Page 1

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-A

Section 14

Contents

Lubricator Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-B

L07 Miniature Micro-Fog® Lubricator 1/8" and 1/4" Ports . . . . . . . ALE-14-2

L72 Excelon Micro-Fog and Oil-Fog Lubricator

1/4" and 3/8" Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-4

L73 Excelon Micro-Fog and Oil-Fog Lubricators

1/4", 3/8", and 1/2" Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-6

L74 Excelon Micro-Fog and Oil-Fog Lubricators

3/8", 1/2", and 3/4" Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-8

L64 Olympian Plus Micro-Fog and Oil-Fog Lubricators

1/4", 3/8", 1/2", and 3/4" Ports . . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-10

L68 Olympian Micro-Fog and Oil-Fog Lubricator

3/4", 1, 1-1/4", and 1-1/2" Ports. . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-12

L17 Micro-Fog and Oil-Fog Lubricators

3/4", 1", 1-1/4" and 1-1/2" Ports . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-14

10-028 Oil-Fog Lubricator 1-1/2" Port . . . . . . . . . . . . . . . . . . . . . . ALE-14-16

10-076 Oil-Fog Lubricator 2" Port . . . . . . . . . . . . . . . . . . . . . . . . . ALE-14-18

10-015 Micro-Fog Machine Bearing Lubricator,

8 to 32 Bearing Inch Ratings, 1/4" Port . . . . . . . . . . . . . . . . . . ALE-14-20

Lubricators

Compressed air tool lubricators are

available in modular or inline

models in port sizes from 1/8" to 2".

Machine bearing lubricators are

available in 8 to 32 inch ratings.

L07

L64M/C

L68

L17 10-028

10-076

10-015

L74M/C

L73M/C

L72M/C

Page 2

Lubricator Overview

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-B

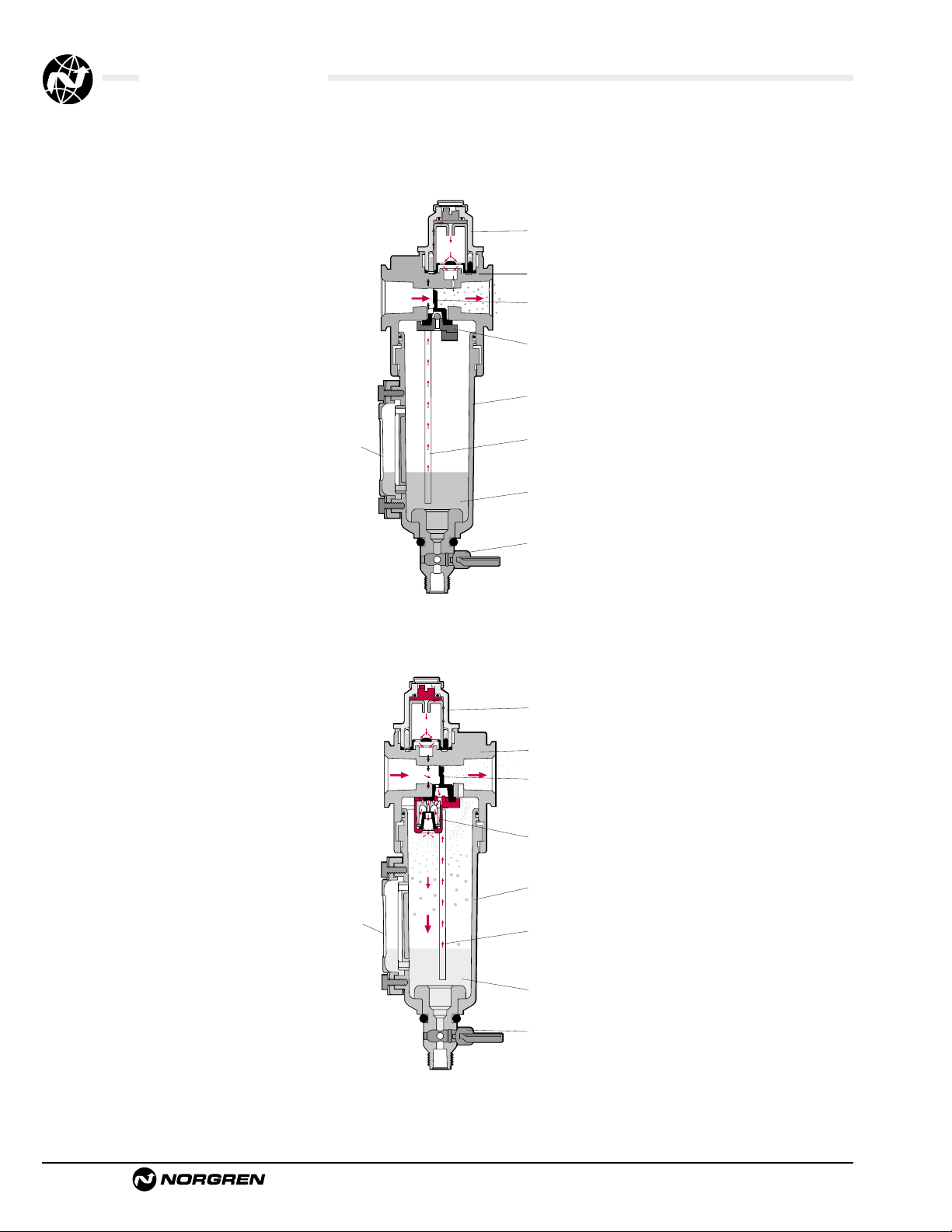

1.1 GENERAL OVERVIEW

Norgren manufactures two main types of lubricators:

Oil-Fog and Micro-Fog. These units are mounted

directly into the pipe and add small amounts of oil

to the air flowing through them.

Oil Fog-Lubricators:

All the oil droplets seen in the sight dome are added

directly into the air flow. This results in relatively

large oil droplets passing downstream, suitable for

heavy lubrication applications eg single cylinders

and tools. Most competitive in line lubricators are

of the Oil-Fog type.

Micro-Fog Lubricators:

The oil droplets seen in the sight dome are atomized

and collected in the area above the oil in the bowl.

The smaller lighter particles are drawn into the air

flow and pass downstream.

As a result typically only 10% of the oil

seen as drops in the sight dome is passed

downstream. The remainder falls back into the oil

reservoir. Consequently, drip rate settings are

somewhat higher than their Oil-Fog equivalent. This

makes setting much easier, particularly in low flow

applications.

The fine Micro-Fog oil particles can travel

long distances through complex pipe work making

Micro-Fog lubricators suitable for multiple valve

and cylinder circuits.

1.2 WHAT ARE THE

DIFFERENCES BETWEEN

MICRO-FOG AND OIL-FOG?

1.2.1 Oil-Fog:

• Large oil particles not as fine as micro-fog.

• All oil drips seen in sight domes are

delivered downstream.

• For applications over short distances.

• Should be mounted at same level or higher

than device being lubricated.

• Standard bowls can be filled under

pressure. (Not on rapid cycle units).

• Suitable for heavy lubrication applications

eg single large cylinders and tools.

• Has a flow sensor which provides constant

oil output density for varying flows.

OIL-FOG LUBRICATOR

MICRO-FOG LUBRICATOR

1.2.2 Micro-Fog:

• Small oil particles; less than 2 micron.

• Only 10% of ‘drip rate’ is delivered

downstream as active lubricant (remainder

is returned to main oil reservoir).

• High drip rates make drip setting easier in

low flow applications.

• Can be mounted above or below the point

of application.

• Cannot be filled without shutting off

upstream air (unless a quick fill cap or

remote fill device is used).

• For use with lengthy air lines, multiple

valve and cylinder circuits.

• Has a flow sensor to provide an almost

constant oil output density for varying

flows.

1.2.3 Can Oil-Fog and Micro-Fog Units be

Converted?

Generally not, simply changing a green (Oil-Fog)

sight dome for a red (Micro-Fog) sight dome does

not change the function.

Some lubricators are designed around a

cartridge insert. In this case it may be possible to

swap the cartridge and sight domes to change the

function.

Metal bowl

sight glass

Sight

dome

Body

Flow

sensor

Check

valve

Bowl

Syphon

tube

Oil

Drain

(optional)

Sight

dome

Metal bowl

sight glass

Body

Flow

sensor

Generator

assembly

Bowl

Syphon

tube

Oil

Drain

(optional)

Page 3

Lubricator Overview

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-C

1.4 SETTING LUBRICATOR

DRIP RATES

1.4.1 What is the Correct Drip Rate Setting?

The drip rate will depend on the application, the

amount of lubrication required, the flow through the

lubricator and the lubricator type. In Micro-Fog

lubricators only 10% of the droplets in the sight

dome are carried downstream. The drip rate in

Micro-Fog lubricators therefore tends to be much

higher.

The following table can be used to estimate

drip rate for required flow. This is very much a rule

of thumb. In practice it is necessary to fine tune the

oil drip rate in each application.

Typical Drip Rate Typical Drip Rate Approx

per Minute per Minute Flow

Micro-Fog Oil-Fog scfm

(dm3/s)

20 2 10 (5)

40 4 20 (10)

60 6 30 (15)

80 8 40 (20)

100 10 50 (25)

120 12 60 (30)

1.3.2 Can the Drip Rate be Shut Off?

In lubricators with needle valve type sight dome,

yes.

Some Norgren sight domes use a felt pad

which is soaked in oil at the point where the drops

are formed. With this type of sight dome the oil

droplets cease once the felt pad dries out.

With the new style dome (L72/73/74 and

L07) complete shut off is not possible. Minimum

adjustment for the drip rate is around 1 drop per

minute.

1.5 FILLING METHODS

1.5.1 Oil-Fog and Micro-Fog Lubricators:

The standard Oil-Fog lubricators can be filled under

pressure ie without switching off the upstream air.

