Page 1

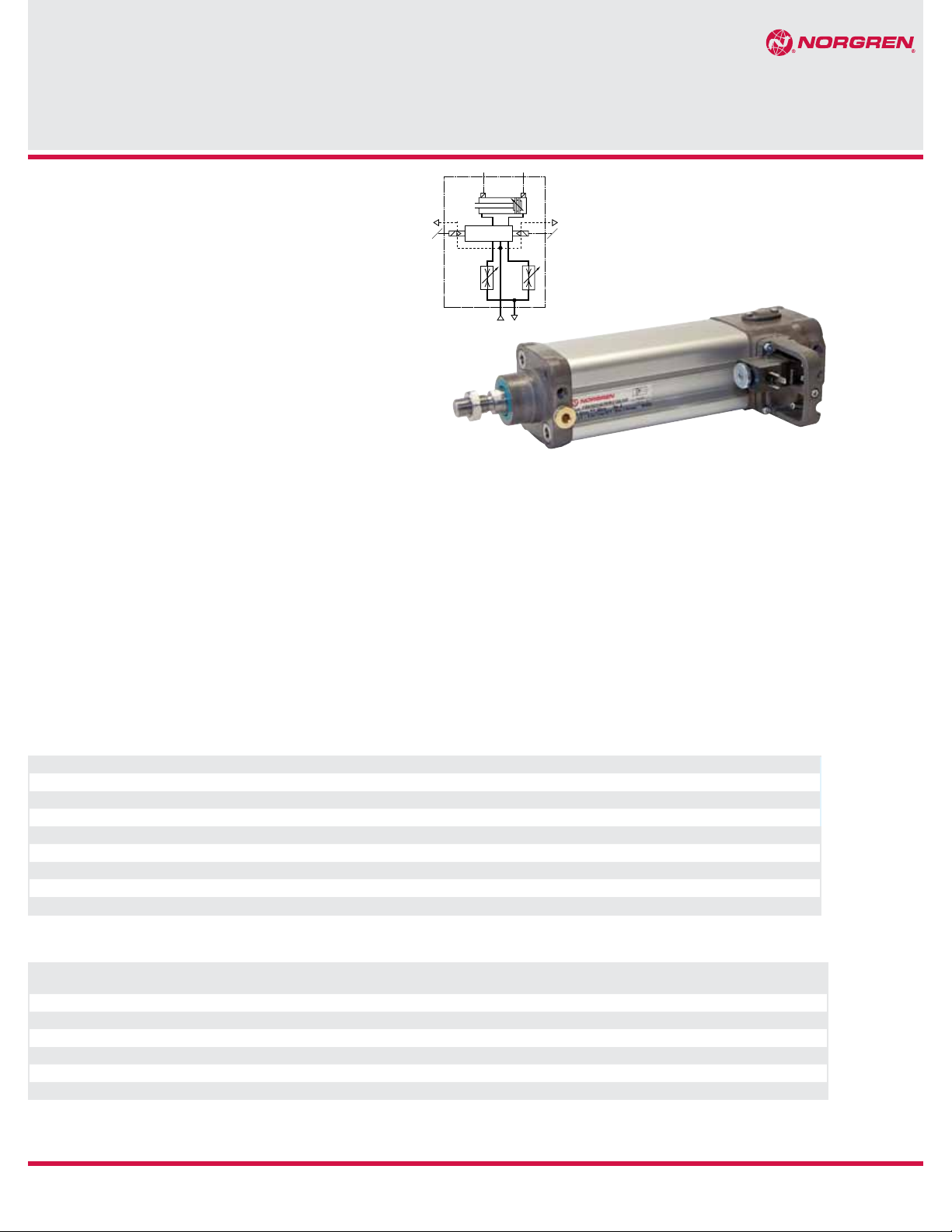

Cylinders and mountings conform to ISO 15552

Complete functional unit

Integrated 5/2 or 5/3 valve

Additional output cylinder ports (2 & 4)

Integrated flow regulator for speed control

PRA/862000/M

IVAC Industrial cylinder

double acting, magnetic piston

Ø 32 ... 100 mm

7

Reed or solid state switches can be mounted

13

flush with the profile barrel

Protection class IP65

Energy efficient

Technical features

Medium:

Compressed air, filtered,

lubricated or non-lubricated

Particles size: Class 7,

ISO 8573 – 1 (dated 2001)

Humidity and water content:

Air supply must be dry.

Corresponding of the application

and working conditions the air

must be dry enough to avoid

condensate. The pressure

dewpoint must be minimum

15° under the application and

working conditions. Oil: Class

4, ISO 8573 – 1 (dated 2001)

Standard:

Based on ISO 15552

(length , mounting pitch and thread

dimensions according to ISO 15552. Some

outside dimensions different to ISO 15552)

Operation:

Double acting, magnetic piston,

adjustable cushioning

Operating pressure:

29 to 116 psig (2 to 8 bar)

Port size:

G1/8, G1/4, G3/8

Cylinder diameters:

32, 40, 50, 63, 80, 100 mm

Standard strokes:

See below

Non-standard strokes:

Available

25 to1000 mm

Operating temperature:

14° to 176°F (-10C to 80°C) max.

Supply voltage:

24 V d.c.

Power consumption:

2 W max

Electrical connection:

DIN EN175301-803, form C

Manual override:

Push and lock

Rating:

100 % continuous duty

Protection class:

IP 65

Technical data

Cylinder Ø (mm) 32 40 50 63 80 100

Air ports

Piston rod Ø (mm)

Piston rod thread

Cushion length inch (mm)

Theoretical thrusts at 87 psig (6 bar) extended lbf. (N)

Theoretical thrusts at 87 psig (6 bar) retracted lbf. (N)

Air consumption at 87 psig (6 bar) extended cu ft/in (l/cm)

Air consumption at 87 psig (6 bar)retracted cu ft/in (l/cm)

G 1/8 G 1/8 G 1/8 G 1/4 G 1/4 G 3/8

12 16 20 20 25 25

M10 x 1.25 M12 x 1.25 M16 x 1.5 M16 x 1.5 M20 x 1.5 M20 x 1.5

0.74" (19) 0.86" (22) 0.94" (24) 0.94" (24) 1.06" (27) 1.34" (34)

108 (482) 170 (754) 265 (1178) 420 (1870) 678 (3016) 1058 (4710)

93 (414) 142 (633) 223 (990) 378 (1680) 612 (2722) 993 (4416)

0.005 (0.056) 0.008 (0.088) 0.012 (0.137 0.019 (0.218) 0.031 (0.350) 0.059 (0.550)

0.004 (0.050) 0.007 (0.076) 0.010 (0.117) 0.018 (0.198) 0.029 (0.324) 0.046 (0.514)

Materials:

Profile barrel:

anodised aluminum,

End covers: pressure diecast

anodised aluminum

Piston rod: stainless steel, see

page 2

Piston rod seals: polyurethane

Piston seals: polyurethane

O-rings: nitrile rubber

Standard strokes

Cylinder

Ø (mm)

32 • • • • • • • • • • •

40 • • • • • • • • • • •

50 • • • • • • • • • • •

63 • • • • • • • • • • •

80 • • • • • • • • • • •

100 • • • • • • • • • • •

4/13

Strokes (mm)

