Page 1

Quality Refrigeration Since 1947

Walk-In

InstallatIon

Manual

for:

kold locker™

fast-trak®

fInelIne™

MInI rooMs

envIro-lIne

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Printed in the USA.

1

Page 2

Table of ConTenTs

Introduction 3

Product Safety Policy 4

Tools Required 5

General Information 6-10

Unpacking / Inspection 6

Foam Panel Storage 8

Construction Diagram 9

Section Latches 10

Walk-in Installation 11-33

Floor Installation 12

Site Selection, Base Preparation 14

Wall and Ceiling Panel Construction 22

Door / Door Section 25

Exterior Ramp 29

Interior Ramp 30

Membrane Roof 31

Electrical Connections 32

Wiring 32

Walk-in Maintenance 34-41

Door Parts 34

Electrical Connection 41

Final Checklist for Installation 42-43

2

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 3

InTroduCTIon

Your Nor-Lake Walk-In Cooler (Freezer) was quality engineered and produced under rigid factory controls.It

features the very latest in manufacturing technology plus innovative design techniques that will provide the ultimate

in user convenience.

Please maintain this service-reference material in a handy file for an immediate answer to any questions you

may have concerning your Nor-Lake Walk-In. This manual was designed not only to provide guidance during

the installation phase, but to serve its owner as a reference source for years to come. It contains information

pertaining to the operation of its various components, electrical wiring details, maintenance procedures and

adjustment techniques or replacement methods for certain parts.

Please take time to read all sections of this manual. You will be rewarded with a better understanding of your

equipment and will gain product knowledge that will assist you in obtaining the performance that you should expect

from your Nor-Lake Walk-In.

Sincerely,

NOR-LAKE, INCORPORATED

Kevin Fink

President

ANY CORRESPONDENCE PERTAINING TO THIS EQUIPMENT MUST CONTAIN THE MODEL NUMBER OR

JOB NUMBER AND THE SERIAL NUMBER AS THEY APPEAR ON THE DATA PLATE LOCATED ON THE

INSIDE OF THE DOOR SECTION.

NOR-LAKE, INC.

727 Second Street

Hudson, WI 54016

800-955-5253 Foodservice Sales

715-386-2323

800-388-5253 Parts/Service

Fax: 715-386-6149

www.norlake.com

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

3

Page 4

ProduCT safeTy PolICy

PRODUCT SAFETY POLICY OF NOR-LAKE, INC.

We strive to provide those who buy and/or use our product with equipment which is:

1. Developed by applying professional engineering principles in product research, development and user safety.

2. Designed to comply with or exceed industry performance and safety regulations.

3. Thoroughly reviewed and professionally tested for function, reliability and product safety.

4. Manufactured according to our professional purchasing, production and quality control standards designed to

assure continued product reliability and safety.

5. Represented in our advertising and/or product literature in an informational and factual manner created to aid

our customer in their product selection.

6. Accompanied by clear, complete installation, operation and maintenance instructions designed to assure many

years of satisfactory product performance.

7. It is only through you, our satisfied customer, that we can continue our past successes in the design,

development and manufacture of refrigeration equipment.

8. Nor-Lake, Incorporated reserves the right to improve upon our products without notice and without imposing

on ourselves, any obligation to make such changes on products previously manufactured.

Warning: Walk-in oor must be kept free of any liquids, food particles or any items that could cause a slip

hazard. Spilt liquids, food particles or any moisture on the walk-in oor can cause the oor to become slippery.

Keep the oor surface clean and dry at all times.

• Inspect non-skid oor strips on ramps and oor surfaces and replace if worn.

• Inspect refrigeration system, door gaskets and hardware for proper operation to prevent moisture on walk-

in oor, ceiling or walls.

• Avoid leaving entry doors open for more than a ve minute period of time, which can cause a lm of ice to

form on oor, ceiling and wall surfaces due to the excessive condensation of warm moist air entering the

walk-in. Vinyl strip curtains can be used to reduce the amount of warm moist air entering the walk-in.

NOR-LAKE, INC.

727 Second Street

Hudson, WI 54016

800-955-5253 Foodservice Sales

715-386-2323

800-388-5253 Parts/Service

Fax: 715-386-6149

www.norlake.com

4

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 5

Tools requIred

TOOLS REQUIRED FOR UNCRATING AND INSTALLATION OF YOUR NOR-LAKE WALK-IN

• LEVEL

• CAULK GUN

• TAPE MEASURE

• SAFETY GLASSES

• HAMMER

• METAL SNIPS

• PRY BAR

• PHILLIPS SCREWDRIVER

• ALLEN WRENCH

• UTILITY KNIFE

• SQUARE

• DRILL DRIVER

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

5

Page 6

Walk-In InsTallaTIon

WALK-IN INSTALLATION GENERAL INFORMATION

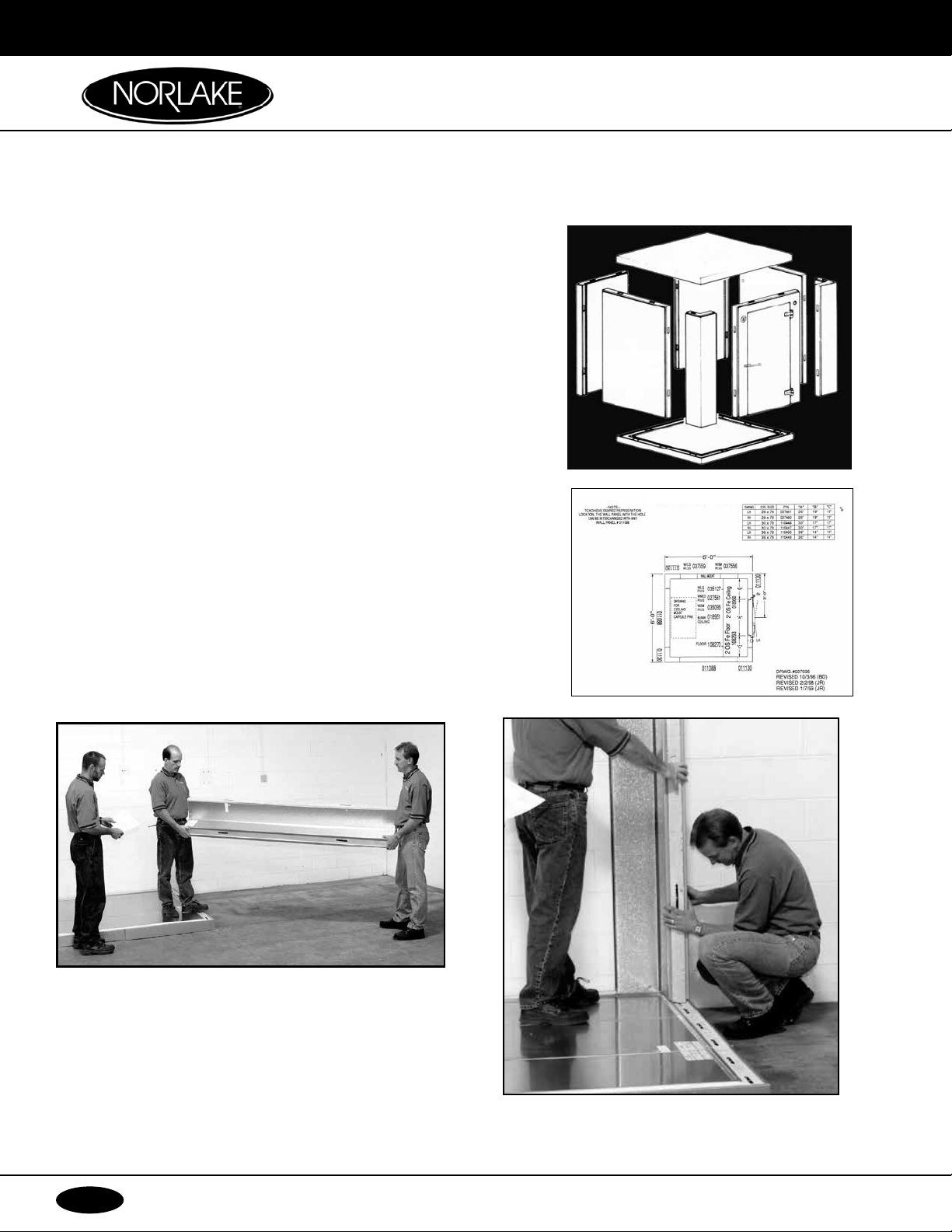

This walk-in cooler or freezer was produced utilizing the latest in

manufacturing technology, the highest quality materials available, along

with innovations that make it a distinctive product in its field. Despite

rigid controls in the production of the product, there is no substitute for

thoroughly reading and UNDERSTANDING the instructions that follow.

The result will be an orderly and efficient installation. Take the time to

follow the steps explicitly! NOTE: The most important step is to start

with a level surface.

NOTE: Indoor walk-in(s) must be in an environmentally controlled space.

Relative humidity should be kept between 30% - 60%, maintaining a dew

point of 50°F or less.

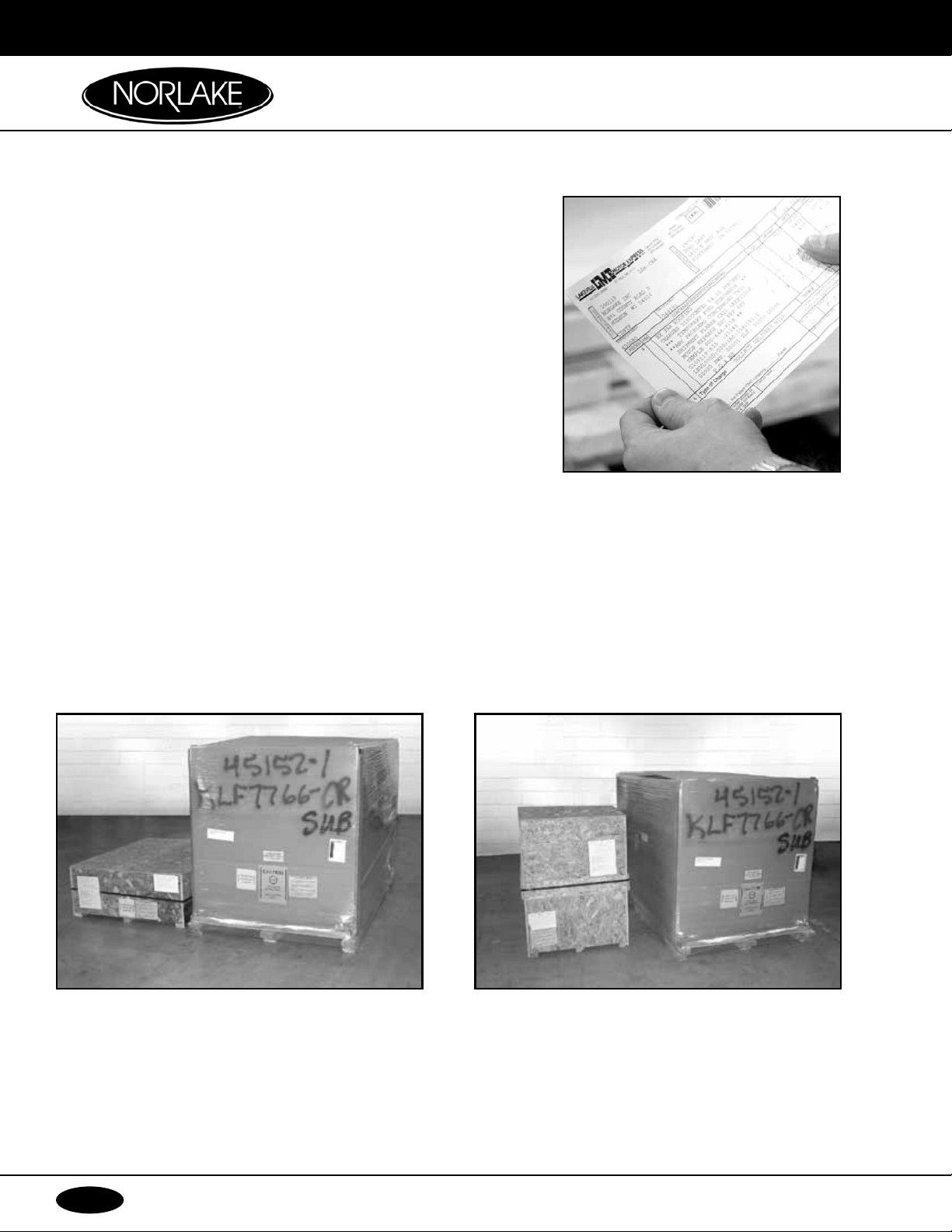

UNPACKING / INSPECTION

Check the Delivery Receipt for the number of pieces that made up the shipment and make sure that the number

of pallets, boxes or crates agrees with that number. Each piece should be clearly marked with the same five-digit

order number that appears on the Delivery Receipt as the shipper's number. Each individual walk-in is color coded.

Examine the general condition of the shipment and, as soon as unpacking is completed, carefully inspect all parts

for possible shipping damage. If damaged parts are discovered, contact Nor-Lake immediately.

Delivery Receipt

Kold Locker™ Walk-in with Ceiling Mount

Capsule Pak™ Refrigeration System

6

Kold Locker™ Walk-in with Remote

Capsule Pak™ Refrigeration System

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 7

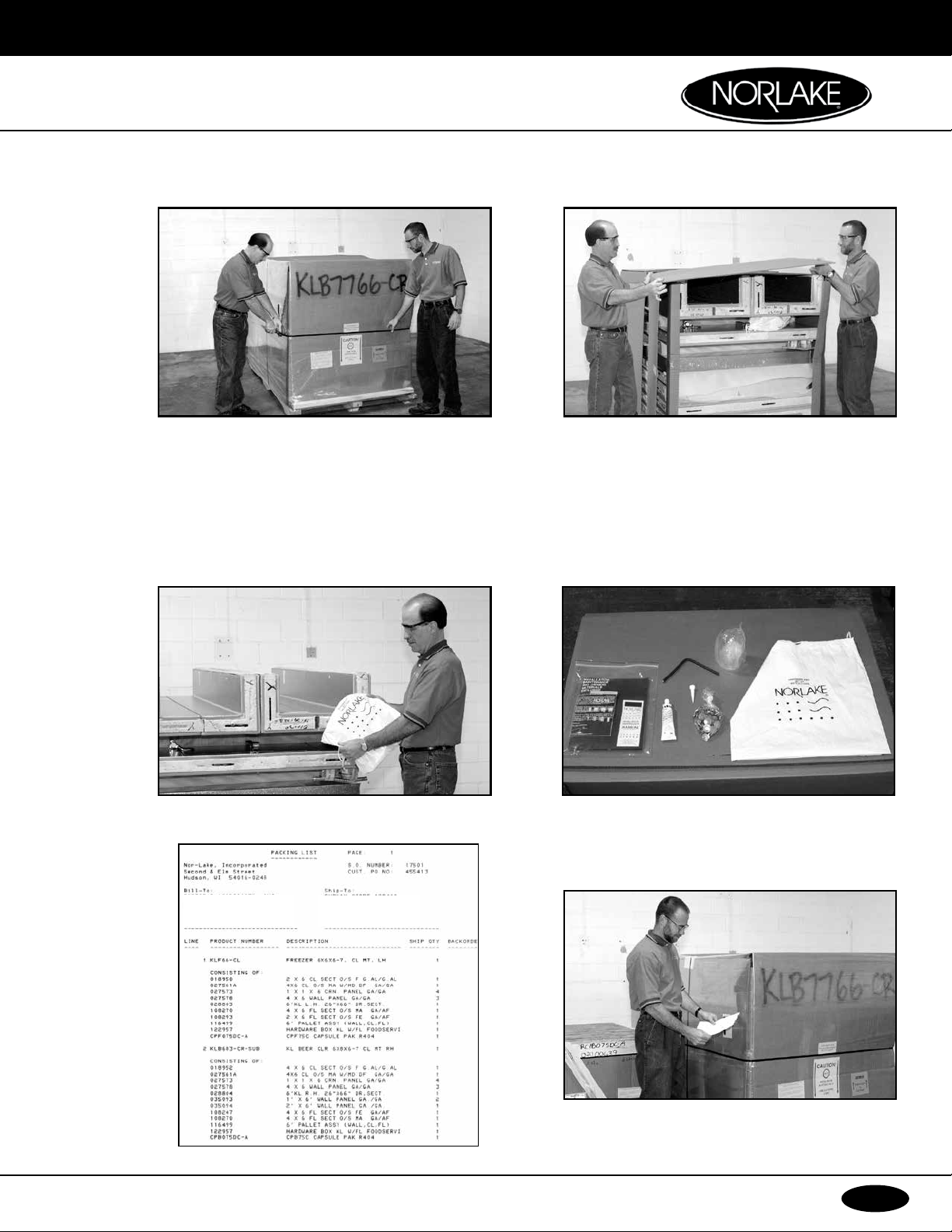

Walk-In InsTallaTIon

Remove protective packaging and locate the hardware bag.

The hardware bag contains accessory parts for this walk-in together with a construction diagram, a layout of the

screed assembly for floorless walk-ins, and a detailed packing list of all parts furnished for this individual walk-in.

All parts should be compared to the packing list.

If discrepancies are found, contact Nor-Lake immediately.

Some walk-ins come with an additional orange hardware box.

Locate packing list and use as a reference during uncrating.

