Page 1

NEN Series NFPA Aluminum Cylinders

1-1/2" to 4" bore sizes

Competitively priced

Magnetic piston standard

Adjustable cushion standard

Sleeve nut construction standard

Stocked strokes

Technical data

Medium:

Filtered compressed air

Operating temperature:

-25°F to 140°F (-5°C to 60°C)

with Viton Seals -23˚F to 300˚F

(-5°C to 150°C)

Operating Pressure:

Minimum 7 psi (.5 bar)

Maximum 140 psi (9.7 bar)

Bore Sizes: 1-1/2", 2", 2-1/2",

3-1/4", 4"

Rod Diameter: 5/8" diameter

piston rod in 1-1/2", 2", 2-1/2"

bore

1" diameter piston rod in 3-1/4"

and 4" bore

Lubrication: None required

Norgren Air Cylinders are rated for

“no lube added” service.

Materials

Head and End Caps:

Die cast aluminum painted for

corrosion protection

Tube: Aluminum alloy, hard coat

anodized

Piston: machined high-strength

aluminum casting.

Rod Bearing: clean metal teflon

composite

Seals: nitrile rod seal/wiper, nitrile

piston seals, nitrile tube end seals

Tie Rods: Nickel plated high-tensile

strength steel, nickel plated

Piston Rod: Hard chrome plated carbon steel,

1

ground and polished.

Head Bearing Housing and cap: Die cast

2

aluminum

Tie-Rods: Nickel plated steel

3

Piston: Machined aluminum .

4

Captive Cushion Needle Adjustment: Provides

5

safe and precise cushion adjustment.

Wear Ring: Teflon® material provides supreme

6

wear and excellent bearing support.

7

Cylinder Tube: Hard anodized aluminum alloy,

with corrosion and score resistant surface finish.

2

11

1

8

10

Piston Rod Wiper/Seal: Abrasion resistant nitrile.

8

Piston Seal: Single Nitrile bi-directional piston

9

seal.

10

Cushion Seal: Nitrile cushion seal is captured

within a precision machined groove allowing for

linear and radial float eliminating misalignment.

Rod Bearing: A composite of Teflon and

11

polyphenylene sulfide and bronze molded to a

steel backing provides low friction and excellent

linear features.

