Page 1

HumDigital operating instructions

HumSpot

HumCenter

A WMH company

Page 2

Contents

1 HumSpot .............................................................................................. 3

1.1 FOG menu ............................................................................................ 4

1.2 DISP menu ............................................................................................ 5

1.3 KEYLO menu ........................................................................................ 6

2 HumCenter ........................................................................................... 7

2.1 Zone menu ............................................................................................ 7

2.1.1 Zone overview menu ............................................................................. 8

2.1.2 Status menu (STAT).............................................................................. 9

2.1.3 Settings menu (SETT) ......................................................................... 10

2.2 Water supply menu ............................................................................. 11

2.2.1 Water supply overview ........................................................................ 12

2.2.2 Status menu ........................................................................................ 13

2.3 Alarms menu ....................................................................................... 16

2.3.1 Pending alarms menu ......................................................................... 17

2.3.2 Alarm log menu ................................ ................................ ................... 17

2.4 HumCenter menu ................................................................................ 18

2.4.1 HumCenter overview ........................................................................... 18

2.4.2 HumCenter settings ............................................................................ 19

3 HumCenter software update ............................................................ 20

3.1 BMS link .............................................................................................. 22

3.1.1 Parameters .......................................................................................... 22

3.1.2 Telegram ............................................................................................. 23

3.1.3 Transfer parameters ............................................................................ 24

3.1.4 CRC checksum ................................................................................... 24

4 Troubleshooting ................................................................................ 26

4.1 HumSpot ............................................................................................. 26

4.2 HumCenter .......................................................................................... 27

Created: 04.06.2007 2

Changed: 21.12.2007

Printed: 02.03.2009

Page 3

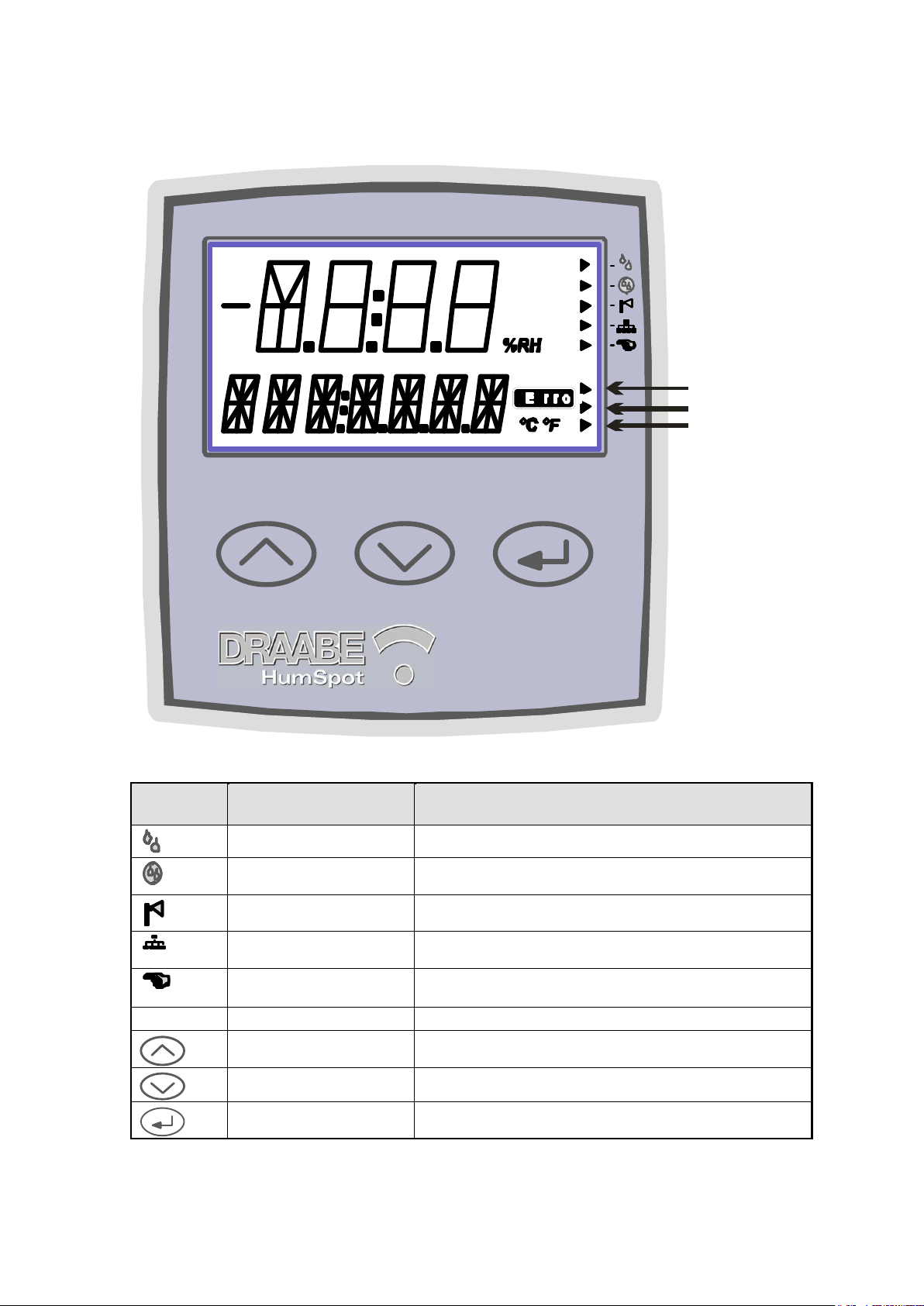

1 HumSpot

H u m i d it y & T e m p e r a t u r e

1

2

3

Symbol Function

Description

Humidification request

The internal hygrostat function or the external hygrostat is

requesting humidification

AFWS request

The automatic fresh water system is requesting

humidification

Atomiser active

The solenoid valves for the atomiser are open.

BUS active

HumiPur is being addressed via the BUS. i.e. there is a

connection to CenterPur.

Manual operation

The hygrostat has been manually overridden.

If "" is set to “no”, this symbol will flash

1 – 3

Mean value

Shows mean value of calculation across 16, 60 and 180 min

Function keys

Select menu points and enter values

Function keys

Call up menu points and enter values

Enter key

Call up menu and confirm values.

