Norlake VOAM48-79 Service Manual

INTRODUCTION

2 STORE CONDITIONS / LOCATION

2 WARNING LABELS AND SAFETY INSTRUCTIONS

3 PRE-INSTALLATION INSTRUCTIONS

3

Inspection for Shipping Damage

3 INSTALLATION INSTRUCTIONS

4

General Instructions

4

Thermometer Installation

4

Shelf and Shelf Lighting Installation

4-8

Plumbing

9 ELECTRICAL

10

STARTING PROCEDURE

10

FINAL CHECK LIST

10

LOADING

11

PLACING PRODUCT IN CABINET

11

CLEANING

11

ELECTRONIC TEMPERATURE CONTROL

12

Fan

12

Defrost

12

Manual Defrost

12

Setpoint

13

How to change parameters

13

List Of Parameters

13

ELECTRICAL CONNECTIONS

13

PROBE CONNECTIONS

13

SENSOR PROBE TEMPERATURE AND RE SISTANCE

14

SERVICE INSTRUCTIONS (Trouble Shooting Guide)

15

PART NUMBERS

16-19

ACCESSORIES LIST

20

WIRING DIAGRAMS

21-24

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

for

HOAM and VOAM Open Air Merchandisers

TABLE OF CONTENTS

1 3/15 Rev. C 157872

INTRODUCTION

Thank you for purchasing this cabinet. This manual contains im portant instructions for installing, us ing and servicing

an Open Air Merchandis er. Read all these documents carefully before installing or servicing your equipment. This

manual should be left in the care of the store owner or manager.

STORE CONDITIONS / LOCATION

The OAM cases are designed to operate in the controlled environment of an air conditioned store. The store

temperature should be at or below +75°F and a relative humidity of 55% or less. At higher temper ature or humidity

conditions, the performanc e of these cases may be affected and the capacity diminished. It is not uncom mon in a

newly constructed store for the temperature and hum idity to be above design conditions. These excessive conditions

may produce sweating in the case until the store is operational and the ambient environment is more desirable.

The OAM case should not be positioned where it is directly exposed to rays of the sun or near a direct source of

radiant heat or air f low. No HVAC return or supply air ducts may be located near case openings. This will adversely

affect the c ase air flow and will result in poor perform ance. Do not open windows or doors that will affect the c ase air

flow. The maxim um air velocity near the case air return is 50 FPM. If this case is to be located against a wall there

should be at least a 6” space between the wall and the back of the cas e. T he cabinet also requires a clearanc e of 10”

at the top. This space will allow for the circulation of air behind the case.

These cases should always be loaded properly. This unit will operate differently when loaded or unloaded. Consult the

section of this manual that specifies loading procedures.

A pipe loop acts as a trap is included with each case. It is important that each case has this installed. Consult the

section of this manual for installing and piping the drain.

NOTICE

Read this manual before installing your cabinet. Keep the manual and refer to it before

doing any service on th e equipment. Failure to do so could result in personal injury or da m age to the cabinet.

DANGER

Improper or faulty hook-up of electrical components of the refrigeration units can result in

severe injury or death. All electrical wiring hook-ups must be done in accordance with all applicable local,

regional or national standards.

NOTICE

Installation and service of the refrigeration and electrical components of the cabinet must be performed by a

refrigeration mechanic and/or a licensed electrician.

The portion of this manual covering refrigeration and electrical c omponents contain technical ins truc tions intended only

for persons qualified to perform refrigeration and electrical work.

This manual c annot cover every installation, use or service situation. If you need additional information, call or write

our Customer Service Department.

2 3/15 Rev. C 157872

CAUTION!

GROUND REQUIRED

FOR SAFE OPERATION

WARNING LABELS AND SAFETY INSTRUCTIONS

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or in this

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recomm ended precautions

and safe operating practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your cabinet is thoroughly familiar with all

safety information and procedures.

