Page 1

Important: Read and save these instructions. This guide to be left with equipment.

2531037-E | 21 FEB 2012

LINKS 2

GSTC / SETC

B+ Models

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your GSTC/SETC B+

Nortec Links2 Options.

Page 2

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

Thank you for choosing NORTEC.

Proprietary Notice

This document and the information disclosed herein are proprietary data of Nortec Humidity Ltd. Neither this

document nor the information contained herein shall be reproduced used, or disclosed to others without the

written authorization of Nortec Humidity Ltd., except to the extent required for installation or maintenance of

recipient’s equipment.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2012, Nortec Humidity Ltd. All rights reserved.

Page 3

Contents

1 Installation

1 Overview

1 Bracket Installation

2 Retrofit Insallation of a NHRS

Links 2 Package

3 Mount the Links 2 Assembly

4 Wiring the Nortec Links 2 Module

9 Multi-Unit Systems (Master /

Slave)

9 Wiring

11 Network Integration

12 Retrieving XIF File Instructions

15 Variable Definition

26 Startup Check List

27 Troubleshooting

27 Indicator Lights

32 Replacement Parts

36 Wiring Diagrams

Page 4

Page 5

Overview

Protocol

BACnet MS/TP

BACnet / IP

Johnson N2

LonWorks

The GS/SE Nortec Links2 Option allows for the integration of a GSTC or SETC Series humidifier

within a BACnet, Johnson N2 or LonWorks network and allows those units to concurrently be

monitored via the Nortec OnLine interface. This option features a Nortec OnLine module coexisting with a gateway that has the capability of converting information from the host Modbus

protocol to a specified secondary protocol.

The following protocol options are available, and must be specified at time of order:

Table 1: Protocol Options

The Nortec Links2 package also includes Nortec OnLine. Nortec OnLine is an advanced web

monitoring package that allows authorized users to remotely monitor humidifier status and

performance from anywhere with an internet connection. Nortec OnLine is available with an

optional service that, among other things, includes factory technicians monitoring the units

weekly. Even if the OnLine service is not ordered, the units can still be connected to an viewed

online at www.norteconline.com For information specifically related to Nortec OnLine consult the

accompanying OnLine manual or your local representative.

Bracket Installation

Links2 can be factory installed inside of the humidifier if the package is included at time of order.

If this is the case, skip ahead through this section.

Links2 can also be retrofit to existing units. The following section explains how to install the

Links2 bracket inside of the humidifier.

Installation| 1

Page 6

Retrofit Installation Of A SETC-50 Nortec Links 2 Package

Step 1 - Installation

Mount the Links2 remote package in a convenient location. Note that the remote package does

not need to be mounted in close proximity to the humidifier, however, the CAT5 cable with RJ-45

connection must reach the humidifiers connection on the keybad PCB.

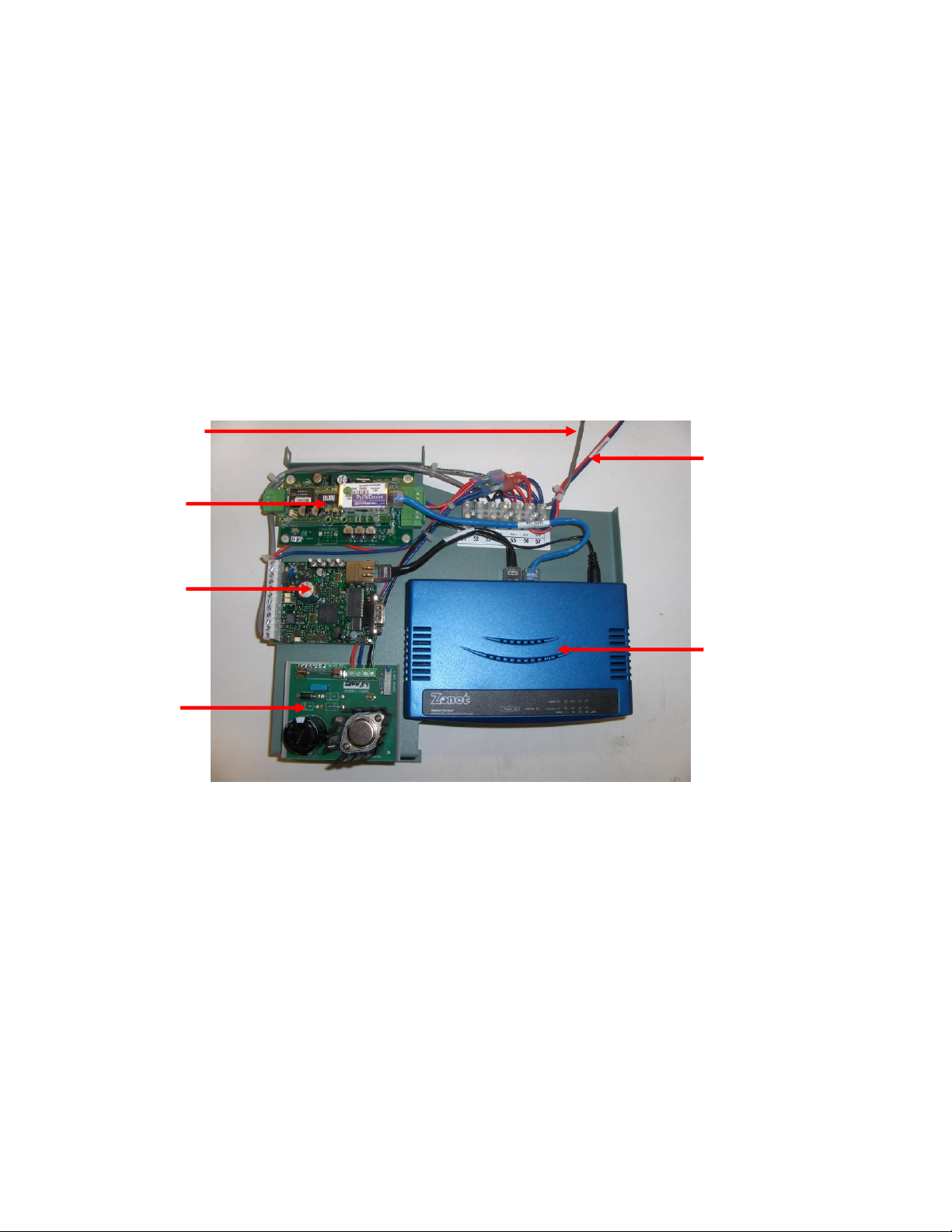

Figure 1: Remote Package

2 | Installation

Figure 2: Humidifier Keypad/Front of PCB

Page 7

RJ-45 connected

Figure 3: Rear of PCB

Connect power to the 24VAC and GND terminals of the Links2 terminal strip. This may be done in

one of two ways:

1. A 120VAC to 24VAC plug-in transformer with screw terminals on the secondary side has been

supplied with this kit. Wire the transformer to the 24VAC and GND terminals on the Links2

terminal strip.

2. Connect power from the humidifier terminal strip (see wiring diagram for details).

3. Note on 2(b) - Power to Links2 module will be lost when the humidifier is switched off.

4. Connect the slave humidifiers (if applicable) to the Nortec Links Module. A twisted pair cable

should be used so that the Net + terminal on the Links module should connect to the first pin

(bottom-most pin) of the connector. The Net – terminal on the module should be connected to

the second pin of the connector. Refer to the unit’s wiring diagram for more information.

Step 2 – Configuring The Humidifiers

Note: If the Links2 remote package was shipped with the humidifiers, this step will have already

been performed by the factory.

1. Since Nortec Links2 can connect to a maximum of 8 units, it will be necessary to set the unit

address for each humidifier. The lead unit can be determined by the presence of the Links2

module. The slave humidifiers can be given a unit address according to the number the unit

will have on the networked chain.

2. In order to change the current modbus address, press the Menu button on the keypad. When

prompted, enter the code 0335.

3. Once the password is set select the modbus address heading and press enter. Use the up and

down arrows to change the address setting.

4. Determine the desired humidifier ordering on the network. To change the network instance

follow step 3 and enter the parameter value of 2 for unit 2, 3 for unit 3 and so on.