Created: 04.06.2007 3

Changed: 21.12.2007

Printed: 02.03.2009

Page 4

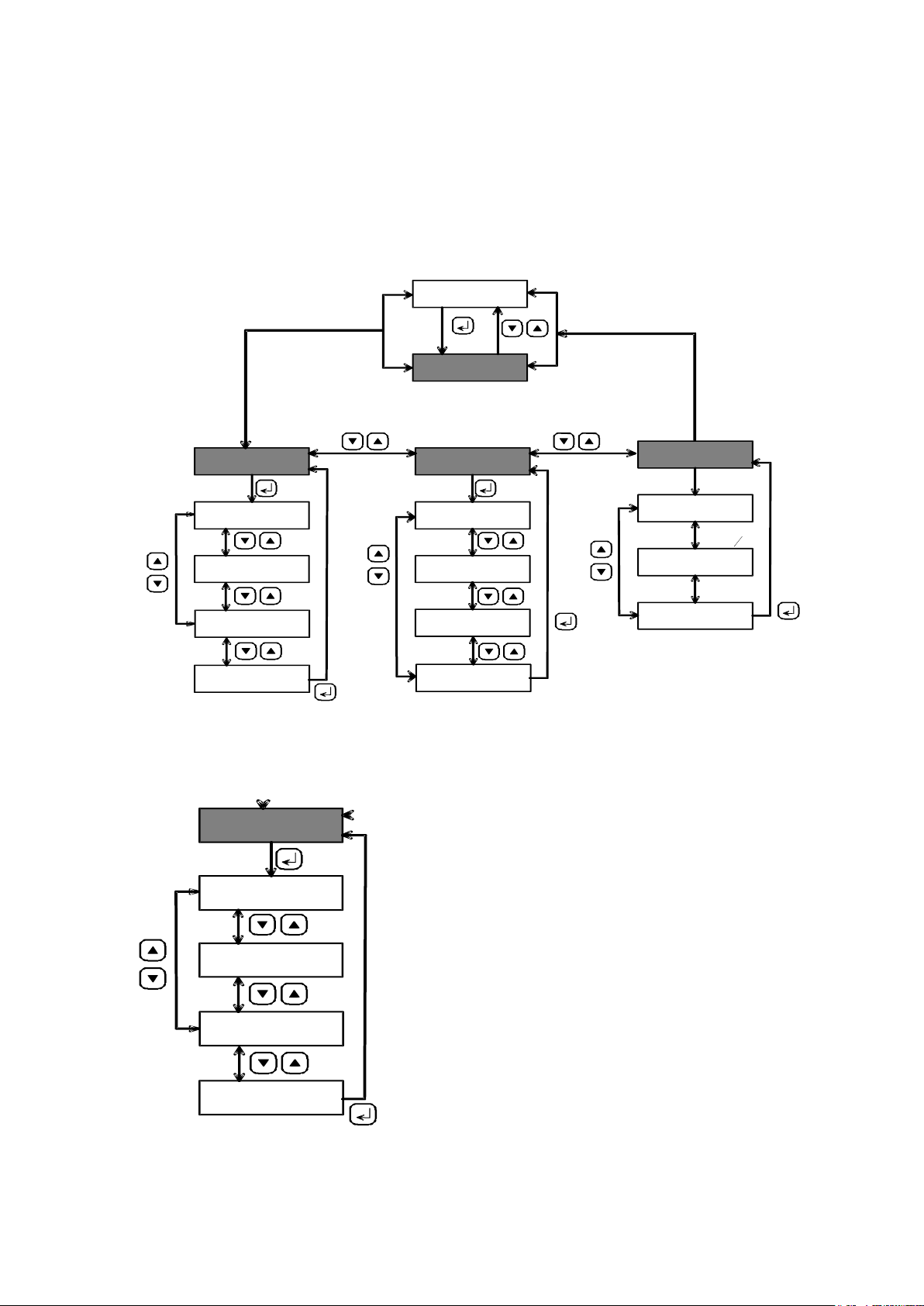

The menu mode can be called up using the enter key. The separate menu

standard parameter

*FOG

target %RH

SETPT

Hysteresis

HYST

exit submenu

EXIT

display controls

*DISP

backlighting.

BGL ON

units °C / °F

UNIT T

if keylocked:

CODE?

LCD display

LCD OUT

Measur. mode

activation

LOCK

exit submenu

EXIT

set code

CODE

keylock code

*KEYLO

exit submenu

EXIT

ACTIVE

INACTIVE

Standby function for

FOGING

2 sec.

Falls

Code = 0

std parameterr

*FOG

target %RH

SETPT

Hysteresis

HYS

T

exit submenu

EXIT

Standby function for

FOGGING

points can be called up with the arrow keys. Each menu has an “EXIT” point

to return to the next higher menu.

If the key lock is enabled, the code must be entered first to access the menu.

The entire menu level is shown in the illustration below. In the following, the

separate menus will be described in greater detail.

1.1 FOG menu

In the FOG menu, the following settings can be made:

Created: 04.06.2007 4

Changed: 21.12.2007

Printed: 02.03.2009

Page 5

Menu

Parameter

Range

FOG

Humidity target

10 – 90 % RH

Steps of 1%,

default: 50%

FOG

Hysteresis

0.5 – 10.0% RH

Steps of 0.1% RH

Default 2% RH

FOG

Fogging

Auto, no

Default: "Auto"

Menu

Parameter

Range

DISP

Backlighting

(BGL)

00:05 – 10:00

[mm:ss]

Steps of 1 s

Default: 1 min

DISP

LCD display

Auto, On

Default: Auto

DISP

Temperature

unit

°C, °F

Default: °C

display controls

*DISP

backlighting

BGL ON

units °C / °F

UNIT T

LCD display

LCD OUT

exit submenu

EXIT

1.2 DISP menu

Created: 04.06.2007 5

Changed: 21.12.2007

Printed: 02.03.2009

Page 6

1.3 KEYLO menu

Menu

Parameter

Range

KEYLO

Code

0000 – 9999

Default: 0000

KEYLO

Activate code

activation

LOCK

exit submenu

EXIT

set code

CODE

keylock code

*KEYLO

Falls

Code = 0

Created: 04.06.2007 6

Changed: 21.12.2007

Printed: 02.03.2009

Page 7

2 HumCenter

„UP/DOWN

key

for “select”

& “scrolling”

LED

memory

access

indicator

“SD Card

“ESC” (back)

function key

„ENTER“

function key

Fixed- value

function keys:

Zones 1–24

(overview / detail)

Containers 1–5

(overview / detail)

Alarm action

(current/list of 60 items)

Head office &

Service

(settings)

Multi-select key

4 x function

softkeys

The HumCenter has several function keys and a display. The separate

function keys are explained below.

