Page 1

STABILITY CHAMBERS

Installation, Operation and

Maintenance Instructions

GENERAL

Inspection 2

Location 2

Installation 2

Door Alignment

Remote Contacts

RS485 Port

Internal Outlet

Access Port

Humidity Installation 3

Drain Installation 3

Shelf Installation

2

2

2

2

2

2

2

Electrical 4

Glycerin Well Assembly 4

OPERATION

MAINTENANCE

Periodic Cleaning 5

Cleaning the Humidifier 6-7

Maintenance Service and Analysis Guide

1/10 Rev. E 132574

4

5

8

Page 2

GENERAL

INSPECTION

When the equipment is received, all items should be carefully checked against the bill of lading to

insure all crates and cartons have been received. All units should be inspected for concealed

damage by uncrating the units immediately. If any damage is found, it should be reported to the

carrier at once, and a claim should be filed with the carrier. This equipment has been inspected

and tested in the manufacturing facility and has been crated in accordance with transportation

rules and guidelines. Manufacturer is not responsible for freight loss or damage.

LOCATION

The refrigeration system located at the top of the cabinet requires free air access for proper

operation. Allow a minimum four-inch clearance on the top, rear, and sides of the cabinet. The

cabinet should also be leveled when it is placed in its permanent location. Do not stack items on

top of the unit. Vibration during shipping and handling may loosen mechanical connections. Check

all connections during installation. Check all wiring, piping and fasteners.

CAUTION

• Do not modify cabinet construction or associated equipment assemblies.

• Do not remove labeling or information supplied with the unit.

INSTALLATION

Door Alignment - If for some reason the doors are not squared up on the cabinet, the doors can

be adjusted. Opening the door(s) and loosening the screws that hold both the top and bottom

hinges to the cabinet can accomplish this. After adjusting the door so that it is

aligned correctly, tighten the screws to securely hold the hinges in place.

Shelving Installation - Locate shelf clips in bag inside cabinet, install in shelf

supports (4 per shelf)