When a fill plug is removed a check valve in the

lubricator body isolates the inlet pressure from the

bowl and the reservoir will depressurize. The

lubricator can then be filled with oil. When the fill

plug is replaced, the reservoir will re-pressurize.

The standard Micro-Fog unit can only be

filled without isolating the upstream pressure if a

remote fill or quick fill nipple accessory is fitted. To

remove the fill plug of a Micro-Fog lubricator whilse

under pressure can be dangerous. If in doubt shut

off the upstream air!

1.5.2 Remote Fill Devices:

The remote oil fill system provides a means of filling

from a remote fill point, a single lubricator or a bank

of lubricators manifolded together. The remote fill

point may be connected to a portable reservoir or to

a centralized, permanent reservoir. A portable

reservoir permits the use of different lubricants in

different groups of lubricators to suit the

requirements of the machinery being lubricated. The

lubrication oil must be fed in at a higher pressure

than exists in the bowl.

The devices are NOT intended for

connection to an oil feed line which is under

constant pressure from a pump or pressurized

reservoir. The device cannot reset until the pressure

is removed. Such lines are a potential safety hazard

if they should leak or become broken.

1.5.3 Quick Fill Nipples:

The quick fill system is an alternative which allows

ease of filling a single Micro-Fog or Oil-Fog

lubricator without switching off the mains air (on

some units the quick fill nipple replaces the filler

plug).

To fill the lubricator, a quick fill connector

piped to a portable oil reservoir is snapped in place

over the quick fill nipple. The main oil reservoir can

now be pumped (or pressurized) to a pressure

greater than the lubricator bowl and the lubricator

filled.

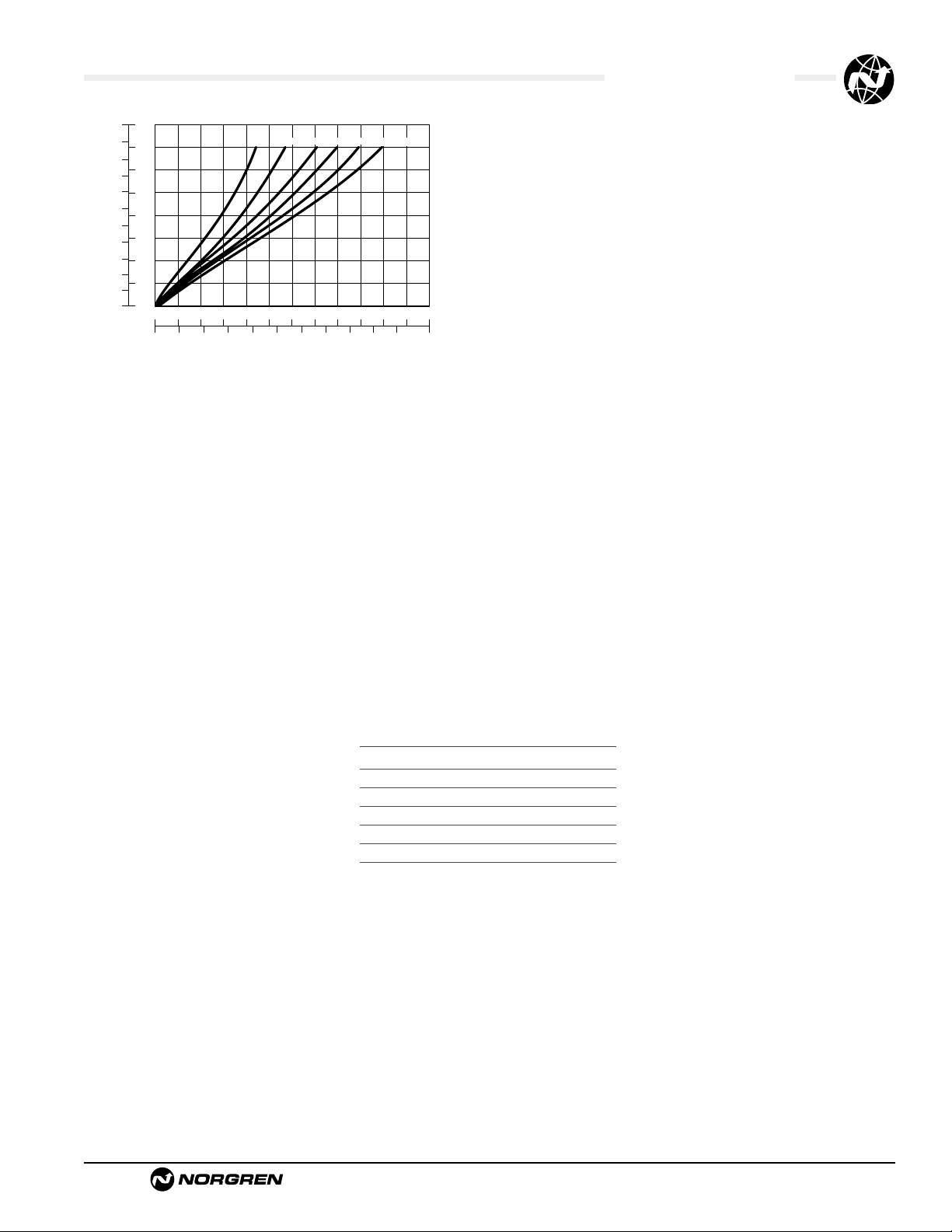

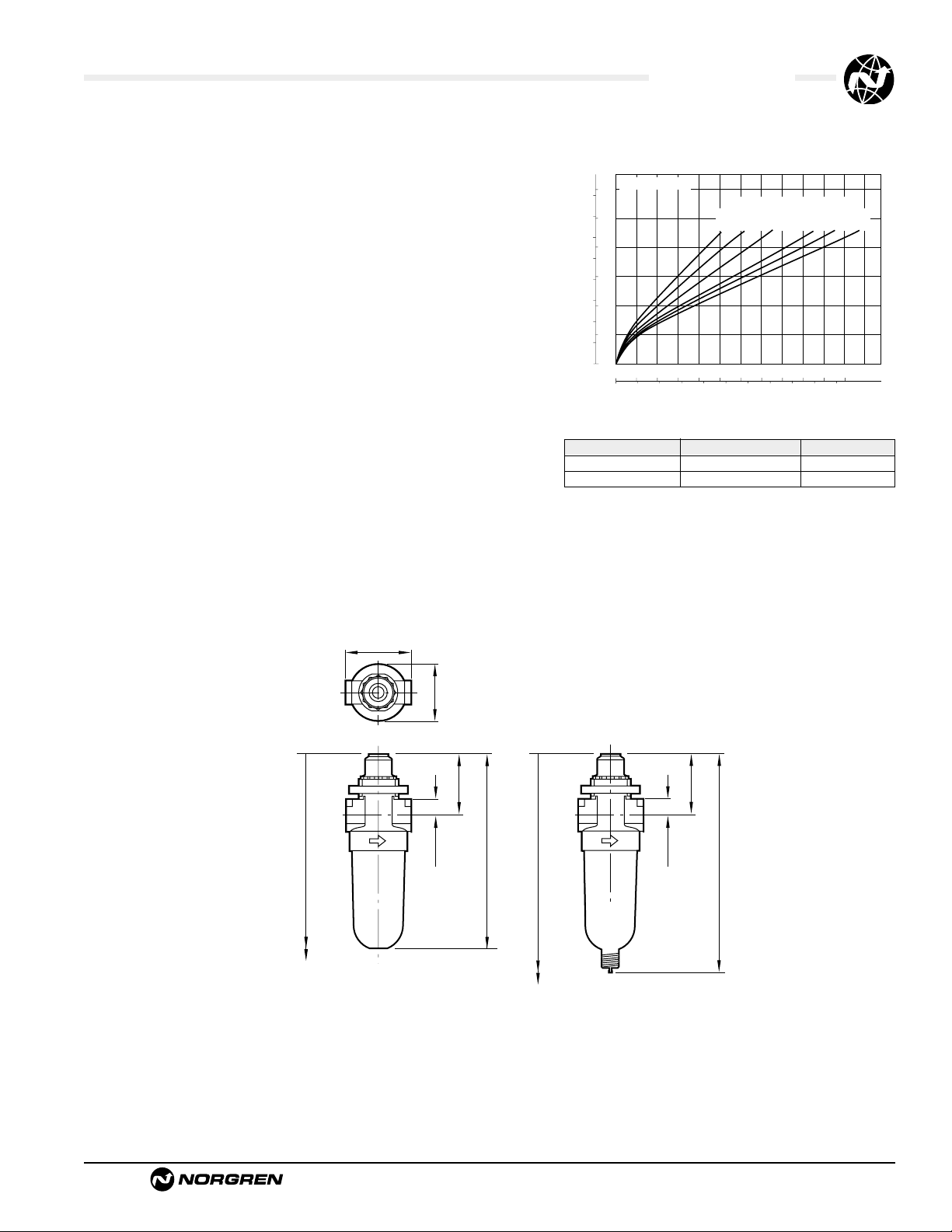

1.3 LUBRICATOR SIZING

Lubricators are sized by downstream flow

requirements. An analysis of air flow use must be

made. After determining how much air flow is

needed, a lubricator can be chosen. Manufacturers’

curves will be like the one shown. For example, 50

scfm of 90 psig lubricated air is required. Enter the

curve on the horizontal axis at the required flow.

Read up to intersect the 90 psig line. Read the

pressure drop on left, vertical axis as approximately

2.3 psid. Pressure drop should be less than 5 psid.

If pressure drop is more than 5 psid, choose a larger

lubricator.

Always be sure that the lubricants in your system are

compatible with the materials in the lubricator you

choose. This is especially important for plastic

lubricator reservoirs. If in doubt, check with the

factory or use a metal reservoir.