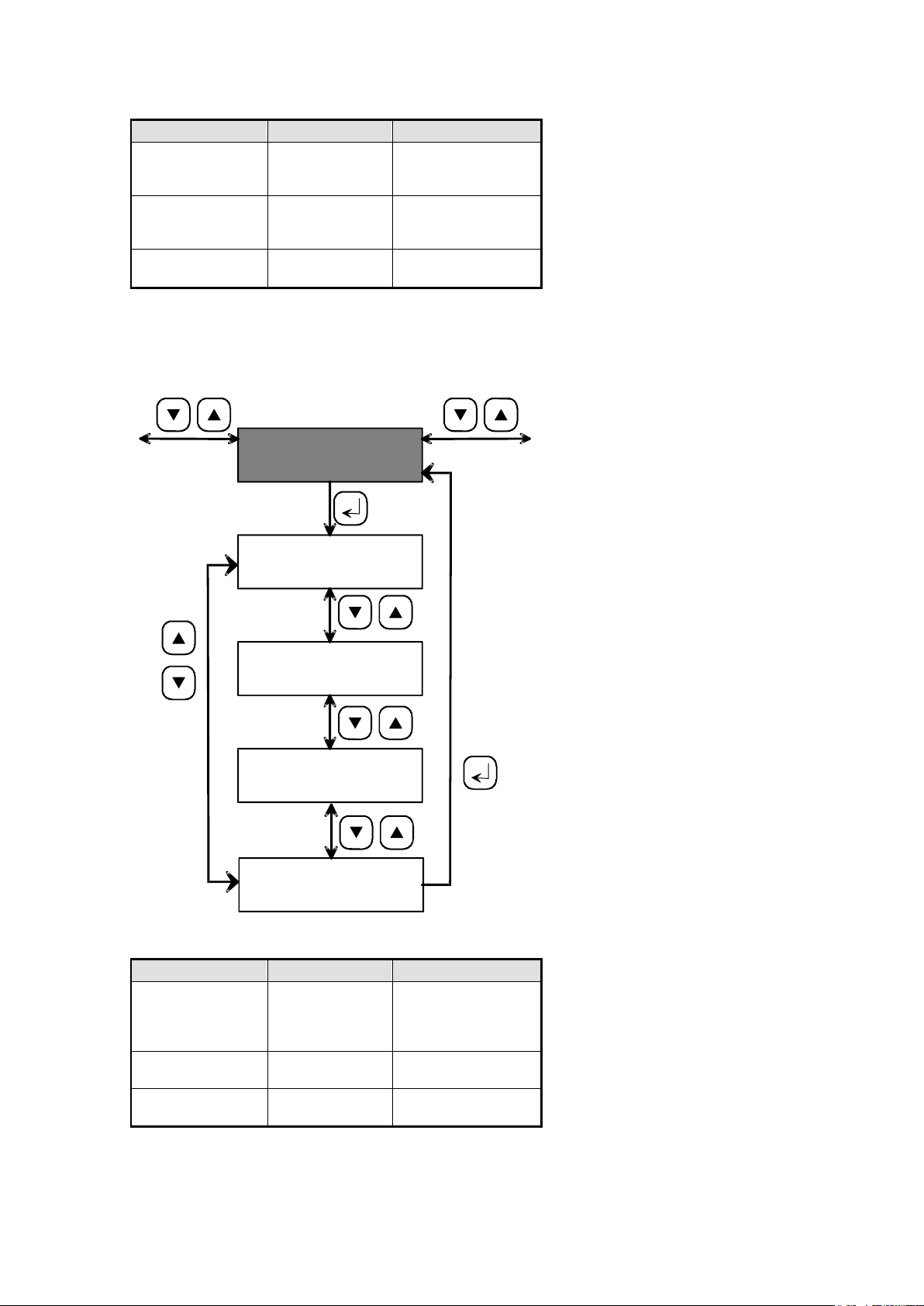

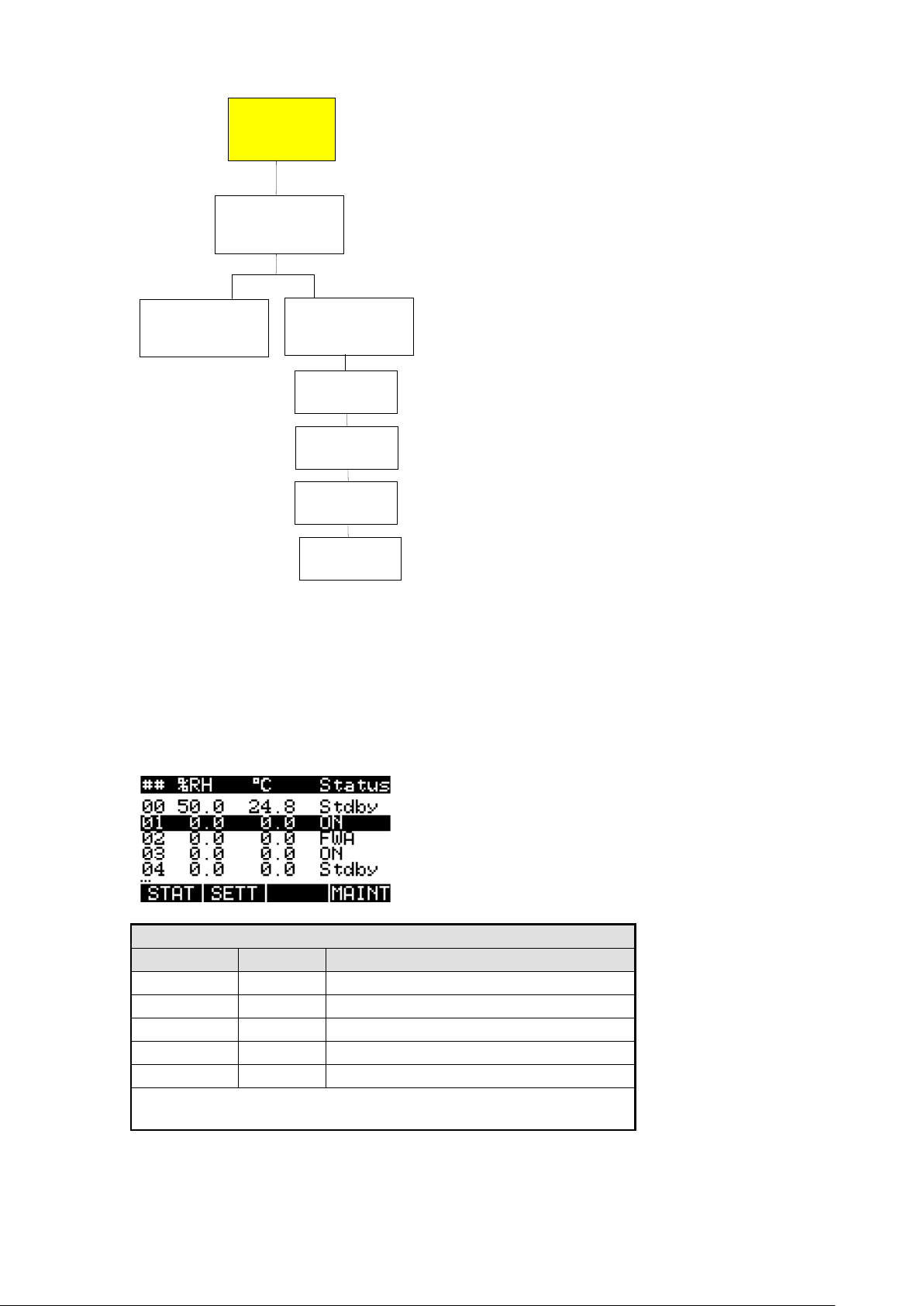

2.1 Zone menu

The zone overview is displayed by pressing the “Zone” function key. The

display shows the first five zones. For every zone, the display indicates the

zone number, the current relative humidity and temperature and a simplified

status report. Select a zone or see more zones using the “UP”/”DOWN keys.

Created: 04.06.2007 7

Changed: 21.12.2007

Printed: 02.03.2009

Page 8

Simplified status

Display

Priority*

Description

ERR

1

Error

ON 2 Humidification or request active

AFWS

3

Automatic fresh water system active

OFF

4

Fogging = No

Stby

5

Humidification off, no request

* When two status reports occur at once, that with lower priority is

shown.

Zones

1–24

Overview of

Zones & status

Details

for a zone

Settings

for a zone