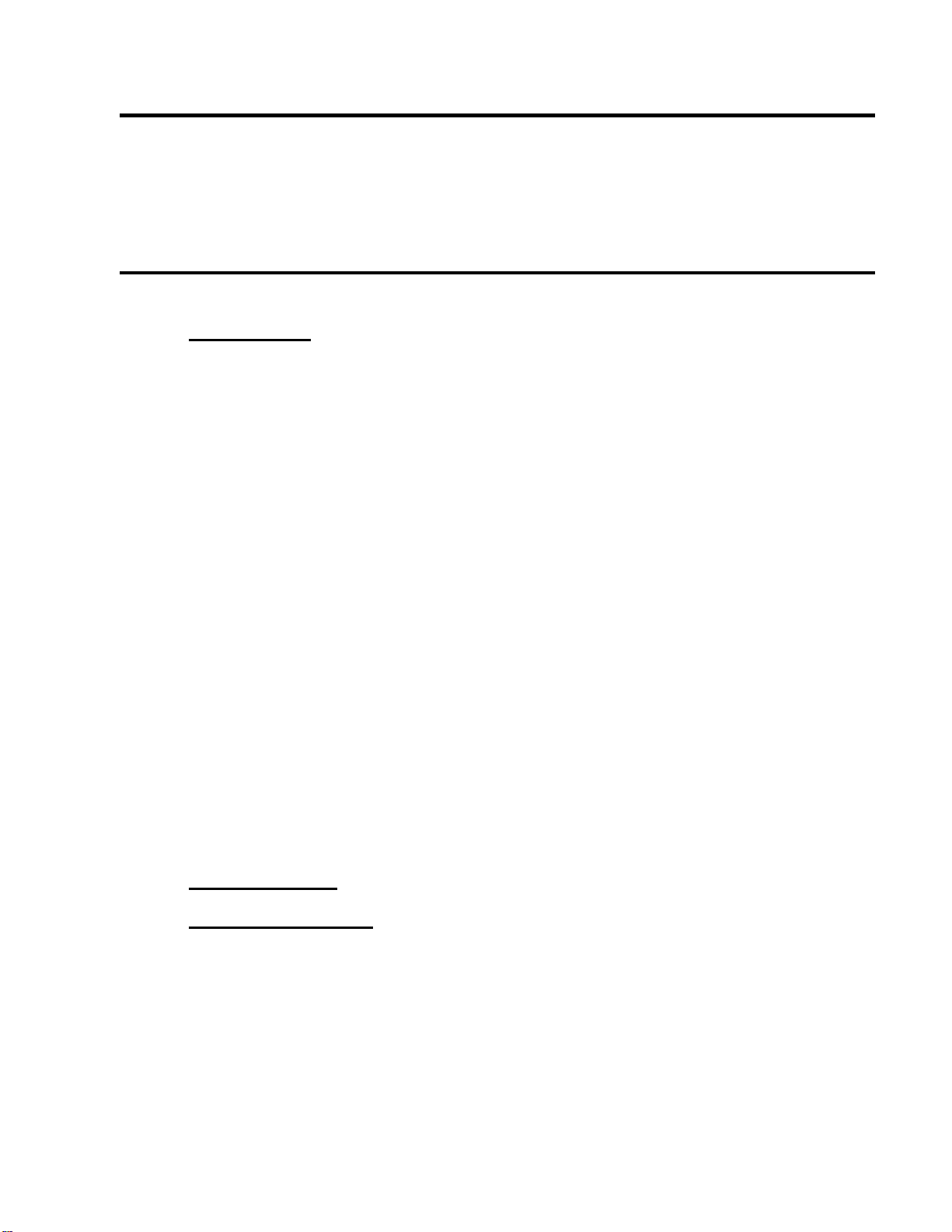

1. Remote Alarms Contacts Access - The factory installed Remote

alarm contacts access box is located at the top of the cabinet behind

the microprocessor control.

2. Remove the cover to access the terminal connections.

3. Select and knock-out a hole to run field leads

into electrical box terminals.

4. The terminal block in the electrical box is

labeled for “normally open” and “normally

closed” activation. End user is responsible for

proper field installation.

Terminal connections are rated for class II

circuits only per NEC table 11(A). (Limited

power source less than 30vac 8 Amp. max,

see applicable notes in NEC).

2-10 volt DC Output, is located at the top of the

control box behind the microprocessor control,

connect wires as per label (4-20 ma optional).

RS485 port - (Optional) terminal board for RS485

port is located behind the cabinet façade, on the left hand side of the control box, connect wires as

per label.

- 2 -

Page 3

Duplex/ or European Outlet - (Optional) is located near the top of the interior cabinet back. This

is a 15 amp 115 volt duplex PN 88010300 with its own power supply cord. Duplex outlet power

cord is wrapped up on the back of the cabinet top. Outlet is not inter-wired thru main cabinet

supply and must be plugged into a 115 volt/ or 220/240V power supply. Locate cabinet within 8

feet of the wall receptacle.

Access Port - (Optional) is provided with a spring loaded cover on the right hand side of the

cabinet.

