Noritz America EZ98DV, EZ111DV Installation Manual

CONDENSING TANKLESS GAS WATER HEATER

Installation Manual

Models : EZ111DV (GQ-C3260WX-FF US)

EZ98DV (GQ-C2860WX-FF US)

WARNING

WARNING

If the information in these instructions is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

•Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

•WHAT TO DO IF YOU SMELL GAS

-Do not try to light any appliance.

-Do not touch any electrical switch; do not use any phone in your building.

-Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

-If you cannot reach your gas supplier, call the fire department.

•Installation and service must be performed by a qualified installer, service agency or the gas supplier.

CAUTION

CAUTION

Requests to Installers

•In order to use the Water Heater safely, read this installation manual carefully, and follow the installation instructions.

•Failures and damage caused by erroneous work or work not as instructed in this manual are not covered by the Noritz America Limited Warranty.

•Check that the installation was done properly in accordance with this Installation Manual upon completion.

•After completing installation, either place this Installation Manual in a plastic pouch and attach it to the side of the Water Heater (or the inside of the pipe cover or recess box if applicable),

or hand it to the customer to retain for future reference. Also, be sure to fill in all of the required items on the warranty and to hand the warranty to the customer along with the Owner’s Guide.

FOR USE IN RESIDENTIAL OR MANUFACTURED HOME APPLICATIONS.

Installation must conform with local codes, or in the absence of local codes, the National Fuel Gas Code, ANSI Z223.1 / NFPA 54latest edition and/or the Natural Gas and Propane Installation Code CSA B149.1- latest edition.

When applicable, installation must conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 or the Canadian Standard CAN/CSA-Z240 MH Mobile Homes, Series M86.

Noritz America reserves the right to discontinue, or change at any time, the designs and/or specifications of its products without notice.

Contact Noritz America at 1-866-766-7489, if you have any questions or concerns.

Low NOx Approved by SCAQMD 14 ng/J or 20 ppm (Natural Gas Only)

NORITZ America Corporation

SBB8164

Rev. 05/19

Contents |

|

|

1 |

Before Installation |

3 |

2 |

About the Water Heater |

5 |

2.1 |

Included Accessories........................ |

5 |

2.2 |

Optional Accessories........................ |

5 |

2.3 |

Specifications.................................... |

7 |

2.4 |

Dimensions....................................... |

8 |

2.5 |

External View.................................... |

10 |

3 |

Choosing an Installation Location |

11 |

4 |

Installation Clearances |

13 |

4.1 |

Indoor Installation............................ |

13 |

4.2 |

Outdoor Installation......................... |

14 |

4.3 |

For Quick Connect Multi-System..... |

14 |

5 |

Installation of the Water Heater |

15 |

5.1 |

Mounting the Water Heater |

|

|

to the wall......................................... |

15 |

5.2 |

Elevation Adjustment Above |

|

|

2,000 ft............................................. |

16 |

5.3 |

Filling the condensate container |

|

|

with water........................................ |

16 |

6 |

Venting the Water Heater |

17 |

6.1 |

Venting Installation Sequence.......... |

17 |

6.2 |

General Requirements..................... |

17 |

6.3 |

Select a Vent Type............................ |

23 |

6.4 |

Vent Pipe Installation (Direct Vent).. |

24 |

6.5 |

Vent Pipe Installation |

|

|

(Non-Direct Vent)............................. |

30 |

6.6 |

Outdoor Installation......................... |

36 |

7 |

Connecting the Gas Supply |

37 |

8 |

Connecting the Water Supply |

41 |

8.1 |

Installation........................................ |

41 |

8.2 |

Water treatment.............................. |

43 |

9 |

Connecting the Condensate Drain 45 |

|

10 |

Connecting Electricity |

47 |

10.1 |

Water Heater.................................... |

47 |

10.2 |

Remote Controller............................ |

47 |

10.3 |

Recirculation Pump.......................... |

48 |

10.4 |

Quick Connect Cord-2...................... |

49 |

11 |

Installation of the Remote Controller |

50 |

11.1 |

General Requirements..................... |

50 |

11.2 RC-7651M-A..................................... |

50 |

|

11.3 RC-9018M......................................... |

52 |

|

12 |

Setting the DIP Switches |

56 |

13 |

Trial Operation |

57 |

14 |

Checklist After Installation |

59 |

15 |

Plumbing Applications |

61 |

16 |

Installation of the Quick Connect |

|

|

Multi-System |

63 |

17 |

Maintenance |

64 |

17.1 |

Periodic Check.................................. |

64 |

17.2 |

Procedure for Flushing the Heat |

|

|

Exchanger......................................... |

65 |

2 Contents

1 Before Installation

Potential dangers from accidents during installation and use are divided into the following four categories. Closely observe these warnings, they are critical to your safety.

DANGER

DANGER

WARNING

WARNING

CAUTION

CAUTION

NOTICE

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Indicates a potentially hazardous situation which, if not avoided, may result in property damage.

DANGER

DANGER

Checkup

Check the fixing brackets and vent pipe yearly for damage or wear. Replace if necessary.

WARNING

WARNING

Precautions on Vent Pipe Replacement

The vent system will almost certainly need to be replaced when this appliance is being installed. Only use vent materials that are specified in this Installation Manual for use on this appliance.

Refer to the “Venting the Water Heater” section for details. If PVC, CPVC, or Category IV listed pipe is already installed, check for punctures, cracks, or blockages and consult with the vent pipe manufacturer before reusing.

If the flexible PP pipe is already installed, replace to the new flexible PP pipe.

Improper venting may result in fires, property damage or exposure to Carbon Monoxide.

Snow Precaution

If this product will be installed in an area where snow is known to accumulate, protect the vent termination from blockage by snow drifts or damage from snow falling off of roofs.

Check the Gas

•Check that the rating plate indicates the correct type of gas.

•Check that the gas supply line is sized for 199,900 Btu/h or 180,000 Btu/h.

199,900 Btu/h: EZ111DV (GQ-C3260WX-FF US)

180,000 Btu/h: EZ98DV (GQ-C2860WX-FF US)

e.g. EZ111DV (GQ-C3260WX-FF US)

Check the Power

The power supply required is 120 VAC, at 60 Hz. Using the incorrect voltage may result in fire or electric shock.

Use Extreme Caution if Using With a Solar PreHeater

Using this appliance with a solar pre-heater can lead to unpredictable output temperatures and possibly scalding. If absolutely necessary, use mixing valves to ensure output temperatures do not get to scalding levels.

Do not use a solar pre-heater with the Quick Connect Multi-System because the system may not operate properly.

Precautions for Mobile Home Installation

•Verify that the gas supply type matches the gas type listed on the rating plate. If a gas conversion must be done, follow the instructions listed in the gas conversion kit manual.

•If this product will be installed indoors, usage of the SV conversion kit (SV-CK-2) and the Flex

Vent 2 in. Conversion Kit (EZ2-CK) are prohibited. Make sure to follow all clearance and venting requirements outlined in this manual.

