Page 1

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-1

Mufflers

Quietaire®Series

Compressed Air Mufflers

Section 8

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-2

Muffler Shape Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-3

Shell Type Quietaire®Mufflers . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-4

Nadir Air Exhaust Silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-5

Sintered Type Quietaire®Mufflers . . . . . . . . . . . . . . . . . . . . . .FIT-8-6

Porous Plastic Type Quietaire Mufflers . . . . . . . . . . . . . . . . . .FIT-8-7

Quietaire

®

Coalescing Mufflers . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-8

High Performance Coalescing Quietaire®Mufflers . . . . . . . .FIT-8-9

Quietaire®Speed Control Mufflers . . . . . . . . . . . . . . . . . . . . . .FIT-8-10

Quietaire®Breather Vents . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-13

Quietaire

®

Small Part Ejectors . . . . . . . . . . . . . . . . . . . . . . . . .FIT-8-14

Page 2

FIT-8-2

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Norgren Quietaire Mufflers

● Mufflers prevent metal chips, abrasive grits,

dust and other contaminants from entering

open exhaust ports and causing premature

valve failure.

● Coalescing Mufflers help prevent oil mist and

solid particles from contaminating factory air.

● Speed Control Mufflers allow the adjustment of

exhaust flow to accurately control cylinder

speed.

● Parts Ejectors use less air than open lines with

only minor reduction of thrust.

● Breather vents prevent damage caused when

dirt, chips and other foreign particles enter

vacuum relief ports or breather tubes.

OSHA Permissible Noise Exposures*

Compressed air exhausts generate high intensity sound energy, much of

it in the same frequency range as normal conversation. Prolonged

exposure to noise causes hearing impairment without noticeable pain or

discomfort. See Table below for permissible noise exposures and graphs

on the following pages for the sound suppression characteristics of

Quietaire products.

Daily Sound

Duration Level

(Hours) (dBa)

890

692

495

397

2 100

1-1/2 102

1 105

1/2 110

1/4 115

*OSHA Safety and Health Standards (29 CFR 1910.95)

Increase Productivity

Continual noise causes worker fatigue, resulting in

reduced productivity and a reduction in profits.

Noise abatement helps prevent noise fatigue, one of

the main causes of industrial inefficiency and

accidents.

Cleaner Work Environment

Open exhaust ports on compressed air devices can

release oil vapors, oil aerosols, and particulates into

the atmosphere. Quietaire coalescing mufflers

remove these contaminants from the exhaust air

and also reduce noise to permissible levels.

Prolong Service Life

Open exhaust ports invite the entry of contaminants

- metal chips, abrasive grits, sweepings (floor

mounted units) and other debris. Quietaire mufflers

prevent the entry of such contaminants, prolonging

the service life of your air valves, air motors and

similar equipment.

Page 3

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-3

Quietaire Muffler Shape Codes

Dimensions in Inches (mm)

Shell Type Quietaire Heavy Duty Mufflers

(MA and MB Series) p. FIT-8-4.

Sintered Type Quietaire Mufflers

(MS and T40 Series) p. FIT-8-6.

Porous Plastic Type Quietaire Mufflers

(C/S, M/S, and MU Series) p. FIT-8-7.

Coalescing Quietaire Mufflers

(MC Series) p. FIT-8-8.

High Performance Quietaire Coalescing Muffler

(MQ Series) p. FIT-8-9.

Quietaire Speed Control Mufflers

(MM and T20 Series) p. FIT-8-10.

Quietaire Breather Vents

(MV and M/1510 Series) p. FIT-8-13.

Quietaire Small Parts Ejectors

(ME Series) p. FIT-8-14.

Nadir Air Exhaust Silencer

(MF and MFT Series) p. FIT-8-5.