"STAT"

"SETT"

Set point

[% RH]

Hysteresis

[% RH]

Fogging

[ No/AUTO ]

CODE

[ xxxx ]

2.1.1 Zone overview menu

Created: 04.06.2007 8

Changed: 21.12.2007

Printed: 02.03.2009

Page 9

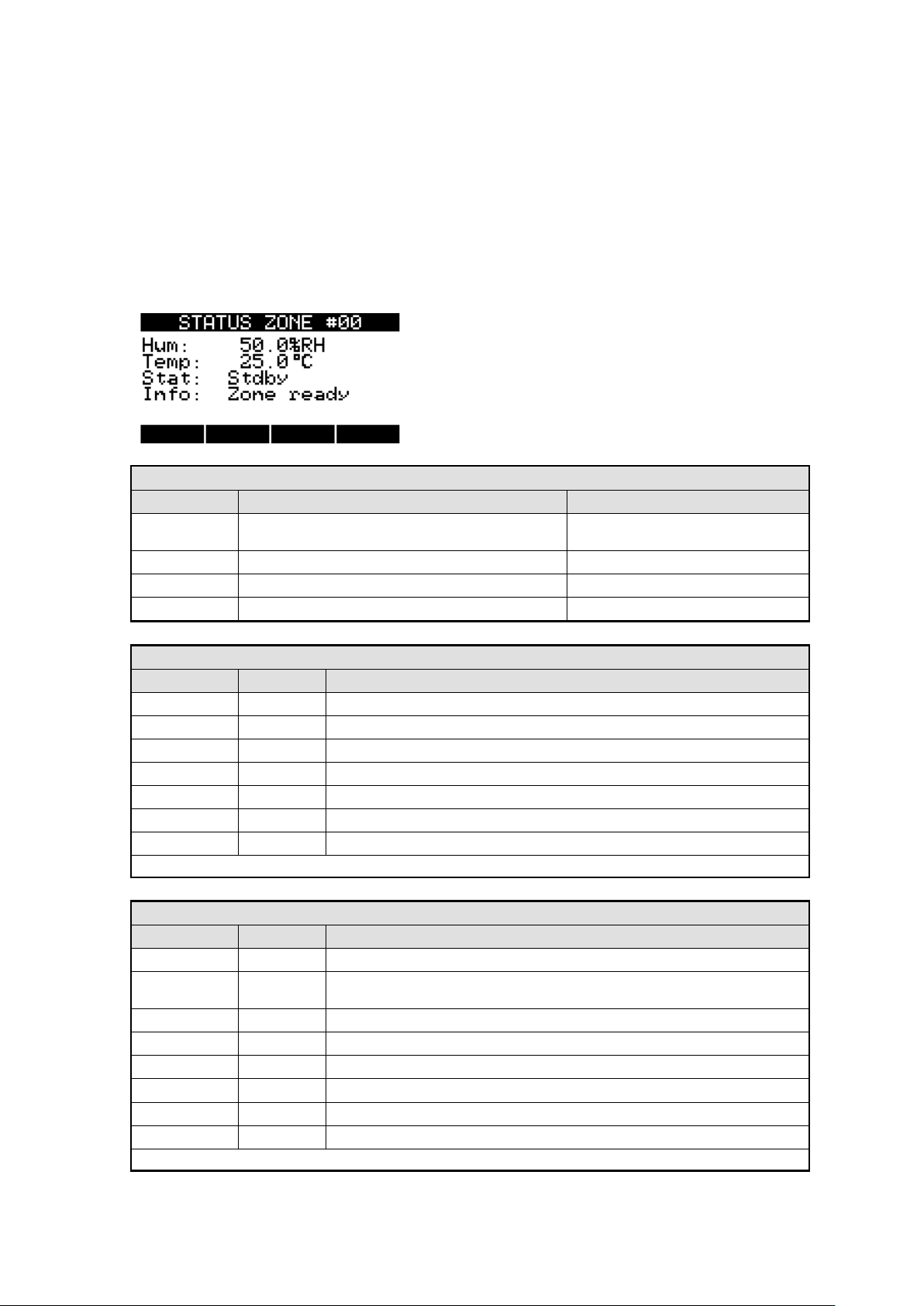

The advanced status display (STAT) or the settings (SETT) for the selected

Parameter

Name

Function

Notes

Hum:

Current humidity [% RH], sensor resolution 0.1 %

RH

Temp:

current temperature [°C] or [°F], resolution 0.1 °C

Stat:

Summary of status

Info:

Additional status information

Status

Display

Priority*

Description

ERR

1

Error

Hand

2

Manual operation on

Humid

3

Humidification active

FWA

4

AFWS active

H req

5

Humidification request

AFWS req

6

AFWS request

Stdby

7

Standby (e.g. target value reached)

* When two status reports occur at once, that with lower priority is shown.

