Page 1

Nortel CallPilot

1002rp Server Hardware Installation

Clicking on a PDF hyperlink takes you to the appropriate page. If necessary,

scroll up or down the page to see the beginning of the referenced section.

NN44200-300

.

ATTENTION

Page 2

Document status: Standard

Document version: 01.01

Document date: 23 February 2007

Copyright © 2007, Nortel Networks

All Rights Reserved.

Sourced in Canada

The information in this document is subject to change without notice. The statements, configurations, technical

data, and recommendations in this document are believed to be accurate and reliable, but are presented without

express or implied warranty. Users must take full responsibility for their applications of any products specified in this

document. The information in this document is proprietary to Nortel Networks.

The process of transmitting data and call messaging between the CallPilot server and the switch or system is

proprietary to Nortel Networks. Any other use of the data and the transmission process is a violation of the user

license unless specifically authorized in writing by Nortel Networks prior to such use. Violations of the license by

alternative usage of any portion of this process or the related hardware constitutes grounds for an immediate

termination of the license and Nortel Networks reserves the right to seek all allowable remedies for such breach.

Trademarks

*Nortel, the Nortel logo, the Globemark, and Unified Networks, BNR, CallPilot, DMS, DMS-100, DMS-250,

DMS-MTX, DMS-SCP, DPN, Dualmode, Helmsman, IVR, MAP, Meridian, Meridian 1, Meridian Link, Meridian

Mail, Norstar, SL-1, SL-100, Communication Server 1000, Supernode, Contact Center, Telesis, and Unity are

trademarks of Nortel Networks.

3COM is a trademark of 3Com Corporation.

ADOBE is a trademark of Adobe Systems Incorporated.

ATLAS is a trademark of Quantum Corporation.

BLACKBERRY is a trademark of Research in Motion Limited.

CRYSTAL REPORTS is a trademark of Seagate Software Inc.

EUDORA is a trademark of Qualcomm.

eTrust and InoculateIT are trademarks of Computer Associates Think Inc.

DIRECTX, EXCHANGE.NET, FRONTPAGE, INTERNET EXPLORER, LINKEXCHANGE, MICROSOFT,

MICROSOFT EXCHANGE SERVER, MS-DOS, NETMEETING, OUTLOOK, POWERPOINT, VISUAL STUDIO,

WINDOWS, WINDOWS MEDIA, and WINDOWS NT are trademarks of Microsoft Corporation.

GROUPWISE and NOVELL are trademarks of Novell Inc.

LOGITECH is a trademark of Logitech, Inc.

MCAFEE and NETSHIELD are trademarks of McAfee Associates, Inc.

MYLEX is a trademark of Mylex Corporation.

NETSCAPE COMMUNICATOR is a trademark of Netscape Communications Corporation.

NOTES is a trademark of Lotus Development Corporation.

NORTON ANTIVIRUS and PCANYWHERE are trademarks of Symantec Corporation.

QUICKTIME is a trademark of Apple Computer, In.

Page 3

RADISYS is a trademark of Radisys Corporation.

SLR4, SLR5, and TANDBERG are trademarks of Tandberg Data ASA.

SYBASE is a trademark of Sybase, Inc.

TEAC is a trademark of TEAC Corporation

US ROBOTICS, the US ROBOTICS logo, and SPORTSTER are trademarks of US Robotics.

WINZIP is a trademark of Nico Mark Computing, Inc.

XEON is a trademark of Intel, Inc.

All other trademarks and registered trademarks are the property of their respective owners.

Information for Japan

Japan Denan statement

The following applies to server models 1005r, 703t, and 1002rp:

Japan VCCI statement

The following applies to server models 1005r, 703t, 201i, and 1002rp:

This is a Class A product based on the standard of the Voluntary Control Council for Interference by Information

Technology Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may occur, in

which case, the user may be required to take corrective action.

Page 4

Page 5

Publication History

February 2007

CallPilot 5.0, Standard 01.01 of , 1002rp Server Hardware Installation is

issued for general release

5

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 6

6 Publication History

1002rp Server Hardware Installation

Nortel CallPilot

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

5.0 23 February 2007

Page 7

Contents

Chapter 1 How to get help 9

Chapter 2 1002rp server description 11

Server features 11

Slot assignments 15

Network connectivity 18

Supported peripheral devices 21

Chapter 3 Preparing for installation 23

Installation overview 23

Unpacking the 1002rp server 26

Removing the front bezel and server cover 27

Inspecting the server interior 29

Chapter 4 Power supply installation 33

Safety precautions 33

Installing the second power supply module (AC or DC) 34

DC wire gauge tables 36

DC rack cabling 37

About the power distribution unit 40

Bringing power and ground into the PDU 42

7

Reference Documents 15

Chapter 5 Installing the server and connecting the peripheral

devices 43

Installing the server 43

Preparing the modem 44

Connecting peripherals to the server 47

Connecting the server to the ELAN subnet 49

Connecting the server to the Nortel server subnet (optional) 51

Installing the Nortel software feature dongle 52

Connecting the server to power 53

Appendix A EMC emission level protection for the 1002rp

Server 57

Index 59

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 8

8 Contents

1002rp Server Hardware Installation

Nortel CallPilot

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

5.0 23 February 2007

Page 9

Chapter 1

How to get help

This section explains how to get help for Nortel products and services.

Getting help from the Nortel Web site

The best way to get technical support for Nortel products is from the Nortel

Technical Support Web site:

h

ttp://www.nortel.com/support

This site provides quick access to software, documentation, bulletins, and

tools to address issues with Nortel products. More specifically, the site

enables you to:

•

download software, documentation, and product bulletins

• search the Technical Support Web site and the Nortel Knowledge Base

for answers to technical issues

9

•

sign up for automatic notification of new software and documentation

for Nortel equipment

•

open and manage technical support cases

Getting help over the phone from a Nortel Solutions Center

If you don’t find the information you require on the Nortel Technical Support

Web site, and have a Nortel support contract, you can also get help over the

phone from a Nortel Solutions Center.

In North America, call 1-800-4NORTEL (1-800-466-7835).

Outside North America, go to the following Web site to obtain the phone

number for your region:

h

ttp://www.nortel.com/callus

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 10

10 Chapter 1 How to get help

Getting help from a specialist by using an Express Routing Code

To access some Nortel Technical Solutions Centers, you can use an Express

Routing Code (ERC) to quickly route your call to a specialist in your Nortel

product or service. To locate the ERC for your product or service, go to:

h

ttp://www.nortel.com/erc

Getting help through a Nortel distributor or reseller

If you purchased a service contract for your Nortel product from a distributor

or authorized reseller, contact the technical support staff for that distributor

or reseller.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 11

Chapter 2

1002rp server description

In this chapter

"Server features" (page 11)

"Slot assignments" (page 15)

"Network connectivity" (page 18)

"Network connectivity" (page 18)

"Supported peripheral devices" (page 21)

Reference documents

11

Server features

Introduction

This section provides a general overview of the 1002rp server.

Server dimensions and weight

Height 320 mm (12.5 in.)

Width 483 mm (19 in.)

Depth (distance from front to back)

•

without front bezel

• with front bezel

Weight of fully loaded system 45.5 kg (100 lb)

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

495 mm (19.5 in.)

533 mm (21 in.)