Installation| 3

Page 8

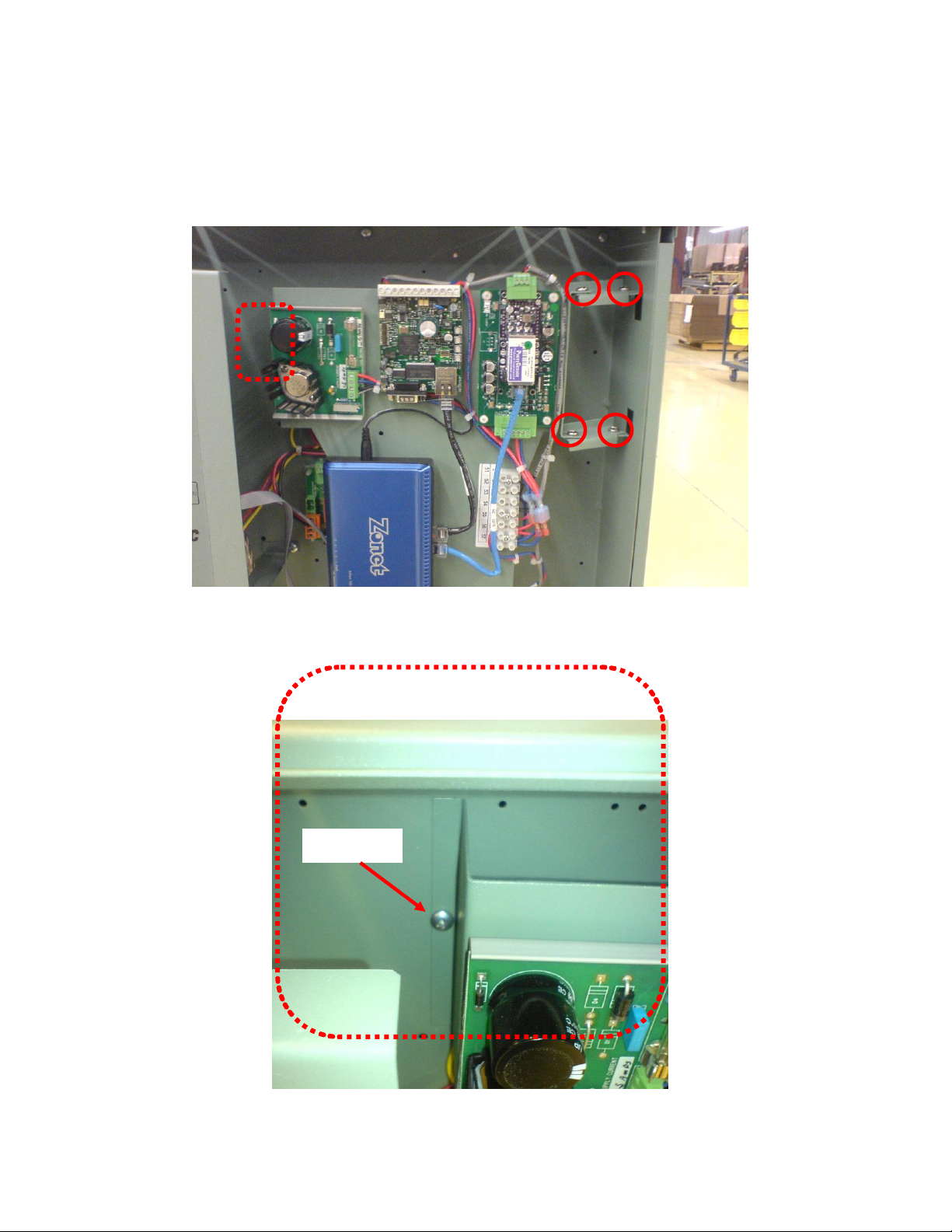

Retrofit Installation Of A GSTC/SETC Nortec Links2 Package

Figure 1. Bracket Placement and Screw Locations

Figure 2. Detailed View of 5th Screw

5th screw

BACNET, LONWORKS And N2 Modules:

Mounting The Links2 Assembly

Install the bracket assembly using 8-32x ½” hex-drive screws. Notice, 4 screws are used for the

hinges, and the 5th screw for fastening the bracket in place.

4 | Installation

Page 9

Wiring The Nortec Links2 Module

Figure 3. Component Identification

LAN

Router or

OnLine

LINKS 2

Router

CAT5 cable

Red and

blue wires

Most of the wiring connections for the new Nortec Links2 module will have already been finished at

the factory, however, there are a few connections that will need to be made to connect the unit the

GS/SE series humidifier. Refer the Links2 wiring diagram included in the package for details.

Module Power Connections: There will be a wire harness provided that will consist of a red and blue

wire. Both red and blue wires are terminated with a ring terminal.

1. The ring terminal of the red wire is to be connected to the power terminal on the 24V side of the

transformer located at the bottom, left of the electrical compartment.

2. The ring terminal of the blue wire is to be connected to the ground terminal on the 24V side of the

transformer.

Humidifier Communication Connection: On the Nortec LINKS 2 assembly there will be a CAT5 cable

with RJ45 connector.

1. This connector is to be plugged into the jack on the bottom right side of the humidifier main PCB

board.

Installation| 5

Page 10

Configuring The Humidifiers

Since Nortec Links2 can connect to a maximum of 8 units, it will be necessary to set the unit address

for each humidifier. The lead unit can be determined by the presence of the Links module. The slave

humidifiers can be given a unit address according to the number the unit will have on the networked

chain.

1. Press the Menu button on the keypad and enter the code 0335.

2. Select Control Settings

3. Select Modbus Paramaters.

4. Set the communication parity to None.

5. Set the appropriate Modbus address according to the unit ordering

6. Place the appropriate Unit Identifier label on each humidifier. These labels should be placed on

the unit where the electrical control punch-outs are located at the top of the humidifier.

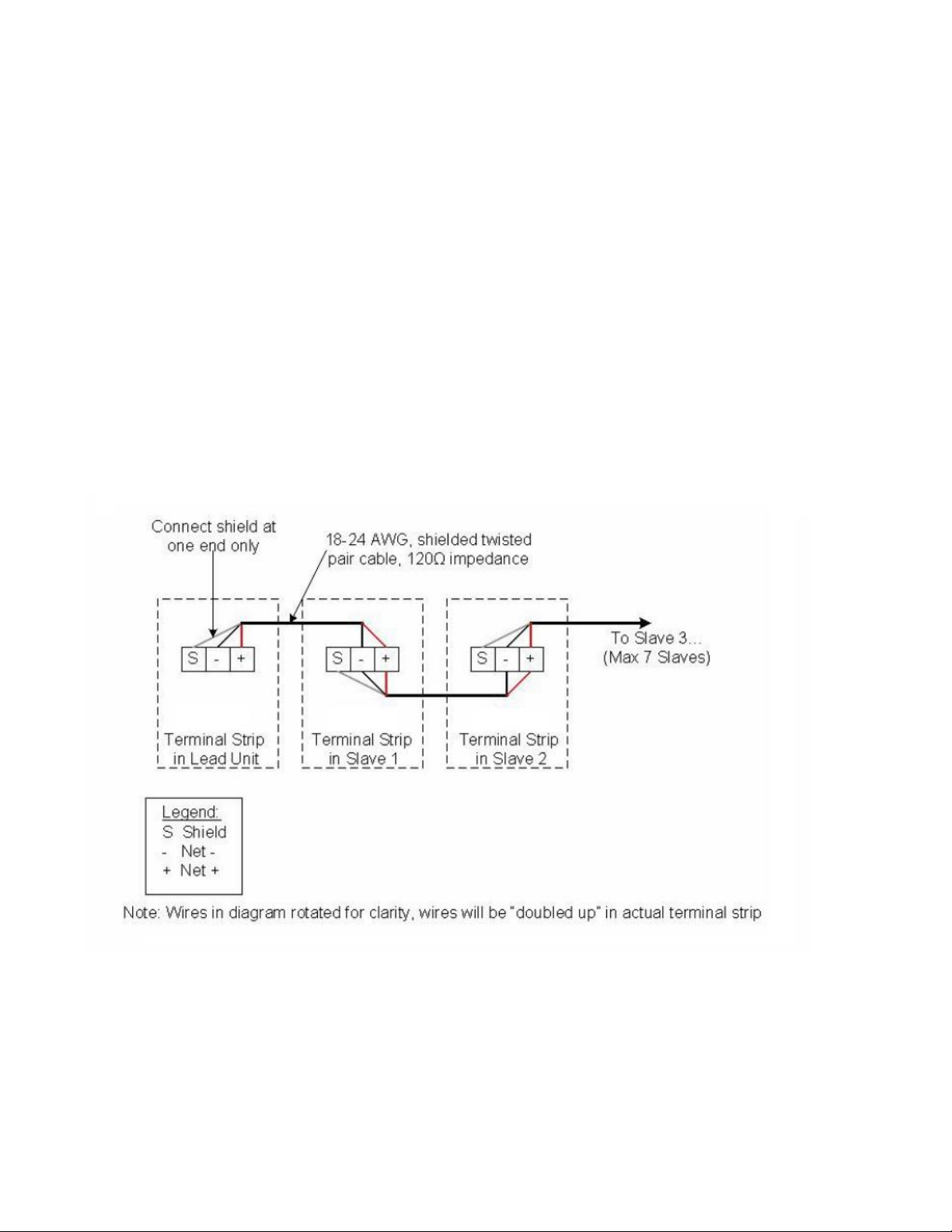

7. Connect the slave humidifiers (if applicable) to the Nortec Links Module. A twisted pair cable

should be used so that the Net (+) terminal on the Links module should connect to the first pin

(bottom-most pin) of the connector. The Net (–) terminal on the module should be connected to

the second pin of the connector. Refer to the unit’s wiring diagram for more information.

