Page 1

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-1

Section 12

B07 Miniature General Purpose Filter/Regulator

1/8" and 1/4" ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-2

B72G Excelon General Purpose Filter/Regulator

1/4" and 3/8" ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-4

B73G Excelon General Purpose Filter/Regulator

1/4", 3/8", and 1/2" ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-6

B74G Excelon General Purpose Filter/Regulator

3/8", 1/2", and 3/4" ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-8

B64G Olympian Plus General Purpose Filter/Regulator

1/4", 3/8", 1/2", and 3/4" ports . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-10

B68G Olympian Plus General Purpose Filter/Regulator

3/4",1", 1-1/4", and 1-1/2" ports . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-12

B39 Miniature Oil Removal Filter/Regulator

1/8" and 1/4" ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-12-14

B38 Instrument Filter/Regulator Aluminum 1/4" ports . . . . . . . . .ALE-12-16

Filter/Regulator Overview and FAQ’s . . . . . . . . . . . . . . . . . . . . . .ALE-12-18

Filter/Regulators

Compressed air, general purpose,

and Instrument Filter/Regulators

1/8" to 1-1/2" port sizes

B07

B72G

B73G

B74G

B64G

B39

B38

B68G

Page 2

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B07

● Compact design

● Full flow gauge ports

● Low torque, non-rising adjusting knob

● Snap action knob locks pressure setting when

pushed in

● Standard relieving models allow reduction of outlet

pressure even when the system is dead-ended

● Protects air operated devices by removing liquid and

solids contaminants

● Screw-on bowl reduces maintenance time

● Can be disassembled without the use of tools or

removal from the air line

Series 07 General Purpose Filter/Regulator

1/8" and 1/4" Port S ize s

ALE-12-2

ISO Symbols

Automatic Drain

Relieving

Manual Drain

Relieving

Automatic Drain

Non Relieving

Manual Drain

Non Relieving

Alternative Models

-

★★★ ★★ ★

-

0★B 7

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Drain Substitute

Automatic A

Manual M

Port Size Substitute

1/8" 1

1/4" 2

Element Substitute

5 µm 1

Bowl Relief Type Gauge Substitute

Transparent Relieving Without 01

Transparent Relieving With 02

Transparent Non-relieving Without 03

Transparent Non-relieving With 23

Metal Relieving Without 33

Metal Relieving With 34

Metal Non-relieving Without 35

Metal Non-relieving With 36

Outlet Pressure Adjustment Ranges* Substitute

1 to 10 psig (0.1 to 0.7 bar) A

5 to 50 psig (0.3 to 3.5 bar) E

5 to 100 psig (0.3 to 7 bar) K

5 to 125 psig (0.3 to 8.6 bar) L

Ordering Information. Models listed include PTF threads, transparent bowl, relieving diaphragm, gauge, automatic drain, 5 µm element, 5 to

100 psig (0.3 to 7 bar) outlet pressure adjustment range* .

Port Size Model Number Flow† scfm (dm3/s) Weight lbs (kg)

1/8" B07-102-A1KA 13 (6.2 dm3/s) 0.57 (0.26)

1/4" B07-202-A1KA 14 (6.5 dm3/s) 0.57 (0.26)

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified

ranges.

† Typical flow with 100 psig (7 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a 15 psig (1 bar) droop from set.

Page 3

B07 Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-3

All Dimensions in Inches (mm)

n

n

** Minimum clearance to remove bowl

Panel mounting hole diameter 1.19" (30 mm)

Panel thickness:0.25" (6 mm)

Typical Performance Characteristics

Service Kits

Item Type Part number

Service kit

Relieving models, 5 µm element 3820-12

Non relieving models, 5 µm element 3820-11

Replacement drains

Manual 773-03

Automatic 3654-02

Service kit includes slip ring, diaphragm, valve seat with o-ring,

valve, valve spring, element, element gasket, and bowl o-ring.

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: 30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C)

Particle removal: 5 µm or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (par ticulates)

Typical flow at 100 psig (7 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a

droop of 15 psig (1 bar) from set

1/8" Ports: 13 scfm (6.2 dm

3

/s) with 5 µm element

1/4" Ports: 14 scfm (6.5 dm3/s) with 5 µm element

Nominal bowl size: 1 fluid ounce (31 ml)

Gauge ports:

1/8" PTF with PTF main por ts

1/8" ISO Rc with ISO Rc main ports

1/8" ISO Rc with ISO G main ports

Drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain operation:Spitter type drain operates momentarily when a rapid

change in air flow occurs or when the supply pressure is reduced.

Materials:

Body: Zinc

Bonnet: Acetal

Valve: Brass/nitrile

Valve seat: Acetal

Bowl

Transparent: Polycarbonate

Metal: Zinc

Element: Sintered polypropylene

Elastomers: Nitrile

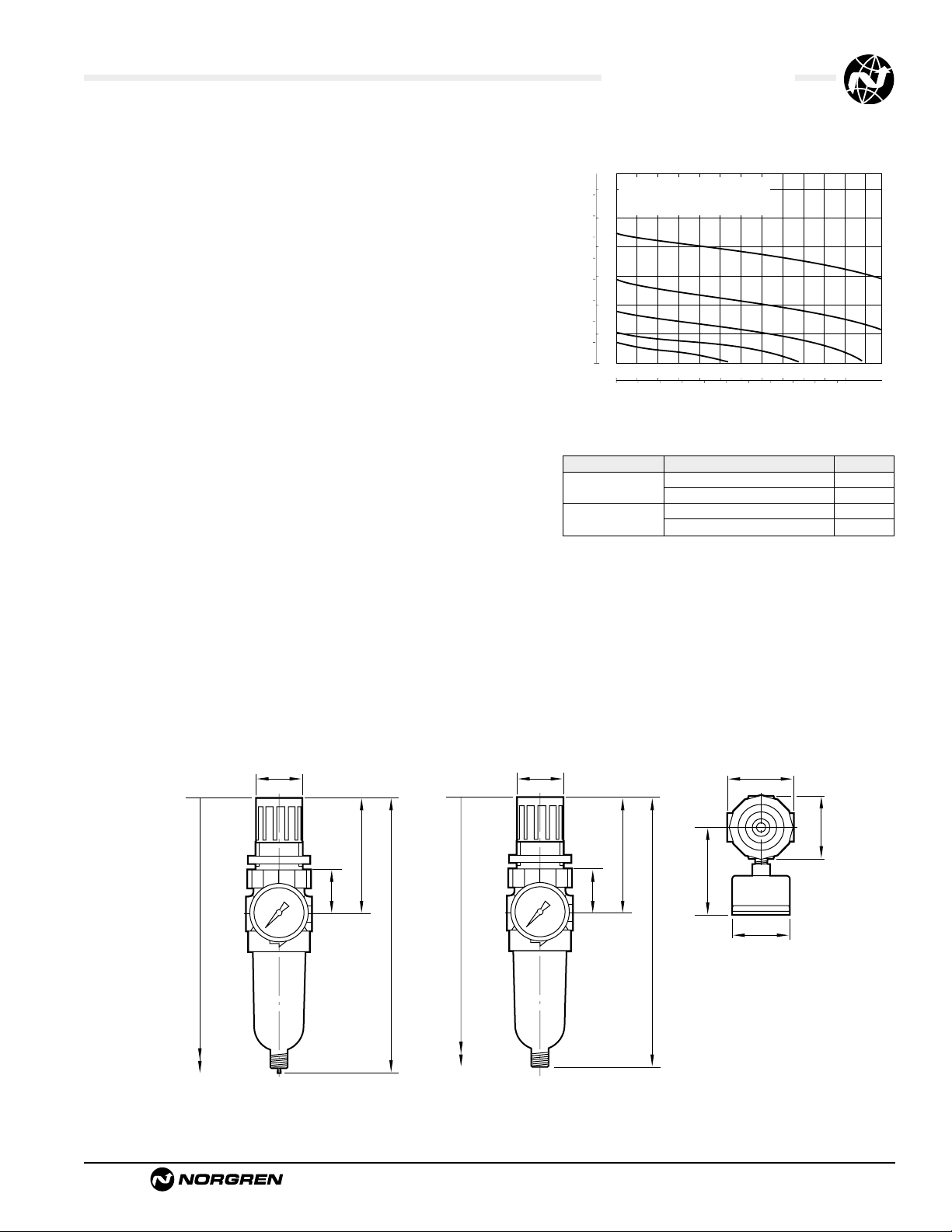

PORT SIZE: 1/4"

psig

bar g

ELEMENT: 40 µm

8

INLET PRESSURE: 150 psig (10 bar g)

RANGE: 5 to 100 psig (0.3 to 7 bar)

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 4 8 12 16 20 24 scfm

0 2 4 6 8 10 dm3/s

FLOW CHARACTERISTICS

AIR FLOW

1.1 (28)

2.67 (68)

1.12 (28)

8.41 (214)**

Manual Drai

6.44 (164)

8.26 (210)**

1.1 (28)

Automatic Drai

1.63 (41)

1.50 (38)

2.67 (68)

2.13 (54)

1.12 (28)

1.50 (38)

6.29 (160)

Page 4

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

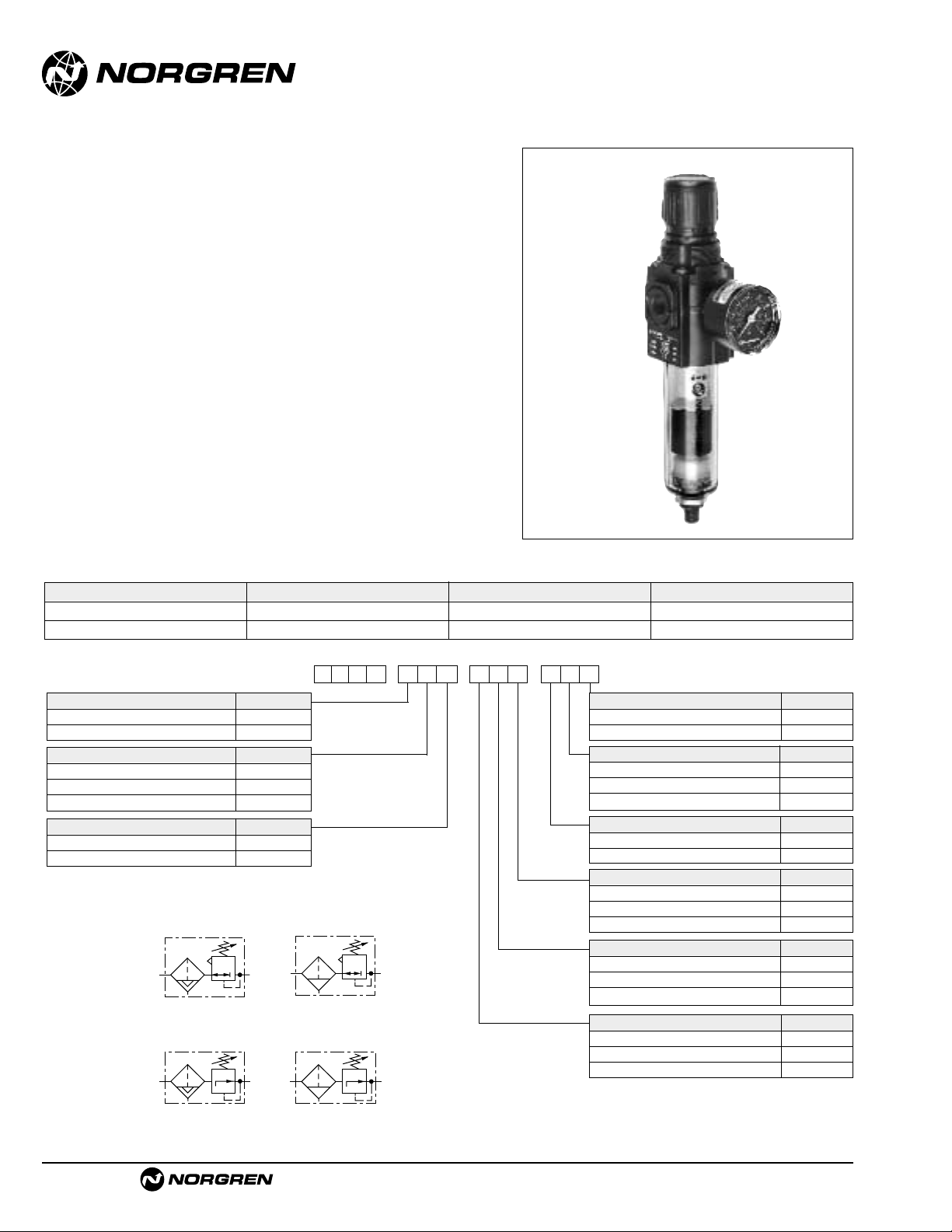

B72G

● EXCELON design allows in-line or modular

installation

● High efficiency water and particle removal

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens on

metal bowls

● Full flow gauge ports

● Balanced valve design for optimum pressure control

● Push to lock adjusting knob with tamper resistant

accessory

● Modular installations with EXCELON 72, 73, and 74

series can be made to suit particular applications

Excelon®72 Series Filter/Regulator

1/4" and 3/8" Port S ize s

ALE-12-4

ISO Symbols

Automatic and

Semi Automatic Drain

Relieving

Manual Drain

Relieving

Automatic and

Semi Automatic Drain

Non Relieving

Manual Drain

Non Relieving

Alternative Models

Ordering Information. Models listed include PTF threads, knob adjustment, automatic drain, transparent bo wl without guard,

40 µm element, relieving diaphragm, 5 to 150 psig (0.3 to 10 bar) outlet pressure adjustment rang*, with gauge.

† Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a 15 psig (1 bar) droop from set.

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

1/4" B72G-2AK-AL3-RMG 80 (38) 1.3 (0.59)

3/8" B72G-3AK-AL3-RMG 80 (38) 1.3 (0.59)

B 7 2-G

★ ★

-

★★ ★ ★

Port Size Substitute

1/4" 2

3/8" 3

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Diaphragm Substitute

Relieving R

Non relieving N

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Adjustment Substitute

Knob K

T-bar T

-

★★ ★

Drain Substitute

1/4 turn manual Q

Semi automatic S

Auto drain A

Gauge Substitute

With G

Without N

Outlet Pressure Adjustment Range* Substitute

5 to 30 psig (0.3 to 2 bar) C

5 to 60 psig (0.3 to 4 bar) F

5 to 150 psig (0.3 to 10 bar) M

* Outlet pressure can be adjusted to pressures in excess of, and less than, those

specified. Do not use these units to control pressures outside of the specified ranges.

Bowl Substitute

Long metal with liquid level indicator E

Long transparent without guard L

Long transparent with guard W

Page 5

B72G Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-5

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure:Transparent bowl: 150 psig (10 bar)

Metal bowl: Manual or semi automatic drain: 250 psig (17 bar)

Automatic drain: 150 psig (10 bar)

Operating temperature*:Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C ).

Particle removal: 5 µm, 25 µm or 40 µm. Within ISO 8573-1, Class 3 and Class 5

Typical flow at 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and

a droop of 1 bar (15 psig) from set: 80 scfm (38 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Semi automatic drain connection: Push on 5/16" (8 mm) ID tube

Semi automatic drain operating conditions (pressure operated):

Bowl pressure required to close drain: Greater than 1.5 psig (0.1 bar)

Bowl pressure required to open drain: Less than 1.5 psig (0.1 bar)

Minimum air flow required to close drain: 1 scfm (0.5 dm

3

/s)

Manual operation: Lift stem to drain bowl

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 0.2 scfm (0.1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Gauge ports: 1/8"PTF with PTF main por ts

1/8" ISO Rc with ISO Rc main ports

1/8" ISO Rc with ISO G main ports

Nominal bowl size: Bowl: 2.2 fluid ounce (65 ml)

Materials

Body: Zinc

Bonnet: Acetal

Valve: Brass

Bowl

Transparent: Polycarbonate

Guard for transparent bowl:Zinc

Metal bowl liquid level indicator lens:

Transparent nylon

Element: Sintered polypropylene

Elastomers: Neoprene and nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

s

m

† Minimum clearance required to remove bowl.

Service Kits

Item Type Part Number

Service kit

Relieving 4383-500

Non relieving 4383-501

5 µm 5925-03

Replacement elements 25 µm 5925-01

40 µm 5925-02

Liquid level lens kit Prismatic 4380-030

1/4 turn manual 619-50

Replacement drains Semi automatic 5379-RK

Automatic 4000-50R

Service kit includes diaphragm assembly, valve assembly,

valve spring, louvre o-ring, bowl o-ring, drain seal.

Panel mounting hole diameter 1.57" (40 mm)

Panel thickness:0.16 (4 mm)

1.97 (50)

1.89 (48)

(35)

1.38

Knob Adjustment T-bar Adjustment

2.48 (63)

1.97 (50)

1.89 (48)

(35)

1.38

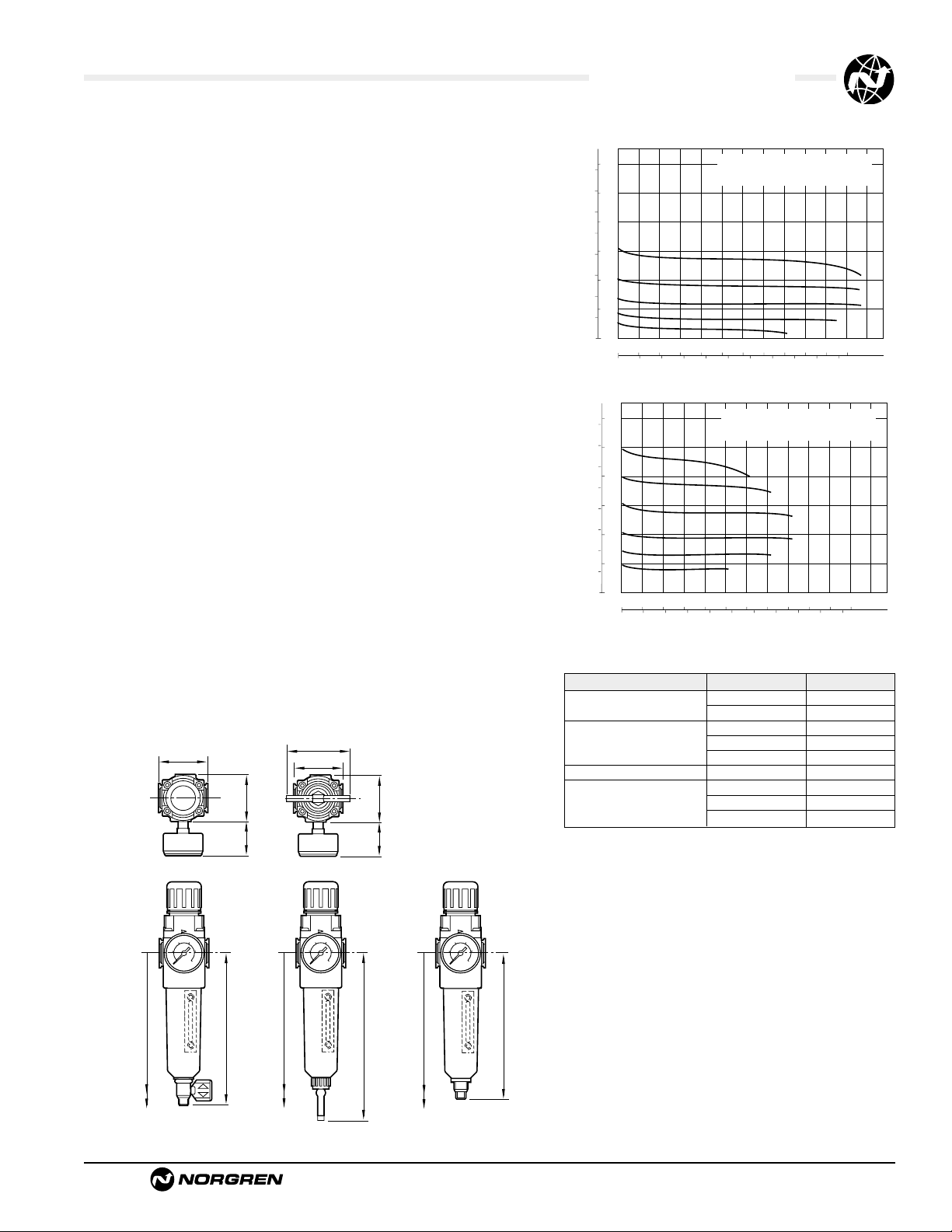

psig

bar g

12

150

9

120

90

6

OUTLET PRESSURE

60

3

30

0

0

0 10 20 30 40 50 60 scfm

0 5 10 15 20 25 dm3/s

psig

bar g

12

150

9

120

90

6

OUTLET PRESSURE

60

3

30

0

0

0 20 40 60 80 100 120 scf

0 10 20 30 40 50 dm3/

FLOW CHARACTERISTICS

PORT SIZE: 1/4" ELEMENT: 40 µm

INLET PRESSURE: 100 psig (7 bar g)