Flow Characteristics

bar

psig

.5

7

6

.4

5

.3

4

3

.2

Pressure Drop

2

.1

1

0

0

0

01020304050

20 40 60 80 100 120 140 160 180 200 scfm

35 60 90 120 160 180 psig

60 70 80 90 100

Air Flow

dm 3/s

Page 4

Lubricator Overview

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-D

1.6 OPTIONS AND

ACCESSORIES

1.6.1 Where can Liquid Level Switches be

Fitted?

Liquid level detection methods can be attached to

the 1 quart bowl and 2 & 5 gallon tanks.

1.6.2 Where can Remote Fill and Liquid Level

Switches be Fitted?

The smaller bowls, L73 and up, are all capable of

either remote fill or liquid level detection (but not

both at the same time!). The 2 quart and 2 & 5

gallon tanks only can have the liquid level switches

fitted.

1.6.3 How do Liquid Level Switches Work?

Liquid level switches are bipolar reed switches

which change state when the float rises and falls.

Liquid level switches are normally

connected to give an electrical signal when the float

falls (ie when the liquid level is too low). In critical

applications the logic could be reversed. Maximum

and minimum settings are possible too.

1.7 LARGE TANKS/RESERVOIRS

1.7.1 Which Units have Large Tanks/Reservoirs?

All units in basic 1/2” and above have optional

larger bowls/tanks.

Olympian Plus and Excelon 74 are limited

to 1 quart as standard. For 2 and 5 gallon capacity

use 15/17 Series, or the 10-028/-076 (2”)

lubricators.

1.8 APPLICATION SPECIFIC

UNITS

1.8.1 Do we Make Bearing Lubricators?

These are aerosol type lubricators. These

lubricators use air to get the oil to the point of

lubrication, however the tool or application is not

powered by the air. Although produced by Norgren,

systems for their application are designed and sold

by Engineering and General Lubrication Systems.

1.8.2 What is a Fixed Venturi (Bi-Directional)

Lubricator?

Standard Norgren lubricators use a flow sensor to

achieve constant oil density with varying flows. In

some applications high flow is more important than

constant density and a fixed venturi can be used

instead of a flow sensor. It may also be useful in

systems with rapid cycling. Consult Air Line for

more details.

1.9 OILS

1.9.1 What Oils are Recommended?

Recommended oils fall into 2 categories:1 Oils recommended for use with all Norgren

units (valves, cylinders, fittings and FRL’s).

2 Oils which can be used with Norgren

lubricators but not necessarily with other

Norgren equipment.

Refer to ALE-29-2 for recommended lubricants.

1.9.2 Can Non-Recommended Oils be Used?

Some oils can be tested for suitability, but Norgren

cannot be responsible for use of non-recommended

lubricants.

Page 5

Lubricators Overview

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-E

Problem

No Drip Rate

Oil Foaming

Oil Emulsified

Drip Rate changes after setting

Possible Cause

Oil adjustment knob fully clockwise.

Low oil level.

Airflow through lubricator too low.

Blocked oil filter screen.

Air leaks.

Over aeration.

Water in lubricator.

Fade.

Remedy

Readjust knob.

Check oil level.

Use smaller size lubricator.

Remove bowl and sight feed adjustment dome and

clear syphon tube.

Remove sight feed adjustment dome and clean or

replace screen located in dome assembly.

Check bowl, filler plug and sight dome seals.

Tighten if necessary.

Check bowl seals for slight leaks.

Fit filter immediately upstream.

Readjust drip rate.

1.10 SIMPLE LUBRICATOR TROUBLESHOOTING

Page 6

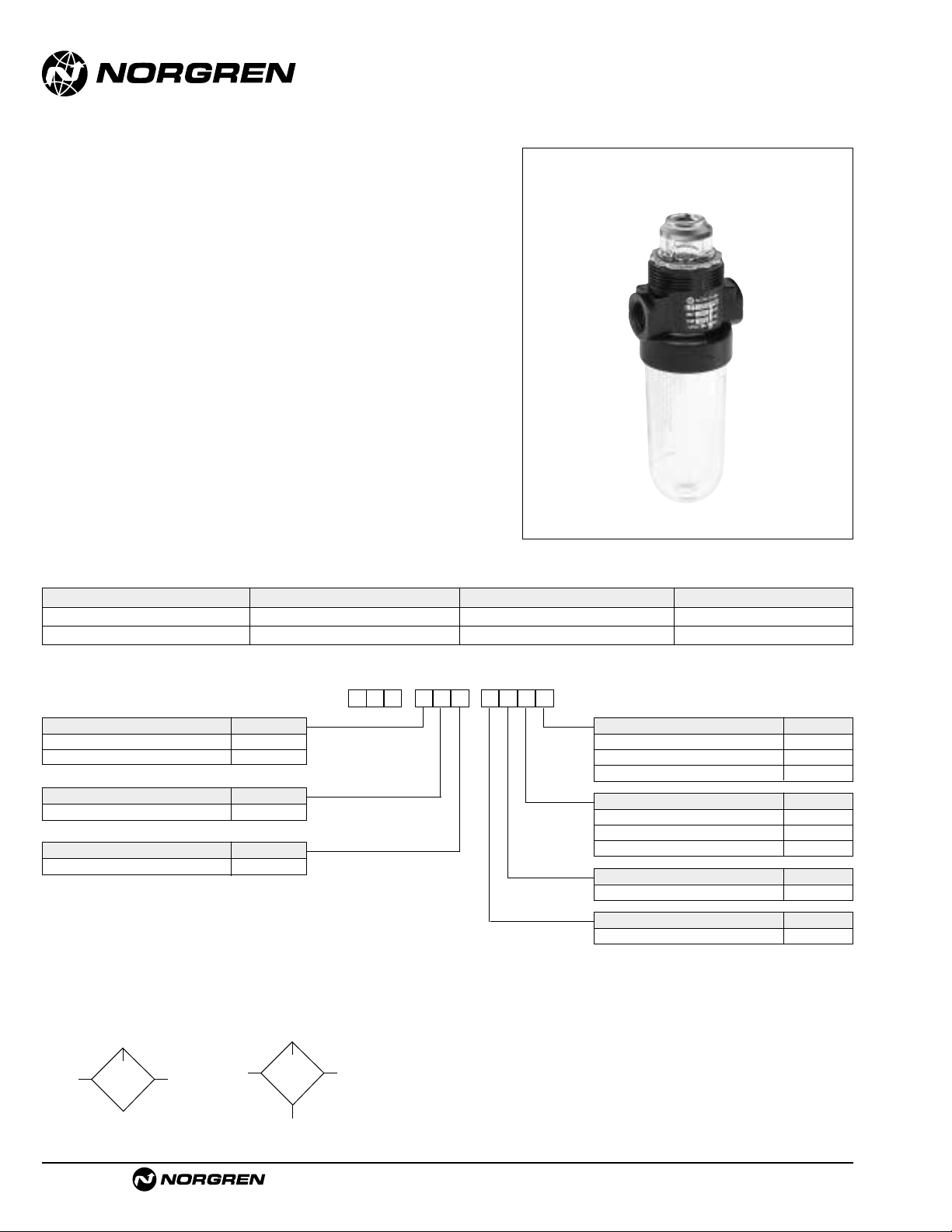

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L07

● Compact design

● Provides air line lubrication to one or more air driven

tools or other devices

● Nearly constant oil density output with varying air

flow

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● Screw-on bowl reduces maintenance time

● Can be disassembled without the use of tools or

removal from the air line

Miniature Series 07 Micro-Fog

Lubricator 1/8" and 1/4" Port Sizes

ALE-14-2

ISO Symbols

No drain Manual drain

Port Size Model Numbers Flow scfm (dm3/s)* Weight lbs (kg)

1/8" L07-100-MPAA 10 (5.0 dm3/s) 0.28 (0.13)

1/4" L07-200-MPAA 14 (6.7 dm3/s) 0.28 (0.13)

Ordering Information. Models listed include PTF threads and transparent bowl with manual drain.

* Approximate flow at 90 psig (6.3 bar) inlet pressure and 7 psig (0.5 bar) pressure drop.

Alternative Models

Port Size Substitute

1/8" 1

1/4" 2

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Option Substitute

Not applicable 0

Bowl and Drain Substitute

Transparent without drain Q

Metal with drain M

Transparent with drain A

Option Substitute

Not applicable 0

Flow Substitute

Unidirection P

Lubricator Type Substitute

Micro-Fog M

-

★PM★★

★

-

0★L 7

Page 7

L07 Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-3

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: 0° to 125°F (-20° to 50°C)

Metal bowl: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below

35°F (2°C)

Start point (i.e. minimum flow required for lubricator operation): 0.5 scfm

(0.24 dm3/s) at 90 psig (6.3 bar) inlet pressure

Typical flow at 90 psig (6.3 bar) inlet pressure at 7 psig (0.5 bar) pressure drop:

1/8" ports: 10 scfm (5 dm

3

/s)

1/4" ports: 14 scfm (6.7 dm

3

/s)

Nominal bowl size: 1 fluid ounce (31 ml)

Drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials

Body: Zinc

Bowl

Transparent: Polycarbonate

Metal: Zinc

Sight-feed dome:Transparent nylon

Elastomers: Neoprene & nitr ile

Typical Performance Characteristics

1.63 (41)

1.45 (37)

7.21 (183)†

0.38 (10)

1.65 (42)

4.72 (120)

Manua Drai

Without Drai

7.60 (193)†

0.38 (10)

1.65 (42)

5.12 (130)

† Minimum clearance to remove bowl.

Service Kits

Item Type Part number

Service kit Seal and o-ring 3795-03

Replacement drain Manual 773-03

Service kit includes o-ring, seal, and bowl o-ring.

