Page 1

05/05

N/UK 8.240.630.01

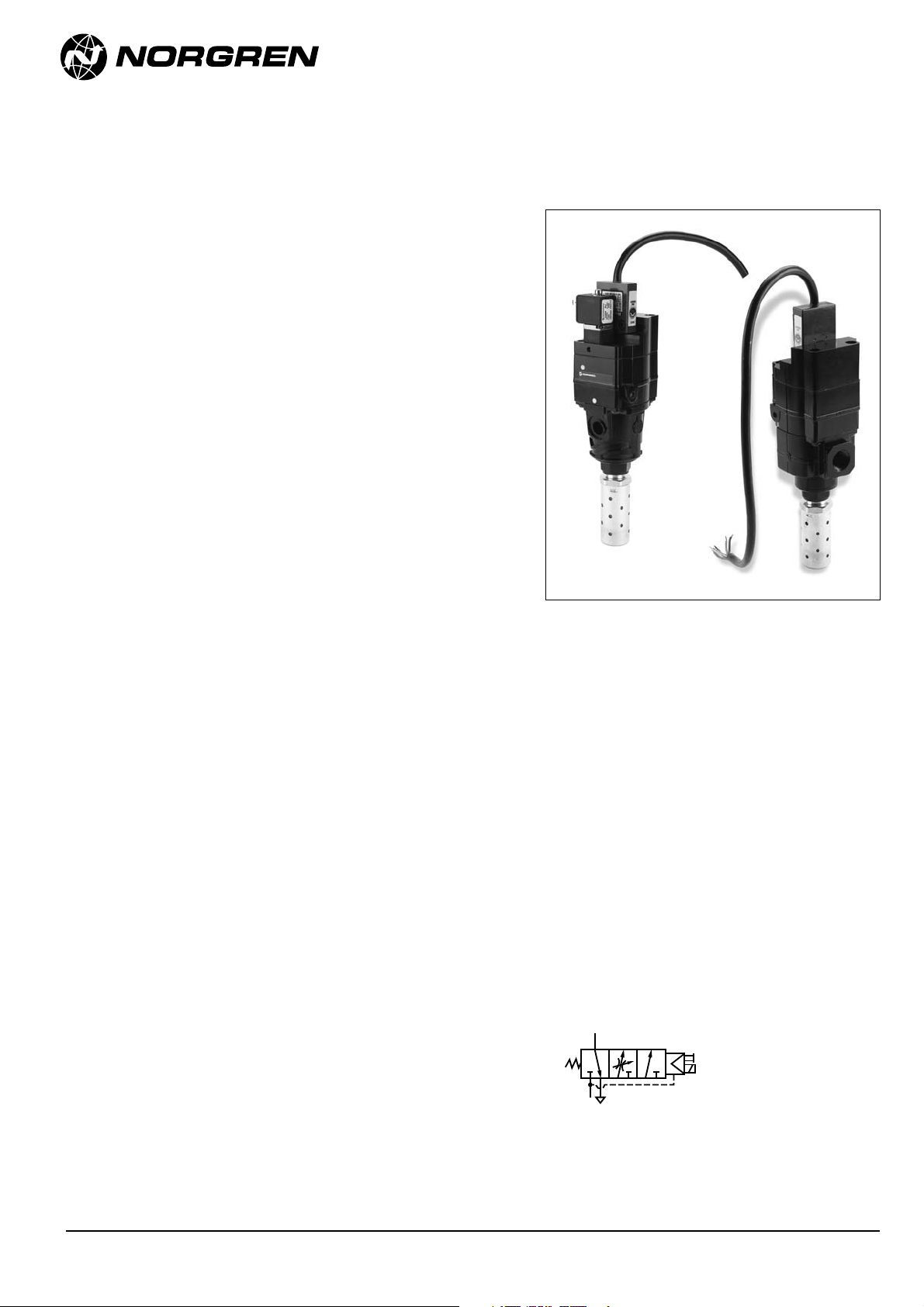

P64S, P74S

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

Olympian Plus and Excelon

Soft Start Monitored Dump Valve

Olympian Plus plug in design or

EXCELON inline / modular installation

Controlled increase of downstream

pressure on start up

Monitored dump function

High forward flow capacity

High flow dump facility

Materials:

Body: zinc alloy

Intermediate body: aluminium

Elastomers: synthetic materials

Filter discs: sintered plastic

Internal components: brass / steel /

stainless steel

Top plate: aluminium

Exhaust Bonnet: zinc alloy

Yoke (P64S only): zinc alloy

Ordering Information

See

Ordering Information

on the following

pages.