25 50 80 100 125 160 200 250 320 400 500

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren Americas 2013

N/us 1.5.250.01

Page 2

PRA/862000/M

24

15

3

V-52-EM-F-spec1

V-52-EMH-F-spec1

24

15

3

V-52-EM-F-spec2

V-52-EMH-F-spec2

24

15

3

V-52B-EM_spec1

V-52B-EMH_spec1

V-53A-EMH-spec1

42

513

V-53A-EM-spec1

V-53E-EMH-spec1

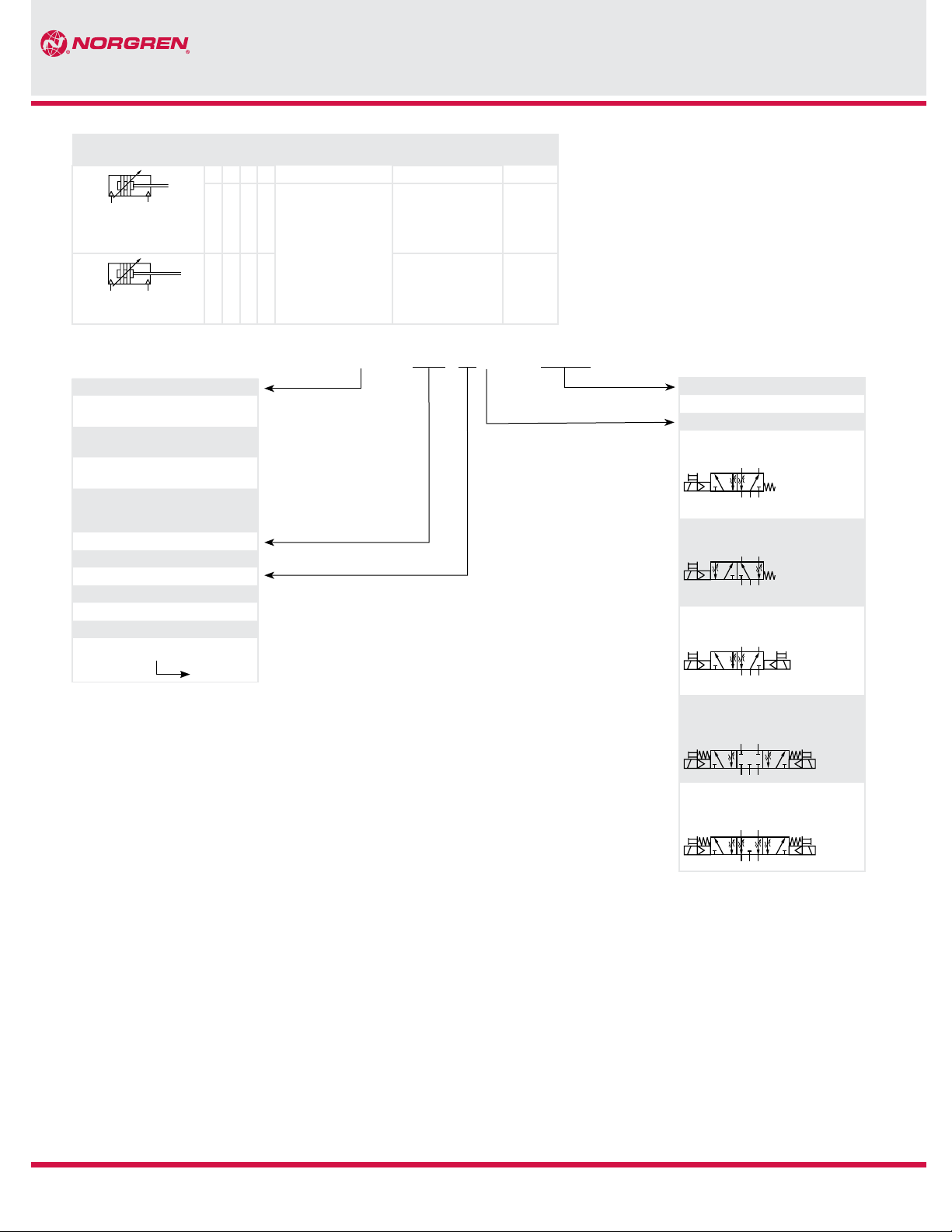

Cylinder variants

Symbol R S C D Model with

magnetic piston

• • • • PRA/862000/M Standard cylinder 4

• • • • PRA/862000/W2 Cylinder with special wiper/

• • • • PRA/862000/MU Cylinder with extended

For the cylinder models style C, D and S see options selector

Option selector

Description Dimensions

Page

seal (suitable for appl. with

4

cement, plaster (stucco),

arizona sand, hoar-frost or

ice)

piston rod

P˙A/862˙˙˙/˙˙˙/213A/˙˙˙˙

Piston rod material Substitute

Stainless steel (martensitic);

Standard wiper seal

Stainless steel (austenitic);

Standard wiper seal

Hard chromium plated;

Standard wiper seal

Stainless steel (austenitic);

hard chromium plated;

Standard wiper seal

Cylinder Ø (mm) Substitute

032, 040, 050, 063, 080, 100

Variants (magnetic piston) Substitute

Standard

Piston rod bellow

Special wiper seal

Extended piston rod

P**/862***/MU/****/***

Extension (mm)

MG

W2

MU

Strokes (mm)

R

1000 max.

Valve function Substitute

S

C

D

MI

5/2 way solenoid operated,

spring return, cylinder retracted

24

15

3

5/2 way solenoid operated,

spring return, cylinder extended

24

15

3

5/2 way solenoid operated,

solenoid return

42

15

3

5/3 way solenoid operated,

solenoid return, all ports

R

E

B

A

blocked (APB)

42

513

5/3 way solenoid operated,

solenoid return, central open

exhaust (COE)

42

C

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

513

N/us 1.5.250.02

Page 3

PRA/862000/M

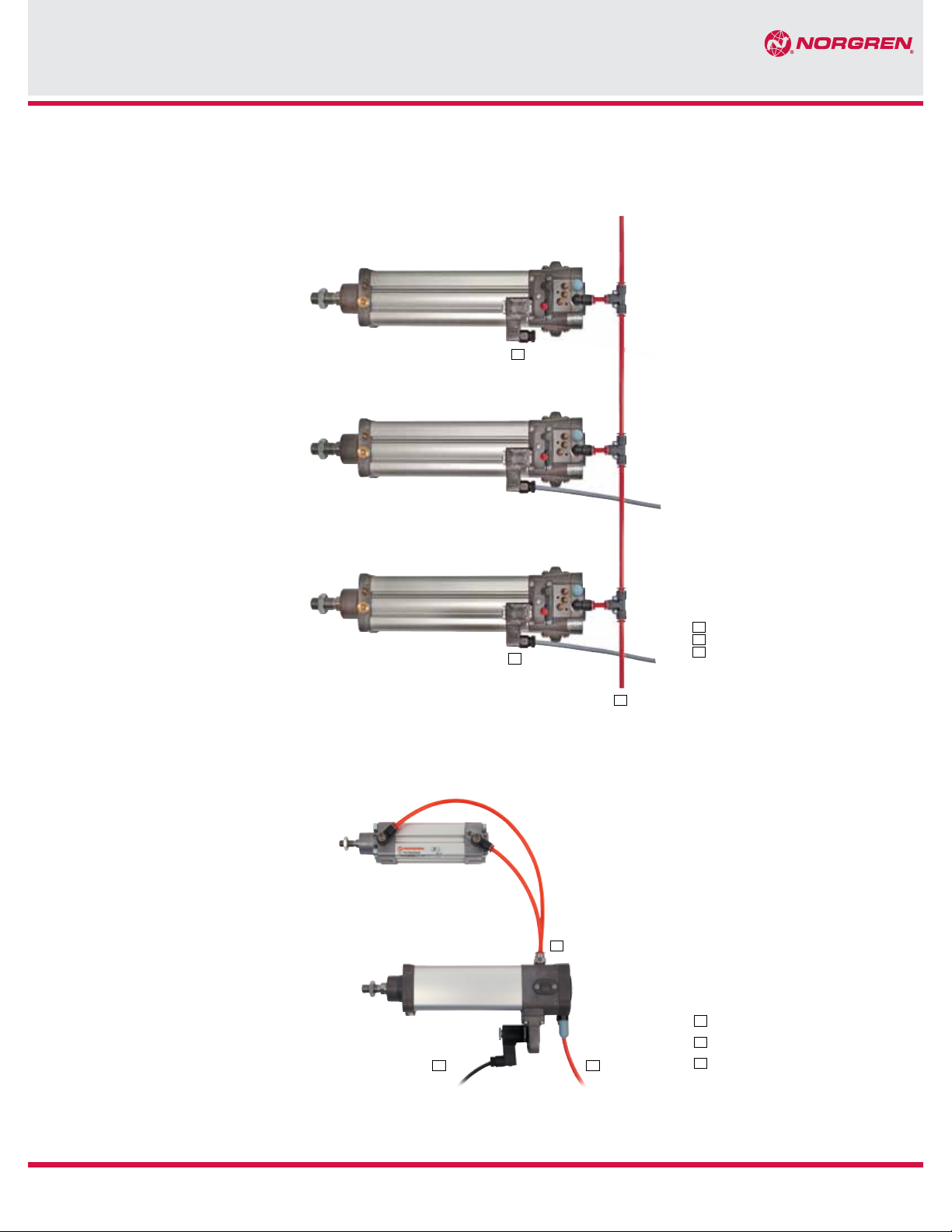

Reduced Installation Time & Cost

To connect the IVAC simply run a single supply line to provide an air supply to each unit. There is no mounting

of valve islands to the machine framework or inside a cabinet and there is no pipework to run around the

machine to connect each valve to each actuator.

4

One of the advantages of the IVAC cylinders is to

use the output cylinder ports (2 & 4) from the main

valve to operate an additional cylinder.

