Page 1

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

FIT-3-1

Function Fittings,

Flow Controls, and

Accessory Valves

Section 3

12 VA0 Right Angle (Banjo) Flow Control (inch-knob adj.) . .FIT-3-3

12 VB0 Right Angle (Banjo) Flow Control (inch-slot adj.) . . .FIT-3-3

10 TA0 Right Angle (Banjo) Flow Control (metric-knob adj.) FIT-3-4

10 K51 Right Angle (Banjo) Flow Control (metric-slot adj.) . .FIT-3-4

T1000 In-line Flow Control (NPT and ISO G) . . . . . . . . . . . . . .FIT-3-6

T15 Push-In Flow Regulators . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-3-8

M/800, C/800 Heavy Duty In-Line Flow Control . . . . . . . . . . . .FIT-3-10

M/600, C/600 Heavy Duty In-Line Flow Control . . . . . . . . . . . .FIT-3-12

M/650, C/650, M/677, C/677 Precision Flow Controls . . . . . . .FIT-3-14

T51/T52/T53 Series, PIF Non Return Valves . . . . . . . . . . . . . .FIT-3-16

T55, T56 Non-Return Valves . . . . . . . . . . . . . . . . . . . . . . . . . . .FIT-3-16

T60 Air Fuse (Excess Flow Check) (NPT and ISO G) . . . . . . .FIT-3-18

Pressure Reducing Fitting (inch and metric) . . . . . . . . . . . . . .FIT-3-23

Pilot Operated Check Valve (inch and metric) . . . . . . . . . . . .FIT-3-26

T70 Quick Exhaust Valves (NPT and ISO G) . . . . . . . . . . . . . .FIT-3-28

T65 1/8" and 1/4" Shuttle Valves (NPT and ISO G) . . . . . . . . .FIT-3-30

Page 2

FIT-3-2

Littleton, CO USA Phone 303-794-2611 Fax 303-795-9487

Function Fittings and Flow Controls

● 360° rotation of the banjo body around the bolt allows for ideal

positioning of tubing.

● Low profile and reduced physical size provide space saving

installations, while internal configuration provides the flow

capacity of much bulkier designs.

● Tapered adjustment needles with large adjustment ranges

provide linear flows and greater precision.

● Knurled adjustment knobs (w/screw driver slot) and lock nuts on

12 VA0 and 10 TA0 series provide finger tip adjustment. Tamper

resistance on the 12 VBO and 10 K51 is provided by a slotted

adjustment screw covered by a protective plastic cap.

● Direct mounting of flow controls on pneumatic actuators

minimizes the adjustment problems encountered due to the

compressibility of air in long tubing runs between the actuator

and control valving. Additionally, direct mounted flow controls

end the confusion over which actuator in a circuit is being

controlled.

● Metallic components are limited to nickel plated all brass

construction, eliminating the potential problems encountered

with products constructed of dissimilar metals.

● Adjustment needles and banjo bodies are retained, preventing

accidental loss of the needle or lock nut.

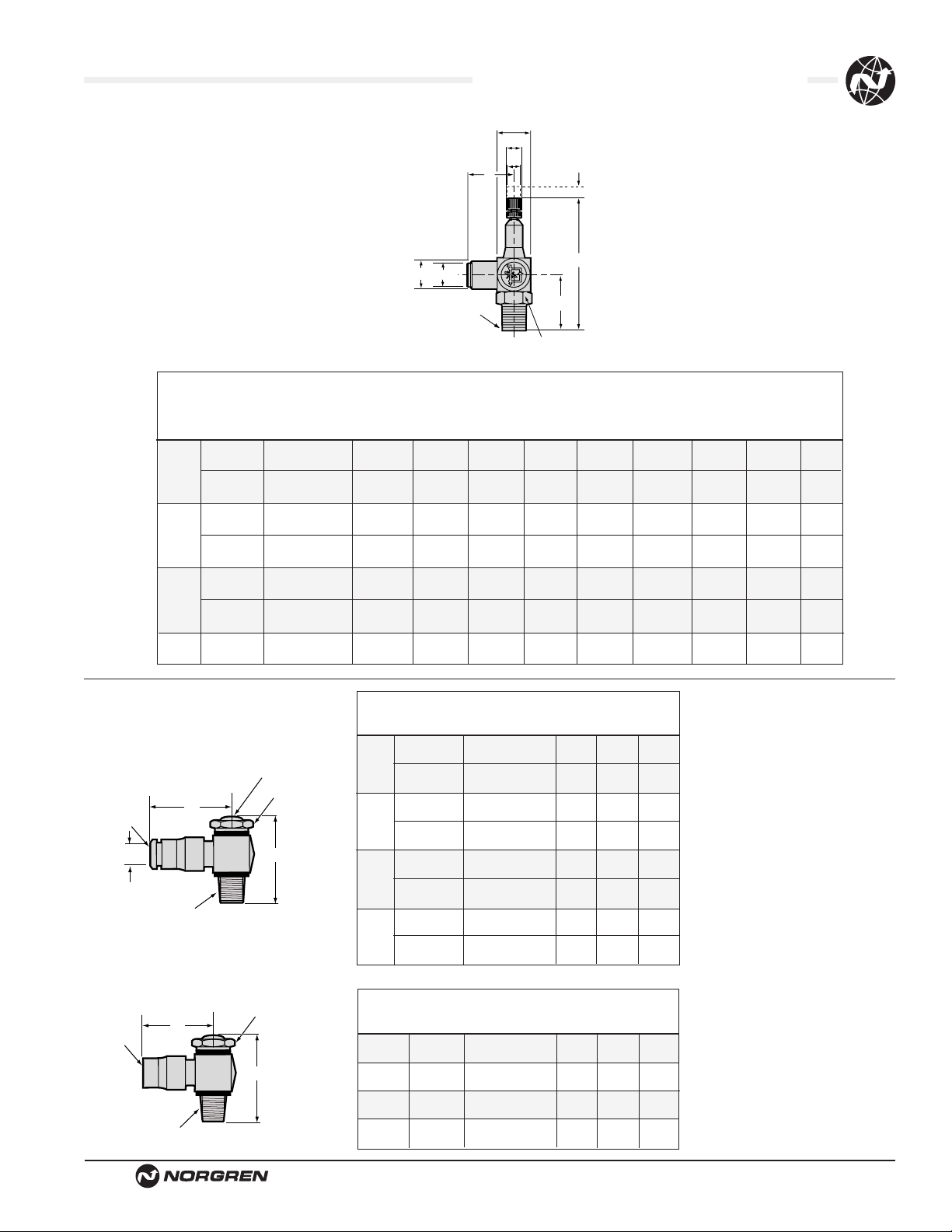

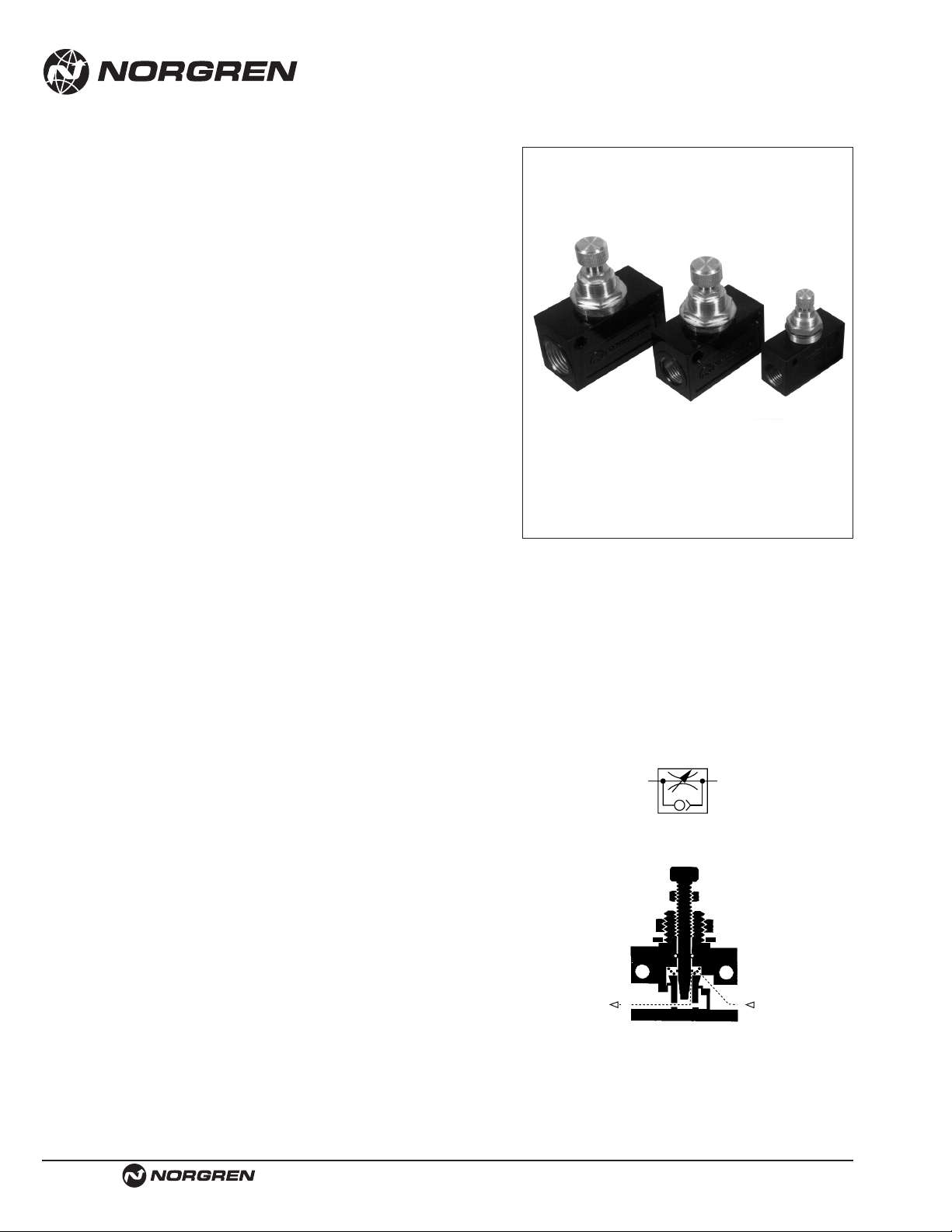

Right Angle (Banjo) Flow Controls

Operation:

Flow Controls are checked adjustable controls of the meter out type.

Compressed air passes freely into the push-in fitting portion of the flow

control, flowing past the check seal and entering the connected

component. In reverse flow conditions, air passes back into the flow

control and energizes the check seal. Air must now flow through the

metered passage controlled by the tapered adjustment needle of the flow

control, and finally exits through the push-in fitting end.

Specifications

Fluid: Compressed air.

Note:

For other types of fluids or compressed gases, please

consult factory.

Working Pressure: 5 to 150 psig (.3 to 10 bar)

Temperature Range: 0° to 175°F (-20° to 80°C)

Materials of Construction:

Banjo bolt, collet, adjustment knob and lock nut: Nickel plated brass

Tapered adjusting needle: Brass

Banjo Body, 12 VA0 XXXX and 10 TA0: Thermoplastic

12 VBO and 10 K51 XXXX: Nickel plated brass

O-rings and check-seal: Silicone free Nitrile

Sealing washer: Thermoplastic (ISO G and 10-32 UNF)

Tubing: Nylon 11 or 12, 95 durometer polyurethane.

Thread Sealant: Thread sealant is applied to the full circumference of

tapered male threads.

Options

Special versions of the flow controls are available, including meter-in

(12 WA0 Series) and bi-directional control configurations.

Please

consult factory with specific quantities and requirements.

Free Flow In

(Metered Flow Out)

Free Flow Out

(Metered Flow In)

Tapered Adjustment

Needle

Check Seal

PneumaticSymbol

Page 3

Detroit, MI USA Phone 800-394-6804 Fax 734-591-1818

FIT-3-3

Function Fittings and Flow Controls

B

A NPT or

Tube UNF KL

O.D. Thread Part Number C D E F G H J A/F Adj

10-32 UNF 12 VA0 0210

0.37 1.04 0.16 0.74 0.38 1.51 0.45

–

0.12

5/32"

(9.5) (26.5) (4.0) (18.7) (9.5) (38.4) (11.4) (3.0)

1/8 12 VA0 0218

0.45 0.87 0.31 0.35 0.63 2.09 0.89

9/16"

0.12

(11.5) (22.0) (8.0) (9.0) (16.0) (53.0) (22.5) (3.0)

1/8 12 VA0 0418

0.51 0.91 0.31 0.35 0.63 2.09 0.89

9/16"

0.12

1/4"

(13.0) (23.0) (8.0) (9.0) (16.0) (53.0) (22.5) (3.0)

1/4 12 VA0 0428

0.53 1.00 0.39 0.43 0.79 2.64 1.16

11/16"

0.24

(13.5) (25.5) (10.0) (11.0) (20.0) (67.0) (29.5) (6.0)

1/4 12 VA0 0628

0.77 1.24 0.39 0.43 0.79 2.64 1.16

11/16"

0.24

3/8"

(19.5) (31.5) (10.0) (11.0) (20.0) (67.0) (29.5) (6.0)

3/8 12 VA0 0638

0.77 1.28 0.47 0.51 0.87 3.07 1.30

3/4"

0.24

(19.5) (32.5) (12.0) (13.0) (22.0) (78.0) (33.0) (6.0)

1/2" 1/2" 12 VA0 0748

0.91 1.50 0.63 0.71 1.06 3.66 1.65

7/8"

0.28

(23.0) (38.0) (16.0) (18.0) (27.0) (93.0) (42.0) (7.0)

VA0 Series

Dimensions in Inches (mm)

A B NPT

Tube or UNF F

O.D. Thread Part Number C A/F G

10-32 UNF 12 VB0 0210

0.74

-

1.06

5/32"

(19) (27)

1/8 12 VB0 0218

0.88

9/16"

1.57

(22) (40)

1/8 12 VB0 0418

0.91

9/16"

1.57

1/4"

(23) (40)

1/4 12 VB0 0428

0.99

3/4"

1.83

(25) (46)

1/4 12 VB0 0628

1.23

3/4"

1.83

3/8"

(31) (46)

3/8 12 VB0 0638

1.29

7/8"

2.22

(33) (56)

3/8 12 VB0 0738

1.46

7/8"

2.22

1/2"

(37) (56)

1/2 12 VB0 0748

1.56

11/16"

2.55

(40) (65)

VB0 Series

Dimensions in Inches (mm)

AB

NPT NPT

Female Male Part Number C F G

1/8 1/8 12 VB0 1818

0.83

9/16"

1.57

(21) (40)

1/4 1/4 12 VB0 2828

1.14

3/4"

