Nortec WB60, WB230, WB120, WB270 Installation Manual

Multi-fuel oil burners

NORTEC WB

Installation manual

Models WB60, WB120, WB230, WB270

www.nortec.pro

2013

2

Read carefully the Guide before installing and using the burner

Nortec WB!

Installation and start works have to be carried out only by specialists.

Power supply must be switched off before the works start!

Neglecting safety rules can cause an accident.

Dear customer!

Thank you for purchasing NORTEC products. We do everything to make sure you use

NORTEC equipment effectively for a long time!

1. Multi-fuel burners NORTEC WB features

NORTEC WB burners use waste engine and transmission oil, kerosene, diesel oil, light fuel oil,

liquid animal and vegetable oil.

Don’t use as fuel:

flammable liquids such as gas, ester, acetone, spirit etc.

The burners combine the functions of fuel supply, heating, spray and air supply, ignition and

flame supervision, so achieving automatic control of the combustion process.

Thanks to their robust and high-quality design NORTEC burners have the following features:

1. Well-automated fuel supply.

NORTEC burners are low pressure burners and compressed air supply with the pressure

from 0.15 to 0.4-0.5 MPa is required for good fuel spray.

2. Optimum mix of air and fuel, stable flame and efficient combustion.

The burners use air swirl technology with a sparger that provides fine and even mix of

sprayed fuel and secondary air, stable, complete and economic combustion.

3. Safe, reliable, automatic control.

NORTEC burners are equipped with an advanced control and safety system from Siemens.

It stops fuel supply and combustion process in case of emergency. Automatic control of fuel

temperature, fuel level in the chamber of preliminary heating, ignition and flame, the system

of automatic shutdown and restart make NORTEC WB burner easy and safe to use.

4. Flexible installation.

Each burner is equipped with long combustion tube and sliding flange that allows to use the

burner with any boiler and heat generator.

5. Easy maintenance.

The burners are easy to dismantle for regular cleaning and service.