Packing List

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

7

Page 8

Walk-In InsTallaTIon

FOAM PANEL STORAGE

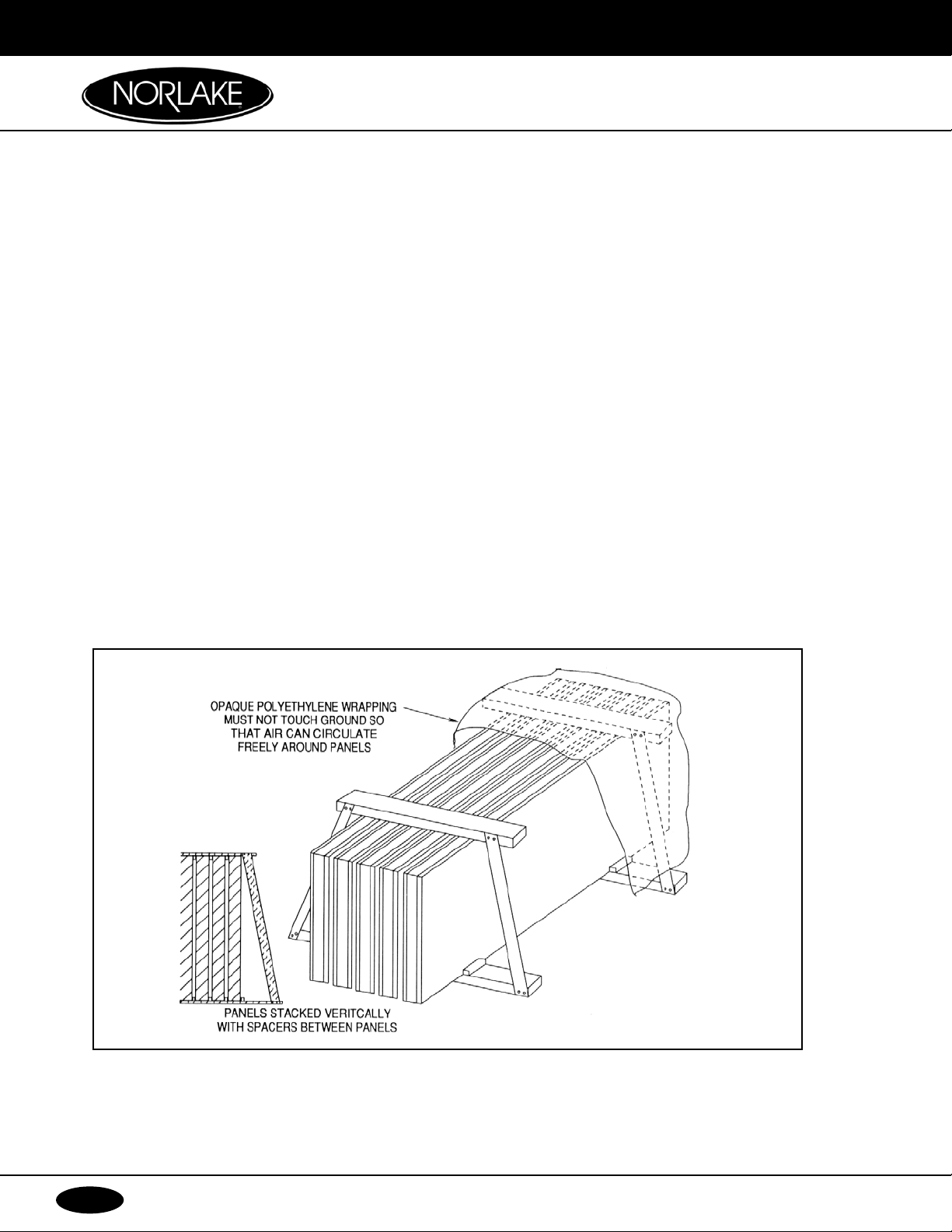

If foam walk-in panels require storage at the job site prior to installation, the following steps must be taken to

protect the panels against both staining from moisture and sunlight, and denting by workers and traffic.

Whenever possible, the panels should be stored indoors, and should remain in the crating pallet they were

originally shipped in. If the panels were uncrated as they were unloaded from the delivery truck, and they are being

stored indoors, they should be stored vertically on skids with spacers between the panels.

When storing panels in a vertical position, always place the female rail (grooved) edge down (see illustration

below.) This method of storing panels will provide proper ventilation, permit drain-off of condensation moisture

and protect panels against the formation of white rust stains.

If the panels must be stored outdoors, follow the same procedure as indicated for indoor storage WITH THIS

ADDITION: Cover the panels completely with an opaque polyethylene water-proof material to protect against rain,

snow, heat and sunlight.

The illustration below shows the method for storage outdoors when panels are not left in palletized crates.

Note: Nor-Lake always recommends equipment to be installed once received but understands storage may be

required. Nor-Lake does not guarantee issues related to storage, such as handling damage, storage damage,

panel aging, etc. We would recommend the locks be oiled and the panels be wiped down with a white oil.

8

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 9

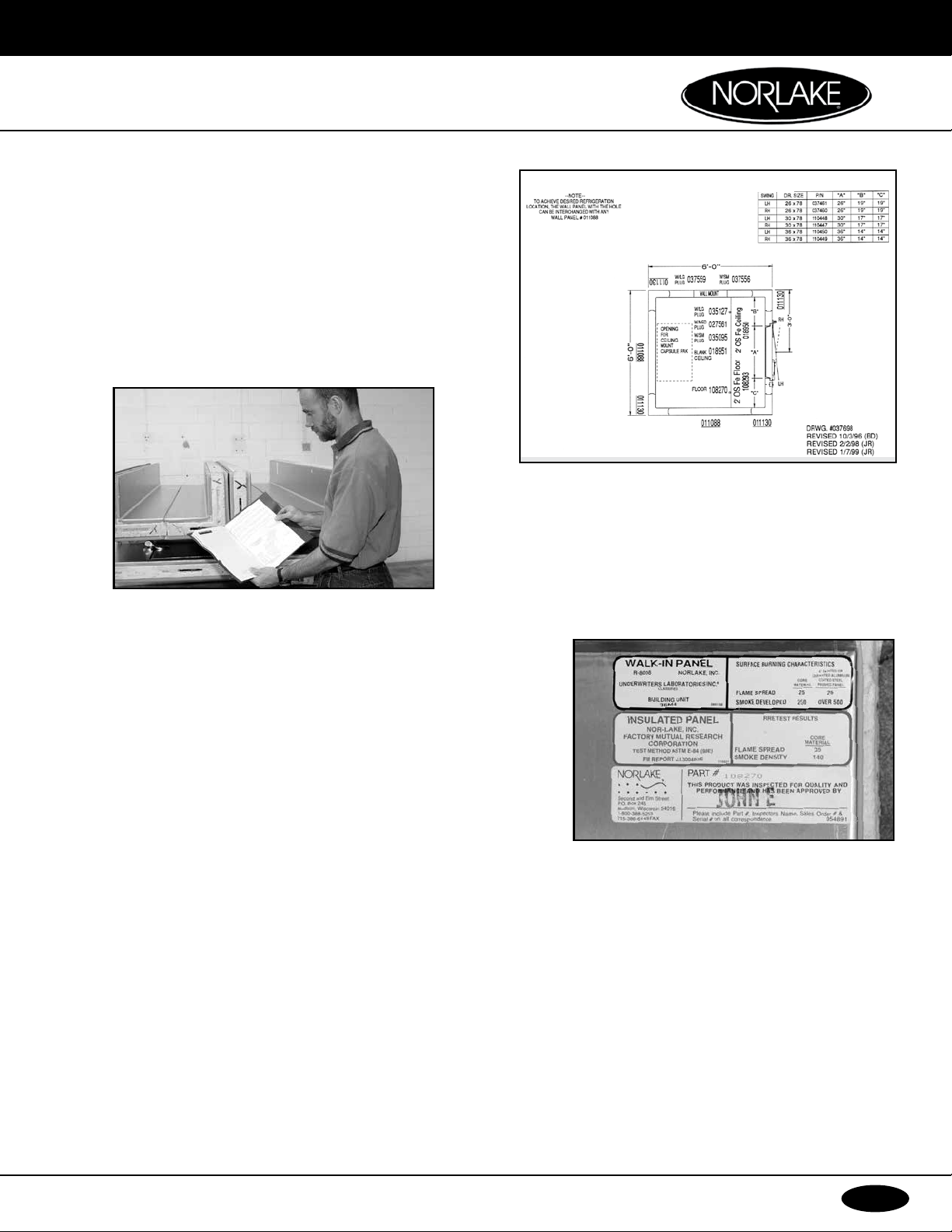

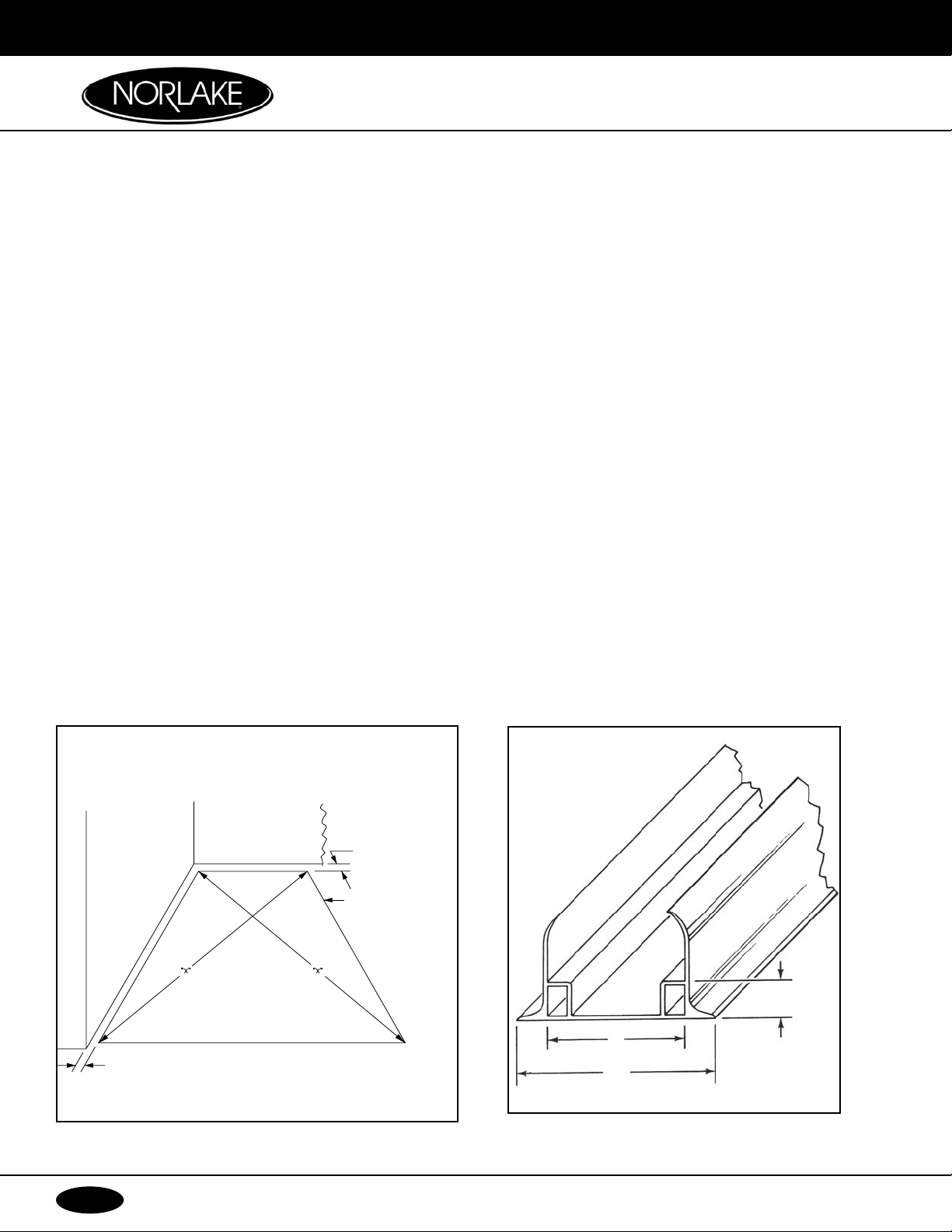

CONSTRUCTION DIAGRAM

The construction diagram, as furnished with each walkin, is a detailed plan that illustrates the placement of

every wall, corner, ceiling and floor panel that comprises

a complete, individual walk-in.

The construction diagram for all installations clearly

shows the direction of the male and female formed

profile of every wall panel and every corner panel.

Walk-In InsTallaTIon

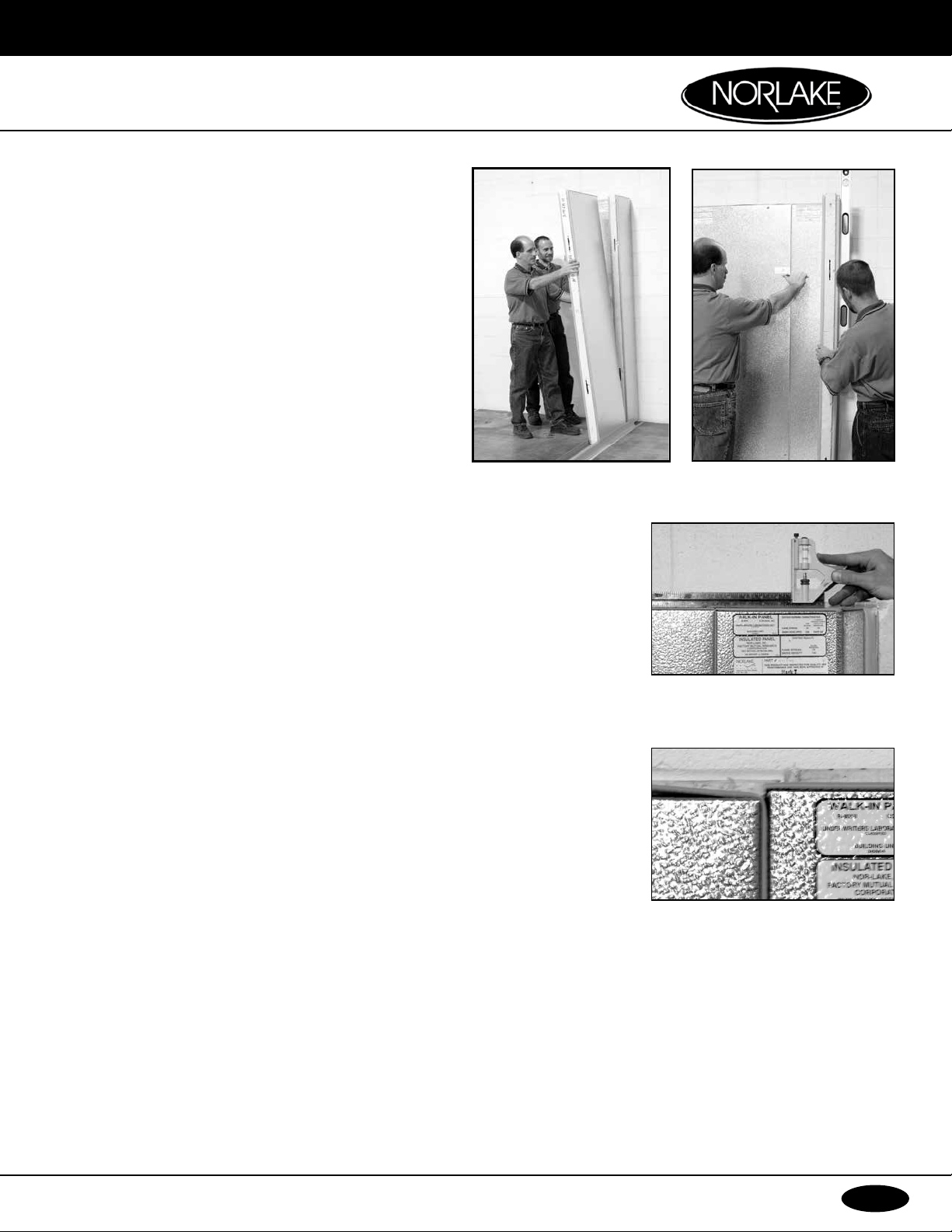

All sections used to construct your walk-in are marked with

a specific part number on the section, corresponding with its

location on the construction diagram.

If the walk-in is floorless, then a diagram showing the vinyl

screed (floor sealer) arrangement is provided.

The vinyl screed combines the capability of retaining the wall

panels in place while providing the inner and outer cove at the

junction of the walls and the building floor (a requirement of

Standard No. 7 of the National Sanitation Foundation (NSF).

IMPORTANT! Do not attempt to erect a floorless walk-in

FREEZER on an existing building floor that has not been

specially prepared and adequately insulated for below

freezing storage temperatures!