1.83

(29) (46)

3/8 3/8 12 VB0 3838

1.24

7/8"

2.22

(31) (56)

1/2 1/2 12 VB0 4848

1.53

11/16"

2.55

(39) (65)

G Square

Ø F

ØE

D

L

Adjustment

ØA

ØC

B

H (Closed)

J

‘K’ A/F Hex

Protective cap

covering adjustment

C

A

ØA

B

C

A

B

F

A/F

G

F

A/F

G

Page 4

FIT-3-4

Detroit, MI USA Phone 800-394-6804 Fax 734-591-1818

Function Fittings and Flow Controls

B

A ISO G or

Tube Metric C

O.D. Thread Part Number A/F D E G L S

M5 X .8 10 K51 0405

8 9.5 26.5 4.0 18.7 2.5

(.31) (.37) (1.04) (.16) (.74) (.10)

4

1/8 10 K51 0418

14 11.0 34.0 6.5 20.6 5.0

(.55) (.43) (1.34) (.26) (.81) (.20)

M5 X .8 10 K51 0505

8 11.0 26.5 4.0 20.2 2.5

5

(.31) (.43) (1.04) (.16) (.80) (.10)

1/8 10 K51 0518

14 11.5 34.0 6.5 21.7 5.0

(.55) (.45) (1.34) (.26) (.85) (.20)

M5 X .8 10 K51 0605

8 12.5 26.5 4.0 22.2 2.5

(.31) (.49) (1.04) (.16) (.87) (.10)

6 1/8 10 K51 0618

14 12.5 34.0 6.5 23.7 5.0

(.55) (.49) (.1.34) (.26) (.93) (20)

1/4 10 K51 0628

17 13.0 36.5 7.0 24.2 8.5

(.67) (.51) (1.44) (.28) (.95) (.33)

1/8 10 K51 0818

14 13.5 34.0 6.0 23.7

–

(.55) (.53) (1.34) (.26) (.93)

1/4 10 K51 0828

17 14.0 36.5 7.0 24.7 8.5

8

(.67) (.55) (1.44) (.28) (.97) (.33)

3/8 10 K51 0838

22 16.5 51.5 10.0 26.7 10.0

(.87) (.65) (2.03) (.39) (1.05) (.39)

10 3/8 10 K51 1038

22 17.0 51.5 10.0 31.2 10.0

(.87) (.67) (2.03) (.39) (1.23) (.39)

12 1/2 10 K51 1248

27 17.5 57.5 10.0 38.2

–

(1.06) (.69) (2.26) (.39) (1.50)

K51 Series

Dimensions in Inches (mm)

AB

Tube ISO R K L

O.D. Thread Part Number C D E F G H J A/F Adj

4 1/8 10 TA0 0418

11.5 22.0 8.0 9.0 16 53 22.5 14 3

(.45) (.87) (.31) (.35) (.63) (2.09) (.89) (.55) (.12)

1/8 10 TA0 0618

13.0 23.0 8.0 9.0 16 53 22.5 14 3

(.51) (.91) (.31) (.35) (.63) (2.09) (.89) (.55) (.12)

6

1/4 10 TA0 0628

13.5 25.5 10.0 11.0 20 67 29.5 17 6

(.53) (1.00) (.39) (.43) (.79) (2.64) (1.16) (.67) (.24)

1/4 10 TA0 0828

15.5 27.0 10.0 11.0 20 67 29.5 17 6

8

(.61) (1.06) (.39) (.43) (.79) (2.64) (1.16) (.67) (.24)

3/8 10 TA0 0838

15.5 28.0 12.0 13.0 22 78 33.0 19 6

(.61) (1.10) (.47) (.51) (.87) (3.07) (1.30) (.75) (.24)

1/4 10 TA0 1028

19.5 31.5 10.0 11.0 20 67 29.5 17 6

(.77) (1.24) (.39) (.43) (.79) (2.64) (1.16) (.67) (.24)

10

3/8 10 TA0 1038

19.5 32.5 12.0 13.0 22 78 33.0 19 6

(.77) (1.28) (.47) (.51) (.87) (3.07) (1.30) (.75) (.24)

G Square

D

Ø F

ØE

J

‘K’ A/F Hex

B

H (Closed)

L

Adjustment

ØC

ØA

TA0 Series

Dimensions in MM (inches)

L

ØD

ØA

B

G

ØS

C

A/F

E

Air Flow

(I/s)

(8)

(7)

(6)

(5)

(4)

(3)

(2)

(1)

scfm

17.0

14.8

12.7

10.0

8.0

6.4

4.2

2.0

0

012345678

Inlet pressure 90 psig (6 bar), flow to atmosphere

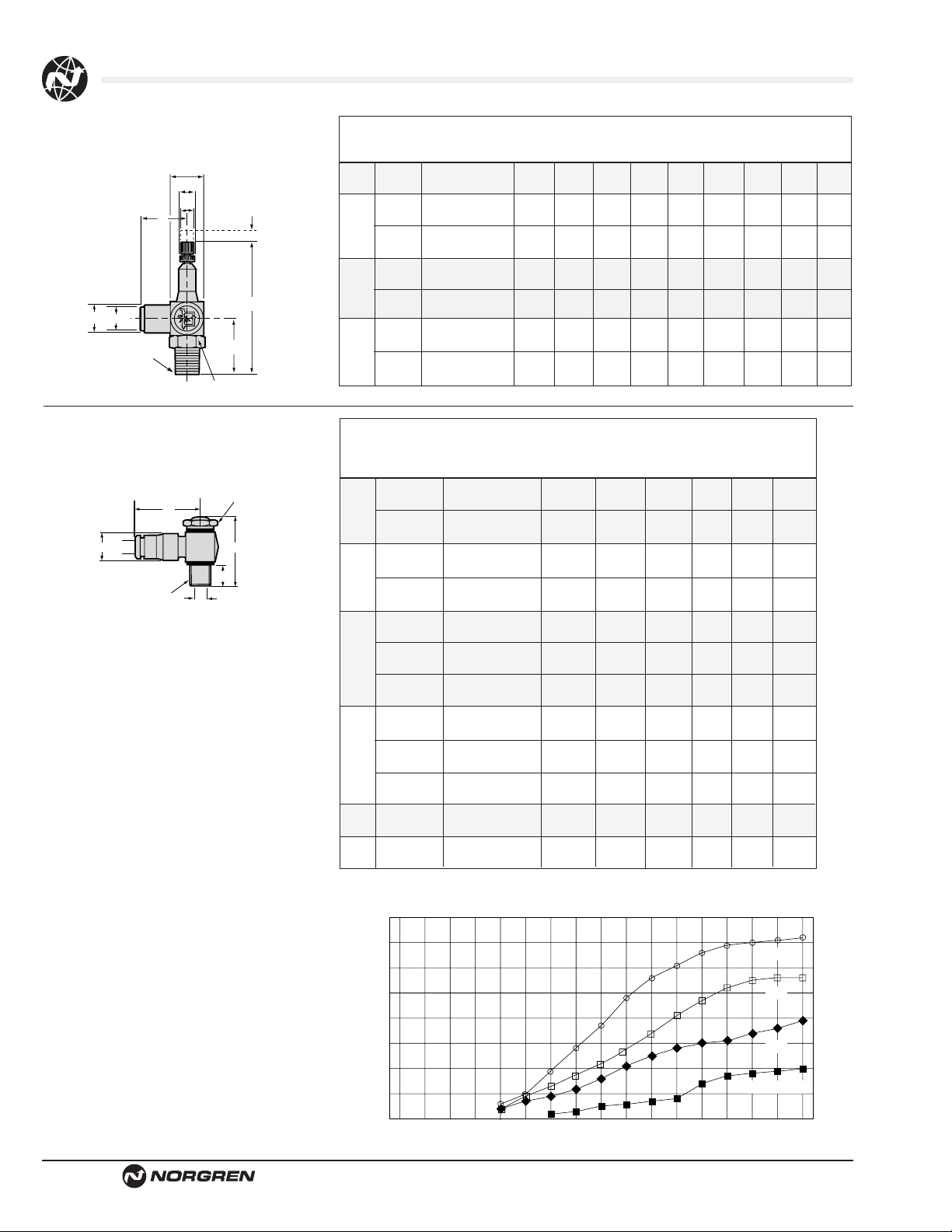

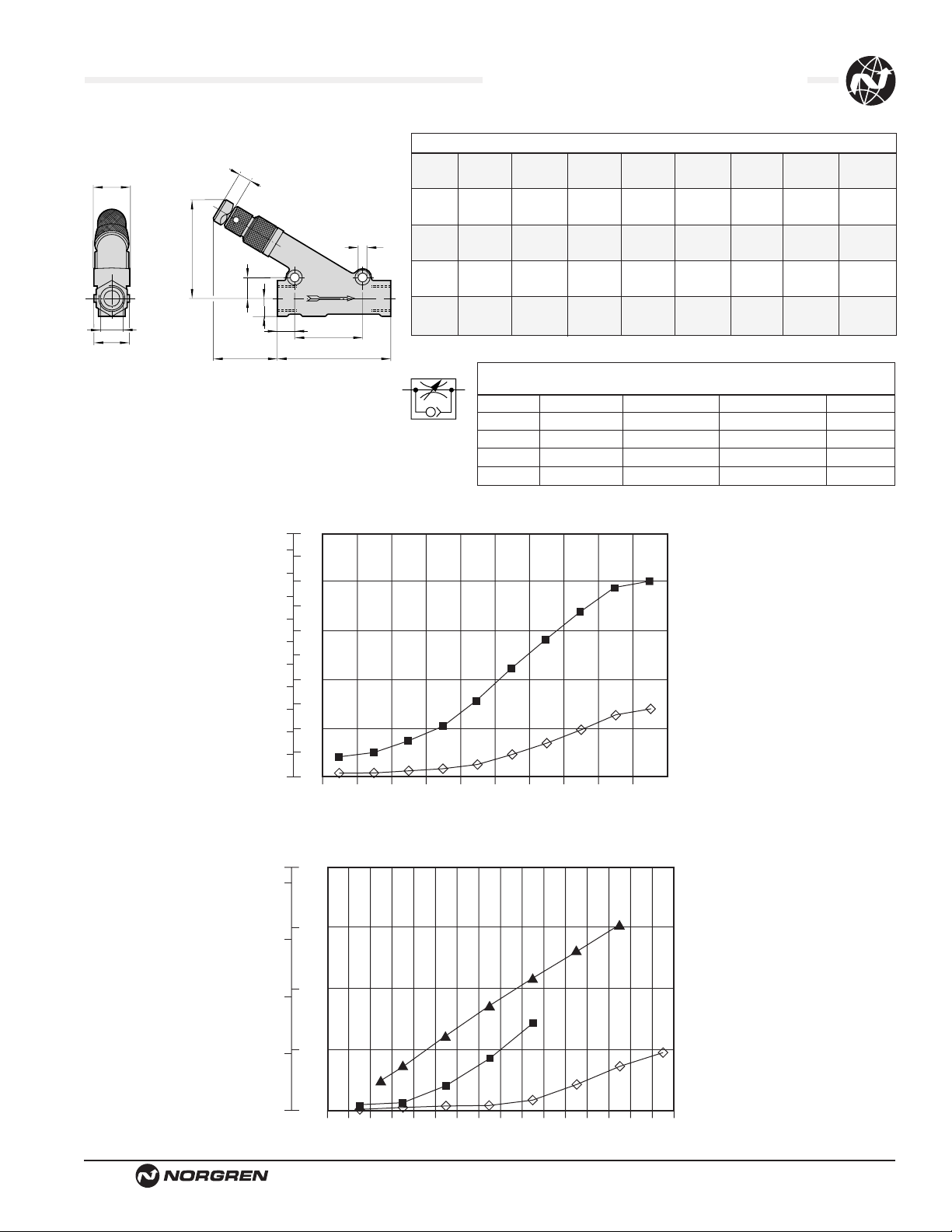

12 VA0 and 10 TA0 BANJO FLOW CONTROL

FLOW CHARACTERISTICS

Number of Turns

3/8

1/4

1/8

10-32 UNF/M5

Page 5

Detroit, MI USA Phone 800-394-6804 Fax 734-591-1818

FIT-3-5

Function Fittings and Flow Controls

Air Flow

(I/s)

(40)

(30)

(20)

(10)

Air Flow

(l/s)

(11)

(10)

(9)

(8)

(7)

(6)

(5)

(4)

(3)

(2)

(1)

scfm

84.8

63.6

42.0

21.0

0

01234567891011

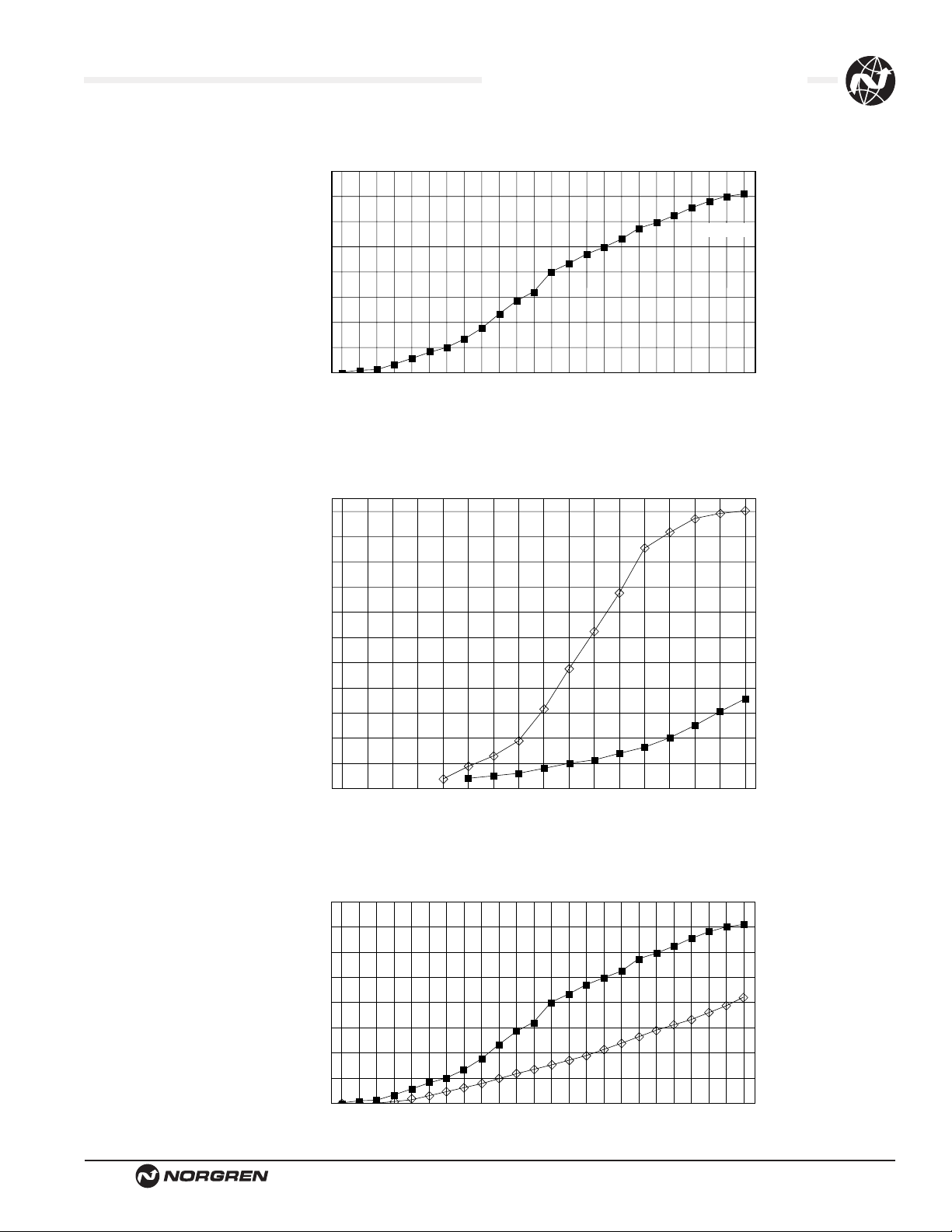

Inlet pressure 90 psig (6 bar), flow to atmoshpere

FLOW CHARACTERISTICS

1/2 NPTF

Number of Turns

12 VB0 and 10 K51 BANJO FLOW CONTROL

FLOW CHARACTERISTICS

scfm

23.0

21.0

19.0

17.0

14.8

12.7

10.6

8.5

6.4

4.2

2.1

0

012345678

12 VAO Banjo Flow Control Flow

Inlet pressure 90 psig (6 bar), flow to atmosphere

Number of Turns

1/4

1/8

Air Flow

(l/s)