8. Ensure shield wiring matches the following pattern if distances between humidifiers is significant.

6 | Installation

Page 11

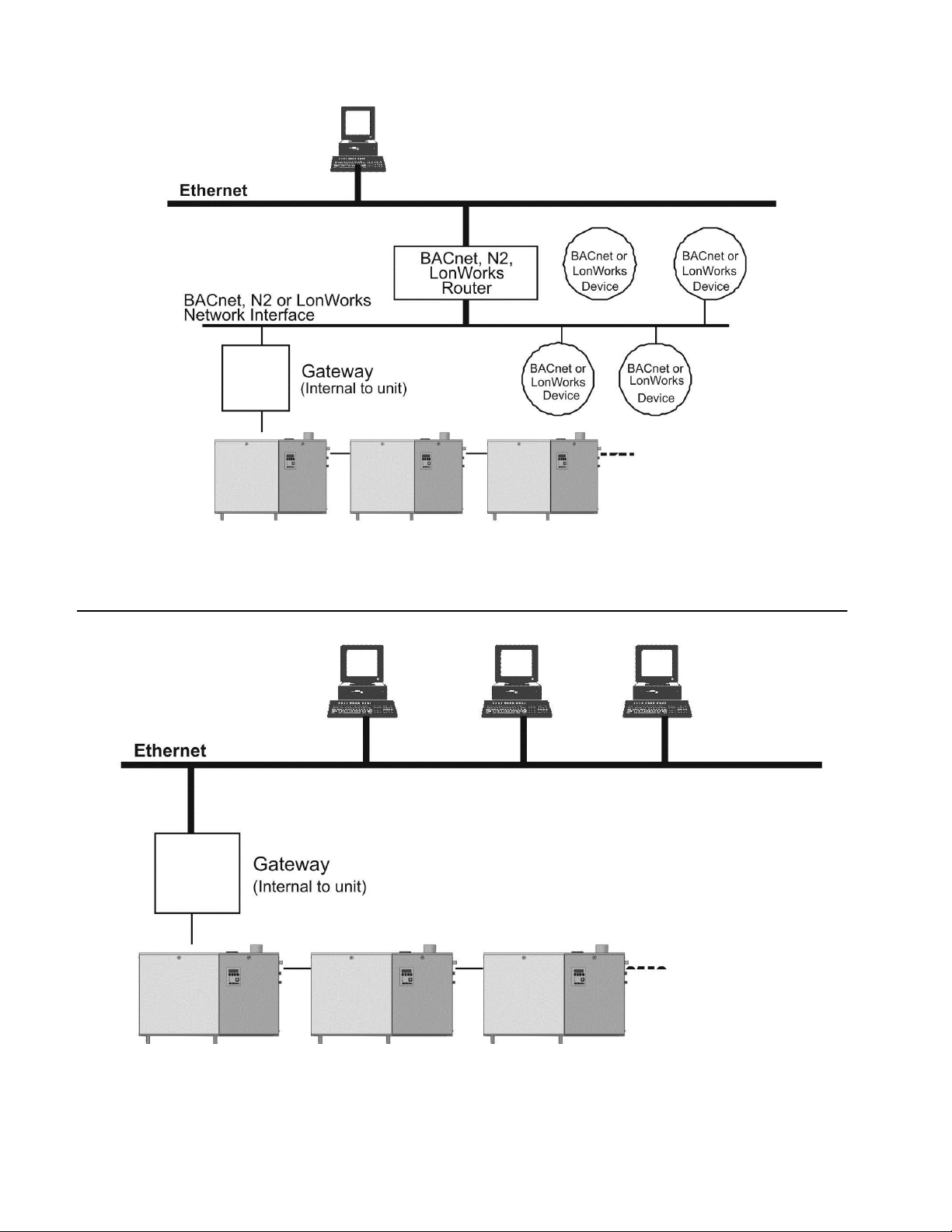

Multi-Unit Systems (“Master/Slave”)

Up to 8 humidifiers can be chained and monitored through a single Links2 package. In this

configuration, the unit with the Links2 package is designated the “Master Unit”, while the

remaining 7 humidifiers are configured as “Slaves”. The master unit is connected to the Building

Management Systems (BMS). Each unit is separately addressed, it is possible to monitor and

control each unit individually.

Different networking configurations may be achieved depending on the type of network being

used. One networking example could have a Gateway installed inside the lead unit, which could

then be daisy-chained to successive units. In turn, the lead unit would connect to a Building

Management System (BMS) network via a shielded, twisted-pair connection. Please see wiring

section for additional detail. A second example could have a series of units directly connected to

an Ethernet network. This is only possible for BACnet communication and is essentially referred to

as a BACnet/IP configuration.

Installation| 7

Page 12

Figure 1: Sample Network with Nortec Links 2

Figure 2: For BACnet IP only

GS/SE (1) GS/SE (2) GS/SE (3)

GS/SE (1) GS/SE (2) GS/SE (3)

8 | Installation

Page 13

Wiring

Protocol

Signal Type

Polarity

Recommended Cable

Maximum Recommended

Distance from Nortec

Module

A

B

BACnet MS/TP

EIA-485,

2-wire

Net +

Net -

18-24 AWG

Shielded, Twisted Pair

2000 ft at 9,600 bps

2000 ft at 38,400 kbps

Johnson N2

BACnet/IP

LAN standard

N/A

N/A

CAT.5E cable with RJ-

45 termination

Depends on cable

manufacturer

LonWorks

FTT-10,

2-wire

Tx

Rx

18-24 AWG

Twisted Pair

Should not exceed 50 ft.

BACnet MS/TP, Johnson N2, and LonWorks

Links2 is pre-installed and factory wired, except for the SETC-050 which is provided in its own

separate enclosure. Connections must be made between the master humidifier and the Building

Management System (BMS), and the master humidifier and any slaves that may be present.

Up to 8 units (1 master, 7 slaves) may be connected to a BMS through a single gateway in the

master unit. The units are daisy chained via the Links / Online terminal strip. The wire shield

should only be connected at one end per pair of units when “daisy chaining”. Older A and B style

units use a different connection method, please refer to revision C of this manual.

Table 2 refers to the recommended wire types and maximum recommended lengths from the

Nortec Links2 module to the front-end of the Building Management System. Since communication

between the humidifiers and Nortec Links 2 occurs via a EIA-485 signal type, Nortec recommends

using a 18-24 AWG shielded, 120 twisted pair wire between the lead humidifier and each of the

slave humidifiers. Total cable length runs between the Nortec Links2 module and the furthest

slave humidifier should not exceed 2,000 feet. Signal boosters or repeaters may be necessary for

longer wire runs or where electrical noise interference is prevalent.

Table 2: Recommended Wire Types and Lengths

BACnet/IP

A standard CAT-5E cable with an RJ-45 ethernet jack is to be connected to port 3,4, or 5 on the

gateway. Refer to wiring diagrams in this manual.

Installation| 9

Page 14

Gateway Configuration

Protocol

Default Baud Rates

BACnet MS/TP

38.4 kbps

BACnet / IP

10BaseT

Johnson N2

9.6 kbps

LonWorks

38.4 kbps

Protocol configuration is made at the factory, prior to final testing. Baud rates are adjusted to the

following values by default.

Table 3: Baud Rates

For BACnet/IP, BACnet/MSTP and Johnson N2 applications, it is necessary to establish the

modules network address parameters in order access it. Address assignments can be configured

at the factory or Nortec can provide instructions to modify the address settings in the field.

LonWorks networks can automatically detect network address parameters and do not need

further configuration.