Construction Diagram

Nor-Lake Inspection Label and

Panel Specific Part Number.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

9

Page 10

Walk-In InsTallaTIon

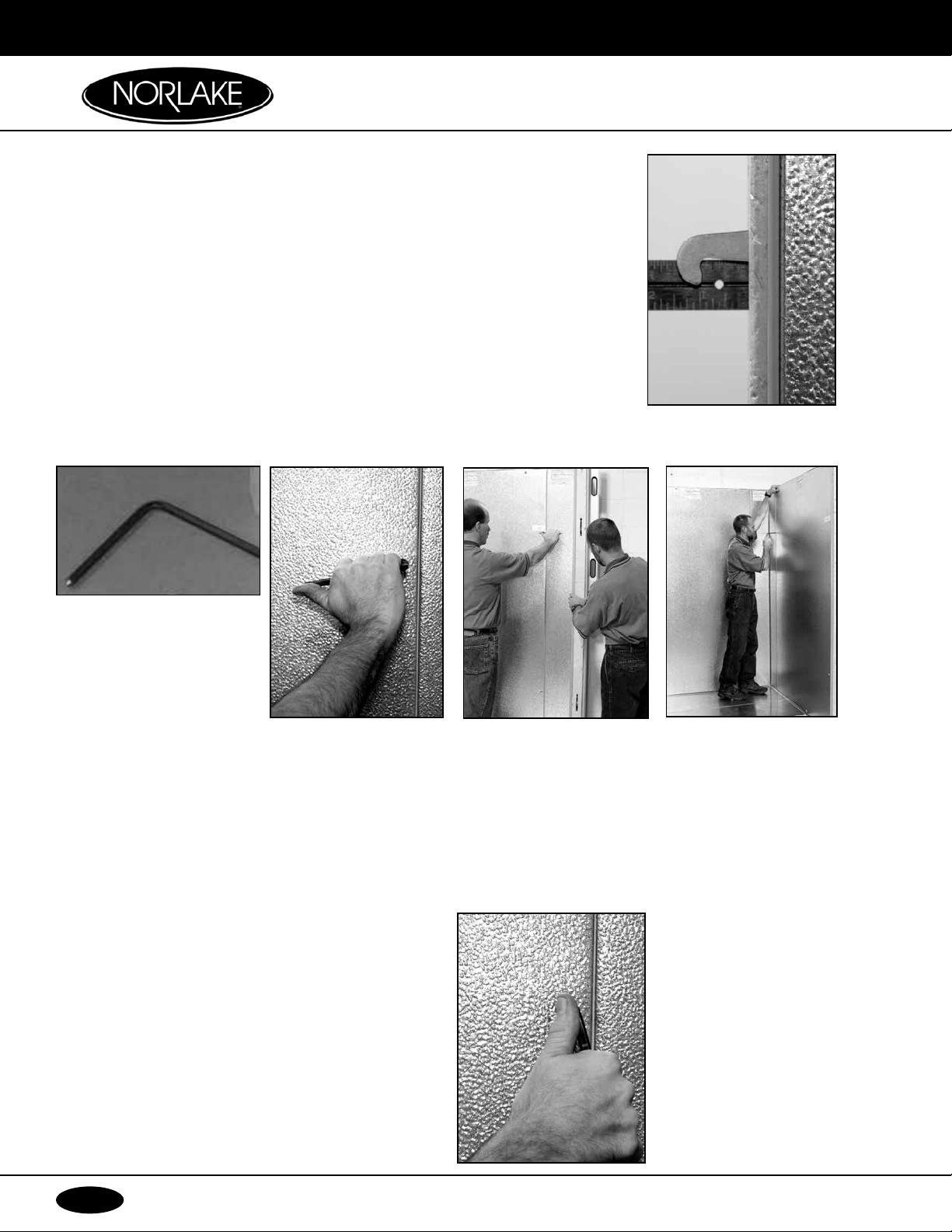

SECTION LATCHES

All wall, corner, ceiling and floor panels are joined and locked together by the

mechanical action of section latches which are integrally foamed into the panels

near the perimeter edges. A section latch consists of two halves – a lock housing

which contains a cam actuated locking arm, or hook, and a strike housing which

contains the engagement pin. Both housing halves are securely anchored in the

foam core of the panel. The lock housing is always located in the male-formed

edge and the strike housing will be found in the female-formed edge of the panel.

TO OPERATE LATCHES

Hex wrench provided in

hardware bag

1. Insert the hex wrench

(packed in the hardware

bag) through the access

hole in the interior

panel metal into the hex

opening of the section

latch. Turn wrench in

a counterclockwise

direction to ensure

that the lock is fully

unlatched

2. Push the sections

tightly together and turn

the wrench 1/4 turn in a

clockwise direction. This

will engage the locking

arm (hook) over the pin in

the strike housing.

Fully Extended Cam Lock

3. Continue turning the

wrench to a full stop

(approximately 3/4 of a

complete turn from the

unlatched position) to

complete the locking

operation.

Latches on some panels

will have to be turned

counterclockwise to

activate the locking cam.

These latches will be

designated by a "TURN"

sticker.

10

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 11

Walk-In InsTallaTIon

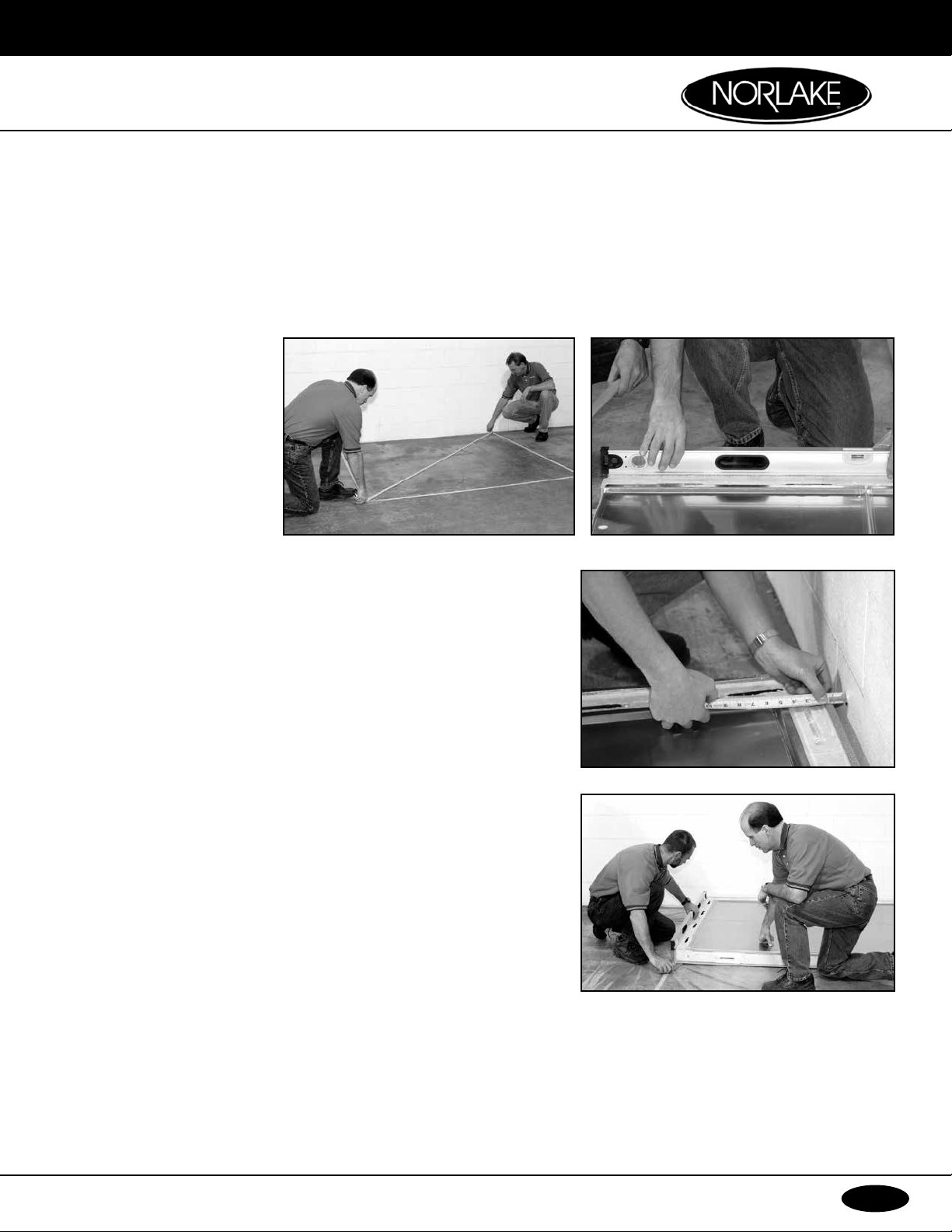

SITE SELECTION, BASE PREPARATION AND LEVELING THE FLOOR

WALK-IN COOLER OR FREEZER WITH A FLOOR

One of the most important considerations in the construction of a walk-in cooler or freezer is the building floor or the

surface upon which the walk-in will rest. As with any structure, a firm and level foundation is essential to achieve

a perfect end result. If the surface is not perfectly level and smooth, appropriate steps must be taken to provide

the proper base. The positive action of self-closing doors, proper door gasket seal and condensate removal all

depend directly upon the level and plumb installation of all panels.

If the walk-in is to

be installed next to

an existing building

wall(s), make sure

that a MINIMUM OF 2"

REMAINS BETWEEN

THE WALK-IN AND

THE BUILDING

WALL(S) to allow for

irregularities of the

building wall(s) and to

permit a free flow of

air between the two surfaces.

NOTE: Indoor walk-in(s) must be in an environmentally controlled

space. Relative humidity should be kept between 30% - 60%,

maintaining a dew point of 50°F or less.

In some cases, the surface upon which the walk-in is to be

installed was especially prepared for installation and it is perfectly

level and smooth. The walk-in floor, in this case, may be installed

without further preparation. Before beginning, however, an

appropriate vapor barrier should be placed over the surface

that the walk-in will occupy. Asphalt felt paper (50#) or a 6 mil

polyethylene film, are suggested materials. These are provided

by the installing contractor.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

11

Page 12

Walk-In InsTallaTIon

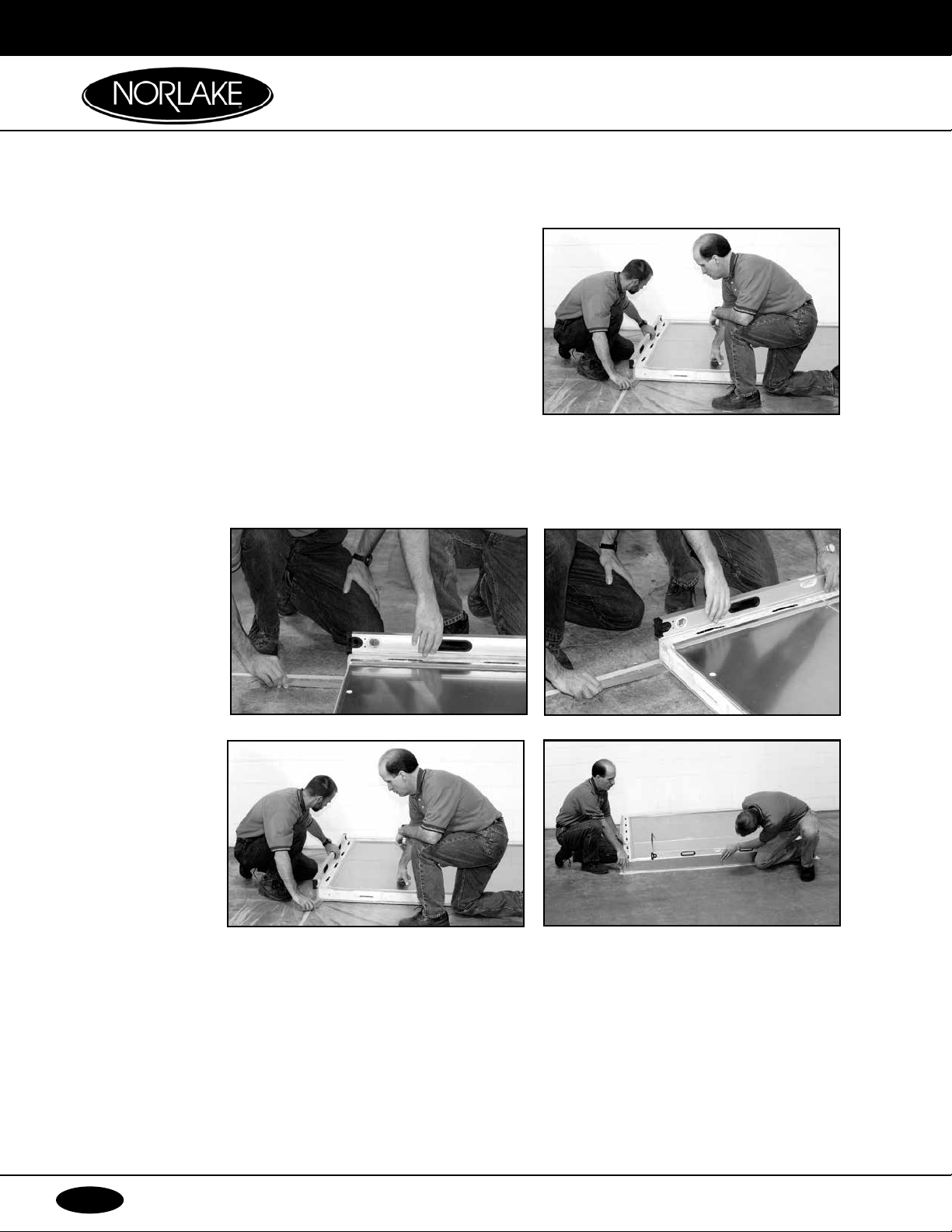

FLOOR INSTALLATION (Shim Leveling Method)

FOR WALK-INS SUBJECT TO LIGHT TO MODERATE LOADS

Locate the highest point within the perimeter lines. A transit or

surveyor’s level or rotary laser level is an ideal instrument to use for

locating this point. When the highest point is located, mark it directly

on the floor and refer to the construction diagram to determine where

the high point is located with respect to the walk-in floor plan.

One of the most important procedures that will be encountered in

the construction of a walk-in with a floor is LEVELING THE FLOOR.

It must be PERFECTLY LEVEL! If it is not, the wall panel will

follow the irregularities of the walk-in floor which will directly affect

subsequent procedures such as latching, panel gasket seal, ceiling

panel assembly among others.

Using the construction diagram as a guide, select the floor panel that will be located directly over the highest point

and place it in that position while observing the drawn outline on the building floor.

After the first floor

panel is positioned,

it must be properly

leveled. To achieve

this, shimming material

of varying thicknesses

must be used. Cedar

building shingles are

ideally suited for this

procedure.

IMPORTANT! EVERY

FLOOR PANEL MUST

BE SUPPORTED ON

ALL FOUR SIDES

AND THE ENTIRE

UNDERSIDE, AT

LEAST EVERY 12"

BY EITHER THE

BUILDING FLOOR

OR BY SHIMMING.

HOWEVER, OTHER

MATERIALS THAT

ARE RESISTANT TO ROTTING OR COMPRESSION ARE ALSO ACCEPTABLE.

After the first floor panel has been leveled perfectly, trim away the excess shim material so that none projects from

the panel at any of the four edges.

From the construction diagram, determine which floor panel will be installed next and where it will be situated on

the floor plan. Prepare shimming material for the second panel at each point where shimming material was used

beneath the first floor panel. The shimming material thickness must be such that it will support the second floor

panel at exactly the same height as the first panel along the entire length of the joint. NOTE: In many cases, the

shimming material will be the same thickness as the adjacent shimming under the first panel.

12

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 13

Place the second panel in position next to the first floor panel but

DO NOT LOCK!

Shim the second panel, where necessary, using the same procedure

as was used on the first panel. When all four edges of the second

floor panel are properly shimmed, lock the two panels securely

together. Using the same technique for leveling, check the levelness

of the two sections in all directions by placing the level across the

joint at several points and, again, check the levelness of the floor

panels in the direction of the panel joint.

Walk-In InsTallaTIon

Refer to the construction diagram and install the remainder of the

floor panels using the same procedure as was used for the first and

second floor panels. When all of the floor panels are installed and

leveled perfectly, check the section latches for full and complete

locking.

Trim excess vapor barrier.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

13

Page 14

Walk-In InsTallaTIon

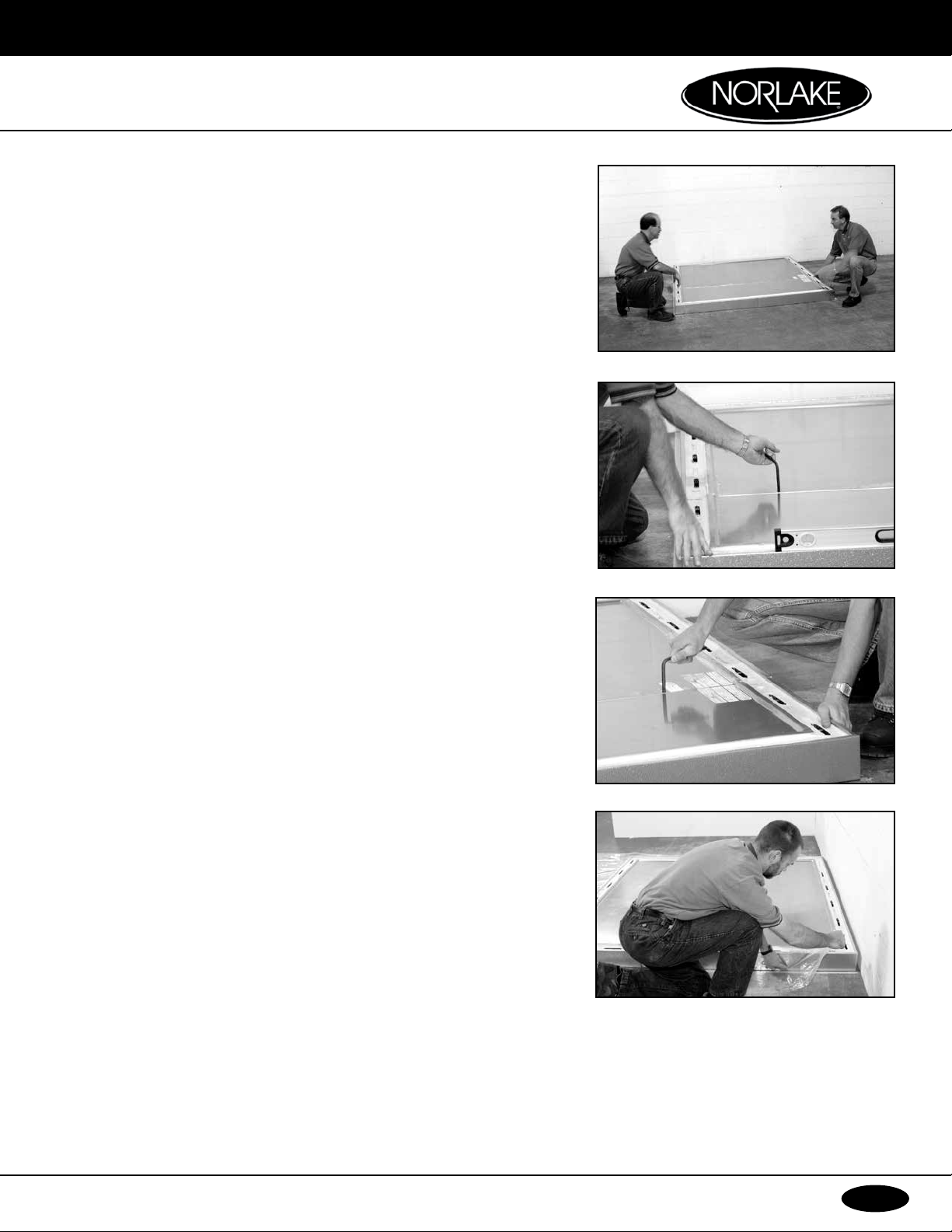

SITE SELECTION, BASE PREPARATION

WALK-IN COOLER WITHOUT A FLOOR INSTALLED ON 1” VINYL SCREED

IMPORTANT! Do not attempt to construct a floorless walk-in FREEZER on a existing building floor that has not

been specially prepared and adequately insulated for below freezing storage temperatures. Note: All thermal

breaks in floor slab must be exposed, including the partition wall.

