Page 1

Digital Proportional Control Valve

To download the product EDS file visit www.odva.org

DeviceNet VP51 Manual Ver. 1, 22/09/03

INSTRUMENT HANDBOOK

DeviceNet VP51

1

Page 2

Table of Contents

1. Introduction

2. Safety

3. Operating Description

4. Dimensional Details

5. Installation

• Pneumatic

• Electrical

• DeviceNet

6. DeviceNet Interface Details

7. Local User Interface Details

8. EC Declaration of Conformity

9. ODVA Declaration of Conformity

1. INTRODUCTION

The DeviceNet VP51 Programmable Digital Proportional Control Valve for industrial pneumatic pressure control

applications. The DeviceNet VP51 can be configured to meet application requirements.

Fluid compressed air

Output Pressure Range 0-150 psig (or 0-10bar) – user definable. For applications where the user defined

Supply Pressure Up to 200psig/14bar max

Flow Capacity 1300 l/min/46SLFM

Control Signal 12 bit polled output from DeviceNet

Electrical Supply Powered from DeviceNet (current consumption < 100mA)

Operating Temperature -20° to 50° C (ambient)

span is less that 50% of maximum (<75psi, 5bar) please consult Norgren.

Warranty

A two year warranty applies to all Norgren products. For terms and conditions ask for a copy of our

‘General Conditions of Sale.’

2. SAFETY

Compressed air in its basic state or in its more sophisticated applied forms can result in accidents if it is not

properly used. We therefore draw your attention to the following paragraphs*: The Health and Safety at Work

Act (1974) makes specific requirements on suppliers and users. To conform with these requirements IMI Norgren

Ltd. has, so far as it is reasonably practicable, designed, constructed and tested its products so as to be safe

when properly used. Many of our customers, being suppliers as well as users, are reminded of the imposed

duties of the above Act and when expediting these duties our technical staff will be pleased to advise. We cannot

accept responsibility for the design of plant which might use our equipment and would recommend the use of

European Norm (EN) standards and BS 4575:Part 3 (1988) , (Note compliance with these standards does not in

itself confer immunity from legal obligation). We also suggest the guidance booklet by the Health and Safety

Executive HS(G)39, “Compressed Air Safety” that offers advice on the safe use of compressed air.

2

Page 3

3. OPERATING DESCRIPTION

The DeviceNet VP51 is a programmable electronic proportional control valve.

The pneumatic section is a diaphragm actuated precision glandless spool valve, pilot pressure applied to the

pneumatic section controls the output pressure of the unit.

The pilot pressure is generated and controlled electronically. The feedback signal from the outlet port is

compared to the control signal required and ensures a consistent, stable output pressure.

The electronics system requires a nominal 24V DC supply signal (supplied from DeviceNet). With a 150 psi

standard unit, the user can define their requirements through DeviceNet parameters, and set the application

parameters needed for the unit, i.e. speed, proportional & integral gain, thresholds etc.