4

3

7

2

6

9

5

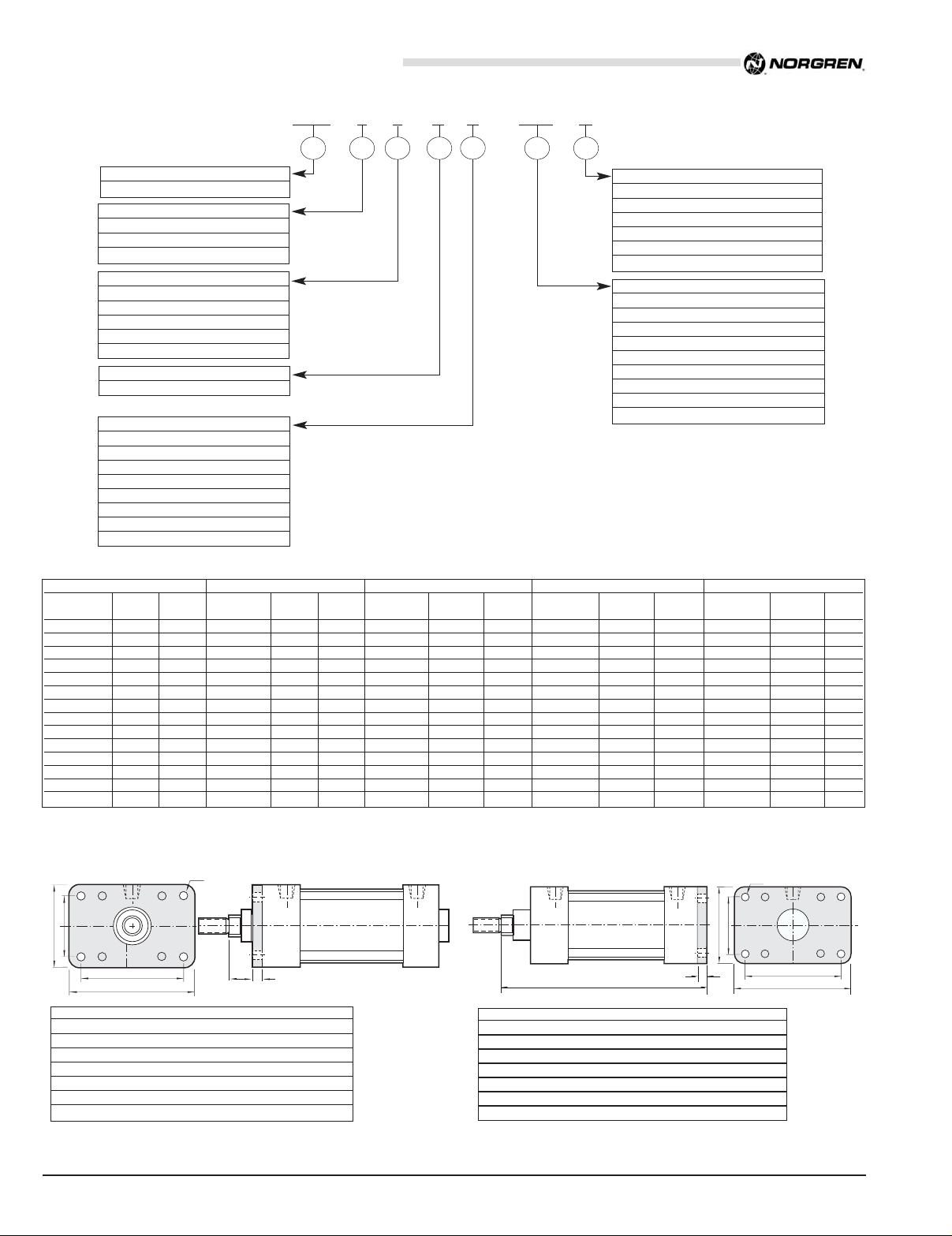

NEN “Add-a-mount” flexibility

NEN cylinders allow you to add NFPA mounts shown below when you order the cylinder from the factory, or add the mounts later.

NFPA MF1

N/US 1.5.507.1

NFPA MF2

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

NFPA MP1

www.norgren.com

NFPA MP2

1/08

Page 2

NEN Series NFPA Aluminum Cylinders

F

RE

TF

FB Holes (4)

ZF + Stroke

UF

All Dimensions in Inches (mm)

Cylinder Order Information

NEN 1 C x 4 E – –MP1 V

1 2 3 4

Series

NEN

Piston Rod Threads

Small Male (Solid) (std) 1

Intermediate Thread Male (Solid) 2

Female 3

Bore Single rod

1-1/2" C

2.0" D

2-1/2" E

3-1/4" F

4.0" G

Stroke (whole inches)

All bores 48" max.*

* Conatact factory for strokes longer than 48".

Fraction of Stroke length

0 Blank

0.125" C

0.250 E

0.375 G

0.500 J

0.625 M

0.750 P

0.875 S

5

6 7

Additional Options

Viton® Seals V

Rod Extension RX

Non-standard piston rod thread T

Piston Rod thread extension TX

Stainless steel piston rod S

Stainless steel tie rods SS

Mounting Options**

MS4 (standard) blank

Head Rectangular Flange MF1

Cap Rectangular Flange MF2

Detachable Cap Clevis MP2

Cap Fixed Clevis MP1

Tie Rod Extended both ends MX1

Tie Rod Extended Cap MX2

Tie Rod Extended Head MX3

Side Lug Mount MS2

** For factory installed mounts specify mounting option in

position 6. If no mount required leave position 6 blank.

