Page 1

GS Series

GSTC/GSP Indoor

GSTC Out door

Engineering Manual

1503540-C

Page 2

PROPRIETARY NOTICE

This document and the information disclosed herein are proprietary data of WALTER MEIER LTD.

Neither this document nor the information contained herein shall be reproduced used, or disclosed to

others without the written authorization of WALTER MEIER LTD., except to the extent required for

installation or maintenance of recipient’s equipment. All re ferences to the NORTEC name should be

taken as referring to WALTER MEIER LTD.

LIABILITY NOTICE

NORTEC does not accept any liability for installations of humidity equipment installed by unqualified

personnel or the use of parts/components/equipment that are not authorized or approved by

NORTEC.

COPYRIGHT NOTICE

Copyright 2008, WALTER MEIER LTD. All rights reserved.

RECORD OF REVISIONS

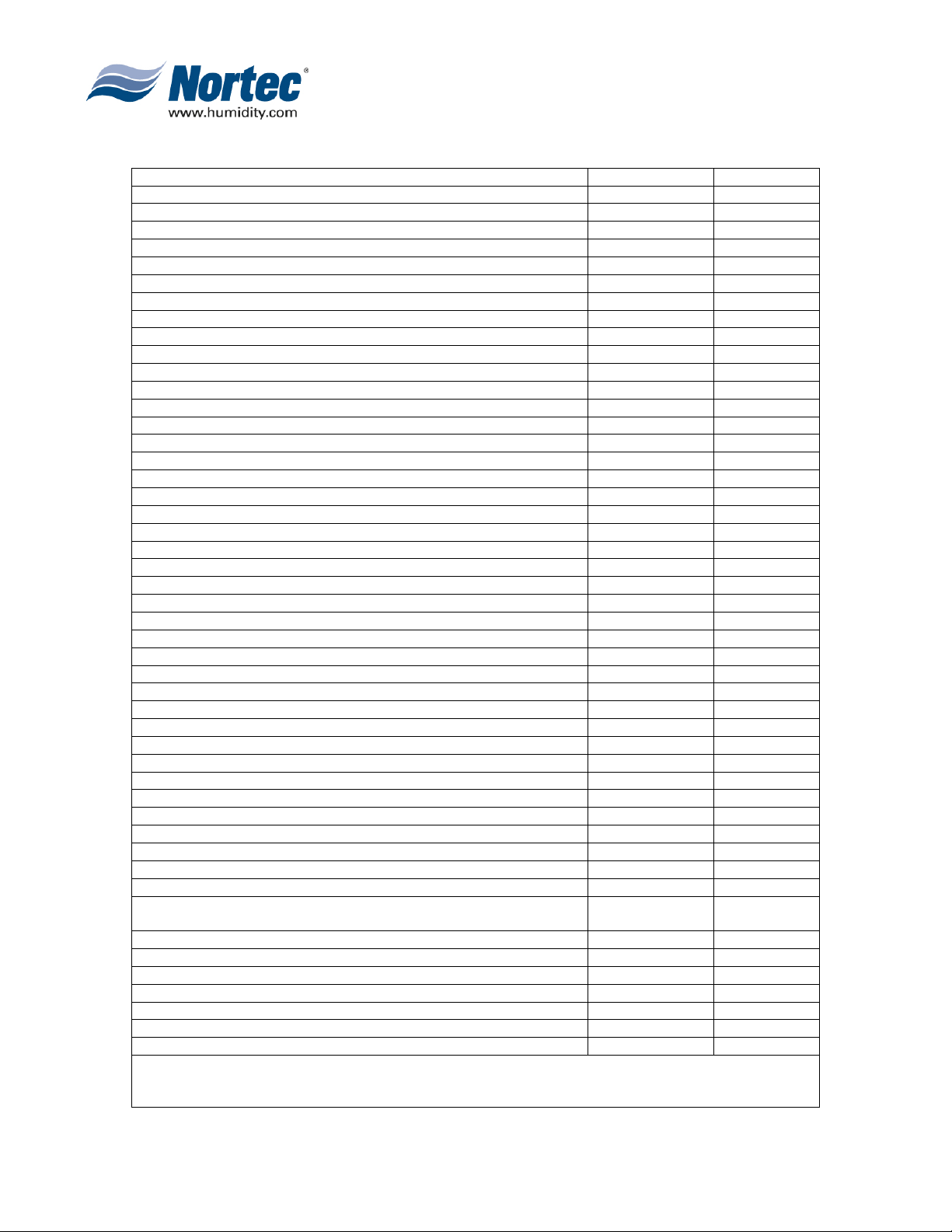

For each revision, put the revised pages in your manual and disca rd the superseded pages. W rite the

revision number and revision date, date put in manual, and the incorporator’s initials in the applicable

columns on the Record of Revisions.

Revision

Number

Revision

Date

Date Put

In Manual By

Revision

Number

Revision

Date

Date Put

In Manual By

2008-10-01

Page 3

TABLE OF CONTENTS

Subject Page

10-00 PRINCIPLE OF OPERATION

1. PRINCIPLE OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

A. COMBUSTION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

10-10 OPERATION

1. WATER MANAGEMENT - BETTER EFFICIENCY THAN EVER . . . . . . . . . . . . . . . . . . . . . . . . . . 8

A. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

B. SAFETY WATER LEVEL CONTROL CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

C. SELF DIAGNOSTIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

D. ENERGY EFFICIENT BLOWDOWN SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

E. INTERNAL DRAIN WATER TEMPERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

F. CAPACITY TURN DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

G. GSTC UNIT NEWTWORKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2. CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

A. INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

B. REMOTE FAULT INDICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

C. MODULATING CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

D. ON/OFF CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3. ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5. CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6. STEAM INSTALLATION GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7. CALCULATION OF ANNUAL OPERATING COSTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

A. NATURAL GAS HUMIDIFIER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

B. ELECTRIC GAS HUMIDIFIER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

C. OPERATING COST SAVINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

10-20 MAINTENANCE

1. WATER CONDITIONS VS. HUMIDIFIER CLEANING REQUIREMENTS . . . . . . . . . . . . . . . . . .18

2. PREVENTIVE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. PRE-CLEANING SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

10-30 OPTIONS & ACCESSORIES

1. OPTIONS AND ACCESSORIES AVAILABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

A. NORTEC MODULATING HUMIDISTAT WITH DIGITAL DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

B. HUMIDISTAT WITH INTEGRAL SENSOR AND CONTROLLER WITH DIGITAL DISPLAY . . . . . . . . . 22

C. HUMIDISTAT WITH INTEGRAL SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

D. NORTEC ON/OFF CONTROLS WITH DIGITAL DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

E. CONFIGURATION OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

F. DIRECT VENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

G. STAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

H. KEEP WARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

I. INDOOR FREEZE PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

J. OUTDOOR FREEZE PROTECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2008-10-01

Page 4

K. ON-LINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

L. LINKS 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

M. OUTDOOR 120 VAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

N. DRAIN WATER SUMP PUMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

O. STEAM DISTRIBUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

P. REMOTE MOUNTED BLOWER PACK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Q. SHORT ABSORPTION MANIFOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

10-40 SPECIFICATION

1. GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

A. QUALITY ASSURANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

B. SUBMITALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

C. EXTRA MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

D. REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

E. COORDINATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2. PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

A. GAS FIRED STEAM HUMIDIFIER - GSTC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3. EXAMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A. EXAMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

B. INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

C. TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

D. TRAINING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

WARRANTY

2008-10-01

Page 5

LIST OF FIGURES

Figure Page

10-00 PRINCIPLE OF OPERATION

Figure 1. GS Indoor Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Figure 2. GS Outdoor Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Figure 3. GSTC Key Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 4. GSP Key Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

10-10 OPERATION

Figure 1. Humidifier Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 2. Physical Dimensions - GS Indoor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 3. Physical Dimensions - GS Outdoor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 4. GSTC / GSP Indoor Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. GSTC Outdoor Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

10-30 OPTIONS & ACCESSORIES

Figure 1. NORTEC LINKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 2. NORTEC OnLine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Figure 3. Steam Distributor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 4. Blower Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Figure 5. Short Absorption Manifold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2008-10-01

Page 6

LIST OF TABLES

Table Page

10-00 PRINCIPLE OF OP ERA T ION

Table 1. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2. Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2008-10-01

Page 7

THIS PAGE INTENTIONALLY LEFT BLANK

2008-10-01

Page 8

10-00

PRINCIPLE OF

OPERATION

10-00

Page 1

2008-10-01

Page 9

1. PRINCIPLE OF OPERATION

A. Combustion System

(1) The combustion system is based on a fully modulating forced draft combustion air

blower, a negative pressure regulated gas valve, and a 100% premix burner. On a

call for humidity, the combustion air blower starts and creates a negative pressure

across an orifice located at the air inlet.