RANGE:

5 to 150 psig (0.3 to 10 bar)

AIR FLOW

FLOW CHARACTERISTICS

PORT SIZE: 1/4" ELEMENT: 40 µm

INLET PRESSURE: 150 psig (10 bar g)

RANGE:

5 to 150 psig (0.3 to 10 bar)

AIR FLOW

7.83 (199) †

5.83 (148)

Bowl with

1/4 Turn Manual Drain

9.84 (250) †

Bowl with

Semi auto Drain

7.48 (190)

7.52 (191) †

Bowl with

Automatic Drain

5.51 (140)

Page 6

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B73G

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Full flow gauge ports

● Balanced valve design minimizes effect of variation

in the inlet pressure on the outlet pressure

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Excelon®73 Series Filter/Regulator

1/4",3/8",1/2" Por t Si zes

ALE-12-6

Ordering Information. Models listed include PTF threads, knob adjustment, automatic drain, metal bowl with liquid level indicator, 40 µm element,

relieving diaphragm, 5 to 150 psig (0.3 to 10 bar) outlet pressure adjustment range* with gauge.

† Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and 15 psig (1 bar) droop from set.

Main Port Size Model Number Flow†scfm (dm3/s) Weight lb (kg)

1/4" B73G-2AK-AD3-RMG 78 (37) 1.76 (0.82)

3/8" B73G-3AK-AD3-RMG 123 (58) 1.76 (0.82)

1/2" B73G-4AK-AD3-RMG 123 (58) 1.76 (0.82)

Alternative Models

B 7 3-G

★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Adjustment Substitute

Knob K

T-bar T

Diaphragm Substitute

Relieving R

Non relieving N

Gauge Substitute

With G

Without N

Bowl Substitute

Metal with liquid level indicator D

Transparent with guard P

Transparent T

Element Substitute

5 µm 1

25 µm 2

40 µm 3

-

★★ ★

*Outlet pressure can be adjusted to pressures in excess of, and less than, those

specified.Do not use these units to control pressures outside of the specified ranges.

**Units with 250 psig (17 bar) outlet pressure range are available only with the

standard metal bowl.

Drain Substitute

Automatic A

Manual, 1/4 turn Q

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

Outlet Pressure Adjustment Range* Substitute

5 to 60 psig (0.3 to 4 bar) F

5 to 150 psig (0.3 to 10 bar) M

10 to 250 psig (0.7 to 17 bar)** S

Page 7

B73G Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-7

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5 µm, 25 µm or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (par ticulates)

Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure

and 15 psig (1 bar) droop from set: 123 scfm (58 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 0.2 scfm (0.1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size: 3.5 fluid ounce (0.1 liter)

Gauge ports:

1⁄4" PTF with PTF main ports

Rc1/4 with ISO Rc main ports

Rc1/8 with ISO G main ports

Materials

Body: Aluminum

Bonnet: Aluminum or Zinc

Valve: Brass

Bowl:

Transparent: Polycarbonate

Transparent with guard: Polycarbonate, steel guard

Metal: Aluminum

Metal bowl liquid level indicator lens:Transparent nylon

Element: Sintered polypropylene

Elastomers: Neoprene and nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid and

on depressurization.

Automatic Drain, Non-Relieving

Manual Drain, Non-Relieving

ISO Symbols

Automatic Drain, Relieving

Manual Drain, Relieving

Typical Performance Characteristics

** Minimum clearance to remove bowl.

Service kit includes diaphragm assembly, valve assembly, valve

spring, bowl o-ring, and automatic drain seal.

Service Kits

Item Type Part Number

Service kit Relieving 4383-600

Non-relieving 4383-601

Replacement elements

5 µm 4438-01

25 µm 4438-02

40 µm 4438-03

Liquid level lens kit Prismatic 4380-020

Replacement drains

Automatic 4000-51R

Manual quarter turn 619-50

Panel mounting hole diameter 1.89" (48 mm)

Panel thickness:0.25 (6 mm)

1.22 (31)

2.68 (68)

2.00 (50)

2.45 (62)

2.20 (56)3.80 (96)5.80 (147)

bar

psig

8

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 40 80 120 160 200 scfm

0 20 40 60 80 100 dm3/s

PORT SIZE: 3/8"

bar

ELEMENT: 40 µm

psig

INLET PRESSURE: 100 psig (7 bar)

RANGE: 5 to 150 psig (0.3 to 10 bar)

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 20 40 60 80 100 scfm

01020304050dm

FLOW CHARACTERISTICS

INLET PRESSURE: 150 psig (10 bar)

RANGE: 5 to 150 psig (0.3 to 10 bar)

AIR FLOW

FLOW CHARACTERISTICS

AIR FLOW

PORT SIZE: 3/8"

ELEMENT: 40 µm

3

/s

0.45 (12)

(31)

1.22

8.15 (207)**

Automatic Drain

4.04 (103)6.15 (156)

8.50 (216)**

1/4 Turn Manual Drain

Page 8

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B74G

● EXCELON design allows in-line or modular

installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Full flow gauge ports

● Balanced valve design minimizes effect of variation

in the inlet pressure on the outlet pressure

● Modular installations with EXCELON 72, 73, and 74

series can be made to suit particular applications

Excelon®74 Series Filter/Regulator

3/8",1/2",3/4" Por t Si zes

ALE-12-8

Ordering Information. Models listed include PTF threads, knob adjustment, automatic drain, metal bowl with liquid level indicator, 40 µm element,

relieving diaphragm, 5 to 150 psig (0.3 to 10 bar) outlet pressure adjustment range*, with gauge.

† Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a 15 psig (1 bar) droop from set.

Main Port Size Model Number Flow†scfm (dm3/s) Weight lb (kg)

3/8" B74G-3AK-AD3-RMG 163 (77) 2.62 (1.19)

1/2" B74G-4AK-AD3-RMG 212 (100) 2.59 (1.17)

3/4" B74G-6AK-AD3-RMG 212 (100) 2.55 (1.16)

Alternative Models

B 7 4-G

★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Adjustment Substitute

Knob K

T-bar T

Diaphragm Substitute

Relieving R

Non relieving N

Gauge Substitute

With G

Without N

Outlet Pressure

Adjustment Range* Substitute

5 to 60 psig (0.3 to 4 bar) F

5 to 150 psig(0.3 to 10 bar ) M

10 to 250 psig (0.7 to 17 bar )** S

Bowl Substitute

Metal with liquid level indicator D

Transparent with guard P

Element Substitute

5 µm 1

25 µm 2

40 µm 3

-

★★ ★

* Outlet pressure can be adjusted to pressures in excess of, and less than, those

specified. Do not use these units to control pressures outside of the specified

ranges.

