Page 1

LiveSteam

Important: Read and save these instructions. This guide to be left with equipment owner.

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your LiveSteam

humidifier

1506160-B| 12 JUNE 2013

Page 2

Thank you for choosing Nortec.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Proprietary Notice

This document and the information disclosed herein are proprietary data of NORTEC HUMIDITY LTD. Neither

this document nor the information contained herein shall be reproduced, used, or disclosed to others without

the written authorization of NORTEC HUMIDITY LTD., except to the extent required for installation or

maintenance of recipient’s equipment. All references to the Nortec name should be taken as referring to

NORTEC HUMIDITY LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2013, NORTEC HUMIDITY LTD. All rights reserved.

Page 3

Contents

2 Installation

2 Receiving & Unpacking

2 Location of the Humidifier in an Air Conditioning System

3 System 1 – Air Handling Unit

4 System 2 – In Duct Near An Elbow

5 System 3 – Multi-Zone System

6 System 4 – Dual Duct

6 System 5 – Primary and Secondary Distributors

7 Steam and Condensate Piping

7 Assembly of Single Distributor Humidifier

8 Assembly of Multiple Distributor Humidifier

9 Installation of LiveSteam Humidifier

10 Changing Orientation of Single Distributor Humidifier

10 Insulated Steam Distributors

10 Duct Support Bracket

12 Pressurized SAM-e

12 Plumbing

12 Installing Actuator to Steam Valve

23 SAM-e with Pressure Steam

23 Mini SAM-e with Pressurized Steam

27 Maintenance

27 Troubleshooting

Page 4

CAUTION: Servicing

Disconnect main power before any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

Walter Meier does not accept any liability for installations of humidity equipment

installed by unqualified personnel or the use of parts/components/equipment

that are not authorized or approved by Walter Meier.

CAUTION: Electrical

All electrical work should be done according to local and national electrical code.

Electrical connection to be performed by a licensed electrician.

CAUTION: Plumbing

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not drain to public sink.

All plumbing work should be done according to local plumbing code.

CAUTION: Installation

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

LiveSteam produces steam at atmospheric pressure no devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat.

1 | LS Installation Manual

Page 5

Installation

Velocity

Inlet Steam Pressure

Up Flow Distance

500

15

2 ft

1000

15

1 ft

500

30

4 ft

1000

30

2 ft

Receiving & Unpacking Equipment

1 Check packing slip to ensure ALL material has been delivered.

2 All material shortages are to be reported to Nortec within 48 hours from receipt of goods.

Nortec assumes no responsibility for any material shortages beyond this period.

3 Inspect shipping boxes for damage and note damages on shipping waybill accordingly.

4 After unpacking, inspect equipment for damage and if damage is found, notify the shipper

promptly.

5 All Nortec products are shipped on an FOB factory basis. Any and all damage, breakage or

loss claims are to be made directly to the shipping company.

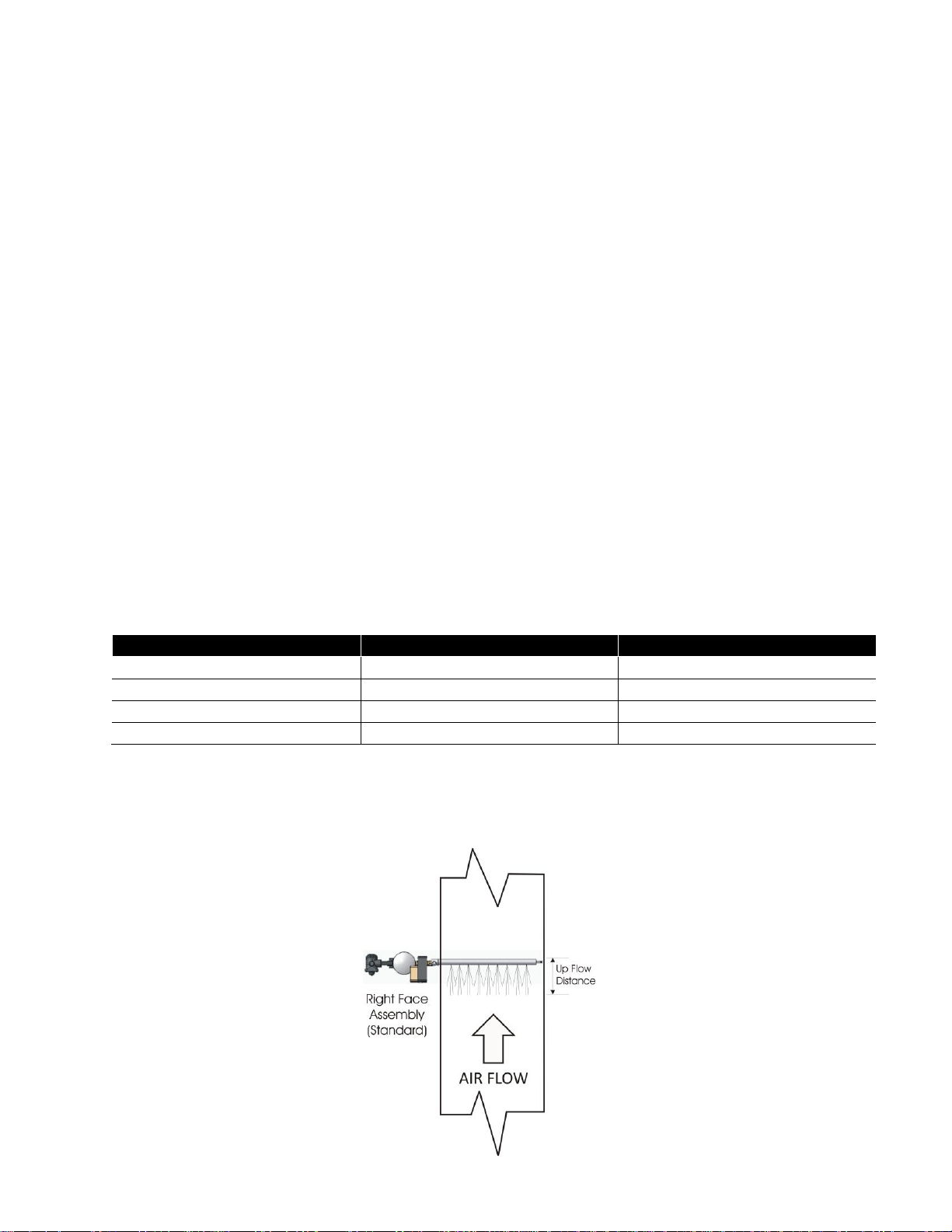

Location of the humidifier in an air conditioning system

Reference the following systems for humidifier location:

Up flow affect

The up flow affect is a result of the air velocity versus the steam velocity leaving the orifices of

the distributor.

The air velocity is a product of the volume flow rate through a present cross sectional area. The

steam velocity leaving the orifices is directly proportional on the internal pressure, inside the

distribution tube. This pressure is reduced when two or more distributors are in use.

The following up flow guidelines has been established from testing:

These up flow distances are only guidelines. Every application presents a multitude of variables

which may shorten or lengthen the up flow distance. The location of the distributor may need to

be changed if condensation occurs.