Chemicals

This product can expose you to chemicals including lead, lead compounds and carbon bisulfide which are known to the State of California to cause cancer, birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Before Installation |

3 |

CAUTION

CAUTION

Do Not Use Appliance for Purposes Other Than Those Specified

Do not use for other than increasing the temperature of the water supply, as unexpected accidents may occur as a result.

Check Water Supply Quality

If the water supply is in excess of 12 grains per gallon (200 mg/L) of hardness, acidic or

otherwise impure, treat the water with approved methods in order to ensure full warranty coverage.

NOTICE

•This appliance is suitable for combination potable water and space heating applications. It cannot be used for space heating applications only.

•Do not use this appliance if any part has been underwater. Immediately call a qualified service technician to inspect the appliance and replace any part of the control system and gas control which has been under water.

4 Before Installation

2 About the Water Heater

2.1 Included Accessories

The following accessories are included with the Water Heater.

Check for any missing items before starting installation.

Anchoring Screw (× 7)

Remote Controller (× 1) (See page 50) [RC-7651M-A]

Owner’s Guide, Warranty card,

Installation Manual (this document) (1 each)

Remote Controller Cord (6 ft (1.8 m)) (× 1)

Wall Mounting Bracket (× 1)

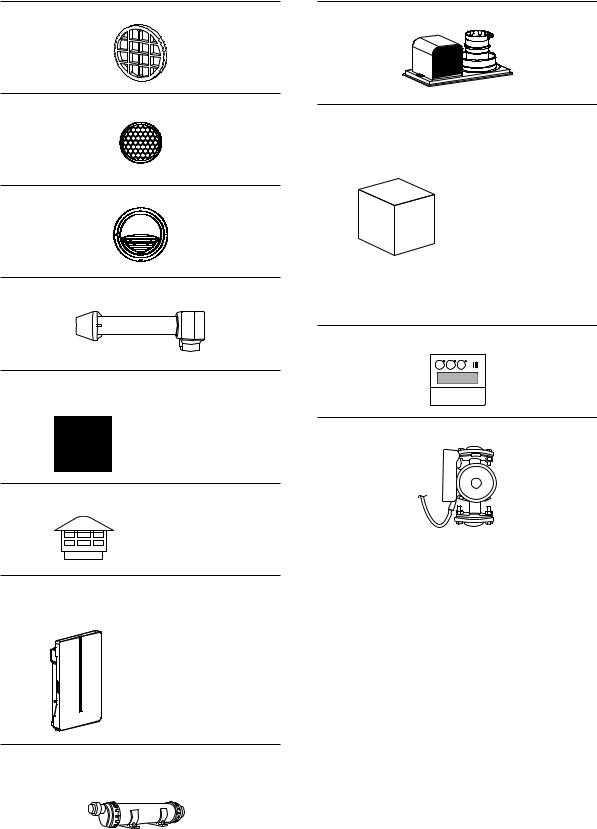

2.2 Optional Accessories

The accessories listed below are not included with the Water Heater, but may be necessary for installation.

NOTE Additional vent pieces are available; consult the latest product catalogue for details.

Quick Connect Cord (× 1) [QC-2]

Remote Controller Cord (26 ft (7.9 m)) (× 1) [RC-CORD26]

Isolation Valves (1 each) (includes pressure relief valve)

Isolation valves are necessary for flushing the Heat Exchanger.

They allow for easy flushing and troubleshooting of the system.

PVC Concentric Termination (× 1) 2 in. (50 mm) : [PVC-2CT]

3 in. (75 mm) : [PVC-3CT]

2 in. SV Conversion Kit (× 1) [SV-CK-2]

• 90° Elbow

(With Inlet Screen)

• 2 in. × 3 in. Increaser coupling

• 2 in. Pipe

• Installation Manual (Check List)

Outdoor Vent Cap (× 1) [VC-6]

About the Water Heater 5

Bird Screen for 2 in. (50 mm) PVC [VT2-PVCS]

Bird Screen for 3 in. (75 mm) PVC [VT3-PVCS]

3 in. (75 mm) Horizontal Hood Termination [PVT-HL]

Universal Concentric Vent Kit

[PVC-UCVK]

Low Profile Termination Kit 2 in.: [PVC-2LPT]

3 in.: [PVC-3LPT]

ULC S636 / UL 1738 certified for use in both Canada and USA

Plastic Rain Cap [PRC-1]

Not approved for use in Canada.

Noritz Connect Wireless Adapter NWC-ADAPTER (× 1)

[NAW-1 US]

Noritz Connect Wireless Adapter enables users to:

• Remote control (Power ON/OFF, Adjust set temperature)

For more information, visit the Noritz America website (http://wifi.noritz.com/).

Neutralizer (× 1) [NC-1S]

(For 1 Water Heater)

Flex Vent 2 in. Conversion Kit [EZ2-CK]

Flex Vent 2 in. Kit – 25 ft [EZ2FVK-1]

Flex Vent 2 in. Kit – 35 ft [EZ2FVP35-3]

During the installation of Flex Vent 2 in. Kit (EZ2FVK-1 and EZ2FVP35-3), ambient temperatures must be greater than 40°F (5°C). Afterwards, installation site ambient temperature must be greater than -4°F (-20°C). Flex vent pipe

breakage may occur if these temperature requirements are not observed.

Remote Controller (× 1) (See page 52) [RC-9018M]

Noritz Recirculation System

[RPK-EXT]

6 About the Water Heater

2.3Specifications

•Specifications may be changed without prior notice.

•The capacity may differ slightly, depending on the water pressure, water supply, piping conditions, and water temperature.

