Page 1

Title page

Nortel Communication Server 1000

Nortel Communication Server 1000 Release 5.5

Communication Server 1000M and

Meridian 1

Large System Installation and Commissioning

Document Number: NN43021-310

Document Release: Standard 02.01

Date: December 2007

Year Publish FCC TM

Copyright © 2007, Nortel Networks. All rights reserved.

Sourced in Canada

LEGAL NOTICE While the information in this document is believed to be accurate and reliable, except as

otherwise expressly agreed to in writing. NORTEL PROVIDES THIS DOCUMENT "AS IS" WITHOUT

WARRANTY OR CONDITION OF ANY KIND, EITHER EXPRESS OR IMPLIED. The information and/or

products described in this document are subject to change without notice.

Nortel, Nortel (Logo), the Globemark, SL-1, Meridian 1, and Succession are trademarks of Nortel Networks. All

other trademarks are the property of their respective owners.

Page 2

Page 3

10

Page 3 of 456

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

New in this release . . . . . . . . . . . . . . . . . . . . . . . . . 11

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

List of Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to get help . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Getting help from the Nortel Web site . . . . . . . . . . . . . . . . . . . . . . . . . 19

Getting help over the telephone from a Nortel Solutions Center . . . . . 19

Getting help from a specialist by using an Express Routing Code . . . . 20

Getting help through a Nortel distributor or reseller .. . . . . . . . . . . . . . 20

Finding the latest updates

on the Nortel web site . . . . . . . . . . . . . . . . . . . . . . . 21

System information . . . . . . . . . . . . . . . . . . . . . . . . . 23

Subject .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Applicable systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Intended audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Conventions .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

NTP feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Related information .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 4

Page 4 of 456 Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Summary of procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Preparing for installation . . . . . . . . . . . . . . . . . . . . 37

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System equipment – UEMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

System options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Cable routing guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Equipment handling precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Preparing the equipment for installation .. . . . . . . . . . . . . . . . . . . . . . . 62

Placing the fourth module on a column . . . . . . . . 65

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Placing the fourth module on a column . . . . . . . . . . . . . . . . . . . . . . . . 65

Positioning and leveling equipment . . . . . . . . . . . 71

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Positioning and leveling the equipment . . . . . . . . . . . . . . . . . . . . . . . . 71

Installing AC power . . . . . . . . . . . . . . . . . . . . . . . . 77

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

AC-powered systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Safety ground/protective earth and logic return wiring . . . . . . . . . . . . 78

Installing safety ground/protective earth and logic return wiring .. . . . 82

Installing UPS ground cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Installing overhead cable tray kits . . . . . . . . . . . . 89

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

NN43021-310 Standard 02.01 December 2007

Page 5

Contents Page 5 of 456

Installing overhead cable tray kits .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Installing DC power . . . . . . . . . . . . . . . . . . . . . . . . . 93

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

DC-powered systems .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Candeo DC power systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Planning and designating a

Main Distribution Frame . . . . . . . . . . . . . . . . . . . . . 133

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

About terminations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Installation and designation .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Terminal block requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Installing the BIX cross-connect terminal .. . . . . . . . . . . . . . . . . . . . . . 134

Installing the Krone cross-connect system (UK) . . . . . . . . . . . . . . . . . 138

Installing Power Failure Transfer Units . . . . . . . . . 145

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

PFTU configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Installing a PFTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Connecting trunks and telephones .. . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Installing QUA6 PFTUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Configuring the system monitor . . . . . . . . . . . . . . 151

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

System monitor cabling .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Configuring the System Monitor .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Cabling the System Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Alarm interfacing to Candeo .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Configuring the alarm ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Customizing alarms .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 6

Page 6 of 456 Contents

Connecting a system terminal or modem . . . . . . 171

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

About the system terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Connecting a terminal .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Connecting a terminal to a COM port . . . . . . . . . . . . . . . . . . . . . . . . . 174

Connecting a switch box and terminal to

COM1 and COM2 ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Connecting a switch box and terminal to

SDI and COM1 ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Connecting a modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Configuring a modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Connecting a modem to an SDI port . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Connecting a modem to switch box, COM2 ports, SDI ports . . . . . . . 183

Cabling Common Equipment in a

Single Group system . . . . . . . . . . . . . . . . . . . . . . . 187

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Cabling guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Core/Net module .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Cabling the Core side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Cabling the I/O panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Cabling the Network side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Configuring and cabling the Clock Controllers . . . . . . . . . . . . . . . . . . 198

Network Group 0: Shelf 0 to Shelf 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Connecting the 3PE faceplates in the Core/Net modules . . . . . . . . . . . 199

Inspecting CNI to 3PE factory installed cables . . . . . . . . . . . . . . . . . . 200

Connecting the Core/Net backplanes . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Optioning the System Utility Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Connecting Core modules to a LAN .. . . . . . . . . . . . . . . . . . . . . . . . . . 204

NN43021-310 Standard 02.01 December 2007

Page 7

Contents Page 7 of 456

Cabling Common Equipment in a

Multi Group system . . . . . . . . . . . . . . . . . . . . . . . . . 207

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Cabling guidelines .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Core/Net module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Cabling the Core/Net module backplane . . . . . . . . . . . . . . . . . . . . . . . 212

Disconnecting cables from the Core/Net module backplane . . . . . . . . 213

Optioning the System Utility Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Core shelf cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Installing the CP PIV to I/O panel cables . . . . . . . . . . . . . . . . . . . . . . . 220

Connecting the Core module to a LAN .. . . . . . . . . . . . . . . . . . . . . . . . 223

Cabling a Dual Ring Fiber Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

FIJI card cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Installing the Shelf 0 fiber optic ring (ascending) .. . . . . . . . . . . . . . . . 231

Installing the Shelf 1 fiber optic ring (descending) .. . . . . . . . . . . . . . . 232

FIJI to FIJI cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Connecting the Clock Controller cables . . . . . . . . . . . . . . . . . . . . . . . . 235

Cabling network modules and loops . . . . . . . . . . . 239

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Network-to-network cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Network module connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Network Group 0: Shelf 0 to Shelf 1 .. . . . . . . . . . . . . . . . . . . . . . . . . . 240

Connecting the 3PE faceplates in the Core/Net modules . . . . . . . . . . . 240

Connecting the Core/Net backplanes . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Connecting Groups 1 through 7: Shelf 0 to Shelf 1 . . . . . . . . . . . . . . . 242

Connecting the Network modules to the Core/Net modules .. . . . . . . . 245

Connecting the 3PE cables to the 3PE fanout panels . . . . . . . . . . . . . . 250

Cabling a Superloop Network Card – single column . . . . . . . . . . . . . . 252

Cabling a Superloop Network Card – multiple columns . . . . . . . . . . . 256

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 8

Page 8 of 456 Contents

Cabling lines and trunks . . . . . . . . . . . . . . . . . . . . 261

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Overview .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Cabling an IPE Module or Media Gateway . . . . . . . . . . . . . . . . . . . . . 263

Connecting lines and trunks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Powering up the system and initial loading . . . . . 299

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Overview .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Installing the Security Device .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Preparing to power up – AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Connecting the AC power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Turning AC power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Resetting the main circuit breakers (AC power) . . . . . . . . . . . . . . . . . 304

Preparing to power up – DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Turning DC power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Installing software .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Testing Core/Net 1 and Core/Net 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Performing acceptance tests . . . . . . . . . . . . . . . . 335

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Acceptance tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

Testing the module power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Testing the blower unit and thermal sensor . . . . . . . . . . . . . . . . . . . . . 337

Testing the sysload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Testing the system terminal and system monitor . . . . . . . . . . . . . . . . . 340

Testing the PFTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Installing earthquake bracing . . . . . . . . . . . . . . . . 343

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

Seismic-approved applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

NN43021-310 Standard 02.01 December 2007

Page 9

Contents Page 9 of 456

Installing seismic bracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

Drilling concrete floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Installing Kit A and Kit B anchor plates .. . . . . . . . . . . . . . . . . . . . . . . 349

Installing earthquake rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Positioning and leveling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Installing non-seismic bracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

Installing a non-seismic anchor kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 359

Adding a module to a column . . . . . . . . . . . . . . . . 363

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Adding a module to the base of a column . . . . . . . . . . . . . . . . . . . . . . . 364

Adding a module between two other modules . . . . . . . . . . . . . . . . . . . 370

Adding a module to the top of a column .. . . . . . . . . . . . . . . . . . . . . . . 374

Installing a Signaling Server . . . . . . . . . . . . . . . . . 383

Contents .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

Readiness checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 385

Installing the CP PM Signaling Server hardware . . . . . . . . . . . . . . . . . 387

Connections .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Installing the Signaling Server software . . . . . . . . . . . . . . . . . . . . . . . . 399

First boot of a new Nortel CP PM Signaling Server . . . . . . . . . . . . . . . 426

Unpacking Help files for Virtual Terminal Emulator . . . . . . . . . . . . . . 445

Logging in to the Signaling Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . 445

Verifying a successful configuration .. . . . . . . . . . . . . . . . . . . . . . . . . . 447

Testing the Leader Signaling Server . . . . . . . . . . . . . . . . . . . . . . . . . . . 447

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 449

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 10

Page 10 of 456 Contents

NN43021-310 Standard 02.01 December 2007

Page 11

12

Page 11 of 456

New in this release

Features

There are no new features in this NTP for CS 1000 Release 5.5.