Page 12

12 Chapter 2 1002rp server description

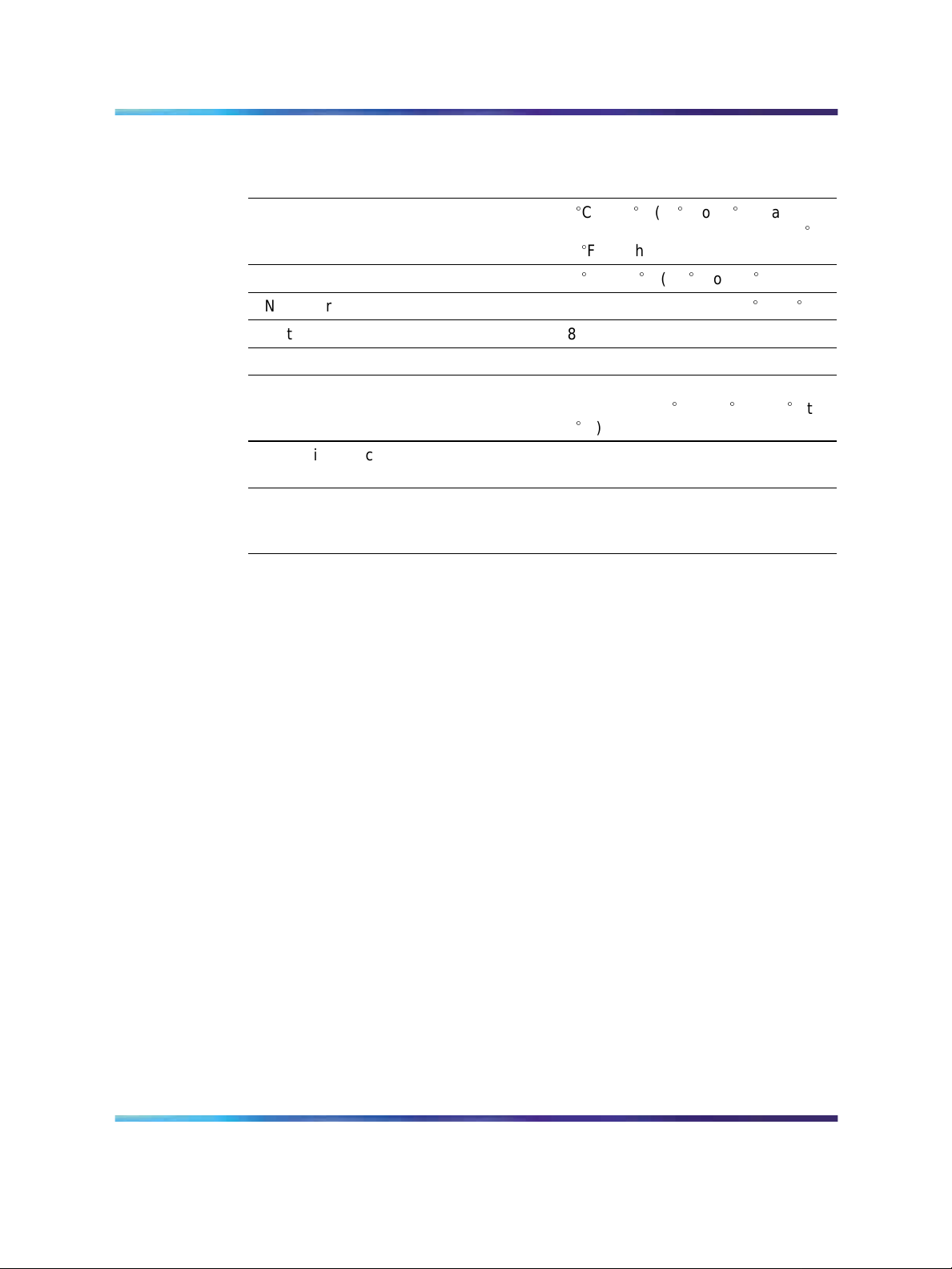

Environmental specifications

Environmental condition

Operating temperature

Non-operating (storage) temperature

Non-operating humidity

Specification

10

Cto35C (50Fto95F) Maximum

rate of change must not exceed 10

(50

F) per hour.

-40

Cto70C (-40F to 158F)

95%, non-condensing at 30

Altitude 1829 m (6000 ft)

Electrostatic discharge 15 kV or more

Acoustic noise 50 dBA in a typical office ambient

temperature (18

77

F])

Operating shock No errors with a half sine wave shock

of 2G (with 1 millisecond duration)

Handling drop Operational after a free fall from 450

mm to 600 mm (18 in. to 24 in.)

(depending on weight)

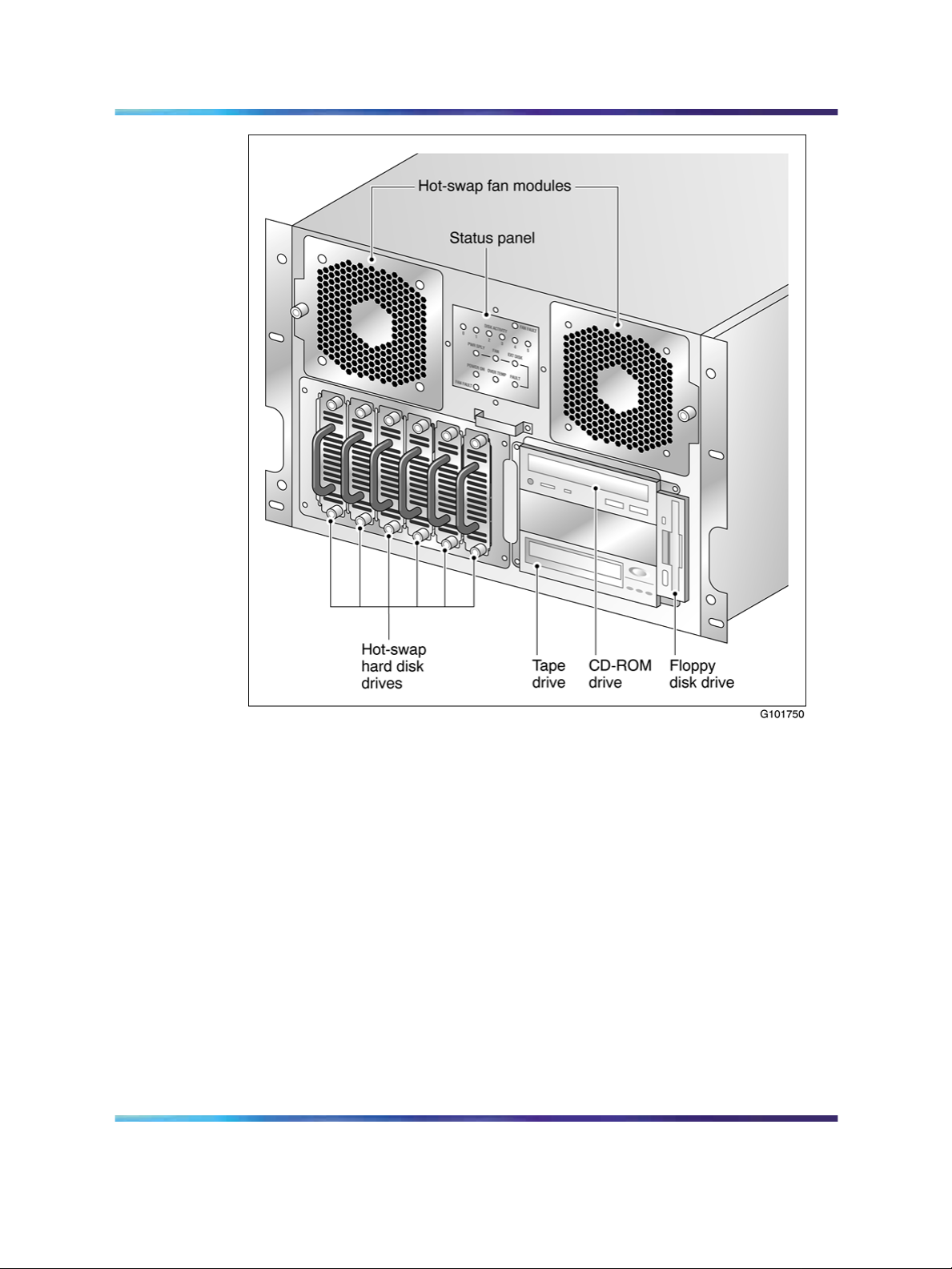

Front panel features (front view without the front bezel)

The front view of the 1002rp server chassis shows redundant dual fans to

the left and the right of the status panel. The left drive bay holds six SCSI

hard drives with hot-pluggable carriers. The media drive bay, located to the

right, houses the CD-ROM, tape drive, and floppy disk drive.

Cto25

C (86F)

C [64.4

Fto

C

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 13

Server features 13

Alarm board

The alarm board is located under the baseboard. It connects to the status

display panel on the front.

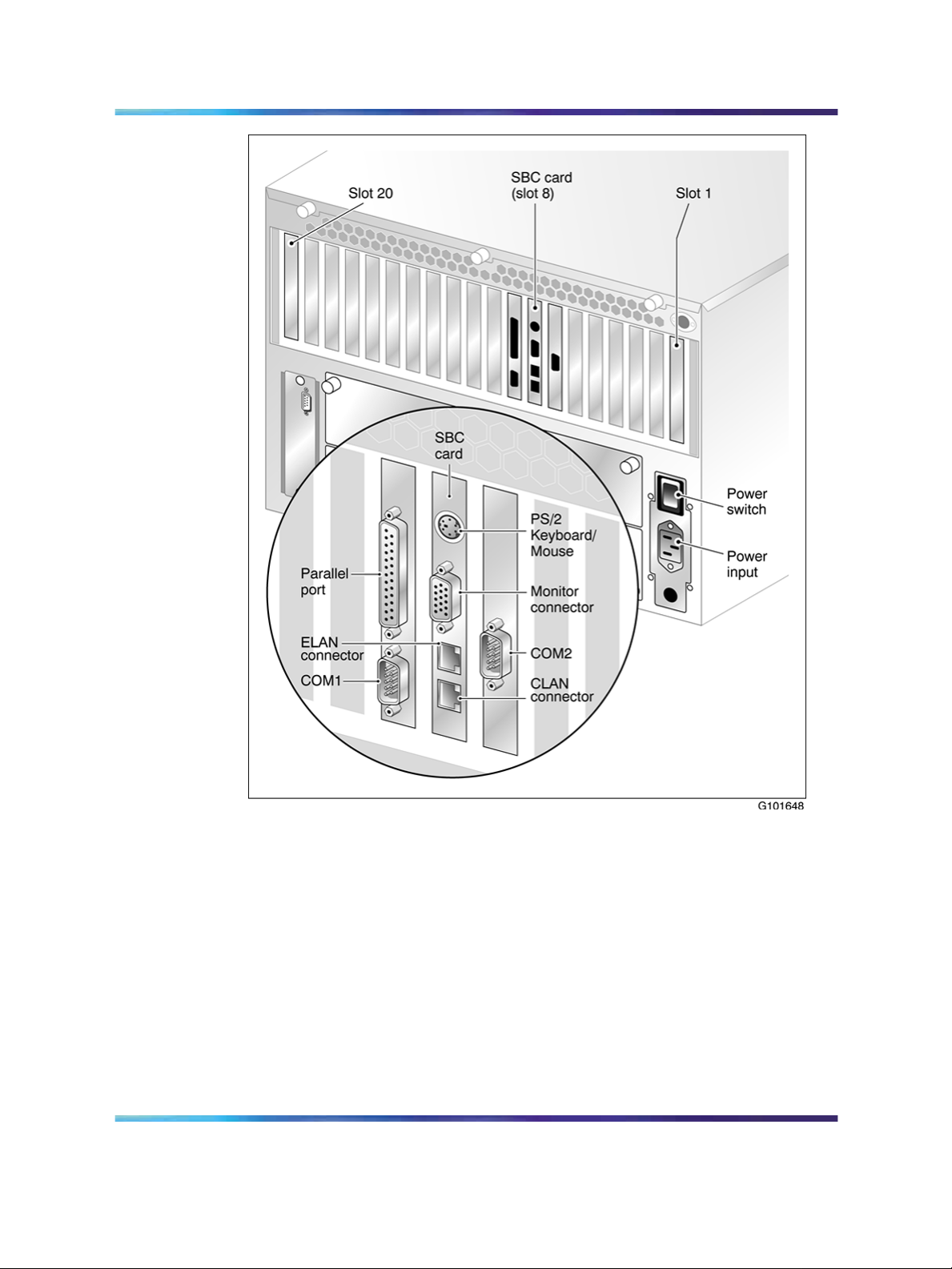

Rear panel diagram

The following diagram shows the slot locations in the rear panel, and the

power switch and power input for an AC server. The rest of the diagram

is the same for AC or DC servers.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 14