Info

Display

Priority*

Description

Com err

1

Communication error with HumiPur

Cap err

2

Capability error: HumiPur cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

no HPS

3

No HPS entered.

Sens err

4

Communication with sensor disturbed (e.g. sensor malfunction)

Max err

5

Maximum hygrostat released

HPS err

6

HPS not released (timeout)

Unkn err

7

Unknown error

Zone Ready

8

Zone ready for operation

* When two status reports occur at once, that with lower priority is shown.

zone can be selected using the softkeys below the display.

2.1.2 Status menu (STAT)

The status menu shows the status in detail. As well as the relative humidity,

temperature and the status there is also additional information on the zone.

This shows whether the zone is ready for operation (zone ready) or which

problem has occurred in case of malfunction.

Created: 04.06.2007 9

Changed: 21.12.2007

Printed: 02.03.2009

Page 10

Return to the overview using the ESC key.

Parameter

Name

Function

Notes

SETPT:

Humidity target [% RH]

10 – 90 % RH

Steps of 1%,

Default: 50%

HYST:

Hysteresis [% RH]

0.5 –10.0% RH

Steps of 0.1% RH

Default 2% RH

FOGGING:

Fogging parameters

Auto, no

Default: "Auto"

CODE:

Keylock code

0000 – 9999

Default: 0000

2.1.3 Settings menu (SETT)

The settings menu shows the following settings for the selected zone:

Select and change the settings using the UP/DOWN keys. After selection,

then click on the “SET” softkey to change the value.

Move the cursor with the arrow keys and set the value with the + and - keys.

Use the ENTER key to confirm and save the new value. Undo the change with

the ESC key.

Created: 04.06.2007 10

Changed: 21.12.2007

Printed: 02.03.2009

Page 11

2.2 Water supply menu

Containers

1–5

Overview of

containers 1–5

Details

for a container

"STAT"

Container

type

Container

serial no.

Container

status

Container

information

Container

conductivity [μS]

Container

P. pressure

Container

flow rate

ALL

ALL

ALL

ALL

SYN/

PER

3200

Only

3200

Only

3200

Press the “water supply” function key to display an overview of the units

attached to the HumCenter and their current status.

Created: 04.06.2007 11

Changed: 21.12.2007

Printed: 02.03.2009

Page 12

2.2.1 Water supply overview

Simplified status for CSF 3121 (PER)

Display

Priority*

Description

ERR

1

Error

FULL

2

Tank full

ON

3

In operation

* When two status reports occur at once, that with lower priority is shown.

Simplified status for CSF 3200 (PER)

Display

Priority*

Description

ERR

1

Error

FULL

2

Tank full

ON

3

In operation

* When two status reports occur at once, that with lower priority is shown.

Simplified status for LS 3400 (SYN)

Display

Priority*

Description

ERR

1

Error

Mntc

2

Maintenance

FWA

3

Circulation

ON

4

In operation

* When two status reports occur at once, that with lower priority is shown.

Simplified status for HPS 3200 (HIG)

Display

Priority*

Description

ERR

1

Error

ON

2

Pump running

Stby

3

No malfunction, pump off

* When two status reports occur at once, that with lower priority is shown.

# TYPE STATUS d

1 HIG ON

2 HIG Stby

3 SYN ERR

4 PER ON

STAT MAINT

Created: 04.06.2007 12

Changed: 21.12.2007

Printed: 02.03.2009

Page 13

2.2.2 Status menu

Parameters for CSF3121 (PER)

Name

Function

Notes

Dtype:

Device type

CSF3121 (M261,M262, M263, D250)

DNum:

Device number

(D250,D251)

Stat:

Summary of status

See table below

Info:

Additional status information

See table below

Status of CSF3121 (PER)

Display

Priority*

Description

ERR

1

Error (M201, M236, M250, M251), com error

Full

2

Tank full (M235)

ON

3

In operation

* When two status reports occur at once, that with lower priority is shown.

Info on CSF3121 (PER)

Display

Priority*

Description

Com err

1

Communication error

Cap err

2

Capability error: CSF cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Safety press. err

3

Safety pressure error (M201)

Inlet press. err

5

Inlet pressure error (M236)

Conductivity err

6

Conductivity error (M250)

Motor prot. err

4

Motor protection error (M251)

PerPur ready

7

PER ready for operation

* When two status reports occur at once, that with lower priority is shown.

Select a unit with the UP/DOWN keys and display the detailed status with the

“STAT” softkey.

## STATUS HIG #1 d

Dtype: HPS3200

DNum: 4294967296

Stat: ON

Info: HighPur ready

Created: 04.06.2007 13

Changed: 21.12.2007

Printed: 02.03.2009

Page 14

Parameters for CSF3200 (PER)

Name

Function

Notes

Dtype:

Device type

CSF3200 (M261,M262, M263,

D250)

DNum:

Device number

(D251,D252)

Con:

Conductivity

µS (D240)

Press:

Pump pressure

bar (D239)

Flow rate:

Flow rate

L/h (D238)

Stat:

Summary of status

See table below

Info:

Additional status information

See table below

Status of CSF3200 (PER)

Display

Priority*

Description

ERR

1

Error (M200, M201, M204, M236, M237, M253), com error

Full

2

Tank full (M239)

ON

3

In operation

* When two status reports occur at once, that with lower priority is shown.