Mounting kits can be ordered separately

Contact factory for mounting kits, or visit www.norgren.com

Stock Stroke Cylinders

Model Cylinder Stroke Model Cylinder Stroke Model Cylinder Stroke Model Cylinder Stroke Model Cylinder Stroke

Number Bore Number Bore Number Bore Number Bore Number Bore

NEN1C x 1 1-1/2 1.00 NEN1D x 1 2 1.00 NEN1E x 1 2-1/2 1.00 NEN1F x 1 3-1/4 1.00 NEN1G x 1 4 1.00

NEN1C x 2 1-1/2 2.00 NEN1D x 2 2 2.00 NEN1E x 2 2 1/2 2.00 NEN1F x 2 3-1/4 2.00 NEN1G x 2 4 2.00

NEN1C x 3 1-1/2 3.00 NEN1D x 3 2 3.00 NEN1E x 3 2 1/2 3.00 NEN1F x 3 3-1/4 3.00 NEN1G x 3 4 3.00

NEN1C x 4 1-1/2 4.00 NEN1D x 4 2 4.00 NEN1E x 4 2 1/2 4.00 NEN1F x 4 3-1/4 4.00 NEN1G x 4 4 4.00

NEN1C x 5 1-1/2 5.00 NEN1D x 5 2 5.00 NEN1E x 5 2 1/2 5.00 NEN1F x 5 3-1/4 5.00 NEN1G x 5 4 5.00

NEN1C x 6 1-1/2 6.00 NEN1D x 6 2 6.00 NEN1E x 6 2 1/2 6.00 NEN1F x 6 3-1/4 6.00 NEN1G x 6 4 6.00

NEN1C x 8 1-1/2 8.00 NEN1D x 8 2 8.00 NEN1E x 8 2 1/2 8.00 NEN1F x 8 3-1/4 8.00 NEN1G x 8 4 8.00

NEN1C x 10 1-1/2 10.00 NEN1D x 10 2 10.00 NEN1E x 10 2 1/2 10.00 NEN1F x 10 3-1/4 10.00 NEN1G x 10 4 10.00

NEN1C x 12 1-1/2 12.00 NEN1D x 12 2 12.00 NEN1E x 12 2 1/2 12.00 NEN1F x 12 3-1/4 12.00 NEN1G x 12 4 12.00

NEN1C x 14 1-1/2 14.00 NEN1D x 14 2 14.00 NEN1E x 14 2 1/2 14.00 NEN1F x 14 3-1/4 14.00 NEN1G x 14 4 14.00

NEN1C x 16 1-1/2 16.00 NEN1D x 16 2 16.00 NEN1E x 16 2 1/2 16.00 NEN1F x 16 3-1/4 16.00 NEN1G x 16 4 16.00

NEN1C x 18 1-1/2 18.00 NEN1D x 18 2 18.00 NEN1E x 18 2 1/2 18.00 NEN1F x 18 3-1/4 18.00 NEN1G x 18 4 18.00

NEN1C x 20 1-1/2 20.00 NEN1D x 20 2 20.00 NEN1E x 20 2 1/2 20.00 NEN1F x 20 3-1/4 20.00 NEN1G x 20 4 20.00

N/A - 24.00 NEN1D x 24 2 24.00 NEN1E x 24 2 1/2 24.00 NEN1F x 24 3-1/4 24.00 NEN1G x 24 4 24.00

1-1/2" Bore 2.0" Bore 2-1/2" Bore 3-1/4" Bore 4.0" Bore

NFPA (MF1) 03 Head Rectangular Flange Mount

FB Holes (4)

RE

F

TF

UF

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

E 2.000 2.500 3.000 3.750 4.500

F .375 .375 .375 .625 .625

FB .313 .375 .375 .438 .438

R 1.428 1.838 2.192 2.758 3.323

TF 2.750 3.375 3.875 4.688 5.438

UF 3.375 4.125 4.625 5.500 6.250

W .625 .625 .625 .750 .750

All dimensions ± .015 unless otherwise noted.