14 Chapter 2 1002rp server description

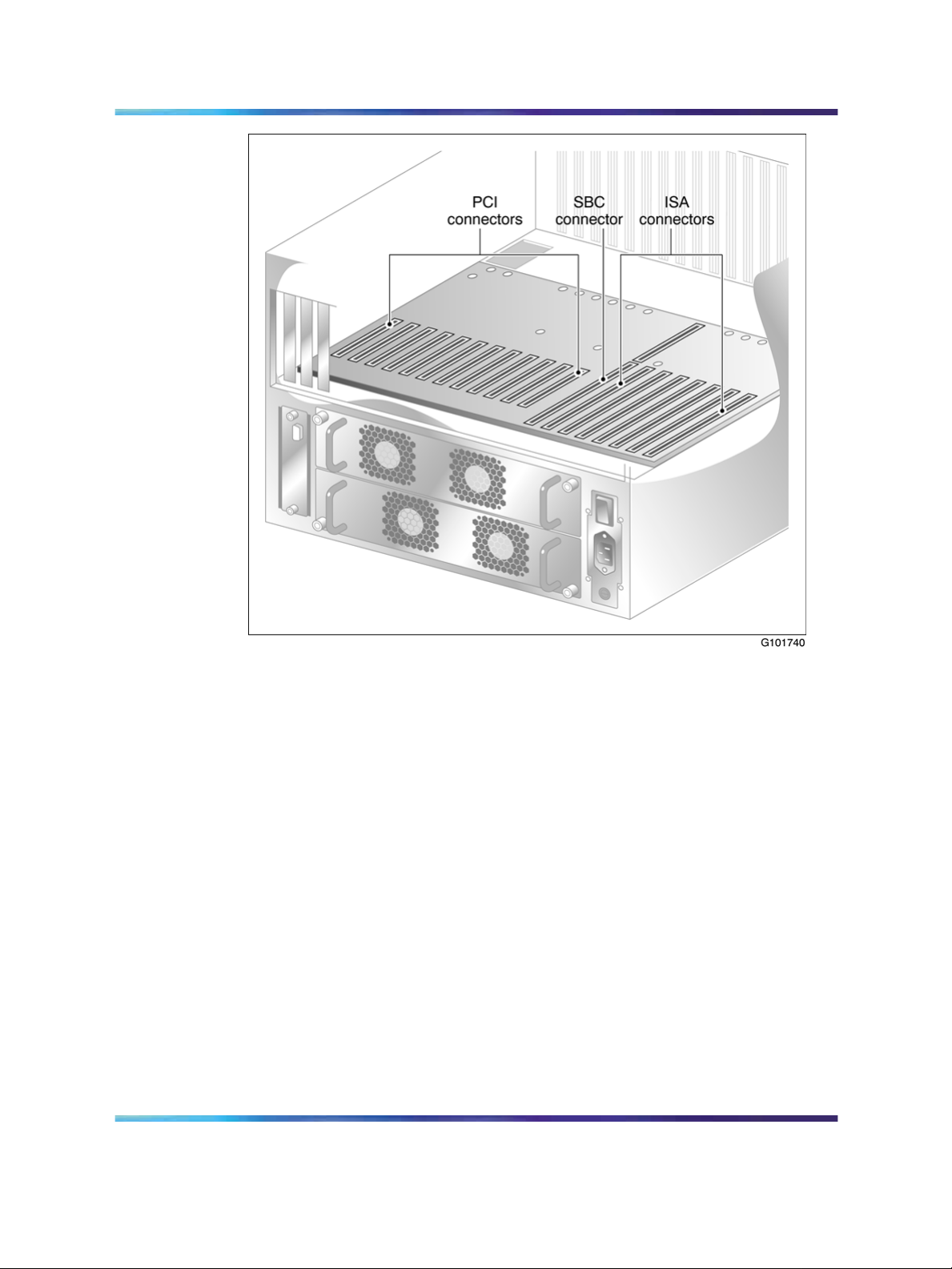

Overhead view of empty server showing PCI and ISA connectors

The following diagram shows the location of the PCI, SBC, and ISA

connectors inside the server. The view in the diagram is from the rear of the

server. For slot assignments, see "Slot assignments" (page 15). You must

be able to identify slot locations for later steps in the CallPilot installation.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 15

Slot assignments 15

Slot assignments

Introduction

The slot assignment tables show the following:

•

the physical location of boards inside the server, relative to other boards

•

the order in which boards are installed (for example, board #1, 2, 3)

•

how the boards are represented in some CallPilot Manager applications

(such as the Maintenance Administration page)

•

the maximum capacity for each switch connectivity

Note: Your server can vary depending on what was ordered from

Nortel. Therefore, your server may not have all of the slots populated.

Reference Documents

For a list of all CallPilot documents, see the following CallPilot Customer

Documentation Map.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 16

16 Chapter 2 1002rp server description

1002rp Server Hardware Installation

Nortel CallPilot

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

5.0 23 February 2007

Page 17

Slot assignments 17

Slot definition and slot numbering

In these tables, the term slot refers to the available slot openings in the

chassis, not the PCI or ISA connectors inside the server.

Look at the server from the rear (see "Rear panel diagram" (page 13)). The

slots are numbered from right to left, 1 to 20. Now, look at the server from

the front. The slots are numbered from left to right.

Note: For Meridian 1 and Communication Server 1000, the first

MPB16-4 board must be installed in slot 11. You can install up to a

maximum of two MPB16-4 boards.

1002rp slot assignments

Meridian 1*/

Communication

Slot

number

CallPilot-assigned

board label

a

Slot 1 BRD01 Not used Not used

Slot 2 BRD02 Not used Not used

Server*

1000 T1/SMDI

Slot 3 BRD03 Not used Not used

Slot 4 BRD04 Not used Not used

Slot 5 BRD05 Not used Not used

Slot 6 BRD06 Not used Not used

Slot 7 BRD07 Reserved for COM2

I/O bracket

b

Slot 8

BRD08 Single board

computer

Slot 9 (PCI Slot 1) BRD09 Reserved for COM1

and parallel port I/O

bracket

Reserved for COM2

I/O bracket

Single board

computer

Reserved for COM1

and parallel port I/O

bracket

Slot 10 (PCI Slot 2) BRD10 PCI RAID controller PCI RAID controller

Slot 11 (PCI Slot 3) BRD11 MPB16-4 #1 or

MPB96 board #1

MPB96 #1

Slot 12 (PCI Slot 4) BRD12 MPB16-4 #2

D/480JCT-2T1

(optional)

a. On some CallPilot Manager screens, the CallPilot-assigned board label is displayed. This label

corresponds to the slot number. For example, BRD12 refers to the board in slot 12.

b. The SBC card includes two onboard NICs (for connection to the ELAN subnet, and the Nortel

server subnet) and an onboard video card. The NIC and monitor connectors are on the SBC

faceplate.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 18

18 Chapter 2 1002rp server description

Slot

number

CallPilot-assigned

board label

a

Meridian 1*/

Communication

Server*

1000 T1/SMDI

Slot 13 (PCI Slot 5) BRD13 MPB16-4 #2

D/480JCT-2T1

(optional)

Slot 14 (PCI Slot 6) BRD14 MPB16-4 #2

(optional) or MPB96

MPB96 board #2

(optional)

#2 (optional)

Slot 15 (PCI Slot 7) BRD15 MPB16-4 #2

(optional)

Slot 16 (PCI Slot 8) BRD16 MPB16-4 #2

(optional)

Slot 17 (PCI Slot 9) BRD17 MPB16-4 #2

D/480JCT-2T1

(optional)

D/480JCT-2T1

(optional)

MPB96 #3 (optional)

(optional) or MPB96

#3 (optional)

Slot 18 (PCI Slot

10)

Slot 19 (PCI Slot

BRD18 MPB16-4 #2

Not used

(optional)

BRD19 Not used Not used

11)

Slot 20 (PCI Slot

BRD20 Not used Not used

12)

a. On some CallPilot Manager screens, the CallPilot-assigned board label is displayed. This label

corresponds to the slot number. For example, BRD12 refers to the board in slot 12.

b. The SBC card includes two onboard NICs (for connection to the ELAN subnet, and the Nortel

server subnet) and an onboard video card. The NIC and monitor connectors are on the SBC

faceplate.