(40)

(30)

(20)

(10)

12 VB0 and 10 K51 BANJO FLOW CONTROL

scfm

84.8

63.6

42.0

21.0

0

01234567891011

Inlet pressure 90 psig (6 bar), flow to atmosphere

FLOW CHARACTERISTICS

Number of Turns

1/2

3/8

Page 6

FIT-3-6

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Compact size/low weight/In-line units

● High Flow Performance

● Suitable for panel and wall mounting

● Provides linear flow adjustment

● Locking adjustment

● Captive adjustment needle will not blow out

when unscrewed

● Index line on adjusting knob

● Available in M5, 1/8, 1/4, 3/8, and 1/2 porting

T1000 Series In-Line Flow Controls

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operation:

Uni-directional flow control.

Mounting:

In-line. Panel mounted by hexagonal mounting nut. Wall mounted via

through-holes in regulator body.

Port size: NPT ISO G

T1000M0500 - M5

1/8 T1000A1800 T1000C1800

1/4 T1000A2800 T1000C2800

3/8 T1000A3800 T1000C3800

1/2 T1000A4800 T1000C4800

Operating pressure:

15 to 145 psig (1-10 bar)

5 to 145 psig (0.3 to 10 bar) -M5

Operating Temperature:

0° to 175°F (-20° to 80°C)

Consult our technical service for use below 35°F (2°C)

Opening Pressure (N-R Valve)

15 psig (1 bar)

Materials

1/8, 1/4: Aluminum alloy body, Nitrile seals, brass needle and

internal parts, external parts in aluminum alloy.

3/8, 1/2: Aluminum alloy body, Nitrile seals, brass needle and

internal parts, external parts in aluminum alloy.

M5: Aluminum alloy body, nitrile seals and brass needle.

Ordering Information

To order, quote product number from table on page

FIT-3-7: i.e. T1000A2800 for 1/4 NPT model.

Alternate Models:

T1100C1800 - 1/8" Bi-directional ISO G

T1100A1800 - 1/8" Bi-directional NPT

T1100C2800 - 1/4" Bi-directional ISO G

T1100A2800 - 1/4" Bi-directional NPT

2

1

ISO Symbol

1

2

Page 7

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-7

Function Fittings and Flow Controls

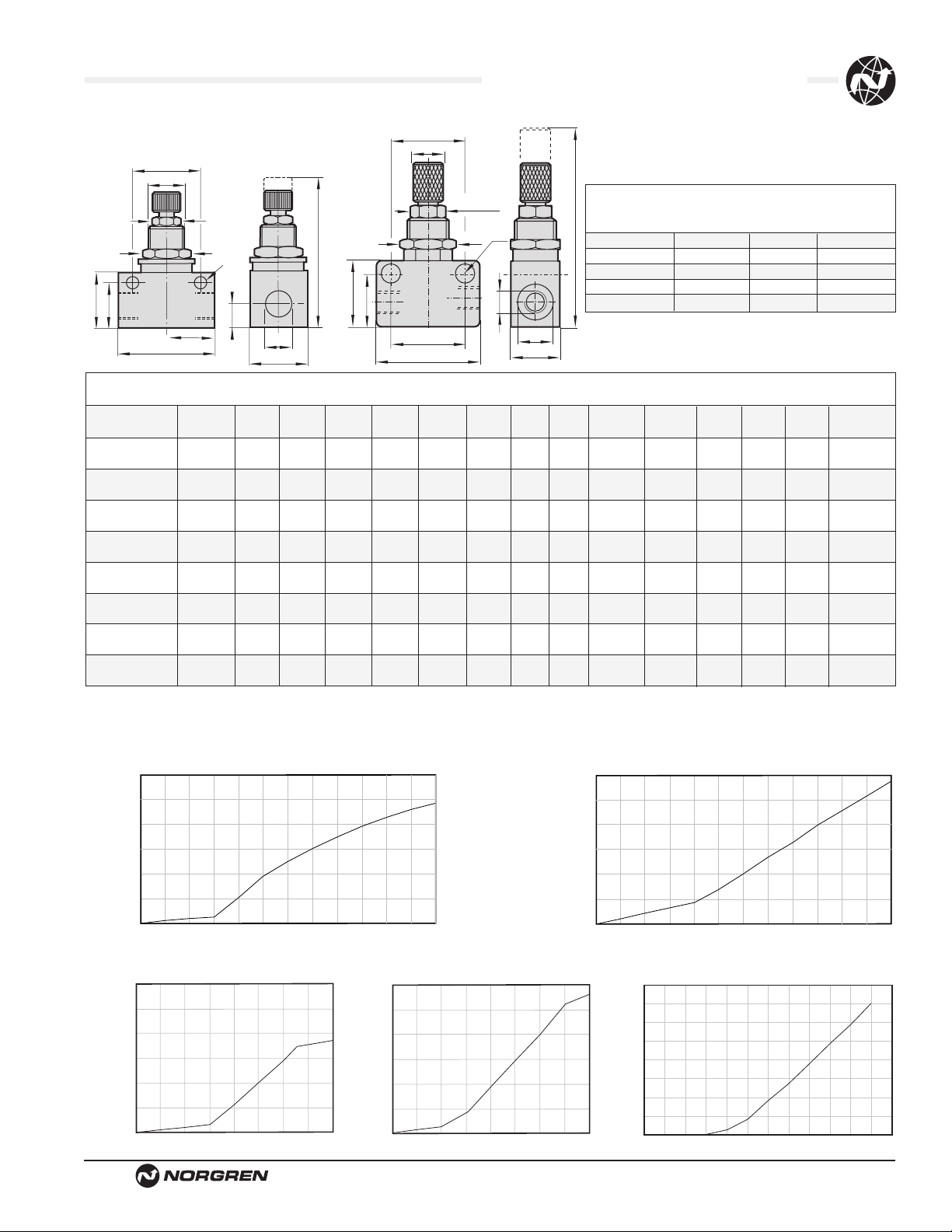

Model T1000A and T1000C

A/F Panel Max Panel

Model A B C D F G H J K L M N P Hole Thickness

T1000M0500 M5

0.98 0.59 1.77 0.47 0.70 0.17 0.47 0.21 M10x.75 0.31 0.47 0.49 0.41 0.15

(25.0) (15.0) (45.0) (12.0) (18.0) (4.5) (12.0) (5.5) – (8) (12) (12.5) (10.5) (4.0)

T1000C1800 G1/8

1.33 0.78 2.0 0.64 0.94 0.17 0.62 0.31 M12 x 1 0.39 0.55 0.66 0.49 0.15

(34.0) (20.0) (51.0) (16.5) (24.0) (4.5) (16.0) (8.0) – (Ø10) (14) (17.0) (12.5) (4.0)

T1000C2800 G1/4

1.77 1.0 2.42 0.82 1.26 0.17 0.74 0.37 M14 x 1 0.39 0.66 0.88 0.57 0.15

(45.0) (25.5) (61.5) (21.0) (32.0) (4.5) (19.0) (9.5) – (Ø10) (17) (22.5) (14.5) (4.0)

T1000C3800 G3/8

2.28 1.27 3.9 1.06 1.69 0.25 1.1 0.51 M20 x 1 0.55 0.94 1.14 0.80 0.15

(58.0) (32.5) (78.5) (27.0) (43.0) (6.5) (28.0) (13.0) – (14) (24) (29.0) (20.5) (4.0)

T1000C4800 G1/2

2.55 1.41 3.22 1.20 1.96 0.25 1.18 0.59 M20 x 1 0.55 0.94 1.27 0.8 0.15

(65.0) (36.0) (82.0) (30.5) (50.0) (6.5) (30.0) (15.0) – (14) (24) (32.5) (20.5) (4.0)

T1000A1800 1/8 NPT

1.33 0.79 2.0 0.65 0.94 0.18 0.63 0.38 M12 x 1 0.39 0.55 0.67 0.49 0.16

(34.0) (20.0) (51.0) (16.5) (24.0) (4.5) (16.0) (8.0) – (Ø10.0) (14.0) (17.0) (12.5) (4.0)

T1000A2800 1/4 NPT

1.77 1.0 2.42 0.82 1.26 0.18 0.75 0.38 M14 x 1 0.39 0.67 0.89 0.57 0.16

(45.0) (25.4) (61.5) (20.8) (32.0) (4.5) (19.0) (9.7) – (Ø10.0) (17.0) (22.5) (14.5) (4.0)

T1000A3800 3/8 NPT

2.28 1.28 3.09 1.06 1.69 0.26 1.10 0.51 M20 x 1 0.39(a/f) 0.94 1.14 0.81 0.16

(58.0) (32.5) (78.5) (27.0) (43.0) (6.5) (28.0) (13.0) – (14.0) (24.0) (29.0) (20.5) (4.0)

T1000A4800 1/2 NPT

2.56 1.42 3.23 1.20 1.97 0.26 1.18 0.29 M20 x 1 0.39 (a/f) 0.94 1.28 0.81 0.16

(65.0) (36.0) (82.0) (30.5) (50.0) (6.5) (30.0) (15.0) – (14.0) (24.0) (32.5) (20.5) (4.0)

Dimensions in Inches (mm)

Flow vs Turns at 90 psi (6 bar)

(500) 17.7

(400) 14.1

(300) 10.6

(200) 7.1

(100) 3.5

1

2

3

4

6

810

5

7

9

11 12

(600) 21.2

(NI/min) scfm

Turns

T1000A2800

T1000A4800

T1000M0500 (M5)

T1000A3800

T1000A1800

(250) 8.8

(200) 7.1

(150) 5.3

(100) 3.5

(50) 1.8

1

2

3

4

6

810

5

7

9

11 12

Turns

(NI/min) scfm

Cv Cv Free Weight

Regulating Flow grams

Model NPT port NPT port oz. (g)

T1000M0500 0.07 0.07 .0007 (.020)

T1000A1800 0.14 0.37 1.1 (31)

T1000A2800 0.32 0.69 2.0 (56)

T1000A3800 1.00 1.45 5.3 (150)

T1000A4800 1.60 1.90 6.3(180)

NPT according to ANSI B 1.20.1

Model T1000M

G

L

M

(a/f or

Ø knurled)

C

F

B

N

ØH

K

P

D

C

F

A

J

G

L

M/SW

N

ø H

D

K

P

B

A

J

sfcm

(NI/min)

(3000)

106.0

(2500)

88.3

(2000)

70.6

53.1

(1500)

(1000)

35.3

(500)

17.7

2468

Turns

10

12

16

14

scfm

(NI/min)

(3000)

106.0

88.3

(2500)

70.6

(2000)

53.1

(1500)

35.3

(1000)

17.7

(500)

2468

Turns

scfm(Nl/min)

1.6

(45)

(40)

1.4

(35)

1.2

(30)

1.0

(20)

0.8

(15)

0.6

(10)

0.4

(5)