|

|

Item |

Specification |

||

Model Name |

|

EZ111DV (GQ-C3260WX-FF US) |

EZ98DV (GQ-C2860WX-FF US) |

||

Type |

|

Installation |

Indoor / Outdoor Wall mounted |

|

|

|

Air Supply / Exhaust |

Power Vented |

|

||

|

|

|

|||

Ignition |

|

|

Direct Ignition |

|

|

Operating Pressure |

15-150 psi |

|

|||

(Recommended 50 to 80 psi for maximum performance) |

|||||

|

|

|

|||

Minimum Activation Flow Rate* |

0.5 GPM (2.0 L/min) |

|

|||

Minimum Operating Flow Rate* |

0.29 GPM (1.1 L/min) |

|

|||

Dimensions (Height) × (Width) × (Depth) |

27.0 in. (687 mm) × 18.5 in. (471 mm) × 14.1 in. (359 mm) |

||||

Weight |

|

70 lbs. (32 kg) |

|

||

Water Holding Capacity |

0.83 Gallon (3.1 L) |

|

|||

|

|

Water Inlet |

NPT 3/4 in. |

|

|

Connection |

|

Hot Water Outlet |

NPT 3/4 in. |

|

|

Sizes |

|

Gas Inlet |

NPT 3/4 in. |

|

|

|

|

Condensate Drain |

NPT 1/2 in. |

|

|

|

|

Supply |

120 VAC (60 Hz) |

|

|

Power |

|

Consumption |

NG: 96 W LP: 80 W |

NG: 75 W LP: 64 W |

|

Supply |

|

Freeze Prevention: 114 W |

Freeze Prevention: 114 W |

||

|

|

||||

|

|

Maximum Current |

4 Amps |

|

|

|

|

|

•Front Cover: Hot-dipped zinc-aluminum-magnesium-alloy-coated |

||

|

|

Casing |

steel w/ Polyester Coating |

|

|

Materials |

|

|

•Casing: Zincified Steel Plate / Polyester Coating |

||

|

Flue Collar |

PP |

|

||

|

|

|

|||

|

|

Primary Heat Exchanger |

Stainless Steel Sheeting, Stainless Steel Tubing |

||

|

|

Secondary Heat Exchanger |

Stainless Steel Sheeting, Stainless Steel Tubing |

||

Safety Devices |

Flame Rod, High Limit Switch, Lightning Protection Device (ZNR), |

||||

Freezing Prevention Device, Fan Rotation Detector |

|||||

|

|

|

|||

Included Accessories |

Remote Controller, Remote Controller Cord, Anchoring Screws, Wall |

||||

Mounting Bracket |

|

||||

|

|

|

|

||

* Minimum flow rate may change by setting temperature and water temperature.

Performances

Item |

|

|

Performance |

|

||

|

EZ111DV (GQ-C3260WX-FF US) |

EZ98DV (GQ-C2860WX-FF US) |

||||

|

|

|||||

|

|

Maximum |

Minimum |

Maximum |

Minimum |

|

Gas Consumption |

NG |

199,900 Btu/h |

18,000 Btu/h |

180,000 Btu/h |

18,000 Btu/h |

|

|

LP |

199,900 Btu/h |

18,000 Btu/h |

180,000 Btu/h |

18,000 Btu/h |

|

Maximum Hot Water Capacity |

8.7 GPM (33 L/min) |

7.6 GPM (29 L/min) |

||||

(45°F (25°C) Rise) |

|

|||||

|

|

|

|

|

||

Capacity Range |

|

0.5-11.1 GPM (2-42 L/min) |

0.5-9.8 GPM (2-37 L/min) |

|||

Temperature Settings |

°F Mode |

100-140°F (In 5°F intervals) (9 Options) |

|

|||

°C Mode |

37-48°C (In 1°C intervals), 50-60°C (In 5°C intervals) (15 Options) |

|||||

|

||||||

About the Water Heater 7

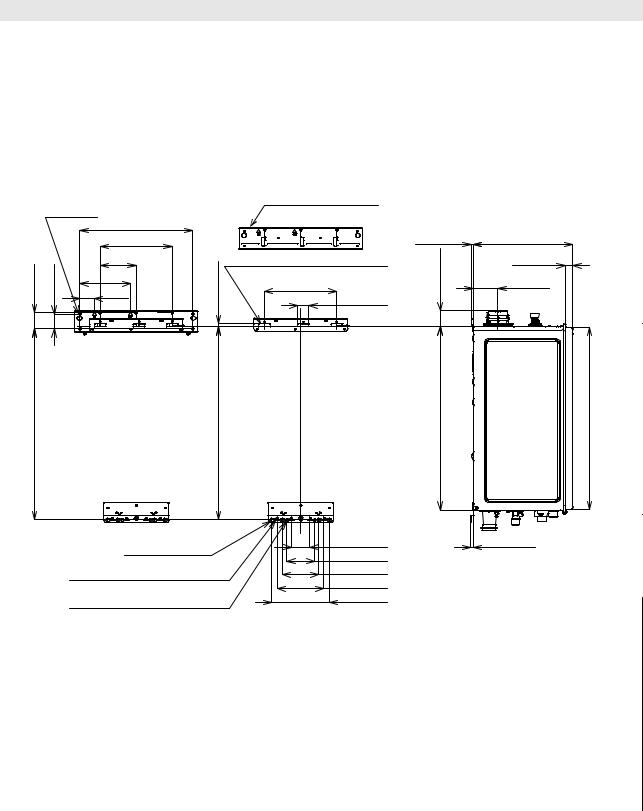

2.4 Dimensions

7×Φ0.2”[Φ6]

|

|

16.0”[406] |

|

|

|

|

10.2”[260] |

|

|

2.3”[58] |

2.0”[52] |

5.1”[130] |

0.5”[12] |

|

7.2”[183] |

||||

|

|

|

||

|

|

2.1”[5.3] |

|

27.1”[690] |

27.4”[696] |

4×Φ0.5”[Φ13]

4×0.24”×0.6”[6×15]OBLONG HOLE

2×0.4”×0.24”[10×6]OBLONG HOLE

WALL MOUTING BRACKET (INCLUDED ACCESSORY)

3×0.5”[12]×1.6”[40]RECTANGLE HOLE

10.2”[260]

1.6”[40]

2.2”[56]

3.9”[100]

5.2”[132]

6.7”[169]

8.1”[206]

0.3”[8]

2.3”[59]

26.0”[661]

14.1”[359]

1.1”[27]

3.5”[89]

25.9”[658]

0.4”[10]

8 About the Water Heater

17.8”[452]

14.2”[362]

HOT WATER OUTLET(3/4”)

WATER DRAIN VALVE

18.5”[471]

17.8”[451]

5.1”[130] |

10.5”[266] |

I.DΦ2.4”[Φ61]

AIR INLET

2.4”[60] |

8.7”[220] |

WATER DRAIN VALVE (WATER FILTER)

COLD WATER INLET(3/4”)

I.DΦ2.4”[Φ61]

FLUE COLLAR

27.0”[687]

<inch [mm]>

(VIEW FROM BOTTOM)

|

|

WATER DRAIN VALVE |

|

|

|

WIRING THROUGHWAY |

CONDENSATE DRAIN(1/2”) |

|

|||

WIRING THROUGHWAY |

|

GAS INLET(3/4”) |

|

||

(AC120V) |

|

|

|

|

|

11.3”[288] |

9.7”[246] |

|

|

|

|

1.7”[42] |

|

|

|

|

|

5.7”[144] |

|

|

2.2”[56] |

3.3”[83] |

6.0”[152] |

|

|

11.2”[284] |

|||

|

|

|

|

|

|

|

|

15.4”[392] |

|

|

|

|

|

15.6”[397] |

|

|

|

HEIGHT OF EACH FITTING FROM CASE

HOT WATER OUTLET |

TOP |

1.9”[49] |

COLD WATER INLET |

TOP |

2.1”[53] |

CONDENSATE DRAIN |

BOTTOM |

1.7”[42] |

GAS INLET |

BOTTOM |

2.2”[56] |

About the Water Heater 9

2.5 External View

Indoor Installation |

|

Indoor Installation |

Hot Water |

Intake Pipe Exhaust Pipe |

Flex Vent 2 in. Conversion Kit |

|

|

|

Valve |

|

Water Supply Valve |

Water Drain Valve

(with Water Filter)

Pressure Relief

Valve

Outdoor Installation

Outdoor Vent Cap

Gas Supply Valve

Condensate Drain Pipe

10 About the Water Heater

3 Choosing an Installation Location

DANGER

DANGER

Locate the vent terminal and make sure there are no obstacles around the termination for exhaust to accumulate or be obstructed.