Network connectivity

Introduction

This section describes how the 1002rp server can be integrated into your

network. The integration depends on the type of switch you are using.

ATTENTION

To secure the CallPilot server from unauthorized access, ensure that the CallPilot

network is inside your organization’s firewall.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 19

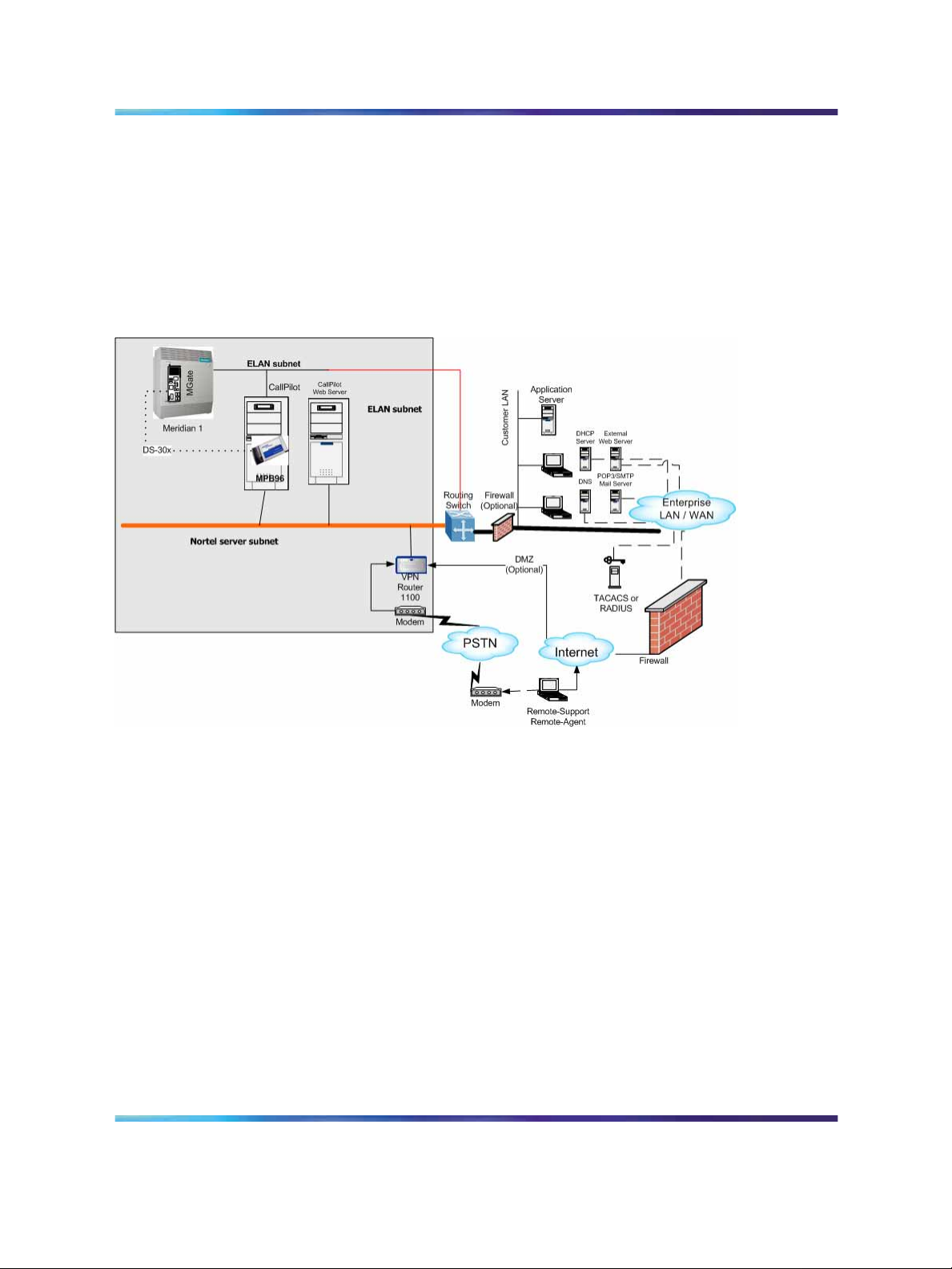

Sample network setup: Meridian 1

The following diagram shows a CallPilot server sample network setup with a

Meridian 1 switch. The Meridian 1 switch can be one of the following:

•

Option 11C or Option 11C Mini

•

Option 51C

•

Option 61C

•

Options 81 and 81C

Network connectivity 19

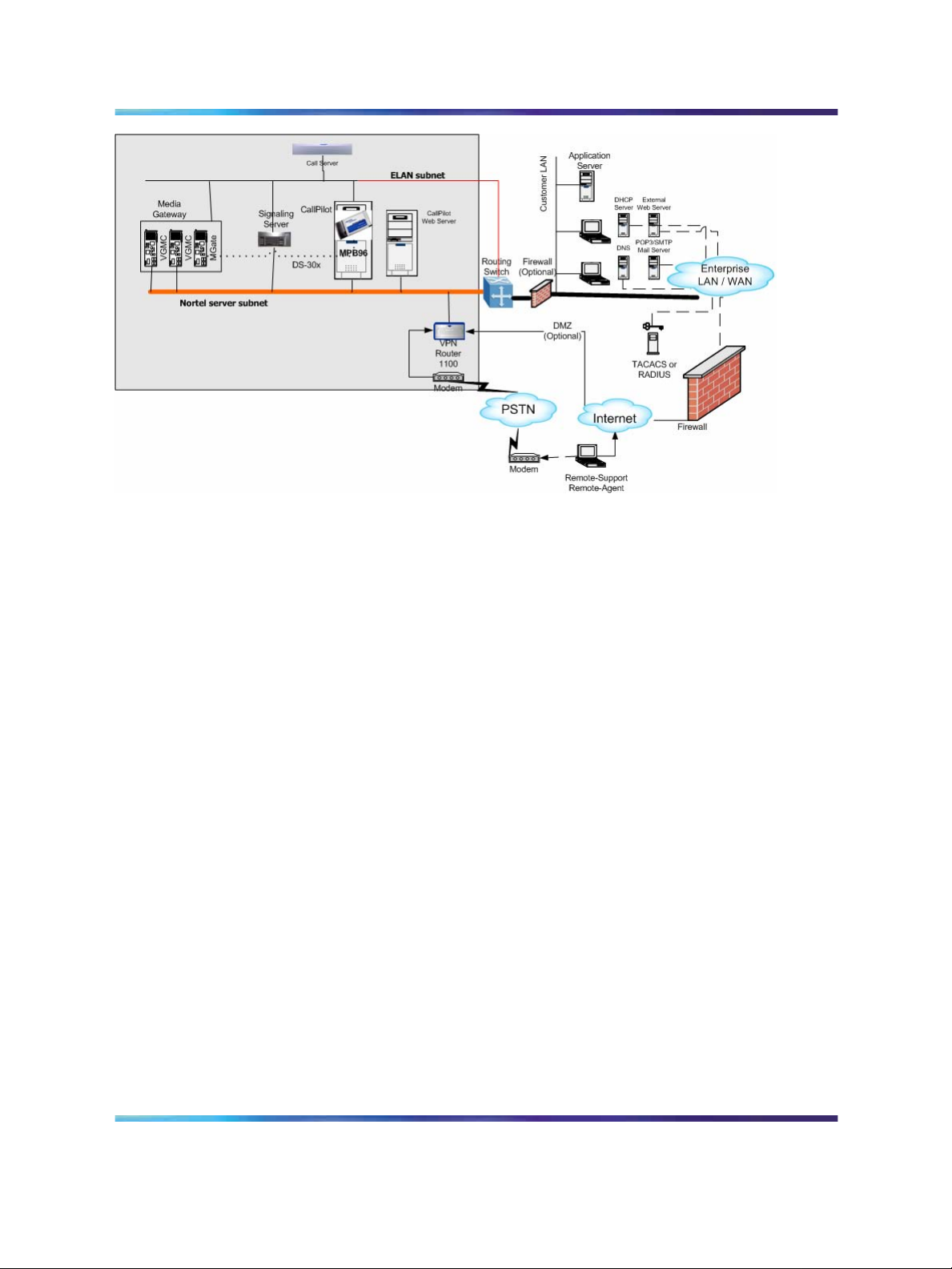

Sample network setup: Communication Server 1000

The following diagram shows a CallPilot server network setup with a

Communication Server 1000 system.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 20

20 Chapter 2 1002rp server description

Switch connectivity

For more details about how the 1002rp server and switch connection

is established, refer to the Installation and Configuration Task List

(NN44200-306).

CallPilot ELAN subnet and Nortel server subnet setup

The 1002rp server provides 10/100Base-T Ethernet connectivity through

NICs installed in the server. See "Slot assignments" (page 15) for details

on the location of NICs. The function of the NIC varies based on switch

connectivity, as described below:

Meridian 1 or Communication Server 1000 systems

•

One NIC provides connectivity to the ELAN subnet.

For information about the purpose and requirements of the ELAN, see

the Planning and Engineering Guide (NN44200-200).

•

A second NIC is optional.