0.2

10

12

16

14

1234 6

Turns

810111257

9

Page 8

FIT-3-8

Littleton, CO USA Phone 303-794-2611 www.norgren.com

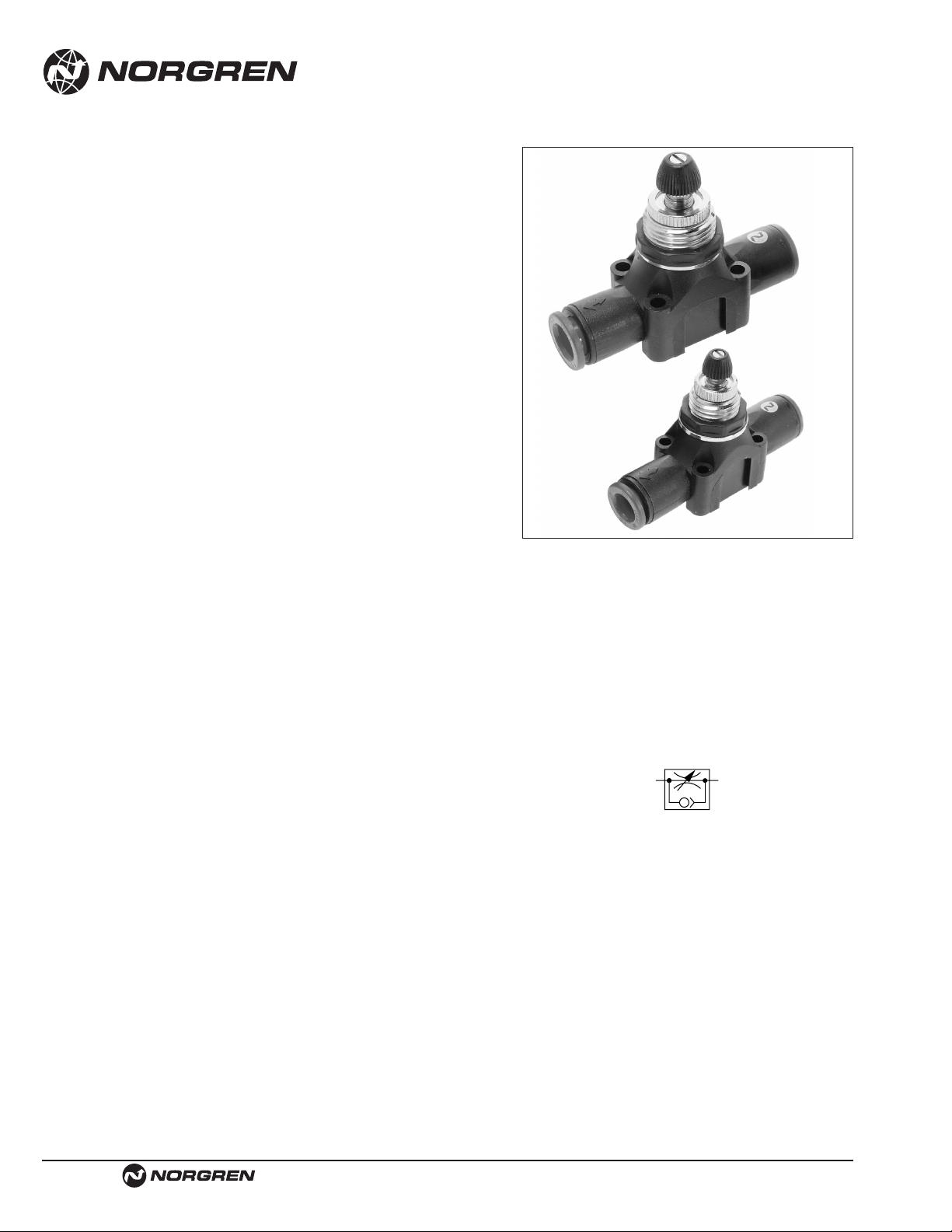

Push-In Flow Regulators

● High flow performance

● Suitable for panel/wall mounting and manifold

● Adjustment can be locked

● Captive regulator needle will not blow out when

unscrewed

● Adjusting knob position

● Releasable grab ring technology combining plastic

and brass components for a compact and superior

fitting design

● Color coding option with tamper-resistant feature

● Red release sleeve indicating metric tube sizes

● Grey release sleeve indicating inch tube sizes

● Reliable and corrosion resistant

T-15 Series

Inch and Metric O/D Tube

Technical Data

Medium: Compressed Air, filtered

Operation: Uni-directional

Operating Pressure:

1.5 to 145 psig (0.1 to 10 bar)

Ambient Temperature:

0° to 175°F (-20˚C* to 80˚C)

Consult our Technical Service for use below 35°F (2°C)

Mounting:

In-line. Panel mounted by hexagonal mounting nut. Wall mounted by

through-holes in regulator body. Manifold by quick connection

Alternative Models

Block form flow regulators, T1000 series

Heavy duty flow regulators, M/800, M/600

Precision flow regulators, M/650, M677 and S/790

Materials

1/8" (3mm), 5/32" (4mm), 3/16" (5mm), 1/4" (6mm),

5/16" (8mm), 3/8" (10mm)

Body: plastic PBT

Seals: silicone free nitrile seal, external metal parts: nickel plated brass

Internal parts: brass

Spring: stainless steel

Grab ring: stainless steel, BS 1440 Pt 2, grade 301.S21

Knob and panel nut: plastic POM

3/16" (5mm), – 1/2" (12mm)

Collet: nickel plated brass

Ordering Information

To order, quote model number from table on page

FIT-3-9, e.g. T15Y0004 to order 1/4" model.

ISO Symbol

1

2

Page 9

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-9

Function Fittings and Flow Controls

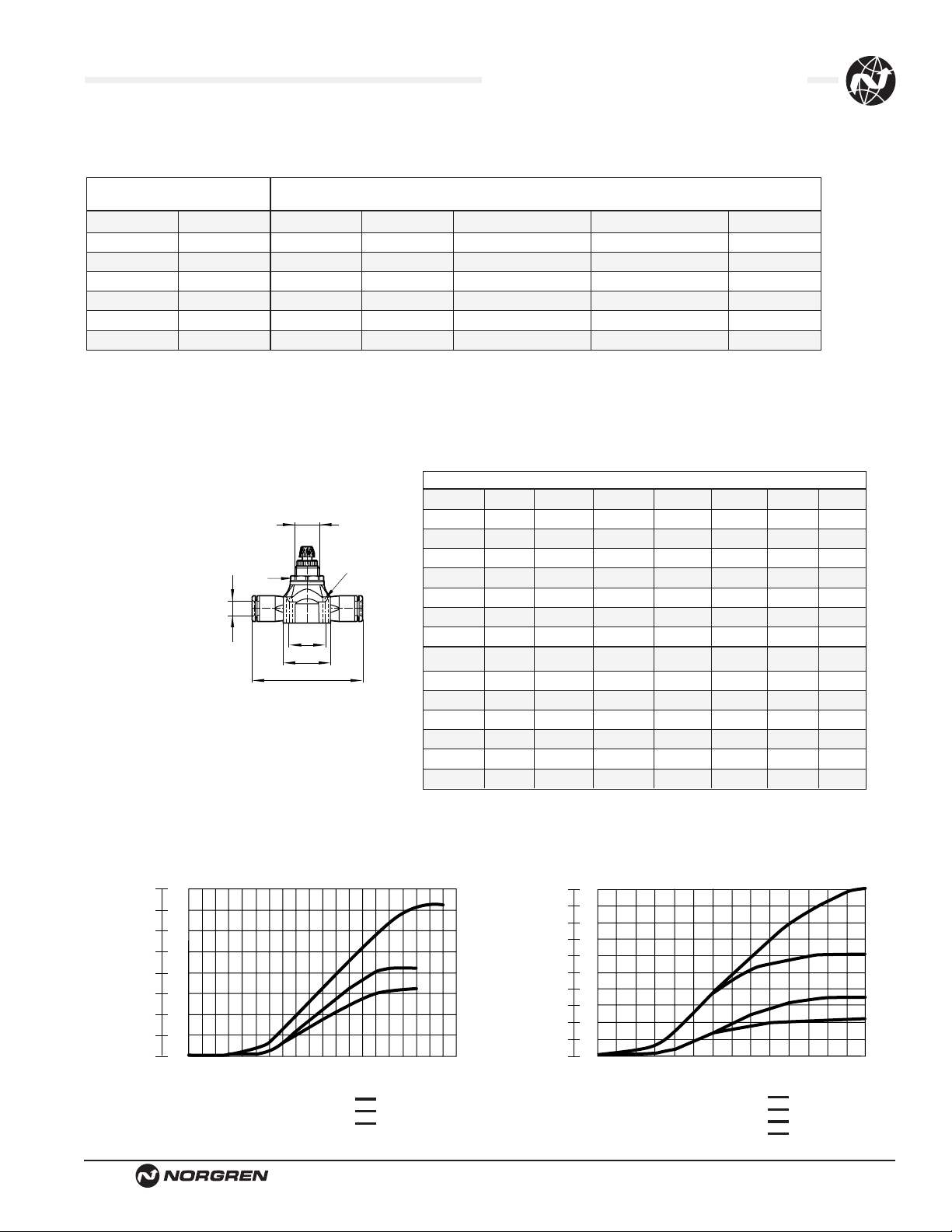

* Available in collet system

** C measured in dm3/(s.bar) Cv measured in US gal/min

Metric A B C D E F ØG

T15P0003 0.12 (3) 0.51 (13) 0.67 (17) 1.81 (46) 0.51 (13) M10x1 0.09 (2)

T15P0004 0.16(4) 0.51 (13) 0.67 (17) 1.81 (46) 0.51 (13) M10x1 0.09 (2)

T15P0005 0.20(5) 0.75 (19) 0.98 (25) 1.93 (49) 0.59 (15) M12x1 0.14 (4)

T15P0006 0.24(6) 0.75 (19) 0.98 (25) 2.17 (55) 0.59 (15) M12x1 0.14 (4)

T15P0008 0.31(8) 0.83 (21) 1.06 (27) 2.58 (66) 0.71 (18) M14x1.5 0.14 (4)

T15P0010 0.39(10) 1.04 (27) 1.34 (34) 3.02 (77) 0.94 (24) M20x1.5 0.17 (4)

T15P0012 0.47(12) 1.12 (29) 1.42 (36) 3.64 (93) 0.94 (24) M20x1.5 0.17 (4)

Inch A B C D E F ØG

T15Y0001 1/8 0.51 (13) 0.67 (17) 1.81 (46) 0.51 (13) M10x1 0.09 (2)

T15Y0002 5/32 0.51 (13) 0.67 (17) 1.81 (46) 0.51 (13) M10x1 0.09 (2)

T15Y0003 3/16 0.75 (19) 0.98 (25) 1.93 (49) 0.59 (15) M12x1 0.14 (4)

T15Y0004 1/4 0.75 (19) 0.98 (25) 2.17 (55) 0.59 (15) M12x1 0.14 (4)

T15Y0005 5/16 0.83 (21) 1.06 (27) 2.58 (66) 0.71 (18) M14x1.5 0.14 (4)

T15Y0006 3/8 1.04 (27) 1.34 (34) 3.02 (77) 0.94 (24) M20x1.5 0.17 (4)

T15Y0007 1/2 1.12 (29) 1.42 (36) 3.64 (93) 0.94 (24) M20x1.5 0.17 (4)

T15

Push-In Flow Regulators

T-15

Inch Metric Maxi regulated Free flow

Tube Model Tube Model flow factor Cv** factorCv** oz (kg)

1/8" T15Y0001 3 mm T15P0003 0.3 0.3 .46 (0.013)

5/32" T15Y0002 4 mm T15P0004 0.45 0.45 .46 (0.013)

3/16" T15Y0003* 5 mm T15P0005* 0.85 0.85 1.13 (0.032)

1/4" T15Y0004 6 mm T15P0006 1.3 1.3 .99 (0.028)

5/16" T15Y0005 8 mm T15P0008 2.2 2.2 1.66 (0.047)

3/8" T15Y0006 10 mm T15P0010 2.9 3.2 3.28 (0.093)

1/2" T15Y0007* 12 mm T15P0012* 5.4 5.4 .50 (0.0143)

Flow

Turns

Flow

Turns

T15-0D12-1/2

T15-0D10-3/8

T15-0D8-5/16

T15-0D6-1/4

T15-0D5-3/16

T15-0D4-5/32

T15-0D3-1/8

Flow vs turns at 6 bar - flow in dm3/s ANR

F

B

C

D

91011

flG

12

13 14 15 16 171819

E o/f

A

84.8

74.2

63.6

53.0

42.4

Flow

31.8

21.2

10.6

0

scfm

/s

3

dm

40

35

30

25

20

15

10

5

0

3456

2

1

0

78

/s

3

dm

scfm

10

21.2

9

19.0

8

17.0

7

14.8

6

12.7

5

10.6

Flow

20

8.5

6.4

4.2

2.1

4

3

2

1

0

0

0

1

3456

2

78

91011

12

13 14

Page 10

FIT-3-10

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● In-line general purpose flow controls

● Captive adjustment needle will not blow out

when unscrewed

● Lockable, calibrated adjustment knob

● Suitable for wall mounting

● High operating pressure

C/800, M/800 Series Heavy Duty

In-Line Flow Control

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operation:

Uni-directional

Mounting:

Line mounted, concentrically

Port Size:

NPT ISO G Weight lbs. (Kg)

1⁄8 NPT C/836 G1⁄8 S/836 .22 (.10)

1⁄4 NPT C/837 G1⁄4 M/837 .33 (.15)

1⁄2 NPT C/839 G1⁄2 M/839 1.32 (.60)

3⁄4 NPT C/840 G3⁄4 M/840 2.65 (1.20)

1 NPT C/855 G1 M/855 7.72 (3.50)

Operating Pressure:

5 - 230 psig (0.3 - 16 bar)

Operating Temperature:

0°* to 175°F (-20° to +80°C) (Alternative models to 300°F [150°C])

* Consult our Technical Service for use below 35°F (2°C.)

Materials

Brass body, adjusting knob, and locking ring (C/836, C/837, C/839),

aluminum body, adjusting knob and locking ring (C/840, C/855), nitrile

rubber seals.

Repair Kits

Product Number Kit Number

NPT ISO G NPT ISO G

C/836 S/836 QC/520/00 QS/520/00

C/837 M/837 QC/521/00 QS/521/00

C/839 M/839 QC/822/00 QS/522/00

C/840 M/840 QC/523/00 QS/523/00

C/855 M/855 QC/524/00 QS/524/00

Ordering Information

To order, quote model number from table on page

FIT-3-11, e.g. C/837 for the 1/4" NPT model

Alternative models

C/600 range of heavy duty panel mounting Flow

Controls (air & hydraulic), see page FIT-3-12.

T1000 range of Inline Flow Controls, see page

FIT-3-6.

TM, TC/800 High Temperature version (150° C

max.)