Do not enclose the termination with corrugated metal or other materials.

Carbon monoxide poisoning or fire may occur as a result.

WARNING

WARNING

•Avoid places where fires are common, such as those where gasoline, benzene and adhesives are handled, or places in which corrosive gases (ammonia, chlorine, sulfur, ethylene compounds, acids) are present.

If you do not follow the above, a fire or explosion may result causing property damage, personal injury or death.

•Avoid installation in places where dust or debris will accumulate.

Dust may accumulate and reduce the performance of the fan of the appliance. This can result in incomplete combustion.

•Avoid installation in places where special chemical agents (e.g. hair spray or spray detergent) are used.

Ignition failures and malfunctions may occur as a result.

•Do not install this Water Heater in a recreational vehicle or on a boat as this may be a Carbon Monoxide Poisoning Hazard.

•The manufacturer does not recommend installing the Water Heater in an attic due to safety issues.

If you install the Water Heater in an attic:

-Make sure the appliance will have enough combustion air and proper ventilation.

-Keep the area around the Water Heater clean. Dust may accumulate and reduce the performance of the fan of the appliance. This can result in incomplete combustion.

-A drain pan, or other means of protection against water damage, is required to be installed under the Water Heater in case of leaks.

CAUTION

CAUTION

Do not install in the following places

•A location where it is not free from obstacles and stagnant air.

•Near staircases or emergency exits.

•A place where it may be threatened by falling objects, such as under shelves.

•On common walls as the appliance will make some operational noises while it is running.

Consideration to the surroundings

•Do not install the Water Heater where the exhaust will blow on outer walls, other walls or material not resistant to heat. Also consider the surrounding trees and animals. The heat and moisture from the Water Heater may cause discoloration of walls and

resinous materials, or corrosion of aluminum materials.

•Do not locate the vent termination directed towards a window or any other structure which has glass or wired glass facing the termination.

•Take care that noise and exhaust gas will not affect neighbors.

•If the appliance is installed in a location with very high humidity, condensate may form inside the appliance and/or cause incomplete combustion, damage to the electrical components, or electric leakage.

Install according to regulations and manual

•Install the Water Heater in an area that allows for the proper clearances to combustible

and non-combustible construction. Consult the rating plate on the appliance for proper clearances.

•The Water Heater must be installed according to manual.

•Before installing, make sure that the exhaust flue termination will have the proper clearances according to the National Fuel Gas Code (ANSI Z223.1- latest edition) or the Natural Gas and Propane Installation Code (CSA B149.1).

Choosing an Installation Location 11

CAUTION

CAUTION

Installation in the vicinity of gas ranges, stoves, fans, and range hoods

•Avoid installation above gas ranges or stoves.

•Avoid installation between the kitchen fan and stove. If oily fumes or a large amount of steam are present in the installation location, take measures to prevent the fumes and steam from entering in the appliance.

NOT

CORRECT

•Install in a location where the exhaust gas flow will not be affected by fans or range hoods.

CORRECT |

NOT |

|

CORRECT |

NOTICE

•Place the appliance for easy access for maintenance and repair.

•Do not install the Water Heater in a location where the appliance will be exposed to excessive winds.

•Locate the appliance in an area where leakage from the appliance or connections will not result in damage to the area adjacent to the appliance or to the lower floors of the structure. When such installation locations cannot be avoided, a suitable drain pan, adequately drained, must be installed under the appliance. The pan must not restrict combustion air flow.

•As with any water heating appliance, the potential for leakage at some time in the life of the product does exist. The manufacturer will not be responsible for any water damage that may occur.

•Water quality:

If this Water Heater will be installed in a location where the hardness of the supply water is high, scale Build-up may cause damage to the Heat Exchanger.

Perform suggested treatment and maintenance measures in reference to “8.2 Water Treatment”.

Damage to the Water Heater as a result of the below is not covered by the Noritz America Limited Warranty.

-Water in excess of 12 gpg (200 mg/L) of hardness

-Poor water quality (see the following table)

Contaminant |

Maximum Allowable Level |

Total Hardness* |

200 mg/L (12 gpg) or less |

Aluminum |

0.05 to 0.2 mg/L or less |

Chloride |

250 mg/L or less |

Copper |

1.0 mg/L or less |

Iron |

0.3 mg/L or less |

Manganese |

0.05 mg/L or less |

pH |

6.5-8.5 |

Total Dissolved Solids |

500 mg/L or less |

Zinc |

5 mg/L or less |

Sulfate |

250 mg/L or less |

Residual chlorine* |

4 mg/L or less |

Source: EPA National Secondary Drinking Water

Regulations (40 CFR Part 143.3) * Maximum limit suggested by Noritz.

NOTE Consult with the customer concerning the location of installation.

12 Choosing an Installation Location

State of California: The Water Heater must be braced, anchored or strapped to avoid moving during an earthquake. Contact local utilities for code requirements in your area or call 1-866-766-7489 and request instructions.

The Commonwealth of Massachusetts:

1)This Water Heater can only be used in outdoor applications if the usage is restricted to summertime usage exclusively.

2)The Water Heater can be used for hot water only and not in a combination of domestic and space heating.

For Venting Manufacturers Requirements, see the Noritz America website (www.noritz.com).

4Installation Clearances

WARNING

WARNING

Before installing, check for the following:

Install in accordance with relevant building and mechanical codes, as well as any local, state or national regulations, or in the absence of local and state codes, refer to National Fuel Gas Code ANSI Z223.1 / NFPA 54latest edition. In Canada, see the Natural Gas and Propane Installation Code CSA B149.1- latest edition for detailed requirements.

4.1 Indoor Installation

Required Clearances From the Water Heater

Maintain the clearances from both combustible and non-combustible materials.

12 in. (300 mm) or more

4 in. (100 mm) or more

3 in. (76 mm) or more

Securing of space for inspection/repair

In order to facilitate inspection and repair, the minimum clearances should be met.

*

Exhaust

Exhaust

*

** |

** |

|

24 in. |

|

(610 mm) |

|

or more |

|

* 3 in. (76 mm) or more |

|

** 8 in. (203 mm) or more |

Choosing an Installation Location / Installation Clearances 13

Cooking Equipment

When utilizing an indoor air supply, if the Water Heater will be installed in the vicinity of a permanent kitchen range or stove that has the possibility of generating steam that contains fats or oils, use a dividing plate or other measure to ensure that the Water Heater is not exposed to air containing such impurities.

Exhaust hood

The dividing plate should be of non-combustible material of a width greater than the Water Heater.

Range

Surrounding the area of installation

[When installing the Water Heater in a common side corridor]

the bottom edge of the exhaust port

47 in. (1,194 mm) or more

84 in. (2,134 mm) |

|

or more |

Handrail |

|

Common side corridor

4.2 Outdoor Installation

Required Clearances From the Water Heater

Maintain the clearances from both combustible and non-combustible materials.