4

Plug

5

Plug with molded cable

6

5

6

3

2

1

Air supply

1

Air supply

2

Electrical connection

3

Output ports (2&4)

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.03

Page 4

PRA/862000/M

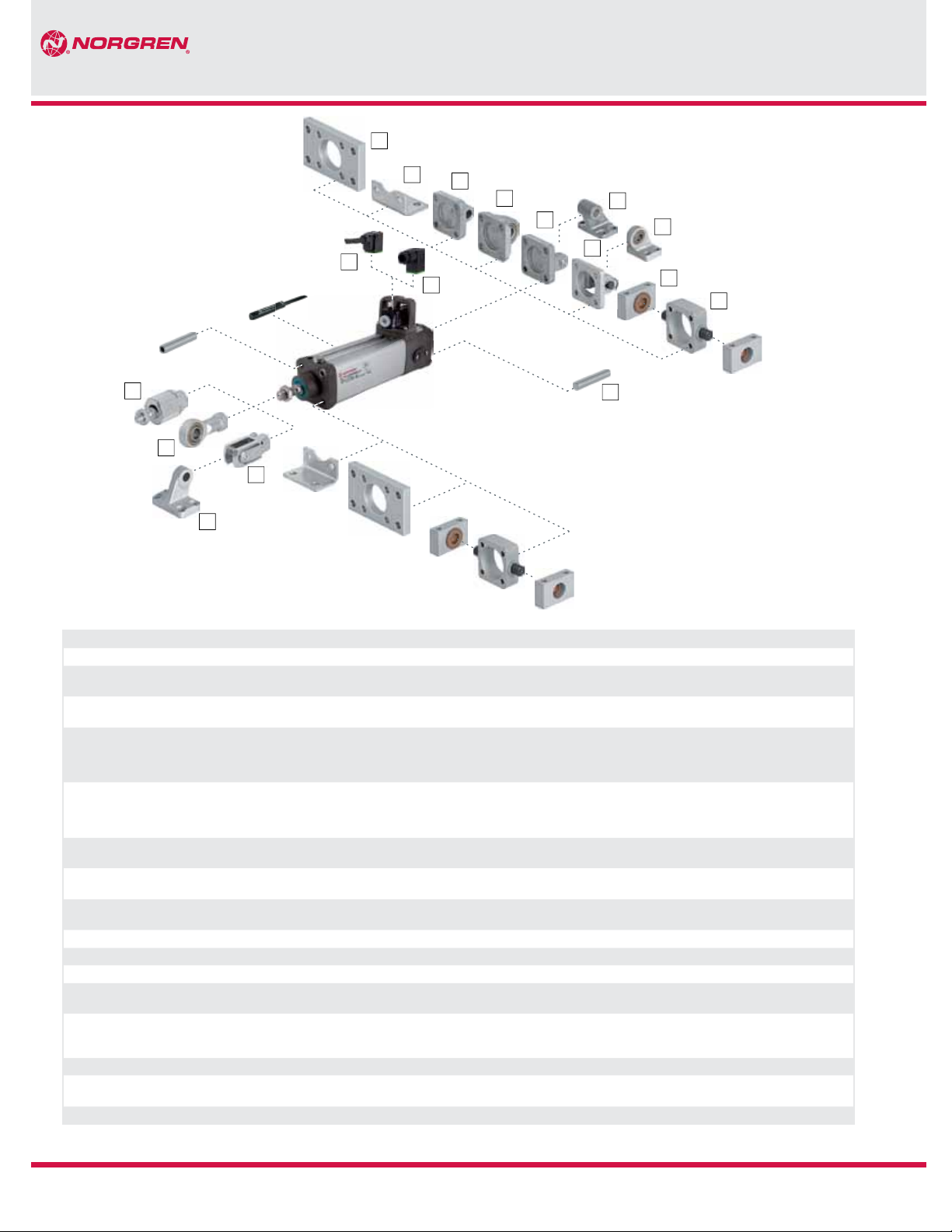

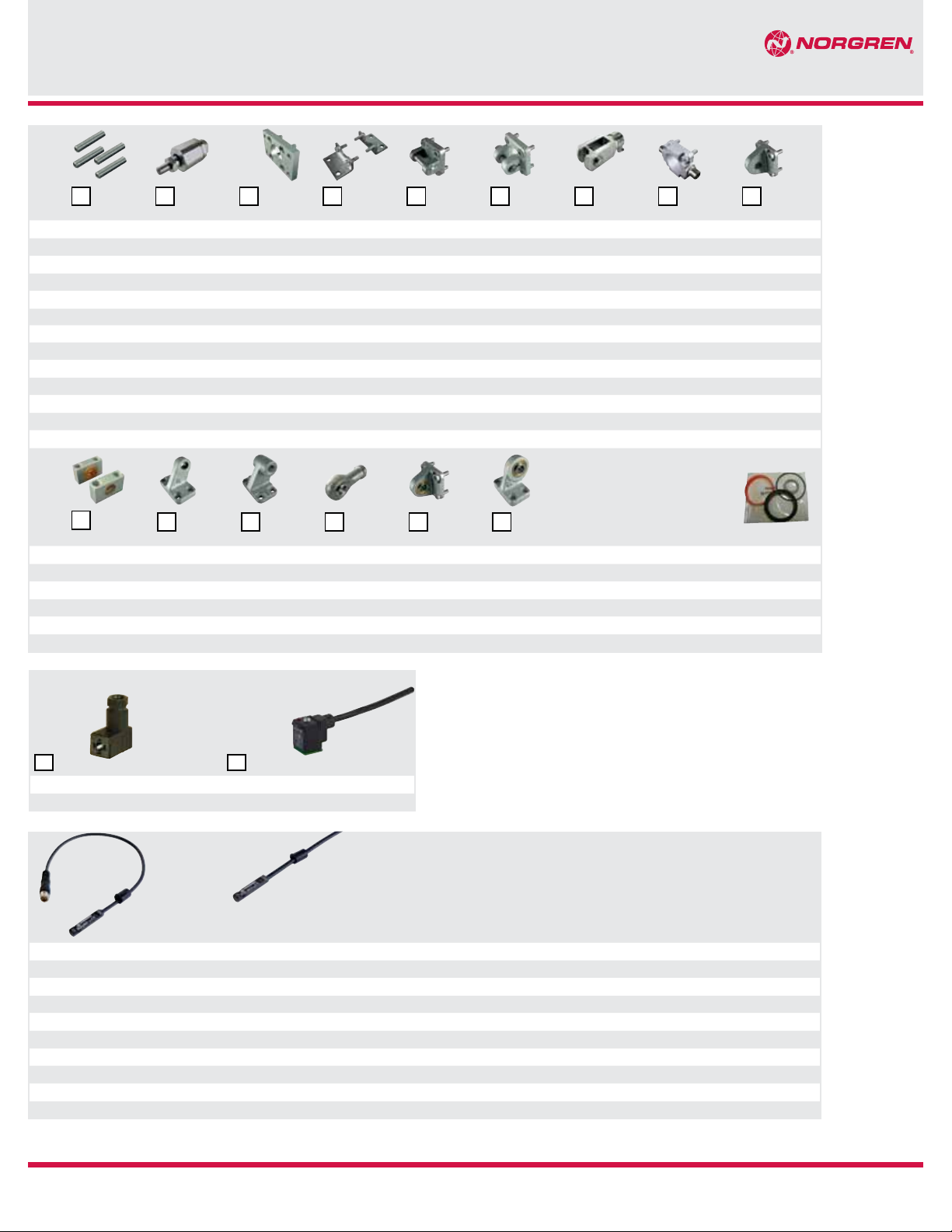

Mountings

1

18

17

16

15

21

2

3

4

5

6

8

7

22

12

9

10

Position Style Standard Corrosion protected

1 B, G Clear anodized aluminum Clear anodised aluminium. Screws: A2

2 C Galvanized steel (ø 32 ... 63 mm)

Painted steel (ø 80 & 100 mm)

3 R Diecast aluminum Black corrosion protected diecast aluminium. Certified

4 UR Galvanized aluminum

Inner ring: steel

Outer ring: brass

5 D Diecast aluminum

Bolt: galvanized steel (martensitic)

Circlip: galvanized steel

6 SW Diecast aluminum Black corrosion protected diecast aluminum

7 US Galvanized aluminium. Inner ring: steel

Outer ring: brass

8 D2 Painted cast iron. Bolt: stainless steel (martensitic)

Circlip: galvanized steel

9 FH Cast iron —

10 A Galvanized steel —

11 Screw — —

12 S Clear anodised aluminum

Bearing: brass

15 F Galvanized steel

Bolt: galvanized steel

Circlip: Galvanized steel

16 SS Painted cast iron —

17 UF Galvanized steel. Inner ring: steel

Outer ring: brass

18 AK Galvanized steel —

—

for the food industry. Screws: A2

Black corrosion protected diecast alumin um

Certified for the food industry

Inner ring: stainless Steel (austenitic)

Outer ring: nickel plated hardened steel

Black corrosion protected diecast aluminum

Certified for the food industry

Bolt: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

Circlip: Stainless steel (martensitic). Screws: A2

Certified for the food industry

—

—

Nickel plated steel

Circlip: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

Bolt: X 10 Cr Ni S 18 9 (1.4305, AISI 303)

Nickel plated steel. Inner ring: stainless steel (austenitic)

Outer ring: nickel plated hardened steel.