Other

Revision History

December 2007

Standard 02.01. This document is up-issued for Communication Server 1000

Release 5.5.

July 2007

Standard 01.03. This document is up-issued for Communication Server 1000

Release 5.0.

July 2007

Standard 01.02. This document is up-issued for Communication Server 1000

Release 5.0.

May 2007

Standard 01.01. This document is up-issued for Communication Server 1000

Release 5.0. This document contains information previously contained in the

following legacy document, now retired: Communication Server 1000M and

Meridian 1: Large System Installation and Configuration (553-3021-210).

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 12

Page 12 of 456 New in this release

April 2006

Standard 4.00. This document is up-issued with corrections from CR

Q01311083. The corrections appear in the “Configuring the System Monitor'

section (page 153 to page 157).

August 2005

Standard 3.00. This document is up-issued to support Communication

Server 1000 Release 4.5.

September 2004

Standard 2.00. This document is up-issued to support Communication

Server 1000 Release 4.0.

October 2003

Standard 1.00. This document is a new NTP for Succession 3.0. It was created

to support a restructuring of the Documentation Library, which resulted in the

merging of multiple legacy NTPs. This new document consolidates

information previously contained in the following legacy documents, now

retired:

• Cabling Guide (553-3001-109)

• System Installation Procedures (553-3001-210)

NN43021-310 Standard 02.01 December 2007

Page 13

18

Page 13 of 456

List of Procedures

Procedure 1

Preparing the equipment for installation . . . . . . . . . . . . . . . . . . . . . 62

Procedure 2

Placing the fourth module on a column . . . . . . . . . . . . . . . . . . . . . . 66

Procedure 3

Positioning and leveling the equipment . . . . . . . . . . . . . . . . . . . . . . 71

Procedure 4

Installing safety ground/protective earth and logic return wiring . 82

Procedure 5

Installing the UPS ground cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Procedure 6

Installing the overhead cable tray kits . . . . . . . . . . . . . . . . . . . . . . . 90

Procedure 7

Installing and connecting the power plant frame ground leads . . . 113

Procedure 8

Installing safety ground/protective earth wiring . . . . . . . . . . . . . . . 123

Procedure 9

Connecting power from the power plant to the PDU (NT4N49AA) . 125

Procedure 10

Connecting UK power to the Four-Feed PDU . . . . . . . . . . . . . . . . . 129

Procedure 11

Installing the BIX cross-connect terminal . . . . . . . . . . . . . . . . . . . . 135

Procedure 12

Installing the Krone Test Jack Frame (UK) . . . . . . . . . . . . . . . . . . . . 138

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 14

Page 14 of 456

Procedure 13

Installing a PFTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Procedure 14

Connecting trunks and telephones . . . . . . . . . . . . . . . . . . . . . . . . . 149

Procedure 15

Configuring the System Monitor (NT8D22) . . . . . . . . . . . . . . . . . . . 153

Procedure 16

Cabling the System Monitor (NT8D22) . . . . . . . . . . . . . . . . . . . . . . . 158

Procedure 17

Configuring the alarm ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Procedure 18

Connecting a terminal to a COM port . . . . . . . . . . . . . . . . . . . . . . . . 174

Procedure 19

Connecting a switch box and terminal to COM1 and COM2 ports 175

Procedure 20

Connecting a switch box and terminal to the SDI and COM1 ports 177

Procedure 21

Configuring a modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Procedure 22

Connecting a modem to an SDI port . . . . . . . . . . . . . . . . . . . . . . . . 181

Procedure 23

Connecting a modem to a switch box, COM2 and SDI ports . . . . . 183

Procedure 24

Installing the CP PIV to I/O panel cables . . . . . . . . . . . . . . . . . . . . . 196

Procedure 25

Connecting the Clock Controller cables . . . . . . . . . . . . . . . . . . . . . 199

Procedure 26

Connecting the 3PE faceplates in the Core/Net modules . . . . . . . . 200

Procedure 27

Inspecting NT4N29AA factory installed cables . . . . . . . . . . . . . . . . 200

Procedure 28

Connecting the Core/Net backplanes . . . . . . . . . . . . . . . . . . . . . . . . 202

NN43021-310 Standard 02.01 December 2007

Page 15

Page 15 of 456

Procedure 29

Connecting the Core module to a LAN . . . . . . . . . . . . . . . . . . . . . . . 205

Procedure 30

Cabling the Core/Net module backplane . . . . . . . . . . . . . . . . . . . . . 213

Procedure 31

Disconnecting cable connectors from the backplane . . . . . . . . . . . 214

Procedure 32

Installing the CP PIV to I/O panel cables . . . . . . . . . . . . . . . . . . . . . 221

Procedure 33

Connecting the Core module to a LAN . . . . . . . . . . . . . . . . . . . . . . . 223

Procedure 34

Installing the Shelf 0 fiber optic ring (ascending) . . . . . . . . . . . . . . 231

Procedure 35

Installing the Shelf 1 fiber optic ring . . . . . . . . . . . . . . . . . . . . . . . . . 232

Procedure 36

Connecting the FIJI to FIJI cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Procedure 37

Connecting the Clock Controller cables . . . . . . . . . . . . . . . . . . . . . . 236

Procedure 38

Connecting the 3PE faceplates in the Core/Net modules . . . . . . . . 240

Procedure 39

Connecting the Core/Net backplanes . . . . . . . . . . . . . . . . . . . . . . . . 241

Procedure 40

Connecting Groups 1 through 7: Shelf 0 to Shelf 1 . . . . . . . . . . . . . 243

Procedure 41

Connecting the Network Shelf 0 3PE cards to Core/Net 0 . . . . . . . 251

Procedure 42

Connecting the Network Shelf 1 3PE cards to Core/Net 1 . . . . . . . 251

Procedure 43

Basic cabling for single-row network connections . . . . . . . . . . . . . 252

Procedure 44

Basic cabling for multiple-row network connections . . . . . . . . . . . 256

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 16

Page 16 of 456

Procedure 45

Cabling an IPE Module (NT8D37) or Media Gateway . . . . . . . . . . . 264

Procedure 46

Connecting lines and trunks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Procedure 47

Installing the Security Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Procedure 48

Preparing to power up – AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Procedure 49

Option 1: Using the installed power plug (recommended) . . . . . . . 302

Procedure 50

Option 2: Hard-wiring the power connections (optional) . . . . . . . . 303

Procedure 51

Turning AC power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Procedure 52

Resetting the main circuit breakers (AC power) . . . . . . . . . . . . . . . 304

Procedure 53

Preparing to power up – DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Procedure 54

Turning DC power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Procedure 55

Installing the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Procedure 56

Testing Core/Net 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330

Procedure 57

Switching call processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

Procedure 58

Testing Core/Net 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Procedure 59

Testing module power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

Procedure 60

Testing blower unit and thermal sensor . . . . . . . . . . . . . . . . . . . . . 337

NN43021-310 Standard 02.01 December 2007

Page 17

Page 17 of 456

Procedure 61

Sysload test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

Procedure 62

Testing system terminal and system monitor . . . . . . . . . . . . . . . . . 340

Procedure 63

Testing the PFTU and its interface . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Procedure 64