24 in. (610 mm) or more

36 in. (910 mm) or more

Outdoor Vent Cap (VC-6)

Outdoor Vent Cap (VC-6)

3 in. (76 mm) or more

4.3 For Quick Connect Multi-System

The Quick Connect Cord is 6 ft (1.8 m) long. Install the Water Heaters 3-18 in. (76-457 mm)

apart from each other to ensure the cord will be able to reach between the Water Heaters.

3-18 in.

(76-457 mm)

14 Installation Clearances

5 Installation of the Water Heater

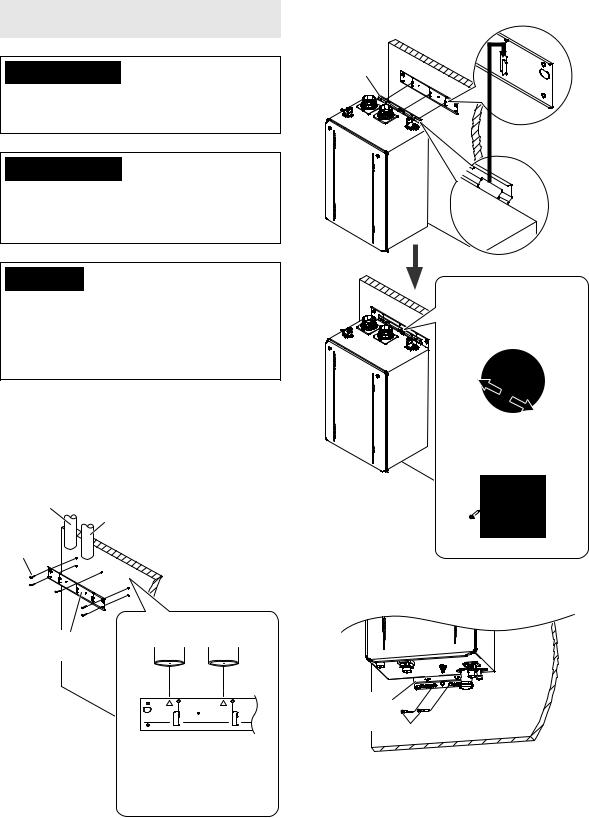

5.1Mounting the Water Heater to the wall

WARNING

WARNING

Do not drop or apply unnecessary force to the appliance when installing. Internal parts may be damaged and may become highly dangerous.

CAUTION

CAUTION

•Protect your hands with gloves and take caution to not inflict injury.

•Be careful not to hit electrical wiring, gas, or water piping while drilling holes.

NOTICE

•The weight of the appliance will be applied to the wall. If the strength of the wall is not sufficient, reinforcement must be done to prevent the transfer of vibration.

•Install the appliance on a vertical wall and ensure that it is level.

1.Ensure that the Wall Mounting Bracket is leveled.

Drill holes for the Wall Mounting Bracket and affix the Wall Mounting Bracket securely to the wall by 5 screws.

Finally, make sure the bracket can support the weight of the Water Heater.

Intake |

|

Vent |

Exhaust |

Anchoring |

Vent |

|

|

Screw |

|

2.Hang the Water Heater on the Wall Mounting Bracket.

Moun ng Bracket (Upper)

Hang

After hanging the Water Heater, you have the ability to move either left or right to position the Water Heater in the appropriate spot.

Once positioned, a screw (see below) can be fastened to ensure no horizontal movement will occur.

(Not supplied from Noritz.)

Wall Mounting

Bracket

Intake Exhaust

Vent Vent

IN |

OUT |

The bracket has marking to assist with ensuring properly aligned connections. Align the intake and exhaust vent center line with the corresponding mark on the bracket.

3.Affix the Mounting Bracket (Lower) to the wall by 2 screws.

Mounting

Bracket

(Lower) Anchoring Screw

Installation of the Water Heater 15

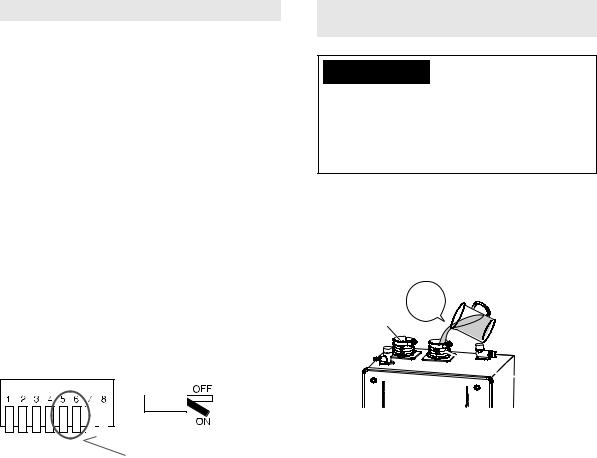

5.2Elevation Adjustment Above 2,000 ft

•Adjust the DIP switches as illustrated in the table below, if this Water Heater is installed at an altitude of 2,000 ft (610 m) or higher.

•Disconnect the electrical power and then adjust the DIP switches.

Refer to page 56 for the location of the DIP switch bank and how to change the DIP switches. Failure to perform this step will result a “73” code displayed on the Remote Controller and a cease in operation.

If this occurs, disconnect, then reconnect the electrical power to the Water Heater to reset the system.

NOTE Do not change any other DIP switches.

ON = ●/ OFF = ○

High elevation adjustment |

DIP switches |

||

#5 |

#6 |

||

|

|||

0-2,000 ft (0-610 m) |

○ |

○ |

|

2,001-4,000 ft (611-1,219 m) |

● |

○ |

|

4,001-7,000 ft (1,220-2,134 m) |

○ |

● |

|

7,001-10,000 ft (2,135-3,048 m) |

● |

● |

|

Here |

5.3Filling the condensate container with water

DANGER

DANGER

Prior to initial start up, make sure that you fill the condensate container with water.

This is to prevent dangerous exhaust gases from entering the building.

Failure to fill the condensate container could result in severe personal injury or death.

Follow the procedure described below to ensure that the condensate container is filled with water.

Fill the condensate container by pouring approx. 10 oz. (280 mL) of water into the exhaust flue on the top of the Water Heater as illustrated below.

10 oz.

280 mL

Intake

Exhaust

Exhaust

If the vent pipe has already been installed: After installing the condensate drain pipe, make

sure that the area around the Water Heater is well ventilated; open a window or a door if necessary. Then, operate the Water Heater and verify that condensate is coming out of the condensate drain pipe.

(During normal use of the Water Heater, condensate will begin to discharge from the condensate drain pipe within 15 minutes of use. However, depending on the season and/or installation site conditions, it may take longer.)

16 Installation of the Water Heater

6 Venting the Water Heater

WARNING

WARNING

CARBON MONOXIDE POISONING

Follow all vent system requirements in accordance with relevant local or state regulation, or, in the absence of local or state code, if in the U.S., refer to the National Fuel Gas Code ANSI Z223.1 / NFPA 54latest edition, and if in Canada, in accordance with the Natural Gas and Propane Installation Code CSA B149.1 - latest edition.