N/US 1.5.507.2

W

We reserve the right to amend, without notice, the specifications given in this document.

NFPA (MF2) 04 Cap Rectangular Flange Mount

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

E 2.000 2.500 3.000 3.750 4.500

F .375 .375 .375 .625 .625

FB .313 .375 .375 .438 .438

R 1.428 1.838 2.192 2.758 3.323

TF 2.750 3.375 3.875 4.687 5.438

UF 3.375 4.125 4.625 5.500 6.250

ZF 5.000 5.000 5.125 6.250 6.250

All dimensions ± .015 unless otherwise noted.

Our policy is one of continuous research and development.

www.norgren.com

1/08

Page 3

DD Thds.

4 Places

Both Ends

KK

Thds

NT Tap

ND Depth

XT

SN + Stroke

A

C

VF

LB + Stroke

J

P + StrokeY

øB Bushing

øMM

WF

G

EE NPT (2)

TN

D

(Flats)

R

E Sq.

ZJ + Stroke

AA

NFPA (MS4) Side tap mount standard

NEN Series NFPA Aluminum Cylinders

All Dimensions in Inches (mm)

1/08

øB

KK

Thds.

A Deep

Type 3 Female

C

V

(Optional)

F

øMM

D

Across

Flats

KK

Thds.

ø B

F

øMM

A

C

V

Type 1 Solid

(Small Male)

øB

CC

Thds.

A

C

Type 2 Solid

(Intermediate Thread

Male Optional)

F

øMM

V

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

ø Rod 5/8" 5/8" 5/8" 1" 1"

A 0.750 0.750 (19.05) 0.750 (19.05) 1.125 (28.58) 1.125 (28.58)

AA 2.020 2.600 (66.04) 3.100 (78.74) 3.900 (99.06) 4.700 (119.38)

B 1.124 1.124 (28.55) 1.124 (28.55) 1.500 (38.07) 1.499 (38.07)

BA 1.125 (28.58) 1.125 (28.58) 1.125 (28.58) 1.250 (28.58) 1.250 (28.58)

C 0.375 (9.53) 0.375 (9.53) 0.375 (9.53) 0.500 (12.70) 0.500 (12.70)

CC 1/2-20 1/2-20 1/2-20 7/8-14 7/8-14

D 0.562 (14.27) 0.562 (14.27) 0.562 (14.27) 0.875 (22.23) 0.875 (22.23)

DD 1/4-28 5/16-24 5/16-24 3/8-24 3/8-24

E 2.000 (50.80) 2.500 (63.50) 3.000 (76.20) 3.750 (95.25) 4.500 (114.30)

EE 3/8 3/8 3/8 1/2 1/2

G 1.260 (32.00) 1.260 (32.00) 1.300 (33.02) 1.570 (39.88) 1.570 (39.88)

J 1.010 (25.65) 1.060 (26.92) 1.060 (26.92) 1.180 (29.97) 1.180 (29.97)

KK 7/16-20 7/16-20 7/16-20 3/4-16 3/4-16

LB 3.625 (92.08) 3.625 (92.08) 3.750 (95.25) 4.250 (107.95) 4.250 (107.95)

MM 0.625 (15.88) 0.625 (15.88) 0.625 (15.88) 1.000 (25.40) 1.000 (25.40)

NT 1/4-20 5/16-18 3/8-16 1/2-13 1/2-13

ND 0.281 (7.14) 0.438 (11.13) 0.593 (15.06) 0.625 (15.88) 0.625 (15.88)

P 2.360 (59.94) 2.400 (60.96) 2.480 (62.99) 2.720 (69.09) 2.720 (69.09)