Network Integration

LonWorks.xif file

To facilitate the integration of a LonWorks unit within a network, it may be desirable to obtain an

External Interface File (XIF). Files of type .xif are used to convey the resources, specific objects

and data types which a LonWorks device possesses. The .xif file allows a network integrator to

simulate the presence of a networked humidifier even if it is not yet physically connected to the

network. In fact, if the integrator has the .xif files of all network devices, a complete system could

be simulated and configured off-line. Once the configuration is done, the integrator's software tool

can be connected to the actual system and the configuration information can be downloaded.

10 | Installation

Page 15

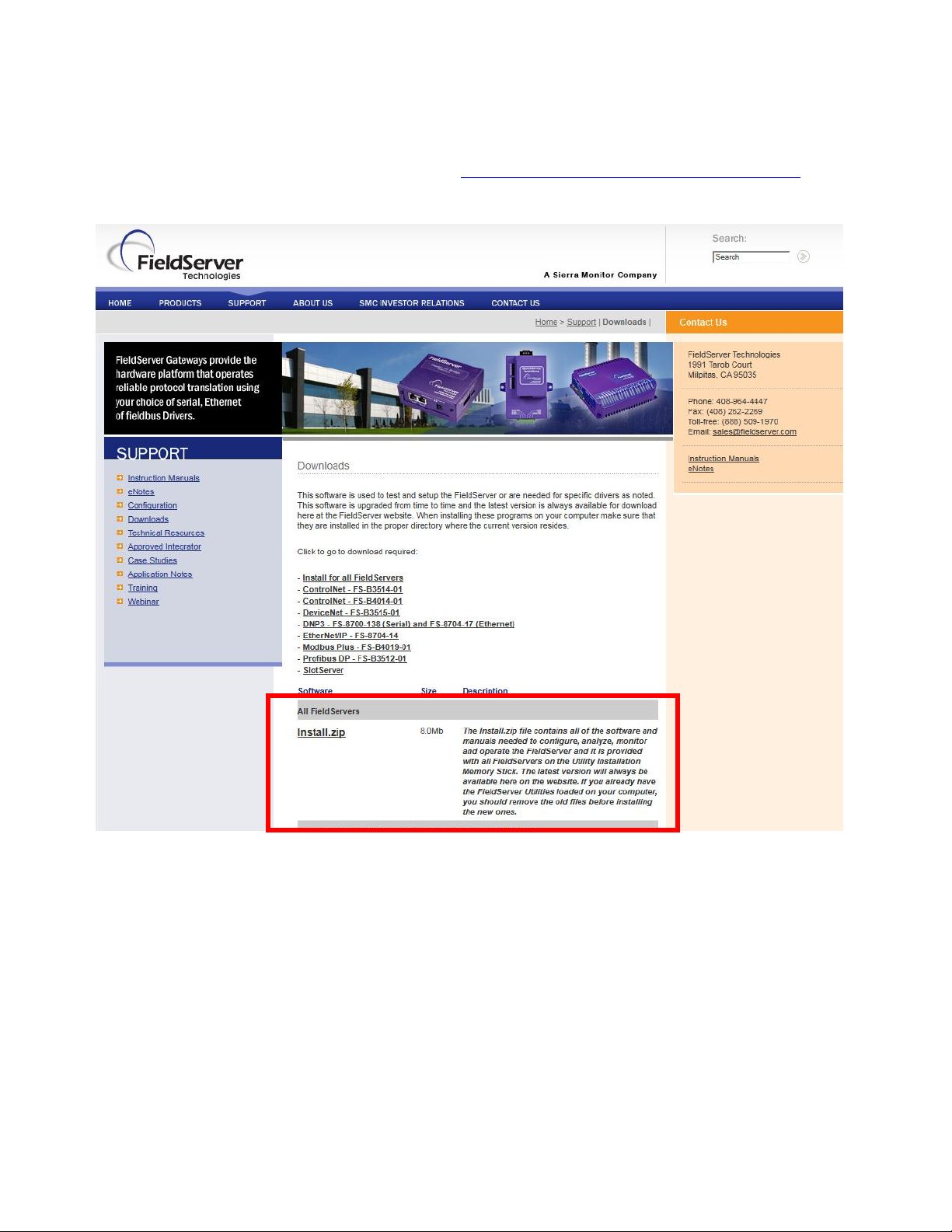

Retrieving XIF file instructions

The XIF file can be retrieved directly from the Links package. A Windows based laptop and an

Ethernet cable are required for this process. This process requires the “Remote User Interface”

tool from Fieldserver. It is available by visiting http://fieldserver.com/techsupport/utility/utility.php and

downloading the “Utility” software:

Once this software has been installed, follow the following procedure:

1. Locate desired MASTER humidifier that contains the Links package. Ensure unit is powered

on and remove the panel on the RIGHT side of the humidifier. Locate the Links package inside

of the unit.

2. For LINKS2 packages (with the blue ZONET router), connect one end of the CAT5 cable to the

router in an available port (ports 3 or 4 should be free) NOTE: Do NOT plug into the “WAN”

port.

For LINKS XPS packages (gateway device on its own), connect the CAT5 cable directly into the

Ethernet port on the gateway.

Installation| 11

Page 16

3. Connect other end of CAT5 cable to the Ethernet port on the laptop.

4. Run the “Remote User Interface” utility by double clicking the shortcut on your desktop (or

Start>Programs>Fieldserver Utilities>Remote User Interface)

5. The program should automatically recognize connected humidifier and bring you to the “Main

Menu”. If it does not, contact Nortec Technical Services at the number on the back cover of

this manual.

6. Type “u” for upload.

7. Type “o” for other. (A warning will appear, press any key to continue.)

8. Type “r” for remote.

9. Enter “fserver.xif”’ and hit the ‘enter’ key.

10. Type “u” to initiate upload from the gateway to the laptop.

11. The .xif file will be saved in the folder “Configuration File Folder” located at

Start>Programs>Fieldserver Utilities>Configuration File Folder.

12. Type ‘q’ twice to exit out of the program

13. Locate file in Configuration File Folder and change name to corresponding humidifier, (ex,

“fserverH1.xif” for Humidifier 1)

14. Repeat this procedure for all Master humidifiers changing the name of the .xif once saved to

correspond with the tag of the appropriate humidifier.

12 | Installation

Page 17

BACnet Pics and Bibs

In the variable name, “_x” denotes the humidifier number. If there is only one humidifier,

all variable names will end in “_1”. If two units are networked together, see Figure 4, the

second unit’s variable names will end in “_2”. For 3 networked units, “_3” and so on. If

unsure of the unit number, each unit will have a label, in the electrical compartment close

to the terminal strip, indicating the device instance of each humidifier.

The Protocol Implementation Conformance Statement or “PICS” describes the BACnet capabilities

of a particular BACnet implementation. It is a written document, created by the manufacturer of a

device, which identifies the particular options specified by BACnet that are implemented in the

device. Please refer to the wiring diagram section for a PICS statement.

BACnet Interoperability Building Blocks (BIBBs) describe a list of services a BACnet device

provides. The main areas that the building blocks are concerned with include: data sharing,

trends, schedules, device and system management. BIBBs help specify the interoperability

capabilities of a BACnet device. Please contact the factory to obtain a PICS statement or BIBBs

profile.

NORTEC OnLine

Firewall Port 5222 must be open to TCP traffic in order for NORTEC OnLine to communicate

properly.

Variable Definition

Nortec Links2 is capable of communicating a variety of variables for each unit that is connected to

it. For a variable listing and definition refer to Table 4. Network variable addresses for the

humidifiers may be seen in Table 5 to Table 12.

Installation| 13

Page 18

Variable Name

R=Read

W=Write

Description

LonWorks SNVT

nvoRHDem1_x

R

Analog Value

Reads %RH in space or %demand

to humidifier. (0%-100%) Choice

determined by nviInputType_x.

SNVT_lev_percent

nvoSet1_x

R

Analog Value

Reads setpoint for relative humidity

in space. (0%-100%)

SNVT_lev_percent

nvoRHDem2_x

R

Analog Value

Reads duct %RH or secondary

space %RH, or secondary

%demand to humidifier. (0%-100%)

Choice determined by

nviInputType_x.

Dip Switch 4/5 on humidifier’s logic

board must be ON.

SNVT_lev_percent

nvoSet2_x

R

Analog Value

Reads setpoint for duct hi-limit

relative humidity, or setpoint for

secondary space relative humidity.

(0%-100%)

Dip Switch 4/5 on humidifier’s logic

board must be ON.