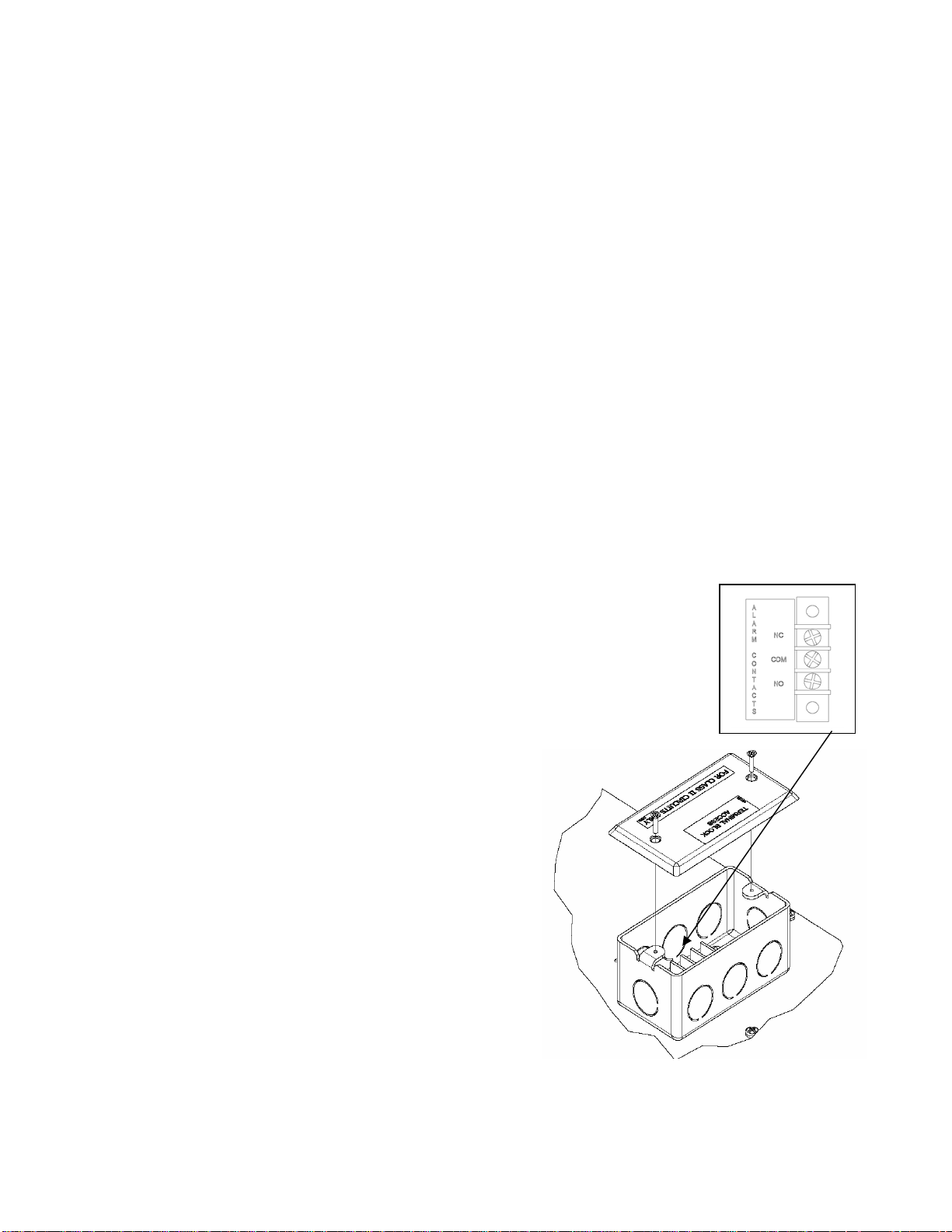

HUMIDITY INSTALLATION (if applicable)

The water supply should have a dedicated shutoff valve and regulator installed. Connect the water

supply to the humidifier (the operating pressure range is 10-60 psi). For best results, provide a

source of reverse osmosis water with a resistance of .05 to 1.0mΩ, which will reduce the scale

build up and cleaning frequency. Unit is equipped for water supply with 1/8” Male Pipe Threads.

The humidifier reservoir water level may be adjusted by using the adjusting thumb screw located

on the float valve (see below).

The humidifier is a precision built instrument that,

given proper care, will provide years of

dependable service. Cleaning the humidifier

periodically is all that is required to insure proper

operation. Depending on local water conditions,

mineral solids and other matter may accumulate

in various parts of the unit. These accumulations

must be removed so that water flows freely for

efficient operation. Failure to clean the humidifier

may result in malfunction which will lead to repairs.

If higher humidity levels are unobtainable, loosen the

reducing coupling clamp and remove reducing coupling

boot and reducer PVC.

DRAIN INSTALLATION

The Stability Chamber has a floor drain in the bottom of the

cabinet. A silicone drain stopper has been placed in this drain.

The drain stopper will prevent undesirable liquids from running

into the drain. The stopper can be removed if any possible

liquids flowing into this drain are acceptable to go to the floor drain.

- 3 -

Page 4

An 18” length of 1/2" I.D. drain hose is shipped inside cabinet. Attach hose to drain stub under

cabinet with supplied clamp and run to an atmospheric floor drain. May substitute longer drain

hose as needed. Humidifier units will require a drain for overflow.

ELECTRICAL

For electrical requirements see data information and wiring unit diagram located in parts bag,

inside of the cabinet.

Check the proposed external power outlet/supply to be used to ensure that the voltage, phase and

current carrying capacity of the circuit from the electrical panel correspond to the requirements of

the cabinet. NEVER

data) for all pertinent electrical information.

Observe all Warning Labels. Disconnect power supply(s) to eliminate injury from electrical

shock or moving parts when servicing equipment.

use an extension cord to wire any unit. Refer to the serial tag (nameplate

GLYCERIN WELL ASSEMBLY

Important: For accurate product temperature reading, the

product-sensing bulb must be immersed in glycerin

solution contained in the provided well.

One glycerin well is furnished with each model. The

purpose of the glycerin is to simulate the product stored in

the Stability Chamber. The glycerin temperature reflects

the product's temperature during normal operation.