Drilling concrete floors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Procedure 65

Installing Kit A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349

Procedure 66

Installing Kit B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351

Procedure 67

Installing earthquake rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 352

Procedure 68

Leveling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Procedure 69

Installing a Floor Mounting Kit (NT8D64BF) . . . . . . . . . . . . . . . . . . . 359

Procedure 70

Adding a module to the base of a column . . . . . . . . . . . . . . . . . . . . 365

Procedure 71

Adding a module between two other modules . . . . . . . . . . . . . . . . 370

Procedure 72

Adding a module to the top of the column . . . . . . . . . . . . . . . . . . . . 374

Procedure 73

Connecting a Nortel CP PM Signaling Server . . . . . . . . . . . . . . . . . 392

Procedure 74

Connecting a CP PM Signaling Server to the ELAN and TLAN subnets of

a CS 1000E system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 393

Procedure 75

Connecting a CP PM Signaling Server to the ELAN and TLAN subnets of

a CS 1000M system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 395

Procedure 76

Connecting an IBM X306m Signaling Server . . . . . . . . . . . . . . . . . . 396

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 18

Page 18 of 456

Procedure 77

Connecting an HP DL320-G4 Signaling Server . . . . . . . . . . . . . . . . 398

Procedure 78

Installing Signaling Server software . . . . . . . . . . . . . . . . . . . . . . . . . 400

Procedure 79

Entering basic system configuration parameters . . . . . . . . . . . . . . 427

Procedure 80

Adding a Follower Signaling Server to an IP Telephony node . . . 441

Procedure 81

Logging in to the Signaling Server . . . . . . . . . . . . . . . . . . . . . . . . . . 446

Procedure 82

Verifying the Signaling Server Ethernet connection . . . . . . . . . . . . 447

NN43021-310 Standard 02.01 December 2007

Page 19

20

Page 19 of 456

How to get help

This section explains how to get help for Nortel products and services.

Getting help from the Nortel Web site

The best way to get technical support for Nortel products is from the Nortel

Technical Support Web site:

www.nortel.com/support

This site provides quick access to software, documentation, bulletins, and

tools to address issues with Nortel products. More specifically, the site

enables you to:

• download software, documentation, and product bulletins

• search the Technical Support Web site and the Nortel Knowledge Base

for answers to technical issues

• sign up for automatic notification of new software and documentation for

Nortel equipment

• open and manage technical support cases

Getting help over the telephone from a Nortel Solutions Center

If you don’t find the information you require on the Nortel Technical Support

Web site, and have a Nortel support contract, you can also get help over the

phone from a Nortel Solutions Center.

In North America, call 1-800-4NORTEL (1-800-466-7835).

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 20

Page 20 of 456 How to get help

Outside North America, go to the following Web site to obtain the phone

number for your region:

www.nortel.com/callus

Getting help from a specialist by using an Express Routing Code

To access some Nortel Technical Solutions Centers, you can use an Express

Routing Code (ERC) to quickly route your call to a specialist in your Nortel

product or service. To locate the ERC for your product or service, go to:

www.nortel.com/erc

Getting help through a Nortel distributor or reseller

If you purchased a service contract for your Nortel product from a distributor

or authorized reseller, contact the technical support staff for that distributor

or reseller.

NN43021-310 Standard 02.01 December 2007

Page 21

22

Page 21 of 456

Finding the latest updates on the Nortel web site

The content of this documentation was current at the time the product

was released. To check for updates to the latest documentation and

software for CS 1000 Release 5.5, click one of the links below.

Latest Software Takes you directly to the Nortel

page for CS 1000 Release 5.5

software.

Latest Documentation Takes you directly to the Nortel

page for CS 1000 Release 5.5

documentation.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 22

Page 22 of 456 Finding the latest updates on the Nortel web site

NN43021-310 Standard 02.01 December 2007

Page 23

30

Page 23 of 456

System information

This document is a global document. Contact your system supplier or your

Nortel representative to verify that the hardware and software described are

supported in your area.

Subject

WAR NING

Before a Large System can be installed, a network

assessment must be performed and the network must be

VoIP-ready.

If the minimum VoIP network requirements are not met,

the system will not operate properly.

For information on the minimum VoIP network

requirements and converging a data network with VoIP,

refer to Converging the Data Network with VoIP

(NN43001-260).

This document provides installation and acceptance testing procedures for

Meridian 1 Large Systems and Communication Server 1000M Large

Systems.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 24

Page 24 of 456 System information

For this document, the CP PIV processor is assumed in the case of the

CS 1000M SG, Meridian 1 PBX 61C, CS 1000M MG, and Meridian 1

PBX 81C. If you are installing a system with a CP PII processor, please refer

to the CS 1000 Release 5.0 version of this document, available on the web at:

www.nortel.com/support

To access the NTP from the Technical Support page, go to the content listing

page for Communication Server 1000M:

1 Select the Browse product support tab on the main page.

2 Select Product Families from the drop-down menu, and then

Enterprise Communication Servers in the first window.

3 Select Communication Server 1000M Cabinet/Chassis from the

second window.

4 Select Documentation from the third window and click the Go button

on the right.

5 Use the filter provided under the Documentation tab to search for

Communication Server 1000M 4.0.

Note on legacy products and releases

This NTP contains information about systems, components, and features that

are compatible with Nortel Communication Server 1000 Release 5.5

software. For more information on legacy products and releases, click the

Technical Documentation link under Support & Training on the Nortel

home page:

www.nortel.com/

Applicable systems

This document applies to the following systems:

• Communication Server 1000M Half Group (CS 1000M HG)

• Communication Server 1000M Single Group (CS 1000M SG)

• Communication Server 1000M Multi Group (CS 1000M MG)

NN43021-310 Standard 02.01 December 2007

Page 25

System information Page 25 of 456

• Meridian 1 Option 51

• Meridian 1 PBX 51C

• Meridian 1 PBX 61C

• Meridian 1 Option 71

•Meridian1 PBX81

• Meridian 1 PBX 81C

Note: When upgrading software, memory upgrades may be required on

the Signaling Server, the Call Server, or both.

System migration

When particular Meridian 1 systems are upgraded to run CS 1000

Release 5.5 software and configured to include a Signaling Server, they

become CS 1000M systems. Table 1 lists each Meridian 1 system that

supports an upgrade path to a CS 1000M system.