Important safety inform ation is presented in this section and throughout this section and throughout the manual. The

following signal words are used in the warnings and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE: This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

The warning and safety labels shown throughout this manual are placed on your Nor-Lake Products cabinet at

the factory. Follow all warning label instructions. If any warning or safety labels become lost or damaged,

call your customer service department at (800) 388-5253 for replacements.

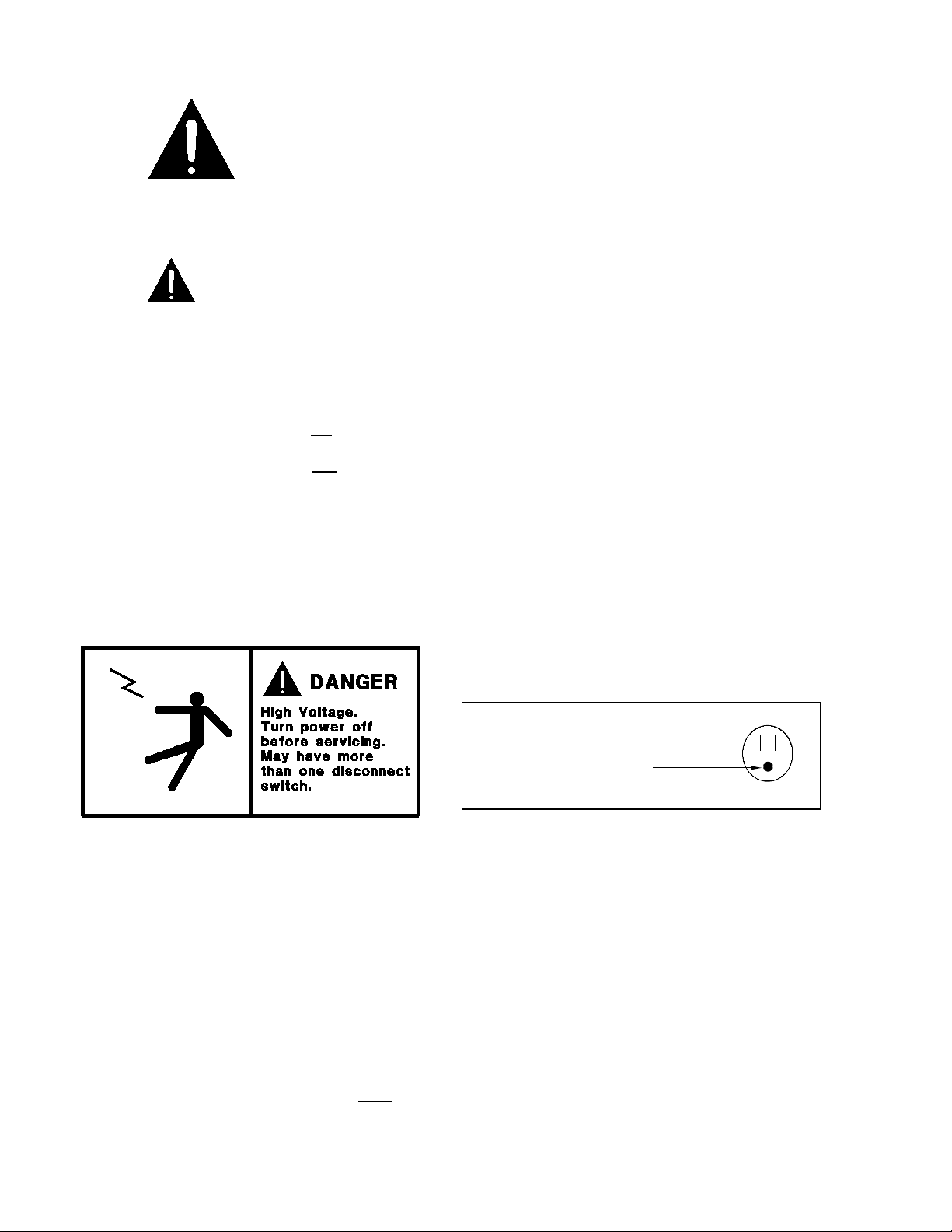

This label is located on the electrical control This label is attached to the cabinet power cord on

box and on the rear access cover. models with a power cord.

