Page 1

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-1

Section 12

R84 Regulator and C84 Regulator Configurations

for Soft Drink Carbonator Service, 1/4" PTF . . . . . . . . . .ALE-12-2

R81 Regulator and C81 Regulator Configurations

for Soft Drink Dispensing Systems, 1/4" PTF . . . . . . . . .ALE-12-6

R82 Regulator for Beer Dispensing Systems, 1/4" PTF . .ALE-12-12

U.L. Listed Beverage

Regulators

Cylinder Gas Pressure (CO2)

Regulators for Soft Drink and

Beer dispensing systems.

R84

R81

R82

Page 2

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

R84 Regulator and C84 Configurations

● Underwriters Laboratories, Inc.listed (file number

SA1089)

● Integral relief valve easily replaced without

disassembly of regulator and without affecting relief

pressure setting

● Back flow check valve, or manifold with integral

check valve at each outlet,can be installed in

regulator outlet port. Manifolds available with 3 or 5

outlets and include one outlet cap.

● Relieving diaphragm allows outlet pressure setting to

be reduced even though the system is dead-ended.

Pressure downstream of check valves will not be

reduced.

● Easily replaceable valve cartridge contains valve,

valve seat, valve spring, and filter element

● Two high pressure ports (inlet and primary gauge)

and two regulated pressure ports (outlet and

secondary gauge)

● Bonnet wrench hex same size as tank adapter - one

wrench fits both

UL Listed, Cylinder Gas Pressure Regulator

1/4" PTF Port Size, CO

2

Regulator for Soft Drink Carbonator

Technical Data

Fluid: Carbon dioxide.The R84 regulator is designed to be used exclusively as a

carbonator regulator in soft drink dispensing systems to control cylinder gas

(carbon dioxide) pressure to the carbonator tank. Other Norgren regulators

(R81 for soft drink syrup containers, R82 for beer, R83 for industrial cylinder

gases) are available for use in other systems.

Maximum pressure: 3000 psig (207 bar)

Operating temperature: 0° to 140°F (-18° to 60°C)

Integral relief valve cracking pressure:

150 ± 5 psig (10.4 ± 0.33 bar)

Materials:

Body: Brass

Bonnet: Zinc

Valve cartridge: Teflon, brass, stainless steel

Diaphragm: Acetal and nitrile

Relief valve:Brass, polycarbonate, nitrile, aluminum

Seals: Nitrile

NOTE

The integral relief valve on the R84 regulator does not meet the

requirements of Paragraph 4.5c of NSDA Pamphlet TD02, Installation

and Operational Procedures for Pressurized Soft Drink Dispensing

Systems, dated July,1980.The end cap on the relief valve is color coded

red for visual identification and is for use only on the Norgren R84

regulator.

ALE-12-2

Page 3

R84, C84 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-3

†† The listed check valves and manifolds with integral check valves are designed for use with Norgren R84 regulators and C84 regulator configurations.They are not

recommended for use with other regulators and regulator configurations unless separate pressure relief protection is provided in each of the outlet lines.

Ordering Information.Models listed include integral relief valve with cracking pressure of 150 ± 5 psig (10.4 ± 0.33 bar), PTF threads,

relieving diaphragm, 5 to 125 psig (0.34 to 8.6 bar) outlet pressure adjustment range†. A gauge is not included.

Port Model Weight lb (kg)

1/4" R84-200-MNLA 1.3 (0.59)

Pipe Plug, Hex Socket Hex Nipple Union Adapter with Cap

Wall Mounting Bracket 1/4" PTF 1/4" PTF male 1/4" PTF to 1/4" tube (45° flare)

Strap Type: 5095-51 2891-97 18-006-067 18-006-068

Adapter only: 18-006-027

Cap only: 3302-50

Nitrogen Service Carbon Dioxide Service

Cylinder Connector Cylinder Connector

2" (Ø 50 mm) diameter, 1/4" PTF connection 0.906-14 RH external thread 0.830-14 RH internal thread

15 psig (1 bar): 18-013-082 CGA No. 580: 18-008-004 1.44" (37 mm) long nipple

30 psig (2 bar), UL Listed: 18-013-030 CGA No. 320: 18-008-002

60 psig (4 bar), UL Listed: 18-013-083 2.25" (57 mm) long nipple

100 psig (7 bar), UL Listed: 18-013-084 18-008-015

160 psig (11 bar), UL Listed: 18-013-085 Replacement gasket: 1390-02

300 psig (20 bar), UL Listed: 18-013-086

2000 psig (135 bar), UL Listed: 18-013-244

3000 psig (205 bar), UL Listed: 18-013-087

Inlet Fittings

Check Valve, 1/4" PTF male to 1/4" tube (45°flare): 16-009-001 2 or 3 outlets, 1/4" PTF male to 1/4" tube (45°flare): 3228-54