This optional NIC is required only for Meridian 1 or Communication

Server 1000 systems that require a connection to the Nortel server

subnet (in addition to the ELAN subnet connection). The Nortel server

subnet provides data connectivity between desktop and Web messaging

clients, Web-enabled administrative PCs, and the CallPilot server.

Network requirements

Appropriate networking equipment must be available for both the Nortel

server subnet and ELAN subnet.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 21

Supported peripheral devices 21

The Nortel server subnet and ELAN subnet must be properly configured

for correct CallPilot operation. To ensure correct configuration, Nortel

recommends that you consult a network specialist.

Remote access connectivity

The RS-232 COM1 connector on the rear of the 1002rp server provides

the connection to an external modem. The modem allows administrators

and technical support personnel to administer the 1002rp server from a

remote location.

pcAnywhere is used to establish the remote access connection to the server.

Supported peripheral devices

Introduction

This section identifies external devices that are supported by the 1002rp

server.

Device Description

Modem A 56-Kbit/s external modem (NTRH9078) provides remote access

to the 1002rp server. The modem connects to the RS-232 COM1

connector on the rear of the server.

Ethernet hub or switch

Since the modem is an external device, it requires its own AC power

source referenced to the same ground as the 1002rp server and the

switch to which it is connected.

A 10Base-T Ethernet hub or switch provides the ELAN subnet

connection between the 1002rp server and the Meridian 1 switch

or Communication Server 1000 system. The customer can

supply an ethernet hub or switch from third-party vendors or from

Nortel.

Since the ethernet hub or switch is an external device, it requires

an AC power source.

ATTENTION

To comply with EMC radiation requirements, a Class A hub

must be located 10 m (33 ft) away from the 1002rp server.

Shielded Ethernet cables must be used.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 22

22 Chapter 2 1002rp server description

Device Description

•

Monitor, keyboard, and

mouse

15-in. monitor: NTRH9011 or N0038380 LCD monitor.

Since the monitor is an external device, it requires its own AC

power source.

•

Keyboard: NTRH9013

•

Mouse: NTRH9014

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 23

Chapter 3

Preparing for installation

In this chapter

"Installation overview" (page 23)

"Unpacking the 1002rp server" (page 26)

"Removing the front bezel and server cover" (page 27)

"Inspecting the server interior" (page 29)

Installation overview

Introduction

This section provides an overview of the steps required to install the 1002rp

server and peripheral devices.

23

Installation checklist

The following checklist identifies the tasks that must be performed when

installing the CallPilot server. For detailed instructions, see "Installing the

server" (page 43) When you are finished with the installation, continue with

the Installation and Configuration Task List (NN44200-306).

Step

1

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Description

Ensure that you have reviewed the "Installing the CallPilot server" section in

the Installation and Configuration Task List (NN44200-306), and completed

stage 1 of the "Installation checklist."

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Check

Page 24

24 Chapter 3 Preparing for installation

Step

2

3

4

5

6

7

Description

Unpack the server, and ensure you have all the items you need (see

"Unpacking the 1002rp server" (page 26)).

Complete the following checklists that are provided in the Installation and

Configuration Task List (NN44200-306):

• "CallPilot software media and documentation checklist"

•

"CallPilot server hardware checklist"

Remove the front bezel and server cover, and inspect the interior (see pages

"Removing the front bezel and server cover" (page 27) and "Inspecting the

server interior" (page 29)).

Replace the server cover.

Install the power supply modules in the server (see "Installing the second

power supply module (AC or DC)" (page 34)).

For a DC-powered server, set up the DC power source (see "DC wire gauge

tables" (page 36)).

Place the 1002rp server in the chosen location (see "Installing the server"

(page 43)).

Check

8

9

10

Replace the front bezel (see page "Inspecting the server interior" (page 29)).

Set the DIP switches on the modem (see "Preparing the modem" (page 44)).

Connect the 1002rp server and devices as follows:

•

Connect the monitor, keyboard, and mouse (see "Connecting peripherals to

the server" (page 47)).

•

Connect the modem (see "Preparing the modem" (page 44)).

•

Connect the 1002rp server to the ELAN hub or switch (Meridian 1 or

Communication Server 1000 only) (see "Connecting the server to the ELAN

subnet" (page 49)).

ATTENTION

To comply with EMC radiation requirements, a Class A hub must be

located 10 m (33 ft.) away from the 1002rp server. Shielded Ethernet

cables must be used.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 25

Installation overview 25

Step

Description

Note: If you are connecting the optional Nortel server subnet, do not power up

unless your antivirus programs and Nortel security updates are installed first.

•

Connect the 1002rp server to the CLAN hub or switch (optional) (see

"Connecting the server to the Nortel server subnet (optional)" (page 51)).

ATTENTION

To comply with EMC radiation requirements, a Class A hub must be

located 10 m (33 ft.) away from the 1002rp server. Shielded Ethernet

cables must be used.

•

Install the software feature dongle (see "Installing the Nortel software feature

dongle" (page 52)).

Check

11

•

Connect the power cords for all devices, and then power them up.

Start the 1002rp server (see "Connecting the server to power" (page 53)).

Conventions for warnings

You may encounter the following types of warnings in this guide. Do not

ignore them.

DANGER

Warns you of an immediate electrical hazard which, if not avoided,

can result in shock, serious injury, or death.

WARNING

Warns you of a situation in which you can be injured if instructions

are not followed exactly as stated.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 26

26 Chapter 3 Preparing for installation

CAUTION

Alerts you to situations where data can be lost or damaged,

equipment can be damaged, actions can result in service

interruption, and productive time can be lost.

Provides information that is essential to the completion of a task.

Unpacking the 1002rp server

Introduction

Follow this procedure to unpack the server and peripherals.

WARNING

The 1002rp CallPilot server weighs approximately 34 kg (75 lb)

as shipped from manufacturing. To prevent personal injury, have

someone help you to unpack and position the server.

ATTENTION

To unpack the equipment

Step Action

ATTENTION

As you unpack each item, check it off against the packing list, as well as against

the following checklists provided in the Installation and Configuration Task List

(NN44200-306):

•

"CallPilot software media and documentation checklist"

•

"CallPilot server hardware checklist"

1

2

3

4

5

Carefully open the cardboard carton containing the server.

Remove the server from the carton; set it on the floor.

Carefully open the cartons containing the monitor, keyboard, mouse,

modem, and ELAN hub (if supplied), and set the peripherals aside.

Put all manuals, CD-ROMs, operating system disks, and any disks

for peripherals in a safe place.

Save all packing materials and cartons in case you must return any

equipment to the carrier.

—End—

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 27

Removing the front bezel and server cover 27

What is next?

Remove the server cover so that you can inspect the interior of the server.

See "Removing the front bezel and server cover" (page 27).

Removing the front bezel and server cover

Introduction

To access the server interior, you must remove both the front bezel and

the server cover.

Two locked doors, located on the front of the server, cover the front panel,

including the CD-ROM drive and tape drive. These doors are part of the

front bezel. You must unlock the front bezel doors before you can remove

the bezel.

To remove the front bezel

Step Action

CAUTION

Do not attempt to move or lift the server before removing the front

bezel; the server can disengage from the bezel and fall.

1

Unlock and open the double doors of the front bezel. See A in the

diagram below.

2 Firmly grasp the front bezel by the hand-holds on either side of the

chassis, and pull the front bezel from the chassis.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 28

28 Chapter 3 Preparing for installation

To remove the server cover

Step Action

DANGER

High current inside the chassis can cause severe injury.

CAUTION

Take precautions to protect internal components. Electrostatic

discharge (ESD) can render boards damaged or unusable. Wear

an ESD wrist strap.

1

Remove the front bezel (see "To remove the front bezel" (page 27)).

—End—

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 29

Inspecting the server interior 29

2

3

Loosen the three thumbscrews at the rear of the top cover.

Remove the server cover by pulling the cover toward the rear of the

chassis, and then lifting it up and off.

4

Clip the lead from your ESD wrist strap to an unpainted metal section

of the chassis.

What is next?

Continue with "Inspecting the server interior" (page 29).

Inspecting the server interior

Introduction

You should perform a visual inspection for loose components, foreign matter,

or shipping damage inside the server.

CAUTION

When working with interior components, use an ESD wrist strap to

protect static-sensitive components.

—End—

To inspect the server interior

Step Action

1 Carefully check all the cards to ensure they are fully seated on the

baseboard.

2

3 Review the slot locations (see "Slot assignments" (page 15)).

4

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Check for any loose wires or foreign objects, such as loose screws,

inside the chassis.

Do one of the following:

IF THEN

you observe any damage contact your Nortel technical

support representative.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 30

30 Chapter 3 Preparing for installation

IF THEN

components have become loose secure them.

Refer to the procedures in the

Installation and Configuration

Task List (NN44200-306).

you are satisfied that the 1002rp

server has arrived at your site

undamaged

replace the server cover and

proceed with the hardware

installation.

See "Installation checklist" (page

23).

Note: Do not reinstall the front

bezel until the server is in its

final location and the CallPilot

installation is complete.

—End—

To replace the front bezel after installation is complete

Step Action

When the CallPilot server installation is complete and the server is in its

final location, replace the front bezel.

1

Align the front bezel with the ball studs located at each faceplate

corner.

See the diagram below:

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 31

Inspecting the server interior 31

2

3

Apply pressure evenly until the bezel snaps onto each ball stud.

Close and lock the double doors of the front bezel.