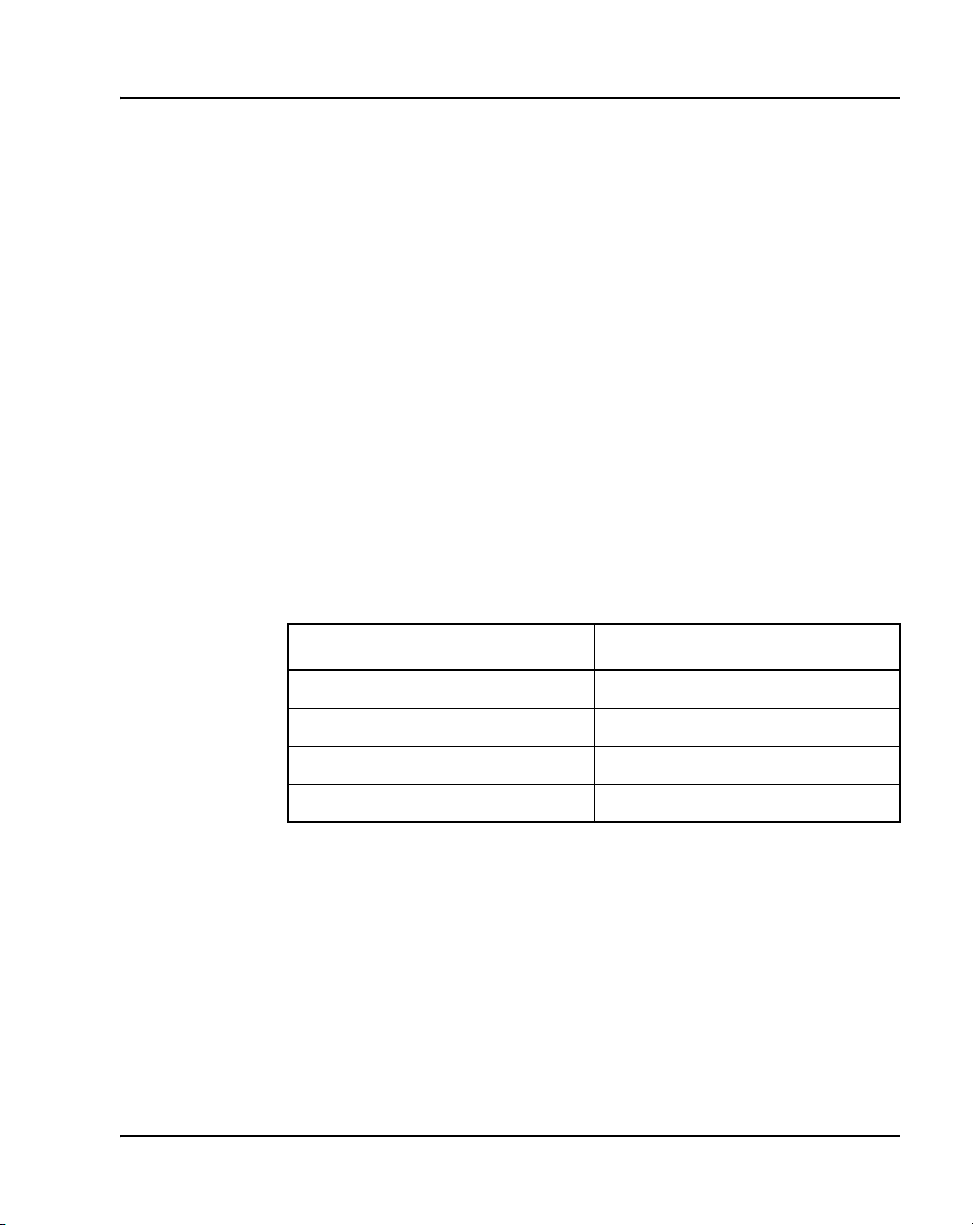

Table 1

Meridian 1 systems to CS 1000M systems

This Meridian 1 system... Maps to this CS 1000M system

Meridian 1 PBX 51C CS 1000M Half Group

Meridian 1 PBX 61C CS 1000M Single Group

Meridian 1 PBX 81 CS 1000M Multi Group

Meridian 1 PBX 81C CS 1000M Multi Group

For more information, see Communication Server 1000M and Meridian 1

Large System Upgrade NTPs (NN43021-458 – NN43021-475).

Intended audience

This document is intended for individuals responsible for installing and

configuring Large Systems. To use this document, you should have a basic

knowledge of Large System equipment and operation. Contact Nortel for

information on installation courses. You should also read and fully

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 26

Page 26 of 456 System information

understand the Communication Server 1000M and Meridian 1: Large System

Overview (NN43021-110) before you install a system.

Conventions

Terminology

The following systems are referred to generically as “Large System”:

• Communication Server 1000M Half Group (CS 1000M HG)

• Communication Server 1000M Single Group (CS 1000M SG)

• Communication Server 1000M Multi Group (CS 1000M MG)

• Meridian 1 Option 51

• Meridian 1 PBX 51C

• Meridian 1 PBX 61C

• Meridian 1 Option 71

•Meridian1 PBX81

• Meridian 1 PBX 81C

NTP feedback

Nortel strives to provide accurate documentation for our customers.

However, if you feel there are errors or omissions in this document, your

feedback is welcome.

Send comments via e-mail to gntsdoc@nortel.com or open a problem report

via the normal procedures.

Please provide as much information as possible including the NTP number,

standard version and date of the document, as well as the page, problem

description, and any supporting documentation and capture files.

NN43021-310 Standard 02.01 December 2007

Page 27

Related information

This section lists information sources that relate to this document.

NTPs

The following NTPs are referenced in this document:

• Circuit Card: Description and Installation (NN43001-311)

• Signaling Server: Installation and Commissioning (NN43001-312)

• System Security Management (NN43001-602)

• Software Input/Output: Administration (NN43001-611)

• Telephones and Consoles: Description, Installation, and Operation

(NN43001-567)

• Software Input/Output: System Messages (NN43001-712)

• Communication Server 1000M and Meridian 1: Large System Overview

(NN43021-110)

• Communication Server 1000M and Meridian 1: Large System Planning

and Engineering (NN43021-220)

• CS 1000M and Meridian 1 Large System Upgrades Overview

(NN43021-458)

System information Page 27 of 456

• CS 1000M and Meridian 1 51C to CS 1000M SG CP PIV Upgrade

(NN43021-459)

• CS 1000M and Meridian 1 Option 51C to CS 1000M MG (CP PIV FNF)

Upgrade (NN43021-460)

• CS 1000M and Meridian 1 61C to CS 1000M SG CP PIV Upgrade

(NN43021-461)

• CS 1000M and Meridian 1 61C CP PII to CS 1000M SG CP PIV

Upgrade (NN43021-462)

• CS 1000M and Meridian 1 61C to CS 1000M MG CP PIV FNF Upgrade

(NN43021-463)

• CS 1000M and Meridian 1 61C CP PII to CS 1000M MG CP PII FNF

Upgrade (NN43021-464)

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 28

Page 28 of 456 System information

• CS 1000M and Meridian 1 61C CP PII to CS 1000M MG CP PIV FNF

Upgrade (NN43021-465)

• CS 1000M and Meridian 1 CS1000M SG CP PIV to CS 1000M MG CP

PIV FNF Upgrade (NN43021-466)

• CS 1000M and Meridian 1 71 to CS 1000M MG CP PIV FNF Upgrade

(NN43021-467)

• CS 1000M and Meridian 1 81 to CS 1000M MG CP PII FNF Upgrade

(NN43021-468)

• CS 1000M and Meridian 1 81C IGS to CS 1000M MG CP PII FNF

Upgrade (NN43021-469)

• CS 1000M and Meridian 1 81C FNF to CS 1000M MG CP PII FNF

Upgrade (NN43021-470)

• CS 1000M and Meridian 1 81C IGS to CS 1000M MG CP PIV FNF

Upgrade (NN43021-471)

• CS 1000M and Meridian 1 CS 1000M MG CP PII IGS to CS 1000M MG

CP PII FNF Upgrade (NN43021-472)

• CS 1000M and Meridian 1 CS 1000M MG CP PII IGS to CS 1000M MG

CP PIV FNF Upgrade (NN43021-473)

• CS 1000M and Meridian 1 CS 1000M MG CP PII FNF to CS 1000M MG

CP PIV FNF Upgrade (NN43021-474)

Other documentation

The following documentation is referenced in this document:

• Candeo Power System User Guide (P0914425)

• Candeo Power System Installation Guide (P0914426)

• Candeo SP 48300 Power System AP6C55AA User Manual (P7000154)

• Candeo SP 48300 Power System AP6C55AA Installation Manual

(P7000289)

NN43021-310 Standard 02.01 December 2007

Page 29

System information Page 29 of 456

Online

To access Nortel documentation online, click the Technical Documentation

link under Support & Training on the Nortel home page:

www.nortel.com

CD-ROM

To obtain Nortel documentation on CD-ROM, contact your Nortel customer

representative.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 30

Page 30 of 456 System information

NN43021-310 Standard 02.01 December 2007

Page 31

36

Page 31 of 456

Introduction

Contents

This section contains information on the following topics:

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Summary of procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Overview

WAR NING

Before a Large System can be installed, a network

assessment must be performed and the network must be

VoIP-ready.

If the minimum VoIP network requirements are not met,

the system will not operate properly.

For information on the minimum VoIP network

requirements and converging a data network with VoIP,

refer to Converging the Data Network with VoIP

(NN43001-260).

This document describes the procedures used to install and configure a

Large System. For proper installation, perform the steps in the sequence

stated in “Summary of procedures.” The summary will refer you to other

sections within this document. After completing the steps listed in those

sections, return to the summary and continue on to the next step.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 32

Page 32 of 456 Introduction

Whenever possible, install external power equipment before the system

installation. If reserve power equipment is used, install it according to the

manufacturer’s instructions.

To install telephones and attendant consoles, see Telephones and Consoles:

Description, Installation, and Operation (NN43001-567).

System installation must be performed by qualified personnel only.

NN43021-310 Standard 02.01 December 2007

Page 33

Summary of procedures

1 Prepare equipment for installation; go to “Preparing the equipment for

installation” on page 62.