SNVT_lev_percent

nvoSysDemand_x

R

Analog Value

Reads humidifier system demand.

(0%-100%)

SNVT_lev_percent

nvoHourOpt_x

R

Analog Value

Indicates the number of hours the

humidifier has been in operation.

SNVT_time_hour

nvoServHours_x

R

Analog Value

Indicates the number of hours

remaining before the next service

interval.

SNVT_time_hour

nviRHDem1_x

W

Analog Value

Writes %RH in space or %demand

to humidifier. Choice determined by

nviInputType_x. (0%-100%)

SNVT_lev_percent

nviRHDem2_x

W

Analog Value

Writes duct %RH or secondary

space %RH, or secondary

%demand to humidifier. (0%-100%)

Choice determined by

nviInputType_x.

Dip Switch 4/5 on humidifier’s logic

board must be ON.

SNVT_lev_percent

nviSet1_x

W

Analog Value

Writes setpoint for relative humidity

in space. (0%-100%).

SNVT_lev_percent

nviSet2_x

W

Analog Value

Writes setpoint for duct hi-limit %RH,

or setpoint for secondary space

%RH. (0%-100%)

Dip Switch 4/5 on humidifier’s logic

must be ON.

SNVT_lev_percent

nvoRHDem1_x

R

Analog Value

Reads %RH in space or %demand

to humidifier. (0%-100%) Choice

determined by nviInputType_x.

SNVT_lev_percent

Table 4: Variable Definitions

14 | Installation

Page 19

Table 4: Variable Definitions - CONTINUED

Variable Name

R=Read

W=Write

Description

LonWorks SNVT

nvoSet1_x

R

Analog Value

Reads setpoint for relative humidity

in space. (0%-100%).

SNVT_lev_percent

nvoRHDem2_x

R

Analog Value

Reads duct %RH or secondary

space %RH, or secondary

%demand to humidifier. (0%-100%)

Choice determined by

nviInputType_x.

Dip Switch 4/5 on humidifier’s logic

board must be ON

SNVT_lev_percent

nvoDisable_x

R

Binary Value

Reads remote disable status.

0=humidifier enabled, 1=humidifier

disabled by network

SNVT_switch

nvoService_x

R

Binary Value

Reads service requirement status.

0=no service required, 1=service

required

SNVT_switch

nvoStatus_x

R

Binary Value

Reads humidifier status. 0=standby,

1=humidifying

SNVT_switch

nvoConnection_x

R

Binary Value

Indicates that the Nortec Links

module is communicating with the

humidifier

SNVT_switch

nvoKeepWarm_x

R

Binary Value

Indicates that the KeepWarm feature

has been enabled

SNVT_switch

nvo3DayDrain_x

R

Binary Value

Indicates that the 3 day drain feature

has been enabled

SNVT_switch

nviDisable_x

W

Binary Value

Writes remote disable status.

0=humidifier enabled, 1=humidifier

disabled from network

SNVT_switch

nviInputType_x

W

Binary Value

Writes the input type status.

0=unit accepts a %demand signal

1=unit accepts on/off signal

SNVT_switch

nviNetSensor _x

W

Binary Value

Writes configuration status for

network-enabled sensing or control.

0=%RH or %demand input is not

from the network

1=%RH or %demand input is from

the network

SNVT_switch

Installation| 15

Page 20

Table 5: Humidifier Variable Addresses – Unit #1

Unit #1

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_1

AV

1

SNVT_time_hour

124 1 1

AI

1

nvoRHDem1_1

AV

2

SNVT_lev_percent

81 2 1

AI

2

nvoSet1_1

AV

3

SNVT_lev_percent

81 3 1

AI

3

nvoRHDem2_1

AV

4

SNVT_lev_percent

81 4 1

AI

4

nvoSet2_1

AV

5

SNVT_lev_percent

81 5 1

AI

5

nvoSysDemand_1

AV

6

SNVT_lev_percent

81 6 1

AI

6

nvoServHours_1

AV

7

SNVT_time_hour

124 7 1

AI

7

nviRHDem1_1

AV

8

SNVT_lev_percent

81 8 1

AO

8

nviRHDem2_1

AV

9

SNVT_lev_percent

81 9 1

AO

9

nviSet1_1

AV

10

SNVT_lev_percent

81

10

1

AO

10

nviSet2_1

AV

11

SNVT_lev_percent

81

11

1

AO

11

Analog Expansion

AV

12

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion

AV

13

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_1

AV

14

SNVT_switch

95

20

2

AO

14

nvoInputType_1

BV 1 SNVT_switch

95

12

2

BI

1

nvoFault_1

BV 2 SNVT_switch

95

13

2

BI

2

nvoNetSensor_1

BV 3 SNVT_switch

95

14

2

BI

3

nvoDisable_1

BV 4 SNVT_switch

95

15

2

BI

4

nvoService_1

BV 5 SNVT_switch

95

16

2

BI

5

nvoStatus_1

BV 6 SNVT_switch

95

17

2

BI

6

nvoKeepWarm_1

BV 7 SNVT_switch

95

18

2

BI

7

nvo3DayDrain_1

BV 8 SNVT_switch

95

19

2

BI

8

Expansion1_1

BV 9 N/A

N/A

N/A

N/A

N/A

nviInputType

BV

10

SNVT_switch

95

21

2

BO

10

nviNetSensor

BV

11

SNVT_switch

95

22

2

BO

11

nvoConnection

BV

12

SNVT_switch

95

23

2

BO

12

Expansion2_1

BV

13

N/A

N/A

N/A

N/A

N/A

Expansion3_1

BV

14

N/A

N/A

N/A

N/A

N/A

GSTC/SETC LINKS 2 Variable Listing

Default BACnet/IP Address: 192.168.10.11; Subnet: 255.255.255.0

Default BACnet/MSTP Address: 79

Default Johnson N2 Address: 175

Default unless otherwise requires at time of order.

