Page 1

HP Series

Important: Read and save these instructions. This guide to be left with equipment owner.

Installation and

Operation Manual

Includes installation, operation

maintenance and troubleshooting

information for your HP Series

humidifier

1507183-C| 05 JUL 2011

Page 2

Thank you for choosing Nortec.

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

INSTALLATION DATE (MM/DD/YYYY)

MODEL #

SERIAL #

CYLINDER #

Proprietary Notice

This document and the information disclosed herein are proprietary data of NORTEC HUMIDITY LTD. Neither

this document nor the information contained herein shall be reproduced, used, or disclosed to others without

the written authorization of NORTEC HUMIDITY LTD., except to the extent required for installation or

maintenance of recipient‟s equipment. All references to the Nortec name should be taken as referring to

NORTEC HUMIDITY LTD.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or

the use of parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2011, NORTEC HUMIDITY LTD. All rights reserved.

Page 3

Contents

2 Introduction

2 About HP

2 Receiving and Unpacking Equipment

3 Absorption Distances

3 Components

6 Water Quality

6 Multiple Zones

8 Installation

8 Pre-Installation

10 Construction of a Wet Duct Section

11 Pump Module

11 Installing the Pump

14 Installation of the HP HVAC Manifolds

18 Installation of the Piping Between Valve

37 HP HVAC Start-up Checklist

38 Operation

39 Maintenance

42 Danfoss Stainless Steel Axial

Piston Pump

42 Electrical Motor Service

43 Inlet Water Filters

43 High and Low Pressure Lines and

Hoses

43 Atomization Nozzles

44 Mist Eliminator Maintenance

44 End of Season Shutdown

45 Decommissioning / Freeze

Protecting

Block and Manifolds

19 Check Valve

19 Installation of the Needle Valve

20 Installation of the Valve Block

22 High Pressure Piping

22 Low Pressure Piping

22 Valve Controller Installation

23 Wiring of the System

25 Pump Controller Wiring Notes

27 Mist Eliminator Installation

34 Startup, Operation, and

Maintenance

35 Commissioning and Startup

45 Inlet Water Pressure Switch

46 Troubleshooting

50 Spare Parts

60 Wiring & Installation

Diagrams

Page 4

CAUTION: Servicing

Disconnect main power before any servicing.

The plumbing and electrical compartments contain high voltage components and

wiring. Access should be limited to authorized personnel only.

During and following operation of the humidifier, the steam and components in

contact with the steam such as the blower pack, steam lines, steam distributors,

and condensate lines can become hot and can burn if touched.

Walter Meier does not accept any liability for installations of humidity equipment

installed by unqualified personnel or the use of parts/components/equipment

that are not authorized or approved by Walter Meier.

CAUTION: Electrical

All electrical work should be done according to local and national electrical code.

Electrical connection to be performed by a licensed electrician.

CAUTION: Plumbing

Plumbing to be performed by a licensed plumber.

Drain water from humidifier can be very hot. Do not drain to public sink.

All plumbing work should be done according to local plumbing code.

CAUTION: Installation

Do not mount on hot surfaces.

Do not mount in area where freezing can occur.

Do not mount on vibrating surface.

Do not mount on floor.

LiveSteam produces steam at atmospheric pressure no devices which could block

steam output should be connected to the steam outlet.

Steam lines must be installed so that no restriction can produce backpressure in

the humidifier.

Regardless of selecting on/off or modulating control method, Nortec humidifiers

must have a closed circuit across its on/off security loop control terminal to

operate. Nortec highly recommends the use of a duct high limit humidistat.

1 | HP Series Installation Manual

Page 5

Introduction

HP HVAC (Adiabatic Humidification System)

Congratulations on the purchase of your NORTEC HP HVAC humidification system. This system

was designed to be efficient and reliable, and is manufactured from high quality materials to

provide long trouble free operation. In order for the system to operate as intended it must be

installed properly.

This guide details the design, installation, commissioning, operation, and troubleshooting of the

HP HVAC system. Please take the time to familiarize yourself with this guide before beginning to

ensure that the system is installed the way it was designed. This ensures a long and trouble

free life of the humidifier.

About HP (Adiabatic Humidification System)

The HP (High Pressure) HVAC system is designed to be installed inside an AHU or duct system to

humidify air to a desired relative humidity. Proper humidity levels have been shown to be

important for health and comfort of occupants. Maintaining proper humidity is also important

for many industrial and manufacturing processes.

The HP system uses a series of nozzles to spray a very fine mist of water droplets into an air

stream. During this process the air absorbs moisture increasing its relative humidity levels. As

the water droplets evaporate, they absorb some energy in the form of heat from the air. This

loss of heat causes the air temperature to drop, resulting in a phenomenon known as adiabatic

cooling.

The HP HVAC adiabatic system has 2 effects:

The relative humidity of the air increases (humidification)

The temperature of the air falls (adiabatic cooling)

Humidification of the air is the main goal of the HP HVAC system. The cooling of the air is

secondary and is frequently beneficial since it is „free‟ cooling. In cases where air-cooling is undesired, preheating of the air is required.

In general a HP system has the following advantages over other humidification technologies:

Low frequency of maintenance, since there are few moving or expendable parts.

Replacing components is quick and requires minimal system disassembly.

A „free‟ air-cooling benefit from water extracting latent heat from the air.

Receiving and Unpacking Equipment

Check packing slip to ensure ALL material has been delivered.

All material shortages are to be reported to Nortec within 48 hours from receipt of goods.

Nortec assumes no responsibility for any material shortages beyond this period.

Inspect shipping boxes for damage and note on shipping waybill accordingly.

HP Series Installation Manual | 2

Page 6

After unpacking, inspect equipment for damage and if damage is found, notify the shipper

promptly.

All Nortec products are shipped on an F.O.B. factory basis. Any and all damage, breakage or

loss claims are to be made directly to the shipping company.

Absorption Distances

An important consideration in the planning of a HP HVAC system is the absorption distance, or

the distance it takes for the droplets to evaporate inside the HVAC system. The absorption

distance is relative to the air velocity, temperature, atmospheric pressure, and the amount of

water in the incoming air. In applications where space is limited, such as in an air-handler,

precautions should be taken to prevent the wetting of sensitive components downstream.

Components

Nortec Supplied

Nortec will supply the following components:

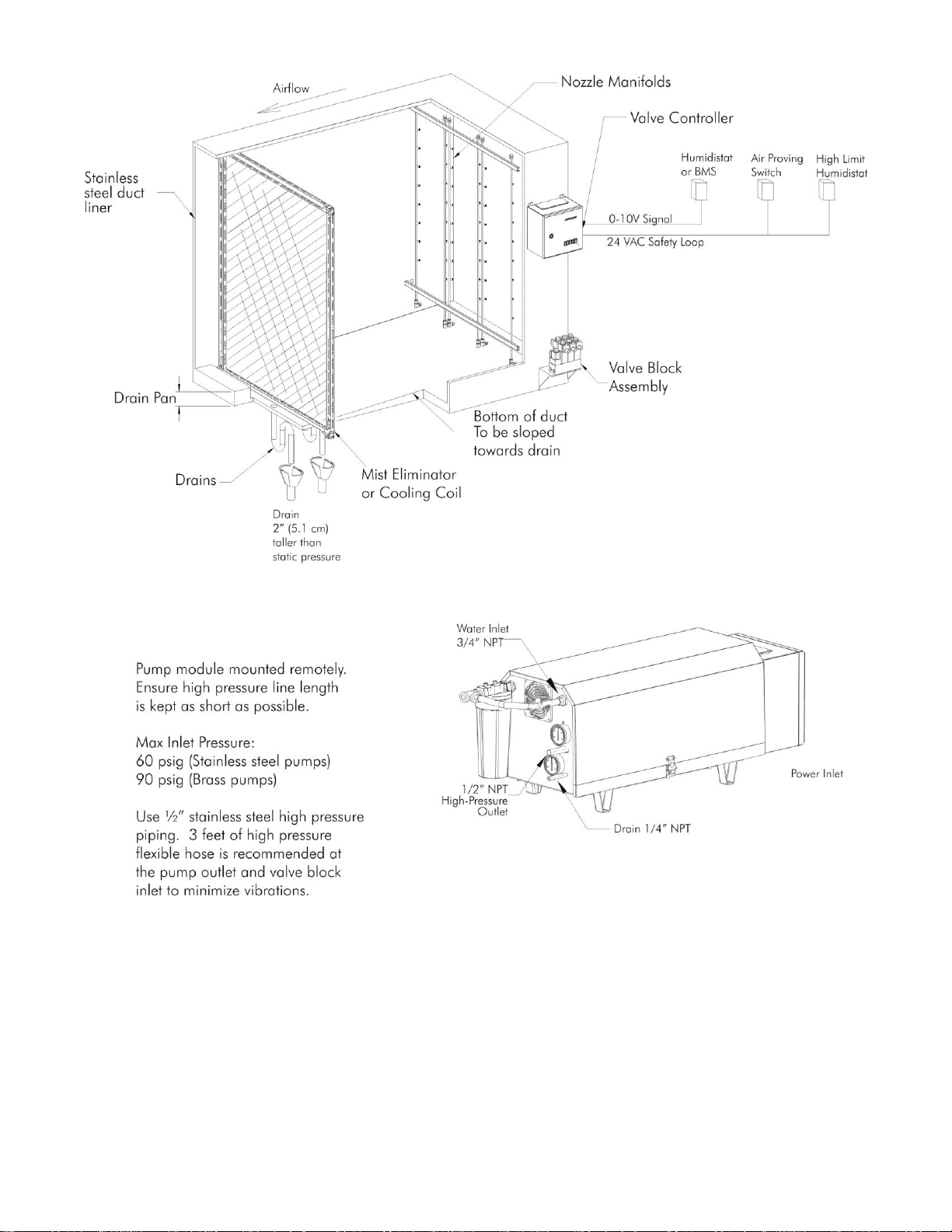

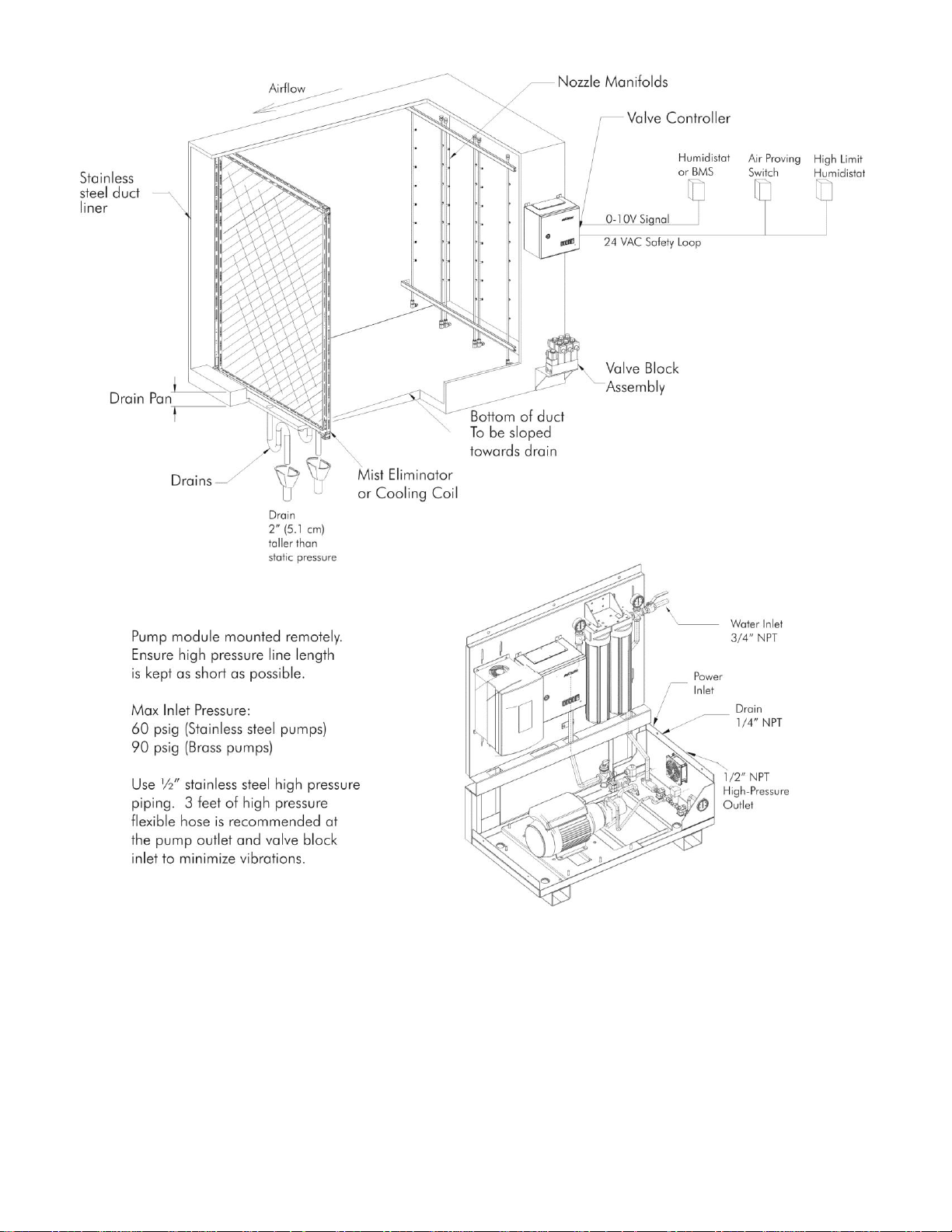

1 High pressure pump skid

2 Valve controller

3 Valve block assembly

4 Nozzle manifolds

5 In-duct plumbing

6 Mist eliminator (optional)

7 Air proving switch (optional)

8 High limit humidistat (optional)

9 Humidistat (optional)

10 Reverse osmosis system (optional)

Field Supplied

The Installer is responsible for supplying the following:

1 Electrical disconnects

2 All electrical wiring

3 Piping from the RO system to pump module

4 High pressure piping between pump and manifolds

5 Flex hose

6 P-traps

7 Drain funnels

8 Wet duct section (drain pans, wall sections, sealants, fasteners)

9 Pump skid vibration dampening

10 Electricity, water, and airflow

3 | HP Series Installation Manual

Page 7

Figure 1: Typical Installation with Medium Pump

HP Series Installation Manual | 4

Page 8

5 | HP Series Installation Manual

Figure 2: Typical Installation with Large Pump

Page 9

Water Quality

Water used with the HP HVAC system must be very pure. Dissolved solids, and impurities

contained in the water will precipitate out when the water evaporates, causing dust and

minerals to be deposited into ducts, and/or the humidified space. Dusting can have adverse

effects on filters, fans, heating and cooling coils, human health, and may promote corrosion and

bacteria growth in ducts.

For this reason only Reverse Osmosis (RO) or De-Ionized (DI) water can be used with a HP HVAC

humidification system. DI water is very aggressive, in applications where DI water is used all

components (including wet section of ducting and drains) must be constructed from stainless

steel.

To ensure that the HP HVAC nozzles do not become blocked or damaged over time, the

following conditions should also be met:

Conductivity: 20 micromhos or less

Ph: 6.2 – 7.5.

Multiple Zones

Oftentimes a single pump package will be used to serve different ducts or zones. In this case

each duct will have its own set of manifolds, valve controller and valve block making it fully

independent of the other zones. The pump should be sized to handle the full flow capacity of all

zones combined to ensure reliable operation.

Care must be taken when laying out the piping between the pump and the valve blocks at each

zone to prevent vibration transmission or water hammering effects. The piping should be

securely supported using appropriate cushion clamps (by others) and long straight runs should

be avoided.

HP Series Installation Manual | 6

Page 10

Installation

7 | HP Series Installation Manual

Page 11

Pre-Installation

Prior to beginning installation of the HP HVAC system, the required tools should be obtained,

and all contractor-supplied parts (indicated as parts “By Others” throughout this manual) should

be gathered.

Required Tools

In order to assemble an HP HVAC system the following tools and supplies are required:

1 Hammer

2 Socket Set, common imperial and sizes

3 Box-end wrenches – various sizes

4 Pipe Bender

5 Screwdriver Set, including standard flathead and Phillips

6 Caulking

7 Caulking Gun

8 Metal Snips

9 Hacksaw

10 Plumbing Tape

Required Components

The following components must also be supplied to complete the installation:

Electrical Disconnect Switches

Disconnect switches must be supplied to isolate the humidifier for maintenance and in the case

of emergency. If the control panel and disconnect is to be located outdoors, NEMA rated

disconnect switches should be used per national and local codes.

Sizing High Pressure Stainless Steel Tubing

Stainless steel piping must be supplied for distances between the HP pump module and the HP

manifolds. These distances should be kept to a minimum to minimize pressure losses and

maximize system performance, however it is important to avoid over-sizing the lines. For most

installations a 1/2” line is appropriate. Stainless Steel Pipe Fittings

Stainless steel compression fittings are required for all high-pressure line connections. When

using swage type fittings to connect feed lines together, use fittings of the same material as the

feel lines. Never use a brass compression fitting on a stainless steel tube, as the brass will not

properly hold the harder stainless steel pipe.

Follow manufacturers instructions when installing fittings.

Recommended tube material: 304L stainless steel tube, ½” Outside Diameter, 0.049” Wall

thickness

Recommended fittings: 316 stainless steel, ½”, double ferrule compression connections.

HP Series Installation Manual | 8

Page 12

Reinforced Flexible Hose

The HP pump module features a modern high precision pump. Despite this some degree of

vibration is unavoidable when the system is operating. Vibration effects can be further

amplified by long lengths of solid piping and can be transmitted over distances. To avoid this

reinforced flexible hose is recommended between the pump outlet and the feed piping, as well

as between the feed piping and the valve block. The lengths of reinforce flexible hose used at

these points should be at least 2ft (61 cm). This will dampen vibrations transmitted from the

pump and air-handler / ducting.

Reinforced flexible hose should be selected to withstand pressures of 1200 psi or greater to

provide a safety factor for any water hammer effects or pump over-pressurization.

Care must be taken when using reinforced flexible hose. It must not be allowed to sag unduly,

vibrate excessively, be bent around a radius of less than 2” (50 mm), or come into contact with

sharp edges. Always leave some extra line when going around corners and making bends.

Avoid twisting and kinking the lines while un-spooling and installing. When supporting the hose,

keep in mind that thermoplastic hose has a tendency to return to position it was supplied in.

Pipe Supports and Fasteners

The installer must also supply support for feed piping. When selecting brackets, pipe strapping,

and various other supports, ensure that local and national plumbing codes are followed. The

use of heavy-duty vibration control clamps is strongly recommended. For long runs, ensure that

there is no more than 5 feet between supports.

Various fasteners may be required to complete the installation of the HP HVAC system. These

should be sized to adequately support any anticipated loads. Follow local codes for installing

pipe hangers and bolts.

Recommended supports: Stauff® Cushion Clamps or equivalent

Primary Wiring for Pump Module

Appropriate primary wiring is required for connection to the pumps. Refer to the specification

labels on the pump and valve controllers for voltages and currents. Follow local and national

codes for wiring.

Vibration Isolation

The pump skid will generate some degree of vibrations by its nature. It is recommended that

the pump skid be installed on a vibration-damping mat or vibration isolators to reduce

vibrations and noise.

9 | HP Series Installation Manual

Page 13

Construction of a Wet Duct Section

General

The section of ductwork that the HP HVAC manifolds are installed to be in needs to be capable

of handling excess water that is not absorbed by the air. Nortec requires that a wet section be

installed in the duct. The wet section should be as long as expected wetting distance. In most

cases Nortec recommends the wet section extend 1.5 feet upstream and 6 feet downstream of

the HP manifolds.

A wet duct section consists of; a double walled plenum, drain pan, and drains. All material used

in the wet section should be made of stainless steel. All seams should be sealed properly with

caulking to prevent leaks.

Double Walled Plenum

A stainless steel liner should be secured to the existing wall. The objective of this is to cover any

exposed insulation, seams, and any existing ducting materials that may not be corrosion

resistant or suited for constant exposure to water. The liner should cover both sides and ceiling

of the plenum. All seams should be caulked and sealed to prevent leakage.

Drain Pan

A stainless steel drain pan should be installed on the floor of the duct. This pan should slope

downwards in the direction of airflow from the HP manifolds to end of the wet section. The

drain pan should terminate with a drain connected to a “P” trap. The “P” trap should be at least

2 inches taller (center to center) that the duct static pressure, and should drain to an open

funnel drain.

For systems up to 750 lb/s per hour a 1” diameter drain should be used. For larger systems a

2” diameter drain, or multiple 1” diameter drains should be used.

HP HVAC systems must NOT drain onto a roof. Building damage could result. Any drain lines

routed outdoors must be insulated and heat traced to protect from freezing.

Ensure that all traps are primed by filling them with water.

Mist Elimination

In some cases, the HP HVAC system will need to be installed in tight spaces or where water

sensitive equipment is present a short distance downstream. In these cases a mist eliminator

is required. The mist eliminator will be located immediately after the drain in the wet section. A

second drain will be then installed immediately after the mist eliminator.

Air Handler Installations

In many cases the HP HVAC system is installed in an air handler upstream of the cooling coil.

Many air handlers include a wet section around the cooling cool as a standard offering. These

cooling coils also function as natural mist eliminators and thus an additional mist eliminator

may not be required. Consult the air handler manufacturer for further information.

HP Series Installation Manual | 10

Page 14

Running the pump on any voltage other than what is listed on the spec label can

serious equipment damage and may ignite a fire.

The above is not true for a heating coil; most heating coils are not designed to be wetted. If

installing upstream of a heating coil a mist eliminator must be used.

Pump Module

The pump module location should be selected with the following guidelines in mind:

Available Power: The pump should be located close to its supply power source.

Available Water: The pump should be located close to its RO or DI water source.

Proximity to Manifolds: The pump should be located as close as possible to the manifolds to

minimize pressure losses in the lines. See Table 4 Piping Pressure Losses for more information.

Available Drain: To prevent damage to other equipment in the event that the pump module

should leak, it is recommended that the pump module be located near a floor drain.

Proper Ventilation: The pump will generate heat during operation. Covered pump modules

include cooling fans, while uncovered pump modules typically rely on natural airflow in the room

for cooling. Ensure that the pump module is located in an area where it can receive a

reasonable amount of airflow. Avoid installing other equipment on top of or in front of the pump

module.

Occupants: The pump will generate some noise and vibration during operation. The pump

should be located somewhere in a place noise and vibrations will not disturb occupants of the

building. Installing the pump module on vibration isolators is recommended to minimize

vibrations. Optional pump covers are available for large pump skids to minimize noise.

Installing the Pump

Move the pump to the location selected and secure it to the floor.

Confirm that primary power source matches the specification label on the pump. It is strongly

recommended that the pump module have a dedicated power supply to prevent brownouts

when the pump module starts. Install a manual disconnect switch for the pump module.

Install connection to the reverse osmosis / de-ionized water supply. Ensure that supply water

pressure from the RO or DI water system is at least 25 psi (1.7 bar) at the inlet to the pump

skid. Never exceed 60 psig inlet pressure (Danfoss Stainless Steel Pump) or 90 psig (Giant

Brass Pumps). The water system capacity must be a minimum of 120% of the humidification

system capacity.