Page 4

FIT-8-4

Littleton, CO USA Phone 303-794-2611 www.norgren.com

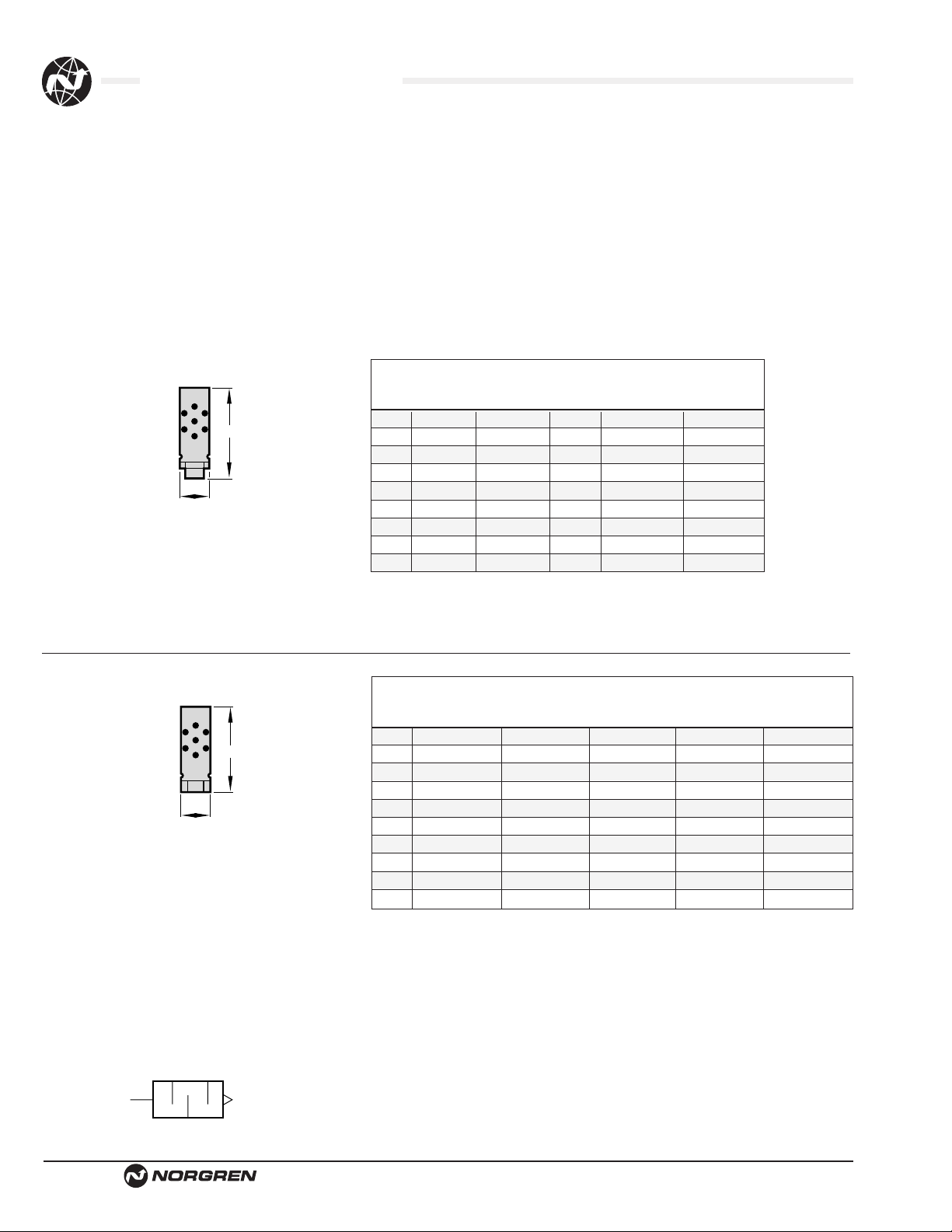

Shell Type Quietaire Mufflers

Dimensions in Inches (mm)

Port

Size NPT ISO R Flow Factor Dimensions

NPT (std) (opt) Cv + -10% Hex. L

1/8 MA001A MA001B 0.8 13/16 (20.6) 1.67 (42.4)

1/4 MA002A MA002B 2.4 13/16 (20.6) 1.78 (45.2)

3/8 MA003A MA003B 5.7 1-1/4 (31.8) 3.08 (78.3)

1/2 MA004A MA004B 6.9 1-1/4 (31.8) 3.29 (83.5)

3/4 MA006A MA006B 18.0 2 (50.8) 4.65 (118.0)

1 MA008A MA008B 20.0 2 (50.8) 4.65 (118.0)

1-1/4 MA010A MA010C 42.0 2-1/2 (63.5) 5.67 (144.0)

1-1/2 MA012A MA012C 39.0 2-1/2 (63.5) 5.67 (144.0)