16 | Installation

Page 21

Table 6: Humidifier Variable Addresses - Unit #2

Unit #2

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_2

AV

15

SNVT_time_hour

124

24

1

AI

15

nvoRHDem1_2

AV

16

SNVT_lev_percent

81

25

1

AI

16

nvoSet1_2

AV

17

SNVT_lev_percent

81

26

1

AI

17

nvoRHDem2_2

AV

18

SNVT_lev_percent

81

27

1

AI

18

nvoSet2_2

AV

19

SNVT_lev_percent

81

28

1

AI

19

nvoSysDemand_2

AV

20

SNVT_lev_percent

81

29

1

AI

20

nvoServHours_2

AV

21

SNVT_time_hour

124

30

1

AI

21

nviRHDem1_2

AV

22

SNVT_lev_percent

81

31

1

AO

22

nviRHDem2_2

AV

23

SNVT_lev_percent

81

32

1

AO

23

nviSet1_2

AV

24

SNVT_lev_percent

81

33

1

AO

24

nviSet2_2

AV

25

SNVT_lev_percent

81

34

1

AO

25

Analog Expansion_2

AV

26

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_2

AV

27

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_2

AV

28

SNVT_switch

95

43

1

AO

28

nvoInputType_2

BV

15

SNVT_switch

95

35

2

BI

15

nvoFault_2

BV

16

SNVT_switch

95

36

2

BI

16

nvoNetSensor_2

BV

17

SNVT_switch

95

37

2

BI

17

nvoDisable_2

BV

18

SNVT_switch

95

38

2

BI

18

nvoService_2

BV

19

SNVT_switch

95

39

2

BI

19

nvoStatus_2

BV

20

SNVT_switch

95

40

2

BI

20

nvoKeepWarm_2

BV

21

SNVT_switch

95

41

2

BI

21

nvo3DayDrain_2

BV

22

SNVT_switch

95

42

2

BI

22

Expansion1_2

BV

23

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_2

BV

24

SNVT_switch

95

44

2

BO

24

nviNetSensor_2

BV

25

SNVT_switch

95

45

2

BO

25

nvoConnection

BV

26

SNVT_switch

95

46

2

BO

26

Expansion2_2

BV

27

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_2

BV

28

N/A

N/A

N/A

N/A

N/A

N/A

Installation| 17

Page 22

Table 7: Humidifier Variable Addresses - Unit #3

Unit #3

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_3

AV

29

SNVT_time_hour

124

47

1

AI

29

nvoRHDem1_3

AV

30

SNVT_lev_percent

81

48

1

AI

30

nvoSet1_3

AV

31

SNVT_lev_percent

81

49

1

AI

31

nvoRHDem2_3

AV

32

SNVT_lev_percent

81

50

1

AI

32

nvoSet2_3

AV

33

SNVT_lev_percent

81

51

1

AI

33

nvoSysDemand_3

AV

34

SNVT_lev_percent

81

52

1

AI

34

nvoServHours_3

AV

35

SNVT_time_hour

124

53

1

AI

35

nviRHDem1_3

AV

36

SNVT_lev_percent

81

54

1

AO

36

nviRhDem2_3

AV

37

SNVT_lev_percent

81

55

1

AO

37

nviSet1_3

AV

38

SNVT_lev_percent

81

56

1

AO

38

nviSet2_3

AV

39

SNVT_lev_percent

81

57

1

AO

39

Analog Expansion_3

AV

40

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_3

AV

41

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_2

AV

42

SNVT_switch

95

66

N/A

AO

42

nvoInputType_3

BV

29

SNVT_switch

95

58

2

BI

29

nvoFault_3

BV

30

SNVT_switch

95

59

2

BI

30

nvoNetSensor_3

BV

31

SNVT_switch

95

60

2

BI

31

nvoDisable_3

BV

32

SNVT_switch

95

61

2

BI

32

nvoService_3

BV

33

SNVT_switch

95

62

2

BI

33

nvoStatus_3

BV

34

SNVT_switch

95

63

2

BI

34

nvoKeepWarm_3

BV

35

SNVT_switch

95

64

2

BI

35

nvo3DayDrain_3

BV

36

SNVT_switch

95

65

2

BI

36

Expansion1_3

BV

37

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_3

BV

38

SNVT_switch

95

67

2

BO

38

nviNetSensor_3

BV

39

SNVT_switch

95

68

2

BO

39

nvoConnection

BV

40

SNVT_switch

95

69

2

BO

40

Expansion2_3

BV

41

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_3

BV

42

N/A

N/A

N/A

N/A

N/A

N/A

18 | Installation

Page 23

Table 8: Humidifier Variable Addresses - Unit #4

Unit #4

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_4

AV

43

SNVT_time_hour

124

70

1

AI

43

nvoRHDem1_4

AV

44

SNVT_lev_percent

81

71

1

AI

44

nvoSet1_4

AV

45

SNVT_lev_percent

81

72

1

AI

45

nvoRHDem2_4

AV

46

SNVT_lev_percent

81

73

1

AI

46

nvoSet2_4

AV

47

SNVT_lev_percent

81

74

1

AI

47

nvoSysDemand_4

AV

48

SNVT_lev_percent

81

75

1

AI

48

nvoServHours_4

AV

49

SNVT_time_hour

124

76

1

AI

49

nviRHDem1_4

AV

50

SNVT_lev_percent

81

77

1

AO

50

nviRHDem2_4

AV

51

SNVT_lev_percent

81

78

1

AO

51

nviSet1_4

AV

52

SNVT_lev_percent

81

79

1

AO

52

nviSet2_4

AV

53

SNVT_lev_percent

81

80

1

AO

53

Analog Expansion_4

AV

54

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_4

AV

55

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_4

AV

56

SNVT_switch

95

89

N/A

AO

56

nvoInputType_4

BV

43

SNVT_switch

95

81

2

BI

43

nvoFault_4

BV

44

SNVT_switch

95

82

2

BI

44

nvoNetSensor_4

BV

45

SNVT_switch

95

83

2

BI

45

nvoDisable_4

BV

46

SNVT_switch

95

84

2

BI

46

nvoService_4

BV

47

SNVT_switch

95

85

2

BI

47

nvoStatus_4

BV

48

SNVT_switch

95

86

2

BI

48

nvoKeepWarm_4

BV

49

SNVT_switch

95

87

2

BI

49

nvo3DayDrain__4

BV

50

SNVT_switch

95

88

2

BI

50

Expansion1_4

BV

51

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_4

BV

52

SNVT_switch

95

90

2

BO

52

nviNetSensor_4

BV

53

SNVT_switch

95

91

2

BO

53

nvoConnection

BV

54

SNVT_switch

95

92

2

BO

54

Expansion2_4

BV

55

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_4

BV

56

N/A

N/A

N/A

N/A

N/A

N/A

Installation| 19

Page 24

Table 9: Humidifier Variable Addresses - Unit #5

Unit #5

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_5

AV

57

SNVT_time_hour

124

93

1

AI

57

nvoRHDem1_5

AV

58

SNVT_lev_percent

81

94

1

AI

58

nvoSet1_5

AV

59

SNVT_lev_percent

81

95

1

AI

59

nvoRHDem2_5

AV

60

SNVT_lev_percent

81

96

1

AI

60

nvoSet2_5

AV

61

SNVT_lev_percent

81

97

1

AI

61

nvoSysDemand_5

AV

62

SNVT_lev_percent

81

98

1

AI

62

nvoServHours_5

AV

63

SNVT_time_hour

124

99

1

AI

63

nviRHDem1_5

AV

64

SNVT_lev_percent

81

100

1

AO

64

nviRHDem2_5

AV

65

SNVT_lev_percent

81

101

1

AO

65

nviSet1_5

AV

66

SNVT_lev_percent

81

102

1

AO

66

nviSet2_5

AV

67

SNVT_lev_percent

81

103

1

AO

67

Analog Expansion_5

AV

68

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_5

AV

69

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_5

AV

70

SNVT_switch

95

112

1

AO

70

nvoInputType_5

BV

57

SNVT_switch

95

104

2

BI

57

nvoFault_5

BV

58

SNVT_switch

95

105

2

BI

58

nvoNetSensor_5

BV

59

SNVT_switch

95

106

2

BI

59

nvoDisable_5

BV

60

SNVT_switch

95

107

2

BI

60

nvoService_5

BV

61

SNVT_switch

95

108

2

BI

61

nvoStatus_5

BV

62

SNVT_switch

95

109

2

BI

62

nvoKeepWarm_5

BV

63

SNVT_switch

95

110

2

BI

63

nvo3DayDrain__5

BV

64

SNVT_switch

95

111

2

BI

64

Expansion1_5

BV

65

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_5

BV

66

SNVT_switch

95

113

2

BO

66

nviNetSensor_5

BV

67

SNVT_switch

95

114

2

BO

67

nvoConnection

BV

68

SNVT_switch

95

115

2

BO

68

Expansion2_5

BV

69

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_5

BV

70

N/A

N/A

N/A

N/A

N/A

N/A

20 | Installation

Page 25

Table 10: Humidifier Variable Addresses - Unit #6

Unit #6

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_6

AV

71

SNVT_time_hour

124

116

1

AI

71

nvoRHDem1_6

AV

72

SNVT_lev_percent

81

117

1

AI

72

nvoSet1_6

AV

73

SNVT_lev_percent

81

118

1

AI

73

nvoRHDem2_6

AV

74

SNVT_lev_percent

81

119

1

AI

74

nvoSet2_6

AV

75

SNVT_lev_percent

81

120

1

AI

75

nvoSysDemand_6

AV

76

SNVT_lev_percent

81

121

1

AI

76

nvoServHours_6

AV

77

SNVT_time_hour

124

122

1

AI

77

nviRHDem1_6

AV