Check Valve, 1/4" PTF male to 1/2-16 BSF: 16-009-002 2 or 3 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-55

Check Valve, 1/4" PTF male to 1/4" PTF female: 16-009-003 4 or 5 outlets, 1/4" PTF male to 1/4" tube (45°flare): 3228-60

4 or 5 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-61

Manifold extension, 1/4" PTF male to 1/4" PTF female: 2340-50

Single Outlet Fittings - Check Valves ††

2 or 3 Port 4 or 5 Port Manifold

Extension

Accessories

Multiple Outlet Fittings - Manifolds with integral check valves ††

† Outlet pressure can be adjusted to pressures in excess of, and less than, that specified.Do not use these units to control pressures outside of the specified range.

Page 4

R84, C84 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-4

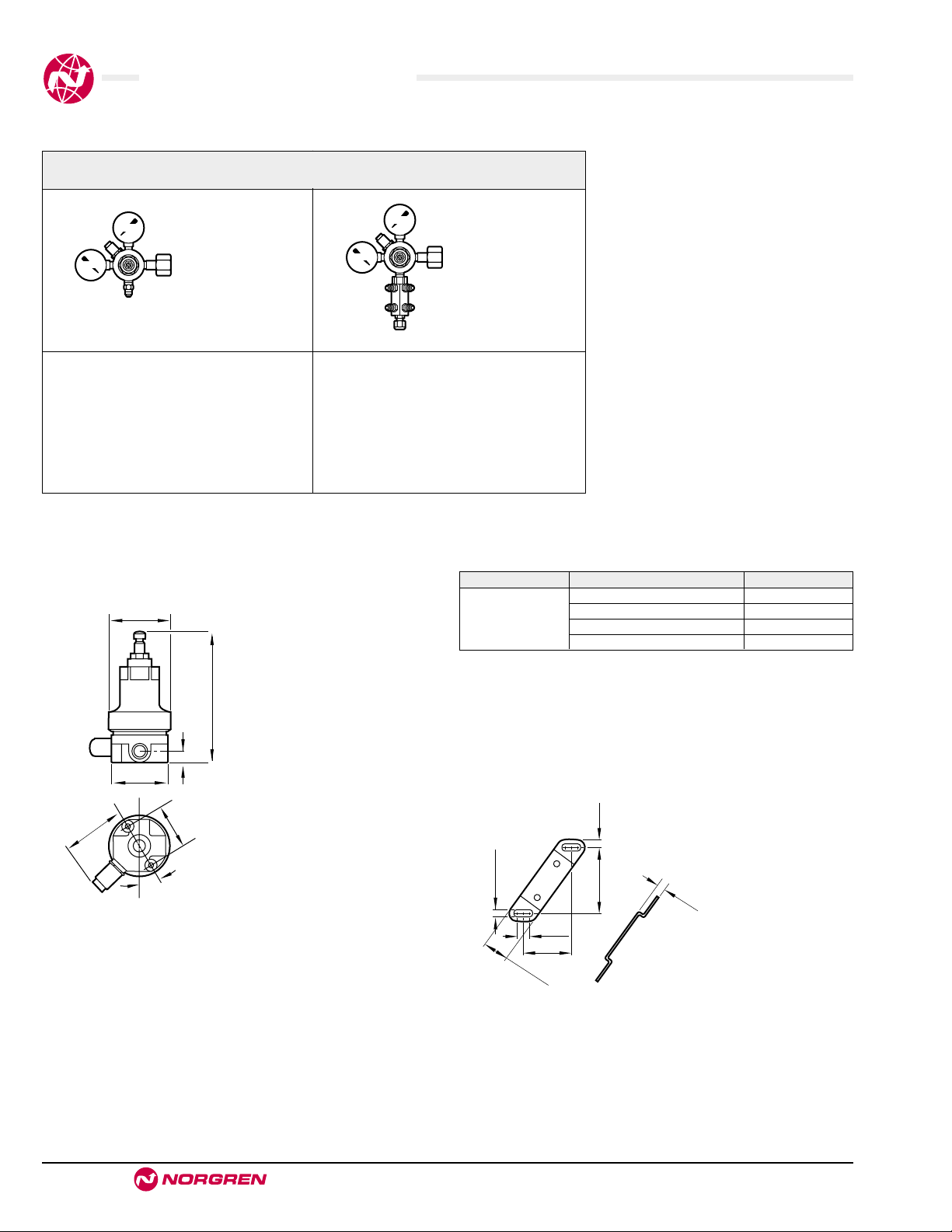

All Dimensions in Inches (mm)

Ordering Information- C84 Regulator Configurations. Models listed include PTF threads, relieving diaphragm, 5 to 125 psig (0.3 to 8.5

bar) outlet pressure adjustment range†.