(2) The blower is energized to purge the system, then the hot surface igniter is activated.

During this time the electronic ignition module does a diagnostic check of safety

systems including the air-proving switch, which senses the negative pressure at the

air inlet orifice. After the function of the safety systems has been verified, the gas

valve will open and the gas/air mixture is ignited by the hot surface igniter.

(3) If a flame is sensed by the flame sensor, the gas valve remains open and

combustion continues. If a flame is not sensed, the above sequence is repeated to a

maximum of three times after which the ignition module will lock out. The gas valve

maintains a constant ratio air to gas independent of blower speed or external

conditions. This air and fuel is thoroughly mixed in the blower and then forced

through the burner ports where ignition occurs.

(4) Hot products of combustion are forced through a baffle inside the heat exchanger

and then vented outside. The heat exchanger has a large flat surface to minimize

scale build-up and promote scale shedding to the bottom of the tank. This selfcleaning action helps to maintain the efficiency of the heat exchanger while the

smooth surfaces allow for easy cleaning when necessary.

(5) The GS 100 has a single removable combustion chamber/heat exchanger. The

combustion system is duplicated on larger units with multiple chambers inside a

common tank.

Table 1. Technical Data

SPECIFICATION GS 100 GS 200 GS 300 GS 400

Rated Capacity: lbs/hr* 25-105 25-210 25-315 25-420

Rated Capacity: kg/hr* 11-48 11-95 11-143 11-191

Input BTU/hr max 140,000 280,000 420,000 560,000

Input kJ/hr max 41 82 124 165

UNIT TYPE

GS 500

25-525

11-238

700,000

206

GS 600

25-630

11-286

840,000

247

Flue Emissions Low CO (< 10 ppm) and Low (NOx <40 ppm)