Panel mounting hole diameter: 1.9" (30 mm)

Maximum panel thickness:0.25” (6 mm)

PORT SIZE: 1/4"

psid

bar d

0.8

10

0.6

8

6

0.4

PRESSURE DROOP

4

0.2

2

0

0

0 4 8 12 16 20 24 scfm

0 2 4 6 8 10 dm3/s

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar g)

36

23

(1.6)

(2.5)

AIR FLOW

(4.0)

58

91

(6.3)

116

150

(10)

(8)

n

n

Page 8

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L72M, L72C

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Flow sensor provides a consistent oil/air ratio over a

wide range of flows

● Highly visible, prismatic liquid level indicator lens on

metal bowls

● All round (360°) visibility of sight-feed dome for ease

of drip rate setting

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Use Micro-Fog models in applications with one or more points of

lubrication.

Use Oil-Fog models to lubricate a single tool, cylinder or other air

driven device.

Excelon 72 Micro-Fog and Oil-Fog

Lubricator 1/4",3/8" Port S iz es

ALE-14-4

Alternative Models

L 7 2

-

★ ★ ★

-

★

P

★ ★

Type Substitute

Oil-Fog C

Micro-Fog M

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Port Size Substitute

1/4" 2

3/8" 3

Options Substitute

None N

Pyrex dome P†

Drain Substitute

Closed bottom bowl E

1/4 turn manual Q

† For use with metal bowl with Pyrex sight glass

Bowl Substitute

Short metal with plastic liquid level indicator D

Short metal with Pyrex liquid level indicator R

Long metal with plastic liquid level indicator E

Long metal with Pyrex liquid level indicator U

Short transparent without guard T

Long transparent without guard L

Long transparent with guard W

Ordering Information. Models listed include PTF threads, manual drain, and long transparent bowl without guard.

* Typical flow with 90 psig (6.3 bar) inlet pressure and a pressure drop of 7 psig (0.5 bar).

Type Main Port Size Model Number Flow* scfm (dm3/s) Weight lb (kg)

†

Micro-Fog 1/4" L72M-2AP-QLN 51 (24) 1.1 (0.49)

3/8" L72M-3AP-QLN 51 (24) 1.1 (0.49)

Oil-Fog 1/4" L72C-2AP-QLN 51 (24) 1.1 (0.49)

3/8" L72C-3AP-QLN 51 (24) 1.1 (0.49)

Page 9

L72M/C Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-5

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Transparent bowl: 0° to 125°F (-20° to 50°C)

Metal bowl: 0° to 150°F (-20° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (i.e. minimum flow required for lubricator operation) at 90 psig (6.3 bar)

inlet pressure:

Micro-Fog: 2.0 scfm (0.94 dm3/s)

Oil-Fog: 1.0 scfm (0.47 dm3/s)

Typical flow at 90 psig (6.3 bar) inlet pressure and 7 psig

(0.5 bar) pressure drop: 51 scfm (24 dm

3

/s)

Nominal reservoir capacity:

Short bowl: 1.9 fluid ounce (56 ml)

Long bowl: 2.2 fluid ounce (65 ml)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials:

Body: Zinc

Reservoir:

Transparent: Polycarbonate

Guard for transparent reservoir: Zinc

Metal: Zinc

Metal reservoir liquid level indicator lens:

Transparent nylon

Sight-feed dome:Transparent nylon

Elastomers: Neoprene, nitrile, and Geolast®

Typical Performance Characteristics

** Minimum clearance required to remove bowl.

† Optional pyrex sight-feed dome.

Service Kits

Item Type Part Number

Service kit Seal and gasket 4382-500

Liquid level lens kit Prismatic 4380-030

Replacement drains 1/4 turn manual 619-50

Service kit includes plug o-ring, sight-feed dome seal, manual drain

o-ring and bowl o-ring.

psid

bar d

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 10 20 30 40 50 60 scfm

0 5 10 15 20 25 dm3/s

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar g)

36

(2.5)58(4.0)

AIR FLOW

PORT SIZE 1/4"

116

91

(8.0)

(6.3)

150

(10.0)

1.98 (50)

1.91 (48)

Micro-Fog

0.75 (19)

8.58 (218)**

Short Bowl with

1/4 Turn Manual Drain

2.51 (64) †

1.63 (41)

5.27 (134)

Oil-Fog

**

7.79 (198)

Short Bowl with

Closed Bottom

4.49 (114)

9.13 (232)**

Long Bowl with

1/4 Turn Manual Drain

5.83 (148)

8.35 (212)**

5.04 (128)

Long Bowl with

Closed Bottom

Page 10

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L73M, L73C

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Flow sensor design provides a nearly constant oil/air

ratio over a wide range of air flows

● Highly visible, prismatic liquid level indicator lens

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Use Micro-Fog models in applications containing one or more

points of lubrication.

Use Oil-Fog models to lubricate a single tool, cylinder, or other air

driven device.

Excelon 73 Micro-Fog and Oil-Fog

Lubricators 1/4",3/8",1/2" Port S i ze s

ALE-14-6

Alternative Models

Ordering Information.

Models listed include PTF threads, manual drain, and metal bowl with plastic liquid level indicator.

* Maximum recommended air flow.Higher flows create excessive air velocity, turbulence, and pressure losses.

Type Main Port Size Model Number Flow*scfm (dm3/s) Weight lb (kg)

Micro-Fog

1/4" L73M-2AP-QDN 60 (28) 1.1 (0.50)

3/8" L73M-3AP-QDN 60 (28) 1.1 (0.50)

1/2" L73M-4AP-QDN 60 (28) 1.1 (0.50)

Oil-Fog

1/4" L73C-2AP-QDN 60 (28) 1.1 (0.50)

3/8" L73C-3AP-QDN 60 (28) 1.1 (0.50)

1/2" L73C-4AP-QDN 60 (28) 1.1 (0.50)

L 7 3

-

★ ★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Air Flow Direction Substitute

Uni-directional P

Options Substitute

None N

Pyrex sight-feed dome † P

Quick fill nipple Q

Type Substitute

Oil-Fog C

Micro-Fog M

Bowl Substitute

Metal with plastic liquid level indicator D

Transparent with guard P

Metal with Pyrex liquid level indicator

†

R

Transparent T

Drain Substitute

Closed bottom E

Manual 1/4 turn Q

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

† Order optional Pyrex sight-feed dome when ordering metal bowl with Pyrex liquid level indicator.

Page 11

L73M/C Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-7

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: 0° to 125°F ( -20° to 50°C)

Metal bowl: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (minimum flow required for lubricator operation): 1.5 scfm (0.71 dm3/s)

at 90 psig (6.3 bar) inlet pressure

Typical flow with 90 psig (6.3 bar) inlet pressure and 3.5 psig (0.25 bar) pressure

drop: 80 scfm (38 dm

3

/s)

Maximum recommended flow: 60 scfm (28 dm3/s). Air flows above 60 scfm

(28 dm3/s) create excessive air velocity, turbulence, and pressure losses. In

addition, the fog produced by the lubricator will wet out on the pipe walls and will

not be carried by the compressed air to the point of application.

Nominal bowl size: 3.5 fluid ounce (0.1 liter)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials

Body: Aluminum

Bowl

Transparent: Polycarbonate

Transparent with guard: Polycarbonate, steel guard

Metal: Aluminum

Metal bowl liquid level indicator lens:Transparent nylon

Sight-Feed dome:Transparent nylon

Elastomers: Neoprene and nitr ile

Typical Performance Characteristics

10.04 (255) With Drain †

2.68 (68)

2.45 (62)

1.22 (31)

2.74 (70) **

1.87 (47)

1.00 (25)

5.38 (137) Closed Bottom

6.15 (156) With Drain

9.29 (236) Closed Bottom †

Service kit includes dome seal, drain seal, bowl seal and fill plug

seal.

Service Kits

Item Type Part Number

Service kit Seal & Gasket 4382-600

Liquid level lens kit Prismatic 4380-020

Replacement drain Manual 1/4 turn 619-50

** Optional pyrex sight-feed dome.

† Minimum clearance to remove bowl.

PORT SIZE: 3/8"

psid

bar d

5

0.3

4

3

0.2

PRESSURE DROP

2

0.1

1

0

0

0 20 40 60 80 100 scfm

01020304050dm

PORT SIZE: 3/8"

psid

bar d

5

0.3

4

3

0.2

PRESSURE DROP

2

0.1

1

0

0

0 20 40 60 80 100 scfm

0 10 20 30 40 50 dm3/s

MICRO-FOG FLOW CHARACTERISTICS

OIL-FOG FLOW CHARACTERISTICS

AIR FLOW

AIR FLOW

INLET PRESSURE:

36 (2.5)

58 (4.0)

90 (6.3)

116 (8.0)

150 (10.0)

INLET PRESSURE:

psig (bar)

36 (2.5)

58 (4.0)

90 (6.3)

116 (8.0)

150 (10.0)

psig (bar)

3

/s

Page 12

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L74M, L74C

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Flow sensor design provides a nearly constant oil/air

ratio over a wide range of air flows

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Use Micro-Fog models in applications with one or more points of

lubrication.

Use Oil-Fog models to lubricate a single tool, cylinder, or other air

driven device.

Excelon 74 Micro-Fog and Oil-Fog

Lubricators 3/8",1/2",3/4" Port S i ze s

ALE-14-8

Alternative Models

L 7 4

-

★ ★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Air Flow Direction Substitute

Bi-directional (Oil-Fog only) E

Uni-directional P

Options Substitute

Low oil level switch *** L

None N

Pyrex dome *† P

Quick fill nipple Q

Type Substitute

Oil-Fog C

Micro-Fog M

Bowl Substitute

1 quart US (1 liter) metal with

Pyrex liquid level indicator ††

A

7 fluid oz. (0.2 liter) metal with

plastic liquid level indicator

D

7 fluid oz. (0.2 liter)

transparent with guard

P

7 fluid oz. (0.2 liter) metal with

Pyrex liquid level indicator††

R

Drain Substitute

Closed bottom E

Manual 1/4 turn Q

Remote fill device - Use only

with 7 fluid oz. (0.2 liter) bowl.