11 | HP Series Installation Manual

Page 15

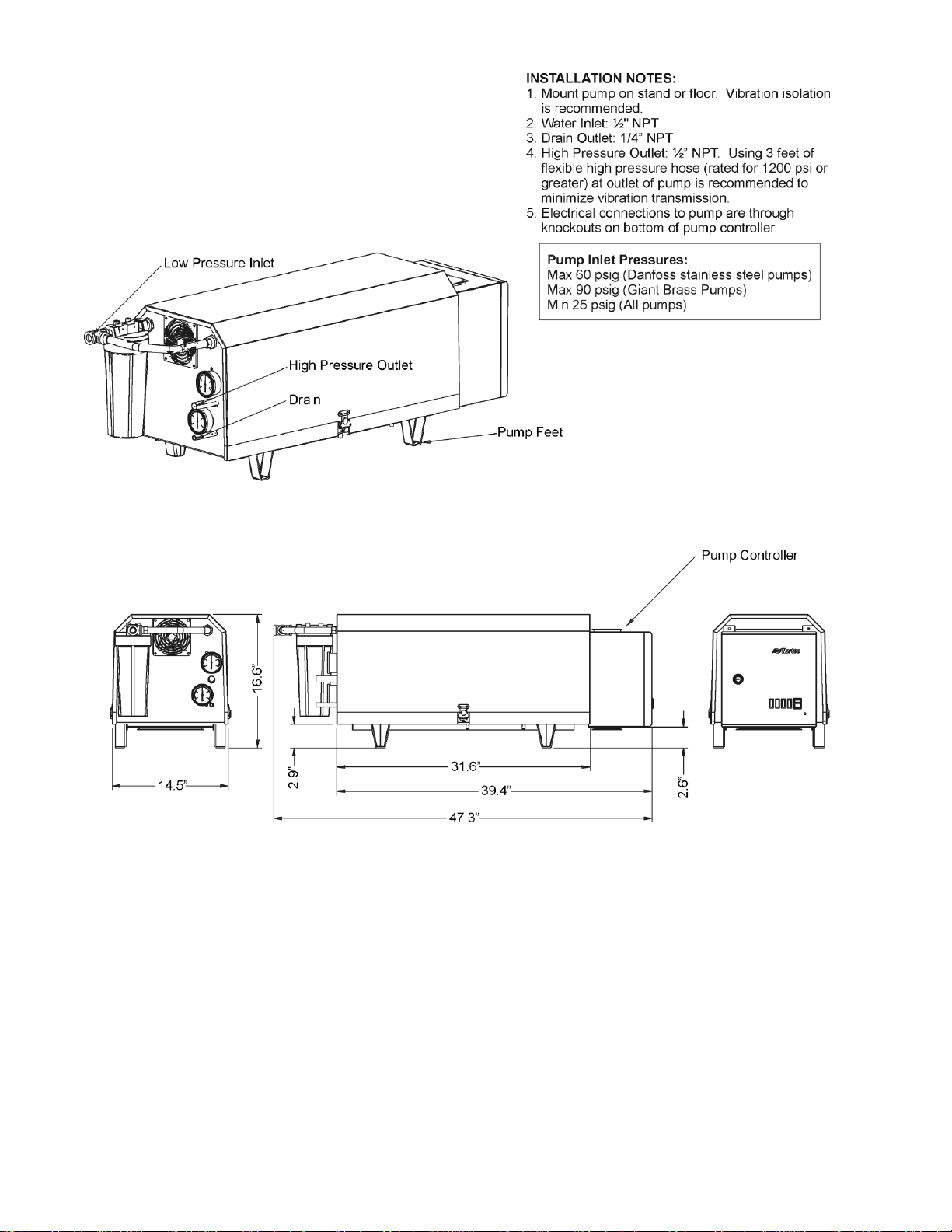

Figure 3: Medium Pump Module Installation Drawing

HP Series Installation Manual | 12

Page 16

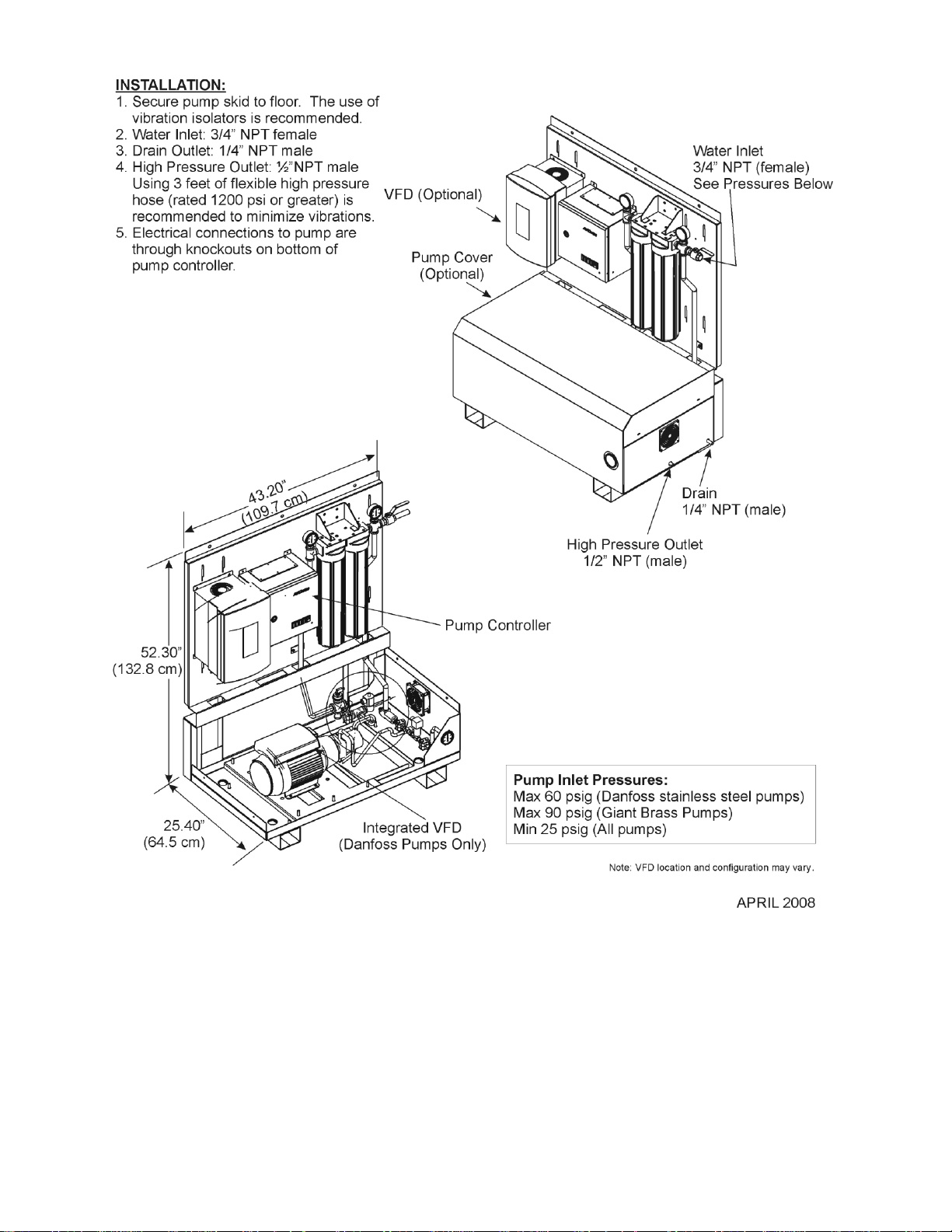

Figure 4: Large Pump Module Installation Drawing

13 | HP Series Installation Manual

Page 17

Only reverse osmosis or de-ionized water can be used with the HP HVAC system.

Connect the primary electrical supply to the pump. Refer to the wiring diagram located in this

manual.

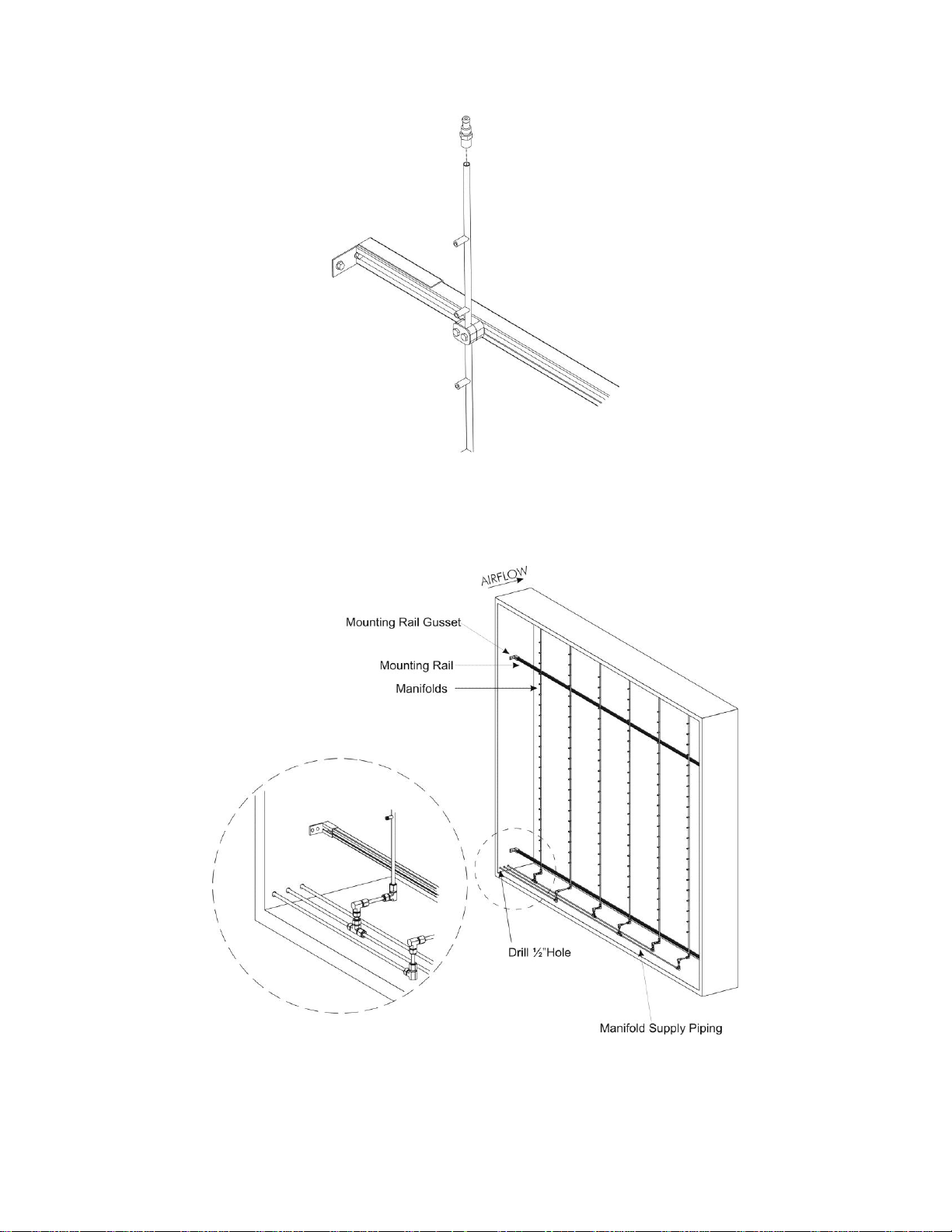

Installation of the HP HVAC Manifolds

The HP HVAC system uses vertical manifolds with that spray into the airstream. These

manifolds are supported at both the top and the bottom by horizontal mounting rails. Since

each system is sized and built to a certain duct size, some test fitting will be necessary to

properly install the rails.

If a wet section has not yet been constructed in the duct or air-handler, it should be constructed

before the humidifier installation has started.

If the duct is greater than 8 feet in width, install mounting rail extensions (P/N 1510135) onto

the mounting rails.

