Page 1

Field Replacement Furnace Vent Transition Kit

INSTALLATION INSTRUCTIONS

For M3RL / M7RL Series Furnaces

IMPORTANT SAFETY INFORMATION

INSTALLER: Please read all instructions before servicing

this equipment. Pay attention to all safety warnings and any

other special notes. Safety markings designate a degree or

level of seriousness and should not be ignored. A WARNING

Indicates a potentially hazardous situation that if not avoided,

could result in personal injury or death.

WARNING:

This kit must be installed by a qualified service

technician in accordance with these instructions

and all codes having jurisdiction. Failure to follow

these instructions could result in serious injury,

property damage, or death.

These instructions are primarily intended to assist qualified

individuals experienced in the proper vent and combustion

intake pipe installations of this appliance. Some local

codes require licensed installation/service personnel for the

installation of this type of equipment. The qualified service

technician performing this work assumes responsibility for

this furnace installation.

ABOUT THE VENT TRANSITION KIT

This kit is to be used for field replacement of a non-condensing

M3RL / M7RL series furnace in manufactured housing. It may

be used at elevations up to 8,000 feet above sea level. M3RL

/ M7RL series furnaces are condensing gas furnaces and

must be vented with PVC or equivalent pipe to prevent vent

corrosion. Using the replacement chase assembly and vent

caps in this kit, you may easily install the vent and combustion

air intake pipes for the new furnace. Before you begin the

installation process, make sure your kit contains all the items

listed in Table 1.