** Units with 250 psig (17 bar) outlet pressure range are available only with the Tbar adjustment; therefore substitute T at the 7th digit and S at the 12th position.

Drain Substitute

Automatic A

Manual, 1/4 turn Q

Port Size Substitute

3/8" 3

1/2" 4

3/4" 6

Page 9

B74G Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-9

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5, 25 or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (par ticulates)

Typical flow with 150 psig (10 bar) inlet pressure, 6.3 (90 psig) set pressure and a

droop of 15 psig (1 bar) from set: 212 scfm (100 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size: 7 fluid ounce(0.2 liter )

Gauge ports:

1⁄4" PTF with PTF main ports

Rc1⁄4 with ISO Rc main ports

Rc1⁄8 with ISO G main ports

Materials

Body: Aluminum

Bonnet: Aluminum

Valve: Brass

Bowl

Transparent: Polycarbonate with steel bowl guard

Metal: Aluminum

Metal bowl liquid level indicator lens:Transparent nylon

Element: Sintered plastic

Elastomers: Neoprene and Nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Automatic Drain, Non Relieving Manual Drain, Non Relieving

ISO Symbols

Automatic Drain, Relieving

Manual Drain, Relieving

Typical Performance Characteristics

Panel mounting hole diameter: 2.06" (52 mm)

Panel thickness:0.06" to 0.25" (2 to 6 mm)

Service kit includes diaphragm assembly, valve assembly, valve

spring, louvre o-ring, bowl o-ring, drain seal.

Service Kits

Item Type Part Number

Service kit Relieving 4383-700

Non relieving 4383-701

Replacement elements

5 µm 4338-04

25 µm 4338-07

40 µm 4338-05

Liquid level lens kit Prismatic 4380-050

Replacement drains

Automatic (1/8 NPT outlet) 3000-10

Manual quarter turn 619-50

** Minimum clearance to remove bowl.

3.15 (80)

psig

bar g

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 40 80 120 160 200 scfm

0 20 40 60 80 100 dm3/s

psig

bar g

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 40 80 120 160 200 scfm

0 20 40 60 80 100 dm3/s

FLOW CHARACTERISTICS

PORT SIZE: 1/2",

INLET PRESSURE: 150 psig (10 bar g)

RANGE: 5 to 150 psig (0.3 to 10 bar)

AIR FLOW

FLOW CHARACTERISTICS

PORT SIZE: 1/2",

INLET PRESSURE: 100 psig (7 bar g)

RANGE: 5 to 150 psig (0.3 to 10 bar)

AIR FLOW

ELEMENT: 40 µm

ELEMENT: 40 µm

2.89 (74)2.20 (56)

1.45 (37)

2.00 (50)

9.06 (230)**

Automatic Drain

1.24 (31)

1.69 (43)

4.98 (127)

5.95 (151)

6.35 (161)

9.69 (246)**

6.95 (177)

Manual Drain

Page 10

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B64G

● Olympian Plus plug in design

● High Efficiency water and particle removal

● Quick release bayonet bowl

● High visibility prismatic sight glass

● Push to lock adjusting knob with tamper resistant

option

Olympian Plus Filter/Regulator

1/4",3/8", 1/2",3/4" Port Sizes

ALE-12-10

Ordering Information.

Models listed include PTF threads, knob adjustment, automatic drain, metal bowl, 40 µm element, relieving diaphragm, 5 to 150

psig (0.3 to 10 bar) outlet pressure adjustment range* with gauge.

† Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a 15 psig (1 bar) droop from set.

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

1/4" B64G-2AK-AD3-RMG 64 (30) 3.80 (1.71)

3/8" B64G-3AK-AD3-RMG 161 (76) 3.76 (1.69)

1/2" B64G-4AK-AD3-RMG 225 (106) 3.69 (1.66)

3/4" B64G-6AK-AD3-RMG 225 (106) 4.49 (2.02)

Alternative Models

B 6 4-G

★ ★

-

★★ ★ ★

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

3/4" 6

No Yoke N

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Diaphragm Substitute

Relieving R

Non relieving N

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Adjustment Substitute

Knob K

T-bar T

Bowl Substitute

Metal with liquid level indicator D

Guarded Transparent P

-

★★ ★

Drain Substitute

1/4 turn manual Q

Automatic A

Gauge Substitute

With G

Without N

Outlet Pressure Adjustment Range* Substitute

5 to 60 psig (0.3 to 4 bar) F

5 to 150 psig (0.3 to 10 bar) M

10 to 250 psig (0.7 to 17 bar) S**

* Outlet pressure can be adjusted to pressures in excess of, and less than, those

specified. Do not use these units to control pressures outside of the specified ranges.

** Units with 250 psig (17 bar) adjustment range are available only with the T-bar

adjustment; therefore substitute T at the 7th digit and S at the 12th position.

Page 11

B64G Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-11

All Dimensions in Inches (mm)

ISO Symbols

Automatic Drain

Relieving

Manual Drain

Relieving

Automatic Drain

Non Relieving

Manual Drain

Non Relieving

Technical Data

Fluid: Compressed air

Maximum pressure

Guarded transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Guarded transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5, 25 or 40 µm. Within ISO 8573-1, Class 3 and Class 5

Typical flow at 90 psig (6.3 bar) inlet pressure:

225 scfm (106 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain operating conditions:

Minimum pressure: 10 psig (0.7 bar).

Drain opens when bowl pressure drops below 3 psig (0.2 bar).

Minimum air flow: 2 scfm (1 dm

3

/s) required to close drain.

Gauge Ports:

1/8" PTF with PTF main ports

1/8" ISO Rc with ISO Rc main por ts

1/8" ISO Rc with ISO G main por ts

Nominal bowl size:

7 fluid ounce (0.2 liter)

Materials:

Body: Zinc

Bonnet: Aluminum

Valve: Brass

Yoke: Zinc

Metal bowl: Aluminum

Standard metal bowl prismatic liquid level indicator lens:Grilamid

Optional metal bowl sight glass: Pyrex

Optional transparent bowl: Polycarbonate

Element: Sintered plastic

Elastomers: Synthetic rubber

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

Service Kits

Item Type Part Number

Service kit

Relieving 4383-200

Non relieving 4383-201

5 µm 4338-01

Replacement elements 25 µm 4338-99

40 µm 4338-02

Replacement Sight Glass

Prismatic (standard) 4380-040

Pyrex 4380-041

Replacement Drains

Automatic 3000-10

Manual 684-84

Service kit includes diaphragm assembly, valve assembly,

valve spring, louver o-ring, bowl o-ring, drain seal.