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

You are responsible for filing all freight claim s with the delivering truck line. Inspec t all cartons and cr ates for dam age

as soon as they arrive. If damage is noted to shipping crates or cartons or if a shortage is found, note this on the bill of

lading (all copies) prior to signing.

If damage is discovered when the cabinet is uncr ated, immediately call the delivering truck line and follow up the call

with a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your

concealed damage item. Crating material must be retained to show the inspector from the truck line.

3 3/15 Rev. C 157872

INSTALLATION INSTRUCTIONS

SHELF

SHELF

SHELF

SHELF BRACE

GENERAL INSTRUCTIONS

1. Be sure the equipment is properly installed by competent service people.

2. Keep the equipment clean and sanitary so it will meet your local sanitation codes. Wipe up all spills, clean with

water and a mild detergent, then rinse with clean water. A reservoir is provided to contain inner spills.

Peridocially inspect reservoir and clean as needed.

3. Rotate your stock so that older stock does not accumulate. A "First-In, First-Out" rotation practice will keep the

products in good salable condition.

4. Product should not be put in the case for at least 2 hours after it is started.

5. Stock cases as quick ly as possible, exposing only small quantities to store temperatures for short periods of

time.

6. When replacing burned out LED light bars, be sure that the electrical power to the lighting circuit is turned off.

To comply with Sanitation requirements, this cabinet must be mounted on casters, legs (6” high min.) or the

base must be sealed to the floor with NSF listed silicone sealant. Minimum clearance as follows: 10” air space

at top, 6” at the rear, and 0” air space at each side required for compliance.

THERMOMETER INSTALLATION

Install provided thermometer at t he clip on the price tag m oulding near the top lef t edge of the c ase. Rem ove the tape

backing and press the thermometer in place.