GSTC/GSP Rated Amps 1.1 1.9 2.7 3.5

Voltage/Phase 208-240/1 Standard

GSTC Outdoor Rated Amps 3.2 4.0 6.9 7.7

Voltage/Phase 208-240/1 Standard

GSTC/GSP Rated Amps 2.1 3.7 5.3 6.8

Voltage/Phase 120/1 Standard

GSTC Outdoor Rated Amps 6.3 7.4 13.7 15.2

Voltage/Phase 120/1 Standard

4.3

10.6

8.4

21.0

2008-10-01

5.2

11.5

10

22.6

10-00

Page 2

Page 10

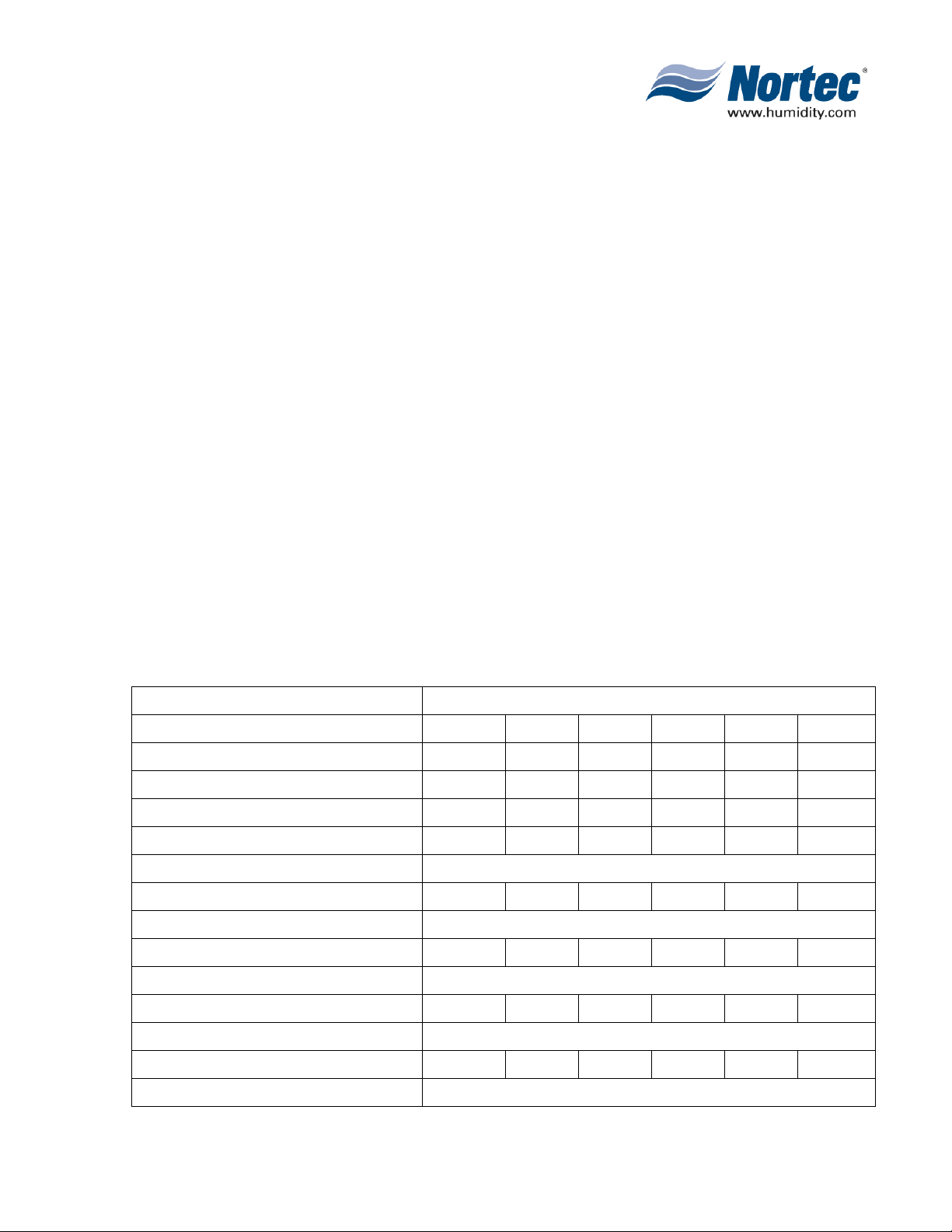

Figure 1. GS Indoor Series

Figure 2. GS Outdoor Series

10-00

Page 3

2008-10-01

Page 11

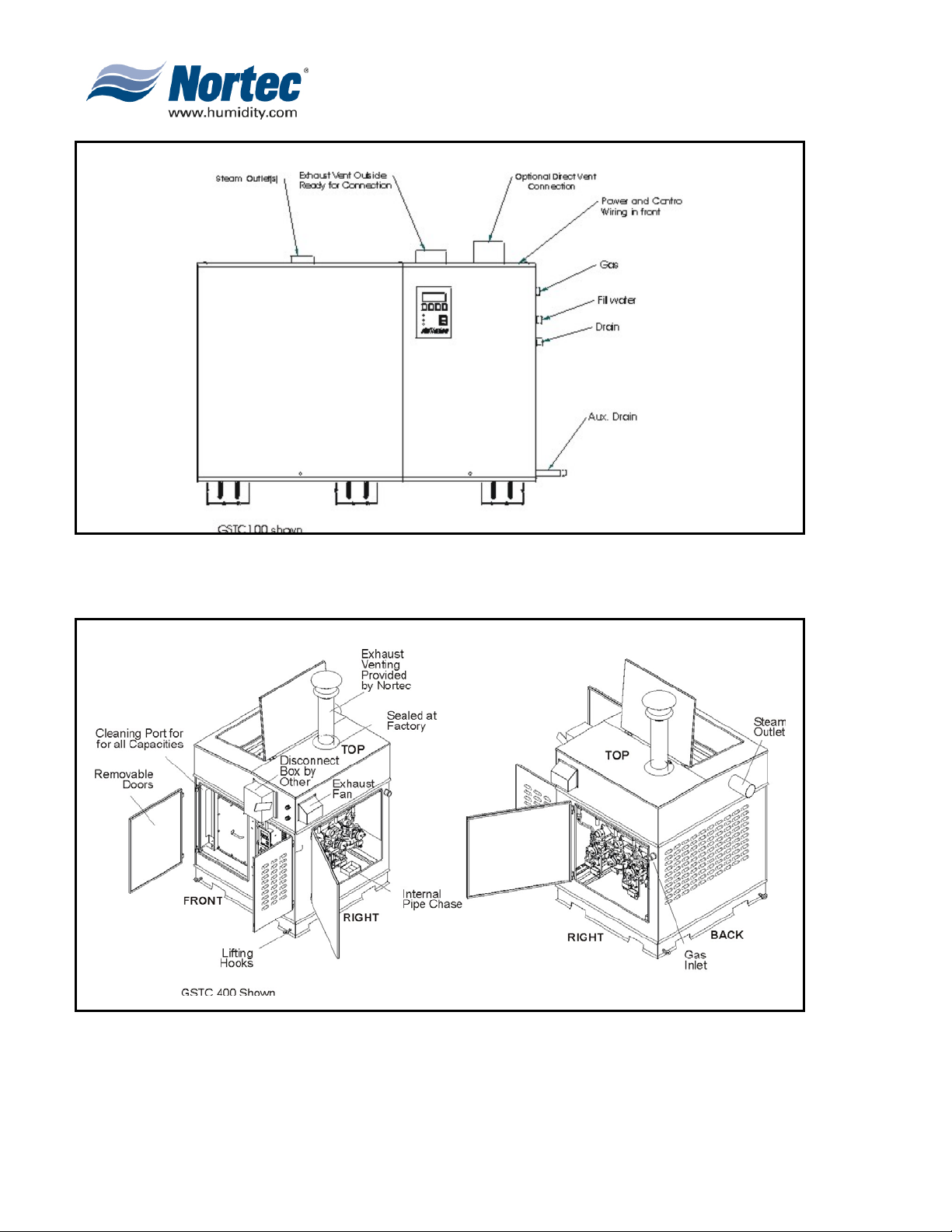

Figure 3. GSTC Key Pad

Figure 4. GSP Key Pad

10-00

Page 4

2008-10-01

Page 12

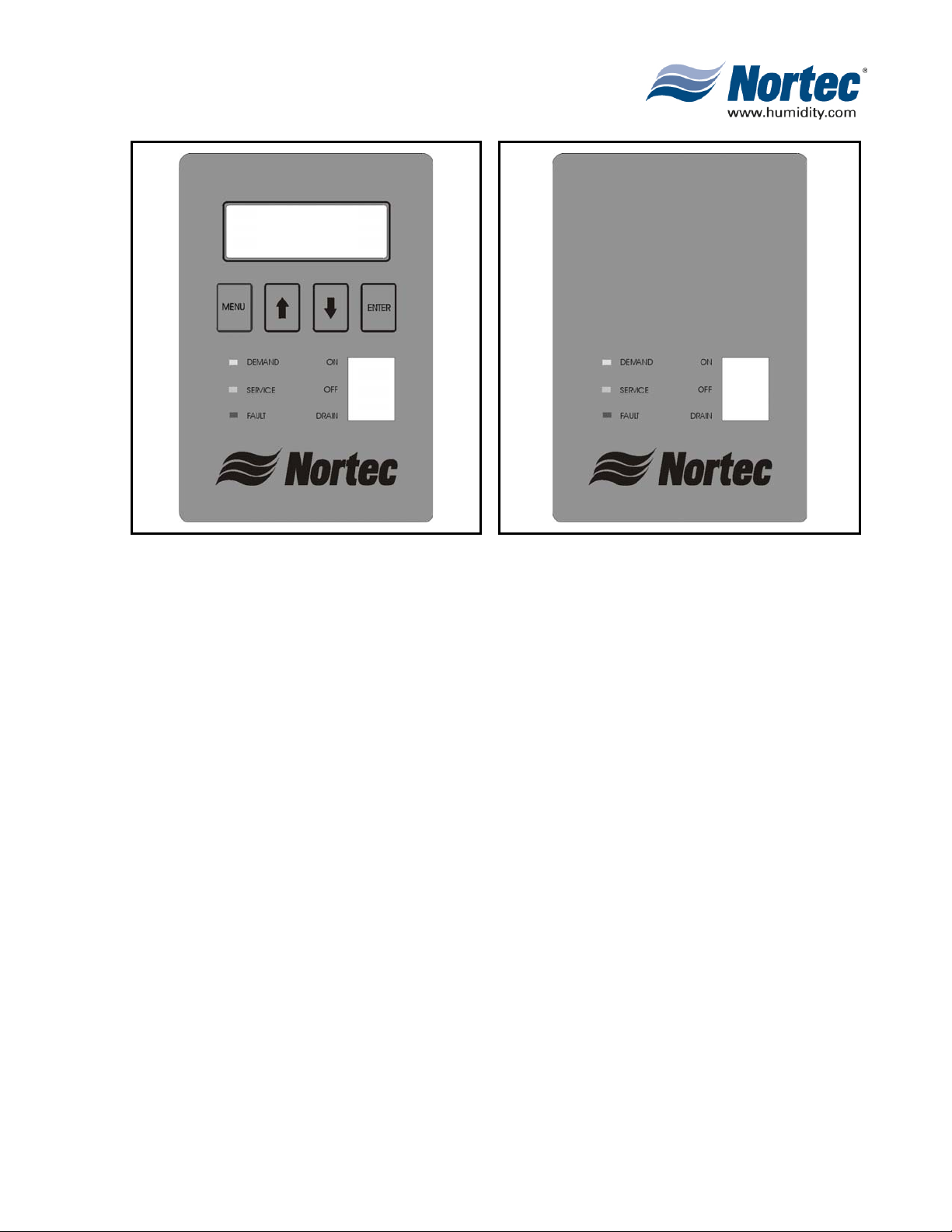

Table 2. Standard Features

Standard Features GSTC GSP*

Steam Capacity adjustment x

Full size alphanumeric display and keypad x

Total Controller with Modbus host protocol x

Transducer signal acceptance x

Individual component diagnostic capability x

Keypad set-point adjustment (humidity) x

Display of relative humidity x

Low and high relative humidity alarms x

Adjustable drain with no call for humidity x

Keep warm feature x

Networking capability up to 10 units x

Pre-cleaning sequence x

Troubleshooting Guide x

Self diagnostic capabilities x

Fault history x

Smart drain water cooling x

On/off cycling prevention x

Full tank blowdown capability via timer or external trigger x x

Board mounted display for fault and demand indication not req. x

Parameter change through jumper settings keypad x

Remote fault indication x x

Single or Dual modulation signal acceptance x x

Industry standard modulation signal acceptance x x

Time to next maintenance alarm x x

Internal Drain water cooler x x

System demand indication x x

Output display x x

Precise five level water level indication x x

Status indicator lamps x x

Backlit display x x

B or BH venting options x x

BH stack vent (outdoor only) x

Large Side tank cleaning port x x

Top access cleaning (300, 400, 500 & 600 lb models) x x

Single water connections x x

Turn-down ratio from maximum output to 25lbs/hr(11kg/hr) x x

Time proportioning below 25lbs/hr(11kg/hr) x x

120V or 208-240V power supply x x

Freeze Protection (Outdoor only) See Section 10-30, Page 24. x

Integral enclosure (outdoor only) x

Nortec Links Building Management System capable using BACnet

or LonWorks N2 protocols

Nortec OnLine for web based monitoring and control o

Sealed combustion / Direct vent o o

Floor stand o o

Distribution Systems

Short Absorption Manifold SAM-e o o

Steam Distributor o o

Blower Pack o o

x = standard o = optional

o o

10-00

Page 5

2008-10-01

Page 13

THIS PAGE INTENTIONALLY LEFT BLANK

10-00

Page 6

2008-10-01

Page 14

10-10

OPERATION

10-10

Page 7

2008-10-01

Page 15

1. WATER MANAGEMENT – BETTER EFFICIENCY THAN EVER

A.