** 4.13 (105) for 1/4", 3/8", and 1/2" ported yokes.

6.18" (157) for 3/4" ported yokes.

† Add 1.46 (37) for units with T-handle adjustment.

†† Minimum clearance required to remove unit.

Add 1.46 (37) for units with T-handle adjustment.

4.92 (125)†

11.30 (287)†

11.99 (303)††

12.60 (320)††

11.97 (304)†

4.13 (105)**

1.46

(37)

2.91 (74)

psig

bar g

8

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 40 80 120 160 200 240 scfm

0 20 40 60 80 100 dm3/s

FLOW CHARACTERISTICS

PORT SIZE: 1/2" 40 µm ELEMENT

INLET PRESSURE: 150 psig (10 bar)

RANGE: 5 to 150 psig (0.3 to 10 bar)

AIR FLOW

Page 12

Littleton, CO USA Phone 303-794-2611 www.norgren.com

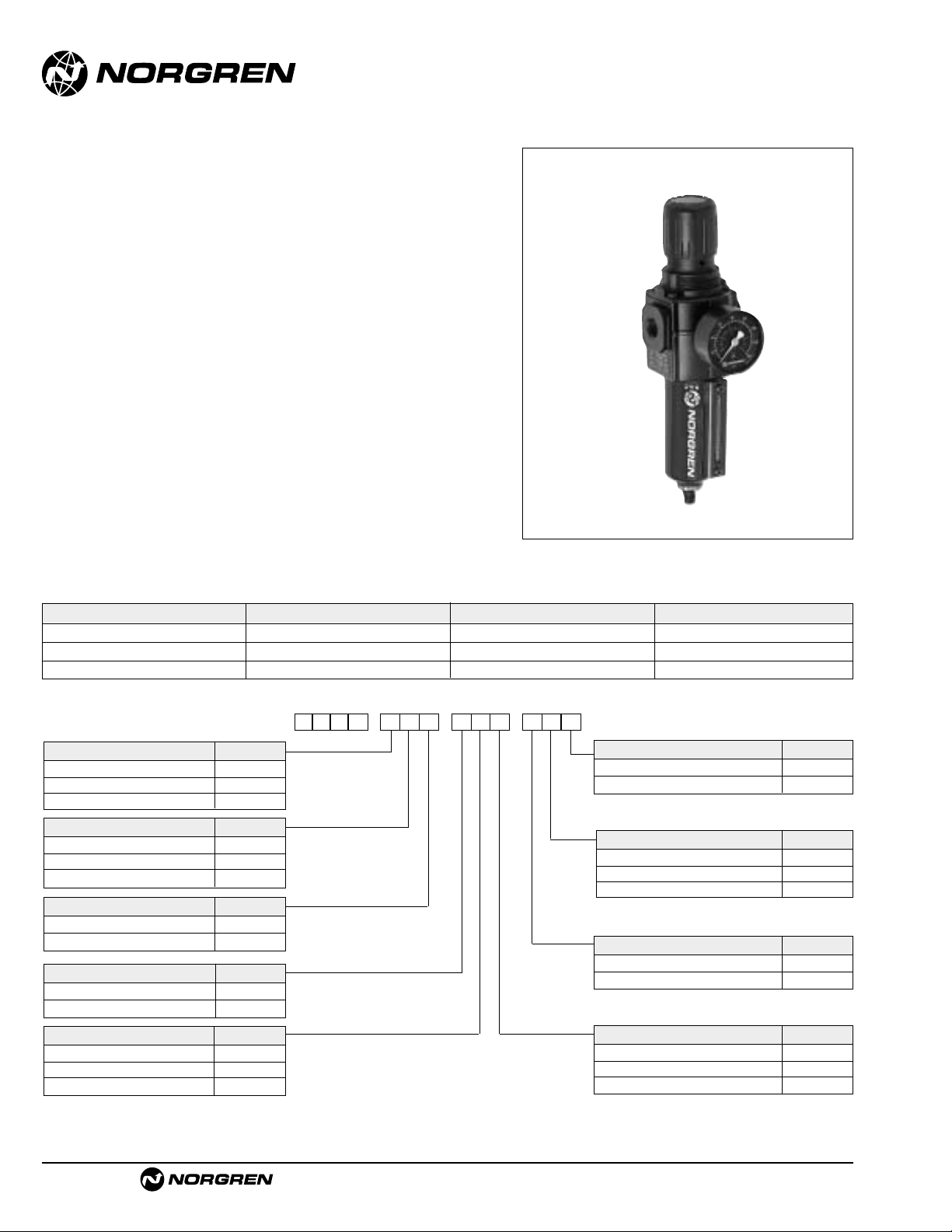

B68E/G

● Olympian Plus plug in system

● Effective liquid removal and positive solid particle

filtration

● Large filter element area provides minimum pressure

drop

● High flow unit with large valve and diaphragm

● Push to lock adjusting knob with tamper resistant

option

● Excellent flow and regulation characteristics

Olympian Plus Filter/Regulator

3/4",1", 1-1/4", 1-1/2" Port Sizes

ALE-12-12

Ordering Information.

Models listed include a 1 quart w/long element, yoke with PTF threads, knob adjustment, automatic drain, 40 µm element, relieving

diaphragm, and a 5 to 120 psig (0.4 to 8 bar) outlet pressure adjustment range*.A gauge is not included.

Port Size Model Flow**scfm (dm3/s) Weight lb (kg)

3/4 B68E-6AK-AU3-RLN 509 (240) 6.47 (2.94)

1 B68E-8AK-AU3-RLN 509 (240) 6.20 (2.82)

1-1/4 B68E-AAK-AU3-RLN 509 (240) 6.42 (2.92)

1-1/2 B68E-BAK-AU3-RLN 509 (240) 6.07 (2.76)

Alternative Models

B 6 8-E

★ ★

-

★★ ★ ★

Diaphragm Substitute

Relieving R

Non relieving N

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Adjustment Substitute

Knob K

T-bar T

Bowl Substitute

1 quart (1 liter) without liquid level

indicator C††

1 pint (0.5 liter) without liquid level

indicator M†

1 pint (0.5 liter) with liquid level

indicator R†

1 quart (1 liter) with liquid level

indicator U

††

-

★★ ★

Gauge Substitute

With G

Without N

Outlet Pressure Adjustment Range* Substitute

0 to 60 psig(0 to 4 bar) F

5 to 120 psig (0.4 to 8 bar) L

10 to 250 psig (0.7 to 17 bar) S***

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified. Do not use these units to control pressures outside of the specified ranges.

** Typical flow with 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and a 15 psig (1 bar) droop from set.

*** Units with 250 psig (17 bar) adjustment range are available only with the T-bar adjustment; therefore substitute T at the 7th digit and S at the 12th position.

† Only available with B68G.