†

Outlet pressure can be adjusted to pressures in excess of, and less than, those specified.Do not use these units to control pressures outside

of the specified ranges.

160

2000

160

2000

1.90 (48)

4.41 (112)

2.10 (53)

0.40 (10)

Mounting Holes (2 Places)

0.18" (4.6mm) dia. by 0.39 (10mm) deep.

Use 10-32 thread forming screws.

30°

1.66 (42)

2.07 (53)

R84 Regulator

5095-51 Strap Type Bracket

Service Kits

Item Type Part number

Service kits

Diaphragm, relieving 570-51

Valve cartridge and seal 5086-55

Kit, major 6309-04 *

Relief valve and seal 5779-54 ††

* Kit contains diaphragm, slip ring, valve cartridge, and o-rings.

†† Relief valve is marked 150 PSIG RELIEF VALVE and has a brass

body with a red end cap.

One Outlet Four or Five Outlets

Model C84-700 Model C84-666

Model C84-700 Includes: Model C84-666 Includes:

● R84-200-MNLA regulator with 150 psig ● R84-200-MNLA regulator with 150 psig

(10.4 bar) integral relief valve (1) (10.4 bar) integral relief valve (1)

● 18-013-244 inlet pressure gauge (1) ● 18-013-244 inlet pressure gauge (1)

● 18-013-085 outlet pressure gauge (1) ● 18-013-085 outlet pressure gauge (1)

● 18-008-002 cylinder connector (1) ● 18-008-002 cylinder connector (1)

● 16-009-001 check valve (1) ● 3228-60 manifold (1)

Typ

0.31 (8)

0.31 (8)

0.28 (7) Typ

0.5 (13)

1.03 (26)

2.75 (70)

2 (51)

Page 5

R84, C84 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-5

WARNING

For safety in systems using Norgren Model R84 regulators, the

following procedures must be followed.

1. Pressure relief valves of sufficient capacity must always be

used in the secondary (outlet) lines downstream of each

pressure regulator, whether as an integral part of the

regulator, as is the case with Norgren Model R84 Regulator,

or separately installed elsewhere in the outlet lines.Do not

remove or attempt to adjust, plug, block or otherwise defeat

the purpose of the relief valve.Do not replace a relief valve

with any but an identical model.The relief valve used on the

R84 regulator is preset and marked 150 PSIG RELIEF

VALVE. Replace only with the same 150 psig relief valve,

part number 5779-54. The end cap on the 5779-54 relief

valve is color coded red for visual identification. Failure to

provide a pressure relief valve of sufficient capacity to hold

outlet pressure below the lowest working pressure rating of

any piece of equipment installed in the outlet lines can result

in equipment damage and/or personal injury.

2. A back flow check valve must always be installed at the

regulator or at each manifold outlet in liquid dispensing

applications to prevent reverse flow through the regulator

and possible introduction of liquids and other contaminants

into the regulator.

3. Regulators must not be used where temperature or pressure

may exceed those specified in the Technical Data

paragraph.

4. The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be used

in conjunction with these products and if inaccurate

indications may be hazardous to personnel or property, the

gauge should be calibrated before initial installation and at

regular intervals during use. For gauge standards refer to

ANSI B40.1.

5. These regulators are not intended for use in life support

systems, beer dispensing systems, with soft drink product

(syrup) containers, or industrial cylinder gas systems.

Page 6

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

R81 Regulator and C81 Configurations

● Underwriters Laboratories, Inc. listed (file number

SA1089)

● The R81 regulator and C81 regulator configurations

with integral relief valve and outlet check valves meet

the requirements of paragraphs 4.5 and 4.6 of NSDA

Pamphlet TD02, Installation and Operational

Procedures for Pressurized Soft Drink Dispensing

Systems, dated July, 1980.

● Integral relief valve easily replaced without

disassembly of regulator and without affecting relief

pressure setting

● Back flow check valve, or manifold with integral

check valve at each outlet,can be installed in

regulator outlet port. Manifolds available with 3 or 5

outlets and include one outlet cap.

● Relieving diaphragm allows outlet pressure setting to

be reduced even though the system is dead-ended.

Pressure downstream of check valves will not be

reduced.

● Easily replaceable valve cartridge contains valve,

valve seat, valve spring, and filter element

● Two high pressure ports (inlet and primary gauge)

and two regulated pressure ports (outlet and

secondary gauge)

● Diametrically opposite inlet ports facilitate

manifolding for multiple dispensing applications.