2 Place the fourth module on a column (if required); go to “Placing the

fourth module on a column” on page 65.

3 Position and level equipment; go to “Positioning and leveling

equipment” on page 71.

Note: If earthquake bracing is required, go to “Installing earthquake

bracing” on page 343. The section will provide procedures for installing

column and floor bracing and positioning and levelling equipment.

When those procedures are complete, return to Step 4 or Step 5 (as

applicable) in this summary.

4 Install overhead cable tray kits (if required); go to “Installing overhead

cable tray kits” on page 89.

5 Install power supplies in all modules:

a Make sure the system is disconnected from any power source.

b Set switches and breakers on all module power supplies or module

power distribution units (MPDU) to OFF.

Introduction Page 33 of 456

c Insert each power supply into the appropriate card cage and hook the

locking devices.

6 Install a NT4N39AA CP PIV Processor Pack and blank faceplate

(N0026096) to cover MMDU slot

7 Install power equipment and ground wiring:

— For AC-powered systems, go to “Installing AC power” on page 77.

— For DC-powered systems, go to “Installing DC power” on page 93.

8 Plan and designate the main distribution frame (MDF); go to “Planning

and designating a Main Distribution Frame” on page 133.

9 Install Power Failure Transfer Units (PFTU) (if required); go to

“Installing Power Failure Transfer Units” on page 145.

10 Configure the system monitor; go to “Configuring the system monitor”

on page 151.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 34

Page 34 of 456 Introduction

11 Connect a system terminal (or modem); go to “Connecting a system

terminal or modem” on page 171.

12 Install cabling:

— To cable Common Equipment, go to “Cabling Common Equipment

— To cable network loops, go to “Cabling network modules and loops”

— To cable IPE Modules to the MDF and to connect lines and trunks,

13 Power up the system and load the system software; go to “Powering up

the system and initial loading” on page 299.

Note: If you are upgrading your system, do not install new software.

Instead, return to the upgrade procedures provided in Communication

Server 1000M and Meridian 1 Large System Upgrade NTPs

(NN43021-458 – NN43021-475).

14 Perform acceptance tests; go to “Performing acceptance tests” on

page 335.

15 To test circuit cards, see “Acceptance tests” in Circuit Card: Description

and Installation (NN43001-311). To test telephones and attendant

consoles, see Telephones and Consoles: Description, Installation, and

Operation (NN43001-567).

in a Single Group system” on page 187.

on page 239.

go to “Cabling lines and trunks” on page 261.

16 Replace all covers and grills on the front and rear of the system.

NN43021-310 Standard 02.01 December 2007

Page 35

Introduction Page 35 of 456

Table 2

List of tasks in subsections

Task Go to page

Preparing for installation 37

Placing the fourth module on a column 65

Positioning and leveling equipment 71

Installing overhead cable tray kits 89

Installing AC power 77

Installing DC power 93

Planning and designating a Main Distribution Frame 133

Installing Power Failure Transfer Units 145

Configuring the system monitor 151

Connecting a system terminal or modem 171

Cabling Common Equipment in a Single

Group system

Cabling Common Equipment in a Multi Group system 207

Cabling network modules and loops 239

Cabling lines and trunks 261

Powering up the system and initial loading 299

Performing acceptance tests 335

Installing earthquake bracing 343

Adding a module to a column 363

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

187

Page 36

Page 36 of 456 Introduction

NN43021-310 Standard 02.01 December 2007

Page 37

64

Page 37 of 456

Preparing for installation

Contents

This section contains information on the following topics:

Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System equipment – UEMs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

System options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Cable routing guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Equipment handling precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Preparing the equipment for installation . . . . . . . . . . . . . . . . . . . . . . . . 62

Requirements

WAR NING

Before a Large System can be installed, a network

assessment must be performed and the network must be

VoIP-ready.

If the minimum VoIP network requirements are not met,

the system will not operate properly.

For information on the minimum VoIP network

requirements and converging a data network with VoIP,

refer to Converging the Data Network with VoIP

(NN43001-260).

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 38

Page 38 of 456 Preparing for installation

Before system equipment is delivered to the installation site, you must

consider these requirements:

• Fire protection and safety requirements

• Equipment room requirements

• Grounding and power requirements

• Cable requirements

Specifications for these requirements and for developing the equipment room

floor plan are provided in Communication Server 1000M and Meridian 1:

Large System Planning and Engineering (NN43021-220).

System equipment – UEMs

Universal Equipment Modules (UEM) are the building blocks of the

communication system. UEMs are generic metal frames equipped with

covers. Each UEM is a self-contained unit with power, a card cage, I/O

panels, and cable routing channels. Each UEM houses sets of equipment used

in system operations (see Figure 1 on page 39).

UEMs are stacked in columns

UEMs are stacked in columns, up to four modules high. Within a column, the

levels are referred to as tiers. The UEMs are numbered 0 to 3 from the bottom

up (see Figure 1 on page 39). Cables connect cards in the same module,

between two modules, and between cards and the I/O panel in the same

module.

Column components

Each column contains a pedestal base, a top cap, and up to four modules.

Pedestals

Each column sits on a pedestal. The pedestal contains power, cooling, and

system monitoring equipment.

• A Power Distribution Unit (PDU) in the back of the pedestal supplies

either AC or DC power to the column.

NN43021-310 Standard 02.01 December 2007

Page 39

Preparing for installation Page 39 of 456

• A System Monitor checks the column’s cooling and power systems.

• A blower unit (accessible from the front of the pedestal) forces air up

through the modules to cool the circuit cards.

Figure 1

Universal Equipment Modules

N

O

R

T

E

Module 3

Module 2

Module 1

Module 0

L

Universal

Equipment Module

N

O

R

T

E

L

Universal

Equipment Module

N

O

R

T

E

L

Universal

Equipment Module

N

O

R

T

E

L

Universal

Equipment Module

Tier 0

Top Cap

N

O

R

T

E

L

Equipment Module

Universal

Module 0

Pedestal

4-tier column

1-tier column

553-AAA1241

Top caps

A top cap is mounted on the top module of each column. It contains:

• Air exhaust grills in the cap that release air from the blowers in the

pedestal.

• A heat sensor that monitors the temperature of the column.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 40

Page 40 of 456 Preparing for installation

• A red LED in the front of the cap’s exhaust grill that lights if the system

overheats or if a power outage occurs.

• Ladder racks for routing cables can also be fitted to the top caps.

Modules

Up to four modules can be included in a column. The modules can include:

• NT4N41 CompactPCI

Large Systems

• NT8D35 Network Module – required for Meridian 1 PBX 81C and

CS 1000M MG

• NT8D37 Intelligent Peripheral Equipment (IPE) Module – required for

all Large Systems

In addition, modules that house application-specific equipment can be

included in a column.

Columns are grouped in rows

A system can have one column, or multiple columns attached in rows.

Column 0 is always the column containing the “Core/Net 0” module.

Column 1 is placed to the left of Column 0 and must contain the “Core/Net 1”

module.

®

(cCPI) Core/Network Module – required for all

Column 0 and Column 1 are placed at the far left of the row (front view).

Column numbering then continues to the right of Core 0 (see Figure 2 on

page 41).

Additional rows are configured with the lowest numbered column on the far

left and the highest numbered column on the far right (front view).

For compliance with electromagnetic interference/radio frequency

interference (EMI/RFI) standards, spacer kits are provided to interconnect the

columns in a multiple-column system.

NN43021-310 Standard 02.01 December 2007

Page 41

Preparing for installation Page 41 of 456

Figure 2

Example of Large System column row

UEMs are identified by function

Each UEM contains a specialized set of equipment to digitalize, process, and

route phone calls and voice messages (see Figure 3 on page 42).

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 42

Page 42 of 456 Preparing for installation

Figure 3

UEMs identified by function

Card cage

Inside each UEM is a metal card cage. This card cage holds the circuit cards,

power card, and related equipment for that module. UEMs are named for the

function of that card cage.

Card cages are bolted inside the UEM case. Card cages can be removed and

replaced for repairs or upgrades.