Info on CSF3200 (PER)

Display

Priority*

Description

Com err

1

Communication error

Cap err M

2

Capability error: CenterPur cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Cap err D

3

Capability error: PER cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Safety press. err

7

Safety pressure error (M201)

Inlet press. err

8

Inlet pressure error (M200)

Conductivity err

3

Conductivity error (M236)

Motor prot. err

6

Motor protection error (M253)

Pump press. err

5

Pump pressure error (M237)

Mntc pump

9

Pump maintenance (M204)

PerPur ready

10

PER ready for operation

* When two status reports occur at once, that with lower priority is shown.

Parameters for LS3400 (SYN)

Name

Function

Notes

Dtype:

Device type

LS3400 (M261,M262, M263,

D250)

DNum:

Device number

(D251,D252)

Con:

Conductivity

µS (D248)

Stat:

Summary of status

See table below

Info:

Additional status information

See table below

Created: 04.06.2007 14

Changed: 21.12.2007

Printed: 02.03.2009

Page 15

Status for LS3400 (SYN)

Display

Priority*

Description

ERR

1

Error (M200–M205), com error

Mntc

2

Maintenance (M234)

FWA

3

Circulation (M235)

ON

4

In operation

* When two status reports occur at once, that with lower priority is shown.

Info on LS3400 (SYN)

Display

Priority*

Description

Com err

1

Communication error

Cap err M

2

Capability error: CenterPur cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Cap err D

3

Capability error: LS cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Safety press. err

7

Safety pressure error (M200)

Inlet press. err

9

Inlet pressure error (M201)

Gas press. err

8

Gas pressure error (M202)

Motor prot. err

6

Motor protection error (M203)

Synthesis err

5

Synthesis error (M204)

Product err

4

Product error (M205)

Mntc Syn

10

Maintenance (M234)

SynPur ready

11

PER ready for operation

* When two status reports occur at once, that with lower priority is shown.

Parameters for HPS 3200 (HIG)

Name

Function

Notes

Dtype:

Device type

HPS3200 (M261, M262, M263, D250)

DNum:

Device number

(D250,D251)

Stat:

Summary of status

See table below

Info:

Additional status information

See table below

Status for HPS 3200 (HIG)

Display

Priority*

Description

ERR

1

Error (M200–M204), com error

ON

2

Pump running (M232)

Stdby

3

No malfunction, pump off

* When two status reports occur at once, that with lower priority is shown.

Created: 04.06.2007 15

Changed: 21.12.2007

Printed: 02.03.2009

Page 16

Info for HPS 3200 (HIG)

Display

Priorit

y*

Description

Com err

1

Communication error

Cap err M

2

Capability error: CenterPur cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Cap err D

3

Capability error: HIG cannot fulfil the function required.

Causes: Firmware not updated, device technology outdated

Motor prot. err

6

Motor protection switch (M204)

Leakage err

4

Leakage error (M201)

Min. press. err

5

Minimum pressure error (M200)

Inlet press. err

8

Inlet pressure error (M202)

Temp. err

7

Temperature error (M203)

HighPur ready

9

Container ready for operation

* When two status reports occur at once, that with lower priority is shown.

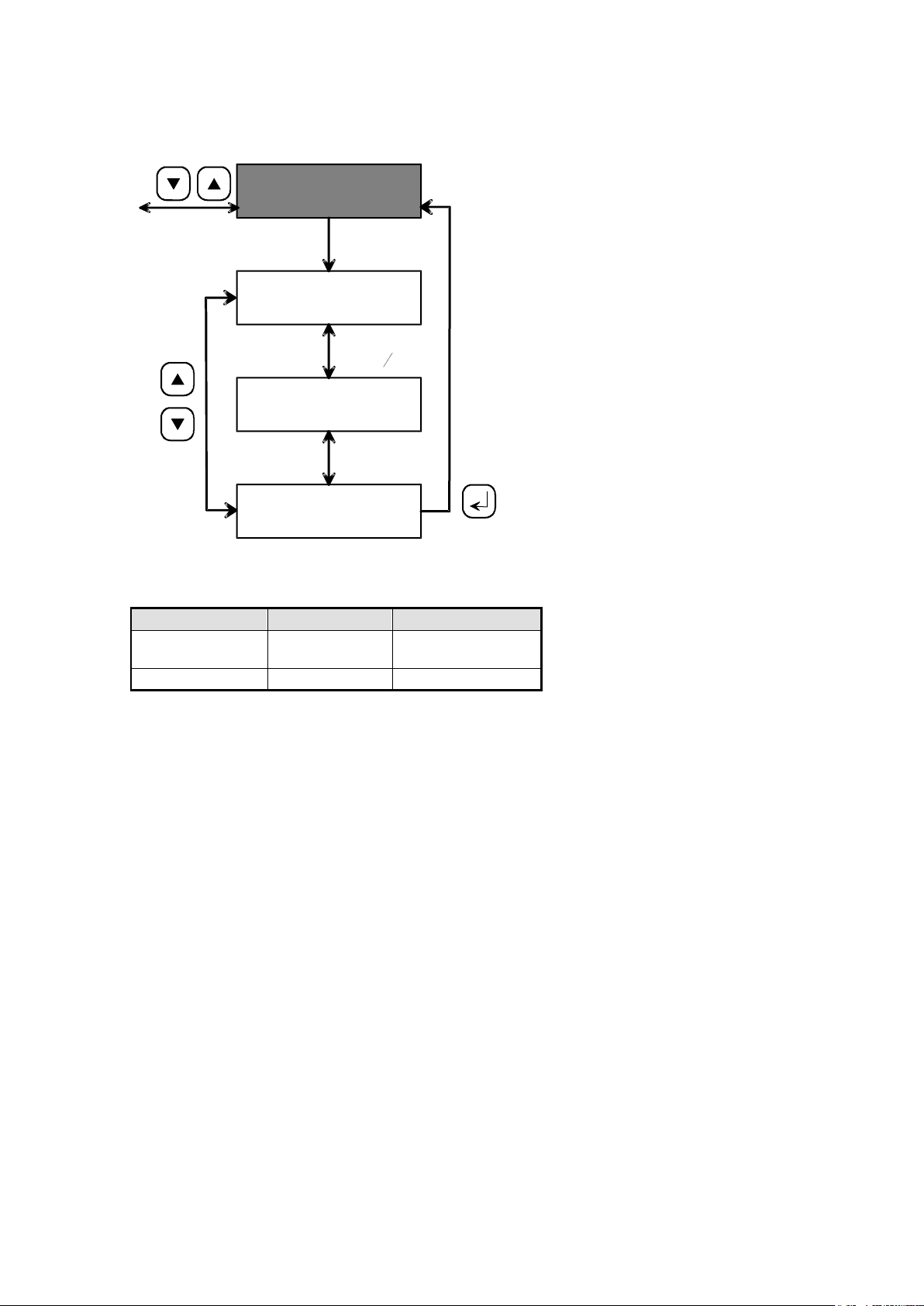

Alarms

Pend/Hyst.