3

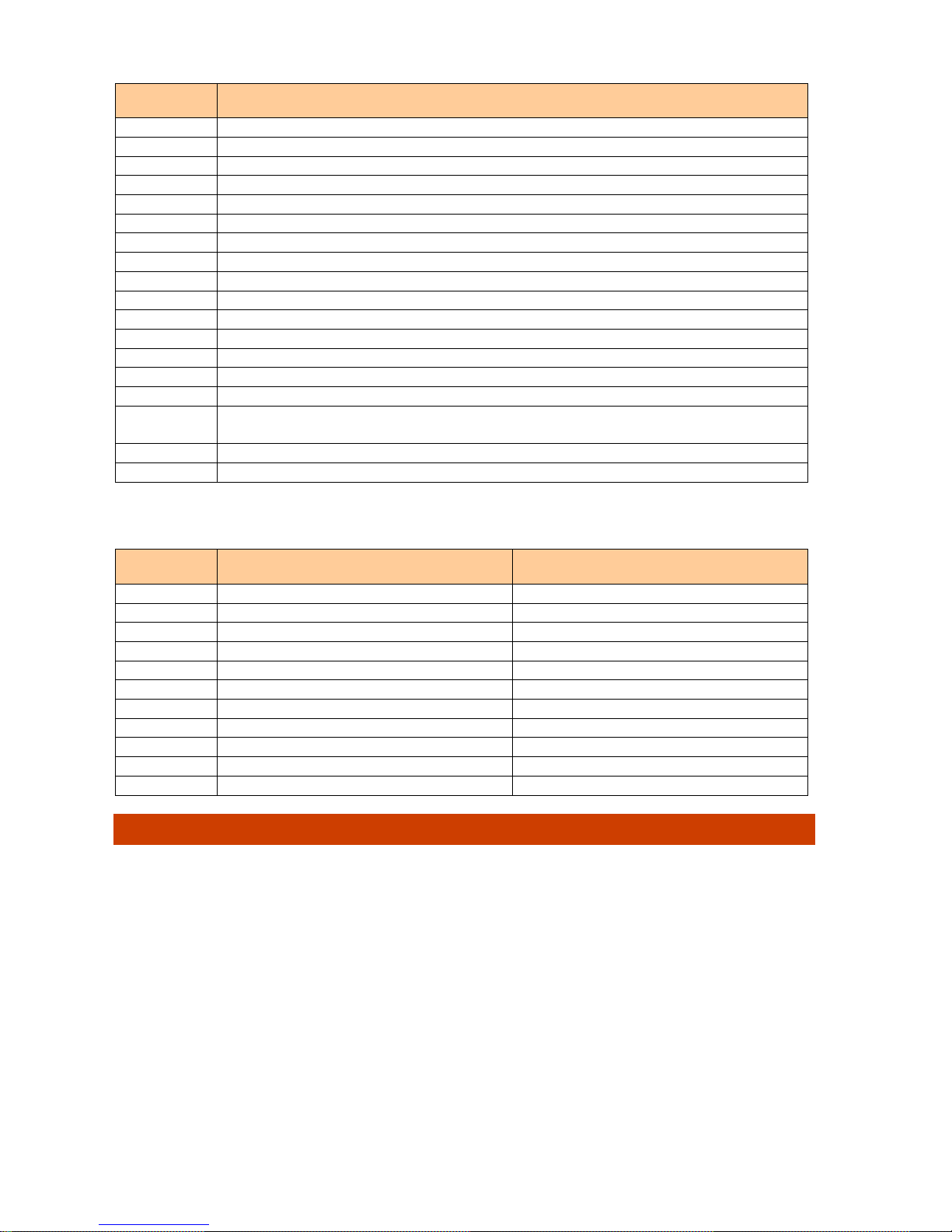

2. Multi-fuel burners NORTEC WB description and features

NORTEC WB burners are designed in 2 frames of typical sizes (see section 4).