To install a vinyl screed assembly on an existing floor, proceed as follows:

Locate the screed (floor sealer) diagram which was packed in the hardware box and, using it as a guide, draw

an outline of the outside dimensions of the installed screed directly onto the building floor where the walk-in will

be situated. These dimensions will be 1 1/2” larger than the overall dimensions of the walk-in in both directions.

If the walk-in is to be installed next to an existing building wall(s), make sure that a

MINIMUM OF 2” REMAINS BETWEEN THE DRAWN OUTLINE AND THE BUILDING WALL (s) to allow

for irregularities of the building wall (s) and to permit a free flow of air between the two surfaces.

CAREFULLY CHECK FOR SQUARENESS by insisting that the two dimensions between opposite corners are

equal (Figure 1).

One of the most important procedures that will be encountered in the base preparation is LEVELING THE SCREED.

It must be PERFECTLY LEVEL! If it is not, the wall panels will follow the irregularities of the building floor which

will directly affect subsequent procedures such as panel latching, panel gasket seal, ceiling panel assembly and

others.

After the outline of the screed assembly is completed, locate the highest point within the outline on the floor where

the screed will be installed. Screed sections are 5 1/2” wide. A transit or surveyor’s level is an ideal instrument

for this purpose. Mark the highest point on the floor (Figure 2) and, referring to the screed diagram, identify and

locate the appropriate screed section and position it directly over the highest point.

1’’ VINYL SEALER

EXISTING WALL

EXISTING WALL

2” MINIMUM

EXACT DIMENSIONS

OF SCREED ASSEMBLY

(REFER TO SCREED

DIAGRAM)

14

2” MINIMUM

NOTE: DIMENSIONS “X-X”

MUST BE EQUAL!

4’’

5 1/2’’

Figure 1

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

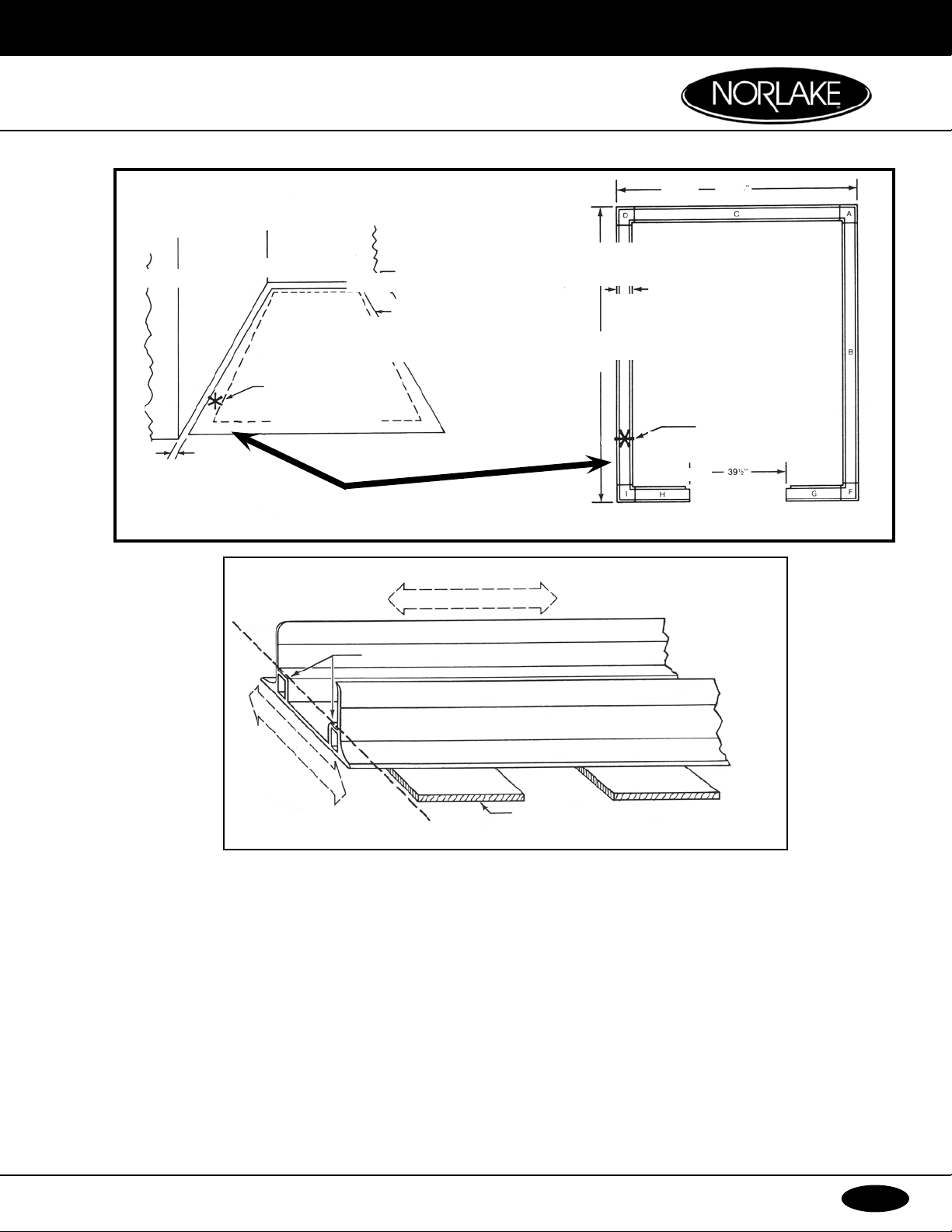

Page 15

Walk-In InsTallaTIon

EXISTING WALL

EXISTING WALL

2’’ MINIMUM

HIGHEST POINT

(EXAMPLE ONLY)

Figure 2

2’’ MINIMUM

EXACT DIMENSIONS

OF SCREED ASSEMBLY

(REFER TO SCREED

DIAGRAM)

Note: All

sealers lettered

alike are

interchangeable.

LEVEL

8’-1 1/2’’

OVERALL SCREED WIDTH THAT

CONTACTS THE FLOOR IS 5 1/2’’

5 1/2’’

Sealers may also be

numbered by part

number

(Screed Diagram)

HIGHEST POINT

(EXAMPLE ONLY)

39 1/2’’

Note: Corners are shipped in two pieces.

Installer to silicone together during the installation

LEVEL THOSE SHOULDERS IN BOTH DIRECTIONS

SHIMMING MATERIAL

Figure 3

After the first screed section is positioned, it must be LEVELED PERFECTLY not only over its length but, across

its width, as well. To achieve this, shimming material will most likely be required. Vinyl floor tile is ideally suited for

this purpose. However, other materials that are resistant to rotting or compression are acceptable. IMPORTANT!

EVERY SECTION OF SCREED MUST BE SUPPORTED AT LEAST EVERY 12’’ BY EITHER THE BUILDING

FLOOR OR BY SHIMMING (Figure 3).

Assuming that the first screed section has been perfectly leveled, refer to the screed diagram and select an

adjoining screed section and level it perfectly in both directions, shimming wherever necessary. Continue leveling

the remainder of the screed sections until the entire assembly is in position. Check the assembly to make sure

that the outer edges are located exactly on the drawn outline on the building floor.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

15

Page 16

Walk-In InsTallaTIon

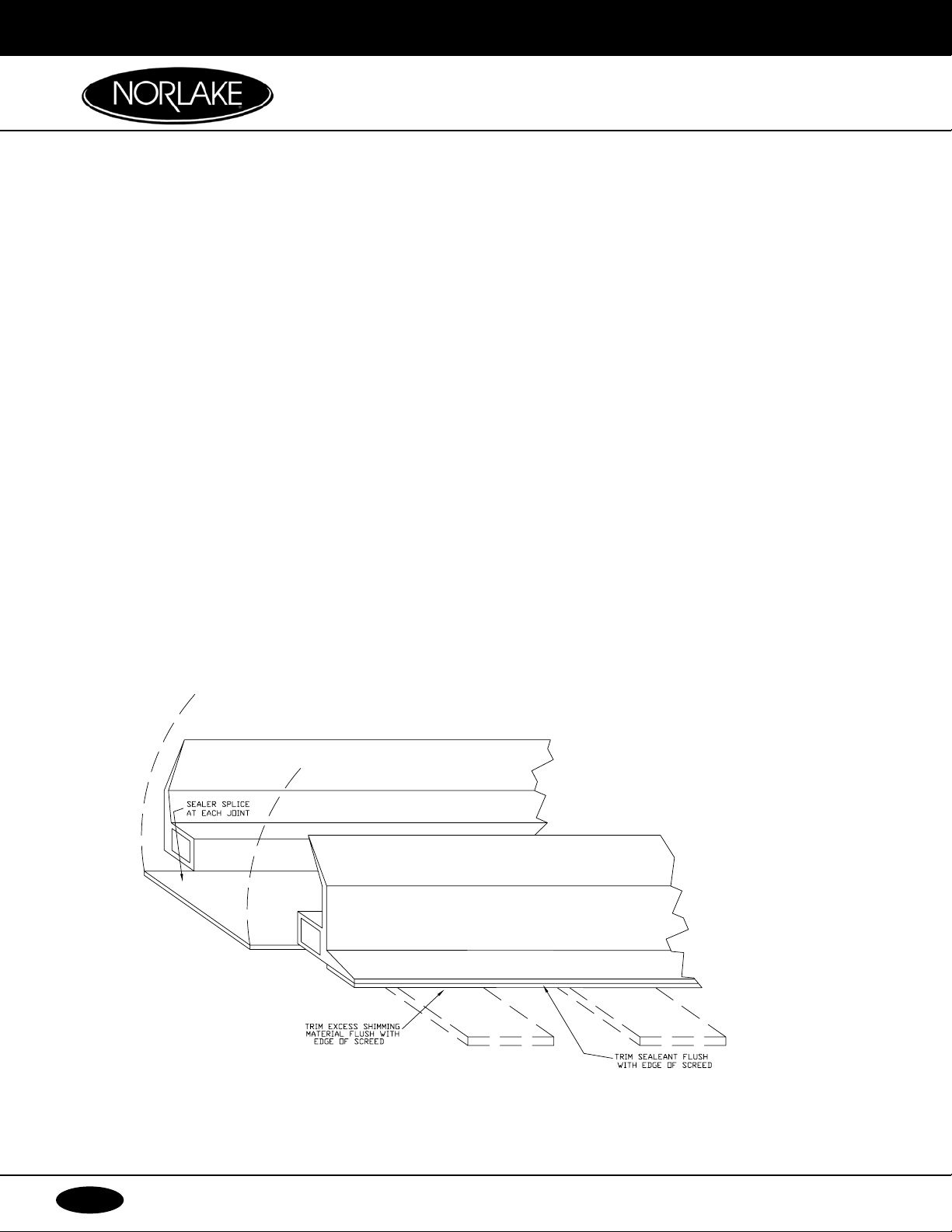

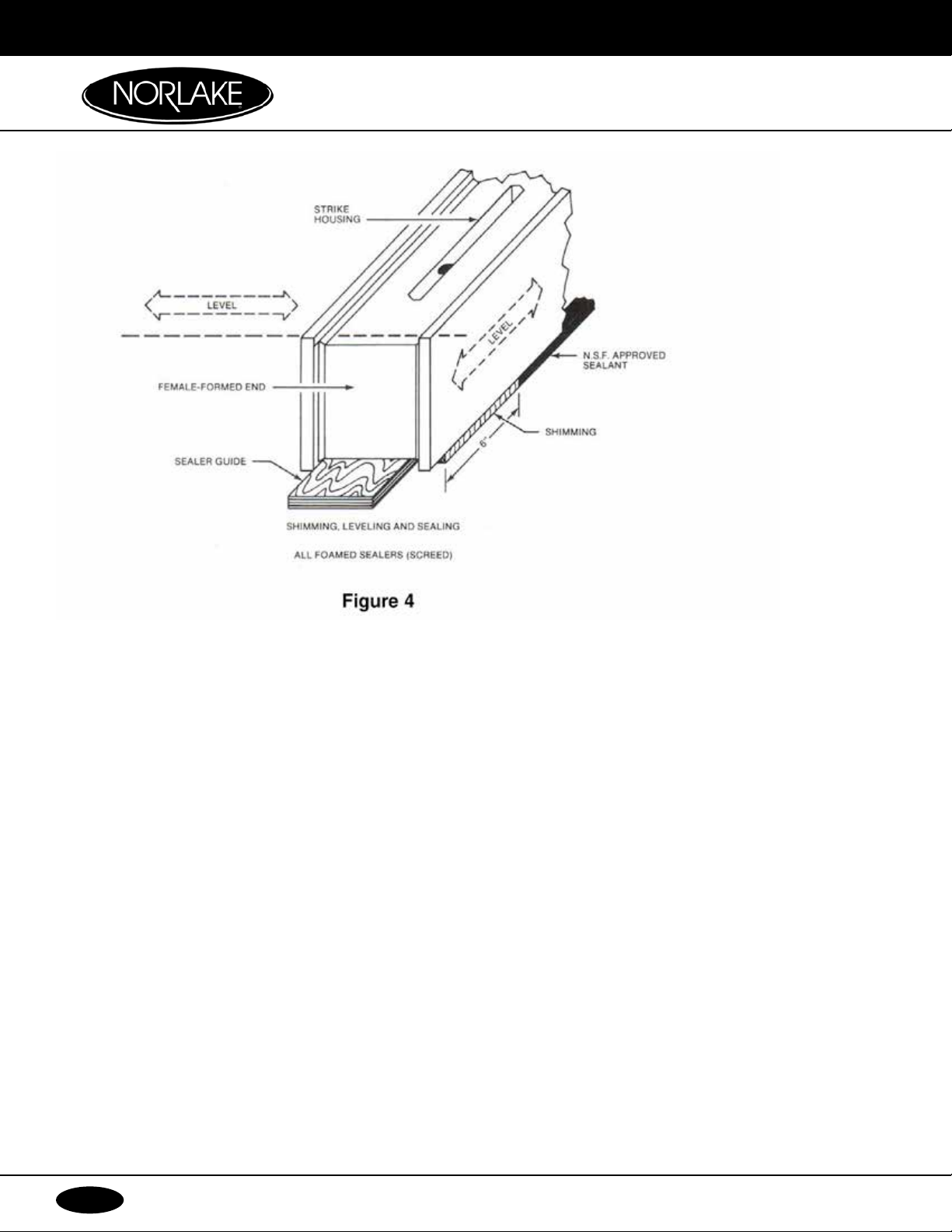

When the entire screed assembly is leveled and supported by shimming, as required,

CAREFULLY AND WITHOUT DISTURBING THE SHIMMING MATERIAL, lift the screed sections, tip them

upside-down and apply a heavy bead of construction sealant to the bottom of the screed section along both of the

edges that contact the building floor surface. The diameter of the sealant bead should be larger than the thickest

shimming material to ensure a complete, air-tight seal along the entire length of the screed (Figure 4). NSF

approved sealant is provided and will be found in the hardware box.

Immediately after applying the construction sealant to a screed section, replace the screed section to its original

location on the building floor WITHOUT DISTURBING THE SHIMMING MATERIAL and place a sealer splice every

joint in the screed assembly (Figure 4). Since the sealer splice is intended to keep adjacent screed sections in

alignment, approximately one-half of the sealer splice should lap each section. It need not be fastened in place

(Figure 4). NOTE: Seal all screed joints with sealant. Make a final check for squareness, levelness and

whether the screed assembly is located properly with respect to the drawn outline on the building floor.

Follow by securing the screed assembly to the building floor with fasteners that are appropriate for the building

floor. These fasteners are not provided and must be obtained by others.

Fasteners should be applied down the center line of the inside of the screed at intervals of approximately 36’’;

however, where shimming is used, apply the fasteners through the shimming material, NOT BETWEEN the

shimming. When the entire assembly is secured in position, trim away all excess construction sealant and

shimming on both edges of the screed. Trim flush with the sealant lip of the screed and touch up any areas where

the construction sealant is not making a perfect seal (Figure 4).

