Page 1

DISASSEMBLY

1. Regulator can be disassembled without removal from air

line.

2. Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero.

3. Turn adjustment (1 & 2) fully counterclockwise to remove

all force on regulating spring (3).

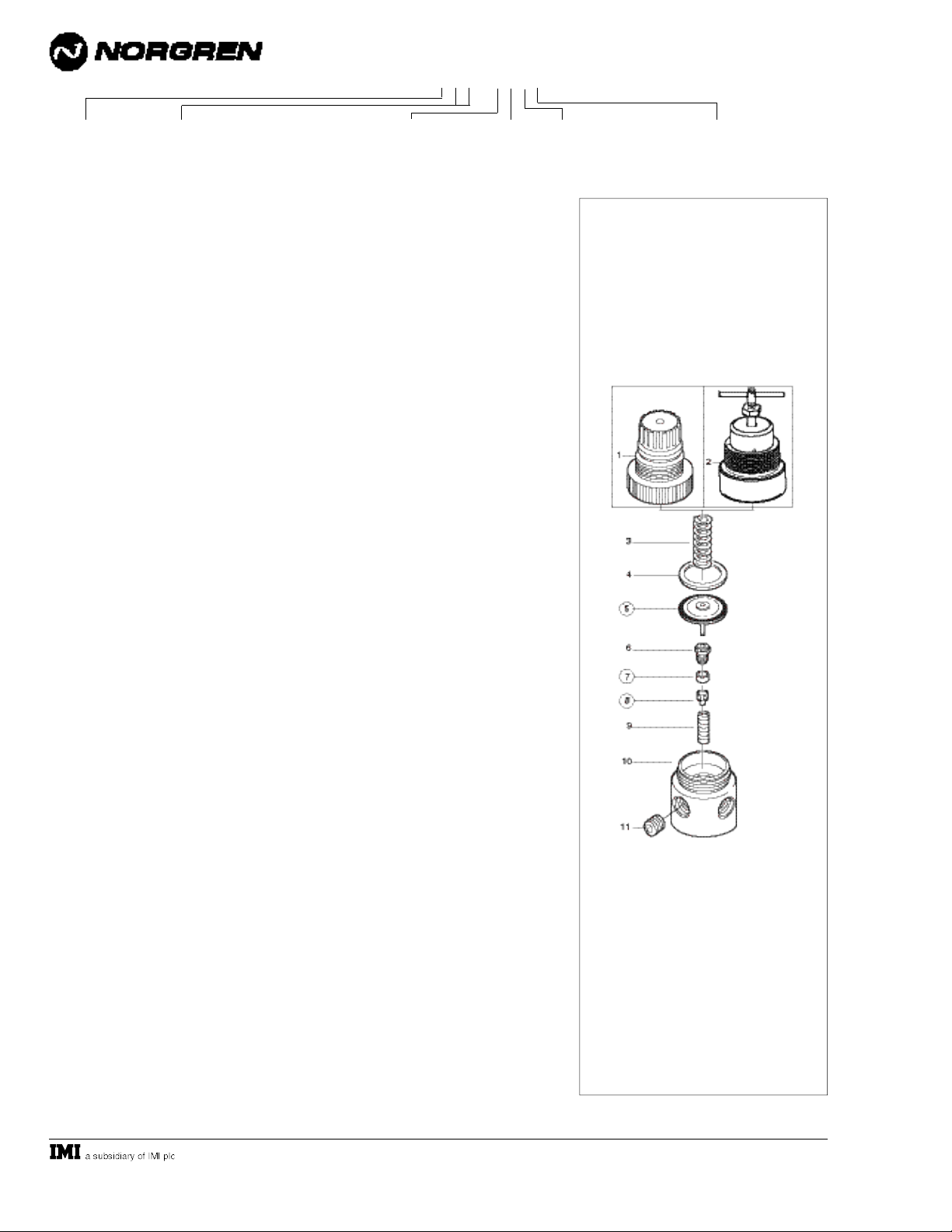

4. Disassemble in general accordance with the item numbers

on exploded view.

CLEANING

1. Clean parts with warm water and soap. Do not submerge

bonnet (1 & 2) in cleaning solution, as lubricant will be

removed.