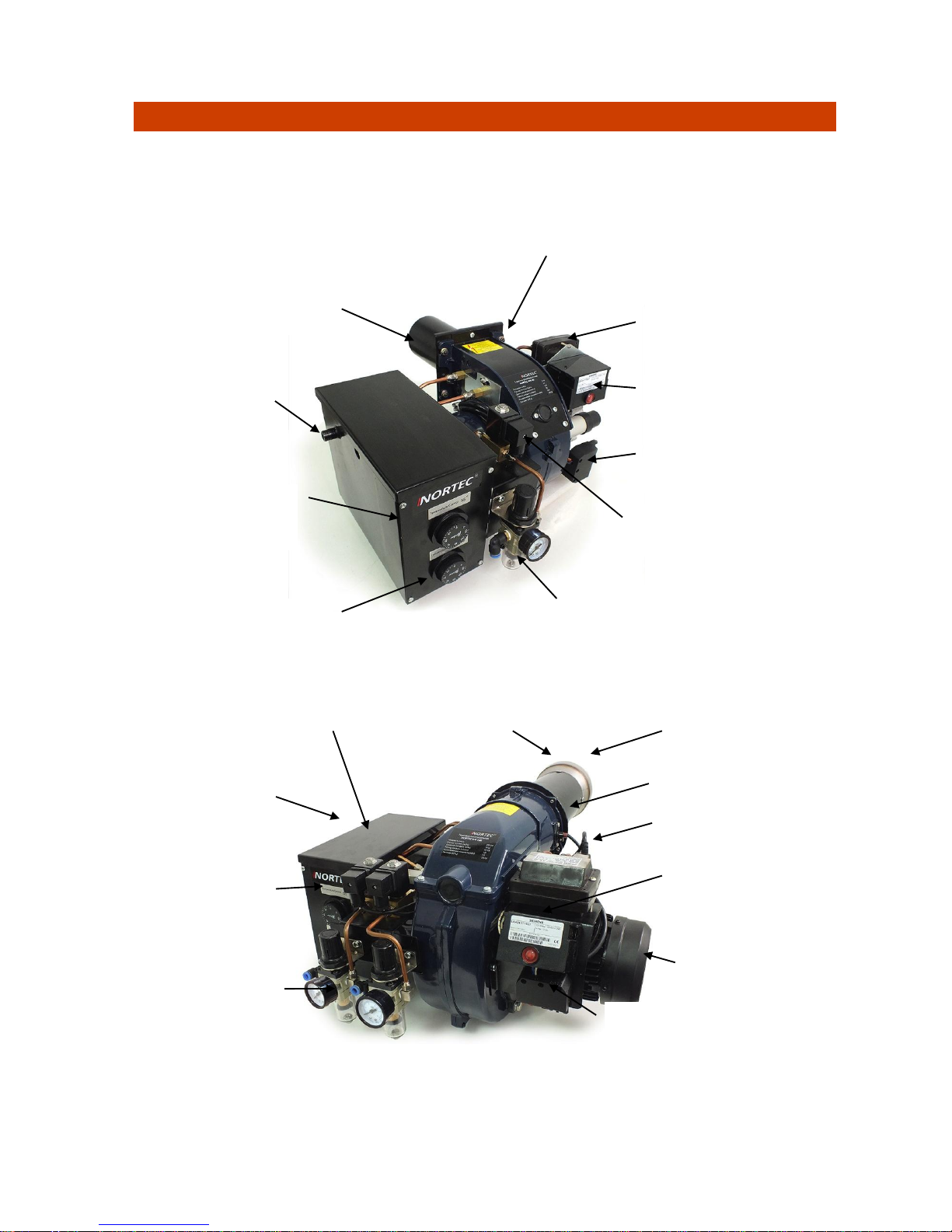

Models WB60/120 (pic. 1) have one line to connect compressed air and one pressure regulator.

Models WB 230/270 (pic. 2) have two lines to connect compressed air and two pressure

regulators what follows the principle of two-stages start.

Pic. 1 Burners NORTEC WB60 and WB 120

Pic. 2 Burners NORTEC WB230 and WB270

Preliminary fuel

heater

Air regulator with a moisture

separating filter and manometer

Control chamber with an

indicator of emergency

shutdown

Electric socket

Electromagnetic

valve

Ignition transformer

Photocell

Fuel heating

thermostat

Nozzle for

adding fuel

Combustion tube

Fuel heating

thermostats

Preliminary fuel heater

Air regulators with a

moisture separating

filter and manometer

Electromagnetic

valves

Electric socket

Control chamber with an

indicator of emergency

shutdown

Ignition transformer

Photocell

Combustion tube

Diffuser

Fan electric engine

4

Technical features of the burners NORTEC WB:

Model

Heat

power

kW

Air

consumption

m3/h

Air

pressure

MPa

Fuel

consumption

kg/h

Power

consumption

kW

(voltage/frequency)

V/Hz

Number and

value of

nozzles

Weigh

t, kg

WB 60

30–59

5

0,15-0,3

3,65–6

1,5 (220/50)

1 / 2.0 –

30о

36

WB 120

55–130

9,5

0,2-0,3

6,03–13

1,5 (220/50)

2 / 2.0 –

30о

37

WB 230

130-230

12

0,2-0,4

14-23

2,6(220/50)

2 / 2.5 –

80о

45

WB 270

190-270

15

0,2-0,4

19-27

2,6(220/50)

3 / 2.5 –

80о

45,5

The sizes of burners – see section 4.

