOLTAGE

INDICATOR

WINDOWS

PRY OUT

KEY

100/120V

JUMPER

CARD

ORIENTATION

220/240V

INDEX PIN

SP13212

Figure 12: MAINS VOLTAGE SELECTION

14

Page 15

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

47. Rotate the jumper card so that the

arrow corresponding to the desired

mains voltage (120 for 110 V or 120

V operation, 220 for 220 V or 240 V

operation) is pointing toward the

inside of the AC power connector

assembly. Orient the nylon key so

that it is seated in the notch on the

outside edge of the card with its

index pin facing outward as shown

in Figure 12.

48. Slide the jumper card into the

tracks on the AC power connector

assembly (ensure that the card is

oriented with its markings toward

the left) and press it firmly into its

socket.

49. Ensure that there are two 2.5 A,

250 V fuses in the fuse holder.

50. Install the fuse holder in the AC

power connector assembly. If the

jumper card has been installed

correctly, the index pin on the

nylon key will be visible in the

desired voltage indicator window.

51. Connect the keyboard, Vitalink

data cable and printer cable (if

applicable) to their ports on the

rear of the ORDM CPU panel.

Refer to Figure 10 for port location

and labeling.

52. Plug the AC power cord into the

rear panel of the CPU.

53. Plug the other end of the AC power

cord into the closest AC

convenience receptacle outlet.

54. Plug the system AC power cord into

a live AC receptacle and enable all

circuit breakers.

55. Turn the System Power switch to

ON.

56. Set the ORDM On-Off switch

(located on the rear ORDM CPU

panel) to the ON position.

57. Verify that the green Power "On"

indicator on the rear panel is

lighted, and the self-diagnostics

screen is displayed. Wait until the

ORDM monitor screen is displayed

before proceeding further. If the

screen gets locked into the "Setting

Time to Host" mode, simultaneously

press the CONTROL and D keys on

the keyboard. This will allow the

ORDM to advance to the Monitor

Screen.

15

Page 16

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

INSTALLATION PROCEDURE (continued)

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

58. Pull out the keyboard and verify

that the EDIT and START/STOP

RECORD keycaps are installed as

shown in Figure 13.

If either of these keycaps are not

present, remove the keyboard cover

and carefully lift off the existing

keycap(s). Press the new keycap(s)

into place. Clean the keyboard

faceplate and install a new

keyboard cover (P/N 4111314).

PATIENT

DRUGS

MONITOR

DATA

1234567890-

QWERT YUIO P

EDIT

CONTROL

SHIFT

ALT

EVENTS NUMERIC GRAPHIC

ASDFGHJKL

ZXCVBNM

CAPS

LOCK

<

,

EDIT KEYCAP

(P/N S010184)

PRINT

RECORD

:

;

>

.

START/

STOP

RECORD

+_)(*&^%$#@!

=

{

[

"

'

?

/

|

\

}

]

SHIFT

START/STOP RECORD

KEYCAP

SELECT

ENTRY

DELETE

ENTRY

BKSPESC

ENTER

STAT

EVENT

ARTIFACTCONFIG

STAT

DRUG

PAGE

(P/N S010183)

SP13213

Figure 13: KEYBOARD LAYOUT WITH CORRECT KEYCAPS

16

Page 17

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 3

1.A Configure the Narkomed 3 serial

port connected to the O.R. Data

Manager (use Port A, B, C or D)

(refer to Narkomed 3 Operator’s

Manual— MONITORING

SYSTEM, Configure Menu)as

follows:

BAUD RATE : 9600

DATA BITS : 8

PARITY : NONE

STOP BITS : 1

PROTOCOL : 03

2.A Press the CONFIG key on the O.R.

Data Manager keyboard to enter the

System Configuration screen on the

remote display. You can also use

the Datagrip to select CONFIG from

the O.R. Data Manager screen

menu.

3.A When the System Configuration

screen is displayed, the cursor will

appear in the first row as shown in

Figure 14A. Press the S key to

select Service functions, or highlight

the choice and press the ENTER

key or the Datagrip trigger.

Figure 14A: SYSTEM CONFIGURATION SCREEN

17

Page 18

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 3 (continued)

4.A Since the Service Functions screen

is intended for NAD service

personnel only, a prompt for the

service password will appear. as

shown in Figure 15A.

Type in the password and press the

ENTER key or the Datagrip trigger.

Figure 15A: PASSWORD SCREEN

18

Page 19

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 3 (continued)

5.A When the NAD Service Functions

screen is displayed, the screen will

display the current

LOCAL/NETWORK configuration

and the current baud rate.

