Page 1

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

Filter Contents

Filter Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-Filter

General Purpose Filters . . . . . . . . . . . . . . . . . . . . . . . .ALE-1-1

Oil Removal (Coalescing) Filters . . . . . . . . . . . . . . . . . .ALE-2-1

Oil Vapor Removal (Adsorbing) Filters . . . . . . . . . . . . .ALE-3-1

Filters

General Purpose Filters, Oil

Removal (Coalescing) Filters, Oil

Vapor Removal (Adsorbing)

Filters, and Compressed Air

Membrane Dryers

Page 2

Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

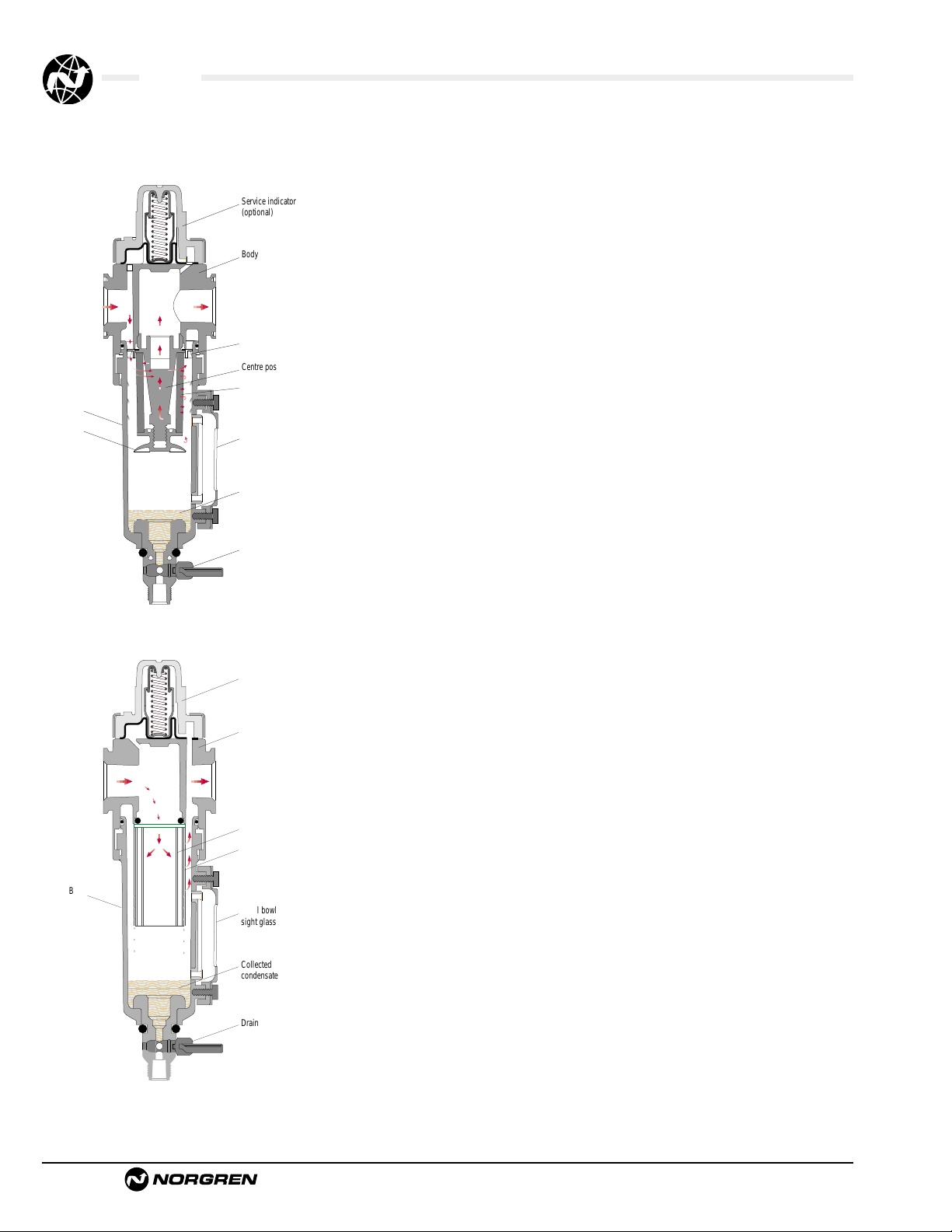

GENERAL PURPOSE FILTER

COALESCING FILTER

1.1 GENERAL OVERVIEW

Three main types of filters exist: The general

purpose filter for water and particles, the coalescing

oil removal filter for oil aerosols and the activated

carbon filter for the removal of oil vapors.

The general purpose filter is used for most

filter applications and is available from 1/8" to 2"

pipe sizes. Uses are main headers, branch lines,

tools, cylinders, valves and valve circuits, air

agitators etc. Oil removal filters are used where very

clean, oil-free air is required, such as for the supply

to fluidic devices, instrumentation, air gauging

equipment and air bearings.

Activated Carbon filters are used for

systems where the oil vapors in the air are not

acceptable; such as instrumentation and paint

spraying.

1.1.1 How Do General Purpose Filters Work?

The dirt and moisture-laden air enters the inlet port

and is directed into the louvers which centrifugally

separate the entrained liquids and dirt which fall to

the bottom of the bowl. Near the bottom of the bowl

a baffle creates a quiet zone, preventing the

turbulent air re-entraining the contaminants. The air,

now free of water droplets and large dirt particles,

passes through the filter element which removes

small dirt particles. Solid particles eventually plug

the element necessitating replacement.

1.1.2 How Do Oil Removal Filters Work?

Air enters the filter and passes through the

element from inside to outside, where oil aerosols

impinge on the borosilicate micro-fibers and are

coalesced into larger drops. The drops are carried

through the element until they reach the outer

porous sock. The outer sock, because of its cellular

construction, retains these liquids and allows them

to drain by gravity to the bottom of the bowl.

Solid partilces are retained in the element

and cause the pressure drop to slowly increase

throught the working life of the element. When the

pressure drop across the element reaches 10 psid,

the service life indicator on top of the filter will

show more red than green and the element should

be replaced.

1.1.3 How do Vapor removal Filters Work?

Carbon filters are used to remove oil vapors and

odors. The activated carbon has a porous structure

which results in a large surface area. The oil vapors

are attracted and adhere to this surface. There is

usually a small sintered medium included in an

activated carbon element to prevent the carbon

particles from migrating downstream. The carbon

filter reduces the maximum oil content of air leaving

the filter to 0.003ppm at 70°F, i.e. To ISO 8573 class

1.7.1. If protected upstream by general and oil

removal filters life is between 400 and 1000 hours.

1.1.4 Why use a Pre-Filter?

A pre-filter is simply a general purpose filter placed

upstream of a higher grade filter to remove the

majority of the water and larger particle

contaminants and thus lengthen the life of the higher

grade filter element.

A 5 micron pre-filter should always be used

ahead of an oil removal filter.

An oil removal (coalescing) filter must be

used ahead of a vapor removal adsorbing filter.

1.2 AIR QUALITY

1.2.1 What is ISO 8573?

(See ALE-1-G for specification)

This is an international standard on air quality. It

covers compressed air for general industrial use.

The air quality is specified using a 3 digit

code expressing the remaining content of a specific

contaminant after the filter (or dryer).

1.2.2 Air Classes for Norgren Filters:

Particulate filters condition compressed air to

different degrees, dependent on the micron rating of

the filter. The finer filter, 5 µm, will achieve ISO 8573

class 3.7. or class 3. Applying a 40 µm filter will

result in ISO 8573 class 5.7. or class 5 air.

Coalescing filters improve the quality of

downstream air to ISO 8573 class 1.7.2, the particle

size is reduced down to 0.01µm, with a remaining

oil content of less than 0.01ppm. Coalescing filters

cannot remove oil which is in the vapor state in the

supply air. One way to remove vapor is to reduce the

temperature of the air flow allowing the vapor to

condense, alternatively remove the vapor chemically

using an activated carbon filter.

Bowl

Baffle

Bowl

Service indicator

(optional)

Body

Louvre

Centre post

Element

Metal bowl

sight glass

Collected

condensate

Drain

Service indicator

Body

Element

Outer sock

Metal bowl

sight glass

Collected

condensate

Drain

Page 3

Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

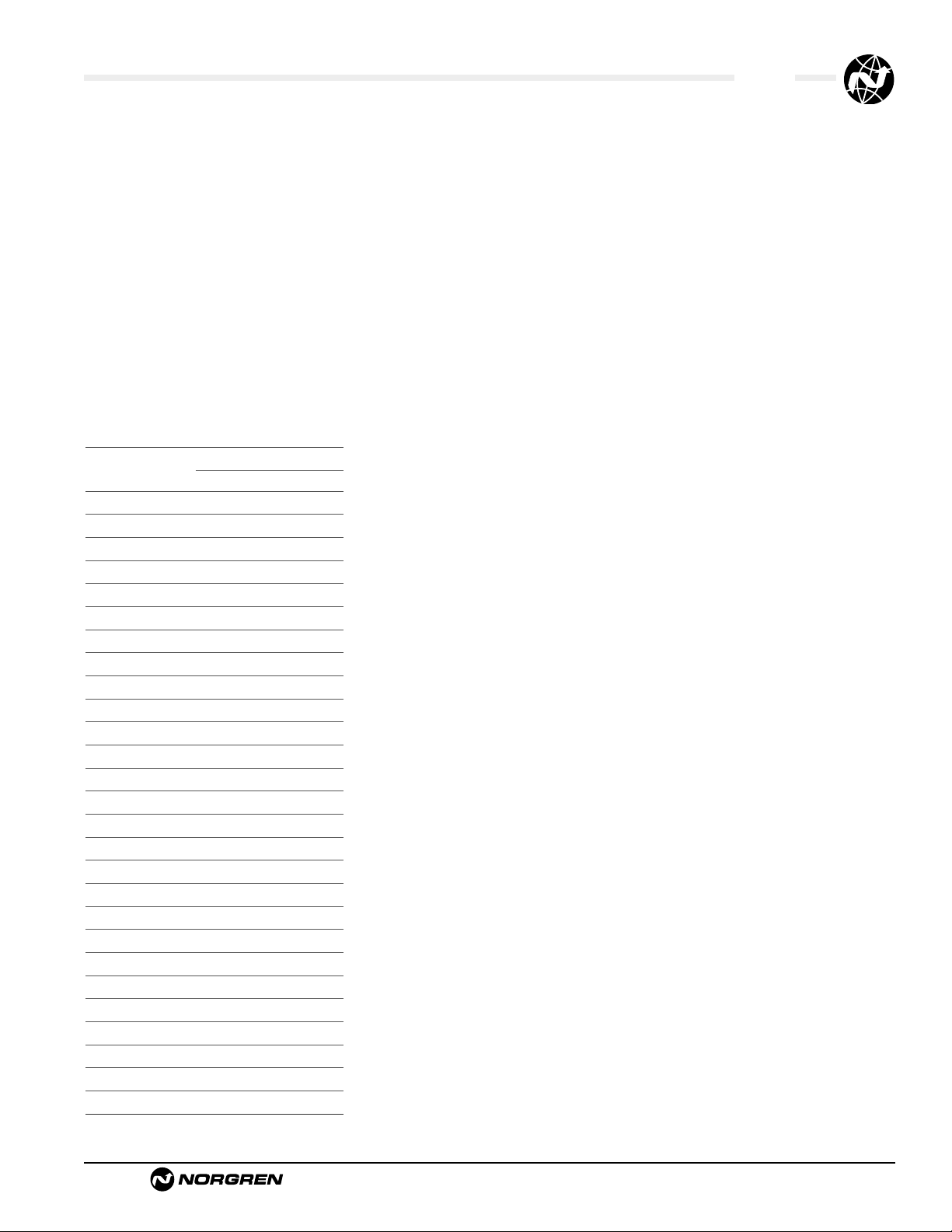

Figure 1. (See “Rating Filter Elements and ISO

Standard 8573-1” in this section.

RECOMMENDED FILTRATION LEVELS.

Application

Typical Quality Classes

Oil Dirt

Air agitation 1 3

Air bearings 2 2

Air gauging 2 2

Air motors 4 4

Brick and glass machines 5 4

Cleaning of machine parts 3 4

Construction 4 5

Conveying, granular products 2 4

Conveying, powder products 1 3

Fluidics, power circuits 2 5

Fluidics, sensors 2 3

Foundry machines 4 5

Food and beverages 1 1

Hand operated air tools 5 5

Machine tools 5 4

Mining 5 5

Micro-electronics manufacture 1 1

Packaging and textile machines5 3

Photographic film processing 1 2

Pneumatic cylinders 3 5

Pneumatic tools 5 4

Pneumatic tools (high speed) 4 3

Process control instruments 2 3

Paint spraying 1 1

Sand Blasting 4 5

Welding macines 5 5

General Workshop air 5 4

1.2.3 What Micron Ratings are Available?

The standard Norgren general purpose elements are

40 and 5 microns, with 40 microns being suitable

for most industrial applications. Certain industries

have 25 or 75 micron as a standard and some

product ranges have these options available.