Each manifolded regulator operates independently as

though attached directly to the gas supply source.

● Bonnet wrench hex same size as tank adapter - one

wrench fits both

UL Listed, Cylinder Gas Pressure Regulator

1/4" PTF Port Size, CO

2

Regulator for Soft Drink Dispensing Systems

Technical Data

Fluid: Carbon dioxide.The R81 regulator is designed for use in soft drink

dispensing systems to control cylinder gas (carbon dioxide, nitrogen, air)

pressure to the product containers. Other Norgren regulators (R84 for soft drink

carbonators, R82 for beer, R83 for industrial cylinder gases) are available for

use in other systems.

Maximum pressure: 3000 psig (207 bar)

Operating temperature: 0° to 140°F (-18° to 60°C)

Integral relief valve cracking pressure:

130 ± 4 psig (9.0 ± 0.28 bar)

Materials:

Body: Brass

Bonnet: Zinc

Valve cartridge: Teflon, brass, stainless steel

Diaphragm: Acetal and nitrile

Relief valve:Brass, polycarbonate, nitrile, aluminum

Seals: Nitrile

ALE-12-6

See Section ALE-25 for Accessories

Page 7

R81, C81 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-7

† Outlet pressure can be adjusted to pressures in excess of, and less than, those specified.Do not use these units to control pressures outside of the specified ranges.

†† The listed check valves and manifolds with integral check valves are designed for use with Norgren R81 regulators and C81 regulator configurations. They are not

recommended for use with other regulators and regulator configurations unless separate pressure relief protection is provided in each of the outlet lines.

* The 16-006-107 check and relief valve meets the pressure and flow requirements of paragraphs 4.5 and 4.6 of NSDA Pamphlet TD02, Installation and Operational

Procedures for Pressurized Soft Drink Dispensing Systems, dated July, 1980.

** Check valves, or manifolds with integral check valves, must be installed in the outlet ports of the wye when the wye is installed in the outlet port of the Norgren R81

regulator.

Ordering Information. Models listed include integral relief valve with cracking pressure of 130 ±4 psig (9.0 ± 0.28 bar), PTF threads,

relieving diaphragm, 5 to 100 psig (0.34 to 6.9 bar) outlet pressure adjustment range†.A gauge is not included.

Port Model Weight lb (kg)

1/4" R81-200-LNKA 1.3 (0.59)

Alternative Models

-

ANL

★

2 0

-

8 0R 1

Outlet Pressure Adjustment Ranges

†

Substitute

1 to 25 psig (0.07 to 1.7 bar) T

2 to 50 psig (0.14 to 3.4 bar) E

5 to 100 psig (0.34 to 6.9 bar) K

Pipe Plug, Hex Socket Hex Nipple Union Adapter with Cap

Wall Mounting Bracket 1/4" PTF 1/4" PTF male 1/4" PTF to 1/4" tube (45° flare)

Strap Type: 5095-51 2891-97 18-006-067 18-006-068

Adapter only: 18-006-027

Cap only: 3302-50

Nitrogen Service Carbon Dioxide Service

Cylinder Connector Cylinder Connector

2" (50 mm) diameter, 1/4 PTF connection 0.906-14 RH external thread 0.830-14 RH internal thread

15 psig (1 bar): 18-013-082 CGA No. 580: 18-008-004 1.44" (27 mm) long nipple

30 psig (2 bar), UL Listed: 18-013-030 CGA No. 320: 18-008-002

60 psig (4 bar), UL Listed: 18-013-083 2.25" (57 mm) long nipple

100 psig (7 bar), UL Listed: 18-013-084 18-008-015

160 psig (11 bar), UL Listed: 18-013-085 Replacement gasket: 1390-02

300 psig (20 bar), UL Listed: 18-013-086

2000 psig(135 bar), UL Listed: 18-013-244

3000 psig (205 bar), UL Listed: 18-013-087

Inlet Fittings

Manifolds with integral check valves †† Streamline Wye **

Check Valve, 1/4" PTF male to 1/4" tube (45° flare): 16-009-001 2 or 3 outlets, 1/4" PTF male to 1/4" tube (45° flare): 3228-54 1/4" NPT male to

Check Valve, 1/4" PTF male to 1/2-16 BSF: 16-009-002 2 or 3 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-55 1/4" NPT female: 16-006-107

Check Valve, 1/4" PTF male to 1/4" PTF female: 16-009-003 4 or 5 outlets, 1/4" PTF male to 1/4" tube (45° flare): 3228-60

Check and Relief Valve, 4 or 5 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-61