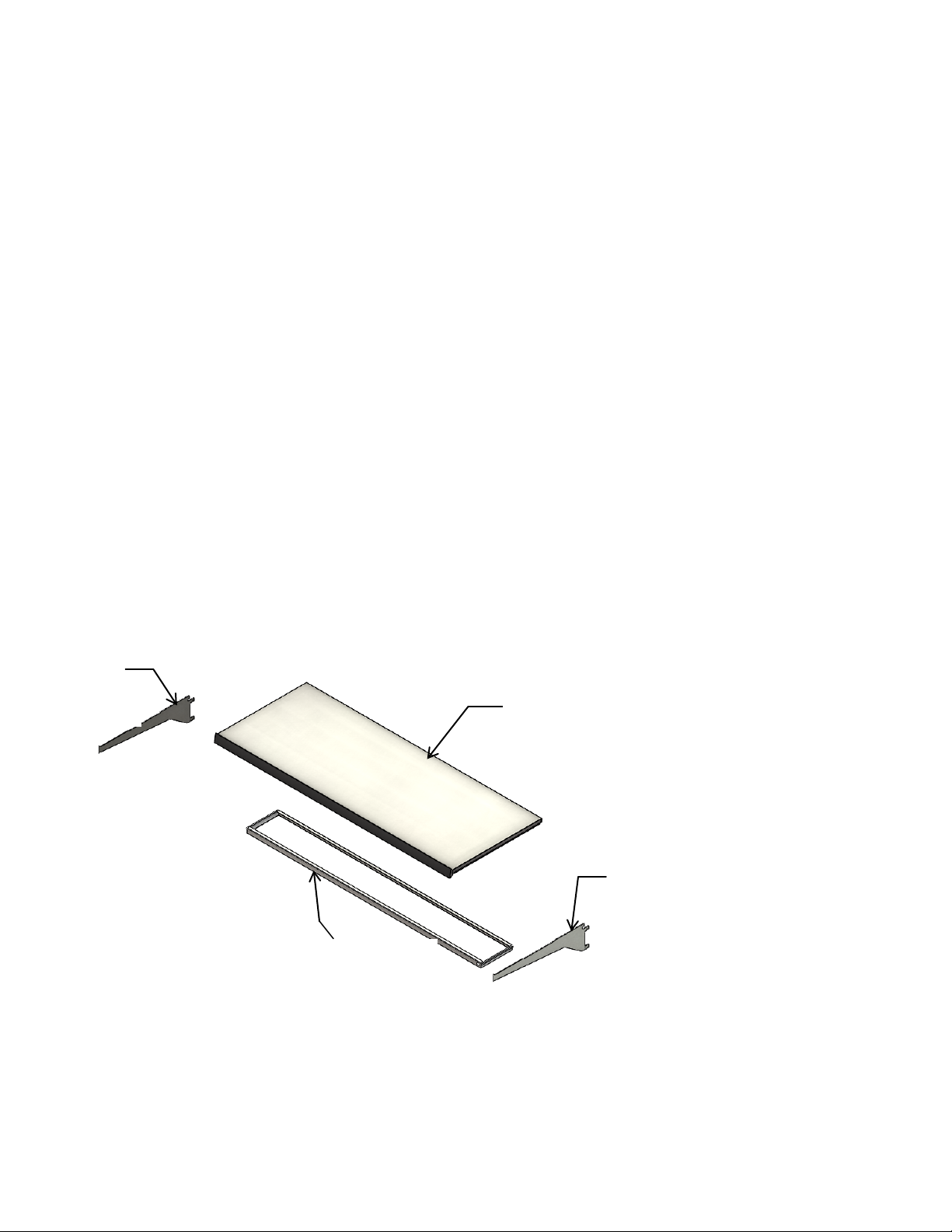

SHELF INSTALL ATION

BRACKET

4 3/15 Rev. C 157872

Shelf Assembly Items

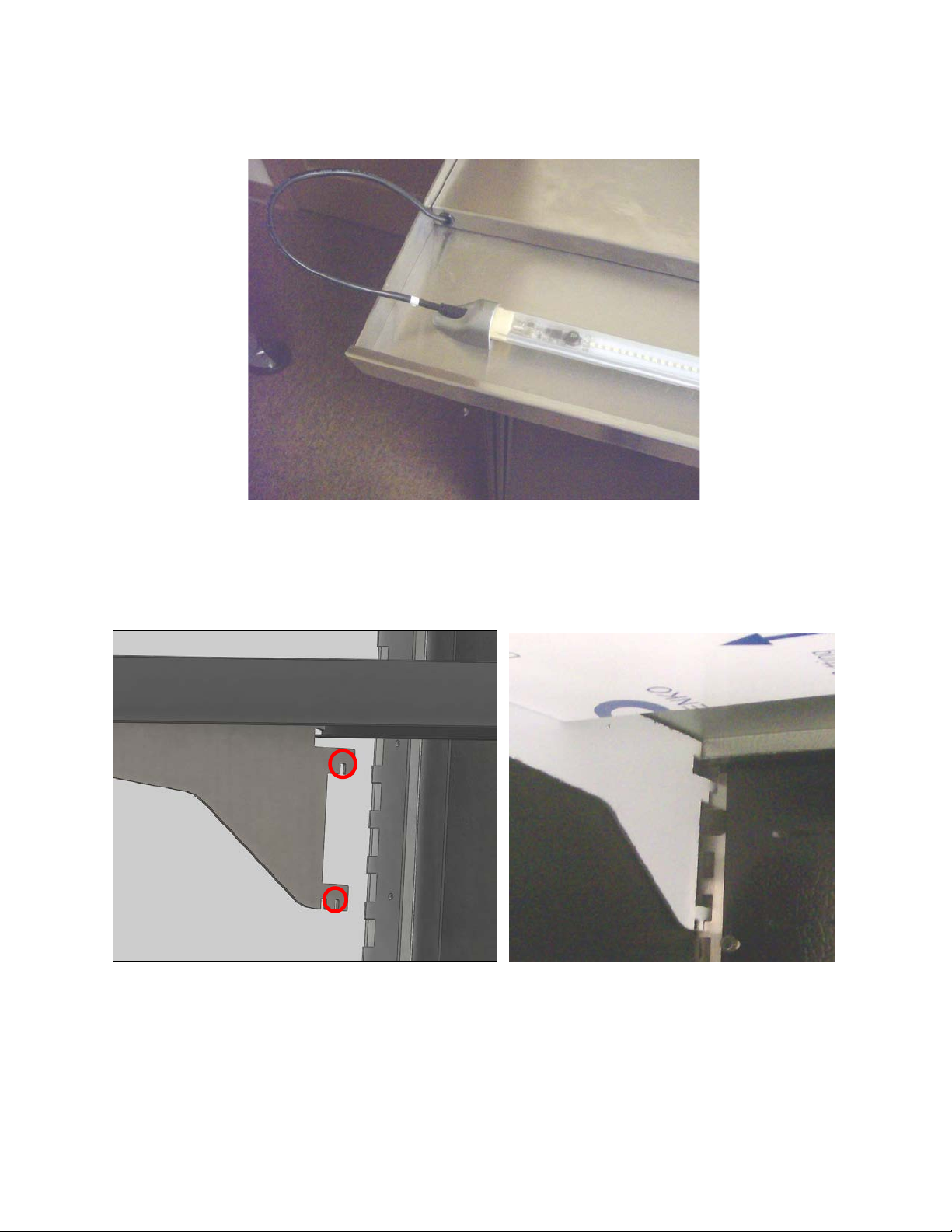

1) If this is a lighted shelf assembly, position shelf brace and cable as shown in the image below. If this is not a

lighted shelf assembly, skip this step and proceed to the next step.

2) With shelf top turned upside down, position shelf brace midway inside shelf top and position the shelf

brace so the electrical outlet hole is to the left side of the shelf top.

OR

5 3/15 Rev. C 157872

ELECTRICAL

HOLE

SHELF

OUTLET

3) Position a shelf bracket with its sides flush with the inside of shelf top and angled as shown in the image

below. To fully secure the shelf bracket, the installer needs to pry the angle of the shelf top ,indicated by

arrow in the image, so the bracket will snap under shelf top while also manuevering the shelf brace so it fits

in the notch of the shelf bracket as the shelf bracket is being lowered into the shelf top. Perform for both

sides of the shelf assembly.

BRACKET

NOTCH

The completed assembly should look similar to the images below.

Upside down view of completed shelf assembly Upright isometric view of shelf assembly

6 3/15 Rev. C 157872

4) If this is the shelf lighting assembly ,mount lighting assembly in desired location on shelf using magnetic

brackets and pull cable as needed to decrease slack in cable.

5) The shelves can be positioned to stock products horizontally or at an angle. To position the shelves

horizontally, use the notches indicated on the shelf bracket at the desired level using the spaces available on

the pilasters. Make sure the corresponding pilaster slots are used on both sides to make sure shelves are

level.

Use the outside notches on shelf bracket to position the shelf assemblies horizontally

7 3/15 Rev. C 157872

6) To position the shelves at a slight angle, use the notches indicated on the shelf bracket at the desired level

using the spaces available on the pilasters. Make sure the corresponding pilaster slots are used on both

sides to make sure shelves are level.

Use the inside notches on shelf bracket to position shelf assemblies at an angle

7) If this is a lighted shelf assembly, plug cable into the nearest outlet located on back panel.

8 3/15 Rev. C 157872

Loading...

Loading...