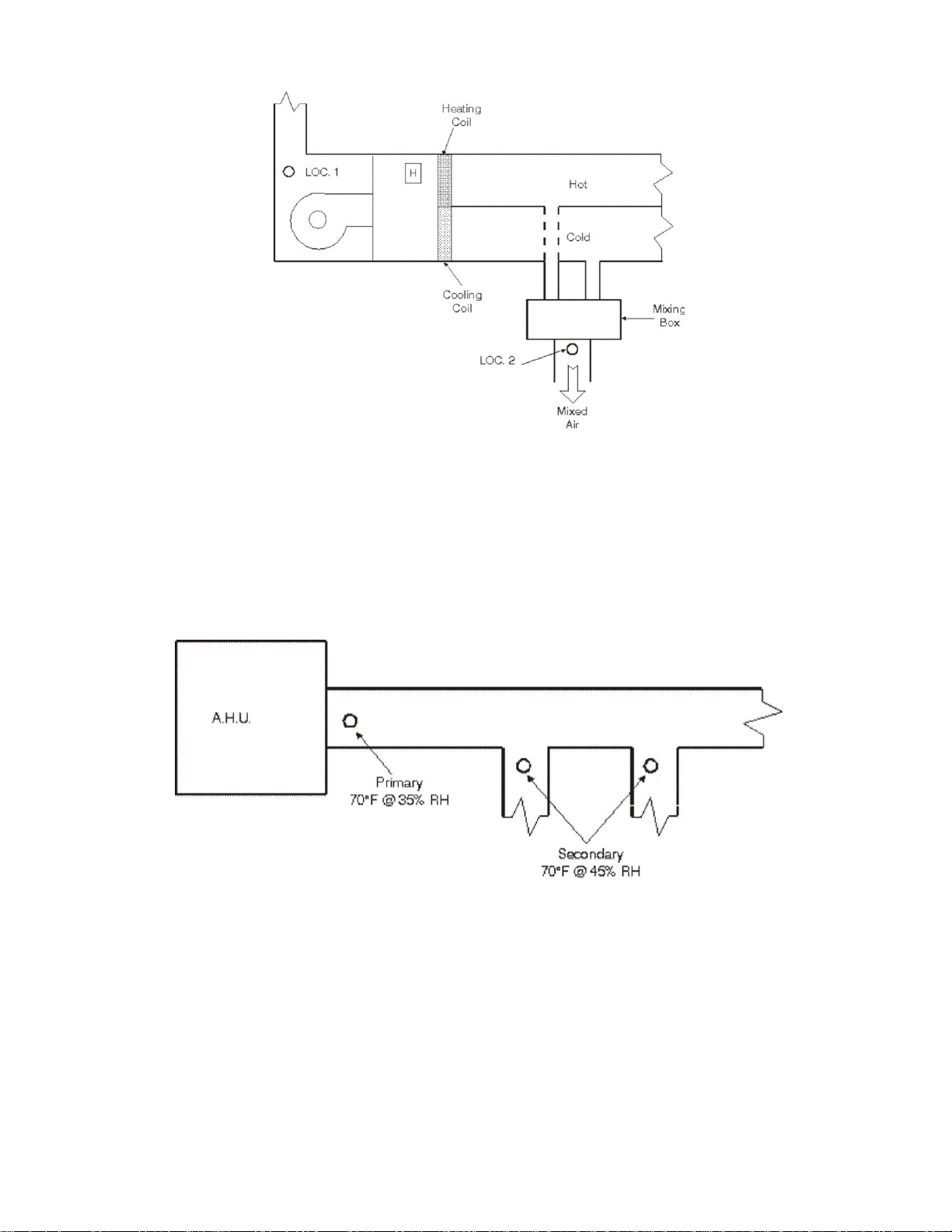

Figure 1: Top View

LS Installation Manual | 2

Page 6

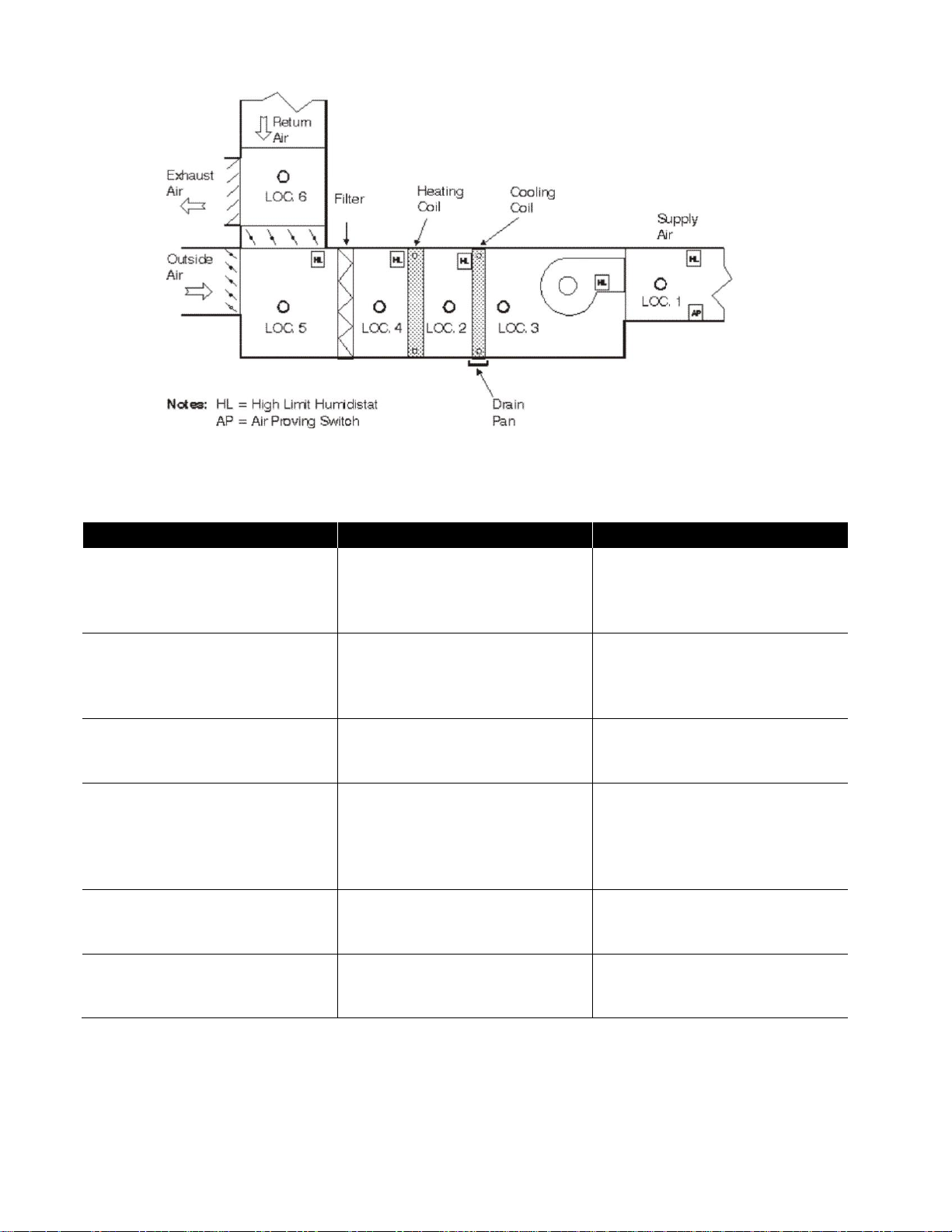

System 1 - Air Handling Unit

Location

Advantages

Disadvantages

LOC. 1

MOST recommended.