2 MA016A MA016C 59.0 3 (76.2) 6.61 (168.0)

2-1/2 MA020A MA020C – 4 (102) 7.13 (181)

Male Thread

Female Thread

Port

Size NPT ISO R Flow Factor Dimensions

NPT (std) (opt) Cv + -10% Hex. L

1/8 MB001A MB001B 2 13/16 (20.6) 2.00 (50.9)

1/4 MB002A MB002B 2.7 13/16 (20.6) 2.17 (55.2)

3/8 MBP03A MBP03B 3.2 13/16 (20.6) 2.17 (55.2)

3/8 MB003A MB003B 4.9 1-1/4 (31.8) 3.47 (88.1)

1/2 MB004A MB004B 5.9 1-1/4 (31.8) 3.62 (91.9)

3/4 MBP06A MBP06B 5.9 1-1/4 (31.8) 3.64 (92.4)

3/4 MB006A MB006B 13.5 2 (50.8) 5.28 (134.0)

1 MB008A MB008B 16.7 2 (50.8) 5.43 (138.0)

1-1/4 MBP10A MBP10B 17.4 2 (50.8) 5.51 (140.0)

Technical Data

Maximum Pressure: 300 psig (20.7 bar)

Maximum temperature: 176°F (80°C)

Materials

Element: Brass wire

Base: Aluminum

Shell: Aluminum

Graphic Symbol

● Superior sound attenuation

● High flow capacity

● Low back pressure

● Corrosion resistant construction

● Brass mesh screen and aluminum construction provide improved

flow, longer life, and a cleanable element.

● 60 x 50 mesh – .007 wire diameter (several layers)

L

Hex.

L

Hex.

