Page 1

L73M, L73C

Installation & Maintenance

Instructions

FILL RESERVOIR (MICRO-FOG LUBRICATORS)

Shut off inlet air pressure and reduce pressure in reservoir

to zero. Remove fill plug (2), add oil, and reinstall fill plug.

Do not remove the fill plug when the reservoir is

pressurized, as oil will blow out the fill plug hole. Micro-

fog lubricators can be filled under pressure only if equipped

with the optional quick fill cap (4), which requires a quick

fill connector and oil pump. Fill to maximum fill line on

transparent reservoirs. Oil level must always be visible in

lens on metal reservoirs. DO NOT OVERFILL.

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a constant

rate of air flow thru the lubricator. Monitor drip rate thru

sight feed dome (6).

3. Oil-Fog Lubricators - Determine the average rate of flow

thru the lubricator. Turn green rotator in sight feed dome

(6) to obtain one drop per minute for each 5 dm

3

/s (10

scfm). For example, if the average flow is 19 dm

3

/s (40

scfm), set the drip rate at 4 drops per minute. Turn

rotator counterclockwise to increase and clockwise to

decrease the drip rate. Total travel of rotator is 320°.

4. Micro-Fog Lubricators - Determine the average rate of

flow thru the lubricator. Turn red rotator in sight feed

dome (6) to obtain the recommended drops per minute.

See Drip Rate Chart. Turn rotator counterclockwise to

increase and clockwise to decrease the drip rate. Total

travel of rotator is 320°.

Drip Rate Chart for Micro-Fog Lubricators

Flow - dm

3

/s (scfm) Drops per Minute

2 (5) 3

5 (10) 4

10 (20) 7

15 (30) 9

20 (40) 12

25 (50) 15

5. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the oil

delivery at the device appears either excessive or low.