For a given element size, the smaller the

micron rating the higher the pressure drop across

the filter. The service life between cleaning is also

less for the smaller micron filters, as small holes

plug more quickly than bigger holes.

1.2.4 How do Service Life Indicators Work?

The service life (pressure drop) indicator found on

top of coalescing or general purpose filters is green

when the filter is new. As a pressure differential

develops across the filter element with use, a spring

biased red outer sleeve is pushed up. When more

red is visible than green, then the pressure

differential across the element is in excess of 10 psi

(0.7 bar) and the element should be replaced.

1.2.5 When does the Carbon Pack Indicator Turn

Pink?

The white ring around the base of the vapor

removal carbon pack turns pink in the presence of

liquid oil. Therefore if the ring turns pink the

coalescing filter is passing liquid oil and needs

replacing. If this occurs soon after the filter has

been installed then it usually indicates a seal failure

in the coalescing filter. Remember that visual

detection is a not a substitute for scheduled

maintenance.

1.2.6 How Long does an Element Last?

This depends entirely on the quality of the inlet air.

If it is very poor the elements will need replacing

more frequently.

In general, air service equipment should

be maintained annually. Use, quality of air and

condition at examination may indicate adjustment

of the maintenance interval.

The following guidelines can be given:

General Purpose Replace/maintain annually. The

Filter: element can lose 15% efficiency

each time it is cleaned. Elements

are low cost, so it is advisable to

replace them.

Coalescing: Evaluate after 12 months of

servicing. If the pressure drop

across the element exceeds 10

psig (0.7bar) then the element

requires changing.

Activated Carbon Should be changed every 1,000

Packs: hours usage or when odor is

detected. The life depends

significantly on ambient

temperature.

1.3 PLASTIC BOWLS

Norgren transparent plastic bowls are made from

polycarbonate. Some competitors use other

materials such as Grilamid.

Both these materials are extremely resilient and have

an excellent safety record. However these

transparent plastics will degrade when subjected to

excessive heat, solvents and some chemicals, which

can lead to crazing and finally bowl failure.

Over the last few years metal bowls and

guarded plastic bowls have become increasingly

popular driven by the emergence of guidelines

recommending the use of guards.

Some organizations have their own internal

standards which call for guarded plastic or metal

bowl and the general market trend is away from

plastic bowls in the 1/2” or above port size units.

This trend is reflected in our latest Excelon 74 and

Olympian Plus product ranges. Plastic bowls remain

the most common option for 1/4” and smaller units.

Never use polycarbonate bowls at

conditions which exceed the maximum rated

pressure and temperature of 150 psig (10 bar) and

125°F (50°C).

Certain chemicals, common in some oils

and solvents, can attack polycarbonate and cause

the bowl to burst. If the compressor intake is located

in an area containing incompatible vapors, these

contaminants can be drawn into the compressor and

conveyed to the bowl in the compressed air. This

can result in bowl failure.

Synthetic compressor oils may be drawn in

from the compressor and can also result in bowl

failure.

If doubt exists as to the compatibility of

certain fluids with polycarbonate, please contact

Applications Engineering.

Metal bowls should be used where

temperatures exceed 125°F (50°C) and/or pressures

exceed 150 psig (10 bar), or when materials are

present which are incompatible with polycarbonate.

Maximum rated operating conditions for metal

bowls depend on the range; check APC-104.

Page 4

Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

1.4 DRAINS

1.4.1 Semi Automatic:

A semi-auto drain is one which operates when the

air-line is depressurized eg at the end of a shift. It is

a normally open two-way valve which is held closed

by 7-10 psig (0.7-0.8 bar). When the filter is

pressurized, the drain may be operated manually by

pushing the tube, which protrudes outside the bowl,

upwards.

1.4.2 Automatic:

An automatic drain is a two-way valve, which will

close when the system is pressurized. The drain

opens when the float rises due to accumulated liquid

and on depressurization.

1.4.3 Where should an Automatic Drain be Used?

Automatic Drains should be used where the filter

location may make servicing difficult, where filters

may be hidden from view and consequently be

overlooked or where equipment is in continual use.

Areas where large quantities of liquid may

accumulate over a short period of time should also

be equipped with auto-drain filters. High labor costs

for draining a large number of filters manually will

generally justify the use of auto-drains.

Machines which have been shut down for a

long period of time, such as over a weekend, can

draw slugs of water during start-up which can

overload a filter unless drained immediately. (This

situation can normally be handled by a drip leg

drain, see.)

Norgren float type automatic drains are

‘normally open’ type drains. During periods when

the air line pressure is shut off, the automatic drain

will open allowing liquids to drain rather than flood

the air line piping system. When re-pressurizing the

air line, the automatic drain valve will close when

pressure reaches approximately 10 psig (0.7bar).

This results in a flow through the drain to

atmosphere of about 1.77 scfm (0.84dm3/s) until

the valve automatically closes. (See 1.4.4 below.)

1.4.4 Where should a Low Flow Automatic Drain

be used?

In systems where the compressor capacity is

insufficient to close a number of standard auto

drains a ‘low flow’ drain is available which requires

only 0.5 scfm flow before closing. An ultra low flow

auto drain is also available. ‘Low flow’ drains have

less clearance around the valve for expelling

contaminants, so should only be used where the

standard unit cannot be used. ‘Low flow’ drains can

be identified by red plastic parts.

1.4.5 07 Automatic (spitter) Drain:

When a rapid increase in flow occurs through the

filter it results in the pressure above the drain’s

diaphragm being less than that below it. This

differential pressure causes the drain to

momentarily lift and ‘spit’ out the condensate

collected underneath the drain.

1.4.6 Where should a Drip Leg Drain be Used?

The drip leg drain is a system protection device.

Most compressed air distribution systems have

varying flows and/or are shut down at the end of a

working day. As the system cools, water in the

compressed air condenses and collects in the

distribution pipe work. This water will run along the

pipe work and settle at the low point(s). On start up

of the plant this water can be pushed under

pressure into the nearest device or process and

cause malfunction or damage.

By running a vertical pipe down from

these low points water will flow into the drip leg

drain where the automatic drain will expel it.

A filter screen within the drip leg drain

prevents particles interfering with the auto-drain

operation. A ball valve should be included above

the drip leg drain to allow for maintenance when

the system is running.

1.5 PERFORMANCE

1.5.1 Performance of General Purpose Filters

Filters have their flow measured in terms of the

pressure drop across them. As the flow increases

then the pressure drop also increases. These

pressure drops are energy losses in the system.

A well designed filter not only removes

water and particles efficiently, but also has a low

pressure drop at a given flow. The flow figures

quoted in Norgren catalogues for general purpose

filters are at a pressure drop of 5 psig (0.3 bar),

from a 100 psig (7 bar) inlet pressure.

Beware! not all competitors quote their

flows under the same conditions. If a higher inlet

pressure is used or a higher pressure drop is quoted

then the apparent flow will be higher. This does not

mean it is a better unit , simply that a different point

on the curve has been selected. Often the only way

to compare units is to test them under the same

laboratory conditions.

1.5.2 Performance of Coalescing Filters:

The maximum flow of an oil removal filter is usually

determined by the oil removal efficiency under

saturated conditions. In the catalog there are

maximum flows quoted ‘to maintain stated oil

removal characteristics.’ These are the steady state

flows which should not be exceeded to guarantee

that the oil in the outlet air remains below the

0.01ppm (parts per million) quoted. Cyclic or

pulsating flows will result in oil carry over, as will

elevated temperatures.

If a higher oil carry over is acceptable (or

there is no oil in the air-line) then higher flows are

achievable, and will be determined by the

‘acceptable’ pressure drop. For a new (dry) element

a flow which gives a pressure drop of less than 5

psid (0.3 bar) is recommended.

Page 5

Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

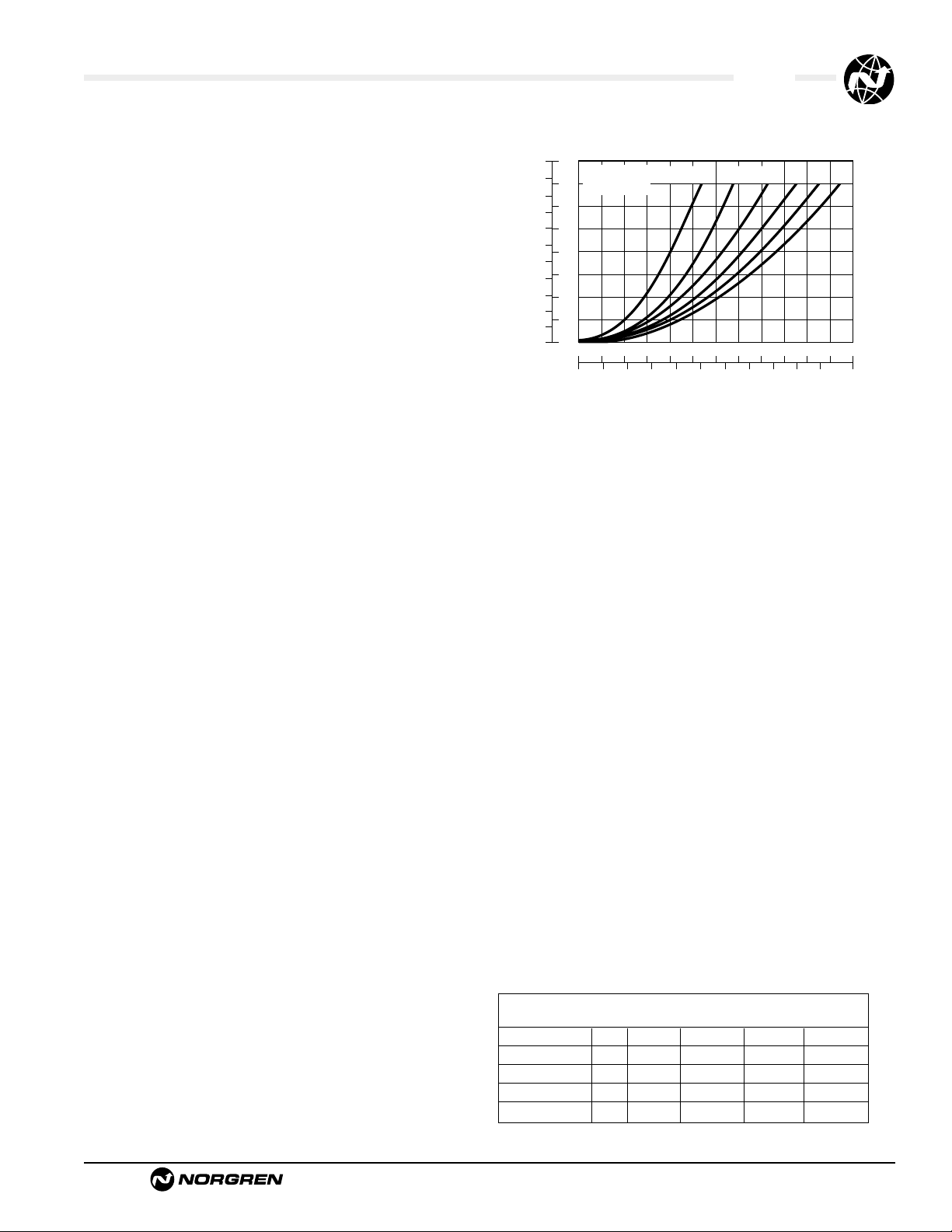

1.6 FILTER SIZING

Selecting the proper size of filter for any

application should be done by determining the

maximum allowable pressure drop which can

be caused by the filter. The pressure drop can

be determined by referring to flow curves

provided by the manufacturer.

The flow characteristic curves should relate to

the fluid used, pressure, pipe port size and

micron rating of the filter element. Often the

parameters of pressure and flow are labeled in

metric and imperial units. The vertical axis is

the pressure drop across the filter, and the

horizontal axis is the air flow through the filter.

Each curved line represents the filter flow and

pressure drop characteristics for different

operating pressures.

Example Find the pressure drop across the

filter when operating at 90 psig (6.2 bar) and

when 50 scfm (24 dm

3

/s) is flowing through

the filter.