—End—

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 32

32 Chapter 3 Preparing for installation

1002rp Server Hardware Installation

Nortel CallPilot

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

5.0 23 February 2007

Page 33

Chapter 4

Power supply installation

In this chapter

"Safety precautions" (page 33)

"Installing the second power supply module (AC or DC)" (page 34)

"DC wire gauge tables" (page 36)

"DC rack cabling" (page 37)

"About the power distribution unit" (page 40)

"Bringing power and ground into the PDU" (page 42)

33

Safety precautions

Equipment handling guidelines

External power equipment, such as an uninterruptible power supply (UPS),

is usually very heavy. This equipment requires special handling procedures

and additional personnel for unloading and installation. Be aware of weight

distribution, and prevent the equipment room floor from being overly

stressed.

Safety information

In DC systems, locate the service panel near the entry to the room

containing the DC power system that supplies the server.

DANGER

Procedures involving electrical connections must be performed

only by qualified personnel.

Ensure that you obey all displayed warning notices on power

equipment and connections.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 34

34 Chapter 4 Power supply installation

Installing the second power supply module (AC or DC)

Introduction

One power supply module is shipped installed. The second power supply

module must be installed on-site.

AC versus DC systems

The power supply modules are similar in appearance for both AC and DC

1002rp servers. The procedures in this section apply to both AC and DC

1002rp servers.

About the power supply module

After the server is powered up (later in this guide), the power supply module

LED indicates its status.

A green LED on the power supply module indicates that the module is

working properly. If the LED is unlit or red, the module is failing or has failed.

A problem with the power supply module is also indicated if an alarm sounds

or the power supply LED on the front of the server turns red.

The diagram below shows the location of the power supply modules in a

server that has two power supply modules installed:

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 35

Installing the second power supply module (AC or DC) 35

To install the power supply module

DANGER

High current inside the chassis can cause severe injury.

The server is shipped with one power supply module installed in the bottom

power supply bay. You must install the second power supply module, as

described here:

Step Action

1

2

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Align the power supply module with the top power supply bay.

Slide the power supply module into the bay until the module is

secured by its connector.

Use some force, if necessary.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 36

36 Chapter 4 Power supply installation

3

Secure the power supply module to the chassis with two

thumbscrews at the corners of the power supply faceplate.

What is next?

Do one of the following:

IF THEN

this is an AC-powered server

this is a DC-powered server

DC wire gauge tables

Introduction

The tables in this section specify the DC power feed wire requirements.

Cabinet and module DC feed recommended wire gauge specifications

—End—

continue with "Installing the server"

(page 43) on page "Installing the

server" (page 43).

continue with "DC wire gauge tables"

(page 36).

Junction

box #4

Length #10 AWG #8 AWG #6 AWG

0-30 m (100 ft)

0-45 m (150 ft)

0-75 m (250 ft)

0-135 m (450 ft)

Notes:

1.

The cabinet and module ground wire specification is #10 AWG insulated green safety ground wire.

2.

The cabinet conduit can be 19.1 mm (0.75-in.) or 31.8 mm (1.25-in.), and must be insulated

from the cabinet ground.

yes yes yes yes yes

no yes yes yes yes

no no yes yes yes

no no no yes yes

AWG

Junction

box #4

AWG

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 37

DC rack cabling 37

Length #10 AWG #8 AWG #6 AWG

0-210 m (700 ft)

Over 210 m (700 ft)

no no no no yes

no no no no no

Junction

box #4

AWG

Junction

box #4

AWG

Notes:

1.

The cabinet and module ground wire specification is #10 AWG insulated green safety ground wire.

2.

The cabinet conduit can be 19.1 mm (0.75-in.) or 31.8 mm (1.25-in.), and must be insulated

from the cabinet ground.

Metric wire conversion

Industry standard

AWG No.

nominal (sq mm)

2 35 0.05

Resistance at 20 C

(Ohm/100 m)

4 25 0.08

6 16 0.13

8 10 0.20

10 6 0.33

12 4 0.63

14 2.5 1.00

16 1.5 1.40

18 1 2.00

20 0.75 2.90

22 0.5 4.60

DC rack cabling

The following photograph shows typical rack power cabling:

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 38

38 Chapter 4 Power supply installation

Note: The cables are marked with Red and Green tape. The cables

with the Red tape connect to the Negative (-) Red side (on the left in the

photograph), and the cables with the Green tape connect to the Positive

(+) Green side (on the right in the photograph). The sides are identified

on the power connections. The ground wire enters at the lower right and

attaches to the ground lug.

Main panel wiring diagram with product number.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 39

DC rack cabling 39

Rack power and grounding

To ensure a complete power and grounding installation:

•

In rackmount server installations, ensure the CallPilot server chassis

and equipment racks are isolated from other foreign sources of ground.

Acceptable isolation methods include: isolation pads, grommeted

washers, chassis side rail strips, and non-conducting washers.

•

In rackmount server installations where other equipment is also installed

in the same 19" rack, ensure that all equipment derives ground from

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 40

40 Chapter 4 Power supply installation

the same service panel as CallPilot and the switch, whether or not the

equipment is AC- or DC-powered.

-48 V DC power distribution rationale

•

Minimum installation is one power distribution unit (PDU) with four 48 V

DC branch circuits fused at 20 amperes.

•

The customer must be able to shut off any branch to ensure every unit

at the site continues to function properly.

• DC-powered configuration fits into this scheme as follows:

— Each PDU receives four branch circuits.

— Each server receives a feed from each PDU and a different branch

circuit.

•

In this fashion, with dual hot-swappable power supplies, there is no

single point of failure in the power system. For example, you can remove

any power supply, including a PDU, and everything continues to work.

•

This is applicable to either North American or European installation

sites (with a 230 V AC inverter).

•

The secondary rack supports four servers and follows a similar scheme.

About the power distribution unit

Introduction

A PDU is installed in a rack that has DC-powered servers. Power from

the DC supply source enters the PDU and can then be distributed to one

or more servers. A single PDU can supply DC power to four DC power

supply modules. A server can have either one or two power supply modules

installed. You can determine the number of PDUs to install in a rack by

counting the number of power supply modules in each rack.

PDU power and grounding

To ensure a complete power and grounding installation:

•

In rackmount DC-powered server installations, ensure the PDU (Power

Distribution Unit for DC applications) is installed on the same rack as

the CallPilot server. This is required since the main ground wire for the

PDU is not insulated from the metal enclosure.

Multiple PDUs

A server operates on a single power supply module. Its total capacity is

two installed power supply modules. The second power supply module is

the redundant power supply module.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 41

A PDU can distribute power to a maximum of four power supply units that

can be installed in two or more servers. Therefore, if there are three or four

servers installed in a rack, then you must install a second PDU.

Note: The power supply module installs in the server. It does not refer

to a UPS, which is a separate unit on the rack.

PDU terminal blocks and wiring diagram

A PDU consists of eight terminal blocks within a metal enclosure. Before

installing the PDU, connect the terminal blocks so that each output

connector receives power from a separate -48 V dc branch circuit, as shown

in the following diagram. Use AWG 10 wires for these connections.

Single PDU wiring diagram

About the power distribution unit 41

DC power input

DC power input into the distribution unit connects BAT-1 to BAT-4 and BR-1

to BR-4. Refer to the preceding diagrams for the location of these terminals.

Connect the input wires before installing the PDU on the rack.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 42

42 Chapter 4 Power supply installation

Bringing power and ground into the PDU

Introduction

Install BAT/BATRTN wires in pairs. Each pair of wires supplies voltages to a

module through a power harness. The module harnesses are installed in

the cabinet PDU and connected to the modules at the factory. See "About

the power distribution unit" (page 40).

To bring DC power and ground into the PDU

Step Action

1

If you are using a conduit, terminate the 32 mm (1-1/4 in.) or 19 mm

(3/4 in.) conduit at the top rear of the cabinet or at the bottom front of

the cabinet using the knockouts provided. The number of wire pairs

you can run in each conduit depends on the wire gauge.

Note: To preserve ground integrity, the conduit must be

insulated.

2

Select a power feed with a circuit breaker dedicated to each module,

and identify it with an appropriate tag.

3

Select a wire size to suit the required feed length from the power

source (see "DC wire gauge tables" (page 36)).

4

Use pliers to strip 6 mm (1/4 in.) to 13 mm (1/2 in.) of the insulation

from one end of all power and ground feed wires.

5

6

7

8

9

Undo the terminal block screws at (-) positions 0, 1, 2, and 3.

Insert the red wires into terminal block positions 0, 1, 2, and 3.

Secure the wires in the terminal block by tightening the screws.

Undo the terminal block screws at (+) positions 0, 1, 2, and 3.

Insert the black wires into terminal block positions 0, 1, 2, and 3.

10

11

Secure the wires in the terminal block by tightening the screws.

Select a #10 AWG green wire safety ground and attach it to the

cabinet.

12 Measure the module ground continuity by touching one multimeter

lead to any BATRTN terminal block connector and the other end

to the GND terminal block connector. Ensure the measurement is

between 0-0.5 ohms.

—End—

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 43

43

Chapter 5

Installing the server and connecting the

peripheral devices

In this chapter

"Installing the server" (page 43)

"Preparing the modem" (page 44)

"Connecting peripherals to the server" (page 47)

"Connecting the server to the ELAN subnet" (page 49)

"Connecting the server to the Nortel server subnet (optional)" (page 51)

"Installing the Nortel software feature dongle" (page 52)

"Connecting the server to power" (page 53)

Installing the server

Introduction

Before you install the 1002rp server, ensure that the chosen location meets

the requirements identified on the "Site inspection checklist" provided in the

Installation and Configuration Task List (NN44200-306).