1/4" PTF male to 1/4" tube (45° flare): 16-006-107 Manifold extension, 1/4" PTF male to 1/4" PTF female: 2340-50

Single Outlet Fittings

Check Valve†† Check Valve†† Check and Relief Valve, *

Relief cracking pressure:

130 ± 4 psig

(9.0 ± 0.28 bar)

2 or 3 Port 4 or 5 Port Manifold

Extension

Accessories

Multiple Outlet Fittings

Page 8

R81, C81 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-8

Model C81-700 (One Outlet) Model C81-702 (One Outlet) Model C81-651 (One Outlet)

Model C81-700 Includes: Model C81-702 Includes: Model C81-651 Includes:

● R81-200-LNKA regulator (1) ● R81-200-LNKA regulator (1) ● R81-200-LNKA regulator (1)

● 18-013-244 (2000 psi) inlet pressure gauge (1)) ● 18-013-244 (2000 psi) inlet pressure gauge (1) ● 18-013-244 (2000 psi) inlet pressure gauge (1)

● 18-013-085 (160 psi) outlet pressure gauge (1) ● 18-013-084 (100 psi) outlet pressure gauge (1) ● 18-013-084 (100 psi) outlet pressure gauge (1)

● 18-008-002 cylinder connector (1) ● 18-008-002 cylinder connector (1) ● 18-008-002 cylinder connector (1)

● 16-009-001 check valve (1) ● 16-009-001 check valve (1) ● 16-009-002 check valve (1)

160

2000

Model C81-269 (One Outlet) Model C81-684 (One Outlet)

Model C81-269 Includes: Model C81-684 Includes:

● R81-200-LNEA regulator (1) ● R81-200-LNKA regulator (1)

● 18-013-244 (2000 psi) inlet pressure gauge (1) ● 2891-97 pipe plug (1)

● 18-013-083 (60 psi) outlet pressure gauge (1) ● 18-013-085 (160 psi) outlet pressure gauge (1)

● 18-008-002 cylinder connector (1) ● 18-008-002 cylinder connector (1)

● 16-009-001 check valve (1) ● 16-009-001 check valve (1)

Model C81-685 (Two or Three Outlets)

Model C81-685 Includes:

● R81-200-LNKA regulator (1)

● 18-013-244 (2000 psi) inlet pressure gauge (1)

● 18-013-085 (160 psi) outlet pressure gauge (1)

● 18-008-002 cylinder connector (1)

● 3228-54 manifold (1)

100

2000

100

2000

160

60

2000

160

2000

Cylinder Connected,Two Regulator Configurations

Cylinder Connected, One Regulator Configurations

Model C81-254 (Two Outlets) Model C81-652 (Two Outlets)

Model C81-254 Includes: Model C81-652 Includes:

● R81-200-LNEA regulator (1) ● R81-200-LNKA regulator (2)

● R81-200-LNKA regulator (1) ● 18-013-244 (2000 psi) inlet pressure gauge (1)

● 18-013-244 (2000 psi) inlet pressure gauge (1) ● 18-013-084 (100 psi) outlet pressure gauge (2)

● 18-013-083 (60 psi) outlet pressure gauge (1) ● 18-006-067 hex nipple (1)

● 18-013-085 (160 psi) outlet pressure gauge (1) ● 18-008-002 cylinder connector (1)

● 18-006-067 hex nipple (1) ● 16-009-002 check valve (2)

● 18-008-002 cylinder connector (1)

● 16-009-001 check valve (2)

Model C81-573 (Four to Six Outlets)

Model C81-573 Includes:

● R81-200-LNKA regulator (2)

● 18-013-244 (2000 psi) inlet pressure gauge (1)

● 18-013-085 (160 psi) outlet pressure gauge (2)

● 18-006-067 hex nipple (1)

● 18-008-002 cylinder connector (1)

● 3228-55 manifold (2)

100100

2000

16060

2000

160

2000

160

2 to 50 psig range†

5 to 100 psig range†

5 to 100 psig range† 5 to 100 psig range†

2 to 50 psig range†

5 to 100 psig range†

5 to 100 psig range†

5 to 100 psig range† 5 to 100 psig range† 5 to 100 psig range†

Page 9

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-9

Model C81-541 (One Outlet)

Model C81-541 Includes:

● R81-200-LNKA regulator with 9,0 bar

(130 psig) integral relief valve (1)

● 18-013-084 (100 psi) outlet pressure gauge (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 16-009-001 check valve (1)

● 5095-51 mounting bracket (1)

100

Wall Mounted,One Regulator Configurations

5 to 100 psig range†

Model C81-554 (Two or Three Outlets)

Model C81-554 Includes:

● R81-200-LNKA regulator with 9,0 bar

(130 psig) integral relief valve (1)

● 18-013-084 (100 psi) outlet pressure gauge (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 3228-54 manifold (1)

● 5095-51 mounting bracket (1)

100

5 to 100 psig range†

Model C81-559 (Four or Five Outlets)

Model C81-559 Includes:

● R81-200-LNKA regulator with 9,0 bar

(130 psig) integral relief valve (1)

● 18-013-084 (100 psi) outlet pressure gauge (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 3228-60 manifold (1)

● 5095-51 mounting bracket (1)

100

5 to 100 psig range†

Model C81-540 (Three or Four Outlets)

Model C81-540 Includes:

● R81-200-LNKA regulator (2)

● 18-013-084 (100 psi) outlet pressure gauge (2)

● 18-006-067 hex nipple (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 16-009-001 check valve (1)

● 3228-54 manifold (1)

● 5095-51 mounting bracket (2)

100

100

Wall Mounted,Two Regulator Configurations

5 to 100 psig range†

Model C81-570 (Four to Six Outlets)

Model C81-570 Includes:

● R81-200-LNKA regulator (2)

● 18-013-084 (100 psi) outlet pressure gauge (2)

● 18-006-067 hex nipple (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 2340-50 manifold extension (1)

● 3228-54 manifold (2)

● 5095-51 mounting bracket (2)

100

100

5 to 100 psig range†

Model C81-657 (Five or Six Outlets)

Model C81-657 Includes:

● R81-200-LNKA regulator (2)

● 18-013-084 (100 psi) outlet pressure gauge (2)

● 18-006-067 hex nipple (1)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter with cap (1)

● 16-009-001 check valve (1)

● 3228-60 manifold (1)

● 5095-51 mounting bracket (2)

100

100

5 to 100 psig range†

Wall Mounted,Three Regulator Configuration

Model C81-724 (Five to Eight Outlets)

Model C81-724 Includes:

● R81-200-LNKA regulator (2) ● 2340-50 manifold extension (1)

● 18-013-084 (100 psi) ● 3228-56 manifold (1) - Same as

outlet pressure gauge (2) 3228-54 but includes two caps

● 18-006-067 hex nipple (1) ● 3228-60 manifold (1)

● 18-006-027 half-union adapter (1) ● 5095-51 mounting bracket (2)

● 18-006-068 half-union adapter (1)

100

100

5 to 100 psig range†

Model C81-324 (Six to Nine Outlets)

Model C81-324 Includes:

● R81-200-LNKA regulator (3) ● 2340-50 manifold extension (1)

● 18-013-084 (100 psi) ● 3228-54 manifold (3)

outlet pressure gauge (3) ● 5095-51 mounting bracket (2)

● 18-006-067 hex nipple (2)

● 18-006-027 half-union adapter (1)

● 18-006-068 half-union adapter (1)

100 100

100

5 to 100 psig range†

† Outlet pressure can be adjusted to pressures in excess of, and less than, those specified.Do not use these units to control pressures outside of the

specified ranges.

R81, C81 Beverage Regulators

Page 10

R81, C81 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-10

All Dimensions in Inches (mm)

Service Kits

Item Type Part number

Service kits

Diaphragm, relieving 570-51

Valve cartridge and seal 5086-55

Kit, major 6309-04 *

Relief valve and seal 5779-55 †

* Kit contains diaphragm, slip ring, valve cartridge, and o-rings.

† Relief valve is marked 130 PSIG RELIEF VALVE and has a brass

body with a black end cap.

1.90 (48)

4.41 (112)

2.10 (53)

0.40 (10)

Mounting Holes (2 Places)

0.18" (4.6 mm) dia. by 0.39 (10 mm) deep.

Use 10-32 thread forming screws.

30°

1.66 (42)

2.07 (53)

5095-51 Strap Type Bracket

R81 Regulator

Typ

0.31 (8)

0.31 (8)

0.28 (7) Typ

0.5 (13)

1.03 (26)

2.75 (70)

2 (51)

Page 11

R81, C81 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-11

WARNING

Soft drink dispensing systems must be designed, installed, and

operated in accordance with the guidelines set forth in NSDA

pamphlet TD02, Installation and Operational Procedures for

Pressurized Soft Drink Dispensing Systems, dated July,

1980 or subsequent revisions.