R

Port Size Substitute

3/8" 3

1/2" 4

3/4" 6

*** Low oil level switch requires 1 litre bowl, type ‘A’ at 9th digit.

*† Pyrex dome used only with bowl type ‘A’or ‘R’ at 9th digit.

†† Pyrex liquid level indicator used only with option ‘P’ at 10th digit.

Ordering Information. Models listed include PTF threads, manual drain, and 7 fluid ounce (0.2 liter) metal bowl with plastic liquid level indicator.

* Models listed in the order table must not be located downstream of frequently cycling directional control valves. Order the optional bi-directional Oil-Fog Lubricator

for use under such conditions.

** Typical flow with 90 psig (6.3 bar) inlet pressure and a pressure drop of 7 psig (0.5 bar).

† Lubricators with 1 quart (1 litre) metal bowl: Add 2.01 lbs (0.91 kg).

Type Main Port Size Model Number * Flow** scfm (dm3/s) Weight lb (kg)

†

Micro-Fog

3/8" L74M-3AP-QDN 114 (54) 1.70 (0.77)

1/2" L74M-4AP-QDN 154 (73) 1.61 (0.73)

3/4" L74M-6AP-QDN 142 (67) 1.55 (0.71)

Oil-Fog

3/8" L74C-3AP-QDN 118 (56) 1.70 (0.77)

1/2" L74C-4AP-QDN 192 (91) 1.61 (0.73)

3/4" L74C-6AP-QDN 186 (88) 1.55 (0.71)

Page 13

See Section ALE-25 for Accessories

L74M/C Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-9

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Transparent bowl: 0° to 125°F (-20° to 50°C)

Metal bowl: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (i.e. minimum flow required for lubricator operation): 2.5 scfm

(0.94 dm3/s) at 90 psig (6.3 bar) inlet pressure

Typical flow with 90 psig (6.3 bar) inlet pressure and 7 psig (0.5 bar) pressure drop

Micro-fog: 154 scfm (73 dm

3

/s)

Oil-fog: 192 scfm (91 dm

3

/s)

Nominal bowl size:

Standard: 7 fluid ounce (0.2 liter)

Optional: 1 quart US (1 liter)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials

Body: Aluminum

Bowl

Transparent: Polycarbonate with steel bowl guard

Metal: Aluminum

Metal bowl liquid level indicator lens:

7 fluid ounce (0.2 liter):Transparent nylon

1 quart US (1 liter): Pyrex

Sight-feed dome:Transparent nylon

Elastomers: Neoprene and Nitr ile

ISO Symbols

No Drain

With Drain

Typical Performance Characteristics

2.40 (61)

4.32 (110)

3.15 (80)

11.14 (283) Closed Bottom

1.00 (25)

1.86 (47)

20.00 (508) †

2.89 (74)

1.00 (25)

1.45 (37)

3.15 (80)

6.18 (157) Closed Bottom

1.86 (47)

10.87 (276) †

6.95 (177) With Drain

11.93 (303) With Drain

2.69 (68)**

** Optional pyrex sight-feed dome.

† Minimum clearance required to remove bowl.

2.69 (68)**

Service kit includes dome seal, drain seal, bowl seal and

fill plug seal

Service Kits

Item Type Part Number

Service kit Seal & Gasket 4382-700

Liquid level lens kit

7 fluid ounce (0.2 liter) bowl 4380-050

1 quart US (1 liter) bowl 2273-22

Replacement drain Manual 1/4 turn 619-50

MICRO-FOG

psid

PORT SIZE: 1/2"

bar d

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 40 80 120 160 200 scfm

0 20 40 60 80 100 dm3/s

OIL-FOG

psid

PORT SIZE: 1/2"

bar d

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

36

(2.5)

FLOW CHARACTERISTICS

90

58

(6.3)

(4.0)

AIR FLOW

INLET PRESSURE: psig (bar)

36

58

(2.5)

(4.0)

116

(8.0)

150

(10.0)

90

(6.3)

116

(8.0)

150

(10.0)

0

0

0 40 80 120 160 200 scfm

0 20 40 60 80 100 dm3/s

AIR FLOW

Page 14

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L64M, L64C

● Olympian Plus plug in design

● Constant oil density output with varying flow

● Easy fill with quick release bayonet bowl

● High visibility prismatic sight glass

Use Micro-Fog models in applications with one or more points of

lubrication.

Use Oil-Fog models to lubricate a single tool, cylinder or other air

driven device.

Olympian Plus Micro-Fog and Oil-Fog

Lubricators 1/4",3/8", 1/2",3/4" Port Sizes

ALE-14-10

ISO Symbol

Ordering Information. Models listed include PTF threads and 7 fluid ounce (0.2 liter) metal reservoir with drain.

Type Port Size Model Weight lb ( kg)

1/4" L64M-2AP-QDN 3.13 (1.42)

Micro-Fog

3/8" L64M-3AP-QDN 3.09 (1.40)

1/2" L64M-4AP-QDN 3.02 (1.37)

3/4" L64M-6AP-QDN 3.81 (1.73)

L 6 4

-

★ ★ ★

-

★

P

★ ★

Type Substitute

Oil-Fog C

Micro-Fog M

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

No yoke N

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

3/4" 6

No yoke N

Options Substitute

None N

Quick fill device Q

Bowl Substitute

7 oz.Metal with liquid level indicator D

7 oz. Transparent with guard P

1 qt. metal with pyrex liquid level A

indicator

Drain Substitute

Closed bottom bowl E

Manual 1/4 turn Q

Remote fill device R

Use only with 7 oz. (0.2 liter) bowl.

Alternative Models

Page 15

L64M/C Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-11

Technical Data

Fluid: Compressed air

Maximum pressure:

Guarded transparent bowl: 150 psig (10 bar)

Metal bowll: 250 psig (17 bar)

Operating temperature*

Guarded transparent bowl: 0° to 125°F (-20° to 50°C)

Metal bowl: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (i.e. minimum flow required for lubricator operation) at 90 psig (6.3 bar)

inlet pressure

Micro-Fog: 3.2 scfm (1.5 dm3/s)

Oil-Fog: 3.2 scfm (1.5 dm

3

/s)

Typical flow at 90 psig (6.3 bar) inlet pressure and 7 psig (0.5 bar) pressure drop:

153 scfm (72 dm3/s)

Nominal bowl capacity

Transparent bowl without guard: 7 fluid ounce (0.2 liter)

Metal bowl: 7 fluid ounce (0.2 liter) standard, 1 quar t US (1 liter) optional

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials

Body: Zinc

Yoke: Zinc

Metal bowl: Aluminium

Standard metal bowl prismatic liquid level indicator lens:Grilamid

Optional metal bowl sight glass [standard on 1 quart (1 liter bowl)]: Pyrex

Optional transparent bowl: Polycarbonate

Sight-feed dome: Polycarbonate

Elastomeric materials: Synthetic rubber

Typical Performance Characteristics

Standard 7 fluid ounce (0.2 liter) bowl

Optional 1 quart US (1 liter) bowl

Service Kits

Item Type Part Number

Service kit All models 4382-200

Prismatic (standard) 4380-042

Replacement sight glass

7 fluid oz. (0.2 liter bowl)

Pyrex (optional) 4380-041

Replacement sight glass

Pyrex 2273-22

1 quart US (1 liter)

Service kit includes all seals, flow sensor, eyelet, dome screen, ball

and spring.

All Dimensions in Inches (mm)

(37)

1.46

4.13 (105)**

2.91 (74)

4.92 (125)

psid

PORT SIZE 1/2"

bar d

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 40 80 120 160 200 240 scfm

0 20 40 60 80 100 dm3/s

4.13 (105)**

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar g)

36

(2.5)58(4.0)

AIR FLOW

91

(6.3)

116

(8.0)

150

(10.0)

OPTIONAL

1-QUART

(1-LITER)

BOWL

15.67 (398)†

4.33 (110)

2.76 (70)

2.48 (63)

14.41 (366)

1.46 (37)

2.91 (74)

2.48 (63)

10.16 (258)†

9.53 (242)

** 6.18" (157) for models with 3/4" ports.

† Minimum clearance required to remove unit.

Page 16

See Section ALE-25 for Accessories

ALE-14-12

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L68M, L68C

● Olympian plug-in design

● Built in flow sensor gives almost consistant oil/air

ratio over a wide range of flows

● 1 pint and 1 quart US (0.5 and 1 liter) models can be

filled under pressure

● Simple and accurate drip rate adjustment, snap

action lock

● Ideal for general lubrication applications

Use Micro-Fog models in applications with one or more points of

lubrication.

Use Oil-Fog models to lubricate a single tool, cylinder or other air

driven device.

Use Fixed Venturi for high flow general purpose applications.

Olympian Micro-Fog and Oil-Fog Lubricator

3/4", 1, 1-1/4", 1-1/2" Po rt S i ze s

Ordering Information. Models listed include yoke with PTF threads, 1/4 turn manal drain, and 1 quart bowl with sight glass.

Type Main Port Size Model Number Flow*scfm (dm3/s) Weight lb (kg)

Micro-Fog 3/4 L68M-6AP-QUN 424 (200) 4.63 (2.10)

1 L68M-8AP-QUN 424 (200) 4.49 (2.04)

1-1/4 L68M-AAP-QUN 424 (200) 4.59 (2.08)

1-1/2 L68M-BAP-QUN 424 (200) 4.67 (2.12)

Oil-Fog 3/4 L68C-6AP-QUN 396 (187) 4.63 (2.10)

1 L68C-8AP-QUN 396 (187) 4.49 (2.04)

1-1/4 L68C-AAP-QUN 396 (187) 4.59 (2.08)

1-1/2 L68C-BAP-QUN 396 (187) 4.67 (2.12)

* Typical flow with 90 psig (6.3 bar) inlet pressure and a pressure drop of 7 psig (0.5 bar).