†† Only availab le with B68EE

Port Size Substitute

3/4" 6

1" 8

1-1/4" A

1-1/2" B

No Yoke N

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

No Yoke (N in 5th position) N

Rc threaded gauge ports

No Yoke (N in 5th position) A

PTF threaded gauge ports

Bowl/Element Type Substitute

1 quart (1 liter) bowl w/long element E

1 pint (0.5 liter) bowl w/short element G

Drain Substitute

Automatic A

No drain (Closed bowl) E

Manual M

Manual, 1/4 turn Q

Page 13

1 Pint US

(0.5 Liter) Bowl

† Add 1.46" (37 mm) for unit with T-bar adjustment. * Dimension also applies to closed bottom bowl.

** For 1-1/4" and 1-1/2" ported yokes, add 0.39" (10 mm). ¶ Minimum clearance required to remove bowl.

Manual Drain

1/4 Turn Manual Drain

1 Quart US

(1 Liter) Bowl

1/4 Turn Manual Drain

13.5 (343) ¶ *

7.5 (190)*

5.32 (135) †

2.40

(61)

Automatic Drain

.

13.8 (350) ¶

7.8 (197)

Manual Drain

14.2 (361) ¶

8.2 (208)

10.6 (269)

18.2 (463) ¶

10.2 (258)

17.8 (452) ¶

17.5 (445) ¶ *

Automatic Drain

.

9.9 (251)*

5.32 (135) †

2.40

(61)

7.48 (190)**

2.13

(54)

B68E/G Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-13

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to +175°F (-20° to +80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below +35°F (+2°C).

Partical removal: 5, 25 or 40 µm

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow at 150 psig (10 bar) inlet pressure, 90 psig (6.3 bar) set pressure and

a droop of 15 psig (1 bar) from set: 509 scfm (240 dm3/s)

1/4 turn manual drain connection: 1/8" pipe thread

Automatic drain connection: 1/8" pipe thread

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm3/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size:

1 pint U.S.(0.5 liter)

1 quart U.S. (1 liter)

Gauge ports:

1/8 PTF with PTF yoke ports

Rc1/8 with ISO Rc yoke ports

Rc1/8 with ISO G yoke ports

Materials:

Body: Aluminum

Yoke: Aluminum

Bonnet: Aluminum

Adjusting knob: Acetal resin

Optional T-bar adjusting screw: Steel

Valve: Aluminum

Bowl: Aluminum

Sight glass: Pyrex

Element: Sintered bronze or polypropylene

Elastomers: Synthetic rubber

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

Service Kits

Item Type Part Number

Service kit

Relieving 4383-300

Non relieving 4383-301

5 µm (1 pint bowl) 5576-97

25 µm (1 pint bowl) 5576-98

Replacement 40 µm (1 pint bowl) 5576-99

elements 5 µm (1 quart bowl) 5311-01

25 µm (1 quart bowl) 5511-02

40 µm (1 quart bowl) 5511-03

Replacement 1 pint bowl 4380-060

sight glass kit 1 quart bowl 4380-061

Replacement Automatic (G 1/8 outlet) 3000-97

Drains Automatic (1/8 NPT outlet) 3000-10

Manual 684-84

Manual quarter turn 619-50

Service kit includes, valve spring, slip ring, valve assembly,

diaphragm assembly and necessary seals and ‘o’rings.

Automatic Drain

Relieving

Manual Drain

Relieving

Automatic Drain

Non Relieving

Manual Drain

Non Relieving

See Section ALE-24 for Accessories

psig

bar g

120

8

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 80 160 240 320 400 480 scfm

0 40 80 120 160 200 dm3/s

FLOW CHARACTERISTICS

PORT SIZE: 1", ELEMENT: 40 µm

INLET PRESSURE: 150 psig (10 bar)

RANGE: 5 to 120 psig (0.4 to 8 bar)

AIR FLOW

Page 14

See Section ALE-24 for Accessories

ALE-12-14

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B39

● Compact design

● High efficiency oil and particle removal

● Low torque, non-rising adjusting knob

● Snap action knob locks pressure setting when

pushed in

● Standard relieving models allow reduction of outlet

pressure even when the system is dead-ended

Miniature Series 07 Oil Removal

Filter/Regulator 1/8" and 1/4" Port S ize s

ISO Symbols

Automatic Drain

Relieving

Manual Drain

Relieving

Automatic Drain

Non Relieving

Manual Drain

Non Relieving

Ordering Information. Models listed include PTF threads, transparent bowl, relieving diaphragm, gauge, automatic drain, 5 to 100 psig (0.3 to 7

bar) outlet pressure adjustment range* .

Port Size Model Number Flow† scfm (dm3/s) Weight lbs (kg)

1/8" B39-102-A0KA 4.0 (1.9) 0.57 (0.26)

1/4" B39-202-A0KA 4.0 (1.9) 0.57 (0.26)

† Maximum flow with 90 psig (6.3 bar) inlet pressure to maintain stated oil removal performance.

Alternative Models

-

★★★ ★★ ★

-

3★B 9

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Drain Substitute

Automatic A

Manual M

Element Substitute

Coalescing 0

Bowl Relief T ype Gauge Substitute

Transparent Relieving Without 01

Transparent Relieving With 02

Transparent Non-relieving Without 03

Transparent Non-relieving With 23

Metal Relieving Without 33

Metal Relieving With 34

Metal Non-relieving Without 35

Metal Non-relieving With 36

Outlet Pressure Adjustment Ranges* Substitute

1 to 10 psig (0.1 to 0.7 bar) A

5 to 50 psig (0.3 to 3.5 bar) E

5 to 100 psig (0.3 to 7 bar) K

5 to 125 psig (0.3 to 8.6 bar) L

* Do not use these units to control pressures outside of the specified ranges.

Port Size Substitute

1/8" 1

1/4" 2

Page 15

ALE-12-15

All Dimensions in Inches (mm)

B39 Oil Removal Filter/Regulator

Littleton, CO USA Phone 303-794-2611 www.norgren.com

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C)

Particle removal: Down to 0.01 µm

Air quality: Within ISO 8573-1, Class 1 (par ticulates) and Class 2 (oil content)

Maximum remaining oil content in outlet air: 0.01 ppm at 70°F (21°C) with an inlet

concentration of 17 ppm.

Maximum flow with 90 psig (6.3 bar) inlet pressure

†

:

4.0 scfm (1.9 dm

3

/s)

† Maximum flow to maintain stated oil removal performance.

Nominal bowl size: 1 fluid ounce (31 ml)

Gauge ports:

1/8" PTF with PTF main por ts

1/8" ISO Rc with ISO Rc main ports

1/8" ISO Rc with ISO G main ports

Drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain operation:Spitter type drain operates momentarily when a rapid

change in air flow occurs or when the supply pressure is reduced.