Page 5

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-5

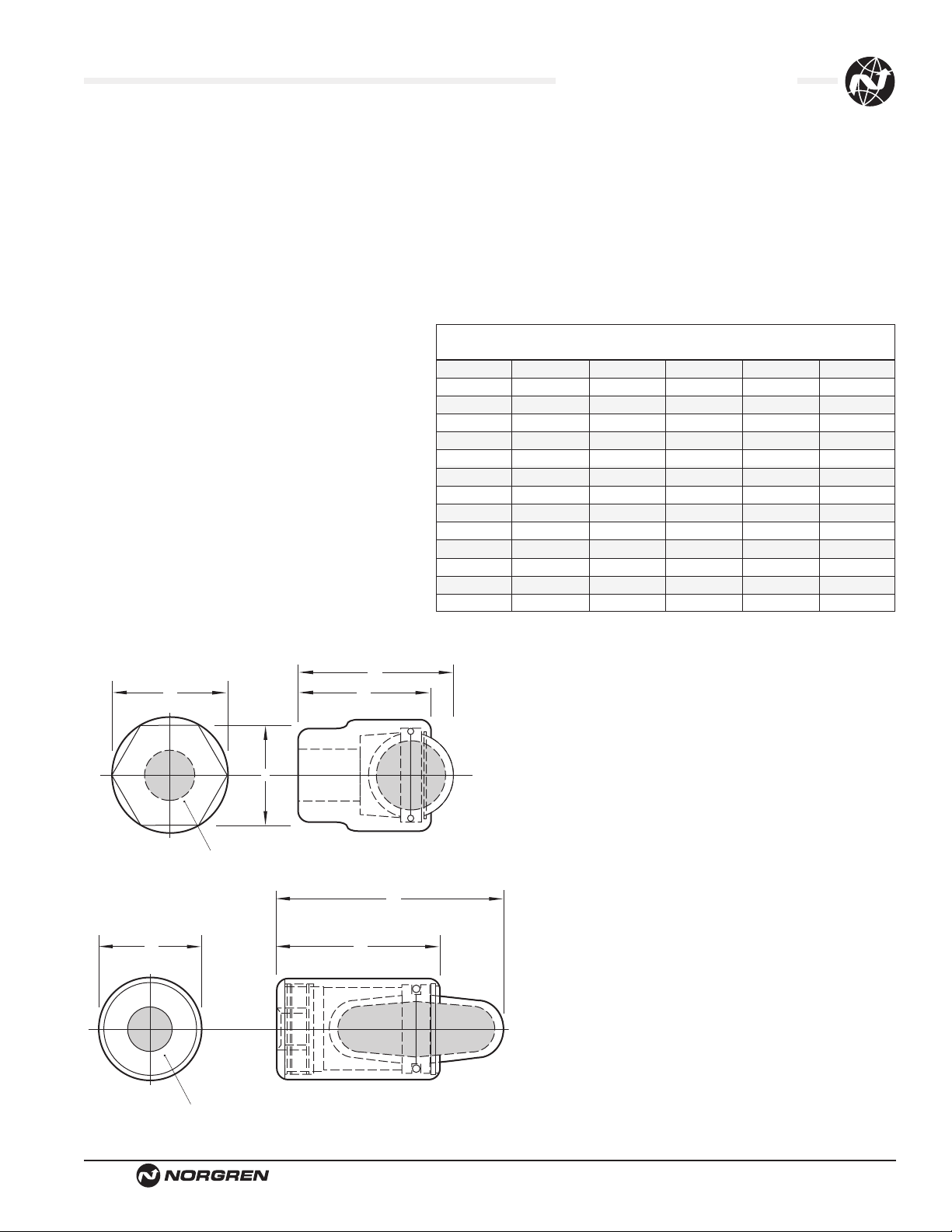

Nadir Air Exhaust Silencer

Dimensions in Inches (mm)

ABCDE

Model Barrell Overall Dia Thread Flats

MF-14 1-15/32 1-15/16 1-1/4 1/4 NPT 1-5/32

MFT-38 1-15/32 1-15/16 1-1/4 3/8 NPT 1-5/32

MF-38 1-3/4 2-5/16 1-1/2 3/8 NPT 1-1/4

MFT-12 1-3/4 2-5/16 1-1/2 1/2 NPT 1-1/4

MF-12 1-7/8 2-5/8 1-3/4 1/2 NPT 1-1/2

MFT-34 1-7/8 2-5/8 1-3/4 3/4 NPT 1-1/2

MF-34 3-5/16 4-7/8 2-3/8 3/4 NPT

MFT-1 3-5/16 4-7/8 2-3/8 1 NPT

MF-100 4-3/8 6-1/2 3 1 NPT

MFT-114 4-3/8 6-1/2 3 1-1/4 NPT

MF-114 5-9/16 8-11/32 4 1-1/4 NPT

MFT-112 5-9/16 8-11/32 4 1-1/2 NPT

MF-112 6-1/2 9-7/8 4-1/2 1-1/2 NPT

MFT-200 6-1/2 9-7/8 4-1/2 2 NPT

● Meets all OSHA standards

● Machined from high tensile aluminum with no

plastics or castings

● Will pass particle contaminates to 100 microns

● Easily cleaned for longer service life

● Can withstand temperatures of 1000 degrees F

Dimensional Data

Dimensional Data

Technical Data

Maximum Pressure: 150 psi (10 bar)

Maximum temperature: 1000°F (538°C)

Materials

Aluminum and Sintered Bronze

Graphic Symbol

C A

E

B

C A

D

D

B

Page 6

FIT-8-6

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Sintered Type Quietaire Mufflers

Dimensions in Inches (mm)

Port

Size Part Flow Factor Dimensions

NPT Number Cv Hex. L

10-32 MS000A – 5/16 0.70 (18)

1/8 MS001A 0.7 7/16 1.13 (29)

1/4 MS002A 1.4 9/16 1.38 (35)

3/8 MS003A 1.9 11/16 1.50 (38)

1/2 MS004A 3.8 7/8 1.88 (48)

3/4 MS006A 6.5 1-1/16 2.25 (57)

1 MS008A 10.5 1-5/16 2.88 (73)

1-1/4 MS010A 11.8 1-11/16 3.25 (83)

1-1/2 MS012A 18.3 2 3.69 (94)

Male Thread

Performance Characteristics

Technical Data

Maximum Pressure: NPT - 300 psig (20.7 bar)

ISO - 150 psig (10 bar)

Maximum temperature: NPT - 300°F (149°C)

ISO - 175°F (80°C)

Materials

Element: Sintered bronze

Base: Nickel plated steel (NPT), Brass (ISO)

● Reduces noise levels of pneumatic

equipment

● Cleanable 40-micron diffuser elements

● Compact design

● Corrosion resistant construction

● Prevents dirt ingress

Port

Size Part Flow Factor Dimensions

ISO G Number Cv Hex. L

M5 T40M0500 0.2 7 0.79 (20)