NN43021-310 Standard 02.01 December 2007

Page 43

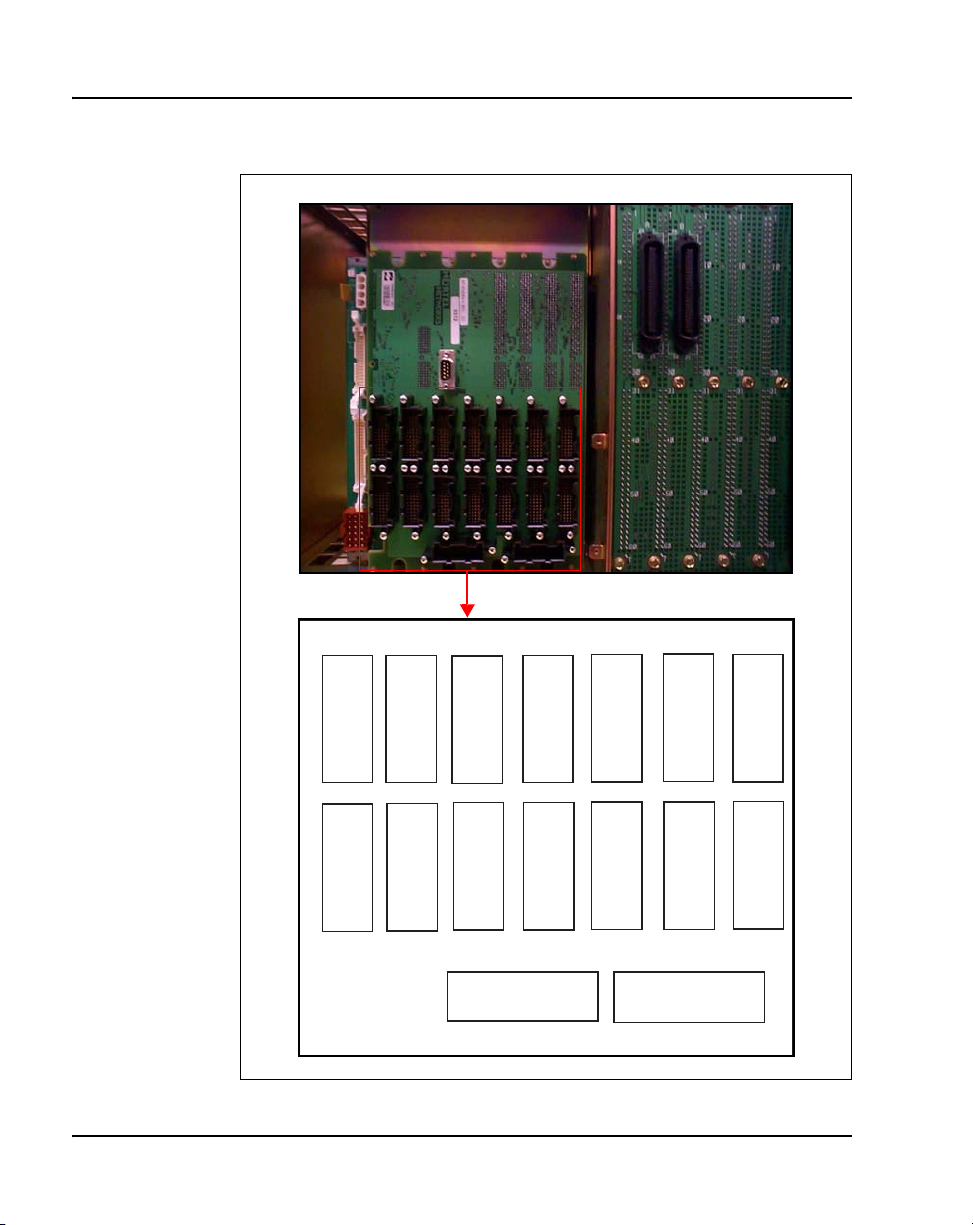

Core/Net module

Large Systems feature the NT4N41 Core/Net module. The Core/Net module

provides a unified hardware platform for single group and multi-group

configurations. The Core/Net module supports:

• An integrated cPCI shelf.

• A NT4N48 System Utility card that incorporates the functionality of the

System Utility Transition card, LCD display, and the security device

holder.

• A fanout panel (see Figure 4 on page 44) to provide connectivity to the

network shelf.

• Upgrades from single group to multi-group configurations (requiring a

new keycode file and any additional hardware necessary for a

multi-group system).

Preparing for installation Page 43 of 456

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 44

Page 44 of 456 Preparing for installation

Figure 4

NT4N41 Core/Net shelf fanout panel (backplane)

j4

slot 12

port 1

Group 6

j3

slot 12

port 0

j4

slot 12

port 0

Group 7

j3

slot 12

port 1

NN43021-310 Standard 02.01 December 2007

Group 3Group 4Group 5

j3

slot 11

port 1

j4

slot 11

port 1

j3

slot 11

port 0

j4

slot 11

port 0

j3

slot 10

port 1

j4

slot 10

port 1

j3

slot 10

port 0

j4

slot 10

port 0

j3 slot 9 port 0 j4 slot 9 port 0

Group 0

Group 1Group 2

j3

slot 9

port 1

j4

slot 9

port 1

Page 45

System options

The procedures in this document apply to the following system options:

• Meridian 1 PBX 61C: dual CPU, full network group

• Meridian 1 PBX 81C: dual CPU, multiple network groups

• CS 1000M SG: a Meridian 1 PBX 61C system upgraded to include a

• CS 1000M MG: a Meridian 1 PBX 81C system upgraded to include a

All system options are available in both AC- and DC-powered versions.

System architecture and module types are described in Communication

Server 1000M and Meridian 1: Large System Overview (NN43021-110).

The components of AC-powered systems, DC-powered systems, and reserve

power options for both are described in this document.

Preparing for installation Page 45 of 456

Signaling Server (see note below)

Signaling Server (see note below)

Note: For information about Signaling Server installation and

configuration, see Signaling Server: Installation and Commissioning

(NN43001-312).