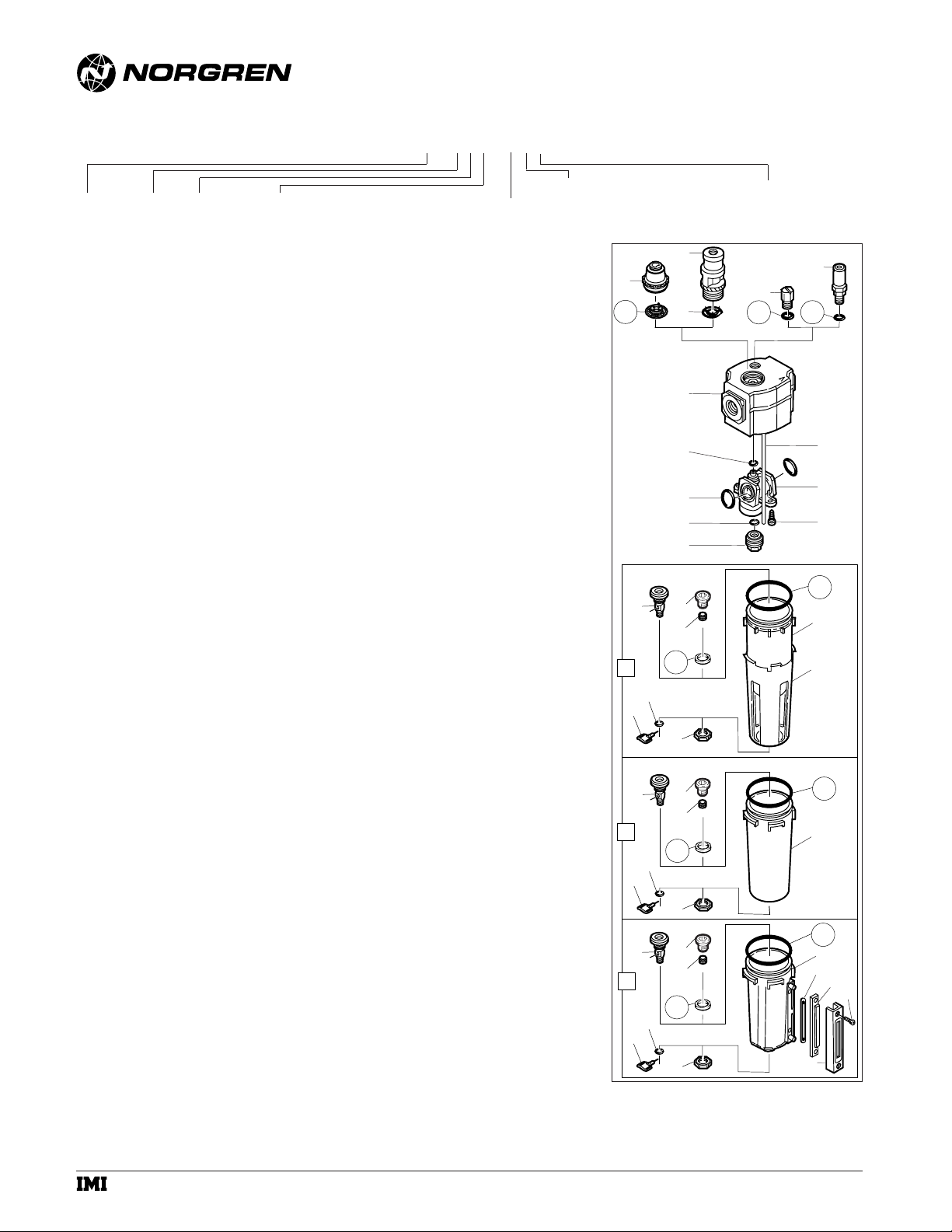

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero. Loosen fill plug (2).

2. Remove reservoir - push into body and turn

counterclockwise.

3. Disassemble in general accordance with the item

numbers on exploded view. Do not remove the manual

drain unless replacement is necessary. Remove and

replace drain assembly only if drain malfunctions. Do not

remove siphon tube (49). Remove and replace items 50

thru 55 only if lubricator malfunctions. O-ring (55) is

only used on Micro-Fog lubricators.

CLEANING

1. Clean plastic reservoir with warm water only. Clean other

parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with clean,

dry compressed air.

3. Inspect parts. Replace parts found to be damaged. If

plastic reservoir shows signs of cracking or cloudiness,

replace with a metal reservoir.

ASSEMBLY

1. Lubricate o-rings, the portion of the manual drain body

(18, 28, 37) that contacts the bowl, and the hole in the

manual drain body that accommodates the stem of drain

valve (19, 29, 38) with o-ring grease.

2. Assemble lubricator as shown on exploded view.

3. Torque Table N-m (Inch-Pounds)

2 (Fill Plug), 4 (Quick-fill cap) 1,1 to 1,6 (10 to 14)

6, 8 (Dome) 2,3 to 2,8 (20 to 25)

43 (Screw) 1,3 to 2,0 (12 to 18)

50 (Screw) 2,0 to 2,5 (18 to 22)

4. Push reservoir, or reservoir with guard, into body and

turn fully clockwise.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 10 bar (150 psig)

Metal bowl: 17 bar (250 psig)

Operating temperature*:

Transparent bowl: -20° to +50°C (0° to +125°F)

Metal bowl: -20° to +80°C (0° to +175°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Start point (minimum flow required for lubricator operation)

at 6,3 bar (90 psig) inlet pressure:

0,71 dm

3

/s (1.5 scfm)

Maximum recommended flow: 28 dm

3

/s (60 scfm). Air flows

above 28 dm

3

/s (60 scfm) create excessive air velocity,

turbulence, and pressure losses. In addition, the fog

produced by the lubricator will wet out on the pipe walls

and will not be carried by the compressed air to the point

of application.