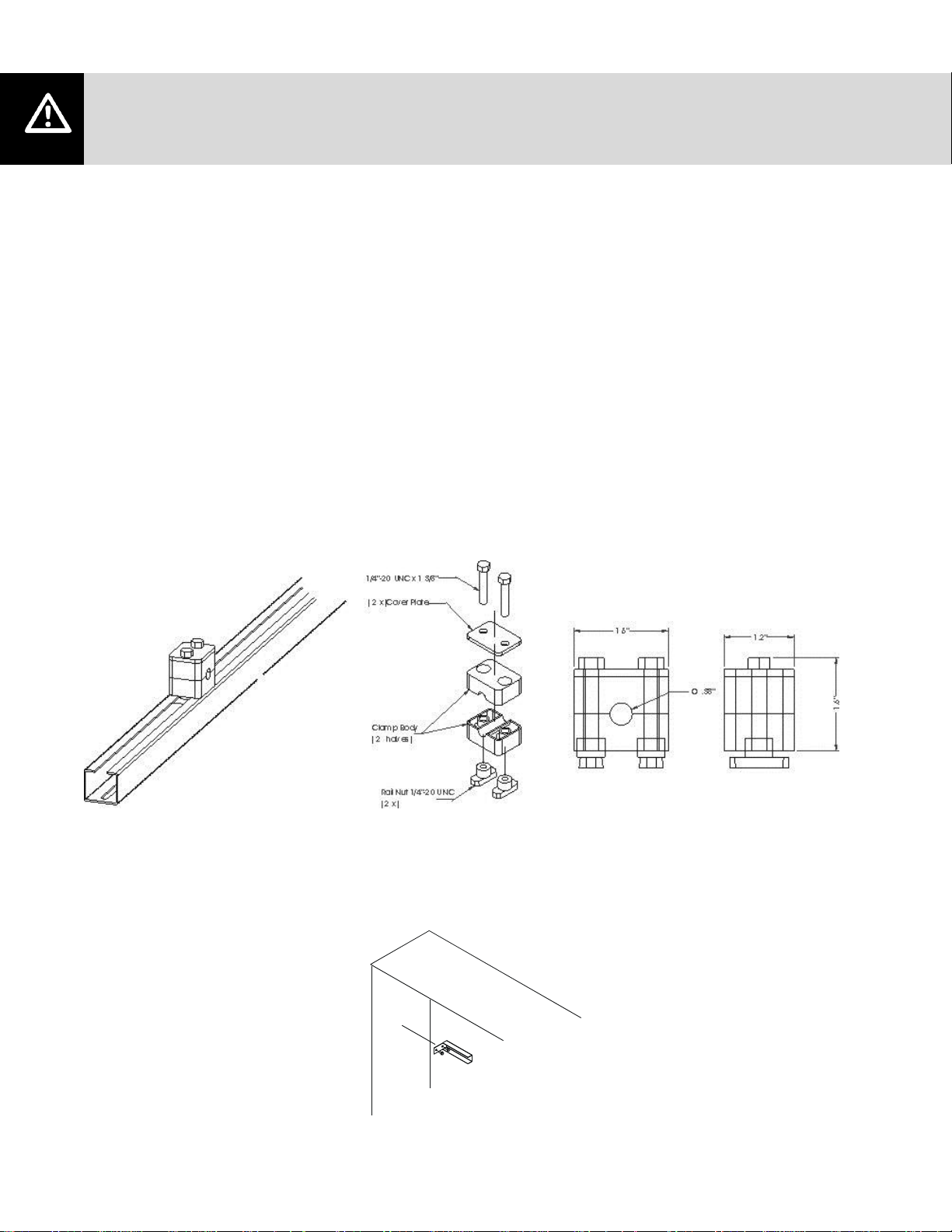

Assemble all vibration clamps on the mounting rails as detailed in the following figure. There

should be an equal number of clamps on both of the supplied mounting rails. Leave the clamps

loosely installed for now, to allow for movement and the installation of the HP manifolds.

Figure 5: Vibration Clamps

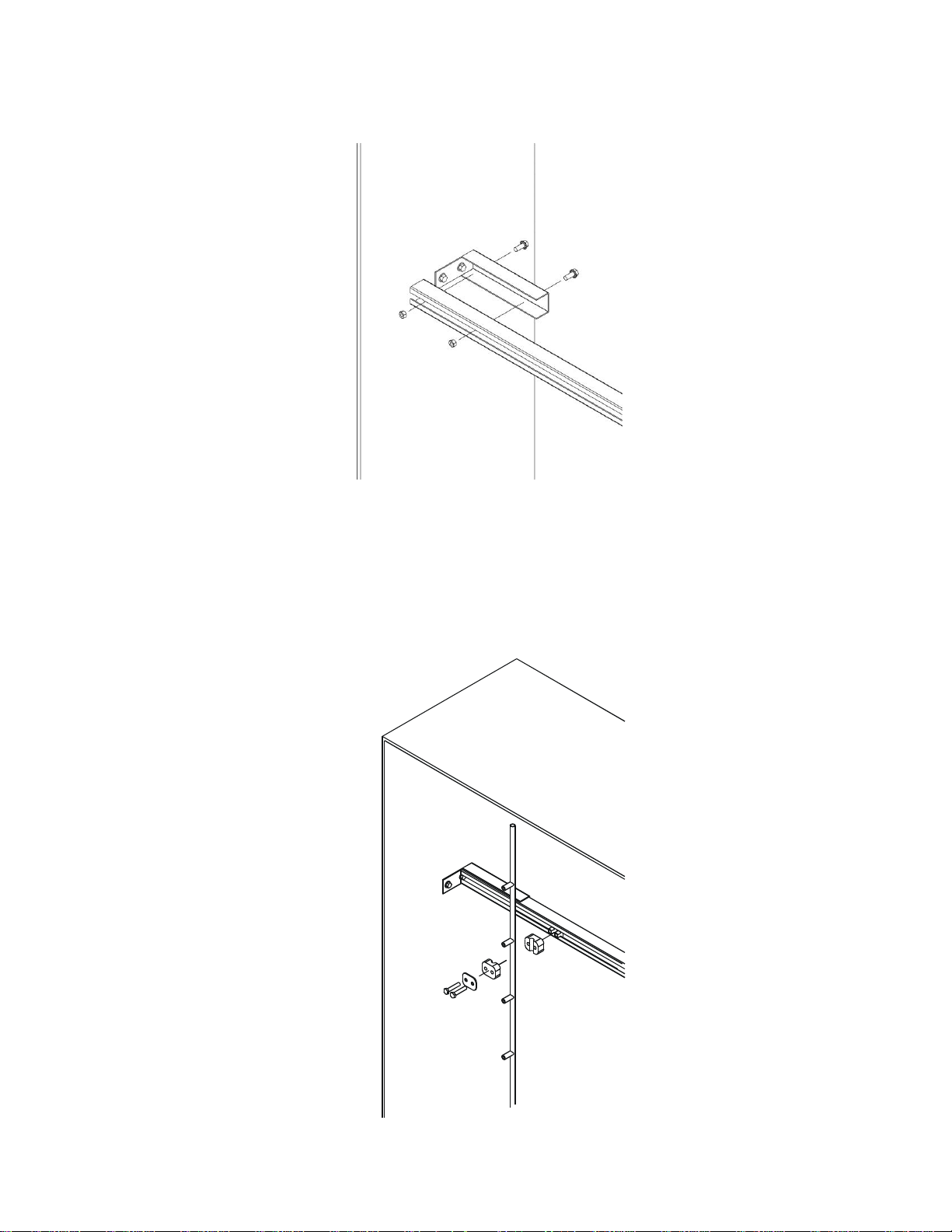

Securely fasten the gusset to vibration pad and duct walls with the supplied screws. (2 screws

per gusset).

Figure 6: Gusset

HP Series Installation Manual | 14

Page 18

Secure the mounting rails to the gussets using the supplied fasteners. (1 – 3 fasteners per

gusset).

Figure 7: Mounting Rail Installation

Install the manifolds onto the mounting rails using the previously installed mounting rail clamps.

The manifolds should be equally spaced in the duct. There should be at least 6” from the top

of the duct to the mounting rails. Mounting rails should be installed on the upstream side of the

manifolds.

15 | HP Series Installation Manual

Figure 8: Rail and Clamp

Page 19

Install the air break end caps onto the one end of the HP manifolds.

Figure 9: Endcap

Install the manifold fittings to the bottom end of the HP manifolds.