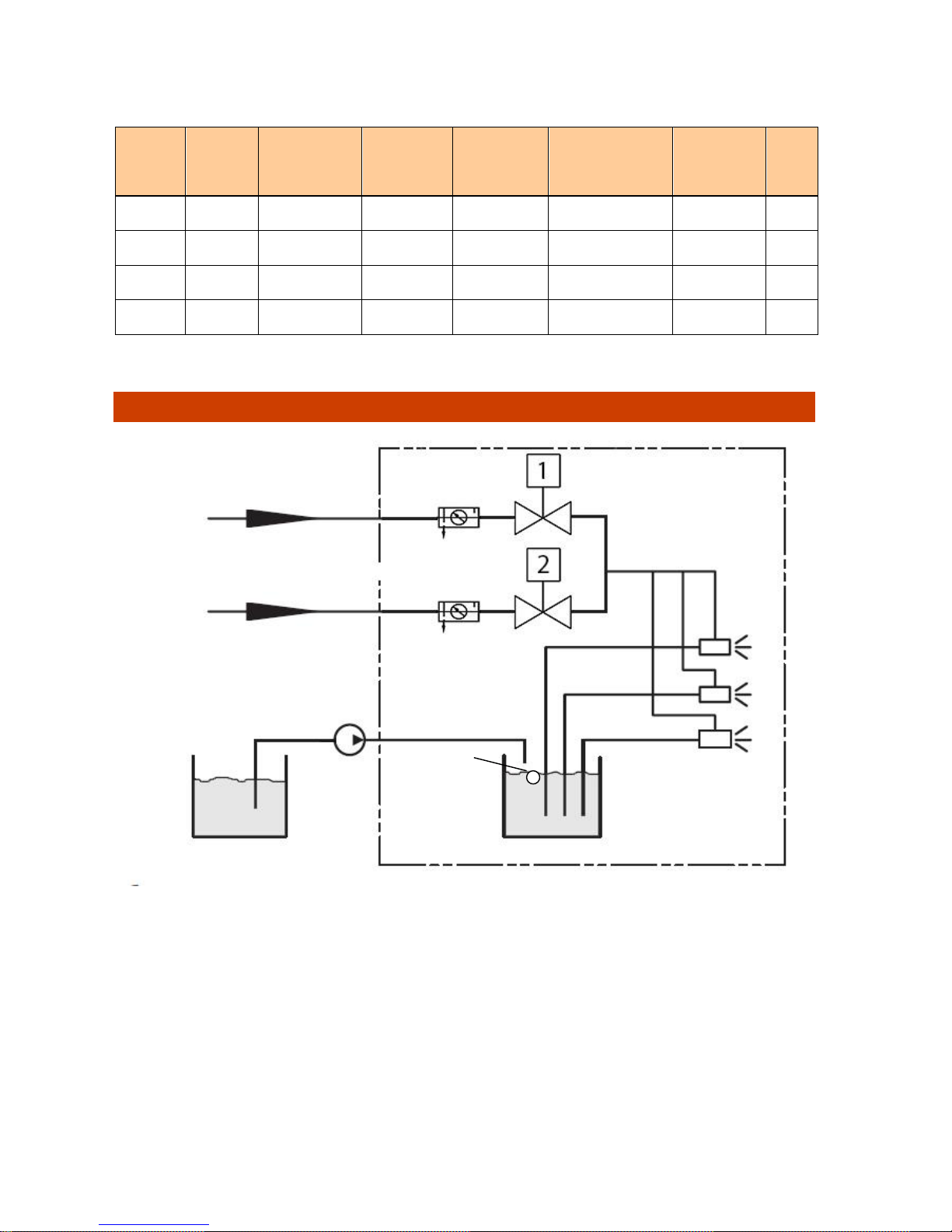

3. Diagram and function of NORTEC WB burners

* *not in the models NORTEC WB60 and WB120

** model NORTEC WB60 has 1 nozzle, WB120 and WB230 have 2 nozzles each and WB 270 - 3 nozzles

1. After getting a signal from the float placed in the preliminary fuel heater box the pump of

the lifting unit starts filling the box. At some point depending on the position of the float a

micro switch goes off which means that the box is full and the pump is off.

2. The thermostats of the preliminary fuel heating box set the maximum and minimum

temperature for heating the fuel.

3. From the thermostats signal the heaters start heating the fuel. At the minimum temperature

of the fuel one of the thermostats switches off and only one heater remains to work.