Assuming there is

sufficient straight duct for

absorption.

High velocity may create long

absorption distances.

LOC. 2

Warm air from heating coil.

Good absorption will help

evaporate steam.

Cooling coils designed for

water.

Possible capacity drop due to

condensation on the coil.

LOC. 3

Warm air.

Good absorption.

If absorption distance is too

long it may wet the fan.

LOC. 4

Heating coils will help

evaporate steam.

Air is mixed well.

Absorption may be a problem.

No drain pan on heating coil.

Cold air.

LOC. 5

Not Recommended.

Filters may get saturated.

Cold air.

LOC. 6

Not Recommended.

Outside air may cause

condensation problems.

Problematic RH control.

Figure 2: Air Handling Unit

Table 1: Air Handling Unit

3 | LS Installation Manual

Page 7

System 2 - In Duct Near An Elbow

Location

Advantages

Disadvantages

LOC. 1

MOST recommended. More

air on the outside of the turn.

Uneven air flow in the duct.

LOC. 2

Even air flow over the whole

duct.

Possibility of wetting of the

turning vanes.

Note: If not calculated, dimension “X” is minimum 6’ before or after bend or transition. See up flow

effect on page 6 for calculation.

Figure 3: In Duct Near An Elbow

Table 2: In Duct Near An Elbow

Warning: This type of distributor may produce a whistling noise as the pressurized steam decompresses

within the distributor and is introduced into the airstream. This noise may be increased with higher

pressure applications. For noise dampening recommendations, please consult the factory.

LS Installation Manual | 4

Page 8

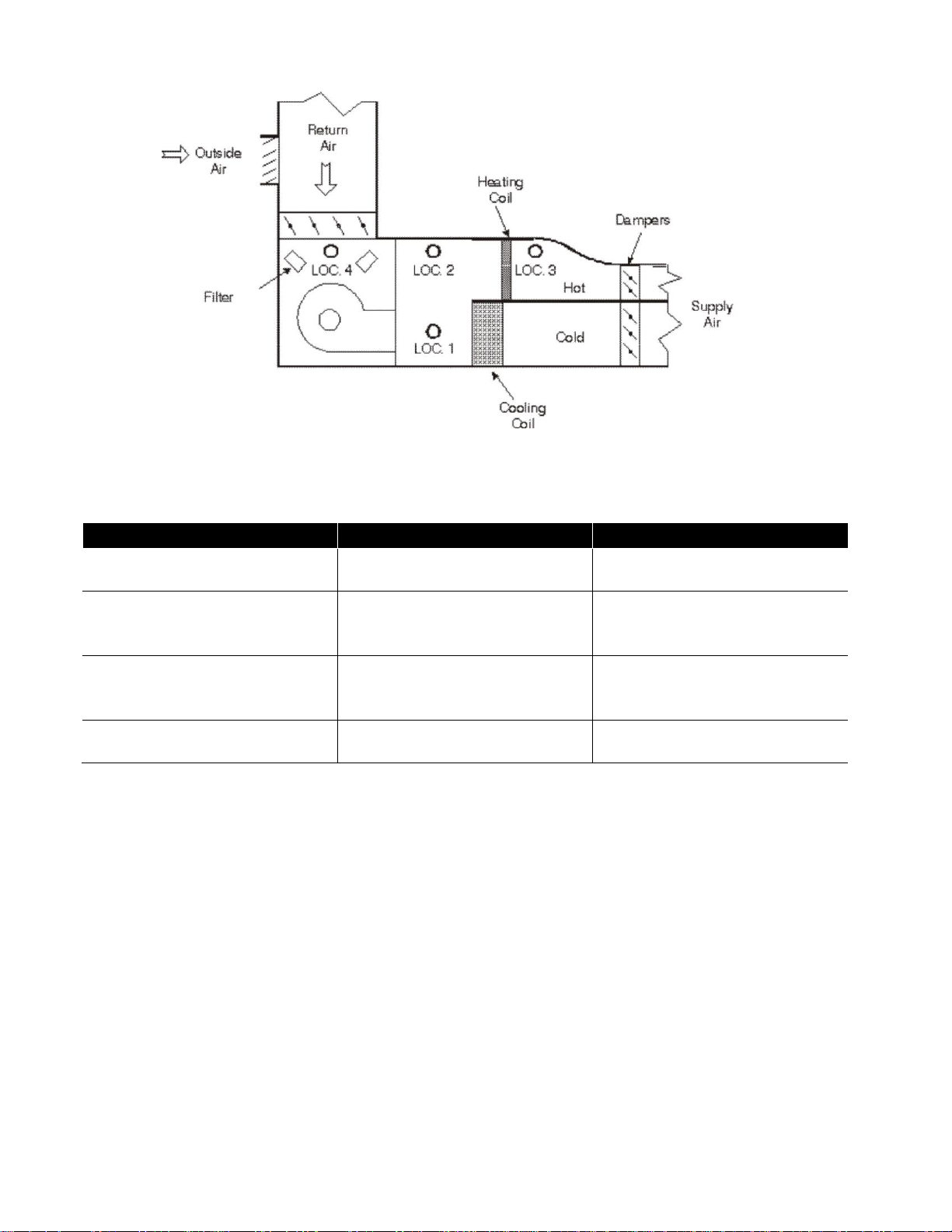

System 3 - Multi-Zone System

Location

Advantages

Disadvantages

LOC. 1

Maximum absorption distance

to dampers.

Possible loss of capacity to

condensate on cooling coils.

LOC. 2

Heating coil will help absorb

steam.

Minimum distance to the

dampers could result in

wetting.

LOC. 3

Warm air.

Minimum distance to the

dampers could result in

wetting.

LOC. 4

Not recommended.

Filters may get saturated.

Cold air.

Figure 4: Multi-zone System

Figure 3: Multi-zone System

If one zone requires most of the air quantity supplied to the system, this zone should be the

location for the humidifier. Humidity will eventually equalize when the system has been in

operation for a while.