NOTE: In the event that the building floor was specially prepared for the installation and no low or high points are

detectable, it is possible that no shimming will be necessary. It will then only be necessary to apply construction

sealant to the bottom of the screed and secure the screed directly to the building floor. The entire procedure, as

described, must be followed explicitly, however, except for the details that pertain to the shimming.

16

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 17

TAPE z

Walk-In InsTallaTIon

SHIMMING MATERIAL

SEALANT

Figure 5

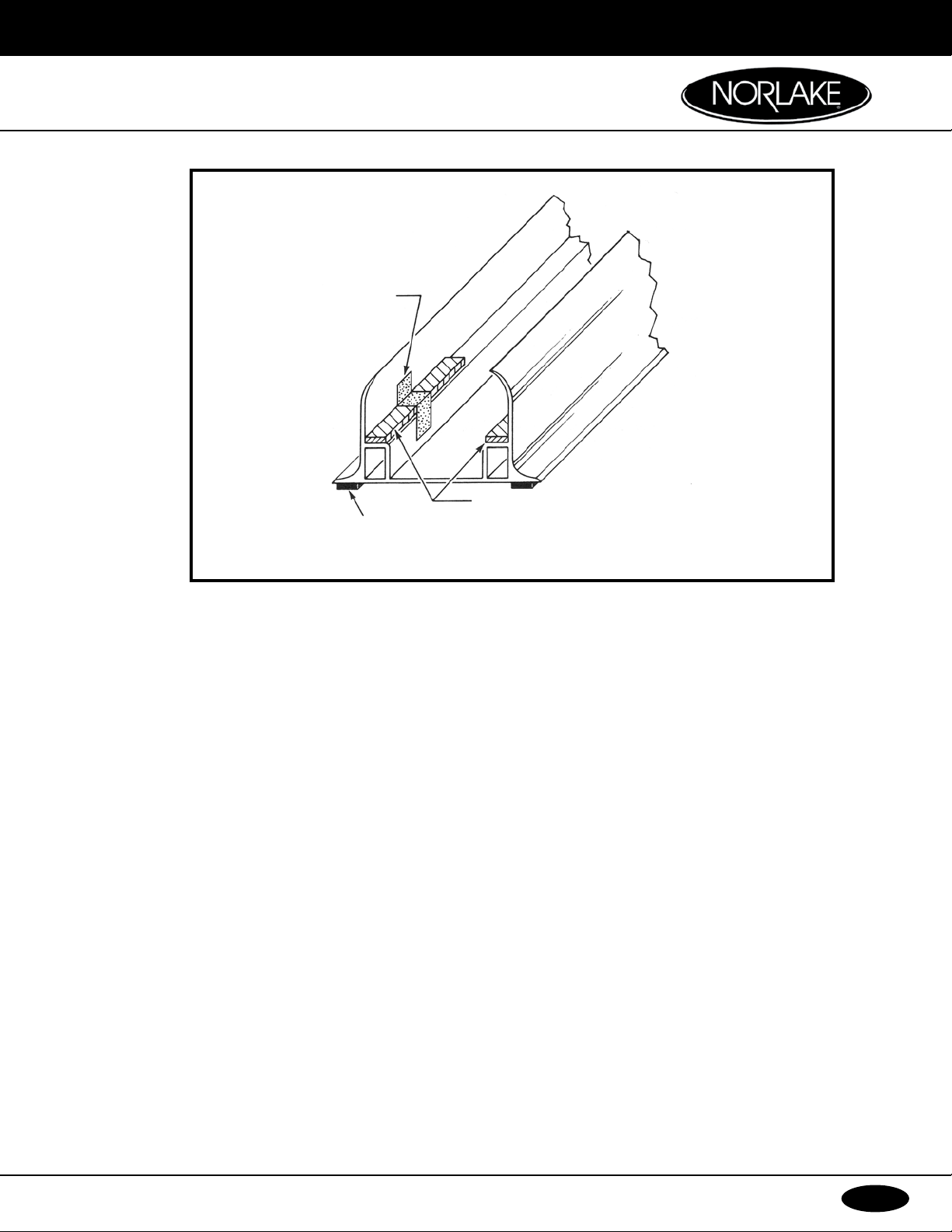

ALTERNATE SHIMMING METHOD FOR 1’’ VINYL SCREED

If the surface that the vinyl screed will occupy is level, except for an occasional low point, the screed may be

secured directly to the building floor and compensation for the low points may be achieved by shimming the

support shoulders on the inside of the screed.

When employing this method, the low points should be marked on the building floor in the vicinity of the drawn

outline for reference. After the screed has been sealed and secured, leveling may proceed with special attention

being focused in the areas marked as being low points.

Vinyl floor tile is often chosen as shimming material and strips (5/8’’ wide maximum) are cut and placed on top

the supporting shoulders of the screed to provide a level surface for the wall sections to rest upon. Strips of tape

should be applied to hold the shimming material in place (Figure 5).

IMPORTANT! Shimming the support shoulders on the inside of the screed is ideally suited for minor irregularities

on the building floor and has the advantage of complete screed-to-floor contact over the entire perimeter of the

assembly. IT IS NOT RECOMMENDED, HOWEVER, FOR EXTREMELY IRREGULAR BUILDING FLOORS.

Excessively thick shimming material on the support shoulders may elevate the wall panels to a point where the

effectiveness of the uppermost screed sealing flanges would be compromised. Shimming thickness of more than

3/4’’ should be avoided! If shimming the support shoulders of the screed is selected, the entire procedure, as

described, must be followed explicitly to ensure squareness and levelness over the entire screed assembly.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

17

Page 18

Walk-In InsTallaTIon

SITE SELECTION, BASE PREPARATION

WALK-IN COOLER OR FREEZER WITHOUT A FLOOR INSTALLED ON FOAMED SEALERS

IMPORTANT! Do not attempt to erect a floorless walk-in FREEZER on an existing building floor that has not been

specially prepared and adequately insulated for below freezing storage temperatures. Note: All thermal breaks

in floor slab must be exposed, including the partition wall. To install a foamed sealer (screed) assembly on

an existing floor, or on a properly prepared floor for freezers, proceed as follows:

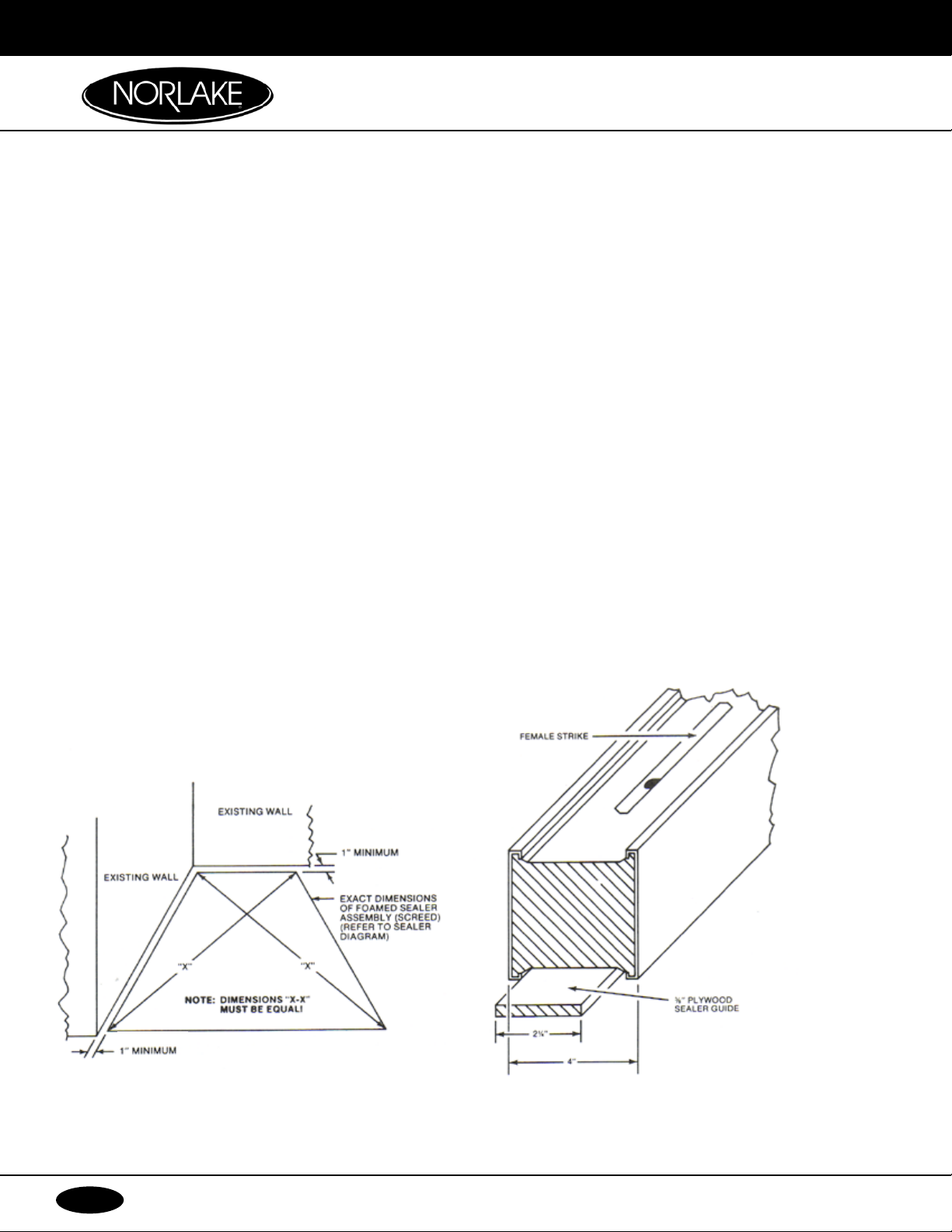

Locate the floor sealer (screed) diagram that was packed in the hardware box and, using it as a guide, draw an outline

dimensions of the installed sealer (screed) assembly directly onto the building floor precisely where the walk-in will

be situated. These lines will be exactly the same dimensions as the dimensions of the walk-in in both directions.

If the walk-in is to be installed next to an existing building wall(s), make sure that a MINIMUM OF 2” REMAINS

BETWEEN THE DRAWN OUTLINE AND THE BUILDING WALL(S). This space will allow for irregularities in the

building wall(s) and will permit a free flow air between the two surfaces. CAREFULLY CHECK FOR SQUARENESS

by insisting that the dimensions between opposite corners are equal (Figure 1).

Since the foamed sealer (screed) is retained in position by a 3/8” thick plywood sealer guide, which will be secured

to the building floor, it is imperative that the sealer guide be accurately located, as well, on the building floor. Refer

to the sealer guide diagram which was also packed in the hardware box. On the diagram, you will notice that

the sealer guide is located 78” INSIDE the drawn outline which represents the outside dimensions of the sealer

(screed) assembly. Further, Fig. 1 illustrates that the sealer guide is 2 1/4” wide centered beneath a 4” wide sealer

leaving a border of 7/8” along each edge. Draw another outline of the outside dimensions of the sealer guide

directly onto the floor. There should be exactly 7/8” between the new sealer guide outline and the previously drawn

sealer (screed) outline (Figure 2, on next page).

18

2" MINIMUM

2" MINIMUM

Figure 1

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 19

)LJXUH

2” MINIMUM

Walk-In InsTallaTIon

2” MINIMUM

Figure 2

2” MINIMUM

2” MINIMUM

Figure 3

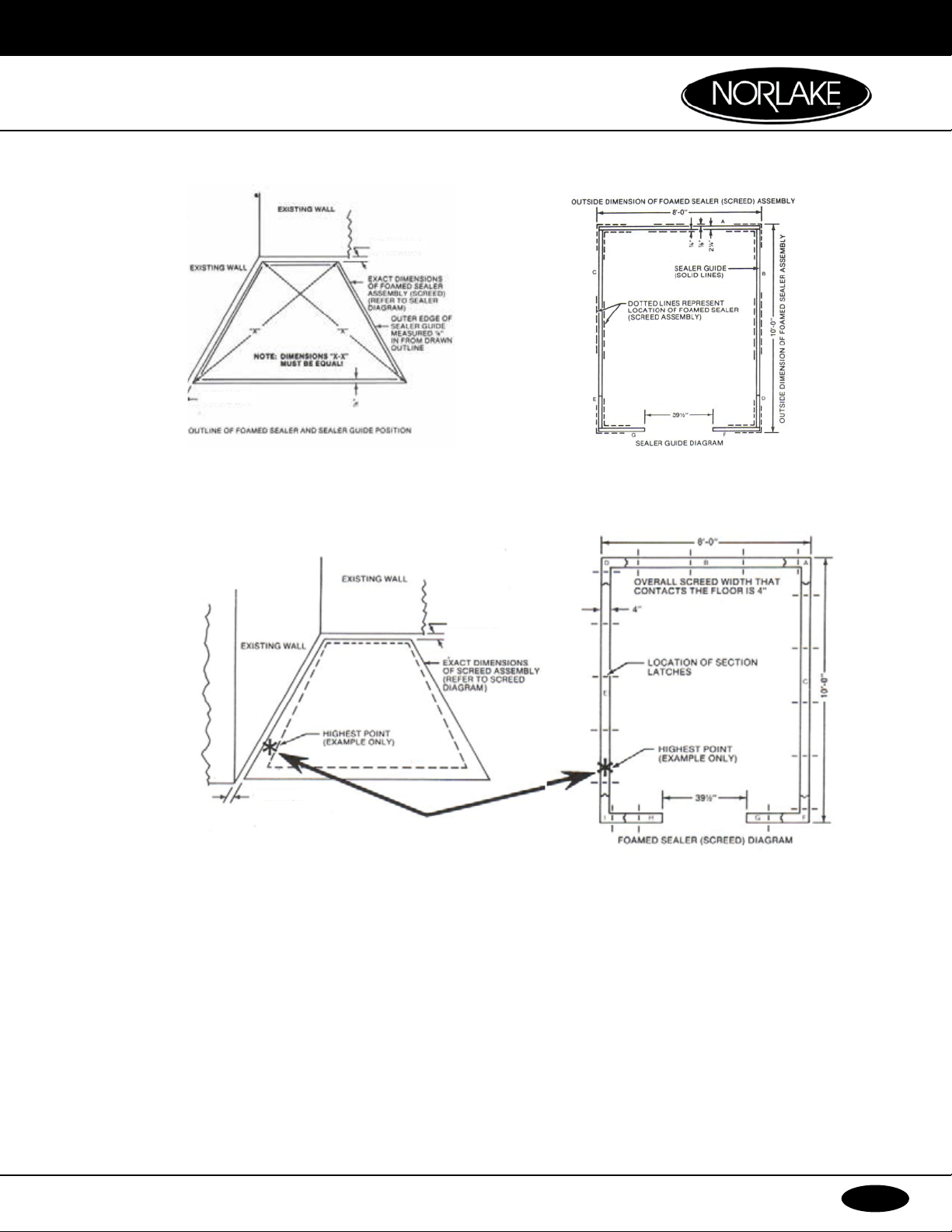

One of the most important procedures that will be encountered in the base preparation is LEVELING THE

SEALER (SCREED). It must be PERFECTLY LEVEL! If it is not, the wall panels will follow the irregularities of the

building floor which will directly affect subsequent procedures such as panel latching, panel gasket seal, ceiling

panel assembly and other.

After the outline of the sealer (screed) and the sealer guide is completed, as shown in Figure 2, locate the highest

point within the outline on the floor where the screed (sealer) will be installed. (Sealer sections are 4” wide). A

transit or surveryor’s level is an ideal instrument for this purpose. Mark the highest point on the floor as illustrated

on Figure 3.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

19

Page 20

Walk-In InsTallaTIon

SEALER GUIDE INSTALLATION

Locate the SEALER GUIDES. They are bundled together and packed along with the walk-in corner or wall panels

and are labeled accordingly. Sealer guides are strips of 3/8” plywood 2 1/4” wide as shown in Figure 1.

Refer to the SEALER GUIDE DIAGRAM. Select the proper sealer guides and position them as shown by the

circled letters on the diagram. Each length of sealer guide is marked with a circled letter that corresponds to the

circled letters on the sealer guide diagram.

Each sealer guide, when positioned properly, will have its outer edge precisely over the INSIDE OUTLINE drawn

on the building floor, Figure 2, and its outer edge will be exactly 7/8” from the outline which represents the foamed

sealer outer edge. The quality of workmanship performed in locating and securing the sealer guides will be

transmitted directly to the location of the foamed sealers (screeds) and, subsequently, to the overall construction

of the complete walk-in. BE EXACT! Refer to Figure 1 and Figure 2.

When all sealer guides are in position, make a final CHECK FOR SQUARENESS and secure them to the building

floor with fasteners that are appropriate for the surface. NOTE: This can either be a mechanical fastener or

construction grade adhesive. If the sealer guide is positioned over a polystyrene or polyurethane thermal breaker,

a compatible construction adhesive may be used.

FOAMED SEALER (Screed) INSTALLATION

Refer to the FOAMED SEALER DIAGRAM. Identify and locate the sealer section that will be positioned directly

over the highest point which was determined earlier and marked on the building floor (Figure 3).

NOTE: All foamed sealers are male-formed on one end and female formed on the opposite end. The configuration

of the ends is clearly indicated on the diagram. Also, make certain that the strike housing portion of the section

latches is visible on the upper edge of the sealer when it is in position (see Figure 1 and Figure 2).