ISO Symbol

Solenoid operated

Technical Data

Fluid: Compressed air

Maximum Pressure: 16 bar (240 psig)

Minimum Operating Pressure: 3 bar (45 psig)

Operating Temperature: -20°C to 50°C

(Solenoid rating max is 50°C whilst unit max is 80°C. Consult our technical service

below +2°C)

Gauge Ports: Rc1/8

Exhaust Ports: ISO G1/2 with ISO G and Rc main ports,

1/2“ PTF with PTF main ports

Typical flow with 6,3 bar (90psig) inlet pressure and

outlet pressure drop of 0,5 var (7 psig)

57dm

3

/s (120 scfm) (P1 to P2 = Cv 4.2) (P2 to P3 Cv = 5.6)

Snap pressure: Full flow when downstream pressure reaches

35% - 60% of inlet pressure

Charge time: For 2 litre downstream volume and inlet pressure of

6,3 bar (90 psig), 0,2s minimum, 75 secs. maximum

Solenoid operator

22 mm, 24V DC, 2W only (no manual overide)

Soft start valves allow a controlled increase of

pressure onto downstream cylinders / machines

offering protection to personnel equipment.

The positively driven micro switch ensures a

monitored dump function.

Note: Turn on system air supply prior to applying

signal to operator. Failure to do so may cause valve to

continuously exhaust.