5 | LS Installation Manual

Page 9

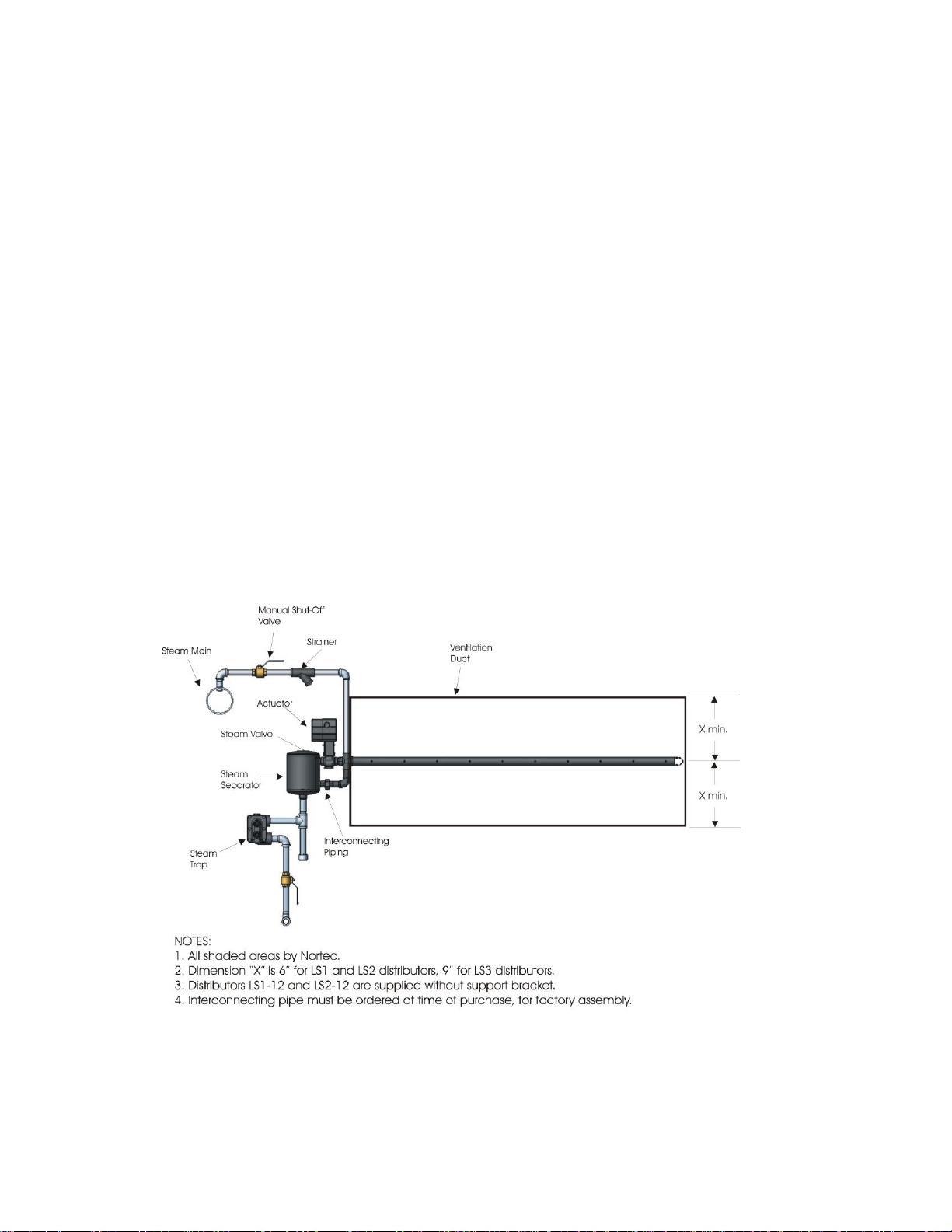

System 4 - Dual Duct

Figure 5: Dual Duct

This system usually requires two steam distributors. The primary load (LOC.1) will go upstream

of the fan. The humidistat is located after the fan and before the hot and cold decks. The

secondary load (LOC. 2) will go downstream to the mixing boxes and will be controlled by a

humidistat in the space. Please consult your Nortec agent if absorption distance is a problem.

High limit humidistat is recommended in the mixed air duct.

System 5 - Primary And Secondary Distributors

Figure 6: Primary and Secondary Distributors

On occasion you may need a secondary load to reach a higher RH level in one part of your

operation (i.e. Hospitals). In this case, the primary load will maintain the normal space

condition (70°F at 35% RH) and the secondary load will satisfy the higher RH level (70°F at

45% RH) needed for that zone. High limit humidistats are recommended for each duct.