Figure 1

After the unit is put into operation. Check to make sure that

the temperature indicating or alarm sensing bulb is

positioned inside the glycerin well. As far as possible

without touching the well itself.

OPERATION

The Stability Chambers are designed for an operating range of 4°C to 70°C Temperature only, 5°C

to 60°C Temperature with Humidity.

These units employ a programmable controller to control the temperature, defrost and humidity

settings. The controller, which is located on the facade of the unit, is factory set. Please see the

separate instructions, part number 113635, on the operation of the controller used in the Stability

Chambers.

The cabinets use an evaporator coil, located on top of the cabinet as the heat-removing source.

Through the refrigeration process, heat is captured in the evaporator, transferred to the

condensing unit on top of the cabinet, and expelled to the surrounding outside air. It is extremely

important to allow a four-inch clearance on the top, rear, and sides of the unit for the refrigeration

process to function properly.

- 4 -

Page 5

The cabinets utilize electrically operated heaters to warm the cabinets in the heating mode. The

heating elements are located in the interior cowl. The programmable control is factory set with a

cutout temperature to prevent the cabinet from exceeding its design limits.

Note: The cabinets are equipped with two switches located on the façade. One is the main power

ON/OFF switch for the unit. The other is a three-position switch for the battery-powered alarm. The

alarm switch is placed in the middle, or OFF position, for shipment. When the Stability Chamber is

put into operation, the top of the switch should be pushed in to the ON position. With the switch in

the ON position, the battery will sound the alarm if the main power to the cabinet is interrupted.

The switch flipped to the bottom position is used to test the battery. This test must be done with

power uninterrupted

done periodically. The battery is located on the backside of the control box that is on top of the unit

behind the façade.

to the cabinet. The alarm will sound if the battery is good. This test should be

MAINTENANCE

PERIODIC CLEANING

Disconnect power source, including optional duplex power cord if equipped, before servicing or

cleaning.

Beginning with the initial installation, the interior surfaces of the cabinet should be periodically

wiped down with a solution of warm water and baking soda. This solution will remove any odors

from spillage that has occurred. The exterior of the cabinet should also be cleaned frequently with

a commercial grade of glass cleaner. Caution: Do not use an abrasive or alkaline solution.

Monthly cleaning of the condenser will aid the heat transfer characteristics of the refrigeration

system and increase its efficiency. Dust, dirt, and lint may accumulate on the fins of the

condensing unit. This obstruction may affect the flow of air through the condenser, thereby

lowering the efficiency of the system. A wire brush or a brush with stiff bristles can be used to

loosen these particles that are attached to the fins so that they may be removed with a vacuum

cleaner. Important: Failure to keep the condenser coil clean and clear of obstructions could

result in temperature loss and damage to the compressor. All moving parts have been

permanently lubricated and will generally require no maintenance.

- 5 -

Page 6

CLEANING THE HUMIDIFIER

Before Cleaning:

1. Disconnect the electrical plug from power source. Turn off water supply. (See Figure D)

2. Unfasten the Dome Strap and remove the Dome from the humidifier assembly by lifting it from

the chromed Motor Pan (Figure B).

3. Lift out the Atomizing Unit that rests freely on the Reservoir.

Figure B

Figure D

Figure C

- 6 -

Page 7

4. Clean the Atomizing Unit. Do not submerge in water.

a. Slightly twist the Cylindrical Screen out of the lock position and remove.

b. Remove the Impeller Cap from the Pump Tube by tapping lightly against the bottom edge

of the Cap with a flat object, such as a knife or file. Do not tap the face of the Impeller

Cap.

c. Free the three Apertures in the pump bushing of accumulated solids (Figure C). To do this,

insert a pointed scraper or pipe cleaner through the open end of the Pump Tube into the

three Apertures on the side of the pump bushing. You may not actually see the Apertures,

but you can feel them. Gently poke and free the Apertures of any solids that may have

accumulated. Scrape out waste materials along the inner walls of the Pump Tube.

d. Replace the Impeller Cap on the Pump Tube and lightly tap around the edge of the Cap

until it is in place. Do not tap the face of the Impeller Cap.

e. Spin the Pump Tube by hand to insure that it rotates freely.

f. Replace the Cylindrical Screen by twisting it into the lock position.

g. Brush the Vapor Maker Comb clean by using a small wire brush or an old toothbrush.