1.Pressure relief valves of sufficient capacity must always be

used in the secondary (outlet) lines downstream of each

pressure regulator, whether as an integral part of the

regulator, as is the case with Norgren Model R81 Regulator,

or separately installed elsewhere in the outlet lines.Do not

remove or attempt to adjust, plug, block or otherwise defeat

the purpose of the relief valve.Do not replace a relief valve

with any but an identical model.The relief valve used on the

R81 regulator is preset and marked 130 PSIG RELIEF

VALVE. Replace only with the same 130 psig relief valve,

part number 5779-55. The end cap on the 5779-55 relief

valve is color coded black for visual identification. Failure to

provide a pressure relief valve of sufficient capacity to hold

outlet pressure below the lowest working pressure rating of

any piece of equipment installed in the outlet lines can result

in equipment damage and/or personal injury.

2. A back flow check valve must always be installed at the

regulator or at each manifold outlet in liquid dispensing

applications to prevent reverse flow through the regulator

and possible introduction of liquids and other contaminants

into the regulator.

3. Regulators must not be used where temperature or pressure

may exceed those specified in the Technical Data

paragraph.

4. The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be used

in conjunction with these products and if inaccurate

indications may be hazardous to personnel or property, the

gauge should be calibrated before initial installation and at

regular intervals during use. For gauge standards refer to

ANSI B40.1.

5. These regulators are not intended for use in life support

systems, beer dispensing systems, soft drink carbonator

systems, or industrial cylinder gas systems.

Page 12

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

R82 Regulator

● Underwriters Laboratories, Inc. listed (file number

SA1089)

● The R82 regulator with integral relief valve meets the

requirements of Proposed Section 9.7, Draught Beer

Dispensing Equipment and Related Components

(Seventh Draft dated October 17, 1980), of ANSIASME F2.1-1975, Food, Drug, and Beverage

Equipment.

● Integral relief valve easily replaced without

disassembly of regulator and without affecting relief

pressure setting

● Back flow check valve, or manifold with integral

check valve at each outlet,can be installed in

regulator outlet port. Manifolds available with 3 or 5

outlets and include one outlet cap.

● Relieving diaphragm allows outlet pressure setting to

be reduced even though the system is dead-ended.

Pressure downstream of check valves will not be

reduced.

● Easily replaceable valve cartridge contains valve,

valve seat, valve spring, and filter element

● Two high pressure ports (inlet and primary gauge)

and two regulated pressure ports (outlet and

secondary gauge)

● Diametrically opposite inlet ports facilitate

manifolding for multiple dispensing applications.

Each manifolded regulator operates independently as

though attached directly to the gas supply source.

● Bonnet wrench hex same size as tank adapter - one

wrench fits both

UL Listed, Cylinder Gas Pressure Regulator

1/4" PTF, CO

2

Regulator for Beer Dispensing Systems

Technical Data

Fluid: Carbon dioxide.The R82 regulator is designed for use in beer dispensing

systems to control cylinder gas (carbon dioxide) pressure to the beer keg.

Other Norgren regulators (R81 for soft drink syrup containers, R84 for soft drink

carbonators, R83 for industrial cylinder gases) are available for use in other

systems.

Maximum pressure: 3000 psig (207 bar)

Operating temperature: 0° to 140°F (-18° to 60°C)

Maximum outlet pressure adjustment limit: Factory set at 40 to 45 psig (2.8 to 3.1 bar)

Integral relief valve cracking pressure:

60 ± 4 psig (4.1 ± 0.28 bar)

Materials:

Body: Brass

Bonnet: Zinc

Valve cartridge: Teflon, brass, stainless steel

Diaphragm: Acetal and nitrile

Relief valve:Brass, polycarbonate, nitrile, aluminum

Seals: Nitrile

ALE-12-12

See Section ALE-25 for Accessories

Page 13

R82 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-13

† Outlet pressure can be adjusted to pressures in excess of, and less than, that specified.Do not use these units to control pressures outside of

the specified range.

†† The listed check valves and manifolds with integral check valves are designed for use with Norgren R82 regulators.They are not

recommended for use with other regulators unless separate pressure relief protection is provided in each of the outlet lines.

Ordering Information.Models listed include integral relief valve with cracking pressure of 60 ± 4 psig (4.1 ± 0.28 bar), PTF threads, relieving

diaphragm, 2 to 45 psig (0.14 to 3.1 bar) outlet pressure adjustment range†.A gauge is not included.