LS Installation Manual | 6

Page 10

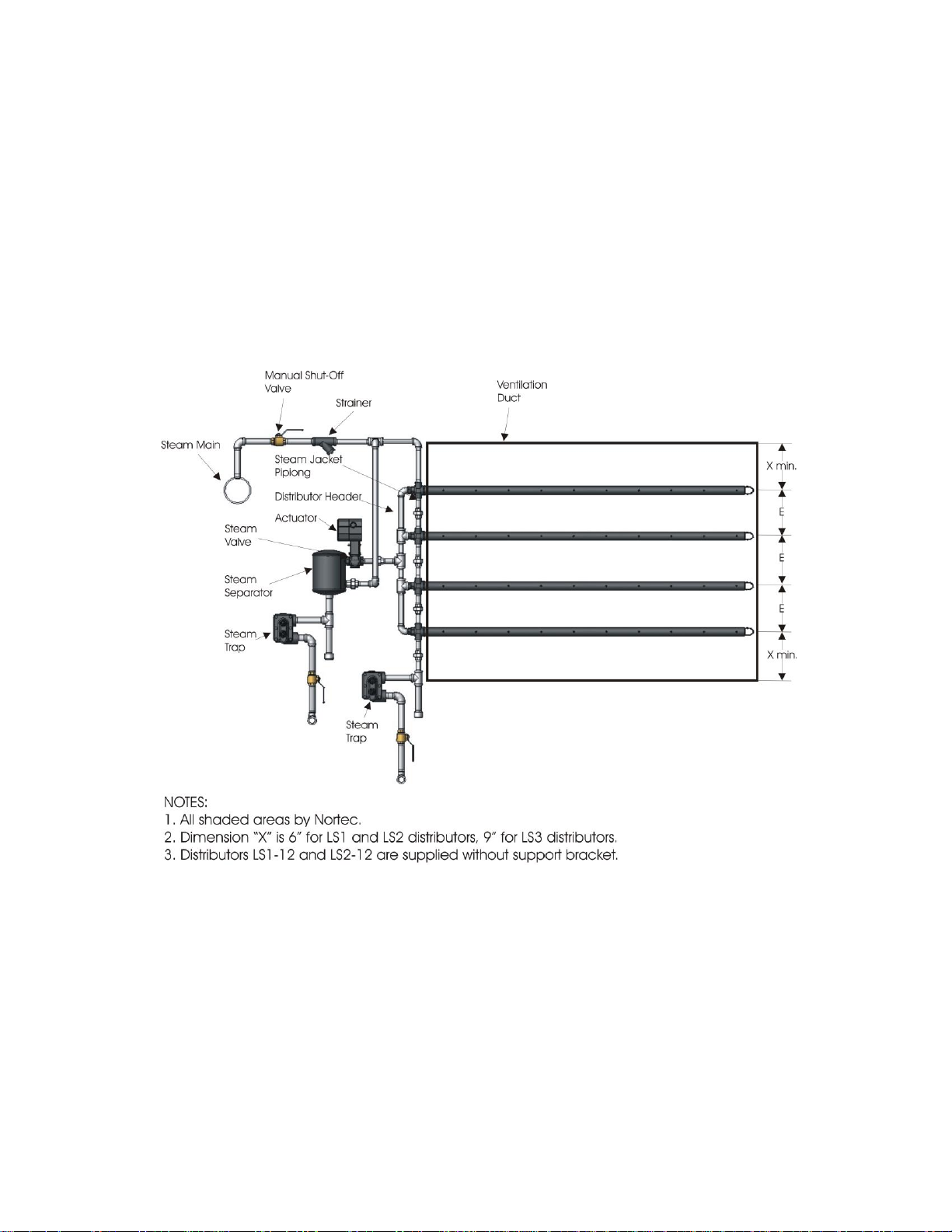

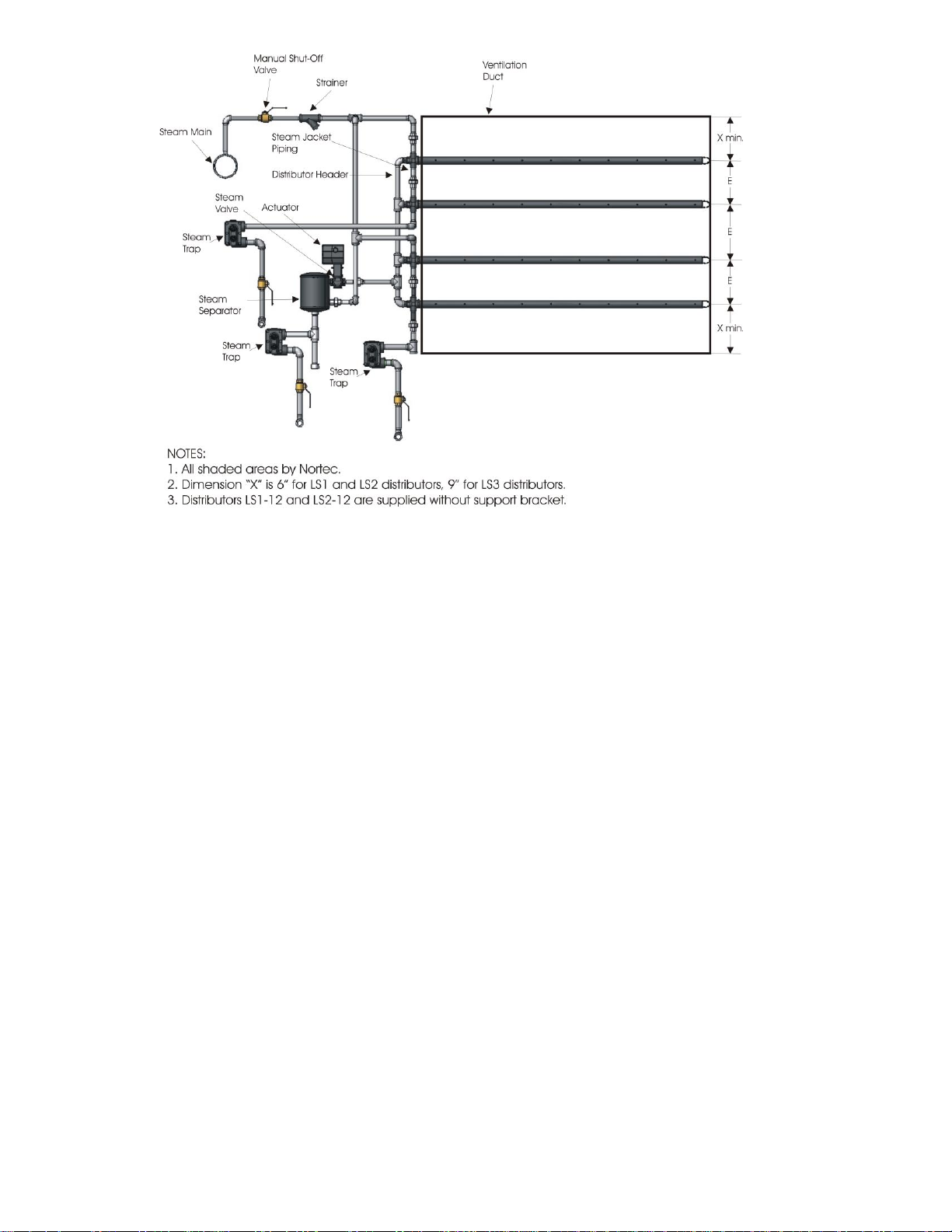

Steam and Condensate Piping

1 Steam supply must be taken from the top of the main supply to the humidifier. Do not take

from the sides or the bottom. See Figure 8.

2 For removal of condensate from the steam trap the condensate line should not be under

pressure. Nortec recommends a check valve be installed after the steam trap if the

condensate return line is pressurized.

3 Proper design and sizing of steam supply lines should be performed by a qualified firm.

Assembly Of Single Distributor Humidifier

Note: Follow all general instructions provided with valve and actuator.

All single distributor humidifiers will be assembled at the factory if the interconnecting piping

option is selected at time of order.

1 Match the separator/valve assembly with the correct distributor assembly (Nortec will tag

both assemblies).

2 The o-ring in the tube adaptor should be lubricated (use silicone based lubricant).

3 Slide the distributor into the tube adapter. Make sure that the o-ring is not damaged.

Tighten tube adapter. The adapter should be hand tightened plus ¼ turn (25 in-lbs ± 5 inlbs).

Figure 7: Single Distributor Humidifier

4 The union halves come together and are tightened to make a snug fit. The humidifier is

ready to be installed in the duct. Single tube comes factory assembled, multi-tube must be

field assembled.

7 | LS Installation Manual

Page 11

5 It is also possible to install distributor in the duct and then attach the separator/valve

assembly.

6 Follow the steps listed in “Installation Of LiveSteam Humidifier” section to complete

installation.

Assembly Of Multiple Distributor Humidifier

Make a plan of distributors’ layout (if not already done). See Figure 8. Multiple distributor

humidifiers require field assembly. The following steps should be taken into consideration:

1 Match the separator valve assembly with the correct distributors (Nortec will tag both

assemblies).

2 To ensure the same output from each dispersion tube, connect steam supply from separator

close to the middle of distributor header.

Figure 8: Multiple Distributor Humidifier

3 Steam jacket piping has to be secured to the distributor header to avoid possible

separation. Use gear clamp or similar device.

4 Distributors have to be equally spaced in the duct. Distance to the top and bottom of the

duct should be one half of “E” but not less than 6" for LS1 and LS2 distributors and not less

than 9" for LS3 distributors.

5 Use additional steam trap if total length of distributors of Type LS1 exceeds 40’, Type LS2

exceeds 30’, and Type LS3 exceeds 20’. See Figure 9.

LS Installation Manual | 8

Page 12

Figure 9: Multiple Distributor Humidifier with Multiple Traps

6 Follow the steps listed in “Installation Of LiveSteam Humidifier” section to complete

installation.

Installation Of Livesteam Humidifier

Note: Follow all general instructions provided with valve and actuator.