R 1.430 (36.32) 1.840 (46.74) 2.190 (55.63) 2.760 (70.10) 3.320 (84.33)

SN 2.250 (57.15) 2.250 (57.15) 2.375 (60.33) 2.625 (66.68) 2.625 (66.68)

TN 0.625 (15.88) 0.875 (22.23) 1.250 (31.75) 1.500 (38.10) 2.063 (52.40)

VF 0.625 (15.88) 0.625 (15.88) 0.625 (15.88) 0.875 (22.23) 0.875 (22.23)

WF 1.000 (25.40) 1.000 (25.40) 1.000 (25.40) 1.375 (34.93) 1.375 (34.93)

XT 1.938 (49.23) 1.938 (49.23) 1.938 (49.23) 2.438 (61.93) 2.438 (61.93)

Y 1.710 (43.43) 1.710 (43.43) 1.750 (44.45) 2.340 (59.44) 2.340 (59.44)

ZJ 4.750 (120.65) 4.750 (120.65) 4.870 (123.95) 5.820 (147.83) 5.820 (147.83)

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

www.norgren.com

N/US 1.5.507.3

Page 4

NEN Series NFPA Aluminum Cylinders

LB + Stroke

L

øCD

MR

CB

CW CW

Supplied with

Standard Pin

XC + Stroke

LR

XD + Stroke

L

øCD

MR

LR

CB

CW CW

Supplied with

Standard Pin

FL M

All Dimensions in Inches (mm)

MP1 Mount

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

CB 0.750 0.750 0.750 1.250 1.250

CD 0.500 0.500 0.500 0.750 0.750

CW 0.500 0.500 0.500 0.625 0.625

L 0.750 0.750 0.750 1.250 1.250

LB 3.625 3.625 3.750 4.250 4.250

LR 0.625 0.625 0.625 0.875 0.875

MR 0.625 0.625 0.625 0.875 0.875

XC 5.375 5.375 5.500 6.875 6.875

MP2 Mount

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

CB 0.750 0.750 0.750 1.250 1.250

CD 0.500 0.500 0.500 0.750 0.750

CW 0.500 0.500 0.500 0.625 0.625

FL 1.125 1.125 1.125 1.875 1.875

L 0.750 0.750 0.750 1.250 1.250

LR 0.750 0.750 0.750 1.250 1.250

M 0.500 0.500 0.500 0.875 0.750

MR 0.625 0.625 0.625 0.875 0.875

XD 5.750 5.750 5.875 7.500 7.500

NFPA (MX1) (4) Extended Tie Rods Both Ends Mount

NFPA (MX2) Cap Tie Rods Extended Mount

NFPA (MX3) Head Tie Rods Extended Mount

DD threads

R

C

VF

BB BB

ZB + Stroke

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

AA 2.020 2.600 3.100 3.900 4.700

BB 1.000 1.125 1.125 1.375 1.375

C 0.375 0.375 0.375 0.500 0.500

DD 1/4 – 28 5/16 – 24 5/16 – 24 3/8 – 24 3/8 – 24

K 0.250 0.313 0.313 0.375 0.375

R 1.428 1.838 2.192 2.758 3.323

VF 0.625 0.625 0.625 0.875 0.875

ZB 4.875 4.938 5.063 6.000 6.000

All dimensions ± .015 unless otherwise noted.

K

AA

R

N/US 1.5.507.4

We reserve the right to amend, without notice, the specifications given in this document.

Our policy is one of continuous research and development.

www.norgren.com

1/08

Page 5

NEN Series NFPA Aluminum Cylinders

SB thru Dia.

SC - C Bore

SD Deep

XS

C

SU

TS

US

ZB + Stroke

SU

SY

SS + Stroke

SL

SH

ST

ER Radius

L

CE

KK Thds.