Introduction

(1) The GS Series of humidifiers is equipped with a unique float chamber water level

monitoring device. Two magnetic floats (one is a backup) measure 5 different water

levels in the humidifier for proper operation. The float chamber and board are located

away from the boiling action to increase reading accuracy and reduce mineral buildup since it is not in the boiling water.

(2) The float chamber is connected to the tank under the water level and above the

water level to ensure equalization of pressure between the tank and float chamber.

In addition cooling water is introduced in the float chamber to reduce scale build-up.

(3) The unit also includes an internal 1” air gap and a vacuum breaker to prevent

siphoning effect.

(4) On initial start-up, the solenoid operated fill valve fills the tank. The water level will

reach the backup float first and then the main float. As a safety precaution, if the

back-up and main float read a different water level at any time during the operation of

the unit, the unit will shut down on a fault.

(5) On initial start-up, the unit will fill to the top yellow position, and activate an internal

test to confirm operation of the drain pump to ensure the drain is not blocked.

(6) The drain pump is then activated until the water level goes down to the green middle

level, and the combustion sequence will start upon a demand for humidity. During

the steam production, the unit will also self-check if the floats and drain pump are

operational by activating a drain sequence every 24 hours (adjustable to time of

day).

Figure 1. Humidifier Tank

10-10

Page 8

2008-10-01

Page 16

Model A B C D Vent Dia Vent Dia Shipped

GSTC

100 20.8 52.8 6.3 16 9.3 23.6 16.1 40.8 4 10.2 3 7.6 267 121 423 192

GSTC

200 27.2 69 11.6 29.5 14.6 37.1 22.4 56.8 5 12.7 4 10.2 355 161 599 272

GSTC

300 42.7 109 10.9 27.8 14.6 37.1 38 96.4 7 17.8 5 12.7 485 220 970 440

GSTC

400 42.7 109 10.9 27.8 14.6 37.1 38 96.4 7 17.8 5 12.7 529 240 992 450

GSTC

500 58.3 148 7.4 18.7 14.4 36.6 53.6 136 8 20.3 6 15.2 659 299 1364 619

GSTC

600 58.3 148 7.4 18.7 14.4 36.6 53.6 136 8 20.3 6 15.2 703 319 1384 628

in cm in cm in cm in cm in cm in cm lbs kg lbs kg in cm

B Type BH Type

Weight

Figure 2. Physical Dimensions – GS Indoor Humidifier

Operating

Weight

10-10

Page 9

2008-10-01

Steam Outlet Gas Supply

in

1 x

1.75

1 x 3 1 x

1 x 3 1 x

1 x 4 1 x

1 x 4 1 x

1 x 4 1 x

(NPT)

1 x

4.4 0.5 1.27

7.6 0.75 1.91

7.6 1 2.54

10.2 1 2.54

10.2 1.25 3.18

10.2 1.25 3.18

cm

(NPT)

Page 17

Figure 3. Physical Dimensions – GS Outdoor Humidifier

10-10

Page 10

2008-10-01

Page 18

B. Safety Water Level Control Check

(1) To ensure safe operation, the humidifier constantly monitors the back up float of

the humidifier and also performs float checks at regular intervals.

C. Self Diagnostic

(1) This feature allows the user to activate various hardware elements within the

system to prove operational compliance.

D. Energy Efficient Blowdown Sequence – Unique to Nortec

(1) Fill valve and blow down sequences are based on steam production and not time

of operation to increase efficiency of the unit. If the demand signal controls the unit

at the minimum output, of 25 lbs/hr, only 25% of 25 lbs/hr will be drained.

E. Internal Drain Water Tempering

(1) The unique design for the internal Drain Water Cooler from NORTEC will ensure

water tempering at all times of the water going to drain. The fresh fill water will

completely mix with incoming hot water from the tank during blow down or drain

cycles and ensure water does not exit the system at more then 140ºF (60ºC).

(2) When the “SMART” feature is enabled on the TC version, the temperature of the

tank is monitored and fresh cold water will be used only when drain water is above

140ºF (60ºC).

F. Capacity Turn Down

(1) The GS humidifier is capable of full modulation of the output of each burner down

to 25 lbs/hr. For example on a four-burner system, such as the GS 400, the

turndown ratio is 6% of total output.

(2) When the control signal requires less than 25 lbs/hr output, the internal controller of

the unit takes over with a unique time proportioning algorithm and to control the

output and modulate down to 0 lbs/hr.

G. GSTC Unit Networking

(1) The new TC controller of the GS Series allows staged modulation through

networking of up to 10 units when higher capacities of steam require multiple units.

The modulating signal will be wired to the master unit and this one will control the

output of the other units for seamless modulation from 25 lbs/hr up to 6300 lbs/hr.

All units will be configured as master or staged. The operational range of each unit

will be set in the internal controller at the factory. A control modulation signal to the

master unit and a three-wire connection between each unit being staged is all that

is required.

2. CONTROLS

A.

Introduction

(1) The GSTC model features a backlit alphanumeric keypad for user interface, which

allows for adjustment of operating parameters and displays system operating status.

(2) The GSP model uses status indication lights.

10-10

Page 11

2008-10-01

Page 19

(3) All control electronics are integral to humidifier cabinet and do not require separate

cabinet on the humidifier.

B. Remote Fault Indication

(1) The GS Series provides output signals of the following type:

(a) Humidifier “ON”

(b) Humidifier “Active”

(c) Humidifier “Service”

(d) Humidifier “Fault”

C. Modulating Controls

(1) All models accept a single or dual channel input control signal(s) of the following

type(s):

(a) 0-20 mA

(b) 4-20 mA

(c) 0-5 VDC

(d) 1-5 VDC

(e) 0-10 VDC

(f) 2-10 VDC

(2) The GS Series can accept the following inputs:

(a) Two different modulating inputs demand or transducer signal.

(b) Full tank blowdown activation (24 VAC).

D. On / Off Controls

(1) Safety on/off controls are available from NORTEC as safety accessories. These

controls are highly recommended by NORTEC for high limit or air proving. If controls

were not ordered with the humidifier, they must be supplied by others.

3. ELECTRICAL

(1) Humidifiers require field wiring to primary voltage terminal blocks. The power

requirement is a 120 or 208-240 V single-phase supply. Wiring is fed through a 7/8"

hole on lower right hand side of control compartment.

(2) External wiring sizes must be in accordance with NEC and/or CEC and existing local

electrical codes and by-laws.

4. VENTING

(1) The GS Series of Gas Steam humidifiers offer tremendous venting capability.

Whether you use galvanized B venting or special BH venting, the GS Series comes

ready for field connection. Please make sure that the correct size of vent is used

and follows local codes for proper operation of the unit.

(2) Humidifiers can be vented up to 100 ft (30 m) equivalent without requiring power

assistance . The GS Series can be vented horizontally through the wall or vertically

10-10

Page 12

2008-10-01

Page 20

through the roof without any special requirements when using BH venting. Required

vent flue size depends on unit model. All connections to the flue pipes are made

without having to open the humidifier cabinetry.

(3) The GS Outdoor Series comes complete with BH vent, ready for easy assembly.

5. CLEARANCES

(1) The clearance dimensions shown in Figure 4 and 5 are for reference only and are

the minimum requirements for maintenance of the humidifier.