78

SNVT_lev_percent

81

123

1

AO

78

nviRHDem2_6

AV

79

SNVT_lev_percent

81

124

1

AO

79

nviSet1_6

AV

80

SNVT_lev_percent

81

125

1

AO

80

nviSet2_6

AV

81

SNVT_lev_percent

81

126

1

AO

81

Analog Expansion_6

AV

82

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_6

AV

83

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_6

AV

84

SNVT_switch

95

135

1

AO

84

nvoInputType_6

BV

71

SNVT_switch

95

127

2

BI

71

nvoFault_6

BV

72

SNVT_switch

95

128

2

BI

72

nvoNetSensor_6

BV

73

SNVT_switch

95

129

2

BI

73

nvoDisable_6

BV

74

SNVT_switch

95

130

2

BI

74

nvoService_6

BV

75

SNVT_switch

95

131

2

BI

75

nvoStatus_6

BV

76

SNVT_switch

95

132

2

BI

76

nvoKeepWarm_6

BV

77

SNVT_switch

95

133

2

BI

77

nvo3DayDrain__6

BV

78

SNVT_switch

95

134

2

BI

78

Expansion1_6

BV

79

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_6

BV

80

SNVT_switch

95

136

2

BO

80

nviNetSensor_6

BV

81

SNVT_switch

95

137

2

BO

81

nvoConnection

BV

82

SNVT_switch

95

138

2

BO

82

Expansion2_6

BV

83

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_6

BV

84

N/A

N/A

N/A

N/A

N/A

N/A

Installation| 21

Page 26

Table 11: Humidifier Variable Addresses - Unit #7

Unit #7

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_7

AV

85

SNVT_time_hour

124

139

1

AI

85

nvoRHDem1_7

AV

86

SNVT_lev_percent

81

140

1

AI

86

nvoSet1_7

AV

87

SNVT_lev_percent

81

141

1

AI

87

nvoRHDem2_7

AV

88

SNVT_lev_percent

81

142

1

AI

88

nvoSet2_7

AV

89

SNVT_lev_percent

81

143

1

AI

89

nvoSysDemand_7

AV

90

SNVT_lev_percent

81

144

1

AI

90

nvoServHours_7

AV

91

SNVT_time_hour

124

145

1

AI

91

nviRHDem1_7

AV

92

SNVT_lev_percent

81

146

1

AO

92

nviRHDem2_7

AV

93

SNVT_lev_percent

81

147

1

AO

93

nviSet1_7

AV

94

SNVT_lev_percent

81

148

1

AO

94

nviSet2_7

AV

95

SNVT_lev_percent

81

149

1

AO

95

Analog Expansion_7

AV

96

N/A

N/A

N/A

N/A

N/A

N/A

Analog Expansion_7

AV

97

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_7

AV

98

SNVT_switch

95

158

2

BO

98

nvoInputType_7

BV

85

SNVT_switch

95

150

2

BI

85

nvoFault_7

BV

86

SNVT_switch

95

151

2

BI

86

nvoNetSensor_7

BV

87

SNVT_switch

95

152

2

BI

87

nvoDisable_7

BV

88

SNVT_switch

95

153

2

BI

88

nvoService_7

BV

89

SNVT_switch

95

154

2

BI

89

nvoStatus_7

BV

90

SNVT_switch

95

155

2

BI

90

nvoKeepWarm_7

BV

91

SNVT_switch

95

156

2

BI

91

nvo3DayDrain_7

BV

92

SNVT_switch

95

157

2

BI

92

Expansion1_7

BV

93

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_7

BV

94

SNVT_switch

95

159

2

BO

94

nviNetSensor_7

BV

95

SNVT_switch

95

160

2

BO

95

nvoConnection

BV

96

SNVT_switch

95

161

2

BO

96

Expansion2_7

BV

97

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_7

BV

98

N/A

N/A

N/A

N/A

N/A

N/A

22 | Installation

Page 27

Table 12: Humidifier Variable Addresses - Unit #8

Unit #8

BACnet

Lonworks

N2

Variable Name

Type

Instance

SNVT

SNVT #

NV Index

Element

Type

Instance

nvoHourOpt_8

AV

99

SNVT_time_hour

124

162

1

AI

99

nvoRHDem1_8

AV

100

SNVT_lev_percent

81

163

1

AI

100

nvoSet1_8

AV

101

SNVT_lev_percent

81

164

1

AI

101

nvoRHDem2_8

AV

102

SNVT_lev_percent

81

165

1

AI

102

nvoSet2_8

AV

103

SNVT_lev_percent

81

166

1

AI

103

nvoSysDemand_8

AV

104

SNVT_lev_percent

81

167

1

AI

104

nvoServHours_8

AV

105

SNVT_time_hour

124

168

1

AI

105

nviRHDem1_8

AV

106

SNVT_lev_percent

81

169

1

AO

106

nviRHDem2_8

AV

107

SNVT_lev_percent

81

170

1

AO

107

nviSet1_8

AV

108

SNVT_lev_percent

81

171

1

AO

108

nviSet2_8

AV

109

SNVT_lev_percent

81

172

1

AO

109

Analog

Expansion_8

AV

110

N/A

N/A

N/A

N/A

N/A

N/A

Analog

Expansion_8

AV

111

N/A

N/A

N/A

N/A

N/A

N/A

nviDisable_8

AV

112

SNVT_switch

95

181

2

BO

112

nvoInputType_8

BV

99

SNVT_switch

95

173

2

BI

99

nvoFault_8

BV

100

SNVT_switch

95

174

2

BI

100

nvoNetSensor_8

BV

101

SNVT_switch

95

175

2

BI

101

nvoDisable_8

BV

102

SNVT_switch

95

176

2

BI

102

nvoService_8

BV

103

SNVT_switch

95

177

2

BI

103

nvoStatus_8

BV

104

SNVT_switch

95

178

2

BI

104

nvoKeepWarm_8

BV

105

SNVT_switch

95

179

2

BI

105

nvo3DayDrain_8

BV

106

SNVT_switch

95

180

2

BI

106

Expansion1_8

BV

107

N/A

N/A

N/A

N/A

N/A

N/A

nviInputType_8

BV

108

SNVT_switch

95

182

2

BO

108

nviNetSensor_8

BV

109

SNVT_switch

95

183

2

BO

109

nvoConnection

BV

110

SNVT_switch

95

184

2

BO

110

Expansion2_8

BV

111

N/A

N/A

N/A

N/A

N/A

N/A

Expansion3_8

BV

112

N/A

N/A

N/A

N/A

N/A

N/A

Installation| 23

Page 28

Configuration Variables

nviInputType_x = 1

nviNetSensor_x = 1

Control Variables

nviSet1_x = Room Setpoint (0-100%)

nviSet2_x = Hi-Limit Setpoint (0-100%)

nviRHDem1_x = Room %RH (0-100%)

nviRHDem2_x = Hi-Limit %RH (0-100%)

nviDisable_x = 1 Unit Disabled

= 0 Unit Enabled

Readable Variables

nvoStatus_x = 1 Humidifying

= 0 Standby

nvoService_x = 1 Service Required

= 0 No Service Required

nvoFault_x = 1 Fault

= 0 No Fault

nvoSysDemand_x = System Demand (0-100%)

nvoDisable_x = 1 Unit Disabled

= 0 Unit Enabled

Configuration Variables

nviInputType_x = 0

nviNetSensor_x = 1

Control Variables

nviSet1_x = Room Setpoint (0-100%)

nviSet2_x = Hi-Limit Setpoint (0-100%)

nviRHDem1_x = Room %RH (0-100%)

nviRHDem2_x = Hi-Limit %RH (0-100%)

nviDisable_x = 1 Unit Disabled

= 0 Unit Enabled

Readable Variables

nvoStatus_x = 1 Humidifying

= 0 Standby

nvoService_x = 1 Service Required

= 0 No Service Required

nvoFault_x = 1 Fault

= 0 No Fault

nvoSysDemand_x = System Demand (0-100%)

nvoDisable_x = 1 Unit Disabled

= 0 Unit Enabled

Figure 3: Sample Humidification Applications

Room-Sensed %RH Feedback with Duct Hi-Limit Sensing

24 | Installation

Figure 4: Sample Humidification Applications

Control Feedback (0-100%) with Duct Hi-Limit Sensing

Page 29

Configuration Variables

nviInputType_x = 1

nviNetSensor_x = 0

Control Variables

nviSet1_x = Room Setpoint (0-100%)

nviSet2_x = Hi-Limit Setpoint (0-100%)

nviRHDem1_x = Room %RH (0-100%)

nviRHDem2_x = Hi-Limit %RH (0-100%)

nviDisable_X = 1 Unit Disabled

= 0 Unit Enabled

Readable Variables

nvoStatus_x = 1 Humidifying

= 0 Standby

nvoService_x = 1 Service Required

= 0 No Service Required

nvoFault_x = 1 Fault

= 0 No Fault

nvoSysDemand_x = System Demand(0-100%)

nvoDisable_x = 1 Unit Disabled

= 0 Unit Enabled

Room-Sensed %RH Feedback with Duct High-Limit Sensing (0-10V Signal Directly to Humidifier)

Figure 5: Sample Humidification Applications

Installation| 25

Page 30

NORTEC Links 2 Start-up Checklist

Humidifier-to-Humidifier Connection:

Each individual humidifier linked to lead unit.

Connection must be daisy-chained from the lead unit to the end unit, with shield wire

connected only on the lead unit.

Check that each humidifier has a unique modbus address.

BMS Network Connection:

Lead unit wired to BMS system (Twisted Pair or Ethernet).

Network activity verified.

Shields should be connected at BMS end only.

Controls Wired:

Directly to humidifiers or through BMS network.

Ensure power is being supplied to the humidifier, NORTEC Links Module and NORTEC

OnLine module. For BACnet/IP adjust network IP settings. (If this information is provided,

factory will perform necessary IP assignment).