Answer Locate 50 scfm (24 dm3/s) on the

horizontal axis. Read up to the intersecting

point on the 90 psig (6.2 bar)operating curve.

The pressure drop (or ∆ p) is approximately .6

psid (.04bar) on the vertical axis on the left of

the graph. (See graph)

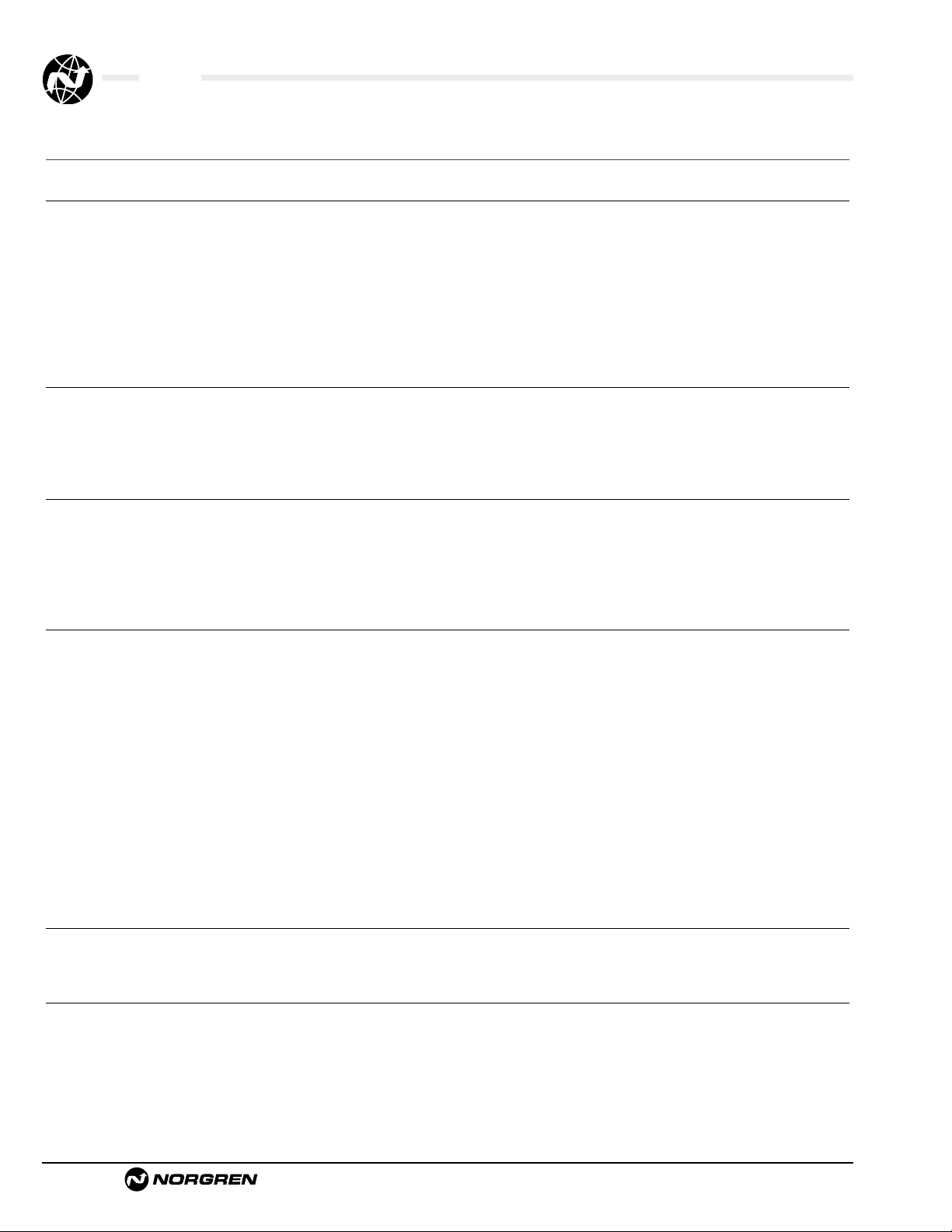

1.7 MEMBRANE DRYERS

For those applications where a low-pressure

dewpoint and low installation/operational cost

are required, Norgren provides an Excelon®

Membrane Dryer. This new product can

provide dewpoint suppression up to 80°F

(26°C) below ambient temperature and is

available with nominal flows of 2, 5, 10, 20,

and 30 scfm.

The Membrane Dryer is a variable dew point

suppression device constructed of an anodized

aluminum body with end caps. Inside the

body are bundles of special hollow fibers

(membranes) which are semi-permeable.

Moisture-laden air enters the fibers and water

vapor permeates through the walls to the

outside of the fibers. Dry air exits the device

through the outlet port. A small percentage of

dry air is diverted across the outside of the

fibers to sweep away and vent water vapor to

atmosphere.

This device provides variable dew point

suppression inversely related to flow. Lower

flows through a unit will increase contact time

with the membrane fibers, resulting in greater

dew point suppression. Higher flows will

result in a decreased level of dew point

suppression. Additionally, dew point

suppression is directly related to operating

pressure. Increasing the pressure applied will

result in a greater level of dew point

suppression. Therefore, it is always

recommend placing regulators downstream of

a membrane dryer to ensure the highest

pressure possible through the membrane dryer.

Model Port Outlet Inlet Purge Press.

Flow Flow Flow Drop

W07M2ANNNA 1/4" 2 scfm 2.2 scfm 0.2 scfm 0.4 psid

W72M2ANNNB 1/4" 5 scfm 5.6 scfm 0.6 scfm 0.32 psid

W72M2ANNNC 1/4" 10 scfm 11.2 scfm 1.2 scfm 0.90 psid

W74M4ANNND 1/2" 20 scfm 22.2 scfm 2.2 scfm 0.65 psid

W74M4ANNNE 1/2" 30 scfm 33.4 scfm 3.4 scfm 1.35 psid

Typical Flows for Membrane Dryers

bar d

psid

7

45

6

40

35

5

30

4

25

3

20

Pressure Drop

15

2

10

1

05

0

0

0

0 1020304050

Flow Characteristics

180

150

120

90

60

35

INLET

PRESSURE

20 40 60 80 100 120 140 160 180 200 220 scfm

psig

(bar)

(4.1)

(2.4)

60 70 80 90 100

Air Flow

(6.2

(8.3)

(10.4)

(12.5)

dm 3/s

Page 6

Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

Malfunction Possible cause Remedy

Excessive pressure drop. Micron rating of element to small Use larger micron element size for application.

Filter element blocked. 1. Clean element (not

coalescing element). Note: Some residual

contamination will remain.

2. Replace with new element.

Flow requirement greater than Use larger filter.

filter capacity.

Dirt passing through filter. Element seals missing or Replace seal

defective. (N.B. Seals not 2. Tighten element.

required on some units).

Damaged element. Replace element.

Water passing through filter. Water level in bowl above Drain water.

baffle.

Flow capacity of filter Maintain flow within capacity

exceeded. of filter or change to filter

capable of handling desired flows.

Crazing of Polycarbonate bowl Bowl has been cleaned with Replace bowl.

or milky appearance. incompatible fluid. (Clean only in clean warm water and soap.)

Bowl is being used in an area Replace bowl.

containing fumes or vapors Eliminate source of problem or

incompatible with polycarbonate. convert from plastic to metal bowls.

Compressor oil vapor may be Replace bowl.

causing problem. Eliminate source of problem or

convert from plastic to metal bowls.

Air intake to compressor may Replace bowl.

contain fumes or vapor Eliminate source of problem or

incompatible with polycarbonate.convert from

plastic to metal bowls.

Water beyond the filter Inlet air has a high temperature Fit dryer, pre-cool air or fit

and as it cools downstream, filter immediately prior to application.

moisture condenses to water.

1.7 SIMPLE FILTER TROUBLESHOOTING

Page 7

Rating Filter Elements and ISO Standard 8573-1

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-Filter

Absence of an Industrial Standard for Rating

Pneumatic Filter Elements

There is not an industry wide standard for establishing the micron

rating of pneumatic filter elements. Standards by various industry

associations, including the National Fluid Power Association

(NFPA) and Inter national Standard Organization (ISO), are in

discussion. In the absence of an industr y standard, some

manufacturers of pneumatic filters make claims concerning the

micron rating of their so called “standard” element which can not

be substantiated and are probably not valid.

Norgren’s Method of Rating and Testing

Pneumatic Filter Elements

Norgren particle removal filter elements are rated by the size of

the particle they will trap (i.e., a 40-micron element will remove

particles 40-microns and larger). Norgren tests filter elements by

using standard coarse and fine test dusts of known particle size

distribution. Coarse dust consists of 12% par ticles smaller than

5-microns; fine grain dust consists of 39% particles smaller than

5-microns.Test results show that a Norgren filter element rated at

40-microns actually removes over 98% of particles 5-microns and

larger.

How to Size a Filter Element

The downstream equipment being protected determines the

micron rating of the filter element. Industrial tools, such as air

hammers and drills, typically require only a 40-micron element.

Air operated instruments and small, high speed tools typically

require a 5-micron element. Always consult the equipment

manufacturer for filtration requirements.

Generally, the smaller the micron rating of the element,

● the higher the pressure drop across the filter,

● the shor ter the element ser vice life.

Therefore, the use of a 5-micron element where a 40-micron is

adequate penalizes the customer in increased pressure losses

and frequent down time for changing or cleaning the filter element.

ISO Standard 8573-1. Compressed Air

for General Use

Contaminant’s found in industrial compressed

air systems include solid particles, water, and

oil. ISO 8573-1:1991 provides a simple method

of classifying these contaminant’s.A quality

class required for a particular application can

be defined by listing, in order, the class

required for solids, water, and oil.

Examples:

Air of Quality Class 2.2.2 is filtered to 1µm

solid particle size, dried to -40°F (-40°C)

pressure dewpoint, and filtered to an oil

concentration of 0.1mg/m

3

.

Air of Quality Class 5.3.4 is filtered to 40µm

solid particle size, dried to -4°F (-20°C)

pressure dewpoint, and filtered to an oil

concentration of 5mg/m

3

.

When a class for a particular contaminant

solid, water, or oil is not specified, the number

designating the class is replaced with a

hyphen.

Example: Air of Quality Class 1.–.1 does not

specify the pressure dewpoint.

Table 1. Summary of ISO 8573-1:1991 Air

Quality Classes *

Solid Water Oil

Particle Maximum Maximum

Maximum Pressure Remaining

Quality Size Dewpoint Oil Content

Class µm °F (°C) mg/m

3

** (ppm)

1 0.1 -94 (-70) 0.01 (.0084)

2 1 -40 (-40) 0.1 (.084)

3 5 -4 (-20) 1 (.84)

4 15 38 (3) 5 (4.2)

5 40 45 (7) 25 (21)

6 — 50 (10) —

* See ISO standard 8573-1 for complete

information.