(2) All units have frontal cleaning port access.

(3) For GS 100/200, frontal cleaning port access is required only. For GS 300/400, top

access is accessible from the front without clearance on the left side. For GS

500/600, left side clearance is required to allow cleaning of the back of the heat

exchanger.

10-10

Page 13

2008-10-01

Page 21

Figure 4. GSTC/GSP Indoor Clearance

Figure 5. GSTC Outdoor Clearance

10-10

Page 14

2008-10-01

Page 22

6. STEAM INSTALLATION GUIDELINES

(1) The GS Series humidifier comes with a single steam outlet on all capacities. The GS

100, 200/300, 400/500/600 have respectively (1.75” (4.4 cm) O.D., 3” (7.6 cm) O.D.

and 4” (10.16) O.D.). Consult option and accessories section for more details. Refer

to the Steam Absorption and Distribution Manual, Form #XX-231 for design of the

steam distribution system.

7. CALCULATION OF ANNUAL OPERATING COSTS

A. Natural Gas Humidifier

(1) Annual operating cost equals: annual hours of operation, times energy cost, times

humidifier capacity.

(a) Example: GS 100

(b) Natural gas cost $4.50 (U.S.) per million BTU

(c) $0.45 (U.S.) per Therm (100,000 BTU)Annual hours of operation = 2000 at full

output (Equivalent to comfort humidification in upper mid-west.)

(d) Input of humidifier = 140,000 BTU/hr

(e) Total energy used = 2000 x 140,000 = 280,000,000 BTU

(f) Annual Cost = 238 x 4.50 = $1260.00

B. Electric Gas Humidifier

(1) Annual operating cost equals: annual hours of operation, times energy cost, times

humidifier capacity.

(a) Example: NHMC 100

(b) Electricity cost (usage charge) $0.08 per kw/hr.

(c) Annual hours of operation = 2000 at full output (Equivalent to comfort

humidification in mid-west.)

(d) Input of humidifier = 34 kw

(e) Total energy used = 2000 x 34 = 68,000 kw/hr

(f) Annual Cost = 68,000 x 0.08 = $5,440.00

C. Operating Cost Savings

(1) Gas vs Electric = more than 4 times the operating cost.

10-10

Page 15

2008-10-01

Page 23

THIS PAGE INTENTIONALLY LEFT BLANK

10-10

Page 16

2008-10-01

Page 24

10-20

MAINTENANCE

10-20

Page 17

2008-10-01

Page 25

1. WATER CONDITIONS VS. HUMIDIFIER CLEANING REQUIREMENTS

(1) The GS Series humidifiers are to operate on cold potable, De-Ionized (DI) or

Reverse-Osmosis (RO) water supply and since the output of all GS Series

humidifiers is pure clean steam, minerals from the incoming water are left behind.

These minerals will eventually coat the tank walls or settle to the bottom of the

tank. The mineral content of the incoming water, the unit running time, output

capacity setting and blowdown rate ultimately determine time between each

cleaning.

(2) The Gas Steam humidifier will periodically “blowdown” or skim water from the tank

to reduce the concentration of total dissolved solids that accumulate during longterm operation. The Gas Steam humidifiers are shipped from the factory set at

25% of output. This setting ensures that scale build-up will be minimized for most

water conditions. The amount of blowdown is field adjustable.

(3) The unit also monitors operation time and will indicate to the user when

maintenance is required. This time is adjustable to adapt to your water conditions

but is set from the factory at 500 hours of 100% operation.

(4) Three parameters will help determine the proper blowdown setting of the Gas

Steam humidifier.

(a) Water hardness

(b) Silica content

(c) Chlorides

(5) Due to the wide range of water conditions found throughout North America it is

important that the blowdown is set according to the local water conditions. By

water conditions we are referring to the hardness of the water supplied to the

humidifier. The hardness is measured in grains per gallon. It is also important to

test for silica content. Silicates may cause foaming and contribute to scale buildup

in the humidifier tank and float chamber. When excessive foaming occurs. Consult

factory for possible solutions.

(6) If you are unaware of the hardness or silica content of your water supply, there

are many “do it yourself” kits, which can be purchased, or there are several

companies that will perform the tests for a reasonable price. You can even contact

your municipality for your water condition.

(7) It is possible to reduce this setting according to observation and guidelines in the

blowdown setting table found in the GS Installation Manual (Form # XX-287). Also,

when high silica content has been identified, the humidifier tank and float chamber

will require increased maintenance and the blowdown setting should be increased

to maximum setting. In this case silica content may determine the appropriate

blowdown setting.

(8) Softened water is recommended if the incoming water has a hardness in excess of

8 grains/gal (136 ppm).

(9) Reverse osmosis (RO) water can provide very long times between cleaning since

it is cleaner than softened water. Deionized (DI) water can reduce the

10-20

Page 18

2008-10-01

Page 26

maintenance a step further than RO and all the GS Series components are ready

for RO or DI water use as a standard.

(10) Contact your local Nortec representative for a quotation of a water treatment

system suited for your application.

2. PREVENTIVE MAINTENANCE

(1) The installation manuals of the GS Series of Gas Steam humidifier come with a

complete Maintenance chart in order to guide internal personnel in cleaning and

monitoring activities. Like any other appliance the Gas-Steam humidifier requires

monitoring to ensure efficient operation throughout the life of the unit.

(2) While in operation, the unit will blowdown scaled water through a drain pump

keeping control on the water concentration based on steam output. For longer

intervals between cleaning, the unit may be completely drained down to reduce the

mineral concentration and bring in new fresh water in the system.

(3) The FTBD (Full Tank Blow Down) can be activated through the software or dip

switches based on:

(a) Time of day setting. When the 25 - 400 hours interval (adjustable ) is reached

the unit will wait until the set time of day before activating the full tank

blowdown.

(b) External trigger using 24Vac signal from the building management system to

the input terminal of the humidifier.

(4) Following the full tank blowdown, the unit will refill and perform a float check.

Whenever possible, use this feature to reduce mineral accumulation in the system

and reduce the time required to clean the interior of the reservoir.

3. PRE-CLEANING SEQUENCE

(1) When cleaning of the reservoir is required, use the tank pre-clean feature. This

pre-cleaning sequence will drain the full content of the unit, fill back-up, and redrain any residual scale that has fallen from the cold water refilling. This sequence

is not an alternative to cleaning the humidifier, it is meant to reduce the time

required to clean the tank.

(2) Full Size Frontal Opening: Every GS Series Gas Steam Humidifier comes

complete with a full size frontal opening to allow bottom cleaning of the tank and

heat exchanger. This opening allows quick and easy cleaning without removing

the steam outlet of the unit.

10-20

Page 19

2008-10-01

Page 27

THIS PAGE INTENTIONALLY LEFT BLANK

10-20

Page 20

2008-10-01

Page 28

10-30

OPTIONS &

ACCESSORIES

10-30

Page 21

2008-10-01

Page 29

1. OPTIONS AND ACCESSORIES AVAILABLE

A. Nortec Modulating Humidistat with Digital Display

(1) NORTEC humidistats for GSTC or GSP Gas Steam humidifiers feature

proportional + integral control with setpoint range of 10-95% RH. The humidistat

connects directly to the low voltage terminal strip via 3 wires (shielded if run

exceeds 10 m). The humidistat accurately controls RH in a zone or space.

(2) Humidistat Specifications:

(a) Operating Conditions: 41ºF-122°F (5°C-50°C)

(b) Control: 0-95% RH non-condensing

(c) Sensor: 0-100% RH

(d) Humidity Sensor: Solid-state humidity sensor. Suitable for normal, clean air.

Not to be used in corrosive or harmful environment.