Typical flow with 6,3 bar (90 psig) inlet pressure and 0,5

bar(7 psig) pressure drop:

Oil-Fog models: 75 dm

3

/s (158 scfm)

Micro-Fog models: 65 dm3/s (138 scfm)

Nominal bowl size: 0,1 litre (3.5 fluid ounce)

Manual drain connection: 1/8"

Materials:

Body: Aluminum

Bowl:

Transparent: Polycarbonate

Transparent with guard: Polycarbonate, steel guard

Metal: Aluminum

Metal bowl liquid level indicator lens: Transparent nylon

Sight-Feed dome: Transparent nylon

Elastomers: Neoprene and nitrile

REPLACEMENT ITEMS

Service kit (includes items circled on

exploded view) ...................................................4382-600

Liquid level lens kit (43, 45, 46, 47) ......................4380-020

Manual drain (18, 19, 20) ..........................................619-50

INSTALLATION

1. Shut-off air pressure. Install lubricator in air line -

● vertically (reservoir down),

● with air flow in direction of arrow on body,

● downstream of filters and regulators

● upstream of cycling valves,

● as close as possible to the device being lubricated,

● Oil-Fog Models - Not more than 5,2m (15 feet) from

the device being lubricated, and at the same height or

higher than the device.

2. Connect piping to proper ports using pipe thread sealant

on male threads only. Do not allow sealant to enter interior

of unit.

3. Push reservoir, or reservoir with guard, into body and turn

fully clockwise before pressurizing.

RECOMMENDED LUBRICANTS

Use a good quality, light, misting type oil for compressed air

tools. See Norgren publication N/AL.8.900.935.

FILL RESERVOIR (OIL-FOG LUBRICATORS)

Remove fill plug (2), add oil, and reinstall fill plug. Fill plug

can be removed and oil added without shutting off air

pressure to the lubricator. Fill to maximum fill line on

transparent reservoirs. Oil level must always be visible in

lens on metal reservoirs. DO NOT OVERFILL.

NOTE: Oil fill plug (2) seals easily. Tighten finger-tight only.

Micro-Fog® and Oil-Fog

Tool Lubricators

L73★ - ★★★ - ★★★

Thread Form

A....PTF

B....ISO Rc taper

G....ISO G parallel

Bowl

D....Metal with plastic liquid level indicator

P....Transparent with guard

R....Metal with Pyrex liquid level indicator

T....Transparent

Options

N....None

P....Pyrex sight-feed dome

Q....Quick fill nipple

Drain

E....Closed bottom

Q....Manual, 1/4 turn

Air Flow Direction

P....Uni-directional

Type

C....Oil-Fog

M...Micro-Fog

Port

2....1/4"

3....3/8"

4....1/2"

IM-180.400.01

(5/02)

Supersedes 9/98

© Norgren 2002

a subsidiary of IMI plc

8

6

7

18

17

19

28

27

29

37

36

38

9

1

52

53

55

54

21

23A

23

20

22

31

33A

33

30

32

40

42A

42

39

41

2

3

4

5

49

51

50

26

25

24

34

35

47

48

46

44

45

43

Page 2

L73M, L73C

Installation & Maintenance

Instructions

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

Polycarbonate plastic reservoirs can be damaged and

possibly burst if exposed to such substances as certain

solvents, strong alkalies, compressor oils containing esterbased additives or synthetic oils. Fumes of these

substances in contact with the polycarbonate reservoir,

externally or internally, can also result in damage. Clean

with warm water only

Use metal reservoir in applications where a plastic

reservoir might be exposed to substances that are

incompatible with polycarbonate.

In lubrication applications some oil mist may escape

from the point of use to the surrounding atmosphere.

Users are referred to safety and health standards for

limiting oil mist contamination and utilization of protecting

equipment

Before using these products with fluids other than air,

for nonindustrial applications, or for life-support systems

consult Norgren.

IM-180.400.02

(5/02)

Supersedes 9/98

© Norgren 2002

a subsidiary of IMI plc

Loading...

Loading...