20

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 21

Walk-In InsTallaTIon

Figure 5

After the first sealer (screed) section is positioned over the sealer guide and over the highest point, it must be

LEVELED PERFECTLY not only over its length but, across its width, as well. to achieve this, shimming material

will probably be required. Vinyl floor tile cut in strips 7/8” wide by 6” long make ideal shimming strips that can be

placed beneath the sealer, wherever necessary, to achieve levelness.

IMPORTANT: EVERY SECTION OF SEALER (SCREED) MUST BE SUPPORTED AT LEAST EVERY 24” BY

EITHER THE BUILDING FLOOR OR BY SHIMMING. Avoid using shimming strips less that 6” long whenever

possible (see Figure 4).

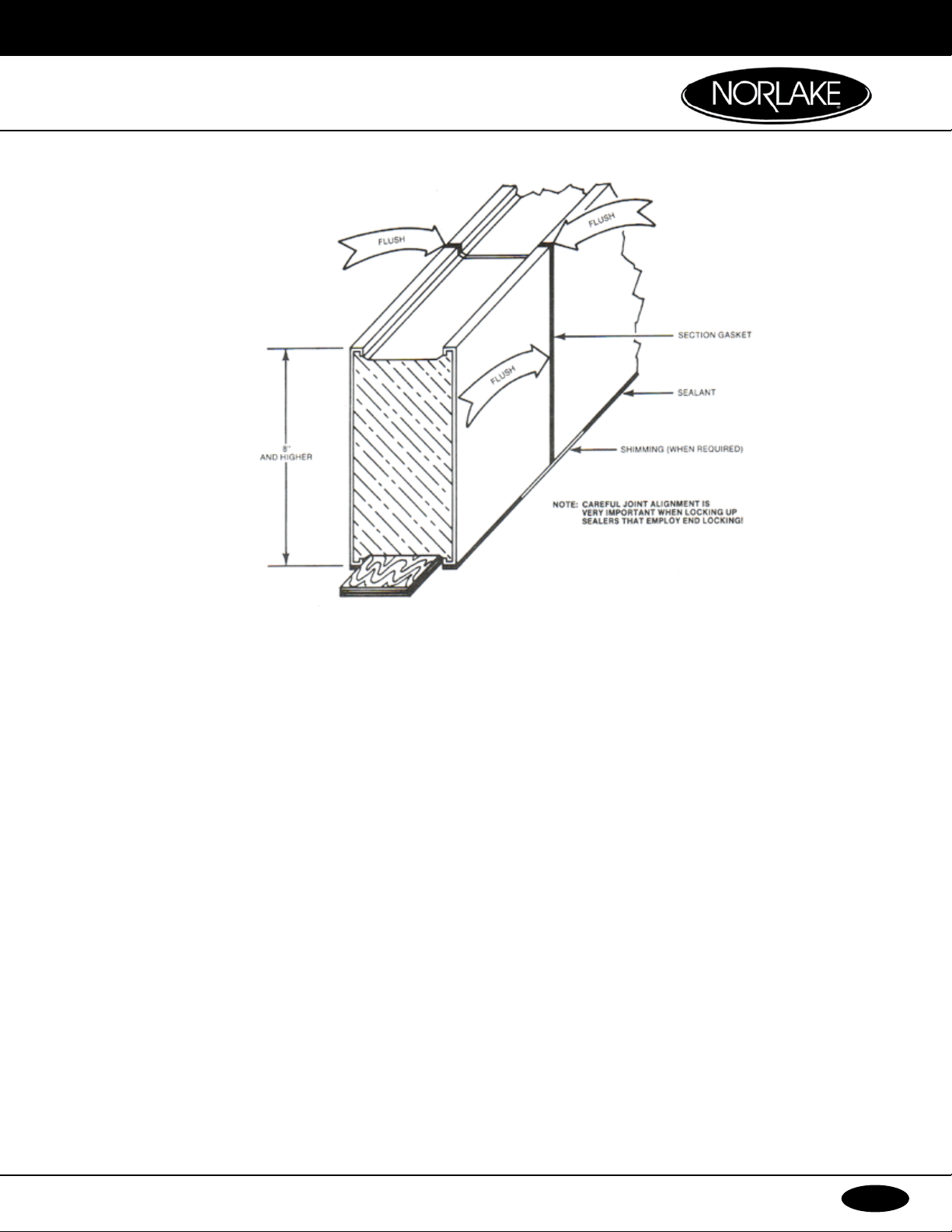

Assuming that the first sealer (screed) section has been perfectly leveled, refer to the sealer diagram and select

an adjoining sealer section and level it perfectly in both directions, shimming wherever necessary. NOTE: Sealer

(screed) sections 8” high or more employ section latches for end-to-end locking. CAREFULLY flush the upper

edges and the inner or outer surfaces of adjoining sealer sections while locking them together (Figure 5). Continue

leveling the remainder of the sealer sections until the entire assembly is in position.

When the entire sealer assembly is leveled, apply NSF approved sealant to achieve a vapor seal between the

bottom edge of the sealer and the building floor. This sealant is provided and is packed in the hardware box. The

sealant must be applied to the inner and outer surfaces of the sealer (screed) assembly. Make certain that the

sealant produces a complete, air-tight seal, without gaps, and that special care is taken to seal the shimming

material appropriately.

After the sealant has had an opportunity to set up, trim away all excess material flush with the edges of the sealer

(screed) assembly and touch up any areas where the sealant is not making a perfect seal (Figure 5.).

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

21

Page 22

Walk-In InsTallaTIon

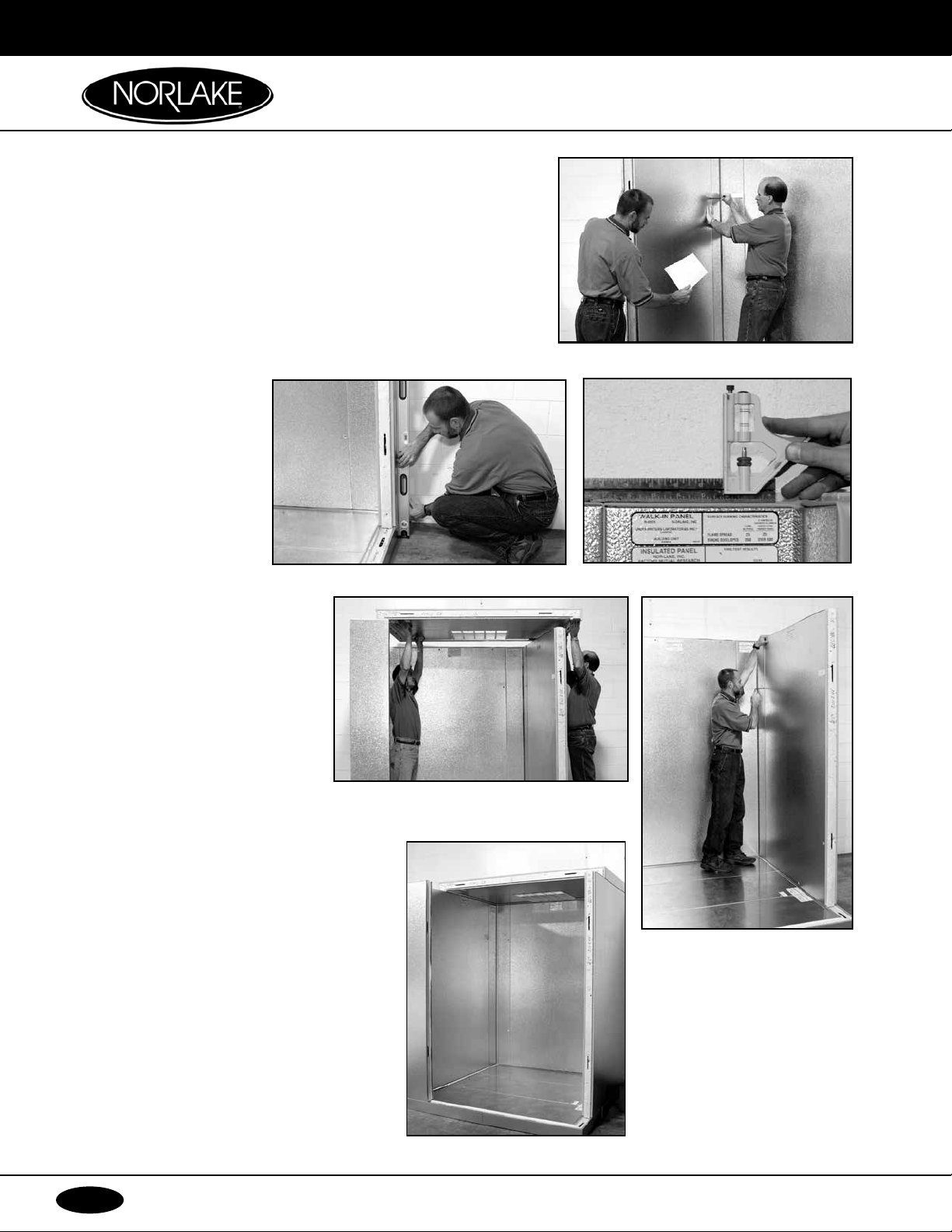

WALK-IN INSTALLATION

WALL AND CEILING PANEL CONSTRUCTION

The installation instructions that follow apply to any walk-in cooler or

freezer where the wall panels are supported either by foamed walk-in

floor panels or by a floor sealer (screed) assembly which has been

accurately located and properly leveled. NOTE: The procedure for

constructing wall and ceiling panels will be identical in all cases. NOTE:

The walls do not lock to vinyl sealers, but will lock to foam sealers when

used.

To aid in the construction process, the floor plan furnished with your

walk-in has part numbers listed for each wall, corner, ceiling and floor

section. Match the part number on the floor plan to the label on the

interior of each panel to determine the current placement for each

panel.

Notice, also, that the section latch access holes on the vertical edge of

the panel are always on the interior of the panel.

Select the first panel to be installed, typically beginning with a CORNER

PANEL. Notice that the panel is labeled "Top" along with a part number

indicating that when the panel is in its proper position, the labeled end

will be up.

Position the corner panel in the proper location on the walk-in floor or

vinyl screed assembly and, IF THE WALK-IN HAS A FLOOR, flush the

corner panel with the corner of the floor panel in both directions and lock

it securely to the floor panel.

22

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 23

If the first corner panel is supported by a 1" vinyl

sealer (screed), seek assistance to support the

corner panel in a vertical position until succeeding

wall panels are installed. Wall and corner panels

do not lock to the vinyl sealer (screed).

Select the next panel as indicated on the floor

plan and position it on the floor or sealer (screed)

close enough to the first panel installed so that

section latch engagement is possible.

Walk-In InsTallaTIon

Making sure that the two panels are perfectly aligned at the TOP EDGE

and that the VERTICAL JOINT of the two panels are perfectly flush, turn the

section latches on the vertical edge of the panel until they are completely

engaged.

IMPORTANT! Insist that the top edges of the adjoining panels are aligned

perfectly.

If misalignment is encountered, merely lift the lowest panel edge while

locking to achieve alignment and, when all latches are engaged, permit the

locked panels to resume their normal position on the walk-in floor or sealer

(screed).

DO NOT SHORT-CUT! TAKE ENOUGH TIME TO PROPERLY ALIGN ALL

SECTIONS.

Correct

Misalignment

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

23

Page 24

Walk-In InsTallaTIon

As each wall panel or corner panel is constructed and locked in an

adjoining panel along the vertical joint, engage the section latches to

the floor panels by turning the hex locking wrench ONLY ABOUT 1/4

TURN CLOCKWISE.

Make certain that the wall or corner panel is perfectly aligned with the

floor panel or foamed sealer before engaging the section latches.

Continue constructing panels

according to the part numbers shown

on the floor plan, and follow, explicitly,

the technique described for panel

alignment.

CEILING PANELS will be constructed

at specific intervals to facilitate the

installation. The intermittent ceiling

panel construction is scheduled to

allow the ceiling panels to serve as

supporting ties between opposite

walls as the installation progresses.

CAUTION! DO NOT SLIDE CEILING PANELS

INTO POSITION! To avoid gasket damage,

elevate the ceiling section clear of the wall

section while bringing it into position.

When adjoining ceiling panels are in position,

adjust the exterior edges so that they are

perfectly flush with one another and with the

wall panels directly below them. Lock the

ceiling panels securely to each other. DO NO

LOCK ceiling panels to wall panels at this time.

NOTE: If local conditions, such as existing

building walls, make it difficult to align ceiling

panels with each other from the exterior, locate

a step ladder near the interior walls to visually

inspect the alignment and adjust as necessary.

24

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 25

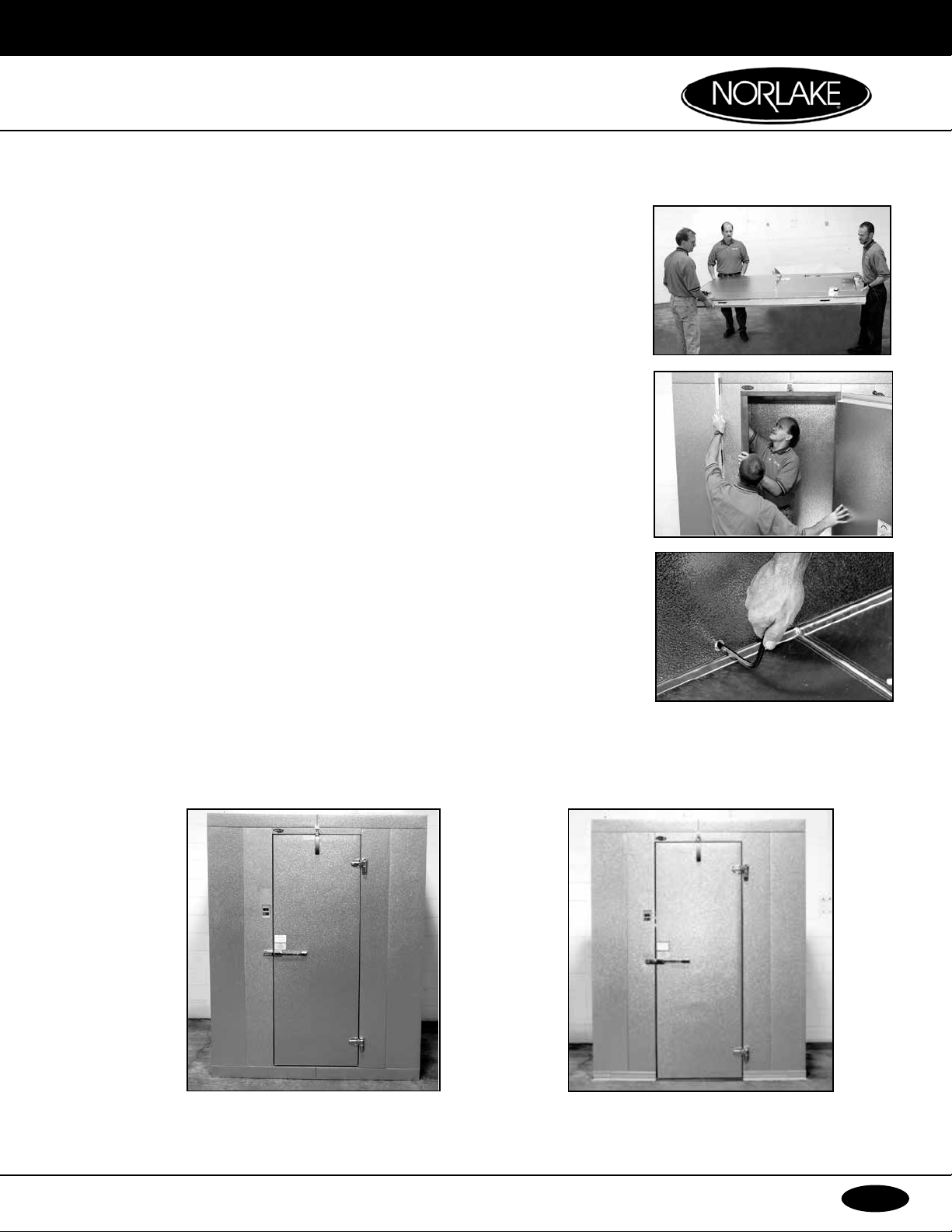

DOOR/DOOR SECTION

A standard door/door section consists basically of a single wall panel

that contains an entrance door and several accessories. The electrical

components contained in this panel were prewired at the factory. They

include the anti-condensate door opening heater, the pilot light, and switch

and a vapor proof interior light.

The door was factory installed on the door panel framing fixture, checked for

squareness and for proper operation under controlled conditions.

CAUTION! While installing the door/door section, extreme care must be

taken to avoid twisting the panel or handling the assembly in such a manner

that it is not square when it is installed. The self-closing feature, door closure

operation and a perfect gasket seal all depend a great deal upon a SQUARE

and PLUMB door/door section.

Walk-In InsTallaTIon

After all the wall and door panels have been constructed and locked securely

together and all the ceiling panels have been positioned above the wall

panels, the ceiling panels have been locked securely to each other, re-check

the position of the ceiling panels with respect to the wall panels.

Now lock all ceiling panels securely to the wall panels.

Recheck the position of the wall panels with respect to the floor panels and

lock them securely together.

NOTE: When a 1" vinyl floor sealer (screed) is used, no attachment to the

wall panels is required.

Completed

Walk-in with floor

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Completed Walk-in floorless- shown

with vinyl floor sealer

25

Page 26

Walk-In InsTallaTIon

NOTE: If, for some reason, conditions on the site prohibit the

installation of the walls and ceilings in the recommended order,

install the wall and ceiling panels in a logical sequence that will

permit accessibility for installation of the last panel. Remember to

schedule ceiling panel installation at the proper intervals to serve as

supporting ties between installed wall panels.