To complete installation follow the steps listed below.

1 Steam outlets of distributor should face into the air stream unless distributor is insulated.

Nortec’s standard is right face.

2 Distributors must be mounted level. There is a support bracket at the end of the distributor

to secure to the duct wall. See Figure 11 to 14 for installation tips.

3 The steam distributor in a Single Distributor Humidifier should be centered in the duct.

4 The steam distributor should be mounted in a straight section of duct. Please consult your

Nortec agent if absorption distance is a problem. For calculation of absorption distance

please refer to Nortec manual Form #163D.

5 Do not locate the steam distributor within 10 feet of high efficiency filters, otherwise the

filter will become saturated.

6 Cut a hole in the side of the duct large enough to insert the steam distributor. Duct plates

are provided to seal any opening.

7 Install actuator. During installation follow instructions shipped with actuator.

8 For ease of maintenance, provide shut-off a valve before humidifier (between strainer and

steam main). It can also be used to minimize heat gains during the non-humidification

period.

9 Install strainer before entering system and steam trap. Connect to steam and condensate

return mains.

9 | LS Installation Manual

Page 13

Right Face

Assembly

(Standard)

Left Face

Assembly

10 Wire (electric) or install control tubing (pneumatic) to the valve actuator.

11 Industry standards recommend the use of drain pans under the steam distributor.

12 Nortec recommends the use of a temperature switch. Valve will not open until the

distributor has reached its operating temperature. This is optional and must be ordered.

13 Nortec recommends the use of an air proving switch to prevent wetting in the duct.

Humidifier will not operate if there is no air movement in the duct.

14 A high limit duct humidistat, which prevents saturation and wetting in the duct, is

recommended downstream 12-14 feet from the humidifier and set at 80 to 90% RH.

Changing Orientation Of Single Distributor Humidifier

Unless otherwise specified at the time of order placement, all uninsulated single tube

distributors will be shipped with right face assembly and steam outlets facing the air stream

(See Figure 10). The steam flow direction can be changed by opening the union and

disengaging the nipple / elbow assembly from the steam distributor, turning the tube assembly

180º and reinstalling the nipple / elbow assembly.

Warning: LS distributors are designed to be supported by the steam piping connected to the

unit. Failure to properly support steam piping can result in stresses on the tube adapter and

damage the o-ring.

Figure 10: Right / Left Face Assembly

Insulated Steam Distributors

When the steam distributor is insulated the distributor should discharge in the direction of air

flow. This is to prevent condensation build-up on the steel insulation jacket.

Duct Support Bracket

Duct support bracket allows for easy installation in the various duct configurations (Figure

#11,12,13,14).

It is designed to be used with maximum bolt size of 3/8" (M10). LS1 and LS2 distributors that

are 12” (30.5 cm) long are not supplied with duct support brackets.

LS Installation Manual | 10

Page 14

Figure 11: Duct Support Bracket Flush with Duct Wall

Figure 12: Duct Support Bracket Away from Duct Wall

11 | LS Installation Manual

Figure 13: Duct Support Bracket with Angled Duct Wall

Page 15

Dura Drive P/N

Nortec P/N

Assembly Instructions

MS51-7203 DURA

DRIVE ACTUATOR

150 7552 0-10VDC,

150 7553 4-20mA,

150 7554 On/Off

For 1-1/2” Bronze Valve for incoming pressures

from 35 to 50 psi, and 2” Bronze Valve for

incoming pressures from 20 to 50 psi.

Warning: Proper design and sizing of steam lines should be performed by a qualified

technician.

Figure 14: Duct Support Bracket with Horizontal Duct Wall

Pressurized SAM-e

Plumbing

Steam Line

Condensate Return Line

When pressurized steam (2-50 psi) enters the SAM-e, steam expansion reduces pressure down

to almost atmospheric pressure. Therefore condensate cannot be lifted after the F+T trap. A

high temperature condensate pump may be used to achieve this.

Condensate from the SAM-e must always be returned to an atmospheric condensate return

main.

Long condensate runs (more than 20 ft.) should be oversized for better flow. Refer to Figure 33

and 34.

For proper trap installation, refer to Figure 15.

Installing Actuator To Steam Valve

LS Installation Manual | 12

Page 16

13 | LS Installation Manual

Page 17

Step 1

Ensure all components are

accounted for:

1. Connecting Pin

2. Stem Extension

3. Set Screw

4. Lock Washer

5. Jam Nut

6. Actuator

Figure 15: Step 1

Step 2

1. Thread jam nut on to valve

stem all the way.

2. Place lock washer over valve

stem so that it seats against jam

nut.

3. Thread stem extension on

valve stem compressing the lock

washer.

Figure 16: Step 2

ASSEMBLY INSTRUCTIONS

LS Installation Manual | 14

Page 18

Step 3

1. Insert hex wrench as

illustrated.

2. Rotate wrench 1 ½ turns

counter-clockwise.

3. Lock actuator by tightening

locking mechanism with a slotted

screwdriver.

Figure 17: Step 3

Step 4

1. Thread actuator on to valve.

2. Tighten valve mounting nut.

3. Manually raise valve stem to

up position (Closed).

Figure 18: Step 4

Step 5

1. Align stem extension hole with

actuator plunger hole.

2. Insert connecting pin.

3. Tighten jam nut against valve

stem.

4. Insert set screw into actuator

on most accessible side.

5. Tighten 20-25 in./lbs.

Figure 19: Step 5

Step 6

1. Release actuator by loosening locking mechanism.

2. Refer to wiring diagram for wiring instructions.

3. Apply power to actuator and ensure proper operation of valve and actuator.

4. Ensure proper response to control signal. 5. The actuator should be putting tension on the

stem and holding it closed (up position).

15 | LS Installation Manual

Page 19

Dura Drive P/N

Nortec P/N

Assembly Instructions

MS51-7103 DURA

DRIVE ACTUATOR

150 7549 0-10VDC,

150 7550 4-20mA,

1507551 On/Off

For Bronze ½”- 2” and St. St. ½”- 3/4” Valves,

for incoming pressures from 2 to 50 psi for all

valves except for 1-1/2” which would be 2 to

34 psi, and 2” which would be 2 to 19 psi

Step 1

Ensure all components are

accounted for:

1. Connecting pin

2. Stem Extension

3. Jam Nut

4. Actuator

Figure 20: Step 1

Step 2

1. Thread jam nut on to valve

stem all the way.

2. Thread stem extension on valve

stem.

3. Manually raise valve stem to up

position (Closed).

Figure 21: Step 2

LS Installation Manual | 16

Page 20

Step 3

1. Insert hex wrench as

illustrated.

2. Rotate wrench 2 turns counterclockwise.

3. Lock actuator by pressing

wrench towards actuator and

rotating 1/8 turn clockwise.

Figure 22: Step 3

Step 4

1. Thread actuator on to valve.

2. Tighten valve mounting nut.

Figure 23: Step 4

Step 5

1. Align stem extension hole with

actuator shaft hole.

2. Insert connecting pin.

3. Tighten jam nut against valve

stem.

4. Release Actuator by turning

hex key 1/8 turn counterclockwise.