1/8 T40C1800 0.54 13 0.94 (24)

1/4 T40C2800 1.6 17 1.30 (33)

3/8 T40C3800 3.5 22 1.73 (44)

1/2 T40C4800 5.1 27 2.20 (56)

3/4 T40C6800 9.0 32 3.15 (80)

1 T40C8800 11.6 41 3.23 (82)

Port

Size Part Flow Factor Dimensions

ISO R Number Cv Hex. L

1/8 T40B1800 0.54 13 1.08 (27.5)

1/4 T40B2800 1.6 17 1.42 (36)

3/8 T40B3800 3.5 22 1.83 (46.5)

1/2 T40B4800 5.1 27 2.36 (60)

3/4 T40B6800 9.0 32 3.35 (85)

1 T40B8800 11.6 41 1.61 (41)

Graphic Symbol

Hex.

L

/s

3

dm

50

40

30

20

Flow @ 80 psig (5.5 bar)

10

0

Sound Level Vs. Air Flow

Measured at

scfm

four feet

from source.

100

80

MS008A

60

40

20

MS001A

0

40 50 60 70 80 90 100 110

MS004A

MS006A

MS002A

MS003A

Sound Level — dBa

MS010A

MS012A

Open

1/2"

Line

/s

3

dm

100

80

60

Air Flow

40

20

0

Back Pressure Vs. Air Flow

scfm

200

160

120

80

40

0

02

4 6 8 10 12

0 .2.4.6.8

Back Pressure

MS012A

MS010A

MS008A

MS006A

MS004A

MS003A

MS002A

MS001A

psig

bar

Page 7

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-7

Porous Plastic Type Quietaire Mufflers

Dimensions in Inches (mm)

Technical Data

Maximum Pressure: Vacuum to 150 psig (10 bar)

Maximum Temperature: 125°F (51.7°C) (MU Series)

Temperature Range: -0° to 175°F (-20° to 80°C) (C/S and M/S series)

Materials (C/S and M/S series): UHMW Polyethylene porous plastic

body and polyethylene base

● Compact and light weight

● Low cost alternative to metal designs

● Threads directly into the exhaust port

● Prevents contamination from dirt

● 75 Micron

Part Number

Port Metric or Dimensions Weight

Size NPT ISO G L (mm) D (mm) oz. (g)

M5 – M/S0* 0.75 (18.9) 0.26 (6.5) 0.01 (.35)

1⁄8 C/S1 M/S1 1.12 (28.3) 0.50 (12.5) 0.06 (1.3)

1⁄4 C/S2 M/S2 1.40 (35.5) 0.62 (15.5) 0.10 (2.9)

3⁄8 C/S3 M/S3 2.20 (56.0) 0.73 (18.5) 0.26 (6.7)

1⁄2 C/S4 M/S4 2.65 (67.0) 0.91 (23.0) 0.41 (11.5)

3⁄4 C/S6 M/S6 4.88 (123.5) 1.50 (38.0) 1.41 (40.0)

1 C/S8 M/S8 5.54 (140.5) 2.00 (49.0) 2.12 (60.0)

**Cv measured in US gal/min

∆ SPL at 3.28 ft. (1m) from unit

Flow

∆Continous

Port Part Number Factor Sound Pressure Level (dBA)

Size NPT ISO G Cv** 10 psig (0.7 bar) 90 psig (6 bar)

M5 M/S0 0.31 59 82.7

1/8 C/S1 M/S1 1.0 67 84

1/4 C/S2 M/S2 1.84 58 84

3/8 C/S3 M/S3 4.0 65 81

1/2 C/S4 M/S4 5.3 59 82

3/4 C/S6 M/S6 8.0 71 98

1 C/S8 M/S8 12.2 70 94

* Due to the pliable nature of the thermoplastic base material this may be

installed in 10-32 UNF ports. (Formerly part number M/1545.)