4. As soon as the given temperature of the oil is reached, the second heater switches off and

the burner gets ready to blow off the chamber of combustion. At this moment the fan of

secondary air works and the primary air valve is closed.

nozzles **

Preliminary fuel

heater

Lifting unit with

a pump and filter

External fuel tank

Compressed air line 1

Solenoid valves

Primary air

regulator 1

fuel

Primary air

Compressed air line 1

Primary air

regulator 2*

float

5

5. After the blow-off is finished, the control chamber sends a signal to start ignition and opens

the electromagnetic valve for compressed air line 1. The air goes through the filter

separating moisture that has a pressure regulator and manometer. The amount of

pressure for primary air of line 1 is set within 0.15 - 0.4 MPa.

6. While going through the nozzle primary air causes vacuum on the fuel line and it starts

sucking the heated fuel from the preliminary heater.

7. In the flow of primary air the fuel gets atomized (becomes finely dispersed) and mixes up

with a swirled flow of secondary air.

8. The spark sent to the ignition electrodes inflames air and fuel mix. The photocell marks the

presence of flame, and the ignition process begins.

9. After a while the control chamber sends a signal to open the electromagnetic valve of line

2 (not in NORTEC WB 60/120 burners) and the burner starts working at full power.

10. For models NORTEC WB 60/120 full power of a burner is shown by the amount of primary

air pressure in line 1, and for models NORTEC WB 230/270 it is shown by the amount of

pressure in both inlets.

11. If the fuel level in the preliminary heater gets lower a certain level, the float goes down and

blocks the pump contact. The fuel is added in the heater.

12. If the flame goes out when the fuel runs out because of too high primary air pressure or

due to other reasons, the photocell switches the burner off and the error signal turns on.

Manual restart is needed.

13. If the temperature of the fuel in the heater is lower than it was given on the thermostat, the

burner stops working and heats the fuel up to the given temperature. The restart is

automatic.