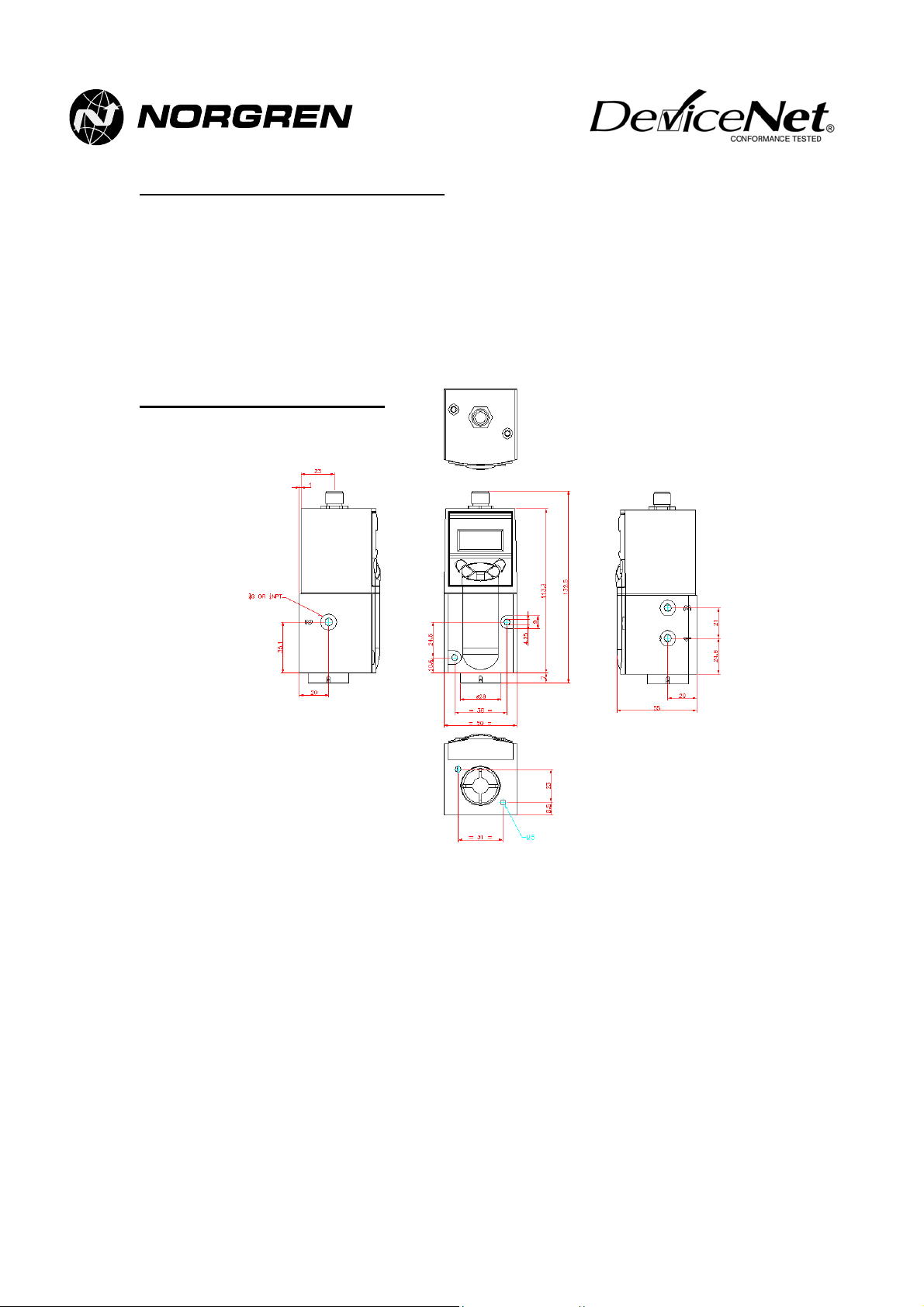

4. DIMENSION DETAILS

1=Inlet Port

2=Outlet Port

3=Exhaust Port

3

Page 4

5. INSTALLATION

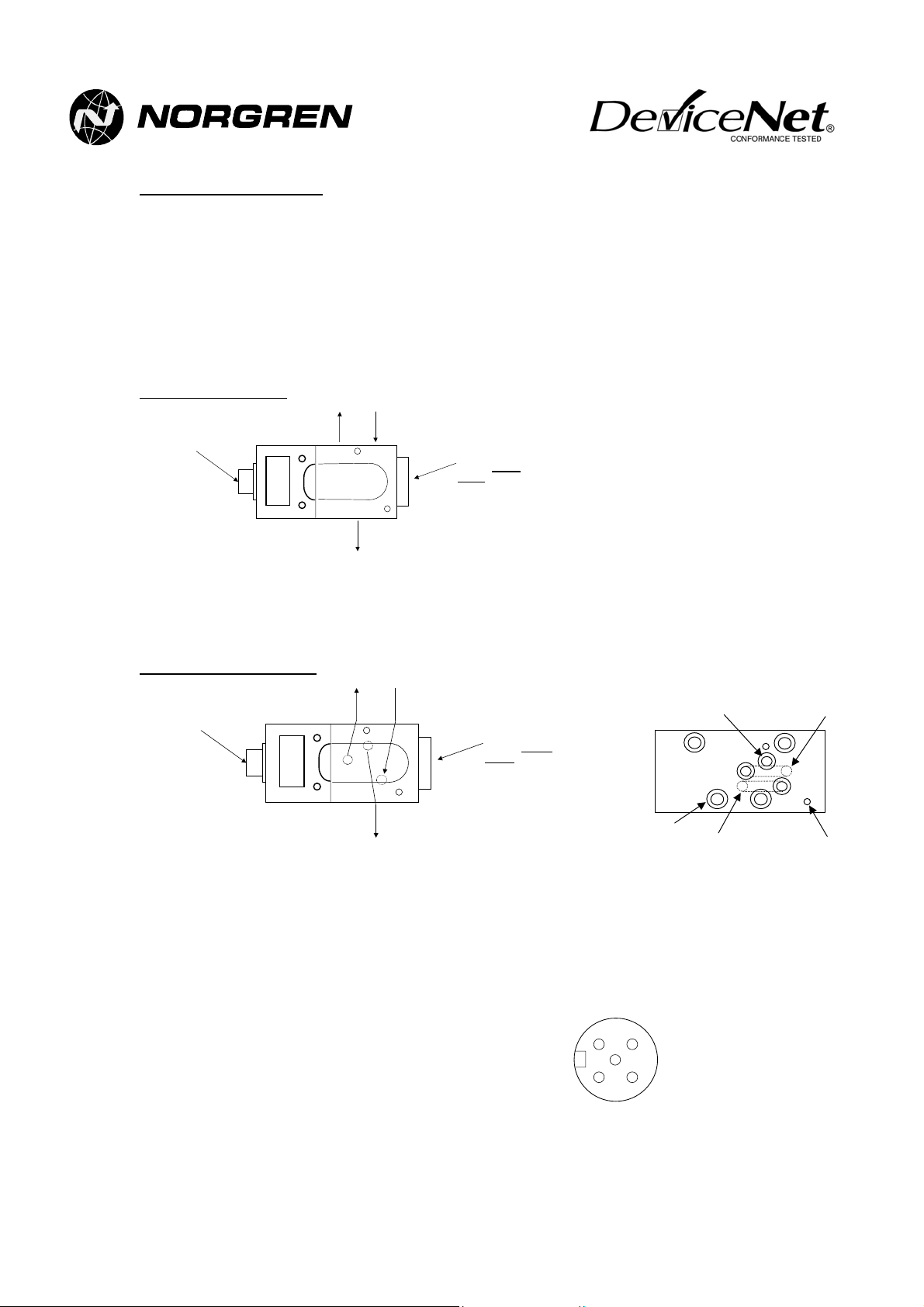

Pneumatic Installation

• Supply Pressure: 15psig above maximum output required

(200psig max.)

• Output Pressure Range: 0-150psig

• Media: clean, dry 50µ filtered air

• Porting: G1/4; 1/4NPT; ISO2 Manifold Mount

•

Use oil-free air

•

Do not use PTFE tape

G1/4 & 1/4NPT variants

Electric al

connector

Exhaust port (3) Supply port

(1)

2

Output port (2)

1

Return spring

housing.

Do not

adjust.

3

• Connect pipe-work using 10mm OD, 8mm ID, plastic pipe, cut cleanly at right angles, with push-fit pipe

connections.

• Fit an exhaust silencer to Port 3 if required (this will only slightly degrade exhaust performance)

ISO2 Manifold Mount variant

Electrical

connector

Exhaust port (3

)

Supply port

Output port (2)

(1)

Return spring

Do not

housing.

adjust.

Output port (2)

ISO-2 sub base

mounting holes

Supply port (1)

Exhaust port (3)

VP51 mounting holes

(M4 tapped) x 2

• Use grub screws provided to plug cross drilled holes in interface plate

• Mount interface plate to ISO-2 sub base with four M6 screws, with gasket between plate and sub base.

• Place three O-rings in three counterbored holes in plate and mount VP51 with two M4 screws.

Electrical Installation

Connect the unit as follows using DeviceNet approved screened cable and a M12 female connector or with a

ready made M12 DeviceNet cable:

Pin 1: Drain (bare)

Pin 2: V+ (red)

Pin 3: V- (black)

Pin 4: CAN_H (white)

Pin 5: CAN_L (blue)

1

2

4

Connector pinout

5

looking onto the end of

the instrument

3

4

Page 5

DeviceNet Installation

• Download the DeviceNet VP51 EDS file from www.odva.org

• Register the EDS file using a DeviceNet configuration tool (e.g. Rockwell RSNetworx).

• The device MACID and baud rate are factory set to address 63 and Autobaud (see notes 1 & 2).