12

Page 11

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-11

Function Fittings and Flow Controls

Dimensions in Inches (mm)

Flow Control

ØA

Typical Model Number: C/839 1⁄2 NPT

M/839 G1⁄2

Type: Uni-directional

Free flow is from ‘2’ to ‘1’, indicated by arrow

Model Max. Regulating Max. Free

Port NPT ISO G Flow Cv Flow Cv

1/8 C/836 S/836 0.17 0.6

1/4 C/837 M/837 0.49 1.0

1/2 C/839 M/839 2.6 3.6

3/4 C/840 M/840 3.7 6.5

1 C/855 M/855 8.4 8.9

Thread NPT G A L C B M (max) D

1/8 C/836 S/836

.96 1.81 1.06 .33 3.11 .67

(25) (46) (27) (8) (79) (17)

1/4 C/837 M/837

1.63 2.36 .98 .20 1.46 .87

(42) (60) (25) (5) (37) (22)

1/2 C/839 M/839

2.25 3.7 2.09 .33 3.11 1.10

(57) (94) (53) (8) (79) (28)

3/4 C/840 M/840

2.99 4.69 2.60 .34 4.09 1.38

(76) (119) (66) (9) (104) (35)

1 C/855 M/855

3.54 5.90 4.22 .51 5.79 2.04

(90) (150) (107) (13) (147) (52)

12

13579

C/837

17.07 scfm

(6-5 bar)

C/836

5.95 scfm

(6-5 bar)

FLOW CHARACTERISTICS

FLOW

NUMBER OF TURNS

0

2

4

0

8

12

16

20

4

6

8

10

dm

3

/s

scfm

13579111315

00

100

200

300

400

50

100

150

200

dm

3

/s

scfm

C/855

324.36 scfm

(6-5 bar)

C/840

152.64 scfm

(6-5 bar)

C/839

101.97 scfm

(6-5 bar)

FLOW CHARACTERISTICS

NUMBER OF TURNS

FLOW

.51 (13)

1.10 (28)

M (max)

.67

(17)

2

.63

ØA

1.06 (27)

A/F

(16)

.52

(13)

C

A

L

B

1

Page 12

FIT-3-12

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Panel mounted general purpose flow controls

● Captive adjustment needle will not blow out

when unscrewed

● Calibrated adjusting knob, can be locked on 1⁄8

and 1⁄2 models

● Panel mount legend plate indicating direction of

flow control supplied as standard

● High operating pressure

C/600, M/600 Series Heavy Duty

In-Line Flow Control

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operation:

Uni-directional

Mounting:

Panel mounted

Port Sizes:

NPT ISO G Weight lbs. (Kg)

1⁄8 NPT C/636 G1⁄ 8 S/636 .29 (.13)

1⁄4 NPT C/637 G1⁄4 M/637 .49 (.22)

1⁄2 NPT C/639 G1⁄2 M/639 1.72 (.78)

Operating Pressure:

5 - 230 psig (0.3 - 16 bar)

Operating Temperature:

0°* to 175°F (-20° to 80°C)

*Consult our Technical Service for use below 35°F (2°C)

Flow

Port Cv Max Cv Max

Product Size Reg Flow Free Flow

C/636 1/8" 0.17 0.51

C/637 1/4" 0.49 1.05

C/639 1/2" 2.94 4.16

Materials

Brass body, chromium plated adjusting knob, locking ring

and panel mounting ring, nitrile rubber seals.

Spares Kits

Product Number Kit Number

NPT ISO G NPT ISO G

C/636 S/636 QC/520/00 QS/520/00

C/637 M/637 QC/521/00 QS/521/00

C/639 M/639 QC/522/00 QS/522/00

Ordering Information

To order, quote model number from table on page

FIT-3-12, e.g. C/637 for the 1/4" model

Alternative models

C/800 range of Heavy duty flow controls,

see page FIT-3-10.

T1000 range of In-Line Flow Controls,

see page FIT-3-6.

TM, TC/800 high temperature version 300°F

(150°C) max.

Page 13

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-13

Function Fittings and Flow Controls

Dimensions in Inches (mm)

Panel Mounted Flow Control

ØA

Model Number: C/636 1⁄ 8 NPT

S/636 G1⁄8

Type: Uni-directional

Free flow is from ‘2’ to ‘1’, indicated by arrow

ØA

Model Number: C/637 1⁄ 4 NPT

M/637 G1⁄4

Type: Uni-directional

Free flow is from ‘2’ to ‘1’, indicated by arrow

12

Panel Mounted Flow Control

1

2

12

ØA

Model Number:

C/639 1⁄2 NPT

M/639 G1⁄2

Type: Uni-directional

Free flow is from ‘2’ to ‘1’, indicated by arrow

Panel Mounted Flow Control

1.30 (33) A/F

1.18 (30) A/F

1.18 (30)

1.50 (38)

2.13 (54)

.94 (24)

.79 (20)

1.14 (29)

.35 (9)

2.13 (54)

3.74 (95)

.35 (9)

1

2

.75 (19)

.24 (6) max.

1.75 (45) min.

2.20 (56) max.

.04 (.9)

2.72 (69)

ØA

12

1.38 (35)

0.87 (22)

.55 (14)

.04 (9) (20 SWG)

.51 (13) A/F

.83 (21)

1.54 (39) max.

1.22 (31)

1.50 (38)

.94 (24)

.69 (18)

.24 (6) max.

1.30 (33) min.

ØA

.25(6)

.94(24)

1.81 (46)

.43 (11)

.31 (8)

.55 (14)

.43 (11)

.67 (17)

.37 (10)

12

12

.71 (18) A/F

1.61 (41) max.

.04 (.9)

.91 (23)

.20 (5) max.

1.30 (33) min.

ØA

.34 (9)

1

2.13 (54)

2

1.18 (30)

.79 (20)

1.44 (37)

.50 (13)

Page 14

FIT-3-14

Littleton, CO USA Phone 303-794-2611 www.norgren.com

PIF Check Valves

● Allow free flow in one direction only

● Low cracking pressure

● PIF-PIF, PIF-Male and Male-PIF alternatives

● Non-PTFE based thread sealant on taper threads

● Releasable grab ring technology combining

plastic and brass components for a compact

and superior fitting design

● Molded mounting brackets on tub connector

designs

● Low weight design

● Red release sleeve indicating metric tube sizes

● Grey release sleeve indicating inch tube sizes

● Easy tube insertion for rapid and quick

assembly of pneumatic circuits

● Reliable and corrosion resistant

● Silicon free

● Color coding option with tamper-resistant

feature

T-51, T-52, T-53 Series

Inch and Metric O/D Tube

Technical Data

Medium: Compressed Air, filtered, lubricated or non-lubricated,vacuum

Operating Pressure:

1.5 to 145 psig (0.1 to 10 bar) (T51, T52)

4.4 to 145 psig (0.3 to 10 bar) (T53)

-1.5 to -14.5 psig (-0.1 to -1 bar) vacuum (T51, T52)

Ambient Temperature:

0° to 175°F (-20˚C* to 80˚C)

Consult our Technical Service for use below 35°F (2°C)

Mounting:

Tube/tube PIF

Tube PIF/male thread

Male threaded/tube PIF

Alternative Models

T55, T56 range of aluminum threaded non return valves.

TS/520 range of brass threaded non return valve.

Materials

5/32" – 5/16"

Body: Plastic PBT

Seal: Silicon free nitrile

Valve: Plastic PBT

Insert: Natural brass

Spring: Stainless steel

Grab Ring: Stainless steel - BS 1440

PT 2, grade 301.S21 (4-6-8 sizes)

OD-5 collet system

T-52 and T-53 series, nickel brass threads.

3/8" – 1/2" sizes

Collet: Nickel plated brass

Body: Black anodized aluminum

Valve and Insert: Aluminum

Ordering Information

To order, quote model number from table on page

FIT-3-15, e.g. T51Y0004 for the 1/4" model.

NOTE: T51 and T52 flow is threaded end to push-

in (check is in reverse).

T53 flow is from push-in to threaded end

(check is in reverse).

21

ISO Symbol

Page 15

Metric Flow factor Cracking

Model A B F ØC C/CV* pressure (bar)

T51P0004 48.8 4 15.5 4.3 0.75/0.18 0.03+0.06

T51P0005* 53.1 5 15.2 4.3 1.16/0.28 0.03+0.06

T51P0006 55.3 6 16.9 4.3 1.9/0.47 0.03+0.06

T51P0008 62.5 8 19.0 4.3 3.5/0.86 0.03+0.06

T51P0010* 77.4 10 – – 4.7/1.15 0.03+0.06

T51P0012* 88.4 12 – – 7.5/1.84 0.03+0.06

Inch Flow factor Cracking

Model A B F ØC C/CV* pressure (bar)

T51Y0002 49.8 5/32 15.5 4.3 0.75/0.18 0.03+0.06

T51Y0003* 53.1 3/16 15.2 4.3 1.16/0.28 0.03+0.06

T51Y0004 55.3 1/4 16.9 4.3 1.9/0.47 0.03+0.06

T51Y0005 62.5 5/16 19.0 4.3 3.5/0.86 0.03+0.06

T51Y0006* 77.4 3/8 – – 4.7/1.15 0.03+0.06

T51Y0007* 88.4 1/2 – – 7.5/1.84 0.03+0.06

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-15

Function Fittings and Flow Controls

Dimensions in Inches (mm)

* Available only with collet tube connection

T52, T53

T51

Inline Push-in Non Return Valves

T-51. T-52 and T-53 Series. Operating pressure: 10 bar (14 psi)

Inch Metric

PIF/Male Thrd. Model # PIF/ISO Rc Model #

5/32" x 1/8" T52A1802 4 x M5 T52M0504

3/16" x 1/8" T52A1803* 4 x 1/8" T52B1804

3/16" x 1/4" T52A2803* 5 x 1/8" T52B1805*

1/4" x 1/8" T52A1804 5 x 1/4" T52B2805*

1/4" x 1/4" T52A2804 6 x 1/8" T52B1806

5/16" x 1/8" T52A1805* 6 x 1/4" T52B2806

5/16" x 1/4" T52A2805 8 x 1/8" T52B1808

8 x 1/4" T52B2808

Inch Metric

Male Thrd./PIF Model # ISO Rc/PIF Model #

1/8 x 5/32" T53A1802 M5 x 4 T53M0504

1/8 x 3/16" T53A1803* 1/8 x 4 T53B1804

1/4 x 3/16" T53A2803* 1/8 x 5 T53B1805*

1/8 x 1/4" T53A1804 1/4 x 5 T53B2805*

1/4 x 1/4" T53A2804 1/8 x 6 T53B1806

1/8 x 5/16" T53A1805 1/4 x 6 T53B2806

1/4 x 5/16" T53A2805 1/8 x 8 T53B1808

1/4 x 8 T53B2808

Inch Metric

PIF/PIF Model # PIF/PIF Model #

5/32" T51Y0002 4 T51P0004

3/16" T51Y0003* 5 T51P0005*

1/4" T51Y0004 6 T51P0006

5/16" T51Y0005 8 T51P0008

3/8" T51Y0006* 10 T51P0010*

1/2" T51Y0007* 12 T51P0012*

** BSPT

Inch

Model A B C** G H

T52A1802 T53A1802 54.4 5/32 1/8 4 9.5

T52A1803* T53A1803* 57.9 3/16 1/8 4 9.5

T52A2803* T53A2803* 62.7 3/16 1/4 4 14.3

T52A1804 T53A1804 59.2 1/4 1/8 4 9.5

T52A2804 T53A2804 64 1/4 1/4 4 14.3

T52A1805 T53A1805 63.7 1/8 1/8 4 9.5

T52A2805 T53A2805 68.5 1/4 1/4 4 14.3

Metric

Model A B C** G H

T52M0504 T53M0504 49.2 4 M5 4 4.3

T52B1804 T53B1804 54.4 4 1/8 4 9.5

T52B1805* T53B1805* 57.9 5 1/8 4 9.5

T52B2805* T53B2805* 59.4 5 1/4 4 11

T52B1806 T53B1806 59.2 6 1/8 4 9.5

T52B2806 T53B2806 60.7 6 1/4 4 11

T52B1808 T53B1808 63.7 8 1/8 4 9.5

T52B2808 T53B2808 65.2 8 1/4 4 11

** NPTF

F

ØC

B

A

B

B

A

G H

C

Page 16

FIT-3-16

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Ordering Information

To order, quote model number from table on page

FIT-3-17.

Alternative Models

T51 Series in-line push-in non-return valves, see

page FIT-3-14

● Permits free flow of air in one direction only

● Simple, reliable design

● Light weight

● Silicone free

● Low cracking pressure

● T56 male connections have an O-ring inparallel

threads

Technical Data

Medium:

Compressed air, filtered, lubricated and non-lubricated

Operation:

Non-return valve

Mounting:

Line mounted

Port Sizes:

Metric ISO G ISO Rc NPT

M5 T55M0500 G1/8 T55C1800 Rc1/8 T55B1800 1/8 NPT T55A1800

M5 T56M0500 G1/8 T56C1800 Rc1/8 T56B1800 1/8 NPT T56A1800

G1/4 T55C2800 Rc1/4 T55B2800 1/4 NPT T55A2800

G1/4 T56C2800 Rc1/4 T56B2800 1/4 NPT T56A2800

G3/8 T55C3800 Rc3/8 T55B3800 3/8 NPT T55A3800

G1/2 T55C4800 Rc1/2 T55B4800 1/2 NPT T55A4800

G3/4 TS/523 3/4 NPT TC/523

G1 TS/524 1 NPT TC/524

*High temperature viton seals

Operating Pressure:

1.5 - 145 psi (0.1 - 10 bar) T55–T56

5 - 230 psi (0.3 - 16 bar) TC/523-TC/524

Operating Temperature:

0°* to 300°F (-20°* to +150°C)

*Consult our Technical Service for use below 35°F (2˚C). For high

temperature applications (300°F [150˚C] Max) TM, TC/520 Series

version should be ordered

Materials

T55: Aluminum body (T55), brass (T56), silicone free nitrile

rubber ‘O’ ring, POM valve, stainless steel spring.

TC/TS: Brass body, aluminum valve

High temp viton seals

Non-Return Valves T55, T56 Series

In-Line, Non-Return Valves

M5, 1/8", 1/4", 3/8, 1/2" ISO G, ISO R, NPT

ISO Symbol

21

Page 17

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-17

Function Fittings and Flow Controls

Dimensions in Inches (mm)

* C measured in dm3/(s.bar) ** Cv measured in US gal/min.

EBG

C

D

D

C

A A/F

ØH

ØF

* Available only with collet tube connection

Model A B C D E F G H

T55MO500 .43 (11) 1.08 (27.5) (M5) .20 (5) .16 (4) .42 (10.7) .12 (3) .47 (12)

T55A1800 .55 (14) 1.67 (42.5) (1/8) – .28 (7) .54 (13.7) .16 (4) .59 (15)

T55B1800 .55 (14) 1.67 (42.5) (1/8) – .28 (7) .54 (13.7) .16 (4) .59 (15)

T55C1800 .55 (14) 1.67 (42.5) (1/8) .28 (7) .28 (7) .54 (13.7) .16 (4) .59 (15)

T55A2800 .67 (17) 2.13 (54) (1/4) – .31 (8) .66 (16.7) .20 (5) .73 (18.5)

T55B2800 .67 (17) 2.13 (54) (1/4) – .31 (8) .66 (16.7) .20 (5) .73 (18.5)

T55C2800 .67 (17) 2.13 (54) (1/4) .41 (10.5) .31 (8) .66 (16.7) .20 (5) .73 (18.5)

T55A3800 .94 (24) 2.48 (63) (3/8) – .35 (9) .93 (23.7) .28 (7) 1.02 (26)

T55B3800 .94 (24) 2.48 (63) (3/8) – .35 (9) .93 (23.7) .28 (7) 1.02 (26)

T55C3800 .94 (24) 2.48 (63) (3/8) .47 (12) .35 (9) .93 (23.7) .28 (7) 1.02 (26)

T55A4800 1.06 (27) 3.03 (77) (1/2) – .47 (12) 1.05 (26.7) .39 (10) 1.18 (30)

T55B4800 1.06 (27) 3.03 (77) (1/2) – .47 (12) 1.05 (26.7) .39 (10) 1.18 (30)

T55C4800 1.06 (27) 3.03 (77) (1/2) .59 (15) .47 (12) 1.05 (26.7) .39 (10) 1.18 (30)

T55 Series

Port Flow Factor Flow Factor Cracking Model

Size Cv** C* pressure (bar) oz (kg) Metric BSPP BSPT NPT

M5 0.19 0.8 0.73 (0.05) 0.35 (0.010) T55MO500

1⁄8 0.59 2.4 0.73 (0.05) 0.53 (0.015) T55C1800 T55B1800 T55A1800

1⁄4 1.35 5.5 0.73 (0.05) 0.88 (0.025) T55C2800 T55B2800 T55A2800

3⁄8 2.20 9.0 0.73 (0.05) 2.12 (0.060) T55C3800 T55B3800 T55A3800

1⁄2 3.70 15.0 0.73 (0.05) 2.82 (0.080) T55C4800 T55B4800 T55A4800

* C measured in dm3/(s.bar) ** Cv measured in US gal/min.