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.04

Page 5

Mountings and service kits

Model ØA

AK

B, G

PRA/862000/M

C

D

D2

F

FH

R

10

Page 7

32 QM/8032/35 QM/8025/38 QA/8032/22 QA/8032/21 QA/8032/23 QA/8032/42 QM/8025/25 QA/8032/34 QA/8032/27

40 QM/8032/35 QM/8040/38 QA/8040/22 QA/8040/21 QA/8040/23 QA/8040/42 QM/8040/25 QA/8040/34 QA/8040/27

50 QM/8050/35 QM/8050/38 QA/8050/22 QA/8050/21 QA/8050/23 QA/8050/42 QM/8050/25 QA/8050/34 QA/8050/27

63 QM/8050/35 QM/8050/38 QA/8063/22 QA/8063/21 QA/8063/23 QA/8063/42 QM/8050/25 QA/8063/34 QA/8063/27

80 QM/8080/35 QM/8080/38 QA/8080/22 QA/8080/21 QA/8080/23 QA/8080/42 QM/8080/25 QA/8080/34 QA/8080/27

100 QM/8080/35 QM/8080/38 QA/8100/22 QA/8100/21 QA/8100/23 QA/8100/42 QM/8080/25 QA/8100/34 QA/8100/27

Corrosion protected mounts

S

Model

12

Ø

32 QA/8032/41 M/P19931 M/P19493 QM/8025/32 QA/8032/33 M/P40310 PRQA/862032/00

40 QA/8040/41 M/P19932 M/P19494 QM/8040/32 QA/8040/33 M/P40311 PRQA/862040/00

50 QA/8040/41 M/P19933 M/P19495 QM/8050/32 QA/8050/33 M/P40312 PRQA/862050/00

63 QA/8063/41 M/P19934 M/P19496 QM/8050/32 QA/8063/33 M/P40313 PRQA/862063/00

80 QA/8063/41 M/P19935 M/P19497 QM/8080/32 QA/8080/33 M/P40314 PRQA/862080/00

100 QA/8100/41 M/P19936 M/P19498 QM/8080/32 QA/8100/33 M/P40315 PRQA/862100/00

Page 10

18

SS

16

Page 7

Page 12

1

Page 8

PVQA/8032/22 PVQA/8032/23 PVQM/8025/25 PVQA/8032/33

PVQA/8040/22 PVQA/8040/23 PVQM/8040/25 PVQA/8040/33

PVQA/8050/22 PVQA/8050/23 PVQM/8050/25 PVQA/8040/33

PVQA/8063/22 PVQA/8063/23 PVQM/8050/25 PVQA/8063/33

PVQA/8080/22 PVQA/8080/23 PVQM/8080/25 PVQA/8080/33

PVQA/8100/22 PVQA/8100/23 PVQM/8080/25 PVQA/8100/33

SW

6

Page 11

2

UF

17

Page 8

Page 10

5

UR

4

Page 9

Page 11

7

US

8

Page 9

Page 12

15

Page 9

9

Page 8

3

Page 10

Service kit

Connectors

Plug with cable gland

Plug with molded cable

22

V10027-D00 V10014-D01 (LED and VDR, cable length 1 m)

V10012-D13 (LED and VDR) V10014-D03 (LED and varistor, cable length 3 m)

21

Magnetically operated switches

Model

Reed *3) Solid state

M/50/LSU/*V – 10 ... 240 10 ... 170 180 -4° to 176° (-20° to 80°) • – 2, 5 or 10 PVC 2 x 0.25 – N/en 4.3.005

M/50/LSU/5U – 10 ... 240 10 ... 170 180 -4° to 176° (-20° to 80°) • – 5 PUR 2 x 0.25 – N/en 4.3.005

TM/50/RAU/2S – 10 ... 240 10 ... 170 180 -4° to 302° (-20° to150°) – – 2 Silicone 2 x 0.25 – N/en 4.3.005

M/50/RAC/5V – 10 ... 240 10 ... 170 180 -4° to 176° (-20° to 80°) – Changeover 5 PVC 3 x 0.25 – N/en 4.3.005

M/50/LSU/CP – 10 ... 60 10 ... 75 180 -4° to 176° (-20° to 80°) • Plug M8x1 5 PVC 3 x 0.25 M/P73001/5 N/en 4.3.005

– M/50/EAP/*V – 10 ... 30 150 -40° to 176° (-40° to 80°) *1) • PNP 2, 5 or 10 PVC 3 x 0.25 – N/en 4.3.007

– M/50/EAP/CP – 10 ... 30 150 -40° to 176° (-40° to 80°) *1) • PNP, Plug M8x1 5 PVC 3 x 0.25 M/P73001/5 N/en 4.3.007

– M/50/EAP/CC – 10 ... 30 150 -40° to 176° (-40° to 80°) *1) • PNP, Plug M12x1 5 PVC 3 x 0.25 M/P34614/5 N/en 4.3.007

– M/50/EAN/*V – 10 ... 30 150 -40° to 176° (-40° to 80°) *1) • NPN 2, 5 or 10 PVC 3 x 0.25 – N/en 4.3.007

– M/50/EAN/CP – 10 ... 30 150 -40° to 176° (-40° to 80°) *1) • NPN, Plug M8x1 5 PVC 3 x 0.25 M/P73001/5 N/en 4.3.007

* Please insert cable length

*1) -40°F to 176°F (-40°C to 80°C) protection class IP65; -4°F to 176°F (-20°C to 80°C) protection class IP67 and IP68, details see data sheet

*2) Supply voltage 24 V d.c. (± 10%) max for P.A/86200/M only *3) For use with 32 mm bore - consult factory.

4/13

Voltage *2)

(V a.c.) (V d.c.)

Our policy is one of continued research and development. We therefore reserve the right to amend,

Current max.

(mA)

Temperature

°F (°C)

without notice, the specifications given in this document.

LED Features Cable length

© Norgren, Inc. 2013

(m)

Cable

type

Cable with

connector

Data sheet

N/us 1.5.250.05

Page 6

PRA/862000/M

ø 32 ... 63

Dimensions Inches (mm)

0.47

(12)

1.16

(29.5)

0.53

(13.5)

G2

2.04 (52)

0.44 (11.3)

0.65 (16.5)

L12

KW

e 11

KK

MM h 9

ø B

KV SW

L2

AM WH

B

ø 32 ... 63 ø 80 & 100

13

14

BG

B

RT

1.89

ø BA e 11

(48)

E4 E3

E2

A

E

RT

A

BH

R

L1

EE

G

8

(26)

1.02

1

0.45

(11.5)

15

4 51 6

ø 80 & 100

PL1

PL2

7

PL

G

9

L8 + #

11

G1

A-A

PL

VA

A-A

A

ø 32 ... 63 ø 80 & 100

13

A

RT

L9

BG

RT

BG

BH

4/13

1

Cushion adjustment front end cover

4

Main valve

5

Pilot block

6

Output ports (2&4)

Our policy is one of continued research and development. We therefore reserve the right to amend,

7

Air supply

8

Exhaust position, do not obstruct

9

Without function - do not use

11

Manual override

without notice, the specifications given in this document.