(e) Resolution: +- 0.1%

(f) Repeatability: 0.5%

(g) Accuracy of Sensor: +/- 3% RH from 0-100% RH Range: 10-90% RH for

32°F-122°F (0°C-50°C)

(h) Temperature Effect: 0.05% /°F

(i) Outputs: 0-10 VDC

(j) Power: 24 VAC -15%, +10% 50/60 Hz; 2 VA

B. Humidistat with Integral Sensor and Controller with Digital Display

(1) 151-0142 - Modulating 0-10 VDC wall mounted humidistat, P + I control humidistat

with setpoint range of 0-95% RH. Connects directly to the GSTC or GSP low

voltage terminal strip via 2 wires (shielded if run exceeds 10 m) and accurately

controls RH in a zone or space. Time proportioning control not acceptable.

(2) 252-0266 - Modulating 0-10 VDC duct mounted humidistat, P + I control humidistat

with setpoint range of 10-95% RH. Connects directly to the GSTC or GSP low

voltage terminal strip via 2 wires (shielded if run exceeds 10 m) and accurately

controls RH in a zone or space. Can be used as a control humidistat if placed in

return air or as high limit if placed in supply. (Time proportioning control not

acceptable.)

C. Humidistat with Integral Sensor

(1) 150-9857 - Remote duct or modulating high limit sensor.

(2) 150-9858 - Remote wall mounted sensor.

(3) 252-0263 - Outdoor duct mounted temperature sensor. Can provide energy

savings and prevent window condensation by reading outdoor temperature and

resets the humidity control to prevent condensation.

10-30

Page 22

2008-10-01

Page 30

D. Nortec On / Off Controls with Digital Display

(1) 252-0273 - Duct Mounted Safety High Limit On/Off Humidistat (if used) is wired to

make on drop in humidity, break on rise to safety setpoint. It should be set to

approximately 85% RH as a safety to prevent saturation and wetting in the duct.

(2) 132-9203 - A Duct Mounted Safety Air-Proving On/Off Switch (if used) is wired to

make on airflow, break on no flow. It is used as a safety to prevent saturation

when no air is flowing through the duct.

(3) Low Humidity Alarm Package - Low limit on/off humidistat duct or wall mounted,

alarm light with engraved faceplate sized to fit standard 2” x 3” recessed electrical

wall box supplied by others. Activates alarm light if duct or room airdrops below

setpoint.

(a) Duct – 253-3365

(b) Wall – 253-3366

(4) High Humidity Alarm Package - High limit on/off humidistat duct or wall mounted,

alarm light with engraved faceplate sized to fit standard 2” x 3” recessed electrical

wall box supplied by others. Stops humidifier and activates alarm light if duct or

room air approaches saturation.

(a) Duct – 253-3363

(b) Wall – 253-3364

E. Configuration Option

(1) 150-7057 - This option allows the Gas Steam humidifier to operate using propane

energy.

F. Direct Vent

(1) GS Indoor Direct Vent Package allows GS unit to be installed in an environment

where the air cannot be used for combustion for one of the following reasons:

chemicals or excessive dust is present in the air or the room is under excessive

negative or positive pressure. All these factors could affect adversely the normal

operation of the unit.

(a) GS 100 - 150-7067

(b) GS 200 - 150-7068

(c) GS 300 - 150-7069

(d) GS 400 - 150-7070

(e) GS 500 - 150-7071

(f) GS 600 - 150-7072

G. Stand

(1) GS Series Stands are optional with all models. The floor stands will help raise the

unit to maximum of 27” (69 cm) high.

H. Keep Warm

(1) 150-7059 - GSP Keep Warm Feature, allow water temperature in the tank to be

maintained between 140ºF (60ºC) and 160ºF (71ºC) allows for quick response of

the unit on a call for humidity and to reduce possible bacteria growth for health

concerns.

10-30

Page 23

2008-10-01

Page 31

I. Indoor Freeze Protection

(1) 150-7058 - GSTC Indoor Freeze protection package provides the unit configured

with keep warm feature, remote fault indication and a normally open drain valve to

protect if freezing conditions may occur. The keep warm feature will ensure the

water temperature is kept between 140ºF (60ºC) and 160ºF (71ºC).

(2) The remote fault indication will allow service personnel to be advised of the unit’s

operational status and the normally open drain valve will ensure the unit is drained

if a power outage.

(3) Drain and fill lines outside of the cabinet, must be protected from freezing with heat

trace. Unit must be enclosed in a weather enclosure with heat source.

(4) A remote alarm must be installed in case the unit faults using remote fault

indication and status indication.

J. Outdoor Freeze Protection (Standard with all GS Outdoor Enclosures)

(1) Outdoor units are configured with the Keep Warm feature enabled to maintain the

tank water temperature between 140ºF (60ºC) and 160ºF (71ºC). Included is a

factory installed normally open drain valve that will ensure the unit drains in the

event of a power outage. Also a factory-installed heater will be included to

maintain an operating temperature range within the electrical compartment. The

heater is powered from the humidifier. Field supplied heat-tracing needs to be

installed on all fill line piping exposed to outdoor temperature. If fill line pipe

freezing is a concern a field supplied normally open valve can be used to drain the

fill line.

(a) 150-8116 - GSTC Outd oor 100

(b) 150-8117 - GSTC Outd oor 200

(c) 150-8118 - GSTC Outdoor 300/400

(d) 150-8119 - GSTC Outdoor 500/600

K. ON-LINE

(1) Nortec OnLine is a remote interactive communication package that allows satellite

contacts to monitor, maintain and control a humidification center from any location

worldwide using standard internet connections. This advanced software shows

graphic representations of the humidifier and its key parameters (up to 75

functions).

L. LINKS 2

(1) Nortec LINKS 2 is the combination of LINKS (building management system

communication hardware) and OnLine (Internet communication hardware) allowing

humidifiers to communicate to a building management system (BMS) as well as

the Internet. Up to 8 humidifiers can be connected to 1 LINKS 2 controller (1

master and 7 slaves). The controller is factory installed and is located internally to

the humidifier. Simply specify at the time of order the operating protocol needed.

LINKS 2 comes standard with Internet capabilities however OnLine service needs

to be specified at time of order.

(2) Operating Protocols:

a) 252-7116 – BACnet / IP

10-30

Page 24

2008-10-01

Page 32

b) 252-7111 - BACnet MSTP

c) 252-7113 – Johnson N2

d) 252-7113 – LonWorks

(3) Features

a) Digital Feedback for unit standby/humidifying mode.

b) Digital feedback for service required.

c) Digital feedback for fault indication.

d) System demand display.

e) Control room setpoint.

f) Control high limit setpoint.

g) Control room %RH.

h) Control high limit %RH.

i) Control enable/disable.

j)

Networking capabilities of linking 8 units to one Nortec controller.

10-30

Page 25

2008-10-01

Figure 1. NORTEC Online

Figure 2. NORTEC LINKS 2

Page 33

M. DRAIN WATER SUMP PUMP

(1) Externally mounted below humidifier. For use when no floor drain is available and

water must be pumped higher than the bottom of the humidifier (special high

temperature model). Rated for use with all GS models. Recommended model:

W.W. Grainger #4RD29 or #4RD32.

N. STEAM DISTRIBUTION

(1) Used in ducts or air handling units, available in stainless steel.

(2) Steam is dispersed through evenly spaced outlet orifices and upward

perpendicular to the airflow.

(3) When steam is dispersed through evenly spread outlet orifices that are along the

steam distributors “active zone”. They are offset 45º from vertical to address

potential static pressure induced by downward airflow. The distributor is rotated

when installed.

O. REMOTE MOUNTED BLOWER PACK

(1) RMBP 208-240V- 1709701 Blower Pack

(2) Direct steam distribution system that allows for direct space/room humidification

when steam introduction into a ducted system is not feasible. The factory

assembled Blower Pack includes integral steam distributor, an internal steam hose

and condensate connection for simple installation including 3 individual 110 cfm

blower fans that can be powered by a separate 115 V single phase power supply

or can be ordered with a factory installed step down transformer for all standard

primary voltages. The Blower Pack features an adjustable fan to provide different

angles allowing for a flexible install. A temperature sensor enables fans when

steam production begins, while maintaining a quiet operational environment. The

Remote Mounted Blower Pack ships fully assembled and ready for easy

installation with NH, GS, SE Technologies.