Page 2

N/UK 8.240.630.02

05/05

P64S, P74S

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

Type Substitute

Olympian Plus 6

Excelon 7

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

3/4" 6

No Yoke (P64S only) N

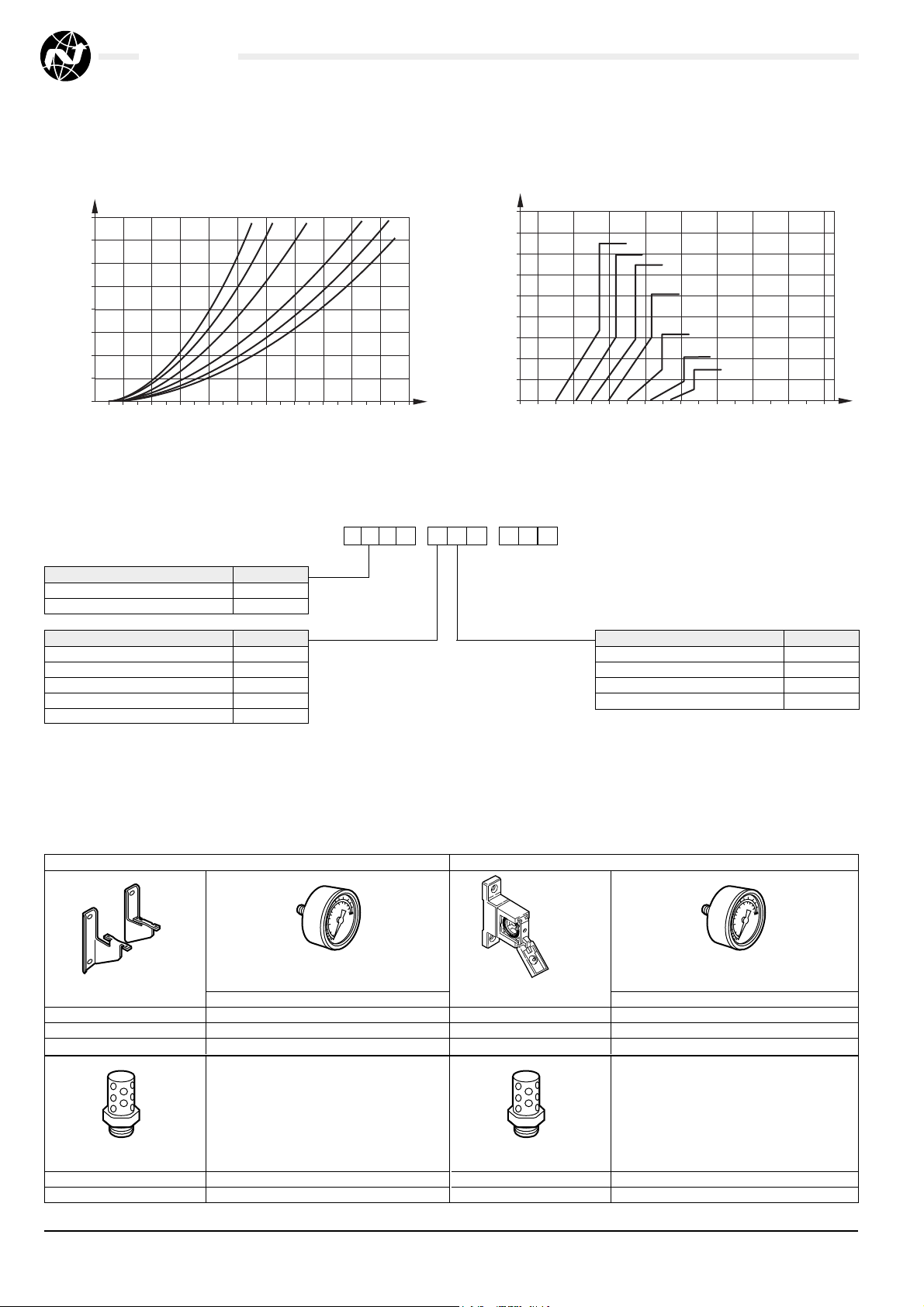

Typical Performance Characteristics

P4-S

-

1C N N

** to order air pilot models also substitute ‘NNN’

at digits 8, 9 and 10 e.g. P64F-2GA-NNN.

Thread Type Substitute

PTF A

ISO Rc Parallel B

ISO G Parallel G

No Yoke (P64S only) N

Accessories

Ordering Information

P74S

Wall Mounting

Ø 50 mm Pressure Gauge

Bracket Kit R1/8 1/8″ PTF

4314-52 4 bar (60 psig): 18-013-012 18-013-202

10 bar (150 psig): 18-013-013 18-013-204

25 bar (360 psig): 18-013-014 18-013-206

Silencer

MB004B (R1/2)

MB004A

P64S

Wall Mounting

Ø 50 mm Pressure Gauge

Bracket Kit R1/8 1/8″ PTF

74504-50 4 bar (60 psig): 18-013-012 18-013-202

10 bar (150 psig): 18-013-013 18-013-204

25 bar (360 psig): 18-013-014 18-013-206

Silencer

MB004B (R1/2)

MB004A

PRESSURE DROP (bar g)

OUTLET PRESSURE (bar g)

MAXIMUM CHARGE TIME

FLOW CHARACTERISTICS

AIR FLOW (dm3/s)

CHARGE TIME (s)

INLET PRESSURE (bar g)

(bar) (bar)

0,8

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

0

10 20 30 40 50 60 70 80 90 100

2 4 6,3 10 12

(bar)

18

14

3

/s)

(dm

16

14

12

10

8

6

4

2

0

0 5 10 15 20 25 30 35 40

(s)

Page 3

06/05

P64S, P74S

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

N/AL.8.1.PXS.03

Dimensions mm (inches)

P74S

76,5

201,5

G 1/2

73

12

168,5

30

84

204

170,5 G 1/2

73

2

30

1

Page 4

N/AL.8.1.PXS.04 06/05

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under ‘Technical Data’.

Before using these products with fluids other than those specified, for

non-industrial applications, life-support systems, or other applications not

within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in fluid

power systems can fail in various modes. The system designer is warned

to consider the failure modes of all component parts used in fluid power

systems and to provide adequate safeguards to prevent personal injury or

damage to equipment in the event of such failure.

System designers must provide a warning to end users in the

system instructional manual if protection against a failure mode

cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with these

products.

Water vapor will pass through these units and will condense into

liquid if air temperature drops in the downstream system. Install an air

dryer if water condensation could have a detrimental effect on the

application.

P64S, P74S

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

Pilz relay

To assist in compliance with the Machinery Directive 89/392/EEC a Pilz

circuit should be used. This requires 2 units.

Switch Details

All electrical connections to be made by a competent licensed electrician

Break - before – Make contact

1 Normally Open / 1 Normally Closed

blue

black

E-stop

StartPliz relay

brown

green/yellow

Soft Start

Monitored dump valves

black

blue

Zb

black black

O.P. 1

O.P. 2

brown

green/yellow

24V

E-stop

24V

2

2

3 213 2

0V

P P

1

1

2

2

2

31

3

Soft Start

Monitored dump valves

V1 V2

3

1

3

212 10

1

212 10

StartPilz relay

0V

V1

V2 V3 V3

Loading...

Loading...