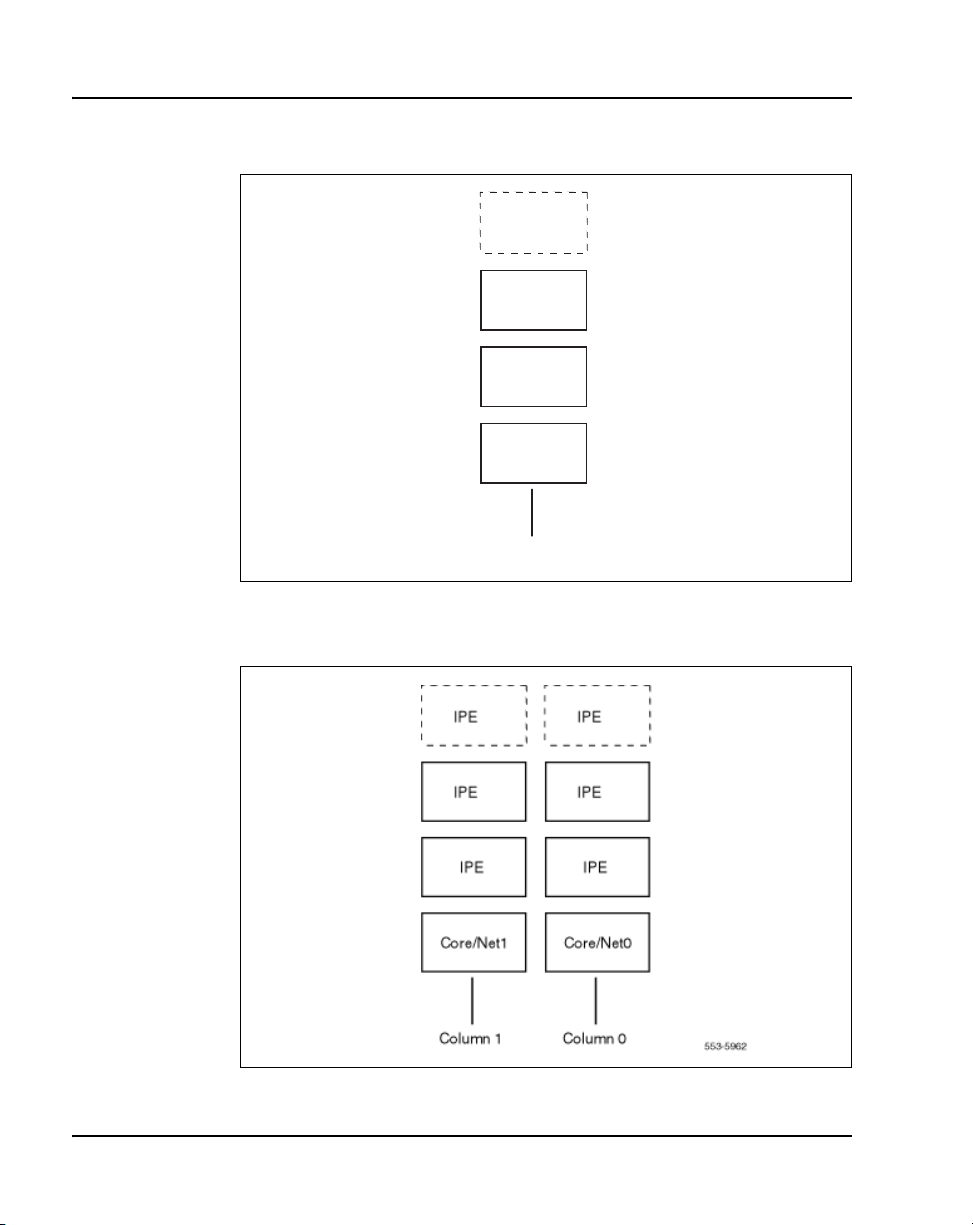

Meridian 1 PBX 61C and CS 1000M SG

These systems feature a dual Pentium Processor with standby processing

capability, fully redundant memory, and a full network group. Two Core/Net

modules and one IPE module are the minimum installation requirements.

Additional IPE modules and application modules can be used. The modules

are stacked (see Figure 5 on page 46) or installed side-by-side (see Figure 6

on page 46).

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 46

Page 46 of 456 Preparing for installation

Figure 5

Meridian 1 PBX 61C stacked configuration

IPE

IPE

Core/Net 1

Core/Net 0

Main column

Figure 6

Meridian 1 PBX 61C side-by-side configuration

553-5960

NN43021-310 Standard 02.01 December 2007

Page 47

Preparing for installation Page 47 of 456

Meridian 1 PBX 81C and CS 1000M MG

These systems feature a dual Pentium Processor with standby processing

capability, two Core/Net modules installed side-by-side, and two or more

network groups. The Core/Net modules provide the first network group, and

network module pairs provide additional network groups.

These systems support up to eight network groups, as shown in Figure 3 on

page 42. Fiber Network Fabric provides complete non-blocking

communication between the network groups, eliminating busy signals for

network-blocked calls between groups.

Figure 7 on page 47 shows a multi-group system with four network modules.

If the ceiling height is too low for the four-tier column, a three-tier column

can be used, as shown in Figure 8 on page 48.

Figure 7

Four-tier multi-group system

IPE

NET

NET

Core 1 Core 0

IPE

NET

NET

UEM

IPE

IPE

553-AAA1242

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 48

Page 48 of 456 Preparing for installation

Figure 8

Three-tier multi-group system

NET

NET

NET

NET

Core 1 Core 0

CP PIV

A Call Processor Pentium IV (CP PIV) Large System processor was

introduced for CS 1000 Release 4.5. It features the following enhancements:

• a PCI-based design that is compatible with current CP PII architecture

• an Intel Pentium M processor

• two Compact Flash (CF) sockets (one on-board and one hot-swappable

on the faceplate). The on-board CF is referred to as the Fixed Media Disk

(FMD), and the faceplate CF is referred to as the Removable Media Disk

(RMD). See Figure 9 on page 50 and Figure 10 on page 51.

IPE

IPE

IPE

UEM

IPE

IPE

553-AAA1243

• 512 MBytes of DRAM memory

NN43021-310 Standard 02.01 December 2007

Page 49

Preparing for installation Page 49 of 456

New system types

There are two new system types for CP PIV:

• 3521 (Meridian 1 Option 61C and CS 1000M SG)

• 3621 (Meridian 1 Option 81C and CS 1000M MG, CS 1000E)

New hardware

CP PIV features the following new hardware:

• A CP PIV processor board. See Figure 9 on page 50 (side view) and

Figure 10 on page 51 (front view).

• A blank panel that replaces the NT4N43 MMDU. The blank panel is

designed to fill the gap and ensure proper air flow direction.

Note: The front panel USB port on the CP PIV card is reserved for

future applications.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 50

Page 50 of 456 Preparing for installation

Figure 9

CP PIV call processor card (side)

Fixed

Media

Drive (FMD)

Removable Media Drive (RMD)

512 MBytes DDR memory

Rear

CPU

Front

NN43021-310 Standard 02.01 December 2007

Page 51

Figure 10

CP PIV call processor card (front)

Removable Media Drive (RMD)

Preparing for installation Page 51 of 456

Lan 1

USB Port

COM 1

INIT

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Lan 2

COM 2

RESET

Page 52

Page 52 of 456 Preparing for installation

Signaling Server

CS 1000M systems use a Signaling Server. The Signaling Server provides a

central processor to drive the signaling for IP Phones and IP Peer

Networking. The Signaling Server is an industry-standard PC-based server

that provides signaling interfaces to the IP network, using software

components that operate on the VxWorks™ real-time operating system.

The Signaling Server can be installed in a load-sharing redundant

configuration for higher scalability and reliability. The following software

components can operate on the Signaling Server.

• Terminal Proxy Server (TPS)

• SIP/H.323 Gateway Signaling software

• Network Routing Service (NRS) (optionally redundant)

• Element Manager web server

• Application Server for Personal Directory, Redial List, and Callers List

for UNIStim IP Phones

Signaling Server is an application server which houses any combination of

Gatekeeper, H.323 Gateway, Line Terminal Proxy Server and Element

Manager. The Signaling Server is mounted on a 480 mm (19 in.) rack (see

Figure 11).

NN43021-310 Standard 02.01 December 2007

Page 53

Figure 11

CS 1000M Large System

Engineering rules

Each system is defined using the following assumptions and general

engineering rules.

1 A system may be upgraded to the next larger system type as defined in

Preparing for installation Page 53 of 456

Business Policy

Switch

Signaling

Server

553-AAA0561

Communication Server 1000M and Meridian 1 Large System Upgrade

NTPs (NN43021-458 – NN43021-475).

2 When expanding to the next system type, the changes to the physical

configuration should be kept as simple as possible to reduce downtime

and installation costs.

3 A module column should be built up to the maximum of four modules

before moving to the next new column. In installations where the ceiling

does not allow four-high columns, the alternate configuration of

three-high tiers can be used.

4 Vertical routing of the internal signal cables should be done only on the

right side of a module.

5 The CPU modules must be on the bottom of a column or one level up for

proper cooling and reliability.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 54

Page 54 of 456 Preparing for installation

6 Sending and receiving cables must be of equal lengths and as short as

possible.

7 In order to optimize network FIJI cabling, mount the NTD35 network

modules in pairs in the same column, one module on top of the other in

the middle tiers. The modules must be stacked in one contiguous

equipment bay. The longest FIJI cable (NTRC48FA) is 8 m (26 ft),

which is the maximum distance of the furthest network module from the

Core/Net modules.

8 The IPE modules can be located separately from the CPU and network

bay, by up to the maximum network cable length of 13.5 m (45 ft).

9 Core/network modules can also be on top of each other in the first and

second tier in multi-group systems.

Cable routing guidelines

A system layout, preconfigured at the factory, is included in the software box

with each system shipment. Before you route cables, refer to the “to-from”

cable connections in the system layout. Note that there are a variety of cable

lengths. Make sure you install the designated cable for each connection.

Because the cable troughs (see Figure 12 on page 55) and spaces on the sides

of each module are within the EMI shielding of the system, unshielded cables

can be routed in those areas. The corner vertical channels in the rear of the

module are outside of the EMI shield. Cables routed in the vertical channels

must be shielded, and must enter and exit the EMI-shielded area through I/O

panels and adapters.

NN43021-310 Standard 02.01 December 2007

Page 55

Preparing for installation Page 55 of 456

Figure 12

Cable routing troughs – front view of module

Cabling troughs

553-3117

A typical routing scenario from the faceplate of a printed circuit pack (PCP)

to one of the I/O panels is as follows:

• The cable comes off the faceplate of a PCP and drops down into the front

horizontal cable trough.