2. Rinse and dry parts. Blow out internal passages in body

with clean, dry compressed air.

3. Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate adjusting screw threads inside bonnet (1 & 2)

with a small amount of Lubriplate 110 (or equivalent).

2. Assemble the unit as shown on the exploded view.

3. Torque Table

TORQUE

ITEM NM (INCH-POUNDS)

1 (Bonnet) 7.34 to 8.47 (65 to 75)

6 (Valve seat) 0.45 to 0.68 (4 to 6)†

† Diaphragm pin (4) must slide freely thru valve seat after

torquing.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

If outlet pressure in excess of the regulator pressure

setting could cause downstream equipment to rupture or

malfunction, install a pressure relief device downstream of

the regulator. The relief pressure and flow capacity of the

relief device must satisfy system requirements.

The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be used

with these products and if inaccurate indications may be

hazardous to personnel or property, the gauge should be

calibrated before initial installation and at regular intervals

during use.

Before using these products with fluids other than air, for

non industrial applications, or for life-support systems

consult Norgren.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure: 17 bar (250 psig)

Operating temperature*: -34° to +65°C (-30° to +150°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Typical flow with 7 bar (100 psig) inlet pressure, 6.3 bar

(90 psig) set pressure and 1 bar (15 psig) droop from

set: 3.3 dm3/s (7 scfm)

Gauge ports: 1⁄8 PTF

Materials - Metallic parts are NACE (National Association of

Corrosion Engineers) approved metals meeting hardness

requirements. NACE Recommendation MR-01-1975 (1980

Revision) “Material requirement - sulfite stress cracking

resistant metallic material for oil field equipment”.

Body: 316 stainless steel

Bonnet : Acetal or stainless steel with stainless steel

adjusting screw

Valve: Stainless steel with fluorocarbon elastomer

Valve seat: Acetal

Springs: Stainless steel

Elastomers: Fluorocarbon

REPLACEMENT ITEMS

Service kit (includes items circled on exploded view)

Relieving...............................................................3407-71

Non-relieving........................................................3407-72

PANEL MOUNTING DIMENSIONS

Panel mounting hole diameter: 30 mm (1.19")

Maximum panel thickness: 6 mm (0.25")

INSTALLATION

1. Shut off air pressure. Install regulator in air line -

●

with inlet air connected to the port marked IN.

●

upstream of lubricators and cycling valves.

●

as close as possible to the device being serviced.

●

at any angle.

2. Connect piping to proper ports using pipe thread sealant

on male threads only. Do not allow sealant to enter

interior of regulator.

3. Install a pressure gauge or plug the gauge ports. Gauge

ports can also be used as additional outlets for regulated

air.

4. Install a Norgren general purpose filter upstream of the

regulator.

ADJUSTMENT

1. Before applying inlet pressure to regulator, turn

adjustment (1 & 2) counterclockwise to remove all force

on regulating spring (3).

2. Apply inlet pressure, then turn adjustment clockwise to

increase and counterclockwise to decrease pressure

setting.

3. Always approach the desired pressure from a lower

pressure. When reducing from a higher to a lower

setting, first reduce to some pressure less than that

desired, then bring up to the desired pressure.

NOTE

With non-relieving regulators, make pressure

reductions with some air flow in the system. If

made under no flow (dead-end) conditions, the

regulator will trap the over-pressure in the

downstream line.

4. Push lockring on adjusting knob downward to lock

pressure setting. Pull lockring upward to release.

R05

Installation & Maintenance

Instructions

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

Stainless Steel Regulator

R05 - ★★★ - ★★★★

Thread Form

A....PTF

Port

2....1/4"

Spring (Outlet Pressure Range) *

E....0,3 to 3,5 bar (5 to 50 psig)

L....0,3 to 8,5 bar (5 to 125 psig)

Diaphragm

R....Relieving

N....Non relieving

Gauge

N....Without

IM-500.200

(2/05)

Replaces NIP-236

© Norgren 2005

Bonnet

Standard (Acetal) . . . . .00

Stainless Steel . . . . . . .32

Loading...

Loading...