Current

"pending"

ALARMS

"Pend"

"LOG"

History

"old"

ALARMS

Detailed

ALARM

information

Detailed

ALARM

information

"DET"

"DET"

select line

Delete

"LOG" ALARMS

[only old]

"CLR"

2.3 Alarms menu

Press the “Alarms” function key to display the “Alarms” overview menu. In this

menu you can switch between the two menu levels “Pending” and “Log”.

Created: 04.06.2007 16

Changed: 21.12.2007

Printed: 02.03.2009

Page 17

2.3.1 Pending alarms menu

In the “Pending” menu, all current pending alarm reports are shown. For

further details

2.3.2 Alarm log menu

In the “Log” menu, all past alarm reports are shown.

Created: 04.06.2007 17

Changed: 21.12.2007

Printed: 02.03.2009

Page 18

2.4 HumCenter menu

Parameter

Line

Parameter

Notes

1

VXX.XX

Version of the CenterPur software

2

Installation:

Display of unit

3

Operator:

Name of customer

4

Date & time:

Current time

6:

Service phone:

Number in case of malfunction

HumCenter

Overview

Hum

Center

Detail

User settings

Hum

Center

"SETT"

Clock

[TT:DD:MM:YY]

UNIT

[°C / °F]

LCD

[ 1....9]

LOG

[hh:mm]

User

[ XXXX ]

LOCK

[ Set ]

Press the “HumCenter” function key to display the HumCenter overview

menu.

2.4.1 HumCenter overview

Created: 04.06.2007 18

Changed: 21.12.2007

Printed: 02.03.2009

Page 19

Further settings can be made using the “SETT” softkey.

Parameter

Name

Function

Notes

Clock setting...

Submenu to set the clock

Unit temperature:

Temperature unit (only CenterPur)

°C or °F

LCD contrast:

Display contrast

LOG Int:

Interval for logger [hh:mm]

Interval for data logger

Load Configuration

Load configurations from SD card

Save Configuration

Save configurations on SD card

Reboot System

Reboot HumCenter

Code:

CenterPur code

Lock...:

Activate code immediately

2.4.2 HumCenter settings

Created: 04.06.2007 19

Changed: 21.12.2007

Printed: 02.03.2009

Page 20

3 HumCenter software update

The HumCenter software can be updated very simply using the SD card. The

current software is sent by e-mail, copied onto the SD card and then installed

on the HumCenter.

Carry out the following steps:

1. Remove the SD card from the HumCenter and connect it to a

computer.

2. Enclosed in the e-mail are the files “boot.sys” and “flash.bin”.

3. Copy these files and save them on the SD card.

Created: 04.06.2007 20

Changed: 21.12.2007

Printed: 02.03.2009

Page 21

4. Re-insert the SD card in the HumCenter.

5. Select the “HumCenter” menu.

6. Press the “SETT” key and select "Reboot system".

HumCenter V1.06 d

Save Configuration

Load Configuration

Reboot System mmm

Code: ****

SETT

7. Confirm the request with “yes” and keep the “HumCenter” key pressed

during the reboot until “Flash Programmer” appears in the display. The

new software is now automatically updated.

After the installation, restart the HumCenter. All previous settings are retained.

Created: 04.06.2007 21

Changed: 21.12.2007

Printed: 02.03.2009

Page 22

3.1 BMS link

Identifier

Parameter

Format

BACnet

Option

Objects

Notes

A

Date/time

U8;U8;U16;U8;U8;U8

(DD;MM;YYYY;HH;MM;SS)

Example:

A07;11;2007;11;45;15

AI 201

Time

telegram

sent

B

Zone alarms

U32

Bit0=Zone1, Bit1=Zone2 etc.

Examples:

B0 = no alarm

B1 = zone 1 alarm

B3 = zone 1 and zone 2 alarm

BI 1-24

Objects are true

if faulted.

Example if BI...

1=1 Zone 1 fault

4=0 Zone 4 ok

7=1 Zone 7 fault

C

Container alarms

U8

Bit0=Container1 etc.

Examples:

C0 = no alarm

C1 = container 1 alarm

BI 101-105

Objects are true

if faulted.

Example if BI...

101=1 Ctn 1 fault

104=0 Ctn 4 ok

105=1 Ctn 5 fault

D

Current zone

values

Float, Float

(HH.H;TT.T)

Example:

D1:39.5;23.8

AI 1-24 Humidity

AI 101-124 Temp

AI 1=39.5 is

39.5%rh

AI 101=23.8 is

23.8°C

HH.H in

[%RH]

TT.T in

[°C]

Z

CRC

U16

The HumCenter has an interface to link to the building services management

system. The HumCenter is designed so that the parameters to be transferred

are converted to the bus system using an external converter (e.g. RS232

Ethernet converter).

The converter is connected at the RS232 interface on the top of the

HumCenter next to the SD card slot. The maximum cable length between the

HumCenter and the converter is 3m.

3.1.1 Parameters

The following parameters are transferred:

- Date/time

- Zone alarms

- Container alarms

- Current zone values (humidity, temperature)

Each parameter is labelled in the telegram using identifiers:

Created: 04.06.2007 22

Changed: 21.12.2007

Printed: 02.03.2009

Page 23

The parameters transferred can only be read; it is not possible to change the

Symbol

Description

Notes

*

Start symbol

Start of telegram

A – Z

Identifier

Identifies the parameter

:

Index

Index in case of array data (D:1)

;

Data separator

Separates the data (D:1; 25.0; 50.0 – “;”

separates the data from the index and

the temperature from the humidity)

.

Decimal point

CR+LF

End of line

Lines of telegram finish with a “carriage

return” and “line feed”.

settings via the BMS.

3.1.2 Telegram

Every five seconds, the HumCenter sends a telegram with the parameters

described above. The following is an explanation of the symbols used in the

telegram and the telegram layout, using an example.