Figure 10: HP HVAC Manifold and Plumbing Installation

HP Series Installation Manual | 16

Page 20

ZO NE VALVE

4” Min

4” Min 4” Min4” Min

6” Min

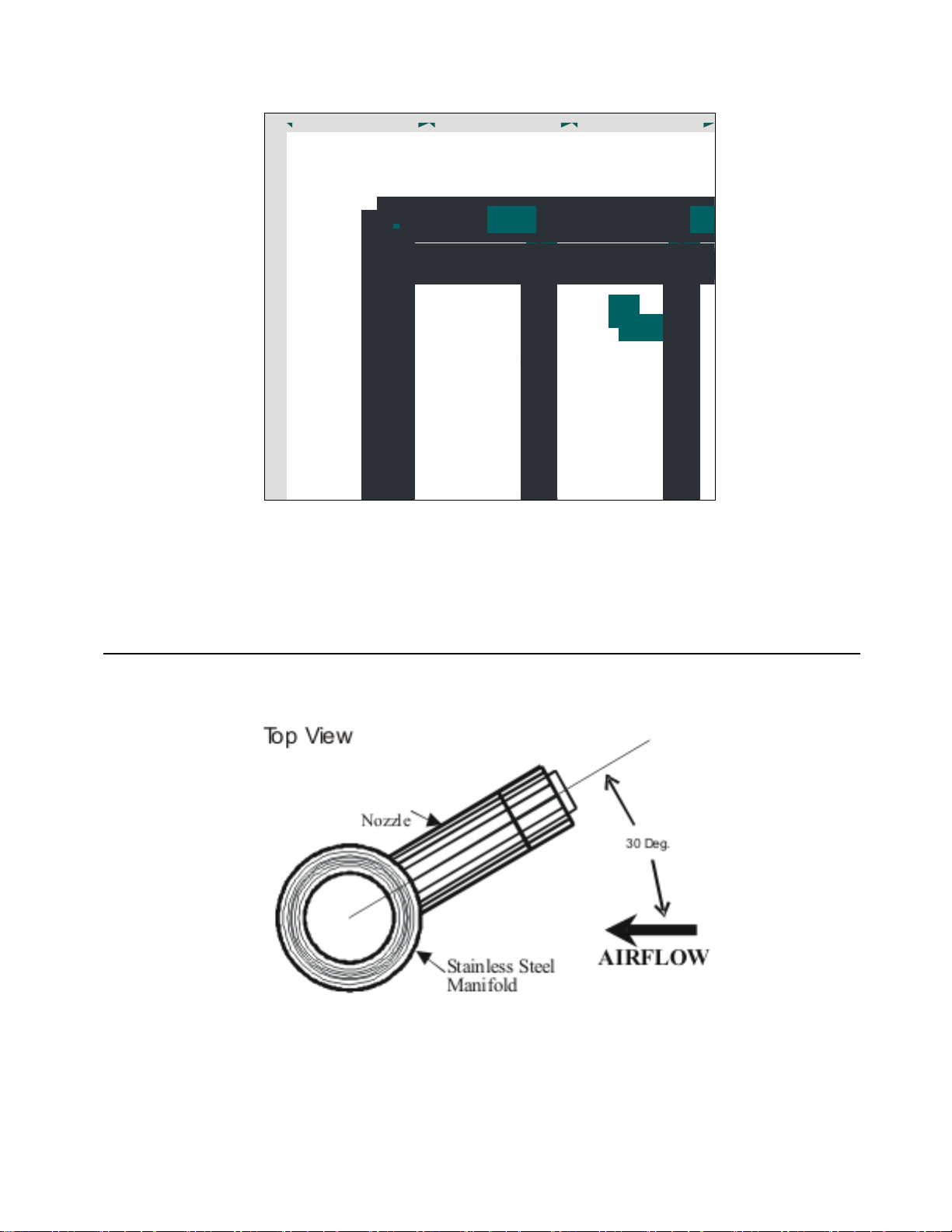

Figure 11: Manifold Minimum Spacing

17 | HP Series Installation Manual

Figure 12: Nozzle Aiming

Page 21

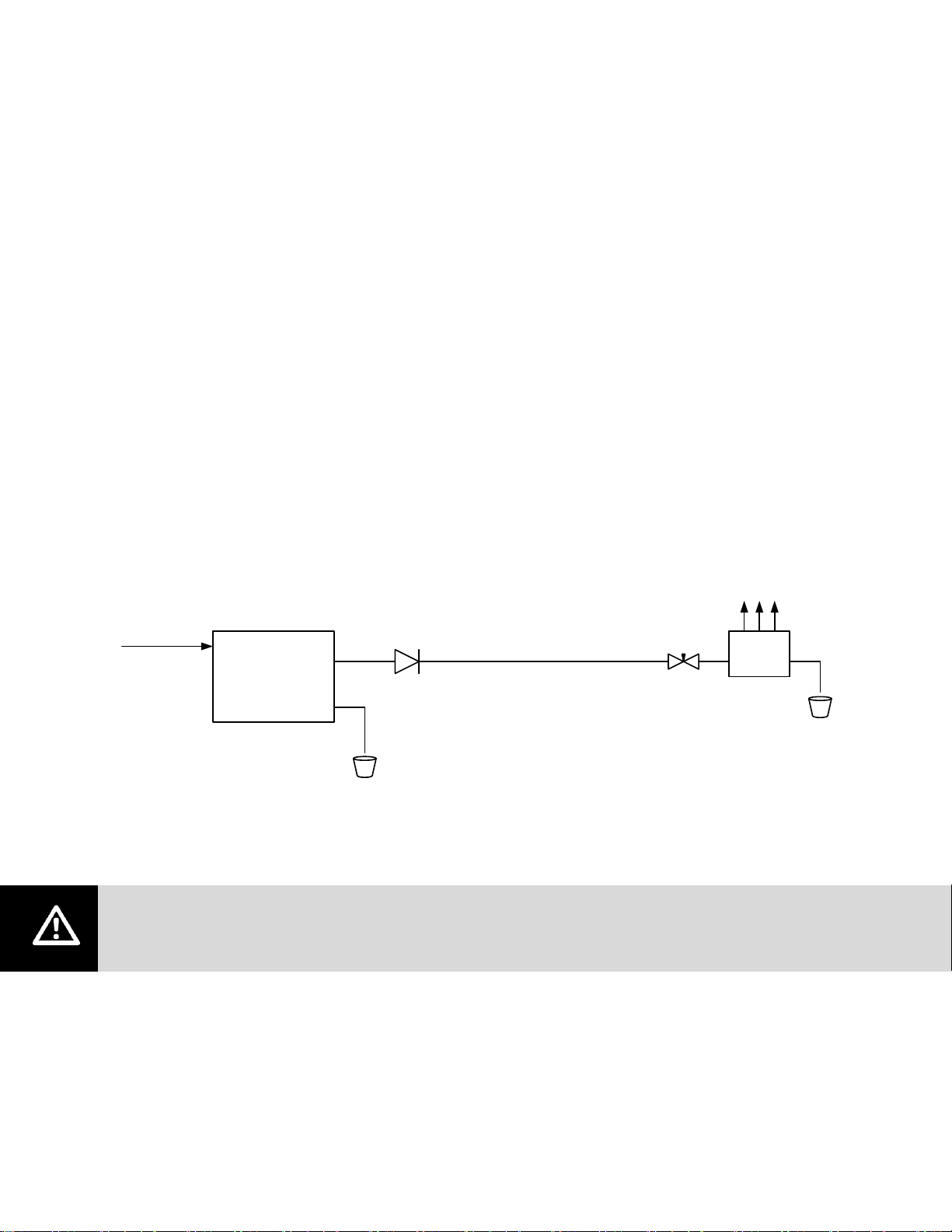

Pump Skid

Valve

Block

RO or DI Water

25 – 60 psig

Funnel drain

with air gap

Check valve

(2546701)

½” OD SS Tube

Needle Valve

(2527660)

To Manifolds In Duct

(3/8" OD SS Tube)

It is strongly recommended to flush all lines with clean with clean water prior to installation.

This prevents any accumulated dirt, loose flash, or metal fillings from degrading nozzle

performance.

Installation of the Piping Between Valve Block and Manifolds

The valve block should be located in such a way as to feed the manifolds using the supplied

piping and fittings. Refer to the piping diagram for your specific unit (On/Off, 3 Stage, 6 Stage).

For High-Resolution HP HVAC installations, refer to the piping diagram included in the

documentation package from proper piping.

It is helpful to place the valve block in its approximate location to assist with measuring piping

lengths and placing fittings. The valve block can be installed in the duct or outside of the duct.

The piping between the valve block and the manifolds should have a slight decline towards the

valve blocks. This allows for water to drain from the manifolds and lines when the system is not

in use.

In installations where water hammer is of concern, it is recommended to install some flexible

piping between the valve block and the manifold feed lines. Using flexible feed lines between

the valve block and the manifold supply piping can also simplify the installation procedure and

allow for some misalignment among the manifold feed lines and the valve block. The valves are

threaded to accept ½” G fittings.

A qualified plumber should install all pipe-fittings and perform connections.

Figure 13: Hydraulic Schematic for HP Systems

HP Series Installation Manual | 18

Page 22

3.1 in.

( 78 mm )

0.9 in.

( 23 mm )

O

0.5 in.

( 13 mm )

1.0 in.

( 24 mm )

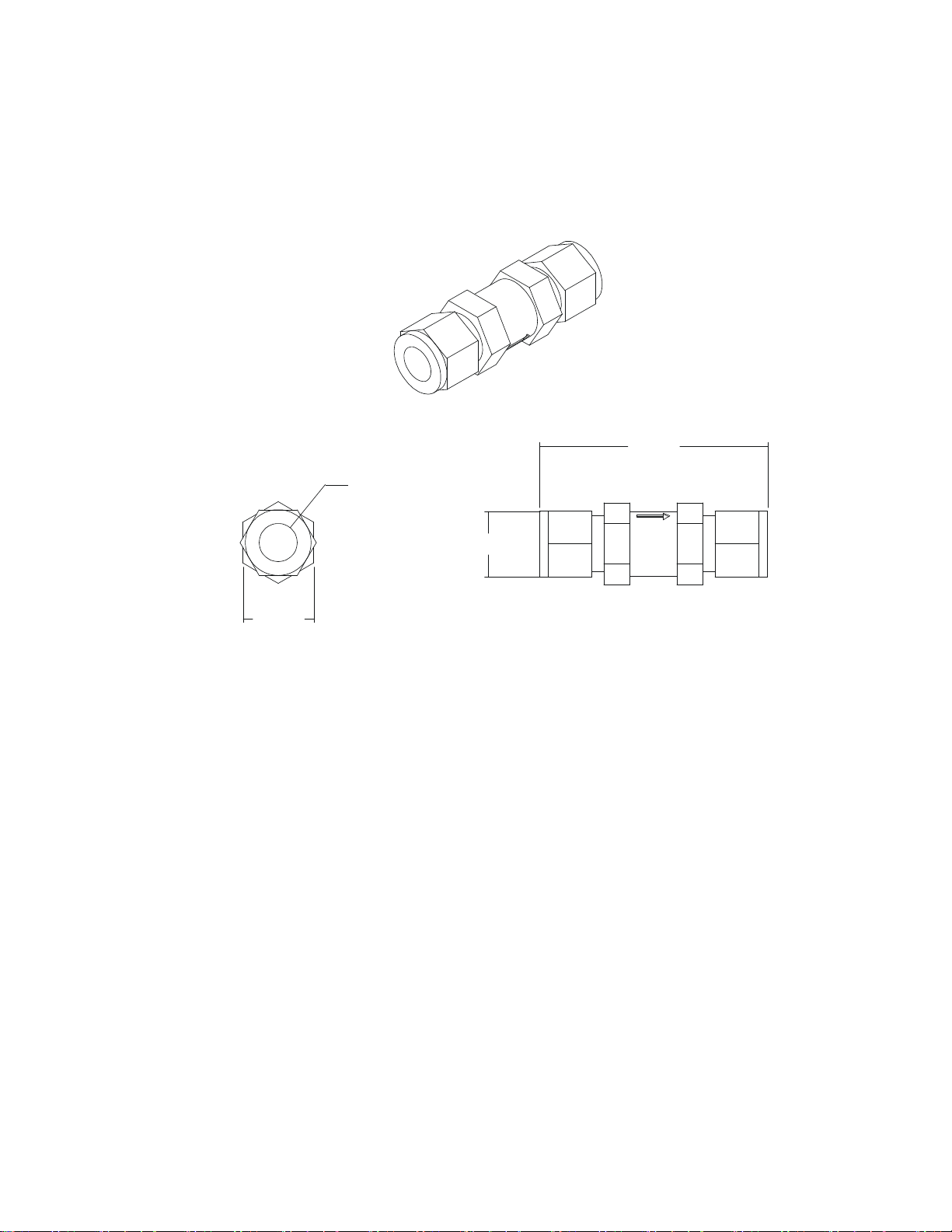

Check Valve

Install check valve as close to pump as possible

Ensure that arrow matches direction of flow.

Tighten compression fittings.

Figure 14: P/N 2546701 – Check Valve

Installation of the Needle Valve

Connection Type - ½” compression fittings on the inlet and outlet. Install near inlet to valve

block.

19 | HP Series Installation Manual

Page 23

Please refer to the valve block schematics for your specific unit in the Wiring Diagram Section

for clarification of the below instructions. For High-Resolution systems, please refer to the

schematics that were included in the documentation package.

Vibrations can be transmitted from air-handlers, the HP pump modules, or other mechanical

room equipment, it is strongly recommended to use a 2 ft (0.6 m) length of flexible piping at

the valve blocks, and HP pump module to protect the equipment from damage.

Install drain piping on the valve block. When the manifolds are not in use, they are drained to

prevent stagnant water, which can lead to microbial growth. The volume of water drained is

equal to the volume of the manifolds and their supply lines. The drain line can be solid pipe or

flexible hose for convenience. It must flow to an open-air funnel or nearby floor drain. The

water can also be reclaimed and returned to the RO system for processing.

The drain line must flow to an open-air funnel. Solid connection to a drain can result in

backflow, failure to drain, and dripping nozzles.

Installation of the Valve Block

Securely fasten the valve block in place. The valve block can either be installed inside or

outside of the duct, however installing in-duct reduces the quantity of holes which must be

drilled through the duct.

The valves have threaded connections with a ½” G thread. Connect the high-pressure supply

line from the pump to the valve block inlet. It is recommended to use a 2 foot flexible hose

connection between the pump supply line and soft charge valve block. This flexible line

prevents the transmission of vibrations through piping. If the pump is only a short distance

away it is recommended to use high pressure flexible hose for the entire run.

HP Series Installation Manual | 20

Page 24

21 | HP Series Installation Manual

Figure 15: Typical Valve Block Assembly

Page 25

Flush piping prior to installation to clear any debris. Debris will inhibit nozzle operation.

Flush low pressure piping with water prior to installation to clear any debris.

The valve controller should be located near the pump and valve blocks. Refer to schematics

for valve controller dimensions.

High Pressure Piping

Install high pressure piping between the valve blocks and the HP pump module. The valve

blocks are threaded to accept ½” G fittings. For short runs, it is recommended to install flexible

piping for this purpose. For longer runs use flexible piping at the pump outlet and valve inlet to

minimize vibration transmission. Ensure that flexible piping is rated for pressure and water type

in the application.

Low Pressure Piping

Low-pressure piping should be connected to the inlet of the pump. Ensure that water inlet

pressure is between 20 and 100 psig.

The pump inlet accepts a 3/4” NPT threaded connection. The low-pressure inlet connection

can be a flexible hose or a stainless steel pipe. Stainless steel pipe is recommended for longer

runs of piping, while flexible hose is recommended for shorter runs. If stainless lines are used,

it is recommended to install a length of flexible hose between the metal piping and the pump

inlet to minimize vibration transmission.

A drain line for the pump must also be connected; this line should connect flow to an open-air

funnel or floor drain to prevent backpressure on the pump. Water can also be reclaimed and

returned to the RO or DI system for processing. The pump drain port is threaded to accept a ¼”

NPT connection.

Valve Controller Installation

Using suitable screws, mount the control panel at a convenient height on a wall or suitable

structure.

Refer to the spec label on the valve controller; ensure that the voltage matches the electrical

voltage being supplied to it. In most cases this voltage will be 120VAC 60Hz single phase. At

this voltage, the controller draws 2.7A (except high resolution systems). Install a dedicated

disconnect on the electricity source to allow the controller to be isolated.

HP Series Installation Manual | 22

Page 26

Leave the disconnect in an open (off) position until all wiring has been completed

The humidifier will only operate if there is continuity between terminals 1 and 2. If no on/off style

safeties are to be used, install a jumper between terminals 1 and 2.

Connect the input voltage to the valve controller. Input voltage connections are clearly indicated

by labels inside of the valve controller box.

Wiring of the System

On-Off Safety Devices

Safety switches are available to prevent the humidifier from operating excessively or at incorrect

times. These may include; air proving switches (A), duct high limit switches (B), disable switches

(C), other on-off type devices.

Install these devices in accordance with their respective installation instructions. All on-off style

devices should be wired in series and connected between terminals 1 and 2 on the valve

controller terminal strip.

The circuit between terminals 1 and 2 is a 24VDC circuit, 16 or 18 AWG standard wire should

be used for this purpose.

23 | HP Series Installation Manual

Page 27

Figure 16: HP HVAC Terminal Strip

Installation Notes

Connect wiring as shown. Use 16 or 18 AWG standard wire.

For multiple On/Off safeties, connect devices in series.

Valve 2 and 3 connections not used for single stage systems.

Flush valve is always connected to valve controller terminals 13 (+) and 14 (-)

Pump controller terminal 9 (GND) is an available accessory ground.

Single Stage Control Options

Time proportioning control: Connect a 0-10 humidistat to valve terminals 3 and 4.

On/Off Control: Connect a humidistat between valve controller terminals 1 and 2. Also connect

a jumper between terminals 1 and 3.