5. The actuator should be putting

tension on the stem and holding it

closed (up position).

Figure 24: Step 5

17 | LS Installation Manual

Page 21

Dura Drive P/N

Nortec P/N

Assembly Instructions

MS61-7203 DURA

DRIVE ACTUATOR

150 7556 0-10VDC,

150 7557 4-20mA,

150 7558 On/Off

For 1”- 2” St. St. Valves, for incoming pressures

from 2 to 50 psi

Step 1

Ensure all components are

accounted for:

1. Actuator

2. Hex Wrench

3. Stem Extension Kit

4. Linkage Assembly

Figure 25: Step 1

Step 2

Linkage Kit Includes:

1. Connecting Pin

2. Stem Extension

3. Large Lock Washer

4. Small Lock Washer

5. Nut (Not Used)

6. Sticker

Figure 25: Step 1

Step 6

1. Refer to wiring diagram for wiring instructions.

2. Apply power to actuator and ensure proper operation of valve and actuator.

3. Ensure proper response to control signal.

LS Installation Manual | 18

Page 22

Step 3

Stem Extension Kit Includes:

1. Spacer

2. Stem Extender

3. Valve Mounting Nut

4. Copper Ring (not used)

5. Lock Washer

Figure 26: Step 3

Step 4

Thread the two stem extensions

together with the lock washer as

shown in the illustration.

Figure 27: Step 4

Step 5

1. Thread the spacer on to the

valve.

2. Tighten the spacer as far down

as possible.

Figure 28: Step 5

19 | LS Installation Manual

Page 23

Step 6

1. Thread Extension Assembly

from Step 4 on to valve stem.

2. Hand tighten as far down as

possible.

3. Manually position the valve in

the fully open position.

Figure 29: Step 6

Step 7

Pre-loading Actuator:

1. Insert Hex wrench as

illustrated.

2. Rotate 1 ½ turns counterclockwise.

3. Lock Actuator by turning

locking mechanism clockwise with

a slotted screwdriver.

Figure 30: Step 7

LS Installation Manual | 20

Page 24

Step 8

1. Insert valve with extension into

actuator.

2. Loosely thread Valve Mounting

Nut and Lock Washer on to

Spacer as illustrated.

3. Adjust Stem Extension by

rotating to align holes on valve

stem extension and actuator.

Figure 31: Step 8

Step 9

1. Insert Connecting Pin through

hole in Stem Extension and

actuator plunger.

Figure 32: Step 9

21 | LS Installation Manual

Page 25

Step 10

1. Tighten Valve Mounting Nut

compressing Lock Washer.

2. Tighten Stainless Steel Jam

Nut on actuator against the

Spacer.

Figure 33: Step 10

Step 11

1. Release actuator by loosening locking mechanism.

2. Refer to wiring diagram for wiring instructions.

3. Apply power to actuator and ensure proper operation of valve and actuator.

4. Ensure proper response to control signal.

5. The actuator should be putting tension on the stem and holding it closed (up position)

LS Installation Manual | 22

Page 26

23 | LS Installation Manual

Page 27

LS Installation Manual | 24

Page 28

Strainer

Manual Shut-Off

Valve (By Others)

Pressurized

Steam Main

F & T Steam Trap

Duct/AHU Width

Duct/AHU

Height

Separator

Actuator & Valve

Pressurized condensate

return main

1” Air Gap

Drain

Manual Shut-Off

Valve (By Others)

6” min.

6” Min

Return to non-pressurized

condensate return main

Tap steam from top of

pressurized steam main

• Steam components in grey are provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters the SAM-e, the pressure drops down to almost atmospheric

pressure. Therefore, it must be drained atmospherically, and the use of a condensate pump

(rated for 212ºF) must be used to raise the condensate to a higher elevation.

SAM-e with Pressure Steam

Pressurized Plumbing with External Separator

25 | LS Installation Manual

Page 29

1” A ir Gap

Drain

Strainer

Manual Shut-Off

Valve (By Others)

Pressurized

Steam Main

6” min.

Return to non-pressurized

floor drain

Pressurized condensate

return main

Tap steam from top of

pressurized steam main

Note: The SAM-e header functions as a steam separator, therefore an external

steam separator is not required.

• Steam components in grey are provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters the SAM-e, the pressure drops down to almost atmospheric

pressure. Therefore, it must be drained atmospherically, and the use of a condensate pump

(rated for 212ºF) must be used to raise the condensate to a higher elevation.

Pressurized Plumbing without External Separator

LS Installation Manual | 26

Page 30

Strainer

Manual Shut-Off

Valve (By Others)

Steam Main

F & T Steam Trap

Separator

Actuator & Valve

Pressurized condensate

return main

1” A ir Gap

Drain

Steam from top of main

Manual Shut-Off

Valve (By Others)

6” min.

6” min

Return to non-pressurized

condensate return main

Duct Width

Duct

Height

Duct Floor

Mounting

bracket

• Steam components in grey are provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters the SAM-e, the pressure drops down to almost atmospheric

pressure. Therefore, it must be drained atmospherically, and the use of a condensate pump

(rated for 212ºF) must be used to raise the condensate to a higher elevation.

Mini SAM-e with Pressurized Steam

Mini SAM-e Pressurized with External Separator

27 | LS Installation Manual

Page 31

Mini SAM-e Pressurized without External Separator

Strainer

Manual Shut-Off

Valve (By Others)

Steam Main

1” A ir Gap

Drain

Steam from top of main

6” min.

Return to non-pressurized

condensate return main

Pressurized condensate

return main

• Max steam pressure of 15 psig when no separator is used.

• Steam components in grey are provided by Nortec.

• Tap steam from top of pressurize steam main to avoid excess condensate.

• Condensate from separator to be returned to pressurized condensate main.

• Condensate from SAM-e to be returned to atmospheric floor drain.

When pressurized steam enters the SAM-e, the pressure drops down to almost atmospheric

pressure. Therefore, it must be drained atmospherically, and the use of a condensate pump

(rated for 212ºF) must be used to raise the condensate to a higher elevation.

LS Installation Manual | 28

Page 32

Maintenance

Elements Of LiveSteam Humidifier

Tube Adapter - consists of 3 pieces (See Figure 35). To maintain proper seal hand tighten tube

adapter nut, plus ¼ turn. Additional o-ring is shipped with this manual. If o-ring has to be

replaced do so as follows:

1. Disconnect actuator.

2. Dismount union by the separator.

3. Replace o-ring in the tube adapter.

4. Lubricate o-ring with silicone based lubricant.

Figure 35: Adapter Assembly

Strainer - Should be cleaned shortly after the system has begun operating (3 to 7 days) and

then annually.

Separator - No maintenance required.

Distributor - No maintenance required.

Valve - Should be inspected annually to confirm that steam is not leaking from the stem

packing, and the valve closes tightly. Repack if necessary.

Valve Seat - Lap seat if necessary.

Pneumatic Actuator - Should be inspected annually to confirm that the diaphragm is not leaking

air, and the valve operates properly.

Electric Actuator - Should be inspected annually to confirm that the valve operates properly.