• Connect the DeviceNet VP51 to a DeviceNet network.

• Use the keypad or your DeviceNet configuration tool to change the MACID and baud rate parameters as

required.

• Map the polled i/o to a DeviceNet master device (e.g. PLC scanner).

• Control the pressure by polling the polled input ‘Demand Pressure’ over the range 0-4095 (=0-105% of

output pressure range).

• Use a DeviceNet configuration tool (e.g. Rockwell RSNetworx) to change the DeviceNet VP51 parameters

to suit the application (see note 3).

Notes:

1)

MACID -

can be changed either over the DeviceNet network or using the instrument’s keypad. If the DeviceNet

VP51 detects that another device on the network already has its MACID, it will display a “Set Node

Address” message instructing you to change the its MACID using the keypad. See section 7 of this

manual for more details.

2)

Baud rate -

the network, detects the baud rate and selects its own baud rate accordingly. In order for this to work, it

is necessary for the DeviceNet network to already have two or more other devices actively

communicating on the network. After successful Autobaud detection, the baud rate parameter

automatically switches to the selected baud rate. To run the Autobaud function again, the baud rate

setting must be changed back to Autobaud via the keypad or DeviceNet. If Autobaud detection is

unsuccessful or if the instrument has previously been set to an incorrect baud rate, it will automatically

display a “Set Baud Rate” message instructing you to change the baud rate using the keypad. See

section 7 of this manual for more details.

3)

ADR facility -

configured to provide this feature and a DeviceNet VP51 is replaced with a new one, the PLC will

automatically detect the new one and configure its address and parameters to be the same as the

device it is replacing. Refer to the PLC and DeviceNet configuration tool instructions for more details.

The DeviceNet VP51 MACID is factory set to 63. Once the DeviceNet VP51 is powered, this

The DeviceNet VP51 is factory set with Autobaud detection. This means that it ‘listens’ to

The DeviceNet VP51 supports ADR (Automatic Device Recovery). If the PLC has been

5

Page 6

6. DEVICENET INTERFACE DETAILS

I/O Data

Name I/O Type

Demand Pressure Polled Output 2 12 bit integer (0 to 4095)

Actual Pressure Polled Input 2 12 bit integer (0 to 4095)

Status Byte Polled Input 1 Bit 0: Set if difference between Demand

Notes

:

1) Inputs and Outputs are defined from the perspective of the DeviceNet network.

2) For 150 psi variant Demand Pressure value= 26 x (Required Pressure in psi), e.g. to output 100 psi, set

Demand Pressure value to 2600.

For 10 bar variant Demand Pressure value = 390 x (Required Pressure in bar), e.g. to output 6 bar, set

Demand Pressure value to 2340.

IMPORTANT - Only 12 of the 16 bits in the two Demand Pressure bytes are used. The four most

significant bits are ignored. Setting the Demand Pressure value above 4095 or below 0 may lead

to unpredicted output pressures.

3) If the polled input is read as a single value of 3 or more bytes, the two least significant bytes hold the

actual pressure and the third least significant is the status byte. For example, a returned value of

266044 (0x040F3C) represents an actual pressure of 0x0F3C = 3900 = 100% full scale and a status

byte of 0x04 = bit 2 set.

DeviceNet Parameters

The following parameters are available via a DeviceNet configuration tool (e.g. RSNetworx) or via DeviceNet

explicit messaging, using the class, instance, attribute and byte length details in the table. To use a DeviceNet

configuration tool, it is necessary to register the DeviceNet VP51 EDS file on the configuration tool. The EDS file

can be downloaded from

www.odva.org

Parameter

No.

1 Baud Rate Selectable from:

2 Serial

3 Demand

Name Format Default

number

Pressure

(see Note 1)

Autobaud, 125Kb/s, 250Kb/s,

500Kb/s (see note 1)

Read only 4 byte integer Factory

Read only integer, 0-4095

0 = minimum (zero) pressure

4095 = full scale output + 5%

span

(same as polled output, see

note 2)

No. Bytes Format

.

0 = minimum (zero) pressure

4095 = full scale output + 5% span

(see Note 2)

0 = minimum (zero) pressure

4095 = full scale output + 5% span

(see Note 3)

Pressure and Actual Pressure exceeds Error

Limit (see parameter 10).