HP Series Installation Manual | 24

Page 28

Pump Controller Wiring Notes

Connections to Nortec Valve Controller

The pump controller can accept control input from many different valve controllers at once. This

is useful for cases when a single large pump skid is used to supply high-pressure water to

different zones / manifold groups. For example, 1 large pump skid supplies water to 3 different

air-handlers, each with their own manifolds, valves, and valve controller.

If there are more than 4 valve controllers, additional controllers can be added by doubling up

wires on the pump controller terminal strip. For example; valve controller 5 would share

terminals 1 and 5 with valve controller 1.

Connections to Valve Controllers by Others

Non-Nortec valve controllers can be used with the HP HVAC system. In these cases the valve

controller is wired to the pump controller, as it would be with a Nortec valve controller. The

valve controller need only close the loop, and does not need to provide a voltage or current. If

the valve controller does provide a signal, it should be wired to a relay which will then close the

pump controller loop.

Remote Monitoring

The pump controller terminal strip features several sets of dry contacts to allow for connections

to a building management system, status lights, or other types of equipment. They are

controlled by a relay and activated under certain conditions. Wire gauge is determined by the

equipment to be using the contacts. Refer to the manufacturers recommendations.

On (Terminals 10 and 11): Closed when the HP HVAC system is powered on and ready.

Active (Terminals 12 and 13): Closed when the HP HVAC system is humidifying.

Service (Terminals 14 and 15): Closed when the HP HVAC system requires regular

maintenance. (See Chapter X for service information.)

Fault (Terminals 16, 17 and 18): Terminal 16 is normally open and closes when an operation

fault occurs. Terminal 18 is normally closed and opens when an operational fault occurs.

Terminal 17 is a common terminal for both cases.

25 | HP Series Installation Manual

Page 29

Figure 18: Valve Wiring

Figure 17: Valve Coils

HP Series Installation Manual | 26

Page 30

Mist Eliminator Installation

General

The Nortec Mist Eliminator is a single bank water droplet removal system installed at a predefined distance from the water entry point. The highly humidified air is to come into contact

with the Mist Eliminator and any un-absorbed droplets of water are removed from the air

stream. The collected water accumulates on the media then descends downward towards the

bottom of the Mist Eliminator. During this process much of the collected water is absorbed into

passing air while any remaining water is funneled to one of two drains via a pre-installed drain

pan. See Figure 19: Mist Eliminator Overview.

The Mist Eliminator is available in standard sizes ranging from 4ft high x 4ft wide to 12ft high x

20ft wide with 4ft increments between. If a duct size does not fall under one of our standard

sizes simply order the next larger size then cut to fit.

The drain pan is to be installed at the bottom of the plenum to remove the water collected by

the Mist Eliminator. The height of the drain pan should be not be any less than 3 inches

(7.5cm) and should extend past the filter bank 8 inches (20.3cm). A drain with trap before and

after the Mist Eliminator is required, shown in Figure 20: For this the duct‟s static pressure must

be known. The drain traps must be 2 inches larger than the duct‟s static pressure. Ensure that

the drain trap is filled with water prior commissioning a high-pressure system.

27 | HP Series Installation Manual

Figure 19: Mist Eliminator Overview

Page 31

Figure 20: Drainage and Drains

Figure 21: Mounting Angles

Installation of Mounting Angles

Measure the duct height and width.

Height = _________

Width = _________

The mounting angles are to completely surround the duct. Mark the duct floor with a line a

minimum of 8” from the end of the drain pan and perpendicular to the ducts airflow. Now

continue the line up vertically up the walls and finally across the ducts ceiling.

Each angle measures 95.5 inches. Enough length of angle is supplied to cover the perimeter of

the duct but they must be cut to fit. Over-lapping joints slightly is recommended for the floor

angles only as they should be sealed along the entire length of angle with appropriate caulking

to prevent free air flow through the drain pan. Angles may have to be cut in half to make-up two

4ft lengths. When securing the mounting angles to the duct place the side with circular holes

against the duct and the bent edge along the marked line.

Orient the mounting angle as shown in Detail A in Figure 21: Mounting Angles. Using field

supplied self taping screws attach the mounting angle to the duct via the round mounting holes.

A screw every 18 inches is recommended.

HP Series Installation Manual | 28

Page 32

Duct Width

Mounting Position

Number of Channels

4ft - 8ft

Middle

1

8ft - 12ft

Offset 2ft from middle

2

12ft - 16ft

Middle

3

16ft - 20ft

Offset 2ft from middle

4

Installation of Mounting Channels

Before installing the mounting channel or channels the starting mounting point needs to be

determinedusing the duct width. If the duct width is 4ft or less then there is no need for a

mounting channel, continue to the next step.

Table 1. Mounting Channel Locations

Once the mounting location is determined the mounting channel(s) are ready to be cut to fit,

keeping in mind that drain pans are not level and lengths may vary. From the starting point,

each additional mounting channel is placed at 4ft centers. In the figure below a typical 4ft x 8ft

installation is shown with the mounting angle surrounding the perimeter and a mounting

channel installed vertically at the center point of the duct.

In Figure 23: Large Duct Mounting Channel Locations, a 6ft high x 10ft wide mist eliminator

frame is shown. Notice how the mounting channel placement is offset from the center.

Installations between 8ft x 12ft to 16ft x 20ft may involve the removal of excess material.

Excess material is removed equally from both sides of the frame not from the middle.

To secure the mounting channel in place use the factory supplied ½ inch self-threading screws.

Use the center row of slotted holes to attach the mounting channel to the mounting angle.

Place one screw at the top and one at the bottom making sure that the mounting channel is

level or square to the ceiling, this will help for mounting the wire mesh. See Figure 24:

Mounting Channel Installation.

If the duct height greater than 8 feet a channel extension is needed in order to link 2 mounting

channels together. The extension slides inside the mounting channel. Use 4 ½ inch factory

supplied screws for each mounting channel as shown in Figure 25: Mounting Channel Extension

Kit.

29 | HP Series Installation Manual

Page 33

Figure 22: Mounting Channel Location

Figure 23: Large Duct Mounting Channel Locations

Figure 24: Mounting Channel Installation

Figure 25: Mounting Channel Extension Kit

HP Series Installation Manual | 30

Page 34

Installing 1 inch Screws/Studs

In the final step of this instruction Media Clamping Strips are used to secure the media to the

frame. In this step the screws used to fasten the Media Clamping Strip to the finished assembly

must be installed. Each Media Clamping Strip requires 3 screws evenly spaced. Clamping

strips are 46 inches in length upon arrival from the factory however if the Clamping Strip is cut

to fit the duct size it will still require 3 screws evenly spaced to properly secure it. After each

screw is installed use the factory supplied nuts to lock them in place.

Figure 26: 1 Inch Screw / Stud Installation

Installation of Wire Mesh

The 4ft wide Wire Mesh can now be cut to length (duct height or top mounting stud to bottom

mounting studs.) To fasten the Wire Mesh to the assembly use the factory supplied selfthreading ½ inch screws starting from the top angle and middle channels working out and

down. Be sure to install the wire mesh square when first fastened otherwise it will not align

properly at the opposing end. Notch around screws previously installed for best results.

31 | HP Series Installation Manual

Figure 27: Mesh Installation

Page 35

Media Installation

The recommended way to install the media is taking the entire roll and securing its leading edge

to the top of the assembly by working the 1inch screws/studs though the media, see Figure 28:

Mesh Installation. Then carefully rolling it downward until it reaches the bottom of the duct. Cut

the media at the bottom of the assembly to fit. Once cut, go back and work the rest of the

screws through the media. If the recommended method cannot be followed, use a flat, clean

surface to pre-cut the media. Be sure to cut the media with precision so not to be short on the

final section of the assembly.

Figure 28: Mesh Installation

Media Clamping Strip Installation

The final step is to secure all components of the assembly using the media clamping strip.

Place the strips so the 1 inch screw/studs pass through the slotted holes on the media

clamping strip then fasten a factory supplied nut to hold the assembly in place. See Figure 29:

Clamping Strip Installation.

Figure 29: Clamping Strip Installation

HP Series Installation Manual | 32

Page 36

33 | HP Series Installation Manual

Page 37

Startup, Operation, & Maintenance

HP Series Installation Manual | 34

Page 38

Under some circumstances humidistat wiring has not been completed at the time of

commissioning. For startup and testing procedures only:

- It is acceptable to use a jumper to close terminals 1 and 2.

- If no 10 Vdc signal is readily available, connecting a fresh 9V battery to terminals 3 and 4 will

simulate a demand signal. (Terminal 3 is negative, terminal 4 is positive.)

The air handler should be operating during this step.

Commissioning and Startup

Once the HP HVAC system has been installed, it can be commissioned. Prior to undertaking the

commissioning procedure ensure that the supply water system has been started and that a

supply of water is available.

1 Bleed the filters. For Giant pumps, open the water supply valve and press the red button.

For Danfoss pumps, disconnect the manifold supply line from the outlet of the pump and

wait until water begins to flow. It is helpful to connect a hose to the outlet and route to

drain.

2 Disconnect the manifold supply line from the outlet of the pump if not already done in step

1. Connect a hose and route to a suitable container.

3 Turn on pump and run for 1 minute. This will bleed the pump and clear any glycol used to

protect the pump during shipping. Temporarily connecting a jumper between terminals 1

and 5 on the pump controller terminal strip will activate the pump.

4 Reconnect the manifold supply line to the outlet of the pump.

5 Disconnect the manifold supply line at the inlet to the valve blocks. Connect a hose and

route to drain. In the case where 1 pump feeds multiple zones, work with only 1 zone at a

time.

6 Turn on the pump for several minutes and check for leaks. Again, the pump can be

activated temporarily using a jumper on terminals 1 and 5.

7 Reconnect the manifold supply line at the valve inlet.

8 Disconnect the manifolds from their individual feed lines ensuring that there is a provision

for drainage. This will allow for the valves and lines to be flushed and help protect the

nozzles.

9 Apply a 10 Vdc signal to the valve controller to activate it. Setting the humidistat to its

maximum value will provide this signal. If the humidifier will still not activate, ensure that all

safeties on valve controller terminals 1 and 2 are closed.

10 Start the pump in manual mode and check for leaks in the system.

35 | HP Series Installation Manual

Page 39

11 Shut the system off and reconnect the manifolds. Restart the system as per step 9 and

observe the spray patterns and check for leaks.

12 Ensure that the spray pattern is uniform does not strike duct walls.

13 Ensure that water collects in the drains and does not pool in the duct.

14 If a mist eliminator or cooling coil is used for mist elimination, ensure that no mist is passing

through.

15 Select AUTO on the pump skid, ensuring that all testing jumpers have been removed. The

system is now ready to run.

Calibration

The needle valve is used to reduce water that may occur when the valves open and close. For it

to work correctly, it must be calibrated.

1 Install the needle valve, and adjust the valve to the fully open position by turning the handle

counterclockwise.

2 Run the humidifier full output, so that all valves are open and all nozzles are spraying water.

3 Observe the nozzle spray near the top of the manifolds. Increase the flow restriction by

turning the needle valve clockwise until nozzle spray near the top of the manifolds begins to

visibly decrease.

4 Turn the needle valve two full turns counterclockwise. Turn the system off and back on.

5 Ensure that the water hammer has decreased. Observe the nozzles to ensure that they are

still spraying correctly. Note: After installing the needle valve, the manifolds may take a few

seconds to charge and begin spraying.

HP Series Installation Manual | 36

Page 40

HP HVAC High Pressure Atomizing Humidifiers Start-up Checklist

Humidifier Serial Number: ___________________________________________________

Tag / Zones Served: ___________________________________________________

Pump Model: ________________________ Pump Voltage: ____________________

System Configuration: On/Off

3-Stage

6-Stage

High-Resolution

Pump Inspection

RO or DI water supply connected

RO or DI water pressure between 20 and 60 psig (do not exceed 60psig)

Check valve installed on pump outlet (Danfoss PAH pumps only)

Drain line connected to pump

Supply voltage matches pump specification label

Valve Controller Inspection

120 VAC supply voltage connected

0-10V control signal connected to terminals 3 and 4

On/Off safety devices (or jumper) connected to 1 and 2

Valve Block Inspection

Valve coils wired to valve controller

High pressure supply connected and tight

Drain line connected

High pressure supply lines flushed

Manifold supply lines connected

Manifold Inspection

Air-handler drains are connected and open

Nozzle manifolds are securely mounted

Mist eliminator installed (if applicable)

Certification

Water piping is free of leaks

Pump is installed and operating normally

Manifolds and valves installed and operating normally

Installed by: ___________________________________________________________________

(Company Name and Business Address)

Inspected by: ___________________________________________________________________

(Company Name and Business Address)

Signed: ____________________________ Date: _______________________

37 | HP Series Installation Manual

Page 41

Operation

When the humidification system has been installed and commissioned it will function as

follows:

1 The humidistat calls to the valve controller for humidity.

2 If On-Off Safety controls (air proving, high limit humidistat) are closed, the humidifier will

activate.