Model A B C D F G H I

T56MO500 .43 (11) 1.25 (31.8) (M5) .20 (5) .42(10.7) .12 (3) .47 (12) .17 (4.3)

T56A1800 .55 (14) 1.93 (49) (1/8) (–) .54 (13.7) .16 (4) .59 (15) .37 (9.5)

T56B1800 .55 (14) 1.93 (49) (1/8) (–) .54 (13.7) .16 (4) .59 (15) .37 (9.5)

T56C1800 .55 (14) 1.77 (45) (1/8) .28 (7) .54 (13.7) .16 (4) .59 (15) .22 (5.5)

T56A2800 .67 (17) 2.46 (62.5) (1/4) (–) .66 (16.7) .20 (5) .73 (18.5) .56 (14.3)

T56B2800 .67 (17) 2.32(59) (1/4) (–) .66 (16.7) .20 (5) .73 (18.5) .43 (11)

T56C2800 .67 (17) 2.21 (56.2) (1/4) .41 (10.5) .66 (16.7) .20 (5) .73 (18.5) .31 (8)

Model A B C D E

C/523 1.42 (36) 3.6 (92) 3⁄4 .71 (18) .71 (18)

S/523 1.42 (36) 3.6 (92) 3⁄4 .71 (18) .71 (18)

C/524 1.93(49) 4.88 (124) (1) .98 (25) .98 (25)

S/524 1.93(49) 4.88 (124) (1) .98 (25) .98 (25)

T56 Series

Port Flow Factor Flow Factor Cracking Model

Size Cv** C* pressure (bar) oz (kg) Metric BSPP BSPT NPT

M5 0.19 0.55 0.73 (0.05) 0.64 (0.018) T56MO500

1⁄8 0.59 2.4 0.73 (0.05) 1.59 (0.045) T56C1800 T56B1800 T56A1800

1⁄4 1.23 5.0 0.73 (0.05) 2.82 (0.080) T56C2800 T56B2800 T56A2800

DE

B

C

C

A

‘1’ ‘2’

Model Port Flow factor Cracking Weight Spares Kit

NPT ISO G Size Cv Pressure psi (bar) lbs. (kg) NPT ISO G

C/523 S/523 3⁄4 6.5 0.9 (0.06) 1.21 (.55) QC/523/00 QS/523/00

C/524 S/524 1 8.9 0.9 (0.06) 2.43 (1.10) QC/524/00 QS/524/00

Note : For high temperature applications a T should be added on spares kit part number (i.e. TQS/520/00)

Initial cracking pressure may be higher if valve has been stored for a long period.

C/523 – C/524 Series

B

I

G

E

A

A/F

C

ØF

C

D

ØH

Page 18

FIT-3-18

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Assists in complying with OSHA and related

safety regulations

● Tamper proof

● Compact

● Low pressure drop

● Automatically resets after failure correction

● High air pressure rating

T60 Air Fuse

1⁄4" to 1-1⁄2" NPT, ISO G

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operation:

Fixed uni-directional excess flow automatic shut off valve (air fuse)

Mounting:

In-line two way valve

To be inserted between fixed air supply and flexible air lines

See guidelines for typical installation

Port Size: Female Thread

NPT ISO G

1⁄4 NPT T60A289* G 1⁄4 T60C289*

3⁄8 NPT T60A389* G 3⁄8 T60C389*

1⁄2 NPT T60A489* G 1⁄2 T60C489*

3⁄4 NPT T60A689* G 3⁄4 T60C689*

1 NPT T60A889* G 1 T60C889*

1-1⁄2 NPT T60AB89* G 1-1⁄2 T60CB89*

* Last digit depends on flow range

Operating Pressure:

Maximum 232 psi (16 bar)

Minimum according to hose length

Drop pressure at shut-off flow: 2 to 4.5 psi (0.14 or 0.3 bar)

Operating Temperature:

0°** to 175° F (-20° to 80°C)

**Consult our Technical Service for use below 35°F (2˚C)

At low temperature ensure air fuse is not subjected to freezing

conditions which may prevent its function.

Materials

Aluminium body, brass internal parts, stainless steel spring

Ordering Information

To order, quote appropriate product number

from the tables on the following pages.

i.e. T60A2890 for the 1⁄4 NPT with 2 psi

pressure drop at shut off.

T60A2890

Thread

Type

1

Thread

Size

Flow

Range

2

2

Series

Number

Simplified Symbol

1

ISO Symbol

Page 19

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-19

Function Fittings and Flow Controls

Dimensions in Inches (mm)

General Information

Air Fuse

(Excess Flow Check)

Drop pressure at Shut off flow rate Flow at 100 psi (7 bar)

Model shut off flow at ∆P 1 psi (0.07 bar) Weight

NPT ISO G Port size psi (bar) 100 psi (7 bar) scfm (dm3/s) oz. (Kg)

T60A2890 T60C2890

1⁄4

2.0 (.14) 17.6 (8) 13.8 (7) 1.4 (.04)

T60A2891 T60C2891 4.4 (.3) 29.7 (14) 13.8 (7) 1.4 (.04)

T60A3890 T60C3890

3⁄8

2.0 (.14) 41.1 (19) 28.6 (14) 2.3 (.07)

T60A3891 T60C3891 4.4 (.3) 68.2 (32) 28.6 (14) 2.3 (.07)

T60A4890 T60C4890

1⁄2

2.0 (.14) 68.2 (32) 49.2 (23) 5.3 (.15)

T60A4891 T60C4891 4.4 (.3) 102.3 (48) 49.2 (23) 5.3 (.15)

T60A6890 T60C6890

3⁄4

2.0 (.14) 102.3 (48) 91.1 (43) 4.6 (.13)

T60A6891 T60C6891 4.4 (.3) 169.5 (80) 91.1 (43) 4.6 (.13)

T60A8890 T60C8890

1

2.0 (.14) 195.0 (92) 144 (68) 19.0 (.54)

T60A8891 T60C8891 4.4 (.3) 271.0 (128) 144 (68) 19.0 (.54)

T60AB890 T60CB890

1-1⁄2

2.0 (.14) 394.0 (186) 307 (145) 38.8 (1)

T60AB891 T60CB891 4.4 (.3) 568.0 (268) 307 (145) 38.8 (1)

NPT : according to ANSI-B1.20.1.

ISO G : according to BS2779 and ISO-228/1

Flow and pressure test conducted according to ISO-6358 test circuit. Mean measured flow values are provided at

standard reference conditions.

B

C

D

D

C

A A/F

F

E

Model T60A289* T60C289* T60A389* T60C389* T60A489* T60C489* T60A689* T60C689* T60A889* T60C889* T60AB89* T60CB89*

NPT ISO G NPT ISO G NPT ISO G NPT ISO G NPT ISO G NPT ISO G

A

0.81 0.81 0.94 0.94 1.25 1.25 1.25 1.25 2.00 2.00 2.50 2.50

(21) (21) (24) (24) (32) (32) (32) (32) (51) (51) (64) (64)

B

2.01 2.01 2.44 2.44 3.07 3.07 3.54 3.54 4.65 4.65 5.71 5.71

(51) (51) (62) (62) (78) (78) (90) (90) (118) (118) (145) (145)

C 1/4 1/4 3/8 3/8 1/2 1/2 3/4 3/4 1.0 1.0 1.5 1.5

D

0.39 0.43 0.41 0.55 0.59 0.54 0.56 0.75 0.66 1.00 0.68 1.00

(10) (11) (10) (14) (15) (14) (14) (19) (17) (26) (17) (26)

E

0.12 0.12 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20 0.20

(3) (3) (5) (5) (5) (5) (5) (5) (5) (5) (5) (5)

F

0.81 0.81 0.94 0.94 1.25 1.25 1.25 1.25 2.00 2.00 2.50 2.50

(21) (21) (24) (24) (32) (32) (32) (32) (51) (51) (64) (64)

Page 20

FIT-3-20

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

Guidelines for Typical Installation

The air fuse should be installed directly between fixed or rigid pipework and the flexible tube to protect the whole

length of the flexible tube. Only tubing after the air fuse is protected. The air fuse must be installed in the correct

orientation. Failure to do this will render it ineffective. When a shut off valve is located before the air fuse, the

valve must be opened slowly in order to control initial air flow and avoid decompression effects which may trip the

air fuse.

It should be noted that the OSHA standard (29 CFR ChXVII Para 1926.302-b7) relating to pneumatic power tools

states “All hoses exceeding 1/2" inside diameter shall have a safety device at the source of supply or branch

line to reduce pressure in the case of hose failure.”

Choosing an Air Fuse*

a) The port size of the air fuse should be nominally equal to that of the supply lines - e.g. a 1⁄2 (12.7 mm) air fuse

should be used with a 1⁄2'' (12.7mm) ID hose.

b) Always select the high flow model (91) if there is sufficient system pressure for the length of hose to be

protected. See tables hose length vs. minimum supply pressure.

c) If there is insufficient system pressure, or long hose lengths are to be protected, use model 90.

d) After installation always test each valve for proper function. See section below on how to check an air fuse.

e) The pneumatic system must be capable of delivering the flow required to activate the air fuse. For this reason,

the air fuse is not suitable for use with the Norgren R07 miniature range in certain installations.

f) For use with spring coils consult table. See table flow vs. pressure supply.

Verifying Operation of an air fuse

● Install the air fuse following the instructions supplied

● Connect tool or complete circuit to the air line

● Switch on operation to ensure a complete cycle is performed

● If tool or complete circuit starts and runs satisfactorily, stop operation and drain air line. Disconnect hose from

tool or circuit and secure hose end. Turn on air supply progressively (to avoid decompression effect). Prior to

fully reaching operation conditions, the air fuse should suddenly activate and cut off the flow. A slight air flow

will remain as part of the automatic re-set function. If the air fuse is not activated the unit should be

disconnected and the lower flow range air fuse should be used.

* Consult factory for the availability of Excel™ based sizing program.

AIR SUPPLY

TOOL

TOOL

TOOL

TOOL

TOOL

TOOL

RIGID LINE FLEXIBLE LINE

Air Fuse

Air Fuse

Air Fuse

Air Fuse

Air Fuse

Air Fuse

Page 21

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-21

Function Fittings and Flow Controls

Flow (±10%) vs pressure supply (1⁄4 to 1⁄2)

Hose length vs

minimum pressure supply

(1⁄4 to 3⁄8)

Hose length vs

pressure supply

(1 to 1-1⁄2)

Hose length vs

minimum pressure supply

(1⁄2 to 3⁄4)

Flow (±10%) vs pressure supply (3⁄4 to 1-1⁄2)

KEY

— 6 - T60 * 6890

— 7 - T60 * 6891

— 8 - T60 * 8890

— 9 - T60 * 8891

— 10 - T60 * B890

— 11 - T60 * B891

KEY

— 1 - T60 * 2890

— 2 - T60 * 2891

— 3 - T60 * 3890

— 4 - T60 * 3891

— 4 - T60 * 4890

— 5 - T60 * 4891

KEY

1 - T60 * 2890 ID = 0.30'' (7.5mm)

2 - T60 * 2891 ID = 0.30'' (7.5mm)

3 - T60 * 3890 ID = 0.35'' (9.0mm)

4 - T60 * 3891 ID = 0.35'' (9.0mm)

KEY

— 9 - T60 * 8890 ID = 1.00'' (25.0mm)

— 10 - T60 * 8891 ID = 1.00'' (25.4mm)

— 11 - T60 * B890 ID = 1.50'' (38.1mm)

— 12 - T60 * B891 ID = 1.50'' (38.1mm)

KEY

5 - T60 * 4890 ID = 0.51'' (13mm)

6 - T60 * 4891 ID = 0.51'' (13mm)

7 - T60 * 6890 ID = 0.75'' (19mm)

8 - T60 * 6891 ID = 0.75'' (19mm)

(12) 174

(11) 160

(10) 145

(9) 131

(8) 116

(7) 102

(6) 87

(5) 73

(4) 58

(3) 44

(2) 29

(1) 15

0

(13) 189

(14) 203

(bar) psi

1

2

3

4

(1)

(2) (3) (4) (5) (6) (7) (8) (9) (10) meters

3

7101316 202326

30 33 feet

Hose Length

Pressure Supply

0

Hose Length

Pressure Supply

7

5

8

6

(6) 87.0

(5.5) 79.8

(5) 72.5

(4.5) 65.3

(4) 58.0

(3.5) 50.8

(3) 43.5

(2.5) 36.3

(2) 29.0

(1.5) 21.8

(1) 14.5

(6.5) 94.3

(7) 101.5

(7.5) 108.8

(8) 116.0

(2) (4) (6) (8) (10) (12) (14) (16) (18) (20)

7 132026333946535966

feet

meters

(0.5) 7.3

(bar) psi

Measurements

- Flow and pressure tests conducted according to

ISO-6358 test circuit

- Mean measured flow values are provided at standard

reference condition 68°F, 15 psi, (20°C, 1.01 bar)

- Indicated pressure values are relative pressure in bar.

Hose Lengths

- Graphs are for indicated hose internal diameter in key.

- Consult our Technical Service for hose lengths and

Internal diameters different from the recommended one.