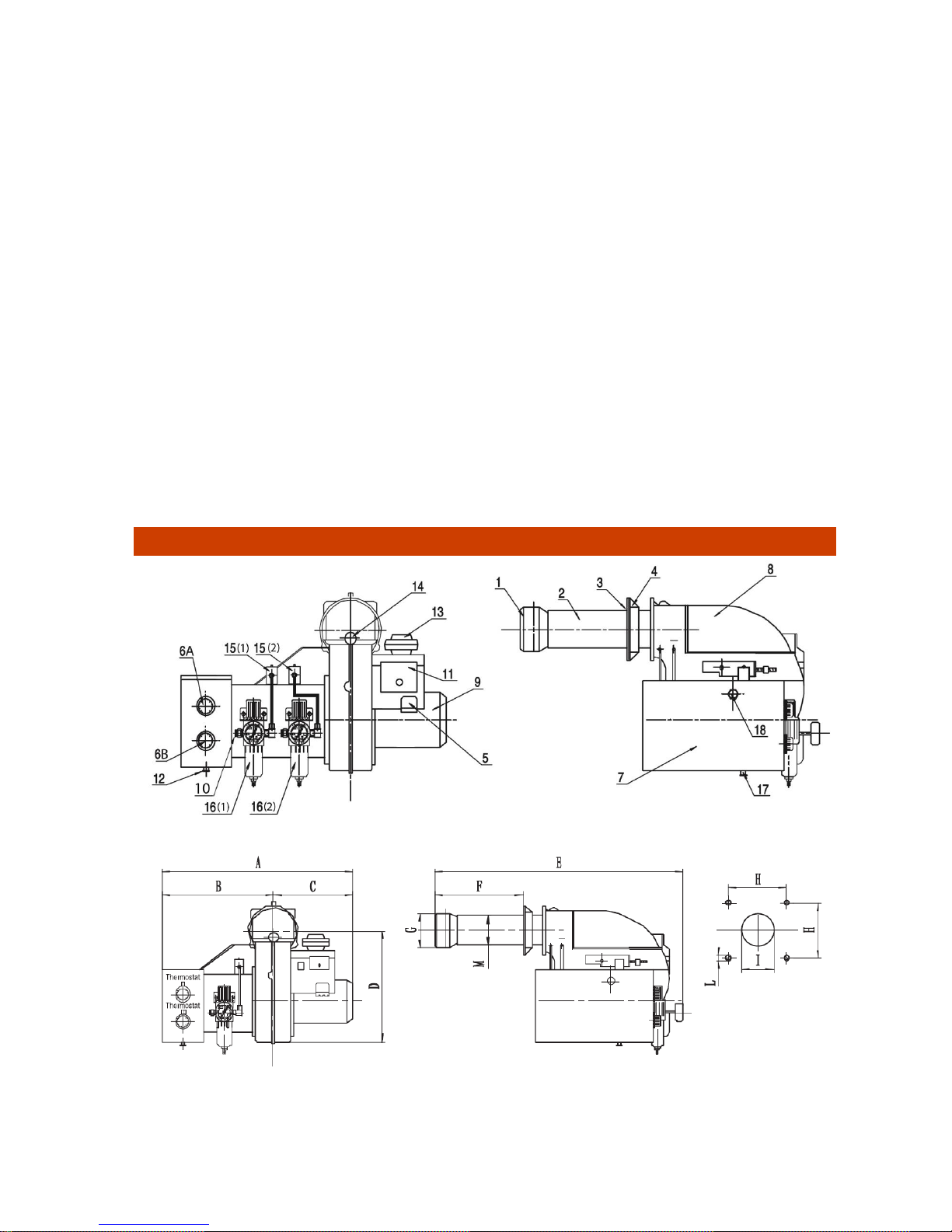

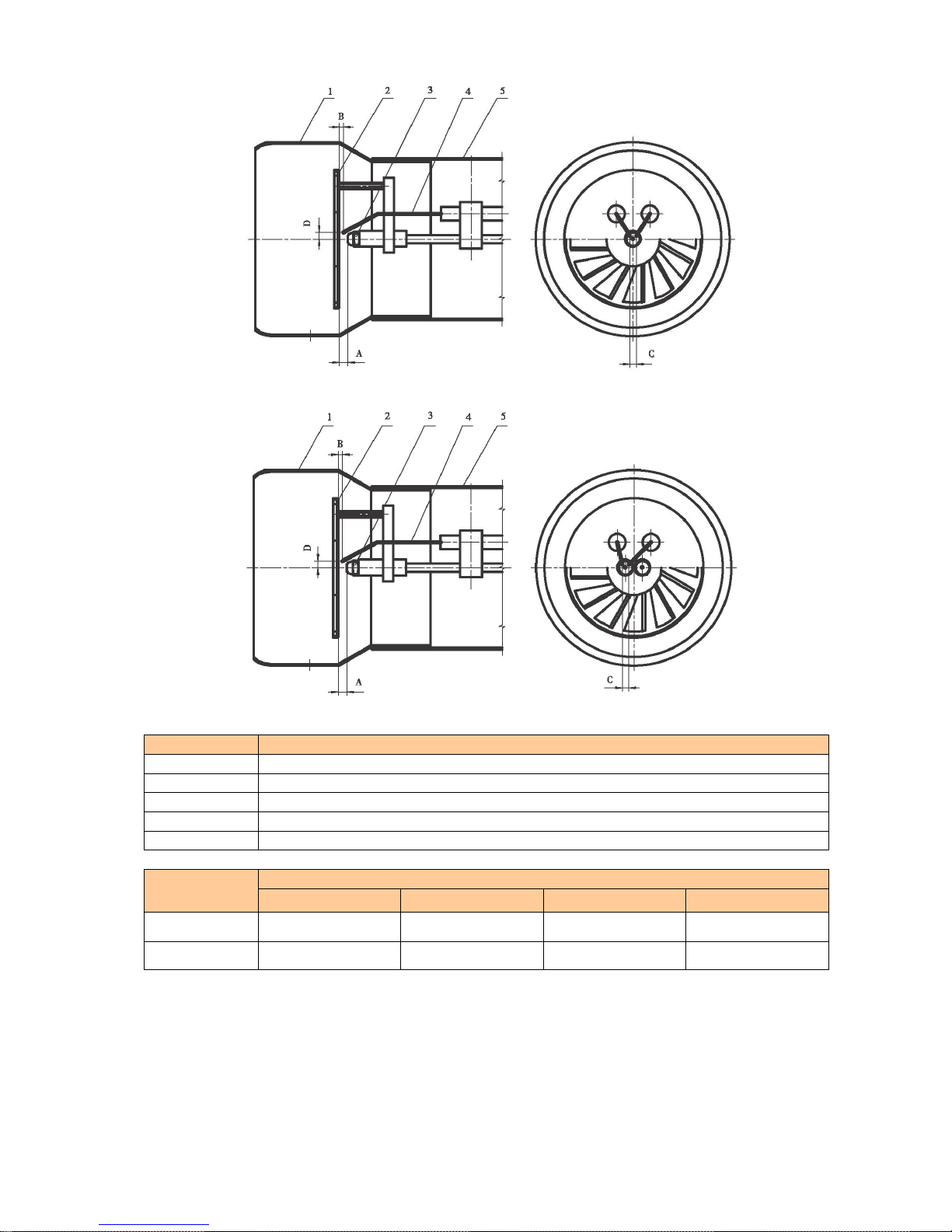

4. Design, main elements and sizes of NORTEC WB burners

Pic.3 NORTEC WB burners elements

Pic.4 NORTEC WB burners dimensions

6

* Air line 2 is in NORTEC burners WB 230 and WB 270

Dimension and set-up sizes of burners NORTEC WB

5. Burner head (electrodes and dispenser position) adjustment

Consistent ignition, optimum flame shape and the most efficient combustion depend on correct

adjustment of such elements as dispenser, nozzles, combustion tube and ignition electrodes in

relation to each other.

An incorrect electrode position causes inconsistent ignition or contamination of the electrodes.

An incorrect dispenser position may change the flame shape and burner power, cause drops of

unburnt fuel on the bottom of the combustion chamber.

To adjust the burner head correctly use the diagrams (pic. 5 and pic.6) and the chart showing

distance between the elements.

Before starting the adjustment take the combustion tube off by unscrewing 4 fixing screws that

attach the tube to the burner shell.

Adjustment of the burner with 3 nozzles (WB 270) is similar to the one for the burner with 2

nozzles (WB 230).

#

Element name (pic.1)

1

Diffuser (not used in models WB60 and WB120)

2

Combustion tube

3

Asbestos heatproof pad

4

Installation flange

5

7-pin socket for power and fuel pump connection

6 А, B

Thermostats unit for preliminary fuel heating