© Norgren, Inc. 2013

13

Speed control adjustment

14

Cushion adjustment rear end cover

15

M/50 switches can be mounted

flush with the profile

N/us 1.5.250.06

Page 7

PRA/862000/M

Dimensions Inches (mm)

Ø AM Ø B

32 0.87 1.18 1.18 0.63 0.24 1.85 1.08 1.08 1.08 G1/8 0.55 2.32 1.20 M10x1.25 0.20 2.70 0.79 3.70 0.16 0.24

(22.0) (30.0) (30.0) (16.0) (6.0) (47.0) (27.5) (27.5) (27.5) (14.0) (59.0) (30.5) (5.0) (68.5) (20.0) (94.0) (4.0) (6.0)

40 0.94 1.38 1.38 0.63 0.24 2.36 1.36 1.34 1.34 G1/8 0.55 2.32 1.20 M12x1.25 0.24 2.70 0.83 4.13 0.16 0.26

(24.0) (35.0) (35.0) (16.0) (6.0) (60.0) (34.5) (34.0) (34.0) (14.0) (59.0) (30.5) (6.0) (68.5) (21.0) (105.0) (4.0) (6.5)

50 1.26 1.57 1.57 0.63 0.31 2.81 1.57 1.54 1.54 G1/8 0.55 2.48 1.36 M16x1.5 0.31 3.64 1.10 4.17 0.20 0.26

(32.0) (40.0) (40.0) (16.0) (8.0) (71.5) (40.0) (39.0) (39.0) (14.0) (63.0) (34.5) (8.0) (92.5) (28.0) (106.0) (5.0) (6.5)

63 1.26 1.77 1.77 0.63 0.31 3.23 1.81 1.79 1.79 G1/4 0.75 2.60 1.50 M16x1.5 0.31 3.60 1.10 4.76 0.20 0.26

(32.0) (45.0) (45.0) (16.0) (8.0) (82.0) (46.0) (45.5) (45.5) (19.0) (66.0) (38.0) (8.0) (91.5) (28.0) (121.0) (5.0) (6.5)

80 1.57 1.77 1.77 0.67 0.63 3.90 2.13 2.13 2.24 G1/4 0.75 2.93 1.83 M20x1.5 0.39 4.33 1.38 5.04 - 0.30

(40.0) (45.0) (45.0) (17.0) (16.0) (99.0) (54.0) (54.0) (57.0) (19.0) (74.5) (46.5) (10.0) (110.0) (35.0) (128.0) - (7.5)

100 1.57 2.17 2.17 0.67 0.63 4.69 2.56 2.56 2.56 G3/8 0.96 3.19 2.09 M20x1.5 0.39 5.69 1.50 5.43 - 0.39

(40.0) (55.0) (55.0) (17.0) (16.0) (119.0) (65.0) (65.0) (65.0) (24.5) (81.0) (53.0) (10.0) (144.5) (38.0) (138.0) - (10.0)

Ø MM

Ø

h9

32 0.47 0.28 0.39 0.14 1.28 M6 0.12 0.24 1.02 0.00 0.67 0.39 0.20 0.47 1.46 lb. 0.15 lb. PRA/862032/MI+/213A/*

(12.0) (7.0) (10.0) (3.5) (32.5) (3.0) (6.0) (26.0) (0.0) (17.0) (10.0) (5.0) (12.0) (0.66 kg) (0.07 kg)

40 0.63 0.28 0.41 0.16 1.50 M6 0.14 0.24 1.18 0.00 0.75 0.51 0.20 0.47 2.27 lb. 0.24 lb. PRA/862040/MI+/213A/*

(16.0) (7.0) (10.5) (4.0) (38.0) (3.5) (6.0) (30.0) (0.0) (19.0) (13.0) (5.0) (12.0) (1.03 kg) (0.11 kg)

50 0.79 0.28 0.49 0.16 1.83 M8 0.14 0.24 1.46 0.06 0.94 0.67 0.20 0.47 3.48 lb. 0.40 lb. PRA/862050/MI+/213A/*

(20.0) (7.0) (12.5) (4.0) (46.5) (3.5) (6.0) (37.0) (1.5) (24.0) (17.0) (5.0) (12.0) (1.58 kg) (0.18 kg)

63 0.79 0.37 0.57 0.24 2.22 M8 0.16 0.24 1.46 0.00 0.94 0.67 0.24 0.59 5.34 lb. 0.42 lb. PRA/862063/MI+/213A/*

(20.0) (9.5) (14.5) (6.0) (56.5) (4.0) (6.0) (37.0) (0.0) (24.0) (17.0) (6.0) (15.0) (2.42 kg) (0.19 kg)

80 0.98 0.37 0.55 0.24 2.83 M10 0.16 0.24 1.81 0.24 1.18 0.87 0.24 0.59 9.08 lb. 0.64 lb. PRA/862080/MI+/213A/*

(25.0) (9.5) (14.0) (6.0) (72.0) (4.0) (6.0) (46.0) (6.0) (30.0) (22.0) (6.0) (15.0) (4.12 kg) (0.29 kg)

100 0.98 0.47 0.65 0.33 3.50 M10 0.16 0.24 2.01 0.26 1.18 0.87 0.31 0.75 1.46 lb. 0.77lb. PRA/862100/MI+/213A/*

(25.0) (12.0) (16.5) (8.5) (89.0) (4.0) (6.0) (51.0) (6.5) (30.0) (22.0) (8.0) (19.0) (14.0 kg) (0.35 kg)

* Please insert standard stroke length (mm)

+ Please insert valve function

Ø BA

e11

PL PL1 PL2 R RT VA VD WH X1

BG BH E E2 E3 E4 EE G G1 G2 KK KW L1 L2 L8 L9 L12

e11

KV SW 1 2

at 0 mm per 25mmModel

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.07

Page 8

PRA/862000/M

3

2

4

1

BB

øABøA

P*A/862000/MG*/213A/* Cylinder with piston rod bellow

B

Mountings

Front or rear stud mounting A

Conforms to ISO 15552, type MX1

Cyl.ØØ A Stroke max

per bellow

32 1.57 2.36 1.18 0.98 P#A/862032/MG+/213A/*

(40) (60) (30) (25)

40 2.48 5.71 1.97 1.26 P#A/862040/MG+/213A/*

(63) (145) (50) (32)

50 2.48 5.71 1.57 1.26 P#A/862050/MG+/213A/*

(63) (145) (40) (32)

63 2.48 5.71 1.57 1.26 P#A/862063/MG+/213A/*

(63) (145) (40) (32)

80 3.15 9.84 1.97 1.77 P#A/862080/MG+/213A/*

(80) (250) (50) (45)

100 3.15 9.81 1.97 1.77 P#A/862100/MG+/213A/*

(80) (250) (50) (45)

* Standard stroke length

# Piston rod material

+ Valve function

Piston rod extention B

for first for further

bellow bellows

Model

Piston rod swivel AK

DD

Standard

Ø BB DD TG lb. (kg) Model (A)

32/40 0.67 M6 1.28/1.5 0.04 QM/8032/35

(17.0) (32.5/38) (0.02)

50/63 0.91 M8 1.83/2.22 0.11 QM/8050/35

(23.0) (46.5/56.5) (0.05)

80/100 1.10 M10 2.83/3.5 0.18 QM/8080/35

(28.0) (72/89) (0.08)

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

TG

TG

© Norgren, Inc. 2013

4∞

KK

4∞

Standard

Ø KK B1 F L L2

32 M10x1.25 0.20 1.02 2.87 0.79 0.75 0.47 0.67 1.18 0.44 QM/8025/38

(5) (26) (73) (20) (19) (12) (17) (30) (0.2)

40 M12x1.25 0.24 1.02 3.03 0.94 0.75 0.47 0.75 1.18 0.44 QM/8040/38

(6) (26) (77) (24) (19) (12) (19) (30) (0.2)

50/63 M16x1.5 0.31 1.34 4.17 1.26 1.18 0.75 0.94 1.65 1.43 QM/8050/38

(8) (34) (106) (32) (30) (19) (24) (42) (0.65)

80/100 M20x1.5 0.39 1.65 4.80 1.57 1.18 0.75 1.18 1.65 1.58 QM/8080/38

(10) (42) (122) (40) (30) (19) (30) (42) (0.72)

L 2

B 1

1

L

2 3 4

KK

F

lb. (kg) Model (AK)

N/us 1.5.250.08

Page 9

PRA/862000/M

UF

L 1

Front flange B, G

Conforms to ISO 15552, type MF1 and MF2

TF

MF

E

R

FB

Standard

Ø E Ø FB MF R TF UF lb. (kg) Model (B, G)

32 1.97 0.28 0.39 1.26 2.52 3.15 0.55 QA/8032/22

(50) (7) (10) (32) (64) (80) (0.25)

40 2.17 0.35 0.39 1.42 2.83 3.54 0.77 QA/8040/22

(55) (9) (10) (36) (72) (90) (0.35)

50 2.56 0.35 0.47 1.77 3.54 4.33 1.54 QA/8050/22

(65) (9) (12) (45) (90) (110) (0.7)