Alternative Models

L 6 8

-

★ ★ ★

-

★★ ★ ★

Type Substitute

Oil-Fog C

Micro-Fog M

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

None N

Type Substitute

Uni directional P

Fixed venturi (Oil-Fog) E

Port Size Substitute

3/4" 6

1" 8

1-1/4" A

1-1/2" B

None N

Options Substitute

None N

Quick fill device Q

Drain Substitute

Closed bottom bowl E

Manual M

No drain N

Manual, 1/4 turn Q

Remote fill R*

Bowl Substitute

1 quart US (1 liter), without sight glass C*

2 gallons US (8 liter) X

5 gallons US (20 liter) Y

1 pint US (0.5 liter), without sight glass M*

1 pint US (0.5 liter) with sight glass R*

1 quart US (1 liter) with sight glass U*

* Remote fill only available with 1 pint and 1 quart US (1/2 and 1 liter bowls)

ISO Symbol

Page 17

L68M/C Lubricators

ALE-14-13

All Dimensions in Inches (mm)

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

Typical Performance Characteristics

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to +175°F (-20° to +80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below +35°F (+2°C).

Start point (i.e. minimum flow required for lubricator operation) at

90 psig (6.3 bar) inlet pressure:

Micro-Fog: 13 scfm (6 dm3/s)

Oil-Fog: 13 scfm (6 dm3/s)

Fixed venturi: 110 scfm (52 dm3/s)

Typical flow at 90 psig (6.3 bar) inlet pressure and 7 psig

(0.5 bar) pressure drop:

Micro-Fog: 424 scfm (200 dm3/s)

Oil-Fog: 396 scfm (187 dm3/s)

Fixed venturi: 848 scfm (400 dm3/s)

Nominal bowl sizes:

1 pint US (0.5 liter)

1 quart US (1 liter)

2 gallons US (8 liter)

5 gallons US (20 liter)

Recommended lubricants: See page ALE-29-2

Materials:

Body: Aluminum

Yoke: Aluminum

Bowl, 1 pint US (0.5 liter) and 1 quart US (1 liter): Aluminum

Bowl sight glass: Pyrex

Reservoirs, 2 gallons US (8 liter) and 5 gallons US (20 liter):

Steel

Reservoir sight tube: Polythene

Elastomers: Synthetic r ubber

1 Pint US

(0.5 Liter) Bowl

1/4 Turn Manual Drain

8.2 (208)

14.2 (361)†

Closed Bowl

(No Drain)

7.5 (190)

2.91

(74)

2.40

(61)

.

13.5 (343)†

Manual Drain

7.8 (197)

13.8 (350)†

7.48 (190)**

2.13

(54)

** Add 0.39" (10 mm) for 1-1/4" and 1-1/2"models. † Minimum clearance required to remove bowl.

1 Quart US

(1 Liter) Bowl

1/4 Turn Manual Drain

10.6 (269)

18.2 (463)†

Manual Drain

10.2 (258)

17.8 (452)†

Closed Bowl (No Drain)

9.9 (251)

17.5 (445)†

2.40

(61)

.

2.91

(74)

Service Kits

Item Type Part Number

Micro-Fog 4382-301

Service kit Oil-Fog 4382-300

Fixed venturi 4382-302

Replacement

1 pint US (0.5 liter) 4380-060

sight glass

1 quart US (1 liter) 4380-061

2 & 5 gal (8 & 20 liter) 2274-01

Replacement drain

Manual 684-84

Manual, 1/4 turn 619-50

Service kit includes sight dome, screen, filler plug, seals and o-rings.

Oil fog service kit also contains check valve spring.

psid

bar d

0.8

0.6

0.4

PRESSURE DROP

0.2

0

0.8

0.6

0.4

PRESSURE DROP

0.2

0

0.8

0.6

0.4

PRESSURE DROP

0.2

PORT SIZE: 1"

MICRO-FOG

10

8

6

4

2

0

0 80 160 240 320 400 480 scfm

0 40 80 120 160 200 dm3/s

psid

bar d

PORT SIZE: 1"

OIL-FOG

10

8

6

4

2

0

0 80 160 240 320 400 480 scfm

0 40 80 120 160 200 dm3/s

FIXED VENTURI

psid

bar d

PORT SIZE 1 1/2"

10

8

6

4

2

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

36

(2.5)58(4.0)

AIR FLOW

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

36

(2.5)58(4.0)

AIR FLOW

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

36

(2.5)58(4.0)

(6.3)

91

(6.3)

116

91

(8.0)

91

(6.3)

116

(8.0)

150

(10.0)

116

(8.0)

150

(10.0)

150

(10.0)

0

0

0 200 400 600 800 1 000 scfm

0 100 200 300 400 500 dm3/s

Top View

2 and 5 Gallon

(8 and 20 liter)

Reservoirs

AIR FLOW

7.18 (182) 2 gal

11.18 (284) 5 gal

7.81 (198) 2 gal

11.81 (300) 5 gal

Front View

7.48 (190)**

(74)

2.91

21.2 (538) 2 gal Reservoir

24.2 (614) 5 gal Reservoir

Page 18

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

L17

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● Screw-on bowl reduces maintenance time

● Can be serviced without the use of tools or removal

from the air line

● Flow sensor design provides a nearly constant oil/air

ratio over a wide range of air flows

Use Micro-Fog models in applications containing one or more

points of lubrication

Use Oil-Fog models to lubricate a single tool, cylinder, or other air

driven device

17 Series Micro-Fog and Oil-Fog Lubricators

3/4",1", 1-1/4" and 1-1/2" Port S i ze s

ALE-14-14

ISO Symbol

Manual drain

Alternative Models

-

★★★ ★★ ★

-

1★L 7

Threads Substitute

PTF A

ISO Rc taper B

BSPP (1-1/2" ported units) C

ISO G parallel (not available G

with 1-1/2" ported units)

Reservoir Substitute

1 quart US (1 liter) metal, drain, sight glass D

1 quart US (1 liter) metal, remote fill, sight glass 4

2 quart US (2 liter) metal, drain, sight glass H

2 gallon US (8 liter) metal, drain, sight glass J

5 gallon US (20 liter) metal, drain, sight glass K

Lubricator Type Substitute

Micro-Fog M

Oil-Fog O

Port Size Substitute

3/4" 6

1" 8

1-1/4" A

1-1/2" B

Flow Substitute

Bi-directional (Oil-Fog only) E

Uni-directional P

Option Substitute

Not applicable 00

Ordering Information. Models listed are uni-directional and include a 1 quart US (1 liter) metal bowl with drain, sight glass, and PTF threads.

Port Size Micro-Fog Models* Oil-Fog Models* Flow† scfm ( dm3/s) Weight lbs ( kg)

3/4" L17-600-MPDA L17-600-OPDA 160 (76) 3.73 (1.69)

1" L17-800-MPDA L17-800-OPDA 275 (130) 3.56 (1.62)

1-1/4" L17-A00-MPDA L17-A00-OPDA 275 (130) 4.65 (2.11)

1-1/2" L17-B00-MPDA L17-B00-OPDA 275 (130) 3.67 (1.67)

* Models listed in the order table must not be located downstream of frequently cycling directional control valves.Order the optional

bi-directional Oil-Fog Lubricator for use under such conditions.

† Typical flow with 90 psig (6.3 bar) inlet pressure and a pressure drop of 5 psig (0.35 bar).

Page 19

L17 Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-15

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (minimum flow required for lubricator operation): 8 scfm (3.8 dm3/s) at

90 psig (6.3 bar) inlet pressure

Typical flow with 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure

drop:

1" ports: 275 scfm (130 dm

3

/s)

Nominal reservoir size

Standard: 1 quar t US (1 liter)

Optional: 2 quar t US (2 liter)

2 gallon US (8 liter)

5 gallon US (20 liter)

Manual drain connection on 1 quart reservoir: Will fit 1/8-27 and 1/8-28 pipe thread

Recommended lubricants: See Section ALE-29.

Materials

Body: Aluminum

Reservoir:

1 quart US (1 liter): Aluminum

2 quart US (2 liter) and larger: Steel**

Reservoir sight glass: Pyrex

Sight-feed dome

Standard:Transparent nylon

Optional: Pyrex and aluminum

Elastomers: Neoprene and nitr ile

** The 2 and 5 gallon (8 and 20 liter) steel reservoirs are ASME rated according to

the ASME Pressure Vessel Code, Section VIII

Typical Performance Characteristics

Reservoir A B ∅ C

2 quart US (2 liter) 13.1 ( 333) 4.63 (118) 5.38 (137)

2 gallon US (8 liter) 21.2 (538) 6.25 (159) 7.44 (189)

5 gallon US (20 liter) 24.2 (614) 10.3 (260) 11.4 (291)

† Standard dome:2.03" (52 mm)

Pyrex dome: 2.72"(69 mm)

†† Minimum clearance required to remove bowl.

Service kit 5771-02 includes o-rings, seals and gaskets.

Reservoir sight glass kits, include all o-rings, seals, glass,

guard, and sight glass hardware.

Service Kits

Item Type Part Number

Service kit Oil-Fog and Micro-Fog 5771-02

Reservoir sight glass kit

1 quart US (1 liter) 2273-22

2 quart US (2 liter) 2273-04

2/5 gallon US (8/20 liter) 2274-01

Replacement drain 1/4 Turn 619-50

150

INLET PRESSURE:

psid

bar d

psig (bar g)

5

0.3

4

3

0.2

PRESSURE DROP

2

0.1

1

0

0

0 80 160 240 320 400 scfm

0 40 80 120 160 200 dm3/s

36 (2.5 ) 58 (4.0)

AIR FLOW

90 (6.3)

116 (8.0)

PORT SIZE: 1"

(10.0)

180

(12.5)

L17 Micro-Fog

4.50 (114)

L17 Oil-Fog Micro-Fog shown,

Typical of Oil Fog

4.32 (110)

(52)

2.03†

16.9 (429)††

10.4 (265) with drain

10.0 (254) without drain

2.40

(61)

C

1 quart US (1 liter) reservoir

1/4 turn drain 2 quart US (2 liter) reservoir

2 gallon US (8 liter) reservoir

5 gallon US (20 liter) reservoir

A

B

Page 20

See Section ALE-25 for Accessories

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-16

10-028

● Designed to lubricate a single tool, valve, cylinder, air

motor,or other air driven device.