Materials

Body: Zinc

Bonnet: Acetal

Valve: Brass/nitrile

Valve seat: Acetal

Bowl

Transparent: Polycarbonate

Metal: Zinc

Element: Synthetic fiber and polyurethane foam

Elastomers: Nitrile

Typical Performance Characteristics

n

n

2.13 (54)

1.63 (41)

1.50 (38)

1.50 (38)

8.41 (214)**

1.12 (28)

2.67 (68)

6.44 (164)

1.1 (28)

8.26 (210)**

1.12 (28)

2.67 (68)

6.29 (160)

1.1 (28)

Panel mounting hole diameter: 1.19" (30 mm)

Maximum panel thickness: 0.25" (6 mm)

** Minimum clearance to remove bowl

Service Kits

Item Type Part number

Service kit

Relieving models 3407-66

Non relieving models 3407-65

Element 4141-10

Replacement drains

Manual 773-03

Automatic 3654-02

Relieving and non-relieving service kits include slip ring,

diaphragm, valve seat with o-ring, valve, and valve spring. Element

kit contains element, element gasket, and bowl o-ring.

FLOW CHARACTERISTICS

PORT SIZE: 1/8

psig

bar g

INLET PRESSURE: 150 psig (10 bar g)

8

RANGE: 5 to 100 psig (0.3 to 7 bar)

100

6

80

60

4

OUTLET PRESSURE

40

2

20

0

0

0 1 2 3 4 5 6 scfm

0 0.5 1 1.5 2 2.5 dm3/s

"

AIR FLOW

Manual Drai

Automatic Drai

Page 16

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

B38

● Compact instrument units with high performance

● Stable regulation and temperature compensation

● Excellent flow and regulation characteristics

Instrument Filter/Regulator

Aluminum Model 1/4" PTF

ALE-12-16

ISO Symbols

Automatic Drain, Relieving

Automatic Drain,

Non Relieving

Manual Drain, Relieving

Manual Drain,

Non Relieving

Alternative Models

Port Size Substitute

1/4” PTF 2

Type Substitute

Aluminum 0

Diaphragm Substitute

Relieving 0

Non relieving 1

Relieving, bracket and nut 2

Non relieving, bracket and nut 3

Relieving with nut 4

Non relieving with nut 5

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel D

API.LP.INT K

Port Size Model Number Flow†scfm (dm3/s) Weight lbs (kg)

1/4" PTF B38-200-B2CA 17 (8) 1.18 (0.53)

Ordering Information. Models listed are relieving type with PTF threads, manual drain, 25 µm element, screw adjustment, 0.6 to 30 psig

(0.04 to 2 bar) outlet pressure adjustment range and without gauge.

Outlet Pressure Adjustment Ranges* Substitute

0.6 to 30 psig (0.04 to 2 bar) C

1 to 60 psig (0.07 to 4 bar) F

3.6 to 100 psig (0.25 to 7 bar) K

Element Substitute

5 µm 1

25 µm 2

83B

★ ★ ★ ★ ★ ★ ★

--

Drain Substitute

Manual B

* Outlet pressure can be adjusted to pressures in excess of, and less than, those

specified. Do not use these units to control pressures outside of the specified ranges.

† Typical flow 100 psig (7bar) inlet pressure, 15 psig (1 bar) set pressure, and a droop of 1 psig (0.05 bar) from set.

Page 17

B38 Instrument Filter/Regulators

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-17

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure

Manual drain: 300 psig (20 bar)

Operating temperature: -40° to 175°F (-40° to 80°C) *

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5 µm or 25 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (par ticulates)

Typical flow with 100 psig (7 bar) inlet pressure, 15 psig (1 bar) set pressure and a

droop of 1 psig (0.05 bar) from set:

17 scfm (8 dm

3

/s)

Manual Drain

Nominal bowl size:

2.4 fluid ounce (70 ml)

Gauge ports:

1/4" PTF

Materials

Body: Aluminum

Bonnet: Aluminum

Bowl: Aluminum

Adjusting screw: Steel

Elements

25 µm: High density polyethylene

5 µm: Ceramic pyrolith

Elastomeric materials: Synthetic rubber

Typical Performance Characteristics

INLET PRESSURE - 100 psig (7 bar g)

FLOW CHARACTERISTICS -

PORT SIZE: 1/4"

0 2 4 6 8 10 dm3/s

AIR FLOW

0 4 8 12 16 20 24 scfm

OUTLET PRESSURE

4

3

2

1

0

bar g

50

40

30

20

10

0

psig

** Minimum clearance required to remove bowl.

Panel mounting hole diameter: 1.65" (42 mm)

Maximum panel thickness: 0.24" (6 mm)

Service Kits

Item Type Part number

30 psig (2 bar) range Relieving R38-100R

Non relieving R38-100NR

60 and 100 psig Relieving R38-101R

(4 bar and 7 bar) range Non relieving R38-101NR

5 micron element B38-100A (5)

25 micron element B38-100A (25)

Service kits includes diaphragm assembly, o-ring, valve, valve

spring and 8 pan head screws.

2.52 (64)

1.26 (32)

REGULATION CHARACTERISTICS - PORT SIZE: 1/4"

MAXIMUM RECOMMENDED

psig

FLOW THROUGH 1/4

bar g

10%

60

100%

4

200%

50

3

40

30

2

OUTLET PRESSURE

20

1

10

"

PIPE

100% FLOW

scfm dm3/s

7.9 3.7

5 2.4

3.6 1.7

2.5 1.2

2.52 (64)

9.17 (233)**

0.51 (13)

1/8" PTF

2.09 (53)

3.11 (79)

2.95 (75)

5.71 (194)

0

0

0 20 40 60 80 100 psig

0 2 4 6 8 bar g

INLET PRESSURE

Page 18

Filter/Regulator Overview and FAQ’s

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-12-18

GENERAL PURPOSE FILTER/REGULATOR

1.1 GENERAL OVERVIEW

Filter/regulators combine the features of a filter and

regulator with a single compact body.

Air passes through the filter section first

removing water and particle contaminants, and is

then regulated by the top regulator section.

See individual filter and regulator sections

for details.

1.2 PERFORMANCE

CHARACTERISTICS

The regulator section of the filter/regulator

determines the flow and regulation characteristics of

the unit.

Flow is therefore measured in terms of

pressure droop from set pressure (see regulators)

and not flow versus pressure drop as in a filter.

Regulation characteristics are determined

in the same way as regulators.

1.3 SPECIALS

1.3.1 Can we do a Coalescing Filter/Regulator?

Yes. We have a B39 unit in the 07 Series. Other

sizes could be considered for volume customers.

1.3.2 Can we do special materials?

Units are available in stainless steel (B05 and B38)

for harsh environments and process applications.

Spring rest

Relief seat

Bowl

Baffle

Knob

Adjusting screw

Adjusting nut

Control spring

Diaphragm

Valve pin

Valve

Valve spring

Center post

Element

Metal bowl

sight glass

Collected

condensate

Drain

Loading...

Loading...