Bit 1: Set if Bit 0 has been set for longer

than Error Delay (see parameter 11).

Bit 2: Set if Actual Pressure ≥ Threshold A

(see parameter 12).

Bit 3: Set if Actual Pressure ≥ Threshold B

(see parameter 13).

Bits 4-7: Not used.

(See Note 3)

Value

Autobaud 3 1 2 1

set

- 3 1 114

Class

Id

1 1 6 4

Instance

Id

Attribute

Id

(0x72)

Byte

length

2

6

Page 7

Parameter

No.

4 Actual

5 Status

6 Speed Selectable integer, 0-7

7 Prop Gain Selectable integer 0-7

8 Int Gain Selectable integer 0-7

9 Dither

10 Error Limit Selectable 0=105% (0-4095)

11 Error Delay Integer 0-999

12 Threshold A Selectable 0-105% (0-4095)

13 Threshold B Selectable 0-105% (0-4095)

14 Pressure

15 Signal

Name Format Default

Read only integer, 0-4095

Pressure

0 = minimum (zero) pressure

Value

- 4 13

Class

Id

4095 = full scale output + 5%

span

(same as polled input)

Byte

Read only byte (same as

polled input)

- 4 13(0x0D) 3 1

0 3 1 104

0 = fastest, 7 = slowest

See fig. 1

4 3 1 105

0 = low gain, 7 = high gain

(see note 3) See fig. 3

4 3 1 106

0 = low gain, 7 = high gain

(see note 3) See fig. 3

Amplitude

Selectable integer 0-7

0 = no dither, 7 = maximum

4 3 1 107

dither

0 = Error Limit Off

10%

(390)

3 1 109

105% = Full scale output + 5%

Set in 100ths of a second

0 = Status Bit 2 always set

200

(2 secs)

50%

(1950)

3 1 110

3 1 111

105% = Full scale output + 5%

0 = Status Bit 3 always set

100%

(3900)

3 1 112

105% = Full scale output + 5%

Units

Selectable from:

Bar, psi, kPA, Atm, kg/cm^2

Sets units for pressure display

Depends

on part

number

3 1 108

on LCD

Failure

Mode

Selectable from Fail Safe, Fail

Freeze

Sets operation of device on

Fail Safe 3 1 113

loss of polled signal from

network (see note 2).

Instance

Id

(0x0D)

Attribute

Id

3 2

(0x68)

(0x69)

(0x6A)

(0x6B)

(0x6D)

(0x6E)

(0x6F)

(0x70)

(0x6C)

(0x71)

Notes:

1) If the baud rate parameter is set to Autobaud the Device will automatically listen to the network and

work out the correct baud rate. The baud rate parameter will then automatically be set to the

appropriate baud rate and will remain at its new setting even after removing power from the Device. In

order to run the Autobaud function again, the baud rate must be changed back to Autobaud via

DeviceNet or via the keypad.

2) Demand Pressure can only be set by means of a polled I/O message. It can be read but not set by

explicit messaging. If no polled message is received, the output pressure is set according to parameter

15 – Signal Failure Mode. If Fail Safe is selected, the output pressure will be zero when no polled

messages are being received. If Fail Freeze is selected, the output pressure will remain at its last set

value when no polled messages are being received.

3) To set the

proportional gain

best possible response time without causing unacceptable overshoot or oscillations.

Once proportional gain is set correctly, increase

without causing unacceptable hunting (slow oscillations) on the output. See figs 2 & 3.

, first set the integral gain to 0, then adjust the proportional gain to give the

integral gain

to achieve the best possible accuracy

Byte

length

1

1

1

1

1

2

1

1

1

1

7

Page 8

1

Fig. 1 - Speed Setting Effects

at default Proportional and Integral Gain

12

10

8

6

Pressure, bar

4

2

0

Time

Fig. 2 - Proportional Gain Effects

at default Integral Gain and Speed

12

10

8

6

Pressure, bar

4

2

0

Time

Fig. 3 - Integral Gain Effects

10.2

10.1

at default Proportional Gain and Speed

10.0

Pressure, bar

9.9

9.8

Time

8

Page 9

x

x

x

7. LOCAL USER INTERFACE DETAILS

The DeviceNet VP51 includes an integral keypad and LCD display. During normal operation, this will display the

current output pressure of the instrument and its DeviceNet MACID (node address number). The keypad can be

used to locally set the device MACID and baud rate. The complete menu structure is shown in fig. 4.