● One Oil-Fog lubricator should be provided for each

device requiring lubrication

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● Lubricators equipped with 1 and 2 quart (1 and 2 liter)

reservoirs can be filled under pressure

● The 2 and 5 U.S. gallon (8 and 20 liter) reservoirs are

rated to ASME Pressure Vessel Code, Section VIII

Oil-Fog Lubricator

1-1/2" Po rt Si ze

ISO Symbol

With Drain

* Models with 1 and 2 quart reservoirs must not be located downstream of frequently cycling directional control valves.Models with the 2 and 5 gallon reser voirs may

be located downstream of frequently cycling directional control valves.

** At 100 psig (6.9 bar) inlet pressure and pressure drop of 5 psid (0.35 bar).

Reservoir Recommended

Reservoir Working Capacity Operating Flow Range** Weight

Model Number Nominal Size Fluid Ounce (Liter) scfm (dm3/s) lbs (kg)

10-028-045 1 quart (1 liter) * 19 (0.56) 110 to 590 (52 to 278) 5 (0.91)

10-028-046 2 quart (2 liter) * 45 (1.33) 110 to 590 (52 to 278) 6 (2.72)

10-028-047 2 U.S. gallon (8 liter) 113 (3.34) 110 to 590 (52 to 278) 16 (7.26)

10-028-048 5 U.S. gallon (20 liter) 316 (9.34) 110 to 590 (52 to 278) 28 (12.70)

Ordering Information. Models listed have 1-1/2" PTF parallel threads.

Alternative Models

2

★

-

★

★★ ★

8

- -

0

1

Option Add

Factory installed quick fill nipple -2J

Factory installed sight feed dome -8W

★

Threads Substitute

PTF 0

ISO G parallel 8

Page 21

10-028 Lubricators

ALE-14-17

All Dimensions in Inches (mm)

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (minimum flow required for lubricator operation) at 90 psig (6.3 bar)

inlet pressure: 103 scfm (49 dm3/s)

Typical flow at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop:

568 scfm (268 dm3/s)

Nominal reservoir sizes:

1 quart (1 liter)

2 quart (2 liter)

2 U.S.gallon (8 liter)

5 U.S.gallon (20 liter)

Recommended lubricants: See Section ALE-29.

Materials

Body: Aluminum

Reservoir: Steel

Reservoir liquid level indicator lens:Pyrex

Sight-feed dome

Standard:Transparent nylon

Optional: Pyrex and aluminum

Elastomers: Neoprene and Nitr ile

Typical Performance Characteristics

Reservoir A B C D

1 quart (1 liter) 4.72 (120) 4.06 (103) 8.27 (210) 15 (376)

2 quart (2 liter) 5.28 (134) 4.63 (118) 10.52 (267) 19 (477)

2 gallon (8 liter) 7.81 (198) 7.18 (182) 18.34 (466) 32 (813)

5 gallon (20 liter) 11.81 (300) 11.18 (284) 21.59 (548) 37 (940)

C

5.25 (133)

2.19

(56)

1 and 2 quart (1 and 2 liter) reservoir 2 and 5 gallon (8 and 20 liter) reservoir

** Optional pyrex sight-feed dome.

† Minimum clearance required to remove bowl.

5.25 (133)

2.19

(56)

C

D †

D †

B

A

A

B

3.03

(77)**

3.03

(77)

**

Liquid level lens kit include sight glass, sight glass guards, seals,

and hardware.

Service Kits

Item Type Part Number

1 quart reservoir 2272-02

Liquid level lens kit 2 quart reservoir 2273-04

2 and 5 gallon reservoir 2274-01

Replacement drain Manual petcock 684-01

bar

psig

200

12

8

INLET PRESSURE

4

0

A: Minimum flow based on oil drip rate of 5 drops per minute.

B: Maximum flow based on pressure drop of 5 psid (0.35 bar).

A

160

120

80

40

0

0 200 400 600 800 1000 scfm

0 100 200 300 400 500 dm3/s

OPERATING RANGE

Oil: SAE 10

Oil Feed Setting: Maximum

B

AIR FLOW

Page 22

See Section ALE-25 for Accessories

ALE-14-18

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

10-076

● Designed to lubricate a single tool, valve, cylinder, air

motor,or other air driven device

● One Oil-Fog lubricator should be provided for each

device requiring lubrication

● All around (360°) visibility of the sight-feed dome

simplifies installation and adjustment

● The 2 and 5 U.S. gallon (8 and 20 liter) reservoirs are

rated to ASME Pressure Vessel Code, Section VIII

Oil-Fog Lubricator

2" Po rt Si ze

ISO Symbol

With Drain

* At 100 psig (6.9 bar) inlet pressure and pressure drop of 5 psid (0.35 bar).

Reservoir Recommended

Reservoir Working Capacity Operating Flow Range* Weight

Model Number Nominal Size Fluid Ounce (Liter) scfm (dm3/s) lbs (kg)

10-076-004 2 U.S. gallon (8 liter) 113 (3.34) 250 to 1000 (118 to 472) 19 (8.6)

10-076-005 5 U.S. gallon (20 liter) 316 (9.34) 250 to 1000 (118 to 472) 32 (14.5)

Ordering Information. Models listed have 2" PTF threads.

Alternative Models

7

★

-

★

★★ ★

6

- -

0

1

Option Add

Factory installed pyrex sight feed dome 8W

★

Threads Substitute

PTF 0

ISO G parallel 8

Page 23

10-076 Lubricators

ALE-14-19

All Dimensions in Inches (mm)

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Start point (minimum flow required for lubricator operation) at 90 psig (6.3 bar)

inlet pressure: 240 scfm (123 dm3/s)

Typical flow with 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure

drop: 1300 scfm (614 dm3/s)

Nominal reservoir sizes:

2 U.S.gallon (8 liter)

5 U.S.gallon (20 liter)

Recommended lubricants: See Section ALE-29.

Materials

Body and adapter: Aluminum

Reservoir: Steel

Reservoir liquid level indicator lens:Pyrex

Sight-feed dome

Standard:Transparent nylon

Optional: Pyrex and aluminum

Elastomers: Nitrile

Typical Performance Characteristics

Reservoir A B C D

2 gallon (8 liter) 7.81 (198) 7.18 (182) 21.53 (547) 35 (887)

5 gallon (20 liter) 11.81 (300) 11.18 (284) 24.78 (629) 40 (1014)

C

5.13 (130)

2.31

(59)

2 and 5 gallon (8 and 20 liter) reservoir

** Optional pyrex sight-feed dome.

† Minimum clearance required to remove bowl.

D †

A

B

3.15

(80)**

Reservoir sight glass kits include sight glass, sight glass guards,

seals, and hardware.

Service Kits

Item Type Part Number

Liquid level lens kit 8 and 20 liter reser voir 2274-01

Replacement drain Manual petcock 684-01

bar

psig

240

16

200

12

160

120

8

80

INLET PRESSURE

4

40

0

0

A: Minimum flow based on oil drip rate of 5 drops per minute.

B: Maximum flow based on pressure drop of 5 psid (0.35 bar).