63 2.95 0.35 0.47 1.97 3.94 4.92 1.76 QA/8063/22

(75) (9) (12) (50) (100) (125) (0.8)

80 3.94 0.47 0.63 2.48 4.96 6.06 2.97 QA/8080/22

(100) (12) (16) (63) (126) (154) (1.35)

100 4.72 0.55 0.63 2.95 5.91 7.32 4.84 QA/8100/22

(120) (14) (16) (75) (150) (186) (2.2)

Corrosion protected mounts

32 1.97 0.28 0.39 1.26 2.52 3.15 0.55 PVQA/8032/22

(50) (7) (10) (32) (64) (80) (0.25)

40 2.17 0.35 0.39 1.42 2.83 3.54 0.77 PVQA/8040/22

(55) (9) (10) (36) (72) (90) (0.35)

50 2.56 0.35 0.47 1.77 3.54 4.33 1.54 PVQA/8050/22

(65) (9) (12) (45) (90) (110) (0.7)

63 2.95 0.35 0.47 1.97 3.94 4.92 1.76 PVQA/8063/22

(75) (9) (12) (50) (100) (125) (0.8)

80 3.94 0.47 0.63 2.48 4.96 6.06 2.97 PVQA/8080/22

(100) (12) (16) (63) (126) (154) (1.35)

100 4.72 0.55 0.63 2.95 5.91 7.32 4.84 PVQA/8100/22

(120) (14) (16) (75) (150) (186) (2.2)

Foot mounting C

Conforms to ISO 15552, type MS1

AH

AT

AOAU

Standard

Ø Ø AB AH AO AT AU E TR lb. (kg) Model (C)

32 0.28 1.26 0.31 0.16 0.94 1.89 1.26 0.4 QA/8032/21

(7.0) (32.0) (8.0) (4.0) (24.0) (48.0) (32.0) (0.15)

40 0.39 1.42 0.35 0.16 1.1 2.09 1.42 0.48 QA/8040/21

(10.0) (36.0) (9.0) (4.0) (28.0) (53.0) (36.0) (0.18)

50 0.39 1.77 0.39 0.2 1.26 2.52 1.77 0.8 QA/8050/21

(10.0) (45.0) (10.0) (5.0) (32.0) (64.0) (45.0) (0.3)

63 0.39 1.97 0.47 0.2 1.26 2.91 1.97 1.04 QA/8063/21

(10.0) (50.0) (12.0) (5.0) (32.0) (74.0) (50.0) (0.39)

80 0.47 2.48 0.75 0.2 1.61 3.86 2.48 2.14 QA/8080/21

(12.0) (63.0) (19.0) (5.0) (41.0) (98.0) (63.0) (0.8)

100 0.55 2.8 0.75 0.2 1.61 4.53 2.95 2.55 QA/8100/21

(14.0) (71.0) (19.0) (5.0) (41.0) (115.0) (75.0) (0.95)

Front or rear detachable trunnion FH

Conforms to VDMA 24562 part 2,

type MT 5/6

UW 1

TD e 9

H11

D

TM h14TL

Standard

Ø Ø Dh11 L1 R Ø TD

32 1.18 0.63 0.04 0.47 0.47 1.97 1.77 0.44 QA/8032/34

(30) (16) (1) (12) (12) (50) (45) (0.2)

40 1.38 0.79 0.06 0.63 0.63 2.48 2.17 0.84 QA/8040/34

(35) (20) (1.6) (16) (16) (63) (55) (0.4)

50 1.57 0.94 0.06 0.63 0.63 2.95 2.56 1.32 QA/8050/34

(40) (24) (1.6) (16) (16) (75) (65) (0.6)

63 1.77 0.94 0.06 0.79 0.79 3.54 2.95 2.42 QA/8063/34

(45) (24) (1.6) (20) (20) (90) (75) (1.1)

80 1.77 1.10 0.06 0.79 0.79 4.33 3.94 4.18 QA/8080/34

(45) (28) (1.6) (20) (20) (110) (100) (1.9)

100 2.17 1.50 0.08 0.98 0.98 5.20 4.72 7.70 QA/8100/34

(55) (38) (2) (25) (25) (132) (120) (3.5)

TL TM

e9

UW1 lb. (kg) Model (FH)

h14

ø AB

TR

E

R

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.09

Page 10

PRA/862000/M

LH

B2

CL

RK

Rear clevis D

Conforms to ISO 15552, type MP2

CB

UB

H 14

FL

L

Standard

H14

Ø CB

32 1.02 0.39 0.87 0.51 2.05 0.35 1.77 0.24 QA/8032/23

40 1.10 0.47 0.98 0.63 2.36 0.47 2.05 0.35 QA/8040/23

50 1.26 0.47 1.06 0.67 2.68 0.47 2.36 0.48 QA/8050/23

63 1.57 0.63 1.26 0.87 3.11 0.59 2.76 0.75 QA/8063/23

80 1.97 0.63 1.42 0.87 3.90 0.59 3.54 1.19 QA/8080/23

100 2.36 0.79 1.61 1.06 4.69 0.79 4.33 1.98 QA/8100/23

Corrosion protected mounts

32 1.02 0.39 0.87 0.51 2.05 0.35 1.77 0.24 PVQA/8032/23

40 1.10 0.47 0.98 0.63 2.36 0.47 2.05 0.35 PVQA/8032/23

50 1.26 0.47 1.06 0.67 2.68 0.47 2.36 0.48 PVQA/8050/23

63 1.57 0.63 1.26 0.87 3.11 0.59 2.76 0.75 PVQA/8063/23

80 1.97 0.63 1.42 0.87 3.90 0.59 3.54 1.19 PVQA/8080/23

100 2.36 0.79 1.61 1.06 4.69 0.79 4.33 1.98 PVQA/8100/23

Ø EK f8FL L LH MR UB lb. (kg) Model (D)

(26) (10) (22) (13) (52) (9) (45) (0.11)

(28) (12) (25) (16) (60) (12) (52) (0.16)

(32) (12) (27) (17) (68) (12) (60) (0.22)

(40) (16) (32) (22) (79) (15) (70) (0.34)

(50) (16) (36) (22) (99) (15) (90) (0.54)

(60) (20) (41) (27) (119) (20) (110) (0.9)

(26) (10) (22) (13) (52) (9) (45) (0.11)

(28) (12) (25) (16) (60) (12) (52) (0.16)

(32) (12) (27) (17) (68) (12) (60) (0.22)

(40) (16) (32) (22) (79) (15) (70) (0.34)

(50) (16) (36) (22) (99) (15) (90) (0.54)

(60) (20) (41) (27) (119) (20) (110) (0.9)

MR

Rear clevis D2

Conforms to ISO 15552, type AB6

H 14

B1

EK f 8

R2

FL

R1

B3

h 9

EK

Standard

H14

Ø B1

32 0.55 1.34 0.13 0.39 0.87 0.43 0.67 0.44 QA/8032/42

40 0.63 1.57 0.17 0.47 0.98 0.47 0.79 0.51 QA/8040/42

50 0.83 1.77 0.17 0.63 1.06 0.57 0.87 0.79 QA/8050/42

63 0.83 2.01 0.17 0.63 1.26 0.71 0.98 1.21 QA/8063/42

80 0.98 2.56 0.17 0.79 1.42 0.87 1.18 1.98 QA/8080/42

100 0.98 2.95 0.17 0.79 1.61 0.87 1.26 3.19 QA/8100/42

B2 B3 Ø EK h9FL R1 R2 lb. (kg) Model (D2)

(14) (34) (3.3) (10) (22) (11) (17) (0.2)

(16) (40) (4.3) (12) (25) (12) (20) (0.23)

(21) (45) (4.3) (16) (27) (14.5) (22) (0.36)

(21) (51) (4.3) (16) (32) (18) (25) (0.55)

(25) (65) (4.3) (20) (36) (22) (30) (0.9)

(25) (75) (4.3) (20) (41) (22) (32) (1.45)

Piston rod clevis F

Conforms to DIN ISO 8140

CE

LE

ER

KK

CL

CM

h11

ø CK

StandardStandard

Ø KK CE Ø CK

32 M10x1.25 1.57 0.39 0.79 0.39 0.63 0.79 1.10 0.20 QM/8025/25

(40) (10) (20) (10) (16) (20) (28) (0.09)

40 M12x1.25 1.89 0.47 0.94 0.47 0.75 0.94 1.26 0.29 QM/8040/25

(48) (12) (24) (12) (19) (24) (32) (0.13)