CH Across

Hex Flats

CB

CW CW

øCD

RE

TF

UF

F

FB Holes (4)

MS2 Mount

Bore 1-1/2" 2" 2-1/2" 3-1/4" 4"

SB 0.438 0.438 0.438 0.563 0.563

SC 0.690 0.690 0.690 0.800 0.800

SD 0.030 0.030 0.030 0.030 0.030

SH 1.000 1.250 1.500 1.875 2.250

SL 1.875 1.875 1.875 2.500 2.500

SY 0.940 0.940 0.940 1.250 1.250

SS 2.875 2.875 3.000 3.250 3.250

ST 0.620 0.620 0.750 1.000 1.000

SU 0.940 0.940 0.940 1.250 1.250

TS 2.750 3.250 3.750 4.750 5.500

US 3.500 4.000 4.500 5.750 6.500

XS 1.375 1.375 1.375 1.875 1.875

ZB 5.190 5.190 5.310 6.380 6.380

All Dimensions in Inches (mm)

NEN Cylinder Accessories and Kits

RE (rod eye)

RC (rod clevis)

Kit number KK CB CD. CE CH CW ER L

NENC-RC 7/16-20 0.750 0.500 1.500 1.000 0.500 0.500 0.750

NENF-RC 3/4-16 1.250 0.750 2.375 1.250 0.625 0.750 1.250

RC and RE rod accessories come complete with pivot pin and retaining clips.

MS2 Mounting Kit

SB Dia. Thru

SL

ST

SY

SU

Kit number SB SC SD SY ST SU TS US

MK-NENC-MS2 0.41 0.69 0.03 0.94 0.62 0.94 2.75 3.50

MK-NEND-MS2 0.41 0.69 0.03 0.94 0.62 0.94 3.25 4.00

MK-NENE-MS2 0.41 0.69 0.03 0.94 0.75 0.94 3.75 4.50

MK-NENF-MS2 0.52 0.80 0.03 1.25 1.00 1.25 4.75 5.75

MK-NENG-MS2 0.52 0.80 0.03 1.25 1.00 1.25 5.50 6.50

1/08

SC - C bore x SD Deep

TS

US

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

www.norgren.com

CD

CD

ER Radius

CD

CE

A

KK Thds.

CB

øCD

Kit number KK A CB CD CE ER

NENC-RE 7/16-20 0.750 0.750 0.500 1.500 0.563

NENF-RE 3/4-16 1.125 1.250 0.750 2.063 0.875

NFPA MF1 / MF2 Mounting Kit - MK-NEN-MF1

Kit number UF TF FB E R F

MK-NENC-MF1 3-3/8 2-3/4 5/16 2.00 1.43 3/8

MK-NEND-MF1 4-1/8 3-3/8 3/8 2-1/2 1.84 3/8

MK-NENE-MF1 4-5/8 3-7/8 3/8 3.00 2.19 3/8

MK-NENF-MF1 5-1/2 4-11/16 7/16 3-3/4 2.76 5/8

MK-NENG-MF1 6-1/4 5-7/16 7/16 4-1/2 3.32 5/8

N/US 1.5.507.5

Page 6

NEN Series NFPA Aluminum Cylinders

F

øCD

ER

LR

CB

CW CW

FL

D

G

DD

FL

F

øCD

MR

CB

CW CW

LR

D

G

DD

øCD

LP

LH

E

All Dimensions in Inches (mm)

EB (eye bracket)

LR Radius

F

FL

øCD

M Radius

E

BA

øDD

4 Places

CB

BA

E

NFPA Eye Bracket NENC-EB NENF-EB

BA 1.625 2.563

CB 0.750 1.250

CD 0.500 0.750

DD 0.406 0.531

E 2.500 3.500

F 0.375 0.625

FL 1.125 1.875

LR 0.750 1.250

M 0.500 0.750

All dimensions ± .015 unless otherwise noted.