** At 1 bar absolute pressure.

Page 8

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-1

Section 1

F07 Miniature General Purpose Filter 1/8" and 1/4" Ports . . . . . . . . .ALE-1-2

F72G Excelon General Purpose Filter 1/4" and 3/8" Ports . . . . . . . .ALE-1-4

F73G Excelon General Purpose Filter 1/4" to 1/2" Ports . . . . . . . . . .ALE-1-6

F74G Excelon General Purpose Filter 1/4" to 3/4" Ports . . . . . . . . . .ALE-1-8

F64G Olympian Plus General Purpose Filter 1/4" to 3/4" Ports . . . .ALE-1-10

F68G Olympian Plus General Purpose Filter 3/4" to 1-1/2" Ports . .ALE-1-12

F17 General Purpose Filter 3/4" to 1-1/2" Ports . . . . . . . . . . . . . . . .ALE-1-14

F18 General Purpose Filter 1-1/2" and 2" Ports . . . . . . . . . . . . . . . .ALE-1-16

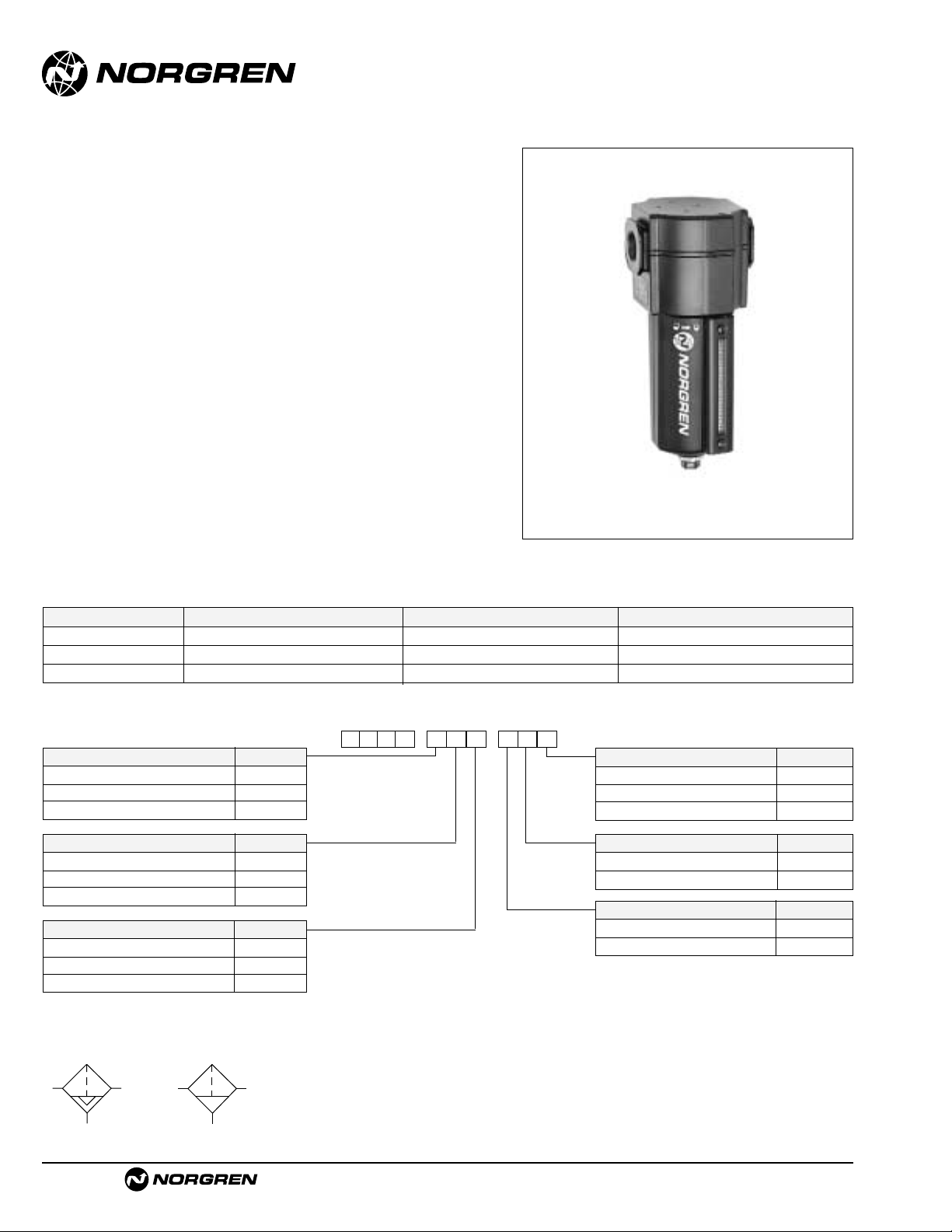

General Purpose Filters

Compressed air, general

purpose filters are available in

modular or inline models, in port

sizes from 1/8" to 2".

F07

F72G

F73G F74G F64G

F17

F68

F

18

Page 9

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

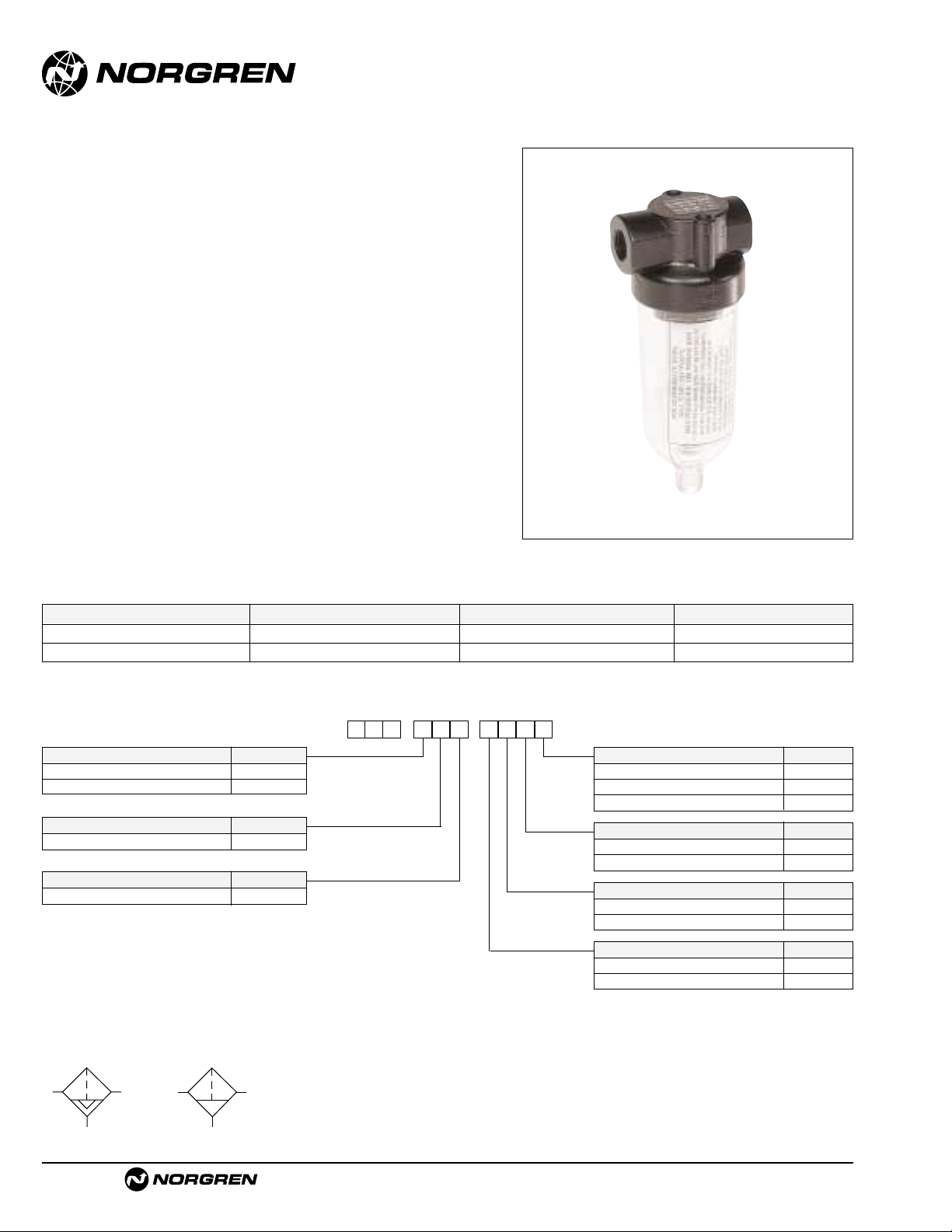

F07

● Compact design

● Protects air operated devices by removing liquid and

solid contaminants

● Screw-on bowl reduces maintenance time

● Can be disassembled without the use of tools or

removal from the air line

Miniature Series 07 General Purpose Filter

1/8" and 1/4" Port Sizes

ALE-1-2

Port Size Model Numbers Flow scfm (dm3/s) * Weight lbs (kg)

1/8" F07-100-A1TA 19 (9) 0.28 (0.13)

1/4" F07-200-A1TA 24 (11.5) 0.28 (0.13)

Ordering Information. Models listed include PTF threads, automatic drain, transparent bowl and 5 µm element.

* Approximate flow at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Alternative Models

Port Size Substitute

1/8" 1

1/4" 2

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Option Substitute

Not applicable 0

Bowl Substitute

Transparent T

Metal M

Option Substitute

Not applicable 0

Element Substitute

5 µm 1

40 µm 3

Drain Substitute

Automatic A

Manual M

-

★★★★★

★

-

0★F 7

ISO Symbols

Auto Drain

Manual Drain

Page 10

F07 General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-3

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature:*

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below

35°F (2°C)

Particle removal: 5 µm or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow at 90 psig (6.3 bar) inlet pressure at 5 psig (0.35 bar) pressure drop:

1/8" Ports, 5 µm element: 19 scfm (9 dm3/s)

1/4" Ports, 5 µm element: 24 scfm (11.5 dm

3

/s)

Nominal bowl size: 1 fluid ounce (31 ml)

Drain connection: 1/8" pipe thread

Automatic drain operation:Spitter type drain operates momentarily when a rapid

change in air flow occurs or when the supply pressure is reduced.

Materials

Body: Zinc

Bowl

Transparent: Polycarbonate

Metal: Zinc (without sight glass)

Element: Sintered polypropylene

Elastomers: Neoprene & nitrile

For water extraction information please contact Applications Engineering.