50/63 M16x1.5 2.52 0.63 1.26 0.63 0.98 1.26 1.63 0.73 QM/8050/25

(64) (16) (32) (16) (25) (32) (41.5) (0.33)

80/100 M20x1.5 3.15 0.79 1.57 0.79 1.26 1.57 1.97 1.47 QM/8080/25

(80) (20) (40) (20) (32) (40) (50) (0.67)

Corrosion protected mounts

32 M10x1.25 1.57 0.39 0.79 0.39 0.63 0.79 1.10 0.20 PVQM/8032/25

(40) (10) (20) (10) (16) (20) (28) (0.09)

40 M12x1.25 1.89 0.47 0.94 0.47 0.75 0.94 1.26 0.29 PVQM/8040/25

(48) (12) (24) (12) (19) (24) (32) (0.13)

50/63 M16x1.5 2.52 0.63 1.26 0.63 0.98 1.26 1.63 0.73 PVQM/8050/25

(64) (16) (32) (16) (25) (32) (41.5) (0.33)

80/100 M20x1.5 3.15 0.79 1.57 0.79 1.26 1.57 1.97 1.47 PVQM/8080/25

(80) (20) (40) (20) (32) (40) (50) (0.67)

CL CM ER LE RK lb. (kg) Model (F)

h11

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.010

Page 11

PRA/862000/M

FL

ø D 3

Rear eye R

Conforms to ISO 15552, type MP4

EW

L

Standard

Ø Ø CD H9EW FL L MR lb. (kg) Model (R)

32 0.39 1.02 0.87 0.51 0.35 0.20 QA/8032/27

(10) (25.8) (22) (13) (9) (0.09)

40 0.47 1.09 0.98 0.63 0.47 0.24 QA/8040/27

(12) (27.8) (25) (16) (12) (0.11)

50 0.47 1.25 1.06 0.67 0.47 0.37 QA/8050/27

(12) (31.7) (27) (17) (12) (0.17)

63 0.63 1.56 1.26 0.87 0.59 0.53 QA/8063/27

(16) (39.7) (32) (22) (15) (0.24)

80 0.63 1.96 1.42 0.87 0.59 0.81 QA/8080/27

(16) (49.7) (36) (22) (15) (0.37)

100 0.79 2.35 1.61 1.06 0.79 1.30 QA/8100/27

(20) (59.7) (41) (27) (20) (0.59)

Corrosion protected mounts

32 0.39 1.02 0.87 0.51 0.35 0.20 PVQA/8032/27

(10) (25.8) (22) (13) (9) (0.09)

40 0.47 1.09 0.98 0.63 0.47 0.24 PVQA/8040/27

(12) (27.8) (25) (16) (12) (0.11)

50 0.47 1.25 1.06 0.67 0.47 0.37 PVQA/8050/27

(12) (31.7) (27) (17) (12) (0.17)

63 0.63 1.56 1.26 0.87 0.59 0.53 PVQA/8063/27

(16) (39.7) (32) (22) (15) (0.24)

80 0.63 1.96 1.42 0.87 0.59 0.81 PVQA/8080/27

(16) (49.7) (36) (22) (15) (0.37)

100 0.79 2.35 1.61 1.06 0.79 1.30 PVQA/8100/27

(20) (59.7) (41) (27) (20) (0.59)

MR

H 9

CD

Trunnion support S

Conforms to ISO 15552, type AT4

H7

B 1

ø D 2

A

T 1H 2

ø D 1

H 1

F x 45°

C

B 2

Standard

Ø A B1 B2 C Ø

32 1.26 1.81 0.71 0.41 0.47 0.26 0.43 0.04 1.18 0.59 0.27 0.22 QA/8032/41

(32) (46) (18) (10.5) (12) (6.6) (11) (1) (30) (15) (6.8) (0.1)

40/50 1.42 2.17 0.83 0.47 0.63 0.35 0.59 0.06 1.42 0.71 0.35 0.31 QA/8040/41

(36) (55) (21) (12) (16) (9) (15) (1.6) (36) (18) (9) (0.14)

63/80 1.65 2.56 0.91 0.51 0.79 0.43 0.71 0.06 1.57 0.79 0.43 0.40 QA/8063/41

(42) (65) (23) (13) (20) (11) (18) (1.6) (40) (20) (11) (0.18)

100 1.97 2.95 1.12 0.63 0.98 0.55 0.79 0.08 1.97 0.98 0.51 0.75 QA/8100/41

(50) (75) (28.5) (16) (25) (14) (20) (2) (50) (25) (13) (0.34)

D1

H7

ØD1Ø D3F x

45°

H1 H2 T1 lb.

(kg)

Model (S)

Universal piston rod eye UF

Conforms to DIN ISO 8139

CE

ER

H 7

CN

LE AX

KK

EN -0,1

Z

Z

Standard

Ø Thread KKAX CE Ø

32 M10x1.25 0.79 1.69 0.39 0.55 0.55 0.59 0.20 QM/8025/32

(20) (43) (10) (14) (14) (15) 13° (0.09)

40 M12x1.25 0.87 1.97 0.47 0.63 0.63 0.67 0.29 QM/8040/32

(22) (50) (12) (16) (16) (17) 13° (0.13)

50/63 M16x1.5 1.10 2.52 0.63 0.83 0.83 0.87 0.73 QM/8050/32

(28) (64) (16) (21) (21) (22) 15° (0.33)

80/100 M20x1.5 1.30 3.03 0.79 0.98 0.98 1.02 1.47 QM/8080/32

(33) (77) (20) (25) (25) (26) 15° (0.67)

Corrosion protected mounts

32 M10x1.25 0.79 1.69 0.39 0.55 0.55 0.59 0.20 PVQM/8025/32

(20) (43) (10) (14) (14) (15) 13° (0.09)

40 M12x1.25 0.87 1.97 0.47 0.63 0.63 0.67 0.29 PVQM/8040/32

(22) (50) (12) (16) (16) (17) 13° (0.13)

50/63 M16x1.5 1.10 2.52 0.63 0.83 0.83 0.87 0.73 PVQM/8050/32

(28) (64) (16) (21) (21) (22) 15° (0.33)

80/100 M27x2 2.01 4.33 1.18 1.46 1.38 1.42 2.97 PVQM/8080/32

(51) (110) (30) (37) (35) (36) 15° (1.35)

CN

EN

ER LE Z lb. (kg) Model (UF)

H7

-0,1

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.011

Page 12

PRA/862000/M

EM

L 1

G 1

EN

FL

Wide hinge SW

Conforms to ISO 15552, type AB7

H 9

ø CK

ø D

ø S

K 1

K 2

R

CA

H 2

G 2

G 3

Standard

Ø CA Ø

CK

32 1.26 0.39 0.43 0.28 1.00 0.83 0.71 1.22 1.50 1.97 0.06 0.39 0.26 0.11 M/P19493

(32) (10) (11) (7) (25.5) (21) (18) (31) (38) (50) (1.6) (10) (6.6) (0.05)

40 1.42 0.47 0.43 0.35 1.08 0.94 0.87 1.38 1.61 2.13 0.06 0.43 0.26 0.15 M/P19494

(36) (12) (11) (9) (27.5) (24) (22) (35) (41) (54) (1.6) (11) (6.6) (0.07)

50 1.77 0.47 0.59 0.43 1.24 1.30 1.18 1.77 1.97 2.56 0.06 0.51 0.35 0.31 M/P19495

(45) (12) (15) (11) (31.5) (33) (30) (45) (50) (65) (1.6) (13) (9) (0.14)

63 1.97 0.63 0.59 0.47 1.56 1.46 1.38 1.97 2.05 2.64 0.06 0.59 0.35 0.40 M/P19496

(50) (16) (15) (12) (39.5) (37) (35) (50) (52) (67) (1.6) (15) (9) (0.18)

80 2.48 0.63 0.71 0.55 1.95 1.85 1.57 2.36 2.60 3.31 0.10 0.59 0.43 0.62 M/P19497

(63) (16) (18) (14) (49.5) (47) (40) (60) (66) (84) (2.5) (15) (11) (0.28)

100 2.80 0.79 0.71 0.59 2.34 2.17 1.97 2.76 2.99 3.70 0.10 0.75 0.43 0.92 M/P19498

(71) (20) (18) (15) (59.5) (55) (50) (70) (76) (94) (2.5) (19) (11) (0.42)

Corrosion protected mounts

32 1.26 0.39 0.43 0.31 1.04 0.83 0.71 1.22 1.50 2.01 0.06 0.39 0.26 0.11 M/P40459

(32) (10) (11) (8) (26.5) (21) (18) (31) (38) (51) (1.6) (10) (6.6) (0.05)