MP2 Mount kit - MK - NEN - MP2

Kit number CD FL F B CW D ER G DD

MK-NENC-MP2 0.502 1.13 0.38 0.76 0.50 2.00 0.62 1.43 0.28

MK-NEND-MP2 0.502 1.13 0.38 0.76 0.50 2.50 0.62 1.84 0.34

MK-NENE-MP2 0.502 1.13 0.38 0.76 0.50 3.00 0.62 2.19 0.34

MK-NENF-MP2 0.752 1.88 0.63 1.26 0.62 3.75 0.87 2.77 0.41

MK-NENG-MP2 0.752 1.88 0.63 1.26 0.62 4.50 0.87 3.32 0.41

P (pin)

NFPA Pin NEN-5 NEN-7

CD 0.500 0.750

E 0.109 0.125

LH 2.094 2.875

LP 1.875 2.625

MP1 Mount kit - MK-NEN-MP1

Kit number CD FL F B CW D MR G LR DD

MK-NENC-MP1 0.502 0.75 0.38 0.76 0.50 2.00 0.62 1.43 0.62 0.28

MK-NEND-MP1 0.502 0.75 0.38 0.76 0.50 2.50 0.62 1.84 0.62 0.34

MK-NENE-MP1 0.502 0.75 0.38 0.76 0.50 3.00 0.62 2.19 0.62 0.34

MK-NENF-MP1 0.752 1.25 0.63 1.26 0.62 3.75 0.87 2.77 0.87 0.41

MK-NENG-MP1 0.752 1.25 0.63 1.26 0.62 4.50 0.87 3.32 0.87 0.41

MP1 and MP2 kits come complete with mounting hardware, pivot pin and retaining clips.

MX1 Mount kit - MK-NEN-MX1

MX2/MX3 Mount kit-MK-NEN-MX2

DD

A

MX1 Mount Kit-MK-NEN-MX1

Tie Rod extended Both Ends

Kit number DD A B

MK-NENC-MX1 1/4-28 1.375 1.375

MK-NEND-MX1 5/16-24 1.500 1.500

MK-NENE-MX1 5/16-24 1.500 1.500

MK-NENF-MX1 3/8-24 1.812 1.937

MK-NENG-MX1 3/8-24 1.812 1.937

MX2 Mount Kit-MK-NEN-MX2

Tie Rod Extended Cap End

Kit number DD A B

MK-NENC-MX2 1/4-28 N/A 1.375

MK-NEND-MX2 5/16-24 N/A 1.500

MK-NENE-MX2 5/16-24 N/A 1.500

MK-NENF-MX2 3/8-24 N/A 1.937

MK-NENG-MX2 3/8-24 N/A 1.937

MX3 Mount Kit-MK-NEN-MX3

Tie Rod Extended Head End

Kit number DD A B

MK-NENC-MX2 1/4-28 1.375 N/A

MK-NEND-MX2 5/16-24 1.500 N/A

MK-NENE-MX2 5/16-24 1.500 N/A

MK-NENF-MX2 3/8-24 1.812 N/A

MK-NENG-MX2 3/8-24 1.812 N/A

DD

B

WARNING

These products are intended for use in industrial compressed air systems only. Do not use these

products where pressures and temperatures can exceed those listed under

TTeecchhnniiccaall DDaattaa

Before using these products with fluids other than those specified for non-industrial

applications, life-support systems, or other applications not within published specifications,

consult Norgren.

Through misuse, age, or malfunction, components used in fluid power systems can fail in

various modes.

N/US 1.5.507.6

Our policy is one of continuous research and development.

We reserve the right to amend, without notice, the specifications given in this document.

The system designer is warned to consider the failure mode of all component parts used in fluid

.

power systems and to provide adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end users in the system instructional

manual if protection against a failure mode cannot be adequately provided.

System designers and end users are cautioned to review specific warnings found in instruction

sheets packed and shipped with these products.

www.norgren.com

1/08

Loading...

Loading...