6.1Venting Installation Sequence

1.Install the Water Heater.

2.Determine the termination method—horizontal or vertical, etc.

3.Determine proper location for wall or roof penetration for each termination.

NOTE Do not exceed maximum allowed vent lengths as described in this manual.

4.Install termination assembly as described in this manual or in the vent manufacturer’s installation instructions.

If necessary, install Bird Screen (not supplied with Water Heater).

5.Install combustion air and exhaust vent piping from Water Heater to termination.

6.Slope the horizontal vent 1/4 in. upwards for every 12 in. (305 mm) toward the termination.

7.Install supports and hanger straps allowing for movement from expansion, or as per vent pipe manufacturer’s instructions or local code requirements.

6.2General Requirements

6.2.1 Vent Piping Material

6.2.1 Vent Piping Material

•This is a Category IV appliance.

Only vent materials approved for use with Category IV appliances shall be used.

•Under normal conditions, this Water Heater will not produce an exhaust flue temperature in excess of 149°F (65°C).

For PVC/CPVC/PP material

•Schedule 40 PVC pipe may be used as the vent material. If required by local code, use schedule

40/80 CPVC or PP.

•This Water Heater must be vented with plastic pipe materials as specified in the table below. Vent installations in Canada which utilize plastic vent systems must comply with ULC S636.

[Exhaust Vent / Air Intake]

Material |

United States |

Canada |

|||

Exhaust |

Air Intake |

Exhaust |

Air Intake |

||

|

|||||

Schedule 40 |

ANSI/ASTM D1785 |

|

CSA |

||

PVC |

ULC S636 |

B137.3 |

|||

PVC-DWV |

ANSI/ASTM D2665 |

Certified |

CSA |

||

Materials |

B181.2 |

||||

Schedule 40 |

ANSI/ASTM F441 |

Only |

CSA |

||

CPVC |

|

B137.3 |

|||

|

|

|

|||

Polypropylene |

Centrotherm |

- lnnoFlue® |

|

||

|

(certified ULC S636), |

|

|||

(PP)* |

|

|

|||

DuraVent PolyPro® (certified ULC S636) |

|||||

|

|||||

System 1738TM |

IPEX Management Inc. |

||||

PVC Fuel Gas |

|||||

|

(certified UL 1738) |

|

|||

Venting |

|

|

|||

|

|

|

|

||

*Only listed manufacture specified vent parts may be used for this Water Heater.

Refer to the manufacture’s literature for detailed information.

-Approved Vent Manufacture:

-CentrothermlnnoFlue® PP

|

Parts # |

|

Single Wall Pipe |

ISVL02xx(UV)/03xx(UV), |

|

(2 in. / 3 in.) |

ISEP02xx/03xx, ISIA0203 |

|

Elbow |

ISELL0287(UV)/0387(UV), |

|

ISELL0245/0345 |

||

|

||

Termination** |

ISELL0287UV/0387UV, |

|

ISTT0220/0320 |

||

|

||

Bird Screen |

IASPP02/03 |

- DuraVent PolyPro®

|

Parts # |

|

Single Wall Pipe |

2PPS-xxBL/3PPS-xxBL, |

|

(2 in. / 3 in.) |

2PPS-xxL/3PPS-xxL |

|

Elbow |

2PPS-E90(B)L/3PPS-E90(B)L, |

|

2PPS-E45(B)L/3PPS-E45(B)L |

||

|

||

Termination** |

2PPS-E90(B)L/3PPS-E90(B)L, |

|

|

2PPS-T(B)L/3PPS-T(B)L |

|

Bird Screen |

2PPS-BG/3PPS-BG |

**Applicable vent termination are “90° elbow” or “Tee type”. Concentric vent termination of polypropylene are prohibited.

[Pipe Cement / Primer]

Material |

United States |

Canada |

|

PVC |

ANSI/ASTM D2564 |

ULC S636 |

|

|

|

Certified Materials |

|

CPVC |

ANSI/ASTM F493 |

||

Only |

NOTE Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel® (polyphenylsulfone) in non-metallic venting system is prohibited.

Venting the Water Heater 17

•Use only solid PVC / CPVC (schedule 40) or PP pipe.

•2 in. or 3 in. schedule 80 pipe may also be used on this Water Heater, however the Btu/h input of the Water Heater will be reduced by up to 9%.

•Maintain the same vent pipe diameter from the Water Heater flue to the termination.

•In Canada, plastic vent systems must be certified to ULC S636. The components of the certified vent system must not be interchanged with other vent systems or unlisted pipe/fittings.

•In Canada, specified primers and glues of the ULC S636 certified vent system must be from a single system manufacturer and not intermixed with other system manufacturer’s vent system parts.

NOTE Covering non-metallic vent pipe and fittings with thermal insulation is prohibited.

For 2 in. flexible PP material

•Flex Vent 2 in. Conversion Kit (EZ2-CK) must be used when using 2 in. flexible PP pipe for vent pipe installation. Refer to the instructions provided with Flex Vent 2 in. Conversion Kit for additional detail.

•During the installation of Flex Vent 2 in. Kit (EZ2FVK-1 and EZ2FVK-2), ambient temperatures must be greater than 40°F (5°C). Afterwards, installation site ambient temperature must be greater than -4°F (-20°C). Flex vent pipe breakage may occur if these temperature requirements are not observed.

•Only listed manufacturer specified vent parts may be used for this Water Heater.

[Information regarding certified “Flexible vent pipe and connections”]

-Flex Vent 2 in. Kit – 25 ft (EZ2FVK-1)

-Flex Vent 2 in. Kit – 35 ft (EZ2FVP35-3)

Standard(s) |

ULC-S636-08 Standards for type BH Gas |

Venting Systems |

|

|

25 ftFlex Pipe 2 in.- LE, Flex Vent 2 in. |

Product |

Rigid 45 Elbow SetLE, 35 ftFlex Pipe |

|

2 in.- LE |

Brand name Living Engineering Co,Ltd.

•Do not intermingle any other venting material with allowable polypropylene venting mentioned.

•The Btu/h input of the Water Heater will be reduced by up to 9% when maximum vent length.

For flexible pipe for chimney

•During the installation, ambient temperatures must be greater than 40 °F (5 °C). Afterwards, installation site ambient temperature must be greater than -4 °F (-20 °C). Flexible vent pipe breakage may occur if these temperature requirements are not observed.

•Only listed manufacture specified vent parts may be used for this appliance. Refer to the manufacture’s literature for detailed information.