3 The pump module will activate and charge the lines to 1000psi.

4 The soft charge valves will open, softly charging the manifolds to prevent water hammer

effects.

5 The valve assembly will open valves as needed to provided water flow to the manifolds. The

manifolds will then spray water into the air stream, humidifying the air.

6 When the humidity targets have been met, the valve controller will close the valves and shut

off the pump, stopping the spray of water.

7 Water will drain from the manifolds to reduce the microbial growth that may occur in

standing water. An air break cap at the top of the manifolds will allow air to enter the lines

to facilitate this process.

8 Once every 24 hours, the valve controller will activate the system for 2 minutes to purge the

lines of any standing water. This process occurs regardless of demand for humidity at that

time.

HP Series Installation Manual | 38

Page 42

1 stage (on/off) valve assembly:

Stage 0

Valve 1 "OFF" - 0% Output

Stage 1

Valve 1 "ON" - 100% Output

3 stage valve assembly:

Stage 0

Valve 1,2 "OFF" - 0% Output

Stage 1

Valve 1 "ON" - 33% Output

Stage 2

Valve 2 "ON" - 66% Output

Stage 3

Valve 1 and 2 "ON" - 100 % Output

6 stage valve assembly:

Stage 0

Valve 1,2,3 "OFF" - 0% Output

Stage 1

Valve 1 "ON" - 17% Output

Stage 2

Valve 2 "ON" - 33% Output

Stage 3

Valve 3 "ON" - 50% Output

Stage 4

Valve 1 and 3 "ON" - 67% Output

Stage 5

Valve 2 and 3 "ON" - 83% Output

Stage 6

Valve 1, 2, and 3 "ON" - 100% Output

Staging for High-Resolution systems are unique to each installation. Please refer to the

documentation package that accompanies the humidifier for further information.

The service indicator light will not illuminate to indicate that the break-in period has elapsed.

Table 2. Valve Staging

Maintenance

Triplex Ceramic Plunger Pump Maintenance

1 The triplex ceramic plunger pumps (pump skids with Giant pumps) are oil lubricated and

require maintenance. The pump has a break-in period of 50 hours. After this time has

elapsed, the crankcase oil must be changed.

2 After the initial break-in period, the oil must be changed every 500 hours. The Service

indicator light will illuminate after 400 hours of run time. The pump will then continue to run

for another 100 hours before shutting down. The service and fault indicator lights will

illuminate to indicate this condition.

3 Remember 500 hours is:

Every 9 weeks if operated for 8 hours every day.

Every 3 weeks if operated continuously for 24 hours per day.

39 | HP Series Installation Manual

Page 43

Pump Model

Oil Capacity - Do Not Overfill

Giant P205REIB

9 fl. oz

Giant P208REIB

9 fl. oz

Giant P217REIB

9 fl. oz

Giant P218REIB

9 fl. oz

Giant P219REIB

9 fl. oz

Giant P220REIB

9 fl. oz

Giant P56W

14 fl. oz

Giant P420A

30 fl. oz

- Synthetic 75w-90 grade oil is recommended for all applications (Mobile1 or equivalent).

- Synthetic 15w-50 grade oil can be used as an alternate grade. (Mobile1 or equivalent).

- All labels on pump supersede this manual.

Incorrect oil grades can cause pump damage. Damage resulting from incorrect oil grades is

considered misuse and is not covered by warranty.

4 Changing Oil:

Identify your pump from the figures on the adjacent page.

Remove the oil fill cap and the oil drain plug(s).

Dispose of spent oil as per local regulations.

Reinstall the drain plug(s). Torque to 18 lb-ft (hand tight). Do not over tighten.

Add recommended amount of oil to crankcase. Refer to the chart below for oil capacities.

Ensure that oil reaches the center of sight glass. Do not overfill.

Reinstall the oil fill cap.

Press the reset rocker switch inside the pump controller to reset the counter and shutoff the

service indicator.

Table 3: Crankcase Oil Capacity

HP Series Installation Manual | 40

Page 44

Figure 30: P200 Series Pumps

Figure 32: P420A Pumps

Figure 31: P56W Pump

41 | HP Series Installation Manual

Page 45

Resetting the counter without changing the pump head will allow the pump to be run to

destruction without further warning. Nortec strongly recommends against this, and cannot

offer warranty on downstream components damaged by pump debris resulting from pumps

run past 8000 hours.

Operation

Service Interval

Standard (6 hours/day

Every 3 years

Severe (18 hours/day)

Every year

Seasonal (2000 hours per season)

Beginning of each season

Frame Size

Relubrication Amounts

Volume cu. in.

Fluid oz.

56

0.25

0.14

145

0.25

0.14

180

0.50

0.28

210

0.75

0.42

Danfoss Stainless Steel Axial Piston Pump

1 The stainless steel axial piston pump is water lubricated and does not require any

maintenance. This pump has a lifespan of 8000 hours, after which time pump wear will

reduce its efficiency. If the pump is removed from service at 8000 hours it can usually be

rebuilt and receive another service life.

2 The service indicator light will illuminate after 7900 hours of operation. The pump will

continue to operate for another 100 hours after which time the service and fault indicators

will illuminate and the pump will shut down. Nortec recommends replacing the pump at this

time. Contact your local Nortec representative for further information.

3 After the pump head has been changed, press the reset switch inside the pump controller

housing to reset the service indicator and 8000 hour counter.

Electrical Motor Service

1 Two types of electrical motors are used to drive the pumps; those with sealed rotor bearings

and those with external greased bearings. The sealed rotor bearing types are maintenance

free, while the external bearing types require periodic lubrication. Please refer to the

nameplate on the motor to identify which motor you have.

Table 4. Electrical Motor Service

Table 5. Lubricant Volumes

2 Electrical motors on the pump modules are pre-greased with a polyurea mineral oil NGLI

grade 2-type grease unless stated otherwise on the motor nameplate. Some compatible

brands of polyurea mineral base type grease are: Chevron SRI#2, Rykon Premium #2, Shell

Oil Doilum R, and Texaco Polystar RB. Motors are properly lubricated at time of manufacture

and do not need to be lubricated at the time of installation.

HP Series Installation Manual | 42

Page 46

Over greasing bearings can cause premature bearing and/or motor failure. The amount of grease

added to the motor should be carefully controlled.

Wear eye protection during this procedure.

Inlet Water Filters

The 10 micron water filters must be inspected periodically. Inspection is accomplished by

comparing the pressure valves on the filter inlet and outlet sides. When the pressure drop

across the filters reaches or exceeds 10 psi, the filters are considered spent and should be

replaced. The longevity of the filters depends entirely on the quality of the water being supplied

to the pump. Nortec recommends replacing the filters at a once per year as preventative

maintenance regardless of measured pressure drop.

Steps:

1 Turn the pump controller to off.

2 Turn the supply water valve to off.

3 Using a filter wrench, remove the filter housings.

4 Replace filter cartridges paying attention to any directional arrows.

5 Reinstall the filter housings, tighten hand tight with the filter wrench.

6 Turn the supply water back on.

7 Turn the power back on.

High and Low Pressure Lines and Hoses

The hoses and lines should be periodically inspected for damage, cracking, leaking. Ensure that

the pipes are rubbing on any vibrating equipment.

Atomization Nozzles

The Nortec HP HVAC system is designed to operate only on reverse osmosis or de-ionized water

supplies. This allows for long trouble free operation of the nozzles. Occasionally because of

either water quality or dirt, an atomization nozzle may become blocked. With the system

running, use a nozzle cleaning tool, or .007” (0.177mm) wire inside the nozzle orifice. Spin the

tool around until the blockage dislodges. If you are still unable to clear the blockage, contact

Nortec for a replacement nozzle.

A proper spray pattern should be circular and measure 2” (50mm) across at a distance of 2”

(50mm) from the nozzle. See Figure 33 Nozzle Spray Pattern.

Please refer to Figure 34: Nozzle Components for assembly and disassembly of nozzle

components.

43 | HP Series Installation Manual

Page 47

Figure 33: Nozzle Spray Pattern

Figure 34: Nozzle Components

Do not use any solvents or chemicals for cleaning mist eliminator media. Odors produced

could be harmful to occupants downstream. As well, chemicals and solvents could degrade

the fire and antibacterial coatings on the media.

Mist Eliminator Maintenance

1 The HP HVAC system should typically be installed downstream of air filters to minimize Mist

Eliminator maintenance. In any case, Nortec recommends an annual inspection of mist

eliminator media.

2 If the media is becoming contaminated with dust, it should be removed and cleaned with a

vacuum or gentle water spray.

3 For optimum performance, Nortec recommends replacing mist eliminator media annually.

End of Season Shutdown

1 At the end of a humidification season the system can either be left in standby or shutdown

for the off-season.

2 A properly installed system can be left in stand-by as it will flush itself automatically. It may

save time and maintenance to allow the HP HVAC system to stay active in standby mode

during an off-season. Please note that in standby mode the system will consume some

water periodically to flush itself.

HP Series Installation Manual | 44

Page 48

Stainless steel pumps should not be inactive for more than 2 weeks without following the above

shutdown procedure.

3 The system can also be shut down for the off-season. If the system is to be shutdown for an

extended period of time, all automatic drain valves should be removed and the system

completely flushed. Then all water remaining in the lines should be air purged. The supply

water to the pump module should be turned off. Empty filter housings of any remaining

water and replace filter cartridges with new dry cartridges. Turn off electrical power to the

pump module. This will protect against corrosion and damage to the pump and lines.

Decommissioning / Freeze Protecting

If the system is to be decommissioned (shut-down for an extended period of time), or stored in a

cold area, the following procedure is applicable:

1 Disconnect the low pressure line at the inlet of the pump.

2 Connect the pump inlet to a canister containing a mixture of 35% glycol and water.

3 Disconnect the high pressure supply line at the inlet to the valve block.

4 Run the pump briefly to circulate the glycol mixture through the pump and supply lines.

5 Reconnect the high pressure supply lines to the valve block.

6 Disconnect the glycol canister and cap the pump inlet.

7 Decommission the RO system as per manufactures instructions (if applicable).

Inlet Water Pressure Switch

The inlet water pressure switch is hydraulically actuated, and completes a 24Vac control circuit.

The switch is rated to 150 psi, and cut off sensitivity is adjustable between 12 and 100 psi.

This switch is preset at 20 psi at the factory and does not require adjustment.

45 | HP Series Installation Manual

Page 49

Troubleshooting

Troubleshooting | 46

Page 50

Problem

Cause / Solution

Recommendations

Pump module will not run.

The power supply to pump is

off and needs to be turned on.

Turn the power supply on.

Circuit breaker has interrupted

the pumps power supply.

Check that the power supply connection to

pump is wired correctly.

The power supply circuit could be overloaded.

Motor contactor is not making

contact.

Check for correct voltage on transformer

120/208/230/460/575.

Breaker on 24 VAC control circuit has blown,

check for short circuit.

Check alignment and operation of contactor

mechanism.

Contact surfaces of contactor may be

damaged.

Check low inlet water pressure.

VFD has faulted out.

Reset, check error messages for more

information.

The pump motor may be

damaged.

The motor bearings may be damaged and

have caused a lock up. Inspect and replace if

necessary.

The motor may have shorted or have been

single phased or overloaded without

protection.

Pump head mechanism may

have been damaged.

Brass pump crank bearings/connecting rods

may have become damaged /frozen causing

the motor to lock up. Disassemble pump head

and repair/replace as required.

Pump module has stopped

running and red lamp is on.

Thermal overload circuit has

blown. The pump module

motor could have overheated

and its thermal protection

circuit needs reset.

Check motor FLA rating and check overload

setting.

Check for a short in the circuit running

optional control equipment.

Reset Overload and measure actual motor

amp draw.

The pump module must never be operated

above 1200 P.S.I. (83 BAR).

Proper ventilation must be provided to prevent

the motor from over-heating.