• The cable is routed to the right side of the module in the horizontal cable

trough to the vertical cable trough.

• The cable is routed to the back of the module and into the rear horizontal

cable trough.

• The cable is routed to the left or right I/O panel at the rear of the module.

When connecting two half-group networks together, the cables are routed

vertically through the square holes in the rear horizontal cable trough.

All other internal vertical cable routing from one module to another should be

done only in the right vertical cable trough.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 56

Page 56 of 456 Preparing for installation

6

Since all faceplate to I/O panel cables are the same length and card positions

in the card cage vary, a cable can contain excess slack. It is therefore

recommended that cables from cards in the left side of the card cage use the

right I/O panel and cables from cards in the right side of the card cage use the

left I/O panel whenever possible, as shown in Figure 13.

Figure 13

Top view of front to I/O connector panel routing

Right I/O Connector Panel

I/O Panel

PS

This side uses right I/O Connector PanelThis side uses left I/O Connector Panel

Left I/O Connector Panel

Card Cage

553-749

As space permits, cables can be routed:

1 Horizontally in the cable troughs at the front, rear, and sides of the

module

Note: In a DC-powered module, because there is no MPDU, there is

room to route cables horizontally from front to rear on the left side (front

view) of the module.

NN43021-310 Standard 02.01 December 2007

Page 57

Preparing for installation Page 57 of 456

7

2 Vertically on the sides of the module

3 Vertically in the corner channels in the rear of the module (shielded

cables only)

CAUTION

Damage to Equipment

Cables must be routed as perpendicular as possible

to any nearby power cables. Avoid routing cables

near power cables if alternate routing is available. (At

the rear of the module, cables routed between the I/O

panel and the rear cover can be parallel to the power

cables because the panel provides EMI shielding.)

Nortel recommends that you use the 90° connector end of the cable to route

the cable through a module or cabinet instead of the 180° end, since some

openings are small (see Figures 14 and 15). Furthermore, Nortel recommends

that you route cables top-to-bottom so gravity will ease installation.

Figure 14

90° cable connector

553-749

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 58

Page 58 of 456 Preparing for installation

8

Figure 15

180° cable connector

Equipment handling precautions

To avoid personal injury and equipment damage, review the following

guidelines before handling the equipment.

553-749

Unloading equipment

Special ramps, packed inside the pallet holding Column 0, must be used to

move the equipment off the pallet. Follow the instructions provided with the

ramps.

CAUTION

Damage to Equipment

Never pry up the pedestal to lift the column. This

could damage to the pedestal. Manually slide the

column down the ramps provided.

NN43021-310 Standard 02.01 December 2007

Page 59

Working with power supplies

There are no user-repairable components in the power supply. If a power

supply fails, the complete unit must be replaced. Do not disassemble a power

supply under any circumstances.

DANGER OF ELECTRIC SHOCK

To avoid the danger of electric shock, be careful

when working with power equipment and

connections.

Comply with all Warnings.

External power supplies such as a UPS, power plant, or batteries, may be

heavy and require special handling procedures and additional personnel for

unloading and installation. Also, be aware of weight distribution and keep the

equipment room floor from being overly stressed.

Handling circuit cards

Follow these precautions when handling circuit cards.

1 Unpack or handle cards away from electric motors, transformers, or

similar machinery.

Preparing for installation Page 59 of 456

2 Handle cards by the edges only. Do not touch the contacts or

components.

3 Set cards on a protective antistatic bag. If an antistatic bag is not

available, hand-hold the card, or set it in a card cage unseated from the

connectors.

4 Store cards in protective packing.

5 Do not stack cards on top of each other unless they are packaged.

6 Wear a properly connected antistatic wrist strap when you work on the

equipment. If a wrist strap is not available, regularly touch one of the

bare metal strips in the module to discharge static. Figure 16 on page 60

shows the wrist strap connection points and the location of the bare metal

strips you should touch.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 60

Page 60 of 456 Preparing for installation

Figure 16

Static discharge points

Wrist strap

connection point

Power supply slot

Module

rear

Bare metal strip

Wrist strap

connection point

Module

front

Bare metal strip

553-5000

NN43021-310 Standard 02.01 December 2007

Page 61

Preparing for installation Page 61 of 456

DenAn regulatory notice for Japan

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 62

Page 62 of 456 Preparing for installation

Preparing the equipment for installation

Use the equipment room floor plan to position equipment. See

Communication Server 1000M and Meridian 1: Large System Planning and

Engineering (NN43021-220) to prepare the equipment room and floor plan.

WAR NING

A fully loaded column weighs 275 kg (606 lb). More

than one person is required to remove equipment

from shipping pallets.

WAR NING

Module covers are not hinged; do not let go of the

cover. Lift the cover away from the module and set it

out of the work area.

Procedure 1

Preparing the equipment for installation

1 Remove equipment from the shipping pallets; follow the unpacking

instructions that come with the packaging material.

2 Remove the front and rear covers from each module:

NN43021-310 Standard 02.01 December 2007

Page 63

Preparing for installation Page 63 of 456

a. With a flat blade screwdriver, turn the lock clockwise on the two

locking latches (see Figure 17 on page 63).

Figure 17

Locking latches on the module cover

unlatch cover

Turn lock screw

up to lock

Slide to

553-A0132

b. Simultaneously push the latches toward the center of the cover and

pull the cover toward you while lifting it away from the module.

c. Set the covers aside until the installation is complete.

3 Remove the front and rear grills from each pedestal:

a. Loosen the two captive screws that secure the grill.

b. Pull the grill forward and lift it out of the base of the pedestal (see

Figure 18 on page 64).

c. Set the grills aside until the installation is complete.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 64

Page 64 of 456 Preparing for installation

Figure 18

Removing the pedestal grill

4 Make sure all of the items on the system order form are on the packing

slip that comes with the equipment.

Captive screw

Captive screw

553-3054

5 Inspect all equipment for physical damage. Report any damage to your

supplier.

6 Check the option settings on all cards that have a switch symbol on the

faceplate.

For a list of all option switch and jumper settings, refer to Circuit Card:

Description and Installation (NN43001-311).

NN43021-310 Standard 02.01 December 2007

End of Procedure

Page 65

70

Page 65 of 456

Placing the fourth module on a column

Contents

This section contains information on the following topics:

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Placing the fourth module on a column . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview

A four-module column is shipped in two segments. One shipping pallet

carries the pedestal and three modules. Another shipping pallet carries the

fourth module and top cap.

Starting at the bottom of the column, modules are numbered from zero to

three in each column.

Placing the fourth module on a column

Use Procedure 2 to place the fourth module and top cap on the column. To

add a module to a column that is already powered, see the procedures in

“Adding a module to a column” on page 363.

CAUTION

System Failure

Never add a Common Equipment module in the third

or the fourth tier of a column.

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 66

Page 66 of 456 Placing the fourth module on a column

WAR NING

A fully loaded module weighs approximately 60 kg

(130 lb). More than one person is required to place a

module on a column.

Procedure 2

Placing the fourth module on a column

1 Position and secure the fourth module.

a. Locate the positioning guides on the third module (see Figure 19).

b. Position the fourth module so it faces the same direction as the

column.

c. Remove the front and rear module covers on the fourth module and

rear module cover on the third module.

d. Place the fourth module on top of the column and adjust it until it is

seated securely on the positioning guides.

e. Remove the I/O safety panel in the fourth module to gain access for

installing the center mounting bolt.

f. Use a 14 mm (9/16 in.) socket wrench to secure the fourth module

with five mounting bolts (see Figure 20 on page 68).

NN43021-310 Standard 02.01 December 2007

Page 67

Placing the fourth module on a column Page 67 of 456

Figure 19

Module positioning guides

Rear

Positioning guides

Front

Opening for

cables

553-3056

Communication Server 1000M and Meridian 1 Large System Installation and Commissioning

Page 68

Page 68 of 456 Placing the fourth module on a column

Figure 20

Module mounting bolts

Mounting

bolts

553-3057

2 Connect the module-to-module power and system monitor cables.

a. Connect the power connectors between the modules (see Figure 21

on page 69).

b. Connect the system monitor cable from connector J2 on the third

module to J1 on the fourth module.

NN43021-310 Standard 02.01 December 2007

Page 69

Placing the fourth module on a column Page 69 of 456