A

Port Part Weight

Size Number C E F ØK oz (g)

5/32" T45Y0002 1.30 (33.0) 0.67 (17.0) 0.59 (15.0) 0.26 (06.5) 0.04 (1.0)

1/4" T45Y0004 1.77 (45.0) 0.98 (25.0) 0.67 (17.0) 0.49 (12.5) 0.05 (1.5)

3/8" T45Y0006 2.26 (57.5) 1.22 (31.0) 0.91 (23.0) 0.61 (15.5) 0.12 (3.5)

6mm T45P0006 1.77 (45.0) 0.98 (25.0) 0.67 (17.0) 0.49 (12.5) 0.05 (1.5)

8mm T45P0008 1.71 (43.5) 0.87 (22.0) 0.75 (19.0) 0.53 (13.5) 0.07 (2.0)

10mm T45P0010 2.26 (57.5) 1.22 (31.0) 0.91 (23.0) 0.61 (15.5) 0.12 (3.5)

12mm T45P0012 3.21 (81.5) 2.11 (53.5) 1.04 (26.5) 0.73 (18.5) 0.25 (7.0)

T45 Series

ØD

L

ØK

E

F

ØA

C

Page 8

FIT-8-8

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Quietaire Coalescing Mufflers

Dimensions in Inches (mm)

Port

Size Part Flow Factor Dimensions

NPT Number Cv Dia. L

1/2 MC004A 5.2 3.88 (99) 6.00 (152)

3/4 MC006A 9.2 3.88 (99) 6.00 (152)

1 MC008A 15.7 3.88 (99) 6.19 (157)

Performance Characteristics

Male Thread

Technical Data

Maximum Pressure: 300 psig (20.7 bar)

Maximum temperature:160°F (71°C)

Materials

Element: Fiberglass

Base: Aluminum

Shell: Plated steel

Replacement Kit

Element Cartridge: 70039-01

Graphic Symbol

● Easily replaceable cartridge element

● Removal of oil mist from exhaust air provides

cleaner work environment.

● Rugged, corrosion resistant construction

Dia.

L

Sound Level —

Silencer Vs. Open Line

Ear protection mandatory for full time

exposure to noise above this curve.

100

90

80

Sound Level — dBa

70

60

50

63

Octave Band Center Frequencies —

Open 1" Line

Silencer

125

250

500

1000

2000

4000

Cycles Per Second @ 105 scfm

8000

/s

3

dm

150

120

90

Air Flow

60

30

0

Back Pressure Vs. Air Flow

scfm

300

240

180

120

60

0

02

4 6 8 10 12

0 .2.4.6.8

MC008A

MC006A

MC004A

psig

bar

Back Pressure

Page 9

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-9

Dimensions in Inches (mm)

High Performance Coalescing Quietaire Mufflers

Port

Size Part Flow Factor Dimensions

NPT Number Cv Dia. L

1/2 MQ004A 2.5 3.54 (90) 7.09 (180)

3/4 MQ006A 2.5 3.54 (90) 7.09 (180)

1 MQ008A 7.7 4.33 (110) 10.51 (267)

1-1/4 MQ010A 7.7 4.33 (110) 10.51 (267)

Female Thread

Performance Characteristics

Technical Data

Maximum Pressure: 150 psig (10.3 bar)

Maximum Temperature: 160°F (71°C)

Materials

Element: Steel, synthetic foam and fiber

Body: Aluminum

Sump: Polypropylene

Elastomer: Nitrile

Replacement Kits

Element:

MQ004A and MQ006A – 3236-01

MQ008A and MQ010A – 3237-01

Sump with Drain:

MQ004A and MQ006A – 70048-50

MQ008A and MQ010A – 70048-51

Graphic Symbol

● Easily replaceable cartridge element

● Corrosion resistant construction

● Snap-on liquid sump with manual drain to collect

coalesced oil.

● High-performance cartridge removes up to 99% of

the oil mist from the exhaust air.

L

Dia.

110

100

Sound Level — dBa

Sound Level —

Silencer Vs. Open Line

Ear protection mandatory for full time

exposure to noise above this curve.