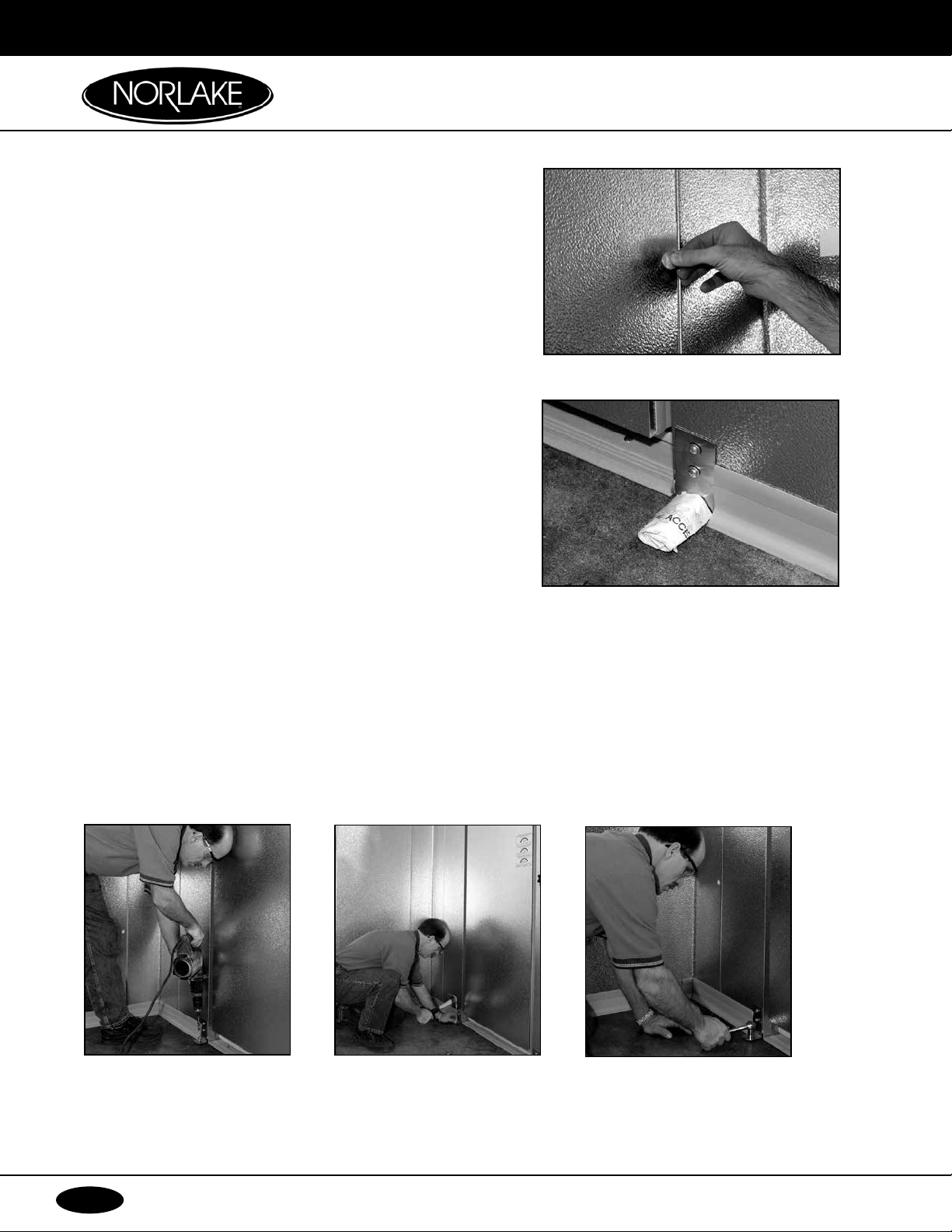

Locate the plug buttons which were packed in the hardware bag

and, after checking to make sure that the hex wrench comes to a

full stop on each section latch, insert a plug button into every latch

access hole.

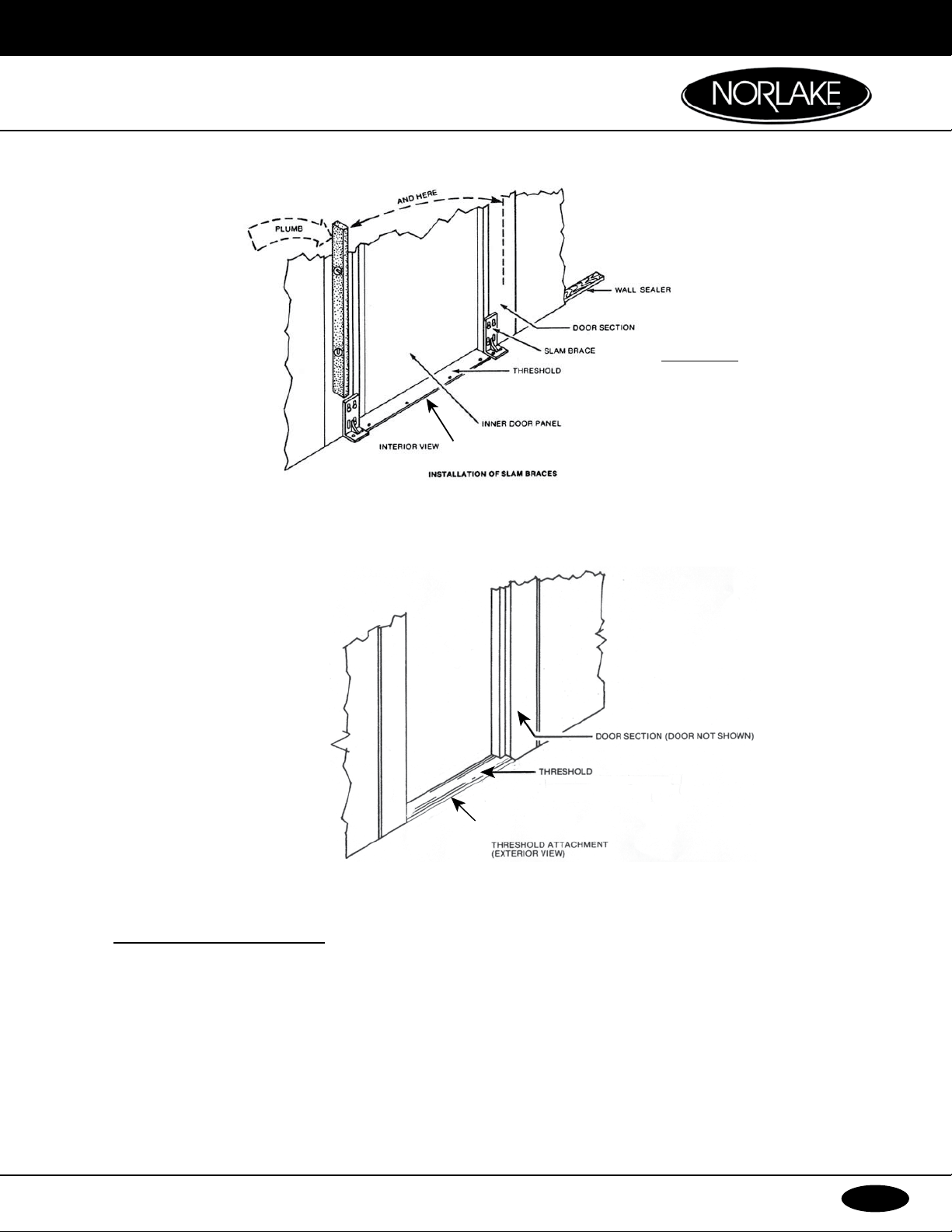

SLAM BRACES

The door/door section frame on most floorless walk-ins will be

fitted with slam braces, one on each of the interior, vertical frame

members. These braces will require attachment to the building floor.

Their purpose is to positively locate the lower extremities of the

door frames and prevent any movement that might occur at the

point where the door frame rests on the floor sealer (screed).

When 1" vinyl floor sealers are furnished, they will be notched to

accommodate the slam brace location.

The slotted holes in the vertical leg of the slam brace permit adjustment in either direction to allow the slam brace

to contact the building floor properly. Fasteners suitable for securing the slam braces to a concrete building floor

are packed in a bag and attached to one of the slam braces. For other types of building floors, the appropriate

fastener must be provided by others.

IMPORTANT! Make sure that the door/door section is PERFECTLY PLUMB before attaching the braces to the

building floor. The holes in the slam brace for attachment to the building floor are intentionally round so that no

shifting can occur after they are secured. Make sure the slam braces have been secured to the building floor.

The recommended hole size for

PARABOLT ANCHOR is 3/8” X

2-1/4”

26

Install anchor Attach slam brace with fastener

provided

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 27

IMPORTANT!

MAKE SURE THAT THE

DOOR/DOOR SECTION IS

PERFECTLY PLUMB BEFORE

ATTA CHING THE SLAM

BRACES TO THE FLOOR.

W

ALK-ININSTALLATION

-D

OOR

/D

OORSECTION

APPLY SEALANT UNDER THRESHOLD

Walk-In InsTallaTIon

THRESHOLD ATTACHMENT

The threshold was attached at the factory to the lower portion of the door section and it is positioned in such

a manner that no adjustment is required. It must, however, be attached to the building floor to complete the

installation.

Figure 11

Note: Add sealant between

threshold and floor to seal.

Apply Sealant Under Threshold

Figure 12

IMPORTANT! Make sure that the slam braces are securely fastened to the door section and to the building floor

before attaching the threshold to the building floor. Both edges of the threshold should be attached with fasteners

that are appropriate for the building floor and, since the floor surfaces vary so greatly in composition, no fasteners

are provided and should be obtained by others (Figure 12).

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

27

Page 28

Walk-In InsTallaTIon

Figure 13

SEALING THE JUNCTURE OF WALLS TO BUILDING FLOOR

Apply a generous amount of NSF approved sealant to achieve a vapor seal between the bottom edge of all wall,

corner, door and partition panels and the building floor. The sealant must be applied to both inner and outer edges

of all perimeter walls and to both edges of partition walls where they meet the building floor. Make certain that

the sealant produces a continuous, air-tight seal, without gaps, and that special care is taken to seal around the

shimming material.

After the sealant has had an opportunity to set up, trim away all excess sealant flush with the edges of the walls.

Touch up any areas where the sealant is not making a perfect seal (Figure 8).

COVE MOLDING

To comply with the requirements of Standard No. 7, National Sanitation Foundation, a cove molding with a

minimum radius of 1/4” must be applied to cover the juncture of the walk-in walls and the building floor. For with

floor models cove molding is required on exterior walls only.

Cove molding and adhesive for application are not normally provided. They are readily available at most building

materials suppliers.

Before applying cove molding, make final inspection of the area that will be covered with the molding to make

sure that the sealant is intact and making perfect vapor seal. If not, add sealant as required. Read and follow

the instructions prepared by the manufacturer of the cove molding and the adhesive before proceeding with the

installation (Figure 13).

If tile and grout are employed as floor material and, if base title is intended to produce the cove required, make

sure that the inside radius of the base tile is at least 1/4”.

28

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 29

Walk-In InsTallaTIon

EXTERIOR RAMP INSTALLATION INSTRUCTIONS

Center ramp in front of door opening. Then using the 1-1/2” x 1-1/2” x 3-1/2” angle the screws provided, attach

the ramp to the walk-in, as in the illustration below.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

29

Page 30

Walk-In InsTallaTIon

INTERIOR RAMP INSTALLATION INSTRUCTIONS

Step 1

After floor sections are in place and fully

locked together, apply approximately

1/8” bead of sealant to the interior metal,

3/8” in from the ramp cut out. Also apply

approximately 1/8” bead of sealant to the

center of the exterior metal lip.

SEALANT

Step 2

Place ramp into position by lining up the predrilled holes in the ramp with the pre-drilled in the

interior floor then secure the ramp into the floor

with the #8 x 1/2” screws provided

Step 3

Install non-skid floor fabric 6” x 24” Nonskid applied to cover ramp base and back

seam of ramp to floor 3” x 24” non skid

applied to cover side seam of ramp base

to floor.

Apply sealant where the door section

meets the interior and exterior of the floor

panel and ramp. Also, apply sealant under

the door threshold.

.

30

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 31

Walk-In InsTallaTIon

MEMBRANE ROOF INSTALLATION INSTRUCTIONS

IMPORTANT NOTE:

IF THIS WALK- IN INCLUDES CEILING MOUNT CAPSULE-PAK™ REFRIGERATION SYSTEMS, PLEASE

REFER TO CAPSULE-PAK™ REFRIGERATION INSTALLATION MANUAL. ALSO, BE SURE THE INTERIOR

COIL IS HUNG CORRECTLY PER THE REFRIGERATION MANUAL INSTRUCTIONS BEFORE INSTALLING

THE MEMBRANE.

Step #1

After walk-in is completely assembled, lay E.P.D.M. over ceiling topside and trim to a 6" overlap on all four sides.

Step #2

Fold all four corners as shown below.

Step #3

Attach trim, refrigeration hood and door hood by using hex headed sheet metal screws provided. All pieces are to

be held down 2" from ceiling topside as shown.

Note: on some models, the trim may have to be cut to fit.

Step #4

Trim off all excess rubber membrane from under aluminum trim and hoods with utility knife. Be careful not to scratch

the surface of the panels with the knife.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

31

Page 32

Walk-In InsTallaTIon

WALK-IN INSTALLATION

Electrical Connections

WALK-IN COOLER OR FREEZER WITH A SINGLE INTERIOR

LIGHT MOUNTED ON THE DOOR SECTION

CAUTION: ELECTRICAL CONNECTIONS TO THE WALK-IN MUST

COMPLY WITH APPLICABLE PORTIONS OF THE NATIONAL

ELECTRICAL CODE AND ANY OTHER ELECTRICAL CODES

THAT MAY HAVE JURISDICTION OVER THE INSTALLATION!

A dedicated electrical power supply circuit for the walk-in is recommended.

WARNING! DISCONNECT THE SELECTED POWER SUPPLY CIRCUIT AND ATTACH A TAG TO THE

DISCONNECT SWITCH INDICATING THAT THE CIRCUIT MUST NOT BE ENERGIZED WHILE SOMEONE IS

WORKING ON THE LINE.

WIRING

The cooler or freezer door panel contains several

electrical components that were prewired at the

factory. They include the anticondensate door

opening heater, the pilot light/switch and LED

interior light mounted on the door panel. NOTE:

It is the electrical contractor's responsibility

to provide the necessary wiring, connections,

conduit and fittings to complete the hook-up.

The junction box adjacent to the light fixture

contains the electrical leads that are prewired to

the electrical components in the door section.

Make your electrical connections here.

Affixed to the interior of the door section is a label which describes the electrical characteristics and the energy

consumption described in watts and amperes.

32

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 33

IMPORTANT! When all field wired connections are completed in the junction

box located on top of the ceiling section, be sure to THOROUGHLY SEAL

the conduit fitting through which the wiring projects into the junction box. The

silicone sealant provided is well suited for this purpose. Failure to do so will

permit moisture to form within the junction box and electrical fixture(s) and

potentially cause a short.

POSITIONING THE THERMOMETER SENSING BULB

For convenient monitoring of the temperature of the storage compartment

of this walk-in, a remote reading thermometer has been installed in the door

section at about eye level. It is a flush panel mount with an LED readout.

For optimum accuracy, the sensing bulb must be

exposed to the air that is being monitored. Make

certain that the sensing bulb is not positioned near

the interior light or any other heat producing device,

nor should it be located where stored products

shield the sensing bulb from the circulating air

pattern within the walk-in. The long sensing lead is more than adequate to provide an

ideal sensing bulb placement on the inside surface of the door section or an adjacent wall

or corner panel. When the location is finalized, an adhesive backed, plastic clip is used

to secure the sensing bulb to that surface.

Walk-In InsTallaTIon

To prevent possible damage to the door opening heater and/or to the protective globe over

the interior light, DO NOT energize the door/door section until the interior temperature

has been reduced to the normal operating range by refrigeration. A caution label is

affixed to the door section near the vapor proof light to serve as a reminder.

PRESSURE RELIEF PORT

If a pressure relief port is supplied,

connect it to a 115/60/1 VAC power

supply.

WIRING DIAGRAM: A wiring diagram

showing the electrical components

contained in the door/door section circuitry

involved as shown. Always refer to the

wiring diagram if it becomes necessary to

replace any of the components.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

33

Page 34

Walk-In MaInTenanCe

ADJUSTABLE HINGE

Nor-Lake 26”, 30”, & 36” wide walk-in doors are provided with an adjustable hinge. The adjustable hinge provides

the ability to square a door within the door jamb.

If a door requires adjustment:

Open the door and you will find a small chrome plug button, on the edge of the door behind the upper hinge.

Before any adjustment you must first slightly loosen the screws on the hinge strap on the door. Then pop off the

chrome plug button. Now you can access the adjustment screw. You should only make minor adjustments and

then close the door to view if the adjustment rectified the situation. When complete replace the chrome plug and

re-tighten the screws on the hinge strap.

NOTE: On doors with a kick plate you may have a center (3rd) hinge. In this case there is a 2nd adjustable

hinge. You will need to loosen the screws on both the top and center hinge(s) and make minor adjustments in

both areas.

REPLACEMENT OF THE MAGNETIC DOOR GASKET ASSEMBLY

For your convenience and safety, it is advisable to remove the entire door assembly

from the walk-in cooler or freezer before attempting to replace the door gasket.