A

0 400 800 1200 1600 2000 scfm

0 200 400 600 800 1000 dm3/s

OPERATING RANGE

Oil: SAE 10

Oil Feed Setting: Maximum

AIR FLOW

B

Page 24

See Section ALE-25 for Accessories

ALE-14-20

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

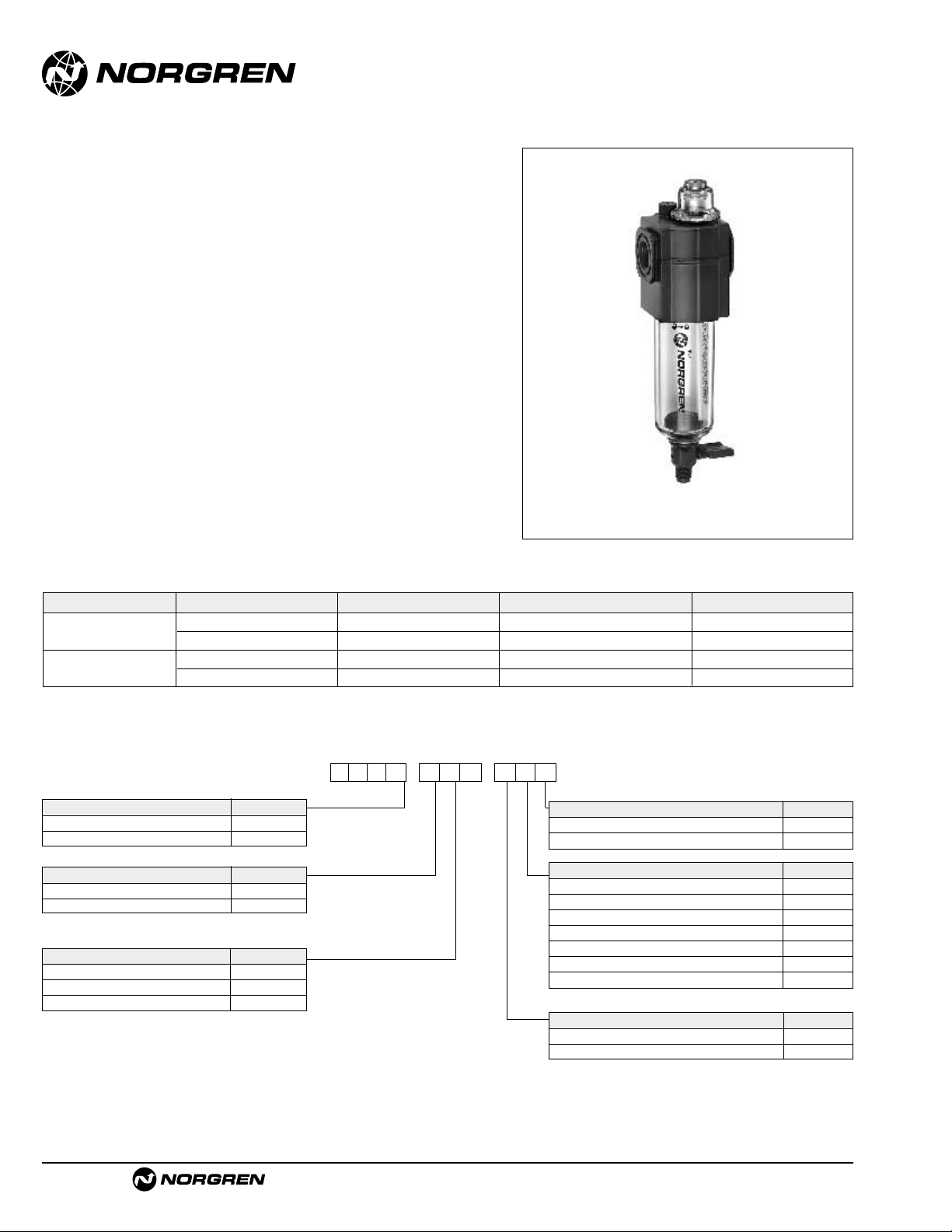

10-015, 10-065

● Provides centralized air-borne lubrication for

machine bearings, gears, chains, slides, ways, etc

● Controls can be installed to start-up and shut-down

the lubricator with the machine

● Delivers a fog of oil to the application points, coating

bearing surfaces with a thin oil film and reducing oil

consumption

● Air carrying the lubricants passes through the

bearing housing, reducing bearing temperature and

contamination, providing longer bearing life

● The 2 and 5 U.S. gallon (8 and 20 liter) reservoirs are

rated to ASME Pressure Vessel Code, Section VIII

● Refer to Norgren Publication NT-1 for system design,

bearing-inch ratings, and reclassifier selection

Micro-Fog® Machine Bearing Lubricator

8 to 32 Bearing Inch Ratings 1/4" Po rt Si ze

ISO Symbol

With Drain

Model Number Reservoir - Nominal Size Reservoir - Working Capacity Weight lbs (kg)

10-015-100 * 1/2 pint (0.25 liter) — 2 (0.91)

10-015-002 1/2 pint (0.25 liter) 5 fluid ounce (0.15 liter) 2 (0.91)

10-015-504 1 quart (1 liter) 19 fluid ounce (0.56 liter) 4.0 (1.8)

10-015-005 2 quart (2 liter) 45 fluid ounce (1.33 liter) 6 (2.72)

10-065-006 2 U.S. gallon (8 liter) 113 fluid ounce (3.34 liter) 15.4 (7.0)

10-065-007 5 U.S. gallon (20 liter) 316 fluid ounce (9.34 liter) 28 (12.7)

Ordering Information. Models listed have 1/4" PTF threads and are rated from 8 to 32 bearing inches.

* Equipped with factory installed remote fill device.

Alternative Models

★

0

-

★

★★ ★★

- -

0

1

Option Add

Wall bracket attached to 10-015 -1B

models

Quick fill -2H

Pyrex sight feed dome -7C

Low oil level switch with 10-015-504 -3A

Low oil level switch with 10-015-005 -3A

Low oil level switch with 10-065-006 -3D

Low oil level switch with 10-065-007 -3E

Bowl guard for 0.5 pint reservoir -2U

★

Page 25

10-015, 10-065 Lubricators

ALE-14-21

All Dimensions in Inches (mm)

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: 0° to 125°F (-20° to 50°C)

Metal bowl: 0° to 175°F (-20° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Nominal reservoir sizes

10-015-002: 1/2 pint (0.25 liter)

10-015-100: 1/2 pint (0.25 liter)

10-015-504: 1 quart (1 liter)

10-015-005: 2 quart (2 liter)

10-065-006: 2 U.S. gallon (8 liter)

10-065-007: 5 U.S. gallon (20 liter)

Recommended lubricants: See Section ALE-29.

Materials

Body: Zinc

Bowl:

Transparent 1/2 pint (0.25 liter): Polycarbonate

Metal

1 quart (1 liter): Aluminum

2 quart, 2 and 5 gallon (2, 8, 20 liter): Steel

Metal bowl liquid level indicator lens:Pyrex

Sight-feed dome

Standard: Polycarbonate

Optional: Pyrex and brass

Elastomers: Neoprene and nitr ile

3.38 (86)

3.81 (97)

1.92

(49)

7.52 (191)

1.91

(49)

9.45 (240) *

5.60 (142)

10-015-002

1/2 pint (0.25 liter) reservoir

* Minimum clearance required to remove bowl.

C

A

D

B

3.38 (86)

1.92

(49)

10-065-006/-007

2 and 5 gallon (8 and 20 liter) reservoir

E *

10-015-504

1 quart (1 liter) reservoir

E *

3.38 (86)

1.92

(49)

D

C

B

A

10-015-005

2 quart (2 liter) reservoir

B

A

3.38 (86)

1.92

(49)

D

C

E *

Reservoir A B C D E

1 quart (1 liter) 4.58 (116) 4.36 (111) 12.73 (323) 10.8 (275) 19 (475)

2 quart (2 liter) 5.28 (134) 4.63 (118) 11.69 (297) 9.77 (248) 18 (457)

2 gallon (8 liter) 7.81 (198) 7.18 (182) 19.51 (496) 17.59 (447) 31 (787)

5 gallon (20 liter) 11.81 (300) 11.18 (284) 22.76 (578) 20.84 (529) 36 (914)

Service kit 714-01 includes dome, o-rings, gaskets, siphon tube

filter, siphon tube check ball.

Reservoir sight glass kits include sight glass, sight glass guards,

seals, and hardware.

Service Kits

Item Type Part Number

Service kit Seal & Gasket 714-01

Liquid level lens kit 1 quart reservoir 2273-22

2 quart reservoir 2273-04

2 and 5 gallon reservoir 2274-01

Replacement drain Manual petcock 684-01

Page 26

10-015, 10-065 Lubricators

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

ALE-14-22

Machine Bearing Lubricators

Machine bearing lubricators deliver a fog of small oil particles through a

manifold system to various machine elements (bearings, gears, chains, etc).

At the machine elements a nozzle-like fitting, called a reclassifier, causes the

small oil particles to combine into larger par ticles. The larger particles cover

the bearing surfaces with a protective film of clean oil.An air line filter and

pressure regulator must be installed immediately upstream of the lubricator.

How to Select

Selection requires a careful analysis of the lubrication requirements of the

machine. After the analysis, the proper lubricator, reservoir, and reclassifiers

may be ordered.The following is an abbreviated summary of the steps

required to analysis lubrication requirements of the machine. See Norgren

Publications NT-1, Design Manual for Machine Lubrication, for complete

details.

1. Determine the bearing inch requirement.

a. List and identify the bearing-inch rating of all machine

elements requiring lubrication.

b. List the reclassifier ratings required at each point of

lubrication.

c. Total the reclassifier ratings. This is the bearing-inch

requirement to use in selecting the lubricator.

2. Determine reservoir capacity required.

a. Calculate rate of oil usage based on bearing-inch rating.

b. Determine how often the reservoir can be refilled.

c. Select reser voir capacity.

3. Determine the air flow required. See the Operating

Ranges and Air Flow Requirements char t for air flow

requirements of the lubricator.

4. Determine any accessories required.

Straight, compression tube Elbow, compression tube Pressure jet, compression tube Straight, pipe thread* 1/4 OD copper tube, solder

Model BI Rating Model BI Rating Model BI Rating Model BI Rating Model BI Rating

18-009-003 0 to 1 18-009-008 0 to 1 18-009-030 0 to 1 18-009-001 0 to 1 18-009-029 2 to 4

18-009-010 1 to 2 18-009-011 1 to 2 18-009-031 1 to 2 18-009-002 0 to 1

18-009-012 2 to 4 18-009-013 2 to 4 18-009-032 2 to 4 18-009-005 2 to 4

18-009-014 4 to 8 18-009-015 4 to 8 18-009-006 2 to 4

18-009-007 4 to 8

Reclassifiers with Bearing Inch (BI) Ratings - Dimensions in mm (inches)

0.5

(13)

1.75 (45)

1 (25)

1 (25)

1/8 NPT

1.25 (32)

* 1/4 NPT female x 1/8 NPT male threads all models except 18-009-002 and -006, which have 1/4 NPT female and male threads.

Operating Ranges and Air Flow Requirements

Bearing Lubricator Manifold

Inch Inlet Pressure Air Flow Pressure

Requirement psig (bar) scfm (dm3/s) Inches H2O

16 8 (0.6) 1.6 (0.76) 8

24 17 (1.2) 2.4 (1.13)

32 26 (1.8) 3.1 (1.46)

16 10 (0.7) 1.8 (0.85) 10

24 20 (1.4) 2.7 (1.27)

32 31 (2.2) 3.6 (1.70)

16 12 (0.8) 2.0 (0.94) 12

24 23 (1.7) 3.0 (1.42)

32 35 (2.4) 4.0 (1.89)

8 6 (0.4) 1.1 (0.52) 15

16 15 (1.0) 2.2 (1.04)

24 26 (1.8) 3.3 (1.56)

32 40 (2.8) 4.5 (2.12)

0.5

1.25 (32)

(13)

1/8 NPT

0.5

(13)

1/8 NPT

1.19 (30)

0.69

1.47 (37)

(18)

0.75 (19)

Copper Tube

Loading...

Loading...