The following symbols are used in the telegram:

Layout of a sample telegram with the following configuration:

- 3 zones (HumSpots)

- 2 containers

Telegram:

*A07;11;2007;11;29;04;B0C2D:1;43.3;24.8;D:2;42.5;23.3;D3:40.8;20.1Z3221

9

The telegram contains the following information:

- Date/time: 07.11.2007, 11:29:04 (A07;11;2007;11;29;04)

- Zone alarms: No alarm (B0)

- Container alarms: Container 2 alarm (C2)

- Zone 1 values: Humidity: 43.3 % rH, temp.: 24.8 °C

(D:1;43.3;24.8)

- Zone 2 values: Humidity: 42.5 % rH, temp.: 23.3 °C

(D:1;42.5;23.3)

Created: 04.06.2007 23

Changed: 21.12.2007

Printed: 02.03.2009

Page 24

- Zone 3 values: Humidity: 40.8 % rH, temp.: 20.1 °C

(D:1;40.8;20.1)

- Checksum: 32219 (Z32219)

3.1.3 Transfer parameters

19,200 bit/s

Data bits: 8

Stop bit: 1

Parity: none

Flow control: none

3.1.4 CRC checksum

It is not usually necessary to calculate and evaluate the checksum.

If desired, it can be calculated as follows:

Up to and including the “Z” identifier, the function “crc_one_byte()” is

accessed for every figure in the telegram, with "*oldchecksum” initialised to 0

at the start of the telegram.

Algorithm

/* calculate 16-Bit CRC */

/* At start of calculation *oldchecksumP must be */

/* initialised to 0 */

/* oldchecksumP (IO): pointer on (previous) checksum*/

/* b: next byte of data stream */

void crc_one_byte(u16 *oldchecksumP, unsigned char b)

{

u16 result;

unsigned char a=b ^ (*oldchecksumP)>>8 ^ (*oldchecksumP)>>4 ^ (*oldchecksumP)>>1

^ (*oldchecksumP)<<1;

result = (*oldchecksumP)<<8 | a ^ a>>7;

*oldchecksumP = result;

}

Created: 04.06.2007 24

Changed: 21.12.2007

Printed: 02.03.2009

Page 25

3.1.5 BACnet Option connection

The BACnet Gateway is a small device that attaches to the HumCenter’s

serial communication port. This is done by connecting the two with a serial

cable with a DB9 female to DB9 male connection. This is a straight cable, pin

1 to 1, 2 to 2 ... 9 to 9. The Gateway is then connected to the BACnet

network with an Ethernet Cable. It must also be supplied with power

(120V/1P)

DB9 Cable connection

Ethernet Connection

BACnet Gateway general specification:

• Powered by 9 to 30VDC @ 0.37A to 0.11A

• 120VAC power supply included (12VDC output)

• FCC Class A, CE Mark

• Operating temperature -40°C to +85°C; Humidity 5% to 90%

Created: 04.06.2007 25

Changed: 21.12.2007

Printed: 02.03.2009

Page 26

4 Troubleshooting

Error message

Possible causes

Possible solutions

BUS ERR

1. The HumCenter is switched off.

2. Bus communication error (wiring

error) between HumSpot and

HumCenter

3. No bus ID or wrong bus ID entered in

HumSpot.

4. Bus ID assigned to a unit without

HumCenter.

1. Check the electricity supply to

the HumCenter.

2. Check the bus connection at

HumSpot and HumCenter.

3. Check the bus ID at HumSpot.

4. Set the bus ID to 0.

CAP ERR

1. Capability error: HumSpot does not

have current firmware.

2.

1. Install the current firmware in the

HumSpot.

2.

No HPS

1. No HPS has been assigned to the

HumSpot

2.

1. Assign an HPS to the HumSpot

using the HumCenter.

2.

SENS ERR

1. Hygrostat malfunction.

1. Replace the sensor.

MAX ERR

1. Maximum hygrostat has triggered

due to high room humidity.

2.

1. Check maximum hygrostat is

functioning.

2. Check hygrostat is functioning.

3. Adjust target value of maximum

hygrostat.

HPS ERR

1. No release received from HPS

(timeout).

1. Check if the HPS is

malfunctioning.

2. Check the wiring between the

HumSpot and HPS.

4.1 HumSpot

Created: 04.06.2007 26

Changed: 21.12.2007

Printed: 02.03.2009

Page 27

4.2 HumCenter

Error message

Possible causes

Possible solutions

COM ERR

(Zone)

1. The HumSpot is switched off.

2. Bus communication error (wiring

error) between HumSpot and

HumCenter

3. No bus ID or wrong bus ID entered in

HumSpot.

4. Bus ID assigned to a unit without

HumCenter.

1. Check the electricity supply to

the HumSpot.

2. Check the bus connection at

HumSpot and HumCenter.

3. Check the bus ID at HumSpot.

4. Set the bus ID to 0.

No HPS

1. No HPS has been assigned to the

HumSpot

1. Assign an HPS to the HumSpot

using the HumCenter.

SENS ERR

1. Hygrostat malfunction.

1. Replace the sensor.

MAX ERR

1. Maximum hygrostat alert has set off

due to high room humidity.

2.

1. Check maximum hygrostat is

functioning.

2. Check hygrostat is functioning.

3. Adjust target value of maximum

hygrostat.

HPS ERR

1. No release received from HPS

(timeout).

1. Check if the HPS is

malfunctioning.

2. Check the wiring between the

HumSpot and HPS.

Error message

Possible causes

Possible solutions

COM ERR

(Water Supply)

1. Unit is switched off.

2. Bus communication error (wiring

error) between unit and HumCenter

1. Check the electricity supply to

the unit.

2. Check the bus connection at the

unit and the HumCenter.

CAP ERR M

1. Capability error: The HumCenter

does not have current firmware.

1. Install the current firmware in the

HumCenter.

Zone:

Water supply

Created: 04.06.2007 27

Changed: 21.12.2007

Printed: 02.03.2009

Page 28

Manufacturer:

DRAABE Industrietechnik GmbH

Schnackenburgallee 18

D-22525 Hamburg

+49 40 853277-0

www.DRAABE.de

A WMH company

Distributer:

Nortec Systems Inc.

1860 Renasissance Blvd.

Sturtevant, WI 53177

262.884.4669

www.nortecsytems.us

Created: 04.06.2007 28

Changed: 21.12.2007

Printed: 02.03.2009

Loading...

Loading...