Removing Unnecessary Parts from the Old

Roof Jack

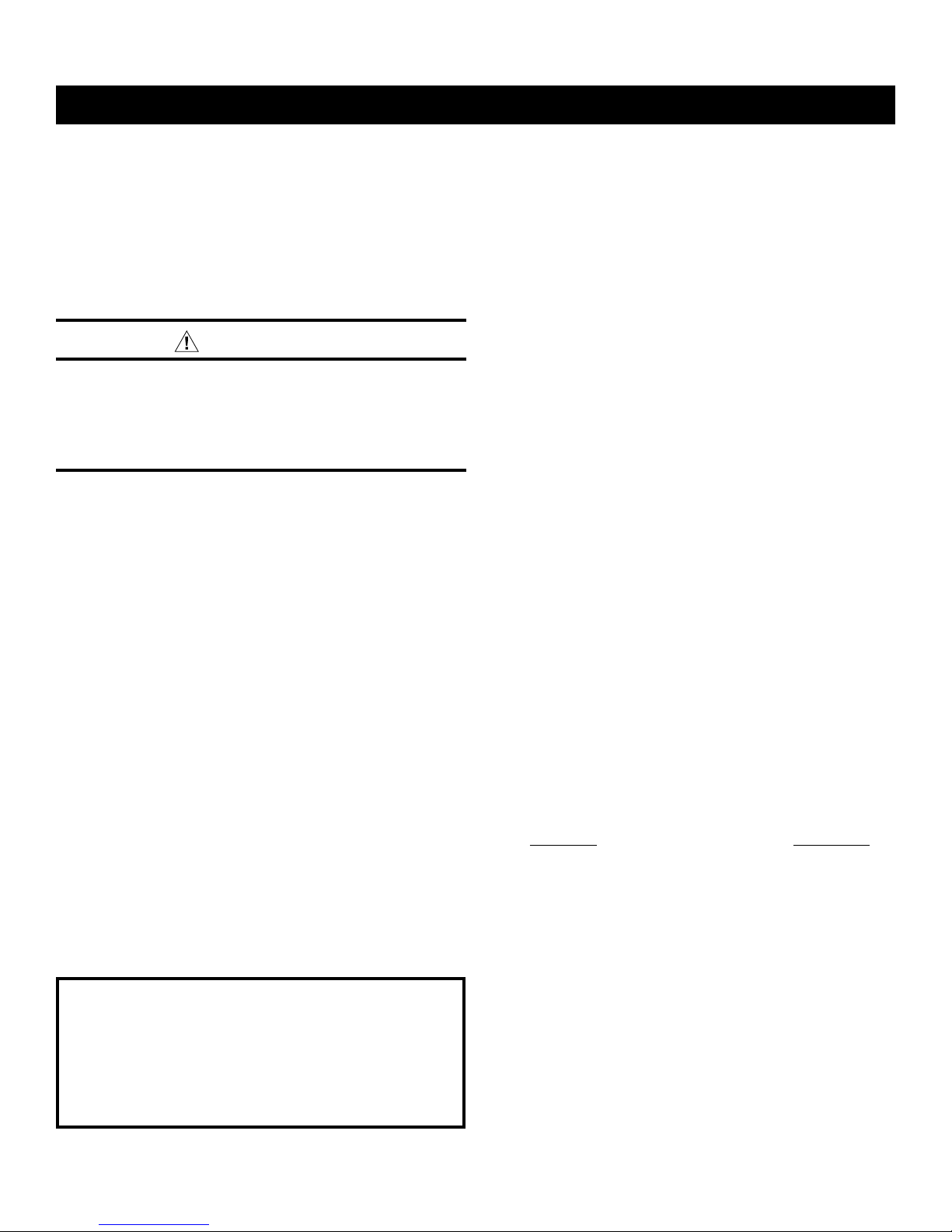

NOTE: Disassembly instructions may vary depending upon

the age and design of the roof jack. See Figure 1.

1. Disassemble the top roof jack by removing the screws

connecting it to the upper combustion air intake pipe.

2. Remove brackets from the combustion air intake upper pipe.

NOTE: The brackets are fastened with 1/8” pop rivets and

can be removed by drilling the rivets with a 1/8” drill bit.

3. Remove the inner and outer flue pipes (6” diameter) from

the roof jack.

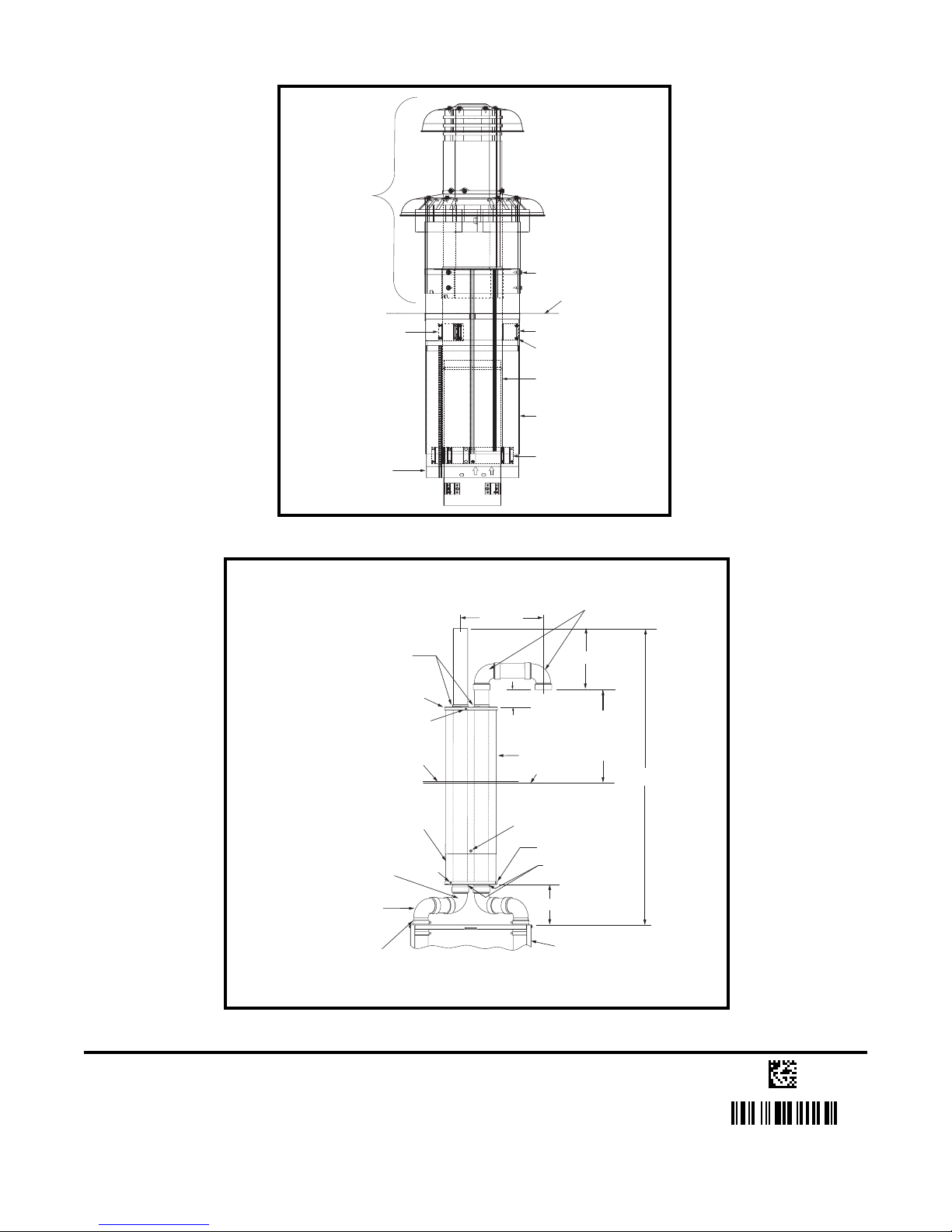

Installing the Vent & Combustion Air Intake Pipe

(After the M3RL / M7RL furnace is set in place)