Steam Trap - Should be inspected annually. Clean and inspect seats and replace required

gaskets if necessary.

Temperature Switch - Should be inspected once a year to ensure proper operation. Test by

supplying steam, which should open at 200ºF.

29 | LS Installation Manual

Page 33

Maintenance Schedule

Date

Personnel

Description

Problem

Cause / Solution

Distributor Discharges Water

Condensate return line not draining:

1. Back pressure on condensate line.

2. Dirty steam trap - repair or replace.

3. Steam trap is wrong type.

Steam supply:

1. Steam pressure is too low (under 2 psi).

2. Steam main flooding due to boiler

discharging water with steam.

3. Steam supply not taken at top of main.

4. Distributor not level.

Troubleshooting Guide

LS Installation Manual | 30

Page 34

Humidifier Leaks Water From Tube Adapter

1. Tighten tube adaptor.

2. Defective o-ring in tube adapter - replace

o-ring.

3. Is the o-ring lubricated?

Over Humidifying

1. Valve stem adjusted too tight and sticking.

2. Valve spring broken.

3. Foreign matter is preventing the valve from

closing.

4. Valve is installed incorrectly.

5. Steam pressure exceeds rating of valve

spring.

6. Controller out of calibration.

Under Humidifying

1. Boiler pressure is inadequate.

2. Steam piping is either undersized or piped

incorrectly.

3. Strainer is plugged.

4. Valve is not fully opened. (Check for leaking

air in actuator.)

5. Humidifier is undersized.

6. Controller is out of calibration.

7. Excess amounts of outside air.

8. Open doors, window, loading / shipping

docks.

Humidity Swings

1. Controller is malfunctioning.

2. Poor location of humidity sensor.

3. Humidifier is oversized.

4. Boiler pressure swings too widely

5. Pressure reducing valve is not working

properly (if installed).

Spitting During Start-Up

1. Add temperature switch.

2. Are drip legs installed?

3. Was the piping supplied undersized?

4. Is the boiler carrying too much condensate?

5. Is the boiler undersized or does it have the

incorrect pressure?

Condensate In Duct

1. Mounting too close to devices (elbows,

dampers, etc.) in duct.

2. Duct surface temperature is too low.

3. Oversized humidifier.

4. Malfunctioning or lack of safety high limit

humidistat.

31 | LS Installation Manual

Page 35

Valve Cross Reference Table

Valve Body Part Number

Nortec PN

Size

Cv

VB-7263-04-31

1594300

0.5"

0.1

VB-7263-0-4-33

1594302

0.5"

0.22

VB-7263-0-4-1

1594304

0.5"

0.4

VB-7263-000-4-35

1594306

0.5"

0.75

VB-7263-0-4-2

1594310

0.5"

1.3

VB-7263-0-4-3

1594314

0.5"

2.2

VB-7263-000-4-38

1594316

0.5"

2.8

VB-7263-0-4-4

1594318

0.5"

4.4

VB-7263-0-4-5

1594322

0.75"

5.5

VB-7263-0-4-6

1594324

0.75"

7.5

VB-7263-0-4-7

1594330

1.0"

10

VB-7263-0-4-8

1594332

1.0"

12

VB-7263-0-4-9

1594341

1.25"

20

VB-7263-0-4-10

1594350

1.5"

28

VB-7263-0-4-11

1594360

2.0"

40

VBS-9263-0-6-31

1594201

0.5"

0.1

VBS-9263-0-6-33

1594203

0.5"

0.22

VBS-9263-0-6-01

1594205

0.5"

0.4

VBS-9263-0-6-35

1594206

0.5"

0.75

VBS-9263-0-6-36

1594207

0.5"

0.95

VBS-9263-0-6-02

1594208

0.5"

1.3

VBS-9263-6-0-37

1594209

0.5"

1.75

VBS-9263-0-6-03

1594210

0.5"

2.2

VBS-9263-0-6-38

1594211

0.5"

2.8

VBS-9263-0-6-04

1594213

0.5"

3.6

VBS-9263-0-6-45

1594221

0.75"

4.3

VBS-9263-0-6-05

1594222

0.75"

5

VBS-9263-0-6-06

1594223

0.75"

6.2

VA7006EC

1594432

1.0"

10

VA7008EC

1594440

1.5"

24

VA7009EC

1594450

2.0"

40

LS Installation Manual | 32

Page 36

Actuator Close-Off Pressure

1507549, 1507550, 1507551 - 1/2 to 2 in, SS 1/2 to 3/4 in

Valve

1/2"

3/4"

1"

1-1/4"

1-1/2"

1-3/4"

2"

Bronze

50 psig

(345 kPa)

50 psig

(345 kPa)

50 psig

(345 kPa)

50 psig

(345 kPa)

34 psig

(234 kPa)

N/A

19 psig

(131 kPa)

SST

50 psig

(345 kPa)

50 psig

(345 kPa)

N/A

N/A

N/A

N/A

N/A

1507552, 1507553, 1507554 - Bronze 2 in

Valve

1/2"

3/4"

1"

1-1/4"

1-1/2"

1-3/4"

2"

Bronze

N/A

N/A

N/A

N/A

50 psig

(345 kPa)

N/A

50 psig

(345 kPa)

1507556, 1507557, 1507558 - 1 to 2 in SS

Valve

1/2"

3/4"

1"

1-1/4"

1-1/2"

1-3/4"

2"

Warren SST

N/A

N/A

50 psig

(345 kPa)

N/A

50 psig

(345 kPa)

N/A

50 psig

(345 kPa)

33 | LS Installation Manual

Page 37

Warranty

Nortec Humidity Inc. and/or Nortec Humidity Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of two years after installation or 30 months from

manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s manufactured and

assembled products, not otherwise expressly warranted (with the exception of the cylinder), are

free from defects in material and workmanship. No warranty is made against corrosion,

deterioration, or suitability of substituted materials used as a result of compliance with

government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the defective

part(s) is returned freight prepaid by the customer. Parts used for repairs are warranted for the

balance of the term of the warranty on the original humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or implied by law. No

liability whatsoever shall be attached to THE COMPANY until said products have been paid for in

full and then said liability shall be limited to the original purchase price for the product. Any

further warranty must be in writing, signed by an officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of the companies manufacture, such as

controls, humidistats, pumps, etc. is limited to the warranty of the original equipment

manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment is installed in

strict accordance with a copy of the catalog and installation manual in effect at the date of

purchase and by a contractor approved by THE COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for consequential

damage or damage resulting directly from misapplication, incorrect sizing or lack of proper

maintenance of the equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for damage resulting

from freezing of the humidifier, supply lines, drain lines, or steam distribution systems.

THE COMPANY retains the right to change the design, specification and performance criteria of

its products without notice or obligation.

Page 38

U.S.A.

Certificate No. 002419

2700 90th St.

Sturtevant, WI 53177

835 Commerce Park Dr.

Ogdensburg, NY 13669-2209

CANADA

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

FAX: 613.822.7964

EMAIL: nortec@humidity.com

WEBSITE: www.humidity.com

Loading...

Loading...