After power-up, verify network communication.

Map desired network variables to BMS.

Verify variable operation after mapping is complete.

Perform regular humidifier start-up check.

Network port 5222 should be open to TCP traffic for NORTEC OnLine operation (when

used).

Wiring

Start-up Procedure

Firewall

26 | Installation

Page 31

Page 32

Troubleshooting

When troubleshooting the communication process for OnLine and/or Links2 modules should be

kept in mind. Humidifier data is first received by the Nortec OnLine module using the modbus

protocol over the serial port connection. It then forwards this data, via modbus/TCP, to the Links2

module over an ethernet link. A router (switch for BACnet/IP applications) Links the two devices

together through their ethernet ports and allows a user to access both devices using only 1

customer installed connection.

Indicator Lights

There is a variety of status LEDs on both the OnLine module and the Links2 module to aid in the

diagnosis of communication problems. Note that communication first occurs between the OnLine

module and the humidifier logic board. The OnLine module then passes information to the Links2

module. If practical, it may be useful to establish a connection with the Nortec OnLine server first

and then establish communication with the Links2 module.

28 | Troubleshooting

Page 33

Figure 6: OnLine Diagnostic LED Locations

Figure 7: BACnet Module LED

Troubleshooting | 29

Page 34

Figure 8: LonWorks Module LED Locations

Figure 9: Ethernet Port LED

30 | Troubleshooting

Page 35

Table 13: OnLine Module Diagnostic LED Description

LED Name

Color

Function

Module Status

Off

Indicates that the Online module is not

receiving power.

Green

Indicates the Online module is operating

normally.

Orange

Indicates that the Online module is loading

the firmware installed on the module.

Serial Port Activity

Flashing Green

Indicates that the Online module is receiving a

network packet from a serial connection.

Flashing Red

Indicates that the Online module is

transmitting a network packet on a serial

connection.

Orange

Displayed when the Online module is booting.

Ethernet Activity/Collision

Flashing Green

Indicates that the Online module is receiving a

network packet from an Ethernet connection.

Flashing Red

Indicates that the Online module is

transmitting a network packet on an Ethernet

connection.

Ethernet Link

Off

No network connection is present.

Green

The Online module has detected the presence

of a 10Mbps network.

Orange

The Online module has detected the presence

of a 100Mbps network.

LED Name

Color

Function

Module Power

Off

Indicates that the Online module is not

receiving power.

Green

Indicates the Online module is operating

normally.

Receive LED (marked as Rx on

processor board)

Flashing Green

Indicates that the Online module is receiving a

network packet from a serial connection.

Transmit LED (marked as Tx on

processor board)

Flashing Green

Indicates that the Online module is

transmitting a network packet on a serial

connection.

Ethernet LINK

Off

Indicates no Ethernet connection is present.

Solid Yellow

Indicates an Ethernet connection has been

detected.

Ethernet Activity

Off

No Ethernet network activity.

Flashing Green

Indicates Ethernet activity.

Table 14: Links 2 Module Diagnostic LEDs

Troubleshooting | 31

Page 36

Table 15: Troubleshooting Communication Problems

Problem

Solution

The BMS network cannot read/write any

information to any of the networked

humidifiers

Verify that the network connection is made and is connected

properly.

Verify that the correct network settings are being used. The

Links2 module may need to be restarted to load the new

settings.

Check the Serial Port Activity LED on the Nortec OnLine

module to ensure proper communication with the humidifiers.

Data is first received from the humidifier to the OnLine

module. The OnLine module then transmits this data, via the

Ethernet port, to the LINKS 2 module.

Check the Ethernet port activity on the Links2 module to

ensure it is receiving data from the Nortec OnLine module.

Check the transmit and receive status LEDs to determine if

there is any network traffic being sent or being received by

the Links2 module from the BMS network

Verify proper connections to networked humidifiers.

Turn the Links2 module and the OnLine module off for

several seconds then switch it back on to reload the control

program. Allow for some time for the network variables to be

polled.

The BMS network can see some of the

networked humidifiers but not others.

Ensure network variables are mapped correctly to the BMS.

Ensure proper connections to the humidifiers.

Disconnect all of the humidifiers from the Links2 package

except for the unit that is not responding to the network. Turn

the Links2 package off and then back on. Check if the

humidifier can now be seen by the BMS

The BMS network receives information

from the networked humidifier(s) but the

information is mismatched or the

humidifier responds un-expectedly

Verify that the network variables have been mapped to the

BMS network correctly. It is possible that the variables have

been cross-linked during the network integration process.

Connect humidifiers one at a time and test units individually.

After sending the humidifier a networkbased demand signal the unit powers

down after several minutes. The

nviNetSensor variable is switched on

and a value has been set for the

nviRHDem1 variable.

When a BMS network demand/RH signal is being used the

network must refresh the nviRHDem signal at least every 5

minutes otherwise the humidifier will revert to a 0 demand

state. This is a safety precaution in case the BMS network

connection is lost.

32 | Troubleshooting

Page 37

Page 38

Table 16: Replacement Parts

Part

Number

Description

Nortec Links2 Options

Specify Unit Type Protocol at time of order

BACnet/MSTP

BACnet/IP

N2

LonWorks

2527101

Links2 Replacement Module, BACnet/IP

X 2527102

Links2 Replacement Module, BACnet/MSTP

X 2527103

Links2 Replacement Module, LonWorks

X 2527104

Links2 Replacement Module, N2

X

1509604

OnLine Replacement Module, Static/IP

X

X X X

2528126

Links2 Replacement Router

X

X X

2531455

Links2 Ethernet Switch

X 2530087

24VAC to 9VDC Power Supply (for switch or router)

X

X X X

34 | Replacement Parts

Page 39

Figure 10: BACnet or N2 Module

Figure 11: LonWorks Module

Replacement Parts | 35

Page 40

Figure 12: OnLine Module

Figure 13: Ethernet Router

36 | Replacement Parts

Page 41

Figure 14: Ethernet Switch

Replacement Parts | 37

Page 42

38 | Wiring Diagrams

Page 43

Wiring Diagrams | 39

Page 44

40 | Wiring Diagrams

Page 45

Wiring Diagrams | 41

Page 46

42 | Wiring Diagrams

Page 47

Wiring Diagrams | 43

Page 48

44 | Wiring Diagrams

Page 49

Warranty

Nortec Humidity Inc. and/or Nortec Humidity Ltd. (hereinafter collectively referred to as THE

COMPANY), warrant for a period of two years after installation or 30 months from

manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s manufactured and

assembled products, not otherwise expressly warranted, are free from defects in material and

workmanship. No warranty is made against corrosion, deterioration, or suitability of substituted

materials used as a result of compliance with government regulations.

THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the defective

part(s) is returned freight prepaid by the customer. Parts used for repairs are warranted for the

balance of the term of the warranty on the original humidifier or 90 days, whichever is longer.

The warranties set forth herein are in lieu of all other warranties expressed or implied by law. No

liability whatsoever shall be attached to THE COMPANY until said products have been paid for in

full and then said liability shall be limited to the original purchase price for the product. Any

further warranty must be in writing, signed by an officer of THE COMPANY.

THE COMPANY’s limited warranty on accessories, not of the companies manufacture, such as

controls, humidistats, pumps, etc. is limited to the warranty of the original equipment

manufacturer from date of original shipment of humidifier.

THE COMPANY makes no warranty and assumes no liability unless the equipment is installed in

strict accordance with a copy of the catalog and installation manual in effect at the date of

purchase and by a contractor approved by THE COMPANY to install such equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for consequential

damage or damage resulting directly from misapplication, incorrect sizing or lack of proper

maintenance of the equipment.

THE COMPANY makes no warranty and assumes no liability whatsoever for damage resulting

from freezing of the humidifier, supply lines, drain lines, or steam distribution systems.

THE COMPANY makes no warranty and assumes no liability whatsoever for equipment that has

failed due to ambient conditions when installed in locations having climates below 14°F (10°C) during January or above 104°F (40°C) during July.

THE COMPANY retains the right to change the design, specification and performance criteria of

its products without notice or obligation.

Page 50

U.S.A.

826 Proctor Avenue

Ogdensburg, NY 13669

CANADA

2740 Fenton Road

Ottawa, Ontario K1T 3T7

TEL: 1.866.NORTEC1

FAX: 613.822.7964

EMAIL: nortec@humidity.com

WEBSITE: www.humidity.com

Loading...

Loading...