Prepare a smooth, clean surface on which the exterior surface of the door assembly

can be placed without marring or scratching the finish.

DOOR ASSEMBLY REMOVAL - ALL FOAMED WALK-IN COOLER OR FREEZERS

WITH CAM LIFT HINGES

NOTE: For doors equipped with a spring hinge, see the door removal instructions label on the interior of the door

near the top hinge. When removing the door assembly from any walk-in, solicit the aid of an assistant during the

door removal and replacement procedures.

1. Open door to dwell position, stopping at approximately 120°.

2. Put mark on floor to indicate position of door, see sketch.

3. Lift door off frame.

4. To replace door, line up door with mark on floor.

5. Place hex hole in hinge straps over hex rods and lower door.

RESETTING SPRING HINGES

For the top spring-loaded hinge, you will need to reset the spring/hexagon pin. With the door installed, closed and

locked, remove the screws from the spring loaded hinge strap on the door only. You will need to hold the hinge

strap against the door to prevent the strap from springing out towards you after the screws are removed. Remove

the strap portion from the door by pulling upward. Hold the strap portion above the remainder of the hinge so that

the strap is flat against the door. Bring the strap portion back down towards the door so that it meets the hexagon

pin. You have now reset the spring. Insert the screws back into the strap and door. Note: Under normal conditions,

the spring has no tension when the door is closed.

34

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 35

Walk-In MaInTenanCe

DOOR GASKET REPLACEMENT

1. Place the door, exterior face down, gasket up, on a clean, smooth surface

that will not mar or scratch the finish.

2. The magnetic door gasket consists of a cavity containing the magnetic

strip, a bellows cavity that permits the gasket to conform to irregular

surfaces, and a base section that features a

dart- shaped projection that serves as the

attachment means when it is forced into the

slot in the door breaker.

3. To remove the original magnetic gasket

assembly, grasp the gasket at one of the

corners and pull the dart-shaped projection

out of the retainer slot in the door breaker.

Pull slowly and examine your progress to

avoid tearing the projection which will then

remain in the retainer slot.

4. Remove the entire gasket assembly and

examine the retainer slot to make sure that it

is free of gasket material or other debris.

5. Starting at one corner, insert the dart-shaped projection of the replacement

gasket into the retainer slot and, using a rubber mallet, drive the dart into

the retainer slot. HINT: Cover the face of the rubber mallet with masking

tape to prevent smudging the gasket. Attach only about two inches (2") of

the gasket in each direction away from the corner.

6. Use the same procedure as in Step 4 at the remaining corners and also

midway between the corners on the long sides of the door.

7. Using the rubber mallet, drive the dart into the retainer slot working from the

center of each side toward the corners.

8. Lift the gasket base on the outer edge of the gasket and examine the

gasket to determine if the dart is engaged by the

retainer slot around the entire perimeter of the door,

except where the sweep gasket is attached. If the

dart has failed to engage in some areas, a small,

slotted screwdriver blade can be used to tuck the

dart into the slot.

9. Replace the door assembly. Simply reverse the

instructions in the "Door Assembly Removal" section.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

35

Page 36

Walk-In MaInTenanCe

SWEEP GASKET

The sweep gasket was factory installed and tested for proper

operation before shipment. It features a unique cross-section

designed to not only seal the gap between the bottom of the

walk-in door and the threshold or building floor, but its off-set

configuration closes an opening that is normally created at both

ends of a conventional sweep gasket. It is attached to the lower

edge of a walk-in door assembly with 3/4" pan head sheet metal

screws and flat washers.

The sweep gasket extrusion consists of three distinct durometers

(hardness) of vinyl extruded in a one-piece profile. The rigid area

forms the attachment section. The flexible portion forms the

sweep projection and provides the end seal and an extremely

flexible lip that contacts the threshold or building floor, depending

upon the installation.

OPERATION

As soon as the door opening sequence begins, the cam-lift

hinges begin raising the door and the sweep gasket releases its

contact with the threshold or building floor. At approximately 90°

from the face of the walk-in, the door will reach the "hold open"

position and will no longer rise by cam action. The sweep gasket

will be lifted about 3/8" above the threshold or building floor.

When in the closed position, the extremely flexible lip of the sweep gasket should merely brush the threshold or

building floor along its entire length.

ADJUSTING THE SWEEP GASKET

(Initial Installation)

With the door COMPLETELY CLOSED, the proper distance between the bottom of the rigid attachment area of

the sweep gasket and the threshold or building floor MUST BE 1/2".

If this dimension is less than 1/2", the sweep gasket will wear prematurely and will produce excess friction for the

door closer to act against during the door closing sequence.

If this dimension is greater than 1/2", the lower lip will not contact the threshold or building floor and the seal will

be compromised, permitting air infiltration to occur in this area. Measure both ends of the sweep gasket with the

door closed and adjust until exactly 1/2" is attained.

ADJUSTING THE SWEEP GASKET

(Normal Wear)

After considerable usage, if examination reveals that the lower lip of the sweep gasket has worn to a point where

noticeable air infiltration is occurring, merely loosen the attachment screws and the lower the gasket only enough

to permit the lower lip to brush the threshold or building floor while the DOOR IS IN THE CLOSED POSITION. Do

not lower the gasket more than is necessary! Tighten the attachment screws and check the operation.

36

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 37

DOOR CLOSER

The door closer was

factory-installed and

tested for proper

operation before

shipment. This small,

but powerful device

provides smooth and

positive closing with

only a minimum of

attention. No lubrication

of any kind is required. It is

recommended that, at least once each month, the relationship of the

hook and roller to each other be examined.

To become familiar with the various components of the closer, see

photo of a closer properly engaged when the walk-in door is closed.

Correct with Door Closed

Walk-In MaInTenanCe

Correct with Door Open

Since the door closer in itself is literally non-adjustable, any

adjustment that becomes necessary must be accomplished at the

closer hook.

CAUTION: DO NOT ATTEMPT TO BEND THE HOOK as a means

of adjustment. The hook is formed and tempered to resist deformation

during normal use.

ROLLER IS TOO LOW: Loosen all hook bracket screws and add flat

washer(s) between the bracket and the header where the TOP two

screws will keep them in place. Tighten the screws and check the

hook position.

ROLLER IS TOO HIGH: Loosen all hook bracket screws and add

washer(s) between the bracket and the header where the BOTTOM

two screws will keep them in place. Tighten the screws and check the

hook position.

If, for any reason, the roller arm is accidentally bumped into a vertical

position while the door is open, IT MUST BE MANUALLY MOVED TO

THE HORIZONTAL POSITION before the door is closed. Failure to

do so may cause serious damage to the door and/or the door closer.

Roller Too Low

Roller Too High

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

A warning label is affixed to the door

section as a reminder.

37

Page 38

Walk-In MaInTenanCe

ANTI-CONDENSATE DOOR OPENING HEATER

To prevent condensate from forming around the outer edges of the door opening, an anti-condensate heater

has been installed around the perimeter of the door opening. This constant-energy, low wattage, electric heater

wire elevates the temperature of the door jambs and threshold sufficiently to maintain these surfaces above the

dewpoint temperature of the surrounding air preventing condensation.

Failure of the heater wire is usually suspected when condensation forms around the perimeter of the door opening.

Moisture accumulates to a point where it causes a problem on the building floor, or when the condensate freezes

around the door opening, as will be the case when a walk-in freezer is involved. There is no cause for alarm,

however, if occasionally a few drops of moisture form during a period of EXCEPTIONALLY HIGH HUMIDITY.

NOTE: The heater wire is designed to provide the proper amount of heat to the surfaces around the door opening

WHILE THE WALK-IN IS AT DESIGN TEMPERATURE! Premature failure will result if the heater wire is energized

over an extended period of time while no refrigeration is occurring within the walk-in cooler or freezer.

HEATER WIRE REPLACEMENT

Three pieces of trim and the threshold must be removed to gain access to the

heater wire. The trim serves as the cover of the heater raceway at the side jambs

and the head jamb. The threshold covers the heater channel in the bottom plate

of the door section.

THRESHOLD REMOVAL

WARNING! Make sure that the electric power to the walk-in is disconnected

before attempting to replace door heater.

To remove the threshold, remove all

visible screws that attach the threshold

to the walk-in floor or to the building

floor. Three screws attach the threshold

to the bottom plate of the door section.

When all screws are removed, pry the

threshold up until it is free and remove it

from the floor section.

STAINLESS STEEL TRIM REMOVAL

Use a screwdriver to remove four screws on each of the three trim pieces.

Remove each trim piece in turn. This will expose the heater wire and hardboard

spacer strip.

38

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 39

Walk-In MaInTenanCe

Again, MAKE SURE THAT THE POWER IS DISCONNECTED and

remove the cover plate from the pilot light and switch on the front of

the door section. Remove the two screws that attach the pilot light and

switch assembly to the switch box and pull the pilot light and switch

assembly out of the switch box enough to expose the terminal screws

on the device.

Examine the wiring in the switch box and identify the two black leads

from the heater wire that are connected either to two switch terminals

or to one switch terminal and to a wire connector. Refer to the wiring

diagram of the walk-in cooler in the "Electrical Connections" section

of this manual. HINT: After positively identifying the two leads to the

heater wire, cut the leads off, but leave an inch or two remaining on

the switch terminal(s) and/or wire connector. In so doing, these short

lengths of lead will positively identify the proper points of connection

when the replacement heater is installed. Remove the original heater wire from the jambs and threshold and

discard it.

INSTALLATION OF THE REPLACEMENT HEATER

Insert the two lead wires of the replacement heater into the access hole in the heater wire raceway that leads to the

pilot light and switch junction box. NOTE: The section where the lead connects to the heater wire SHOULD NOT

BE BENT! Locate the connector sections as close as possible to the access hole, but KEEP THEM STRAIGHT!

Secure the connector sections in place with a short piece of electrical tape.

Temporarily arrange the heater wire assembly.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

39

Page 40

Walk-In MaInTenanCe

Using small pieces of electrical tape, fasten the heater wire in place. Lift the heater wire at each corner and apply

three thicknesses of electrical tape around the insulation over a length of approximately 3".

Follow by forming a small loop at each corner to permit expansion and

contraction of the heater wire without strain at these points. After the loops

are formed, tape them in place with a short strip of electrical tape.

The heater wire should be relatively straight in the head jamb and in the side

jambs, but all excess heater wire must be taken up in the THRESHOLD AREA

ONLY by forming a "zig-zag" configuration. Make sure that this configuration

will be accommodated by the width of the raceway in the bottom plate or

threshold. The extra length of heater wire concentrated in the threshold will

produce more heat per foot in the threshold than in the jambs.

After the heater wire is in place, tape it down where necessary with short

strips of electrical tape to prevent the heater wire from interfering with the

replacement of the chrome trim.

STAINLESS STEEL TRIM REPLACEMENT

Start replacing the stainless steel trim

with the head trim section. Hold

in place while replacing the three

screws. Install the right and left trim

in a similar manner. The trim should

easily be replaced by hand.

THRESHOLD REPLACEMENT

Place the threshold in its original

location and replace all of the screws

in their original locations. Reminder:

The hardboard needs to be in place before replacing the threshold. After the threshold is secured, apply a 3/16"

bead of silicone sealant at both ends of the threshold where they meet the side jambs. With a wet finger, smooth

out the silicone fillet for a neat, professional looking job.

40

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 41

Walk-In MaInTenanCe

ELECTRICAL CONNECTION

Referring to the wiring diagram in the "Electrical Connections" section of this manual, connect the heater wire leads

as shown. If short lengths of the lead wires were left as indicators, connect the replacement heater leads to those

points of connection and discard the short indicator lengths.

NOTE: If one of the heater leads connects to another wire through a wire connector, obtain a properly sized, twiston wire connector for this purpose.

Replace the pilot light and switch in the switch box and attach the switch cover to complete the job. Energize the

walk-in cooler to resume operation.

PANEL CLEANING AND MAINTENANCE RECOMMENDATIONS

During the course of uncrating, handling and installation, the panel surfaces of your walk-in cooler or freezer may

have become stained or dirty. Cleaning all metal type surfaces, door trim and gaskets can be performed with a

mild detergent and hot water. It is important that you remove all excess soap and dry the surfaces

thoroughly. Never, under any circumstances, use an abrasive or alkaline solution.

Occasionally it may become necessary to clean the interior surface for sanitary purposes. A mild solution of baking

soda and warm water will tend to impart a clean, sweet smell to the interior should odors occur from spillage or

container breakage. Never leave standing water inside the walk-in cooler or freezer.

Warning: Walk-in oor must be kept free of any liquids, food particles or any items that could cause a slip hazard.

Spilt liquids, food particles or any moisture on the walk-in oor can cause the oor to become slippery. Keep the

oor surface clean and dry at all times.

• Inspect non-skid oor strips on ramps and oor surfaces and replace if worn.

• Inspect refrigeration system, door gaskets and hardware for proper operation to prevent moisture on walk-in

oor, ceiling or walls.

• Avoid leaving entry doors open for more than a ve minute period of time, which can cause a lm of ice to form

on oor, ceiling and wall surfaces due to the excessive condensation of warm moist air entering the walk-in.

Vinyl strip curtains can be used to reduce the amount of warm moist air entering the walk-in.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

41

Page 42

fInal CheCklIsT for InsTallaTIon

Final Checklist for Installation of Nor-Lake, Inc. Walk-in and Refrigeration

Location#

Sales Order #

Dear Refrigeration Contractor:

Our goal is to supply our customers with the best equipment available. This is accomplished by combining

the highest quality commercial refrigeration equipment with a craftsman like installation that meets all factory

requirements. This document will help you understand and verify the installation meets these requirements.

This document is to be used in conjunction with the Nor-Lake Installation and Operation Instruction Manual and

the floor plan drawings provided with the product.

When the job is complete and equipment is running to factory specifications, the attached inspection report must

be filled out completely and returned to Nor-Lake.

If there are any questions, concerns, service or parts needs, please contact the Nor-Lake Technical Department

at 800-388-5253, ext. 1, or fax to 715-386-4293. Please have the equipment model number and serial number at

the time of your call.

Things to Verify When Inspecting an Installation:

(Shaded areas to be filled out by the installing refrigeration contractor)

Walk-In

1. Were any components that were to be supplied by Nor-Lake missing from the

delivery? Verify all the components delivered to the job site match the Nor-Lake

packing list.

2. Is the surface that the walk-in is to be installed upon smooth and level to within

plus or minus 1/2” over the length of the slab? (It is recommended a string level or

laser level be used to verify the slab meets these requirements.) The walk-in shall

not be installed if the levelness of the slab does not meet these requirements.

3. Was the 6 ml polyethylene film vapor barrier installed prior to the floor panels

being installed?

4. Is the walk-in centered in the space provided with a minimum of 2” clearance

between the walk-in and building walls on each side?

5. Are the cavities between the building envelope and walk-in external walls free of

debris and remain unobstructed?

6. Are there any damaged panels or other components, dents or unsightly scratches

in the supplied walk-in floor, wall or ceiling panels?

7. Is the base of the walk-in caulked around the perimeter?

8. Are all of the wall panels level across the top? Are walls plumb and ceiling level?

Yes No Repairs Made GC Review *

9. Are there any gaps identified between wall panels following engagement of the lock

and strike? The panel gasket must be in contact with the metal edges of both panels.

10. Is the door section and door plug plumb and level? Does the door close properly?

(Verify door closing by opening the door to 90°. Door must close and seal without any

assist).

42

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 43

fInal CheCklIsT for InsTallaTIon

11. Are the lights installed, connected to the light switch and operating correctly?

12. Have all electrical and other penetrations been properly sealed as recommended

by Nor-Lake?

13. Is the temperature sensor extended away from door and mounted on the wall?

14. Is the strip curtain mounted in place and secured?

15. Are the refrigerant piping and electrical cable supported and strain free?

16. Is the serial tag correctly installed?

17. Has the surplus construction material been removed from the top of the walk-in?

18. Does the installation look professional?

Note: Nor-Lake recommends pictures be taken after the installation is complete.

1). Exterior door section (full view)

2). Evaporator section (after installation)

3). Condensing Unit (after installation)

Final Inspection of the Walk-in and Refrigeration Systems

Have the installation and maintenance manuals, wiring diagrams and other walk-in

documents been turned over to the end user?

Walk-In Model Number(s)

Walk-In Serial Number (s)

Yes No Repairs Made GC Review *

By signing below the installer hereby certifies that the installation has been completed in

compliance with Nor-Lake’s standards and to Nor-Lake’s specifications. Items found not in

compliance will be corrected by the installing contractor at no charge.

Refrigeration / Installation Contractor Name: _________________________________

Refrigeration / Installation Contractor Signature: _______________________________ Date: ________________

General Contractor Name: ________________________________________________

General Contractor Signature: _____________________________________________ Date: ________________

Contact Nor-Lake Technical Dept.

Nor-Lake, Inc.

Attn: Technical Department

Hudson, WI 54016

800-388-5253, ext. 1

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

43

Page 44

Nor-Lake, Incorporated

727 Second Street

Hudson, Wisconsin 54016

800-955-5253 Foodservice Sales

800-388-5253 Parts/Service

715-386-2323

715-386-6149 FAX

Email: service@norlake.com

www.norlake.com

44

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Page 45

Refrigeración de calidad desde 1947

Manual de

InstalacIón

de cáMara

frIgorífIca

Para:

kold locker™

fast trak®

fInelIne™

MInI rooMs

envIro-lIne

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

9/18 Rev. K 132617 ©2018 Nor-Lake, Inc. A division of Standex International Corp. All rights reserved.

Printed in the USA.

1

Page 46

Tabla de ConTenIdos