7

Preliminary fuel heater

8

Burner shell

9

Fan engine

10

Socket for compressed air connection

11

Control chamber with an indicator of emergency shutdown

12

Drain tap of the preliminary heater

13

Ignition transformer

14

View hole

15 (1),(2)*

Electromagnetic valves (solenoids) 1 and 2* of air lines

16 (1),(2)*

Air filters separating moisture and regulating primary air pressure in lines 1

and 2*

17

Drain tap of the preliminary heater

18

Fuel way inlet

Size

WB60/120, mm (pic. 2)

WB230/270

A

460

530

B

280

300

C

180

230

D

205

212

E

415

540

F

80 – 110

105 – 200

G

95

134

H

93

137

I

105

150 L M8

M8 M 95

114

7

Pic. 5 Burner with 1 nozzle

Pic. 6 Burner with 2 and 3 nozzles

#

Element name (pic. 1)

1

Diffuser (not for models WB60 and WB120)

2

Dispenser

3

Nozzle

4

Electrode

5

Combustion tube

Burner

model

Relative distance between elements (mm)

A B C

D

WB 60/120

4-5 1 2-4

5.5-6

WB 230/270

5-6 1 3-5

5-7

A dispenser position affects relation of the volumes of straight air going along the outer edge of

the dispenser and swirled air going through the dispenser blades. If distance A gets bigger, the

volume of straight air grows, fuel mixes with air at lower speed, the flame grows higher and

becomes less consistent. If distance A gets smaller, the flame becomes less intensive, air and

fuel mix at higher speed, the flame gets shorter and wider.

Loading...

Loading...