To install the server

Place the 1002rp serverin its chosen location. If you are installing the server

in a rack cabinet, follow the instructions that are provided with the slide rails.

Connect peripheral devices as described in the remainder of this chapter.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 44

44 Chapter 5 Installing the server and connecting the peripheral devices

WARNING

Do not connect the server to the power yet.

Preparing the modem

Introduction

You require a modem to support remote dial-up access to the CallPilot

server. The modem also enables Nortel technical support to connect to

your CallPilot server for troubleshooting purposes. Nortel connects to your

server only when you request technical assistance.

Required equipment

To install the modem, you need the following equipment:

•

an RJ-11 analog phone cord

•

a power adapter cord

•

an analog line jack

•

tweezers, or a screwdriver small enough to use to adjust DIP switches

The following modem is provided with your server:

•

an analog external U.S. Robotics 56-Kbit/s modem (NTRH9078) that

includes a 25-pin male to 9-pin female shielded serial cable for your

modem

Note: Ensure that you have the correct cable for your modem, as

follows:

— 56-Kbit/s modem: A0841984

Modem DIP switches

Set the modem DIP switches before you connect the modem to the CallPilot

server.

Note: This section applies only to the U.S. Robotics 56-Kbit/s external

Sportster modem. If your modem is different, refer to the documentation

for your modem.

The following diagram shows the key components of the external modem,

including the location and required settings of the DIP switches:

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 45

Preparing the modem 45

DIP

switch

1

2

3

To set the modem DIP switches

Use a pair of tweezers or a small screwdriver to set the DIP switches as

described in the Change to column of the following table:

Note: ON is down. OFF is up.

Default

setting

OFF OFF Data Terminal Ready (DTR) override

OFF OFF Verbal/numeric result codes

ON ON Result code display

Change

to Function

•

OFF: Normal DTR operations. (The computer

must provide a DTR signal for the modem to

accept commands. If DTR is dropped, the call is

terminated.)

•

ON: The modem ignores DTR (override).

•

OFF: Verbal (word) results.

•

ON: Numeric results.

•

OFF: Suppresses result codes.

• ON: Enables result codes.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 46

46 Chapter 5 Installing the server and connecting the peripheral devices

DIP

switch

4

5

6

7

Default

setting

Change

to Function

OFF OFF Command mode local echo suppression

•

OFF: Displays keyboard commands.

•

ON: Suppresses echo.

ON ON Auto answer suppression

• OFF: The modem answers on the first ring, or

higher if specified in NVRAM.

• ON: Disables auto answer.

OFF OFF Carrier Detect (CD) override

•

OFF: The modem sends a CD signal when it

connects with another modem; it drops the CD on

disconnect.

•

ON: CD is always ON (override).

OFF OFF Power-on and ATZ reset software defaults

•

OFF: Loads Y or Y1 configuration from user-defined

NVRAM.

•

ON: Loads &F0-Generic template from read-only

memory (ROM).

8

ON ON AT command set recognition

•

OFF: Disables command recognition (dumb mode).

• ON: Enables recognition (smart mode).

What is next?

Continue with "Connecting peripherals to the server" (page 47).

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 47

Connecting peripherals to the server

Rear panel connectors

Connecting peripherals to the server 47

Note: The above diagram shows the power switch and power input

for an AC server. The rest of the diagram is the same for AC or DC

servers. For peripheral device connections, this picture applies to AC

and DC servers.

To connect the mouse, keyboard, and monitor to the server

Step Action

1 Place the monitor, keyboard, and mouse in the same location as

the server.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 48

48 Chapter 5 Installing the server and connecting the peripheral devices

2

Plug the keyboard/mouse dual cable into the PS/2 connector on the

SBC card faceplate (see "Rear panel connectors" (page 47)).

3

Plug the keyboard and mouse into the appropriate connectors on

the keyboard/mouse dual cable.

4

Plug the monitor into the monitor connector on the SBC card.

Tighten the screws on the connector.

5

Ensure that a single-point ground reference is available for all

the power outlets serving the CallPilot server and its peripherals.

Before the CallPilot server installation, a qualified electrician must

implement the single-point ground reference requirement between

the power outlets of the CallPilot server and the power outlets of

the switch.

6

Connect the power cord to the monitor and plug the other end into

a wall receptacle or power bar.

Note: Ensure that the power source is consistent with the SBC

for all ancillary equipment.

7

Turn on the monitor.

—End—

To connect the modem to the server

Step Action

1

2

3

4

5

6

Ensure that the modem AC power cord is not plugged in.

Connect the large 25-pin male connector to the back of the modem.

Tighten the connector screws.

Connect the 9-pin female connector to COM1 at the rear of the

server. Tighten the connector screws.

Connect one end of the telephone cable to the modem RJ-11 jack

labeled LINE.

Connect the other end of the telephone cable to the RJ-11 jack in

the wall.

Ensure that a single-point ground reference is available for all

the power outlets serving the CallPilot server and its peripherals.

Before the CallPilot server installation, a qualified electrician must

implement the single-point ground reference requirement between

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 49

Connecting the server to the ELAN subnet 49

the power outlets of the CallPilot server and the power outlets of

the switch.

7

Connect the power cord to the modem, and plug the other end into

a wall receptacle or power bar.

Note: Ensure that the power source is consistent with the SBC

for all ancillary equipment.

8

Turn on the modem.

—End—

What is next?

Continue with "Connecting the server to the ELAN subnet" (page 49).

Connecting the server to the ELAN subnet

Introduction

ATTENTION

This section applies only if the 1002rp server connects to a Meridian 1 switch or

Communication Server 1000 system.

Connect the CallPilot server to the Meridian 1 switch or Communication

Server 1000 system using the ELAN interface.

ATTENTION

For important considerations about using the ELAN subnet in your network, see

the CallPilot Planning and Engineering Guide (NN44200-306).

ATTENTION

To comply with EMC radiation requirements, a Class A hub must be located 10 m

(33 ft.) away from the 1002rp server. Shielded Ethernet cables must be used.

Media Access Control address

The Media Access Control (MAC) address is a unique number assigned to

network cards and controllers. The procedure below asks you to record

the ELAN MAC address. The MAC address is recorded on a label affixed

to the back of the chassis.

To connect the server to the ELAN subnet

Step Action

1

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

See the diagram on page "Rear panel connectors" (page 47) to

locate the ELAN Ethernet connector.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 50

50 Chapter 5 Installing the server and connecting the peripheral devices

2

Locate the MAC address label on the back of the chassis that

identifies the ELAN controller MAC address.

3

Record the MAC address on the Configuration Wizard worksheet

that is provided in the Installation and Configuration Task List

(NN44200-306).

You need the MAC address to identify the ELAN when running the

Configuration Wizard to configure the CallPilot server.

4

Connect an RJ-45 network cable from the ELAN hub or switch to the

ELAN connector on the server.

Note: The ELAN hub or switch is optional if you use a cross-over

network cable to make a direct point-to-point connection from the

server to the switch. However, if you choose to establish a direct

point-to-point ELAN connection, no other device can connect

to the ELAN.

5

At the switch, connect the ELAN network cable to an MAU (Ethernet)

transceiver for a Meridian 1, or to the RJ45 ELAN connector for a

CS1000. Then complete the connection from the transceiver to the

switch.

What is next?

the server will THEN

be connected to the Nortel server

subnet

not be connected to a Nortel server

subnet

DANGER

MAU model NTRH9069 is not suitable for installation in

ducts, plenums, or other spaces used for environmental

air. Do not install it above a false ceiling or below a raised

floor, unless it can be confirmed that these spaces are not

used to convey environmental air.

—End—

continue with "Connecting the server

to the Nortel server subnet (optional)"

(page 51)

continue with installing the software

feature dongle. See "Installing the

Nortel software feature dongle" (page

52).

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 51

Connecting the server to the Nortel server subnet (optional) 51

Connecting the server to the Nortel server subnet (optional)

Introduction

This section provides instructions to connect the server to the Nortel server

subnet.

Note: The Nortel server subnet is optional. However, a Nortel server

subnet is required to support desktop and Web messaging users.

ATTENTION

To comply with EMC radiation requirements, a Class A hub must be located 10 m

(33 ft.) away from the 1002rp server. Shielded Ethernet cables must be used.

Media Access Control address

The MAC address is a unique number assigned to network cards and

controllers. The procedure below asks you to record the CLAN MAC

address. The MAC address is recorded on a label affixed to the back of

the chassis.

To connect the server to the Nortel server subnet

Step Action

1

See the diagram on page "Rear panel connectors" (page 47) to

locate the CLAN network card.

2

Locate the MAC address label on the back of the chassis that

identifies the CLAN controller MAC address.

3

Record the MAC address on the Configuration Wizard worksheet

that is provided in the Installation and Configuration Task List

(NN44200-306).

You need the MAC address to identify the CLAN when running the

Configuration Wizard to configure the CallPilot server.

Note: When connecting the optional Nortel server subnet, do

not power up unless your antivirus programs and Nortel security

updates are installed first.

4

Connect an RJ-45 network cable from the CLAN hub or switch to

the CLAN connector.

—End—

What is next?

Continue with "Installing the Nortel software feature dongle" (page 52).