Pressure Supply

(bar) psi

(3.5) 50.8

(3.0) 43.5

(2.5) 36.3

(2.0) 29.0

(1.5) 21.8

(1.0) 14.5

(0.5) 7.3

0

7 132026333946535966

(2) (4) (6) (8) (10) (12) (14) (16) (18) (20)

Hose length

10

12

9

11

feet

meters

Shut Off Flow

(dm3/s) scfm

(75) 159

(70) 148

(65) 138

(60) 127

(55) 117

(50) 106

(45) 95

(40) 85

(35) 74

(30) 64

(25) 53

(20) 42

(15) 32

(10) 21

(5) 10.6

0

29 58 87 116 145 174 203 232

(2)

(6)

(4)

Pressure Supply

(8)

(10)

(12) (14) (16)

5

4

3

2

1

psi

(bar)

Shut Off Flow

(dm3/s) scfm

(600) 1272

(550) 1166

(500) 1060

(450) 954

(400) 848

(350) 742

(300) 636

(250) 530

(200) 424

(150) 318

(100) 212

(50) 106

0

29 58 87 116 145 174 203 232

(2)

(6)

(4)

(10)

(8)

Pressure Supply

(12) (14) (16)

11

10

9

8

7

6

psi

(bar)

Page 22

FIT-3-22

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

Valve Thread Hose length Internal Hose Diamter (inch)

Model Size Feet 0.125 0.188 0.215 0.250 0.313 0.370 0.470 0.500 0.590 0.750 1.000 1.250 1.500

T60*2890 1/4 12 124 64 29 16 11 8 8 8 7777

T60*2890 1/4 25 126 52 25 14 9 9 8 7777

T60*2890 1/4 50 244 97 42 21 11 10 8 8777

T60*2890 1/4 100 187 76 35 15 13 10 8777

T60*2891 1/4 12 70 31 17 10 9 8 7777

T60*2891 1/4 25 137 57 27 13 11 9 8777

T60*2891 1/4 50 107 47 19 15 11 8777

T60*2891 1/4 100 207 87 30 23 14 9877

T60*3890 3/8 12 125 52 25 12 11 9 8777

T60*3890 3/8 25 102 45 18 15 10 8777

T60*3890 3/8 50 196 82 29 22 14 9877

T60*3890 3/8 100 157 50 38 20 11 8 7 7

T60*3891 3/8 12 132 57 21 17 11 8877

T60*3891 3/8 25 111 37 28 16 10 8 7 7

T60*3891 3/8 50 215 67 49 25 12 8 8 7

T60*3891 3/8 100 126 91 42 17 9 8 7

T60*4890 1/2 12 132 57 21 17 11 8877

T60*4890 1/2 25 111 37 28 16 10 8 7 7

T60*4890 1/2 50 215 67 49 25 12 8 8 7

T60*4890 1/2 100 126 91 42 17 9 8 7

T60*4891 1/2 12 119 39 30 17 10 8 7 7

T60*4891 1/2 25 74 54 27 13 8 8 7

T60*4891 1/2 50 141 102 46 18 10 8 8

T60*4891 1/2 100 196 85 29 12 9 8

T60*6890 3/4 12 119 39 30 17 10 8 7 7

T60*6890 3/4 25 74 54 27 13 8 8 7

T60*6890 3/4 50 141 102 46 18 10 8 8

T60*6890 3/4 100 196 85 29 12 9 8

T60*6891 3/4 12 96 70 33 15 9 8 7

T60*6891 3/4 25 193 139 62 23 11 8 8

T60*6891 3/4 50 116 38 14 9 8

T60*6891 3/4 100 224 69 20 11 9

T60*8890 1 12 123 89 41 17 9 8 7

T60*8890 1 25 178 78 27 12 9 8

T60*8890 1 50 148 47 16 10 8

T60*8890 1 100 88 24 13 9

T60*8891 1 12 231 166 73 26 11 8 8

T60*8891 1 25 144 46 16 10 8

T60*8891 1 50 85 24 12 9

T60*8891 1 100 163 41 17 11

T60*B890 1-1/2 12 147 47 16 10 8

T60*B890 1-1/2 25 90 25 13 9

T60*B890 1-1/2 50 173 43 18 11

T60*B890 1-1/2 100 78 29 16

T60*B891 1-1/2 12 89 25 13 9

T60*B891 1-1/2 25 179 44 18 12

T60*B891 1-1/2 50 81 30 16

T60*B891 1-1/2 100 154 52 24

Coiled hose selection table

Selection procedure for coiled hose:

Chose the thread size of your hose, the hose internal diameter in inches and the hose length in feet. The minimum

supply pressure in psi is shown in the table below and the appropriate air fuse is shown in the left column. The “*” in

the middle of the part number represents the thread type - put an “A” for NPT and a “C” for ISO G threads. If no

value is shown, it may not be possible to protect your hose with an air fuse. If in doubt, consult a Norgren distributor

or Norgren.

Page 23

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-23

● Compact size

● Easy tube insertion for rapid assembly of

pneumatic circuits

● Push-in and threaded ports

● Optimum pressure utilization

● Safer pneumatic systems

● Hex key adjustment and locking ring

● Relieving

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operating Pressure:

Primary (inlet) pressure 0 to 150 psi (0 - 10 bar)

Maximum secondary (regulated) pressure 115 psi (8 bar)

Operating Temperature:

0° to 175°F (-20° to +80°C)

Outlet Port:

5/32'', 1⁄4'', 5/16'', 3⁄8'', 1/2” O.D. tube Push-in Fittings

1/8, 1⁄4, 3⁄8, 1/2 NPTF Threaded Ports

4, 6, 8, 10mm O.D. tube Push-in Fittings

Inlet Port:

1/8, 1⁄4, 3⁄8, 1/2 NPTF Thread

1/8, 1⁄4, 3⁄8, 1/2 ISO G Thread

Tubing Types:

Nylon 11 or 12, polyurethane (95 durometer or above)

LDPE (Low Density Polyethylene)

Materials

Nickel plated brass body

Nickel plated brass collet

Plastic sealing washer

Nitrile and polyurethane elastomeric parts

Zinc plated brass banjo bolt

Function Fittings and Flow Controls

Pressure Reducing Fitting

Inch and Metric

Ordering Information

To order, quote appropriate product number

from the tables on the following pages.

Product numbering system is designed to

make identification and selection simple:

12_______

Series

Number

Type

Shape

Tube Size/

Thread Size

Thread Size/

Tube Size

124GB

124GB

Port 1

Port 2

2

1

Page 24

FIT-3-24

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

Dimensions in Inches (mm)

C

A

H

E

B

G

I

D

2

1

J

O.D. Tube

Pressure Reducing Fitting - 124GB

AB

Part O/D NPT D E H SQ J

Number Tube Thread C (max) A/F G A/F I A/F

12 4GB 0218 5⁄32 1⁄8

0.89 2.87 0.67

–

0.63 0.78 0.20

(23) (73) (17) (16) (20) (5)

12 4GB 0418 1⁄4 1⁄8

0.91 2.87 0.67

–

0.63 0.78 0.20

(23) (73) (17) (16) (20) (5)

12 4GB 0428 1⁄4 1⁄4

1.0 3.10 0.67 0.64 0.79 1.02 0.20

(25) (79) (17) (16) (20) (26) (5)

12 4GB 0528 5⁄16 1⁄4

1.03 3.10 0.67 0.64 0.79 1.02 0.20

(26) (79) (17) (16) (20) (26) (5)

12 4GB 0538 5⁄16 3⁄8

1.11 3.35 0.87 0.69 0.94 1.14 0.34

(28) (85) (22) (18) (24) (29) (6)

12 4GB 0638 3⁄8 3⁄8

1.29 3.35 0.87 0.69 0.94 1.14 0.34

(33) (85) (22) (18) (24) (29) (6)

12 4GB 0748 1⁄2 1⁄2

1.56 3.54 1.06

–

1.18 1.38 0.24

(40) (90) (27) (30) (35) (6)

1) Inlet Port

2) Outlet Port

Note: For mounting in ports 2 & 4 of a pneumatic directional control valve

C

A

H

E

B

G

I

D

2

1

J

Pressure Reducing Fitting - 124GB

AB

Part NPT NPT D E H SQ J

Number Thread Thread C (max) A/F G A/F I A/F

12 4GB 1818 1⁄8 1⁄8

0.83 2.87 0.67

–

0.64 0.78 0.20

(21) (73) (17) (16) (20) (5)

12 4GB 2828 1⁄4 1⁄4

1.14 3.10 0.67 0.64 0.79 1.02 0.20

(29) (79) (17) (16) (20) (26) (5)

12 4GB 3838 3⁄8 3⁄8

1.20 3.35 0.87 0.69 0.94 1.14 0.24

(31) (85) (22) (18) (24) (29) (6)

12 4GB 4848 1⁄2 1⁄2

1.54 3.54 1.06

–

1.18 0.98 0.24

(39) (90) (27) (30) (35) (6)

1) Inlet Port

2) Outlet Port

Note: For mounting in ports 2 & 4 of a pneumatic directional control valve

C

A

H

E

B

G

I

D

2

1

J

Pressure Reducing Fitting - 102GB

AB

Part O/D ISO G D E H SQ J

Number tube Thread C (max) A/F G A/F I A/F

10 2GB 0418 4 1⁄8

0.89 2.87 0.67 0.25 0.64 0.78 0.20

(22) (73) (17) (6) (16) (20) (5)

10 2GB 0628 61⁄4

1.00 3.54 0.67 0.41 0.79 1.02 0.20

(25) (90) (17) (11) (20) (26) (5)

10 2GB 0828 81⁄4

1.03 3.54 0.67 0.41 0.79 1.02 0.20

(26) (90) (17) (11) (20) (26) (5)

10 2GB 0838 83⁄8

1.11 3.78 0.87 0.43 0.94 1.14 0.24

(28) (96) (22) (11) (24) (29) (6)

10 2GB 1038 10 3⁄8

1.29 3.78 0.87 0.43 0.94 1.14 0.24

(33) (96) (22) (11) (24) (29) (6)

AB

Part ISO G ISO G D E H SQ J

Number Thread Thread C (max) A/F G A/F I A/F

10 2GB 1818 1⁄8 1⁄8

0.69 2.87 0.67 0.25 0.64 0.78 0.20

(18) (73) (17) (6) (16) (20) (5)

10 2GB 2828 1⁄4 1⁄4

0.96 3.19 0.37 0.41 0.79 1.02 0.20

(25) (81) (17) (11) (20) (26) (5)

10 2GB 3838 3⁄8 3⁄8

1.06 3.46 0.87 0.43 0.94 1.14 0.24

(27) (88) (22) (11) (24) (29) (6)

10 2GB 4848 1⁄2 1⁄2

1.34 3.50 1.06 0.37 1.18 1.42 0.24

(34) (89) (27) (10) (30) (36) (6)

1) Inlet Port

2) Outlet Port

Note: For mounting in ports 2 & 4 of a pneumatic directional control valve

Page 25

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-25

Function Fittings and Flow Controls

Flow characteristics at primary pressure of 100 psi (7 bar)

Inch and Metric Versions

(bar) psi

(6) 87.0

(5) 72.5

(4) 58.0

(3) 43.5

(2) 29.0

(1) 14.5

1/8 Pipe

Secondary pressure

0

0

7

(200)

Flow

14

(400)

21

(600)

scfm

(l/min)

(bar) psi

(6) 87.0

(5) 72.5

(4) 58.0

(3) 43.5

(2) 29.0

(1) 14.5

1/4 Pipe

Secondary pressure

0

0 10 20 30 40

(283)

(566) (850) (1132)

Flow

50

(1415)

scfm

(l/min)

(bar) psi

(6) 87.0

(5) 72.5

(4) 58.0

(3) 43.5

(2) 29.0

(1) 14.5

3/8 and 1/2 Pipe

Secondary pressure

0

0 20 40

(566) (1132)

Flow

60

(1699)

scfm

(l/min)

Page 26

FIT-3-26

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Compact size

● Easy tube insertion for rapid assembly of

pneumatic circuits

● Positive tube retention

● Safer pneumatic systems

● Push-in and threaded ports

Pilot Operated Check Valve

Inch and Metric

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operating Pressure:

15-150 psi (1 - 10 bar)

Operating Temperature:

0° to 175°F (-20° to +80°C)

Inlet Port:

1⁄4'', 3⁄8'', 1⁄2'' O.D. tube Push-in Fittings

1⁄8, 1⁄4, 3⁄8, 1⁄2 NPTF Threaded Ports

6, 8, 10, 12mm O.D. tube Push-in Fittings

Outlet Port:

1⁄8, 1⁄4, 3⁄8, 1⁄2 NPTF Thread*

1⁄4, 3⁄8, 1⁄2 ISO G Thread

Signal Port:

10-32 UNF on NPT ported models

M5 on metric models

Tube Sizes

1⁄4'', 3⁄8'', 1⁄2'' O/D

6, 8, 10, 12mm O/D

Tubing Types:

Nylon 11 or 12, polyurethane (95 durometer or above), and

LDPE (Low Density Polyethylene)

Materials

Nickel plated brass body

Nickel plated brass collet

Plastic sealing washer (ISO G)

Nitrile and polyurethane elastomeric parts

Zinc plated brass banjo bolts

Ordering Information

To order, quote appropriate product number

from the tables on the following pages.

Product numbering system is designed to

make identification and selection simple:

12_______

Series

Number

Type

Shape

Tube Size/

Thread Size

Thread Size/

Tube Size

124GA

124GA

Flow Rates (scfm)

Port Size 1/8 1/4 3/8 1/2

From 2 to 1

10.2 23.9 40.8 67.4

P12 = 88 psi

From 1 to 2

4.5 21.8 41.3 66.7

P12 = 0 psi

Pilot

Port 2

Port 1

NPTF Maximum

Thread TIghtening Torque

(male) ft lbs (Nm)

1/8 5 (7)

1/4 11 (15)

3/8 14 (20)

1/2 14 (20)

* Male NPTF threads (port 2) should be assembled hand tight and then

wrenched no more than 1/2 to 3/4 turn.