To configure the O.R. Data Manager

as either LOCAL (floppy disk) or

NETWORK, position the cursor on

the Local/Network cell and press the

SELECT ENTRY key or the Datagrip

trigger to bring up a menu that

contains valid choices for this

configuration.

6.A Select the setting by highlighting

the desired choice and pressing the

ENTER key or the Datagrip trigger.

Figure 16A: SERVICE FUNCTIONS SCREEN

19

Page 20

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 3 (continued)

7.A To configure the serial baud rate,

position the cursor on the Serial

Port Baud Rate cell, and press the

SELECT ENTRY key or the Datagrip

trigger to bring up a menu that

contains valid choices for the baud

rate.

8.A Set the serial port baud rate to

9600 by highlighting the choice and

pressing the ENTER key or the

Datagrip trigger.

9.A Press the CONFIG key to return to

the System Configuration screen.

10.A Press the MONITOR key to return

to the monitor screen.

Figure 17A: SERVICE FUNCTIONS SCREEN, BAUD SELECTION

20

Page 21

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 2B

1.B Configure the Narkomed 2B serial

port connected to the O.R. Data

Manager (use Port A only) (refer to

Narkomed 2B Operator’s Manual—

MONITORING SYSTEM, Configure

Menu) as follows:

BAUD RATE : 1200

DATA BITS : 8

PARITY : NONE

STOP BITS : 1

PROTOCOL : VITALINK

2.B Press the CONFIG key on the O.R.

Data Manager keyboard to enter the

System Configuration screen on the

remote display. You can also use

the Datagrip to select CONFIG from

the O.R. Data Manager screen

menu.

3.B When the System Configuration

screen is displayed, the cursor will

appear in the first row as shown in

Figure 14B. Press the S key to

select Service functions, or highlight

the choice and press the ENTER

key or the Datagrip trigger.

Figure 14B: SYSTEM CONFIGURATION SCREEN

21

Page 22

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 2B (continued)

4.B Since the Service Functions screen

is intended for NAD service

personnel only, a prompt for the

service password will appear. as

shown in Figure 15B.

Type in the password and press the

ENTER key or the Datagrip trigger.

Figure 15B: PASSWORD SCREEN

22

Page 23

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 2B (continued)

5.B When the NAD Service Functions

screen is displayed, the screen will

display the current

LOCAL/NETWORK configuration

and the current baud rate.

To configure the O.R. Data Manager

as either LOCAL (floppy disk) or

NETWORK, position the cursor on

the Local/Network cell and press the

SELECT ENTRY key or the Datagrip

trigger to bring up a menu that

contains valid choices for this

configuration.

6.B Select the setting by highlighting

the desired choice and pressing the

ENTER key or the Datagrip trigger.

Figure 16B: SERVICE FUNCTIONS SCREEN

23

Page 24

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

CONFIGURING THE SERIAL I/O PORT TO A NARKOMED 2B (continued)

7.B To configure the serial baud rate,

position the cursor on the Serial

Port Baud Rate cell, and press the

SELECT ENTRY key or the Datagrip

trigger to bring up a menu that

contains valid choices for the baud

rate.

8.B Set the serial port baud rate to

1200 by highlighting the choice and

pressing the ENTER key or the

Datagrip trigger.

9.B Press the CONFIG key to return to

the System Configuration screen.

10.B Press the MONITOR key to return

to the monitor screen.

Figure 17B: SERVICE FUNCTIONS SCREEN, BAUD SELECTION

24

Page 25

ORDM TEST

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

1. On the ORDM keyboard, press and

hold the ALT key, and press the V

key.

The window shown in Figure 18

will appear at the center of the

remote display for approximately

three seconds. The current software

version number shown on the

remote display should agree with

that marked on the program disk or

its accompanying documentation.

2. Verify the operation of the Datagrip

by pulling the trigger and observing

the menu screen. Use the

thumbwheel to move the cursor in

the menu screen.

3. Ensure that an updated copy of the

ORDM Operator’s Manual (P/N

4111342-006 or later) accompanies

the machine.

4. Perform a complete PMS procedure

on the machine.

ORDM S/W Ver x.x (xxxxH)

Figure 18: SOFTWARE VERSION WINDOW

25

Page 26

NORTH

AMERICAN

DRÄGER

Technical Service Department

3122 Commerce Drive

Telford, PA 18969

(215) 721-5402

(800) 543-5047

(215) 723-5935 Fax

RETURN TO SERVICE PROCEDURE TABLE OF CONTENTS

RETURN TO CD-ROM TABLE OF CONTENTSRETURN TO CD-ROM TABLE OF CONTENTS

®

Quality Service for Life

Part Number: SP00132

Rev: E

Date: February 15, 1995

© 1995 N.A.D., Inc.

Loading...

Loading...