Open Exhaust

90

80

70

60

63

125

250

500

Octave Band Center Frequencies —

1000

Cycles Per Second

/s

3

scfm

dm

100

200

80

160

60

120

Air Flow

40

80

20

40

0

0

02

0.2.4.6.8

2000

4000

MQ008A

MQ010A

MQ004A

MQ006A

8000

Back Pressure Vs. Air Flow

MQ008A

MQ010A

MQ006A

MQ004A

4681012

Back Pressure

psig

bar

Page 10

FIT-8-10

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Quietaire Speed Control Mufflers

Dimensions in Inches (mm)

Port

Size Part Dimensions

NPT Number Dia. L

1/8 MM001A 1/2 1.53 (39)

1/4 MM002A 9/16 1.91 (49)

3/8 MM003A 11/16 1.91 (49)

1/2 MM004A 7/8 2.34 (59)

3/4 MM006A 1-1/16 2.84 (72)

1 MM008A 1-5/16 3.03 (77)

Male Thread

Performance Characteristics

Technical Data

Maximum Pressure: 300 psig (20.7 bar)

Maximum temperature: 160F (71°C)

Materials

Element: Sintered bronze

Base: Brass

Graphic Symbols

● Cleanable 40-micron sintered bronze diffuser

element.

● Corrosion resistant construction.

● Adjustment screw to control rate of exhaust air flow.

● Adjustment screw facilitates a smooth, steady

change to flow when turned.

Hex.

L

/s

3

dm

50

40

30

20

Flow @ 80 psig (5.5 bar)

10

0

Sound Level Vs. Air Flow

scfm

100

80

60

40

20

MS001A

MS001A

0

50 60 70 80 90 100 110 120

MM003A

MM004A

MM006A

MM008A

Sound Level — dBa

Open

1/2"

Line

/s

3

dm

60

40

Air Flow

20

0

Linearity of Adjustment

scfm

120

100

80

60

40

20

0

02468

Adjustment – Number of Turns

MM008A

MM006A

MM004A

MM003A

MM002A

MM001A

Page 11

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-11

● Compact, integral speed control and silencer

units

● Captive adjustment screw will not blow out

when unscrewed

● Reduced dimensions

● Low cost alternative to metal designs

● 75 Micron

Technical Data

Medium:

Compressed air, filtered, lubricated and non-lubricated, inert gases

Mounting:

Threads directly in the exhaust port. (Thread into port until washer under the

element bottoms against the port surface.)

Hex recess adjustment for flow regulation

Port Sizes: Male Thread

NPT Metric ISO G

1⁄8 T20A1800 M5* T20M0500 G1⁄8 T20C1800

1⁄4 T20A2800 G1⁄4 T20C2800

3⁄8 T20A3800 G3⁄8 T20C3800

1⁄2 T20A4800 G1⁄2 T20C4800

Note: Due to the pliable nature of the thermoplastic base these may be used in

conjunction with 10-32 UNF ports.

Operating Pressure:

0 - 145 psi (0 - 10 bar)

Operating Temperature:

-0° to 175°F* (-20° to 80° C)

*Air supply must be dry enough to avoid ice formation at temperatures below 36°F (2°C)

Materials:

Nylon body and washer

(Note: NPT models black, metric and ISO G models red)

Porous polyethylene silencer

Zinc electroplated high tensile steel adjusting screw

M5

Nylon body

Zinc electroplated high tensile steel adjusting screw

Quietaire Speed Control Mufflers

(plastic bodied) T20 Series

M5, 1⁄8 - 1⁄2 NPT and ISO G

Ordering information

To order quote model number from table overleaf,

e.g. T20A4800 for the regulator/silencer 1⁄2

" NPT

speed control muffler.

Flow Regulator/Silencer

Page 12

FIT-8-12

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Quietaire Speed Control Mufflers

Dimensions in Inches (mm)

General Information

Speed Control Muffler

(1/8 - 1/2 pipe)

M5

Performance Characteristics

Flow vs Turns

(at 90 psig [6 bar] inlet pressure)

E

D

A

B

C

F

G

B

A

F

E

G

D

*Cv measured in US gal/min

(80)

(70)

(60)

(50)

(40)

(30)

(20)

(10)

0

012345678

910

Flow (ANR)

Turns

21.0

42.4

63.6

84.7

106.0

127.0

148.3

169.5

dm3/s

scfm

1/2

3/8

1/8

1/4

Performance Characteristics

Flow vs Turns

(at 90 psig [6 bar] inlet pressure)

Part Number Dimensions

Metric or Max. Flow Thread E F Weight

Port Size NPT ISO G Factor Cv* A B C D A/F A/F G oz. (g)

M5 – T20M0500 0.07

0.63 0.43

– M5 1.5

0.31 0.36

.04 (1)