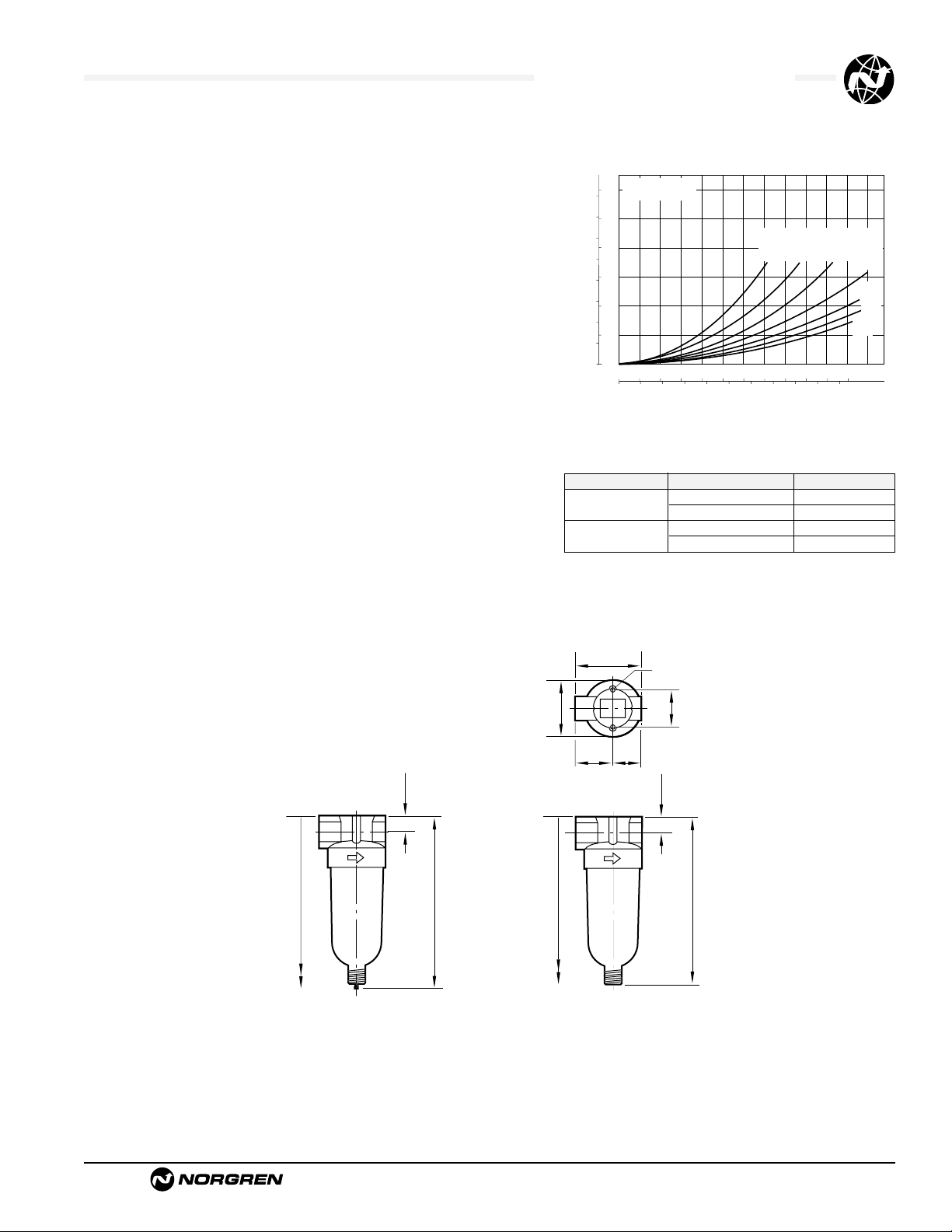

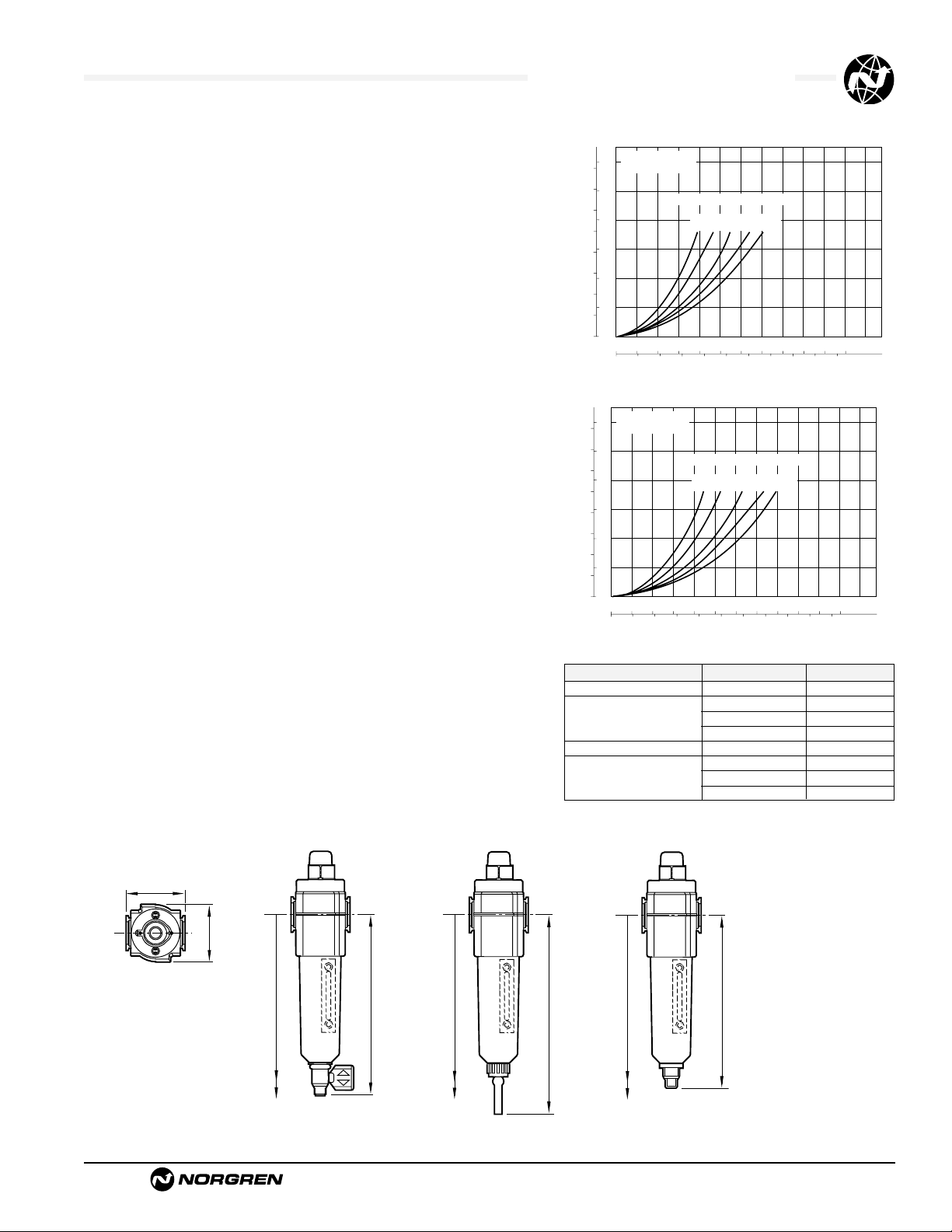

Typical Performance Characteristics

FLOW CHARACTERISTICS

0 2 4 6 8 10 dm3/s

AIR FLOW

0 4 8 12 16 20 scfm

0.8

0.6

0.4

0.2

0

PRESSURE DROP

bar d

10

8

6

4

2

0

psid

PORT SIZE: 1/4"

5 µm ELEMENT

INLET PRESSURE: psig (bar)

25

(1.8)

60

(4.0)

40

(2.8)

90

(6.3)

120

(8)

180

(12)

150

(10)

0.157 (4) Dia †

0.5 (13) Deep †

n

n

1.45 (37)

0.91

(23)

0.73

(19)

0.91

(23)

1.63 (42)

6.07 (154) *

0.38 (10)

4.10 (104)

6.22 (158) **

4.25 (108)

0.38 (10)

** Minimum clearance to remove bowl.

† Mounting holes.

Service Kits

Item Type Part number

Service kit

5 µm element 3652-17

40 µm element 3652-18

Replacement drains

Manual 773-03

Automatic 3654-02

Service kit includes element, element gasket, and bowl o-ring.

All Dimensions in Inches (mm)

Manual Drai

Automatic Drai

Page 11

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F72G

● Excelon design allows in-line or modular installation

● High efficiency water and particle removal

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens on

metal bowls

● Optional service indicator turns from green to red

when the filter element needs to be replaced

● Optional electrical service indicator also available

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Excelon 72 General Purpose Filter

1/4" and 3/8" Port Sizes

ALE-1-4

Ordering Information. Models listed include PTF threads, automatic drain, long transparent bowl without guard, 40 µm element.Models do not

include the service life indicator.

† Typical flow with a 40µm element at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

1/4" F72G-2AN-AL3 55 (26) 1.15 (0.52)

3/8" F72G-3AN-AL3 55 (26) 1.15 (0.52)

F 7 2-G

★ ★

-

★★ ★ ★

Port Size Substitute

1/4" 2

3/8" 3

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Drain Substitute

1/4 turn manual Q

Semi automatic S

Auto drain* A

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Service Life Indicator Substitute

With (visual) D

With (electrical) E

Without N

Alternative Models

Bowl Substitute

Metal with liquid level indicator E

Transparent without guard L

Transparent with guard W

ISO Symbols

Auto Drain

Manual Drain

Page 12

F72G General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-5

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl:

Manual or semi automatic drain: 250 psig (17 bar)

Automatic drain: 150 psig (10 bar)

Operating temperature*:

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

*

Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5 µm, 25 µm or 40 µm.Within ISO 8573-1, Class 3 and Class 5

Typical flow at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop:

5 µm element: 47 scfm (22 dm

3

/s)

40 µm element: 55 scfm (26 dm3/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread.

Semi automatic drain connection: Push on 5/16" (8 mm) ID tube

Semi automatic drain operating conditions (pressure operated):

Bowl pressure required to close drain: Greater than 1.5 psig (0.1 bar)

Bowl pressure required to open drain: Less than 1.5 psig (0.1 bar)

Minimum air flow required to close drain: 1 scfm (0.5 dm

3

/s)

Manual operation: Lift stem to drain bowl

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.35 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 0.2 scfm (0.1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size:

Long bowl: 2.2 fluid ounce (65 ml)

Materials

Body: Zinc

Bowl

Transparent: Polycarbonate

Guard for transparent bowl:Zinc

Metal: Zinc

Metal bowl liquid level indicator lens:

Transparent nylon

Element: Sintered polypropylene

Elastomers: Neoprene and nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

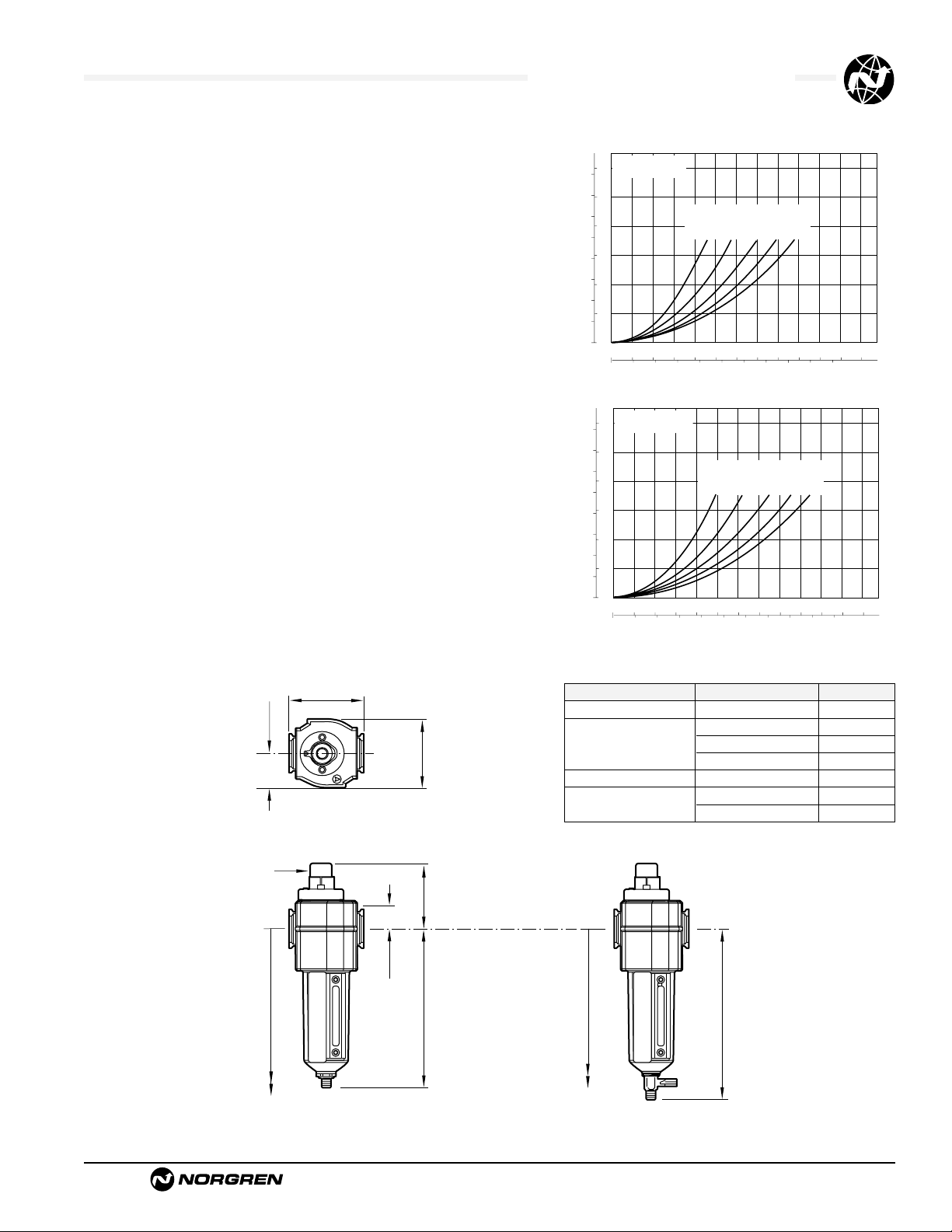

Typical Performance Characteristics

Service Kits

Item Type Part Number

Service kit Seal and gasket 4380-500

5 µm 5925-03

Elements 25 µm 5925-01

40 µm 5925-02

Liquid level lens kit Prismatic 4380-030

1/4 turn manual 619-50

Replacement drains Semi automatic 5379-RK

Automatic 4000-50R

Service kit includes drain and bowl o-rings.

† Minimum clearance required to remove bowl.

All Dimensions in Inches (mm)

PORT SIZE: 1/4"

psid

bar d

5 µm ELEMENT

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 20 40 60 80 100 120 scfm

0 10 20 30 40 50 dm3/s

PORT SIZE: 1/4"

psid

bar d

40 µm ELEMENT

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 20 40 60 80 100 120 scfm

0 10 20 30 40 50 dm3/s

FLOW CHARACTERISTICS

INLET PRESSURE - psig (bar g)

36

(2.5)58(4.0)91(6.3)

FLOW CHARACTERISTICS

INLET PRESSURE - psig (bar g)

36

(2.5)58(4.0)91(6.3)

116

(8.0)

AIR FLOW

AIR FLOW

116

(8.0)

150

(10.0)

150

(10.0)

1.97 (50)

1.89 (48)

(Top)

7.83 (199) †

Bowl with

1/4 Turn Manual Drain

5.83 (148)

9.84 (250) †

Bowl with

Semi auto Drain

7.48 (190)

7.52 (191) †

Bowl with

Automatic Drain

5.51 (140)

Page 13

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F73G

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Optional mechanical service indicator turns from

green to red when the filter element needs to be

replaced

● Optional electrical service indicator provides

electrical output when the filter element needs to be

replaced

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Excelon 73 General Purpose Filter

1/4", 3/8", 1/2" Port Sizes

ALE-1-6

Ordering information.

Models listed include PTF threads, automatic drain, metal bowl with liquid level indicator, and a 40 µm element.

* Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Alternative Models

F 7 3-G

★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Service Indicator Substitute

With electrical service indicator * E

With mechanical service indicator D

Without N

Drain Substitute

Automatic A

Manual, 1⁄4 turn Q

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Bowl Substitute

Metal with liquid level indicator D

Transparent with guard P

Transparent T

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

Port Size Model Flow* scfm (dm3/s) Weight lb (kg)

1/4" F73G-2AN-AD3 53 (25) 1.1 (0.50)

3/8" F73G-3AN-AD3 65 (31) 1.1 (0.50)

1/2" F73G-4AN-AD3 69 (33) 1.1 (0.50)

ISO Symbols

Auto Drain

Manual Drain

Page 14

F73G General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-7

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5 µm, 25 µm, or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig

(0.35 bar) pressure drop: 65 scfm (31 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread.

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 0.2 scfm (0.1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size: 3.5 fluid ounce (0.1 liter)

Materials

Body: Aluminum

Bowl

Transparent: Polycarbonate

Transparent with guard: Polycarbonate, steel guard

Metal: Aluminum

Metal bowl liquid level indicator lens:Transparent nylon

Element: Sintered polypropylene

Elastomers: Neoprene and nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

PRESSURE DROP

0.6

0.4

0.2

0

bar d

10

8

6

4

2

0

psid

PORT SIZE: 3/8"

ELEMENT: 5 µm

36

(2.5)

58

(4.0)

150

(10.0)

90

(6.3)

116

(8.0)

INLET PRESSURE: psig (bar)

01020304050dm

3

/s

AIR FLOW

0 20 40 60 80 100 scfm

FLOW CHARACTERISTICS

Typical Performance Characteristics

** Minimum clearance required to remove bowl.

6.15 (156)

1/4 Turn Manual Drain

8.50 (216) **

1.00 (25)

2.36 (60)

Automatic Drain

Optional

Mechanical

Service

Indicator

5.80 (147)

8.15 (207) **

2.68 (68)

2.45 (62)

1.22 (31)

Service kit includes automatic drain seal and bowl seal.

Service Kits

Item Type Part Number

Service kit Seal & Gasket 4380-600

Replacement elements

5 µm 4438-01

25 µm 4438-02

40 µm 4438-03

Liquid level lens kit Prismatic 4380-020

Replacement drains

Automatic 4000-51R

Manual quarter turn 619-50

PORT SIZE: 3/8"

psid

bar d

ELEMENT: 40 µm

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 20 40 60 80 100 scfm

01020304050dm

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

58

36

(2.5)

(4.0)

AIR FLOW

(6.3)

90

(8.0)

116

150

(10.0)

3

/s

Page 15

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F74G

● Excelon design allows in-line or modular installation

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens

● Optional mechanical service indicator turns from

green to red when the filter element needs to be

replaced

● Optional electrical service indicator provides

electrical output when the filter element needs to be

replaced

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Excelon 74 General Purpose Filter

3/8",1/2",3/4" Po rt S ize s

ALE-1-8

Ordering information.

Models listed include PTF threads, automatic drain, metal bowl with liquid level indicator, and a 40 µm element.

* Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Alternative Models

F 7 4-G

★ ★

-

★★ ★ ★

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Service Life Indicator Substitute

With (visual) D

With (electrical) E

Without N

Drain Substitute

Automatic A

Manual, 1⁄4 turn Q

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Bowl Substitute

Metal with liquid level indicator D

Transparent with guard P

Port Size Substitute

3/8" 3

1/2" 4

3/4" 6

Port Size Model Flow* scfm (dm3/s) Weight lb (kg)

3/8" F74G-3AN-AD3 112 (53) 1.82 (0.83)

1/2" F74G-4AN-AD3 140 (66) 1.79 (0.81)

3/4" F74G-6AN-AD3 140 (66) 1.75 (0.79)

ISO Symbols

Auto Drain

Manual Drain

Page 16

F74G General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-9

Technical Data

Fluid: Compressed air

Maximum pressure

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Transparent bowl: -34° to 125°F (-30° to 50°C)

Metal bowl: -34° to 175°F (-30° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5, 25, or 40 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig

(0.35 bar) pressure drop: 140 scfm (66 dm3/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size: 7 fluid ounce (0.2 liter)

Materials

Body: Aluminum

Bowl

Transparent: Polycarbonate with steel bowl guard

Metal: Aluminum

Metal bowl liquid level indicator lens:Transparent nylon

Element: Sintered polypropylene

Elastomers: Neoprene and Nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

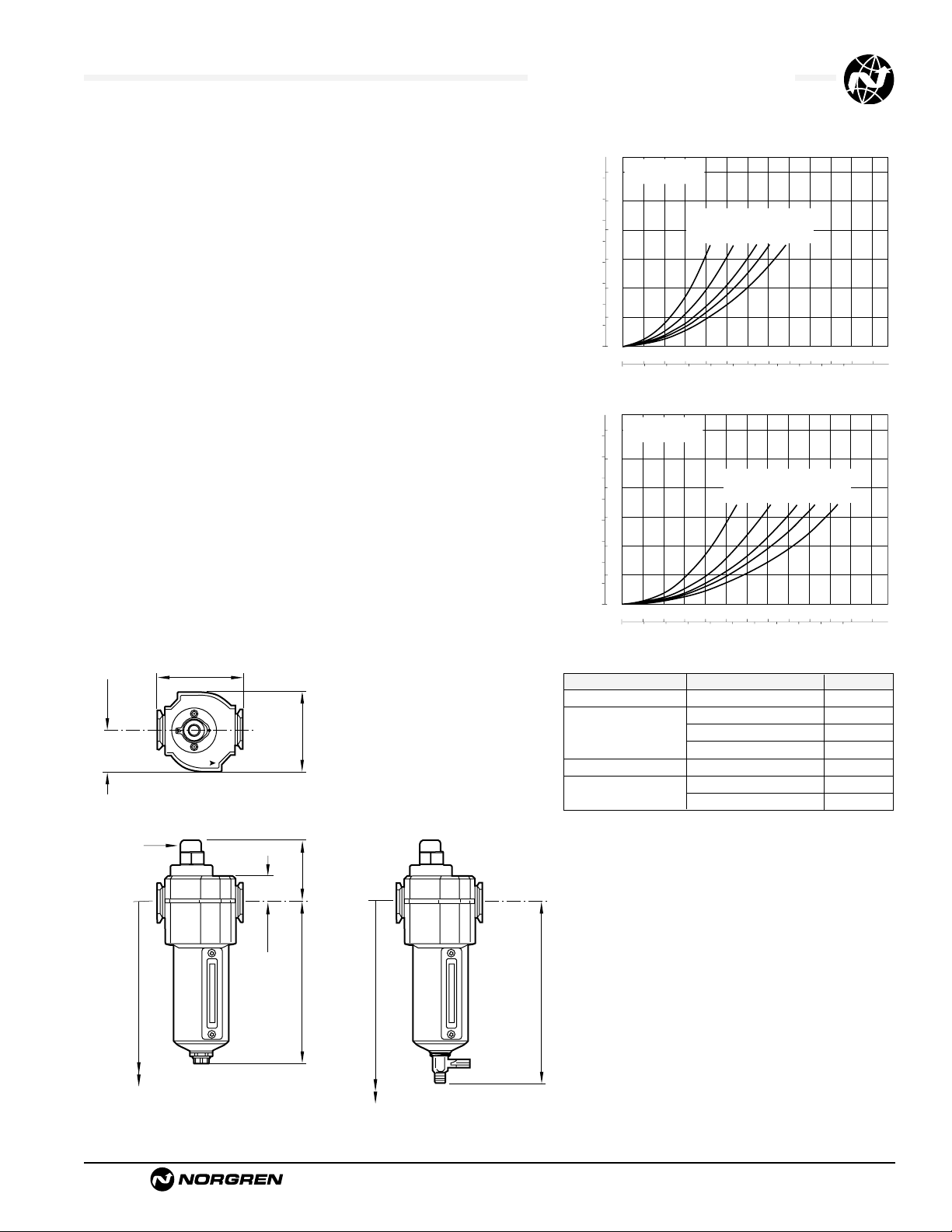

Typical Performance Characteristics

PRESSURE DROP

0.6

0.4

0.2

0

bar d

10

8

6

4

2

0

psid

36

(2.5)

58

(4.0)

150

(10.0)

90

(6.3)

116

(8.0)

INLET PRESSURE: psig (bar g)

0 20 40 60 80 100 dm3/s

AIR FLOW

0 40 80 120 160 200 scfm

PORT SIZE: 1/2"

ELEMENT: 5 µm

FLOW CHARACTERISTICS

PRESSURE DROP

0.6

0.4

0.2

0

bar d

10

8

6

4

2

0

psid

PORT SIZE: 1/2"

ELEMENT: 40 µm

36

(2.5)

58

(4.0)

150

(10.0)

90

(6.3)

116

(8.0)

INLET PRESSURE: psig (bar g)

0 20 40 60 80 100 dm3/s

AIR FLOW

0 40 80 120 160 200 scfm

FLOW CHARACTERISTICS

6.95 (177)

1/4 Turn Manual Drain

9.69 (246) **

3.15 (80)

2.36 (60)

†

1.00 (25)

2.89 (74)

1.45 (37)

Automatic Drain

Optional

Service

Indicator

6.35 (161)

9.06 (230) **

* Minimum clearance required to remove bowl.

† Dimension for alternative electrical service indicator is 1.98" (50.4 mm)

Item

Type Part Number

Service kit Seal & gasket 4380-700

Replacement elements

5 µm 4338-04

25 µm 4338-07

40 µm 4338-05

Liquid level lens kit Prismatic 4380-050

Replacement drains

Automatic (1/8 NPT outlet) 3000-10

Manual quarter turn 619-50

Service kit includes louvre/element seal, drain seal, bowl seal.

Service Kits

All Dimensions in Inches (mm)

Page 17

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F64G

● Olympian Plus plug in design

● High efficiency water and particle removal

● Quick release bayonet bowl

● High visibility prismatic sight glass

● Optional service indicator

Olympian Plus General Purpose Filter

1/4", 3/8", 1/2", 3/4" Port Sizes

ALE-1-10

Ordering Information. Models listed include PTF threads, yoke, automatic drain, metal bo wl, 40 µm element.Models do not include the service life indicator.

† Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and a 5 psig (0.35 bar) pressure drop.

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

1/4" F64G-2AN-AD3 59 (28) 3.13 (1.42)

3/8" F64G-3AN-AD3 118 (56) 3.13 (1.42)

1/2" F64G-4AN-AD3 125 (59) 2.91 (1.32)

3/4" F64G-6AN-AD3 125 (59) 3.79 (1.72)

F 6 4-G

★ ★

-

★★ ★ ★

Port Size Substitute

1/4" 2

3/8" 3

1/2" 4

3/4" 6

No yoke N

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

No yoke N

Drain Substitute

Auto drain A

Manual, 1/4 turn Q

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Service Life Indicator Substitute

With (visual) D

With (electrical) E

Without N

Alternative Models

Bowl Substitute

Metal with liquid level indicator D

Transparent with guard P

ISO Symbols

Auto Drain

Manual Drain

Page 18

F64G General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-11

Technical Data

Fluid: Compressed air

Maximum pressure

Guarded transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature*:

Guarded transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Partical removal: 5 µm, 25 µm or 40 µm.Within ISO 8573-1, Class 3 and Class 5

Typical flow with 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig

(0.35 bar) pressure drop: 125 scfm (59 dm

3

/s)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread.

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size: 7 fluid ounce (0.2 liter)

Materials

Body: Zinc

Yoke: Zinc

Metal bowl: Aluminum

Standard metal bowl prismatic liquid level indicator lens:Gr ilamid

Optional metal bowl sight glass: Pyrex

Optional transparent bowl: Polycarbonate

Element: Polypropylene

Elastomers: Nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

* 6.18" (157 mm) for 3/4" models

† Minimum clearance required to remove bowl.

Automatic Drain

8.54 (217)†

4.13 (105)*

1.46

(37)

2.91

(74)

Optional

Service

Indicator

1.46

(37)

6.45 (164)

2.32 (59)

7.05 (179)

1/4 Turn Manual Drain

9.14 (232)†

Service Kits

Item Type Part Number

Service kit Seal and gasket 4380-200

5 µm 4338-01

Elements 25 µm 4338-99

40 µm 4338-02

Liquid level lens kit

Prismatic 4380-040

Pyrex 4380-041

Replacement drains

Automatic 3000-10

Manual 684-84

Service kit includes port seals, louver o-ring, bowl o-ring and

drain gasket.