Also, clean out the Motor Pan.

5. Empty and clean the Reservoir of all liquids and waste materials. Care should be taken so as

not to disturb the Floats or Float Valve.

6. Reassemble the humidifier by placing the Atomizing Unit on the Reservoir and the Dome on

the chromed Motor Pan.

7. Re-install the humidifier into its bracket. For proper operation Atomizer must be positioned as

shown in Figure D.

MAINTENANCE SERVICE AND ANALYSIS GUIDE

REFRIGERATION SYSTEMS - ALL MODELS

- 7 -

Page 8

MALFUNCTION POSSIBLE CAUSE SOLUTION

Compressor will not start - 1. Service cord unplugged 1. Plug in service cord

no hum 2. Fuse blown or removed 2. Replace fuse

3. Overload tripped 3. Determine reasons and correct

4. Control stuck open 4. Repair or replace

5. Wiring incorrect 5. Check wiring against the diagram

Compressor will not start - 1. Improperly wired 1. Check wiring against the diagram

hums but trips on overload 2. Low voltage to unit 2. Determine reason and correct

protector 3. Starting capacitor defective 3. Determine reason and replace

4. Relay failing to close 4. Determine reason, correct or replace

Compressor starts and runs, 1. Low voltage to unit 1. Determine reason and correct

but short cycles on overload 2. Overload defective 2. Check current, replace overload protector

protector 3. Excessive head pressure 3. Check ventilation or restriction in

refrigeration system

4. Compressor hot-return gas hot 4. Check refrigerant charge, fix leak if

necessary

Compressor operates long 1. Short of refrigerant 1. Fix leak, add refrigerant

or continuously 2. Control contact stuck 2. Repair or replace

3. Evaporator coil iced 3. Determine cause, defrost manually

4. Restriction in refrigeration 4. Determine location and remove restriction

system

5. Dirty condenser 5. Clean condenser

Compressor runs fine, but 1. Overload protector 1. Check wiring diagram

short cycles 2. Cold control 2. Differential too close - widen

3. Overcharge 3. Reduce charge

4. Air in system 4. Purge and recharge

5. Undercharge 5. Fix leak, add refrigerant

Starting capacitor open, 1. Relay contacts stuck 1. Clean contacts or replace relay

shorted or blown 2. Low voltage to unit 2. Determine reason and correct

3. Improper relay 3. Replace

Relay defective or burned out 1. Incorrect relay 1. Check and replace

2. Voltage too high or too low 2. Determine reason and correct

Refrigerated space too warm 1. Control setting too high 1. Reset control

2. Refrigerant overcharge 2. Purge refrigerant

3. Dirty condenser 3. Clean condenser

4. Evaporator coil iced 4. Determine reason and defrost

5. Not operating 5. Determine reason, replace if necessary

6. Air flow to condenser or 6. Remove obstruction for free air flow

evaporator blocked

Standard temperature system 1. Control setting is too low 1. Reset the control

freezes the product 2. Control points stuck 2. Replace the control

Objectionable noise 1. Fan blade hitting fan shroud 1. Reform or cut away small section of shroud

2. Tubing rattle 2. Locate and reform

3. Vibrating fan blade 3. Replace fan blade

4. Condenser fan motor rattles 4. Check motor bracket mounting, tighten

5. General vibration 5. Compressor suspension bolts not loosened

on applicable models - loosen them

6. Worn fan motor bearings 6. Replace fan motor

Pan Area 1. No cooling 1. Make sure switch is in the "on" position

2. Too cold 2. Adjust temperature control - see instructions

under pan area

3. Too warm 3. Adjust temperature control - see instructions

under pan area

Failure to Heat 1. Manual overload tripped 1. Push reset on hi-limit switch

2. Incorrect setting 2. See control manual

3. Alarm enabled 3. See control manual

Humidity level not correct 1. Water supply interrupted 1. Check water supply

2. Clean Humidifier

2. Incorrect control settings 1. See control manual

3. Piping not connected / sealed 1. Connect tubing

4. No power to humidifier 1. Check power connections for humidifier

5. Unable to maintain higher humidity levels 1. Remove restriction on humidity output spout

6. Unable to maintain humidity tolerance. 1. Confirm humidity restrictor is properly positioned in output

Spout

7. Humidity range to high or low 1. Modify humidity ON/OFF parameters

2. Modify dehumidification ON/OFF parameters

2. Seal joints

- 8 -

Loading...

Loading...