40 1.42 0.47 0.43 0.39 1.12 0.94 0.87 1.38 1.61 2.13 0.06 0.43 0.26 0.15 M/P40460

(36) (12) (11) (10) (28.5) (24) (22) (35) (41) (54) (1.6) (11) (6.6) (0.07)

50 1.77 0.47 0.59 0.47 1.28 1.30 1.18 1.77 1.97 2.56 0.06 0.51 0.35 0.31 M/P40461

(45) (12) (15) (12) (32.5) (33) (30) (45) (50) (65) (1.6) (13) (9) (0.14)

63 1.97 0.63 0.59 0.47 1.59 1.46 1.38 1.97 2.05 2.64 0.06 0.59 0.35 0.40 M/P40462

(50) (16) (15) (12) (40.5) (37) (35) (50) (52) (67) (1.6) (15) (9) (0.18)

80 2.48 0.63 0.71 0.55 1.99 1.85 1.57 2.36 2.60 3.39 0.10 0.59 0.43 0.62 M/P40463

(63) (16) (18) (14) (50.5) (47) (40) (60) (66) (86) (2.5) (15) (11) (0.28)

100 2.80 0.79 0.71 0.59 2.38 2.17 1.97 2.76 2.99 3.78 0.10 0.75 0.43 0.92 M/P40464

(71) (20) (18) (15) (60.5) (55) (50) (70) (76) (96) (2.5) (19) (11) (0.42)

H2 EM G1 G2 G3 K1 K2 L1 R Ø Slb.

H9

Ø D

(kg)

Model

(SW)

Universal rear eye UR

Conforms to ISO 15552, type MP6

Z

Z

R

Standard

Ø Ø CN H7EN ER FL R Z lb. (kg) Model (UR)

32 0.39 0.55 0.63 0.87 0.57 0.33 QA/8032/33

(10) (14) (16) (22) (14.5) 13° (0.15)

40 0.47 0.63 0.71 0.98 0.71 0.55 QA/8040/33

(12) (16) (18) (25) (18) 13° (0.25)

50 0.63 0.83 0.83 1.06 0.75 0.88 QA/8050/33

(16) (21) (21) (27) (19) 15° (0.4)

63 0.63 0.83 0.91 1.26 0.94 1.21 QA/8063/33

(16) (21) (23) (32) (24) 15° (0.55)

80 0.79 0.98 1.10 1.42 0.94 1.98 QA/8080/33

(20) (25) (28) (36) (24) 15° (0.9)

100 0.79 0.98 1.18 1.61 1.14 3.30 QA/8100/33

(20) (25) (30) (41) (29) 15° (1.5)

Corrosion protected mounts

32 0.39 0.55 0.63 0.87 0.57 0.33 PVQA/8032/33

(10) (14) (16) (22) (14.5) 13° (0.15)

40 0.47 0.63 0.75 0.98 0.71 0.55 PVQA/8040/33

(12) (16) (19) (25) (18) 13° (0.25)

50 0.63 0.83 0.83 1.06 0.75 0.88 PVQA/8050/33

(16) (21) (21) (27) (19) 13° (0.4)

63 0.63 0.83 0.94 1.26 0.94 1.21 PVQA/8063/33

(16) (21) (24) (32) (24) 15° (0.55)

80 0.79 0.98 1.10 1.42 0.94 1.98 PVQA/8080/33

(20) (25) (28) (36) (24) 15° (0.9)

100 0.79 0.98 1.18 1.61 1.14 3.30 PVQA/8100/33

(20) (25) (30) (41) (29) 15° (1.5)

H 7

CN

ER

4/13

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.012

Page 13

Narrow hinge SS

L 1

EN

PRA/862000/M

EM

G 7

ø CN

ø D

L 1

ø S

K 1

K 2

R

CA

H 2

G 1

G 2

G 3

Standard

Ø CA Ø

32 1.26 0.39 0.43 0.31 0.39 0.83 0.71 1.22 1.50 2.01 0.06 0.39 0.26 0.33 M/P19931

(32) (10) (11) (8) (10) (21) (18) (31) (38) (51) (1.6) (10) (6.6) (0.15)

40 1.42 0.47 0.43 0.39 0.47 0.94 0.87 1.38 1.61 2.13 0.06 0.43 0.26 0.44 M/P19932

(36) (12) (11) (10) (12) (24) (22) (35) (41) (54) (1.6) (11) (6.6) (0.2)

50 1.77 0.63 0.59 0.47 0.63 1.30 1.18 1.77 1.97 2.56 0.06 0.51 0.35 1.06 M/P19933

(45) (16) (15) (12) (16) (33) (30) (45) (50) (65) (1.6) (13) (9) (0.48)

63 1.97 0.63 0.59 0.47 0.63 1.46 1.38 1.97 2.05 2.64 0.06 0.59 0.35 1.10 M/P19934

(50) (16) (15) (12) (16) (37) (35) (50) (52) (67) (1.6) (15) (9) (0.5)

80 2.48 0.79 0.71 0.55 0.79 1.85 1.57 2.36 2.60 3.39 0.10 0.59 0.43 1.65 M/P19935

(63) (20) (18) (14) (20) (47) (40) (60) (66) (86) (2.5) (15) (11) (0.75)

100 2.80 0.79 0.71 0.59 0.79 2.17 1.97 2.76 2.99 3.78 0.10 0.75 0.43 2.64 M/P19936

(71) (20) (18) (15) (20) (55) (50) (70) (76) (96) (2.5) (19) (11) (1.2)

Ø DH2 EM G1 G2 G3 K1 K2 L1 R ØSlb.

G7

CN

(kg)

Model

(SS)

Swivel hinge US

Conforms to VDMA 24562 part 2

-0,1

G 1

G 2

G 3

ø D

H 7

ø CN

EU

ER

Z

Z

CH

H 2

ø S

K 1

K 2

Standard

Ø CH Ø

32 1.26 0.39 0.43 0.55 0.63 0.41 0.83 0.71 1.22 0.39 1.50 2.01 0.06 0.26 0.42 M/P40310

(32) (10) (11) (14) (16) (10.5) (21) (18) (31) (10) (38) (51) (1.6) (6.6) 13° (0.19)

40 1.42 0.47 0.43 0.63 0.71 0.47 0.94 0.87 1.38 0.39 1.61 2.13 0.06 0.26 0.53 M/P40311

(36) (12) (11) (16) (18) (12) (24) (22) (35) (10) (41) (54) (1.6) (6.6) 13° (0.24)

50 1.77 0.63 0.59 0.83 0.83 0.59 1.30 1.18 1.77 0.47 1.97 2.56 0.06 0.35 1.01 M/P40312

(45) (16) (15) (21) (21) (15) (33) (30) (45) (12) (50) (65) (1.6) (9) 13° (0.46)

63 1.97 0.63 0.59 0.83 0.91 0.59 1.46 1.38 1.97 0.47 2.05 2.64 0.06 0.35 1.30 M/P40313

(50) (16) (15) (21) (23) (15) (37) (35) (50) (12) (52) (67) (1.6) (9) 15° (0.59)

80 2.48 0.79 0.71 0.98 1.10 0.71 1.85 1.57 2.36 0.55 2.60 3.39 0.10 0.43 2.27 M/P40314

(63) (20) (18) (25) (28) (18) (47) (40) (60) (14) (66) (86) (2.5) (11) 15° (1.03)

100 2.80 0.79 0.71 0.98 1.18 0.71 2.17 1.97 2.76 0.59 2.99 3.78 0.10 0.43 3.08 M/P40315

(71) (20) (18) (25) (30) (18) (55) (50) (70) (15) (76) (96) (2.5) (11) 15° (1.4)

4/13

CN

H7

ØDEN

-0,1

ER EU G1 G2 G3 H2 K1 K2 L1 Ø SZ lb. (kg) Model (US)

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

© Norgren, Inc. 2013

N/us 1.5.250.013

Page 14

PRA/862000/M

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under »Technical features«.

Before using these products with fluids other than those specified,

for non-industrial applications, life-support systems, or other applications not within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in

fluid power systems can fail in various modes.

Our policy is one of continued research and development. We therefore reserve the right to amend,

4/13

without notice, the specifications given in this document.

see engineering advantage

Scan with a QR code read er – w ww.nor gren.com /us/iv ac

The system designer is warned to consider the failure modes

of all component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end users in

the system instructional manual if protection against

a failure mode cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with

these products.

© Norgren, Inc. 2013

N/us 1.5.250.014

Loading...

Loading...