(3) See Blower Pack distribution for more information.

P. SHORT ABSORPTION MANIFOLD

(1) See Short Absorption Manifold Engineering Manual for model numbers.

10-30

Page 26

2008-10-01

Page 34

Figure 3. Steam Distributor

Figure 4. Blower Pack

Figure 5. Short Absorption Manifold

10-30

Page 27

2008-10-01

Page 35

THIS PAGE INTENTIONALLY LEFT BLANK

10-30

Page 28

2008-10-01

Page 36

10-40

SPECIFICATION

10-40

Page 29

2008-10-01

Page 37

1. GENERAL

A. General

(1) NORTEC GS Series Gas-Fired Humidifier[s] as indicated on drawing[s] and as

indicated on schedule[s].

(2) Complete and operable humidification system [which meets applicable building

codes].

(3) Equipment start-up and project inspection by qualified factory trained

representative.

B. Quality Assurance

(1) Manufacturer: For each product specified, provide components by same

manufacturer throughout.

(2) Electrical Components, Devices, and Accessories: Listed and labeled as defined

in NFPA 70, Article 100, by a testing agency acceptable to authority having

jurisdiction, and marked for intended use.

(3) Comply with ARI 640, “Standard for Commercial and Industrial Humidifiers.”

(4) Products shall be supported with a warranty that ensures the product will be free

from defects in materials and workmanship for a period of two years after

shipment.

(5) Commissioning of a system or systems specified in this section is part of the

construction process. Documentation and testing of these systems, as well as

training of the Owner’s operation and maintenance personnel, is required in

cooperation with the Commissioning Authority. Project Closeout is dependent on

successful completion of all commissioning procedures, documentation, and issue

closure. Refer to Project Closeout, Section 01700, for substantial completion

details. Refer to Section 01810, Commissioning, for detailed commissioning

requirements.

(6) Products specified below are to be manufactured is an ISO 9001-2000 certified

facility.

C. Submittals

(1) Submit product data under provisions of Section 15010. Include product

description, model, dimensions, component sizes, rough-in requirements, service

sizes, and finishes. Include rated capacities, operating weights, furnished

specialties, and accessories.

(2) Submit manufacturer’s installation instructions.

(3) Submit operation and maintenance data.

(4) Submit coordination drawings. Detail fabrication and installation of humidifiers.

Include piping details, plans, elevations, sections, details of components, and

dispersion tubes. Detail humidifiers and adjacent equipment. Show support

locations, type of support, weight on each support, and required clearances.

(5) Submit wiring diagrams including power, signal, and control wiring. Differentiate

between manufacturer-installed and field-installed wiring.

10-40

Page 30

2008-10-01

Page 38

(6) Submit minimum water quality requirements and water pressure requirements.

D. Extra Materials

(1) Furnish extra materials described below that match products installed and that are

packaged with protective covering for storage and identified with labels describing

contents.

E. References

(1) ANSI/NFPA 70 - National Electrical Code.

F. Coordination

(1) Coordinate location and installation of humidifiers in ducts and air-handling units.

Revise locations and elevations to suit field conditions and to ensure proper

humidifier operation.

XXXXX OR XXXXX

(2) Coordinate location and installation of humidifier in the space it serves with the

electrical, mechanical, and plumbing contractors.

2. PRODUCTS

A. Gas Fired Steam Humidifier - GSTC

(1) Packaged unit, floor mounted, gas-fired, steam generating system available at 105

lbs/hr (48 kg/hr), 210 lbs/hr (95 kg/hr), 315 lbs/hr (143 kg/hr), 420 lbs/hr (191

kg/hr), 525 lbs/hr (238 kg/hr), 630 lbs/hr (286 kg/hr), suitable for immediate, or

future, use of all water types including, De-Ionized (DI), Reverse Osmosis (RO),

potable and softened water, without modification required, CSA certified.

(2) Packaged unit, wall mounted, methods of distribution require a steam distributor[s]

or Short Absorption Manifold [s] [SAM-e] for mounting into AHU/duct[s] or Remote

Mounted Blower Pack[s] [RMBP] for direct space applications [refer to options

schedule].

(3) Enclosed cabinet, powder painted steel construction and air gap between cabinet

and insulated humidifier tank ensures safe surface temperature.

(a) Evaporation tank and all internal tank components to be constructed of 304

stainless steel.

(b) Humidifier requires zero clearance to combustibles and shall be installed

against a partition to minimize floor space required. All tank surfaces shall be

insulated with minimum 1" (25 mm) thick insulation and enclosed within unit

cabinetry to ensure safe surface temperature, high overall efficiency, and fast

unit response time. Units with exposed insulation shall not be acceptable.

(c) Maintenance shall not require the removal of the steam lines.

(d) Standard internal drain water cooler to ensure drain water tempering to 140º

F (60 ºC). If external drain water cooler required, provide factory cross-braced

unit stand and factory supplied stainless steel p-trap.

10-40

Page 31

2008-10-01

(e) Blow-down p-trap, factory installed, enclosed in cabinet, prevents steam

leakage to drain. Field installation not acceptable.

Page 39

(f) Provide easily accessible, primary voltage terminal block, internal to

cabinetry, for single point field connection of electrical supply.

(g) Single point connection for gas inlet must be provided. Internal piping from

gas inlet to burners must be factory installed and tested. Field piping from

the gas inlet to the burners is not allowed.

(h) Humidifier to prevent “back-siphoning” using an internal air gap for supply

water, to meet local plumbing codes.

(i) Drain line to include a vacuum breaker to prevent siphon drainage of the

tank.

(j) Allowance for combustion air shall be provided in cabinet ventilation design.

Option for direct vent of combustion must be available for use with BH

exhaust vent.

(4) Gas appliance shall be low emission. Units with Carbon Monoxide (CO) levels

higher than 10 ppm and Nitrous Oxide (NOx) levels above 40 ppm are not

acceptable.

(a) System shall be rated as a class I appliance certified for use with exhaust

vent type B.

XXXXX OR XXXXX

(b) System shall be rated as a class III appliance certified for use with exhaust

vent type BH.

XXXXX OR XXXXX

(c) System shall be rated as a class III appliance certified for use with exhaust

vent type BH and use with direct vent of combustion air. (Must be specified

for factory configuration)

(5) Stainless Steel combustion chamber(s)/heat exchanger(s) shall have flat surfaces

to retard scale build-up. Tubular heat exchangers are not acceptable.

(a) Each burner, capable of true modulation will provide steam production of 25

to 105 lbs/hr (11 to 48 kg/hr). Time proportioning modulation is not

acceptable.

(b) Units with multiple heat exchangers, models 210 to 630 lbs/hr (95 kg/hr to

286 kg/hr) must be capable of producing a minimum output of 25 lbs/hr

(11kg/hr).

(c) Units with multiple heat exchangers, models 210 to 630 lbs/hr (95 kg/hr to

286 kg/hr) must alternate the lead burners (duty cycle) to promote equal

usage.

(d) Gas system with gas valve(s), explosion proof, premix combustion air

blower(s), microprocessor controlled ignition, flame sensing and fault

indicator light(s), 100% premix infrared burner(s), hot surface igniters(s) and

heat transfer efficiency maintained over all operating ranges.

10-40

Page 32

2008-10-01

Page 40

(e) Blower speed rotation must to be monitored to ensure proper control of input

modulation. System will lock out gas valve operation if proper blower speed

is not detected.

(f) A secondary combustion air safety, in addition to blower speed monitoring,

utilizing a mechanical pressure differential switch, must be used with each

blower to ensure combustion air is entering the pre-mix blower properly.

(g) Modular heat exchanger shall be easily removable through unit sidewall.

(h) Removable cover at front of unit facilitates easy cleaning (when applicable)

with complete access to tank and heat exchanger surfaces.

(6) Automatic water level control within a separate float chamber, isolated from the

boiling action, to prevent false water level indication.

(a) Fill rate must modulate to match capacity demand to ensure consistent

output. Fill cycles based on low water only is not acceptable.