2

12

1

Page 27

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-27

Function Fittings and Flow Controls

E

A

J

G

I

D

H

C

12

1

2

B

Inch O.D. Tube x NPTF thread

Pilot Operated Check Valve - 124GA

AB

Product O.D. NPT E H SQ

Number Tube Thread C D A/F G A/F I J

12 4GA 0418 1⁄4" 1⁄8

0.91 1.61 0.51 0.48 0.63 0.78

10-32 UNF

(23) (41) (13) (12) (16) (20)

12 4GA 0428 1⁄4" 1⁄4

0.99 1.89 0.67 0.64 0.79 1.02

10-32 UNF

(25) (48) (17) (16) (20) (26)

12 4GA 0638 3/8" 3/8

1.29 2.16 0.87 0.69 0.94 1.14

10-32 UNF

(33) (55) (22) (18) (24) (29)

12 4GA 0748 1⁄2" 1⁄2

1.56 2.58 1.06 0.87 1.18 1.42

10-32 UNF

(40) (66) (27) (22) (30) (36)

1) Inlet Port

2) Outlet Port

12) Signal Port

Note: For mounting in pairs on a cylinder

1) Inlet Port

2) Outlet Port

12) Signal Port

Note: For mounting in pairs on a cylinder

E

A

J

G

I

D

H

C

12

1

2

B

Pilot Operated Check Valve - 124GA

AB

Product NPT NPT G HSQ

Number Thread Thread C D E A/F A/F I J

12 4GA 1818

1⁄8

1⁄8

0.87 1.61 0.51 0.48 0.63 0.78

10-32 UNF

(22) (41) (13) (12) (16) (20)

12 4GA 2828

1⁄4

1⁄4

1.14 1.89 0.67 0.64 0.79 1.02

10-32 UNF

(29) (48) (17) (16) (20) (26)

12 4GA 3838

3⁄8

3⁄8

1.20 2.17 0.87 0.69 0.94 1.14

10-32 UNF

(31) (55) (22) (18) (24) (29)

12 4GA 4848

1⁄2

1⁄2

1.54 2.58 1.06 0.87 1.18 1.42

10-32 UNF

(39) (66) (27) (22) (30) (36)

Dimensions in Inches (mm)

E

A

J

G

I

D

H

C

12

1

2

B

mm O.D. tube x ISO G thread

Pilot Operated Check Valve - 102GA

AB

Product O/D ISO G E HSQ

Number tube Thread C D A/F G A/F I J

10 2GA 0628 1⁄4

0.99 1.87 0.67 0.41 0.79 1.02

M5

6

(25) (48) (170) (11) (20) (26)

10 2GA 0828 1⁄4

1.03 1.87 0.67 0.41 0.79 1.02

M5

8

(26) (48) (17) (11) (20) (26)

10 2GA 0838 3⁄8

1.11 2.15 0.87 0.43 0.94 1.14

M5

8

(28) (55) (22) (11) (24) (29)

10 2GA 1038 3⁄8

1.29 2.15 0.87 0.43 0.94 1.14

M5

10

(33) (55) (22) (11) (24) (29)

10 2GA 1248 1⁄2

1.56 2.56 1.06 0.50 1.18 1.42

M5

12

(40) (65) (27) (13) (30) (36)

1) Inlet Port

2) Outlet Port

12) Signal Port

Note: For mounting in pairs on a cylinder

Signal Pressure

Secondary Pressure

(1) (4) (5) (6) (7) (8) (9)(2) (3)

1/2"

3/8"

(bar) psi

(6) 87.0

(5) 72.5

(4) 58.0

(3) 43.5

(2) 29.0

(1) 14.5

0

87.0

72.5

58.0

43.529.014.5

101.5

116.0 130.5

(bar)

psi

1/8" & 1/4"

Page 28

FIT-3-28

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Compact units

● Easy tube insertion for rapid assembly of

pneumatic circuits

● Positive tube retention

● Simplifies pneumatic systems

● Eliminates need for electrical reed switches

● Exhausts on signal side (port 2)

Pressure Sensor Fitting

Inch and Metric

Technical Data

Fluid: Compressed air, nitrogen, inert and non-combustible gases

compatible with materials of construction.

Note:

For other types of fluids or compressed gases, please

consult factory.

Operating Pressure:

Cylinder pressure (Pc) 145 psi (10 bar) max

Sensor supply pressure 43 to 145 psi (3 - 10 bar)

Sensor switch pressure 14.5 psi (1.0 bar) typical

Operating Temperature:

0° to 175°F (–20° to +80°C)

Body Ports

5⁄32'' O.D. tube Push-in

4mm O.D. tube Push-in

1⁄8, 1⁄4 NPTF Banjo Bolt

1⁄8, 1⁄4 ISO G Banjo Bolt

Tube Sizes

5⁄32'' O/D

4mm O/D

Tubing Types:

Nylon 11 or 12, polyurethane (95 durometer or above)

and LPDE (Low Density Polyethylene)

Materials

Body, swivel fitting and collet: Nickel plated brass

O-ring: Silicone free Nitrile

Sealing washer (parallel male threads): Thermoplastic

Tubing: Nylon 11 or 12, Polyurethane (95 durometer or above) and LDPE

(Low Density Polyethylene).

Note: Lower durometer polyurethane may be used, however, an internal

tube support is required to prevent internal collapse of the tube wall.

Ordering Information

To order, quote appropriate product number from

the tables on the following pages.

Product numbering system is designed to make

identification and selection simple:

124GD

124GD

12_______

Series

Number

Type

Shape

Tube Size/

Thread Size

Thread Size/

Tube Size

2

1

Page 29

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-29

Function Fittings and Flow Controls

Dimensions in Inches (mm)

mm O.D. tube x ISO G Banjo Bolt

Pressure Sensor Fitting- 102GD

This sensor fitting produces an end of stroke signal when exhaust back pressure in a cylinder

decays below a set value. It should be mounted directly on the cylinder and can be used with a

flow control device mounted into the top port.

It is recommended that the sensor supply pressure to port 1 be the same as the nominal working

pressure of the cylinder.

J 13.220

D BSPP

ØG

H

Inch O.D. tube x NPTF Banjo Bolt

Pressure Sensor Fitting- 124GD

This sensor fitting produces an end of stroke signal when exhaust back pressure in a

cylinder decays below a set value. It should be mounted directly on the cylinder and

can be used with a flow control device mounted into the top port.

It is recommended that the sensor supply pressure to port 1 be the same as the

nominal working pressure of the cylinder.

J 13.220

D BSPP

ØG

H

I

AB E

Product Tube

NPT

NPT J

Number O/D Thread C D Thread F G H I A/F

12 4GD 0218 5/32" 1⁄8

0.35 1.77

1⁄8

0.39 0.39 0.83 1.12

9/16''

(9) (45) (10) (10) (21) (29)

12 4GD 0228 5/32" 1⁄4

0.43 1.85

1⁄4

0.39 0.56 0.83 1.33

3/4''

(11) (47) (10) (14) (21) (34)

AB E

Product Tube

ISO G

ISO G J

Number O/D Thrd C D thread F G H I A/F

10 2GD 0418 41⁄8

0.35 1.77

1⁄8

0.39 0.24 0.83 0.98 0.59

(9) (45) (10) (6) (21) (25) (15)

10 2GD 0428 41⁄4

0.43 1.85

1⁄4

0.39 0.28 0.83 1.14 0.75

(11) (47) (10) (7) (21) (29) (19)

J

E

G

B

C

D

2

A

H

F

1

A

J

I

E

G

B

C

D

2

A

H

F

1

A

Page 30

FIT-3-30

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Enables air to be exhausted quickly from air

reservoirs and cylinders

● Allows higher cylinder speeds to be achieved

● Simple, compact design and construction

● Reliable operation

T70 Series Quick Exhaust Valves

Technical Data

Fluid:

Compressed air, filtered, lubricated and non-lubricated

Operation:

Diaphragm

Mounting:

Line mounted

Port Size:

Female Thread

(Inlet, outlet and exhaust ports)

NPT ISO G

1⁄8 NPT T70A1800 G1⁄8 T70C1800

1⁄4 NPT T70A2800 G1⁄4 T70C2800

3⁄8 NPT T70A3800 G3⁄8 T70C3800

1⁄2 NPT T70A4800 G1⁄2 T70C4800

3/4 NPT C/511*

* Note: C/511 has 1/2" NPT inlet port and 3/4" NPT outlet ports.

Operating Pressure:

7 - 145 psi (0.5 - 10 bar)

Operating Temperature:

0° to 175°F (-20°** to +80°C)

**Consult our Technical Service for use below 35°F (2˚C)

Materials

Zinc or aluminum alloy body and cover, nitrile seals (PU seal on C/511).

Ordering Information

To order, quote model number from page FIT-3-21,

e.g. T70A2800 for the NPT ported version. This

range replaces the C/510 and S/510 models.

Quick Exhaust Valve

Typical Fill and Exhaust Times (seconds)

Model Port Volume Fill Exhaust

size time time

T70A1800 1/8'' NPT 150 cc 0.036 0.021

T70A2800 1/4'' NPT 150 cc 0.023 0.017

T70A3800 3/8'' NPT 1500 cc 0.110 0.080

T70A4800 1/2'' NPT 15,000 cc 0.460 0.480

C/511 3/4'' NPT 15,000 cc 0.480 0.250

Note: Fill time is 0 to 80 psig (0 to 5.5 bar), and exhaust

time is 101 to 20 psig (7.0 to 1.4 bar)

1

2

3

Page 31

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-31

Function Fittings and Flow Controls

Dimensions in Inches (mm)

Model T70A1800 T70C1800 T70A2800 T70C2800 T70A3800 T70C3800 T70A4800 T70C4800 C/511*

A 1⁄8 NPT G1/8 1⁄4 NPT G1/4 3⁄8 NPT G3/8 1⁄ 2 NPT G1/2 1/20 - 3/4

ØB 0.75 (19) 0.75 (19) 0.75 (19) 0.75 (19) 1.18 (30) 1.18 (30) 1.18 (30) 1.18 (30) –

C A/F 0.75 (19) 0.75 (19) 0.75 (19) 0.75 (19) 1.18 (30) 1.18 (30) 1.18 (30) 1.18 (30) –

D 1.10 (28) 1.10 (28) 1.10 (28) 1.10 (28) 1.57 (40) 1.57 (40) 1.57 (40) 1.57 (40) 2.0 (50)

E A/F 1.18 (30) 1.18 (30) 1.18 (30) 1.18 (30) 1.81 (46) 1.81 (46) 1.81 (46) 1.81 (46) 1.87 (47.5)

F 0.60 (15.3) 0.60 (15.3) 0.60 (15.3) 0.60 (15.3) 0.61 (15.5) 0.61 (15.5) 0.61 (15.5) 0.61 (15.5) –

G 0.14 (3.5) 0.14 (3.5) 0.14 (3.5) 0.14 (3.5) 0.16 (4) 0.16 (4) 0.16 (4) 0.16 (4) –

H 2.09 (53) 2.09 (53) 2.09 (53) 2.09 (53) 2.89 (73.5) 2.89 (73.5) 2.89 (73.5) 2.89 (73.5) 3.38 (86)

ØJ 1.14 (29) 1.14 (29) 1.14 (29) 1.14 (29) 1.81 (46) 1.81 (46) 1.81 (46) 1.81 (46) –

K 1.40 (35.5) 1.40 (35.5) 1.40 (35.5) 1.40 (35.5) 1.89 (48) 1.89 (48) 1.89 (48) 1.89 (48) 2.72 (69)

General Information

Quick Exhaust Valve

Model Inlet port Outlet port Exhaust port Cv Flow Factor Cv Flow Factor Weight Repair kit

NPT ISO G Direction 1 - 2* Direction 2 - 3 oz (kg) (seals only)

T70A 1800 T70C 1800 1⁄8 1⁄8 1⁄8 0.9 1.8 5.3 (0.15) T70C1800K0

T70A 2800 T70C 2800 1⁄4 1⁄4 1⁄4 1.9 2.5 4.6 (0.13) T70C2800K0

T70A 3800 T70C 3800 3⁄8 3⁄8 3⁄8 3.8 5.5 7.4 (0.21) T70C3800K0

T70A 4800 T70C 4800 1⁄2 1⁄2 1⁄2 5.3 5.9 6.7 (0.19) T70C4800K0

C/511 S/511 1/2 3/4 3/4 **1.9/5.1 10.8 11.0 (0.31) QS/511/00

* Flow factor measured at 87 psi (6 bar) (inlet) guideline direction

** Alternative Cv shown for 14.5 psi (1 bar). For T70 Series, Cv approximately the same as at 6 bar.

NPT threads per ANSI B1.20.1

E A/F

ØB

C A/F

C A/F

ØJ

K

F

A

H

D

A

A

G

Por t 2

Por t 1

Por t 3

T70 Series Flowrate

Choked flow versus inlet pressure

(1 - 2) + (2 - 3)

* Note the shape of the C/511 is different. Consult our technical department for the exact specifications.

(dm3/s)

(280)

(240)

(200)

(160)

Choked Flow

(120)

(80)

(40)

scfm

588

504

420

336

252

168

84

2-3 Way 3/4"

2-3 Way

1-2 Way

2-3 Way

1-2 Way

2-3 Way

1-2 Way

2-3 Way

1-2 Way

}

}

}

}

1/2"

3/8"

1/4"

1/8"

0

14.5

(1)

29

44 73

(3)

(2)

58

(5) (6) (7) (8) (9) (10)

(4)

Inlet Pressure

102 131

87 116

145

psi

(bar)

Page 32

FIT-3-32

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Function Fittings and Flow Controls

● Allow two independent signal sources to be

connected to a common pilot line

● Can be used to perform an ‘OR’ logic function

● Selects the highest of two applied pressures

● Can be combined to operate from three or more

sources

● Valves can be ganged together

T65 Series 1/8" and 1/4"

NPT and ISO G Shuttle Valves

Technical Data

Fluid:

Compressed air, filtered, lubricated and non-lubricated, inert gases

Operation:

Shuttle valve

Mounting:

Through holes in valve body

Port Size:

Female Thread

NPT ISO G

1⁄8 NPT T65A1800 G1⁄8 T65C1800

1⁄4 NPT T65A2800 G1⁄4 T65C2800

Operating Pressure:

10 to 145 psi (0.7 - 10 bar)

Operating Temperature:

0° to 175°F (-20°* to +80°C)

*Consult our Technical Service for use below 35°F (2˚C)

Materials

Body: Zinc

Ball: Nitrile

Seat: Brass

Ordering Information

To order, quote model number from table on page.

FIT-3-19, e.g. T65A1800 for the 1/8" NPT.

111

2

2

1

Page 33

Littleton, CO USA Phone 303-794-2611 www.norgren.com

FIT-3-33

Function Fittings and Flow Controls

K

ØF G

DE

J

IH B

C

A

Shuttle Valve

Product Number Port Flow Factor Weight

NPT ISO G Size Cv oz. (kg)

T65A1800 T65C1800 1/8 0.42 1.9 (.055)

T65A2800 T65C2800 1/4 0.64 4.6 (.130)

NPT according to ANSI B1.20.1

G according to BS 2779/ISO 228/1

NPT according to ANSI B1.20.1

Dimensions in Inches (mm)

Model ABCDEFGHIJK

T65A 1800 1/8 NPT 0.30 (8) 0.59 (15) 0.79 (20) 0.3 (8) 0.21 (5) 0.39 (10) 0.24 (6) 0.39 (10) 1.00 (25) 1.42 (36)

T65C 1800 G1/8 0.30 (8) 0.59 (15) 0.79 (20) 0.3 (8) 0.21 (5) 0.39 (10) 0.24 (6) 0.39 (10) 1.00 (25) 1.42 (36)

T65A 2800 NPT1/4 0.39 (10) 0.79 (20) 0.98 (25) 0.49 (13) 0.21 (5) 0.49 (13) 0.31 (8) 0.47 (12) 1.18 (30) 2.00 (50)