Port Model Weight lb (kg)

1/4" R82-200-ENEA 1.3 (0.59)

Pipe Plug, Hex Socket Hex Nipple Union Adapter with Cap

Wall Mounting Bracket 1/4" PTF 1/4" PTF male 1/4" PTF to 1/4" tube (45° flare)

Strap Type: 5095-51 2891-97 18-006-067 18-006-068

Adapter only: 18-006-027

Cap only: 3302-50

Nitrogen Service Carbon Dioxide Service

Cylinder Connector Cylinder Connector

Ø 50 mm (2") diameter, 1/4" PTF connection 0.906-14 RH external thread 0.830-14 RH internal thread

15 psig (1 bar): 18-013-082 CGA No. 580: 18-008-004 1.44" (37 mm) long nipple

30 psig (2 bar), UL Listed: 18-013-030 CGA No. 320: 18-008-002

60 psig (4 bar), UL Listed: 18-013-083 2.25" (57 mm) long nipple

100 psig (7 bar), UL Listed: 18-013-084 18-008-015

160 psig (11 bar), UL Listed: 18-013-085 Replacement gasket: 1390-02

300 psig (20 bar), UL Listed: 18-013-086

2000 psig (135 bar), UL Listed: 18-013-244

3000 psig (205 bar), UL Listed: 18-013-087

Inlet Fittings

Check Valve, 1/4" PTF male to 1/4" tube (45° flare): 16-009-001 2 or 3 outlets, 1/4" PTF male to 1/4" tube (45° flare): 3228-54

Check Valve, 1/4" PTF male to 1/2-16 BSF: 16-009-002 2 or 3 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-55

Check Valve, 1/4" PTF male to 1/4" PTF female: 16-009-003 4 or 5 outlets, 1/4" PTF male to 1/4" tube (45° flare): 3228-60

4 or 5 outlets, 1/4" PTF male to 1/2-16 BSF: 3228-61

Manifold extension, 1/4" PTF male to 1/4" PTF female: 2340-50

Single Outlet Fittings - Check Valves ††

2 or 3 Port 4 or 5 Port Manifold

Extension

Accessories

Multiple Outlet Fittings - Manifolds with integral check valves ††

Page 14

R82 Beverage Regulators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-12-14

All Dimensions in Inches (mm)

Mounting Holes (2 Places)

0.18" (4.6 mm) dia. by 0.39" (10 mm) deep.

Use 10-32 thread forming screws.

1.90 (48)

4.75 (121)

2.10 (53)

0.40 (10)

30°

1.66 (42)

2.07 (53)

R82 Regulator

5095-51 Strap Type Bracket

Service Kits

Item Type Part number

Service kits

Diaphragm, relieving 570-51

Valve cartridge and seal 5086-55

Kit, major 6309-04 *

Relief valve and seal 5779-56 †

* Kit contains diaphragm, slip ring, valve cartridge, and o-rings.

† Relief valve is marked 60 PSIG RELIEF VALVE and has a brass

body with a natural (silver colored) aluminum end cap.

WARNING

Beer dispensing systems must be designed,

installed, and operated in accordance with the

applicable guidelines such as the proposed Section

9.7, Draught Beer Dispensing Equipment and

Related Components (Seventh Draft dated October

17, 1980), of ANSI-ASME F2.1-1975, Food, Drug

and Beverage Equipment or subsequent revisions.

1. Pressure relief valves of sufficient capacity must

always be used in the secondary (outlet) lines

downstream of each pressure regulator, whether

as an integral part of the regulator, as is the case

with Norgren Model R82 Regulator, or separately

installed elsewhere in the outlet lines.Do not

remove or attempt to adjust, plug, block or

otherwise defeat the purpose of the relief valve.

Do not replace a relief valve with any but an

identical model.The relief valve used on the R82

regulator is preset and marked 60 PSIG RELIEF

VALVE. Replace only with the same 60 psig relief

valve, part number 5779-56.The end cap on the

5779-56 relief valve is color coded silver for visual

identification. Failure to provide a pressure relief

valve of sufficient capacity to hold outlet pressure

below the lowest working pressure rating of any

piece of equipment installed in the outlet lines can

result in equipment damage and/or personal

injury.

2. A back flow check valve must always be installed

at the regulator or at each manifold outlet in liquid

dispensing applications to prevent reverse flow

through the regulator and possible introduction of

liquids and other contaminants into the regulator.

3. Regulators must not be used where temperature

or pressure may exceed those specified in the

Technical Data paragraph.

4. The accuracy of the indication of pressure gauges

can change, both during shipment (despite care in

packaging) and during the service life. If a

pressure gauge is to be used in conjunction with

these products and if inaccurate indications may

be hazardous to personnel or property, the gauge

should be calibrated before initial installation and

at regular intervals during use. For gauge

standards refer to ANSI B40.1.

5. These regulators are not intended for use in life

support systems, soft drink carbonator systems,

with soft drink product (syrup) containers, or

industrial cylinder gas systems.

Typ

0.31 (8)

0.28 (7) Typ

0.5 (13)

2 (51)

1.03 (26)

2.75 (70)

0.31 (8)

Loading...

Loading...