18 Venting the Water Heater

- DuraVent®- Flex Through Chimney w/ Air Intake

Exhaust |

Flex Chimney Lining Kit (3 in.): 3PPS-FKL, |

|

Flex Length (3 in.): 3PPS-FLEXxx |

||

Intake |

Aluminum Flex Length (3 in.): 3DFA-xx, |

|

Coupler (3 in.): 3DFA-FCP |

||

|

||

|

Elbow (3 in.): 3PPS-E45L, 3PPS-E90L, |

|

Exhaust |

Single-Wall Pipe (3 in.): 3PPS-xxL |

|

& |

Appliance Adapter for PVC Coupler (2 in.): |

|

Intake* |

2PPS-ADL, |

|

|

Increaser: 2PPS-X3L |

- CentrothermlnnoFlue® PP

Exhaust |

Chimney Kit (3 in.): IFCK03xx, |

|

Flexible Pipe PP (3 in.): IFVL03xxx |

||

Intake |

Termination**: ISELL0387UV, ISTT0320, |

|

Bird Screen: IASPP03 |

||

|

||

|

Single Wall Pipe (3 in.): ISVL03xx(UV), |

|

Exhaust |

ISEP03xx |

|

& |

Elbow (3 in.): ISELL0387UV, ISELL0345UV, |

|

Intake* |

ISEL0387, ISEL0345, |

|

|

Increaser: ISIA0203 |

*Recommended items.

**Applicable vent termination are “87° elbow” or “Tee type”.

Concentric vent termination of polypropylene are prohibited.

6.2.2 Installation Instructions

6.2.2 Installation Instructions

WARNING

WARNING

CARBON MONOXIDE POISONING

•Failure to properly seal the vent system could cause flue products to enter the living space.

•(For flexible pipe for chimney) Handle the flexible vent carefully.

Dropping, Crushing and Stacking may cause damage, and may result in fires, property damage or exposure to Carbon Monoxide.

•Follow all general venting guidelines as outlined in this manual.

•Clearance described in this document is the minimum recommendation/required distance. Take appropriate clearance according to the situations of the site.

•Make sure the vent system is gas tight and will not leak.

•Support the vent pipe with hangers at regular intervals as specified by these instructions or the instructions of the vent manufacturer.

•All piping must be fully supported. Use pipe hangers at a minimum of 3 ft (0.9 m) intervals.

NOTE Do not use the Water Heater to support the vent piping.

•Ensure at least 3 ft (0.9 m) or more distance between the near edge of the air intake pipe or exhaust pipe to the inside corner of a wall.

For PVC/CPVC/PP material

3 ft (0.9 m) or more

Inside corner

•When preparing and assembling the pipe, follow instructions as provided by the pipe manufacturer. In general, the following practices must be observed:

-Squarely cut all pieces of pipe.

-Remove all burrs and debris from joints and fittings.

-All joints must be properly cleaned, primed, and cemented. Use only cement and primer approved for use with the pipe material as outlined on page 17.

•PVC, CPVC or PP pipe has been approved for use on this Water Heater with zero clearance to combustibles.

•The pipe shall be installed so that the first 3 ft (0.9 m) of pipe from the Water Heater flue outlet is readily accessible for visual inspection.

•When attaching the piping to the Water Heater, use the appropriate primer and cement to ensure a proper seal.

[How to tighten the Vent Pipe]

1.Continue to insert the Vent Pipe until it reaches to the base of the Water Heater Exhaust and Intake Flue.

•The Vent Pipe will be inserted approximately 2.3 in. (60 mm).

2.Secure the Vent Pipe by tightening the band using a screwdriver.

•The tightening torque shall be the following: - For PVC/CPVC pipe: between 16 and 20 in lb - For PP pipe: between 12 and 15 in lb

Vent Pipe

Exhaust and

Intake Flue

Screwdriver - Flat head

Screwdriver - Flat head

- Box wrench (5/16 in.)

For 2 in. flexible PP material

•Flex Vent 2 in. Kit may be used only in accordance with the installation manual included with the kit.

•Flex Vent 2 in. Kit can be installed at zero clearance to combustible materials.

•The Water Heater can be started up immediately after Flex Vent 2 in. Kit is installed and inspected.

•Flex Vent 2 in. Kit systems expand and contract slightly during heating cycles and must be installed following included instructions.

•Flex Vent 2 in. Kit cannot be painted.

•When installing N-Flex vent, pitch is required as detailed in Flex Vent 2 in. Kit installation manual.

For flexible pipe for chimney

•Every venting system must be properly planned and installed for optimum performance and safety. A flexible pipe installation always begins with an inspection of the existing masonry chimney (Chimney must be clean, sized correctly, properly constructed and in good condition, if being installed in a chimney as a liner). Inspect chimney to make certain it is constructed according to the latest revision of the NFPA211. Local codes may differ from this code and should be checked. Where there is a conflict, the local code will prevail. In Canada refer to the National Building Code or CSA-A405 as applicable.

•Refer to manufacturer’s instructions for assembly of all flexible components including the chimney cap and adaptor to rigid pipe at base of masonry Chimney.

•Ensure none of the vent pipes and chimneys are damaged or blocked.

•Do not use an existing chimney as a raceway for a flue pipe if another appliance or fireplace is vented through the chimney, and do not have any connections inside the chimney chase.

•When using an inoperative chimney as a means of a chase for the vent system, the surrounding space within the chimney cannot be used to draw combustion air or vent another appliance.

•The remaining space surrounding a chimney liner, the flexible pipe within a masonry, metal or factory-built flue shall not be used to supply combustion air to the Water Heater. A separate combustion air intake pipe routed back to the

Water Heater can be used in the remaining space if required, the Water Heater venting system

is approved for zero clearance, and can be run directly beside the combustion air intake pipe. Bolt or screw joints together to avoid sag.

•Flexible pipe vertical offsets must not exceed 45° and are limited to a maximum number of 2.

•Connect flue pipe to the chimney with the shortest possible length of flue pipe.

•Slope the horizontal vent 1/4 in. upwards for every 12 in. (300 mm) toward the chimney from the Water Heater.

Venting the Water Heater 19

•Check and confirm that there is no tension to the flexible pipe by hanging or suspending of anything.

•Check vent piping at least once a season. Verify vent pipe connections to chimney are secure and no obstructions are present. If vent piping shows sign of leaking, replace it immediately.

6.2.3 Termination Considerations

6.2.3 Termination Considerations

• Do not store hazardous or flammable substances near the vent termination and check that the termination is not blocked in any way.

• Steam or condensed water may come out from the vent termination. Select the location for the termination as to prevent injury or property damage.

• If snow is expected to accumulate, make sure the termination will not be covered with snow or hit by falling lumps of snow.

• (For PVC/CPVC/PP material) A bird screen must be installed on the vent terminations to prevent debris or animals from entering the piping. These screens are not supplied with the Water Heater and must be purchased separately.

Vent Material |

Bird Screen Parts # |

2 in. (50 mm) PVC or CPVC |

VT2-PVCS |

3 in. (75 mm) PVC or CPVC |

VT3-PVCS |

Centrotherm- 2 in. (50 mm) PP |

IASPP02 |

Centrotherm- 3 in. (75 mm) PP |

IASPP03 |

DuraVent- 2 in. (60 mm) PP |

2PPS-BG |

DuraVent- 3 in. (80 mm) PP |

3PPS-BG |

• The following termination can also be used.