1. Refer to Table 2 and choose proper vent pipe material.

2. Install 2” rubber couplings on the furnace pipes and assemble

90º SPIG x HUB elbow (large radius). See Figure 2.

3. Place bottom and top replacement caps on the roof jack.

DO NOT screw the caps down at this time.

4. Cut 2” plastic pipes to length and route the vent and

combustion air intake pipes through the replacement caps.

NOTE: The maximum height from the top of the furnace

to the top of the flue pipe must be no longer than 15 feet.

See Figure 2.

IMPORTANT INFORMATION:

• Ventandcombustionairpipeandttingsmustbeone

of the materials listed below and must conform to the

indicated ANSI/ASTM standards.

• CementandprimermustconformtoATSMStandard

D2564 for PVC and Standard D2235 for ABS. When

joining PVC piping to ABS, use PVC solvent cement. In

Canada, cements, cleaners, or primers must be certified

as a system to ULC S636.

• Before permanentlyinstallingPVC components,itis

recommended you dry-fit them first to ensure proper

fit and alignment with other vent pipes.

INSTALLING THE KIT

1. Verify structural integrity of the roof flashing and upper and

lower combustion air pipes. NOTE: Do not use this kit with

existing roof jacks that are unsafe or unstable.

2. Replace the existing furnace with the new M3RL / M7RL

furnace. Refer to the the installation instructions supplied

with the furnace for additional information.

KIT CONTENTS

Replacement Vent Caps ...................................... Qty: 2

2" Rubber Couplings ............................................Qty: 2

2” Diameter Clamps ............................................. Qty: 4

90° Street Elbows ................................................ Qty: 2

#10 Sheet Metal Screws ......................................Qty: 6

Instruction sheet .................................................. Qty: 1

Table 1. Kit Contents

Materials Standards

Schedule 40PVC ........................................ D1785

PVC-DWV ................................................... D2665

SDR-21* & SDR-26* ................................... D2241

ABS-DWV ................................................... D2661

Schedule 40 ABS ....................................... F628

Foam/Cellular Core PVC ............................ F891

5. Permanently bond all PVC components together using

appropriate primer and cement.

6. Screw the top & the bottom replacement caps to the outer

pipes. NOTE: Two or more screws must be used on each cap.

7. Tighten the upper hose clamps on the 2” rubber couplings.

8. Secure the combustion air intake pipe to the lower

combustion air intake pipe at the bottom of the upper pipe

using at least two screws.

9. Seal around the two pipes on the top and bottom replacement

caps with silicone sealant.

Page 2

Top Roof

Jack Assy

Screws

Roof Flashing

Bracket

Lower Combustion

Air Intake Pipe

Figure 1. Typical Existing Roof Jack

Seal With

Silicone Sealant

Replacement Cap

Lower Vent

Chase Pipe

2" X 90o Elbow - Large

Radius Hub X Hub

(Both Sides)

2" X 90o Elbow - Large

Radius Spig X Hub

(Both Sides)

Screw

Roof

Flashing

Screw

Bracket

Rivets

Outer Flue

Pipe Assy

Upper Combustion

Air Intake Pipe

Bracket

5" to 13"

10" Min.

1" Min.

Upper Vent

Chase Pipe

(8" Dia.)

Add 2 or More Screws Thru

Upper & Lower Pipes to

Prevent Telescoping

above roof

or expected

snow level

Roof

Replacement Cap

Seal With

Silicone Sealant

8" Max.

2" X 90o Elbow

Large Radius

Hub x Hub 2 Req.

12” Min.

15' Max.

2" Dia. Rubber

(Both Sides)

Figure 2. Vent & Combustion Air Intake Pipe Installation

Specifications & illustrations subject to change without notice or incurring obligations (05/15).

O’Fallon, MO, © Nortek Global HVAC LLC 2015. All Rights Reserved.

Furnace

Coupling

7093520 (Replaces 708300B)

Loading...

Loading...