Device goes

online

correctly

xxx . psi

Node xx

OK

Password

****

C

C

OK

C

Set-up

Comms

DN

UP

Change

Password

DN

Help

www.norgren.

com

UP

OK

Set Baud

Autobaud

OK

Set Node

x

OK

C

Reset :

Cycle Pow..

New

C

****

OK OK

C

Confirm

****

OK

Incorrect

baud rate or

Autobaud

fails

Duplicate

node address

detected

Figure 4 – Local User Interface Menu Structure

Set Baud

Rate

Set Node

Address

OK

Password

****

OK

Password

****

OK

OK

Set Baud

xx

OK

Set Node

x

OK

Reset :

Cycle Pow..

9

Page 10

Changing MACID or Baud Rate

From Normal Operating Mode

When the Device is in normal operating mode (i.e. communicating on DeviceNet), the baud rate or MACID can

be changed by following the steps detailed below:

• Press

• Enter the password using the numbered arrow keys (see section on Password below).

• Press

• Use the up and

to skip this stage or cancel changes to the baud rate.

• Use the

Alternatively, press C to skip this stage or cancel changes to the MACID.

• If either the baud rate or the MACID have been changed, a message will be displayed reading Reset: Cycle

Power to Activate – Cancel to Abort. In order for the new settings to become active, the DeviceNet VP51

must be reset. This should be done either by disconnecting and reconnecting the device, or cycling the

network power. Alternatively, press C to return to the previous settings.

From Baud Rate Fault Condition

If the baud rate is incorrect or the Autobaud routine has not succeeded, the DeviceNet VP51 display will

automatically switch to display the message Set Baud Rate. Under these circumstances, following the steps

below:

• Press OK to enter the user interface.

• Enter the password using the numbered arrow keys (see section on Password below).

• Use the up and

• Use the

• The message will be displayed reading Reset: Cycle Power to Activate. In order for the new settings to

become active, the DeviceNet VP51 must be reset. This should be done either by disconnecting and

reconnecting the device, or cycling the network power.

From Node Address fault condition

If the DeviceNet VP51 detects that another device on the network already has its MACID (node address), it will

automatically switch to Set Node Address. Under these circumstances, following the steps below:

• Press OK to enter the user interface.

• Enter the password using the numbered arrow keys (see section on Password below).

• Use the

• The message will be displayed reading Reset: Cycle Power to Activate. In order for the new settings to

become active, the DeviceNet VP51 must be reset. This should be done either by disconnecting and

reconnecting the device, or cycling the network power.

from the default screen to enter the user interface.

OK

to enter the Set-up Comms menu.

OK

arrows to select the required baud rate and press

down

up

up

up

and

and

and

arrows to select the required MACID (node address) and press OK to accept.

down

arrows to select the network baud rate and press

down

arrows to change the MACID (node address) if required, and press

down

arrows to change the MACID (node address) and press

down

to accept. Alternatively, press

OK

to accept.

OK

to accept.

OK

to accept.

OK

User Interface Password

Entry into the local user interface is password controlled to prevent unauthorised access. All standard DeviceNet

VP51s are shipped with the password disabled. In this case, press OK from the password screen to enter the

user interface.

To change the Password, enter the user interface and use the up and down arrows to select the Change

Password menu. Press OK then enter and confirm the new password – the password can be any combination

of up to four digits in the range 1 to 4, entered using the numbered arrow keys.

In case the password is forgotten, there is an override facility – from the password screen, press and hold down

then press and hold down OK, whilst keeping C held down. Hold down both until the user interface is entered

C

(approx. 5 secs).

C

10

Page 11

8. EC DECLARATION OF CONFORMITY

The DeviceNet VP51 Digital Proportional Valve complies with the EC Pressure Equipment Directive and the

generic EMC standards.

BS EN 61000-6-4: 2001 Electromagnetic Compatibility

Part 6-4 Generic Standard

Emission standard for industrial environments

BS EN 61000-6-2: 1999 Electromagnetic Compatibility

Part 6-2 Generic Standards –

Immunity for industrial environm

ents

9. ODVA DECLARATION OF CONFORMITY

11

Loading...

Loading...