- Termination Manufacturer: IPEX Management Inc. - Item description

Item |

|

Item # |

|

Universal Concentric Vent Kit (UCVK)* |

PVC-UCVK |

||

(PVC ULC S636/UL 1738Certified for |

|||

(397007) |

|||

use in both Canada and USA) |

|

||

|

|

||

IPEX Low Profile Termination Kit** |

2 in. |

PVC-2LPT |

|

(397100) |

|||

(PVC ULC S636/UL 1738Certified |

|

|

|

|

PVC-3LPT |

||

for use in both Canada and USA) |

3 in. |

||

|

|

(397101) |

|

NOTE Below are additional models approved for use by Noritz and supplied by IPEX. Refer to the IPEX literature or web site for additional details.

* Universal Concentric Vent Kit :

<USA> #397256PVC System 1738

<Canada> #196256PVC System 636 #197256CPVC System 636

** Low Profile Termination Kit :

<USA> #397984- 2” PVC System 1738 #397985- 3” PVC System 1738

<Canada> #196984- 2” PVC System 636 #196985- 3” PVC System 636

20 Venting the Water Heater

6.2.4 Maximum Vent Length

6.2.4 Maximum Vent Length

•This Water Heater has been designed to be vented with either 2 in. (50 mm) or 3 in. (75 mm) PVC, CPVC, PP, or 3 in. (75 mm) flexible pipe for chimney. If you use Flex Vent 2 in. Conversion Kit, you must use 2 in. flexible PP.

•The minimum total vent length including horizontal and vertical vent runs should not be less than:

-PVC/CPVC/PP, 3 in. (75 mm) flexible pipe for chimney: 3 ft (0.9 m)

-2 in. flexible PP: 5 ft (1.5 m)

•The Water Heater can be adjusted to accommodate longer vent runs; refer to the table below. Do not exceed the maximum vent length.

•Disconnect the electrical power and then adjust the DIP switches according to the vent condition noted in the tables below.

Refer to page 56 for the location of the DIP switch bank and how to change the DIP switches. Failure to perform this step will result a “73” code displayed on the Remote Controller and a cease in operation.

If this occurs, disconnect, then reconnect the electrical power to the Water Heater to reset the system.

NOTE • When adjusting the DIP switches for longer vent runs, the Btu/h input of the Water Heater will be reduced by up to 9%.

•Do not change any other DIP switches.

Maximum Vent Length Configurations (For PVC/ CPVC/PP material)

• The maximum vent length when using 2 in. (50 mm) pipe is 65 ft.

• The maximum vent length when using 3 in. (75 mm) pipe is 150 ft.

Both maximum lengths are reduced by the number of elbows used, as shown in the following table:

|

Maximum equivalent |

|

|

|

Vent |

vent length*1 |

Maximum # |

Equivalent |

|

diameter |

V (Vertical) |

of elbows*2 |

length |

|

|

+ |

|

|

|

|

H (Horizontal) |

|

|

|

2 in. |

65 ft (20 m) |

6 |

90° elbow: |

|

5 ft (1.5 m) |

||||

|

|

|

||

3 in. |

150 ft (46 m) |

15 |

45° elbow: |

|

3 ft (0.9 m) |

||||

|

|

|

||

|

|

|

|

*1 The maximum vent length includes elbows.

*2 Not including the termination.

[DIP Switch Adjustment] |

ON = ●/ OFF = ○ |

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

Vent length condition |

|

DIP switches |

||||||||||||

|

|

|

|

|

|

|

|

|

#7 |

|

#8 |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Less than 33 ft using 2 in. (50 mm) pipe |

|

○ |

|

○ |

||||||||||||||||||

33 ft or more using 2 in. (50 mm) pipe |

|

● |

|

○ |

||||||||||||||||||

Less than 75 ft using 3 in. (75 mm) pipe |

|

○ |

|

● |

||||||||||||||||||

75 ft or more using 3 in. (75 mm) pipe |

|

● |

|

● |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

[Vent length Calculation example]

Step 1:

Vent Diameter 2 in.

Step 2:

Straight pipe length

(Vertical length + Horizontal length) 17 ft

Step 3:

Number of elbows 90° elbows: 2 45° elbows: 2

Step 4:

Calculate equivalent length

90° elbows: 2 × 5 ft = 10 ft 45° elbows: 2 × 3 ft = 6 ft

Step 5:

Total vent length

(Add Step 2 and Step 4 together) 17 ft + 16 ft = 33 ft

Step 6:

Check [DIP Switch Adjustment] and select DIP switch settings.

[33 ft or more using 2 in. (50 mm) pipe] (i.e., turn ON DIP switch #7)

Maximum Vent Length Configurations (For Flex

Vent 2 in. Conversion Kit)

Maximum Vent Length Example:

•Actual Vent Length = 13 ft (3.9 m) (with DIP switch set at “Short length” condition)

•Actual Vent Length = 25 ft (7.5 m) (with DIP switch set at “Long length” condition)

ON = ●/ OFF = ○

|

Vent length |

DIP switches |

|

|

#7 |

#8 |

|

|

|

||

Short length |

5 ft (1.5 m) - 15 ft (4.5 m) |

○ |

○ |

Long length |

15 ft (4.5 m) - 35 ft (10.5 m) |

● |

○ |

Here

Here

Maximum Vent Length Configurations (For flexible pipe for chimney)

[DuraVent® - Flex Through Chimney w/ Air Intake (Only 3 in.)]

The vent length condition setting depends on the flexible pipe length, the rigid pipe length and number of elbows. Calculate an each ventilation system equivalent length, then adjust the DIP switch.

Vent |

|

Maximum equivalent |

|

DIP |

vent length* |

Equivalent |

|

length |

switch |

V (Vertical) |

length |

condition |

#7 |

+ |

|

|

|

H (Horizontal) |

|

Short |

|

|

Flexible pipe: |

○ |

< 50 ft (15 m) |

1 ft (0.3 m) |

|

length |

Rigid pipe: |

||

|

|

|

1 ft (0.3 m) |

|

|

|

90° elbow: |

Long |

● |

50 ft (15 m)–75 ft (22.5 m) |

5 ft (1.5 m) |

length |

45° elbow: |

||

|

|

|

3 ft (0.9 m) |

* The maximum vent length includes elbows.

Here |

•Equivalent vent length calculation example: [Example 1]

-Vent Size: 3 in.

-V (Vertical length): 20 ft

-H (Horizontal length): 6 ft

-90° elbow: 2

1 ft × 20 + 1 ft × 6 + 5 ft × 2 = 36 ft

Total equivalent length ≤ 50 ft

Select “Short length”

[Example 2]

-Vent Size: 3 in.

-V (Vertical length): 35 ft

-H (Horizontal length): 10 ft

-90° elbow: 3

1 ft × 35 + 1 ft × 10 + 5 ft × 3 = 60 ft

50 ft < Total equivalent length ≤ 75 ft

Select “Long length”

Venting the Water Heater 21

Loading...

Loading...