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 52

52 Chapter 5 Installing the server and connecting the peripheral devices

Installing the Nortel software feature dongle

Introduction

The software feature key is a security device that stores the unique serial

number of the server. The feature key is embedded in the Nortel software

feature dongle, which plugs into the parallel port.

An illustration of the software feature key embedded in the software feature

dongle is shown below:

Requirements

For installation, you require a Phillips No. 1 screwdriver.

To install the software feature dongle

Step Action

1

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Ensure that there is no cable connected to the parallel port.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 53

Connecting the server to power 53

Note: The parallel port is also known as the printer port or LPT1.

It is located at the back of the server. See the diagram on page

"Rear panel connectors" (page 47).

2

If the software feature key is not preinstalled in the dongle, remove it

from the plastic bag, and carefully insert it into the software feature

slot on the dongle. Make sure that the clips secure it properly and

that the Nortel logo faces outwards.

3

4

Plug the male end of the adapter into the parallel port.

Tighten the connector screws.

What is next?

Continue with "Connecting the server to power" (page 53).

Connecting the server to power

Before you begin

Ensure that proper power and grounding are available for all the power

outlets serving the CallPilot server and its associated peripherals. Power

for these devices must be wired and fused independently of all other

receptacles, and referenced to the same ground as the PBX system.

A qualified electrician must implement the single-point ground reference as

required between the power outlets of the CallPilot server and the power

outlets of the switch.

—End—

Provide a sufficient number of properly grounded power outlets or power

bars for all equipment. For more information, refer to grounding and power

requirements in this document and in the CallPilot Planning and Engineering

Guide (NN44200-200).

The single-point ground (SPG) required by the system can be an isolated

ground (IG) bus or AC equipment ground (ACEG) bus in the service panel

or transformer. The system must be connected to safety ground/protective

earth in accordance with NEC requirements. For international use, the

system must be connected to safety ground/protective earth in accordance

with Paragraph 2.5 of EN60950/IEC950.

Note: Refer to Large System: Planning and Engineering

(553-3021-120) for a complete description of approved ground sources

and methods. Insulated ground wire must be used for system grounding.

Before you connect the server to the power source, review the following

diagram to ensure that all peripheral hardware devices are in place.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 54

54 Chapter 5 Installing the server and connecting the peripheral devices

Note: For details on the DC power source for 1002rp DC servers, see

"Installing the second power supply module (AC or DC)" (page 34)

To connect the 1002rp AC server to power

Step Action

WARNING

The power outlets used by the CallPilot server and its peripheral

devices must be connected to the same single-point ground

reference as the one used by the switch with MGate cards

(NTRB18CA) connected to the CallPilot server. If this requirement

is not met, power transients can cause personal injury, or hardware

failure, or both. Refer to the Installation and Configuration Task

List (NN44200-306) for more information on single-point grounding

requirements.

1

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Plug the server AC power cord into the server rear panel.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 55

Connecting the server to power 55

2

Plug the other end into a wall receptacle or power bar.

—End—

To connect the 1002rp DC server to power

Step Action

DANGER

•

Only qualified personnel can alter electrical connections.

•

Ensure the power distribution unit (PDU) is turned off

until you are instructed to turn it on.

1

2

Connect the DC power cable to the server.

Connect the other end of the DC power cable to the PDU. Use the

supplied clips and screws to secure the plugs.

The following photograph shows the keyed plug of the DC power

cable. This plug connects to the PDU:

Note: If you are not using a Nortel-supplied PDU, have a

qualified electrician connect the cable appropriately to your DC

power plant. The 1002rp uses a negative 48 V power supply,

therefore the red cable is negative (-48 V) and the black cable is

the ground (GND).

3

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Turn on the PDU.

Nortel CallPilot

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

5.0 23 February 2007

Page 56

56 Chapter 5 Installing the server and connecting the peripheral devices

—End—

To start the server

Step Action

1 Press the server power switch to start the server.

2

Observe the Power-On Self Test (POST) and initialization messages

on the monitor.

3 Let the mini-setup sequence run until you are prompted to login

to the operating system.

Note: The system may perform multiple reboots. This is normal.

4

Ensure that the operating system logon window appears on the

monitor.

Note: If the logon window does not appear, refer to the 1002rp

Server Maintenance and Diagnostics (NN44200-701) guide for

troubleshooting instructions.

—End—

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 57

Appendix A

EMC emission level protection for the

1002rp Server

To lower the EMC emission level, ferrite cores are installed with one loop

(see diagram below) on the following external cables:

•

Ferrite Core (TDK and part number ZCAT3035-1330) — for the triple

DS30X I/O cable (Nortel and part number NTRH2014), at each end

of the cable

•

Ferrite Core (TDK and part number ZCAT1325-0530) — for the modem

power supply cable, at each end of the cable

• Ferrite Core (Fair Rite and part number 0431164181) — for the Trenton

combined keyboard and mouse Y connector cable, at the server end

of the cable

•

Ferrite Core (part number WE 742 7111) — for Ethernet port cat5 UTP

cable, at the server end of the cable

57

CAUTION

The ferrite cores are preinstalled on these customer provided

cables. It is not the customer’s responsibility to attach these ferrite

cores to these cables. However, the customer should ensure that

these ferrites are in place to keep the EMC emission levels low.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 58

58 Appendix A EMC emission level protection for the 1002rp Server

Ferrites secured to an external cable

The ferrites are secured to the appropriate cable with plastic enclosure clips.

Ty wraps are added to the cable loop.

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 59

Index

59

Symbols/Numerics

703t server

environmental specifications 12

A

adapter

software feature key, illustration 52

alarm board 13

C

checklist

installation 23

CLAN

media access control address 51

Communication Server 1000 and CallPilot

server network diagram 19

connecting peripherals to the server 47

connecting the server 53

connectivity

Ethernet 20

remote 21

Customer LAN

see CLAN 51

D

DC power 40

DC power and ground 42

DC power input 41

DC wire gauge tables 36

devices, peripheral

Ethernet hub 22

keyboard 22

modem 21

monitor 22

mouse 22

diagram

connection

network, Communication Server

1000 and CallPilot server 19

network, M1 and CallPilot

server 19

front panel 12

PCI and ISA connectors 14

rear panel

slot locations 13

server connections for the power

cord and peripherals 47

DIP switches

modem, function 45

DIP switches, setting

modem 45

dongle 52

E

ELAN

Media Access Control address 49

environmentalspecifications, 703t server 12

equipment

unpacking 26

Ethernet hub

description 22

F

fax modem

illustration 44

required equipment 44

features

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 60

60 Index

server 11

features, front panel

diagram 12

front bezel 27

G

grounding guidelines 36

I

illustration

modem 44

software feature key adapter 52

TLAN 19

inspecting

server interior 29

installation checklist 23

IRQ mapping table 18

K

keyboard

connecting to the server 47

description 22

keylock 52

M

M1 and CallPilot server network diagram 19

Metric wire conversion 37

modem

connecting to the server 48

description 21

DIP switches, setting 45

illustration 44

required equipment 44

monitor

connecting to the server 47

description 22

mouse

connecting to the server 47

description 22

N

network

protocols, supported 20

network interface cards 20

P

part number

Ethernet hub 22

keyboard 22

modem 21

monitor 22

mouse 22

PCI and ISA connectors

diagram 14

PDU 40

multiple PDUs 41

power and grounding 40

single PDU wiring diagram 41

peripheral devices

Ethernet hub 22

keyboard 22

modem 21

monitor 22

mouse 22

peripherals

connecting to the server 47

power connection

AC server 54

DC server 55

power distribution rationale 39, 40

power distribution unit

See PDU 40

power guidelines 36

power supply

bringing power and ground into the

PDU 42

DC wire gauge tables 36

grounding guidelines 36

Metric wire conversion 37

module installation 35

module location 34

overview 34

PDU 40

power distribution rationale 40

rack power and grounding 39

protocols, supported network 20

R

rack power and grounding 39

remote access

connectivity 21

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 61

Index 61

removing

front bezel 27

server cover 28

replacing

server cover 30

S

safety information 33

serial number of the server 52

server

connecting peripherals 47

environmental specifications 12

power connection 53

serial number 52

setting

modem DIP switches 45

slot assignments 15

slot definition 17

slot numbering 17

software feature key 52

specifications, environmental 12

switches, setting DIP

modem 45

T

tables, slot assignment 15

TLAN

illustration 19

U

unpacking

equipment 26

1002rp Server Hardware Installation

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

Nortel CallPilot

5.0 23 February 2007

Page 62

62 Index

1002rp Server Hardware Installation

Nortel CallPilot

NN44200-300 01.01 Standard

Copyright © 2007, Nortel Networks Nortel Networks Confidential

.

5.0 23 February 2007

Page 63

Page 64

Nortel CallPilot

1002rp Server Hardware Installation

Copyright © 2007, Nortel Networks

All Rights Reserved.

Publication: NN44200-300

Document status: Standard

Document version: 01.01

Document date: 23 February 2007

To provide feedback or to report a problem in this document, go to w

Sourced in Canada

The information in this document is subject to change without notice. The statements, configurations, technical data, and

recommendations in this document are believed to be accurate and reliable, but are presented without express or implied

warranty. Users must take full responsibility for their applications of any products specified in this document. The information in

this document is proprietary to Nortel Networks.

*Nortel, the Nortel logo, and the Globemark are trademarks of Nortel Networks.

*Microsoft, MS, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

All other trademarks and registered trademarks are the property of their respective owners.

ww.nortel.com/documentfeedback

Loading...

Loading...