(16) (16) (8) (9.25)

1/8 T20A1800 T20C1800 0.4

0.81 0.57 0.20

1/8 2.5

0.51 0.59

.11 (3)

(20.5) (14.5) (5) (13) (15)

1/4 T20A2800 T20C2800 0.8

1.14 0.87 0.27

1/4 2.5

0.59 0.71

.25 (7)

(29) (22) (7) (15) (18)

3/8 T20A3800 T20C3800 1.7

1.50 1.18 0.41

3/8 2.5

0.79 0.94

.67 (19)

(38) (30) (10.5) (20) (24)

1/2 T20A4800 T20C4800 2.4

1.97 1.57 0.59

1/2 2.5

0.98 1.18

1.52 (43)

(50) (40) (15) (25) (30)

Flow (ANR)

scfm

dm3/s

5.30

(2.5)

(2.0)

4.24

3.18

(1.5)

(1.0)

2.12

1.06

(0.5)

0

123456

0

Turns

M5

Page 13

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-8-13

Quietaire Breather Vents

Dimensions in Inches (mm)

Port

Size Part Flow Factor Dimensions

NPT Number Cv Hex A/F L

1/8 MV001A 0.1 7/16 0.44 (11)

1/4 MV002A 0.1 9/16 0.63 (16)

3/8 MV003A 0.3 11/16 0.75 (19)

1/2 MV004A 0.5 7/8 0.88 (22)

3/4 MV006A 1.3 1-1/16 1.00 (25)

1 MV008A 1.6 1-5/16 1.31 (33)

1-1/4 MV010A 4.2 1-11/16 1.44 (37)

1-1/2 MV012A 5.2 2 1.50 (38)

Male Thread

Performance Characteristics

Technical Data

Maximum Pressure: 150 psig (10.7 bar)

Maximum temperature: NPT - 300°F (149°C)

ISO - 175°F (80°C)

Materials

NPT:

Base - Nickel plated steel

Element - Sintered bronze

ISO G:

Base - Aluminum

Element - Sintered bronze

● Corrosion resistant construction

● Prevents contamination from dirt

● Rugged and compact

● Screws directly into the exhaust port

● Sintered bronze element

Graphic Symbol

Port

Size Part Flow Factor Dimensions Weight

ISO G Number Cv Hex A/F L oz. (g)

1/8 M/1511 0.45 15.0 mm 0.63 (16) 0.2 (6)

1/4 M/1512 1.1 23.5 mm 0.87 (22) 0.6 (18)

1/2 M/1514 1.5 30.5 mm 0.98 (25) 1.0(30)

3/4 M/1516 3.9 42.5 mm 1.22 (31) 1.6 (50)

1 M/1518 5.5 47 mm 1.38 (35) 2.9 (91)

Hex.

L

/s

3

dm

25

20

15

Air Flow

10

5

0

Back Pressure Vs. Air Flow

scfm

50

40

30

20

10

0

02

4 6 8 10 12

0 .2.4.6.8

Back Pressure

MV012A

MV010A

MV008A

MV006A

MV004A

MV003A

MV002A

MV001A

psig

bar

Page 14

FIT-8-14

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Quietaire Small Part Ejectors

Dimensions in Inches (mm)

Port

Size Part Flow Factor Dimensions

NPT Number Cv Dia. L

1/4 ME002A 1.0 .81 (21) 1.84 (47)

Female Thread

Performance Characteristics

Technical Data

Maximum Pressure: 150 psig (10.3 bar)

Maximum temperature: 160°F (71°C)

Force at 12" (305 mm) from Ejector at 80 psig (5.5 bar)

line pressure

ME002A: 34 ozs. (9.5N)

Air Consumption at 80 psig (5.5 bar): 63 scfm (29.7 dm

3

/s)

Materials

Element: Brass cloth

Base: Aluminum

Graphic Symbol

● Reduction in noise and in air consumption

(when compared to an open pipe) with only a

minor reduction in thrust.

● Corrosion resistant construction.

L

Dia.

Applied Pressure Vs. Air Flow

/s

3

dm

scfm

Open

1/4"

50

40

30

Air Flow

20

10

0

Line

100

80

60

40

20

0

020

40 60 80 100 120

02468

Applied Pressure

Part

Ejectors

psig

bar

Loading...

Loading...