(b) System shall fill through the bottom of the tank to reduce steam-quenching

effect and noise level. Filling at top of the tank is not acceptable.

(c) Unit water level is to be continuously monitored with a dual magnetic

electronic float system, located outside of the boiling water to ensure

accurate water level control and reduced maintenance. Cool fill water is to be

supplied into the sensing chamber to keep the device cool. Systems using

conductivity probes or floats located within hot reservoir water are not

acceptable.

(d) Tank and float chamber to be separated with a minimum of 1" (25 mm) rigid

insulation, minimizing potential scale build up on float mechanisms, due to

heating of the contained water.

(e) Humidifier shall have a dual fill valve to feed water to the tank and float

chamber, to reduce scaling and mineral build up on the magnetic floats.

(f) Float chamber to include LED indication of five possible water level

indications.

(g) Ongoing self-diagnostics including periodic float operation and fill/drain rate

verification.

(h) Positive drainage/blow-down using a drain pump, drawing water from the

bottom of the tank, maximizing mineral evacuation (when applicable).

Skimmer not acceptable.

(i) Blow down interval shall be based on actual steam production, and must be

adjustable to compensate for all water conditions, to ensure maximum energy

and maintenance efficiency.

(j) Pre-cleaning flushing feature shall be provided to reduce maintenance time.

(k) Must include end of season blow-down feature to evacuate contained water

and minerals after 72 hours with no demand for humidification.

10-40

Page 33

2008-10-01

Page 41

(7) Factory mounted, full size, backlit, Liquid Crystal Display provides full operational

status. Display to include a keypad for user interface and adjustment of operational

parameters including:

(a) Unit output (lbs/hr or kg/hr) 25 lbs/hr to full output.

(b) Water level in the tank.

(c) Modulating control demand status.

(d) On/off control and safety (High limit, air proving) circuit status.

(e) Actual room and/or duct RH, and humidity set point, when using transducer

input(s).

(f) Controller configuration (Proportional band and integral) when using

transducer input(s).

(g) Troubleshooting guide with scroll down menu.

(h) Fault indication including date and time history.

(i) Maintenance intervals.

(j) Fill and drain status.

(k) Drain/flush intervals and duration.

(l) Date and time.

(m) Capacity limitation.

(n) 72 hours drain enable/disable.

(o) Control type configuration on/off or full modulation when demand signal(s), or

transducer input(s) are provided.

(p) Up to 10 humidifiers, supplying one AHU or area, can be controlled in series

from one modulating humidity control system.

(q) BACnet, LonWorks, or Johnson N2 capable to interface for monitoring and

control from a Building Management System (BMS/BAS).

(r) Total Controller is Modbus native for (BMS/BAS) communication for remote

monitoring and control of humidifier.

(s) Web base capable via the Internet for remote monitoring or control of

humidifier.

NOTE:

All operational parameters factory set to reduce field set-up time.

(8) Standard of acceptance: NORTEC GSTC.

(9) Optional accessories:

(a) Refer to options schedule.

10-40

Page 34

2008-10-01

Page 42

3. EXAMINATION

A. Examination

(1) Examine ducts, air-handling units, and conditions for compliance with requirements

for installation tolerances and other conditions affecting performance.

(2) Examine roughing-in for piping systems to verify actual locations of piping

connections before humidifier installation.

(3) Proceed with installation only after unsatisfactory conditions have been corrected.

B. Installation

(1) Install humidifiers and steam dispersion panels per manufacturers’ instructions.

(2) Seal humidifier dispersion-tube duct penetrations with flange.

(3) Install with required clearance for service and maintenance.

C. Testing

(1) System verification testing is part of the commissioning process. Verification testing

shall be performed by the Contractor and witnessed and documented by the

Commissioning Authority. Refer to section 01810, Commissioning, for system

verification tests and commissioning requirements.

XXXXX OR XXXXX

(2) Manufacturer’s Field Service: Engage a factory-authorized service representative

to inspect field-assembled components and equipment installation, including piping

and electrical connections. Report results in writing.

(a) Leak Test: After installation, charge system and test for leaks. Repair leaks

and retest until no leaks exist.

(b) Operational Test: After electrical circuitry has been energized, start units to

confirm proper unit operation. Remove malfunctioning units, replace with

new units, and retest.

(c) Test and adjust controls and safeties. Replace damaged and malfunctioning

controls and equipment.

10-40

Page 35

2008-10-01

Page 43

D. Training

(1) Training of the Owner’s operation and maintenance personnel is required in

XXXXX OR XXXXX

(2) Engage a factory-authorized service representative to train Owner’s maintenance

cooperation with the Commissioning Authority. Provide competent, factory

authorized personnel to provide instruction to operation and maintenance

personnel concerning the location, operation, and troubleshooting of the installed

systems. The instruction shall be scheduled in coordination with the

Commissioning Authority after submission and approval of formal training plans.

Refer to System Demonstrations, section 01670, for contractor training

requirements. Refer to section 01810, Commissioning, for further contractor

training requirements.

personnel to adjust, operate, and maintain humidifiers.

(a) Train Owner’s maintenance personnel on procedures and schedules for

starting and stopping, troubleshooting, servicing, and maintaining equipment

and schedules.

(b) Review data in maintenance manuals. Refer to Division 1 Section “Contract

Closeout.”

(c) Review data in maintenance manuals. Refer to Division 1 Section “Operation

and Maintenance Data.”

(d) Schedule training with Owner, through Architect, with at least seven days

advance notice.

10-40

Page 36

2008-10-01

Page 44

THIS PAGE INTENTIONALLY LEFT BLANK

10-40

Page 37

2008-10-01

Page 45

WARRANTY

(1) WALTER MEIER INC. and/or WALTER MEIER LTD. (hereinafter collectively referred

to as THE COMPANY), warrant for a period of two years after installation or 30 months

from manufacturer’s ship date, whichever date is earlier, that THE COMPANY’s

manufactured and assembled products, not otherwise expressly warranted (with the

exception of the cylinder), are free from defects in material and workmanship. No

warranty is made against corrosion, deterioration, or suitability of substituted materials

used as a result of compliance with government regulations.

(2) THE COMPANY’s obligations and liabilities under this warranty are limited to furnishing

replacement parts to the customer, F.O.B. THE COMPANY’s factory, providing the

defective part(s) is returned freight prepaid by the customer. Parts used for repairs are

warranted for the balance of the term of the warranty on the original humidifier or

90 days, whichever is longer.

(3) The warranties set forth herein are in lieu of all other warranties expressed or implied

by law. No liability whatsoever shall be attached to THE COMPANY until said produ cts

have been paid for in full and then said liability shall be limited to the original purchase

price for the product. Any further warranty must be in writing, signed by an officer of

THE COMPANY.

(4) THE COMPANY’s limited warranty on accessories, not of the companies manufacture,

such as controls, humidistats, pumps, etc. is limited to the warranty of the original

equipment manufacturer from date of original shipment of humidifier.

(5) THE COMPANY makes no warranty and assumes no liability unless the equipment is

installed in strict accordance with a copy of the catalog and installation manual in effect

at the date of purchase and by a contractor approved by THE COMPANY to install

such equipment.

(6) THE COMPANY makes no warranty and assumes no liability whatsoever for

consequential damage or damage resulting directly from misapplication, incorrect

sizing or lack of proper maintenance of the equipment.

(7) THE COMPANY retains the right to change the design, specification and performance

criteria of its products without notice or obligation.

Page 46

U.S.A.

Walter Meier (Climate USA) Inc.

826 Proctor Avenue

Ogdensburg, NY 13669

TEL: 1-866-NORTEC-1

EMAIL: northamerica.climate@waltermeier.com

WEBSITE: www.humidity.com

CANADA

Walter Meier (Climate Canada) Ltd.

2740 Fenton Road

Ottawa, ON K1T 3T7

TEL: 1-866-NORTEC-1

FAX: (613) 822-7964

Authorized Agent:

Loading...

Loading...