The motor may be operating outside its‟

service factor as a result of power supply low

voltage.

A combination of all of the three previous

points could be in effect.

Table 6: Troubleshooting

47 | Troubleshooting

Page 51

Transformer may be faulty.

Check transformer line voltage and secondary

voltage.

Pump module has stopped

running.

Inlet water pressure has

dropped below 20 PSI.

Check inlet water pressure for low conditions.

You may have to monitor gauge for water

fluctuations.

Water leaks out of thermal

valve.

Water is being restricted from

leaving the pump module and

it is over heating.

Make sure enough nozzles are running to

permit enough water to flow from pump

module to keep it cool.

Filter housing leaks.

O-ring may be displaced or

broken.

Inspect and replace if necessary.

Housing could be cracked.

If water freezes in housing it will be damaged.

Pump module runs but

there is no fog coming out of

the nozzles.

There may be a large leak in

the high-pressure plumbing of

the system

You have loose or missing atomization

nozzles.

A reusable hose fitting or manifold connection

has come loose or has not been made

correctly.

The drain solenoid on the pump module is

stuck open allowing all the pumped water to

leave the system.

An auto drain valve on manifolds isn‟t closing,

verify that the sealing ball is seating properly.

Pump module runs but

there is no fog coming out of

the nozzles.

The water pressure regulator

on the pump module may be

completely backed off.

Check pressure gauge = 1000 psi. Turn the

hand wheel on the regulator clockwise to

increase pressure to 1000 psi.

Valve controller may be

restricting the flow of water to

any of the nozzles.

The pump must never be ran without any high

pressure water leaving the system, otherwise

the pump will overheat.

The low inlet water pressure

safety switch may not be

isolating the pump and

allowing it to run without water.

A very dangerous situation, the pump needs

water to run cool. Check the inlet water

supply and integrity of the pressure switch.

Troubleshooting | 48

Page 52

49 | Troubleshooting

Page 53

Spare Parts

Spare Parts | 50

Page 54

13

12

14

1

This pump c a n either be a stainless

steel pump (as shown) or a triplex

ceramic plunger pump.

15

4

Medium Pump Module Spare Parts

2

Motor shown here is equipped

with a variable freq uency drive,

whic h is an option.

6

5

7

3

8

910

51 | Spare Parts

11

Figure 35: Medium Pump Module Spare Parts

Page 55

5

7

8 9 10 11

3

17

18

5

13

Large Pump Module Spare Parts

16

15

1

This pump can either be a stainless

steel p um p (as sho wn) o r a trip lex

ceramic plunger pump.

Detail View

19

2

Motor shown here is equipped with a

variable frequency drive, which is an

option.

Figure 36. Large Pump Module Spare Parts

Spare Parts | 52

Page 56

Nortec P/N

Item Number

Pump Model

1 2 3 4 5

6

7

Nortec

Part #

Giant

Pumps, No

VFD

Pump

Motor

VFD

PRV

LP Gauge

HP Gauge

20” Filter

Cartridge

10 NOM

20” Filter

Cartridge

10 Abs

10” Filter

Cartridge

10 Abs

1507176

G500 PM

120V/1ph

1504261

1504210

x

1502839

1507311

1601109 x x

1504311

1507169

G500 PM

230V/1ph

1504261

1504210

x

1502839

1507311

1601109 x x

1504311

1507149

G500 PM

230V/3ph

1504261

1504215

x

1502839

1507311

1601109 x x

1504311

1507154

G500 PM

460V/3ph

1504261

1504215

x

1502839

1507311

1601109 x x

1504311

1507159

G500 PM

575V/3ph

1504261

1506563

x

1502839

1507311

1601109 x x

1504311

1507175

G850 PM

120V/1ph

1504197

1504211

x

1502839

1507311

1601109 x x

1504311

1507170

G850 PM

230V/1ph

1504197

1504211

x

1502839

1507311

1601109 x x

1504311

1507150

G850 PM

230V/3ph

1504197

1504579

x

1502839

1507311

1601109 x x

1504311

1507155

G850 PM

460V/3ph

1504197

1504579

x

1502839

1507311

1601109 x x

1504311

1507160

G850 PM

575V/3ph

1504197

1506563

x

1502839

1507311

1601109 x x

1504311

1507174

G1100 PM

120V/1ph

1504259

1504211

x

1502839

1507311

1601109 x x

1504311

1507171

G1100 PM

230V/1ph

1504259

1504211

x

1502839

1507311

1601109 x x

1504311

1507156

G1100 PM

460V/3ph

1504259

1504579

x

1502839

1507311

1601109 x x

1504311

1507161

G1100 PM

575V/3ph

1504259

1506563

x

1502839

1507311

1601109 x x

1504311

1507172

G1550 PM

230V/1ph

1504265

1504212

x

1502839

1507311

1601109 x x

1504311

1507152

G1550 PM

230V/3ph

1504265

1504216

x

1502839

1507311

1601109 x x

1504311

1507157

G1550 PM

460V/3ph

1504265

1504216

x

1502839

1507311

1601109 x x

1504311

1507162

G1550 PM

575V/3ph

1504265

1506563

x

1502839

1507311

1601109 x x

1504311

1507153

G2300 PM

230V/3ph

1504196

1504217

x

1502839

1507311

1601109 x x

1504311

1507158

G2300 PM

460V/3ph

1504196

1504217

x

1502839

1507311

1601109 x x

1504311

1507163

G2300 PM

575V/3ph

1504196

1506562

x

1502839

1507311

1601109 x x

1504311

1505599

G3500 PM

230V/3ph

1505608

1505609

x

1502839

1504307

1601109

1505622

1505621

x

1505600

G3500 PM

460V/3ph

1505608

1505609

x

1502839

1504307

1601109

1505622

1505621

x

1505601

G5450 PM

230V/3ph

1505619

1504219

x

1505639

1504307

1601109

1505622

1505621

x

1505602

G5450 PM

460V/3ph

1505619

1504219

x

1505639

1504307

1601109

1505622

1505621

x

1507165

G5450 PM

575V/3ph

1505619

1506149

1505639

1504307

1601109

1505622

1505621

x

Table 7: HP Spare Parts

53 | Spare Parts

Page 57

Nortec P/N

Item Number

Pump Model

1 2 3 4 5

6

7

Part #

Giant Pump,

With VFD

Pump

Motor

VFD

PRV

LP

Gauge

HP

Gauge

20” Filter

Cartridge

10 NOM

20” Filter

Cartridge

10 Abs

10” Filter

Cartridge

10 Abs

1506934

GVFD950 PM

230V/3ph

1504259

1506495

1506492

1502839

1504307

1601109

1505622

1505621

x

1506929

GVFD950 PM

460V/3ph

1504259

1506495

1506482

1502839

1504307

1601109

1505622

1505621

x

1506939

GVFD950 PM

575V/3ph

1504259

1506494

1506479

1502839

1504307

1601109

1505622

1505621

x

1506935

GVFD1650

PM 230V/3ph

1504259

1506495

1506492

1502839

1504307

1601109

1505622

1505621

x

1506930

GVFD1650

PM 460V/3ph

1504259

1506495

1506482

1502839

1504307

1601109

1505622

1505621

x

1506940

GVFD1650

PM 575V/3ph

1504259

1506494

1506479

1502839

1504307

1601109

1505622

1505621

x

1506936

GVFD2100

PM 230V/3ph

1504259

1505119

1506491

1502839

1504307

1601109

1505622

1505621

x

1506931

GVFD2100

PM 460V/3ph

1504259

1505119

1506481

1502839

1504307

1601109

1505622

1505621

x

1506941

GVFD2100

PM 575V/3ph

1504259

1503891

1506478

1502839

1504307

1601109

1505622

1505621

x

1506937

GVFD3500

PM 230V/3ph

1505608

1505120

1506490

1502839

1504307

1601109

1505622

1505621

x

1506932

GVFD3500

PM 460V/3ph

1505608

1505120

1506480

1502839

1504307

1601109

1505622

1505621

x

1506942

GVFD3500

PM 575V/3ph

1505608

1506493

1506477

1502839

1504307

1601109

1505622

1505621

x

2532703

GVFD5000

PM 230V/3ph

2532707

1505121

1509709

1505639

1504307

1601109

1505622

1505621

x

2532705

GVFD5000

PM 460V/3ph

2532707

1505121

1509705

1505639

1504307

1601109

1505622

1505621

x

2532706

GVFD5000

PM 575V/3ph

2532707

1506149

1509706

1505639

1504307

1601109

1505622

1505621

x

Spare Parts | 54

Page 58

Nortec P/N

Item Number

Pump Model

1 2 3 4 5

6

7

Part #

Danfoss

Pump, No

VFD Header

Pump

Motor

VFD

PRV

LP

Gauge

HP

Gauge

20” Filter

Cartridge

10 NOM

20” Filter

Cartridge

10 Abs

10” Filter

Cartridge

10 Abs

1507182

D500 PM

120V/1ph

1506430

1504210

x

1503900

1506729

1506377 x x

1507033

1507177

D500 PM

230V/1ph

1506430

1504210

x

1503900

1506729

1506377 x x

1507033

1506555

D500 PM

230V/3ph

1506430

1504216

x

1503900

1506729

1506377 x x

1507033

1506545

D500 PM

460V/3ph

1506430

1504216

x

1503900

1506729

1506377 x x

1507033

1506560

D500 PM

575V/3ph

1506430

1506563

x

1503900

1506729

1506377 x x

1507033

1507181

D1100 PM

120V/1ph

1506429

1504210

x

1503900

1506729

1506377 x x

1507033

1507178

D1100 PM

230V/1ph

1506429

1504210

x

1503900

1506729

1506377 x x

1507033

1506554

D1100 PM

230V/3ph

1506429

1504216

x

1503900

1506729

1506377 x x

1507033

1506544

D1100 PM

460V/3ph

1506429

1504216

x

1503900

1506729

1506377 x x

1507033

1506559

D1100 PM

575V/3ph

1506429

1506563

x

1503900

1506729

1506377 x x

1507033

1507179

D1800 PM

230V/1ph

1503899

1504212

x

1503900

1506729

1506377 x x

1507033

1506553

D1800 PM

230V/3ph

1503899

1504216

x

1503900

1506729

1506377 x x

1507033

1506543

D1800 PM

460V/3ph

1503899

1504216

x

1503900

1506729

1506377 x x

1507033

1506558

D1800 PM

575V/3ph

1503899

1506563

x

1503900

1506729

1506377 x x

1507033

1506552

D2900 PM

230V/3ph

1505122

1504217

x

1503900

1505279

1506377

1505622

1507034

x

1506108

D2900 PM

460V/3ph

1505122

1504217

x

1503900

1505279

1506377

1505622

1507034

x

1506557

D2900 PM

575V/3ph

1505122

1506562

x

1503900

1505279

1506377

1505622

1507034

x

1506551

D3650 PM

230V/3ph

1505123

1505609

x

1503900

1505279

1506377

1505622

1507034

x

1506542

D3650 PM

460V/3ph

1505123

1505609

x

1503900

1505279

1506377

1505622

1507034

x

1506556

D3650 PM

575V/3ph

1505123

1506709

x

1503900

1505279

1506377

1505622

1507034

x

55 | Spare Parts

Page 59

Nortec P/N

Item Number

Pump Model

1 2 3 4 5

6

7

Part #

Danfoss

Pump, With

VFD

Pump

Motor

VFD

PRV

LP

Gauge

HP

Gauge

20” Filter

Cartridge

10 NOM

20” Filter

Cartridge

10 Abs

10” Filter

Cartridge

10 Abs

1506404

DVFD500 PM

230V/3ph

1506430

1506495

1506492

1503900

1505279

1506377

1505622

1507034

x

1506390

DVFD500 PM

460V/3ph

1506430

1506409

1503900

1506729

1506377 x x

1507033

1506394

DVFD500 PM

575V/3ph

1506430

1506494

1506479

1503900

1505279

1506377

1505622

1507034

x

1506403

DVFD1100 PM

230V/3ph

1506429

1506495

1506492

1503900

1505279

1506377

1505622

1507034

x

1506389

DVFD1100 PM

460V/3ph

1506429

1506408

1503900

1506729

1506377 x x

1507033

1506393

DVFD1100 PM

575V/3ph

1506429

1506494

1506479

1503900

1505279

1506377

1505622

1507034

x

1506402

DVFD1800 PM

230V/3ph

1503899

1505119

1506491

1503900