All Dimensions in Inches (mm)

PORT SIZE: 1/2"

psid

bar d

40 µm ELEMENT

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 40 80 120 160 200 240 scfm

0 20 40 60 80 100 dm3/s

FLOW CHARACTERISTICS

INLET PRESSURE - psig (bar g)

36

(2.5)58(4.0)91(6.3)

AIR FLOW

116

(8.0)

150

(10.0)

Page 19

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F68E/G

● Olympian Plus plug in system

● Effective liquid removal and positive solid particle

filtration

● Large filter element area provides minimum pressure

drop

● Optional visual service indicator turns from green to

red when the filter element needs to be replaced

● Factory option electrical service life indicator

provides electrical output when the filter element

needs to be replaced - see page ALE-25-23.

Olympian Plus General Purpose Filter

3/4",1", 1-1/4", 1-1/2" Port Sizes

ALE-1-12

Ordering Information.

Models listed include a 1 quart bowl with 40 µm long element, automatic drain, and yoke with PTF threads.

ISO Symbols

Auto Drain

Manual Drain

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

3/4 F68E-6AN-AU3 339 (160) 2.45 (5.3)

1 F68E-8AN-AU3 403 (190) 2.33 (5.1)

1-1/4 F68E-AAN-AU3 424 (200) 2.43 (5.3)

1-1/2 F68E-BAN-AU3 424 (200) 2.30 (5.0)

F 6 8-E

★ ★

-

★★ ★ ★

Drain Substitute

Automatic A

No drain (Closed bowl) E

Manual M

Manual, 1/4 turn Q

Element Substitute

5 µm 1

25 µm 2

40 µm 3

Service Life Indicator Substitute

Visual D

Electrical E

Without N

Alternative Models

Bowl Substitute

1 quart (1 liter) without liquid level

indicator C**

1 pint (0.5 liter) without liquid level

indicator M*

1 pint (0.5 liter) with liquid level

indicator R*

1 quart (1 liter) with liquid level

indicator U**

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

None N

Port Size Substitute

3/4" 6

1" 8

1-1/4" A

1-1/2" B

None N

Bowl/Element Type Substitute

1 pint (0.5 liter) bowl w/short element G

1 quart (1 liter) bowl w/long element E

† Typical flow with a 40µm element at 90 psig (6.3 bar) inlet pressure and 7 psig (0.5 bar) pressure drop.

* Only available with F68G

** Only available with F68E

Page 20

13.5 (343) ¶ *

7.5 (190)*

3.11 (79) †

1.73 (44)

Optional Visual

Service Indicator

2.40

(61)

14.2 (361) ¶

8.2 (208)

13.8 (350) ¶

7.8 (197)

Manual Drain

1 Pint US

(0.5 Liter) Bowl

† For optional electrical service life indicator add 0.20" (5 mm) . *Dimension also applies to closed bottom bowl.

** For 1-1/4" and 1-1/2" ported yokes, add 0.39" (10 mm). ¶ Minimum clearance required to remove bowl.

18.2 (463) ¶

10.6 (269)

Manual Drain

17.8 (452) ¶

10.2 (258)

1/4 Turn Manual Drain

1 Quart US (1 Liter) Bowl

17.5 (445) ¶ *

Automatic Drain

.

2.40

(61)

9.9 (251)*

3.11 (79) †

1.73 (44)

Optional Visual

Service Indicator

.

1/4 Turn Manual Drain

Automatic Drain

7.48 (190)**

2.13

(54)

F68E/G General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-13

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: 0° to +175°F (-20° to +80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below +35°F (+2°C).

Particle removal: 5, 25 or 40 µm

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and a 7 psig

(0.5 bar) pressure drop:

403 scfm (190 dm3/s)

1/4 turn manual drain connection: 1/8" pipe thread

Automatic drain connection: 1/8" pipe thread

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig

(0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm3/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Nominal bowl size:

1 pint U.S.(0.5 liter)

1 quart U.S. (1 liter)

Materials:

Body: Aluminum

Yoke: Aluminum

Bowl: Aluminum

Liquid level indicator: Pyrex

Element: Sintered bronze or polypropylene

Elastomers: Synthetic rubber

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

s

Service Kits

Item Type Part Number

Service Kit Seal and gasket 4380-300

5 µm (1 pint bowl) 5576-97

25 µm (1pint bowl) 5576-98

Replacement 40 µm (1 pint bowl) 5576-99

Elements 5 µm (1 quart bowl) 5311-01

25 µm (1 quart bowl) 5311-02

40 µm (1 quart bowl) 5311-03

Replacement 1 pint bowl 4380-060

Sight Glass 1 quart bowl 4380-061

Automatic (G 1/8 outlet) 3000-97

Replacement Automatic (1/8 NPT outlet) 3000-10

Drains Manual 684-84

Manual, 1/4 turn 619-50

Service kit includes: Louver/element seals, drain seal, bowl seal.

Typical Performance Characteristics

PORT SIZE: 1"

psid

bar d

40 µm ELEMENT

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 80 160 240 320 400 480 scfm

0 40 80 120 160 200 dm3/

FLOW CHARACTERISTICS

INLET PRESSURE - psig (bar)

36

(2.5)58(4.0)

AIR FLOW

(6.3)

116

91

(8.0)

150

(10.0)

Page 21

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F17

● Protects air operated devices by removing liquid and

solid contaminants from compressed air

● Screw-on bowl reduces maintenance time

● Can be serviced without the use of tools or removal

from the air line

● Optional visual service indicator turns from green to

red when the filter element needs to be cleaned or

replaced

● Optional electrical service indicator also available

17 Series General Purpose Filter

3/4", 1", 1-1/4", 1-1/2" Port Sizes

ALE-1-14

Ordering Information. Models listed include automatic drain, 40 µm element, metal bowl with sight glass, and PTF threads.

Port Size Model Numbers Flow scfm (dm3/s)* Weight lbs (kg)

3/4" F17-600-A3DA 325 (153) 4.26 (1.93)

1" F17-800-A3DA 425 (201) 4.15 (1.88)

1-1/4" F17-A00-A3DA 425 (201) 4.39 (1.99)

1-1/2" F17-B00-A3DA 425 (201) 4.30 (1.95)

* Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Alternative Models

-

★★★ ★★ ★

-

1★F 7

Drain Substitute

Automatic A

Manual M

Bowl Substitute

1 quart (1 liter) metal with sight glass D

1 quart (1 liter) metal M

Port Size Substitute

3/4" 6

1" 8

1-1/4" A

1-1/2" B

Element Substitute

5 µm 1

25 µm 2

40 µm 3

75 µm 4

Option Substitute

Not applicable 0

Service Indicator Substitute

With (visual) 1

With (electrical) 4

Without 0

Threads Substitute

PTF A

ISO Rc taper B

BSPP (1-1/2" ported units only) C

ISO G parallel (not available with G

1-1/2" ported units)

ISO Symbols

Auto Drain

Manual Drain

Page 22

F17 General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-15

All Dimensions in Inches (mm)

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature:* -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C)

Particle removal: 5 µm, 25 µm, 40 µm, or 75 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig

(0.35 bar) pressure drop: 425 scfm (201 dm

3

/s)

Nominal bowl size: 1 quart (1 liter)

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread.

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Materials

Body: Aluminum

Bowl: Aluminum

Bowl sight glass: Pyrex

Elastomers: Neoprene and nitrile

Filter element

5 µm: Sintered bronze

25 µm: Sintered bronze

40 µm: Sintered bronze

75 µm: Stainless steel screen

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

** Minimum clearance required to remove bowl

Service Kits

Item Type Part number

Service kits All filters 5578-05

5 µm 5311-01

Replacement elements

25 µm 5311-02

40 µm 5311-03

75 µm 5656-01

Replacement drain

Automatic 3000-10

Manual (1/4 turn) 619-50

Service kit 5778-05 includes bowl o-ring, drain gasket, and element

gasket.

PORT SIZE: 1-1/4"

psid

bar d

ELEMENT: 40 µm

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 100 200 300 400 500 scfm

0 50 100 150 200 250 dm3/s

INLET PRESSURE: psig (bar g)

23

36

(2.5)

AIR FLOW

58

(4.0)72(5.0)91(6.3)

(1.6)

116

(8.0)

45

(10.0)

4.75 (121)

4.32 (110)

Optional

Service Indicator

2.61

(32)

1.25

17.29 (439)**

1/4 Turn

Manual

Drain

2.40

(61)

(66)

10.63 (270)

Optional

Service Indicator

16.71 (424)**

Automatic

Drain

2.40

(61)

(66)

2.61

1.25 (32)

10.06 (256)

Page 23

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F18

● Protects air operated devices by removing liquid and

solid contaminants

● Highly visible, prismatic liquid level indicator lens

● Can be disassembled without removal from the air

line

● Optional visual service indicator turns from green to

red when the filter element needs to be cleaned or

replaced

● Optional electrical service indicator also available

18 Series General Purpose Filter

1-1/2" and 2" Port Sizes

ALE-1-16

Alternative Models

-

★★★ ★★ ★

-

1★F 8

Drain Substitute

Automatic A

Manual 1/4 turn M

Bowl Substitute

Metal with sight glass D

Metal M

Port Size Substitute

1-1/2" B

2" C

Element Substitute

5 µm 1

25 µm 2

40 µm 3

100 µm 4

Option Substitute

Not applicable 0

Service Indicator Substitute

Without 0

With pneumatic 1

With electrical 4

Ordering Information. Models listed include automatic drain, 40 µm element, metal bowl with sight glass, and PTF threads.

Port Size Model Numbers Flow scfm (dm3/s) * Weight lbs (kg)

1-1/2" F18-B00-A3DA 1400 (661) 14.90 (6.76)

2" F18-C00-A3DA 1400 (661) 14.65 (6.65)

* Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig (0.35 bar) pressure drop.

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

ISO Symbols

Auto Drain

Manual Drain

Page 24

F18 General Purpose Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-1-17

Technical Data

Fluid: Compressed air

Maximum pressure: 250 psig (17 bar)

Operating temperature*: -30° to 175°F (-34° to 80°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 5 µm, 25 µm, 40 µm or 100 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5 (particulates)

Typical flow with a 40 µm element at 90 psig (6.3 bar) inlet pressure and 5 psig

(0.35 bar) pressure drop: 1300 scfm (614 dm

3

/s)Nominal bowl size: 7 fluid

ounce (0.2 liter)

Manual drain connection: Will fit 1/8-27 and 1/8-28 pipe thread.

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube

with 3/16" (5mm) minimum I.D.can be connected to the automatic drain. Drain

may fail to operate if the tube I.D. is less than 3/16" (5mm). Avoid restrictions in

the tube.

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than 5 psig (0.3 bar)

Bowl pressure required to open drain: Less than 3 psig (0.2 bar)

Minimum air flow required to close drain: 2 scfm (1 dm

3

/s)

Manual operation: Depress pin inside drain outlet to drain bowl

Materials

Body: Aluminum

Intermediate body: Aluminum

Bowl: Aluminum

Metal bowl liquid level indicator:Transparent nylon

Filter element: Sintered bronze

Elastomers: Neoprene and nitrile

An automatic drain is a two-way valve, which will close when the system is

pressurized.The drain opens when the float rises due to accumulated liquid

and on depressurization.

Typical Performance Characteristics

Service kit contains body o-ring, element gasket, automatic drain

gasket, and bowl o-ring.

Service Kits

Item Type Part Number

Service kit Seal & Gasket 5945-50

5 µm 5882-11

Replacement elements

25 µm 5882-12

40 µm 5882-13

100 µm 5882-14

Liquid level lens kit Prismatic 4380-050

Automatic 3000-10

Replacement drains

Manual quarter turn 619-50

** Minimum clearance required to remove intermediate body and bowl.

All Dimensions in Inches (mm)

8.22 (209)

INLET PRESSURE: psig (bar g)

psid

bar d

PORT SIZE: 2

10

ELEMENT: 40 µm

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 400 800 1200 1600 2000 scfm

0 200 400 600 800 1000 dm3/s

"

36 (2.5) 58 (4.0)

AIR FLOW

90 (6.3)

116

(8.0)

150

(10.0)

180

(12.5)

Body

22.99 (584) **

Intermediate

Body

Bowl

8.16 (207)

1.86 (47)

Optional

Service

Indicator

15.10 (384)

3.16 (80)

23.58 (599) **

15.70 (399)

Automatic Drain

1/4 Turn Manual Drain

Page 25

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-2-1

Section 2

F39 Miniature Oil Removal Filter 1/8" and 1/4" Ports . . . . . . .ALE-2-2

F72C Excelon Oil Removal Filter 1/4" and 3/8" Ports . . . . . . .ALE-2-4

F73C Excelon Oil Removal Filter 1/4", 3/8", and 1/2" Ports . .ALE-2-6

F74C/H Excelon Oil Removal Filter

3/8", 1/2", and 3/4" Ports . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-2-8

F64C/H Olympian Plus Oil Removal Filter

1/4", 3/8", 1/2, and 3/4" Ports . . . . . . . . . . . . . . . . . . . . . . . .ALE-2-10

F68C/H Olympian Plus Oil Removal Filter

1/2", 3/4", and 1" Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ALE-2-12

F46 Oil Removal Filter 3/4", 1", and 1-1/4" Ports . . . . . . . . . .ALE-2-14

F47 Oil Removal Filter 1-1/2" and 2"Ports . . . . . . . . . . . . . . .ALE-2-16

Oil Removal

(Coalescing) Filters

Port sizes from 1/8" to 2"

F39

F72C

F73C F74C/H

F64C/H

F68

F46

F47

Page 26

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

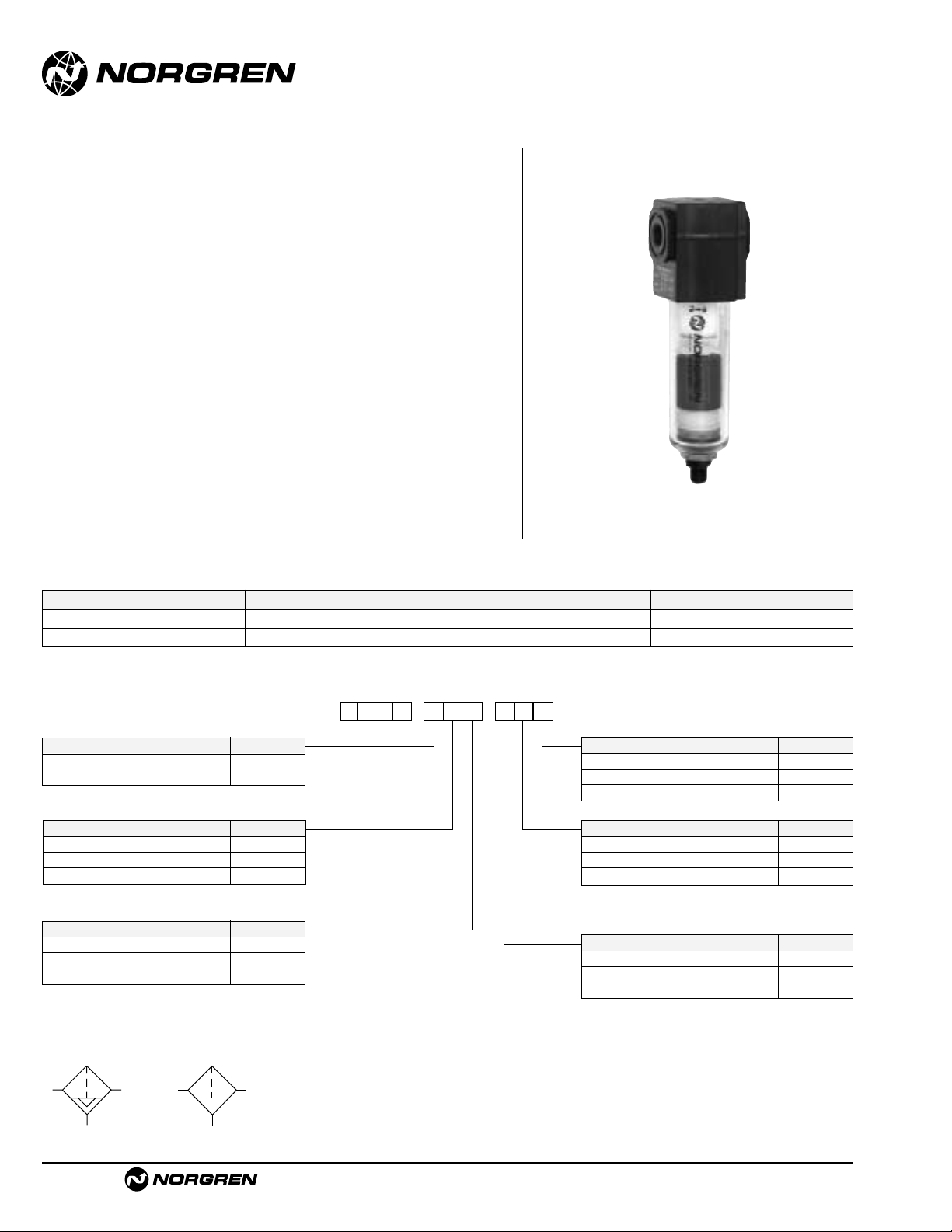

F39

● Compact design

● High efficiency oil and particle removal

● Screw-on bowl reduces maintenance time

● Can be disassembled without the use of tools or

removal from the air line

Miniature Series 07 Oil Removal

(Coalescing) Filter 1/8" and 1/4" Port Sizes

ALE-2-2

Saturated Flow* Dry Flow

Port Size Model Numbers Flow scfm (dm3/s) Flow scfm (dm3/s) Weight lbs (kg)

1/8" F39-100-A0TA 6.0 (2.8) 11.2 (5.3) 0.28 (0.13)

1/4" F39-200-A0TA 6.4 (3.0) 12.2 (5.8) 0.28 (0.13)

Ordering Information. Models listed include PTF threads, automatic drain and transparent bowl.

* Maximum flow at 90 psig (6.3 bar) inlet pressure to maintain stated oil removal performance.

Alternative Models

Port Size Substitute

1/8" 1

1/4" 2

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Option Substitute

Not applicable 0

Bowl Substitute

Transparent T

Metal M

Option Substitute

Not applicable 0

Element Substitute

Coalescing 0

Drain Substitute

Automatic A

Manual M

-

★★★ ★★

★

-

3★F 9

Automatic and

Semi Automatic Drain

Manual Drain

ISO Symbols

Page 27

F39 Oil Removal (Coalescing) Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-2-3

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: 150 psig (10 bar)

Metal bowl: 250 psig (17 bar)

Operating temperature:*

Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below

2°C (35°F)

Particle removal: Down to 0.01 µm

Air quality: Within ISO 8573-1, Class 1 (particulates) and Class 2 (oil content)

Maximum remaining oil content of air leaving the filter: 0.01ppm at 70°F (21°C)

with an inlet oil concentration of 17 ppm.

Maximum flow with 90 psig (6.3 bar) inlet pressure†:

1/8 ports, 6.0 scfm (2.8 dm

3

/s)

1/4 ports, 6.4 scfm (3 dm3/s)

† Maximum flow to maintain stated oil removal performance.

Nominal bowl size: 1 fluid ounce (31 ml)

Drain connection: 1/8" pipe thread

Automatic drain operation:Spitter type drain operates momentarily when a rapid

change in air flow occurs or when the supply pressure is reduced.

Materials:

Body: Zinc

Bowl:

Transparent: Polycarbonate

Metal: Zinc

Element: Synthetic fiber and polyurethane foam

Elastomers: Neoprene & nitrile

0.157 (4) Dia **

0.5 (13) Deep **

n

n

1.45 (37)

0.91

(23)

0.73

(19)

0.91

(23)

6.07 (154) †

0.38 (10)

4.10 (104)

6.22 (158) †

0.38 (10)

4.25 (108)

1.63 (42)

** Mounting holes

† Minimum clearance to remove bowl

Service Kits

Item Type Part number

Service kit All models 4141-10

Replacement drains

Manual 773-03

Automatic 3654-02

Service kit includes element, element o-ring, and bowl o-ring.

Typical Performance Characteristics

All Dimensions in Inches (mm)

PORT SIZE: 1/4"

psid

bar d

ELEMENT: SATURATED

0.8

10

0.6

8

6

0.4

PRESSURE DROP

4

0.2

2

0

0

0 2 4 6 8 10 scfm

0 1 2 3 4 5 dm3/s

PORT SIZE: 1/4"

psid

bar d

0.8

0.6

0.4

PRESSURE DROP

0.2

ELEMENT: DRY

10

8

6

4

2

FLOW CHARACTERISTICS

INLET PRESSURE: psig (bar)

36

23

(1.6)

FLOW CHARACTERISTICS

23

(1.6)

58

(2.5)

(4.0)

AIR FLOW

INLET PRESSURE: psig (bar)

36

(2.5)

58

(4.0)

91

(6.3)

91

116

(6.3)

(8)

Maximum flow to

maintain stated oil

removal performance

150

116

(10)

(8)

150

(10)

180

(12)

180

(12)

0

0

0 4 8 12 16 20 scfm

0 2 4 6 8 10 dm3/s

AIR FLOW

Manual Drai

Automatic Drai

Page 28

See Section ALE-24 for Accessories

Littleton, CO USA Phone 303-794-2611 www.norgren.com

F72C

● Excelon design allows in-line or modular installation

● High efficiency oil and particle removal

● Quick release bayonet bowl

● Highly visible, prismatic liquid level indicator lens on

metal bowls

● Standard visual service life indicator turns from

green to red when the filter element needs to be

replaced

● Optional electrical service indicator also available

● Modular installations with Excelon 72, 73, and 74

series can be made to suit particular applications

Install an F72G filter with a 5 µm filter element upstream of the F72C filter for

optimum coalescing element life.

Excelon F72C Oil Removal Filter

(Coalescing) 1/4" and 3/8" Port Sizes

ALE-2-4

Ordering Information. Models listed include PTF threads, service life indicator, automatic drain, transparent bowl without guard.

† Maximum flow with 90 psig (6.3 bar) inlet pressure, to maintain stated oil removal performance.

Port Size Model Flow†scfm (dm3/s) Weight lb (kg)

1/4" F72C-2AD-AL0 9.5 (4.5) 1.2 (0.54)

3/8" F72C-3AD-AL0 9.5 (4.5) 1.2 (0.54)

Element Substitute

Coalescing 0

Alternative Models

F 7 2-C

★ ★

-

★★ ★ ★

Port Size Substitute

1/4" 2

3/8" 3

Threads Substitute

PTF A

ISO Rc taper B

ISO G parallel G

Drain Substitute

1/4 turn manual Q

Semi automatic S

Auto drain* A

Service Life Indicator Substitute

With (visual) D

With (electrical) E

Without N

Bowl Substitute

Metal with liquid level indicator E

Transparent without guard L

Transparent with guard W

Automatic and

Semi Automatic Drain

Manual Drain

ISO Symbols

Page 29

F72C Oil Removal (Coalescing) Filters

Littleton, CO USA Phone 303-794-2611 www.norgren.com

ALE-2-5

† Minimum clearance required to remove bowl.

Service Kits

Item Type Part Number

Service kit Seal and gasket 4380-500

Element Coalescing 5925-09

Liquid level lens kit Prismatic 4380-030

1/4 turn manual 619-50

Replacement drains Semi automatic 5379-RK

Automatic 4000-50R

Service kit includes bowl o-rings.

Technical Data

Fluid: Compressed air

Maximum pressure:

Transparent bowl: Manual or semi automatic drain: 150 psig (10 bar)

Automatic drain: 116 psig (8 bar)

Metal bowl: Manual or semi automatic drain: 250 psig (17 bar)

Automatic drain: 116 psig (8 bar)

Operating temperature*:Transparent bowl: -30° to 125°F (-34° to 50°C)

Metal bowl: -30° to 150°F (-34° to 65°C)

* Air supply must be dry enough to avoid ice formation at temperatures below 35°F (2°C).

Particle removal: 0.01 µm

Air quality: Within ISO 8573-1, Class 1 (particulates) and Class 2 (oil content)

Maximum remaining oil content in outlet air:

0.01 ppm at 70°F (21°C) with an inlet concentration of 17 ppm.

Maximum flow with 90 psig (6.3 bar) inlet pressure**: 9.5 scfm (4.5 dm

3

/s)

** Maximum flow to maintain stated oil removal performance.

Manual drain connection:Will fit 1/8-27 and 1/8-28 pipe thread.

Semi automatic drain connection: Push on 5/16" (8 mm) ID tube

Semi automatic drain operating conditions (pressure operated):

Bowl pressure required to close drain: Greater than 1.5 psig (0.1 bar)

Bowl pressure required to open drain: Less than 1.5 psig (0.1 bar)

Minimum air flow required to close drain: 1 scfm (0.5 dm

3

/s)

Manual operation: Lift stem to drain bowl

Automatic drain connection:Will fit 1/8-27 and 1/8-28 pipe thread. - Flexible tube